Ball valve

A ball valve and valve body technology, applied in the field of pipeline valves, can solve the problems of increased weight and volume of ball valves, inconvenient installation and use, and easy formation of water hammer, so as to improve the response speed of opening and closing, reduce weight and volume, and improve flexibility and convenience. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

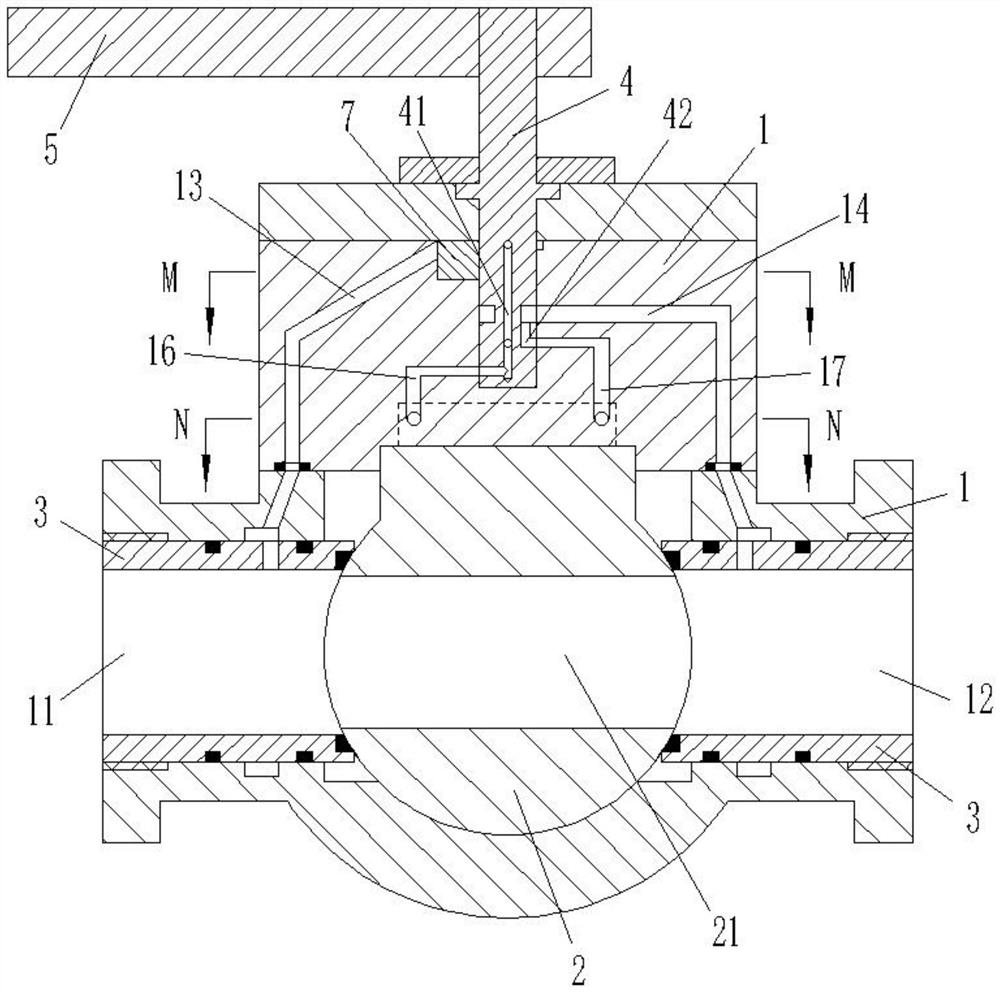

[0029] combine Figure 1 to Figure 6 As shown, the ball valve in this embodiment includes a valve body 1 , a valve ball 2 , a valve seat 3 and a valve shaft 4 .

[0030] An inlet 11, an outlet 12, an inlet channel 13, an outlet channel 14 and a control groove 15 are arranged on the valve body 1, wherein a valve seat 3 is respectively provided at the inlet 11 and the outlet 12, and the valve ball 2 is located on the valve body. The inside of the body 1 and at the same time form a movable sealing connection with the two valve seats 3 through seals.

[0031] A through hole 21 and a control plate 22 are provided on the valve ball 2 . Wherein, the through hole 21 runs through the valve ball 2 in the radial direction, and is used to communicate and cut off the inlet 11 and the outlet 12, and one end of the control plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com