An automobile instrument pointer shaft detection device

A detection device and automotive instrument technology, applied in the direction of angle/taper measurement, etc., can solve the problems of large error, fuzzy detection results, single detection type, etc., and achieve the effect of eliminating manual operation errors, rapid detection, and accurate detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

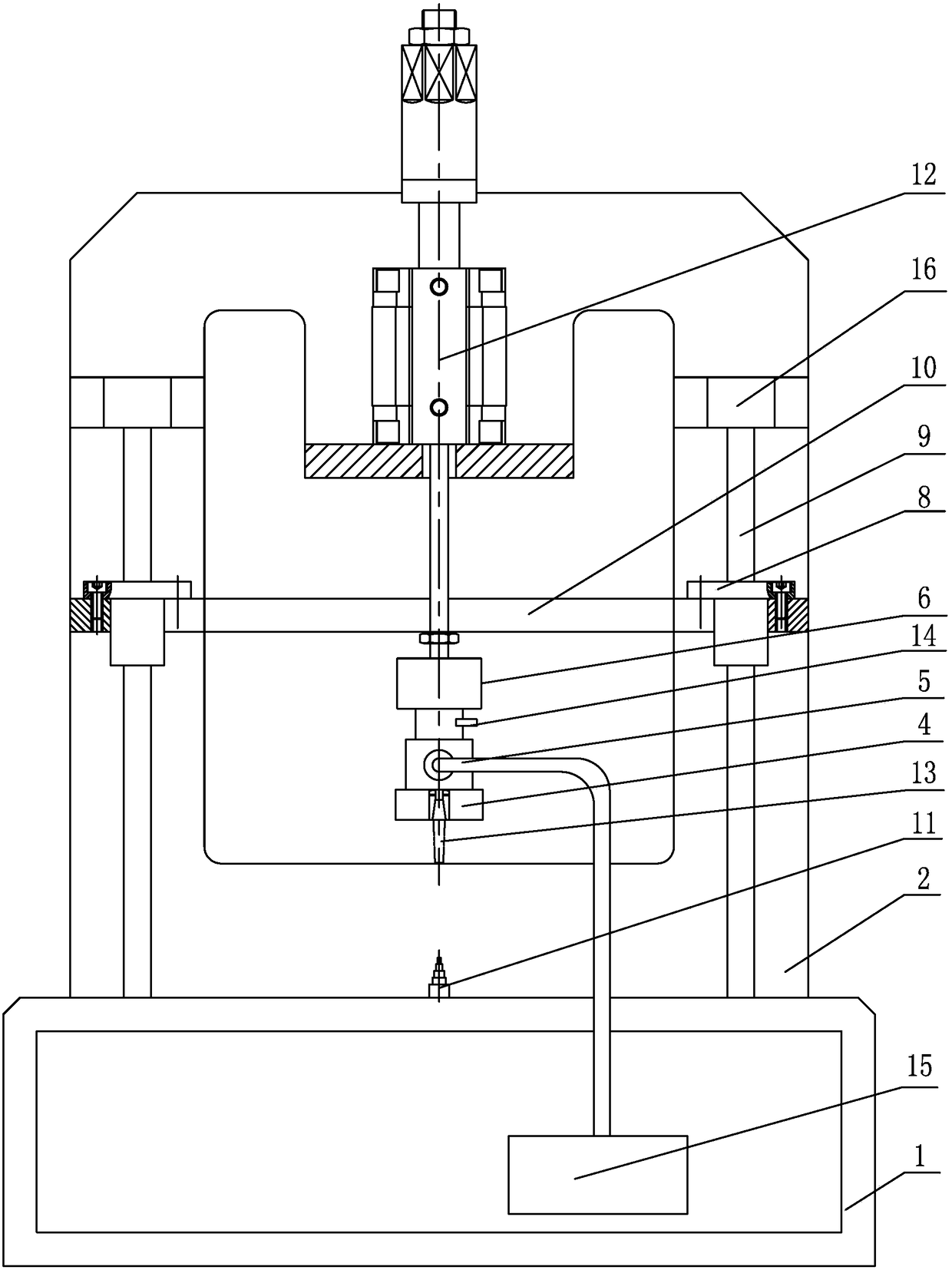

[0011] Specific implementation mode one: combine Figure 1-Figure 3 Explain, a kind of automobile meter pointer axis detection device of this embodiment, it comprises base 1, vertical board 2, pointer holder 4, linear bearing 8, pointer plate 10, cylinder 12, vacuum pump 15 and two guide posts 9;

[0012] The base 1 is fixed with a vertical plate 2, and two guide columns 9 are arranged side by side and installed vertically on the base 1; each of the two guide columns 9 is equipped with a linear bearing 8, and the pointer plate 10 is arranged horizontally and installed on two On the linear bearing 8, the pointer shaft 11 is installed on the base 1, and the vertically arranged cylinder 12 is installed on the vertical plate 2 above the pointer plate 10; the driving rod of the cylinder 12 passes through the pointer plate 10 and the two are fixedly connected, and the cylinder The end of the driving rod 12 is connected with the pointer holder 4, the pointer holder 4 is provided with...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 Note that the instrument pointer shaft detection device of this embodiment also includes a tension-pressure sensor 6, one end of the tension-pressure sensor 6 is connected to the end of the driving rod of the cylinder 12, and the other end of the tension-pressure sensor 6 is inserted into the pointer holder 4 The casing 4-1 and the two are fixed by the top wire 14. Such setting facilitates the circumferential movement of the pointer holder 4 and meets the needs of multi-angle detection of the pointer shaft. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination Figure 4 Explain that the pointer shaft 11 of this embodiment is a five-step shaft, and the pointer shaft 11 is mainly made of a detection part 11-1 and a fixed connection part 11-2. The detection part 11-1 is a five-step shaft section, and the fixed connection part 11 -2 is a fixed segment, when the pointer shaft 11 is vertically inverted, the first-stage shaft segment of the detection part 11-1 is arranged facing the pointer 13, and the fixed connection part 11-2 is connected with the base 1. like image 3 As shown, the pointer shaft 11 of this embodiment can be a five-step shaft, and the pointer shaft 11 is mainly made of a detection part 11-1 and a fixed connection part 11-2. The detection part 11-1 is a five-step shaft section, fixedly connected The part 11 - 2 is a fixed section. When the pointer shaft 11 is inverted, the central axis of the detection part 11 - 1 is arranged facing the pointer 13 . The fixed connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com