Method for managing steel meshes

A management method and stencil technology, applied in data processing applications, instruments, manufacturing computing systems, etc., can solve problems such as high error rate, low efficiency, and inability to guarantee the cleanliness of stencils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

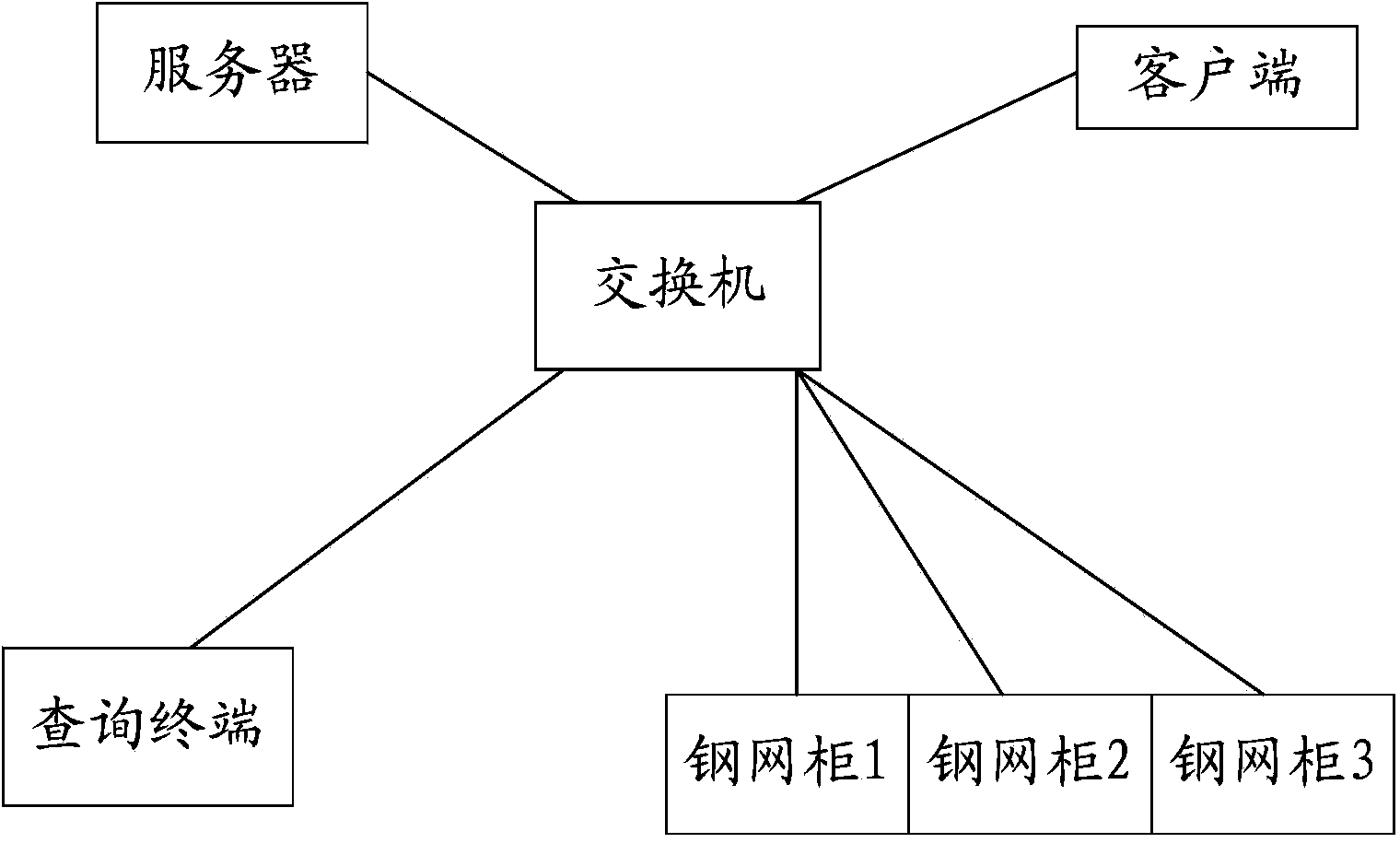

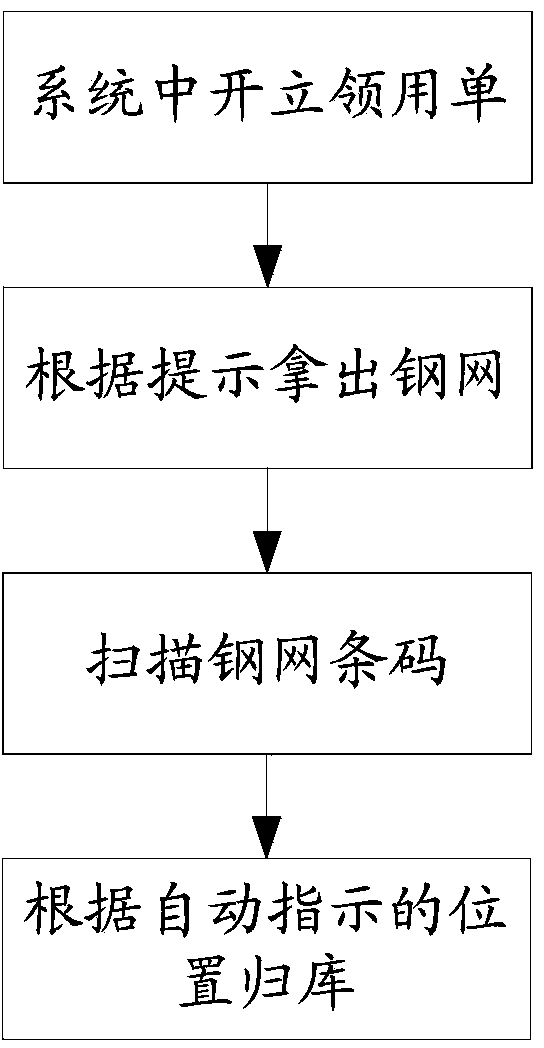

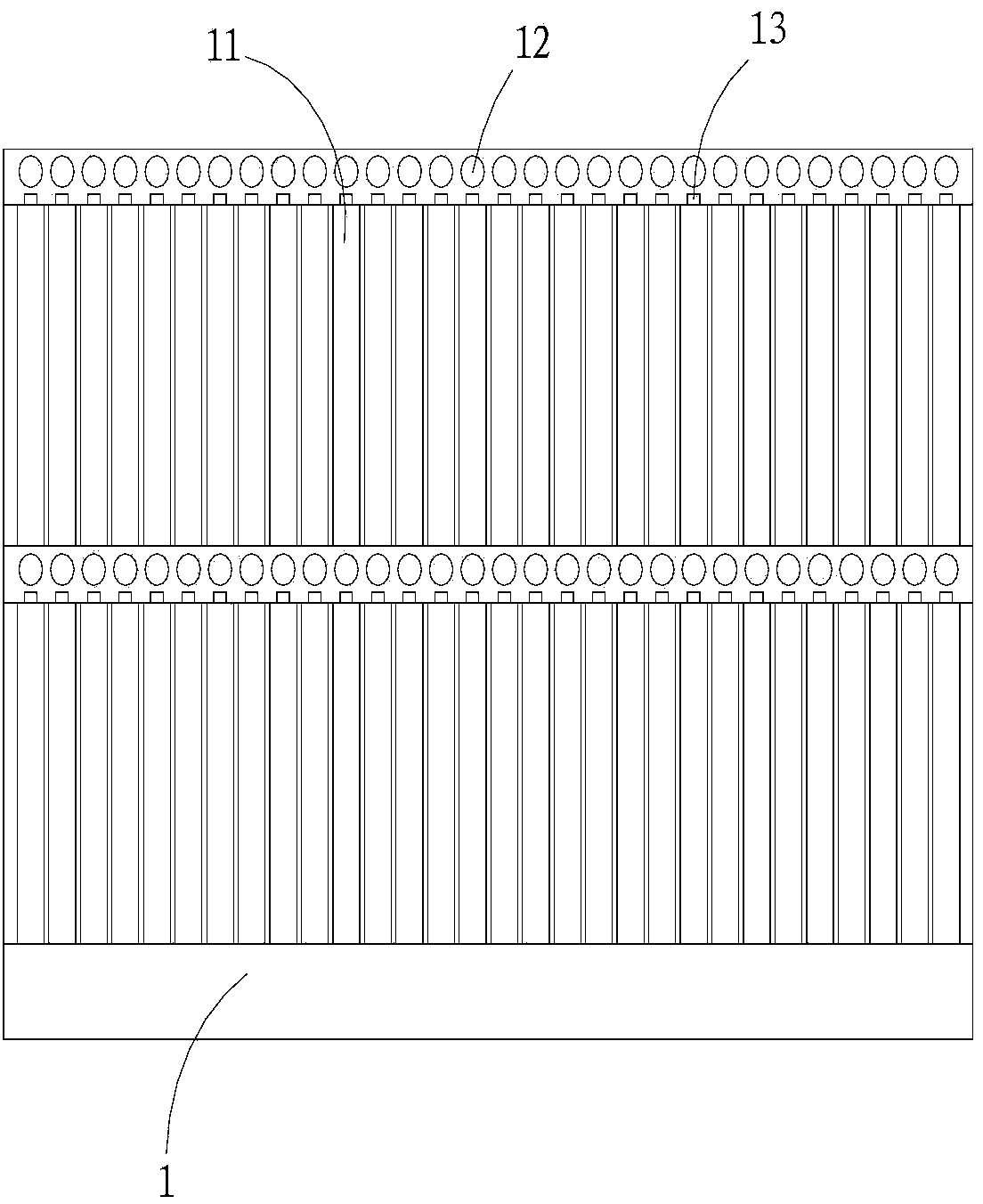

[0027] Such as figure 1 and figure 2 As shown, the management method of the stencil of the present invention is to paste a barcode for each stencil, and the barcode is related to the relevant information of the stencil in the system, including the service life of the stencil, the date of production, and the product information of the corresponding production. ; and mark each stencil storage location, and create a view of the stencil storage room in the system, which is used to visually check the stencil storage situation in each stencil cabinet; when the stencil is used, open it in the client or query terminal With the stand-up collar, the stencil cabinet automatically indicates the corresponding stencil storage position and ejects the stencil, and the operator only needs to take out the stencil according to the prompts; when the stencil is returned to the warehouse, scan the barcode of the stencil at the query terminal, intelligent The stencil cabinet automatically indicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com