Automatic temperature regulating and controlling system

A control system and automatic technology, applied in the direction of air supply adjustment, combustion control, furnace control device, etc., can solve the problems of low degree of automation and inability to realize kiln temperature control, so as to reduce labor, improve kiln temperature control accuracy, and eliminate errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

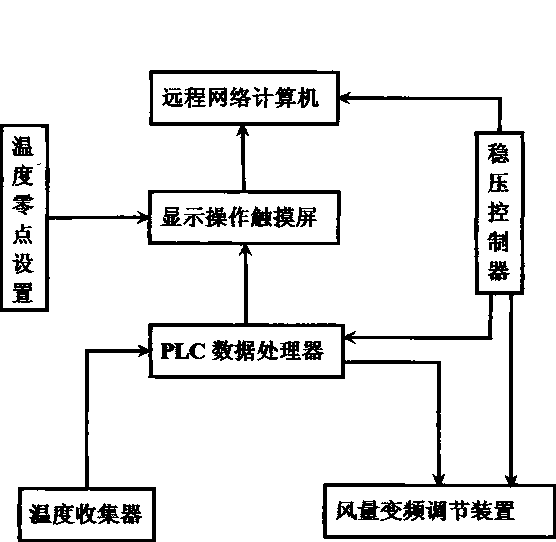

[0014] Such as figure 1 As shown, the automatic continuous water distribution system includes a connected temperature collection device, a PLC data processor, a display operation touch screen, a remote network computer, an air volume frequency conversion adjustment device, and a voltage stabilizing controller.

[0015] There is a temperature zero setting on the display operation touch screen, which is used to set the standard starting temperature of the kiln temperature. .

[0016] The voltage regulator controller is connected separately with raw material automatic sampling hygrometer, raw material weight acquisition device, PLC data processing module, controllable water feeder, liquid flow measuring instrument, finished product automatic sampling hygrometer, and display operation touch screen to ensure the connection The operating voltage of each device is stable, avoiding the impact on the system effect caused by the change of the operating power supply voltage.

[0017] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com