Automatic conveying film sticking machine

A film laminating machine, automatic technology, applied in packaging and other directions, can solve problems such as low production efficiency, unsatisfactory adhesion force, and inability to eliminate the problem of bubbles on the surface of parts, so as to improve production efficiency, save production space, and eliminate surface bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

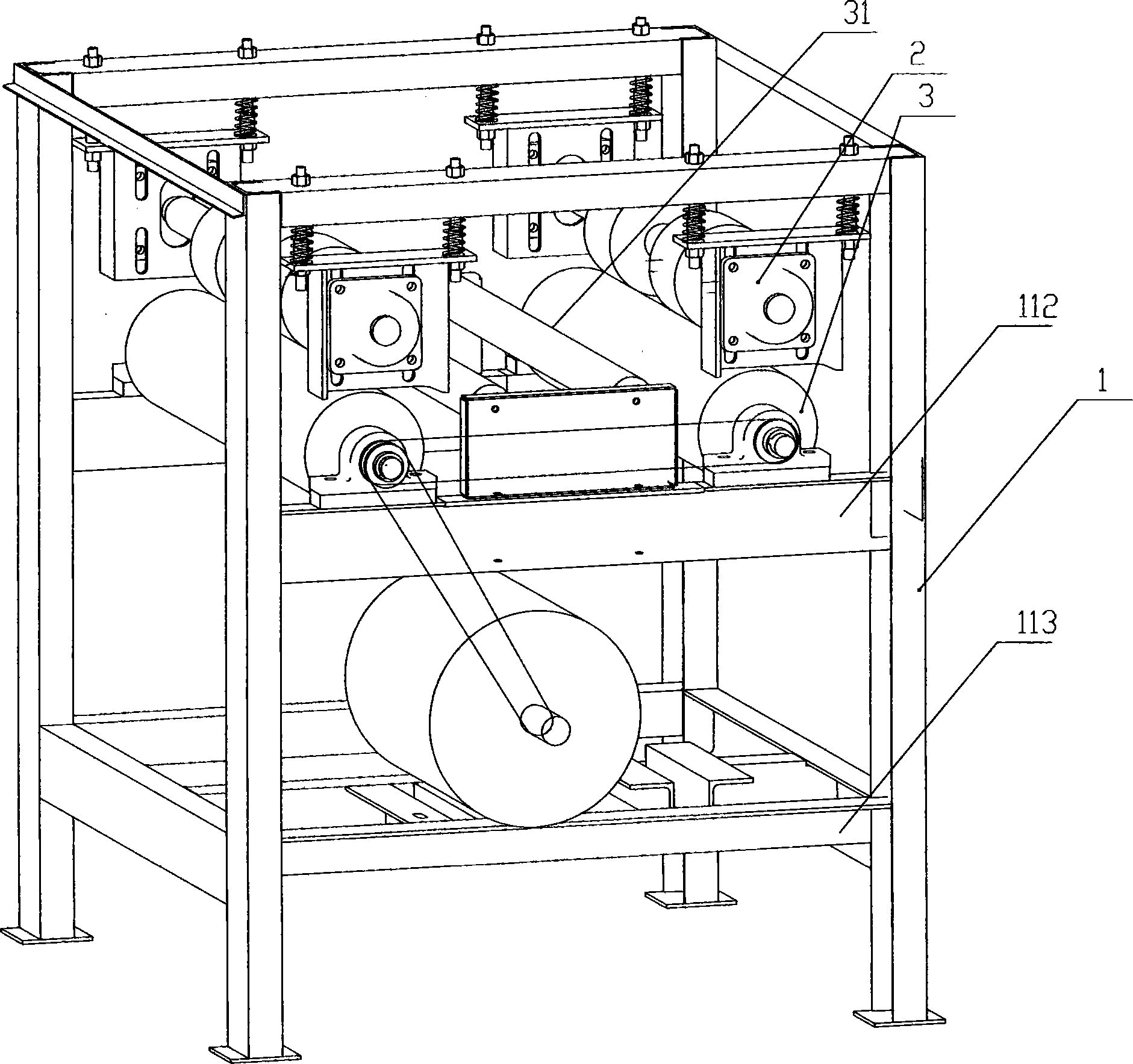

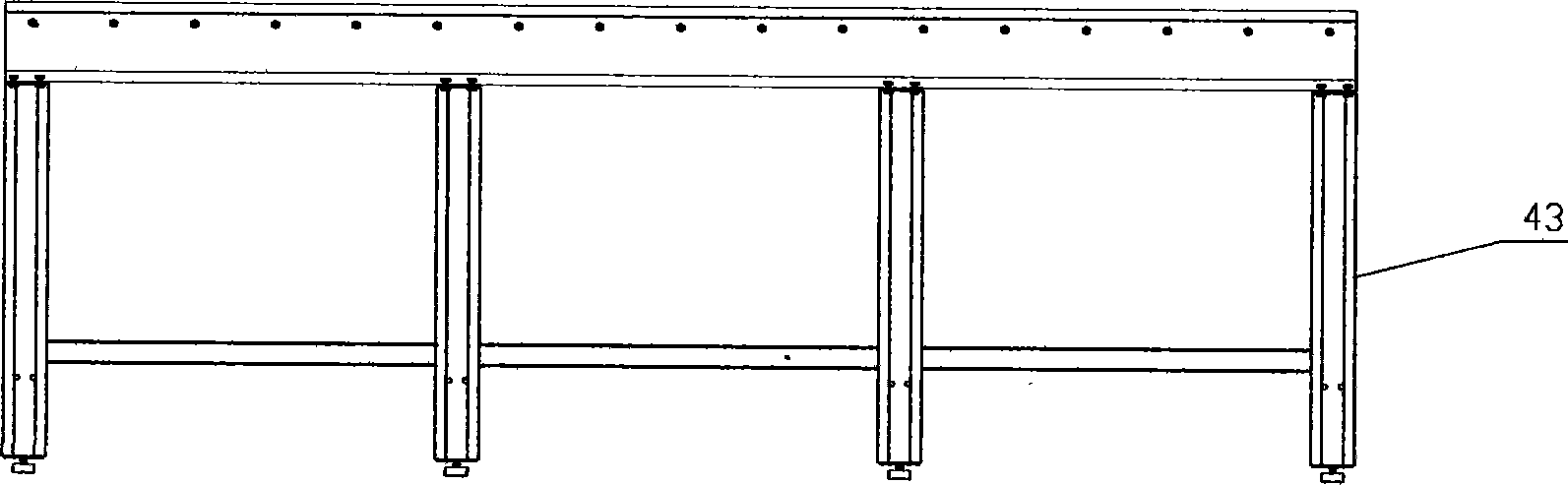

[0024] The automatic conveying film laminating machine of the present invention includes a first unpowered conveying line, a second unpowered conveying line, a butyl tape compacting tool and a film sticking device, wherein the first unpowered conveying line and the second unpowered conveying line are respectively set On both sides of the butyl tape compacting tool; the film sticking device is installed on the butyl tape compacting tool; the workpiece to be filmed enters the butyl tape compacting tool through the first unpowered transmission line, and passes through the film sticking device After the film pasting action is completed, the film pasting workpiece is output from the second unpowered conveying line.

[0025] see figure 1 As shown, it is a schematic diagram of the three-dimensional structure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com