Drilling mold for oblique hole in engine nozzle ring

A technology of inclined hole drilling jigs and nozzle rings, which is applied in the direction of boring/drilling, jigs for workpieces, drilling/drilling equipment, etc., and can solve the problems of difficult debugging of jig jigs, inconvenient operation, cumbersome operation, etc. , to achieve the effect of reliable positioning, easy maintenance and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below in conjunction with the accompanying drawings.

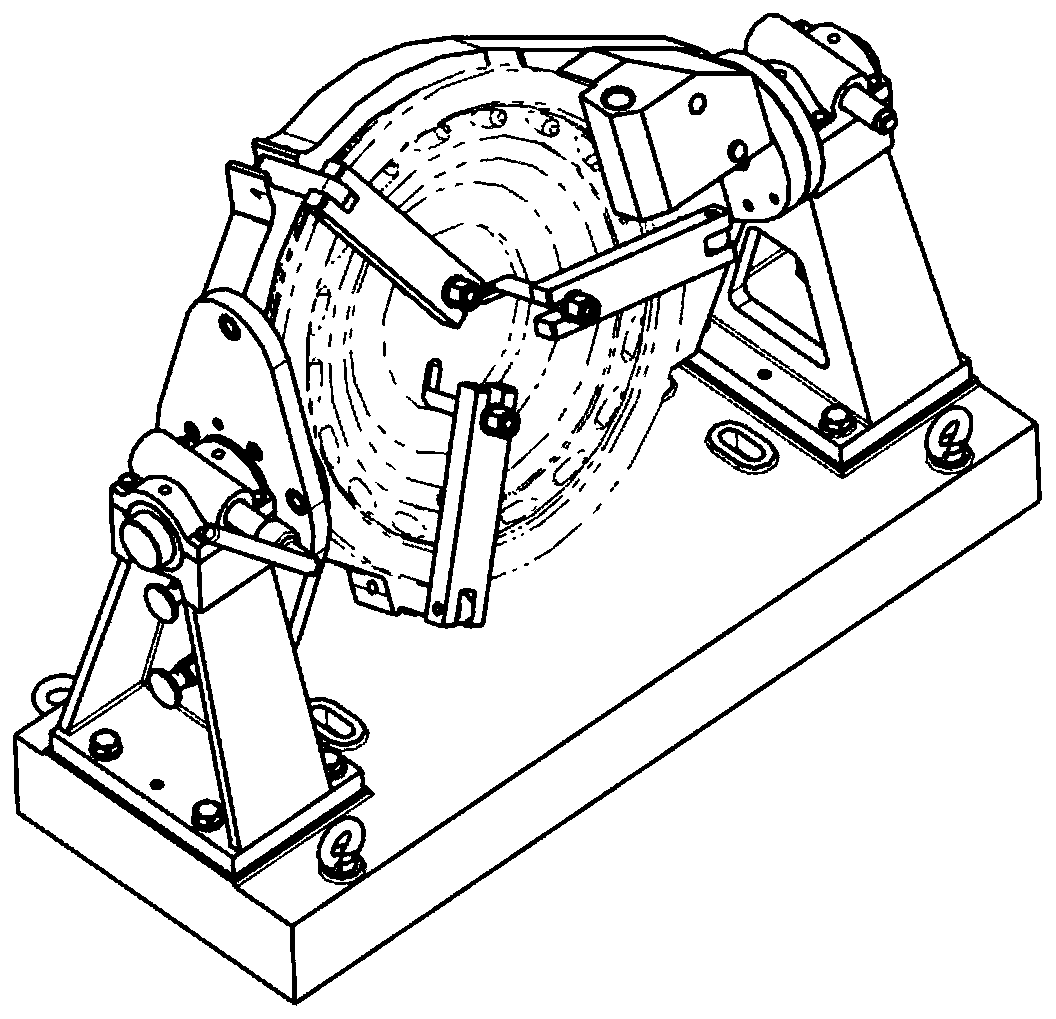

[0028] Such as Figure 2 to Figure 4 Shown is the engine nozzle ring oblique hole drilling template of the present invention, i.e. the basic form of the present invention. Engine nozzle ring inclined hole drilling template includes base 1, support 2, locator 3, mandrel 4, bearing 5, tangential clamping sleeve 6, bearing cap 7, indexing plate 8, positioning ring 9, pressure plate 10, upper Support plate 11, positioning plate 12, handle nut 13, drill sleeve 15, left and right support 2 are fixed on the base 1 by pins and bolts, bearing 5 is installed in the center hole of the upper end of the left and right support, mandrel 4 and positioning plate 12 are fixed by pins It is connected with bolts and placed in the bearing holes at both ends respectively. The bearing cover 7 is located at the upper end of the support 2. The tangential clamping sleeve 6 is located between the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com