Novel inspection rail robot device

An orbital robot and robot technology, which is applied in the field of patrol inspection robots to achieve the effects of reliable positioning method, simple structure and ingenious structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

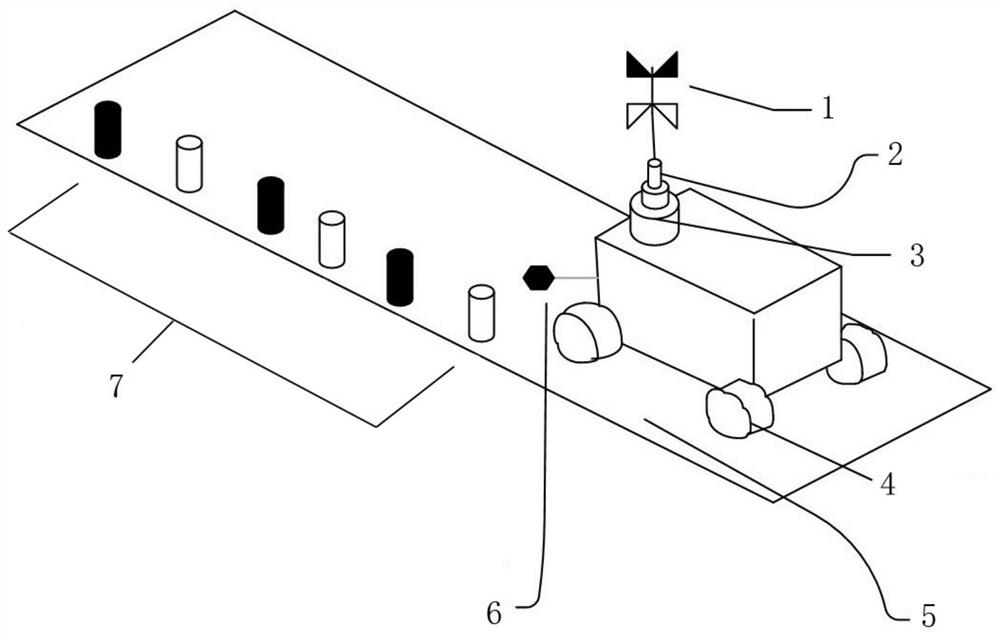

[0023] refer to Figure 1-2 , a new type of rail inspection robot device, including: the design of the precise positioning of the inspection rail robot and the structure design of the best shooting angle in three-dimensional space.

[0024] In this embodiment, the precise positioning design of the inspection track robot includes the design of the driving mode of the inspection track robot and the walking path of the inspection track robot. The driving mode refers to the driving mode of the inspection track robot wheel. The inspection track robot uses the stepper motor wheel 4 to provide forward power for the inspection track robot. Using the stepper motor wheel can accurately calculate The distance traveled in a certain period of time, which can facilitate positioning.

[0025] In this embodiment, the design of the path refers to the inspecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com