Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "No manual assembly required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

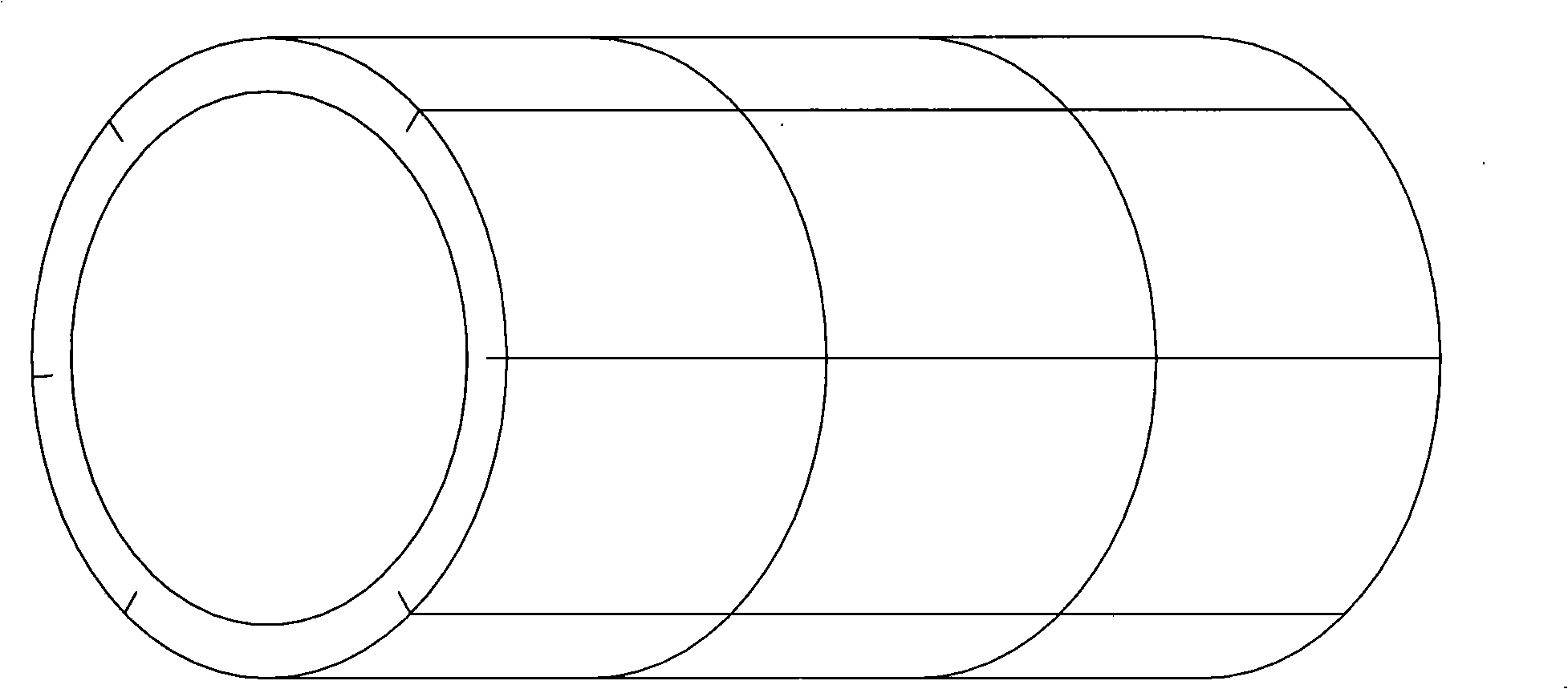

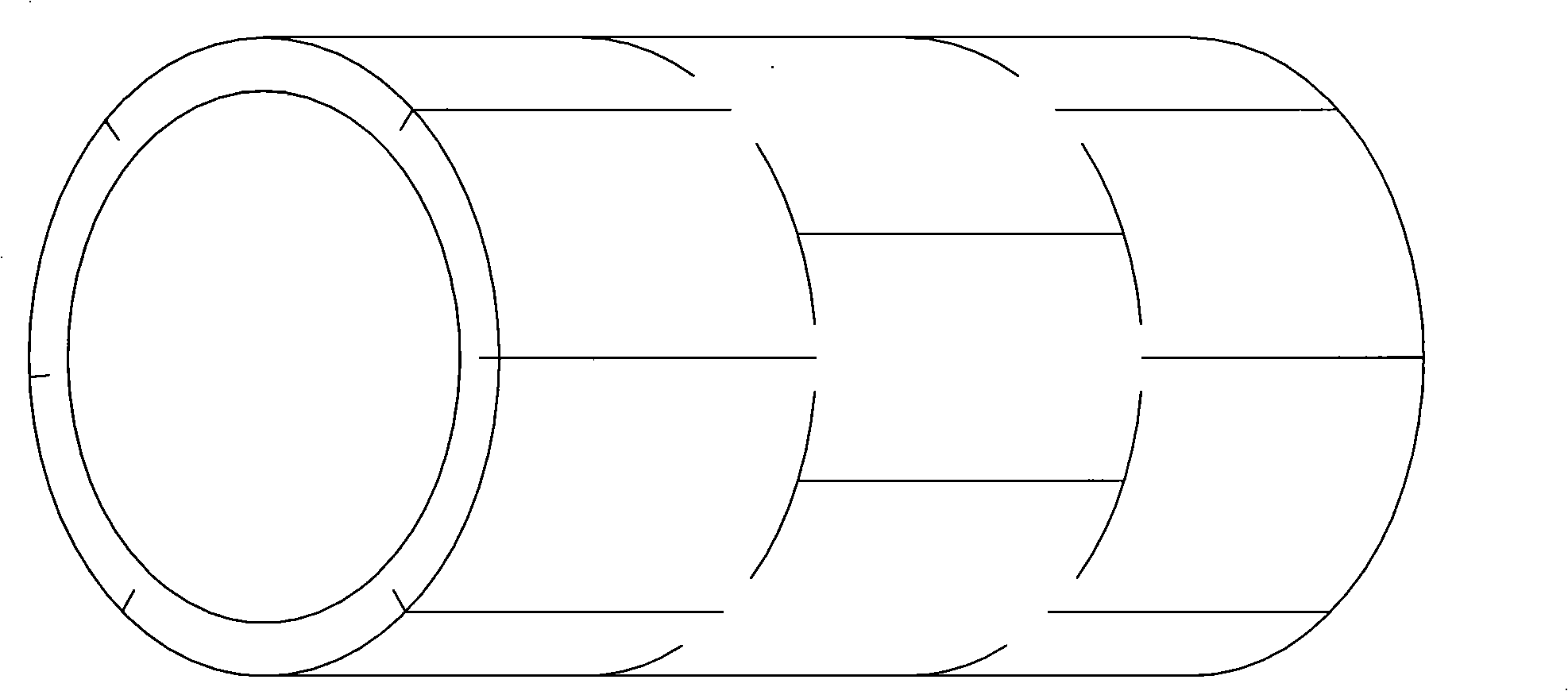

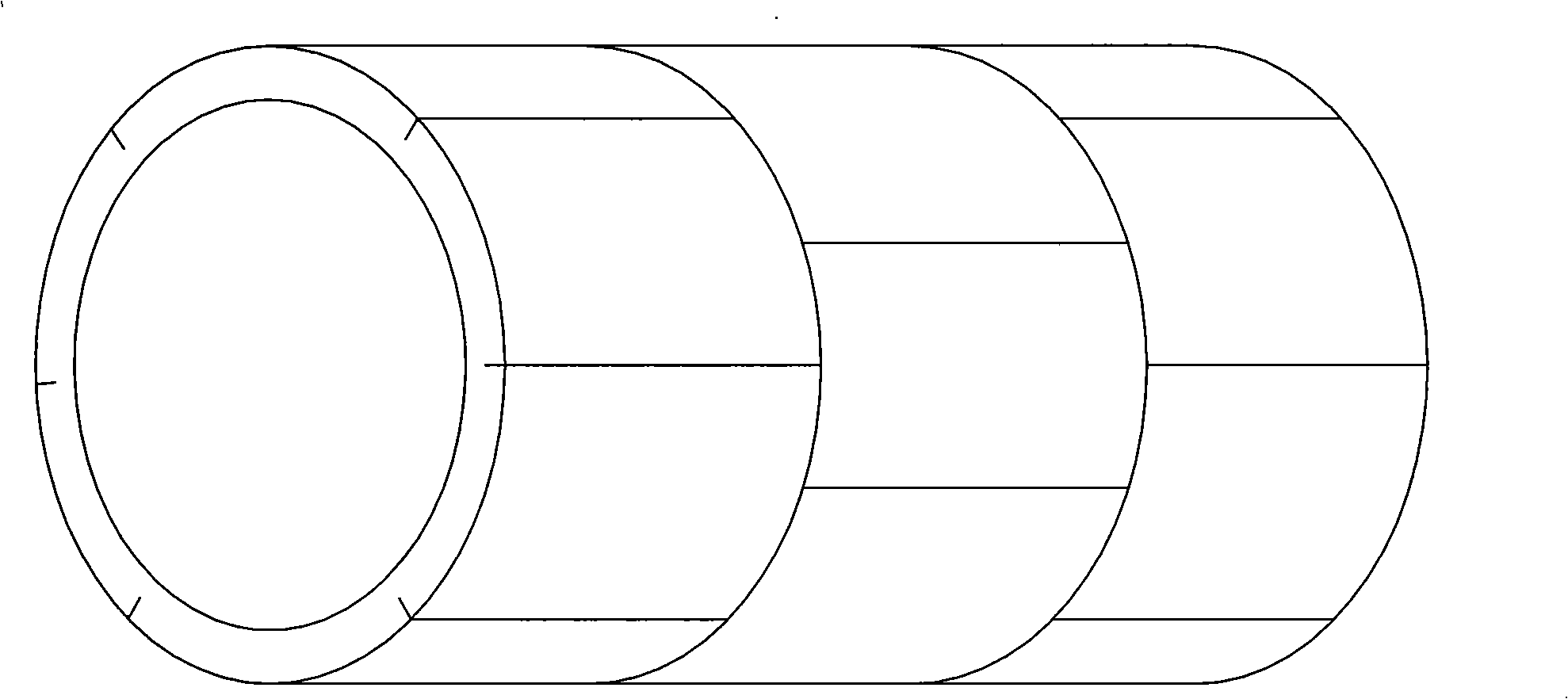

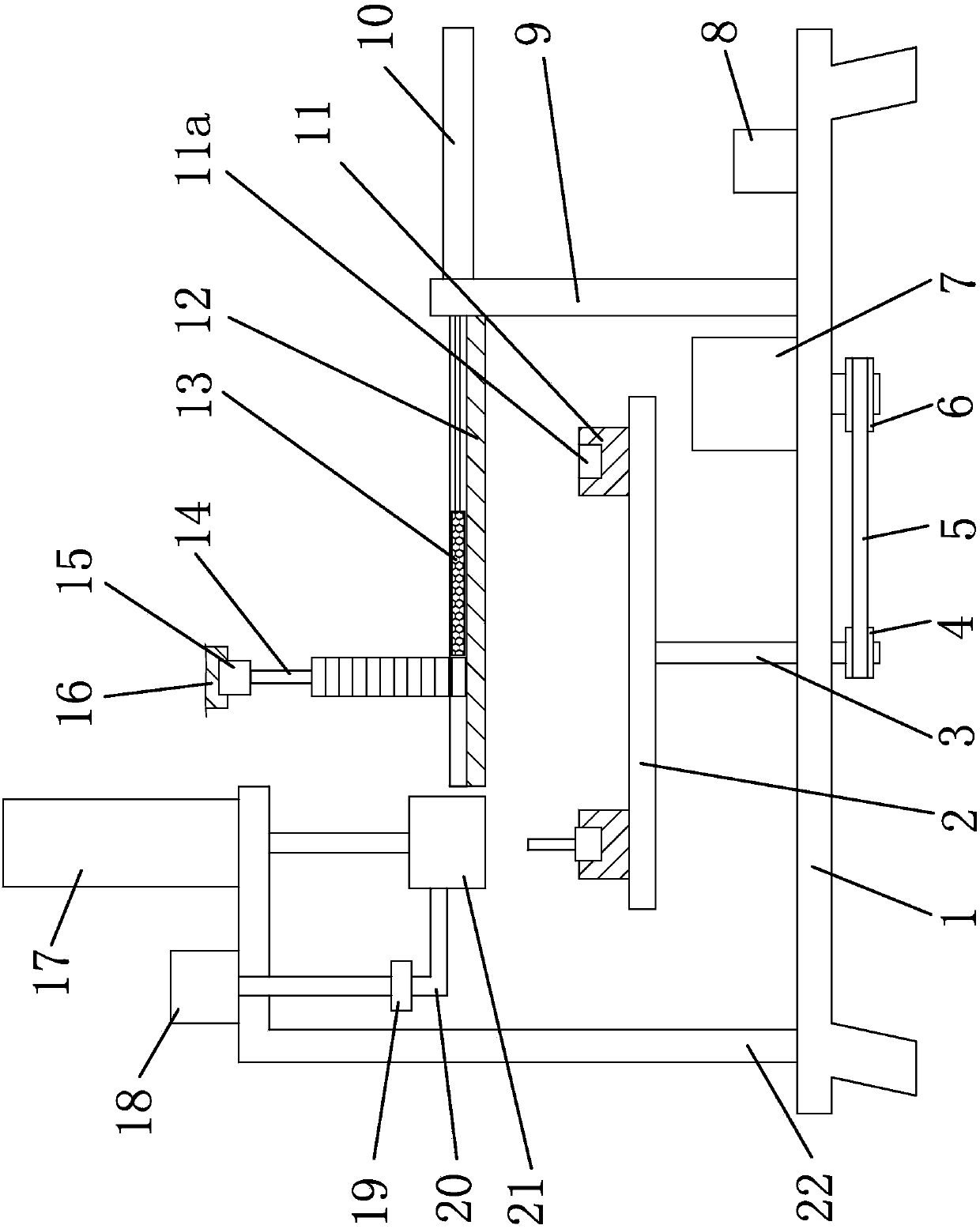

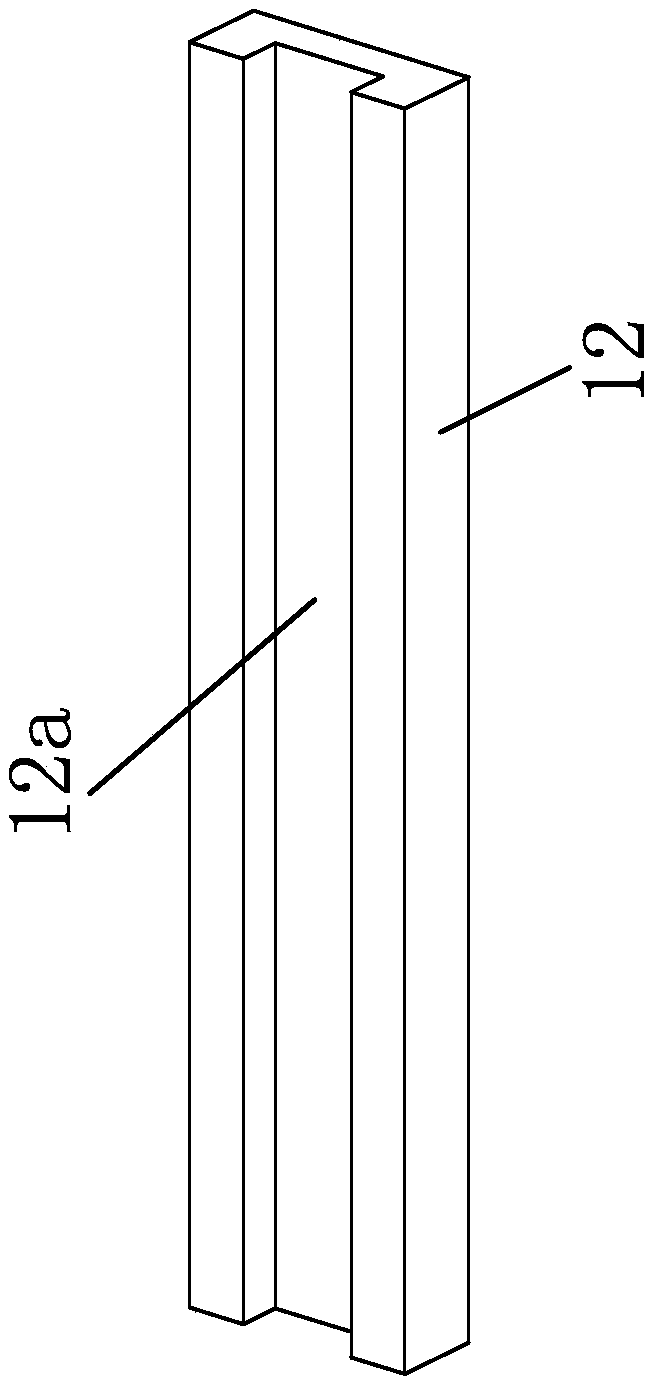

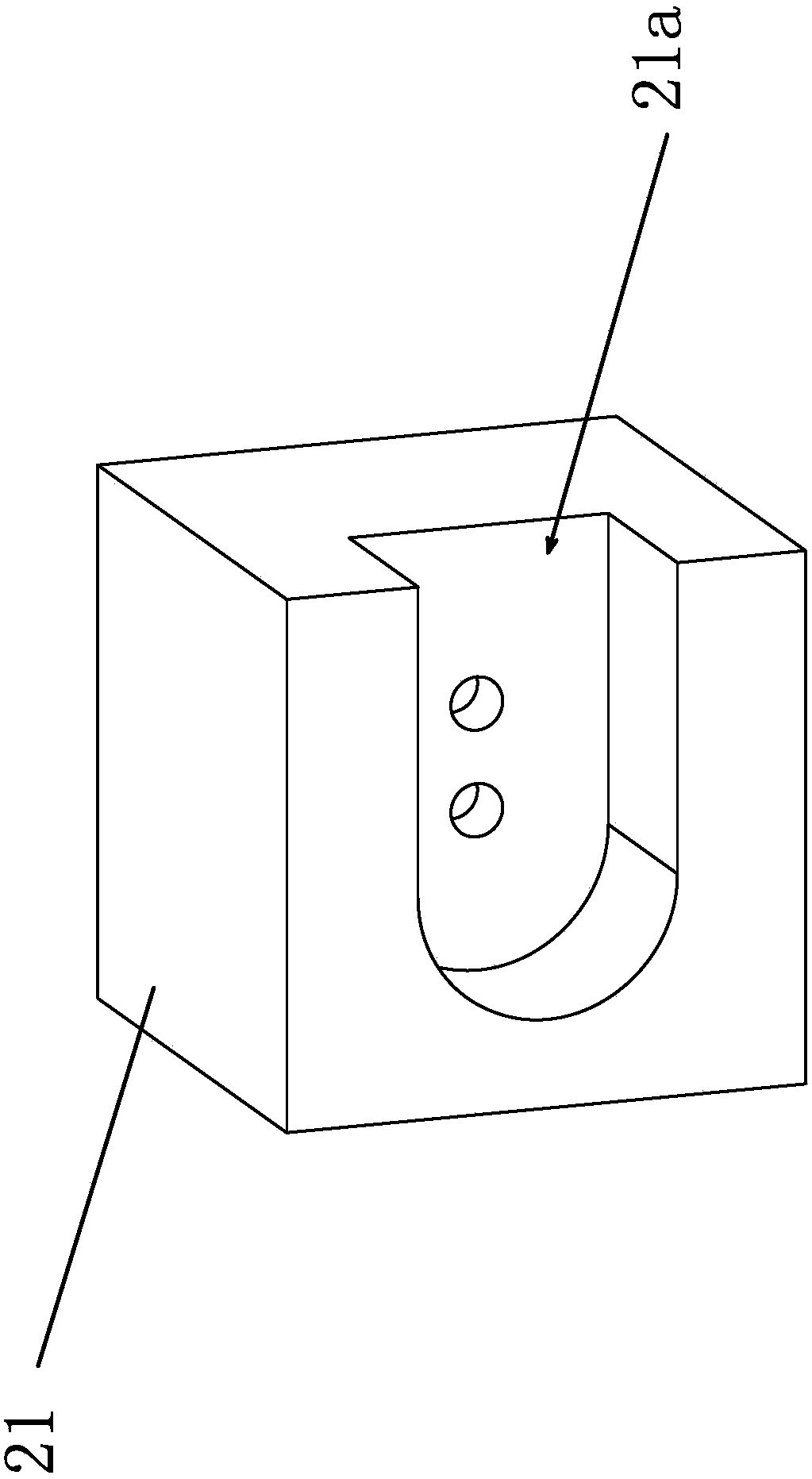

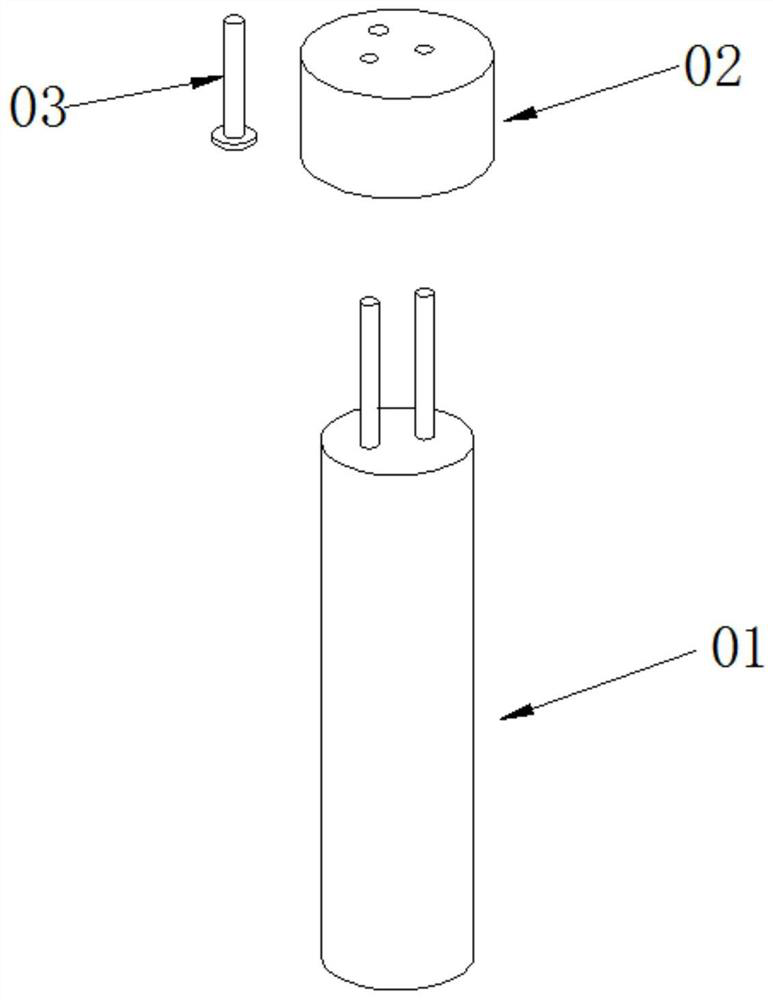

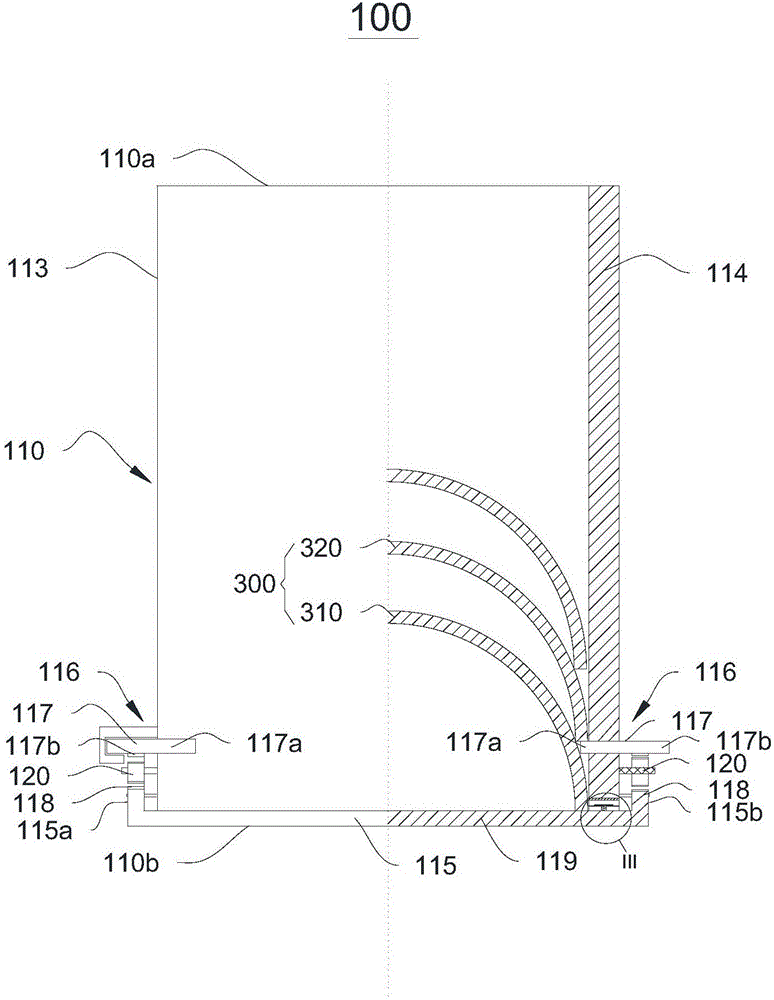

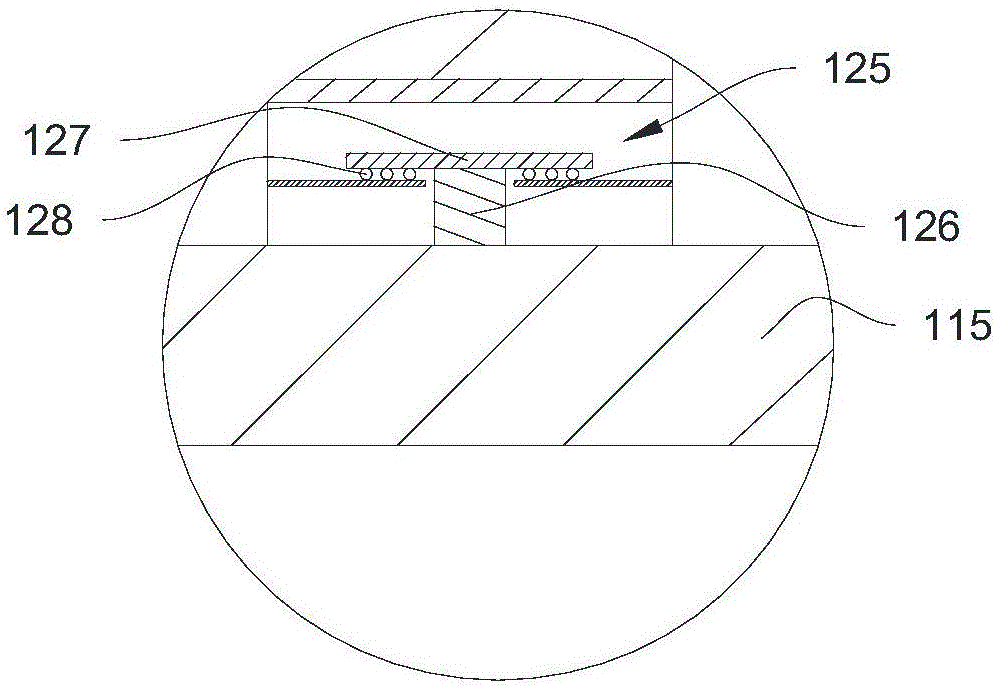

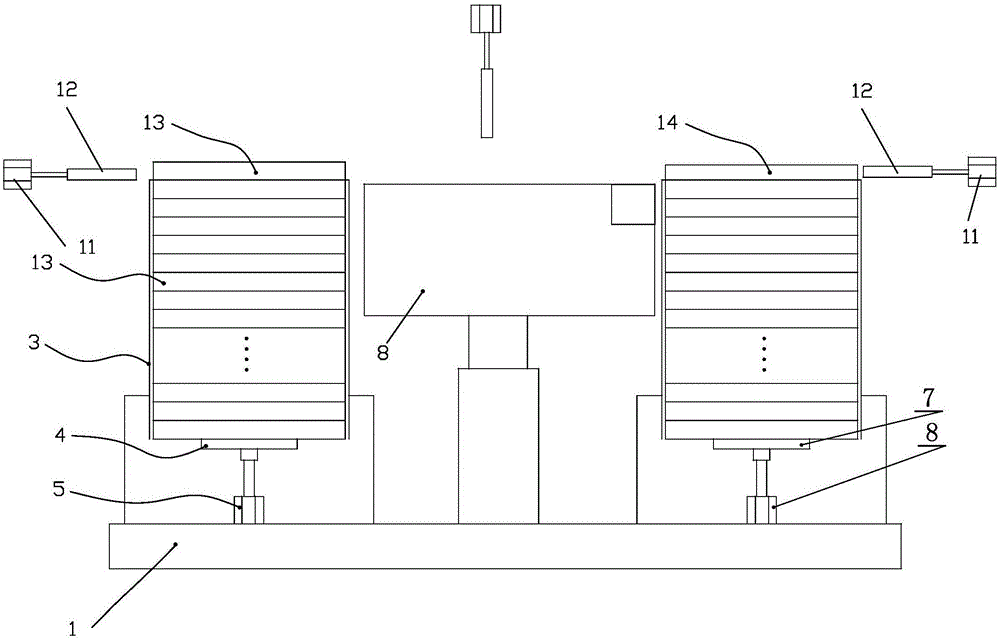

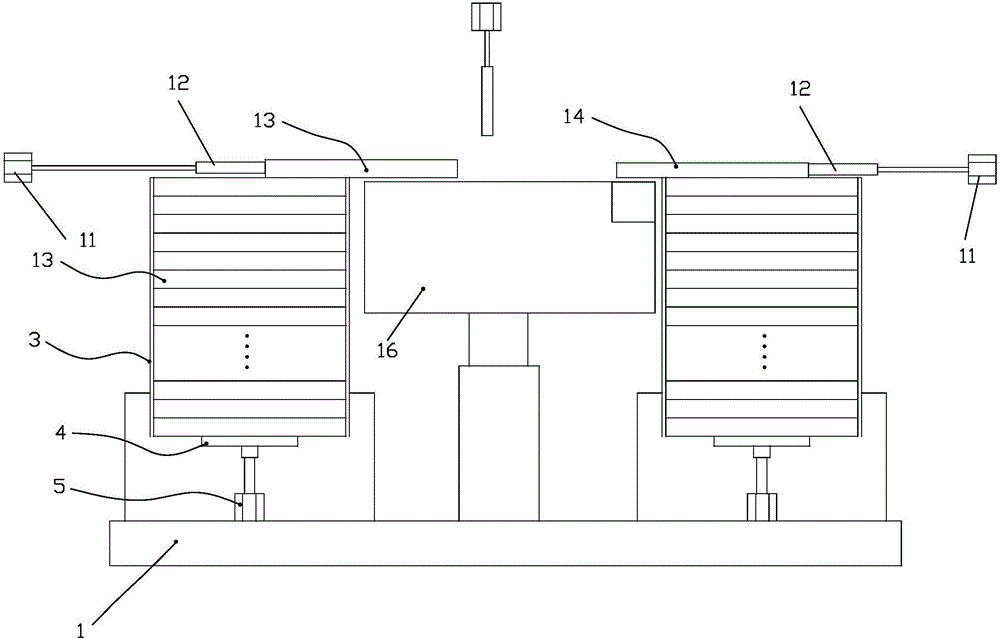

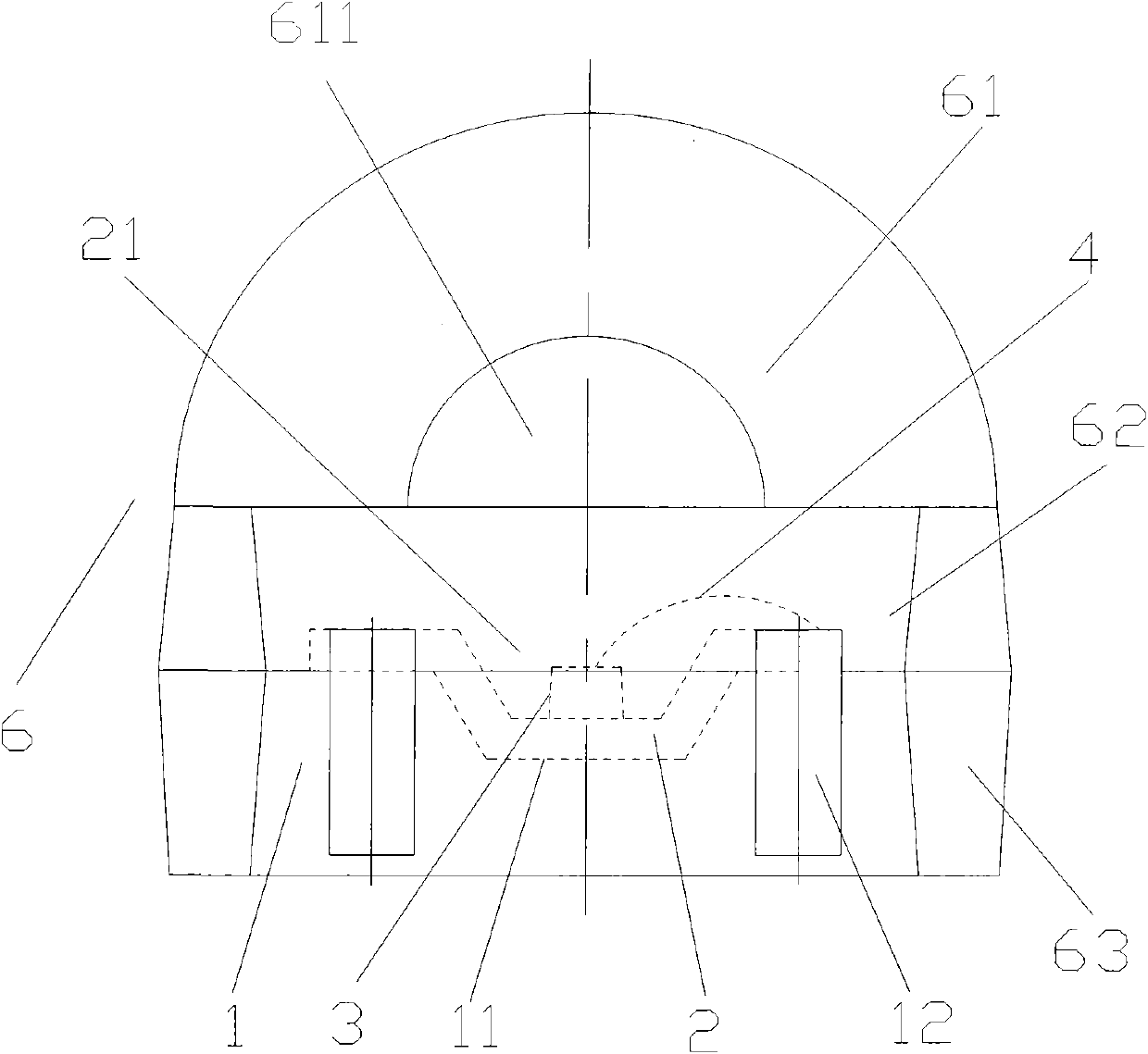

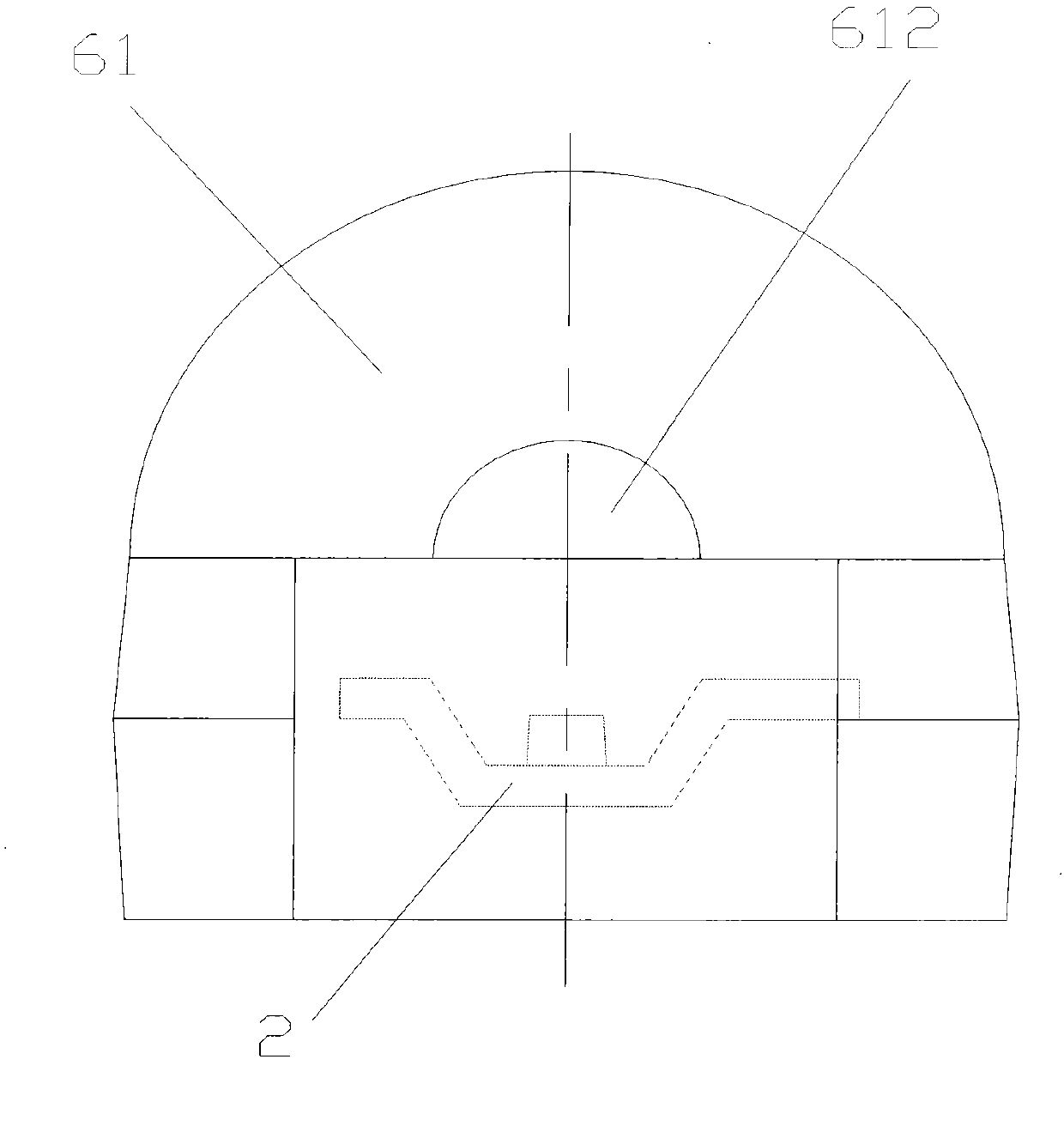

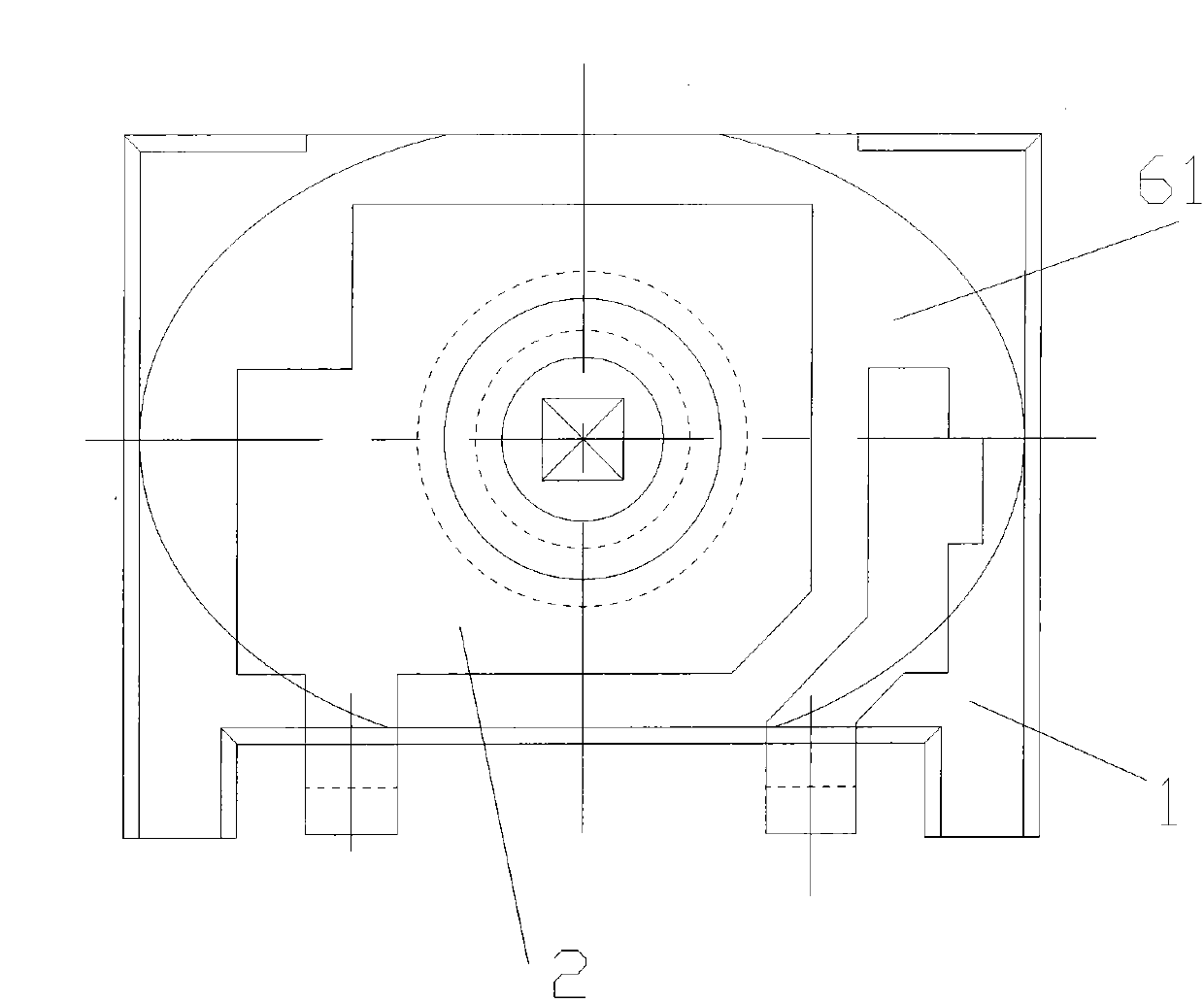

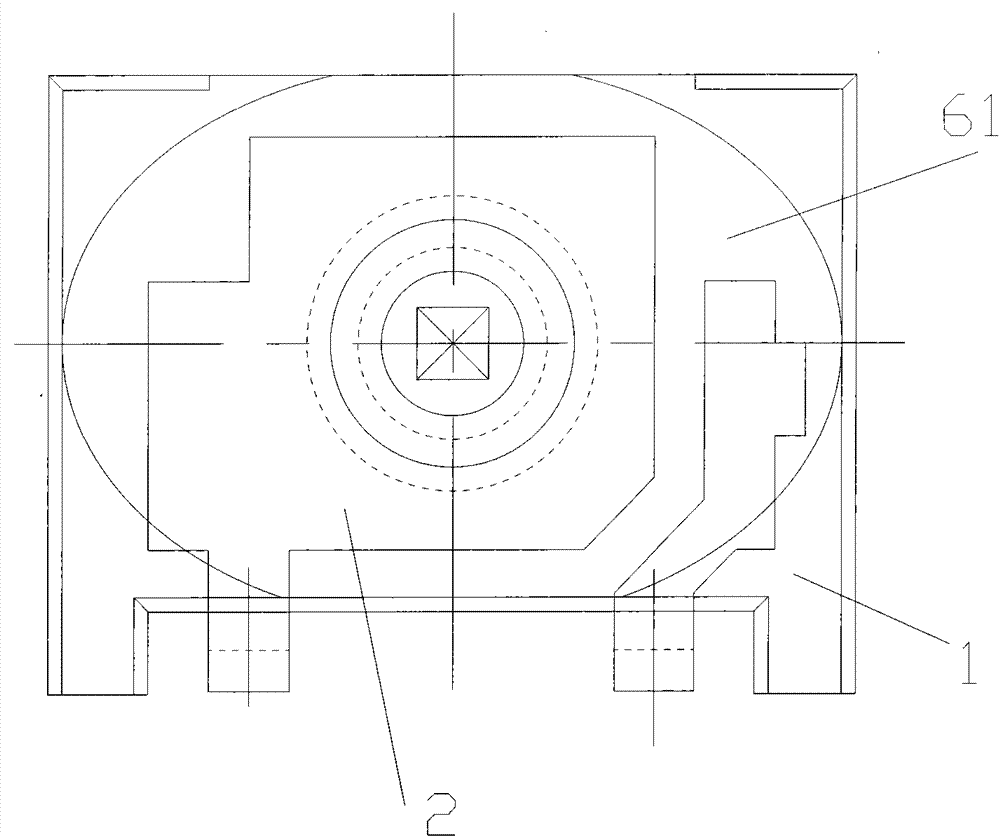

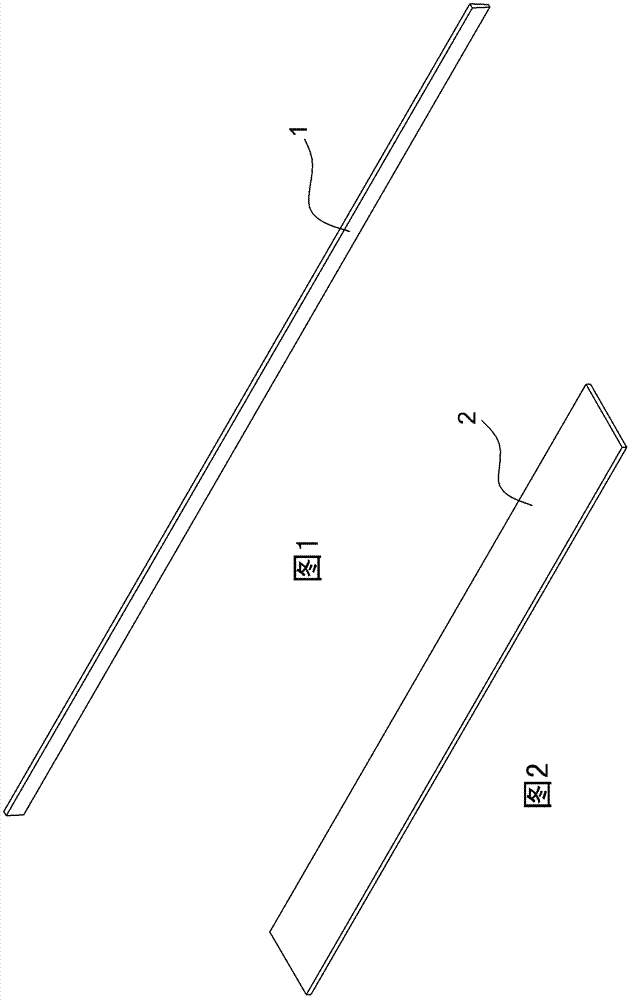

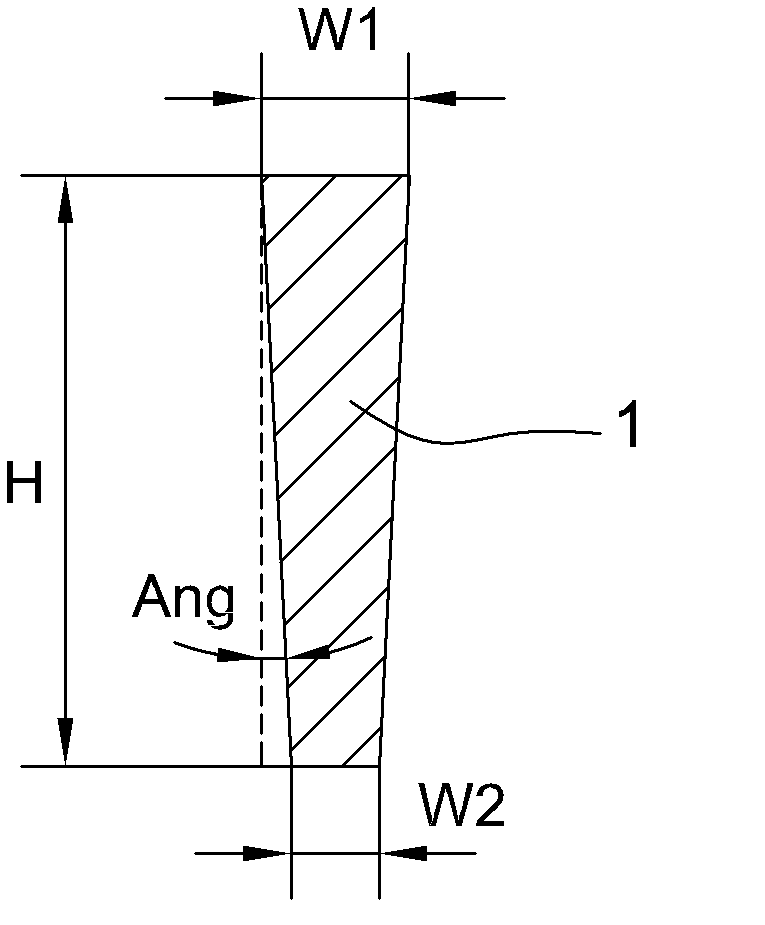

Trial model capable of simulating shield tunnel pipe slice joint and manufacturing method thereof

InactiveCN101299008ANo manual assembly requiredUnderground chambersStructural/machines measurementTest sampleEngineering

The present invention discloses a test model which can simulate the pipe sheet joint of the shield tunnel and a preparing method thereof. The test sample is a pipe which is cut along the annular direction and direction of longitudinal axis on the circumferential surface to correspondingly form an annular joint and a longitudinal joint. According to the invention through cutting in annular direction and direction of longitudinal axis, the longitudinal joint and longitudinal joint are formed on the surface of model thereby that the annular joint and longitudinal joint of pipe sheet on the tunnel structure can be simulated, and the effect of tunnel joint to the stiffness of tunnel can be truly reflected. Additionally, the machine can be used for realizing cutting. Not only the former time-wasting and strength-wasting artificial assembling is replaced, but also the test error can be reduced.

Owner:TONGJI UNIV

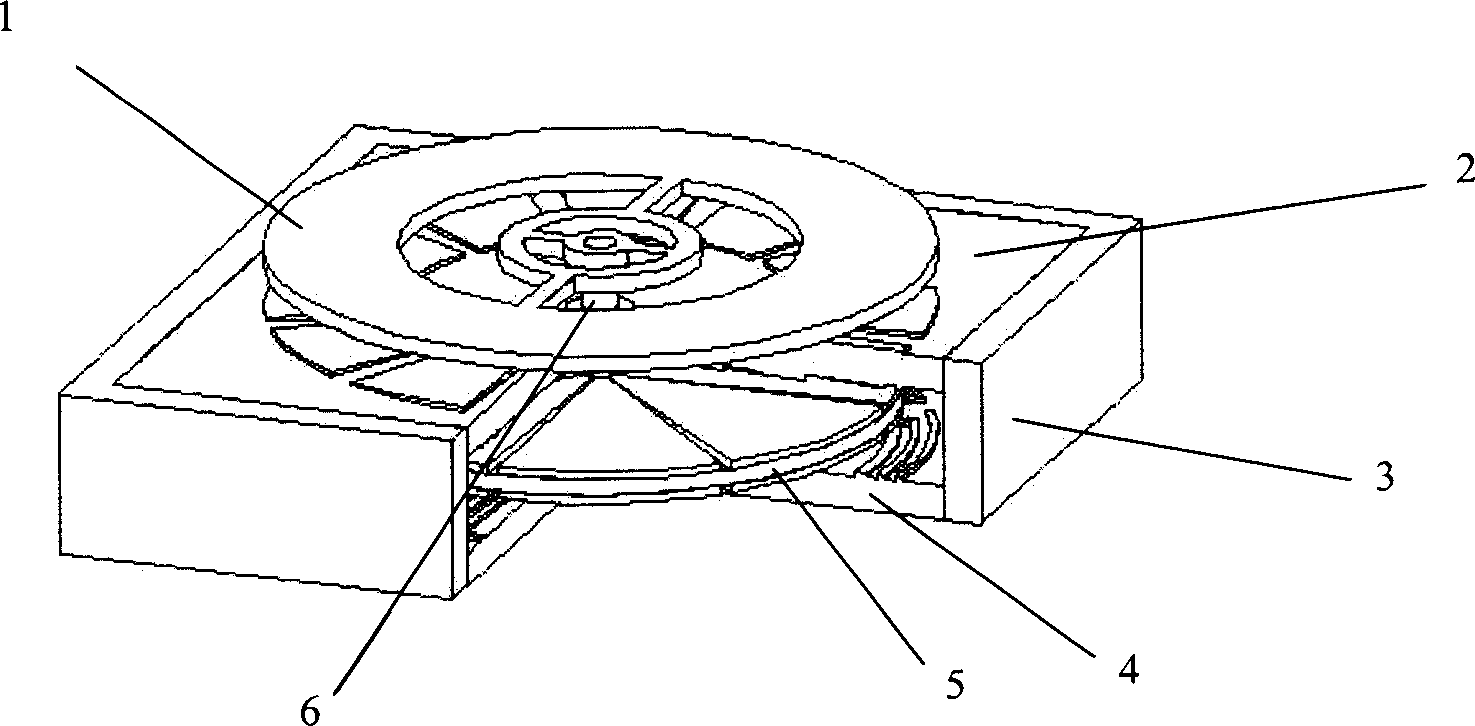

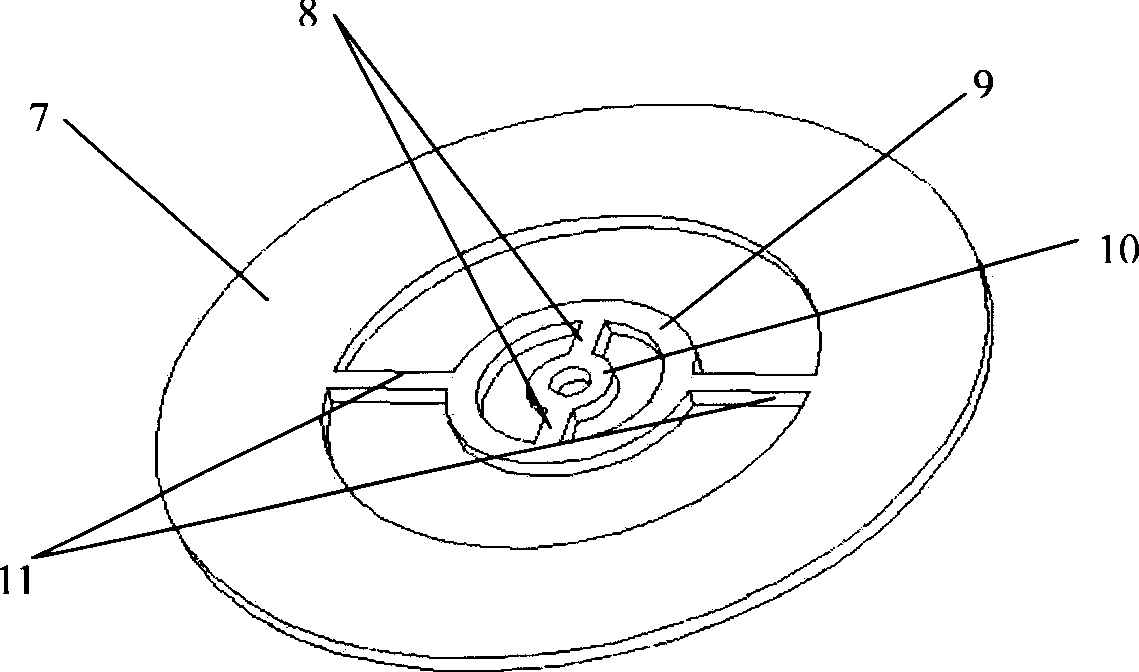

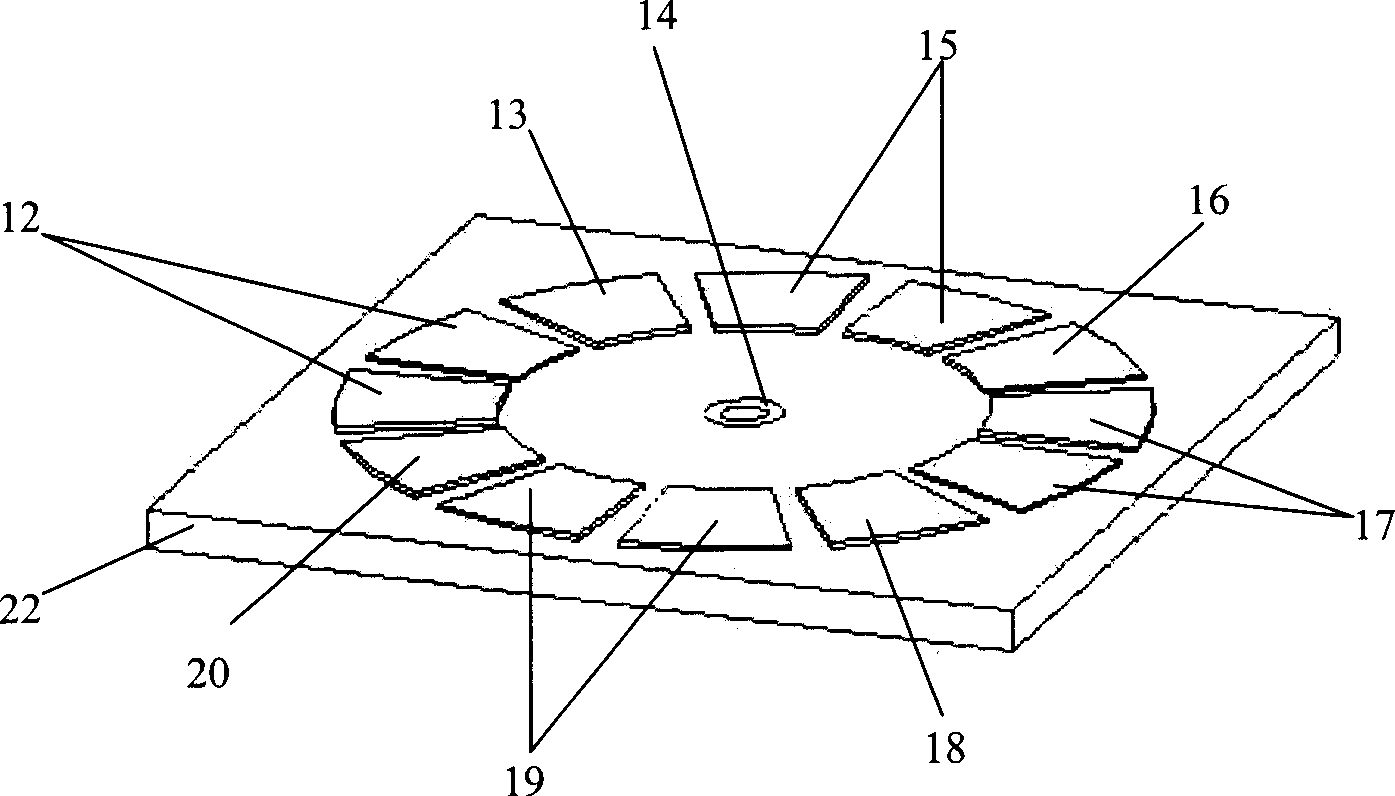

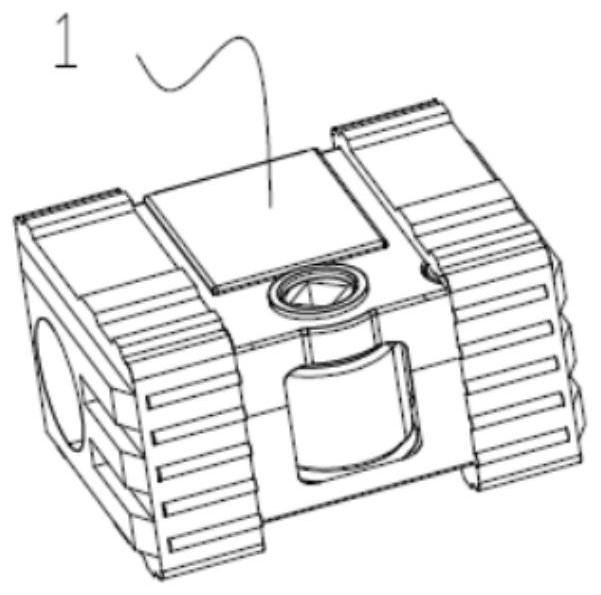

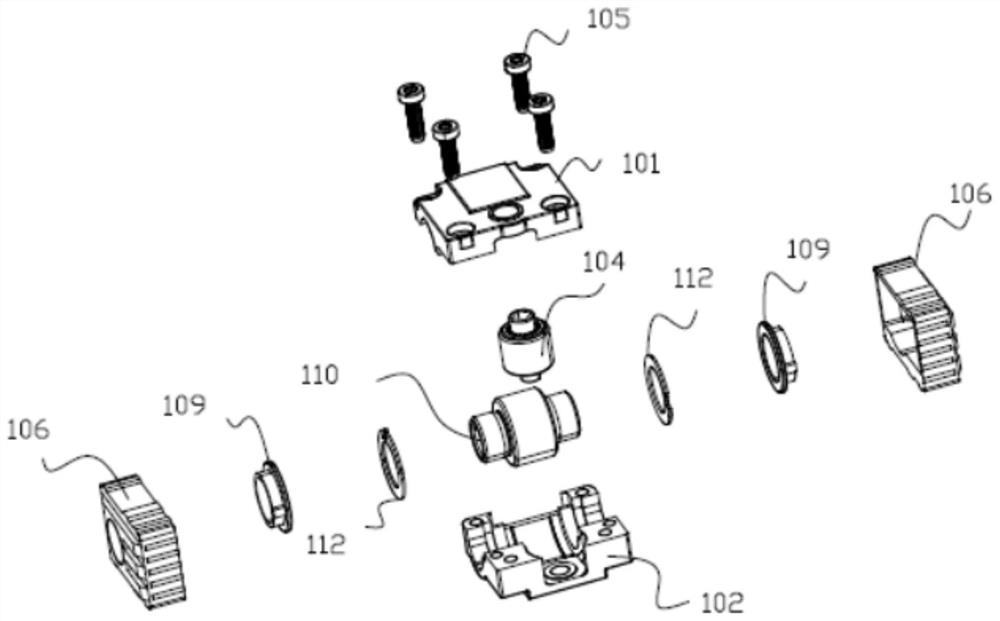

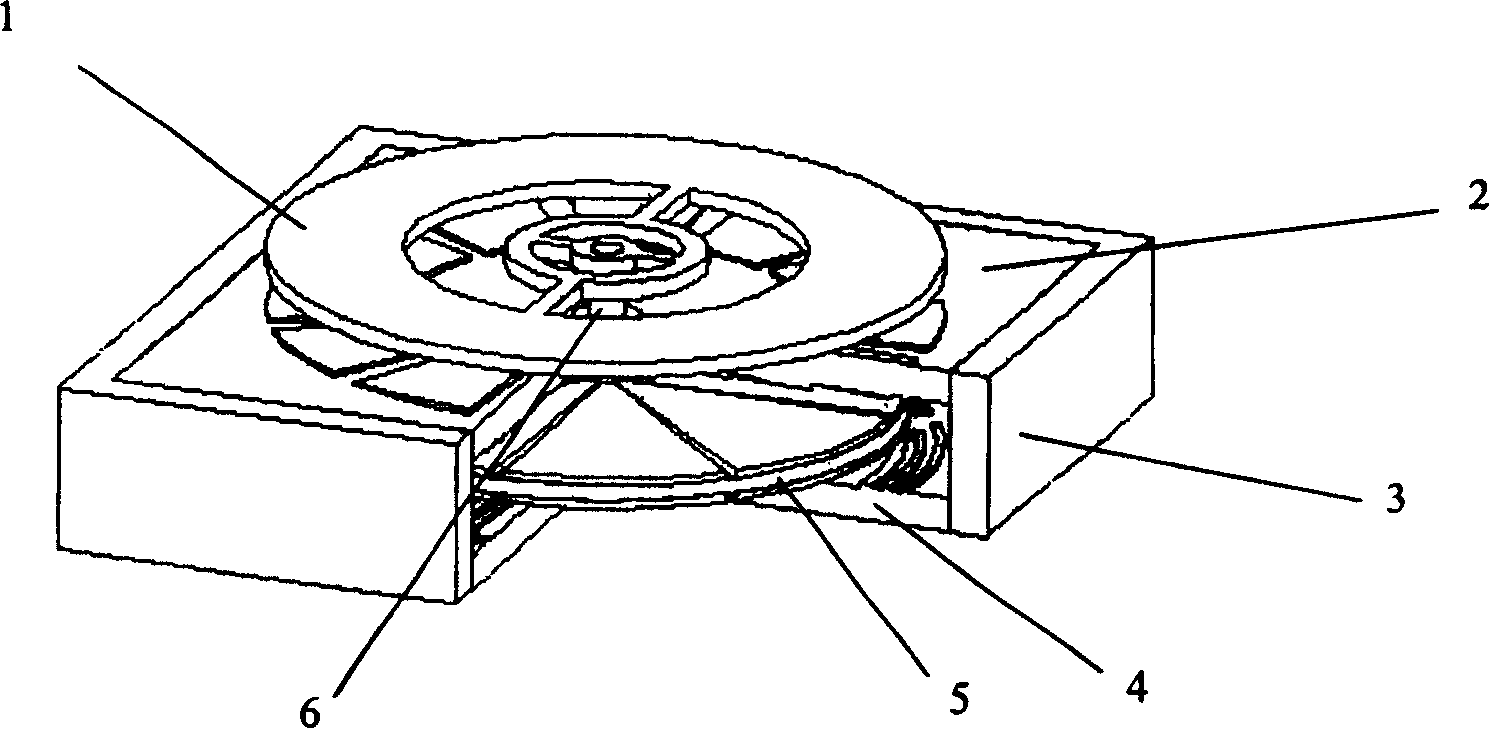

Flexible microgyrorotor and electromagnetic drive and dynamic tune

InactiveCN1712894AWith dynamic tuningAvoid the influence of fixed axisRotary gyroscopesStatorEngineering

A micro-gyroscope of flexible rotor tuned by electromagnetic driving force is prepared by setting top rotor and bottom rotor at top and bottom of shell, setting one jewel bearing at center hole of top rotor, setting another at center hole of bottom rotor, placing shaft on both bearings and driving rotor on shaft between top and bottom rotors, setting gyroscope rotor on shaft above top rotor. The prepared micro-gyroscope can be used as orientational gyroscope.

Owner:SHANGHAI JIAO TONG UNIV

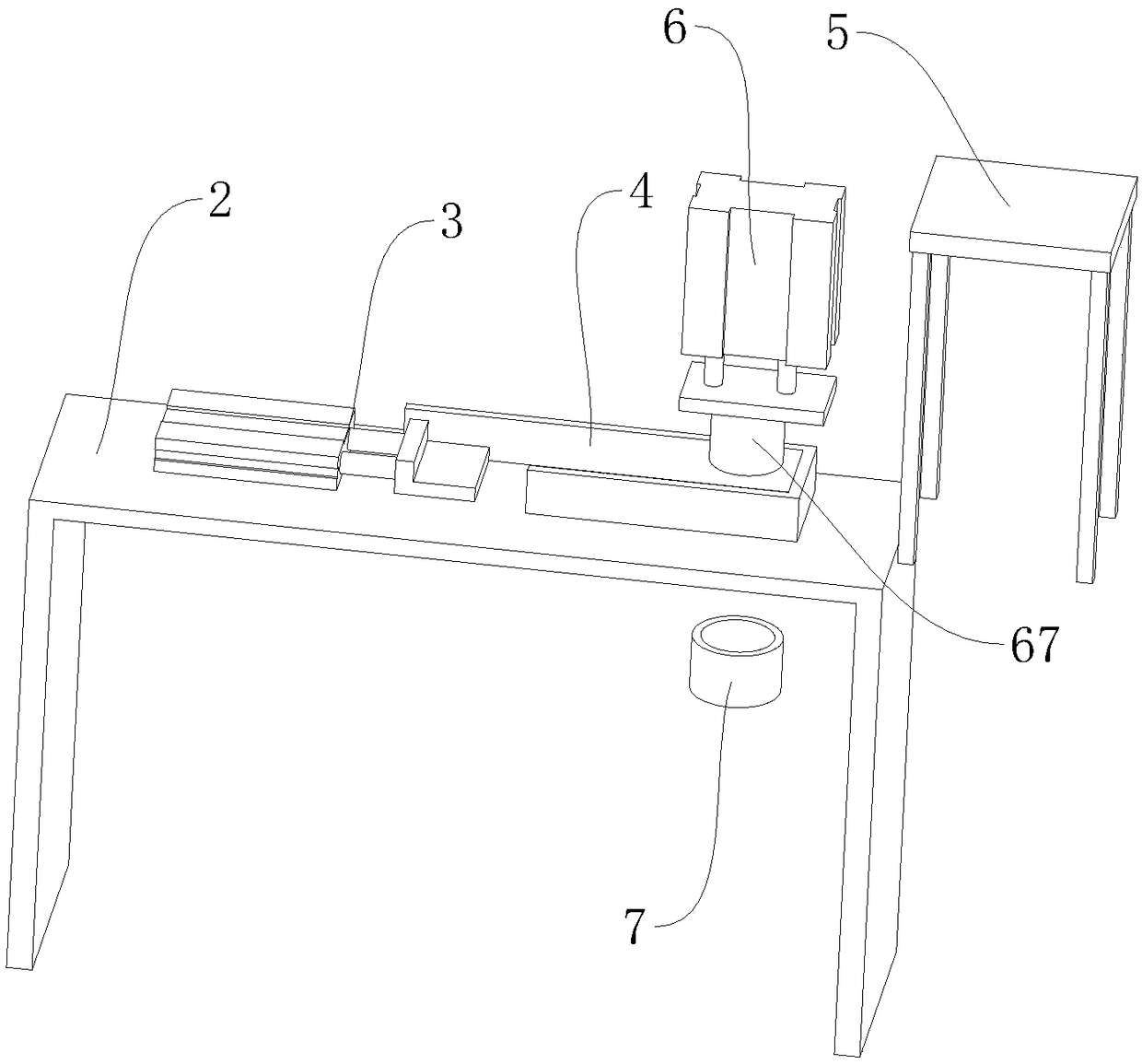

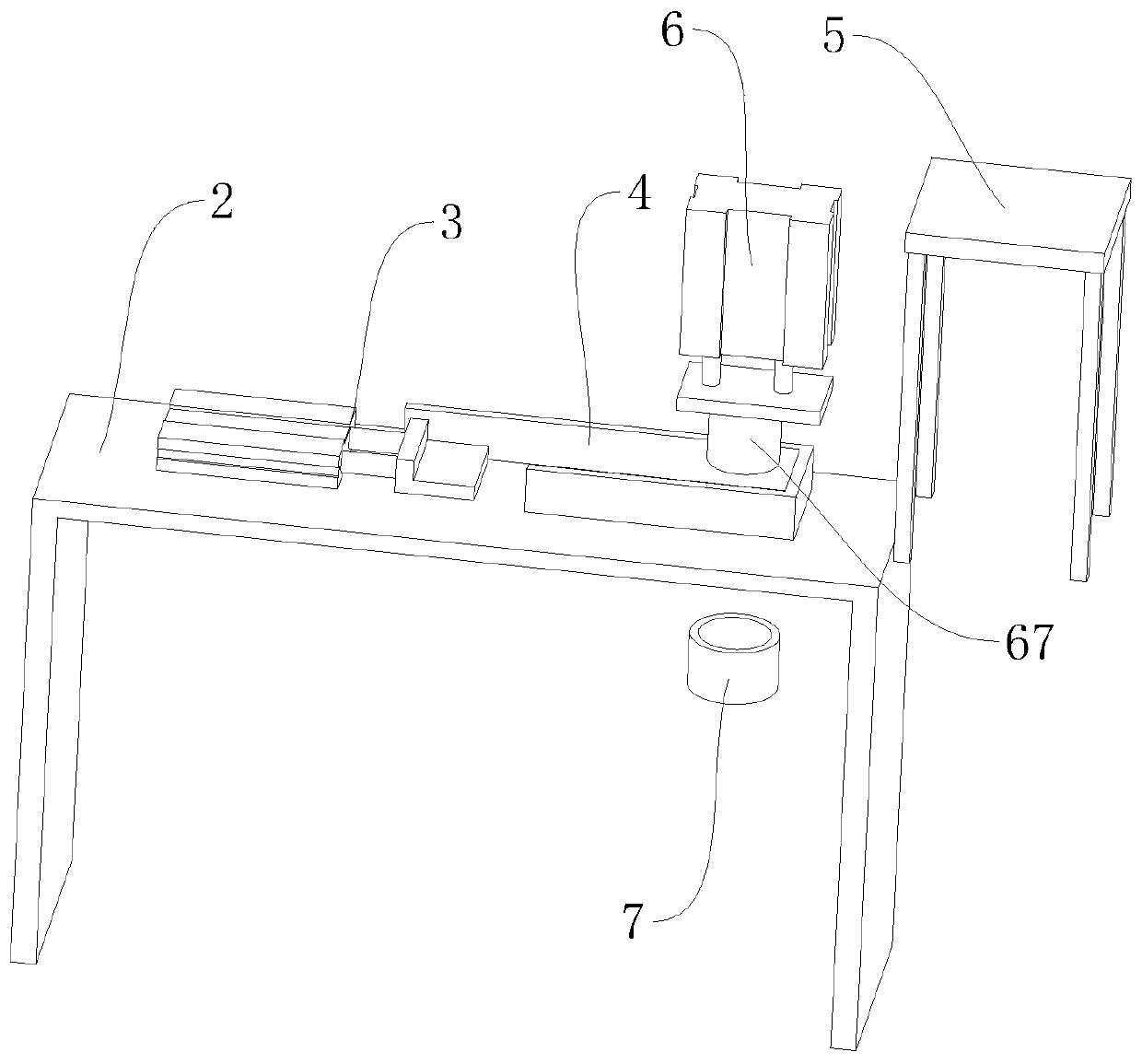

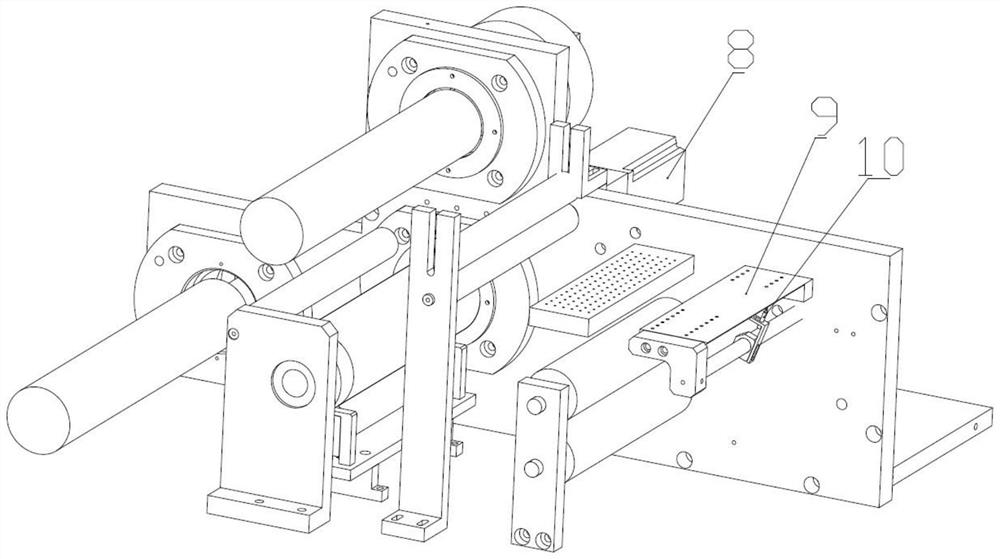

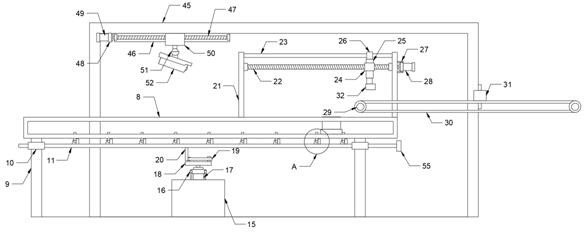

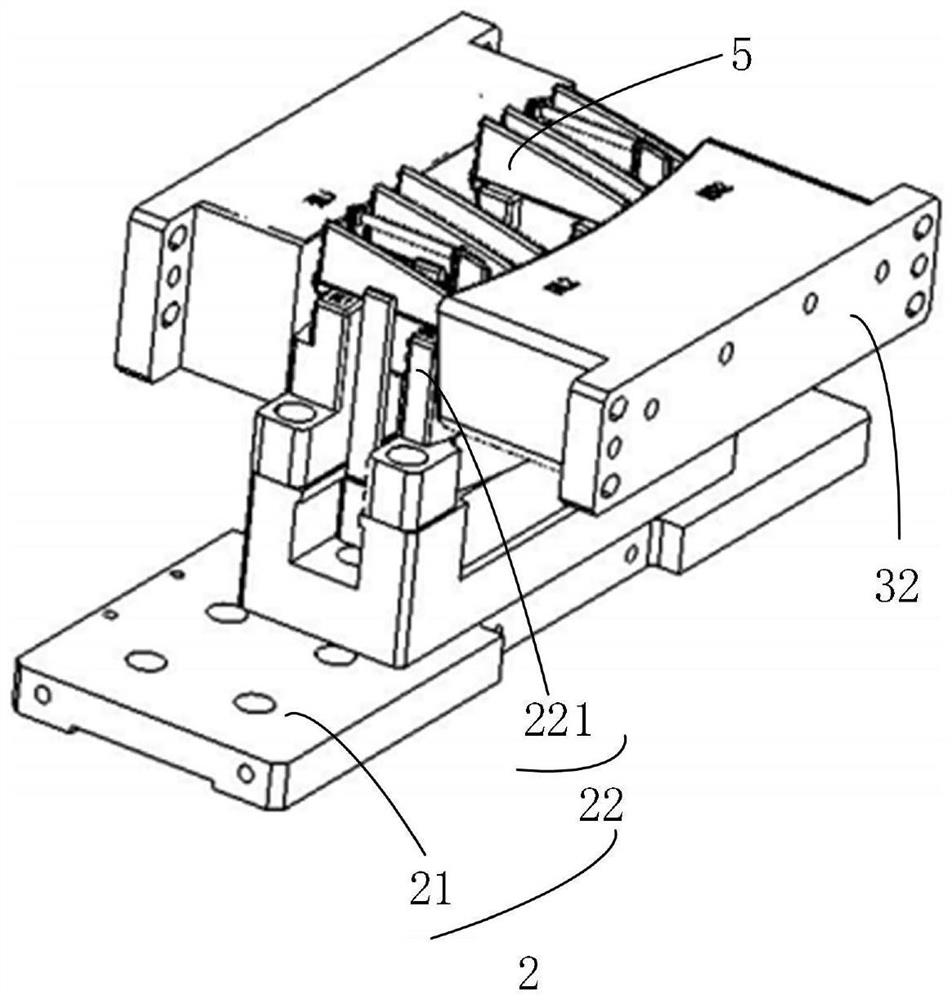

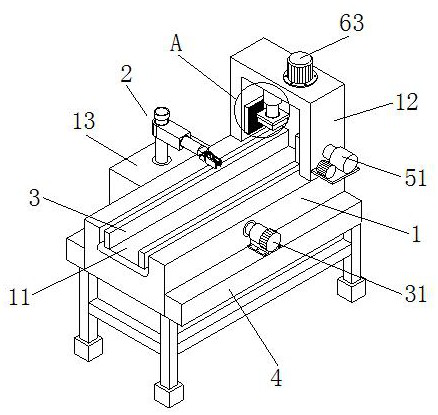

Gasket assembling mechanism

The invention provides a gasket assembling mechanism. The mechanism comprises upper and lower slide rails, which are horizontally and transversely arranged, wherein a first slide rail is fixed on a base; a second slide rail is mounted on the first slide rail by a slide block; a horizontal long bottom plate is placed close to the lower surface of the second slide rail; the bottom plate is mounted on the second slide rail by a slide block; a locating groove and a locating hole matched with each other are respectively formed in the second slide rail and the bottom plate; a spring and a locating block are pressed into the locating hole in sequence; the locating block is impelled upward by the spring; a compression cylinder is placed on one side of the second slide rail; a rack for bearing parts is arranged on the right side of the bottom plate; the rack can lift up and down; and by a double-slide-rail moving mechanism, a gasket is pushed to enter a narrow part recess of a mounting space; full mechanical operation of the whole assembling process can be achieved, manual assembling is not needed and high assembling efficiency is achieved; moreover, the gasket assembling mechanism provided by the invention has the advantages of simple structure, good reliability, accurate assembling position and comparatively low production and machining cost.

Owner:SHANGHAI UNIV OF ENG SCI

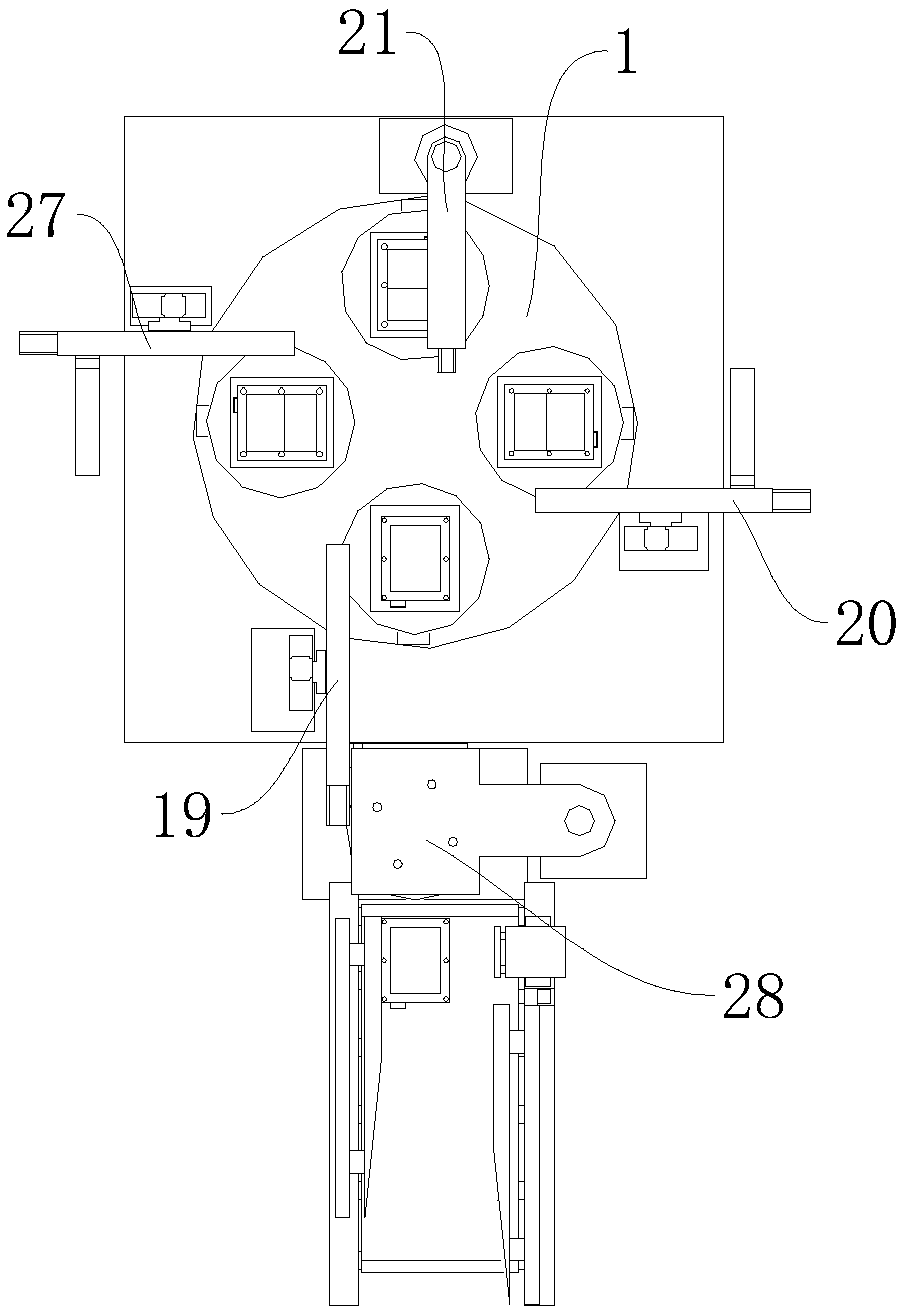

Automatic assembling device for air filter shell

The invention relates to the technical field of automatic assembling, in particular to an automatic assembling device for an air filter shell. The device comprises a workbench and a conveyor, and further comprises a bearing jig, a rotating device, a lower shell feeding device, an upper shell feeding device, an installing device, a finished product unloading device and a lower shell position detecting device, the rotating device is arranged at the top end of the workbench, the rotating device comprises a rotating disc, the bearing jig is arranged at the top end of the rotating disc, the lower shell feeding device, the upper shell feeding device, the installing device and the finished product unloading device are all installed at the top end of the workbench and arranged at the edge of the rotating disc at equal angles in the circumferential direction of the rotating disc, the lower shell position detecting device is arranged at the side of the workbench, and due to cooperation of the bearing jig, the rotating device, the lower shell feeding device, the upper shell feeding device, the installing device, the finished product unloading device and the lower shell position detecting device, the problems that installing is slow and the labor cost is large are solved.

Owner:诸暨市凯贝乐科技有限公司

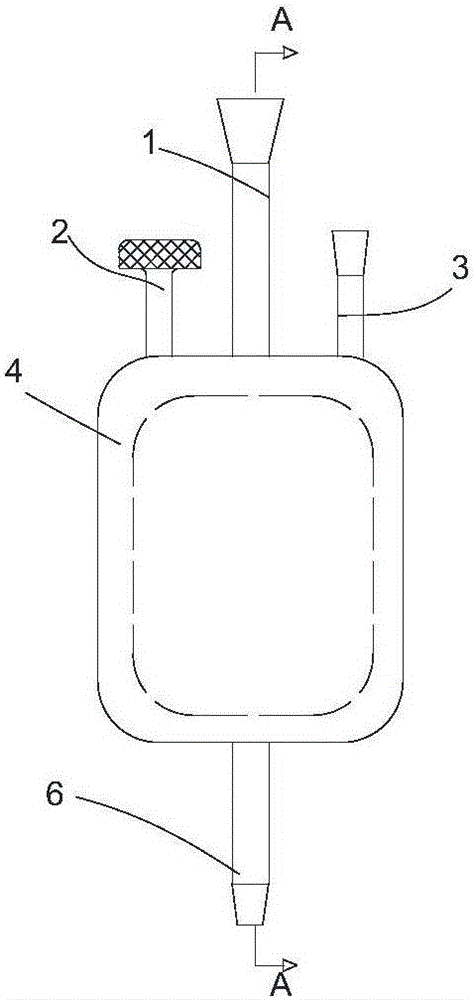

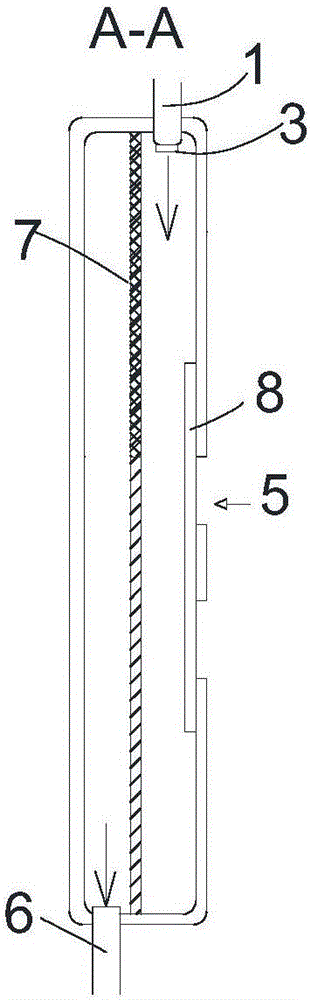

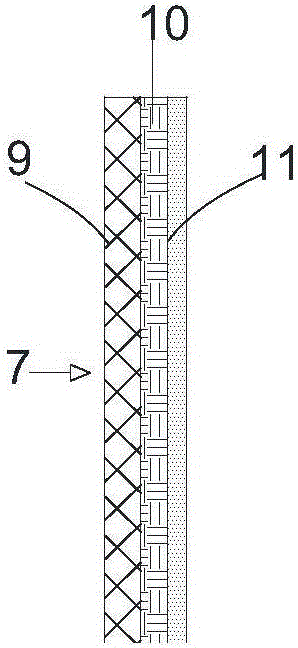

Soft-material high-polymer precision filter used for infusion and manufacturing method thereof

The invention provides a soft-material high-polymer precision filter used for infusion and a manufacturing method thereof. The soft-material high-polymer precision filter used for the infusion comprises a filter bag prepared from a light film material, and a precision filter screen is arranged in the filter bag so as to form a filter cavity and a drainage cavity; an input connector and a drug adding connector are arranged at the upper end of the filter bag, wherein the input connector and the drug adding connector are both communicated with the drainage cavity; an output connector is arranged at the lower end of the filter bag, wherein the output connector is communicated with the drainage cavity; and an exhaust device is further arranged on the filter bag. The soft-material high-polymer precision filter used for the infusion is low in cost, safe in filtration, and convenient to use; moreover, the soft-material high-polymer precision filter is also suitable for midway adding of drugs.

Owner:ZHENGZHOU KANGJIA MEDICAL DEVICE CO LTD +1

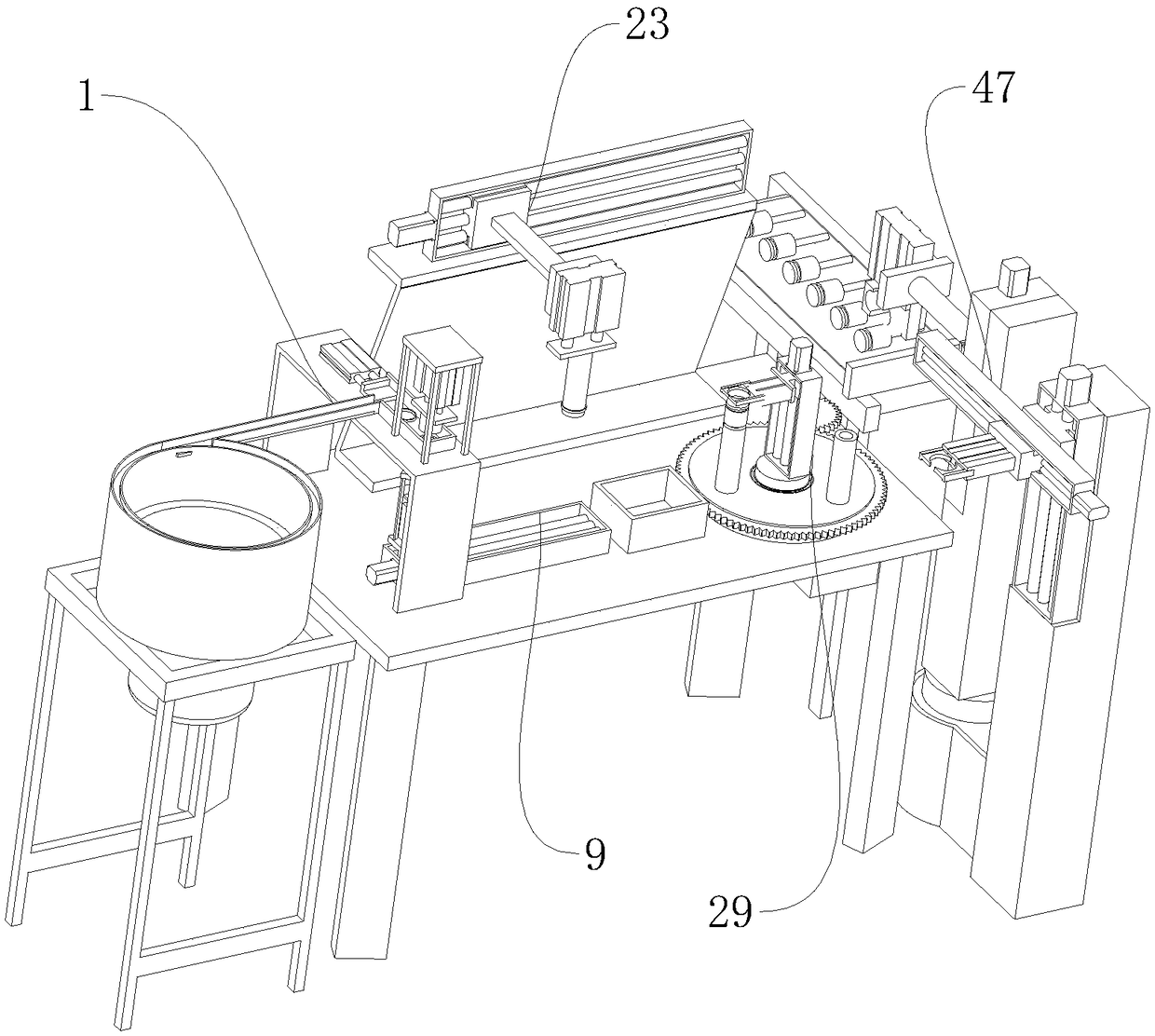

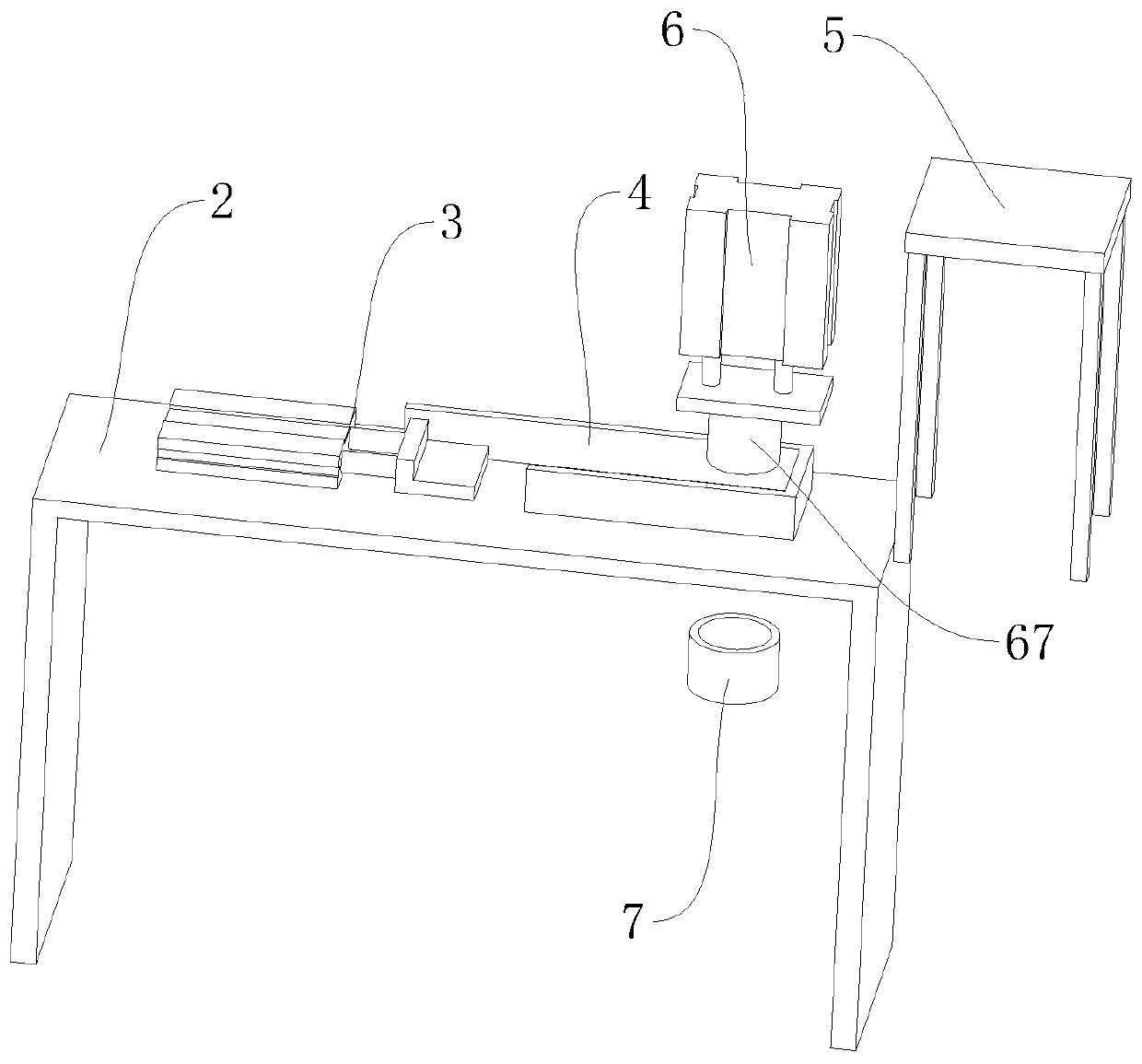

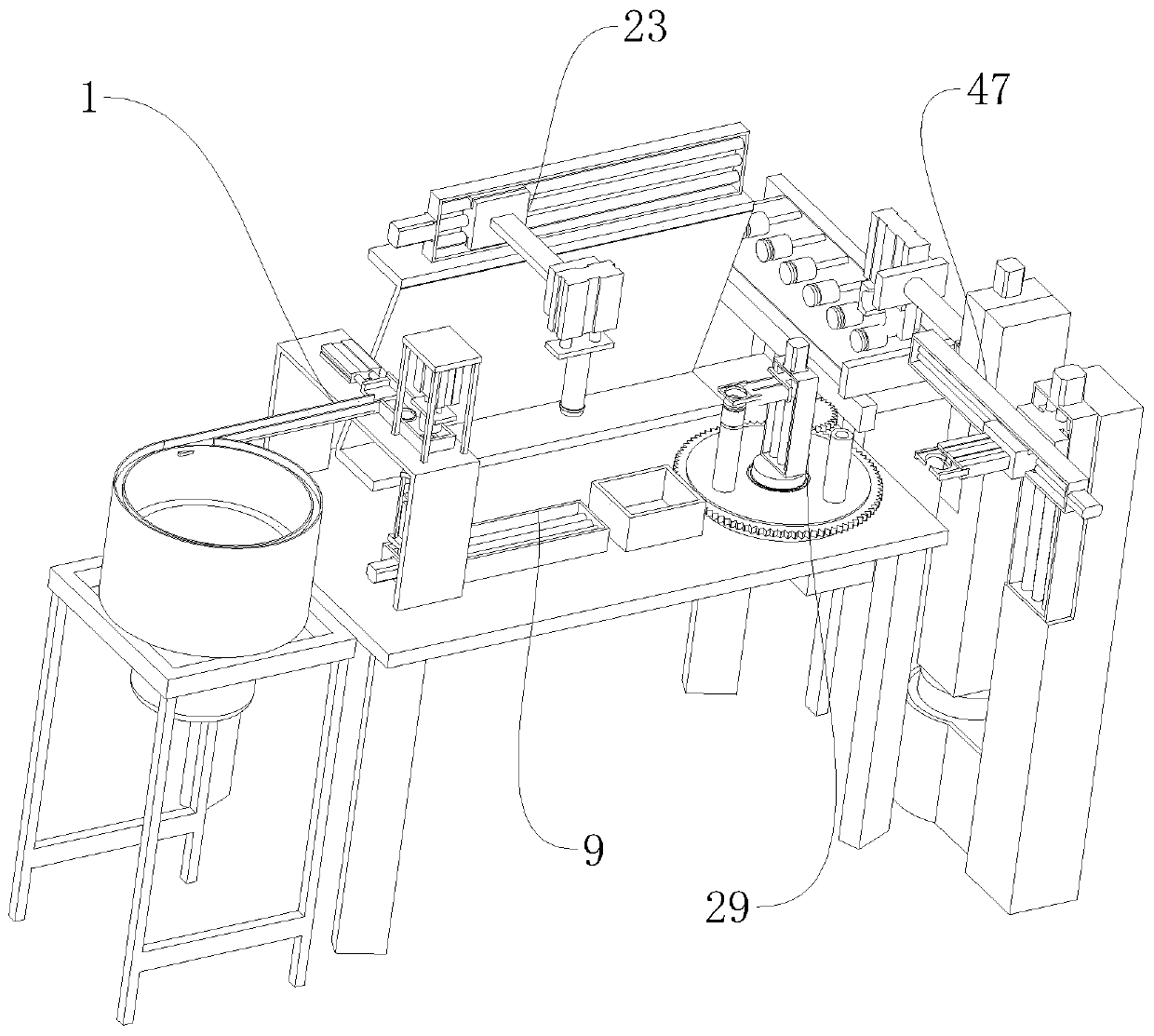

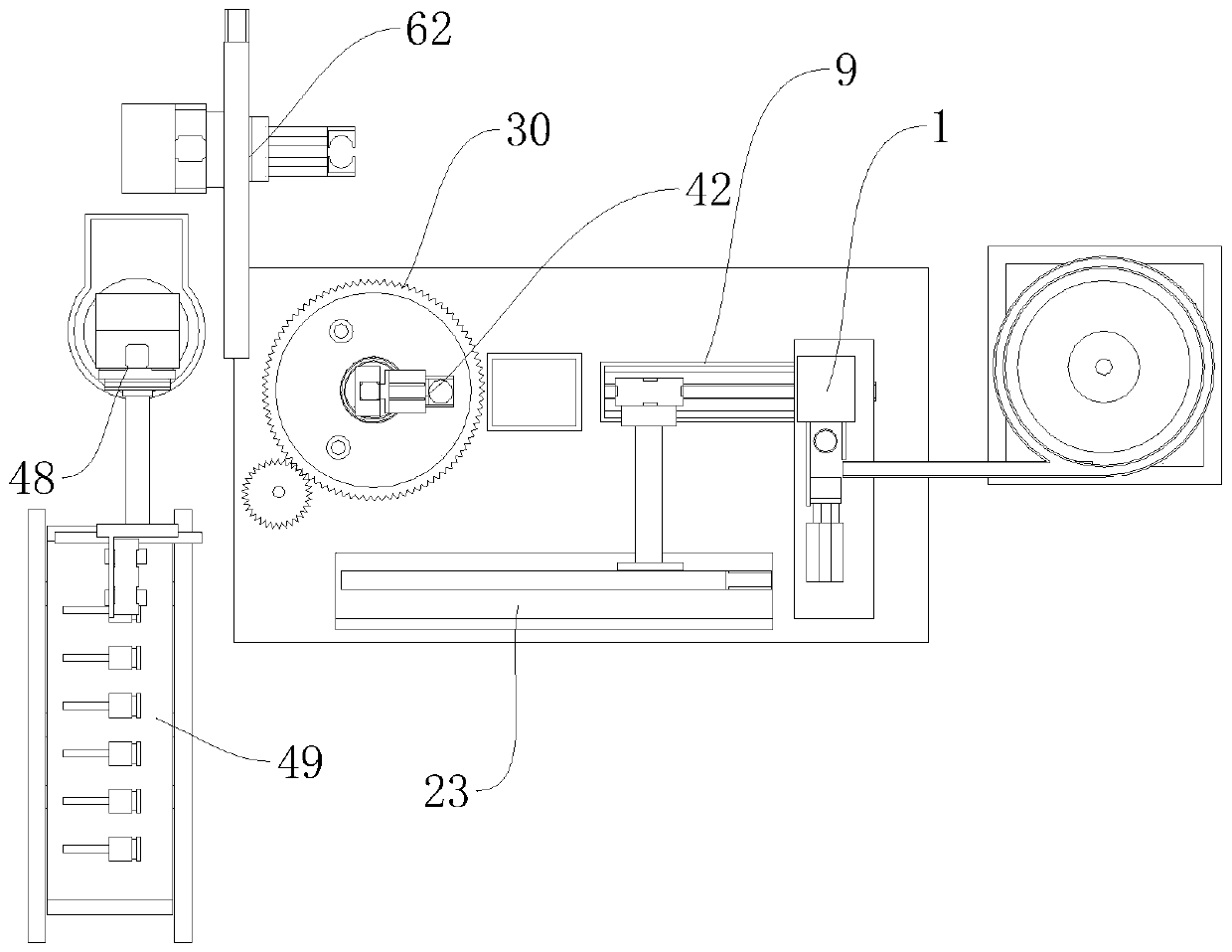

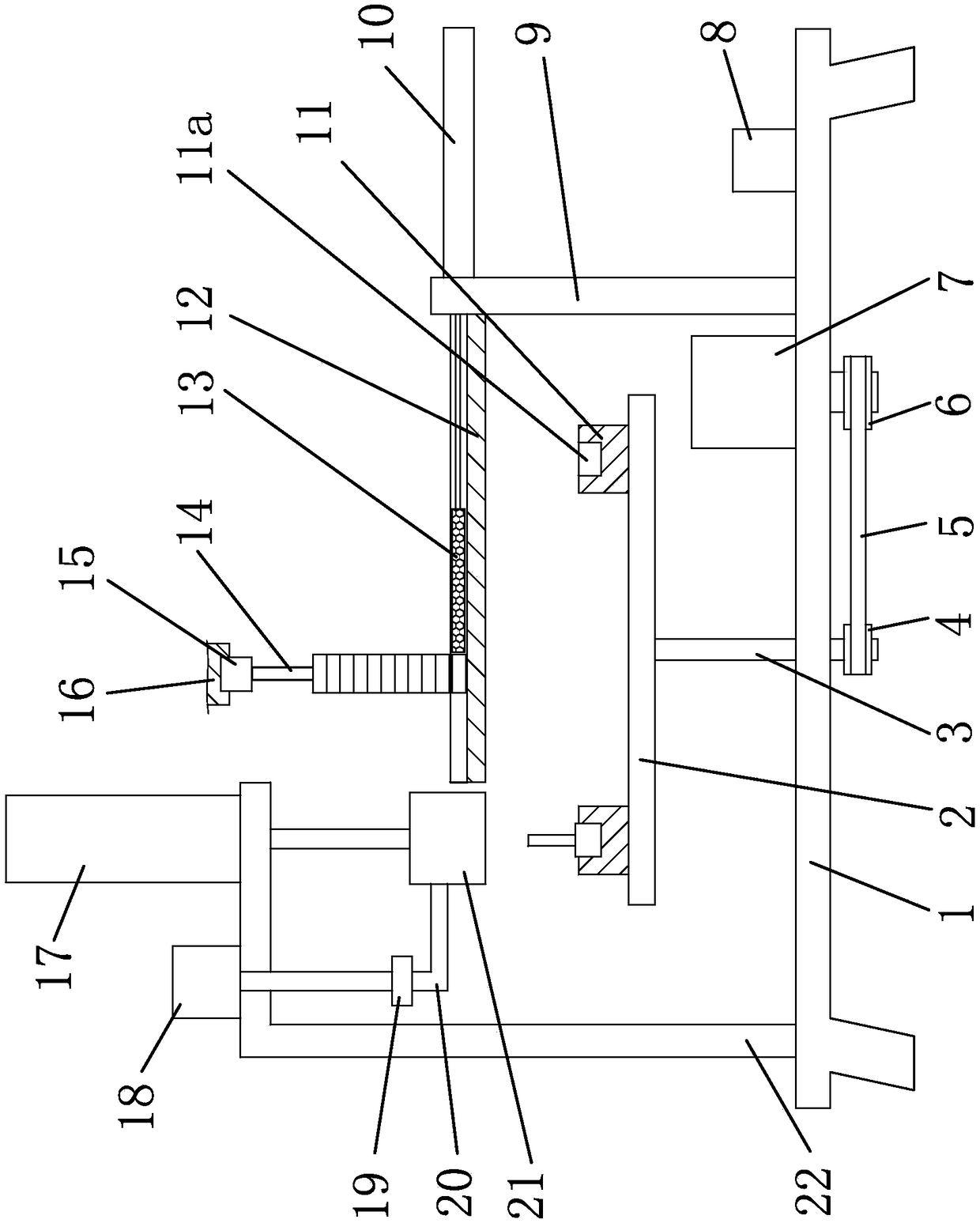

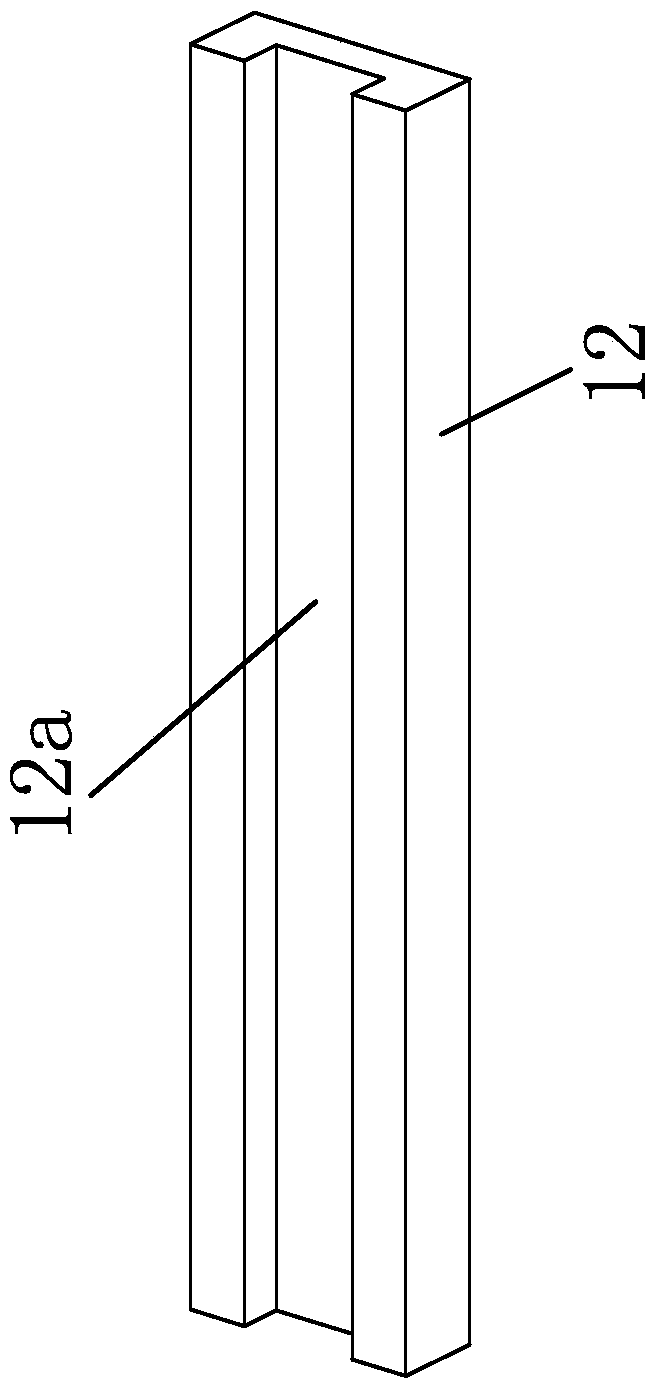

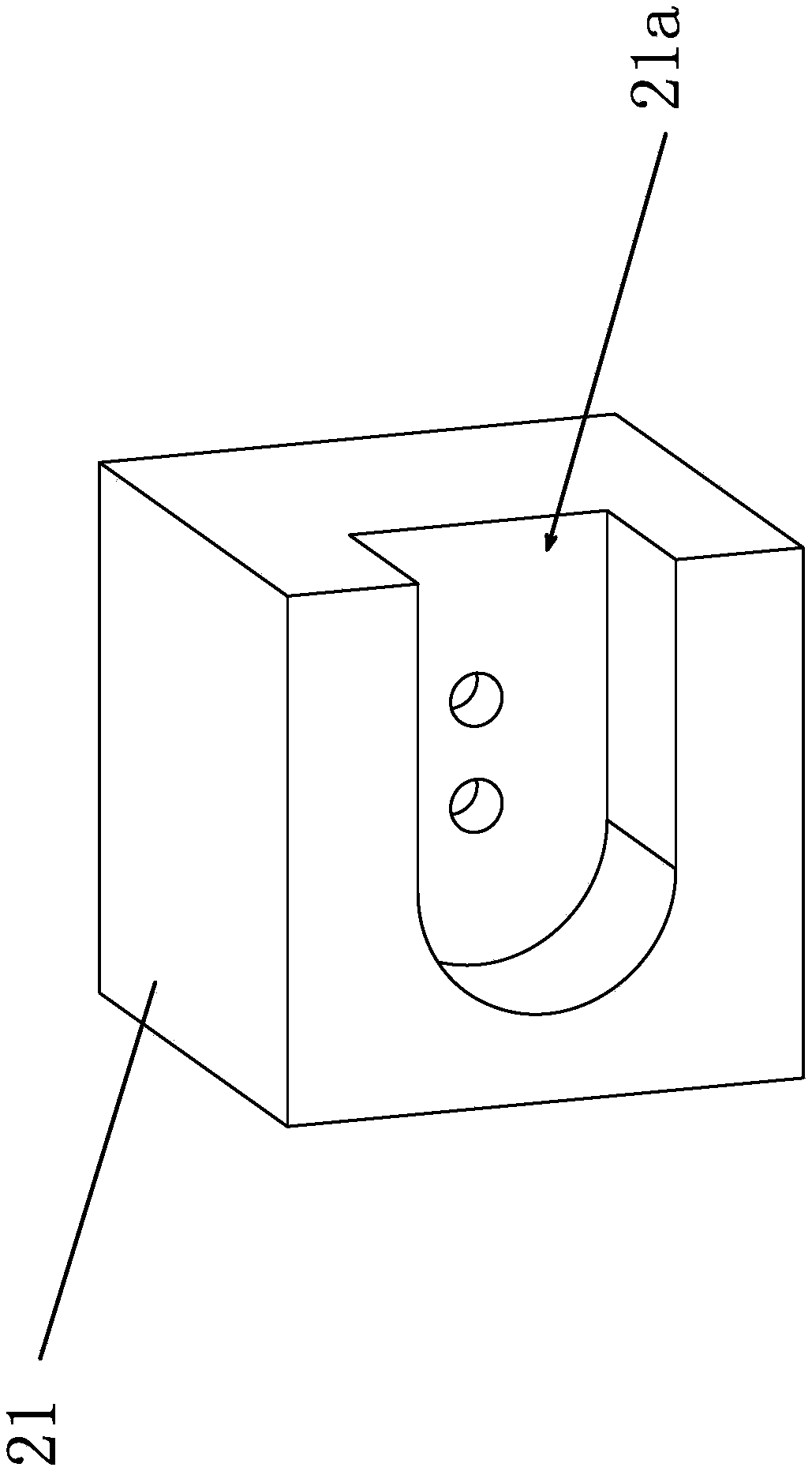

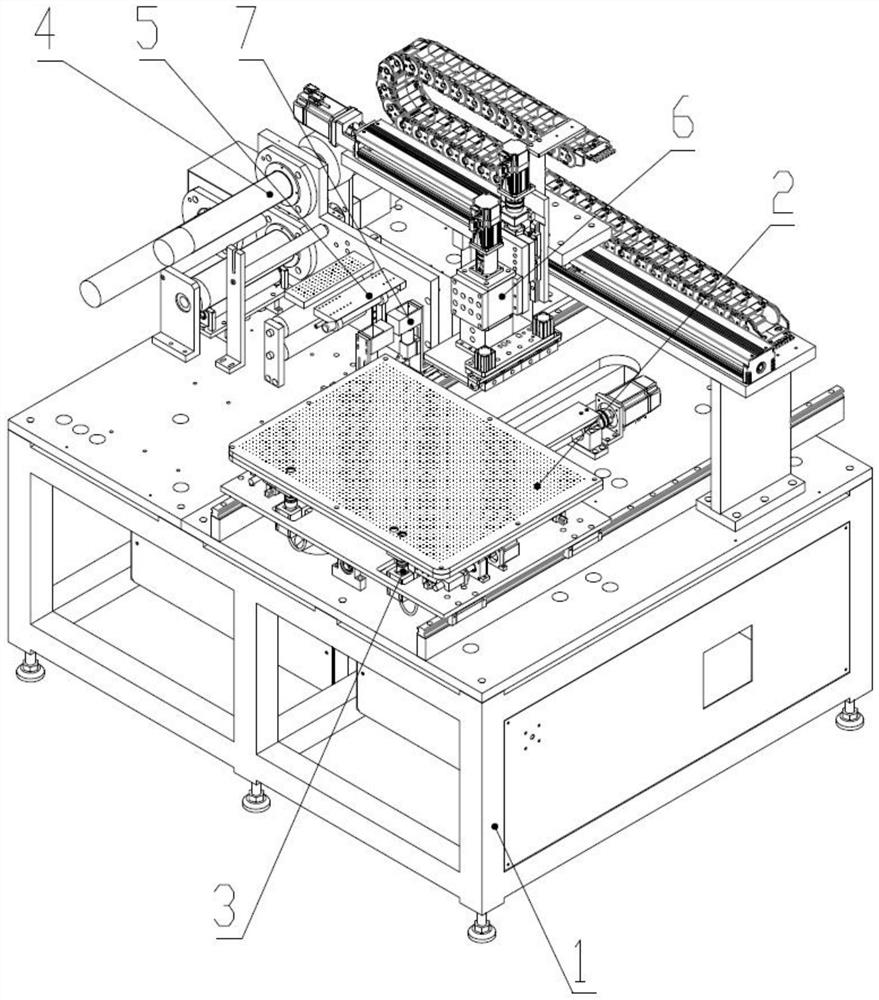

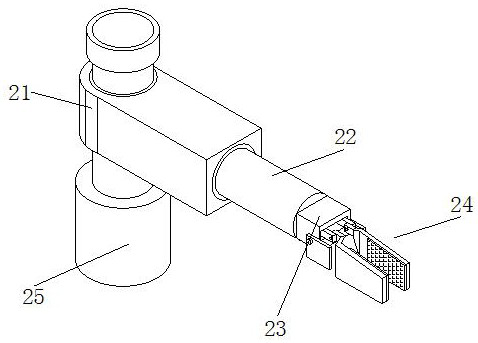

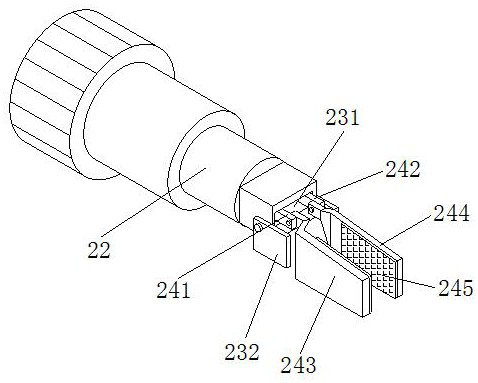

Automatic assembling equipment for piston rod sealing ring

ActiveCN109175937ANo manual assembly requiredLiquid surface applicatorsCoatingsBiochemical engineeringMachining

The invention relates to the technical field of automatic machining, in particular to automatic assembling equipment for a piston rod sealing ring. The automatic assembling equipment comprises a workbench, a vibration disc and an oil pool, and further comprises a feeding device, a transfer device, an oil immersing device, an installation device and a discharging device. The feeding device is arranged on one side of the top end of the workbench, the installation device is arranged on the other side of the top end of the workbench, the transfer device is installed at the top end of the workbenchand located between the feeding device and the installation device, the oil immersing device is installed at the top end of the workbench and located on the side of the transfer device and the installation device, and the discharging device is arranged on the side of the workbench. By means of the mutual cooperation of the feeding device, the transfer device, the oil immersing device, the installation device and the discharging device, the problems that installation is difficult, the production efficiency is low and safety is low are solved.

Owner:溧阳市铭锋机械有限公司

Manufacturing method of screw with metal gasket

The invention provides a manufacturing method of a screw with a metal gasket, and solves the technical problems that no relevant manufacturing method is applied to an existing screw, batch productioncannot be realized and manufacturing speed is slow. The manufacturing method of the screw with the metal gasket comprises the following steps: a, manufacturing the screw: manufacturing the screw through processes of blank manufacturing, molding, grooving and thread rolling; b, manufacturing the metal gasket: heating and fusing metal powdery materials, conducting pouring at 1500 DEG C to 1800 DEG Cafter the metal powdery materials are fused, conducting cooling to 800 to 900 DEG C, putting the metal powdery materials into an insulated cabinet and cooling the metal powdery materials to a room temperature, and finally performing tempering treatment at 280 DEG C to 380 DEG C to obtain the metal gasket; and c, assembling: assembling the metal gasket onto the screw through an assembly productionline to obtain the screw with the metal gasket. The manufacturing method of the screw with the metal gasket disclosed by the invention has the advantage of high-speed manufacturing.

Owner:东莞市品固精密五金制品有限公司

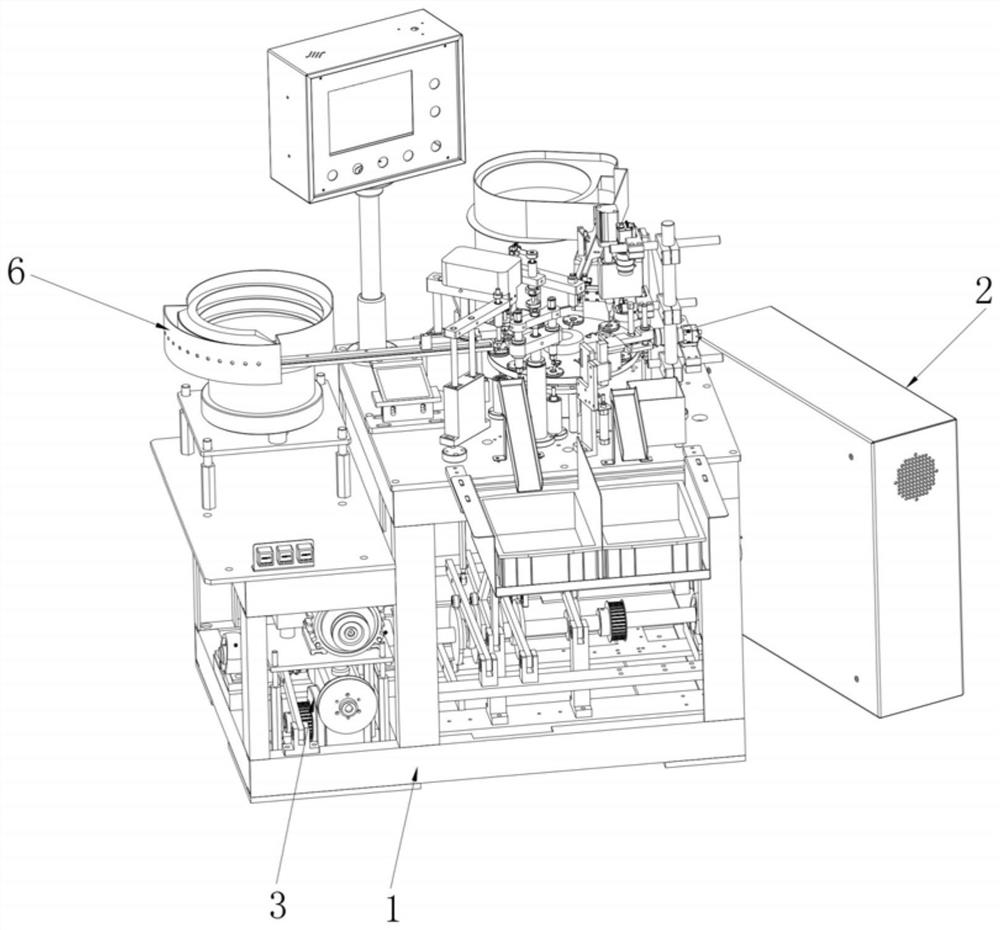

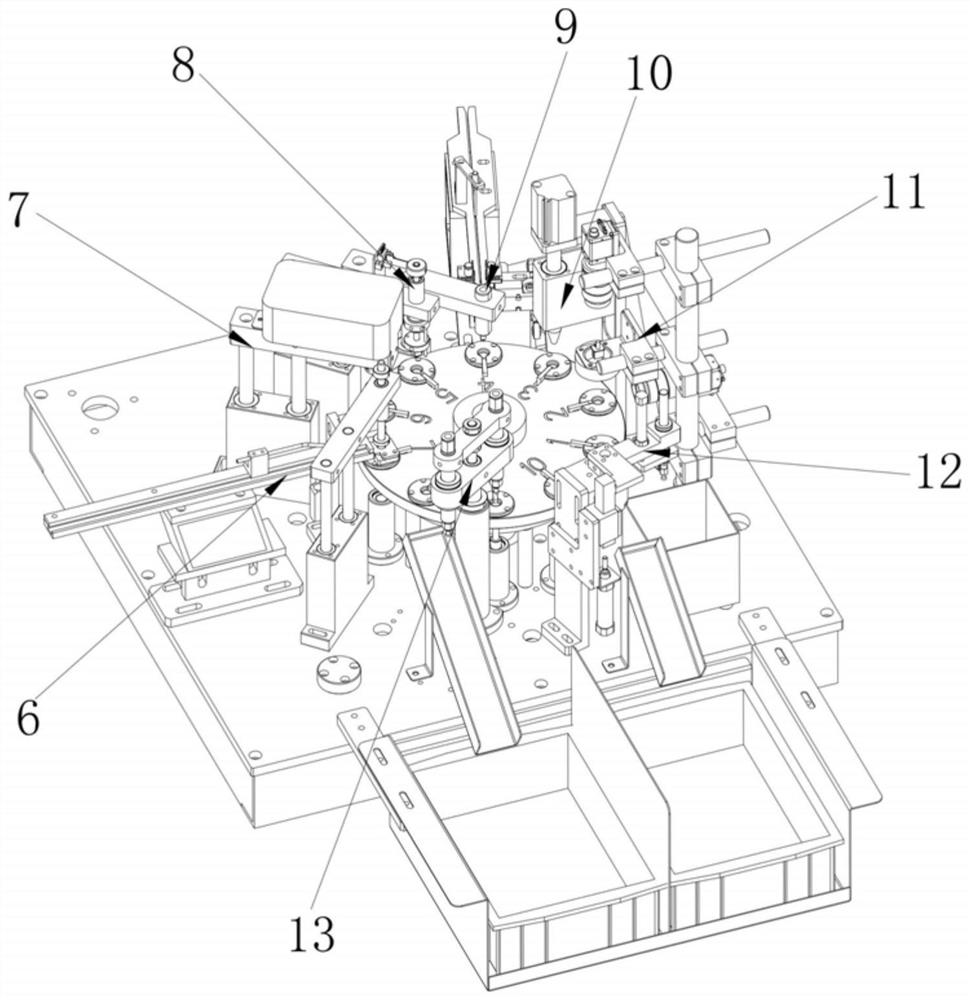

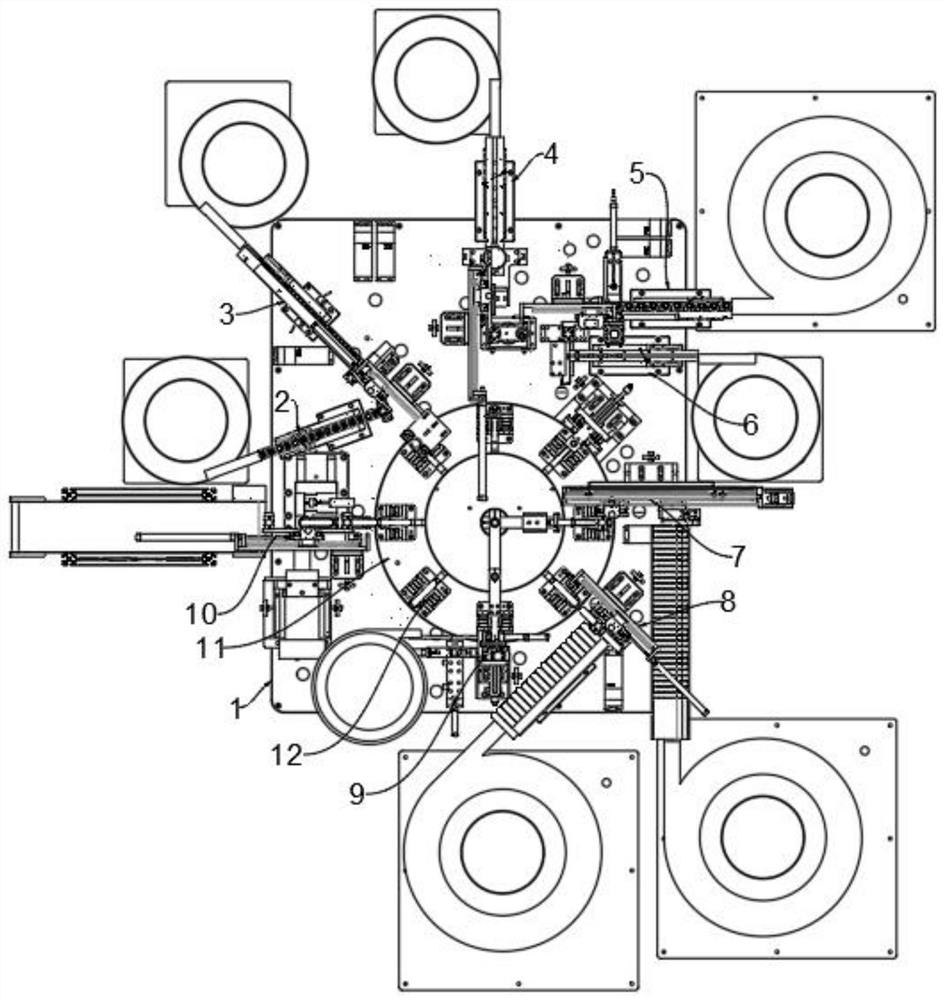

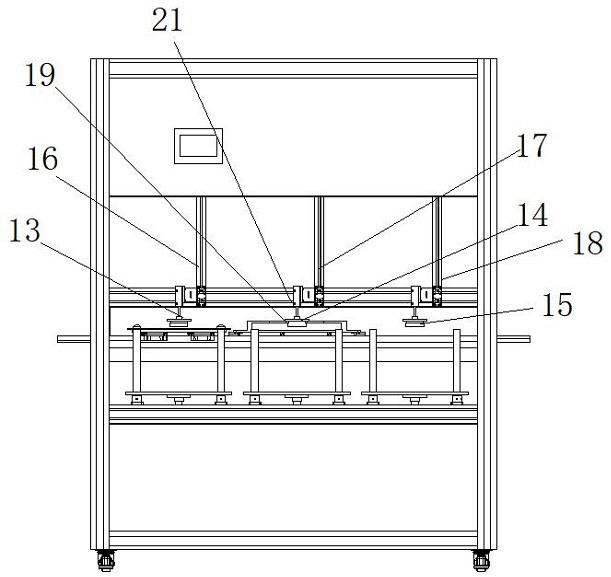

Nail assembling machine and nail assembling method for capacitor rubber cover

PendingCN112917149ANo manual assembly requiredHigh degree of automationAssembly machinesPosition checkStructural engineering

The invention relates to a nail assembling machine and a nail assembling method for a capacitor rubber cover. The nail assembling machine comprises a rack, a control electric box, a main driving mechanism, a rotating disc, a rubber cover jig, a rubber cover conveying mechanism, a rubber cover position adjusting mechanism, a rubber cover position checking mechanism, a nail conveying mechanism, a nail pressing mechanism, an appearance detecting mechanism, a defective product collecting mechanism and a non-defective product collecting mechanism, the rubber cover conveying mechanism drives a capacitor rubber cover to be conveyed into the rubber cover jig, the rubber cover position adjusting mechanism drives the rubber cover to be adjusted in position, the rubber cover position checking mechanism detects whether the position of the rubber cover is correct or not, the nail conveying mechanism drives a nail to be preliminarily assembled on the rubber cover, the nail pressing mechanism drives the nail to be pressed into the rubber cover, the appearance detecting mechanism detects whether the rubber cover in which the nail is pressed have appearance defects or not, the defective product collecting mechanism collects the rubber cover with unqualified appearance detection, and the non-defective product collecting mechanism collects the rubber cover with qualified appearance detection. The automation degree is high, the nail does not need to be manually assembled, the production speed is high, and the production requirement is met.

Owner:东莞市钜业机械有限公司

Equipment for automatically assembling sealing rings of piston rods

InactiveCN111469084ANo manual assembly requiredLiquid surface applicatorsCoatingsEngineeringWorkbench

The invention relates to the technical field of automatic machining, in particular to equipment for automatically assembling sealing rings of piston rods. The equipment comprises a workbench, a vibrating disc and an oil pool and further comprises a feeding device, a transfer device, an oil immersing device, a mounting device and an unloading device. The feeding device is arranged on one side of the top end of the workbench, the mounting device is arranged on the other side of the top end of the workbench, the transfer device is mounted at the top end of the workbench and located between the feeding device and the mounting device, the oil immersing device is mounted at the top end of the workbench and located beside the transfer device and the mounting device, and the unloading device is arranged beside the workbench. Through mutual cooperation of the feeding device, the transfer device, the oil immersing device, the mounting device and the unloading device, the problems that mounting is difficult, the production efficiency is low, and the safety is low are solved.

Owner:何亚群

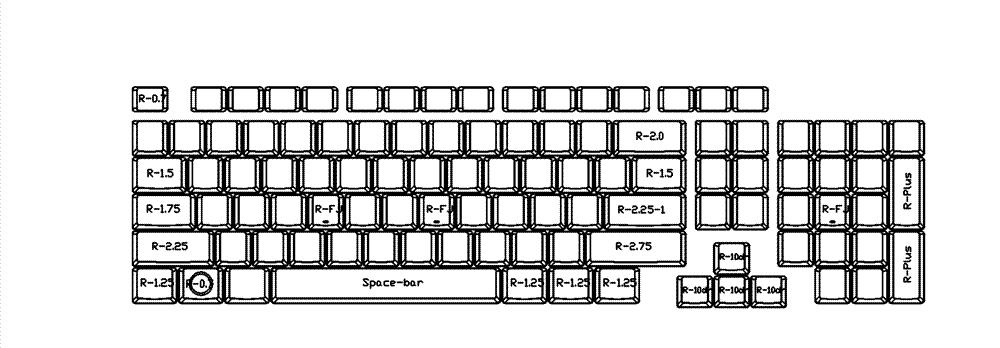

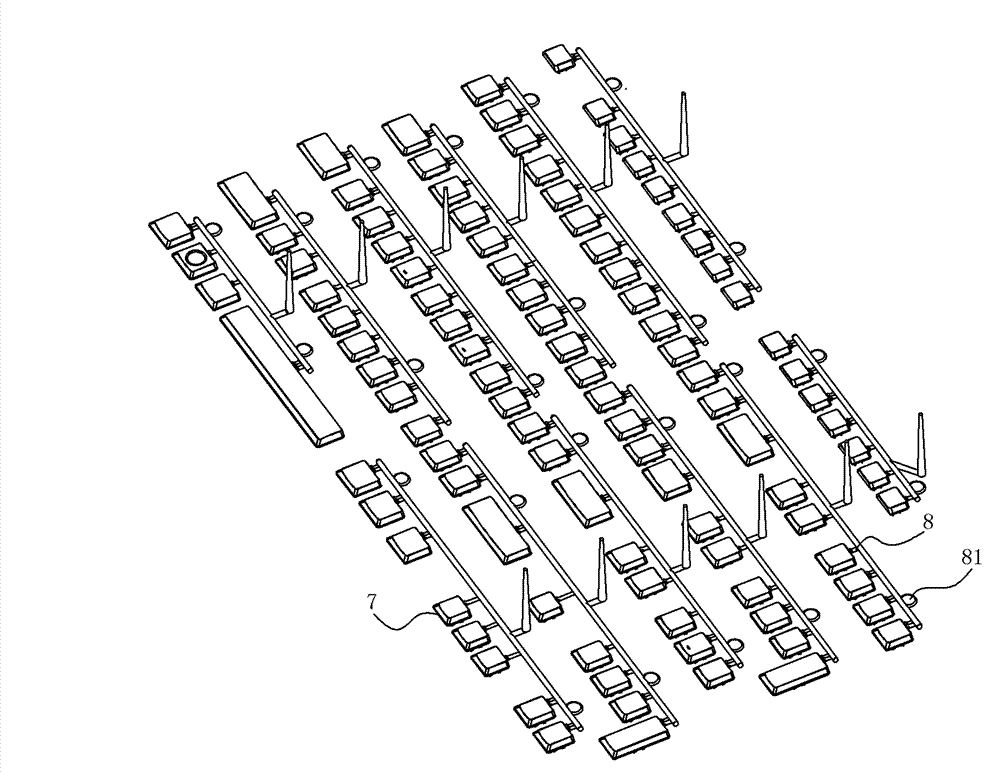

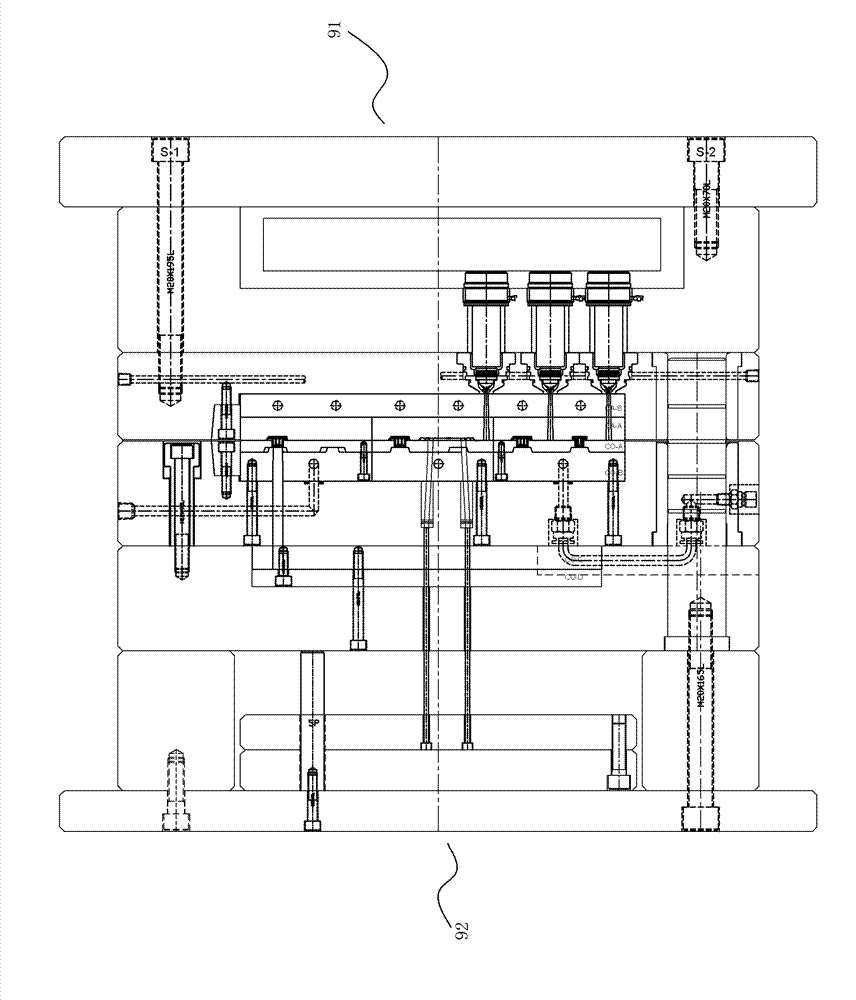

Keyboard key full-pattern injection mold structure and system thereof

InactiveCN102896741AReduce subsequent processesOptimizing the injection molding processHot runnerEngineering

The present invention discloses a keyboard key full-pattern injection mold structure and a system thereof. The keyboard key full-pattern injection mold structure comprises a front mold frame and a rear mold frame, wherein the front mold frame comprises a front mold holder and a front mold core fixed on the front mold holder, and the rear mold frame comprises a rear mold holder and a rear mold core fixed on the rear mold holder. A plurality of molding mold cavities for forming keys of the whole keyboard and a plurality of hot runners communicated between the plurality of the molding mold cavities are arranged between the front mold core and the rear mold core, wherein the hot runners and a hot sprue arranged on the front mold holder are communicated, the molding mold cavities are divided into a plurality of rows, the row distance of the molding mold cavity is greater than the row distance of the keys on the keyboard, and the interval of the molding mold cavity is further greater than the interval of the keys on the keyboard. According to the present invention, the key production of the whole keyboard can be solved by only requiring a set of the mold, and fully automated direct assembly of the followed segments is completely considered, such that all the key caps can be assembled without manual assembly so as to improve production efficiency; and transference stock of the keys is canceled, wherein the key caps are required to be subjected to warehousing after injection molding, and then are assembled by receiving the material through the assembly workshop.

Owner:SHENZHEN RAPOO TECH

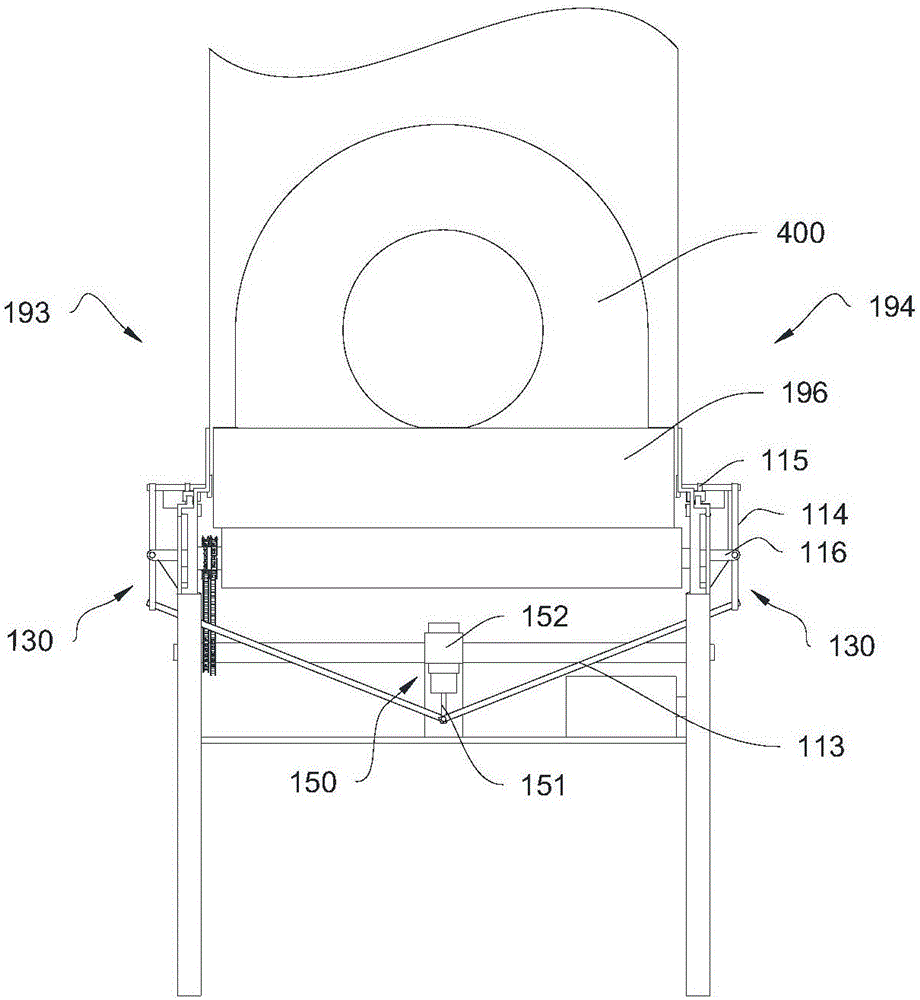

Sealing plate blanking device, sealing plate blanking system and automatic welding production line

ActiveCN106624703AEasy to operateMeet the production needs of automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesProduction lineHeight difference

The invention provides a sealing plate blanking device, a sealing plate blanking system and an automatic welding production line. The sealing plate blanking device comprises a box body, a bottom plate, two limiting pieces and two tension springs. The bottom plate is arranged on the bottom end of the box body and is slidably connected with a third side wall and a fourth side wall; first racks are arranged on two side edges of the bottom plate; each limiting piece comprises a limiting plate; each limiting plate comprises a limiting part and a second rack which are fixedly connected; openings extending from a second side wall of the box body to a first side wall are formed in the third side wall and the fourth side wall of the box body; the limiting parts can be slidably embedded into the openings; the first rack and the second racks are arranged at intervals, and a matched transmission gear is arranged between each first rack and the adjacent second rack; and the distance from each limiting part to the bottom plate is less than the height difference of two overlapped sealing plates. The sealing plate blanking system comprises a conveyor belt and the sealing plate blanking device. The sealing plate blanking device and the sealing plate blanking system can be used for blanking a circular arc-shaped sealing plate each time automatically. The automatic welding production line comprises the sealing plate blanking system.

Owner:东台城东科技创业园管理有限公司

Heat-conducting structural adhesive for power battery pack of new energy automobile

InactiveCN111440592AImprove bonding performanceImprove foundation abilityNon-macromolecular adhesive additivesEpoxy resin adhesivesAutomotive engineeringAddition reaction

The invention discloses a heat-conducting structural adhesive for a power battery pack of a new energy automobile, and specifically relates to the field of new energy vehicles. The heat-conducting structural adhesive comprises a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 10-35 parts of vinyl silicone oil, 1-3 parts of a platinum catalyst, 5-10 parts of a binder and 52-84 parts of a modified heat-conducting filler, and the component B is prepared from the following raw materials in parts by weight: 10-35 parts of vinylsilicone oil, 1-3 parts of hydrogen-containing silicone oil, 1-2 parts of a time delay agent, 5-10 parts of an adhesive and 50-83 parts of a modified heat-conducting filler. According to the invention, the component A and the component B are mixed, the platinum catalyst catalyzes addition reaction cross-linking of vinyl silicone oil and hydrogen-containing silicone oil, the heat-conducting structural adhesive is obtained after curing, the use thickness is half of the thickness of the heat-conducting gasket, the weight is half of the weight of the heat-conducting gasket, the tensile property is improved, full-automatic adhesive dispensing can be achieved in the construction process, manual assembly is not needed, and the assembly efficiency is greatly improved.

Owner:邹雪琳

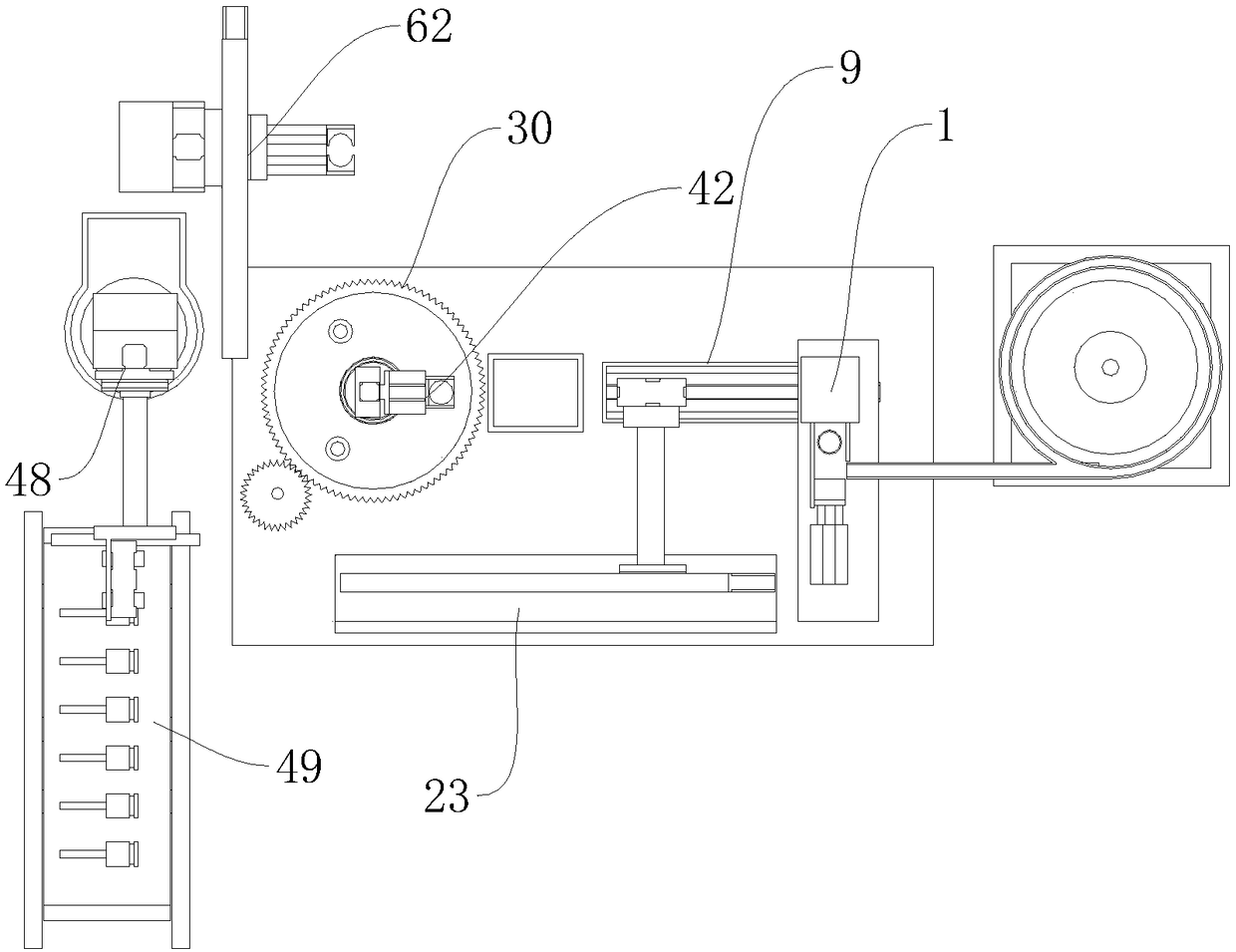

Automatic assembling equipment for seal ring of piston rod

InactiveCN111469083ANo manual assembly requiredLiquid surface applicatorsCoatingsEngineeringPiston rod

The invention relates to the technical field of automatic processing, in particular to automatic assembling equipment for a seal ring of a piston rod. The equipment comprises a worktable, a vibratingdisc and an oil pond and further comprises a loading device, a transfer device, an oil immersing device, a mounting device and an unloading device. The loading device is arranged on one side of the top end of the worktable, the mounting device is arranged on the other side of the top end of the worktable, the transfer device is mounted at the top end of the worktable and is located between the loading device and the mounting device, the oil immersing device is mounted at the top end of the worktable and is located next to the transfer device and the mounting device, and the unloading device isarranged next to the worktable. By matching the loading device, the transfer device, the oil immersing device, the mounting device and the unloading device, problems of difficulty in mounting, low production efficiency and safety are solved.

Owner:何亚群

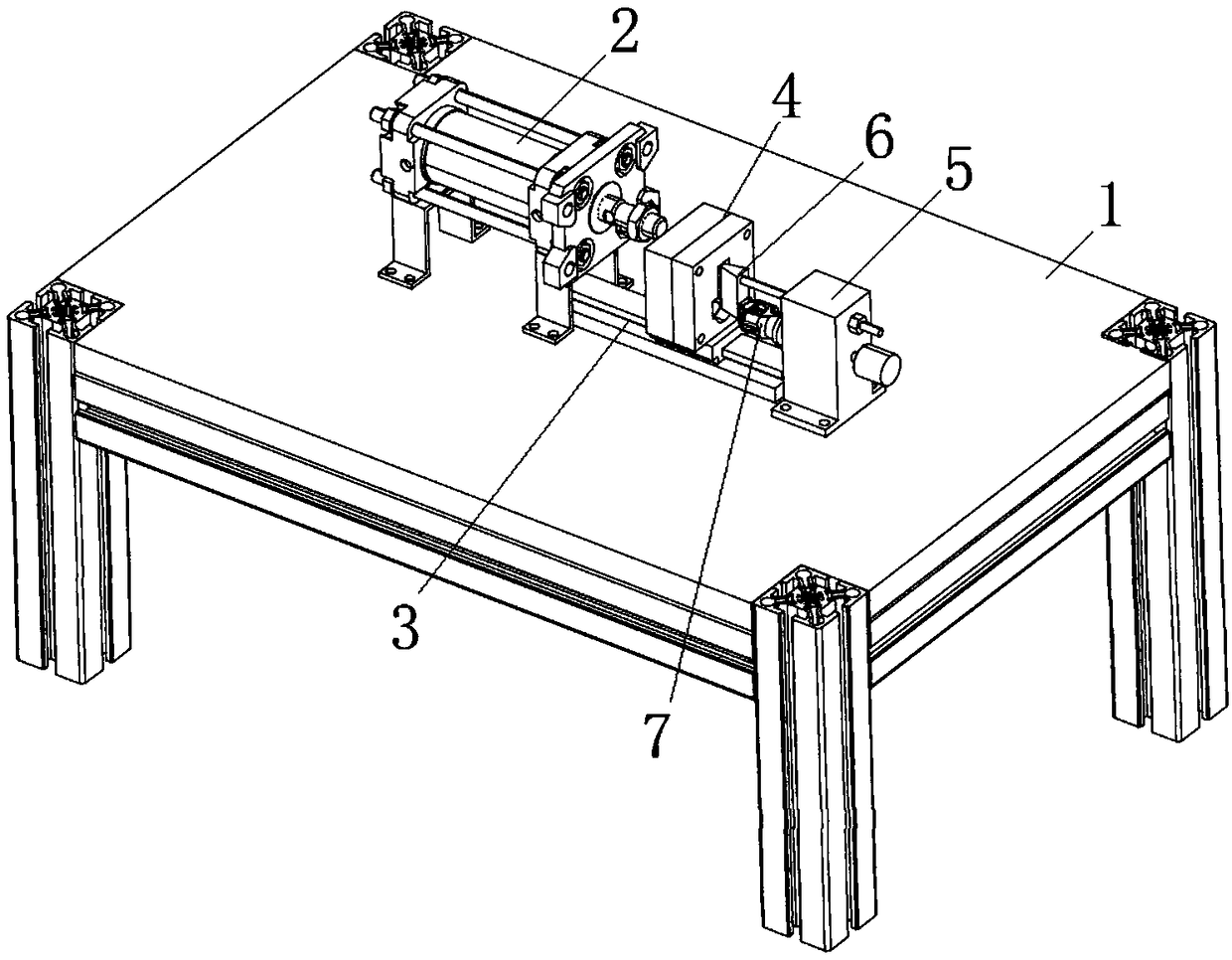

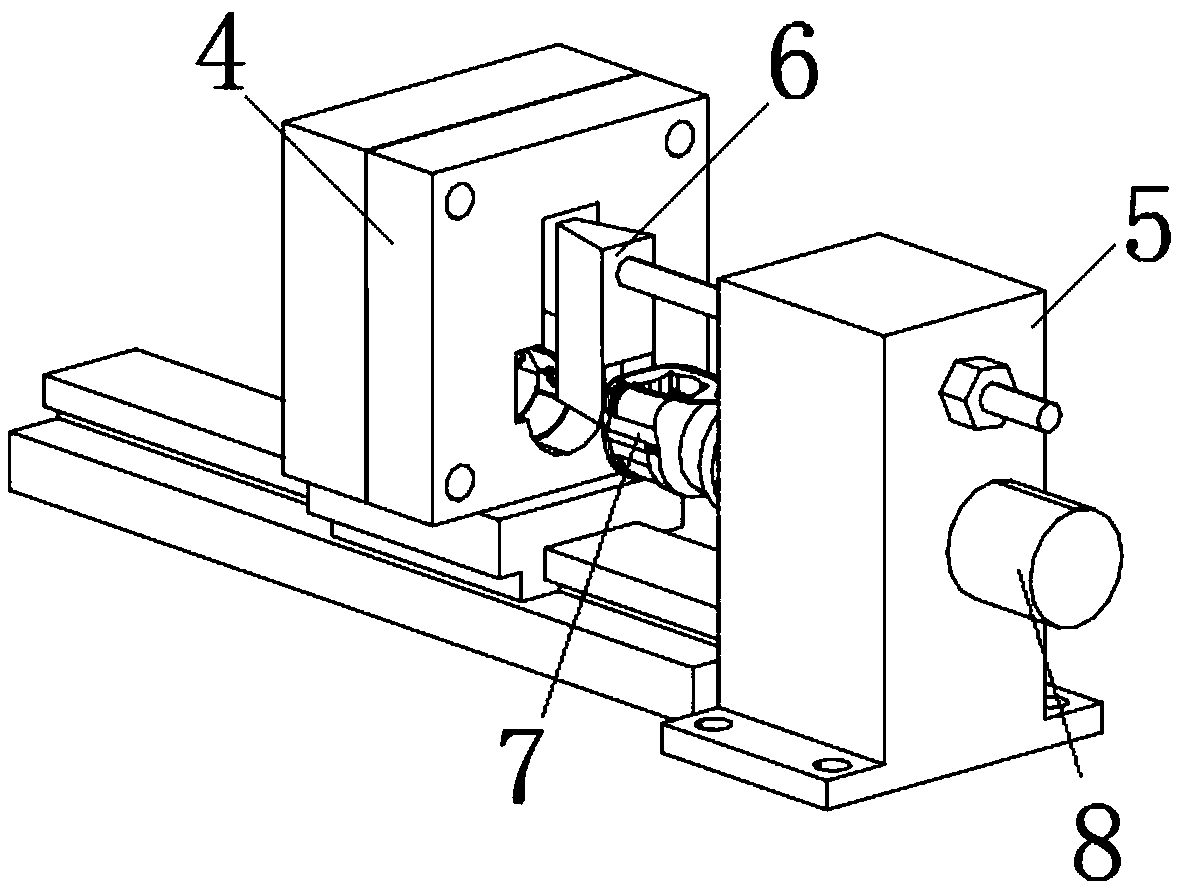

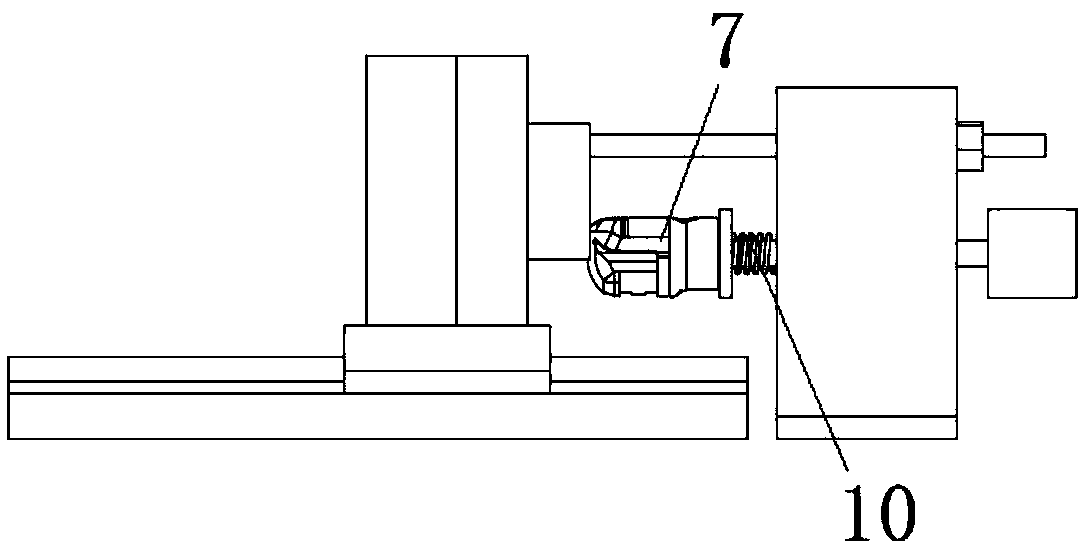

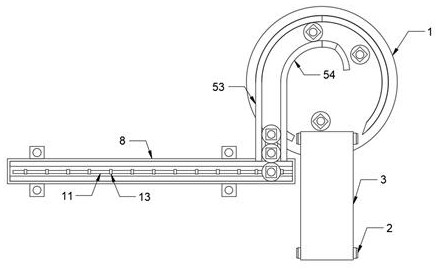

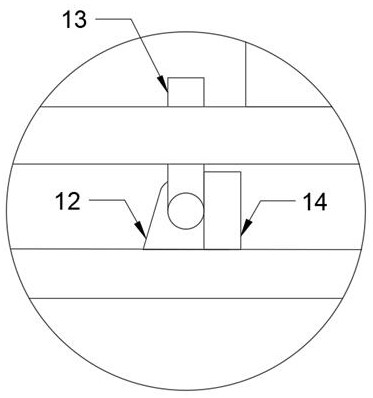

Vehicle tail door support rod bulb clamping spring pressing method

ActiveCN108838658AReasonable designNo manual assembly requiredMetal working apparatusEngineeringMechanical engineering

The invention discloses a vehicle tail door support rod bulb clamping spring pressing method. The method comprises the following steps: 1) a clamping spring is arranged in a clamping spring positioning groove on a slide block; a bulb is arranged on a screw rod of a fixed base; and a clamping spring expansion block is positioned between the slide block and the bulb, and is bonded with the bulb; 2)a cylinder works to drive the slide block to move to the bulb; 3) the clamping spring in the slide block is firstly contacted with the clamping spring expansion block for expansion; and the slide block continuously shifts the clamping spring to sleeve the bulb; and 4) the clamping spring expansion block is deviated from the clamping spring; and the clamping spring is rebounded to clamp on the bulb. The cylinder is controlled to work to push the slide block to slide to automatically finish assembly without needing manual assembly, so that the assembly is convenient, and the assembly efficiencyis greatly improved.

Owner:WUHU MOTIONTEC AUTOMOTIVE

Manufacturing method of improved screw with metal gasket

The invention provides a manufacturing method of an improved screw with a metal gasket. By adoption of the manufacturing method, the technical problems that in the prior art, a relevant manufacturingmethod for screws is no available, mass production of screws cannot be achieved, and the manufacturing speed is low are solved. The manufacturing method of the improved screw with the metal gasket comprises the following steps of a, manufacturing of a screw, specifically, the screw is manufactured through the processes of blank making, forming, groove pressing and thread rolling; b, manufacturingof the metal gasket, specifically, metal powder is heated to be molten, is poured at the temperature of 1720 DEG C after being molten, is cooled to the temperature of 870 DEG C and then is placed in an incubator to be cooled to the room temperature, and finally, tempering is conducted at the temperature of 350 DEG C to obtain the metal gasket; and c, assembling, specifically, the metal gasket is assembled on the screw on an assembly line for assembling, so that the screw with the metal gasket is obtained. The manufacturing method has the advantage of being fast in manufacturing.

Owner:SUMSUN FASTENERS SYST SHENZHEN CO LTD

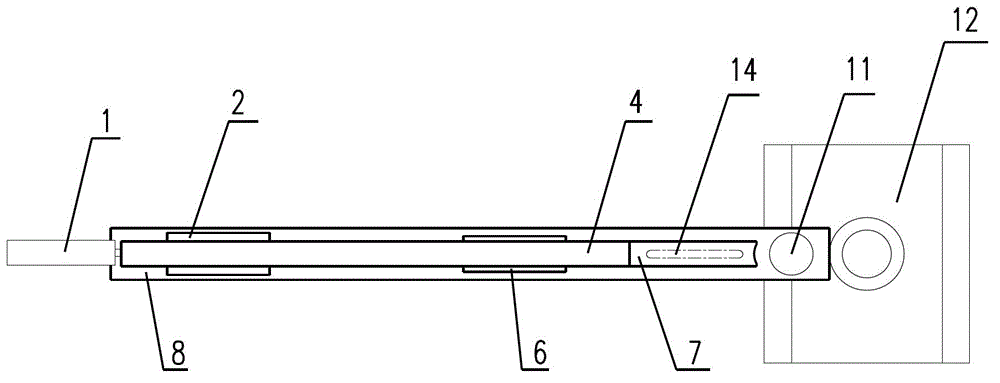

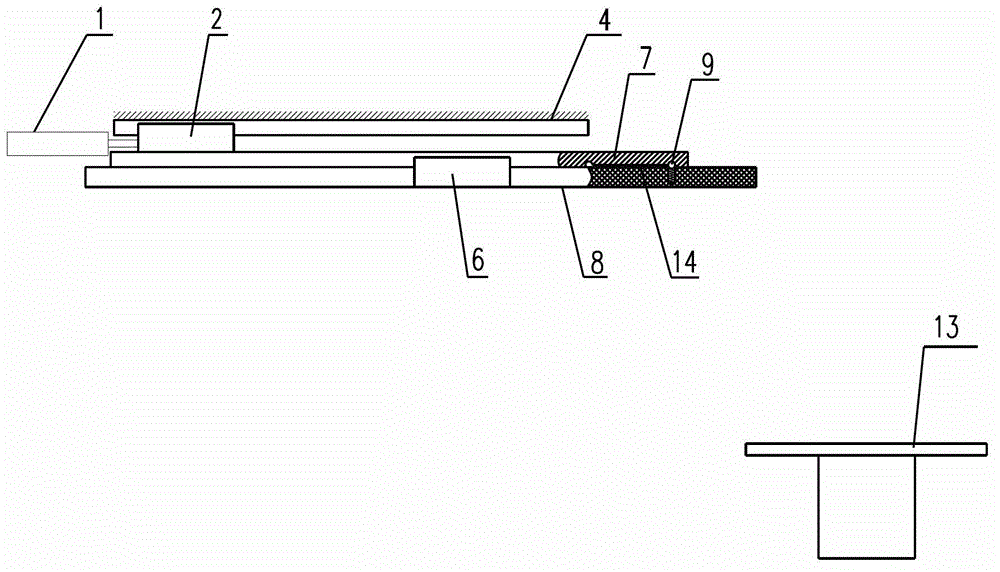

Automatic laminating machine for thin-film circuit board and protective film

PendingCN111907188ASimple and reasonable structural designReduce manufacturing costLamination plant layoutLamination ancillary operationsPhysicsThin membrane

The invention relates to an automatic laminating machine for a thin film circuit board and a protective film, which is structurally characterized in that a protective film coil stock feeding mechanism, an automatic stripping mechanism, a protective film position shooting camera set and a correction platform are sequentially arranged, a protective film taking mechanism is arranged on the side surfaces of the automatic stripping mechanism and the correction platform, and a thin film circuit board MARK point shooting camera set is arranged below the correction platform. The device has the advantages that the structural design is simple and reasonable, the protective film coil stock feeding mechanism is adopted and automatically peeled (peeled into single protective films), the protective films are automatically supplied (release paper waste is automatically collected through the release paper waste collecting shaft), materials are automatically taken, and the camera is used for automatically taking pictures (the positions of MARK points and the protective films of the thin-film circuit board are found respectively); the positions of the thin film circuit board and the protective filmcan be automatically corrected, the thin film circuit board and the protective film are automatically attached and assembled, manual assembly is not needed, time and labor are saved, the production cost is saved, and the production efficiency and the assembly precision are improved.

Owner:无锡市莱科自动化科技有限公司

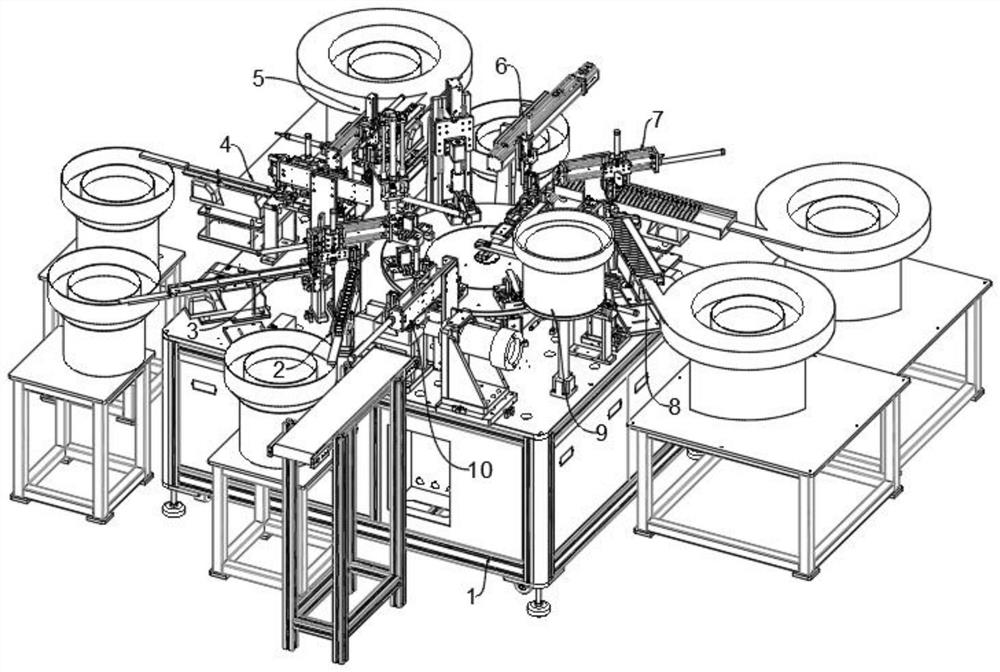

Fire extinguisher valve assembling system

PendingCN114055137ARealize fully automatic assemblyReduce manufacturing costMetal working apparatusEngineeringFire extinguisher

The invention discloses a fire extinguisher valve assembling system which comprises a workbench. The middle portion of the upper surface of the workbench is rotatably connected with a rotating disc, and a plurality of carriers distributed in a circumferential array mode are arranged on the side of the upper surface of the rotating disc; and the vertical pipe base feeding system, the spring feeding system, the sealing ring feeding system, the valve body feeding system, the valve rod feeding system, the screwing system, the lower handle feeding system, the upper handle feeding system, the pin feeding system and the discharging system are sequentially arranged around the workbench. The assembling system has the advantages that full-automatic assembling of the valve can be achieved through an automatic assembling machine for a fire extinguisher valve, the automation degree is high, manual assembling is not needed, the assembling efficiency and the assembling precision are improved to a great extent, a labor force is greatly liberated, and the production cost of fire extinguisher manufacturers can be greatly reduced at present when the labor cost is higher and higher; and popularization and application in fire extinguisher manufacturers are facilitated.

Owner:慈溪市家捷消防阀门有限公司

Combined type warning board splicing system special for power supply system

InactiveCN106181285AImprove assembly efficiencyAvoid operabilityMetal working apparatusComputer moduleEngineering

The invention discloses a combined type warning board splicing system special for a power supply system. The combined type warning board splicing system comprises a first material storage bin used for containing a shell, a first lifting device located at the bottom of the first material storage bin and ejecting the shell out of the first material storage bin, a splicing table, a first pushing device pushing the shell to the splicing table, a second material storage bin used for containing an inner core, a second lifting device located at the bottom of the second material storage bin and ejecting the inner core out of the second material storage bin, a second pushing device pushing the inner core to the splicing table, a conveying belt, a third pushing device used for pushing a spliced warning board on a carrying table to the conveying belt, a control module and a base. Defects of time consuming and labor consuming caused by manual operation are overcome, the splicing efficiency of the warning board is effectively improved, and safety is improved.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

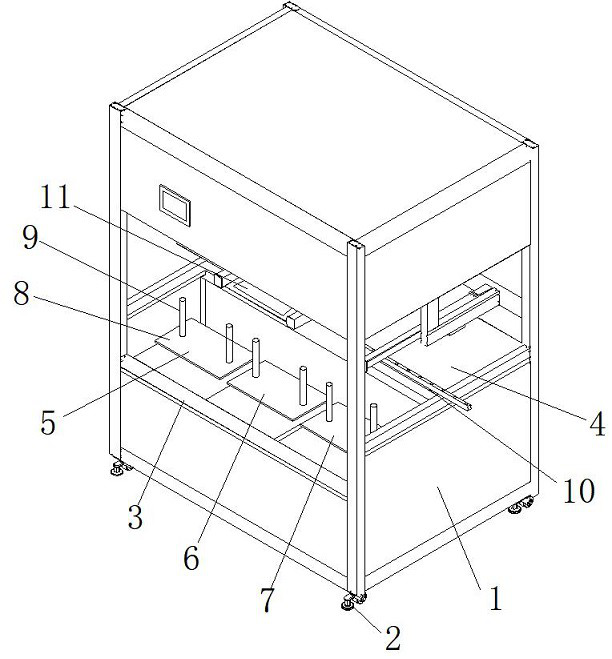

Automatic assembling device for rubber rings of heat exchanger sheets and assembling method of automatic assembling device

PendingCN111774852AReduce labor costsImprove production efficiency and product qualityMetal working apparatusPhysicsEngineering

The invention relates to an automatic assembling device for rubber rings of heat exchanger sheets and an assembling method of the automatic assembling device. The automatic assembling device comprisesa rack. A containing table is arranged on the front side of the rack, and a workbench is arranged on the rear side of the rack. A sheet feeding station, a rubber ring feeding station and a finished product discharging station are sequentially arranged on the containing table from left to right. A guide rail is arranged on the front side of the workbench, a sliding table capable of moving left andright is arranged on the guide rail, a mechanical hand is arranged above the sheet feeding station, the rubber ring feeding station and the finished product discharging station, a clamping jaw assembly is arranged on the rear side of the rubber ring feeding mechanical hand, and the rubber sealing rings are mounted on sheets through pneumatic clamping jaws through loosening and clamping of pincers. Thus, by designing the automatic assembling device, the sheets are adsorbed on the workbench, the rubber sealing rings are automatically mounted on each sheet, finally products are put on a finishedproduct station, automatic continuous actions are achieved in the assembling process, manual assembling is not needed, the labor cost is reduced, and the production efficiency and the product qualityare improved.

Owner:JIANGYIN HUGENAU HEAT EXCHANGE EQUIP

Motor rotor and stator assembling system and assembling method thereof

PendingCN112865448APlay the role of intermittent transmissionEasy to assembleManufacturing stator/rotor bodiesElectric machinesElectric machineCoupling

The invention discloses a motor rotor and stator assembling system and an assembling method thereof. The motor rotor and stator assembling system comprises a rotating disc, a first roller is arranged at one side of the rotating disc, a first conveying belt is arranged on the surface of the outer side of the first roller, a stand column is movably arranged in the middle of the lower end of the rotating disc through a rotating shaft, a first mounting base is fixedly arranged at the upper end in the stand column, a first motor is fixedly arranged in the first mounting base, the output shaft end of the first motor is in transmission connection with a rotating shaft where a rotating disc is located through a coupler, a bottom plate is fixedly arranged at the lower end of the stand column, a fixing frame is arranged on one side of the rotating disc, supports are fixedly arranged at the four corners of the surface of the lower end of the fixing frame, and an intermittent transmission mechanism is arranged between the fixed blocks. According to the invention, the using effect is good, the motor rotor and shell can be automatically assembled, manual contact is not needed, the working efficiency is high, and errors are lower.

Owner:杨广州

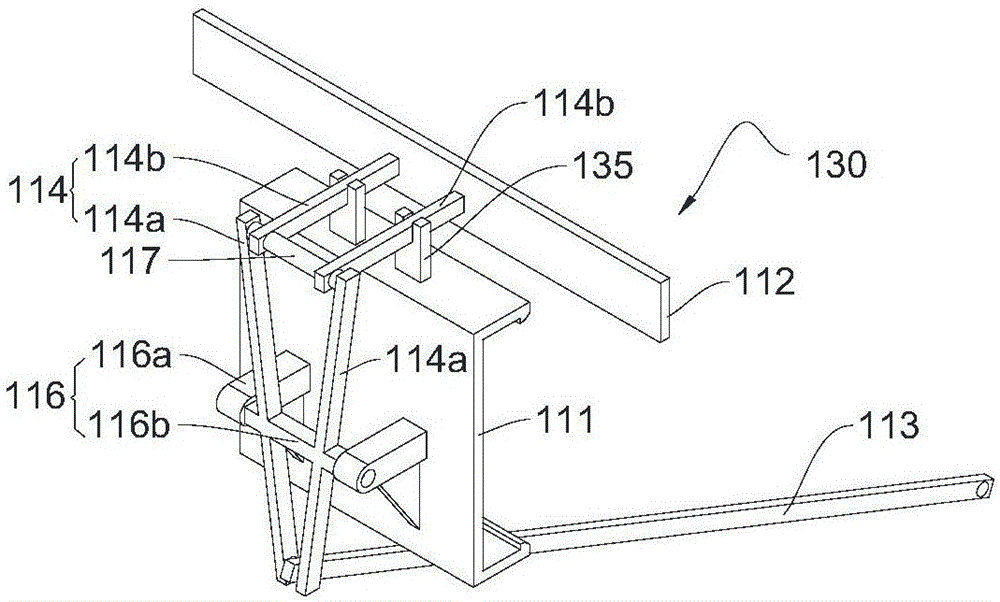

Conveying positioning clamping system and automatic welding production line

ActiveCN106425192AHigh degree of automationIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention discloses a conveying positioning clamping system and an automatic welding production line. The conveying positioning clamping system comprises a clamping device, an unloading device and a conveying belt; the conveying belt includes a first side and a second side opposite to each other, and a third side and a fourth side opposite to each other; a conveying direction of the conveying belt is from the first side to the second side; the unloading device is positioned on the first side; the clamping device is positioned on the second side; two photoelectric switches are arranged on the conveying belt, are respectively positioned on the third side and the fourth side, and are near the second side; the clamping device includes two clamping mechanisms and a driving mechanism; and the unloading device includes a box, a baseplate, two limiting pieces and two tension springs. After accessories of the unloading device are used for automatically unloading, and when the photoelectric switches detect the accessories, the conveying belt is stopped moving, and the clamping device clamps the accessories to perform next machining. The whole conveying positioning clamping system is high in automation degree and working efficiency. The automatic welding production line includes the conveying positioning clamping system.

Owner:东台创跃机电有限公司

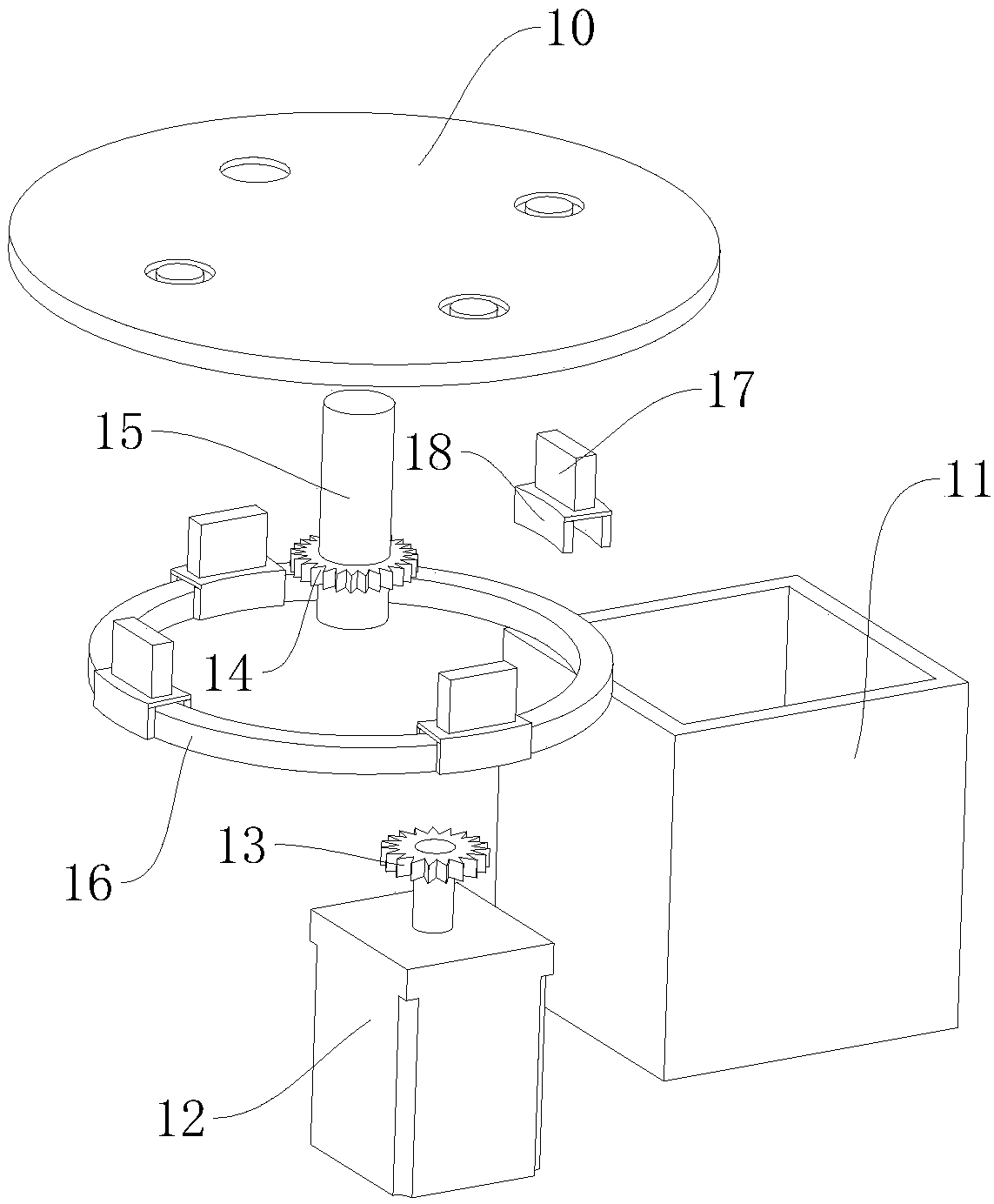

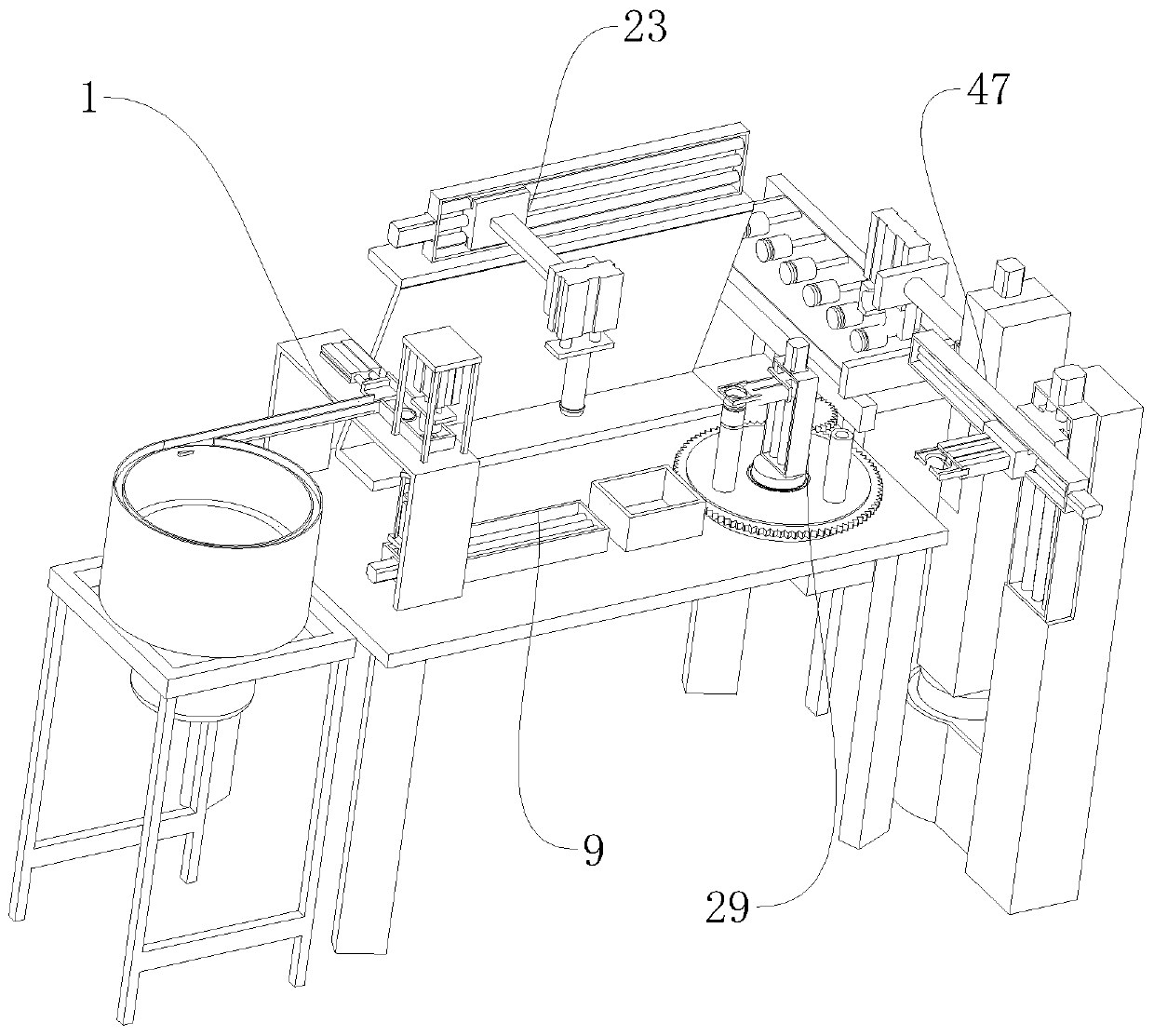

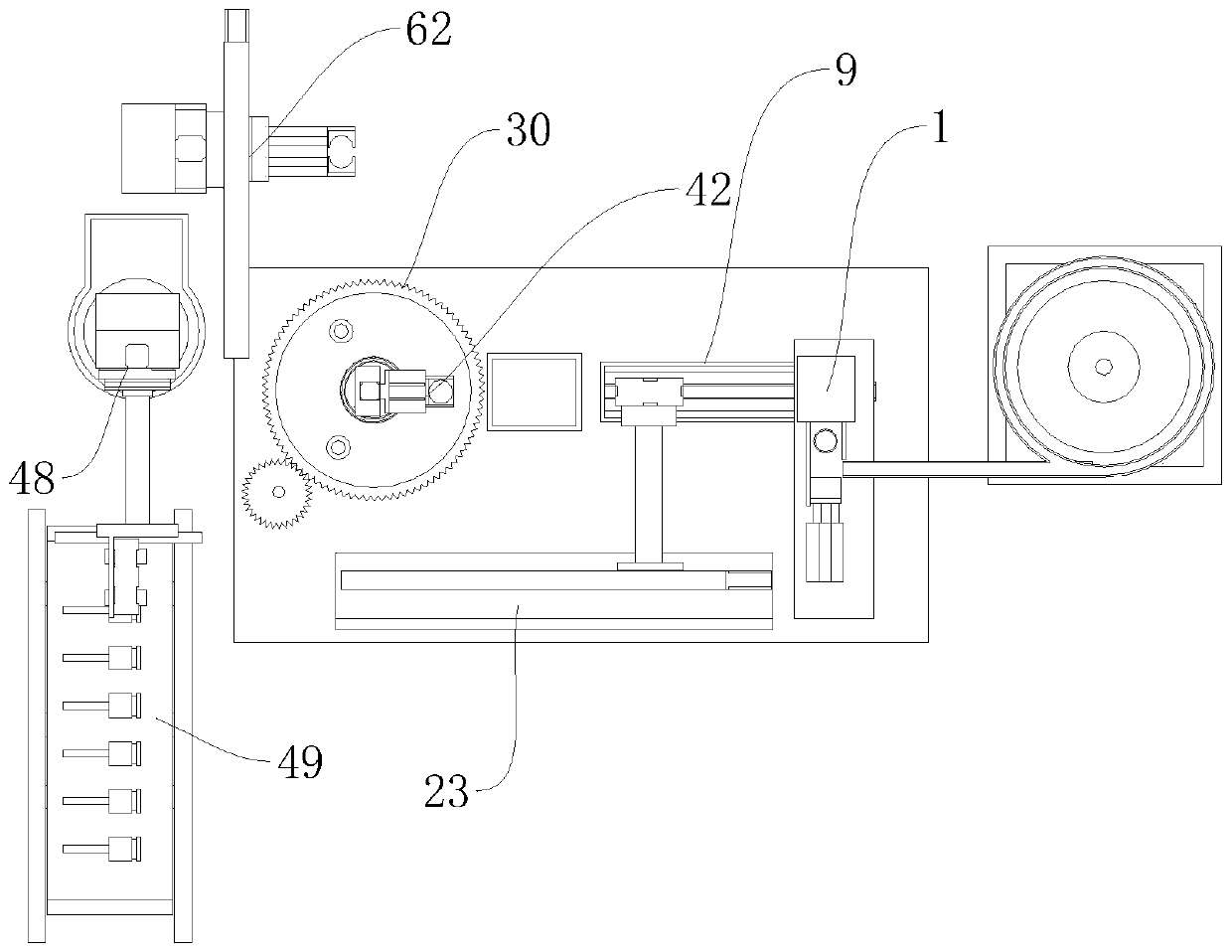

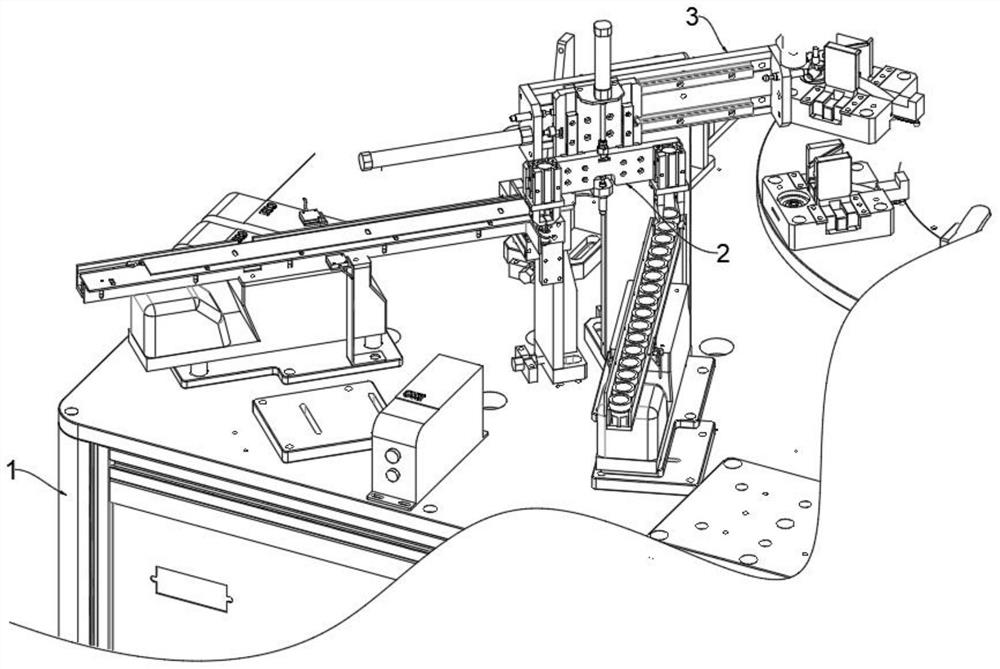

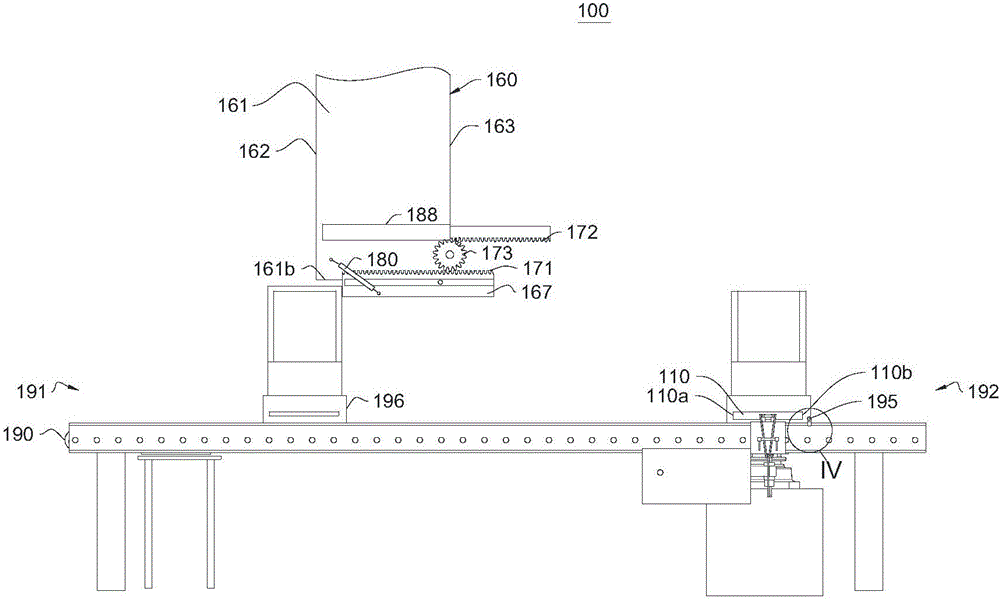

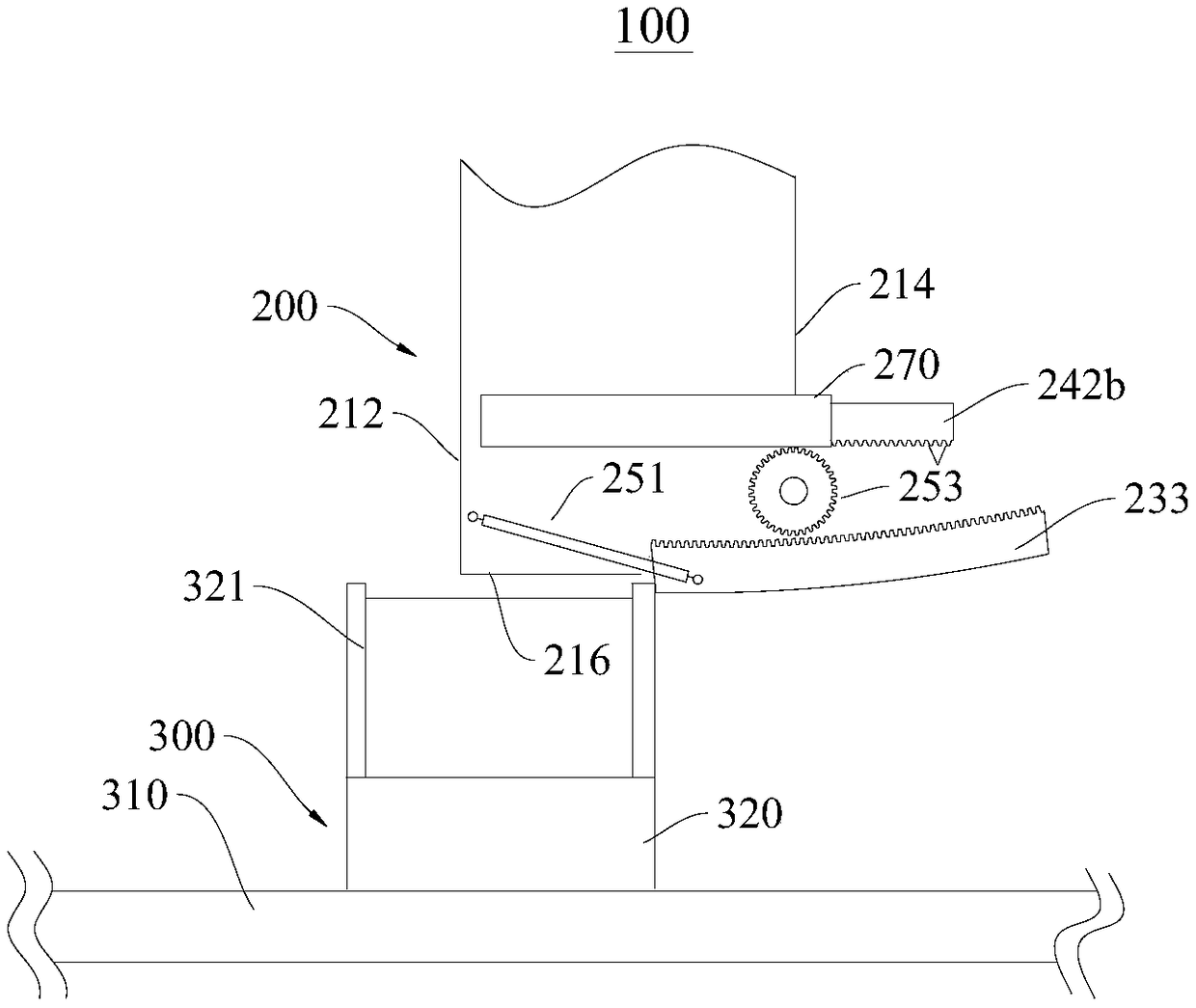

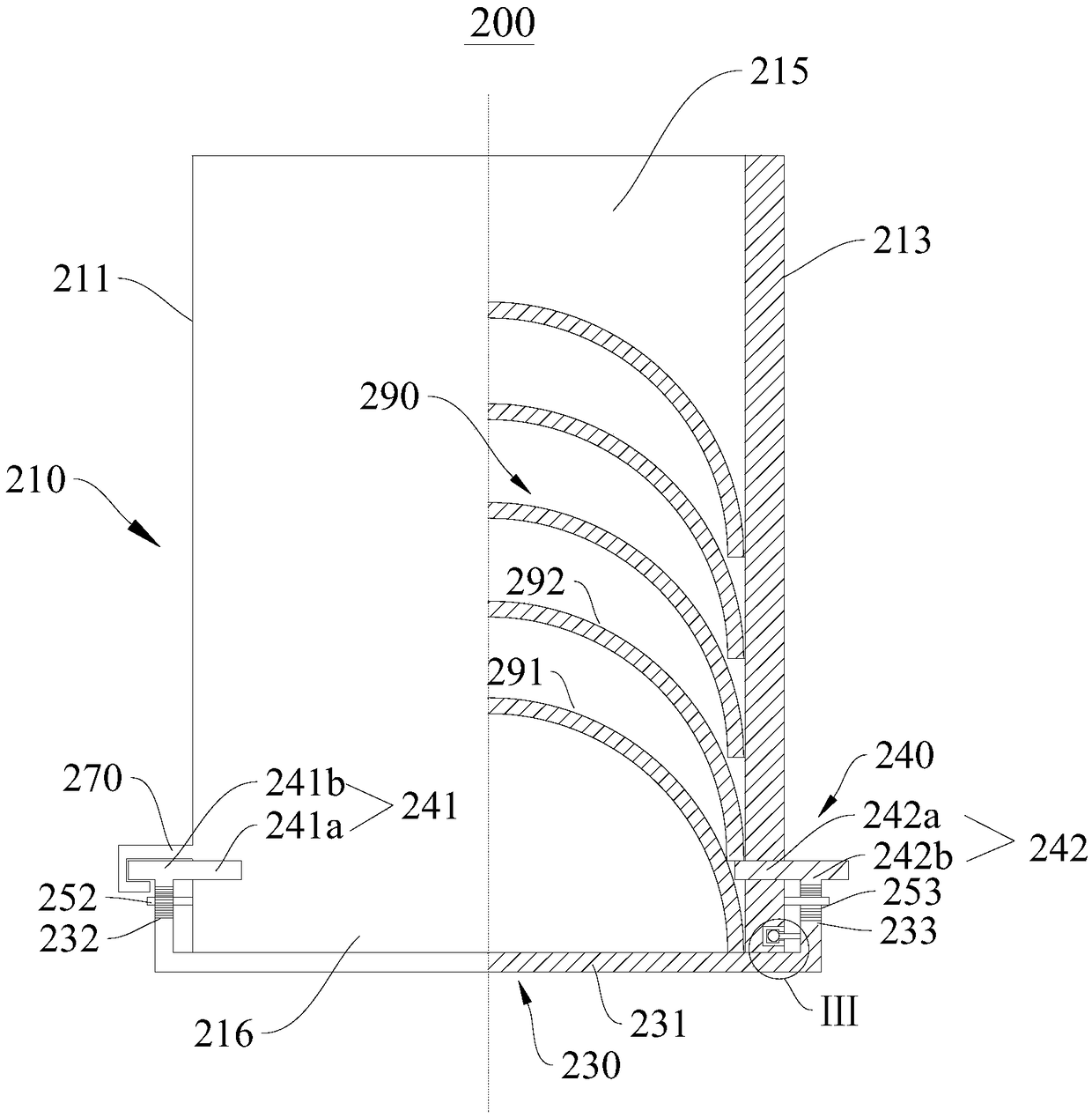

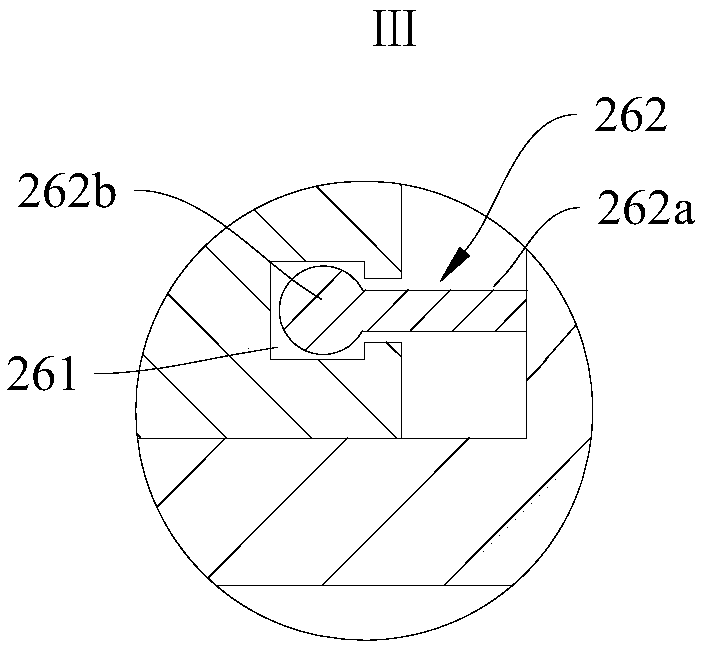

Seat horizontal driver assembly line

PendingCN113290384ARealize automated assemblyNo manual assembly requiredAssembly machinesMetal working apparatusGear wheelAssembly line

The invention discloses a seat horizontal driver assembly line which comprises a lower cover conveying station, a bevel gear assembly conveying station, a worm conveying station, an upper cover conveying station, a screw connecting station, a jacket mounting station and a bevel gear assembly assembling station. A workpiece is conveyed through a conveying chain, so that automatic assembly of the seat horizontal driver can be achieved, manual assembly is not needed, and the assembly efficiency and number are improved.

Owner:宁波昱达智能机械有限公司

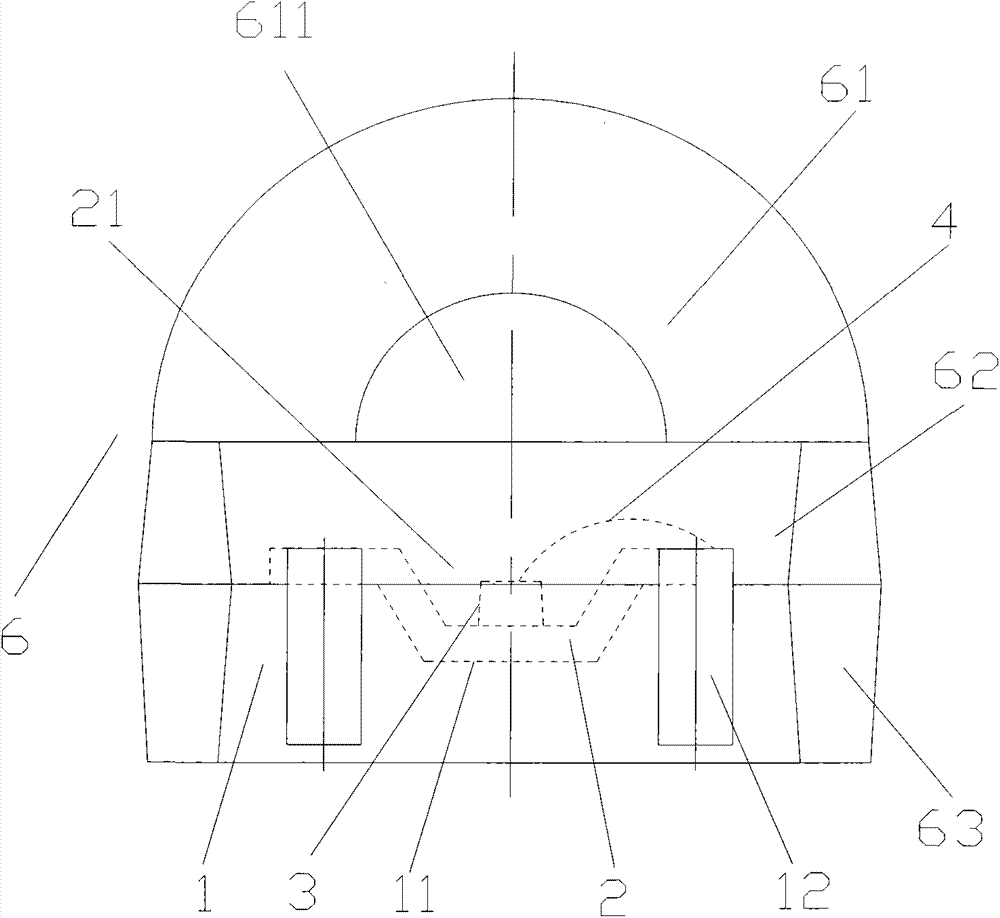

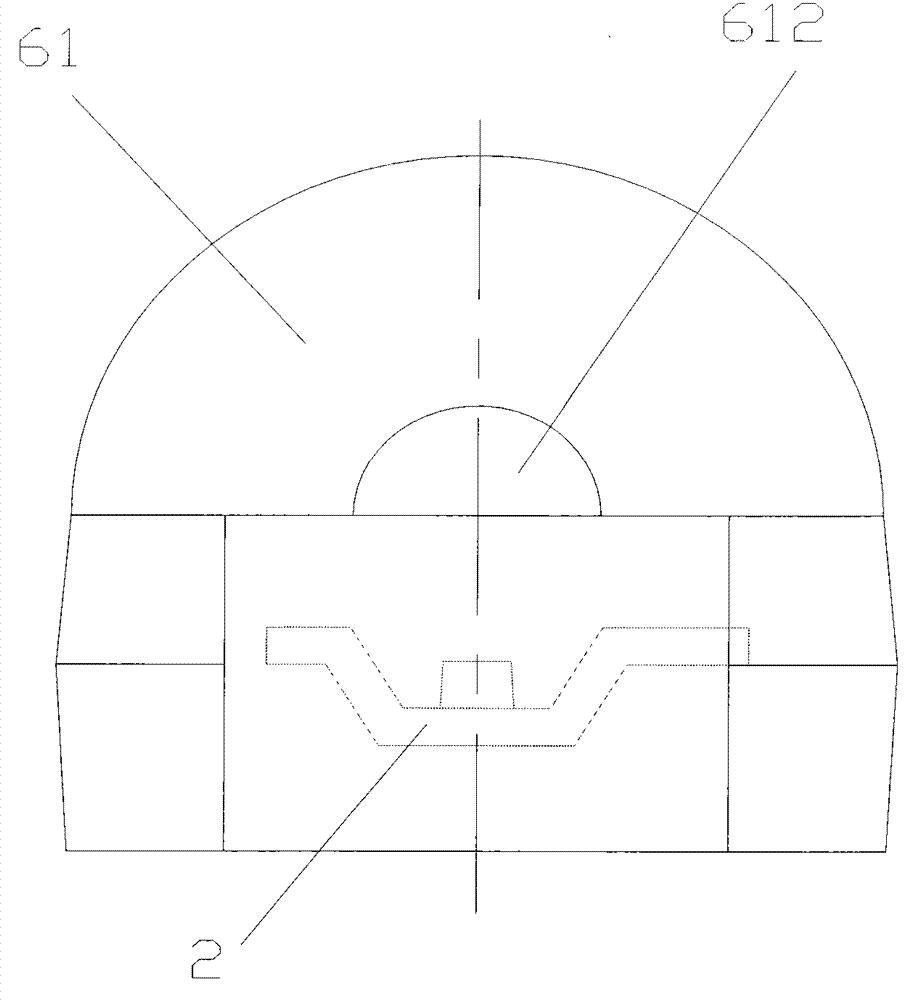

Surface mount type elliptical light concentrating LED (light emitting diode)

ActiveCN103811636AIncrease powerImprove consistencySolid-state devicesSemiconductor devicesSurface mountingEngineering

The invention relates to a surface mount type elliptical light concentrating LED. The surface mount type elliptical light concentrating LED comprises a substrate, a support, an infrared luminous chip and a packaging colloid. A plurality of stand columns which are symmetric relative to the center of the substrate are arranged inside the substrate and provided with conducting layers; the support is arranged in the center of the substrate through the stand columns, and the center of the support is provided with a round cup type hole; the infrared luminous chip is arranged in the center of the bottom of the round cup type hole and electrically connected with the conducting layers of the stand columns; the packaging colloid coats the luminous chip and comprises a top packaging colloid, a middle packaging colloid and side packaging colloids, wherein the top packaging colloid is in a semi-elliptical shape and covers the middle packaging colloid, the middle packaging colloid covers the support and fills up the round cup type hole of the support, and the side packaging colloids wrap the substrate. The surface mount type elliptical light concentrating LED has the advantages of being high in efficiency, large in angle range, good in light concentration and high in reliability.

Owner:SHENZHEN HONGLITAI PHOTOELECTRICITY CO LTD

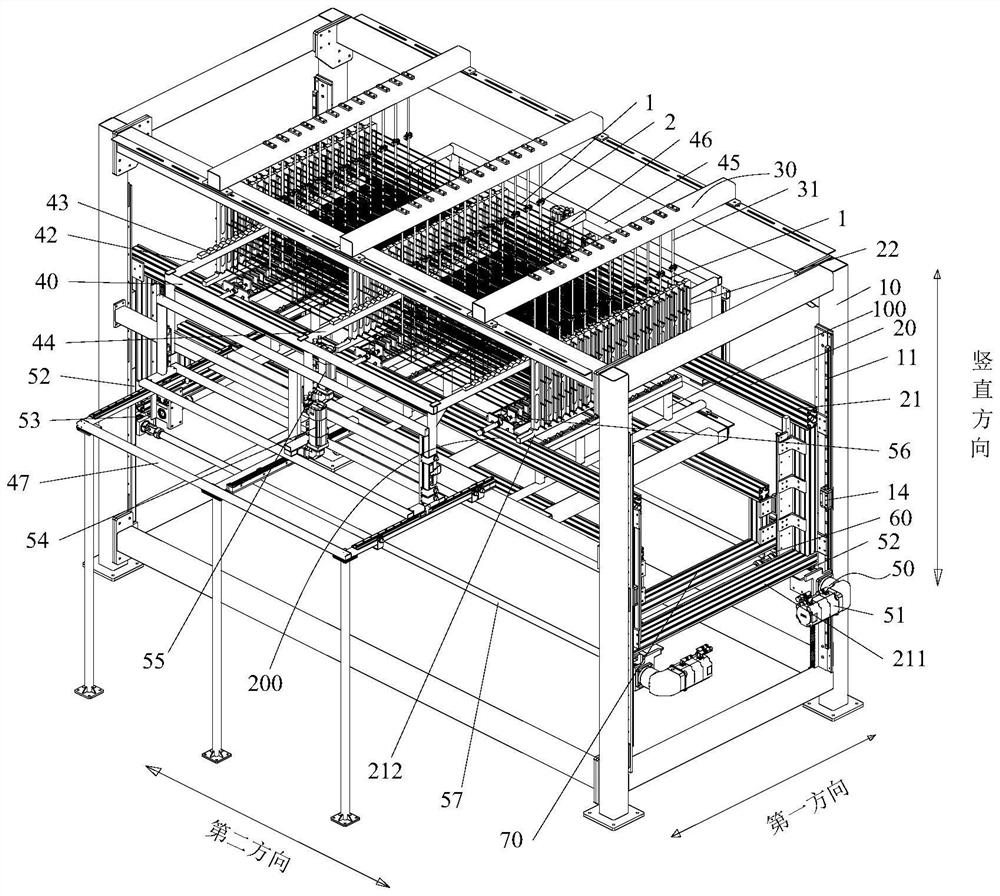

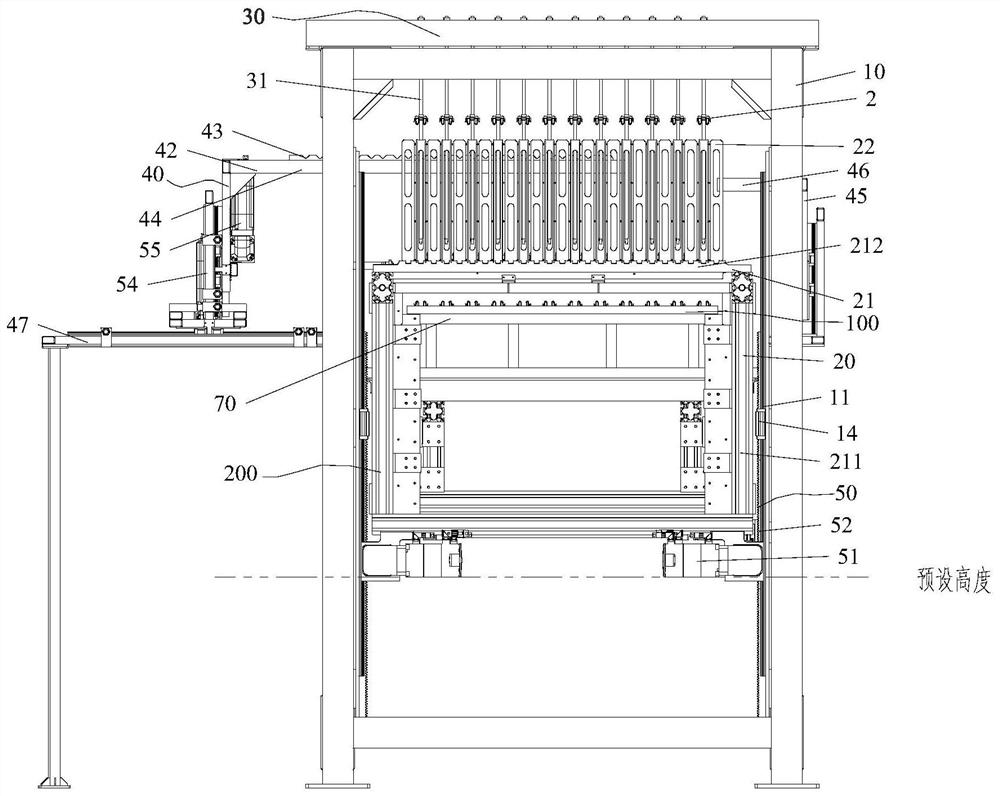

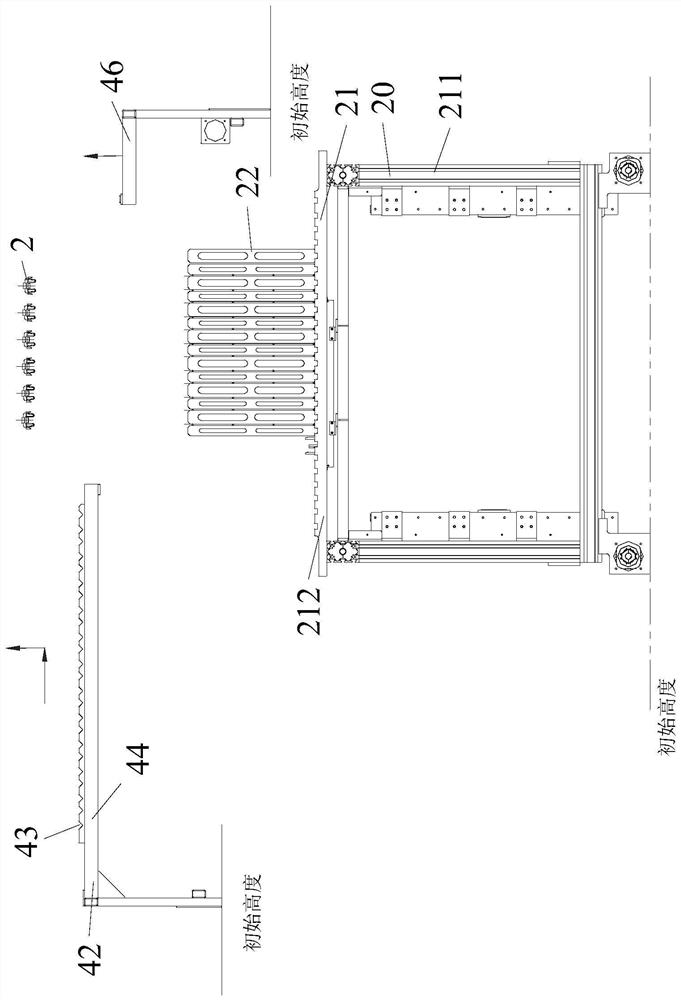

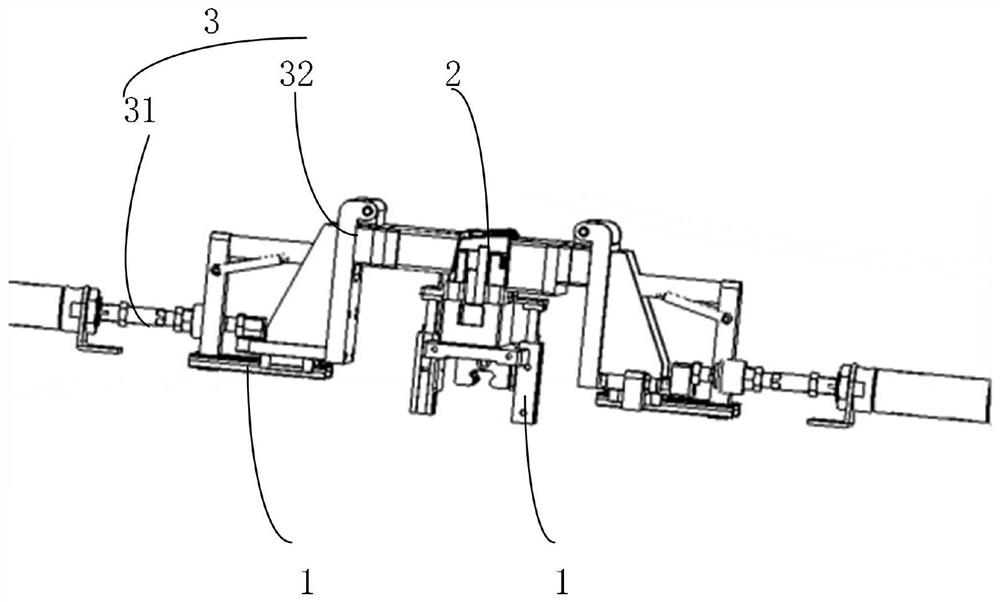

Automatic networking equipment and steel mesh cage processing system

ActiveCN113210544BImprove assembly efficiencyImprove connection efficiencyMetal-working apparatusWire networkMesh reinforcementCantilever

The invention provides an automatic networking equipment and a steel mesh cage processing system. Automatic networking equipment, including: a workpiece support; a workpiece installation mechanism, including a buckle support device with a plurality of installation holes, at least part of the workpiece installation mechanism can be set up and down in a vertical direction; a network mechanism, including a mesh for accommodating At least part of the mesh supporting structure is set up and down in the vertical direction; the mesh lifting mechanism is used to drive part of the mesh supporting structure to move in the vertical direction; the first cantilever structure is located at the bottom of the mesh lifting mechanism. On one side, the first cantilever structure includes a first cantilever portion, and the first cantilever portion is movably arranged along the vertical direction and the first direction, so that at least part of the first cantilever portion can be penetrated in the mesh and aligned at constant intervals. At least one pair of longitudinal ribs of the mesh sheet is supported, and driven by the first cantilever portion, the mesh sheet is clamped with the buckle. In the technical scheme of the present invention, the automatic networking equipment can improve the networking efficiency of workpieces such as mesh sheets.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

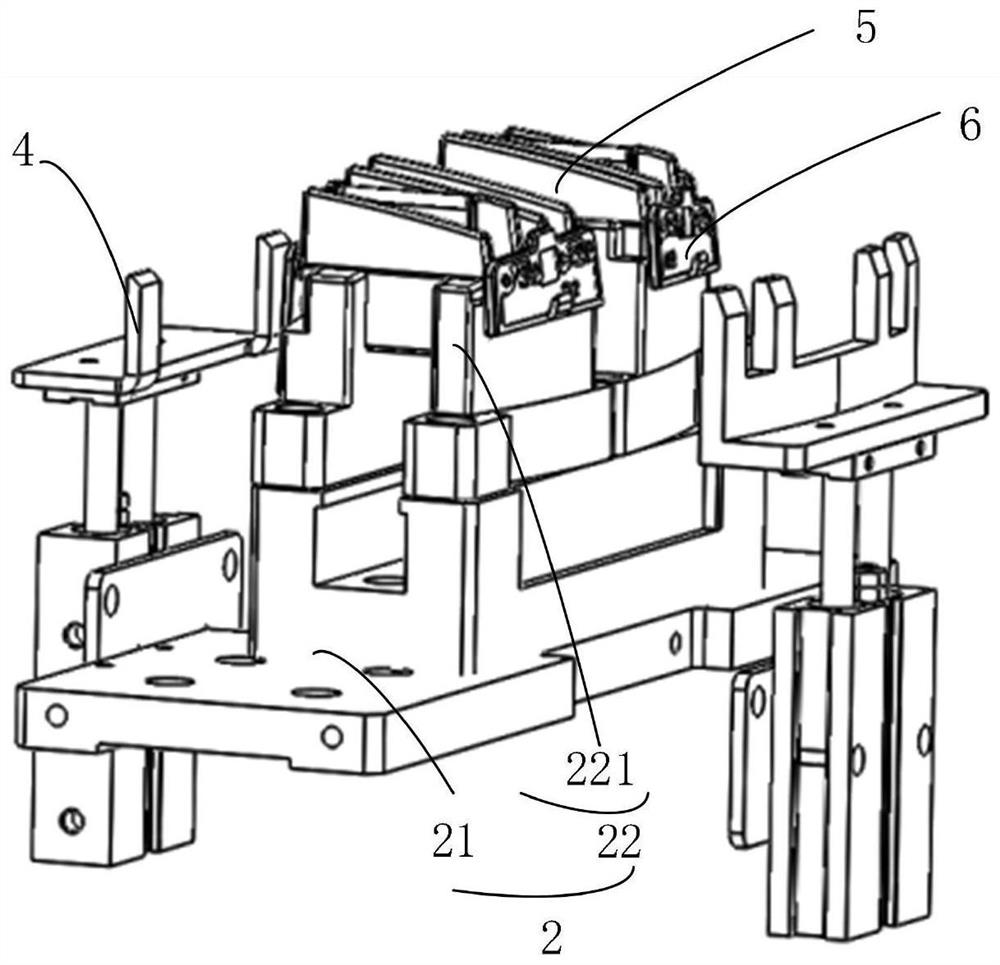

Assembly tooling for connecting rod of air outlet of automobile air conditioner and assembly device of air outlet

ActiveCN112338470BNo manual assembly requiredImprove assembly efficiencyMetal working apparatusClassical mechanicsStructural engineering

Owner:DONGFENG VISTEON AUTOMOTIVE TRIM SYST CO LTD

A SMD Ellipse Concentrating Light Emitting Diode

ActiveCN103811636BIncrease powerImprove consistencySolid-state devicesSemiconductor devicesSurface mountingEngineering

Owner:SHENZHEN HONGLITAI PHOTOELECTRICITY CO LTD

A sealing plate blanking device and a bearing sealing plate welding system

ActiveCN106735983BEasy to operateMeet the production needs of automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesHeight differenceEngineering

The invention provides a sealing plate feeding device and a bearing sealing plate welding system and relates to the field of machining. A box body of the sealing plate feeding device comprises a first side wall, a third side wall, a second side wall and a fourth side wall, wherein the first side wall and the third side wall are oppositely arranged, and the second side wall and the fourth side wall are oppositely arranged. A bottom plate is arranged at the bottom of the box body and is slidably connected with the first side wall and the third side wall. The bottom plate comprises a bottom plate body, a first rack and a second rack, wherein the first rack and the second rack are arc-shaped racks. A limiting piece comprises a limiting portion and a rack. The limiting portion is slidably embedded into an opening of the first side wall and an opening of the third side wall. A transmission gear is rotationally mounted on the first side wall and the third side wall and externally engaged with the first rack / the second rack and the rack at the same time. A Tension spring is connected among the bottom plate, the first side wall and the third side wall. The distance between the limiting piece and the bottom plate body is smaller than the height difference of two stacked sealing plates. By the adoption of the sealing plate feeding device, one set of stacked circular-arc-shaped sealing plates can be fed once, and feeding is convenient; and the bearing sealing plate welding system can achieve automatic welding of the water-cooling bearing seat sealing plates.

Owner:江苏普锐斯机械设备有限公司

Flexible microgyrorotor and electromagnetic drive and dynamic tune

InactiveCN100398994CWith dynamic tuningAvoid the influence of fixed axisSpeed measurement using gyroscopic effectsRotary gyroscopesCircular discGyroscope

A micro-gyroscope of flexible rotor tuned by electromagnetic driving force is prepared by setting top rotor and bottom rotor at top and bottom of shell, setting one jewel bearing at center hole of top rotor, setting another at center hole of bottom rotor, placing shaft on both bearings and driving rotor on shaft between top and bottom rotors, setting gyroscope rotor on shaft above top rotor. The prepared micro-gyroscope can be used as orientational gyroscope.

Owner:SHANGHAI JIAO TONG UNIV

A lead-acid battery automatic assembly production equipment

ActiveCN110788590BImprove assembly efficiencyNo manual assembly requiredMetal working apparatusElectrical batteryControl engineering

The invention discloses a lead-acid battery automatic assembly production equipment, including a working platform, the rear end of the working platform is equipped with a base, the top of the base is provided with a clamping assembly, and the clamping assembly includes an electric lifting Rod, one end of the electric lifting rod is provided with a rotating seat, the inside of the rotating seat is installed with a first electric telescopic rod, one end of the first electric telescopic rod is installed with a fixed seat, and the front end of the fixed seat is set There is a chute, and the front end of the fixed seat is slidably connected with a clamp, and the clamp includes a first slider and a second slider, and the first slider and the second slider are far away from the side of the chute. A first clamping part and a second clamping part are mounted on one end respectively. The invention realizes the assembly of the battery case and the electrode group through the electric lifting rod, the rotating seat, the first electric telescopic rod, the first clamping part and the second clamping part, without manual assembly, and improves the lead-acid battery performance. assembly efficiency.

Owner:ANHUI YONGHENG STORAGE BATTERY

Production method of anti-sand sieve tube

The invention relates to a production method of an anti-sand sieve tube. The method comprises the following steps: 1) preparing materials, and purchasing three raw materials, wherein the first material is a trapezoidal stainless steel wire which is used for producing a filter piece, the second material is a strip-shaped stainless steel plate which is used for producing a protecting cover, and thethird material is a base tube which is an oil / sleeve steel tube conforming to API (American petroleum institute) standards or Chinese national standards; 2) manufacturing a blank of the protecting cover; 3) manufacturing a finished product of the protecting cover; 4) manufacturing a finished product of a filtering component; 5) drilling hole slots on the base tube; 6) manufacturing the sieve tube; and 7) cleaning and polishing. The production method is high in degree of automation, time-saving, effort-saving, labor-saving, raw-material-saving, low in cost, high in production efficiency and high in yield.

Owner:浙江省星炬科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com