Manufacturing method of screw with metal gasket

A technology of metal gaskets and production methods, which is applied in the direction of screws, nuts, bolts, etc., can solve the problems of slow production speed, no production method for screws, and inability to realize mass production, etc., and achieve the effect of fast production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The manufacturing method of the screw with the metal gasket comprises the following steps: a, making the screw: making the screw through blank making, molding, grooving and thread rolling; b, making the metal gasket: making the metal powder Heating and melting, pouring at 1600°C after melting, cooling to 830°C, cooling to room temperature in an incubator, and finally tempering at 2900°C to obtain metal gaskets; The gasket is assembled on the screw to obtain a screw with a metal gasket; the metal powder in step b comprises the following raw materials in parts by weight: 70 parts of iron, 13 parts of copper, 6 parts of phosphorus, 12 parts of magnesium, and 3 parts of silicon , 2 parts of carbon, 4 parts of sulfur, 5 parts of nickel, 3 parts of zirconium, 3 parts of molybdenum, 3 parts of aluminum and 2 parts of manganese.

Embodiment 2

[0047] The manufacturing method of the screw with the metal gasket comprises the following steps: a, making the screw: making the screw through blank making, molding, grooving and thread rolling; b, making the metal gasket: making the metal powder Heating and melting, pouring at 1720°C after melting, cooling to 870°C and cooling to room temperature in an incubator, and finally tempering at 350°C to obtain metal gaskets; c. Assembly: Metal gaskets are assembled through assembly lines The gasket is assembled on the screw to obtain a screw with a metal gasket; the metal powder in step b comprises the following raw materials in parts by weight: 66 parts of copper, 4 parts of iron, 5 parts of nickel, 5 parts of molybdenum, and 3 parts of tantalum , 8 parts of cobalt, 1 part of tungsten and 1 part of niobium.

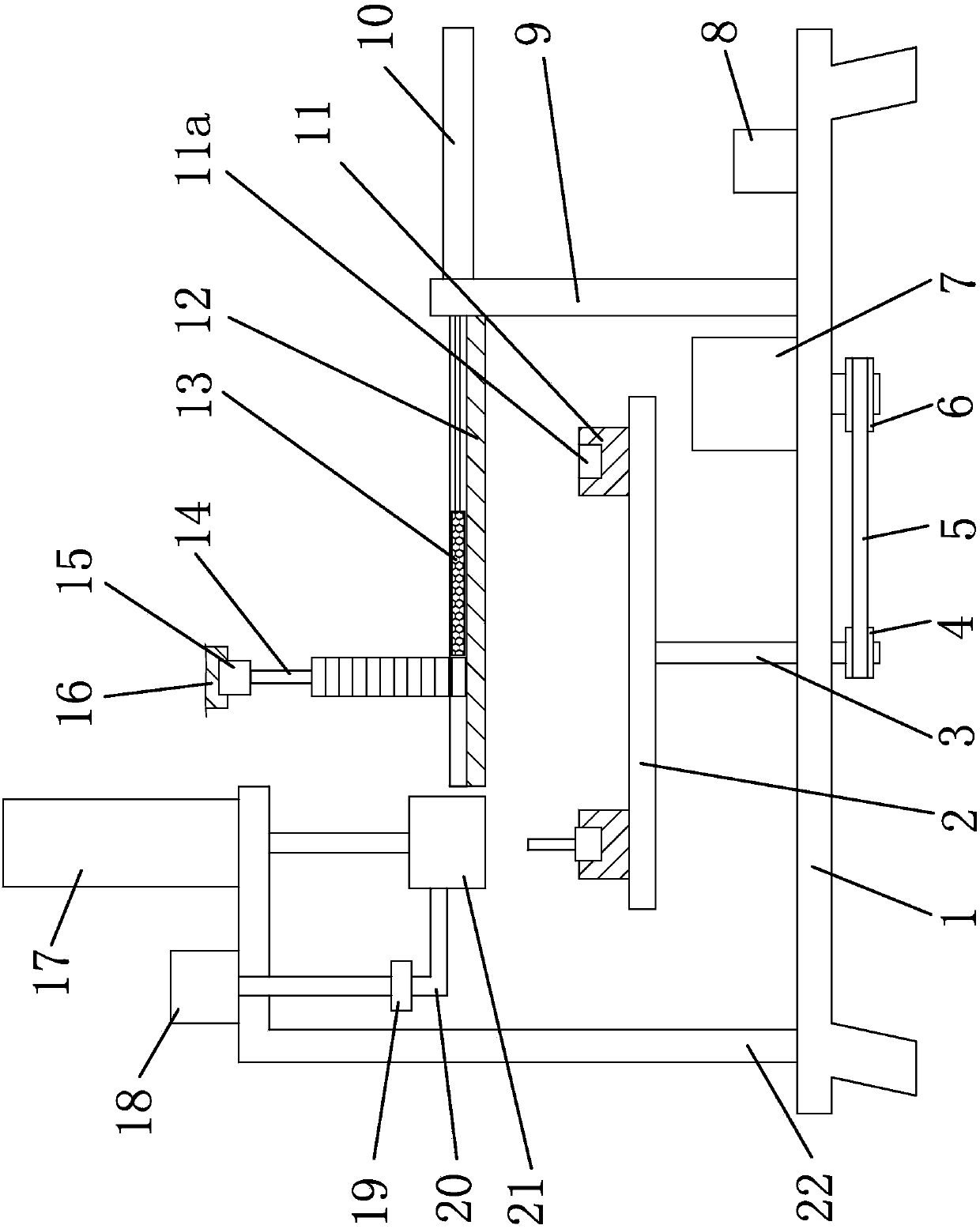

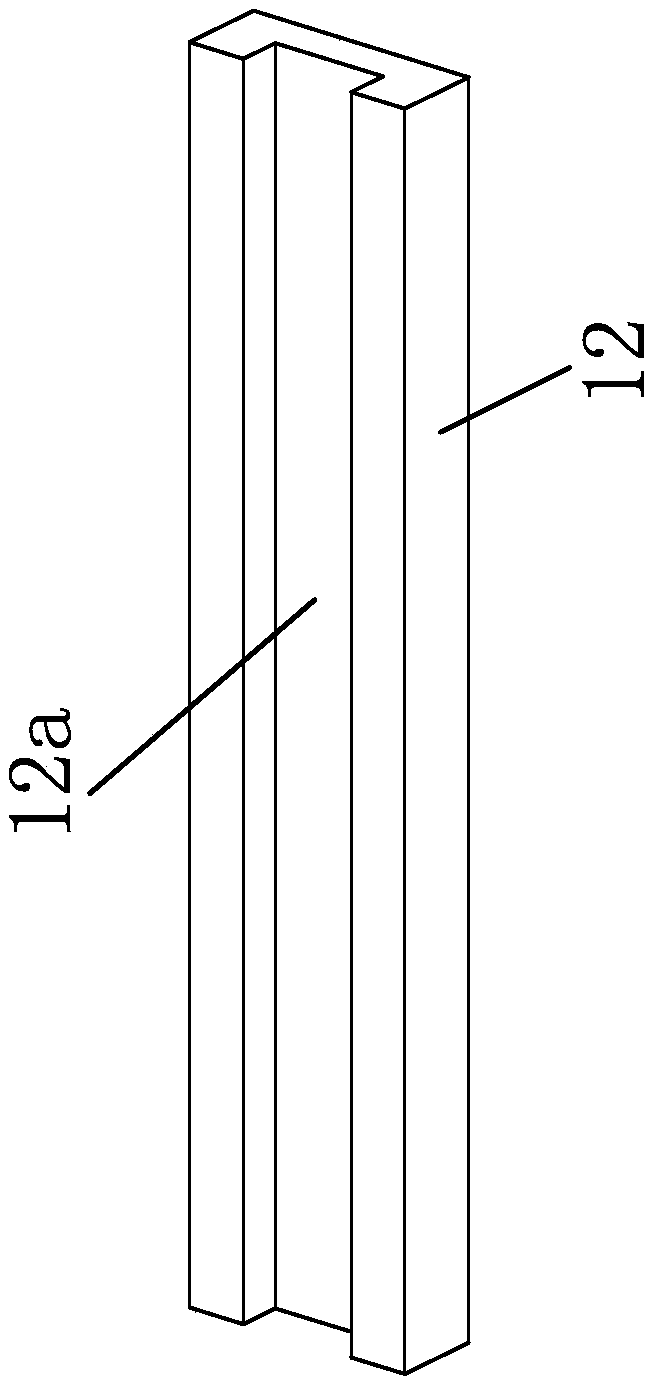

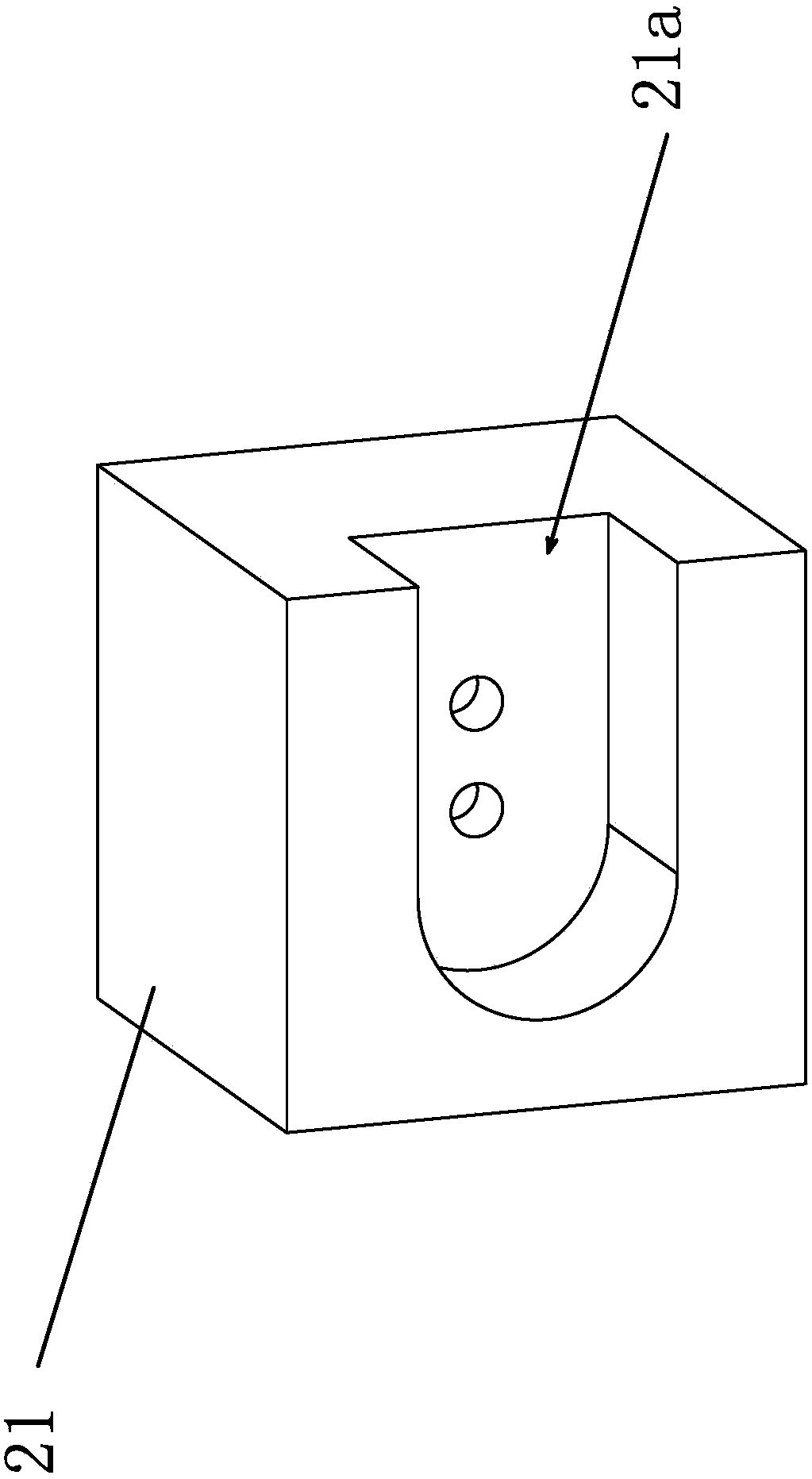

[0048] Such as Figure 1-Figure 6 As shown, the assembly line in step c includes a frame 1, on which a rotating shaft 3 is vertically arranged, the lower end of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com