Trial model capable of simulating shield tunnel pipe slice joint and manufacturing method thereof

A shield tunnel segment and test model technology, which is applied to the test model that can simulate shield tunnel segment joints, the production of test models, and the production of tunnel test models, which can solve the impact of assembly accuracy, test errors, and inability to Consider issues such as the impact of tunnel segment joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

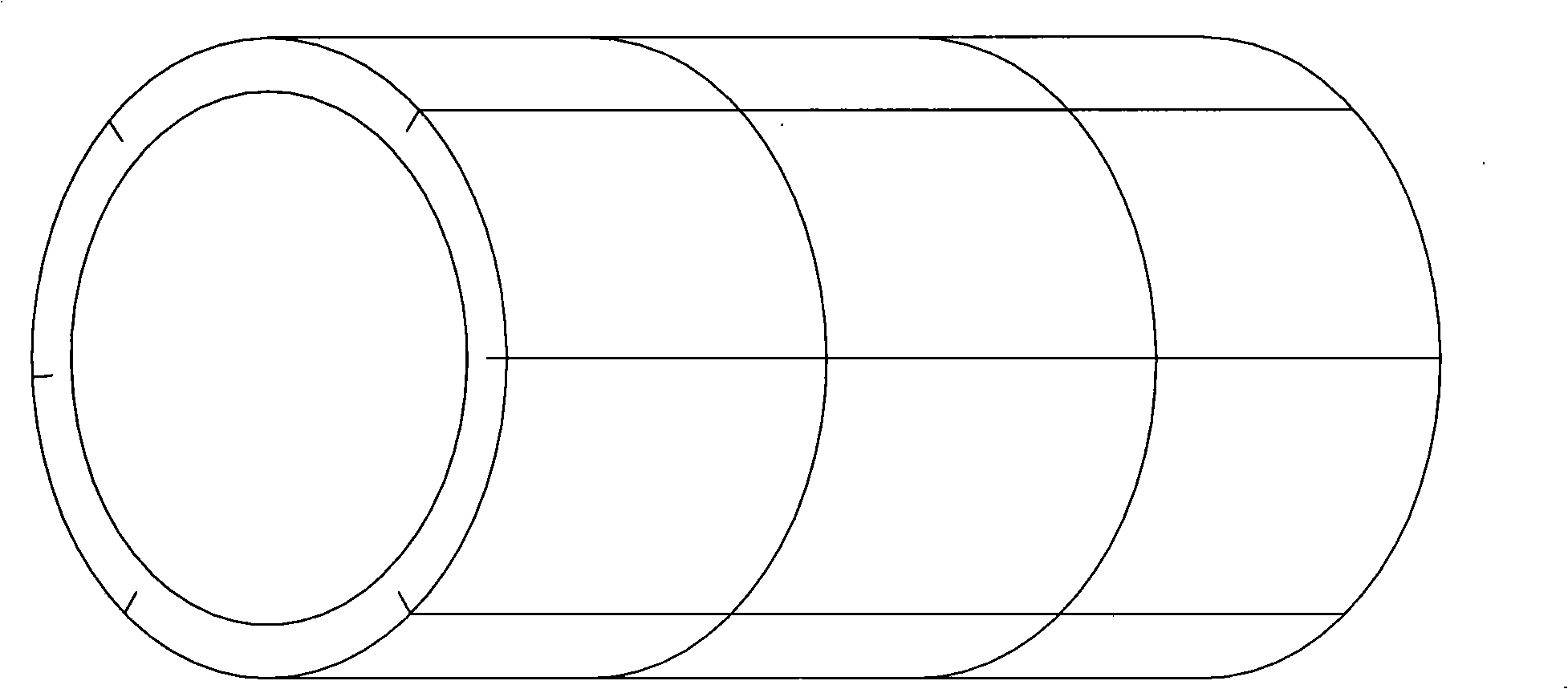

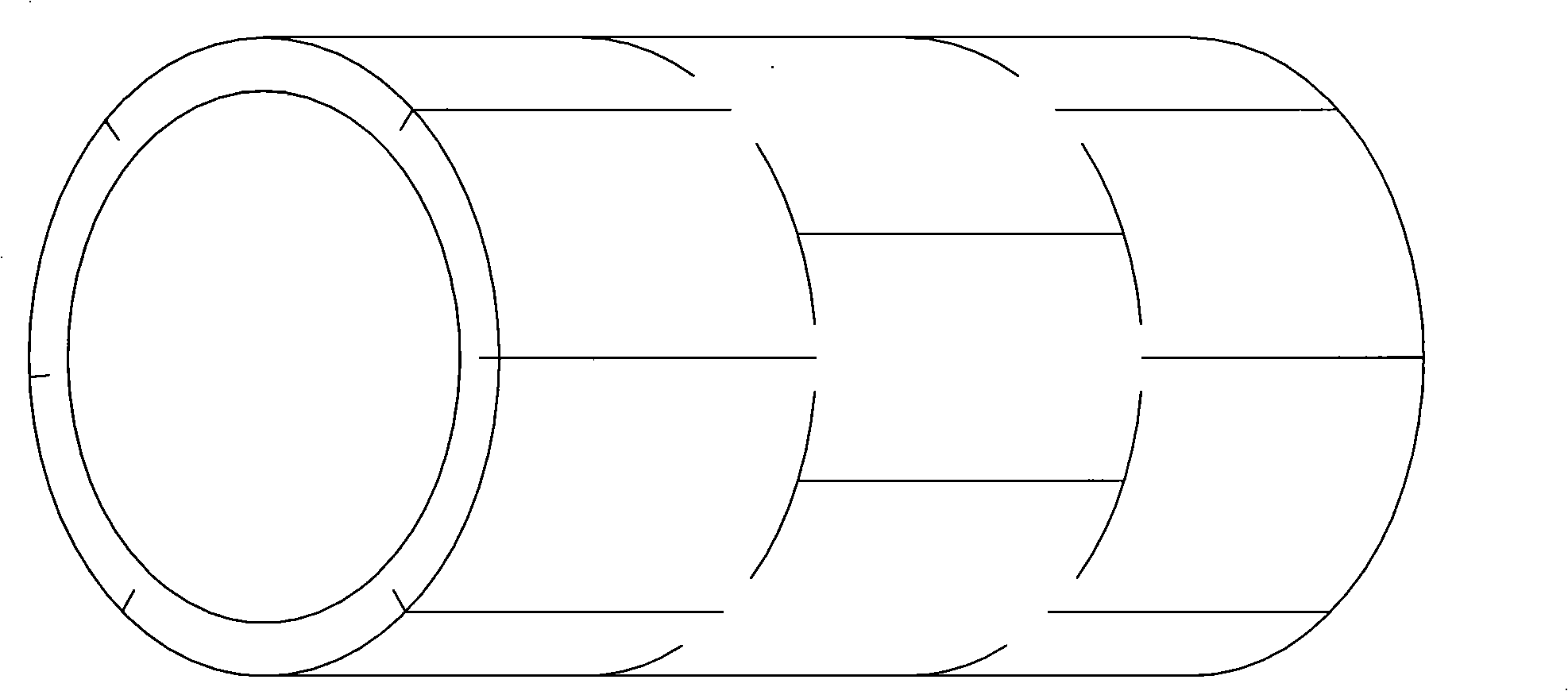

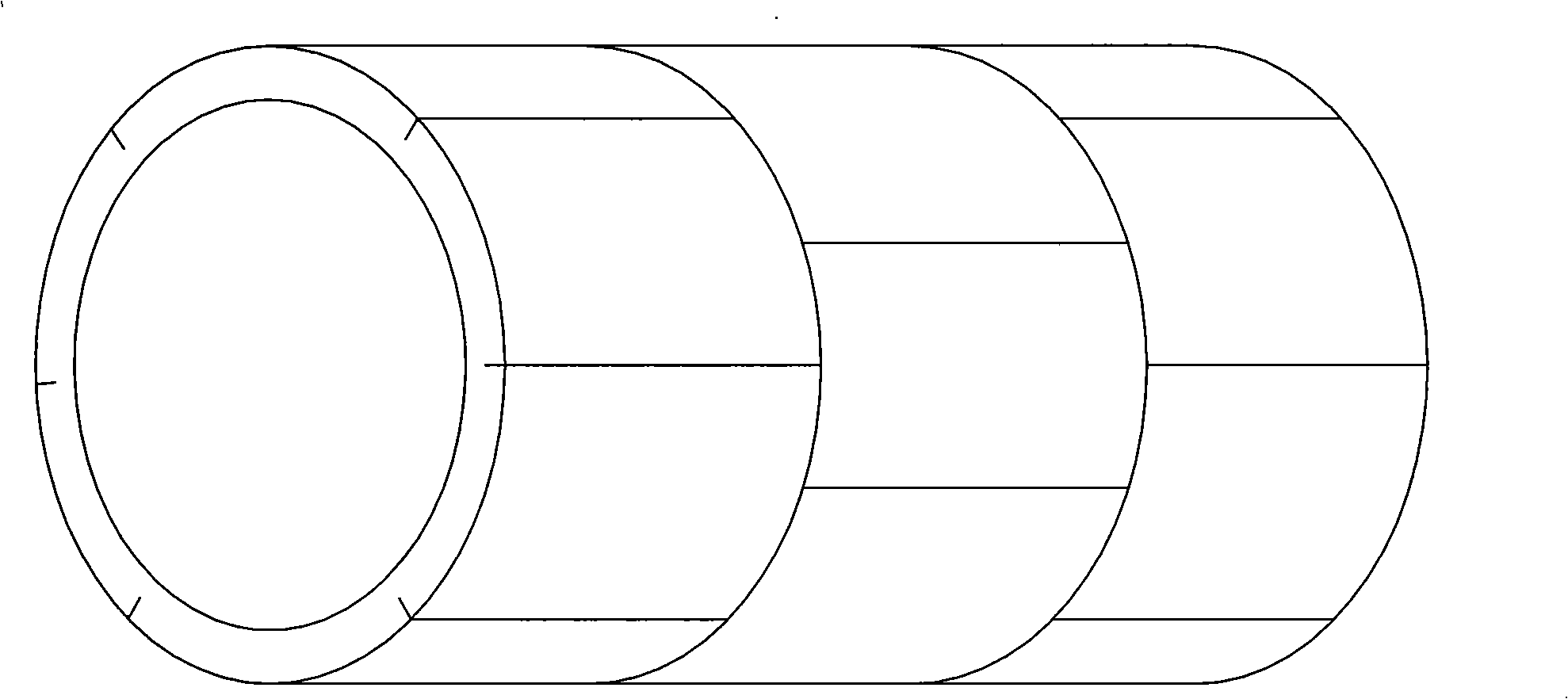

[0025] The actual shield tunnel segments are connected by bolts, thus constituting the circular joints and longitudinal joints of the tunnel. Among them, according to the different longitudinal joints of the tunnel, the longitudinal joints of the tunnel are divided into staggered joint assembly and through joint assembly. In the present invention, in order to effectively reflect the real structure of the tunnel, cuttings can be made on the surface of the model in the circumferential direction and in the longitudinal direction, and the circumferential slits and longitudinal slits are correspondingly formed. This simulation method is relatively close to the actual situation. In the test, the influence of the circumferential joint and the longitudinal joint on the longitudinal and transverse stiffness of the tunnel can be simulated; moreover, the joint does not require manual assembly, and can be precisely processed according to the design requirements of the joint by using digital...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com