Seat horizontal driver assembly line

A driver and assembly line technology, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve problems such as troublesome and low efficiency of manual assembly, and achieve the effect of improving efficiency and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

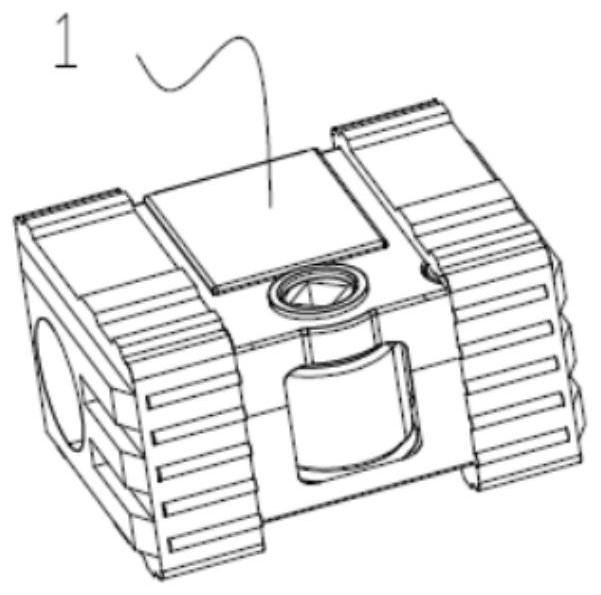

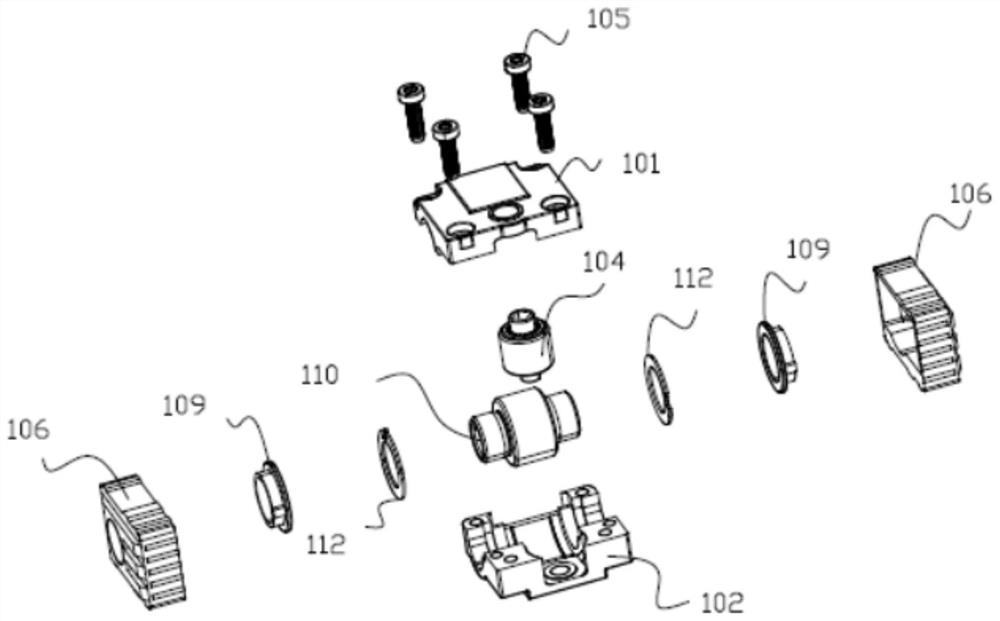

[0075] Example: such as Figure 4-Figure 6 The seat horizontal driver assembly line shown is used to assemble the seat horizontal driver 1, including the following stations,

[0076] Conveyor chain 2 with tray 111, used to move the tray 111 to each station, and the tray 111 is used to place the lower cover 102;

[0077] The lower cover delivery station 3 is used to deliver the lower cover 102 onto the tray 111;

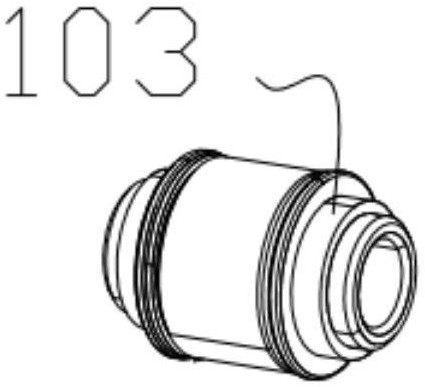

[0078] The helical gear assembly delivery station 4 is used to horizontally install the helical gear assembly 103 into the cavity of the lower cover 102;

[0079] The worm conveying station 5 is used to drive the worm 104 to move longitudinally and spirally into the cavity of the lower cover 102 and mesh with the helical gear assembly 103;

[0080] The oiling station is used to fill the cavity of the lower cover 102, the helical gear assembly 103 installed in the cavity and the worm screw 104 installed in the cavity;

[0081] The upper cover conveying station 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com