Combined type warning board splicing system special for power supply system

A power supply system and warning sign technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of easy scratches in assembly, affect the progress of work, and time-consuming, etc., and achieve the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

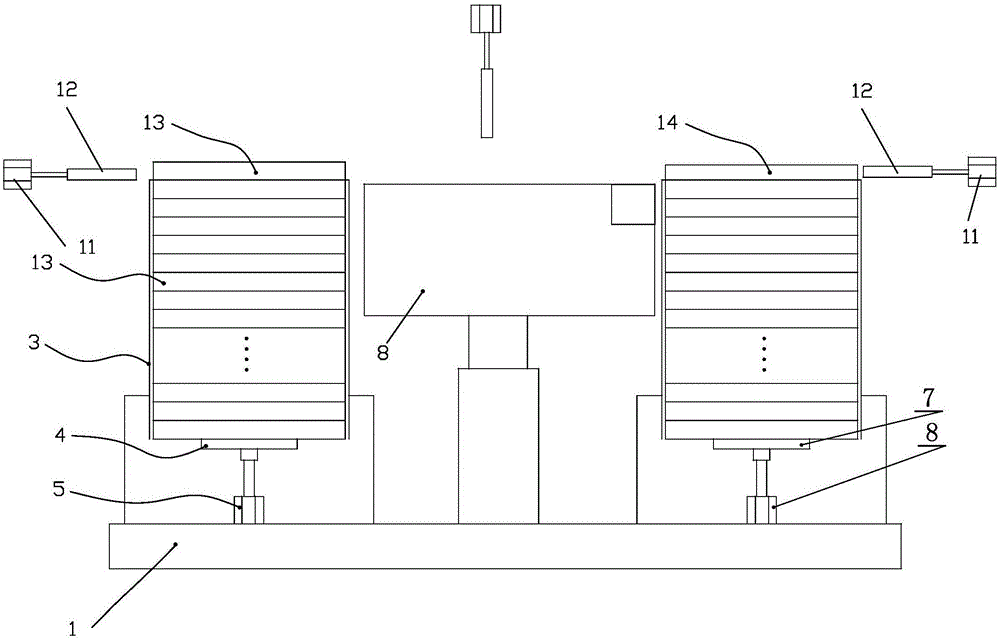

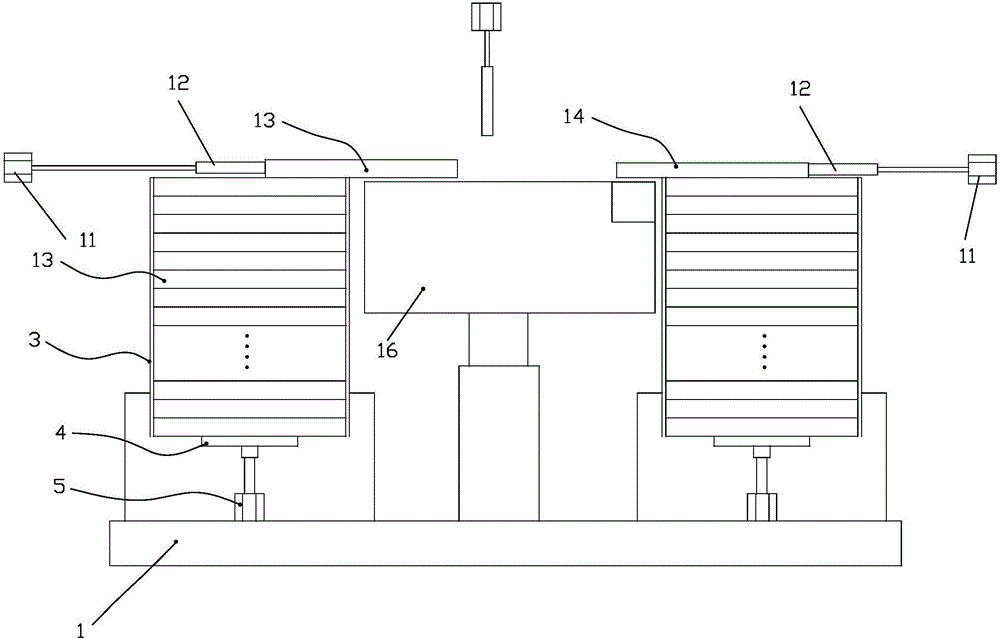

[0039] Feature and principle of the present invention are described in detail below in conjunction with accompanying drawing 1-Fig. 5, and given embodiment is only for explaining the present invention, is not intended to limit protection scope of the present invention with this.

[0040] The warning sign 15 involved in this invention includes a shell 13 and an inner core 14, wherein the shell is a square plate with one side open, and the inner core is installed in the shell, and the two are assembled together.

[0041] like Figure 1(a)-Figure 1(d) As shown, the invention mainly consists of the first storage bin 3 for housing the casing 13, the jacking device for removing the casing 13 from the first storage bin 3, the assembly platform, the first pushing device for pushing the casing to the assembly platform, The second storage bin 6 for holding the inner core, the second lifting device at the bottom of the second storage bin to push the inner core out of the second storage b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com