Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Maintain roundness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

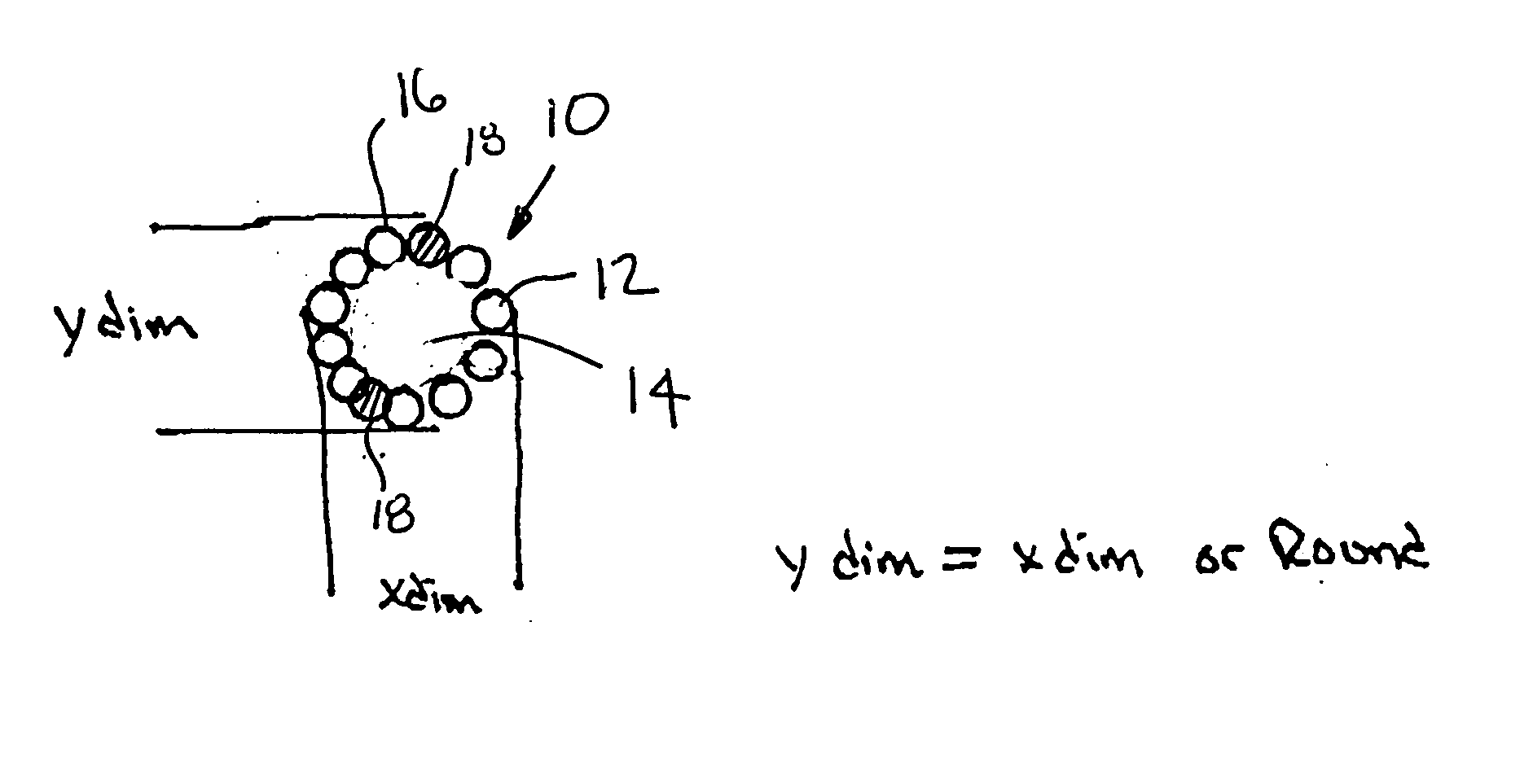

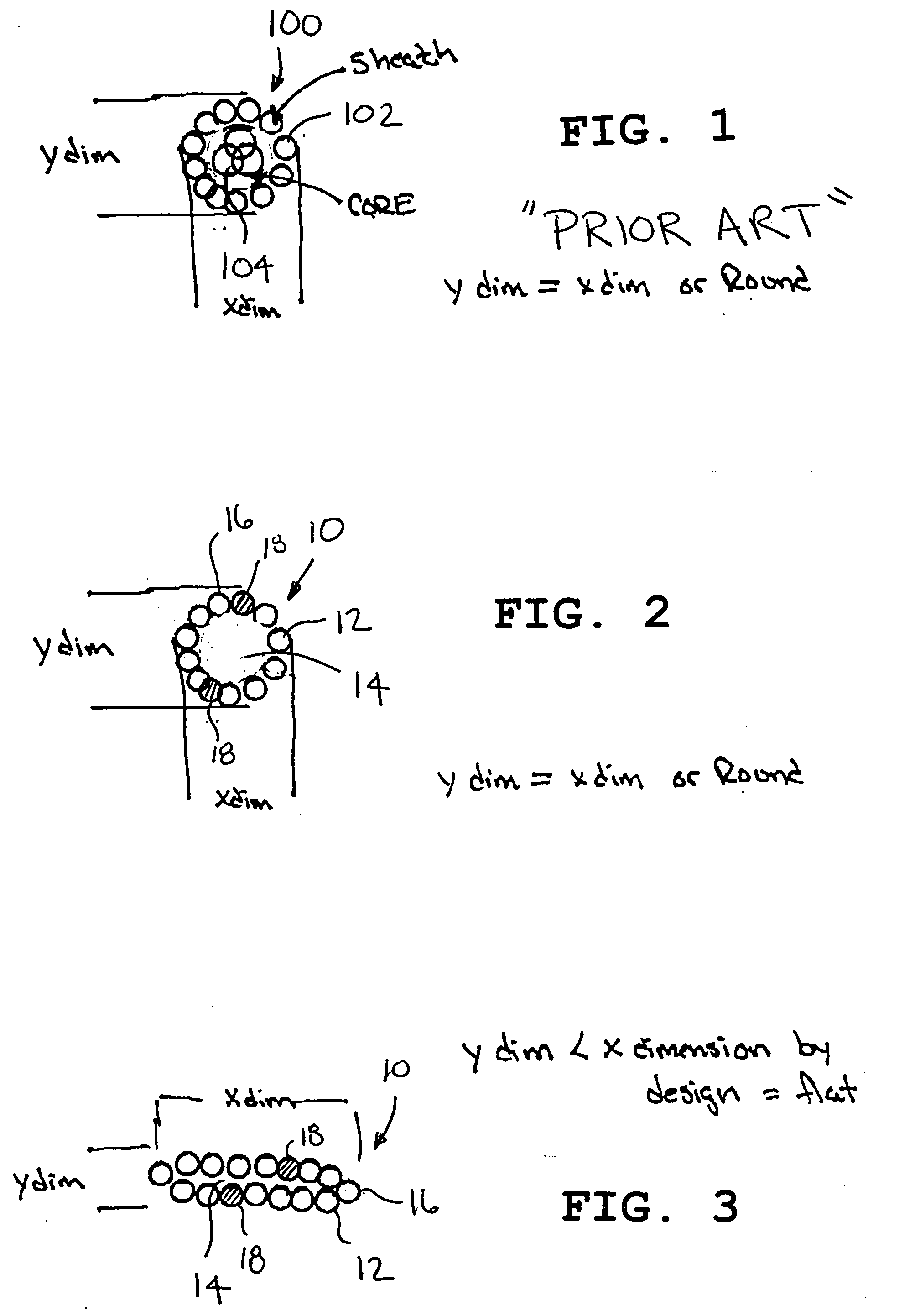

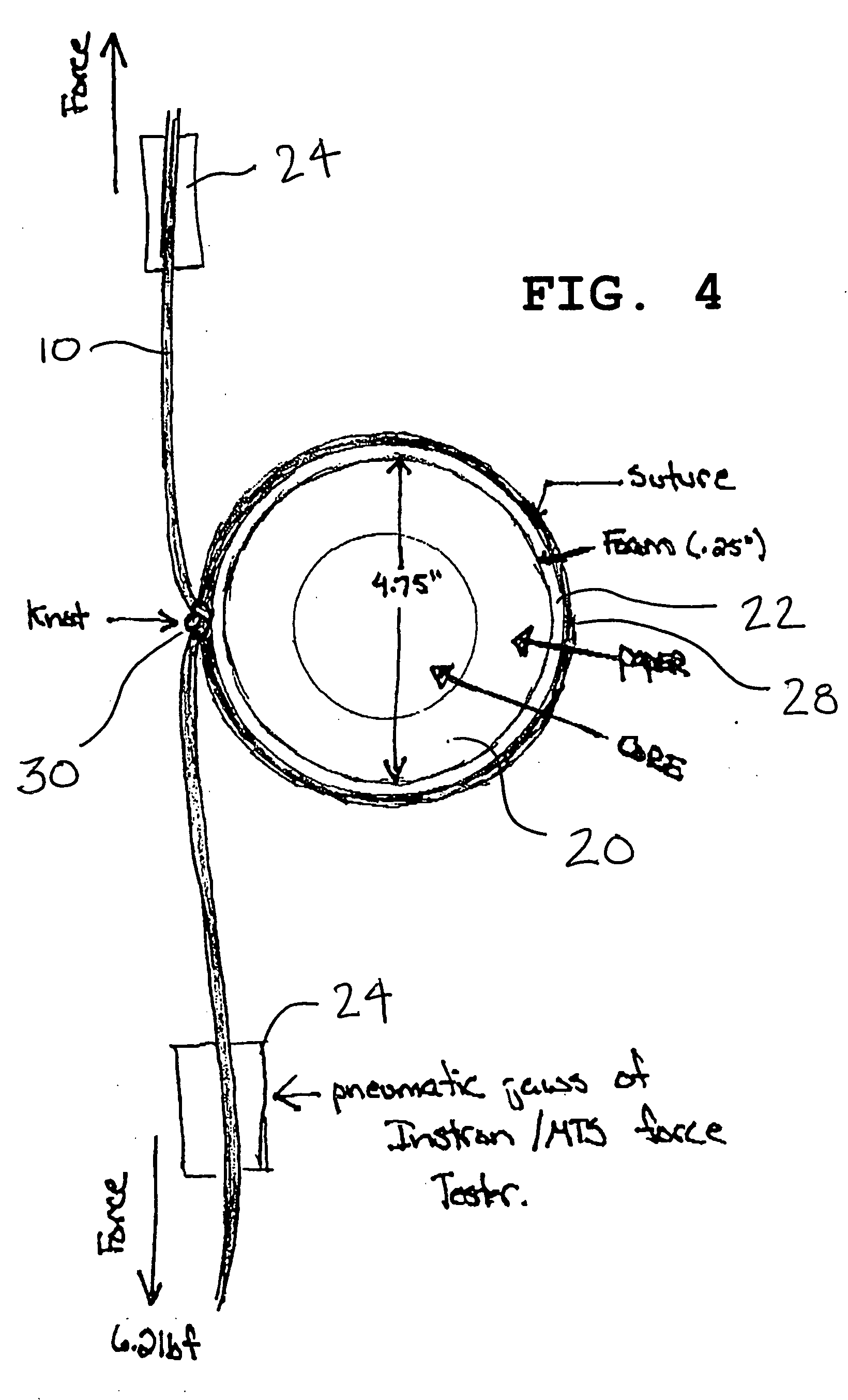

High-strength suture

ActiveUS20050277985A1Improved knot tie down characteristicSuperior knot securitySuture equipmentsSurgical needlesFiberVisibility

A surgical suture is made of an elongate, hollow braid of high strength fibers. The braid defines an elongate, longitudinally-extending, central chamber that is open and without any core material extending therein so that, when a surgeon's knot is tied with the suture, the cross-sectional shape of the braid collapses upon itself and is reduced in size in response to pressures experienced when the knot is tightened thereby producing a low profile knot that resists slippage. Preferably, the braid is of a size corresponding to a USP size 5-0 to USP size 7 suture and has one or more, preferably a pair, of color contrasting monofilaments woven therein to enhance suture visibility. Methods of making a flattened suture and of utilizing the high strength suture to maintain body tissues in an engaged position to promote healing are also provided.

Owner:TELEFLEX MEDICAL INC

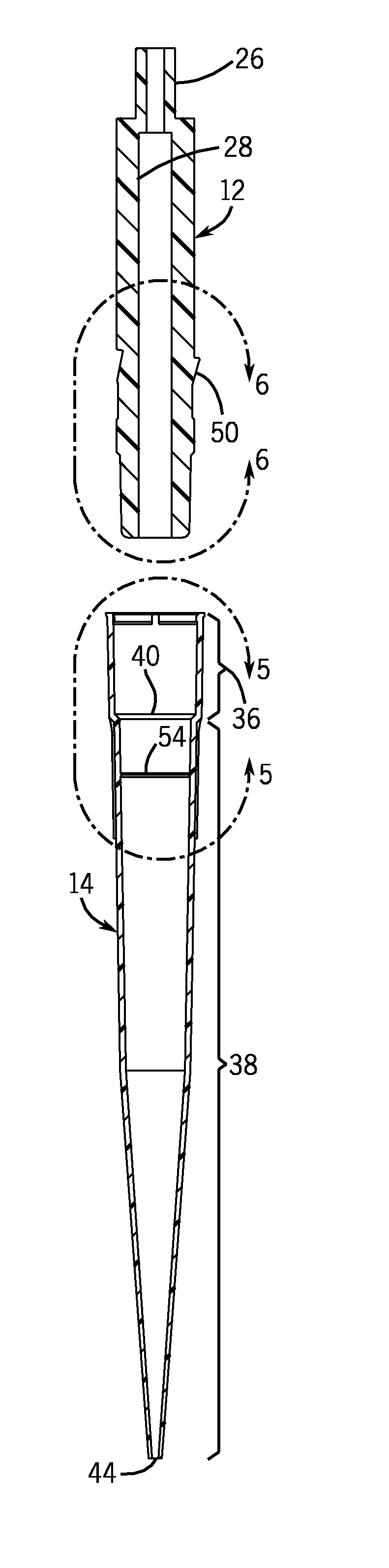

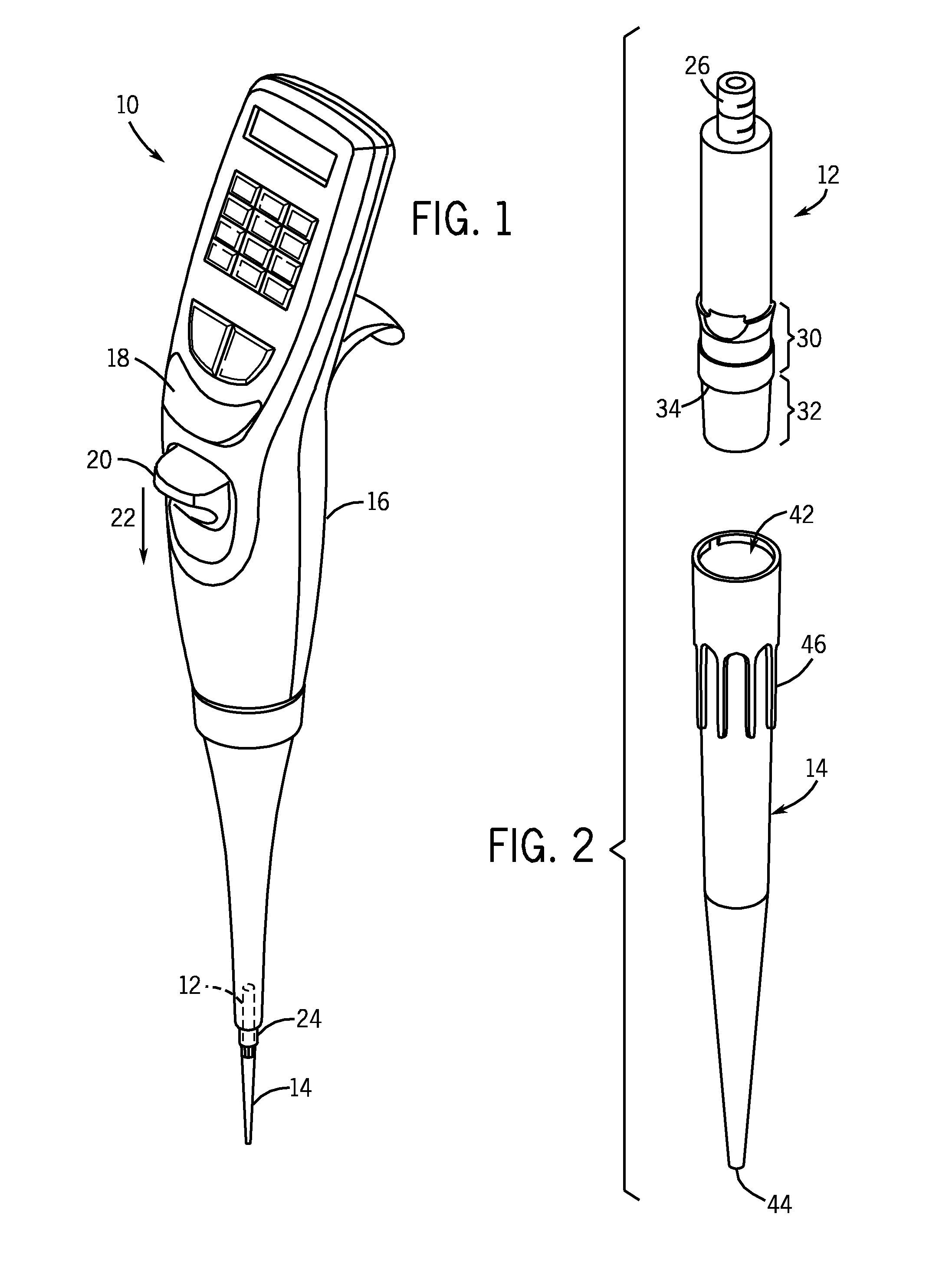

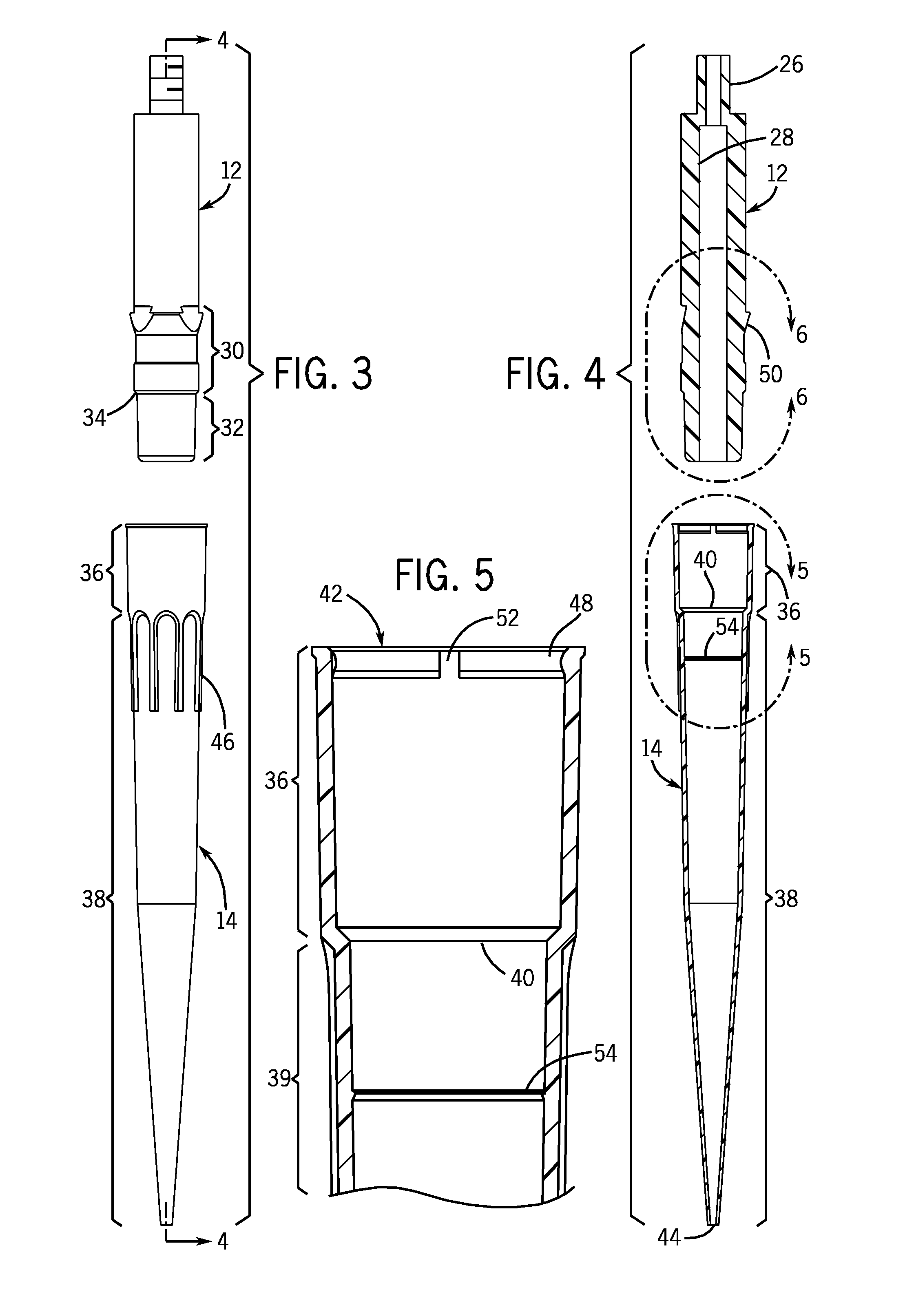

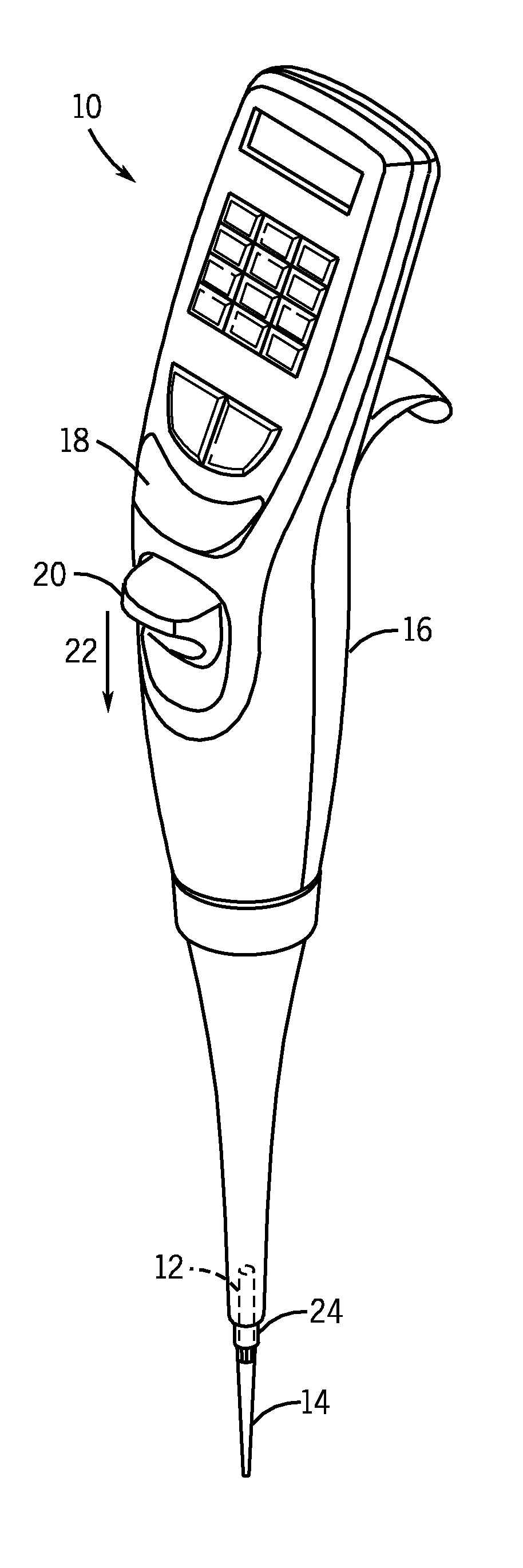

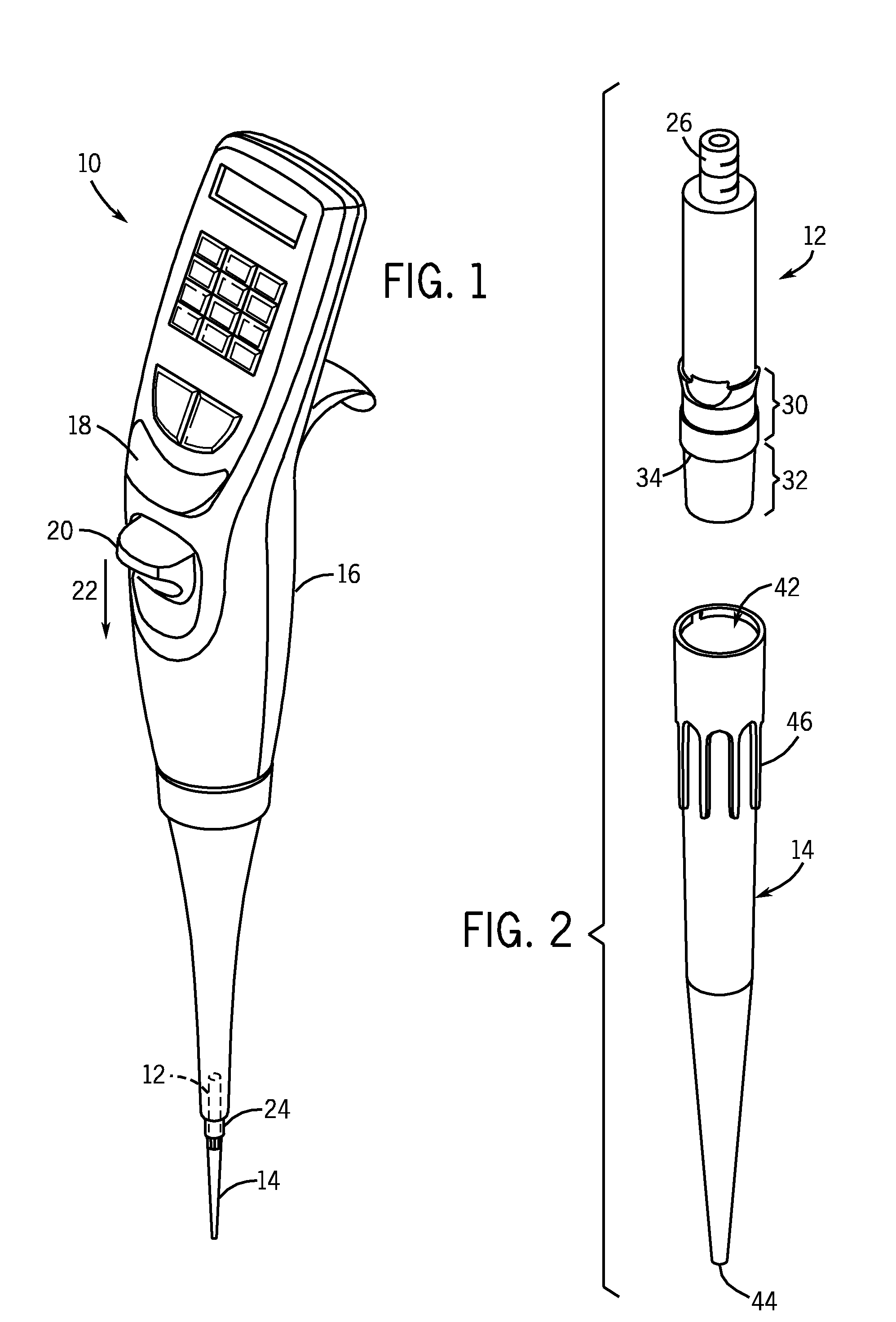

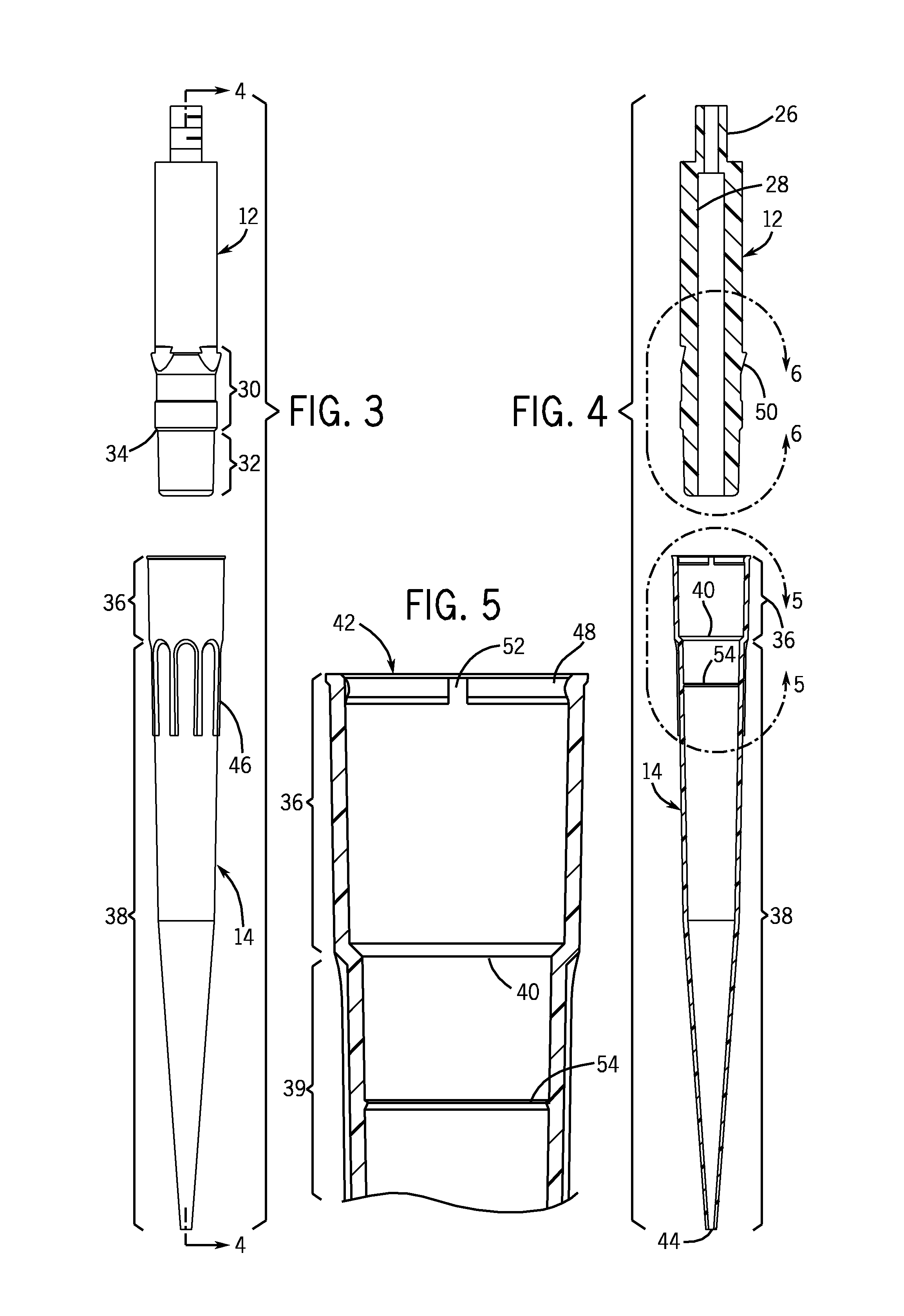

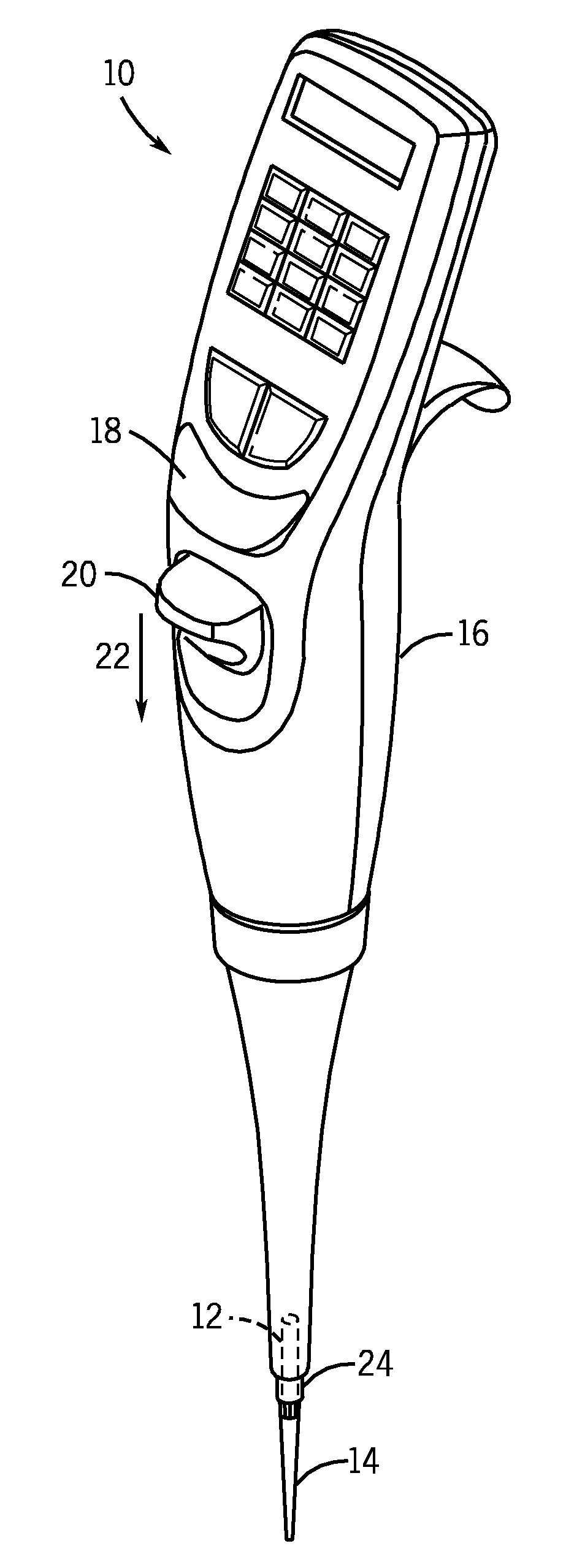

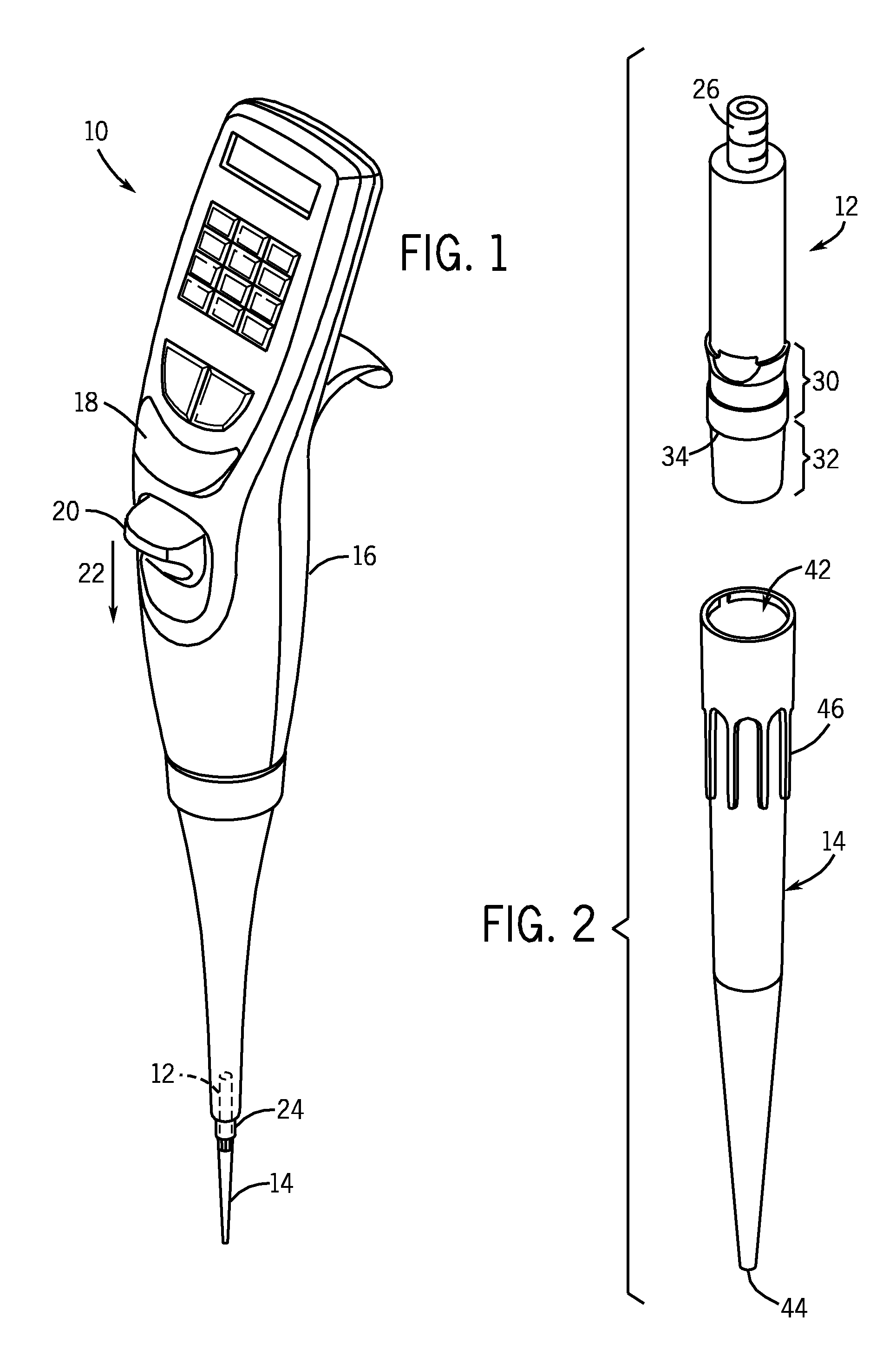

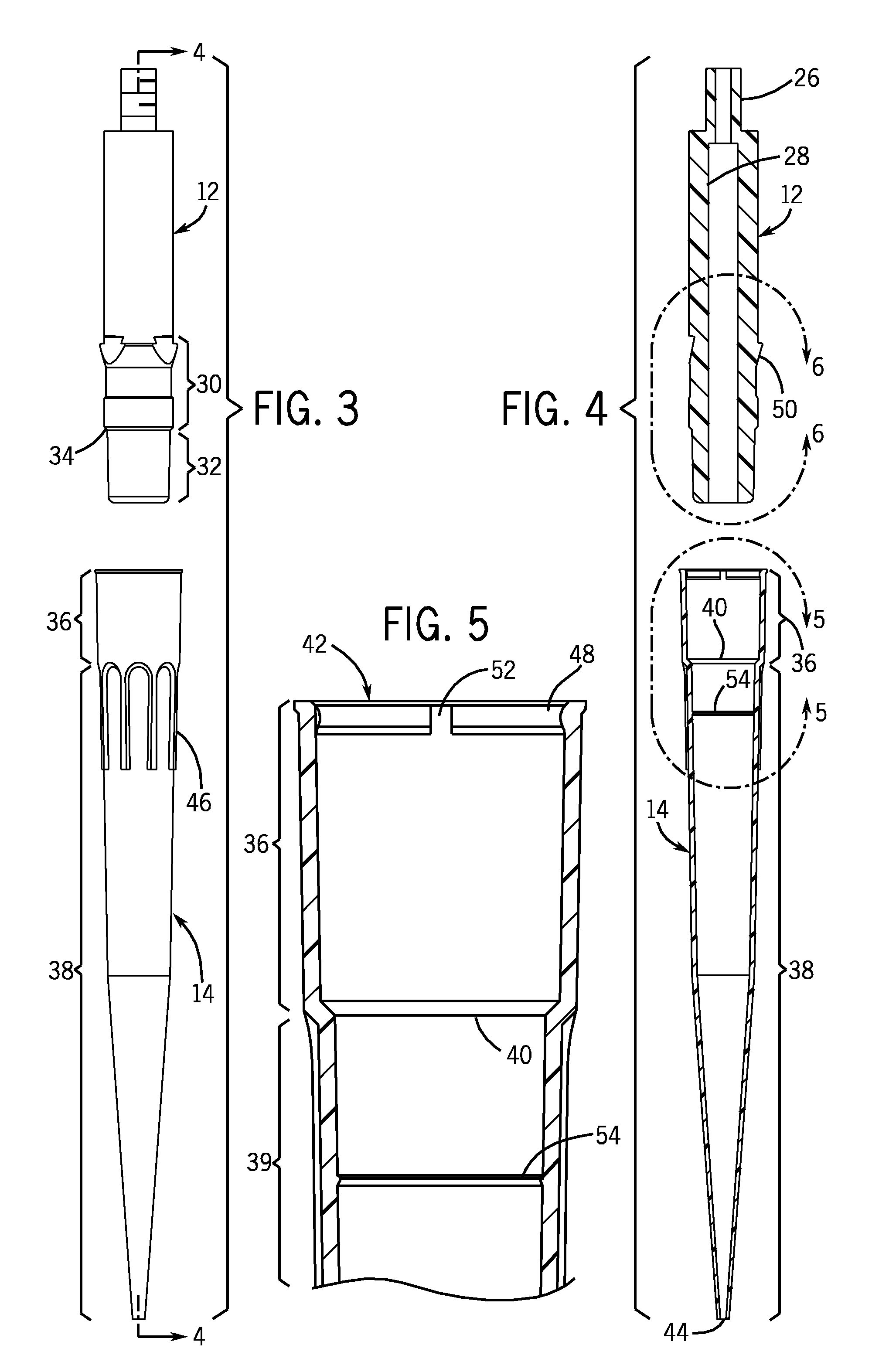

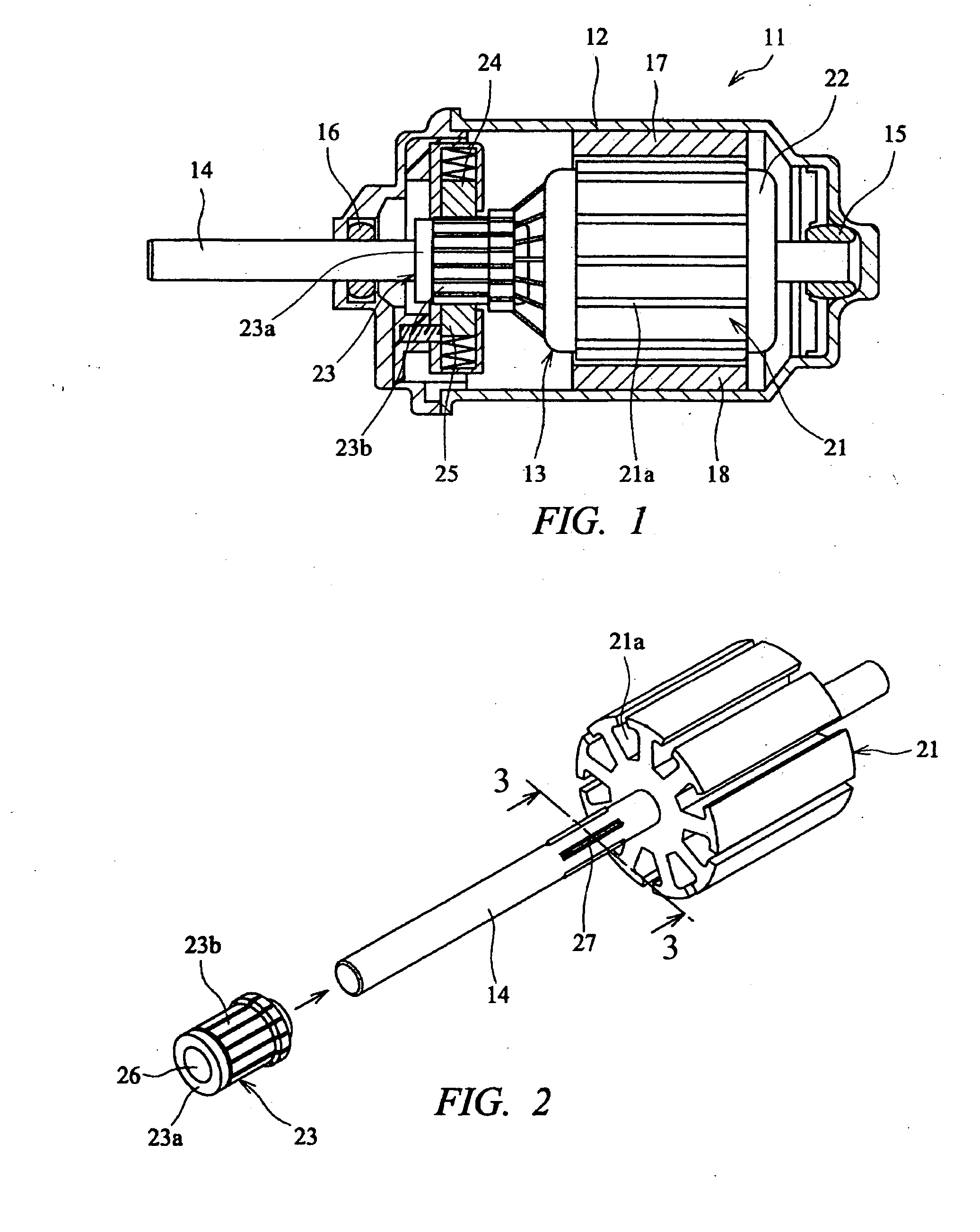

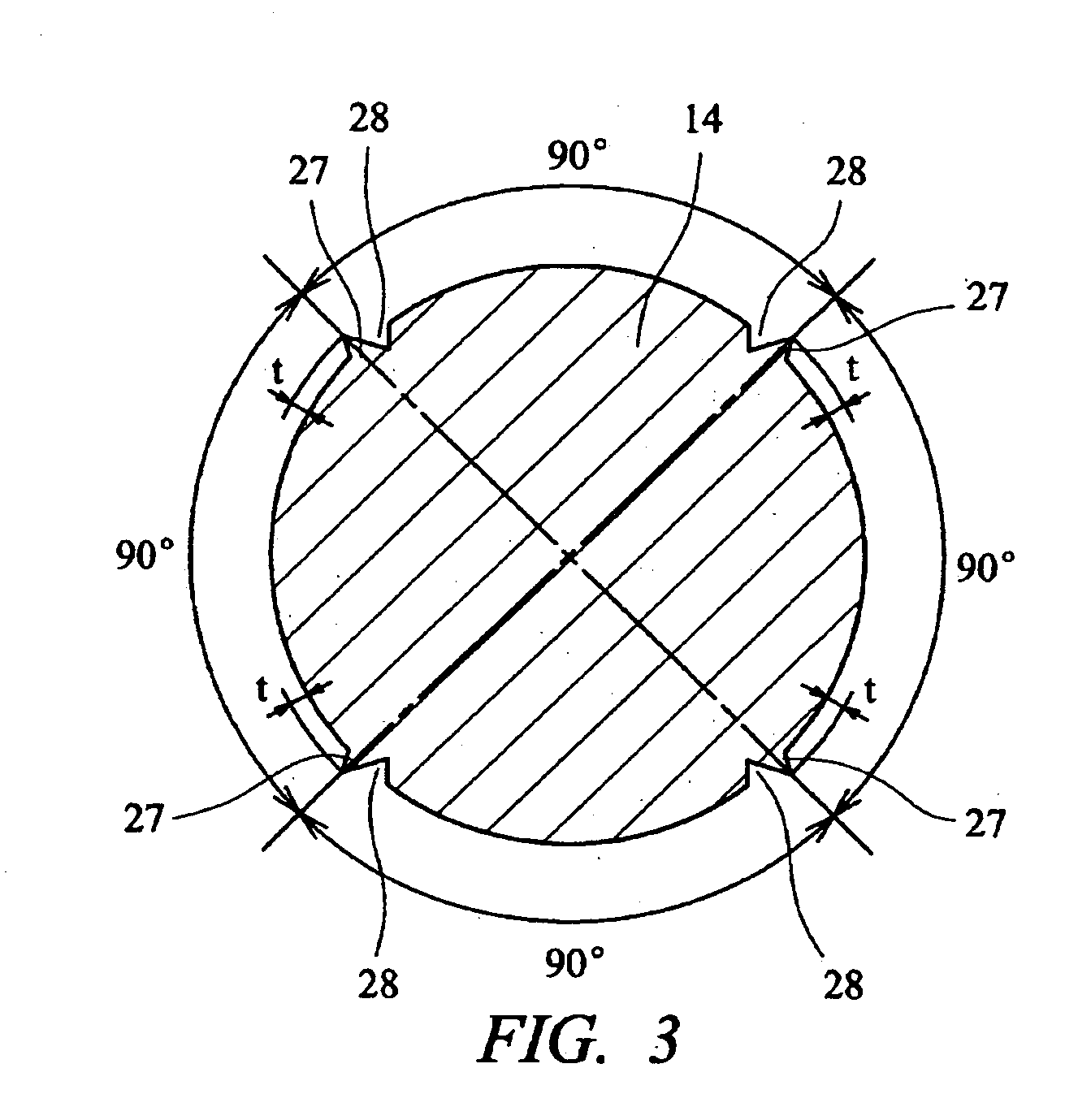

Locking pipette tip and mounting shaft

ActiveUS7662343B2Maintain roundnessFacilitate reliable engagementWithdrawing sample devicesBurettes/pipettesPipetteEngineering

The invention relates to a pipette tip mounting shaft configuration and a disposable pipette tip having a matching configuration. The mounting shaft includes a locking section located above a lower sealing section. The locking section has outwardly extending locking lobes circumferentially spaced around the mounting shaft and located above a stop member that separates the lower sealing section from the upper locking section. When the mounting shaft is fully inserted into the collar of the mating disposable pipette tip, the tip locks onto the mounting shaft. The bore of the pipette tip includes a circumferential shelf separating its upper collar from the tip sealing area which is located below the circumferential shelf. The locking lobes gently flexes and distorts the pipette tip collar out of round as the mounting shaft is inserted in the pipette tip, rather than stretching the tip collar. The circumferential shelf on the pipette tip between the tip collar and the barrel isolates the sealing area at the upper end of the barrel from distortion, thus facilitating reliable sealing engagement.

Owner:INTEGRA BIOSCI CORP

Disposable Pipette Tip

ActiveUS20100034706A1Maintain roundnessFacilitate reliable engagementAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPipetteHand held

In one aspect, the invention relates to a pipette tip mounting shaft configuration and a disposable pipette tip having a matching configuration. The mounting shaft includes a locking section located above a lower sealing section. The locking section has outwardly extending locking lobes located above a stop member and a lower sealing section located below the stop member. In certain embodiments, the diameter of the mounting shaft below the stop member is reduced in order to lessen insertion and ejection forces, which is particularly helpful for hand-held multi-channel pipettors. In these embodiments, the lower sealing section contains either a frustoconical sealing section, or an annular groove and a sealing ring, such as a flouroelastomeric O-ring seal. When the mounting shaft is fully inserted into the collar of the mating disposable pipette tip, the tip locks onto the mounting shaft. The bore of the pipette tip includes a circumferential shelf or shoulder separating its upper collar from the tip sealing area which is located below the circumferential shelf. The tip collar preferably includes a locking ring located at or near the upper opening for the mounting shaft. The dimensions of the collar, and in particular the distance between its circumferential shelf and the locking ring, are selected to match the dimensions of the mounting shaft between the stop member and the upper end of the locking lobes, thus locking the pipette tip in a secure, reliable position and orientation while using ergonomic insertion and ejection forces. The locking lobes preferably include a ramp portion that gently flexes and distorts the pipette tip collar out of round as the mounting shaft is inserted in the pipette tip, rather than stretching the tip collar. The circumferential shelf on the pipette tip between the tip collar and the barrel isolates the sealing area at the upper end of the barrel from distortion, thus facilitating reliable sealing engagement between the lower sealing section of the mounting shaft and the sealing ring in the upper end of the barrel of the pipette tip.

Owner:INTEGRA BIOSCI CORP

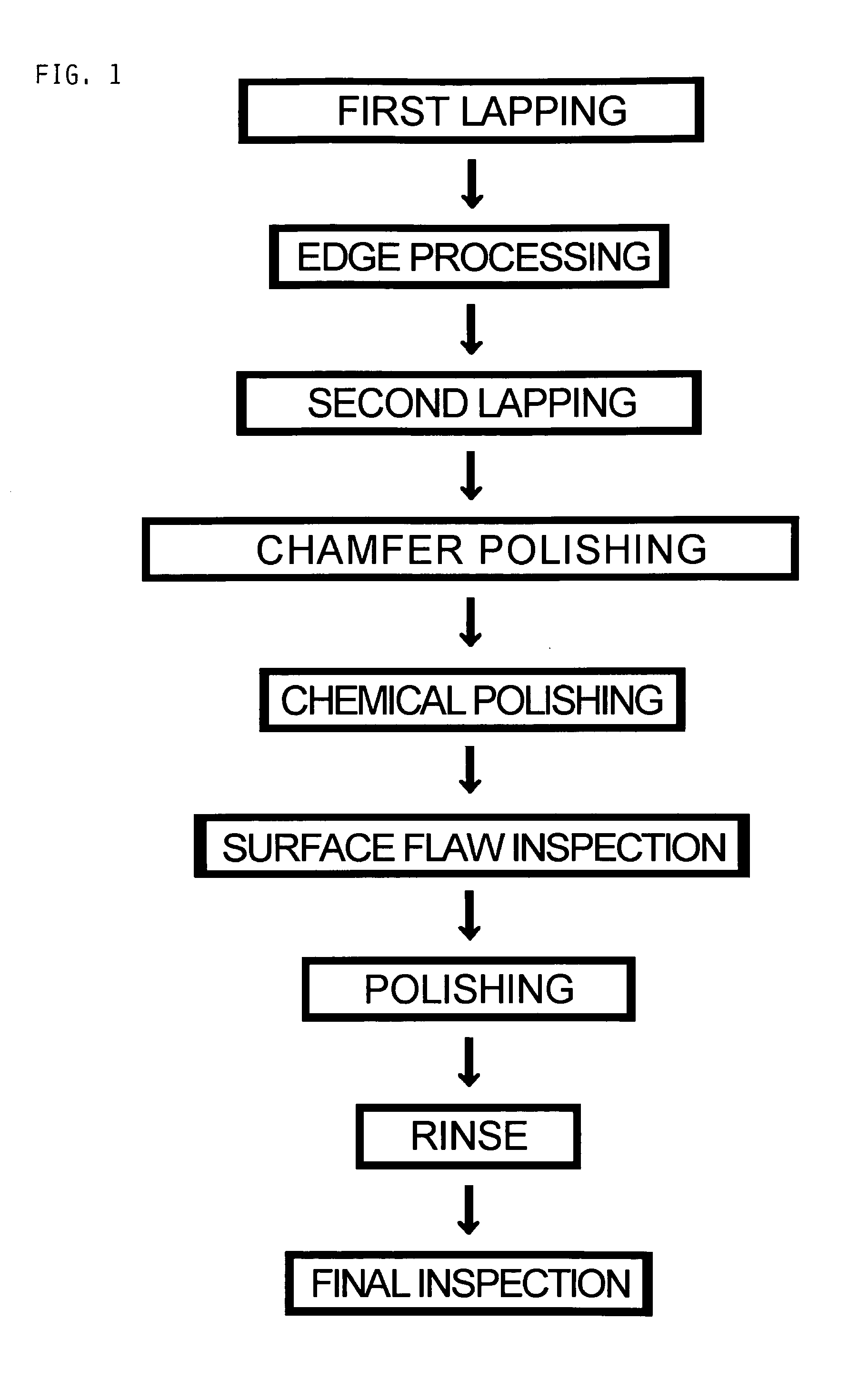

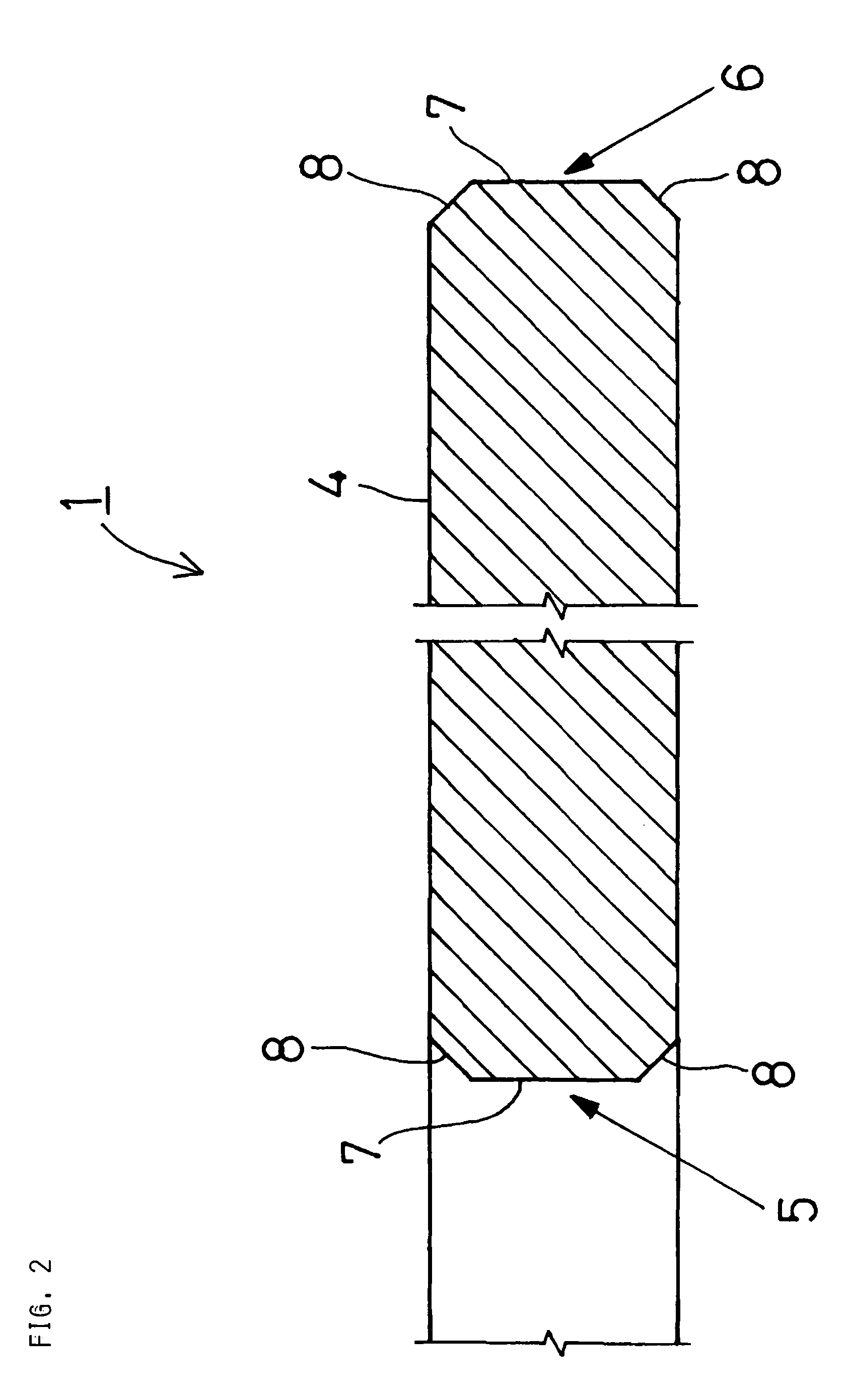

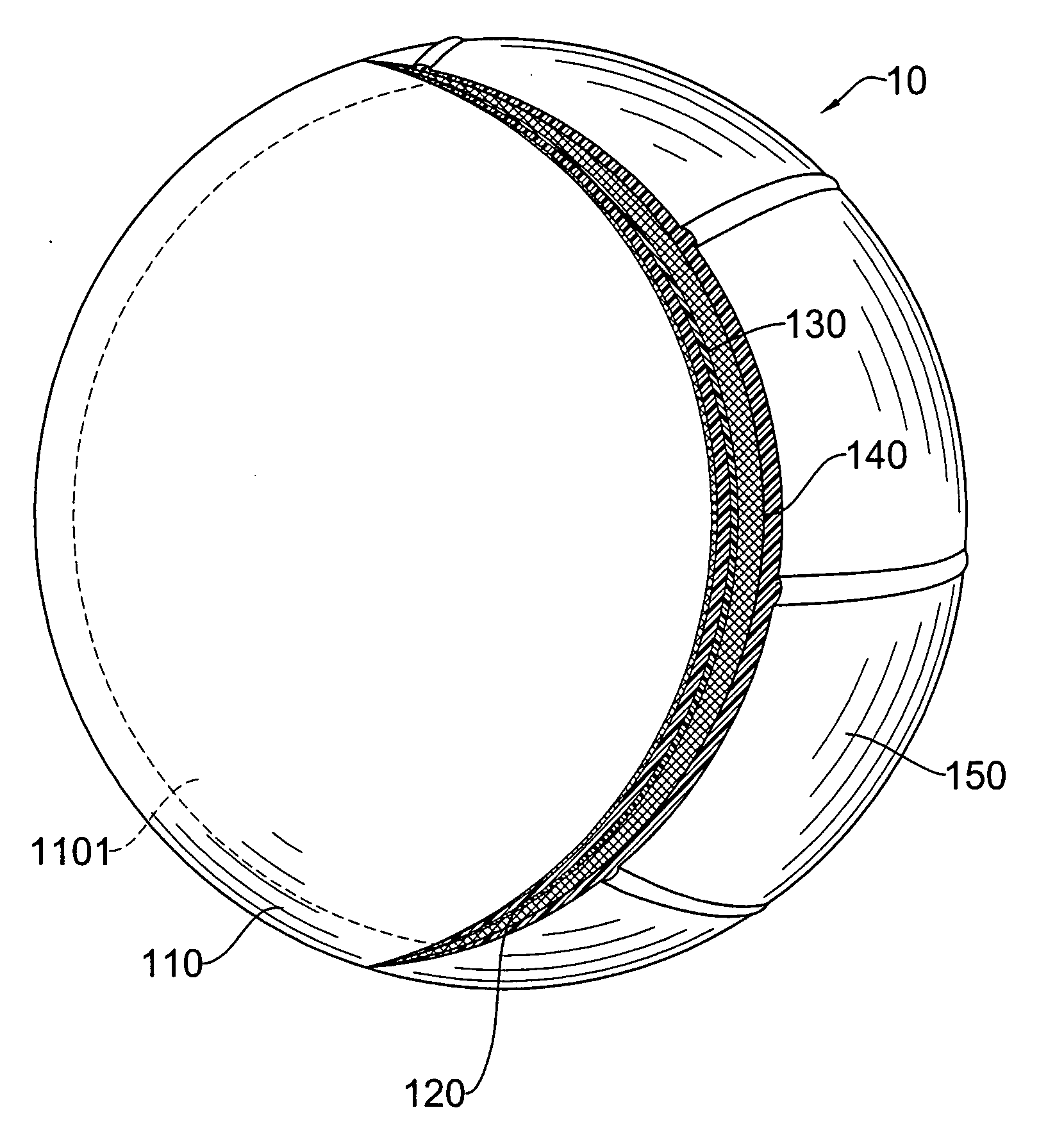

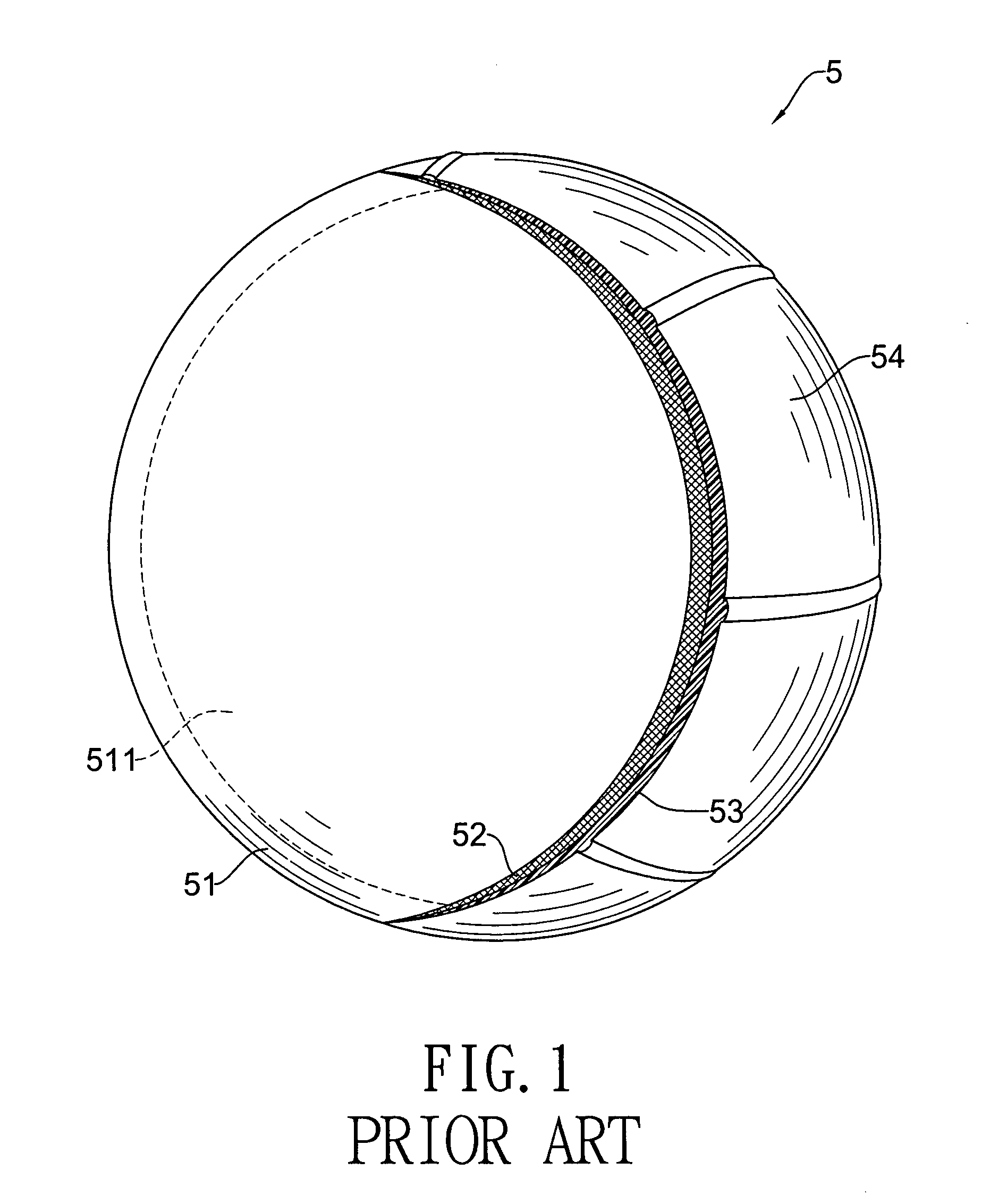

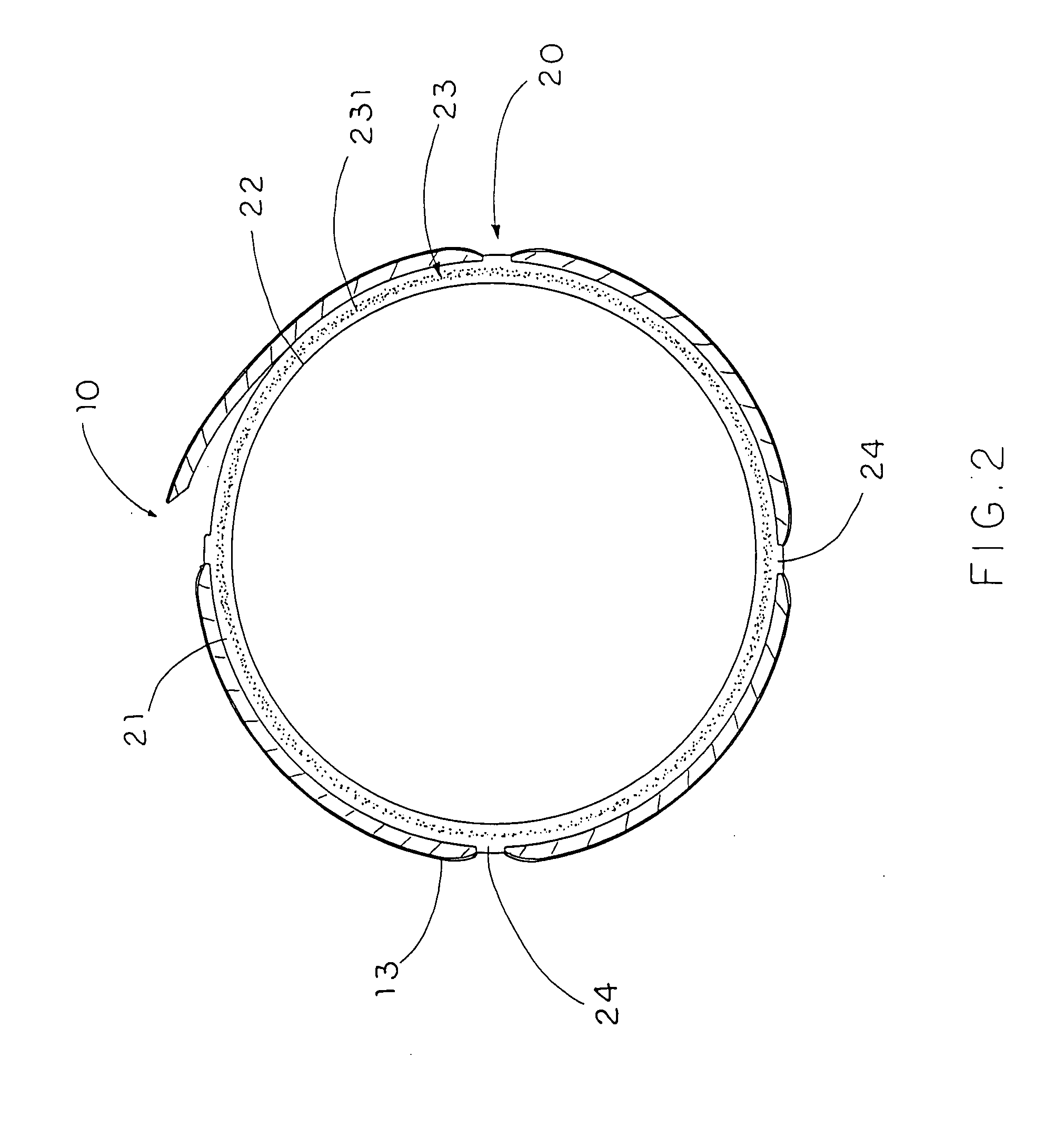

Method of surface-finishing glass substrate for magnetic disks and glass substrate for magnetic disks

InactiveUS20100266874A1Maintain dimensional accuracyMaintain roundnessEdge grinding machinesMagnetic materials for record carriersSurface finishSurface layer

An inner peripheral edge of a toroidal glass substrate for a magnetic disk is subjected to mechanical polishing in such a manner that the surface roughness is no greater than 9 nm in terms of Rmax. Then, the inner peripheral edge is subjected to chemical polishing to remove at least 2 μm of a surface layer. The inner peripheral edge has a non-conventional mirror-finished surface obtained by mechanical polishing. Thus, sufficient ring strength is obtained even when the chemical polishing depth is smaller than in the past. A polishing depth of less than 5 μm is sufficient.

Owner:TOYO KOHAN CO LTD

Locking pipette tip and mounting shaft

ActiveUS20080286157A1Easy to participateLower insertion forceWithdrawing sample devicesBurettes/pipettesDistortionPipette

In one aspect, the invention relates to a pipette tip mounting shaft configuration and a disposable pipette tip having a matching configuration. The mounting shaft includes a locking section located above a lower sealing section. The locking section has outwardly extending locking lobes located above a stop member and a lower sealing section located below the stop member. In certain embodiments, the diameter of the mounting shaft below the stop member is reduced in order to lessen insertion and ejection forces, which is particularly helpful for hand-held multi-channel pipettors. In these embodiments, the lower sealing section contains either a frustoconical sealing section, or an annular groove and a sealing ring, such as a flouroelastomeric O-ring seal. When the mounting shaft is fully inserted into the collar of the mating disposable pipette tip, the tip locks onto the mounting shaft. The bore of the pipette tip includes a circumferential shelf or shoulder separating its upper collar from the tip sealing area which is located below the circumferential shelf. The tip collar preferably includes a locking ring located at or near the upper opening for the mounting shaft. The dimensions of the collar, and in particular the distance between its circumferential shelf and the locking ring, are selected to match the dimensions of the mounting shaft between the stop member and the upper end of the locking lobes, thus locking the pipette tip in a secure, reliable position and orientation while using ergonomic insertion and ejection forces. The locking lobes preferably include a ramp portion that gently flexes and distorts the pipette tip collar out of round as the mounting shaft is inserted in the pipette tip, rather than stretching the tip collar. The circumferential shelf on the pipette tip between the tip collar and the barrel isolates the sealing area at the upper end of the barrel from distortion, thus facilitating reliable sealing engagement between the lower sealing section of the mounting shaft and the sealing ring in the upper end of the barrel of the pipette tip.

Owner:INTEGRA BIOSCI CORP

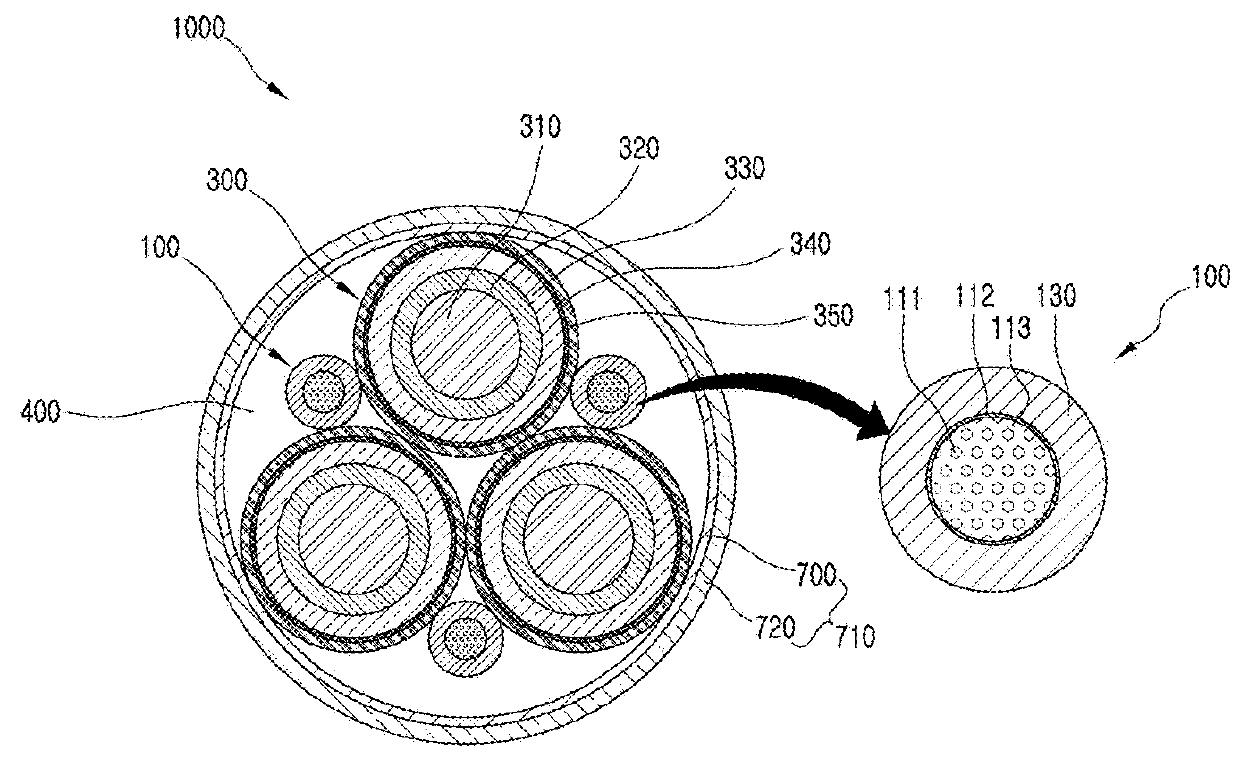

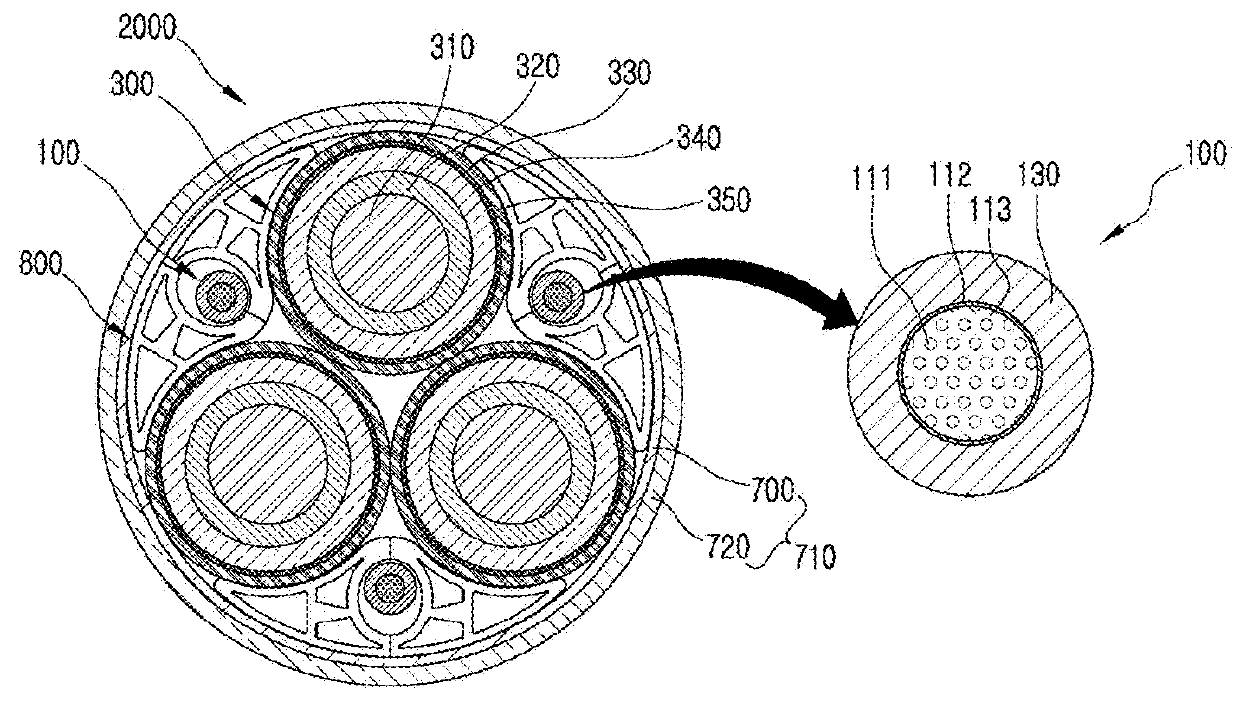

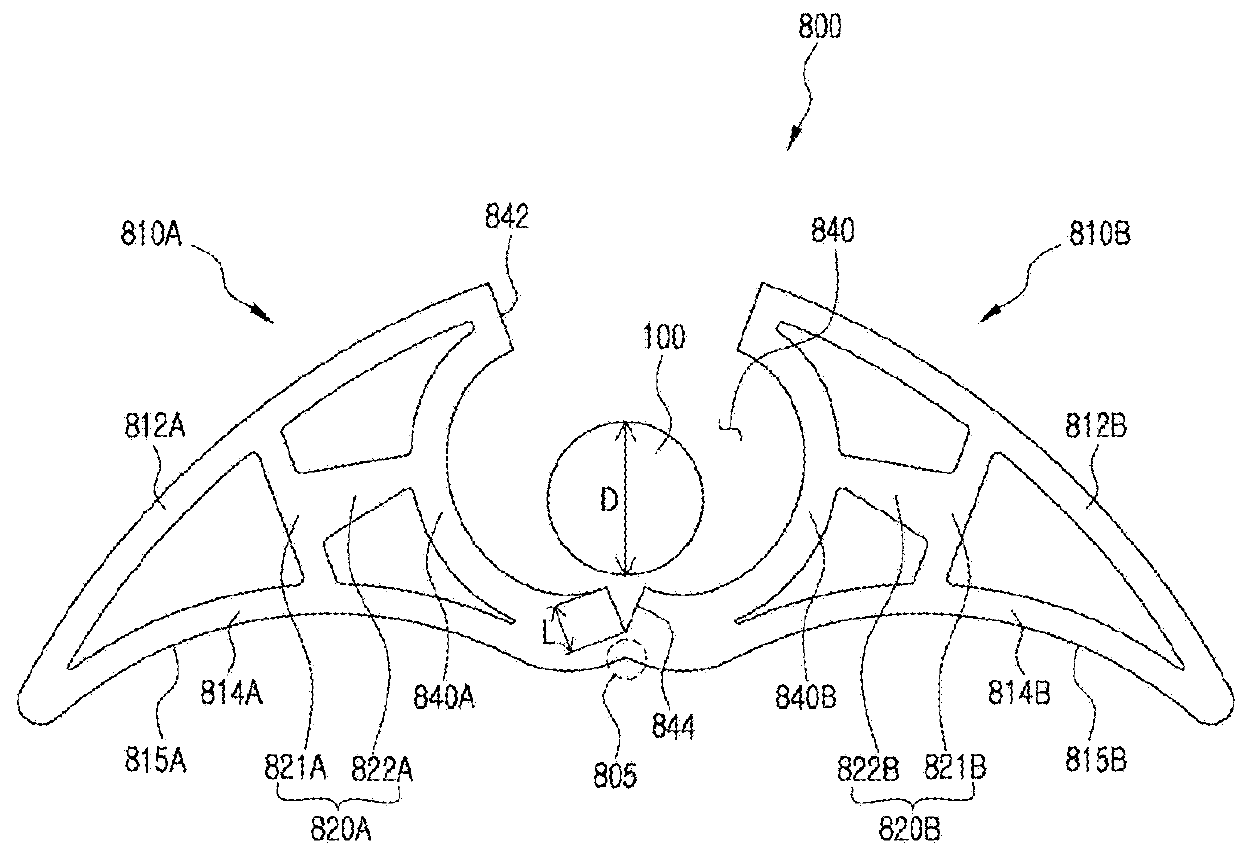

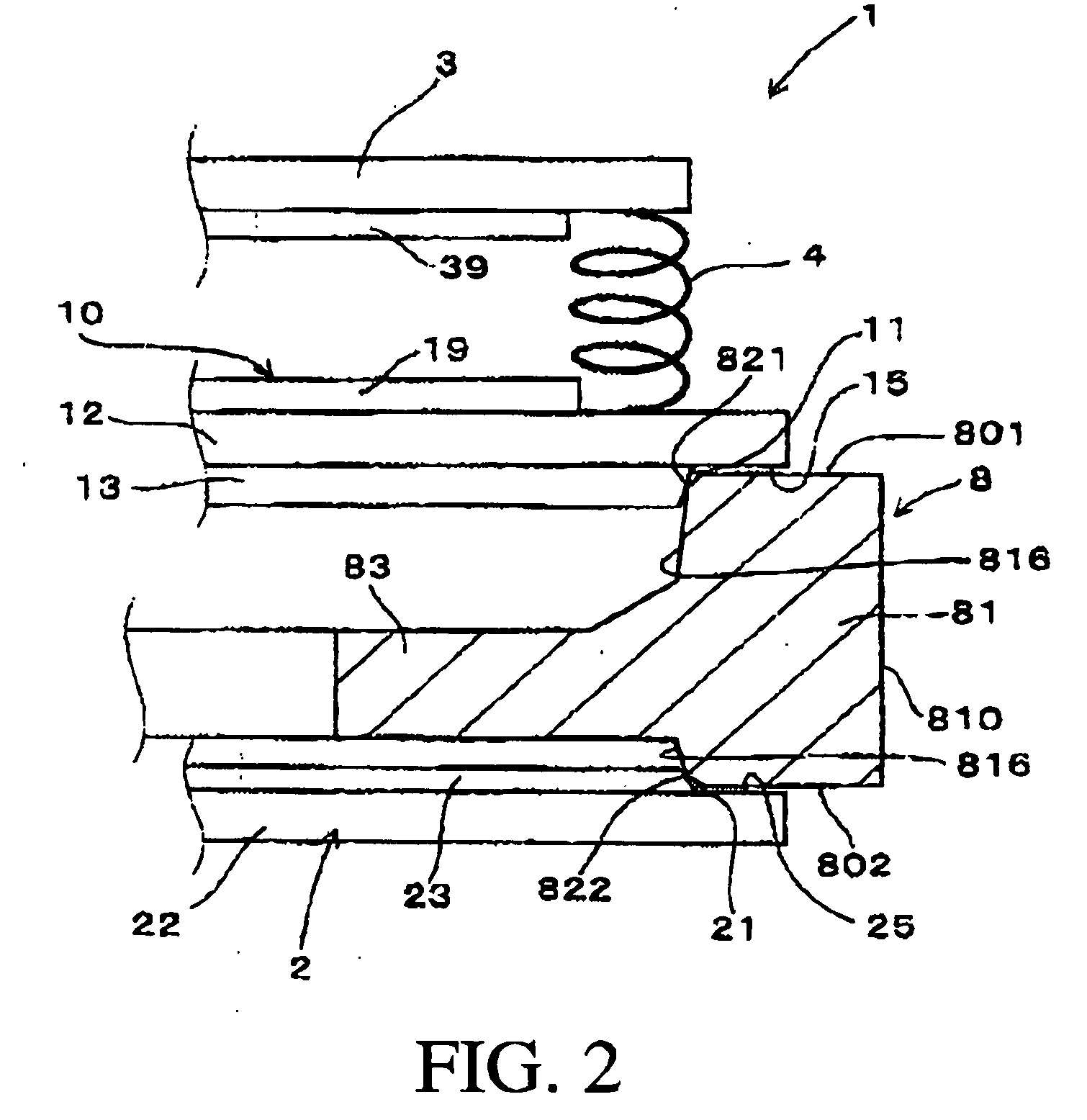

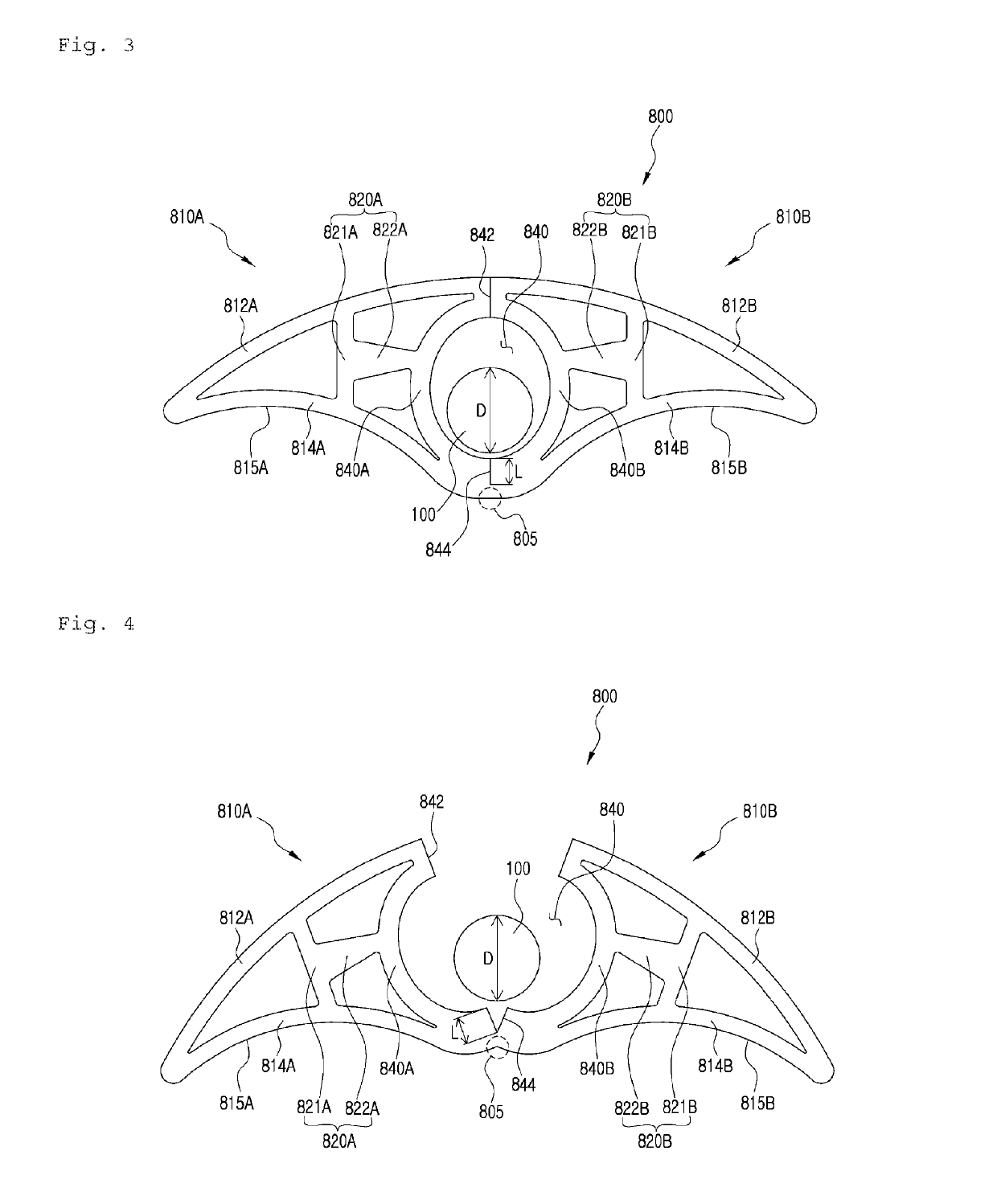

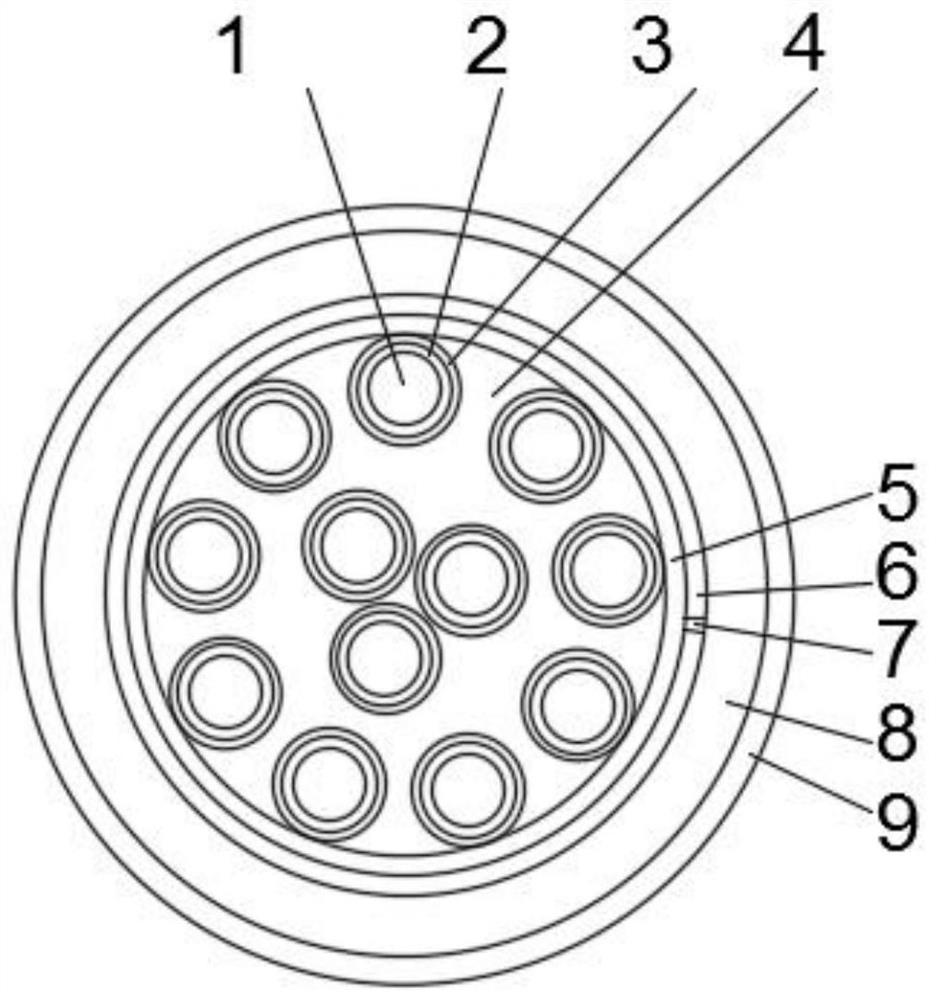

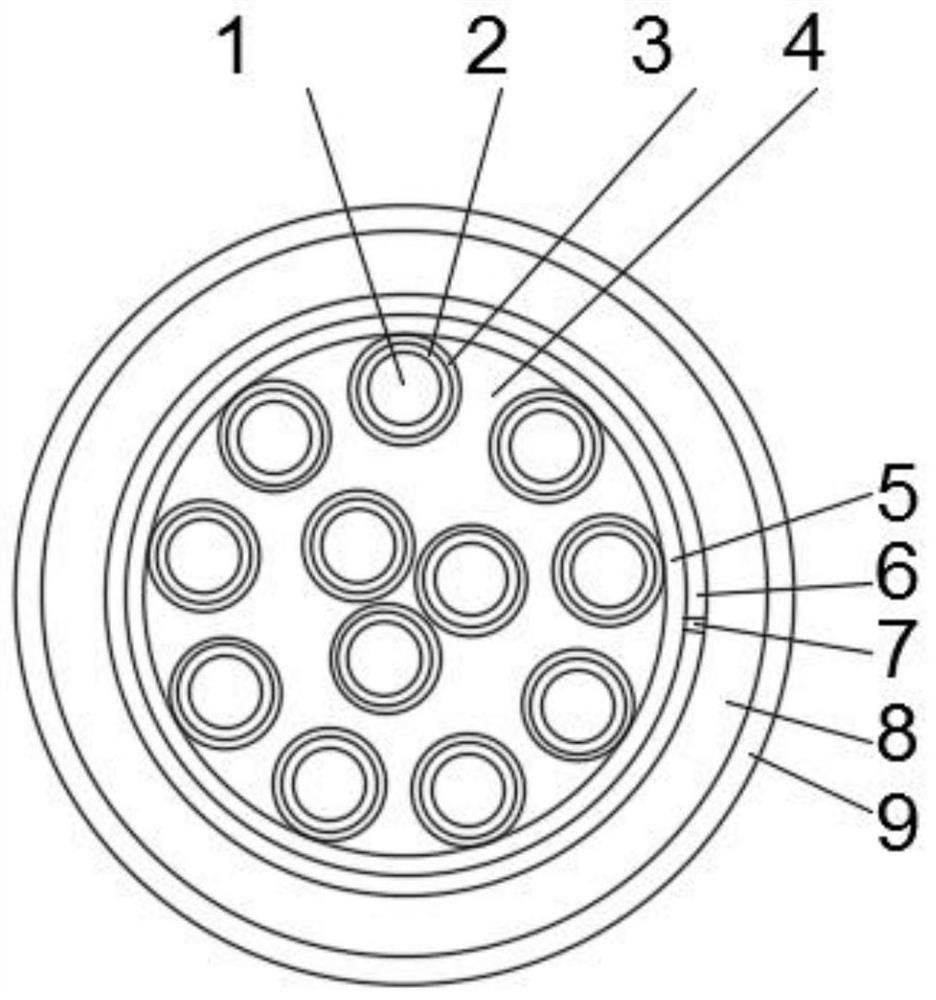

Filler and multicore cable having same

ActiveUS20180268961A1Maintain roundnessConcentric cablesPower cables with screens/conductive layersMulticore cableElectrical conductor

The present invention relates to a filler and a cable having the same and, more particularly, to a filler and a multicore cable comprising a plurality of core portions, which comprises a conductor, and a protective layer that surrounds the core portions, the filler being provided between the core portions and the protective layer of the multicore cable, the filler being characterized by comprising: frame portions comprising a first frame portion and a second frame portion, which are rotated by predetermined angles towards both sides about the center portion thereof and then incised; and a support portion provided between the frame portions so as to connect the frame portions to each other.

Owner:LS CABLE & SYST LTD

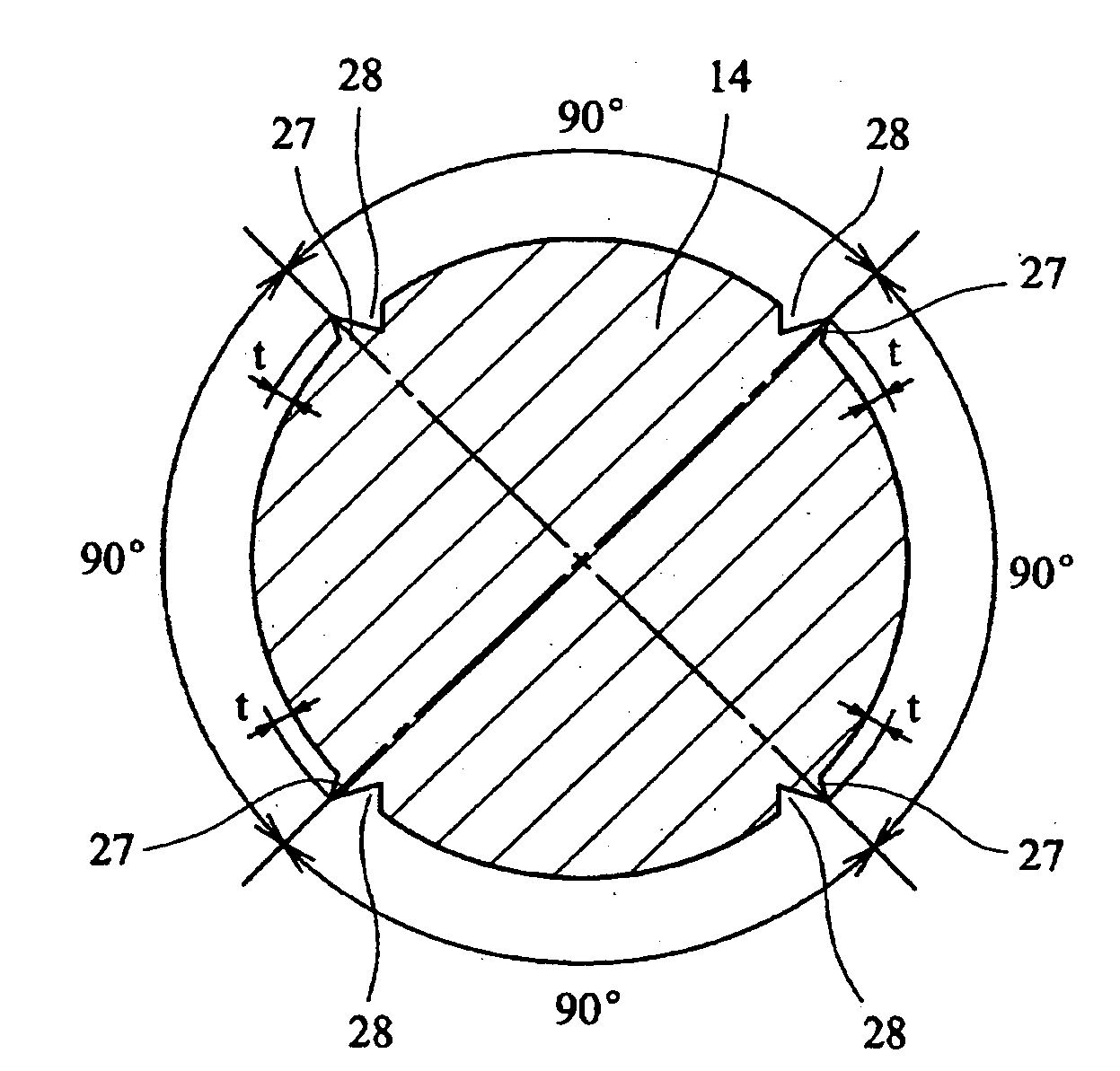

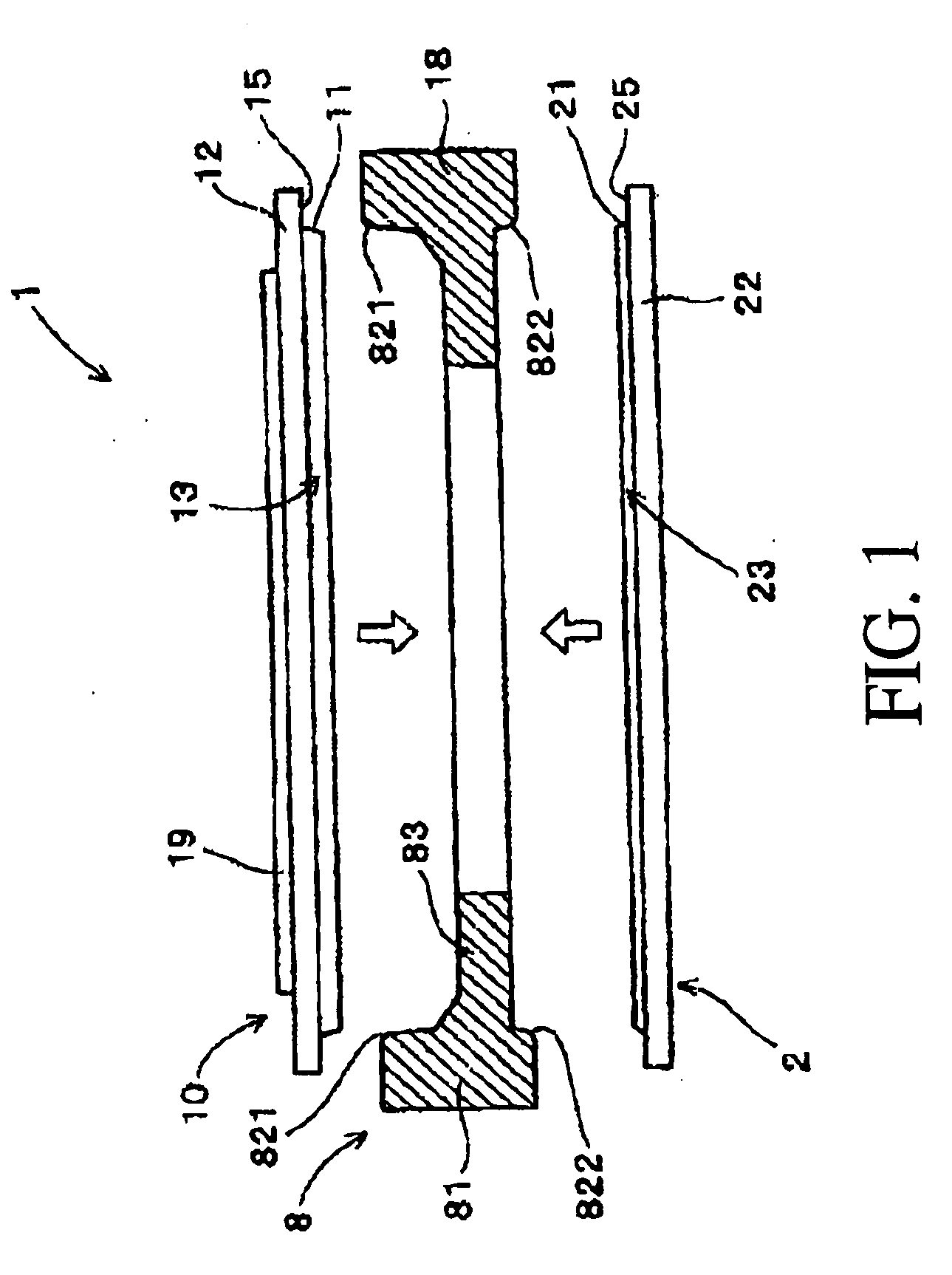

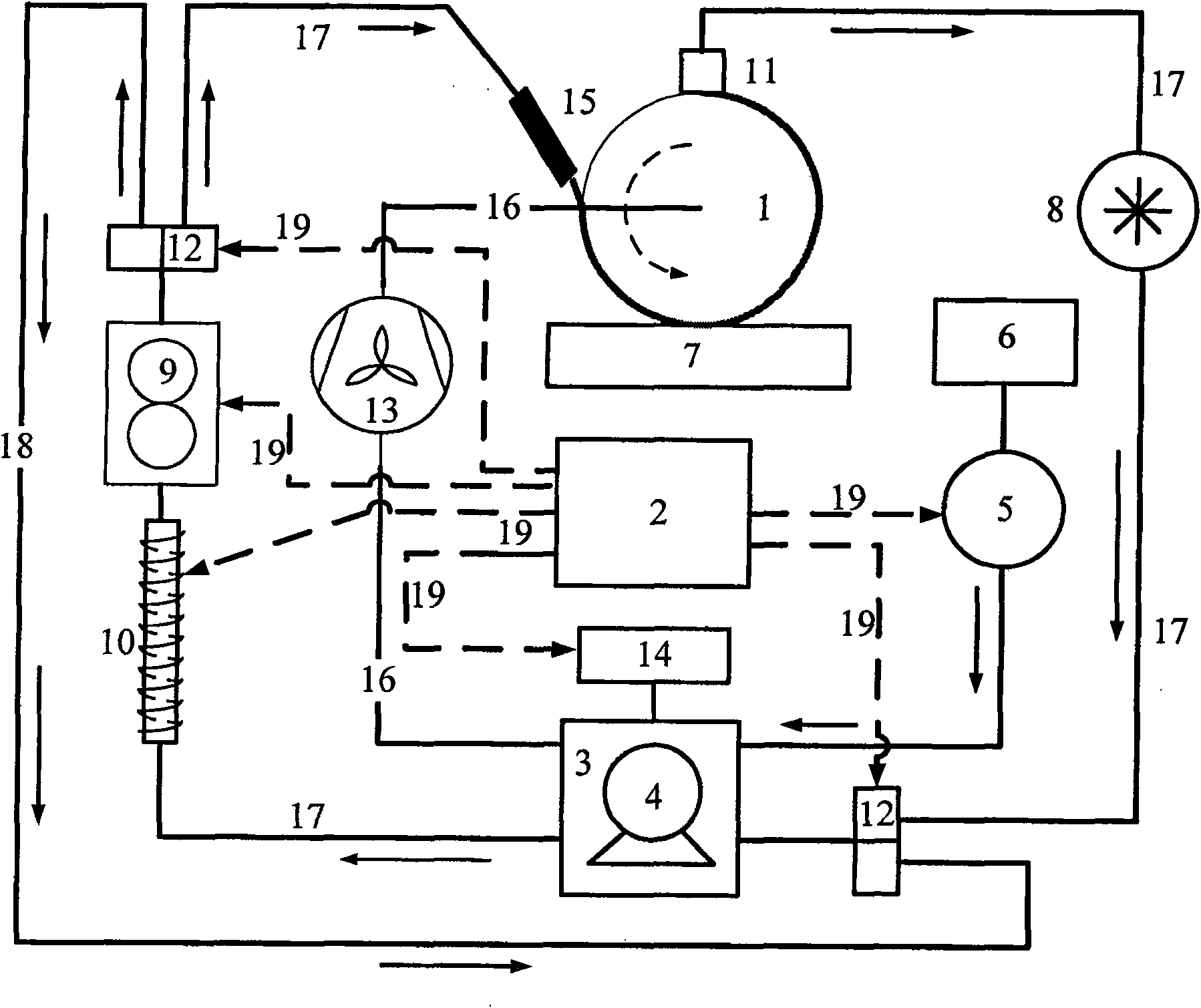

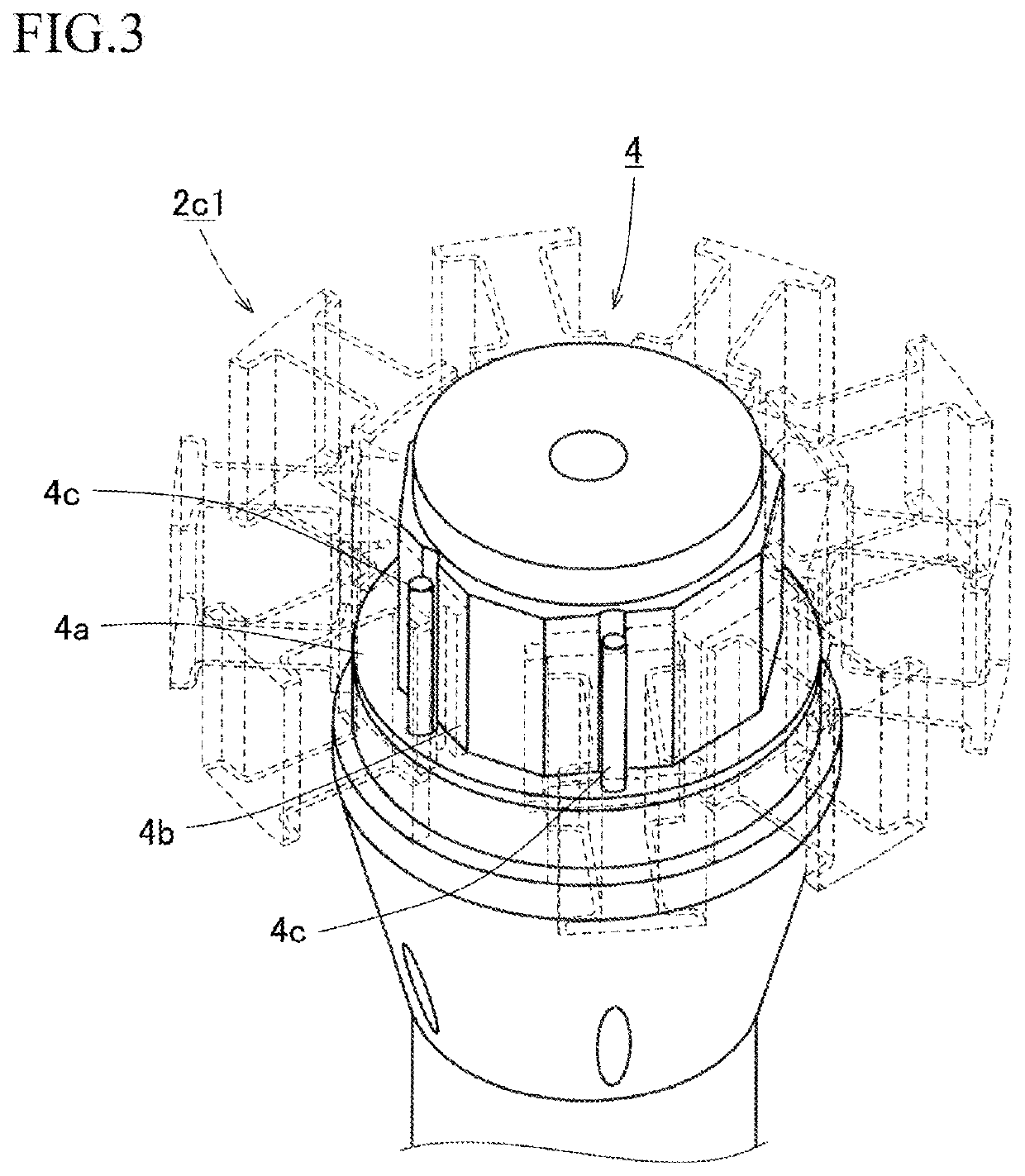

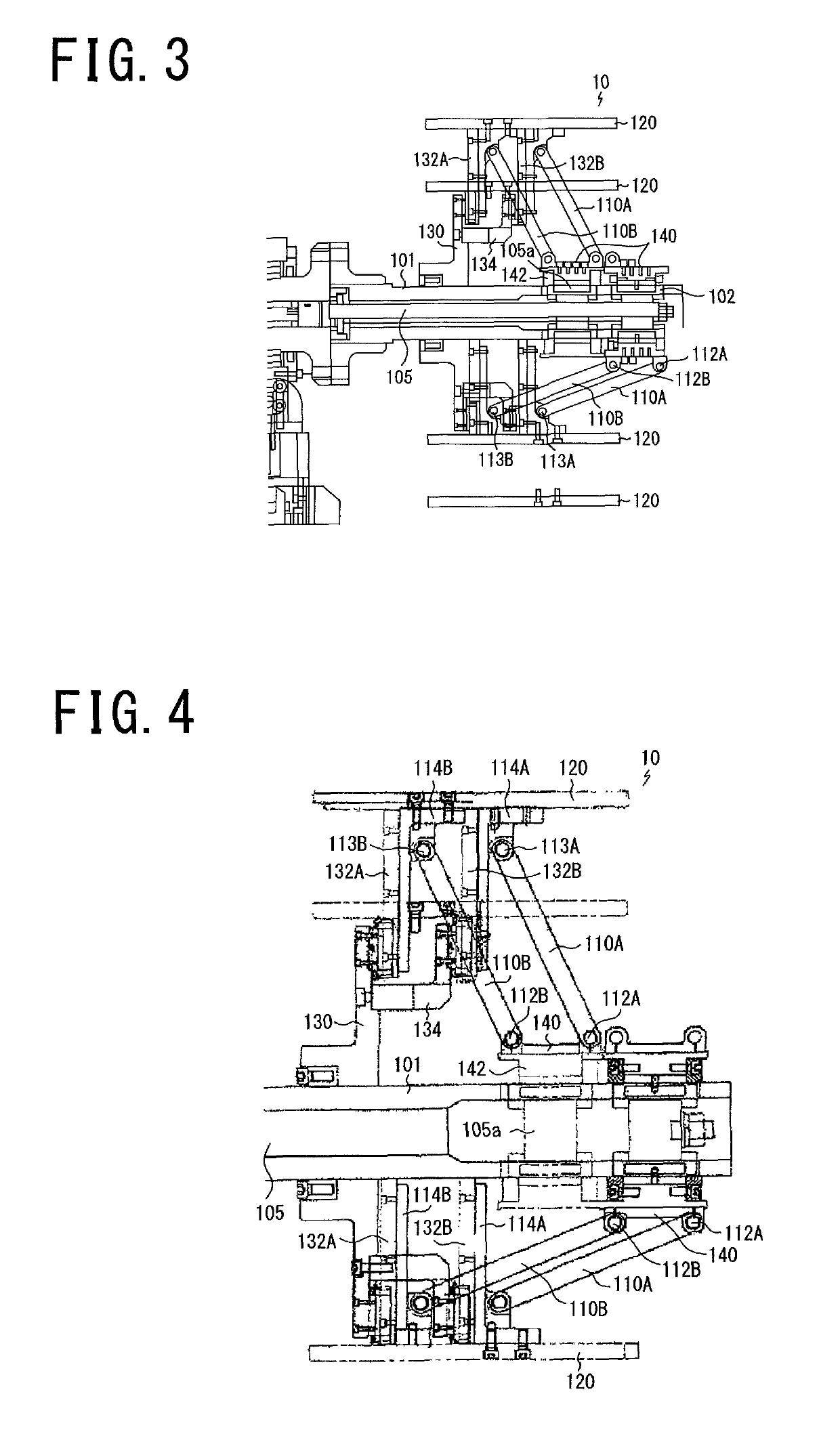

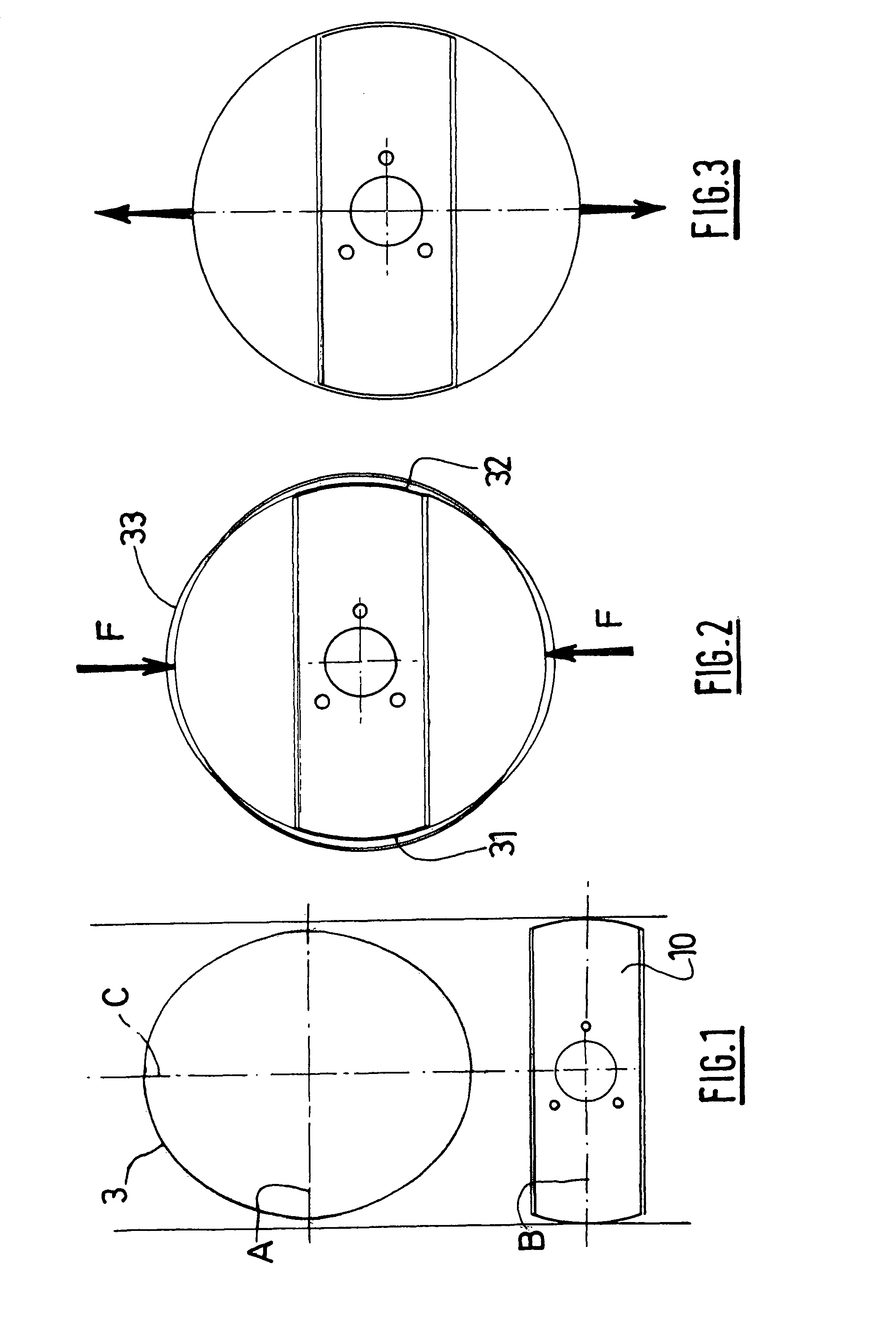

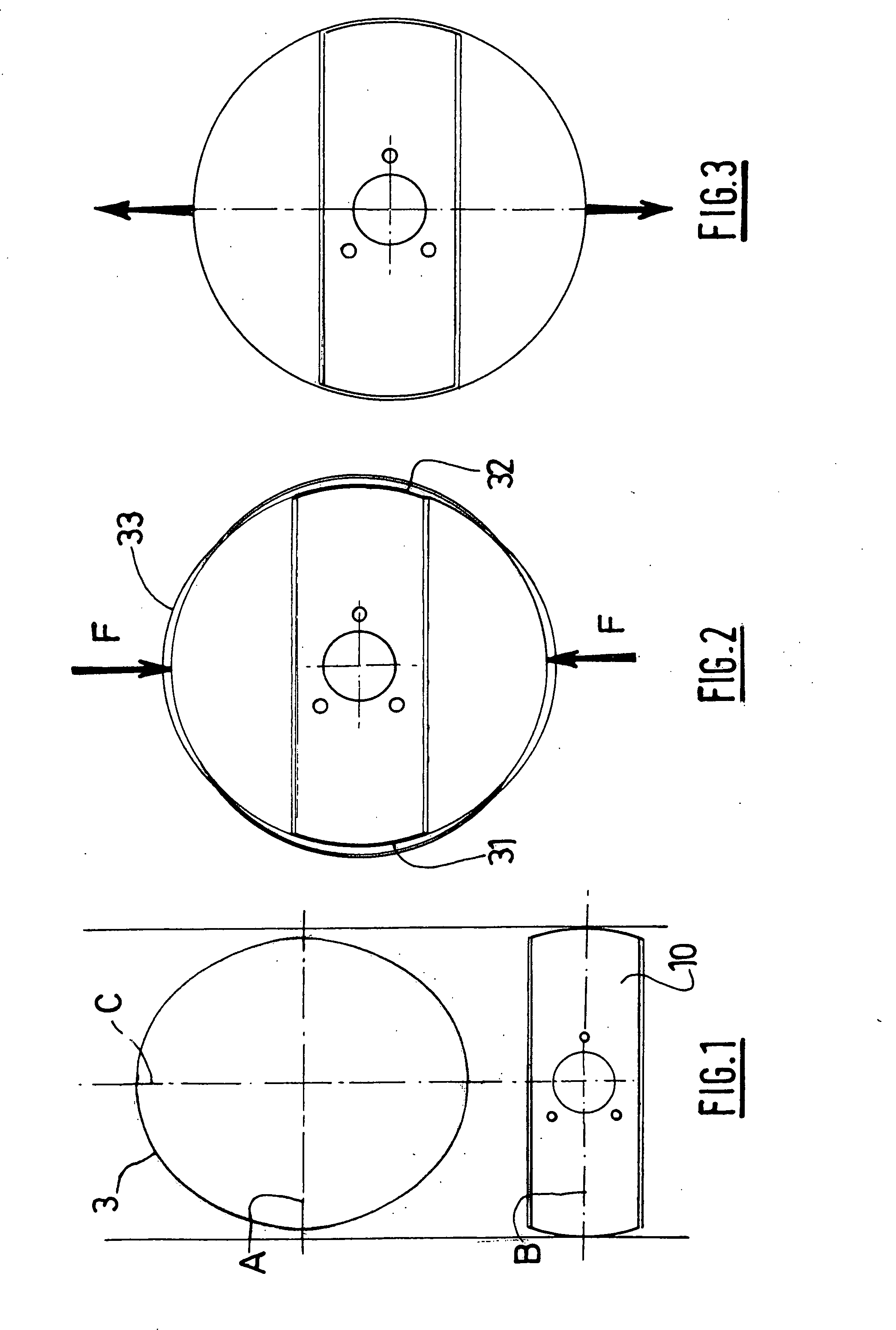

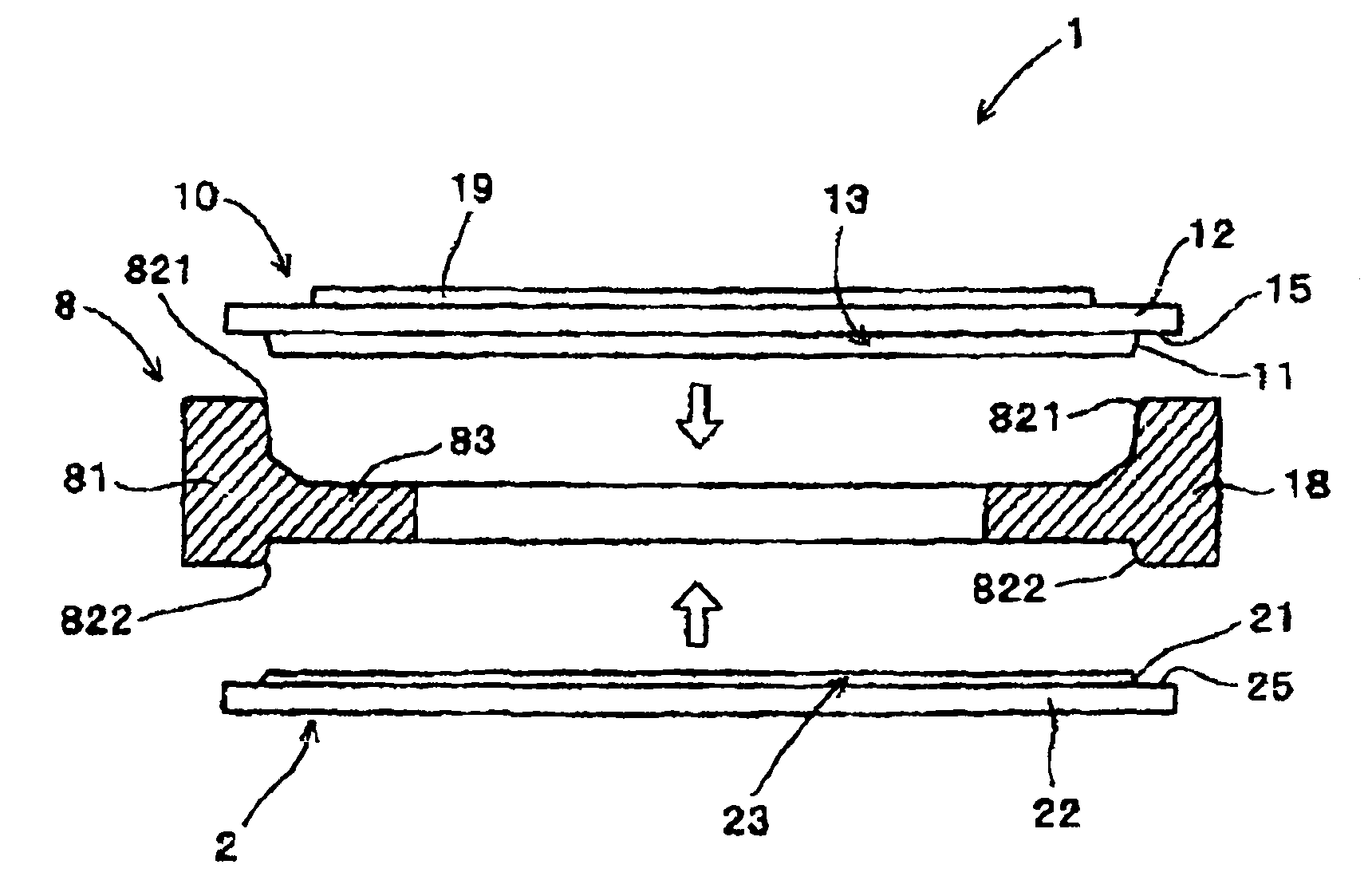

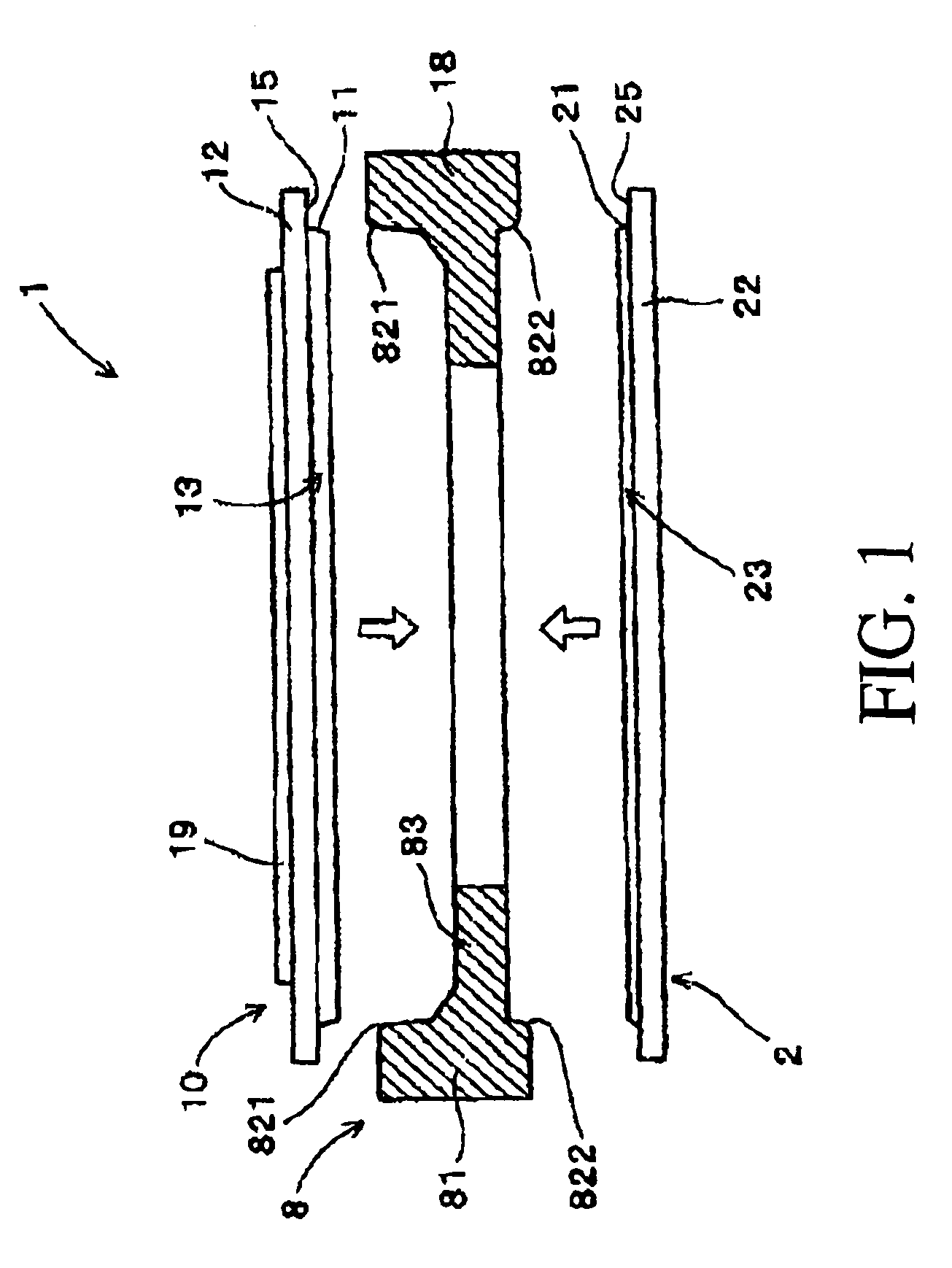

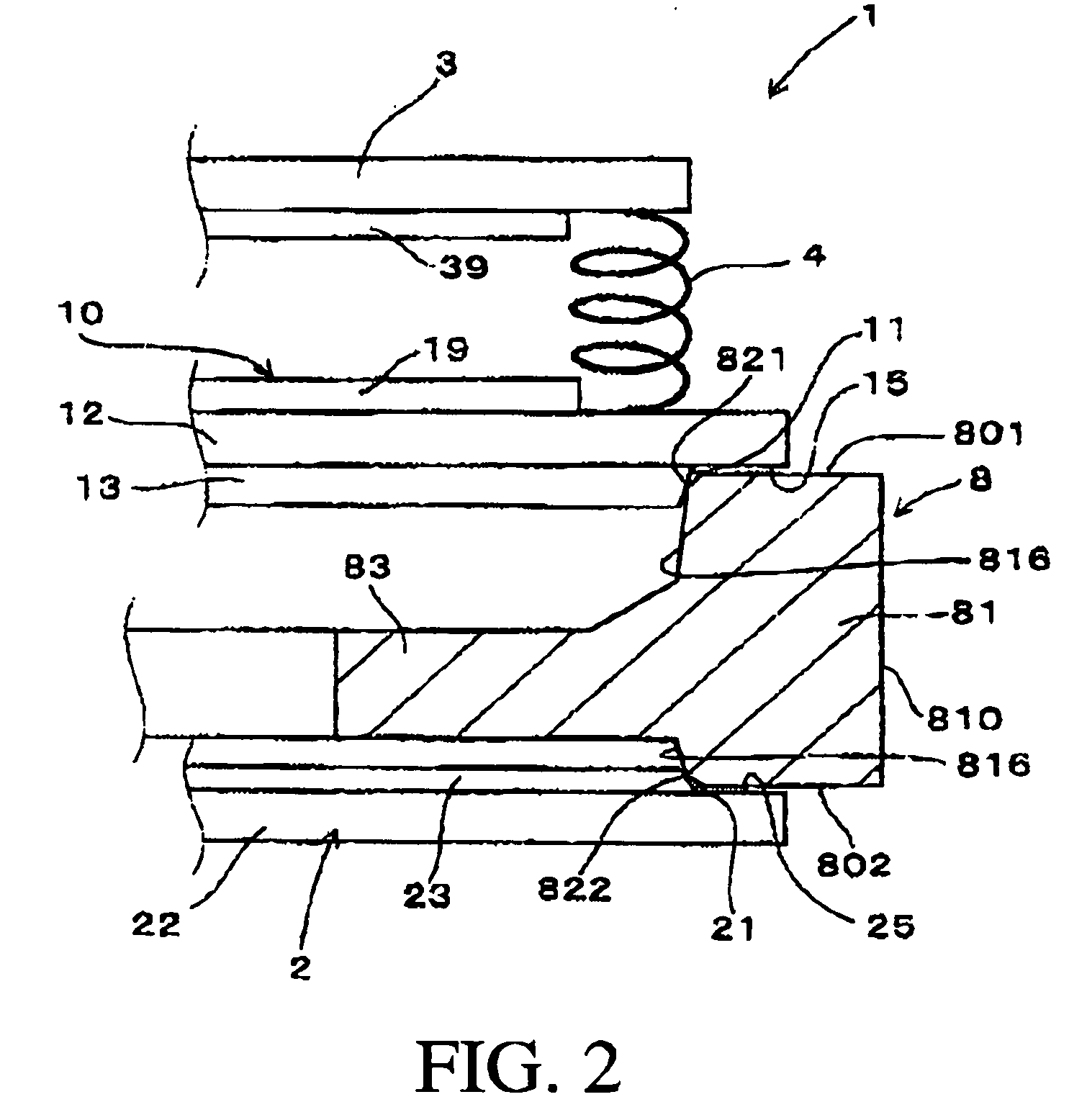

Shaft and shaft molding device

InactiveUS20060193683A1Improve the fixing strengthMaintain roundnessMetal-working apparatusBranching pipesEngineeringMechanical engineering

Four knurls are formed by a molding apparatus (31) to be evenly spaced circumferentially on and protrude from an outer circumferential surface of an armature shaft (14). The molding apparatus (31) has a first mold (32) and a second mold (33), which are movable in directions of being close to and separating from each other, wherein the first mold (32) is provided with a pair of first molding edges (43) and the second mold (33) is provided with a pair of second molding edges (45). The respective molding edges (43) and (45) are formed into parallelogram sections, which have cutting faces (51) and (61) parallel to a moving direction of the second mold (33), extrusion faces (52) and (62) formed at acute angels with respect to the cutting faces (51) and (61), and load supporting faces (53) and (63) parallel to the extrusion faces (52) and (62). By pressing those molding edges (43) and (45) against the outer circumferential surface of the armature shaft (14), the knurls is formed.

Owner:MITSUBA CORP

Airtight ball and a method of fabricating the airtight ball

InactiveUS20090053438A1Improve roundnessHigh strengthHollow inflatable ballsLaminationPolyvinyl alcoholThin layer

An airtight ball has an inner bladder, a sealing layer, a wound layer, a rubber layer and an outer leather covering. The inner bladder is a hollow, resilient sphere and has an inner space and an outer surface. The sealing layer is applied to the outer surface of the inner bladder and has a rubber glue layer, a polyvinyl alcohol (PVOH) layer and a rubber balloon. The rubber glue layer fills in air bubbles or holes formed in the outer surface of the inner bladder. The a PVOH layer forms a thin, airtight membrane on the rubber glue layer, keeps air from leaking out of the inner space of the inner bladder and further maintains roundness and increases bouncing ability of the ball. The rubber balloon is a thin layer of rubber attached to the PVOH layer. The wound layer is wound around the rubber balloon that keeps the wound layer from cutting the PVOH and stabilizes the wound layer. The present invention not only prevents air leakage but also increases the ball's roundness and strength.

Owner:YUAN CHI SPORTS ENTERPRISE

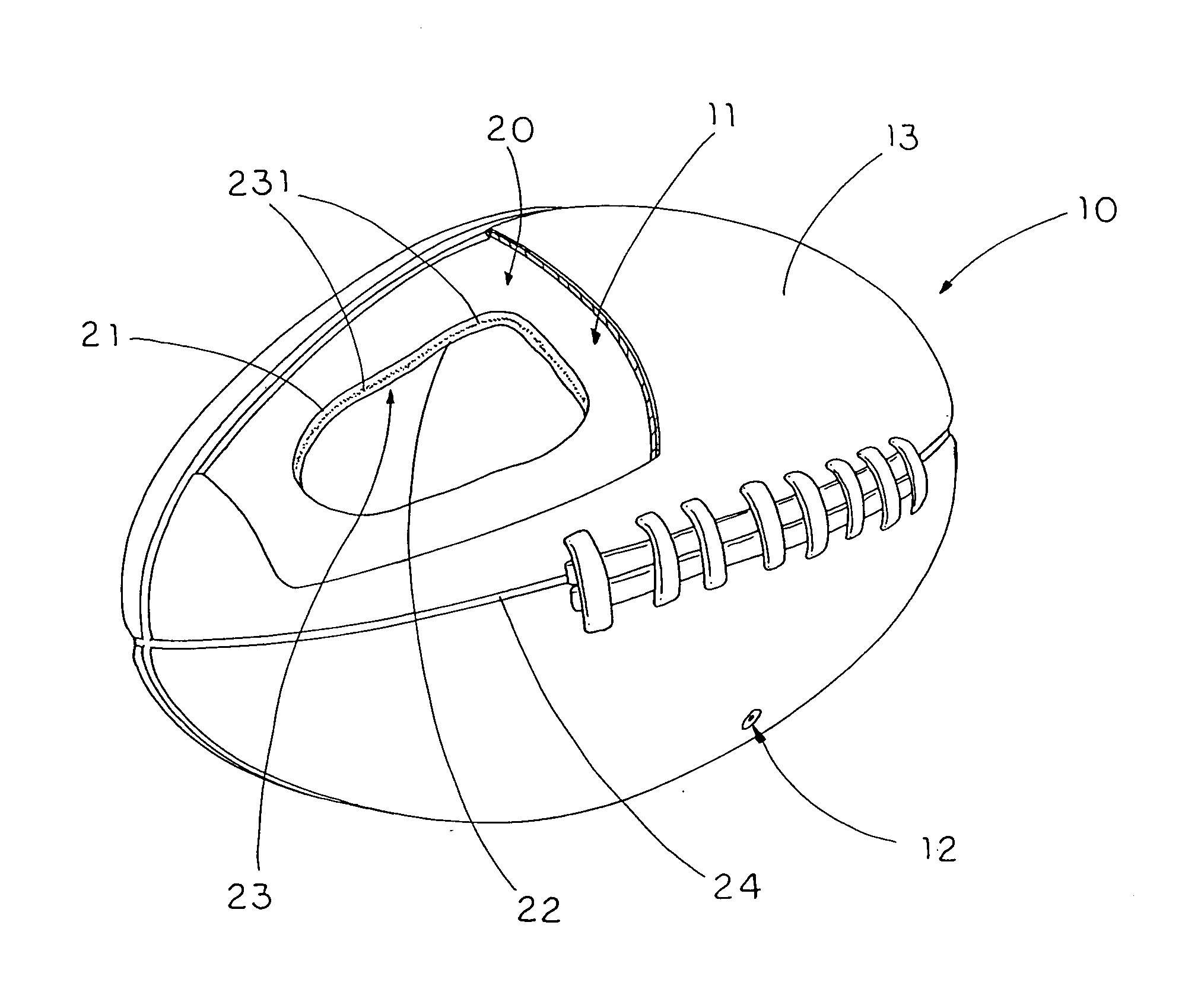

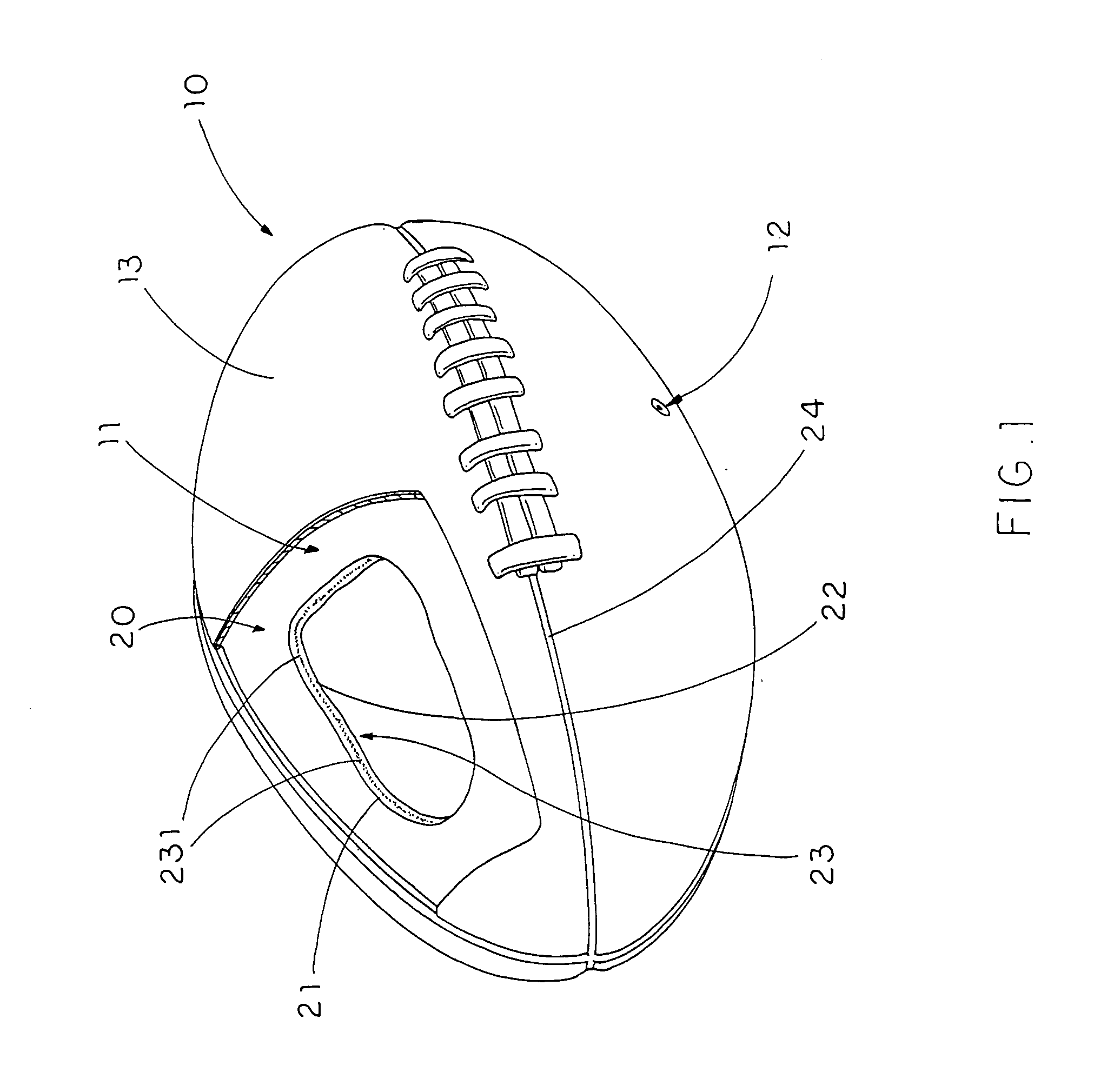

Padded sports ball

InactiveUS20090137352A1High strengthPreventing the inflatable ball bladder from being over inflatedHollow inflatable ballsHollow non-inflatable ballsEngineeringMechanical engineering

A sports ball includes a ball cover having a ball cavity and a valve hole, and an inflatable ball bladder. The inflatable ball bladder, which is disposed in the ball cavity of the ball cover and is adapted to be inflated through the valve hole to support the ball cover, includes an outer bladder portion layer, an inner bladder portion layer disposed in the outer bladder portion layer, and a webbing layer. The webbing layer is disposed between the inner and outer bladder portion layers, wherein the inner and outer bladder portion layers are treated to integrally embed the webbing layer therebetween to enhance the strength of the ball bladder such that the webbing layer allows the ball bladder to be fully inflated for evenly distributing air pressure therein to support the ball cover.

Owner:OU TSUNG MING

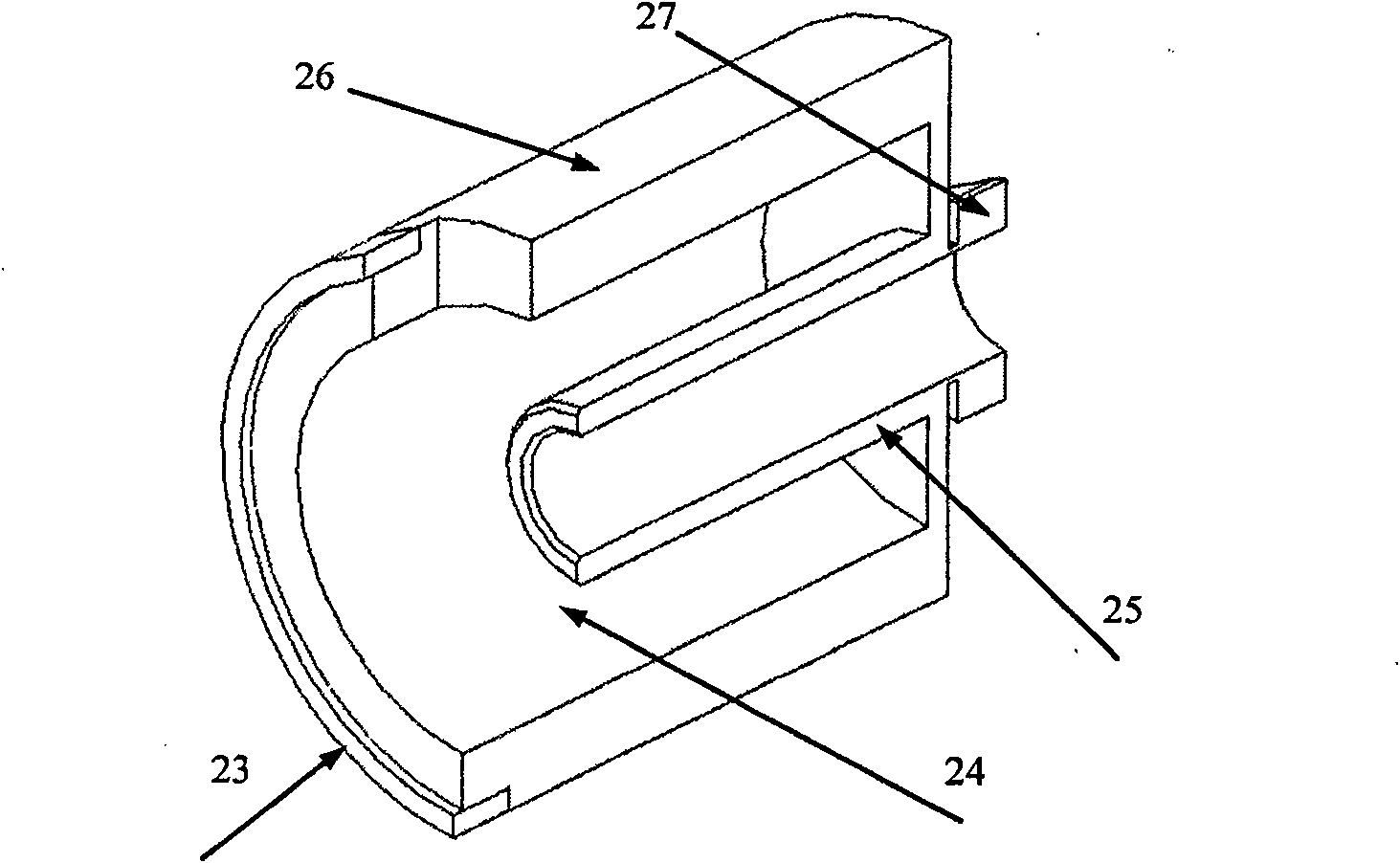

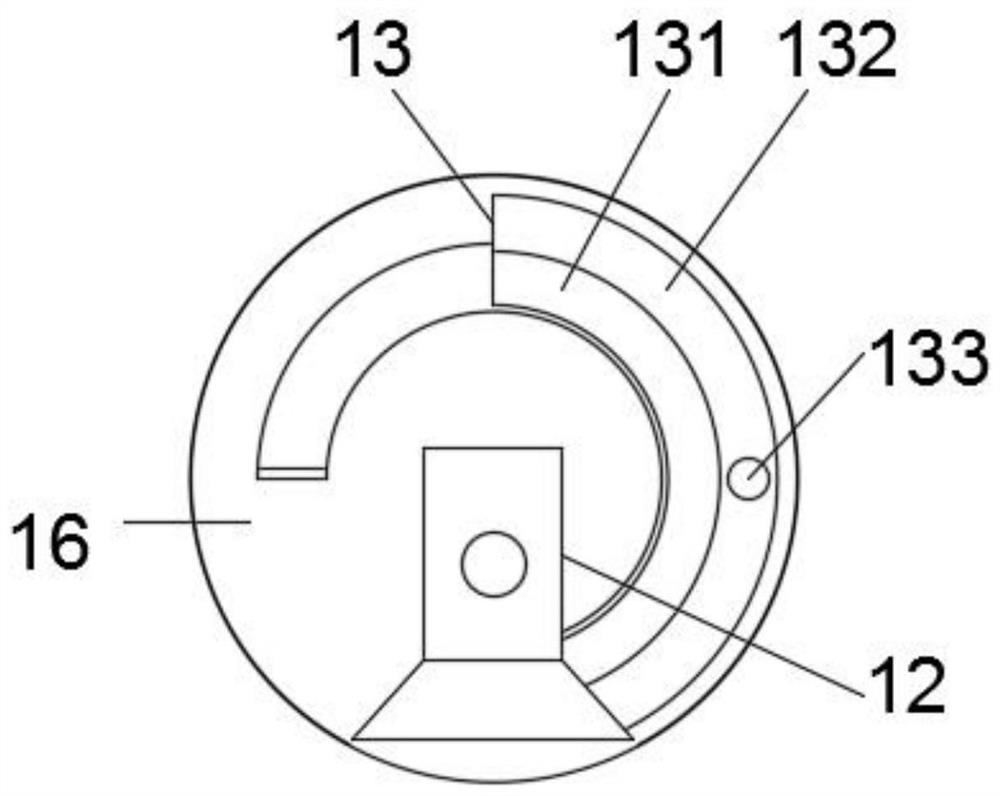

Induction Hardening Method And Jig Used In Induction Hardening Process

InactiveUS20090101246A1Improve roundnessMaintain roundnessIncreasing energy efficiencyFurnace typesInduction hardeningMaterials science

The present invention provides a method for induction hardening of a steel member having an outer ring portion and, more specifically, for induction hardening of an outer circumferential surface of the outer ring portion. The method uses two pressing members, each of which includes a flat basal surface and a projecting portion projecting therefrom. Each of the projecting portions has a cross-section in the shape of a perfect circle. Also, the projecting portions have, on the outer circumferences thereof, respective pressing surfaces. While gaps are maintained between axial end faces of the outer ring portion and the basal surfaces of the pressing members, the pressing members are pressed against the outer ring portion so that the pressing surfaces each abut against the inner circumference side of the outer ring portion. While a biasing force is applied to the pressing members, the induction hardening process is applied to the outer circumferential surface. During the induction hardening process, the pressing members are moved toward each other until the basal surfaces abut against respective axial end faces of the outer ring portion.

Owner:AISIN AW CO LTD

Filler and multicore cable having same

ActiveUS10262772B2Maintain roundnessConcentric cablesPower cables with screens/conductive layersMulticore cableElectrical conductor

A filler and a multicore cable includes a plurality of core portions, which includes a conductor, and a protective layer that surrounds the core portions, the filler being provided between the core portions and the protective layer of the multicore cable, the filler being characterized by including: frame portions including a first frame portion and a second frame portion, which are rotated by predetermined angles towards both sides about the center portion thereof and then incised; and a support portion provided between the frame portions so as to connect the frame portions to each other.

Owner:LS CABLE & SYST LTD

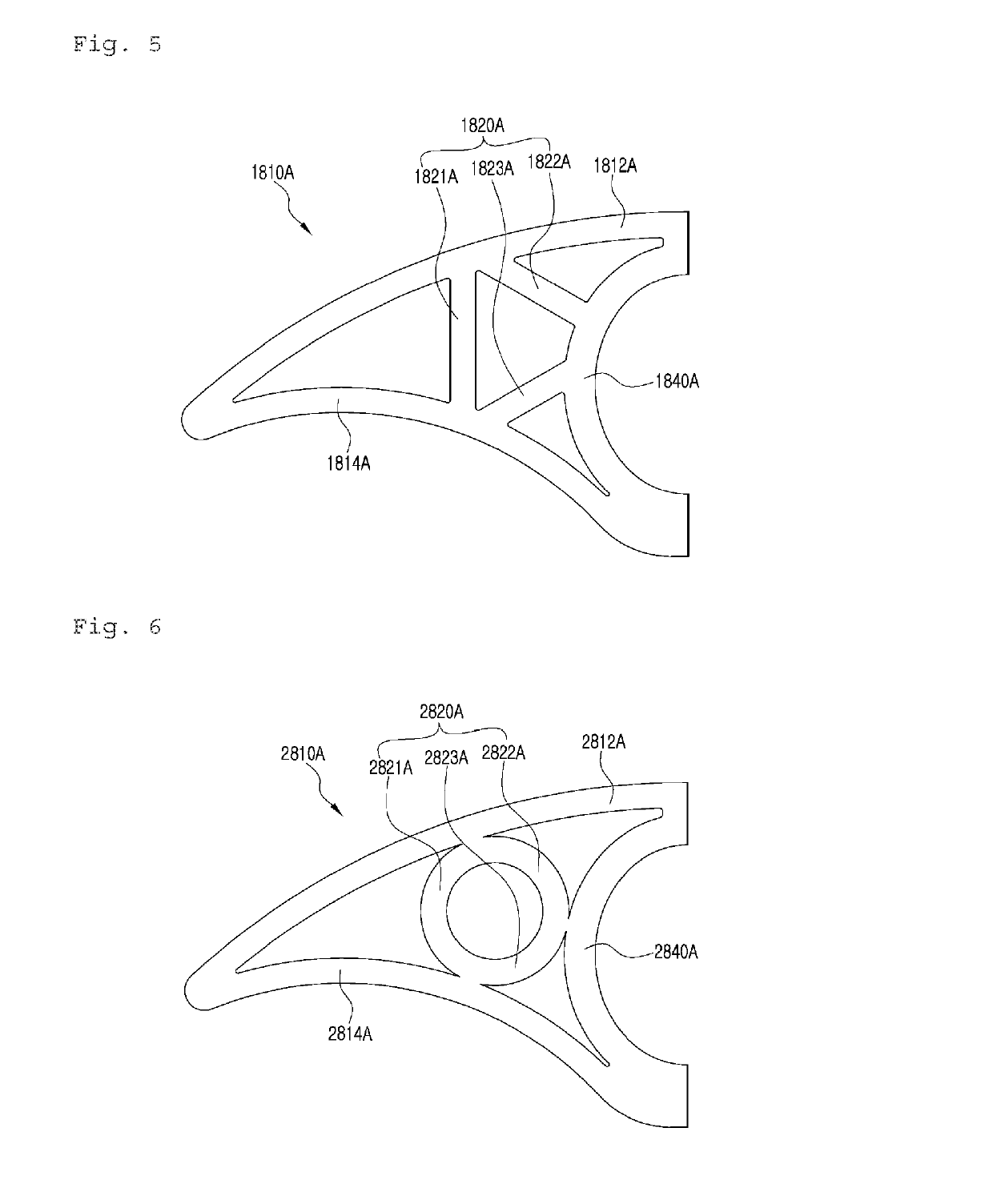

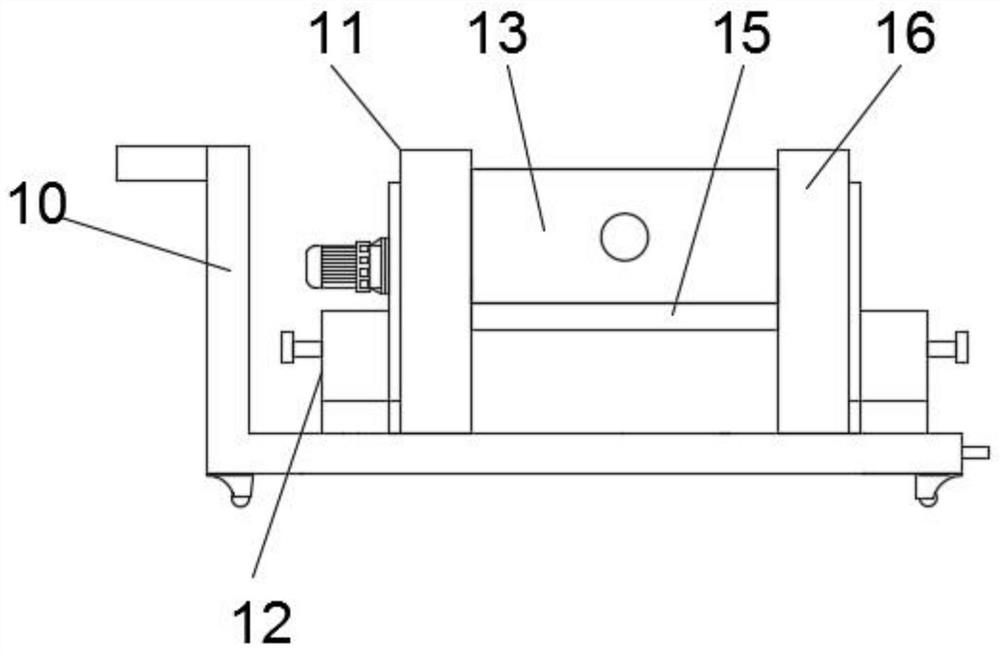

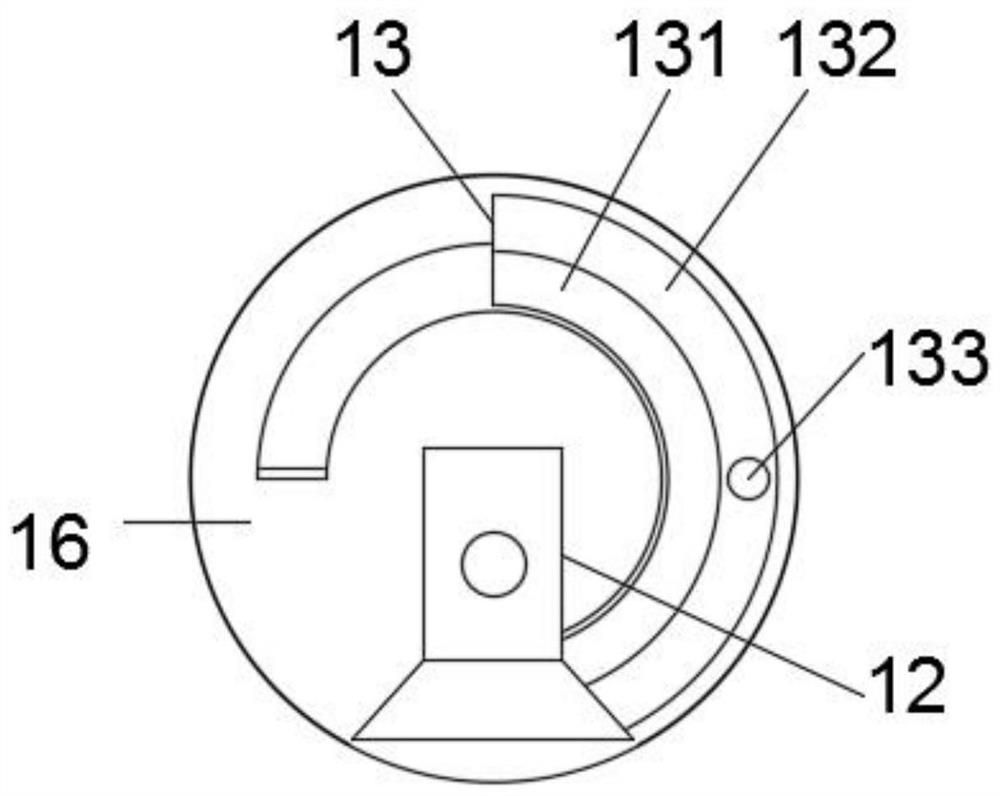

Magnetorheological polishing solution circulating device capable of stabilizing polishing solution performance for a long time

InactiveCN100560296CStable flow rateComposition is stableOptical surface grinding machinesHelical coilLiquid tank

A magneto-rheological polishing liquid circulation device that can stabilize the performance of the polishing liquid for a long time. Its liquid mixing tank is connected to the water tank through a metering pump, and the cooler is connected to the liquid mixing tank through a cooling pipeline; The liquid mixing tank, electromagnetic flowmeter, nozzle, recovery device and recovery pump form a polishing liquid circulation loop, and the liquid mixing tank and electromagnetic flowmeter connected in sequence through the non-polishing circulation pipeline form a non-polishing circulation loop, and the polishing liquid circulation loop and the non-polishing The circulation loop is connected in parallel and a switching control valve is provided at the parallel connection of the two. A helical coil is wound outside a section of pipeline between the liquid mixing tank and the switching control valve; the electromagnetic flowmeter and the helical coil are connected to the input end of the computer, and its control The output ends are respectively connected with the switching control valve, the cooling machine, the power pump and the metering pump. The invention has the advantages of high control precision, good stability, etc., and can provide cheap, reliable and stable magnetorheological polishing liquid for magnetorheological polishing processing for a long time.

Owner:NAT UNIV OF DEFENSE TECH

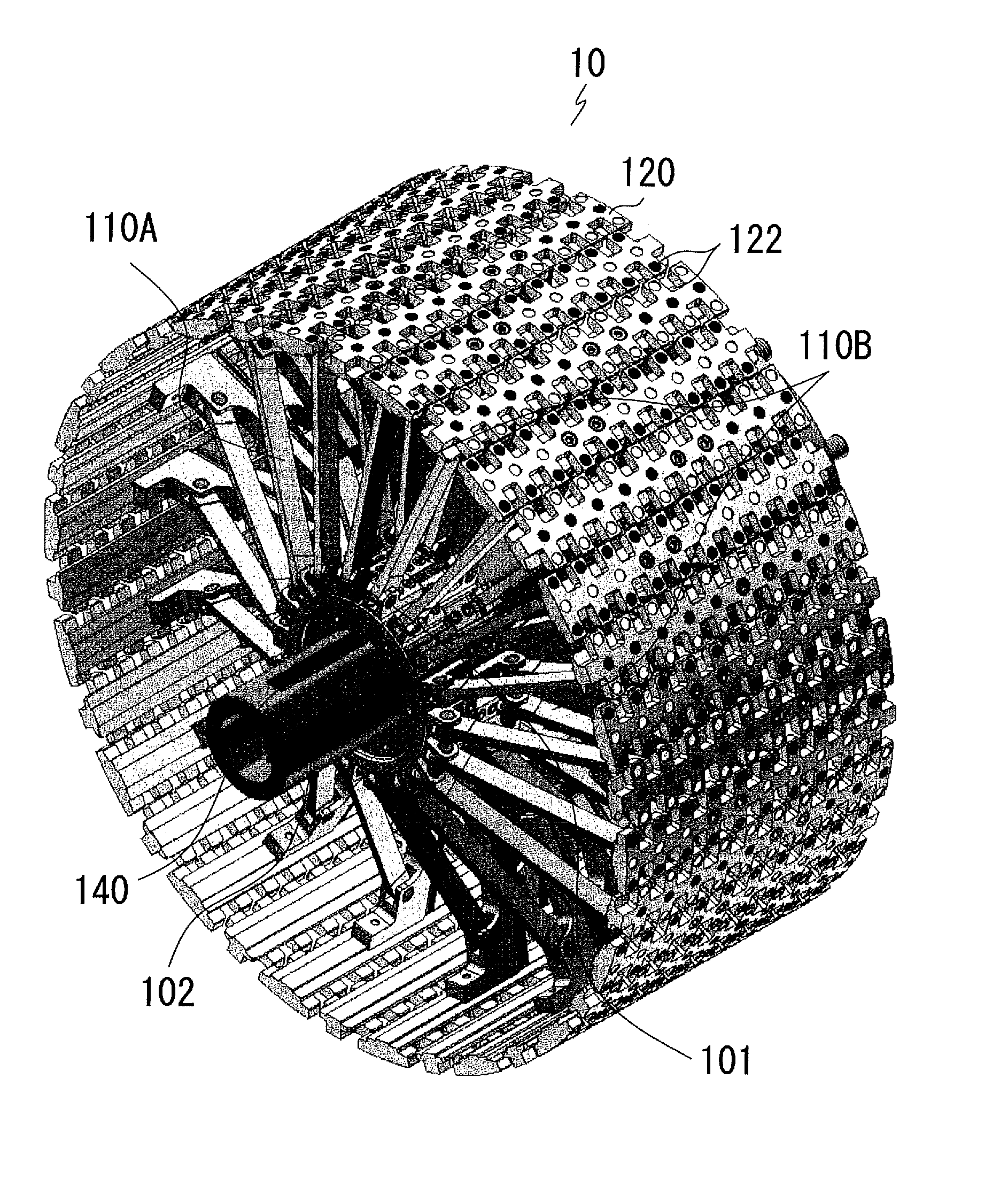

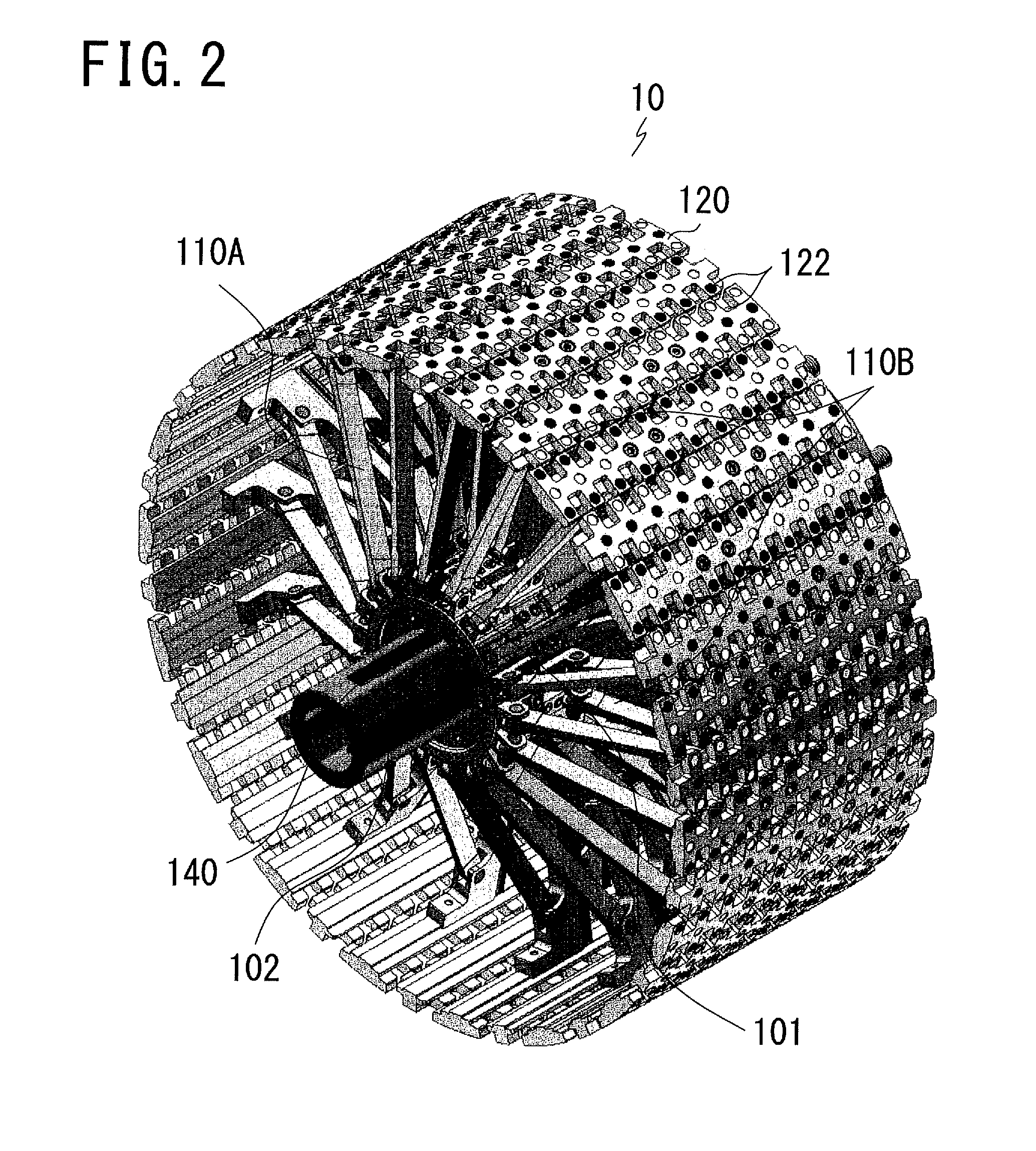

Molding drum

ActiveUS20160023415A1Reduce lengthSmoothly expanded/contractedTyresEngineeringMechanical engineering

Owner:BRIDGESTONE CORP

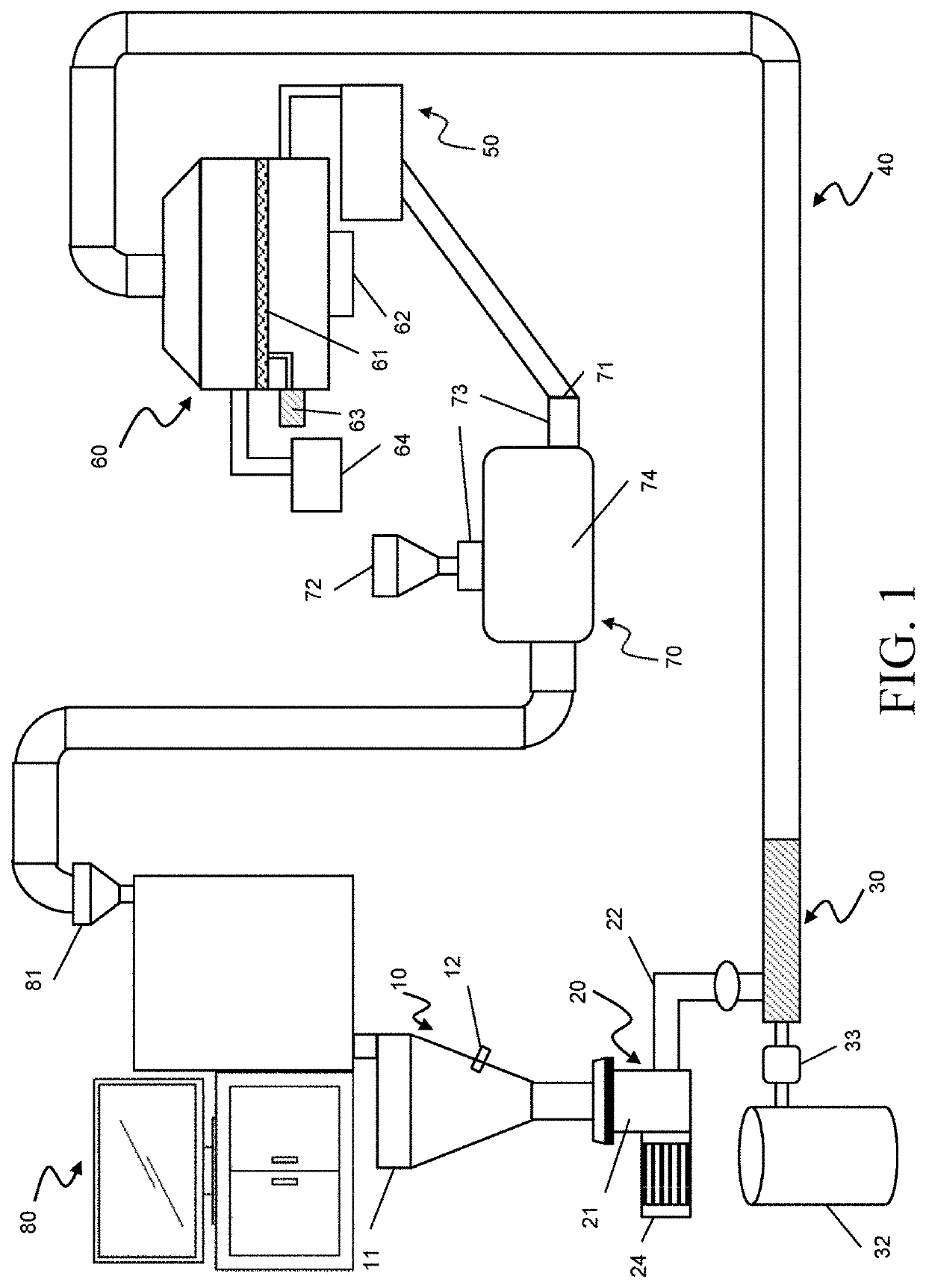

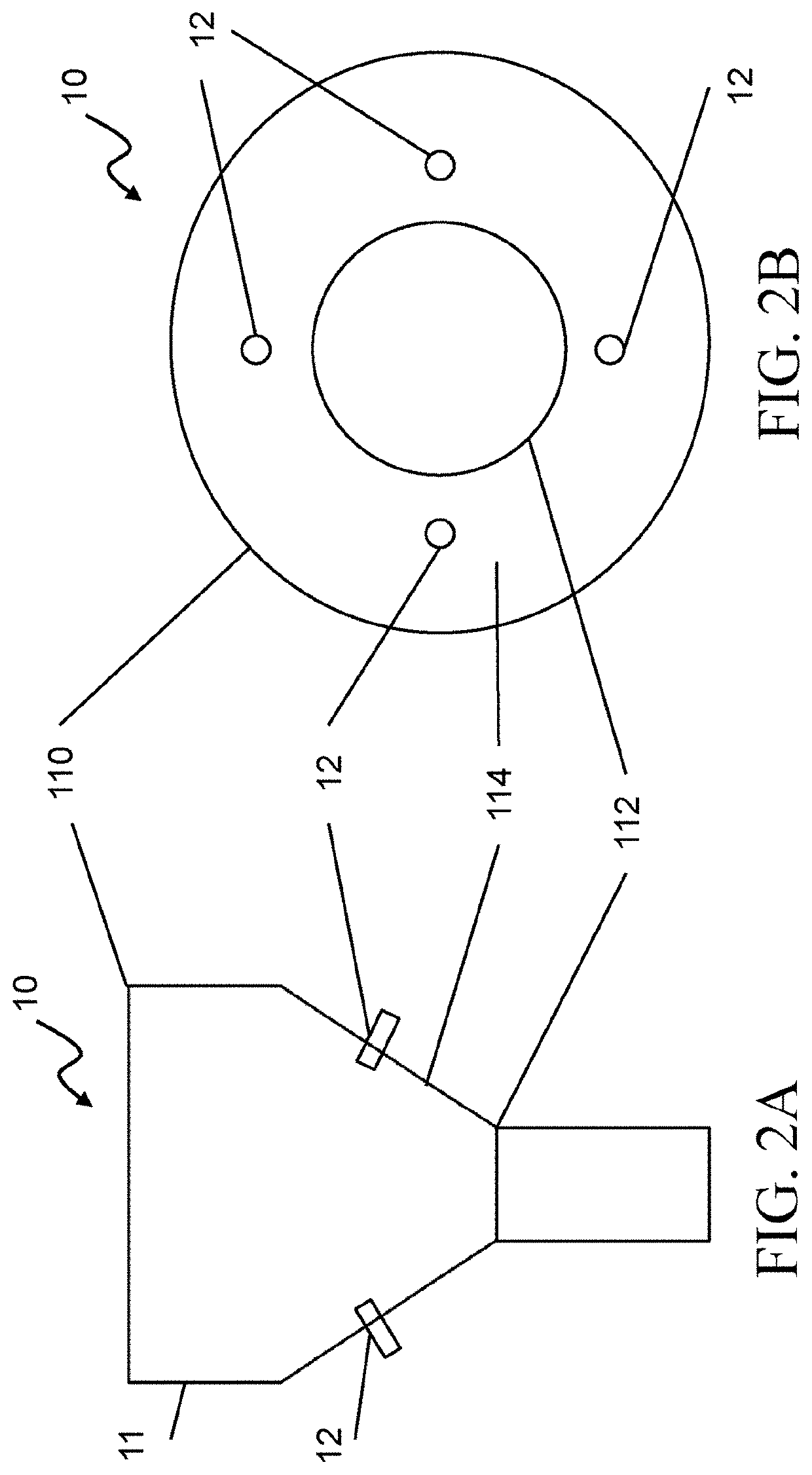

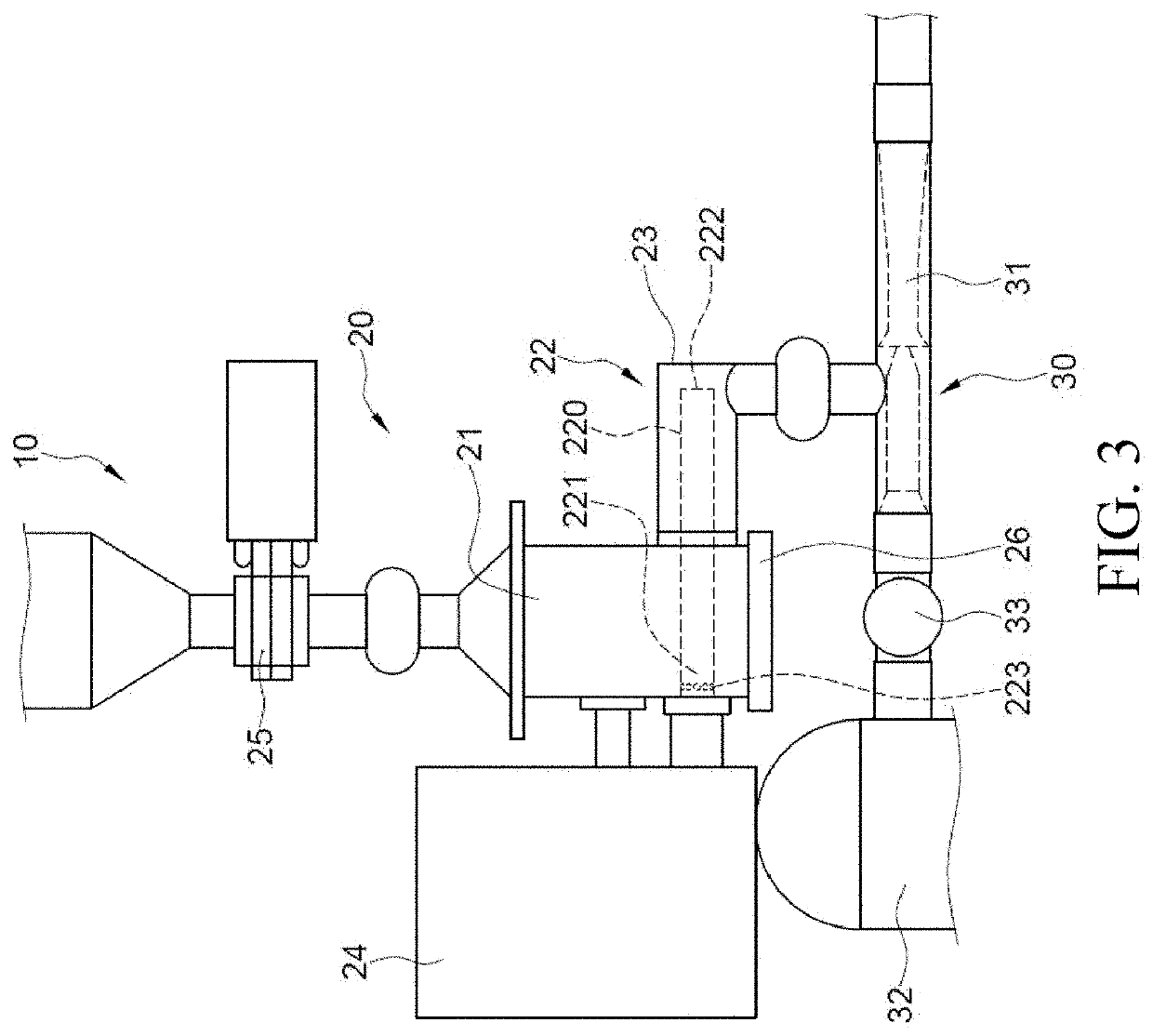

Powder recycling system and continuous loss in weight module applied thereto

ActiveUS10780504B2High recovery rateReducing attritionAdditive manufacturing apparatusIncreasing energy efficiencyWeight changeProcess engineering

A powder recycling system includes a supply tank, a continuous loss-in-weight module, a pneumatic module, a transfer channel, a recycle module, and a refilling tank. The supply tank accommodates recycling powder. The continuous loss-in-weight module includes a storage tank receiving the recycling powder from the supply tank and a rotary output pipe connected to the storage tank to output the recycling powder. The continuous loss-in-weight module controls the mass flow rate of the output of the recycling powder according to the weight change of the storage tank. The pneumatic module enables the recycling powder to float and move in the transfer channel. The recycle module is connected to the transfer channel to receive the recycling powder, sieves the recycling powder, provides virgin powder, and mixes the virgin powder with the recycling powder. The refilling tank is connected to the recycle module to receive the recycling powder and the virgin powder.

Owner:NAT CHUNG SHAN INST SCI & TECH

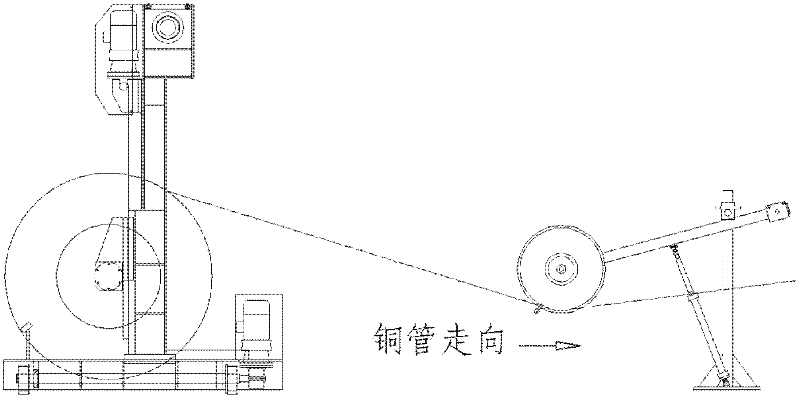

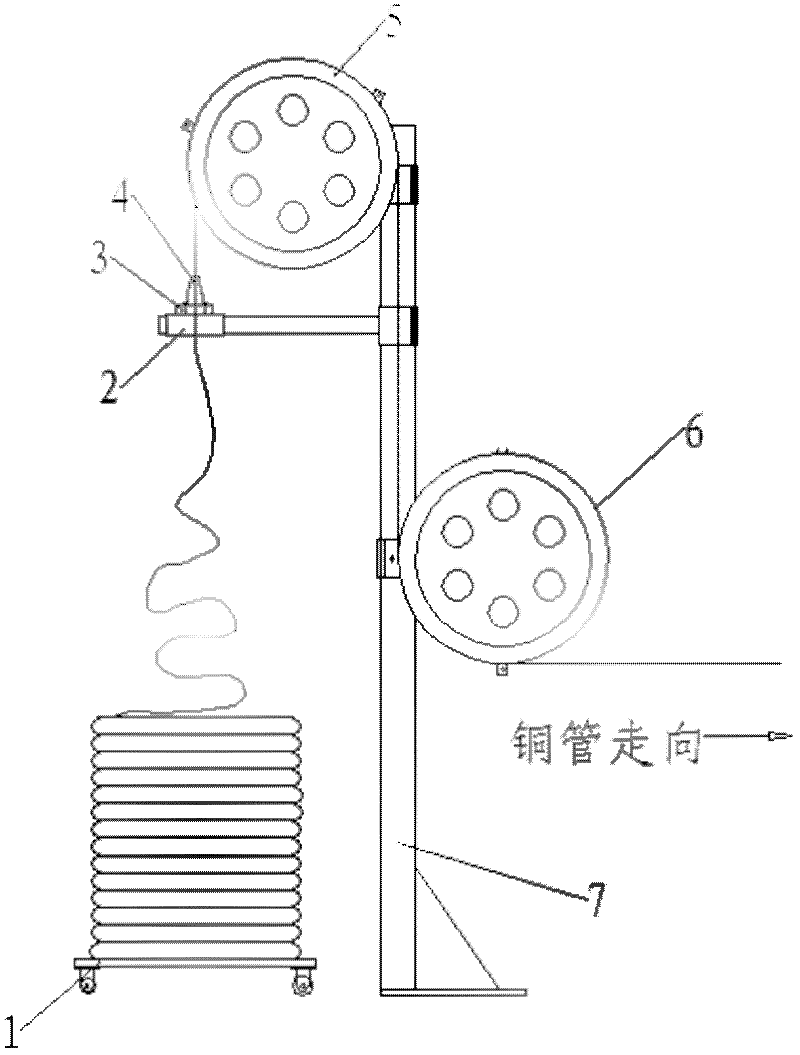

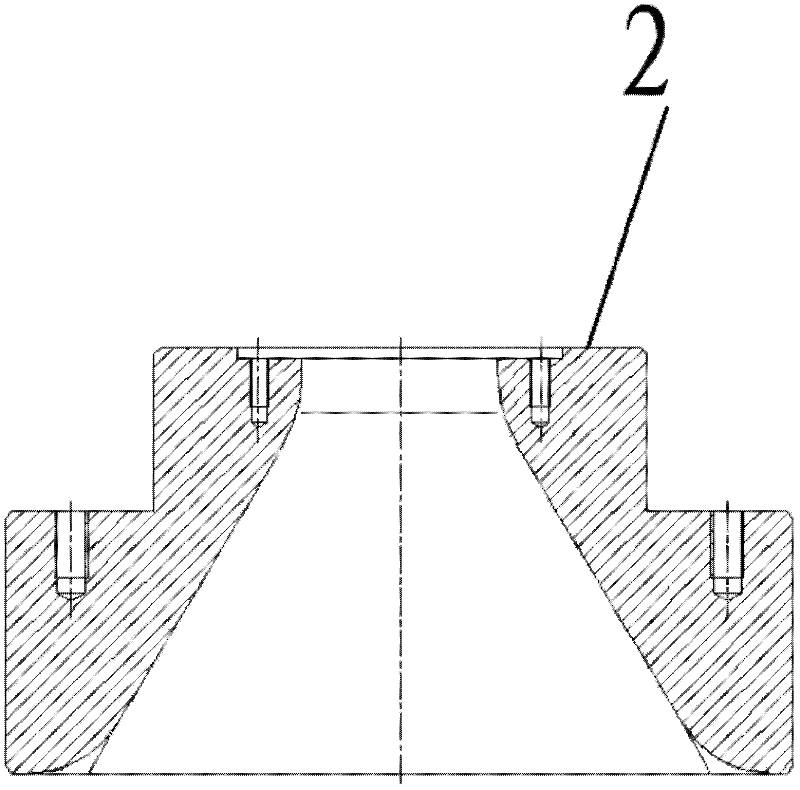

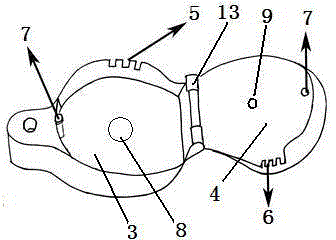

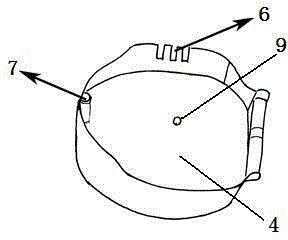

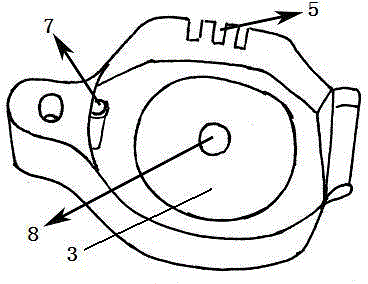

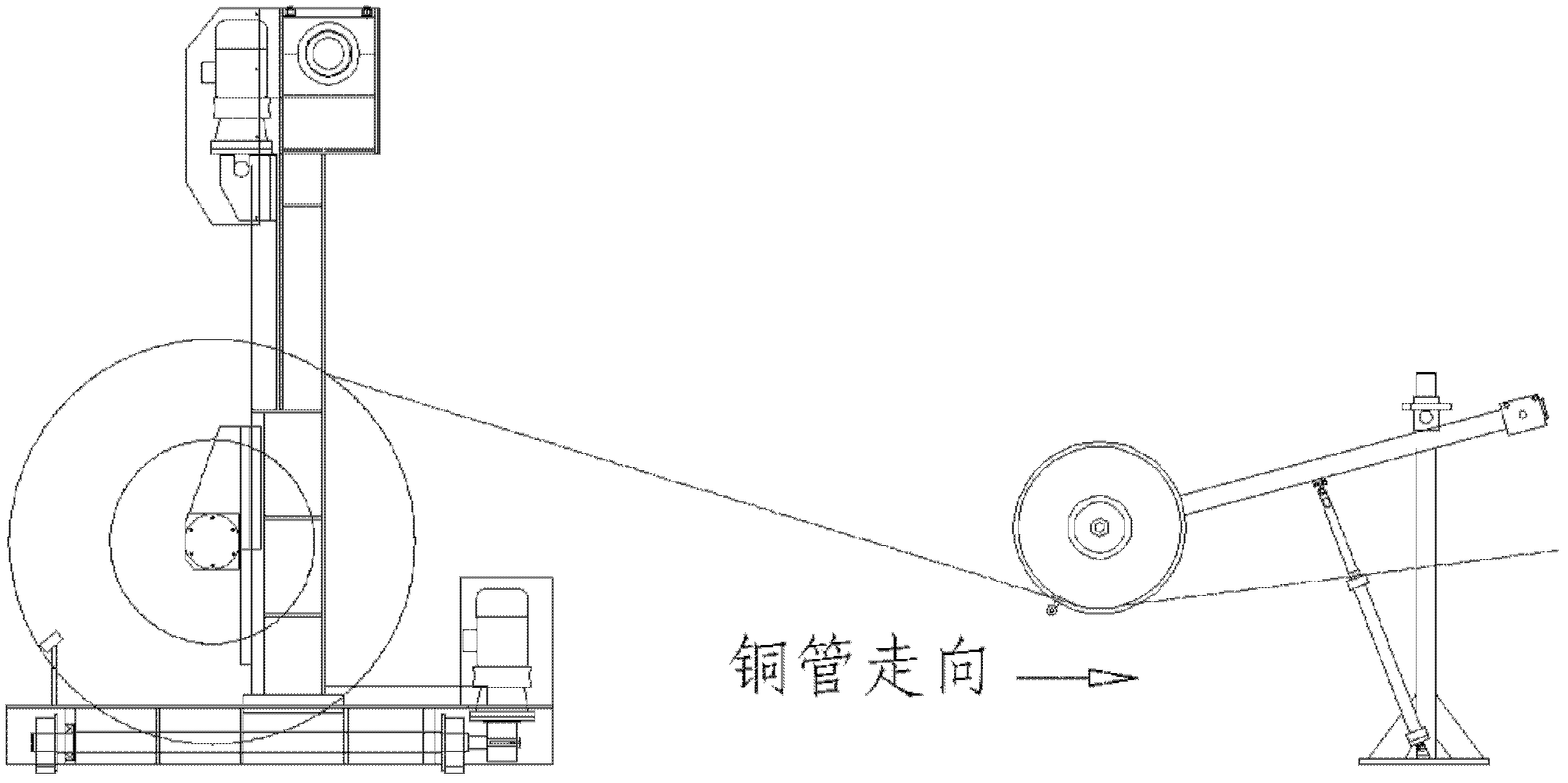

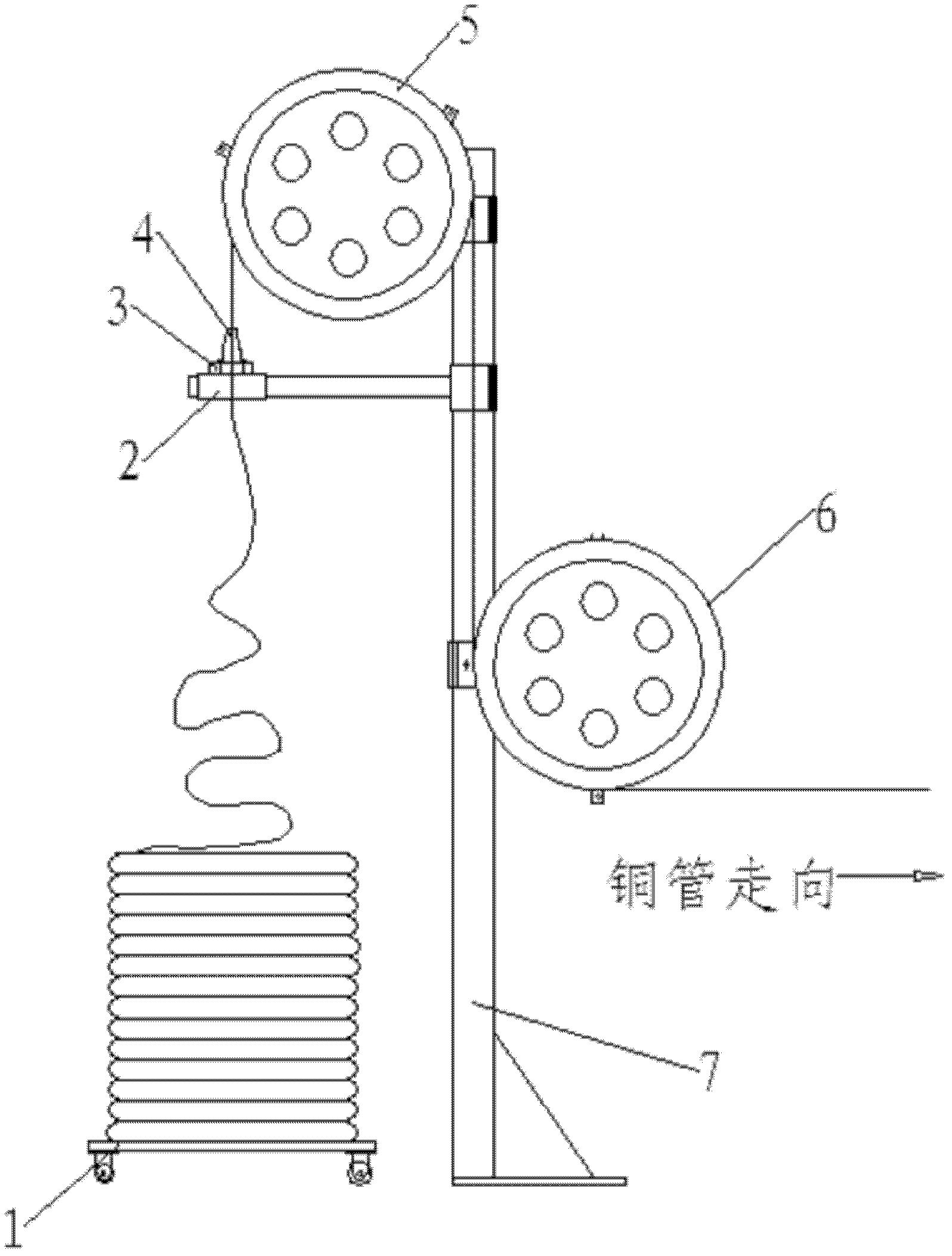

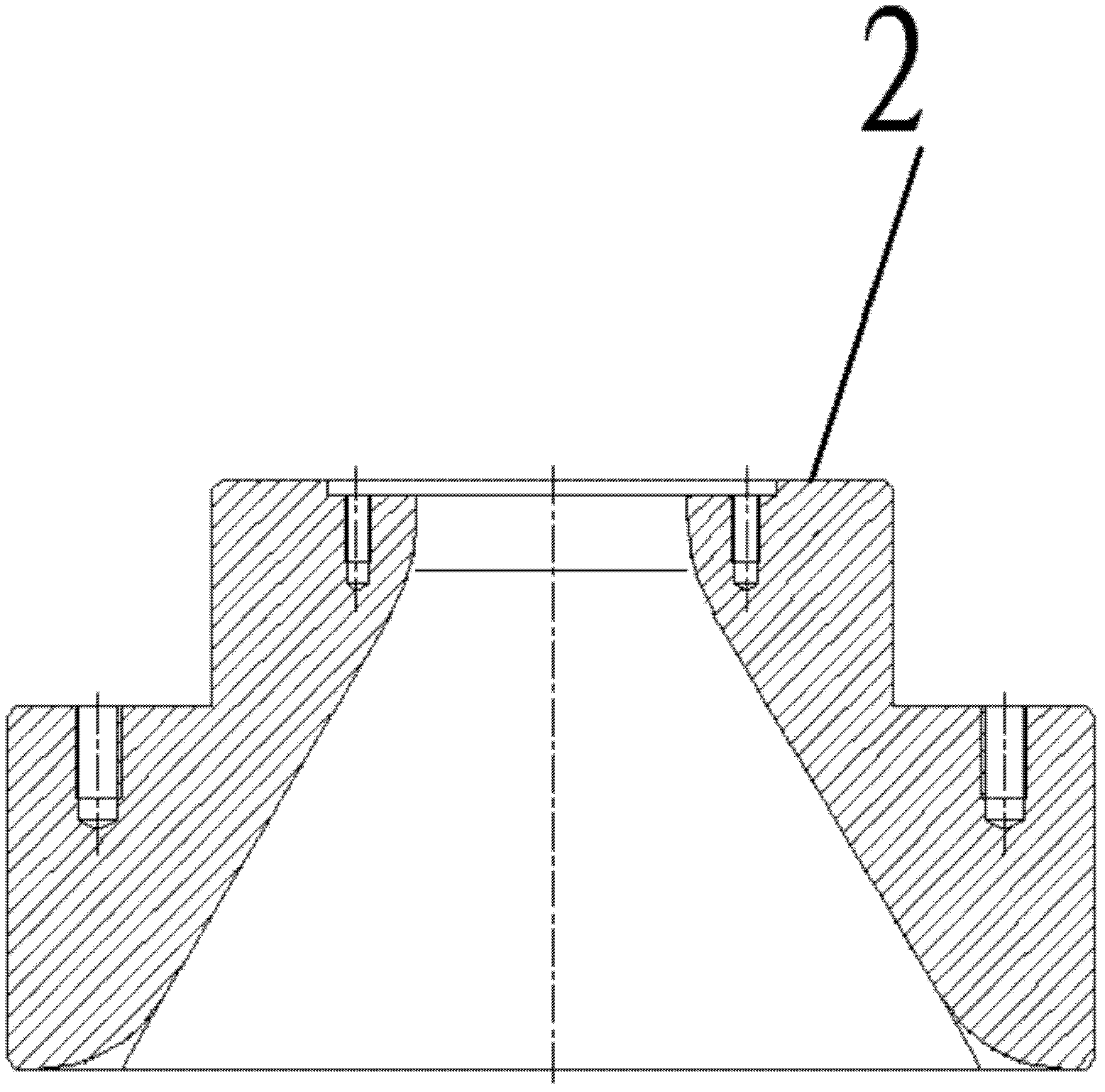

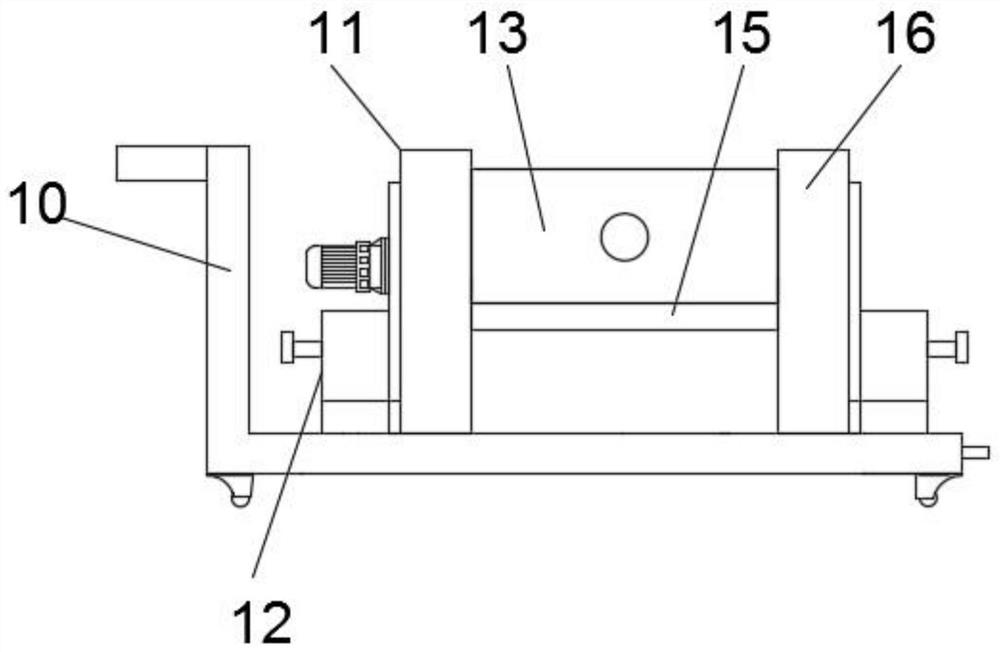

Unreeling device in copper tube

ActiveCN102385960AImprove work efficiencySmall footprintManufacturing co-axial cablesProduction line

The utility model relates to an unreeling device in a copper tube, which comprises a bottom wheel supporting rack (1), a horn mould (2), a connecting plate (3), a wire passing mould (4), an upper guide wheel (5), a lower guide wheel (6) and a base (7). The connecting plate (3) is disposed between the horn mould (2) and the wire passing mould (4). A flange guide structure on the head in the coppertube is employed in the unreeling device, so that floor area is reduced, and two wire plates can be placed at the same time; and a connector can be made in advance, so that a break will not be causedin the process of replacing the wire plates, and continuous production is ensured, thereby improving working efficiency of the whole production line. The unreeling device is simple in manufacturing process, low in cost, high in production efficiency and more reliable in quality of product.

Owner:JIANGSU TRIGIANT TECH

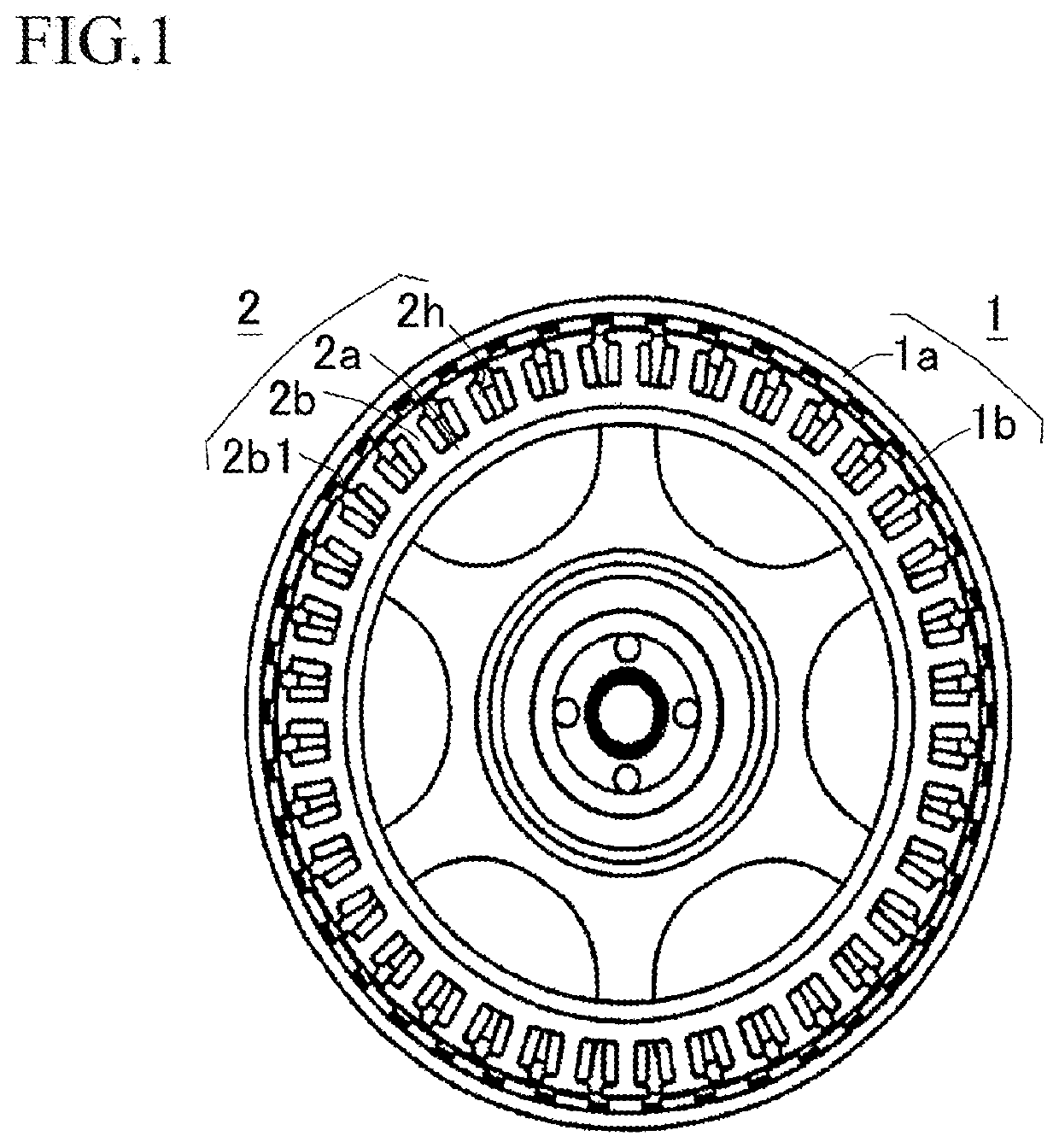

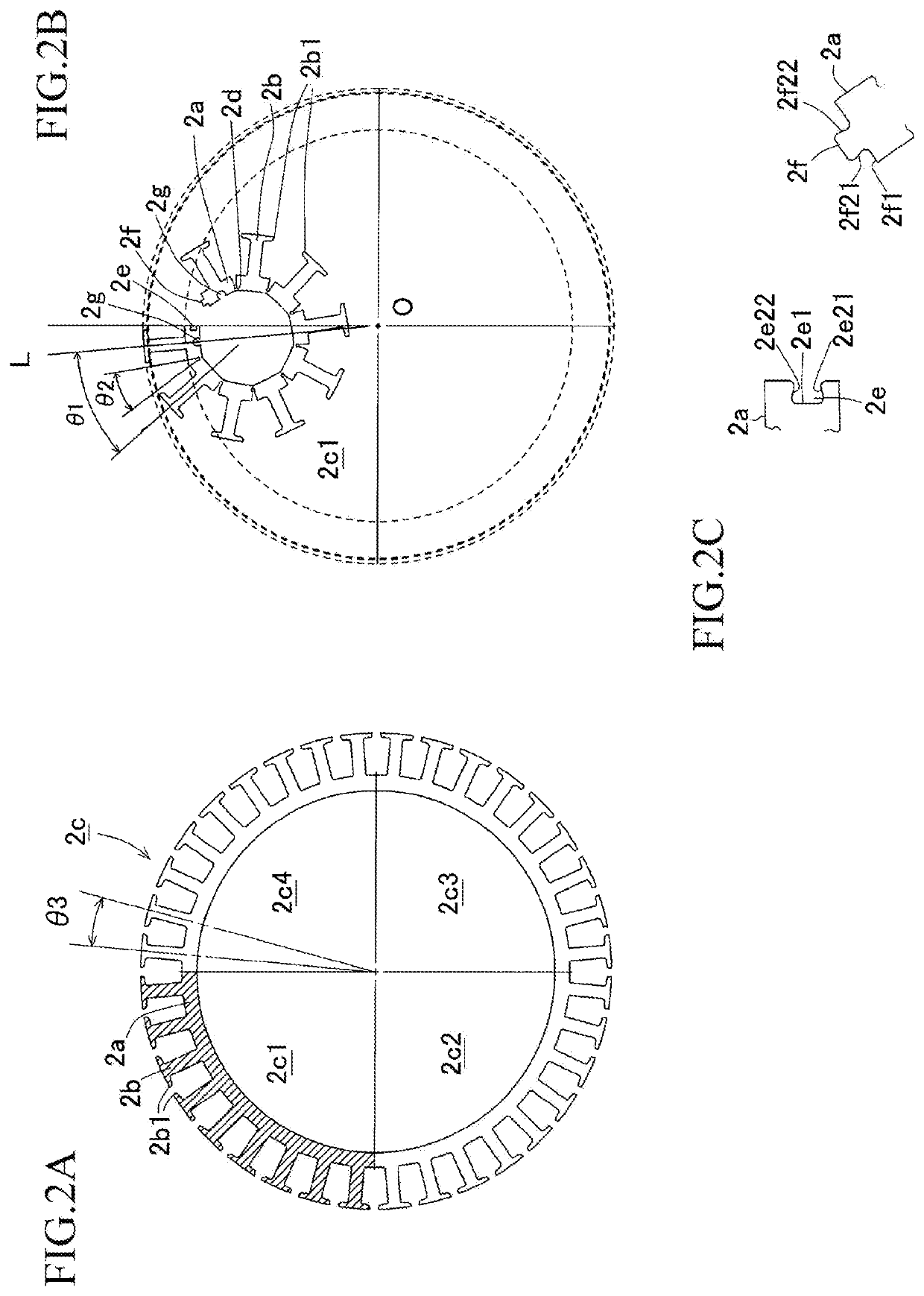

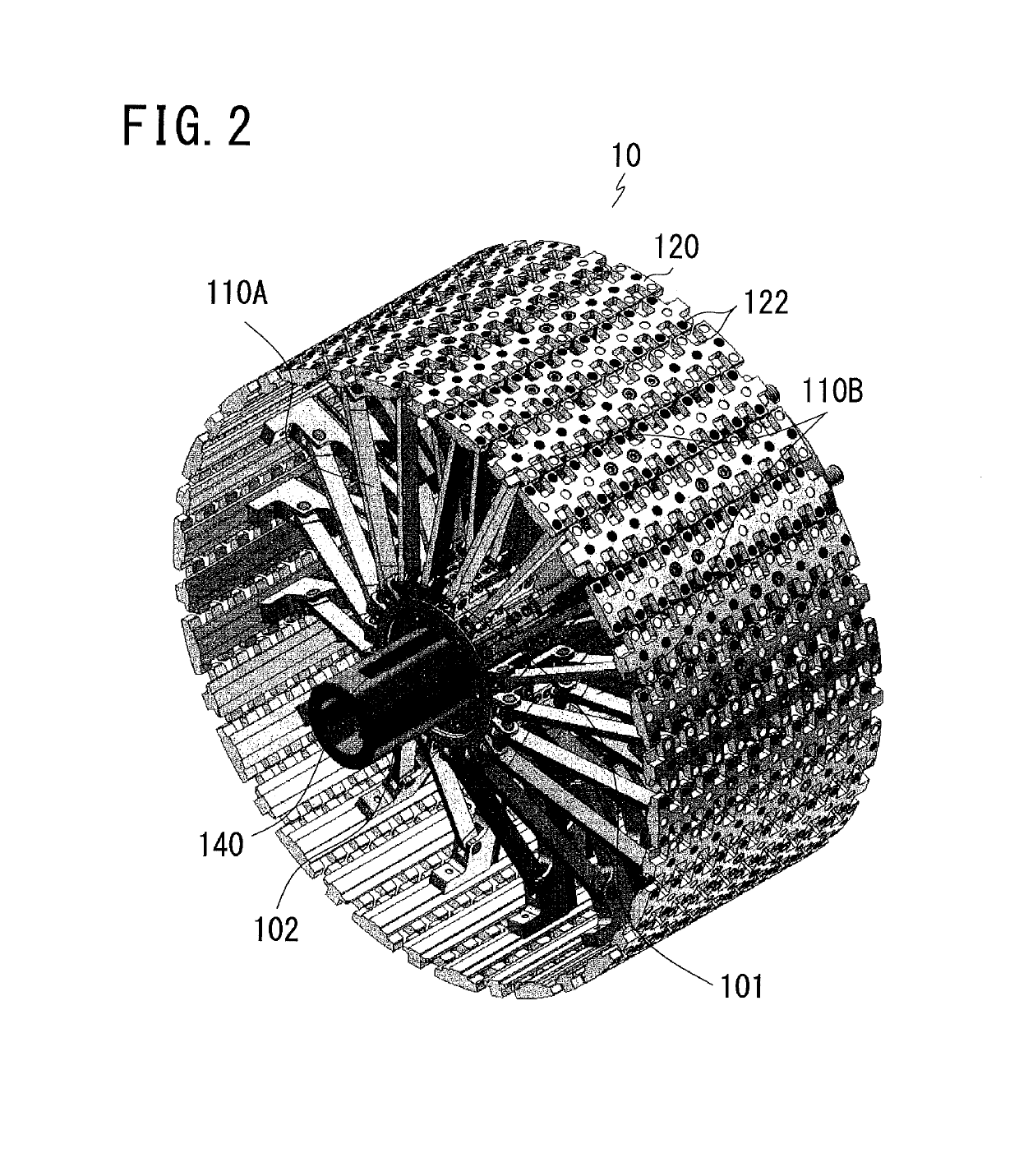

Stator, method of manufacturing stator, and outer rotor type motor

ActiveUS20200403460A1Maintain roundnessImprove productivityMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringPhysics

Owner:SHINANO KENSHI

Environment-friendly oil dipping device

InactiveCN104878530AIncrease production costModerate tightness of upper and lower threadsSewing-machine elementsCost savingsSewing machine

The invention provides an environment-friendly oil dipping device. The environment-friendly oil dipping device comprises an oil storage bin and a base fastened at the bottom of the oil storage bin, the base is provided with a first groove, the bottom of the oil storage bin is provided with a second groove, and the first groove is fastened with the second groove when the base is fastened with the bottom of the oil storage bin. The edge of the first groove is provided with a first inlet and outlet thread groove communicated with the outside, and the edge of the second groove is provided with a second inlet and outlet thread groove communicated with the outside. When the first groove and the second groove are fastened, the first inlet and outlet thread groove and the second inlet and outlet thread groove are not superposed. The first groove and the second groove are fastened to form a cavity filled with a felt oil seepage layer. The environment-friendly oil dipping device is applicable to various sewing machines, thread feeding and discharging of the sewing machines are moderate in tightness, thread stacking of the sewing machines is avoided, and sewing threads are kept full and not easy to loose. The sewn vamps are more attractive in appearance. The environment-friendly oil dipping device is simple in design, cost saving, practical, convenient, small and delicate in appearance and can control oil seepage.

Owner:JIHUA 3513 IND

Traditional Chinese medicine pill for treating myopia, and preparation method of traditional Chinese medicine pill

PendingCN112316040AMaintain hardnessMaintain roundnessSenses disorderPill deliveryPLANTAGO SEEDPharmaceutical drug

The invention discloses a traditional Chinese medicine pill for treating myopia, and a preparation method of the traditional Chinese medicine pill, and is a medicine for treating eye diseases. The traditional Chinese medicine pill is prepared from 5-25g of fructus schizandrae, 5-25g of rhizoma acori tatarinowii, 5-25g of rehmanniae radix, 5-25g of semen plantaginis, 5-25g of semen cuscutae, 5-25gof Poria cocos (Schw.)Wolf. roots, 5-25g of fructus lycii, 5-25g of radix polygalae, 5-25g of carthami flos, 5-25g of pericarpium citri reticulatae, 5-25g of fructus corni, 5-25g of rhizoma chuanxiongand 5-25g of radix salviae miltiorrhizae.

Owner:杨军华

A high tensile signal transmission reel cable

ActiveCN112201388BGuaranteed heat resistanceGuaranteed flame retardant performancePlastic/resin/waxes insulatorsFilament handlingCopper wireEngineering

The invention discloses a high-tensile signal transmission reel cable, which comprises a cable body, the cable body contains soft steel wires, a copper wire braid layer and an insulating layer, the copper wire braid layer is provided with soft steel wires, and the copper wire braid The outer surface of the inner layer is covered with an insulating layer, and the outer surface of the cable body is covered with an inner lining layer, and hemp rope is filled between the inner lining layer and the cable body, and the outer side of the inner lining layer is wrapped with a shielding layer, so The inside of the shielding layer is provided with a drain wire, the outer surface of the shielding layer is covered with an outer protective cover, and the outer surface of the outer protective cover is provided with a steel wire braided layer; the insulating layer is made of a highly flexible flame-retardant PVC insulating material, On the premise of ensuring the excellent electrical insulation performance of the cable, the heat resistance, flexibility, flame retardancy and mechanical properties of the cable are guaranteed; the cable in the present invention has good flexibility, tensile resistance and mechanical properties, and can withstand large tensile forces and bend.

Owner:ANHUI MENTOR CABLE GROUP

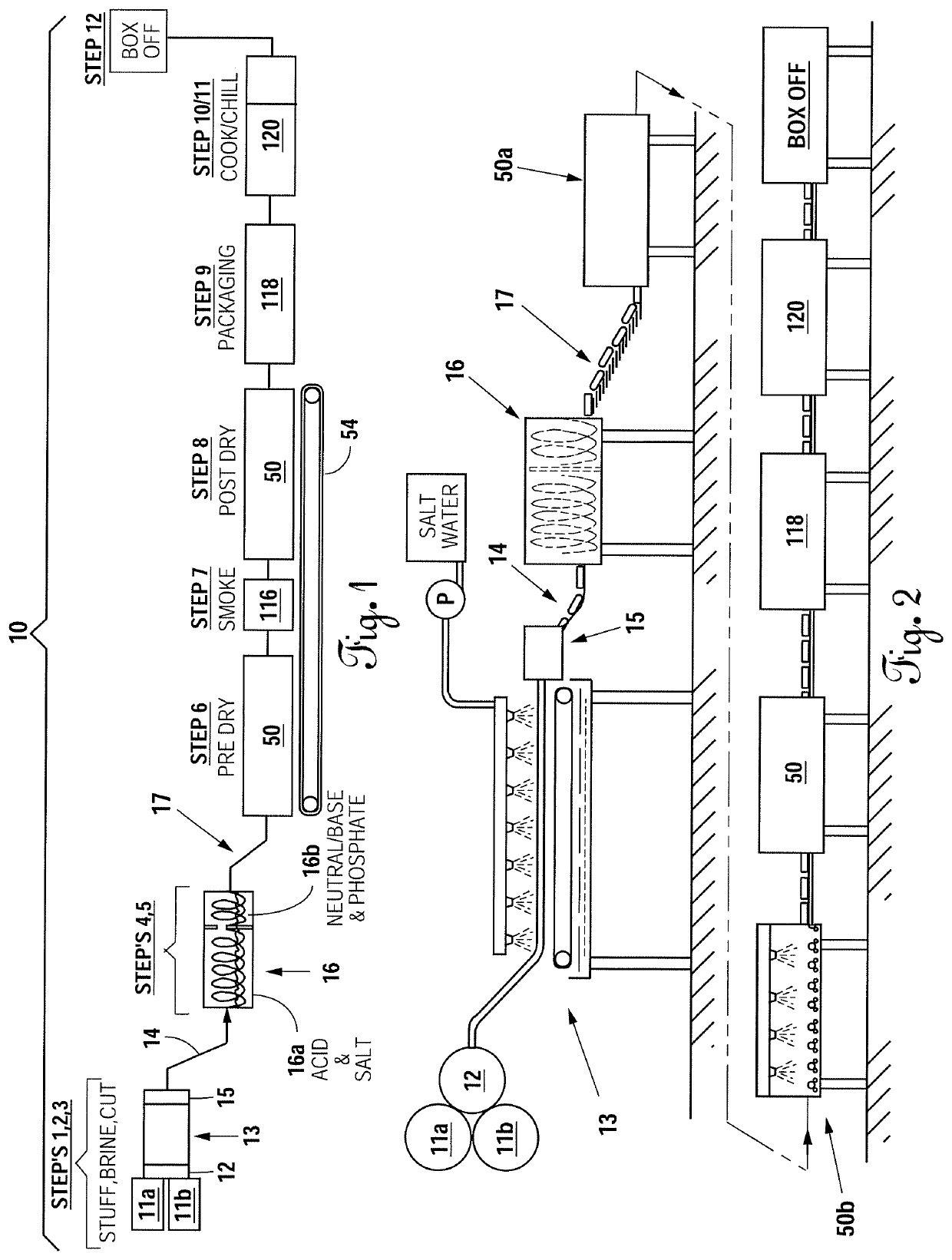

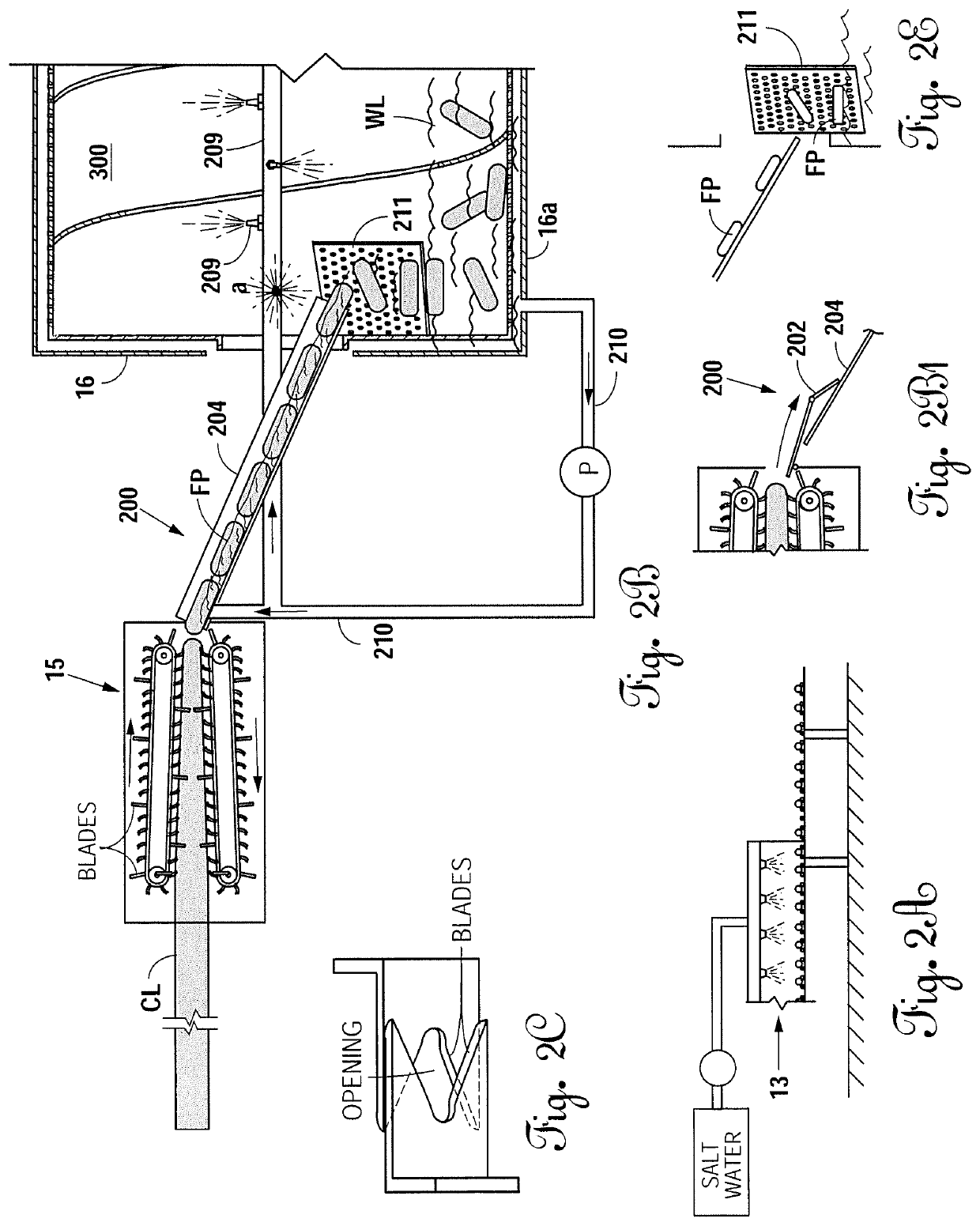

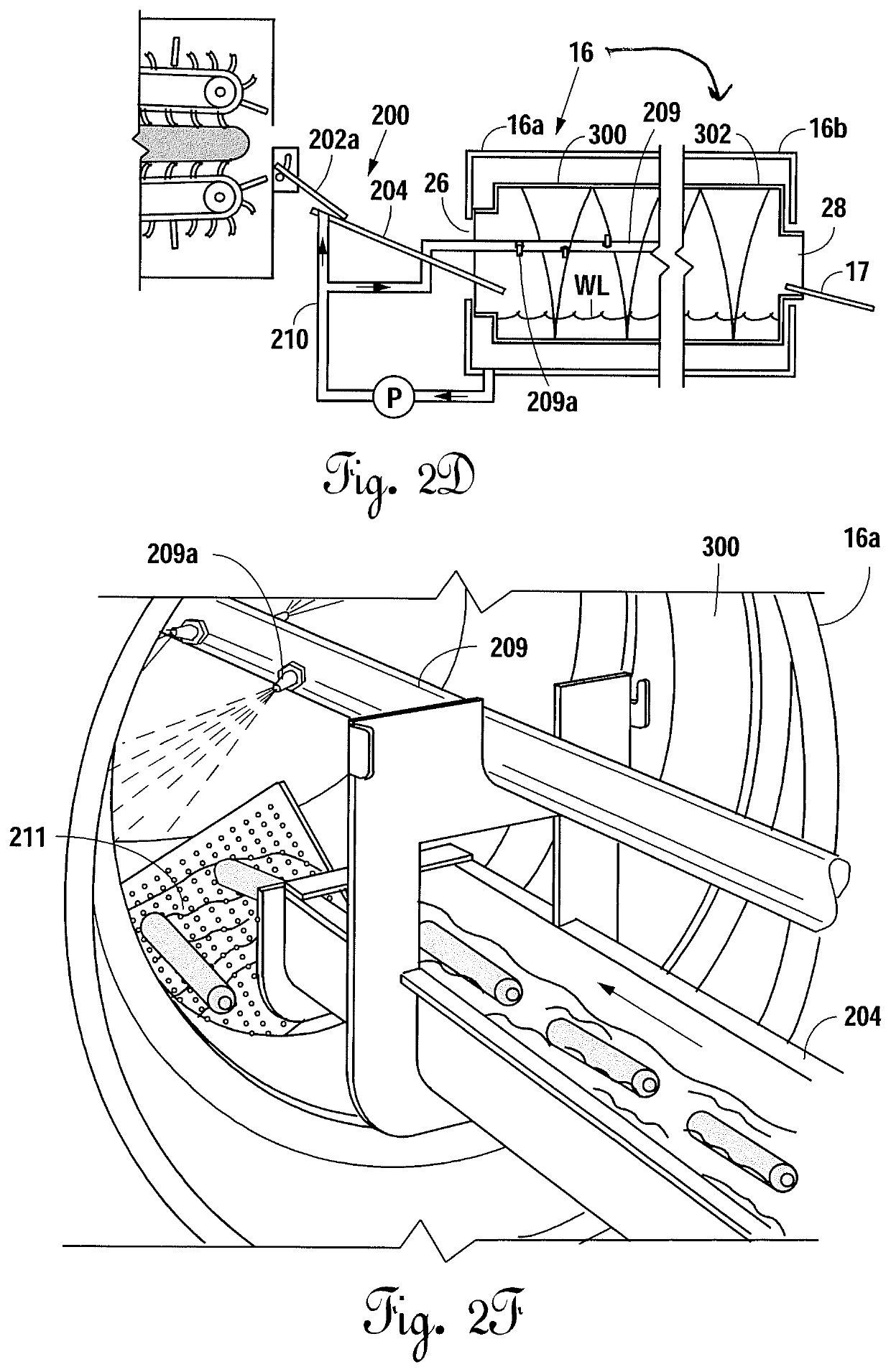

Low profile water bath co-extrusion process for sausage manufacturing, and machines for use therewith

ActiveUS11490626B1Maintain roundnessGood coagulationConveyorsClimate change adaptationChemical treatmentEmulsion

A low profile water bath co-extrusion process for sausage manufacturing is disclosed, along with machines for accomplishing this process. The process is an automated assembly line which begins with co-extruded food product, such as a sausage emulsion coated with collagen and finishes with cooked, boxed, packaged link sausage. The process includes the steps of co-extrusion, linking and cutting the co-extruded food product to individual links. Following these steps and prior to a liquid smoking step, the casing is prepared by steps which includes chemical treatment of the individual links in a water bath, while dehydrating the product in a salt solution, the water bath being a two-part process and following the water bath using a forced hot air drying step. Machines disclosed include a modification of prior art screw driven water bath and a novel roller / conveyor forced hot air drying assembly that subjects individual links of a co-extruded food product to a rolling motion while simultaneously being transported horizontally and being subject to forced hot air drying.

Owner:J & B SAUSAGE

Molding drum

Owner:BRIDGESTONE CORP

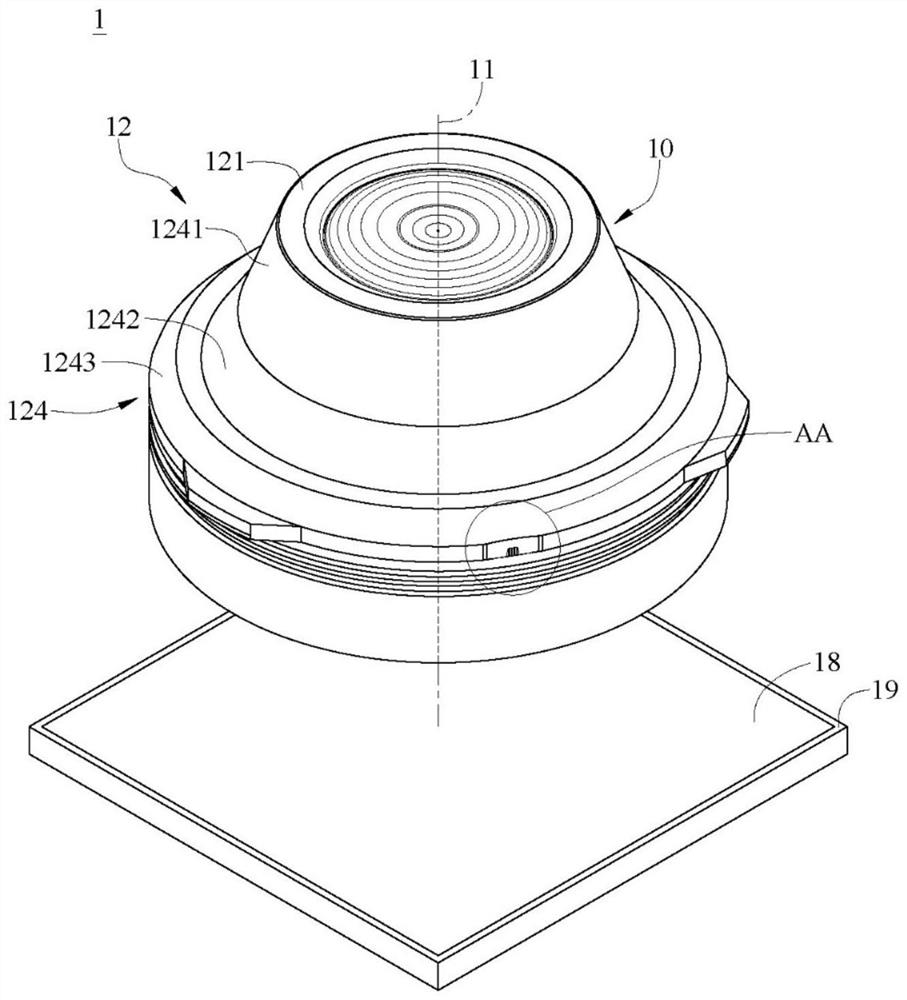

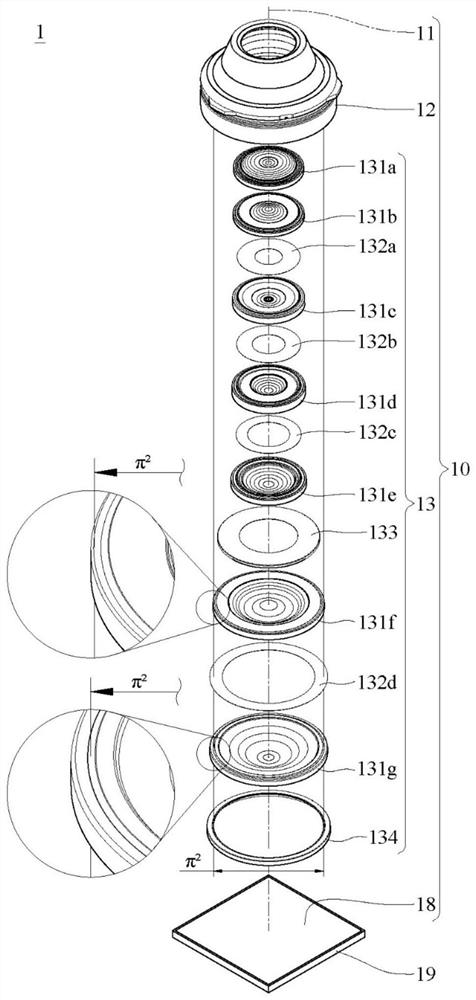

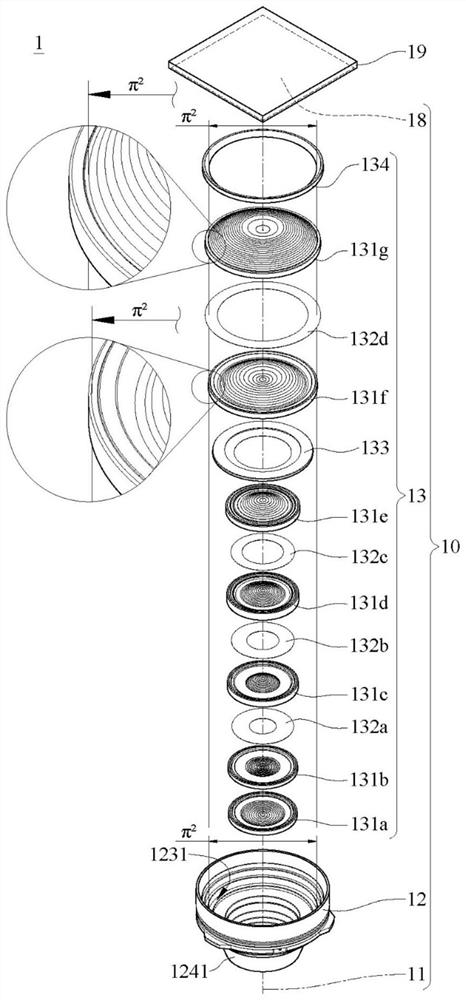

Imaging lens, camera module and electronic device

ActiveCN113325540AIncreased melt flow rateImprove flatnessMountingsCamera body detailsOptical axisEngineering

The utility model provides an imaging lens, which is provided with an optical axis and comprises a plastic lens cone and an imaging lens group. Plastic lens barrel surrounding optical axis. The plastic lens barrel includes an object-side surface, an image-side surface, an inner peripheral portion, and an outer peripheral portion. The object-side surface and the image-side surface are disposed opposite to each other and are substantially perpendicular to the optical axis. The inner peripheral portion and the outer peripheral portion connect the object side surface and the image side surface, and the outer peripheral portion is farther from the optical axis than the inner peripheral portion. The inner peripheral part is provided with a parallel inner edge surface, and the outer peripheral part is provided with a first outer peripheral surface and an injection mark. The imaging lens group is arranged in the plastic lens barrel. The imaging lens group includes a plurality of imaging lens elements. The outer diameter of at least one imaging lens element is larger than [pi]2 mm. The outer edge of at least one imaging lens element is in solid contact with the parallel inner edge surface of the inner peripheral part. The first outer peripheral surface, the material injection mark and the parallel inner edge surface are sequentially arranged from the object side to the image side. The first outer peripheral surface tapers toward the object-side surface. The present invention also provides a camera module with the imaging lens and an electronic device with the camera module.

Owner:LARGAN PRECISION

Unreeling device in copper tube

ActiveCN102385960BImprove work efficiencySmall footprintManufacturing co-axial cablesProduction lineEngineering

Owner:JIANGSU TRIGIANT TECH

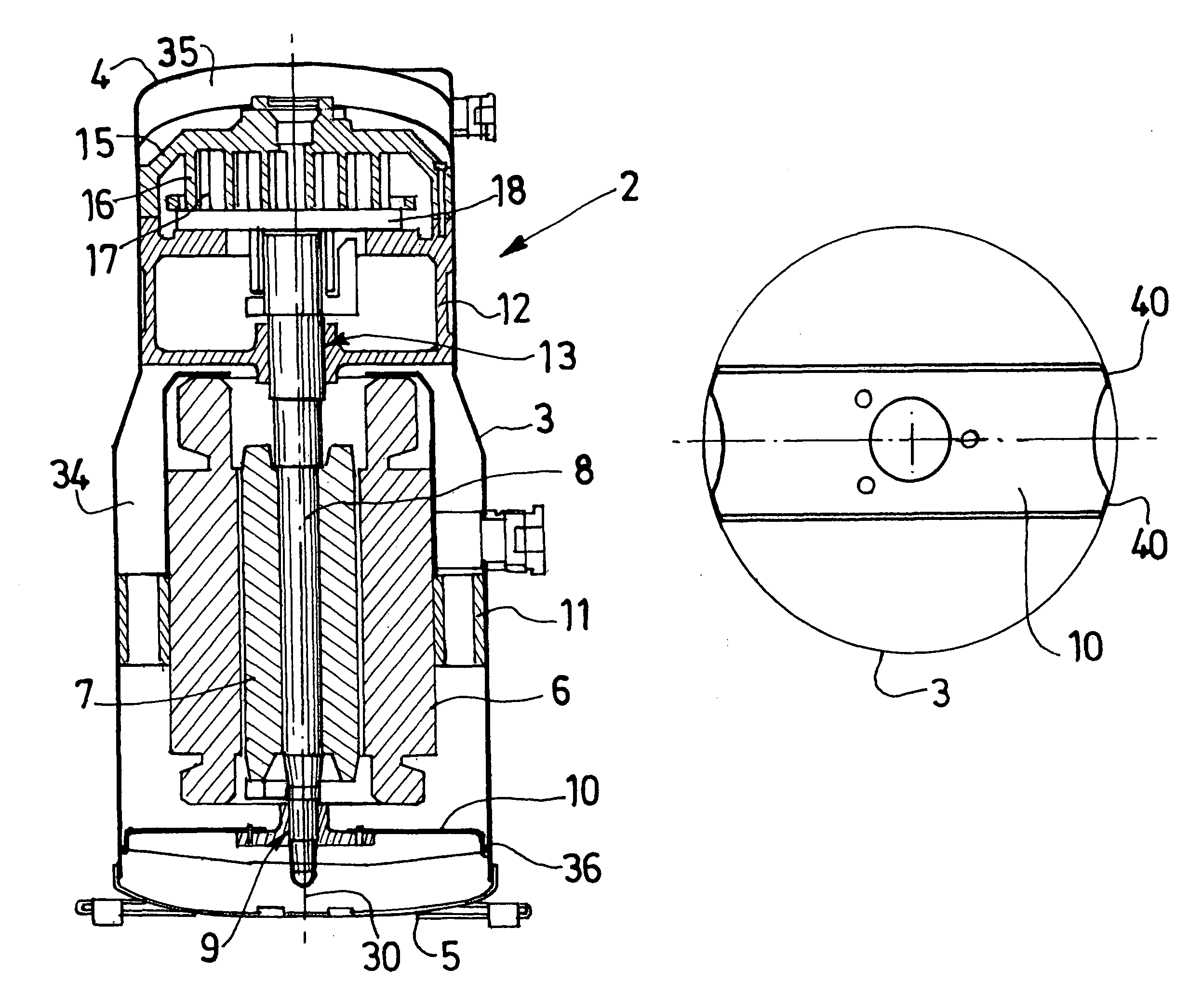

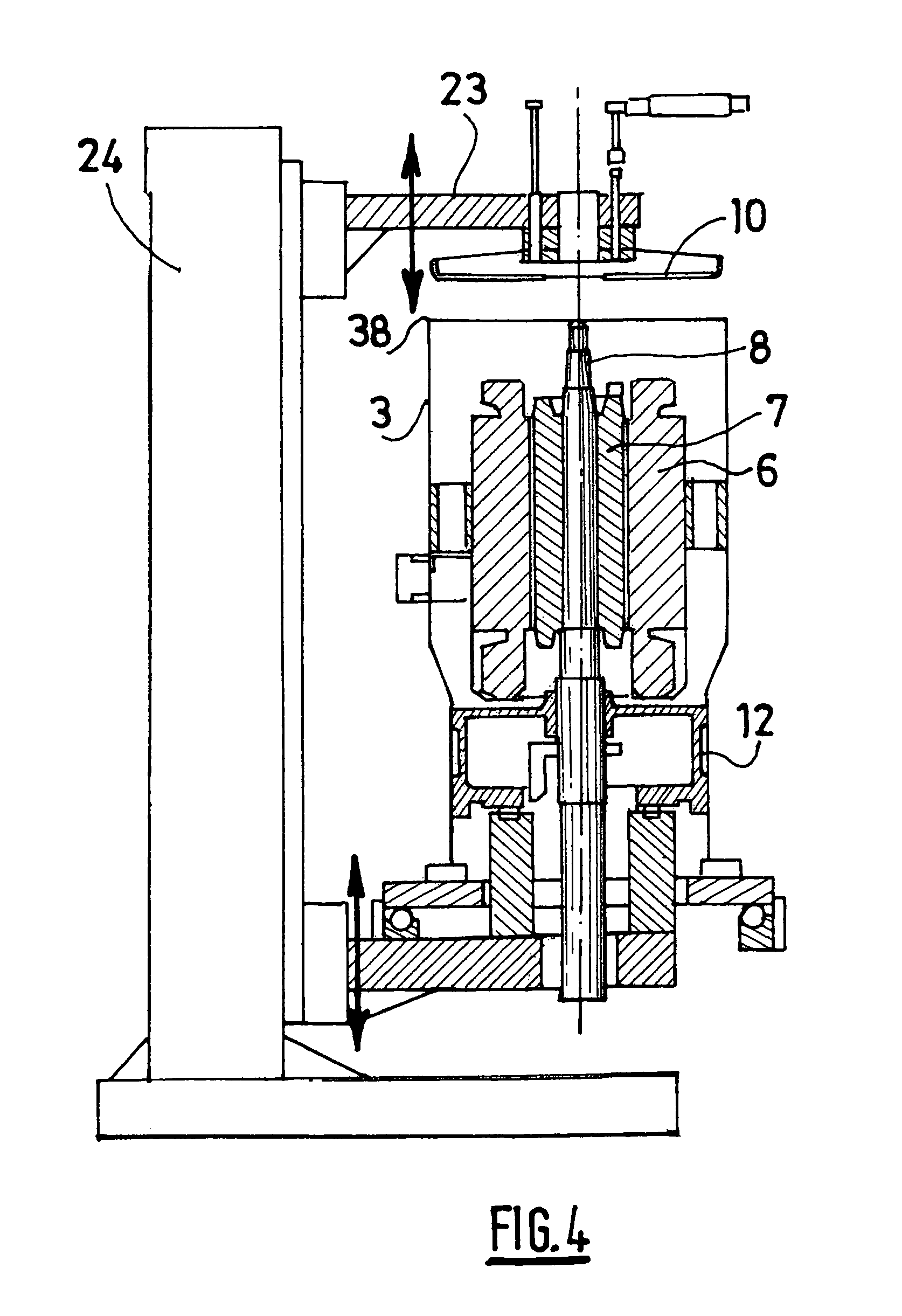

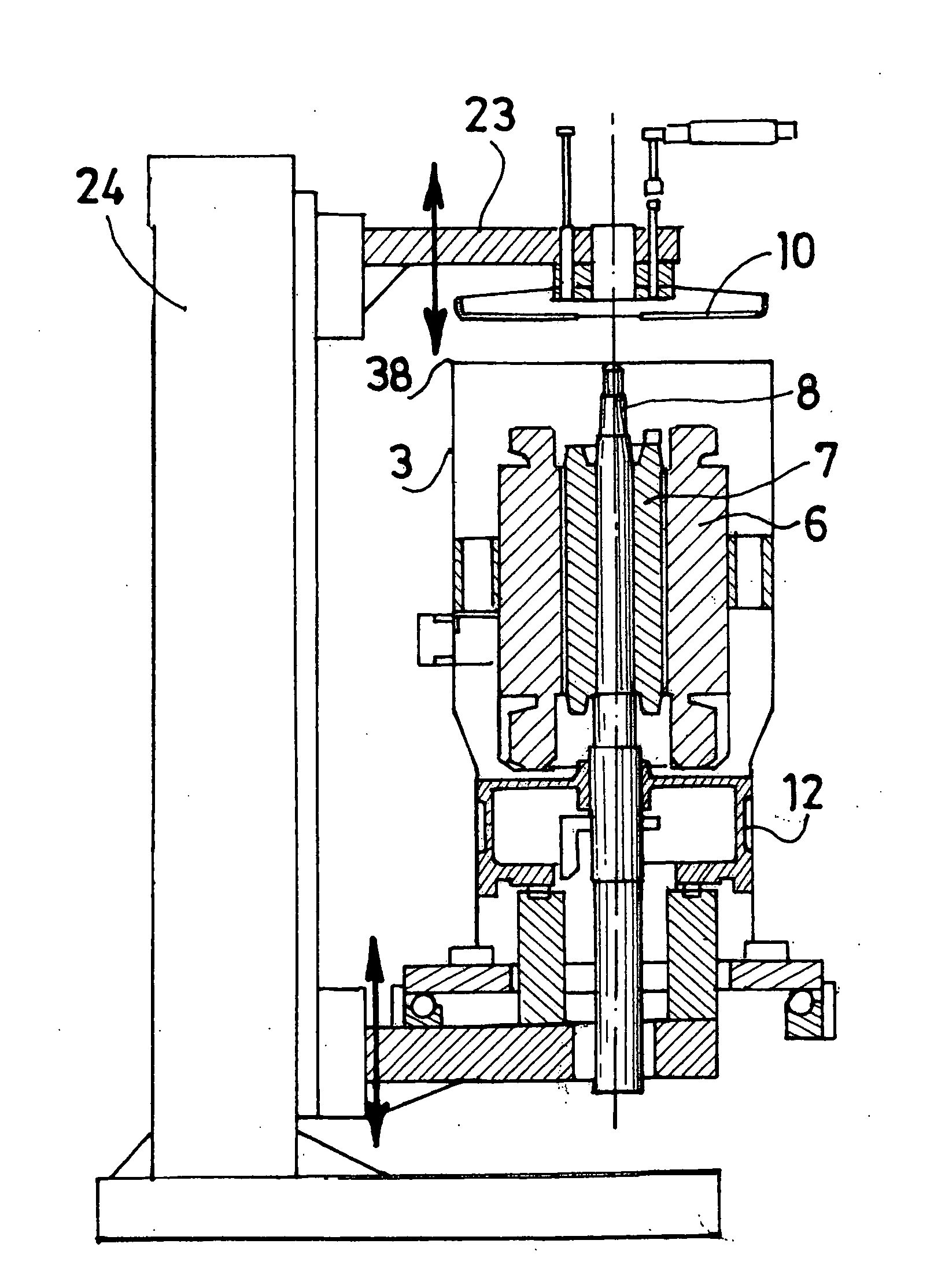

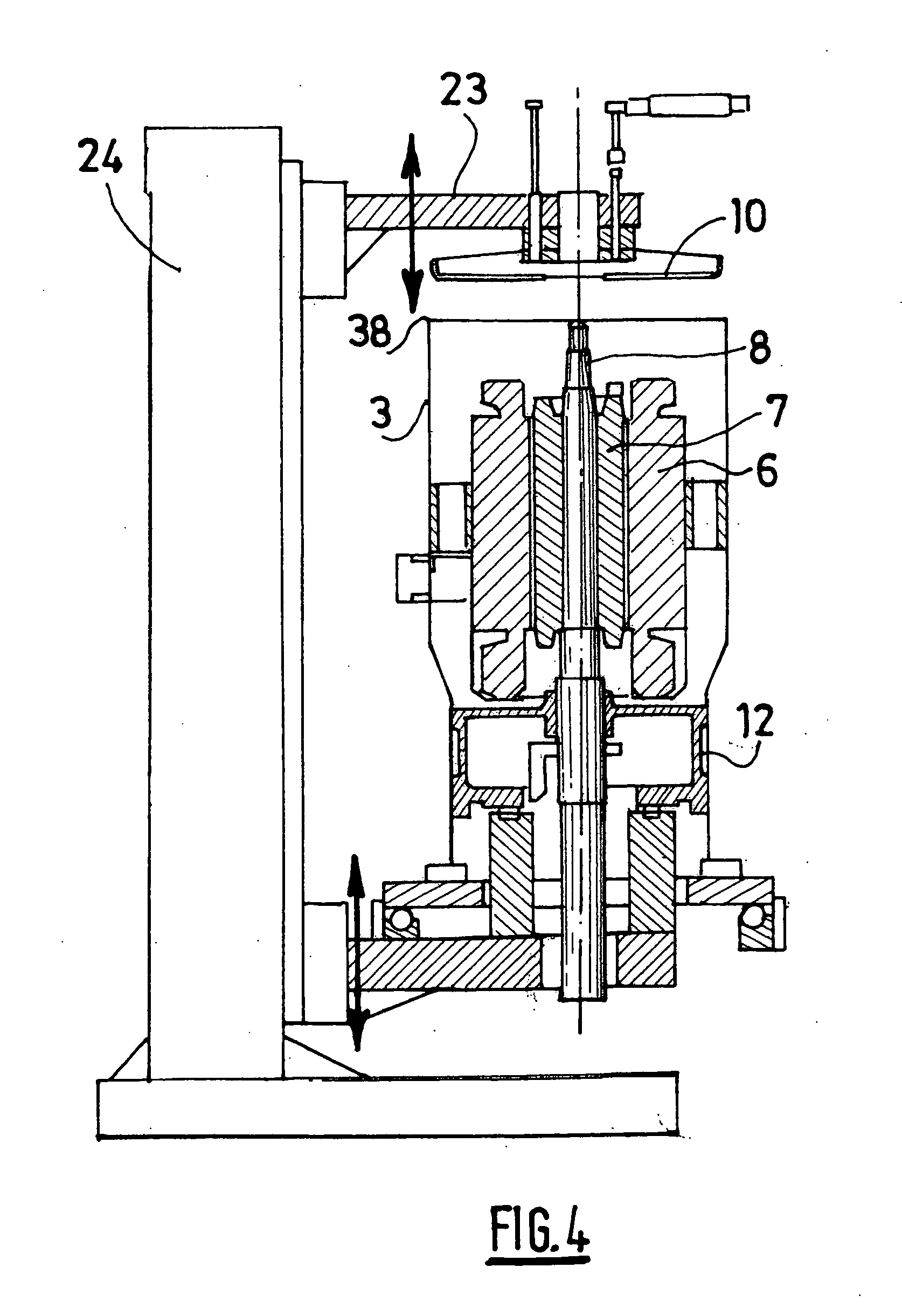

Method of assembling a refrigerating compressor

InactiveUS8454332B2Firmly attachedSimple methodEngine of arcuate-engagement typeOscillating piston enginesRefrigeration compressorDrive shaft

A compressor comprising a sealed chamber delimited laterally by a shell, a drive shaft housed in the shell and guided relative to the other parts of the compressor via at least one bearing provided in a bearing support fixed to the internal wall of the shell. The method comprises steps consisting in supplying a shell have, in the fixing plane of the bearing support, an oval section comprising a small axis to which the bearing support is intended to be mounted, exerting a pressure on the shell in order to elastically deform it so as to increase the length of its small axis, inserting and positioning the bearing support in the fixing plane of the latter, and ceasing to exert a pressure on the shell so that the latter tends to elastically return to its original form and grip the bearing support.

Owner:DANFOSS COMML COMPRESSORS

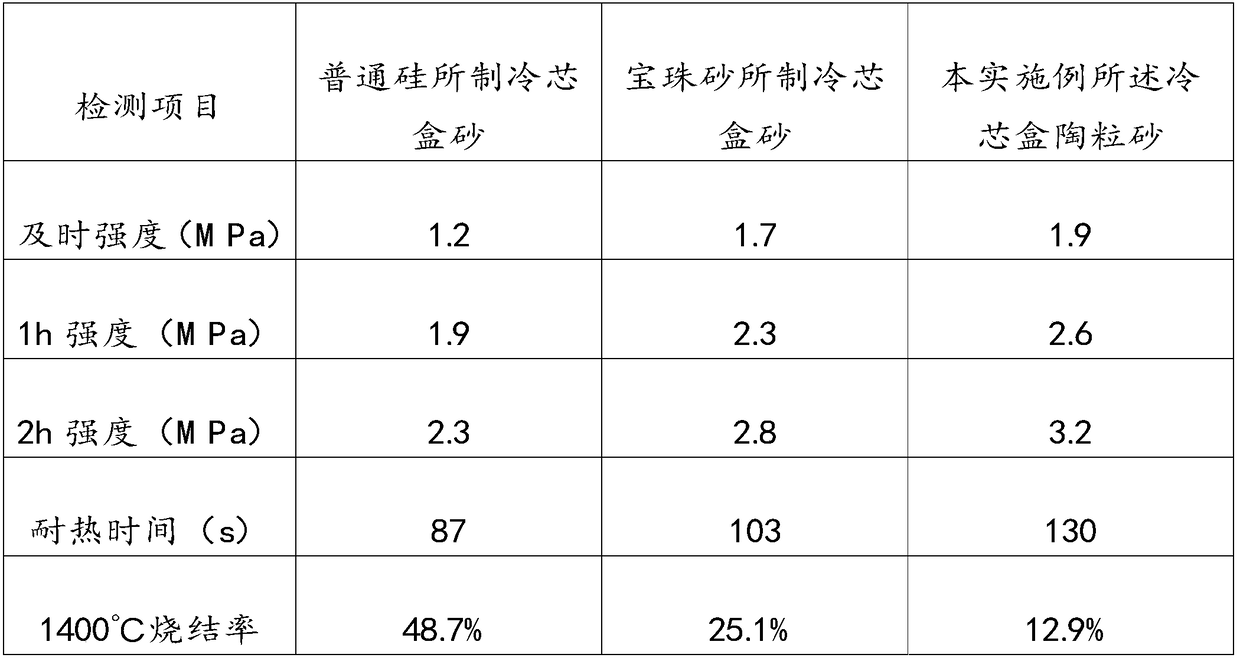

Cold core box ceramsite sand and preparation method thereof

ActiveCN109175216AMaintain roundnessMaintain liquidityFoundry mouldsFoundry coresAluminium powderExpanded clay aggregate

The invention discloses cold core box ceramsite sand and a preparation method of the cold core bo ceramsite sand. The cold core box ceramsite sand is prepared from ceramsite sand, ferroferric oxide, zeolite powder and organic resin. The organic resin is prepared from phenolic resin and polyisocyanate. The cold core box ceramsite sand has the beneficial effects that the cold core box ceramsite sandis prepared from the ceramsite sand, the surface of the ceramsite sand is wrapped by a layer of aluminum powder in the preparation process, an aluminum oxide film will be generated on the surface ofthe ceramsite sand after the wrapping aluminum powder is sintered, and the film not only keeps the roundness and fluidity of the ceramsite sand, but also improves the fire resistance of the ceramsite.When the cold core box ceramsite sand is prepared, the film further can reduce the roughness of the surface of the ceramsite sand, therefore, the resin wrapping performance is improved, and the binding bridge strength is increased. The cold core box ceramsite sand has the low thermal expansion property, the quite high fire resistance degree and excellent resistance to metal penetration and sand adhesion, and a produced casting is smooth, free of sand adhesion defect and good in size precision.

Owner:北京仁创砂业铸造材料有限公司

Method of assembling a refrigerating compressor

InactiveUS20100104460A1Firmly attachedSimple methodEngine of arcuate-engagement typeOscillating piston enginesRefrigeration compressorDrive shaft

A compressor comprising a sealed chamber delimited laterally by a shell, a drive shaft housed in the shell and guided relative to the other parts of the compressor via at least one bearing provided in a bearing support fixed to the internal wall of the shell. The method comprises steps consisting in supplying a shell have, in the fixing plane of the bearing support, an oval section comprising a small axis to which the bearing support is intended to be mounted, exerting a pressure on the shell in order to elastically deform it so as to increase the length of its small axis, inserting and positioning the bearing support in the fixing plane of the latter, and ceasing to exert a pressure on the shell so that the latter tends to elastically return to its original form and grip the bearing support.

Owner:DANFOSS COMML COMPRESSORS

A kind of cold box ceramsite sand and preparation method thereof

ActiveCN109175216BMaintain roundnessMaintain liquidityFoundry mouldsFoundry coresThermal dilatationAluminium powder

The invention discloses cold core box ceramsite sand and a preparation method of the cold core bo ceramsite sand. The cold core box ceramsite sand is prepared from ceramsite sand, ferroferric oxide, zeolite powder and organic resin. The organic resin is prepared from phenolic resin and polyisocyanate. The cold core box ceramsite sand has the beneficial effects that the cold core box ceramsite sandis prepared from the ceramsite sand, the surface of the ceramsite sand is wrapped by a layer of aluminum powder in the preparation process, an aluminum oxide film will be generated on the surface ofthe ceramsite sand after the wrapping aluminum powder is sintered, and the film not only keeps the roundness and fluidity of the ceramsite sand, but also improves the fire resistance of the ceramsite.When the cold core box ceramsite sand is prepared, the film further can reduce the roughness of the surface of the ceramsite sand, therefore, the resin wrapping performance is improved, and the binding bridge strength is increased. The cold core box ceramsite sand has the low thermal expansion property, the quite high fire resistance degree and excellent resistance to metal penetration and sand adhesion, and a produced casting is smooth, free of sand adhesion defect and good in size precision.

Owner:北京仁创砂业铸造材料有限公司

Novel high-tensile signal transmission drum cable

ActiveCN112201388AGuaranteed heat resistanceGuaranteed flame retardant performancePlastic/resin/waxes insulatorsFilament handlingCopper wireHeat resistance

The invention discloses a novel high-tensile signal transmission drum cable, which comprises a cable body, wherein the cable body comprises soft steel wires, a copper wire braided layer and an insulating layer, the copper wire braided layer is provided with the soft steel wires, the outer surface of the copper wire braided layer is sleeved with the insulating layer, the outer surface of the cablebody is sleeved with an inner lining layer, a hemp rope is filled between the inner lining layer and the cable body, the outer side of the inner lining layer is wrapped with a shielding layer, a drainage wire is arranged in the shielding layer, the outer surface of the shielding layer is sleeved with an outer protective sleeve, the outer surface of the outer protective sleeve is sleeved with a steel wire braided layer, and the insulating layer is made of a high-flexibility flame-retardant PVC insulating material, so that the heat resistance, the softness, the flame retardance and the mechanical property of the cable are ensured on the premise of ensuring the excellent electrical insulating property of the cable. The cable provided by the invention has good flexibility, tensile property andmechanical property, and can bear relatively large tensile force and bending.

Owner:ANHUI MENTOR CABLE GROUP

Induction hardening method and jig used in induction hardening process

InactiveUS8034201B2Improve roundnessMaintain roundnessFurnace typesIncreasing energy efficiencyInduction hardeningMaterials science

The present invention provides a method for induction hardening of a steel member having an outer ring portion and, more specifically, for induction hardening of an outer circumferential surface of the outer ring portion. The method uses two pressing members, each of which includes a flat basal surface and a projecting portion projecting therefrom. Each of the projecting portions has a cross-section in the shape of a perfect circle. Also, the projecting portions have, on the outer circumferences thereof, respective pressing surfaces. While gaps are maintained between axial end faces of the outer ring portion and the basal surfaces of the pressing members, the pressing members are pressed against the outer ring portion so that the pressing surfaces each abut against the inner circumference side of the outer ring portion. While a biasing force is applied to the pressing members, the induction hardening process is applied to the outer circumferential surface. During the induction hardening process, the pressing members are moved toward each other until the basal surfaces abut against respective axial end faces of the outer ring portion.

Owner:AISIN AW CO LTD

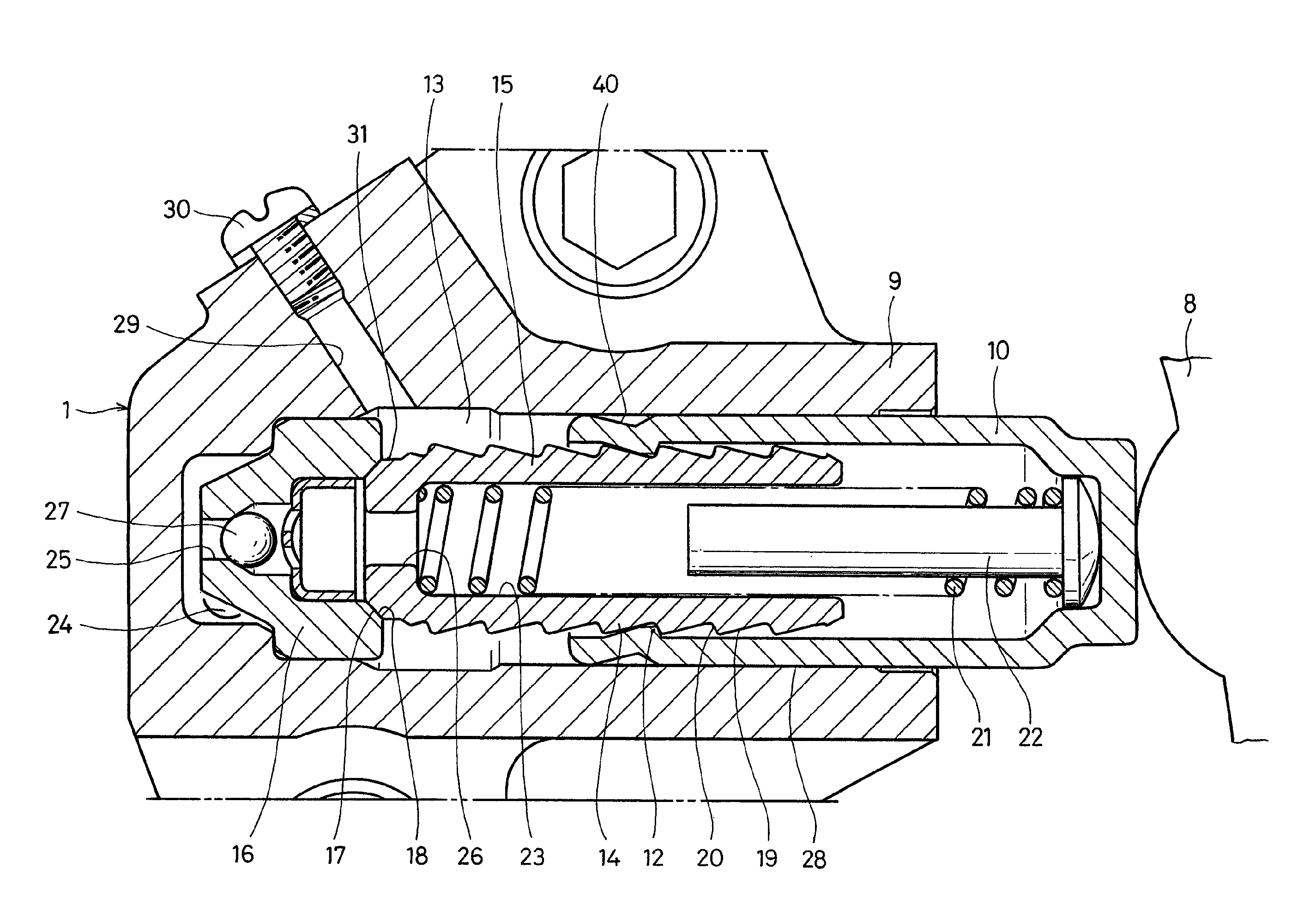

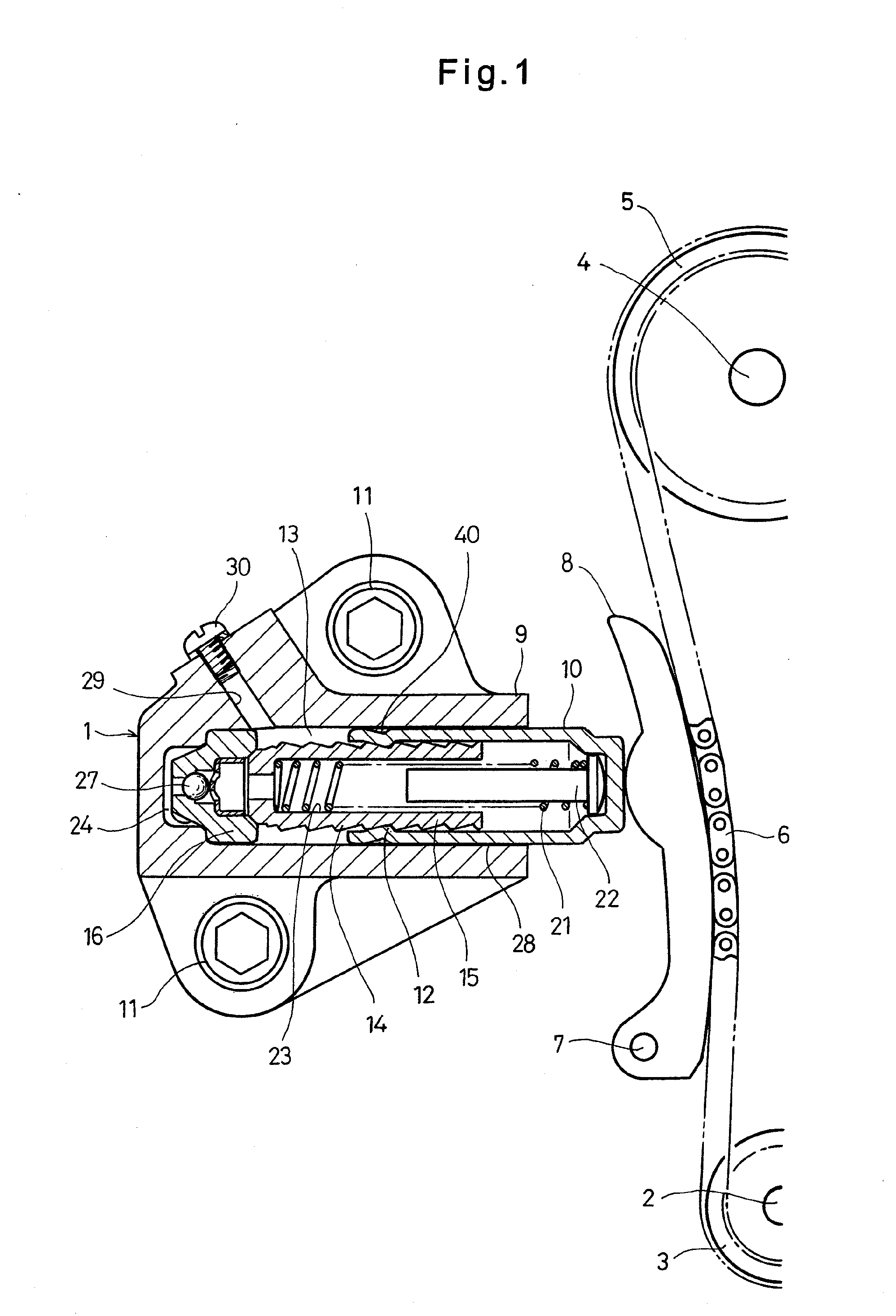

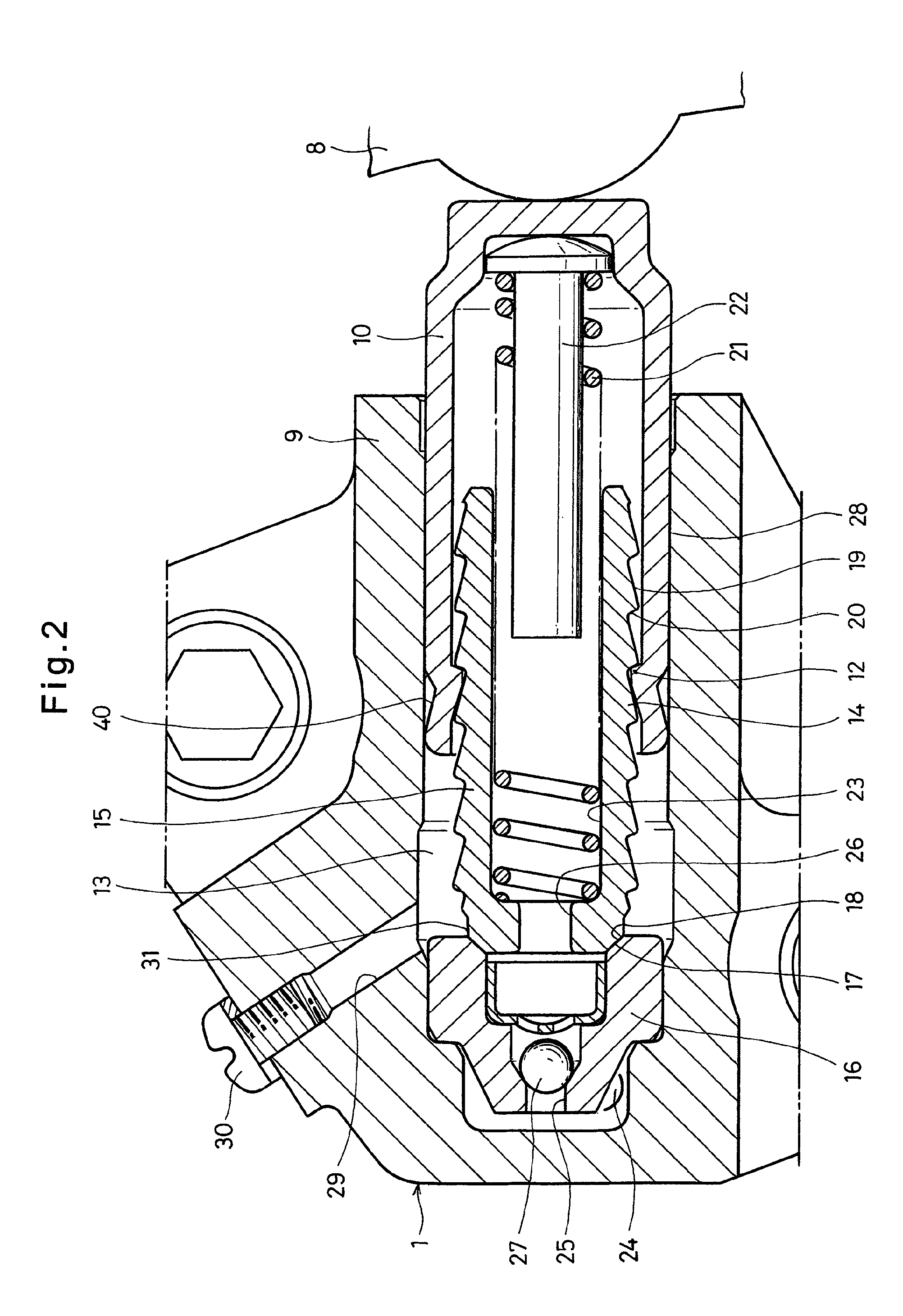

Chain tensioner

Owner:NTN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com