Imaging lens, camera module and electronic device

An imaging lens, imaging lens technology, applied in TV, installation, electrical components, etc., can solve problems such as insufficient roundness, insufficient overall structural strength, and poor melt flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

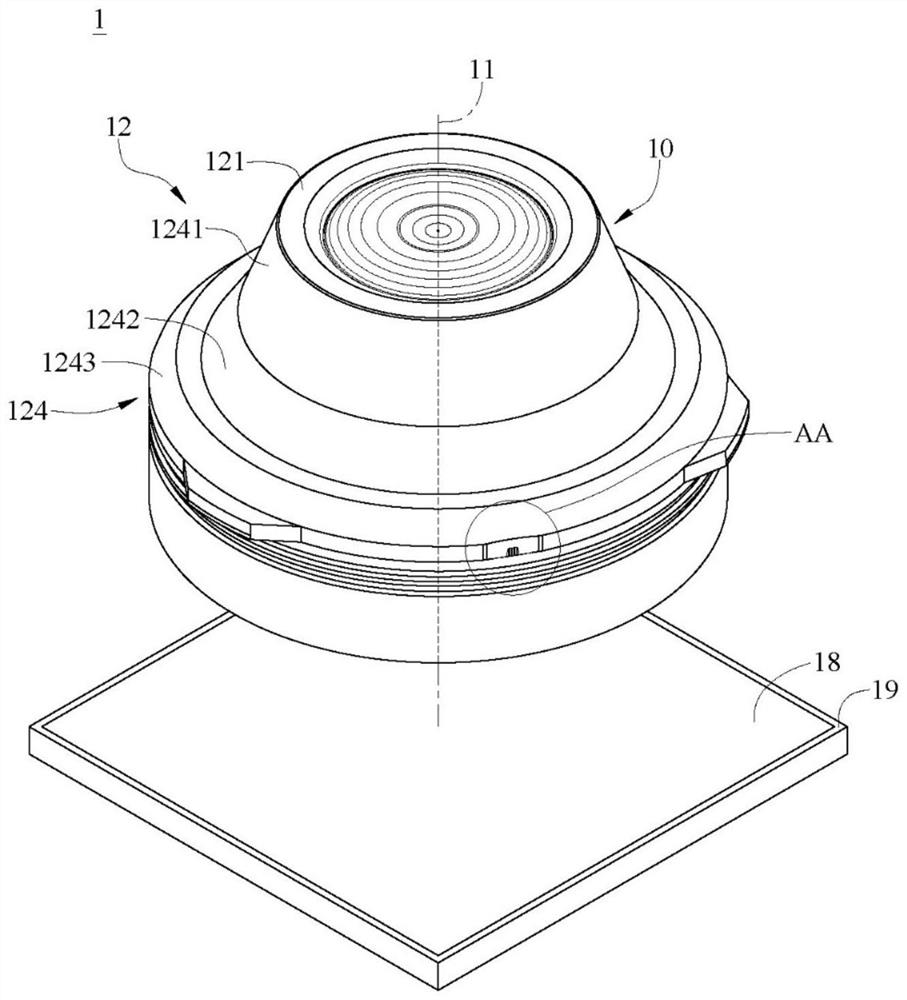

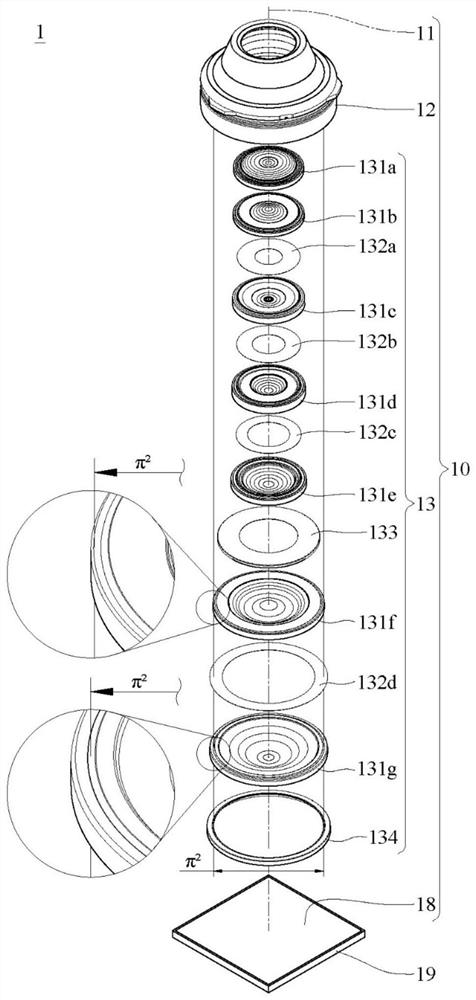

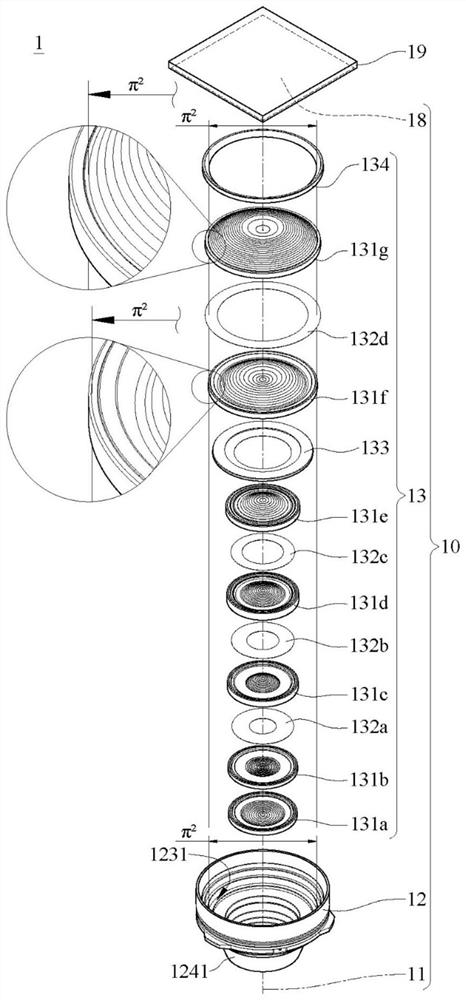

[0117] Please refer to Figure 1 to Figure 10 ,in figure 1 A perspective view showing a camera module according to a first embodiment of the present invention, figure 2 draw figure 1 An exploded schematic diagram of the camera module, image 3 draw figure 1 Another exploded schematic diagram of the camera module, Figure 4 draw figure 1 A partially enlarged schematic diagram of the AA area of the camera module, Figure 5 draw figure 1 The top view diagram of the camera module, Figure 6 draw figure 1 Schematic side view cutaway of the camera module, Figure 7 draw Figure 6 An exploded schematic diagram of the camera module, Figure 8 Shown formed in an injection molding mold figure 1 A schematic diagram of the plastic lens barrel of the camera module, Figure 9 depicting injection molded figure 1 The three-dimensional schematic diagram of the plastic flow direction of the plastic lens barrel of the camera module in the forming process, Figure 10 draw Figu...

no. 2 example

[0134] Please refer to Figure 11 to Figure 17 ,in Figure 11 A schematic perspective view of a camera module according to a second embodiment of the present invention is shown, Figure 12 draw Figure 11 A partially enlarged schematic diagram of the BB area of the camera module, Figure 13 draw Figure 11 The top view diagram of the camera module, Figure 14 draw Figure 11 Schematic side view cutaway of the camera module, Figure 15 draw Figure 14 An exploded schematic diagram of the camera module, Figure 16 depicting injection molded Figure 11 The three-dimensional schematic diagram of the plastic flow direction of the plastic lens barrel of the camera module in the forming process, Figure 17 draw Figure 16 The cross-sectional schematic diagram of the plastic flow direction of the plastic lens barrel in the forming process. In the following, only the differences between the second embodiment of the present invention and the foregoing embodiments will be de...

no. 3 example

[0151] Please refer to Figure 18 to Figure 24 ,in Figure 18 A schematic perspective view of a camera module according to a third embodiment of the present invention is shown, Figure 19 draw Figure 18 A partially enlarged schematic diagram of the CC area of the camera module, Figure 20 draw Figure 18 The top view diagram of the camera module, Figure 21 draw Figure 18 Schematic side view cutaway of the camera module, Figure 22 draw Figure 21 An exploded schematic diagram of the camera module, Figure 23 depicting injection molded Figure 18 The three-dimensional schematic diagram of the plastic flow direction of the plastic lens barrel of the camera module in the forming process, Figure 24 draw Figure 23 The cross-sectional schematic diagram of the plastic flow direction of the plastic lens barrel in the forming process. Only the differences between the third embodiment of the present invention and the foregoing embodiments will be described below, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com