Transparent halogen-free low smoke antiflaming polycarbonate composite material and preparation method thereof

A low-smoke, flame-retardant, polycarbonate technology, applied in the field of polycarbonate composite materials, can solve the problems of PC composite materials such as reduced heat resistance, low melting point, and influence on transparency, so as to achieve improved impact performance, good mold filling fluidity, The effect of excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

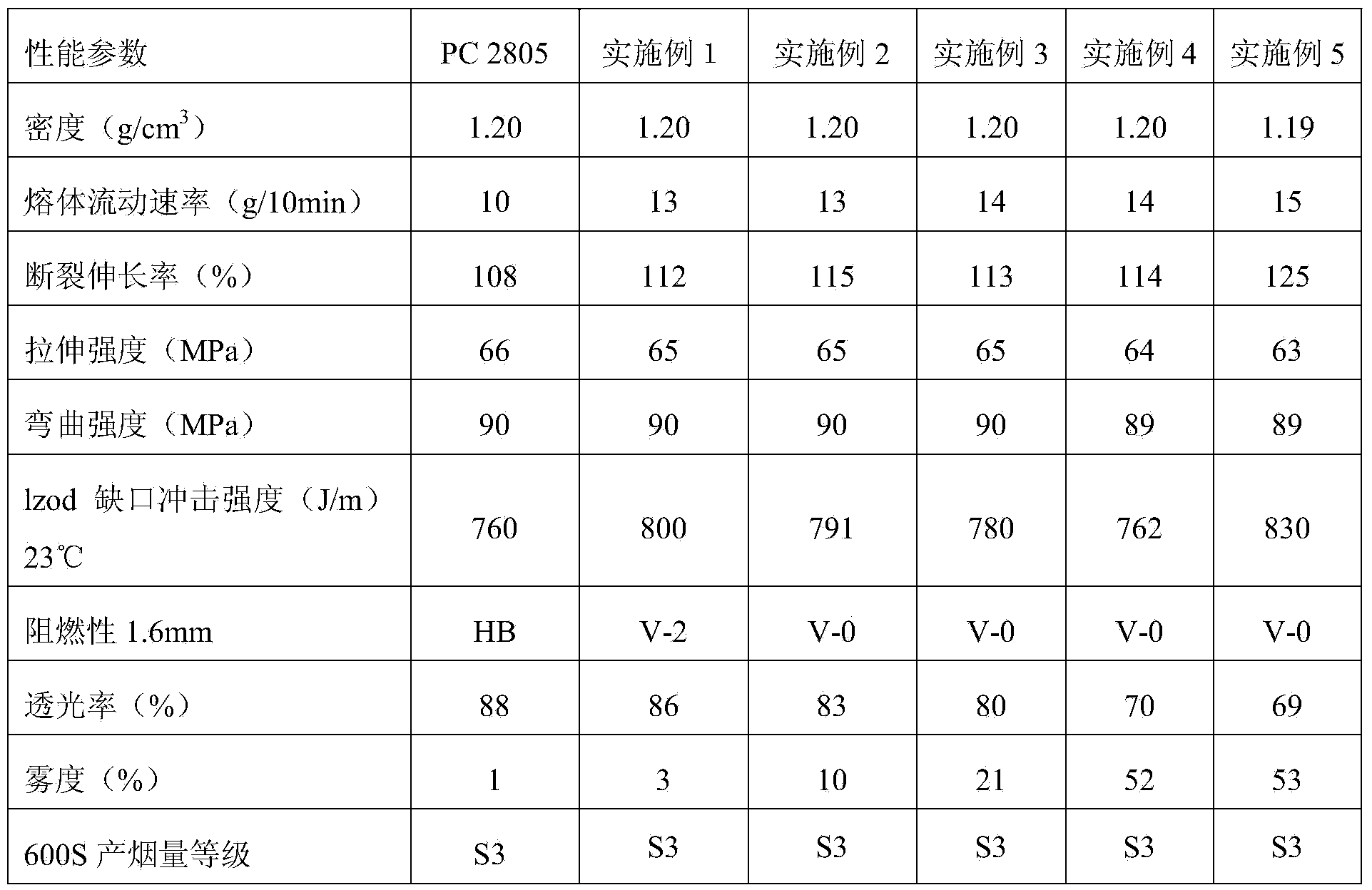

Examples

Embodiment 1

[0028] Example 1. Preparation of transparent halogen-free low-smoke flame-retardant polycarbonate composite material

[0029] The following components in parts by weight: 976 parts of PC model 2805, 10 parts of branched polysiloxane flame retardant FCA-107, 2 parts of antioxidant 168, 1 part of antioxidant 1076, 5 parts of long Chain fatty acid polyfunctional ester, 2.5 parts of light-stabilized 770, 2.5 parts of ultraviolet absorber UV234 and 1 part of toner are mixed in a high-speed mixer for 3 minutes, then extruded through a twin-screw extruder at 250-260 ° C, cooled, Granulation, the resulting pellets are dried at 120°C for 4 hours and then injection molded into standard strips at 260-280°C.

Embodiment 2

[0030] Example 2. Preparation of transparent halogen-free low-smoke flame-retardant polycarbonate composite material

[0031] The following components in parts by weight: 975 parts of PC model 2805, 10 parts of branched polysiloxane flame retardant FCA-107, 1 part of sulfonate flame retardant F535, 2 parts of antioxidant 168 , 1 part of antioxidant 1076, 5 parts of long-chain fatty acid polyfunctional ester, 2.5 parts of light-stabilized 770, 2.5 parts of ultraviolet absorber UV234 and 1 part of toner are mixed in a high-speed mixer for 3 minutes, and then mixed at 250-260 ° C It is extruded by a twin-screw extruder, cooled, and granulated, and the obtained pellets are dried at 120°C for 4 hours, and then injection-molded into standard strips at 260-280°C.

Embodiment 3

[0032] Example 3, Preparation of transparent halogen-free low-smoke flame-retardant polycarbonate composite material

[0033] The following components in parts by weight: 974 parts of PC model 2805, 10 parts of branched polysiloxane flame retardant FCA-107, 2 parts of sulfonate flame retardant F535, 2 parts of antioxidant 168 , 1 part of antioxidant 1076, 5 parts of long-chain fatty acid polyfunctional ester, 2.5 parts of light-stabilized 770, 2.5 parts of ultraviolet absorber UV234 and 1 part of toner are mixed in a high-speed mixer for 3 minutes, and then mixed at 250-260 ° C It is extruded by a twin-screw extruder, cooled, and granulated, and the obtained pellets are dried at 120°C for 4 hours, and then injection-molded into standard strips at 260-280°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com