Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Low frying temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing fried peanut kernels with low peroxide number

The invention discloses a method for producing friend peanut kernels with low peroxide number for fried peanuts with strong oxidation resistance and long quality guarantee period. The method comprises the following steps of: (1). selecting peanut kernels; (2). charging nitrogen: continuously supplementing nitrogen for a frying pan through a nitrogen making machine, wherein the nitrogen charging time is 20-25 minutes, and the nitrogen charging purity is 98.5-99.5%; (3). frying with mixed water and oil, wherein the temperature of oil at the upper layer is within 130-200 DEG C, the temperature of oil at the lower layer is within 55-130 DEG C, and the temperature of the oil water demarcation face is controlled to be below 55 DEG C; (4) processing the fried peanut kernels; (5). coating a film:a film solution is prepared by a pea starch solution with the concentration of 5%, during preparation, the film solution needs to be gelatinized in a boiling water bath for 20 minutes, the temperature of the film solution is maintained to be within 30-40 DEG C, and then the film solution is coated on the surfaces of the fried peanut kernels; and (6). drying the fried peanut kernels subjected to film coating in a vacuum-freezing drying machine, wherein the freezing temperature is minus 35 DEG C, and the vacuum degree is 0.05 MPa.

Owner:QINGDAO BAOQUAN PEANUTS PRODS

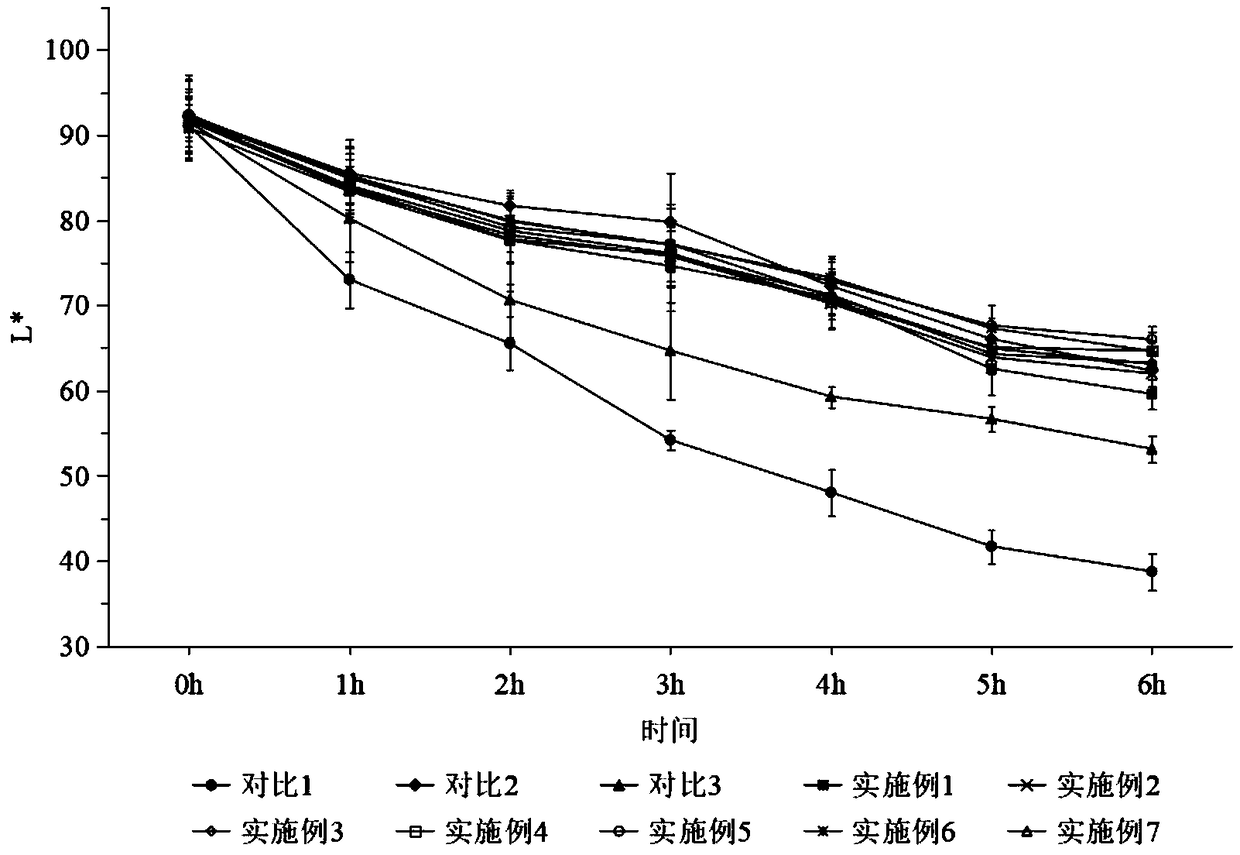

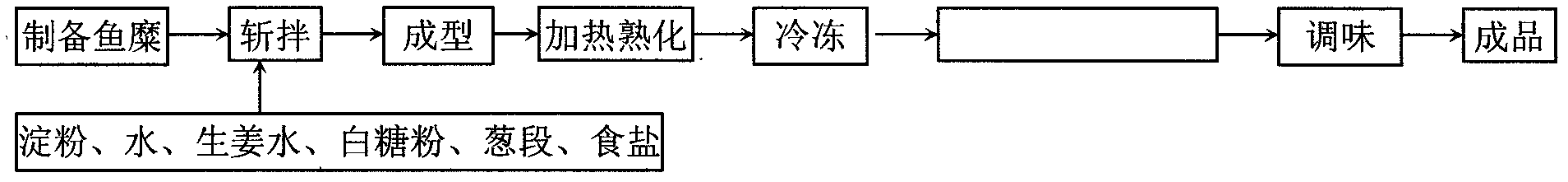

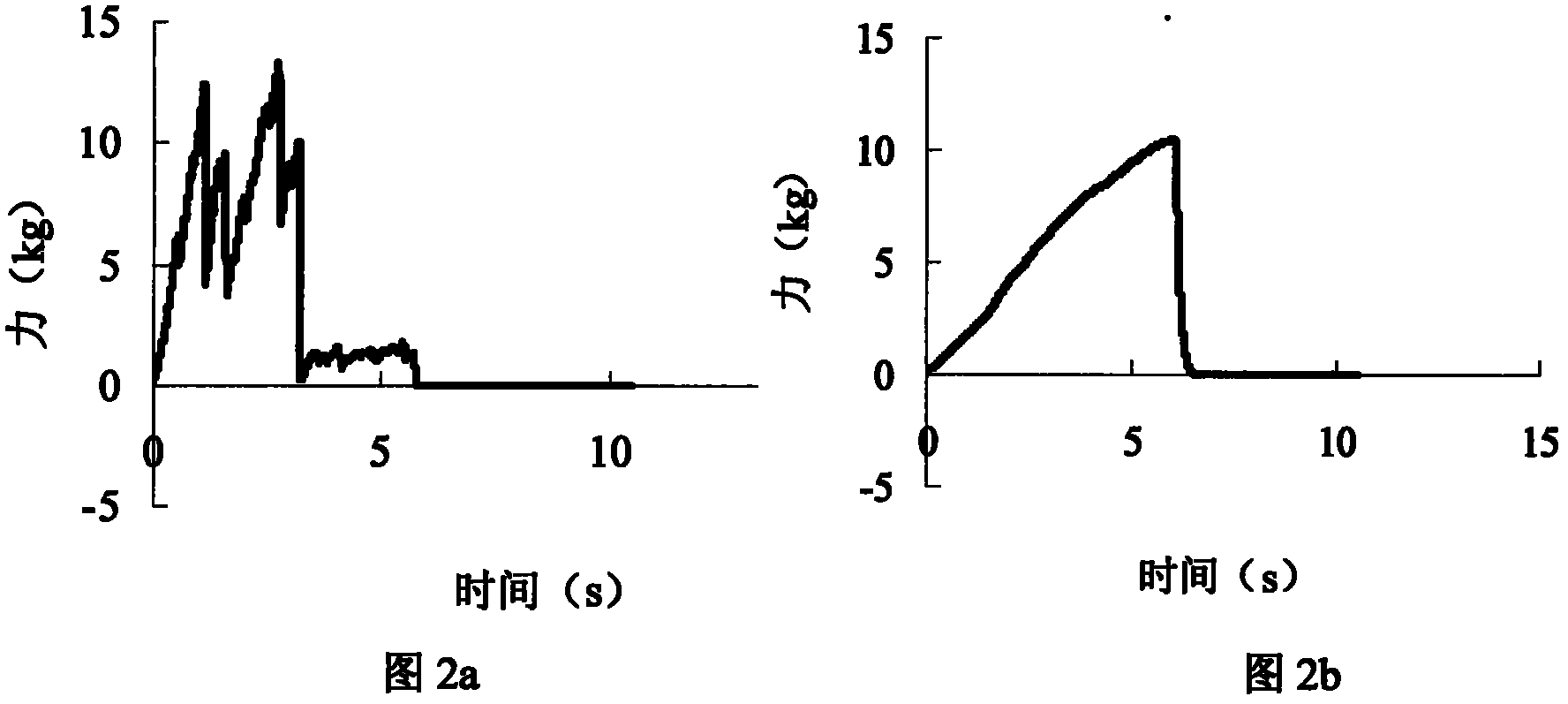

Low-oil content crispy surimi-based product and production method thereof

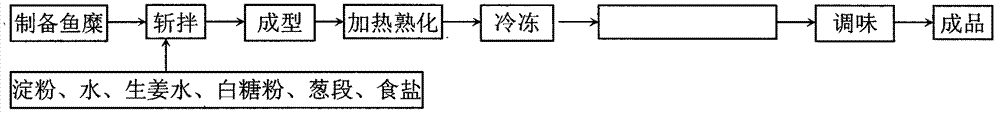

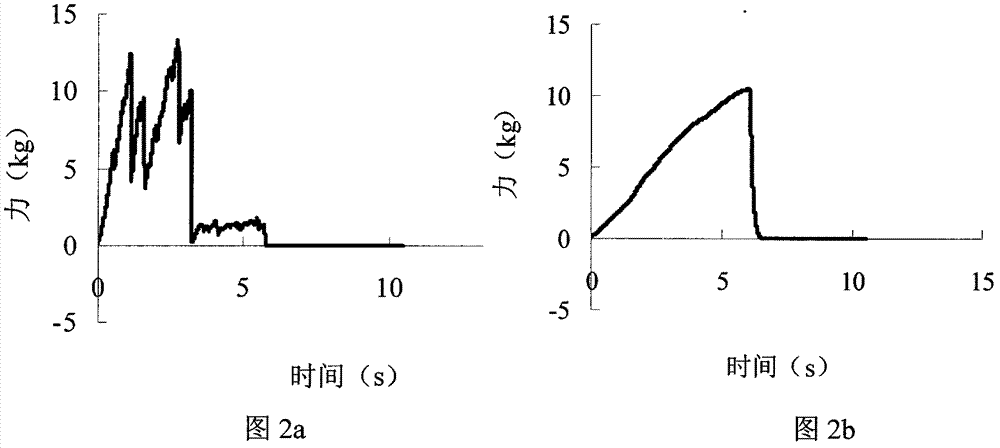

The invention belongs to the technical field of food processing, and particularly relates to a low-oil content crispy surimi-based product and a production method thereof. The finished product with an oil content of less than 13% is prepared through the following steps of: adopting fresh surimi or frozen surimi as the main raw material; chopping for 1-2 minutes; adding starch and water and continuously chopping for 1-2 minutes, then adding gingerade, powdered sugar, gourmet powder and onion sections and chopping for 1-2 minutes, and finally adding salt and chopping for 3-5 minutes; shaping, heating for curing and freezing; and then vacuum frying, deoiling and seasoning the product after freezing. Through the invention, the problems of single variety, poor convenience and edibility and the like of deeply-processed aquatic products in the prior art are solved, and a vacuum frying technology is applied to the development of low-oil content crispy surimi-based products. The crispy surimi-based product obtained by the invention is crispy in taste, nutritional, healthy, convenient to eat and easy to store and is suitable for industrial production.

Owner:HUAZHONG AGRI UNIV

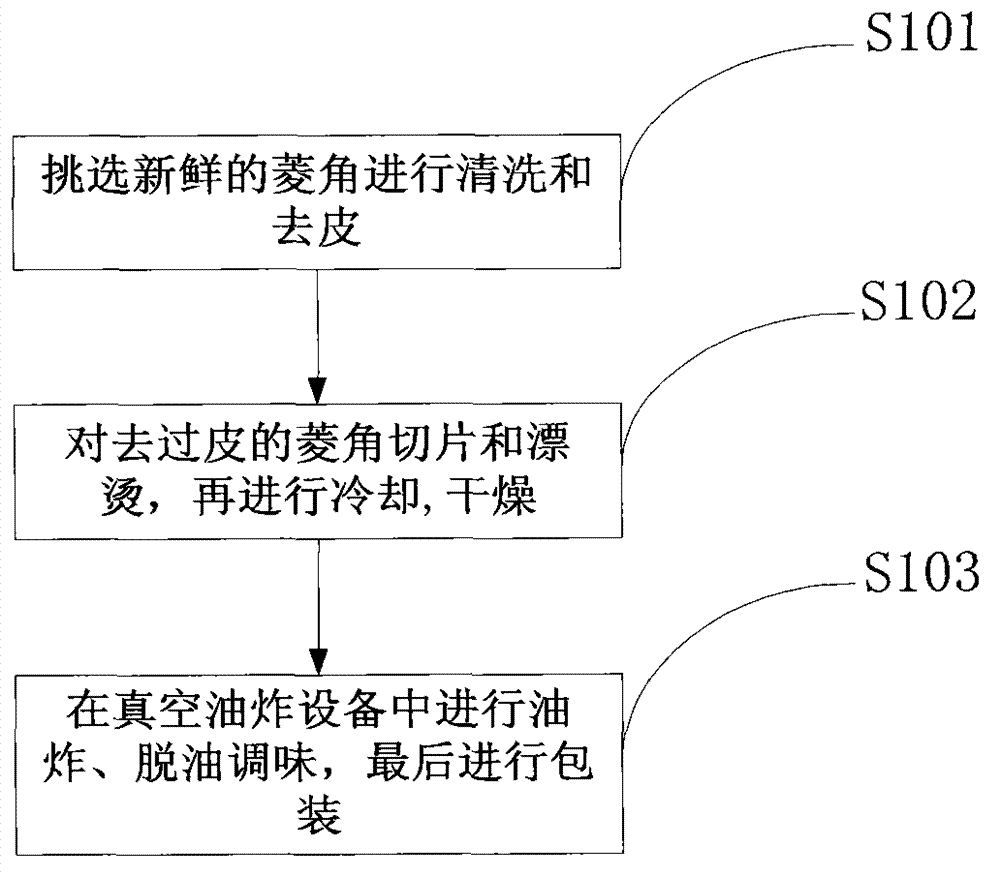

Vacuum-frying preparation technology of water chestnut crisp chips

The invention discloses a vacuum-frying preparation technology of water chestnut crisp chips. The preparation technology comprises the steps of selecting fresh water chestnut, washing and peeling; slicing, blanching and cooling the peeled water chestnut; and seasoning in a frying and deoiling way in vacuum frying equipment, and packing. The vacuum-frying preparation technology uses the vacuum frying characteristic that the drying speed is high, the frying temperature is low, the contact between the material and the oxygen gas is less, and the original aroma and nutritional ingredient of the water chestnut can be furthest kept, so that the preparation technology of the water chestnut crisp chips can be optimized, a leisure and healthcare water chestnut food which is low in fat, low in heat, crispy, tasty, unique in flavor and long in storage period can be prepared, the deep processing technological level of the water chestnut can be improved, and the problem that the original aroma and nutritional ingredient of the water chestnut are influenced since the existing preparation technology of water chestnut crisp chips is low in drying speed can be preferably solved. Furthermore, the preparation technology is simple to operate, the original aroma and nutritional ingredient of the water chestnut can be preferably kept, and the water chestnut crisp chips are very good in application value.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

Fried minced fillet product and preparation method thereof

InactiveCN104489765AEnhance layeringIncrease selenium contentSugar food ingredientsFood preparationIce waterSugar

The invention discloses a fried minced fillet product. The fried minced fillet product is characterized by comprising the following components: frozen minced fillet, silver carp meat, rice, ice water, cornstarch, salad oil, fresh egg white and seasonings. The invention further discloses a preparation method of the fried minced fillet product. The fresh silver carp meat is added, thus the layering sense of the product is improved, the fish smell is stronger, and the meat quality is more tender; after adding the selenium-enriched rice, on one hand, the selenium content in the product is increased, and the product is more nutrient; on the other hand, the cereals and the minced fillet are reasonably matched, and dietary nutrition is balanced; the used fat is soybean oil, and the unsaturated fatty acid content is increased compared with the way of adding fats in the traditional minced fillet product; low-temperature drying frying is adopted, white granulated sugar is replaced by glucose and xylose, and the frying time is shortened and the frying temperature is lowered under the condition of high vacuum degree, thus the product is easier to colour.

Owner:SHANDONG HELI AGRI DEV

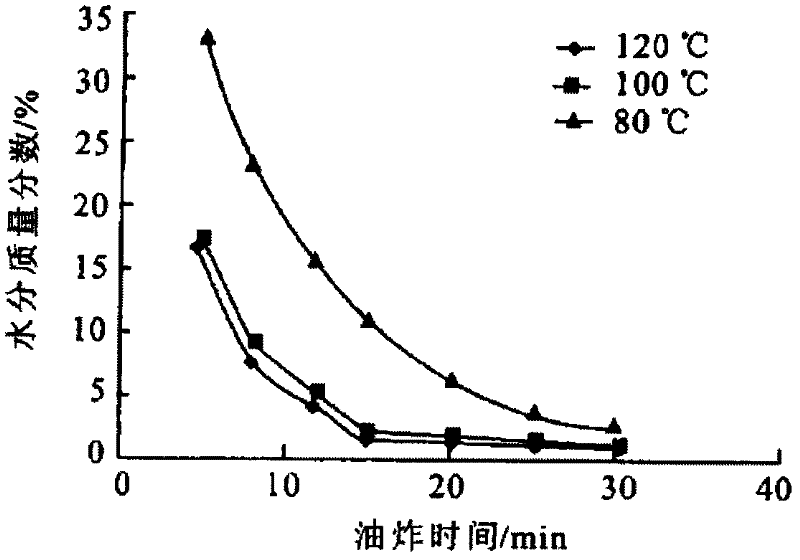

Snack dried bean curd and method for continuously frying same at low temperature

InactiveCN102370010ALow frying temperatureReduce oxygen concentrationCheese manufactureFood scienceWater contentChemistry

The invention discloses snack dried bean curd and a method for continuously frying the same at a low temperature. The water content of the dried bean curd is 40-50% of bean curd. The method comprises the following frying steps of: cutting the bean curd and frying the cut bean curd at a vacuum pressure of 0.06-0.095 MPa and a temperature of 80-120 DEG C for 5-30 min. With the adoption of the method provided by the invention, the snack dried bean can be continuously operated in a frying process so that the frying temperature is greatly reduced; furthermore, the oxygen concentration in a deep fryer is greatly reduced, therefore, the fried food is difficult to fade, change color and be brown, the deterioration degree of oil is greatly reduced, the quality is improved and the technology is simplified. Moreover, in the method provided by the invention, frying is carried out under a vacuum and low-temperature condition; the frying process is completed at a low boiling point; the oil temperature is less than or equal to 90 DEG C so that nutrition constituents of the dried bean curd are not broken; meanwhile, the frying process can be continuously operated and the technology is simplified.However, as the snack dried bean curd is easy to fold in a sheet shape, a part of the snack dried bean curd is not fully fried.

Owner:ZHEJIANG LAOBA FOODSTUFF

Preparation method of breaded shrimps

The invention provides a preparation method of breaded shrimps. The preparation method comprises the following steps: uniformly wrapping the surfaces of shrimp meat with a layer of wrapping paste and treating the shrimp meat wrapped with breadcrumbs by adopting a low-temperature and low-pressure frying technology; preparing the wrapping paste: adding 1.2 weight times of water into the wrapping paste powder, wherein the temperature of the water is 3 to 5 DEG C, uniformly stirring to obtain dilute wrapping paste, wherein the wrapping paste powder is prepared from the following main raw materials in parts by weight: 20 to 30 parts of cassava starch, 20 to 30 parts of gluten powder, 2 to 4 parts of edible salt, 5 to 10 parts of spice, 1 to 5 parts of white granulated sugar, 2 to 6 parts of acetylated distarch phosphate, and 1 to 5 parts of a leavening agent; the low-temperature and low-pressure frying technology is that the pressure is 2 to 5 kPa, the temperature is 60 to 80 DEG C and the frying time is 2.5 to 3 minutes. According to the preparation method provided by the invention, the oil absorption amount of the fried breaded shrimps can be reduced, the quality of a product is improved, and the shelf life of the product is prolonged.

Owner:福清朝辉水产食品有限公司

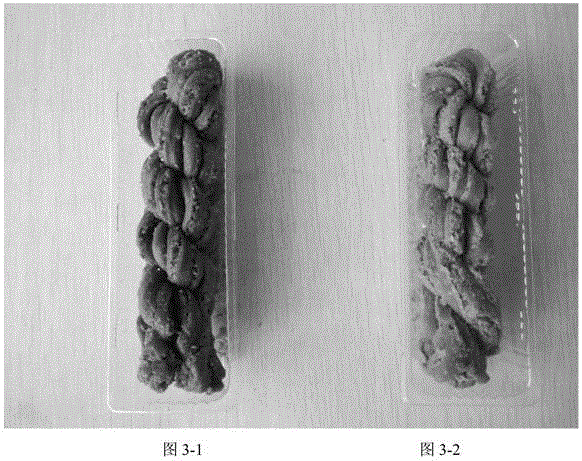

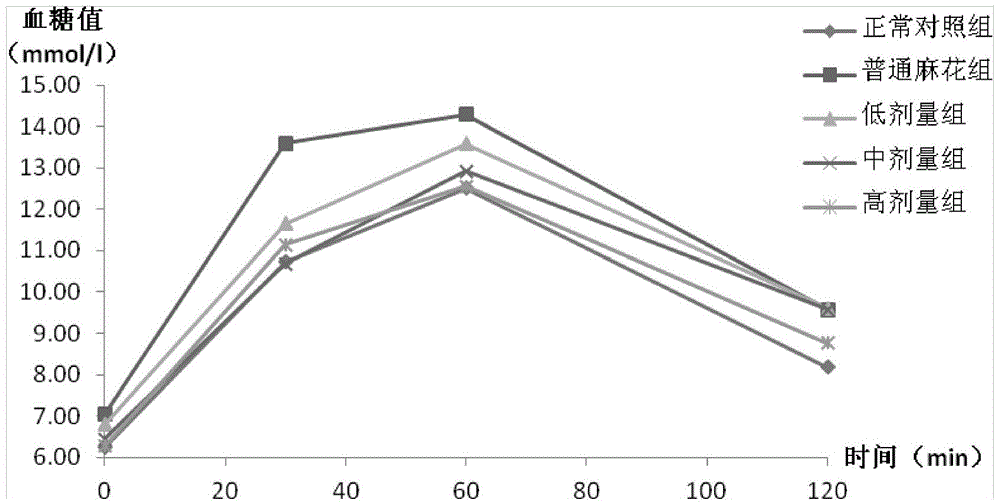

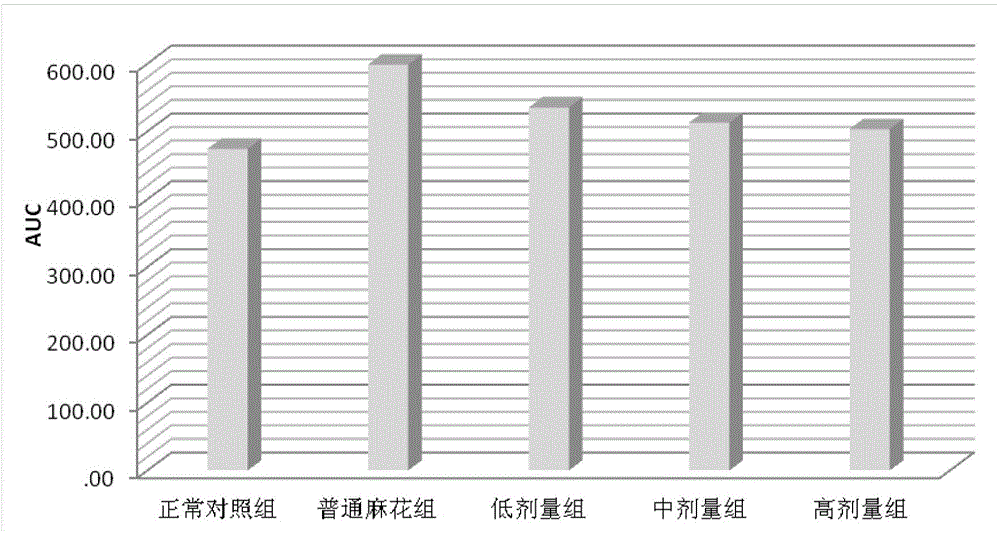

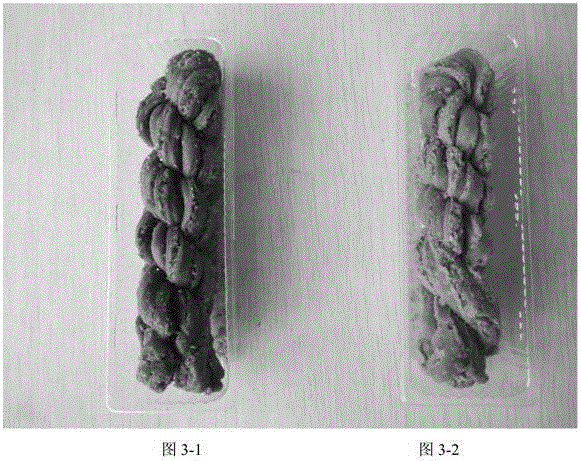

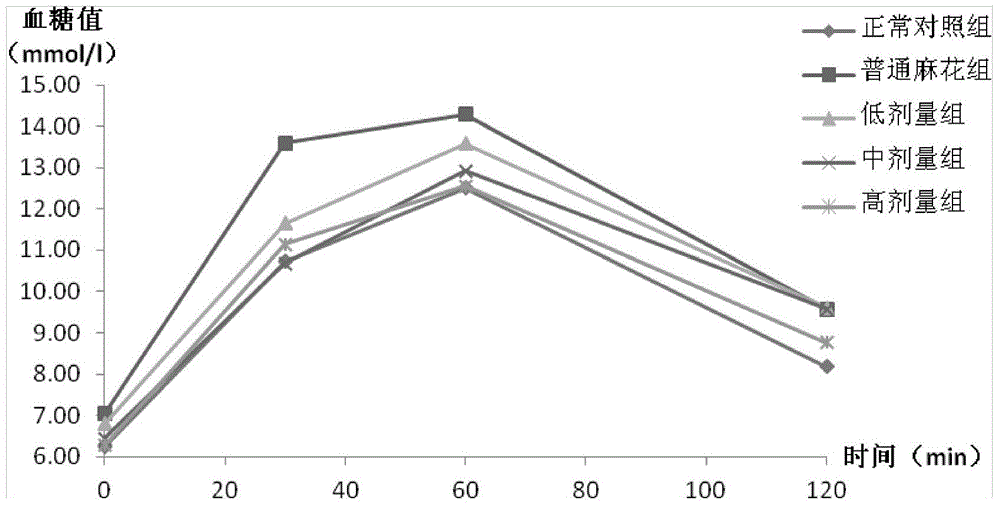

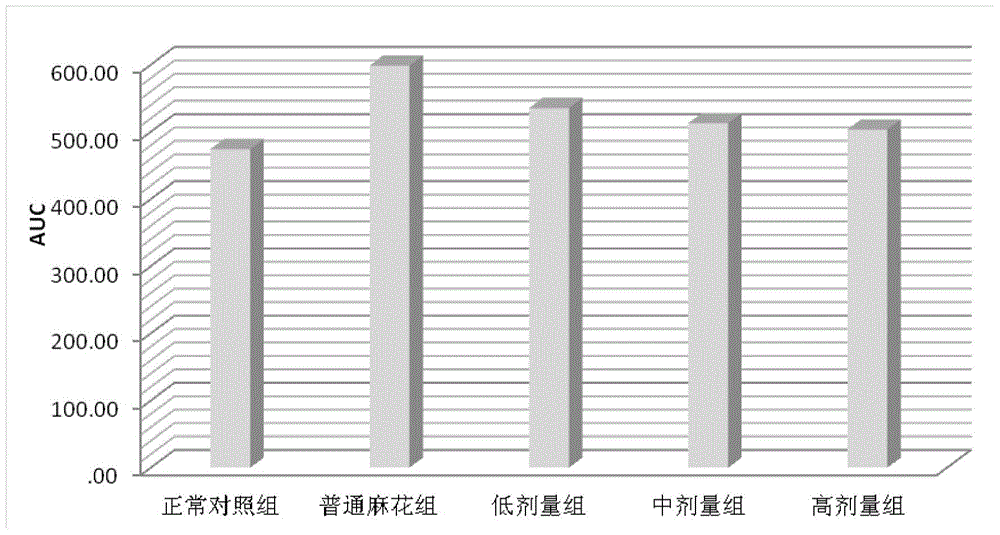

Stuffed fried dough twist being capable of lowering fasting blood-glucose and increasing glucose tolerance and having glycose metabolism regulating function as well as production method thereof

ActiveCN104664383AReduce contentImprove glucose toleranceDough treatmentDeep-fried productsMaillard reactionHealthy diet

The invention relates to a stuffed fried dough twist being capable of lowering fasting blood-glucose and increasing glucose tolerance and having a glycose metabolism regulating function as well as a production method thereof. The fried dough twist comprises a wrapper and stuffing in the mass ratio of 9:(1-8). According to the fried dough twist, wheat flour is partially replaced by wheat fibers, the content of protein in ingredients is decreased, the content of amino acid is further decreased, the Maillard reaction during production is weakened, and the fried dough twist is light in color and attractive in appearance and can promote the appetite of people; compared with common fried dough twists, the fried dough twist can lower the fasting blood-glucose and increase the glucose tolerance, the formula and the production method of the fried dough twist are proper, and effective components are well protected; compared with the common fried dough twists, the fried dough twist can lower the fasting blood-glucose and increase the glucose tolerance and is more suitable for diabetes and health-conscious people, the fried dough twist is suitable for more people, the market blank is filled up, and the relation between healthy diets and high-sucrose food is promoted to a new level.

Owner:天津桂发祥十八街麻花食品股份有限公司

Processing method of instant shrimps

The invention provides a processing method of instant shrimps. The method comprises the following steps of (1) preparing of raw materials; (2) cleaning; (3) precooking, namely putting the cleaned shrimps into boiling water for boiling for 2-8min, quickly fishing up the shrimps and putting the shrimps into the water prepared in advance for rinsing; (4) draining, namely draining off the rinsed shrimps until the dripping water is disconnected; (5) freezing, namely putting the drained shrimps into an instant freezer which is frozen to -10 DEG C to -40 DEG C and quickly freezing the shrimps for 2-8min; (6) vacuum frying, namely putting the frozen shrimps into vacuum frying equipment for frying under the conditions that the oil temperature is 75-95 DEG C and the pressure is 0.001-0.08MPa for 15-45min; (7) deoiling; and (8) seasoning and packaging. Compared with the prior art, the method has the advantages that the whole shrimps with shells and heads can be eaten, and are loose in taste and thick in flavor, relatively long in shelf life after being packaged, and can be marketed as snack products; meanwhile, husking is not needed in the preparation process and preparation is simple and convenient; different flavors can be made according to the requirements through seasoning after frying; and the production convenience is relatively good.

Owner:郭斯统

Processing method for vacuum packaging of freshwater fish heads

The invention relates to aquatic product processing technology, and aims to provide a processing method for vacuum packaging of freshwater fish heads. The method sequentially comprises the following processing steps of: cutting the fish heads; salting; cleaning; bisecting; wrapping powder; frying in vacuum; bagging and adding seasoning solution; sealing bags; and sterilizing to obtain the vacuum-packaged fish head finished products. The vacuum-packaged freshwater fish head products have the quality guarantee period of over 6 months and can be eaten after the bags are opened, and the method has the advantages of improving the comprehensive utilization level for processing freshwater fish and having obvious economic benefit.

Owner:ZHEJIANG UNIV

Food deep-frying method

InactiveCN104957446AAvoid damageReduce generationFood preparationDeep fat fryersDeep fryingResidual oil

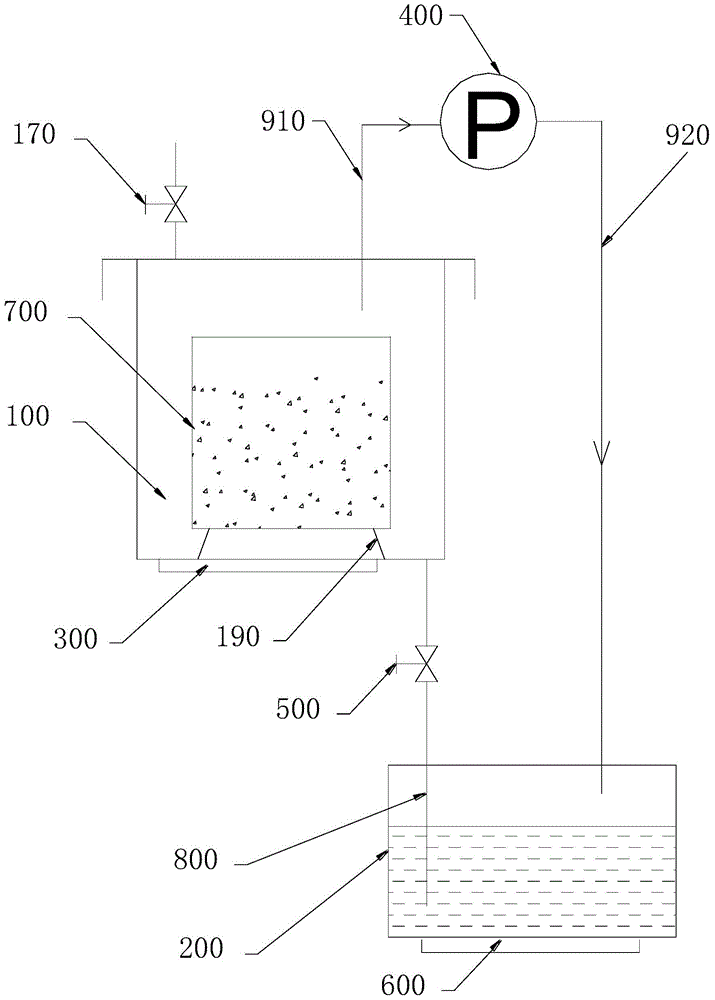

The invention relates to a food deep-frying method. The method comprises the steps: placing food into a first container, then pumping the air in the first container into a second container, and enabling negative pressure to be formed in the first container in the air pumping process; then sucking and conveying oil of the second container into the first container by utilizing the negative pressure, and immersing the food by oil; then heating the first container, continuously exhausting, deep-frying the food at low temperature in a negative-pressure environment, pumping the residual oil, so that the final deep-fried food is low in oil content and very healthy; separating the oil from food in the first container, conveying the oil into the second container, and obtaining low-oil deep-fried food after the oil is separated. The oil conveyed into the second container can be used for the next deep-frying, the oil can be repeatedly circulated between the first container and the second container and can be repeatedly used, the negative-pressure low-temperature deep frying of food in multiple steps can be realized, and the deep-fried food produced in the method is healthy, delicious, energy-saving, oil-saving, time-saving and high in automation degree.

Owner:遂宁市安克拉食品有限公司

Preparation method of vacuum low temperature oil-fried crisp houttuynia cordata

InactiveCN106722457AExtended shelf lifeIncrease economic value addedFood ingredient functionsFood industryFood processing

The present invention provides a preparation method of vacuum low temperature oil-fried crisp houttuynia cordata. Fresh houttuynia cordata is used as a raw material, the houttuynia cordata is firstly washed clean, the washed houttuynia cordata is cut into segments, the cut houttuynia cordata is subjected to a color protection, the color protected houttuynia cordata is blanched, the blanched houttuynia cordata is vacuum soaked, the vacuum soaked houttuynia cordata is quick-frozen, and then the crisp houttuynia cordata is prepared by the vacuum low temperature oil-frying technology. The preparation method solves the problems that the houttuynia cordata is relatively single in processing methods, cannot be processed, produced and sold in large scales, and relatively large in loss of nutrition after the processing, which is not conducive to the development of the houttuynia cordata food industry. The preparation method of the vacuum low temperature oil-fried crisp houttuynia cordata belongs to the field of food processing.

Owner:贵州省马铃薯研究所 +1

Method for preparing diced chicken with composite taste through high-pressure permeation combined low-temperature aroma fixation

InactiveCN110897098AMeeting urgent needsReduce processing timeMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsBiotechnologyPotato starch

The invention discloses a method for preparing diced chicken with composite taste through high-pressure permeation combined low-temperature aroma fixation. The method comprises the following steps: (1) mixing diced chicken, water, sweet potato starch, corn starch, papain, ginger protease, kiwi fruit protease and a pickling material, tenderizing at 8.5-12.5 DEG C, and pickling to be tasty; (2) performing vacuum tumbling on the tenderized and pickled diced chicken; (3) carrying out vacuum packaging, and carrying out high-pressure permeation flavoring and pre-cooking treatment; (4) performing vacuum multi-stage deep-frying, wherein the vacuum degree of the whole vacuum multi-stage deep-frying process is -0.088 MPa to -0.096 MPa; (5) carrying out multi-stage low-temperature treatment to lock and fix fragrance; (6) performing vacuum packaging on the diced chicken meat subjected to fragrance locking and fragrance fixing; and (7) carrying out liquid nitrogen quick-freezing on the diced chicken packaged in vacuum to obtain the diced chicken with the composite taste. According to the method, industrial production of diced chicken is achieved through the technological process, the efficiencyis high, and the taste and mouthfeel of the diced chicken are guaranteed through various technologies.

Owner:XIHUA UNIV

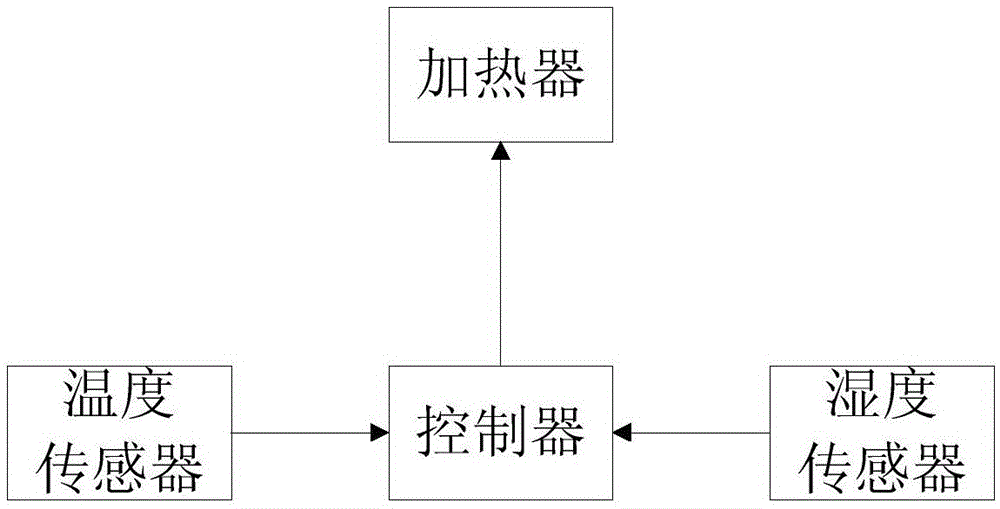

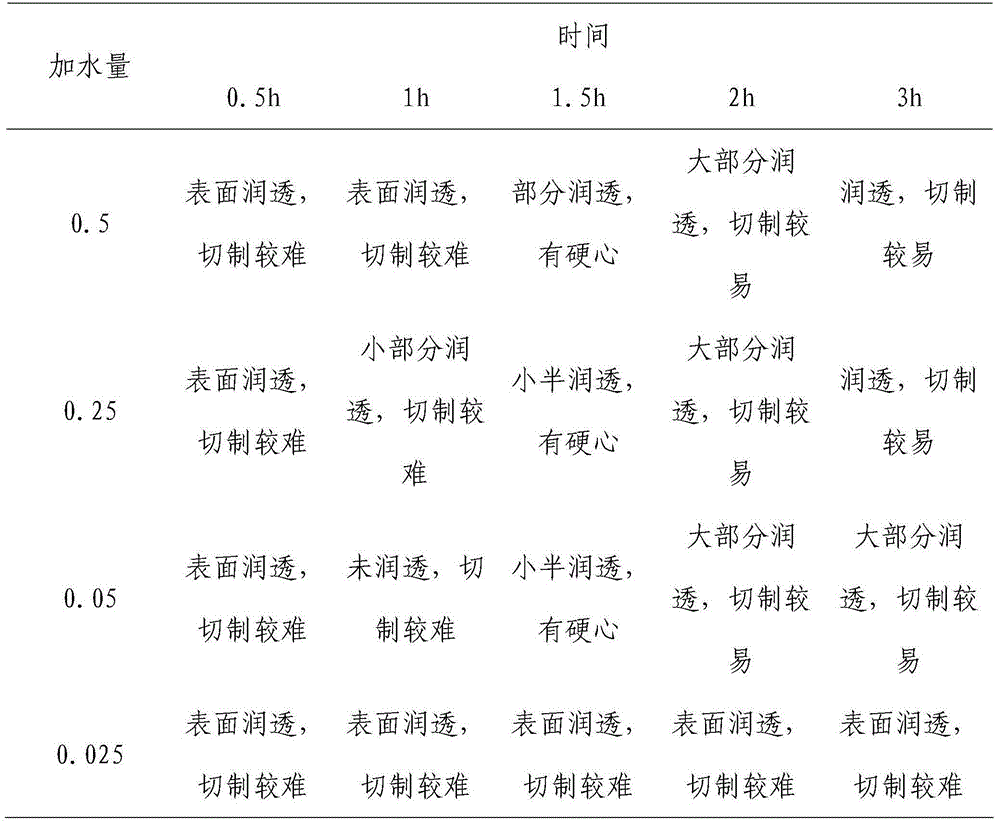

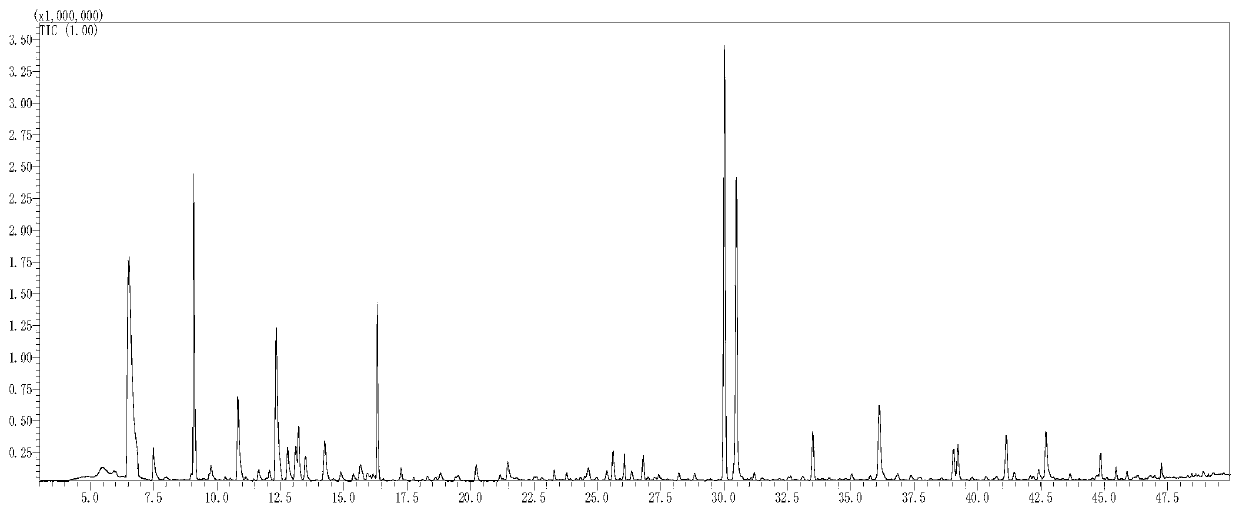

Processing method of rice wine radix salviae miltiorrhizae slices

ActiveCN105030895AIncrease contentImprove product qualityNervous disorderAntipyreticSalvianolic acid BMedicine

The invention discloses a processing method of rice wine radix salviae miltiorrhizae slices. The processing method comprises following steps: 1) radix salviae miltiorrhizae is subjected to impurity removing, residue stem removing, and washing; 2) water is added for 2 to 3h of immersing, wherein the mass amount of water accounts for 0.05 to 0.25 time of that of radix salviae miltiorrhizae; 3) after immersing, radix salviae miltiorrhizae is cut into slices with a thickness of 2 to 4mm, and radix salviae miltiorrhizae slices are obtained via drying; 4) the radix salviae miltiorrhizae slices are added into a rice wine aqueous solution, an obtained mixture is stirred to be uniform, and is subjected to simmering for 2 to 3h, wherein the mass amount of rice wine accounts for 8 to 12% of that of radix salviae miltiorrhizae, and mass concentration of the rice wine aqueous solution is controlled to be 8 to 15%; 5) after simmering, the processed radix salviae miltiorrhizae slices are delivered into a stir-frying container, are subjected to stir-frying for 6 to 9min at 120 to 150 DEG C, are collected, and are cooled so as to obtain finished products. According to the processing method, quality of the obtained products is stabilized via accurate control on temperature, time, and the amount of rice wine; and operability is high. The processing method is low in stir-frying temperature, and short in stir-frying time. Appropriate thickness is obtained via thickness screening of the radix salviae miltiorrhizae slices, so that salvianolic acid B content of the finished products is high, and the highest value of salvianolic acid B content can be 18.92mg / g.

Owner:天圣制药集团重庆药物研究院有限公司

Method for making purple yam chips through microwave vacuum low-temperature oil bath dehydration technology

The invention discloses a method for making purple yam chips through a microwave vacuum low-temperature oil bath dehydration technology (VODT). The method includes the steps that fresh purple yam is cleaned, peeled and cut into chips, the chips are blanched for 30-120 s in water at the temperature of 95 DEG C-100 DEG C, spray cooling is carried out, and the chips are contained on a plate and frozen quickly for 24 h at the temperature of minus 35 DEG C; the thoroughly frozen purple yam chips are contained in a polytetrafluoroethylene material frame, the material frame is moved into a microwave vacuum low-temperature oil bath dehydration integrated machine, vacuumizing is carried out until the pressure is 0.095-0.098 Mpa, microwave heating is started until oil temperature rises to 80-105 DEG C, the material frame is soaked in hot oil to be heated, and water contained in the purple yam chips is greatly sublimated and evaporated for 20-25 min; after oil boiling becomes weaker, oil temperature rises again, the vacuum degree is stabilized at 0.095-0.097 Mpa, the hot oil in a kettle is pumped by an oil pump to a storage tank for use, and the material frame is centrifuged at the speed of 100-300 rpm for 2-5 min to remove oil on the surfaces of the purple yam chips; after centrifugation is stopped, the purple yam chips are taken out, seasoning is mixed while the purple yam chips are hot to obtain needed flavor through blending, and finished products are obtained after cooling and packaging. The produced purple yam chips can keep the color, the fragrance and nutrient ingredients of purple yam well, is fragrant, crispy, tasty and good in mouthfeel, and is leisure food having good market prospects.

Owner:NANJING INST FOR THE COMPREHENSIVE UTILIZATION OF WILD PLANTS CHINA COOP

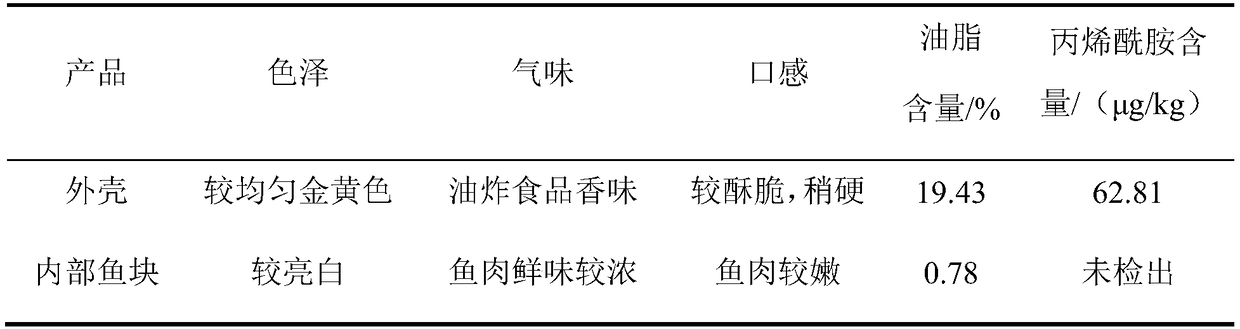

Low-acrylamide deep-fried fish fillet wrapped with paste and processing method thereof

PendingCN108703296AReduce acrylamide contentReduce moisture contentFood ingredientsFlavorDeep frying

The invention discloses a low-acrylamide deep-fried fish fillet wrapped with paste and a processing method thereof. The processing method comprises the steps of fishy smell elimination, curing, preparation of wrapping paste, paste wrapping, drying and deep-frying. The content of acrylamide in the deep-fried wrapping paste fish fillet is obviously lowered and decreased to 40.99 microgram / kilogram from 89.67 microgram / kilogram; the content of oils and fats in the deep-fried fish fillet wrapped with paste is obviously lowered and decreased to 16.61% from 28.05%; the deep-fried fish fillet wrappedwith paste has the specific flavor of deep-fried food and is golden yellow in color and crispy on the outside and soft on the inside in taste. Meanwhile, the production technology is easy and efficient.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Deep-fried fish tofu and preparation method thereof

The invention discloses deep-fried fish tofu and a preparation method thereof. The deep-fried fish tofu is prepared from the following raw materials in part by weight: 10-20 parts of fish meat, 50-60 parts of water, 10-20 parts of soy isolate protein, 10-20 parts of salad oil, 1-5 parts of salt, 2-5 parts of sugar, 5-8 parts of seasoning and 5-8 parts of flavoring oil; the deep-fried fish tofu has the beneficial effects that the color and the luster of the skin of tofu is golden yellow, the tofu contains a great amount of water, and the deep-fried fish tofu has tendered and crispy mouthfeel; the fish meat is matched with the soy isolate protein, the nutrition of the soybeans is kept, and inorganic salt, vitamin A, vitamin D, vitamin B1, vitamin B2, vitamin B12, magnesium element, folic acid and other low-fat mineral substances are added, so that the deep-fried fish tofu has rich nutrition; salad oil at 130 DEG C is adopted for frying, the frying temperature is low, and the nutritional ingredients such as protein can be fully kept; and compared with the other salad oils, the adopted salad oil does not contain cancerogenic substances (aflatoxin and cholesterol), thereby facilitating the human health.

Owner:SHANDONG HUIFA FOODS

The processing method of wine Danshen slices

ActiveCN105030895BEffective controlIncrease contentNervous disorderAntipyreticSalvianolic acid BMedicine

Owner:天圣制药集团重庆药物研究院有限公司

Stuffed twisted twist that can reduce fasting blood sugar, improve glucose tolerance, and regulate glucose metabolism, and preparation method thereof

ActiveCN104664383BReduce contentImprove protectionDough treatmentDeep-fried productsHealthy dietMaillard reaction

The invention relates to a stuffed fried dough twist being capable of lowering fasting blood-glucose and increasing glucose tolerance and having a glycose metabolism regulating function as well as a production method thereof. The fried dough twist comprises a wrapper and stuffing in the mass ratio of 9:(1-8). According to the fried dough twist, wheat flour is partially replaced by wheat fibers, the content of protein in ingredients is decreased, the content of amino acid is further decreased, the Maillard reaction during production is weakened, and the fried dough twist is light in color and attractive in appearance and can promote the appetite of people; compared with common fried dough twists, the fried dough twist can lower the fasting blood-glucose and increase the glucose tolerance, the formula and the production method of the fried dough twist are proper, and effective components are well protected; compared with the common fried dough twists, the fried dough twist can lower the fasting blood-glucose and increase the glucose tolerance and is more suitable for diabetes and health-conscious people, the fried dough twist is suitable for more people, the market blank is filled up, and the relation between healthy diets and high-sucrose food is promoted to a new level.

Owner:天津桂发祥十八街麻花食品股份有限公司

Fragrant and crisp Chinese yam slice and processing method thereof

InactiveCN108813471ASilky meatReduce pile upFood coatingFood ingredient for microbe protectionBiologyRhizome

The present invention discloses a fragrant and crisp Chinese yam slice and a processing method thereof, and relates to the field of food processing. The fragrant and crisp Chinese yam slice comprisesChinese yams, fingerleaf rodgersflower rhizome and citric acid. A layer of fingerleaf rodgersflower rhizome micro-powder is evenly spread on the surfaces of the Chinese yam slice to prevent the browning of the Chinese yam slice. Secondly, the Chinese yams and fingerleaf rodgersflower rhizome are combined; and the fragrant and crisp Chinese yam slice removes greasiness, relieves toxins by frying and roasting, improves digestion, and reduces or even eliminates dyspepsia symptoms possibly happening after eating the oil-fried Chinese yam slice.

Owner:襄阳农博源农业有限公司

Pine nut jujube paste sesame cake and preparation method thereof

InactiveCN105981793APrevent oxidative rancidityGreat tasteDough treatmentBakery productsAlkaline waterSesamum

The invention discloses a pine nut jujube paste sesame cake and a preparation method thereof. The pine nut jujube paste sesame cake is prepared from the following raw materials in parts by weight: 100-110 parts of baked flour, 30-40 parts of white granulated sugar, 10-15 parts of pine nuts, 20-25 parts of jujube paste, 2-3 parts of edible salt, 100-110 parts of high-gluten flour, 35-40 parts of mooncake syrup, 15-20 parts of soybean oil, 5-6 parts of alkaline water, 0.5-1 part of potassium sorbate and proper amount of sesame. The pine nut jujube paste sesame cake is simple in preparation method, and the pine nuts and jujube paste are added during preparation, so that the pine nut jujube paste sesame cake has good body benefiting effect, is improved in taste and is nutritional and healthy green food.

Owner:望江县皖江食品有限公司

Method for producing fried peanut kernels with low peroxide number

The invention discloses a method for producing friend peanut kernels with low peroxide number for fried peanuts with strong oxidation resistance and long quality guarantee period. The method comprises the following steps of: (1). selecting peanut kernels; (2). charging nitrogen: continuously supplementing nitrogen for a frying pan through a nitrogen making machine, wherein the nitrogen charging time is 20-25 minutes, and the nitrogen charging purity is 98.5-99.5%; (3). frying with mixed water and oil, wherein the temperature of oil at the upper layer is within 130-200 DEG C, the temperature of oil at the lower layer is within 55-130 DEG C, and the temperature of the oil water demarcation face is controlled to be below 55 DEG C; (4) processing the fried peanut kernels; (5). coating a film: a film solution is prepared by a pea starch solution with the concentration of 5%, during preparation, the film solution needs to be gelatinized in a boiling water bath for 20 minutes, the temperature of the film solution is maintained to be within 30-40 DEG C, and then the film solution is coated on the surfaces of the fried peanut kernels; and (6). drying the fried peanut kernels subjected to film coating in a vacuum-freezing drying machine, wherein the freezing temperature is minus 35 DEG C, and the vacuum degree is 0.05 MPa.

Owner:QINGDAO BAOQUAN PEANUTS PRODS

Method for conveniently, industrially and continuously producing crispy meat

PendingCN111134284ASolve the difficulty of satisfying people'sSolve its tasteFood ingredient as taste affecting agentFood ingredient as flavour affecting agentNutritionEconomic benefits

The invention belongs to the technical field of preparation of quick-frozen pre-conditioned meat products, and specifically relates to a method for conveniently, industrially and continuously producing crispy meat. The method takes lean pork, starch and whole egg liquid as main raw materials, and obtains crispy meat after ingredients are added. The industrial preparation method includes as follows: raw meat selection-low sodium salt thawing and trimming-preprocessing (ultrasonic tenderization+rolling and rubbing+curing)-precuring-strip cutting-pasting-vacuum frying-quick-freezing-packaging. Through the adopting of scientific and reasonable process technologies, the technologies of traditional crispy meat making can be combined with modern food processing technologies, so that industrialization and standardized production of traditional crispy meat can be realized, the consistency of products and specifications can be guaranteed, and safe, healthy and reliable quality can be achieved; the problems, that requirements of people for the taste, nutrition, health and safety of existing crispy meat are hard to meet, can be solved; and through modern food fresh-keeping and packaging technologies, preservation periods can be prolonged, and the economic benefits of enterprises can be enhanced.

Owner:SICHUAN ACAD OF FOOD & FERMENTATION INDS

Processing method of ready-to-eat stropharia rugosoannulata chips

The invention discloses a processing method of ready-to-eat stropharia rugosoannulata chips. The processing method comprises the following steps of step I, preparing raw materials; step II, performingprecooking and fixation; step III, performing centrifugation draining; step IV, performing vacuum impregnation; step V, performing low-temperature quick freezing; step VI, performing vacuum deep frying; step VII, performing vacuum oil removing; step VIII, performing cooling and seasoning; and step IX, performing inspection and package. The processing method is low in deep-frying temperature, lowin nutrient loss, and short in dehydrating time, original color and original properties of food materials can be maintained to the maximum extent, self fragrance and flavor of the food materials can be reserved, the ready-to-eat stropharia rugosoannulata chips have certain puffing effects, are low in oil consumption, and are not liable to oxidate, besides, the problems that stropharia rugosoannulata inferior goods are backward in processing manner and low in added value, are solved, besides, the defects that foods made by a conventional deep-frying method are poor in taste, are high in oil content, high in loss of nutrient substances and the like, are overcome, shape, color, flavor and nutrient value of the stropharia rugosoannulata are reserved, and the added value of products is increased.

Owner:山东三生万物生物科技有限公司

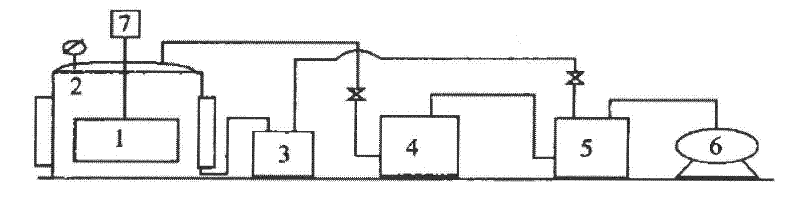

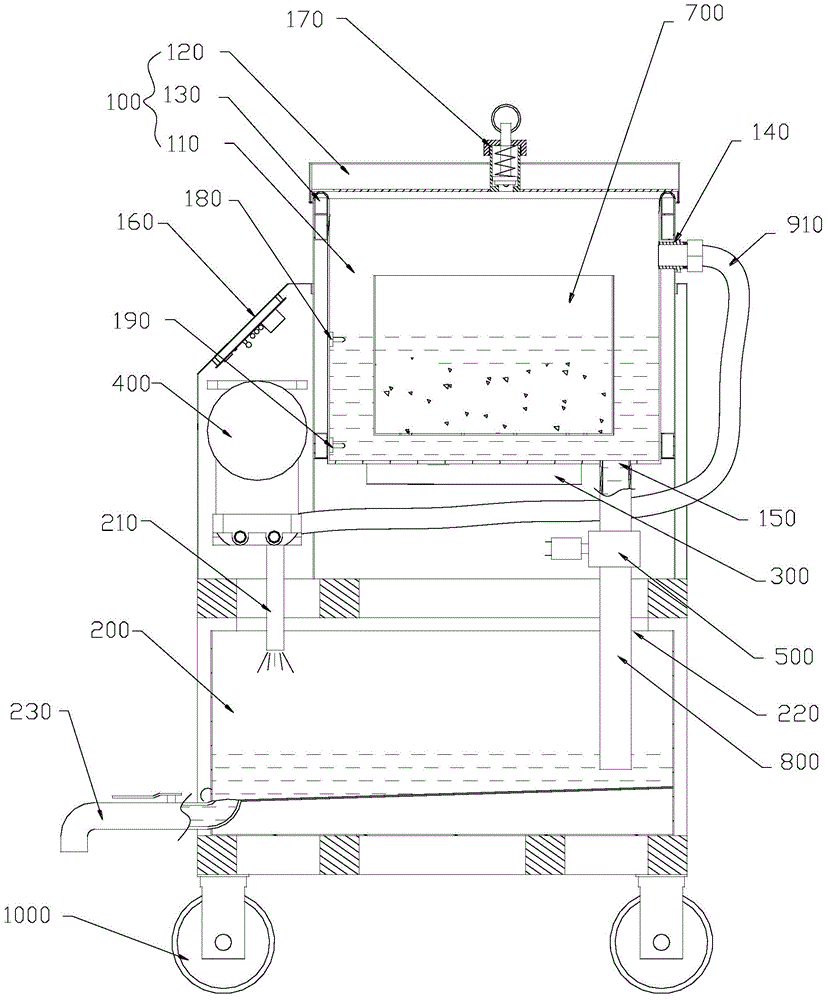

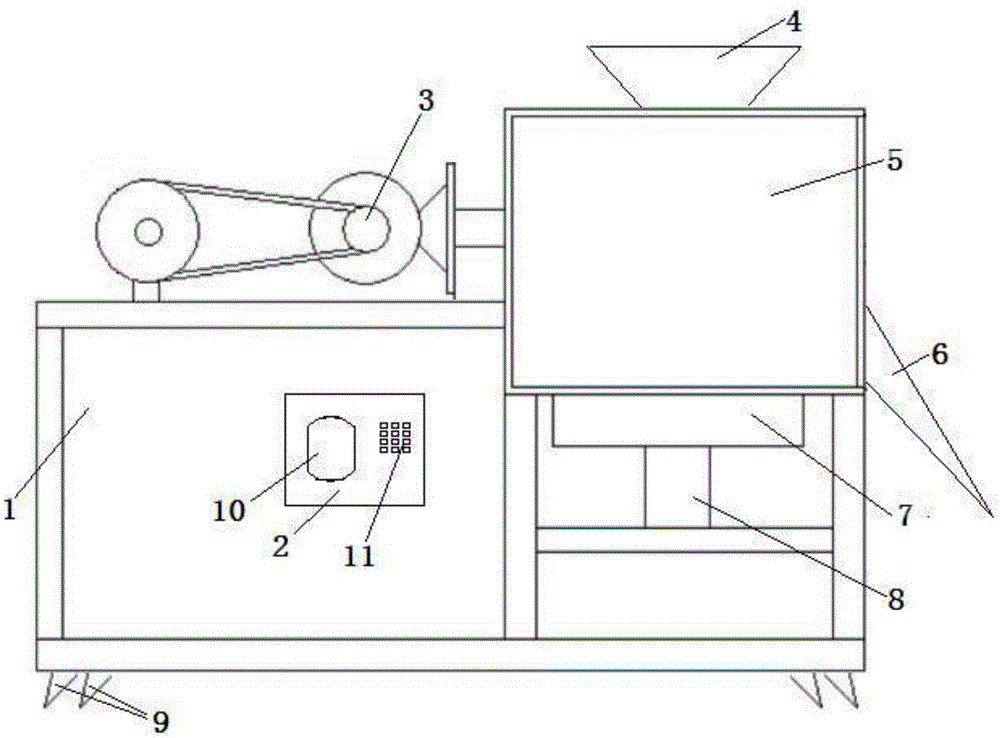

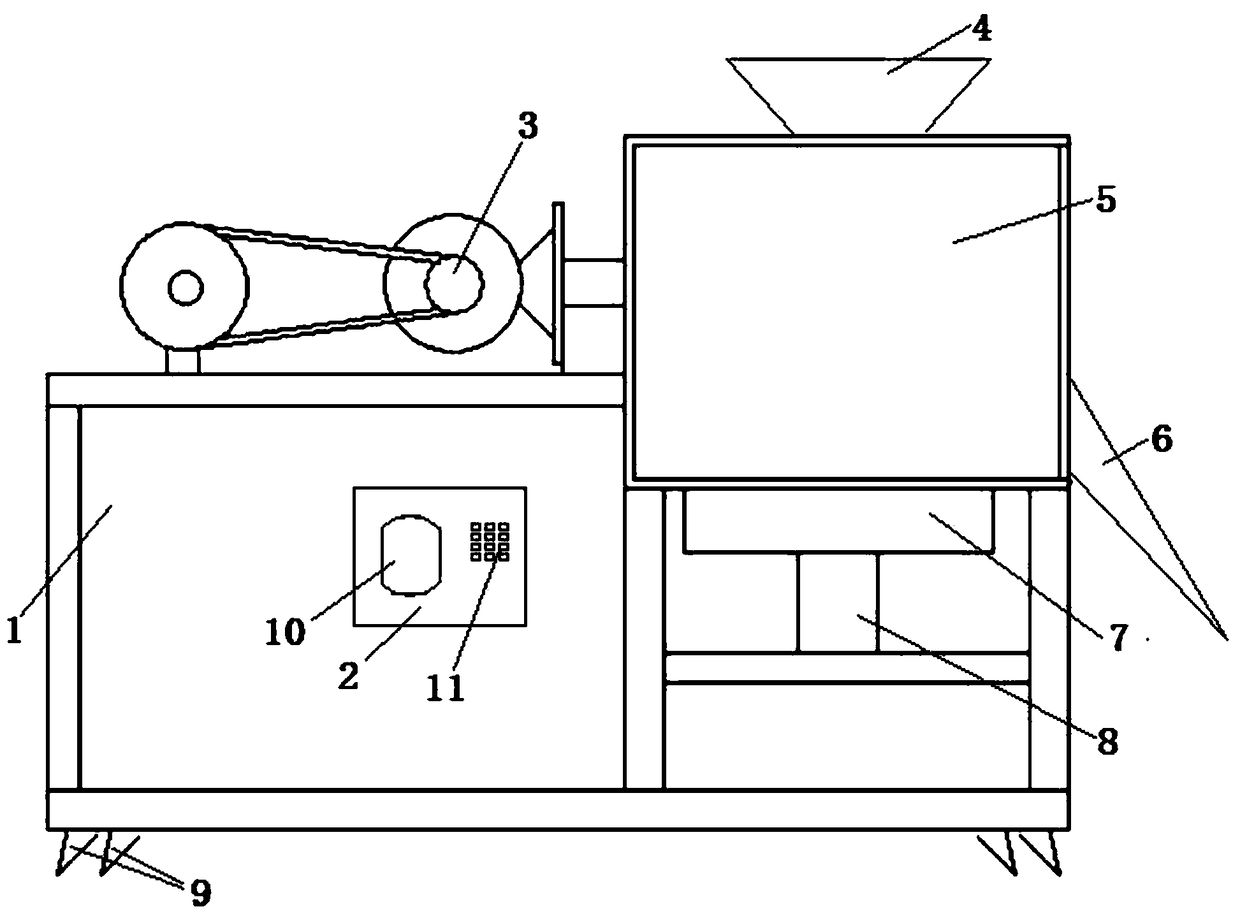

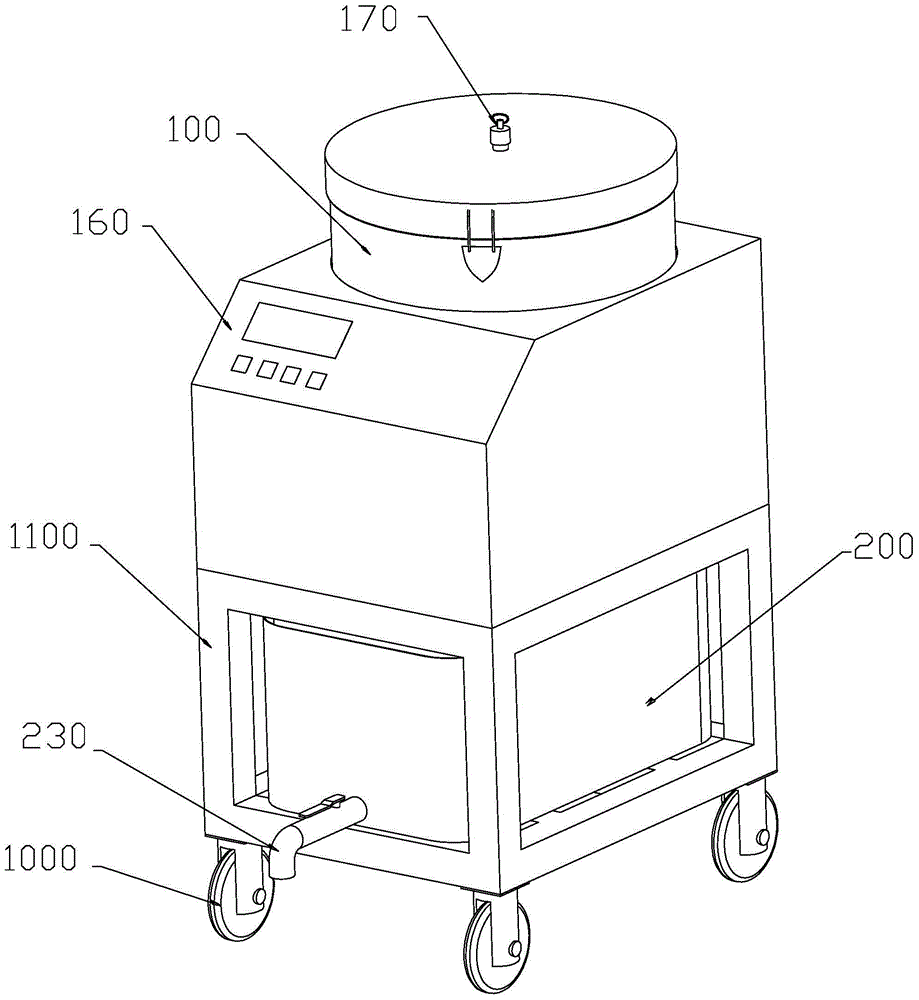

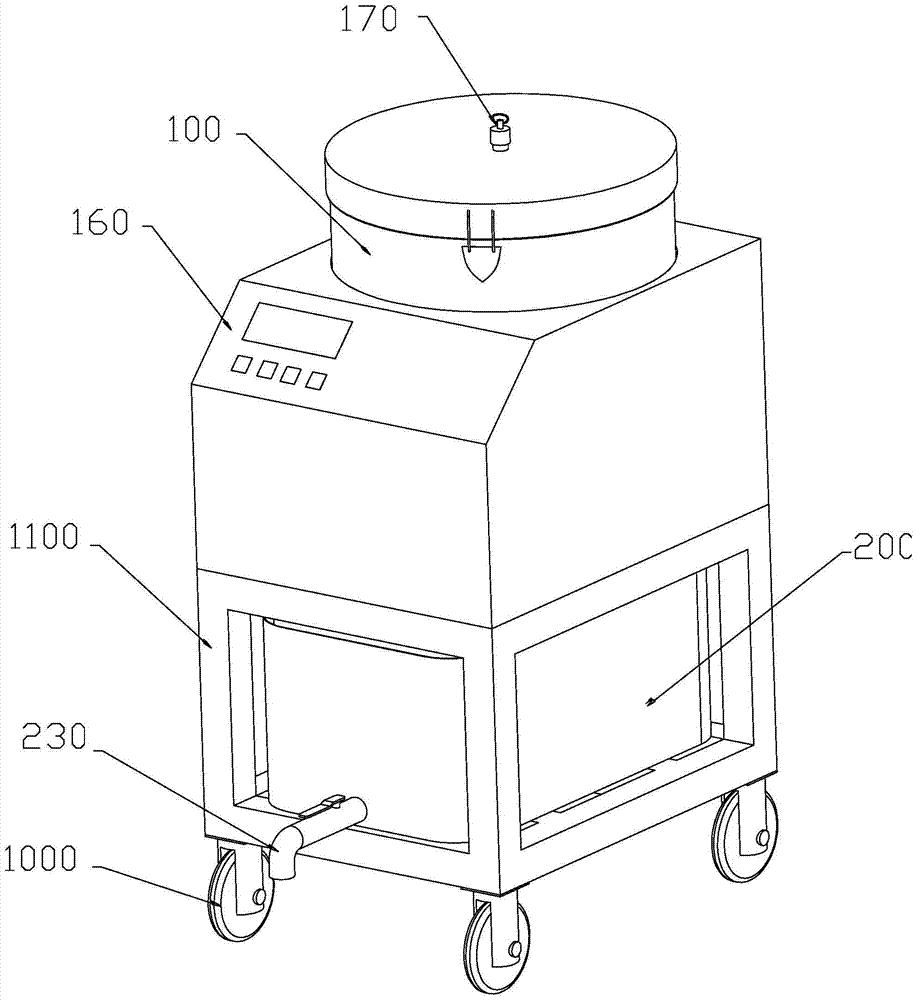

Frying equipment used for food

InactiveCN104957203ARealize negative pressure low temperature fryingHigh degree of automationOil/fat bakingEngineeringEquipment use

Frying equipment used for food comprises a first container, an air extracting device, a second container and a first valve, by opening and closing the air extracting device and the first valve, an annular loop can be formed by the first container, the air extracting device, the second container and the first valve, the food placed in the first container can be fried for multiple times through the loop, and the degree of automation is high. Through the opening and closing of the first valve and the operation of the air extracting device, oil can be cycled repeatedly between the first container and the second container, the oil can be used repeatedly, the food can be fried for multiple times in a negative pressure and low temperature condition, the intelligence, safety and health are achieved, and the energy and time are saved.

Owner:河源市探索人发明科技有限公司

Production method for low peroxide value frying black bean

InactiveCN103564347AReduce oxidation rateHigh nutritional valueFood preparationEconomic benefitsThermal water

The present invention discloses a production method for low peroxide value frying black bean, and belongs to the field of food processing. The production method comprises: (1) selecting black bean, (2) soaking with hot water, (3) carrying out air drying, (4) carrying out water and oil mixing frying, (5) draining the oil, (6) seasoning, and (7) coating an edible film. With the steps, product quality is increase, a product shelf life is prolonged, and the product has a good, crispy and delicious taste, is easily accepted by people, and has significant social and economic benefits.

Owner:QINGDAO BAOQUAN PEANUTS PRODS

Fried potato chips containing tea residues and preparation method of fried potato chips

The invention discloses fried potato chips containing tea residues and a preparation method of the fried potato chips and relates to the technical field of food processing. The fried potato chips are mainly prepared from potatoes, green corn, milk, mung bean soup, jelly, cocoa powder, the tea residues, lyophilized bitter gourd powder, chopped Chinese chives, ginger juice, salt, monosodium glutamate and vegetable oil. The fried potato chips are fried in a low-temperature vacuum manner, the frying temperature is reduced greatly, and the obtained potato chips are rich in nutrition, not prone to fading or browning and capable of better keeping raw material color; part of the vegetable oil can be removed from the potato chips through vacuum-centrifugal oil-removal, and the content of the vegetable oil in the potato chips can be reduced; the corn and the milk contain rich nutrition and have a greasiness solving function, and the problem of high grease content of the fried potato chips is further solved; the tea residues serve as a raw material, waste is changed into wealth, and the production cost is reduced.

Owner:HEFEI YINGCHUAN HOUSEHOLD FARM CO LTD

Preparation method of seasoning burdock crisp chips through microwave-assisted efficient vacuum frying

The invention discloses a preparation method of seasoning burdock crisp chips through microwave-assisted efficient vacuum frying, belonging to the technical field of fruit and vegetable crisp chip processing. The preparation method comprises the steps of: by taking fresh burdock as a raw material, cleaning the burdock, peeling and slicing the burdock in water, soaking the burdock in a color-protecting solution, blanching, dipping, slowly freezing, carrying out microwave-assisted vacuum frying, carrying out vacuum deoiling, seasoning, baking, cooling, packaging, sterilizing a finished product and preserving. The color-protecting agent is used for treating to keep the color and luster of the product; the efficient heating is carried out by using microwave and the puffing under the condition of low temperature is realized; and the brittleness of the product is improved by slow freezing, and a low-temperature vacuum frying technology has the characteristics that the color and luster, unique flavor substances and nutritional ingredients of burdock crisp chips can be maintained, oil content is low, fried grease can not be oxidized easily, the shelf life of the product is long, and the like. The seasoning burdock crisp chips are high in cellulose content, crisp and delicious, not greasy, convenient and hygienic, thus being a leisure food appropriate for both the old and the young. The preparation method adopts the combination of vacuum frying and microwave for dehydration, so that the vacuum frying efficiency is improved by 20%-30%, the types of the burdock processing products are enriched, and great economic benefits are expected to be produced.

Owner:宁波素子园八味食品有限公司 +1

Low-oil content crispy surimi-based product and production method thereof

Owner:HUAZHONG AGRI UNIV

Potato chip capable of preventing and curing hypertension and preparation method thereof

InactiveCN106107693ALow frying temperatureFull of nutritionFood ingredient functionsOil contentMonosodium glutamate

The invention discloses a potato chip capable of preventing and curing hypertension and a preparation method thereof, and relates to the technical field of food processing. The potato chip is mainly prepared by potato, green corn, milk, fresh bamboo leaf, glutinous rice root hair, bamboo fungus, pomegranate blossom, bean dregs, dried persimmon powder, ginger juice, edible salt, monosodium glutamate and vegetable oil. The potato chip is subjected to low-temperature vacuum frying, the frying temperature is greatly reduced, so that the obtained potato chip is rich in nutrition and does not easily fade and brown, and the original color of the raw material can be maintained well; vacuum centrifugal deoiling can remove a part of vegetable oil in the potato chip to reduce the vegetable oil content in the potato chip; the corn and the mill are rich in nutrition and have the effect of neutralizing grease, and the problem of high oil content of the potato chip is further solved; and the bamboo fungus, the fresh bamboo leaf, the pomegranate blossom and the like have the effect of preventing and curing hypertension, so that the potato chip is suitable for hypertension patients to eat.

Owner:HEFEI YINGCHUAN HOUSEHOLD FARM CO LTD

Frying equipment for food

Frying equipment used for food comprises a first container, an air extracting device, a second container and a first valve, by opening and closing the air extracting device and the first valve, an annular loop can be formed by the first container, the air extracting device, the second container and the first valve, the food placed in the first container can be fried for multiple times through the loop, and the degree of automation is high. Through the opening and closing of the first valve and the operation of the air extracting device, oil can be cycled repeatedly between the first container and the second container, the oil can be used repeatedly, the food can be fried for multiple times in a negative pressure and low temperature condition, the intelligence, safety and health are achieved, and the energy and time are saved.

Owner:河源市探索人发明科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com