Method for conveniently, industrially and continuously producing crispy meat

A convenient, meat block technology, applied in the direction of food ingredients as taste modifiers, food ingredients as smell modifiers, food ingredients as taste modifiers, etc. 1. Problems such as poor forming degree of crispy meat, to achieve the effect of retaining flavor and nutrition, quality, safety, hygiene and reliability, and low oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

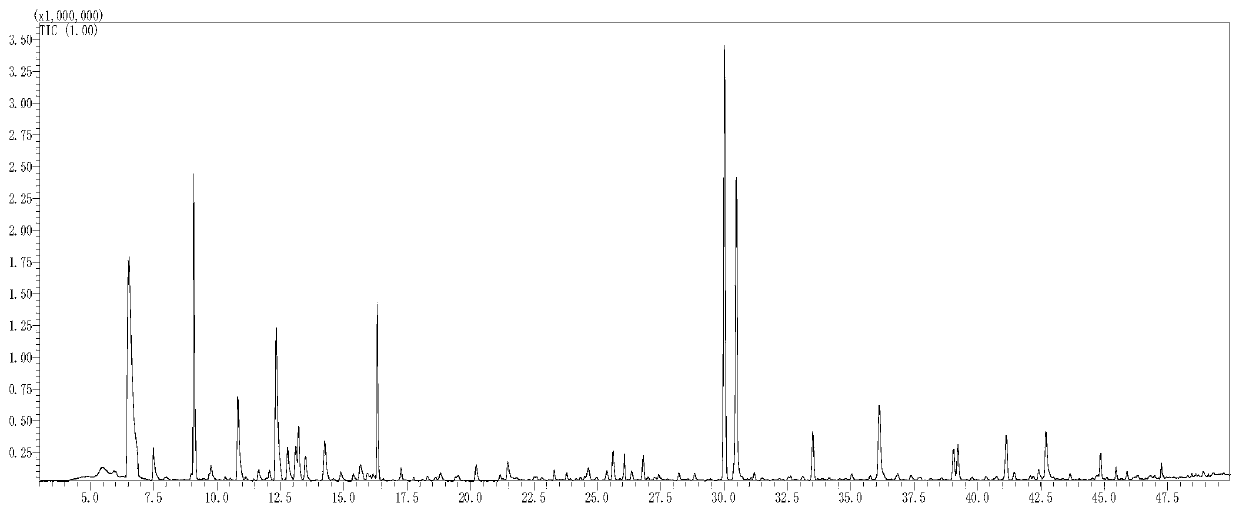

Image

Examples

Embodiment 1

[0031] A method for making convenient industrialized continuous production of crispy meat, comprising the following steps:

[0032] 1) Selection of raw meat: choose healthy, boneless hind legs with no foreign matter, no congestion, and no peculiar smell. Fresh and frozen pork meet the relevant provisions of the GB / T9959.3-2019 "Fresh and Frozen Pork and Pig By-products Part III: Cutting Pork by Part". Fresh pork was stored at -18°C after acquisition.

[0033] 2) Thawing and trimming: thawing adopts the air low sodium salt thawing process, the thawing humidity is 70-85%, the amount of sodium chloride added is 0.85g / 100g, the temperature is controlled at 6±2°C, and the excess fascia on the lean meat is removed after thawing , Divide the meat into 8mm thick meat pieces for later use.

[0034] 3) Pretreatment: Add papain with a meat mass ratio of 25u / g to the meat, and after standing for 25 minutes, use ultrasonic tenderization treatment, the ultrasonic power is 130-160W, the ul...

Embodiment 2

[0040] A method for making convenient industrialized continuous production of crispy meat, comprising the following steps:

[0041] 1) Selection of raw meat: choose healthy, boneless hind legs with no foreign matter, no congestion, and no peculiar smell. Fresh and frozen pork meet the relevant provisions of the GB / T9959.3-2019 "Fresh and Frozen Pork and Pig By-products Part III: Cutting Pork by Part". Fresh pork was stored at -18°C after acquisition.

[0042] 2) Thawing and trimming: thawing adopts the air low sodium salt thawing process, the thawing humidity is 70-85%, the amount of sodium chloride added is 0.75g / 100g, the temperature is controlled at 6±2°C, and the excess fascia on the lean meat is removed after thawing , Divide the meat into 8mm thick meat pieces for later use.

[0043] 3) Pretreatment: Add papain with a meat mass ratio of 20u / g to the meat, and after standing for 30 minutes, use ultrasonic tenderization treatment, the ultrasonic power is 130-160W, the ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com