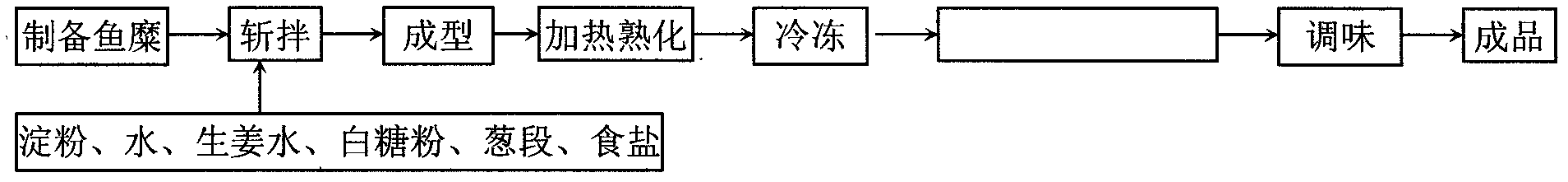

Low-oil content crispy surimi-based product and production method thereof

A technology of surimi products and oil content, which is applied in low oil content crispy surimi products and its production field, can solve the problems of vacuum frying parameters and product indicators, poor convenience and ready-to-eat, and affect acceptability, etc. The effect of frying time, low frying temperature, and easy preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]Get 5000g of fresh surimi, chop and mix for 2min, add 1000g of acetic acidified tapioca starch (purchased from Zhejiang Hangzhou Prostar Starch Development Co., Ltd. product), chop and mix for 2min (before starch is added, use 350g of water to make starch slurry use). Then add 150g of ginger water (after cutting the ginger into froth, add 200g of water to 100g of ginger froth, and stir to get 150g of filtrate, which is ginger water), 100g of green onion, and 50g of cooking wine (purchased from Zhejiang Shaoxing Dongxing Winery). ), 50g of powdered sugar and 50g of monosodium glutamate, chopped and mixed for 2 minutes. Then add 100g of salt, chop and mix for 3 minutes. The chopped surimi was made into fish balls with a diameter of 10mm, and heated in hot water at 90°C for 30min. Cool to room temperature with water, then freeze at -20°C for 24h. The frozen fish balls are put into a vacuum fryer (purchased from Shandong Yantai Hairui Food Equipment Co., Ltd., product mod...

Embodiment 2

[0053] Get 5000g of frozen surimi, make crispy fish balls according to the formula and process in Example 1, and its sensory score is as follows: 7.5 points for tissue shape, 7 points for cross-sectional structure, 8.5 points for color, 7.5 points for fragrance, 7.5 points for taste, and greasy The texture is 8 points, the crispness is 8.5 points, the water content is 2%, and the oil content is 12%.

Embodiment 3

[0055] Get 5000g of fresh surimi, chop and mix for 2min, add 1000g of acetic acidified tapioca starch (purchased from Zhejiang Hangzhou Prostar Starch Development Co., Ltd. product), chop and mix for 2min (before starch is added, use 350g of water to make starch slurry use). Then add 150g of ginger water, 100g of scallion, 50g of cooking wine (purchased from Dongxing Distillery in Shaoxing City, Zhejiang Province), 50g of white sugar powder and 50g of monosodium glutamate, chop and mix for 2 minutes. Then add 100g of salt, chop and mix for 3 minutes. The chopped surimi was made into fish intestines with a diameter of 50 mm, and then the fish intestines were heated in 90°C water for 30 minutes, cooled to room temperature, and the fish fillets were frozen at -20°C for 24 hours. After the frozen fish intestines are peeled off the casings, they are cut into fish fillets with a thickness of 2.5mm, and put into a vacuum fryer (product of Shandong Yantai Hairui Food Equipment Co., L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com