Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Low fluid viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

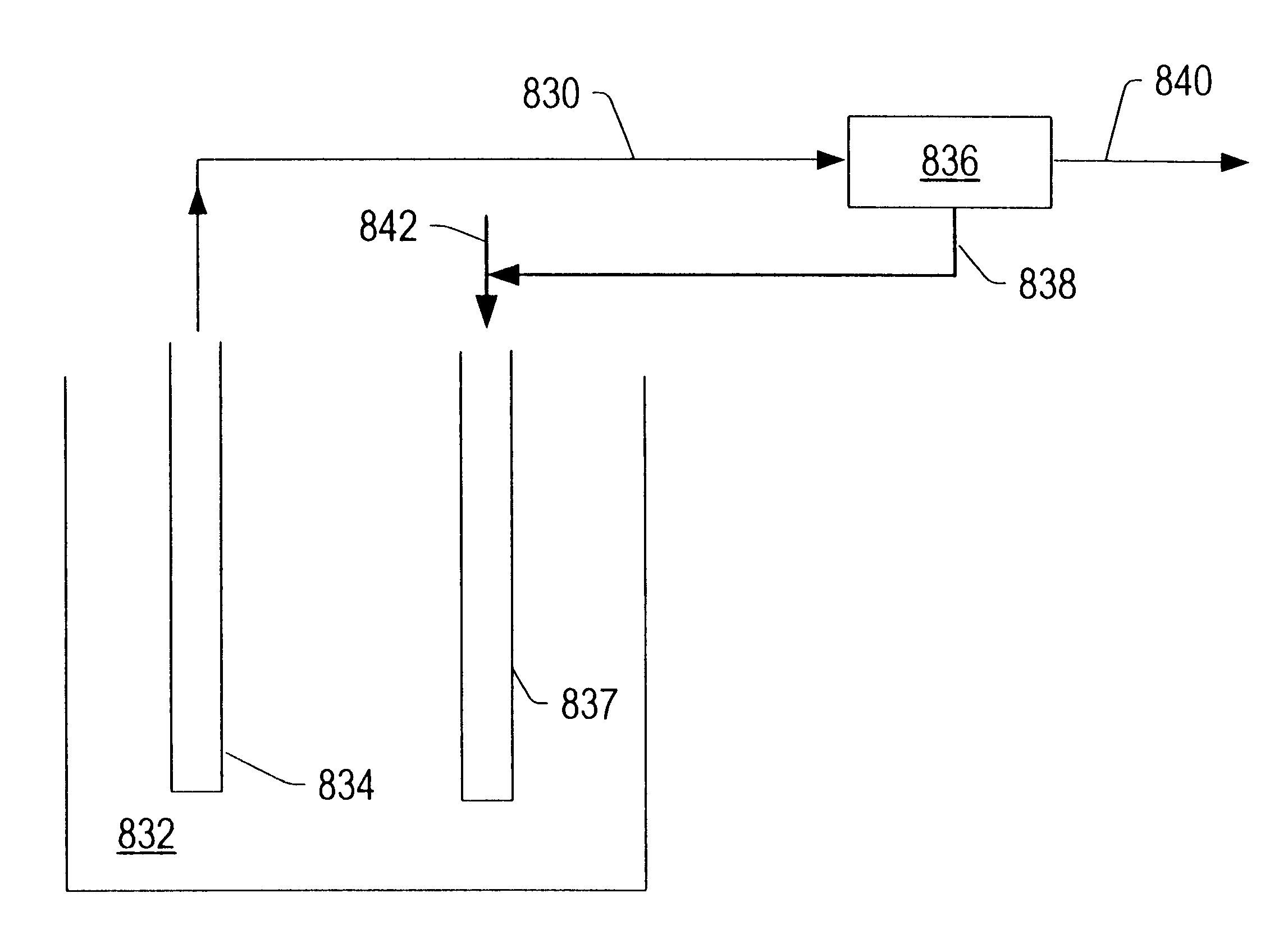

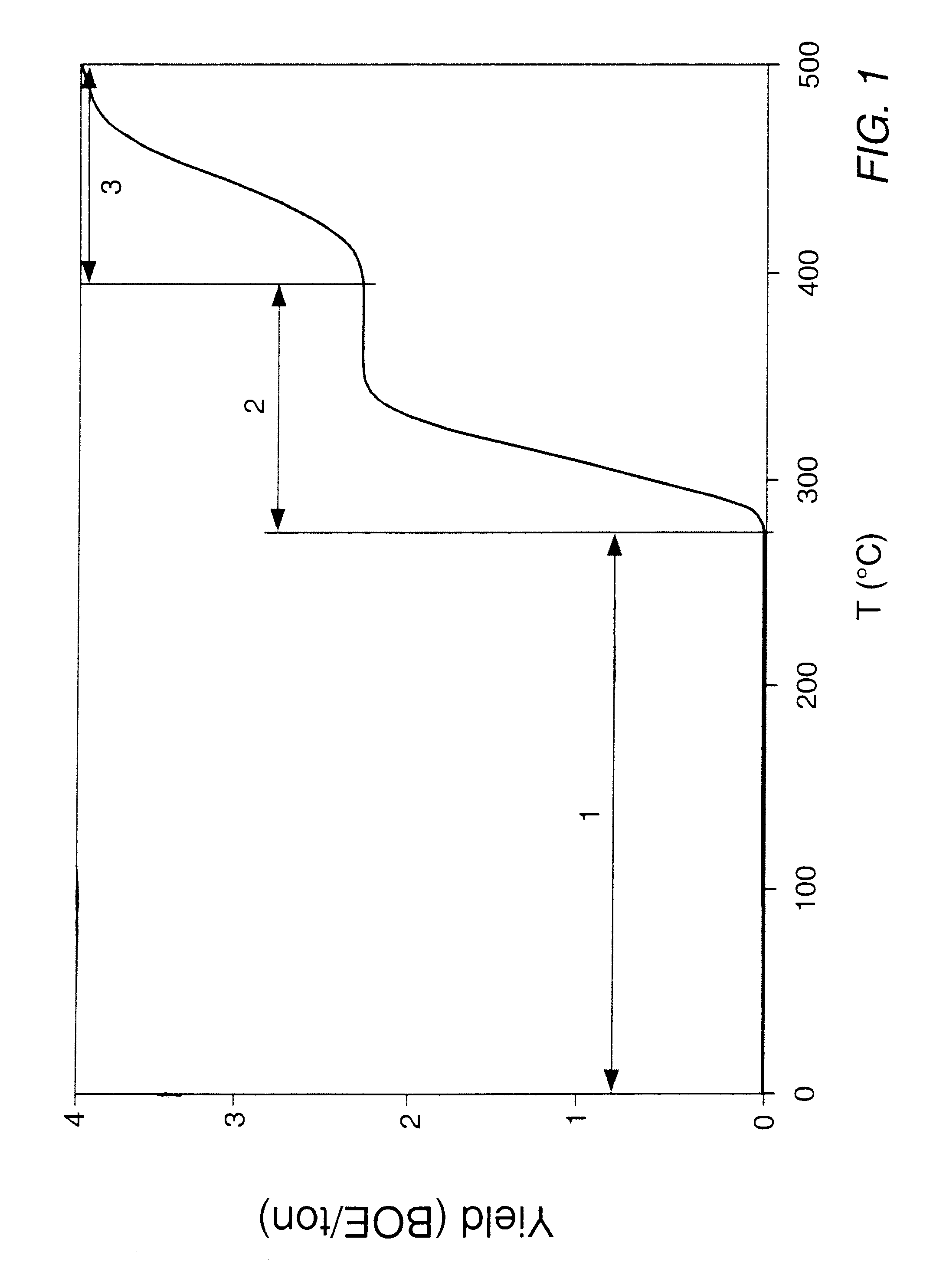

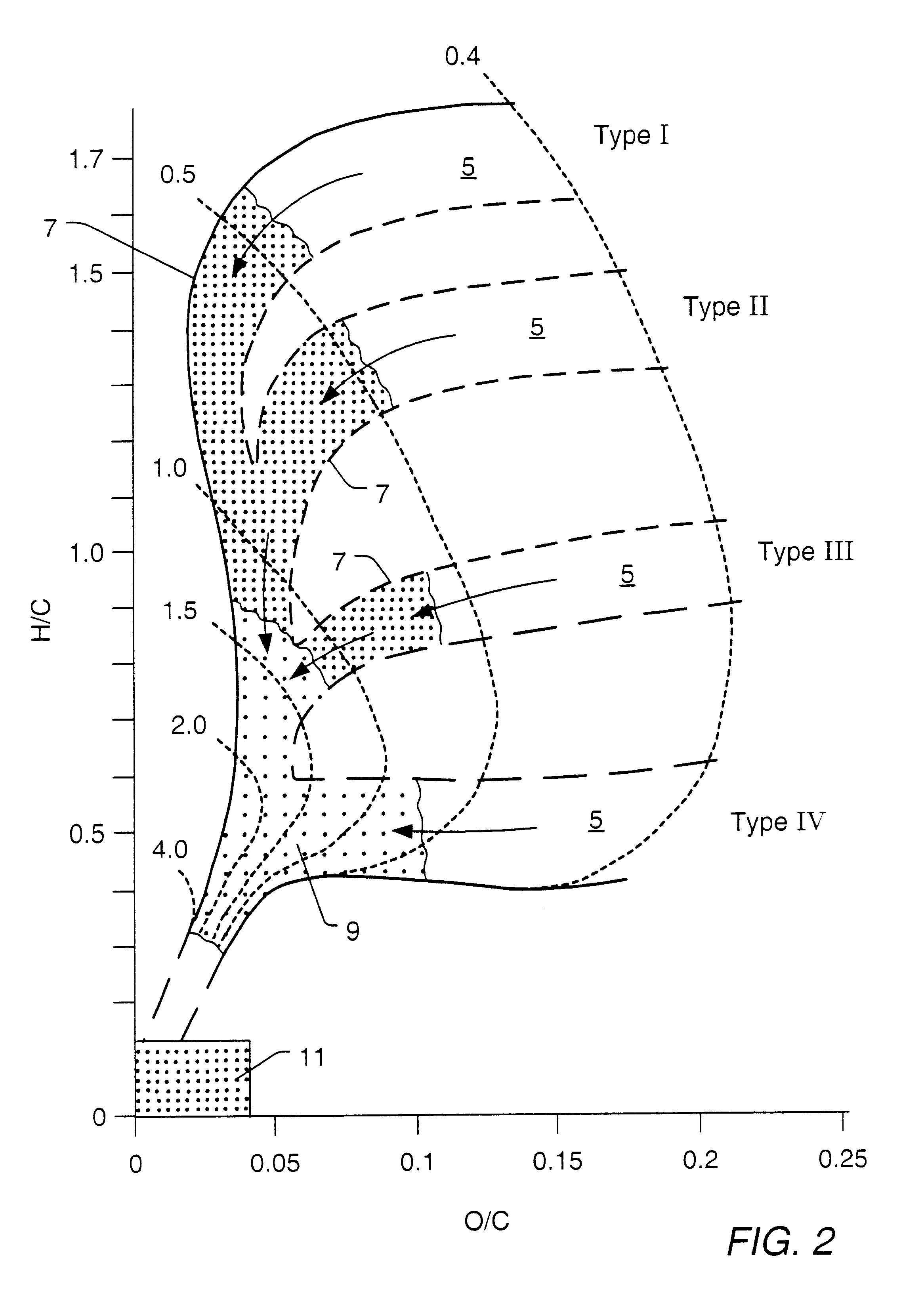

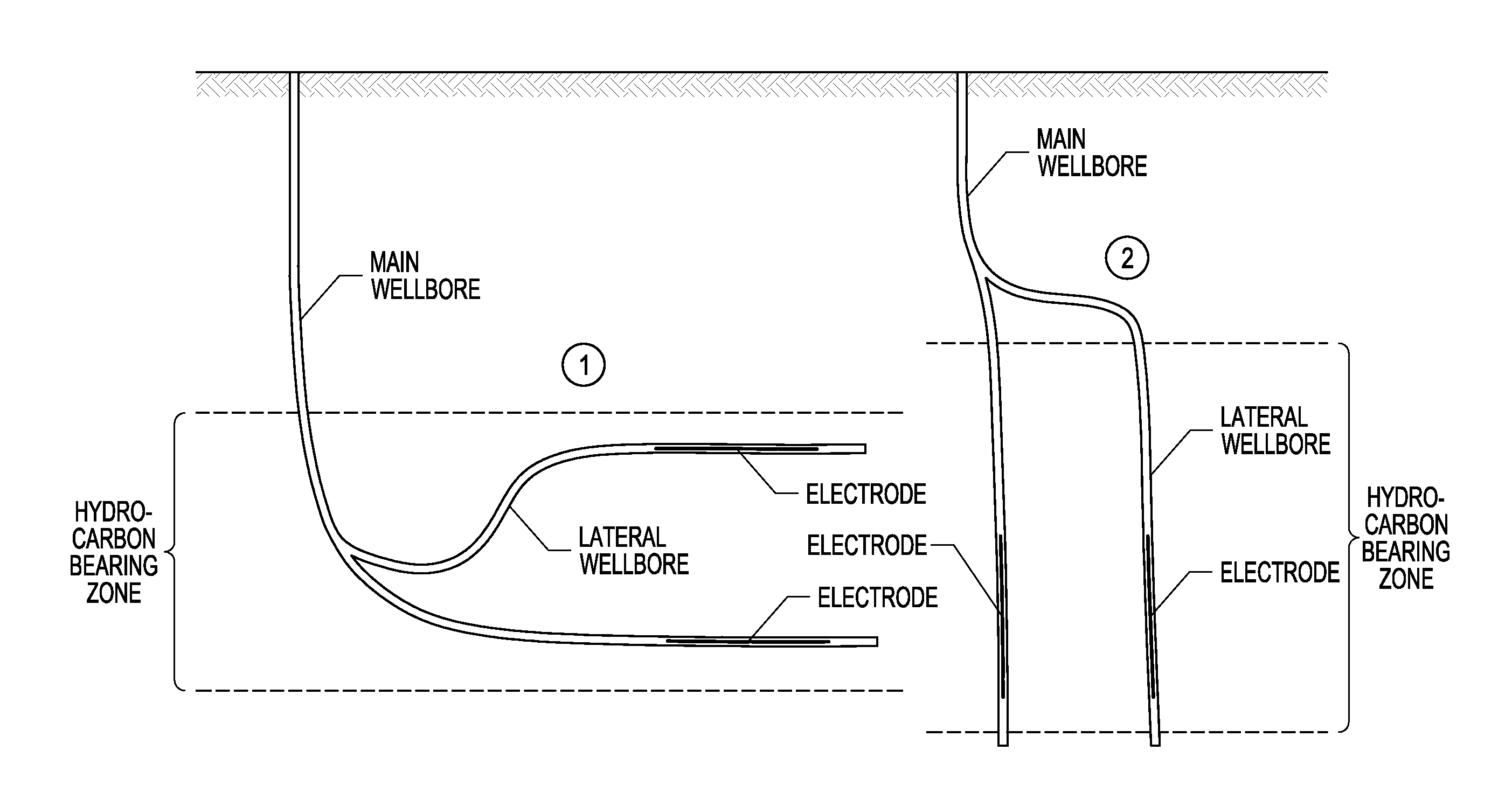

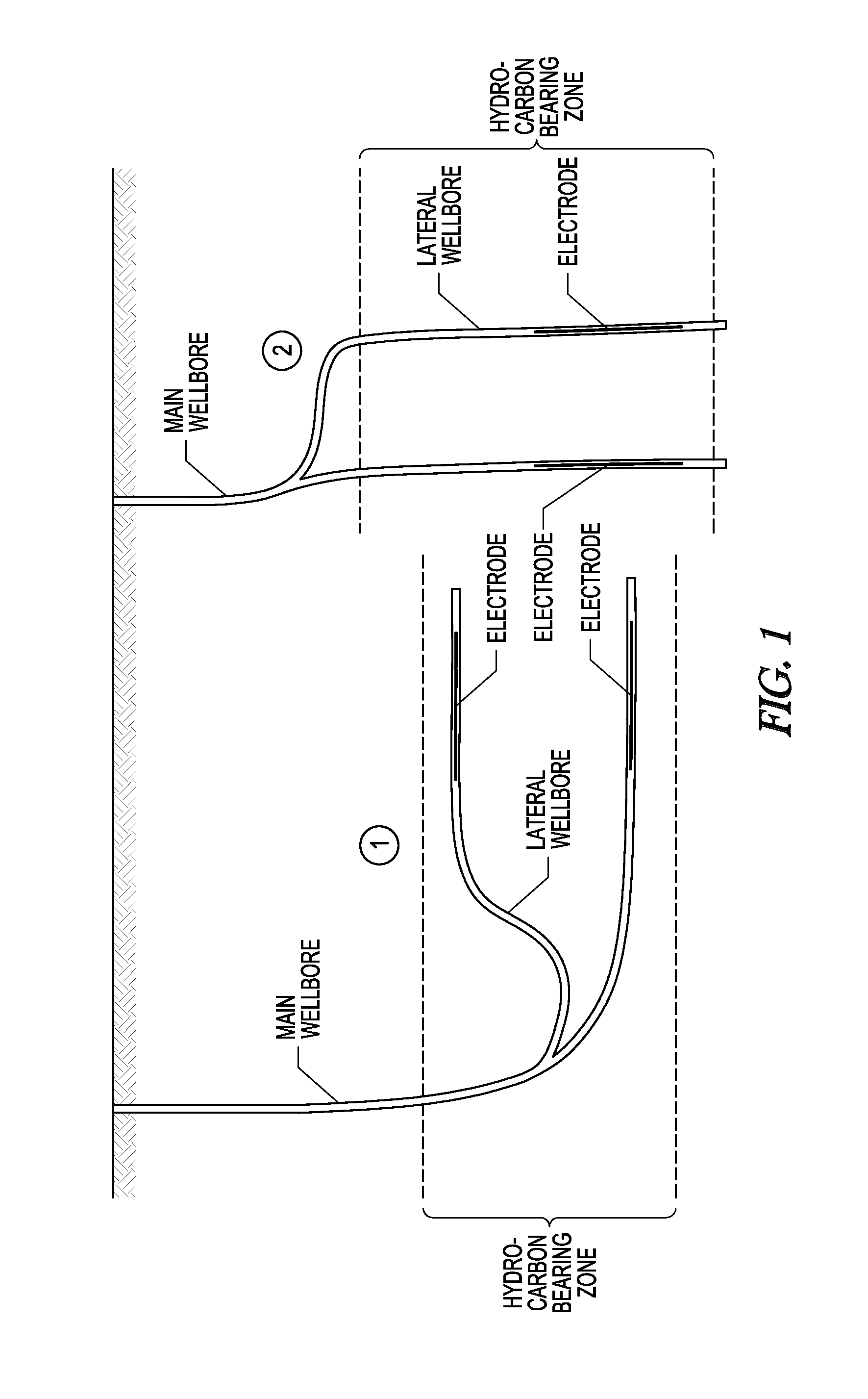

In situ thermal processing of a hydrocarbon containing formation using a controlled heating rate

InactiveUS6745837B2High calorific valueImprove the heating effectSurveyCombustion processFormation fluidHeat energy

A hydrocarbon containing formation may be treated using an in situ thermal process. A mixture of hydrocarbons, H.sub.2, and / or other formation fluids may be produced from the formation. Heat may be applied to the formation to raise a temperature of a portion of the formation to a pyrolysis temperature. A heating rate to a selected volume of the formation may be controlled by altering an amount of heating energy per day that is provided to the selected volume.

Owner:SALAMANDER SOLUTIONS INC

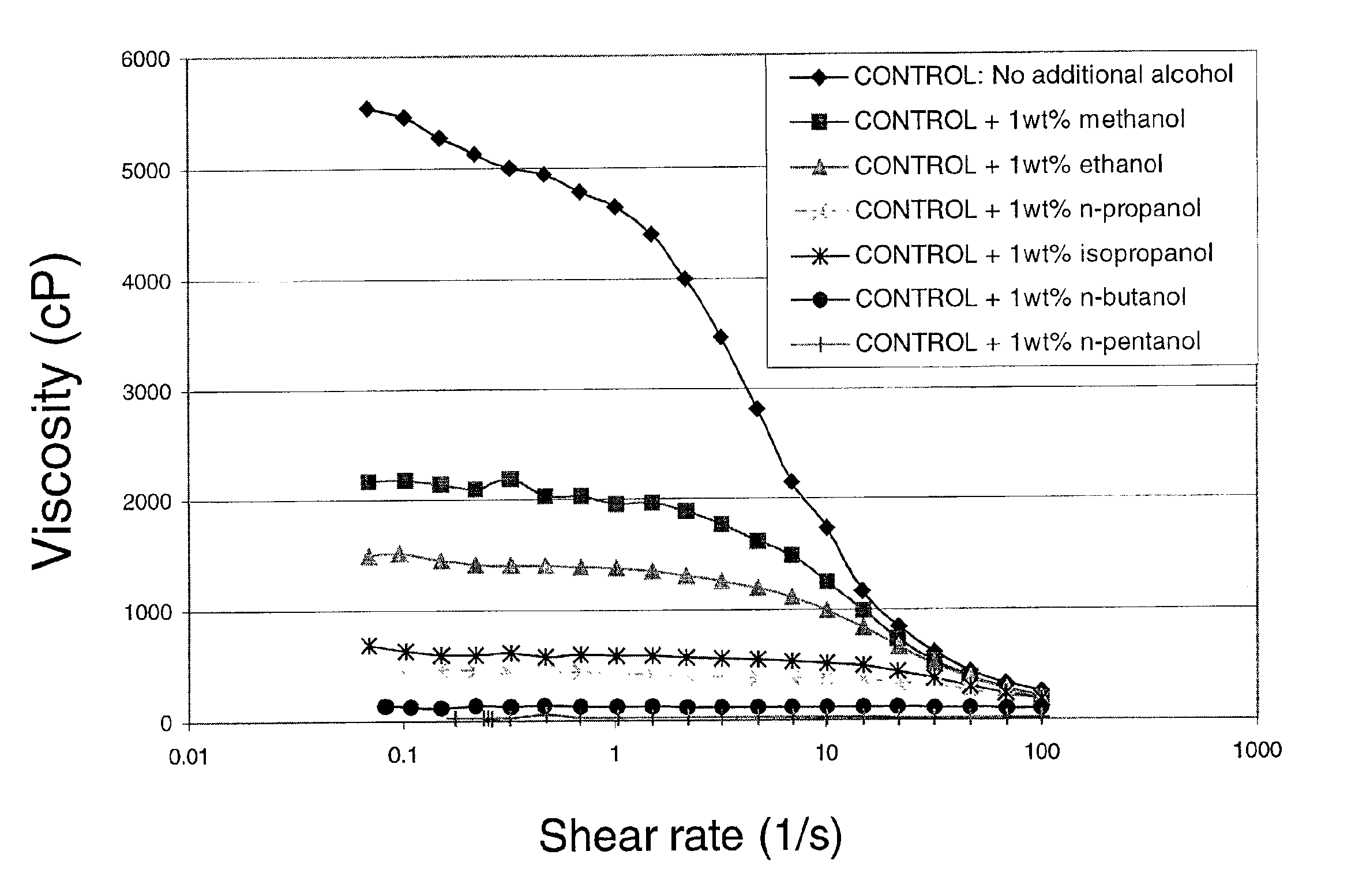

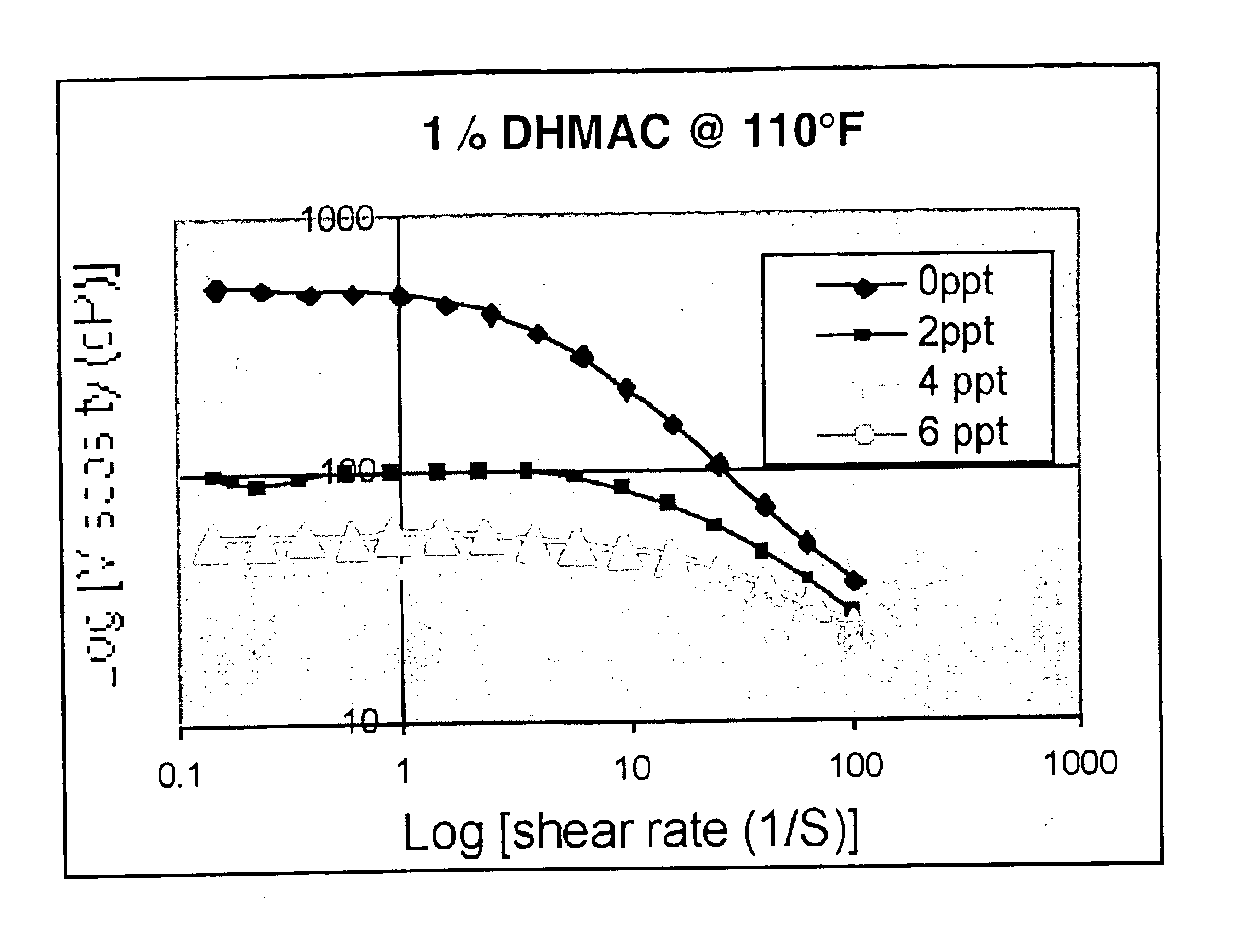

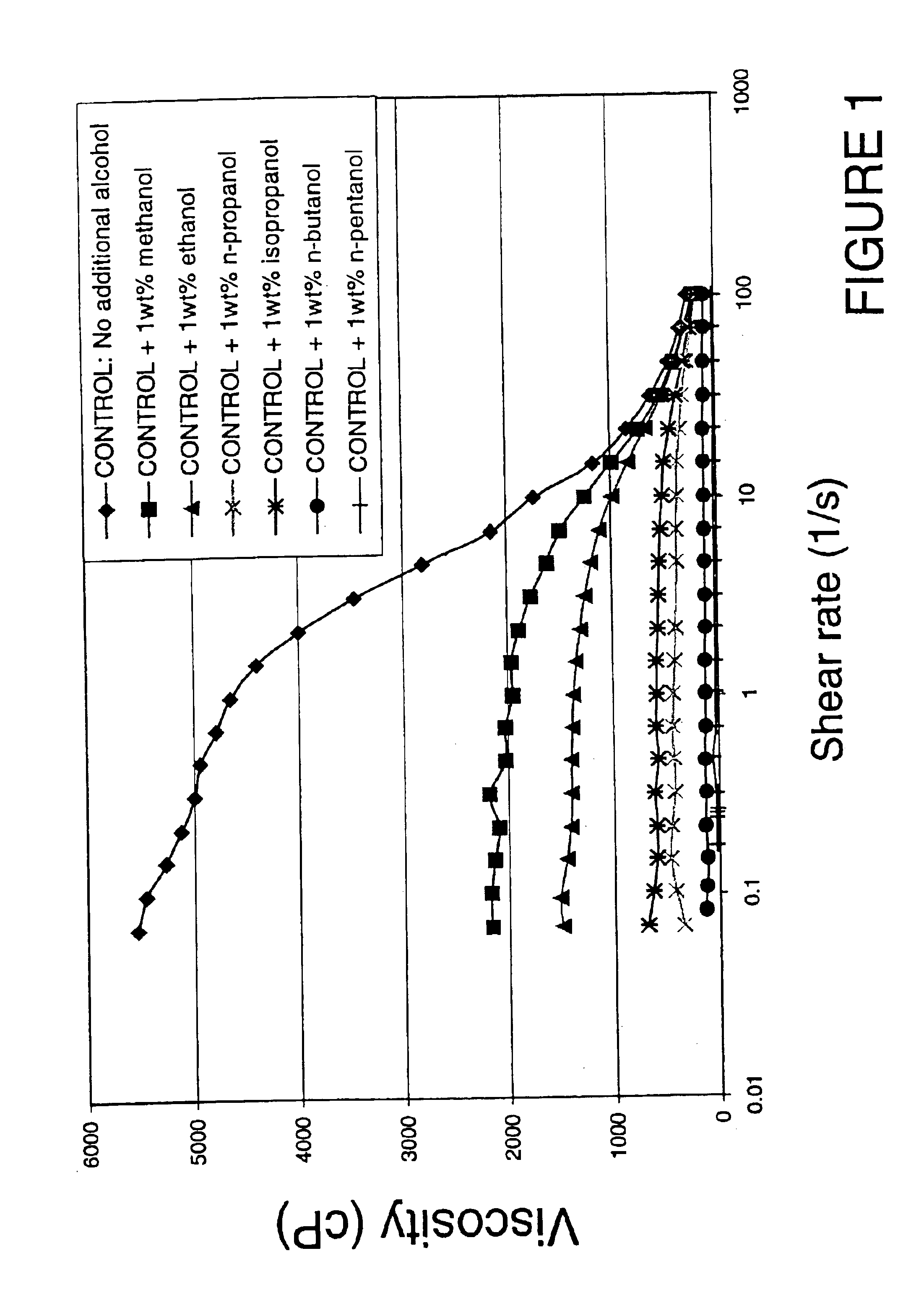

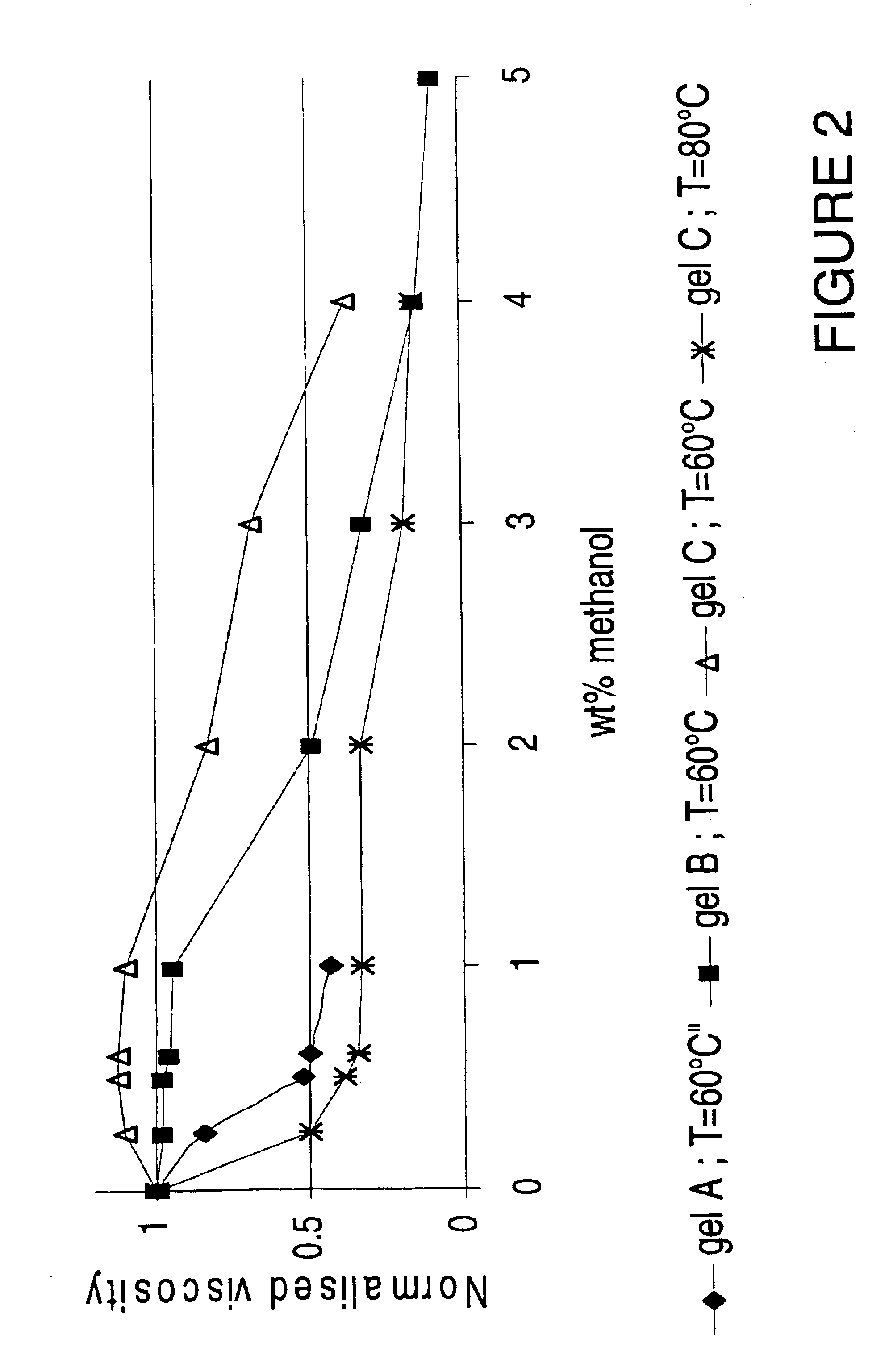

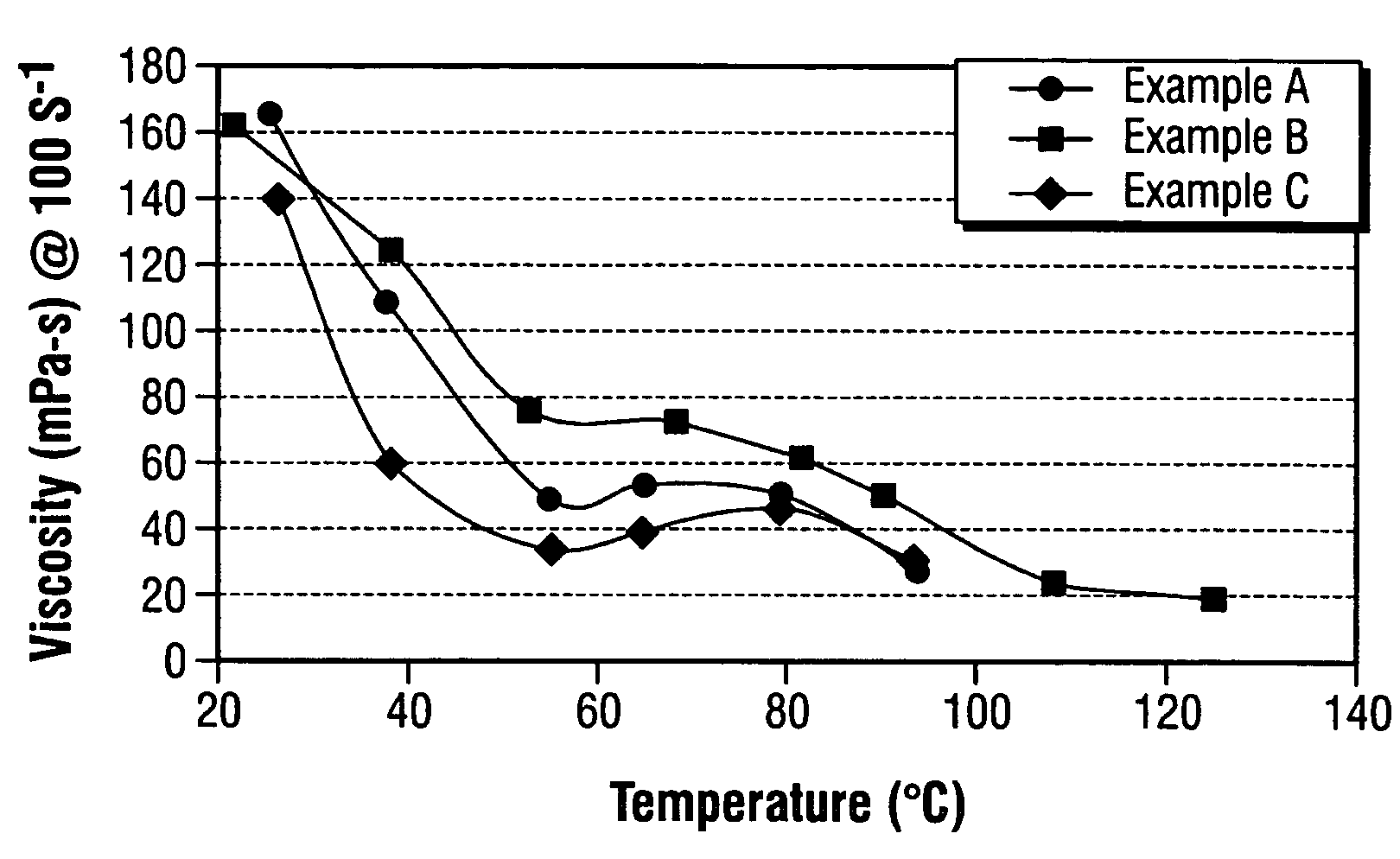

Viscosity reduction of viscoelastic surfactant based fluids

InactiveUS6881709B2Improve efficiencyImproves and optimizes conditionOther chemical processesFluid removalAlcoholSolid particle

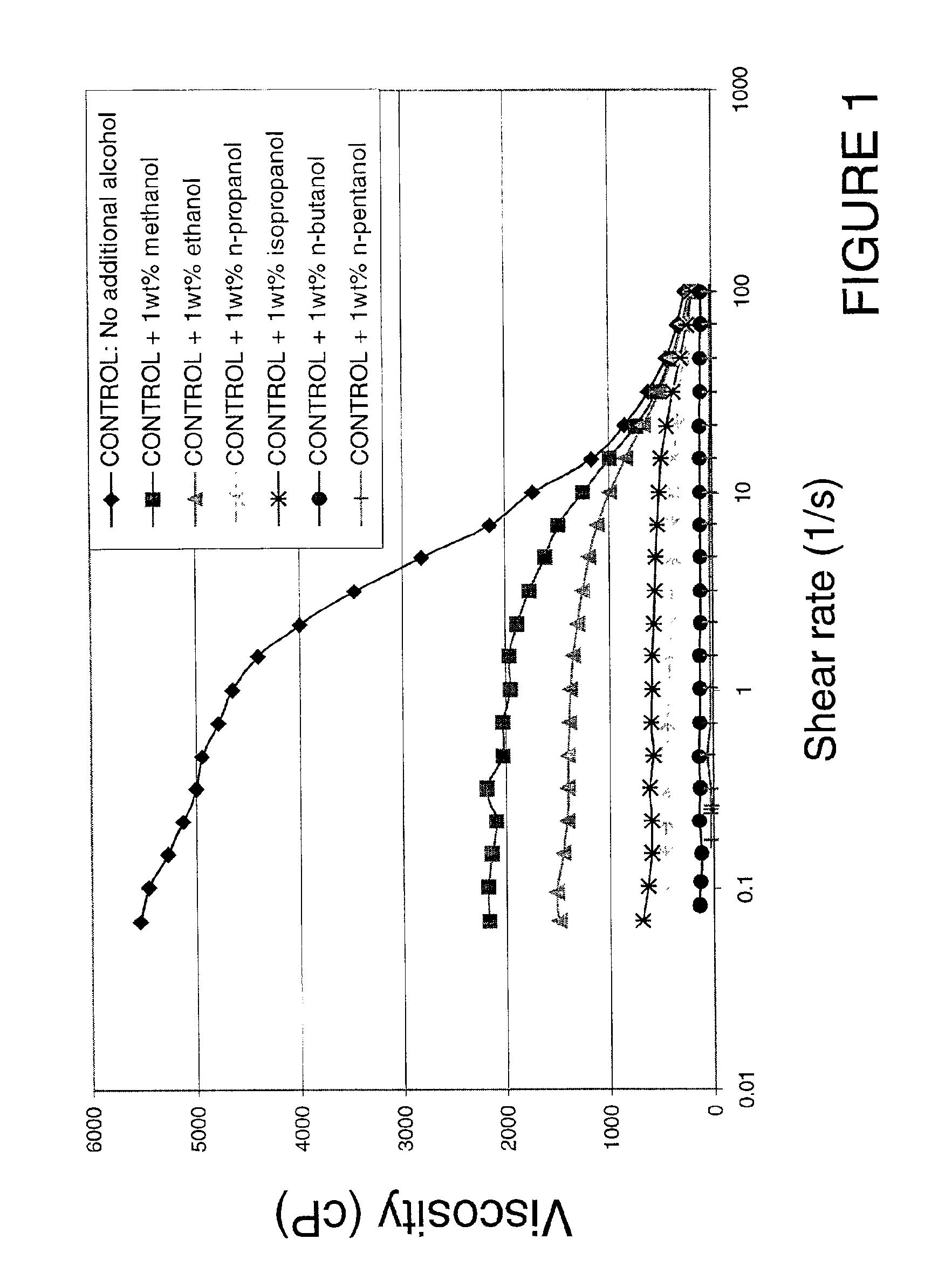

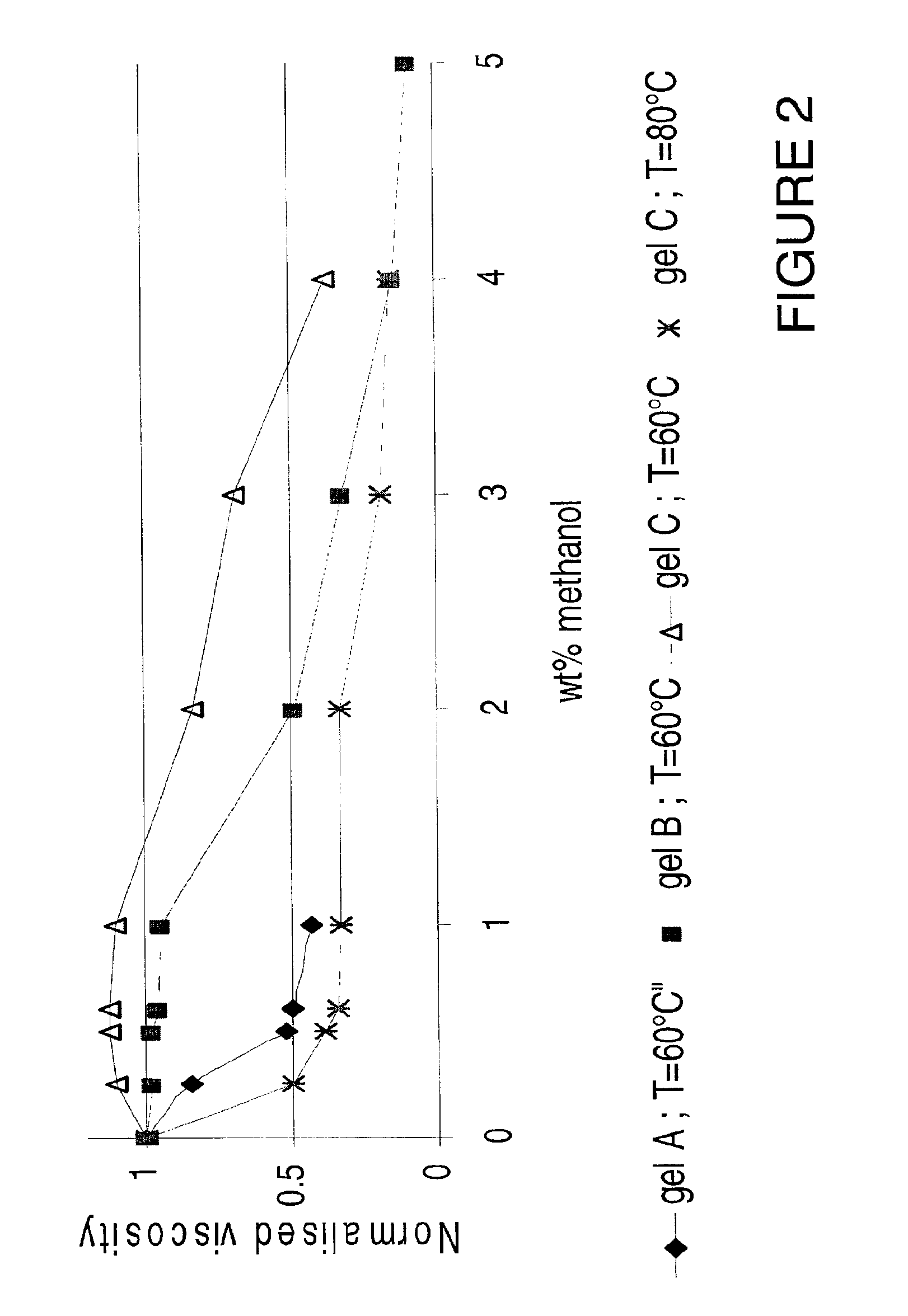

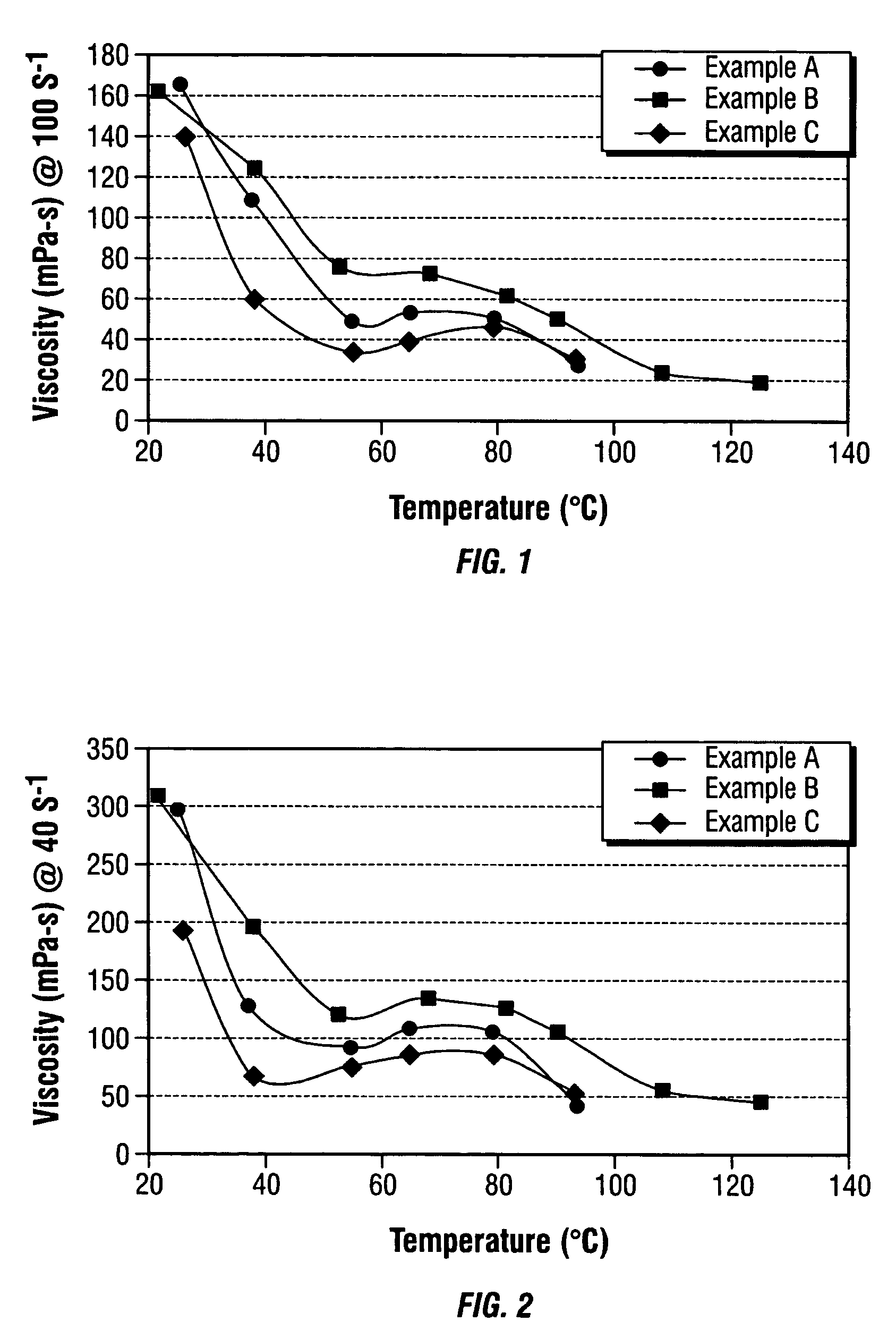

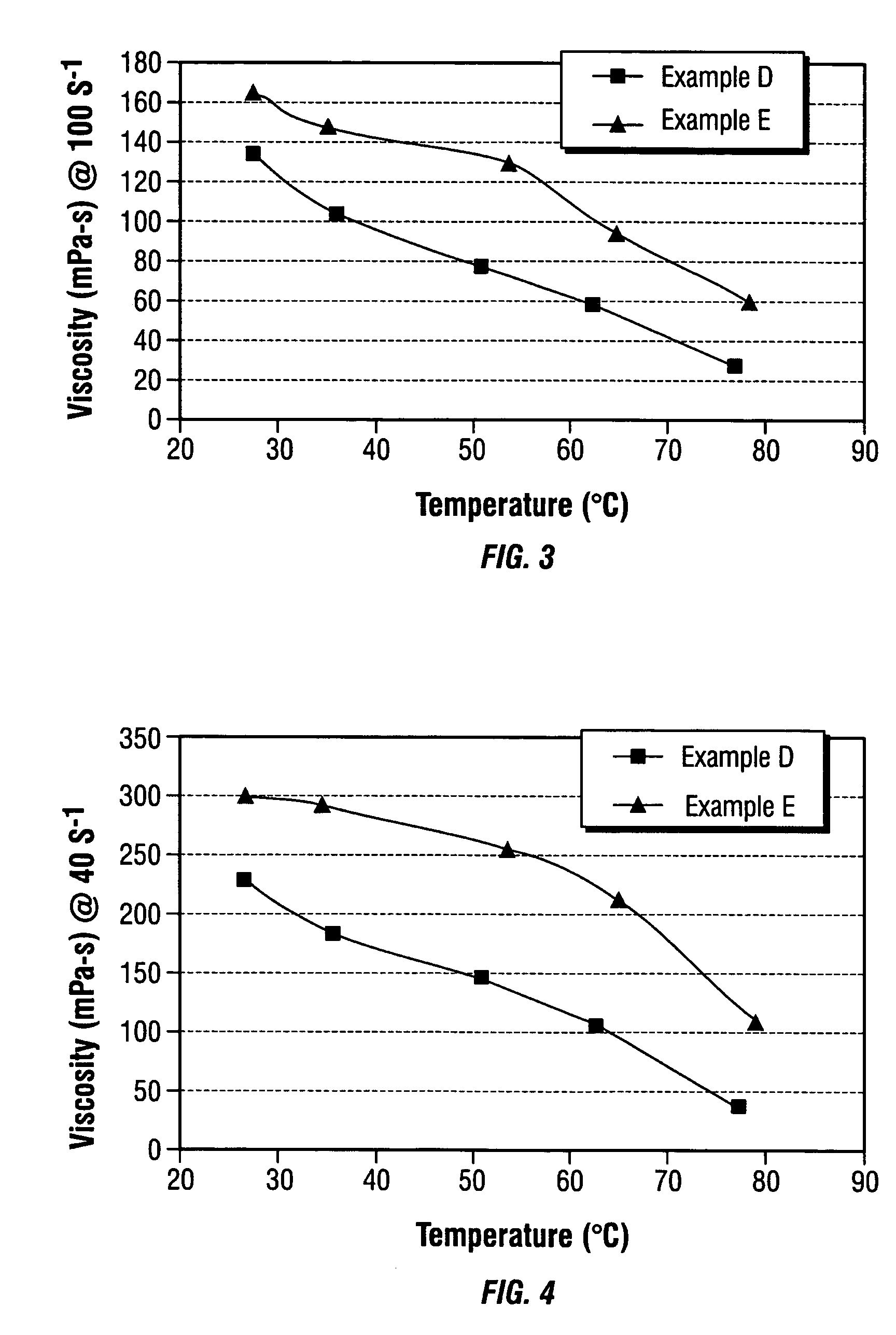

Methods and compositions are disclosed for controlled addition of components that decrease the viscosity of the viscoelastic surfactant fluids or for controlled changes in the electrolyte concentration or composition of the viscoelastic surfactant fluids. One aspect of the invention relates to the use of internal breakers with a delayed activation. Another aspect of the invention relates to the use of precursors that release a breaking system such as alcohol by a process such as melting, slow dissolution, reaction with a compound present in the fluid or added to the fluid during or after the step of injecting, rupture of an encapsulating coating and de-adsorption of a breaking agent absorbed into solid particles. In another aspect of the invention, alcohols are included in a pad to reduce the low-shear viscosity and reduce the resistance to flow of the treatment fluids during a desired phase of the treatment.

Owner:SCHLUMBERGER TECH CORP

Well treatment fluid compositions and methods for their use

InactiveUS6983801B2High viscosityIncrease volumeFluid removalFlushingAlkaline earth metalCarboxylic acid

Owner:COMBINED SYST +1

Viscosity reduction of viscoelastic surfactant based fluids

InactiveUS6908888B2Improve efficiencyImproves and optimizes conditionOther chemical processesFluid removalAlcoholSolid particle

Methods and compositions are disclosed for controlled addition of components that decrease the viscosity of the viscoelastic surfactant fluids or for controlled changes in the electrolyte concentration or composition of the viscoelastic surfactant fluids. One aspect of the invention relates to the use of internal breakers with a delayed activation. Another aspect of the invention relates to the use of precursors that release a breaking system such as alcohol by a process such as melting, slow dissolution, reaction with a compound present in the fluid or added to the fluid during or after the step of injecting, rupture of an encapsulating coating and de-adsorption of a breaking agent absorbed into solid particles. In another aspect of the invention, alcohols are included in a pad to reduce the low-shear viscosity and reduce the resistance to flow of the treatment fluids during a desired phase of the treatment.

Owner:SCHLUMBERGER TECH CORP

Peracid oil-field viscosity breaker and method

InactiveUS20100222242A1Increase viscosity of fluidLow fluid viscosityFluid removalFlushingAcetic acidFluid viscosity

Aqueous well treatment fluid compositions are disclosed comprising an aqueous fluid containing polymer or copolymer for modifying fluid viscosity of the aqueous fluid and, in addition, an agent for effecting a controlled reduction in the aqueous fluid viscosity in a subterranean environment. The viscosity-reducing agent comprises a dilute concentration of peracetic acid. A method of using such compositions in oil- and gas-field treatment operations is also disclosed.

Owner:EVONIK OPERATIONS GMBH

Two stage subterranean zone fracturing fluids and methods

Owner:HALLIBURTON ENERGY SERVICES INC

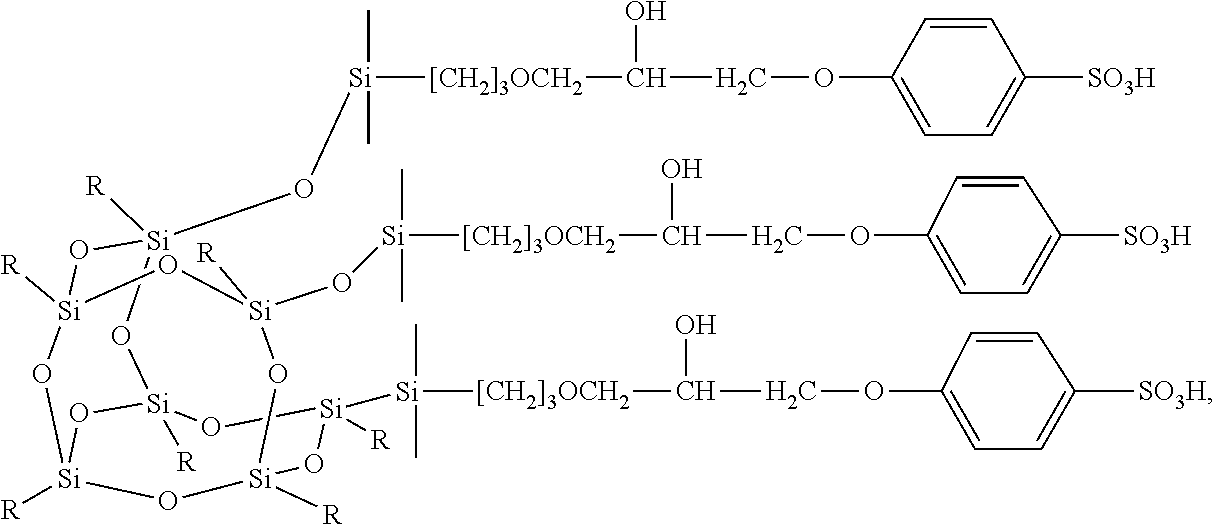

Viscoelastic fluids containing nanotubes for oilfield uses

InactiveUS7244694B2Low fluid viscosityMaterial nanotechnologyFluid removalInorganic saltsOrganic acid

The present invention relates to viscoelastic fluids that contain nanotube structures that may be used advantageously as oilfield stimulation fluids in many different applications, most particularly as a fracturing fluid. Viscoelastic fluid compositions of the present invention include an aqueous medium, a viscoelastic surfactant, an organic or inorganic acids, or salt thereof, organic acid salts, inorganic salts, and a nanotube component. The invention is also called to a methods of treating a subterranean well bores in which the viscoelastic fluid is injected into the wellbore to perform operations such as fracturing, drilling, acid fracturing, gravel placement, removing scale, matrix acidizing, and removing mud cake. Further, a method of preparing a nanotube viscoelastic fluid comprising the steps of effectively mixing a carbon nanotube component into a viscoelastic fluid, and sonicating the mixture in order to incorporate the carbon nanotube component is claimed.

Owner:SCHLUMBERGER TECH CORP

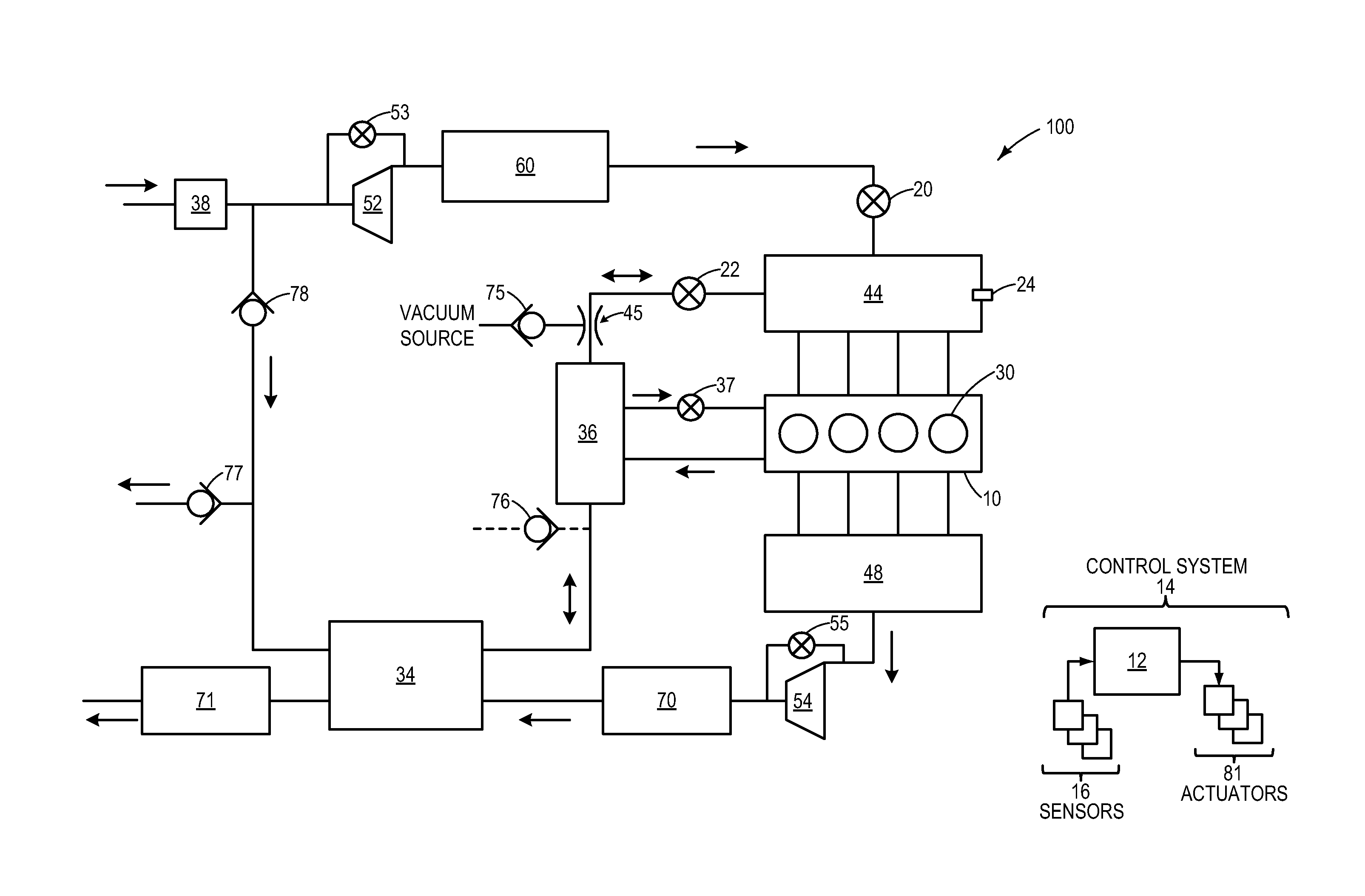

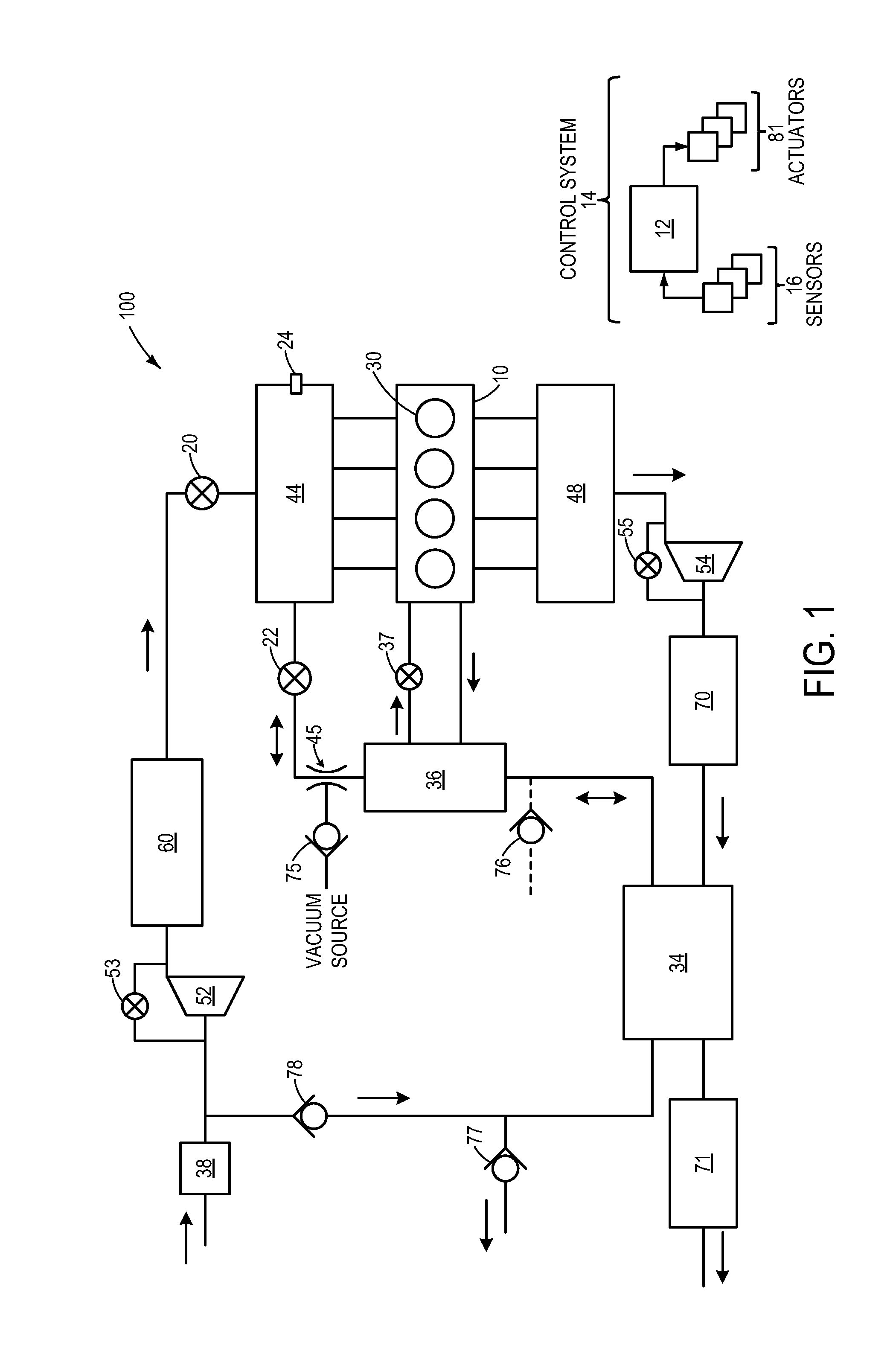

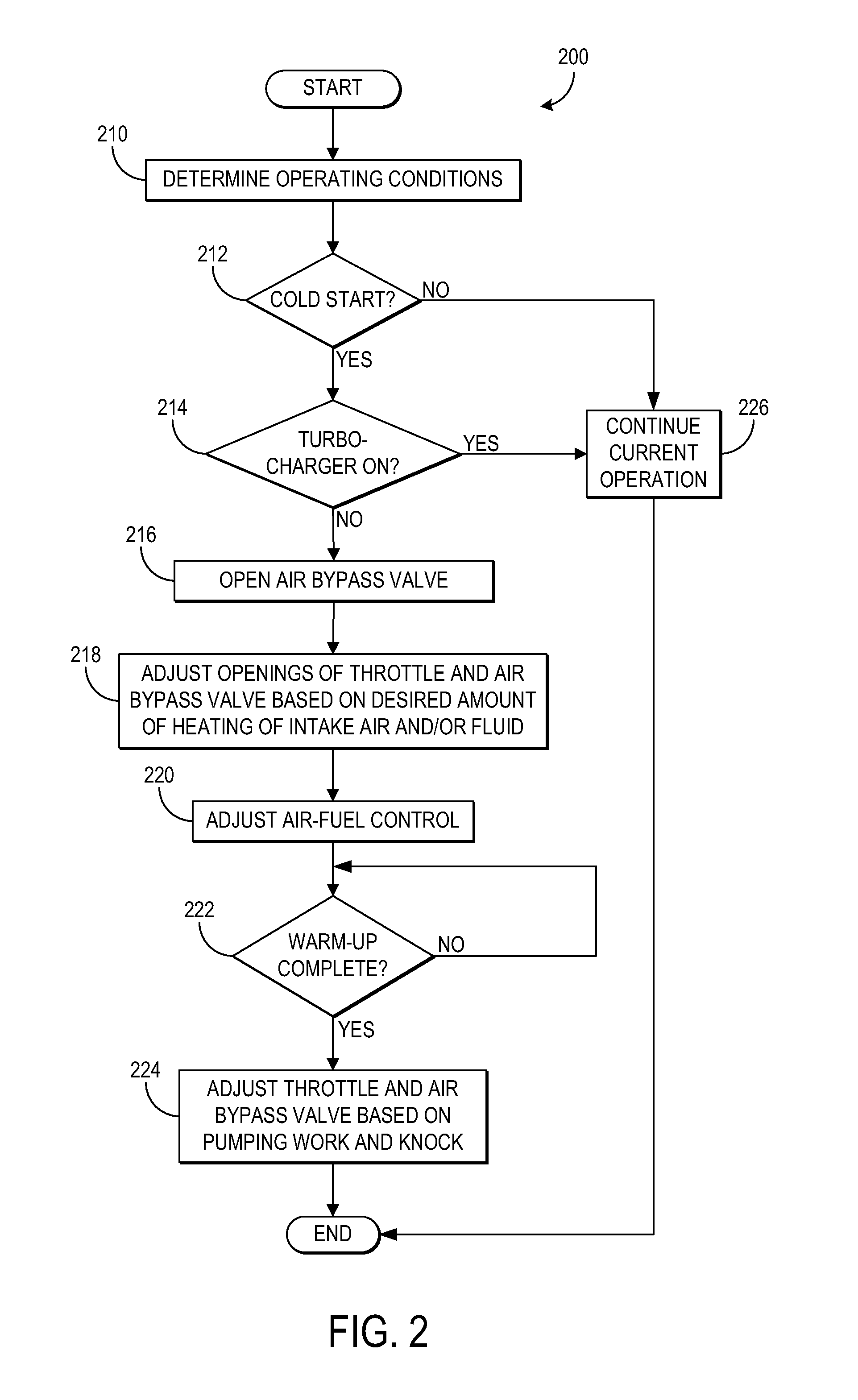

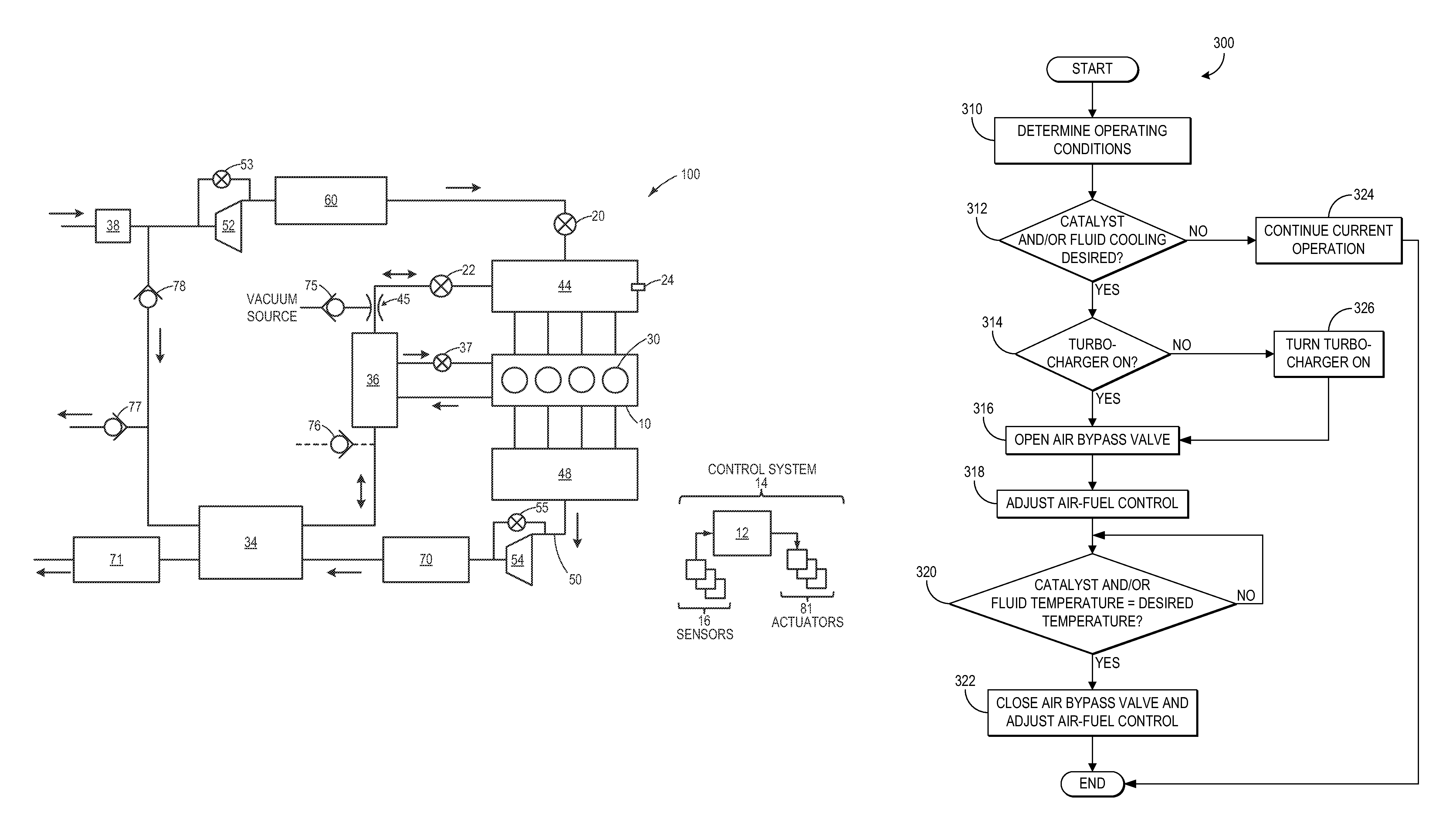

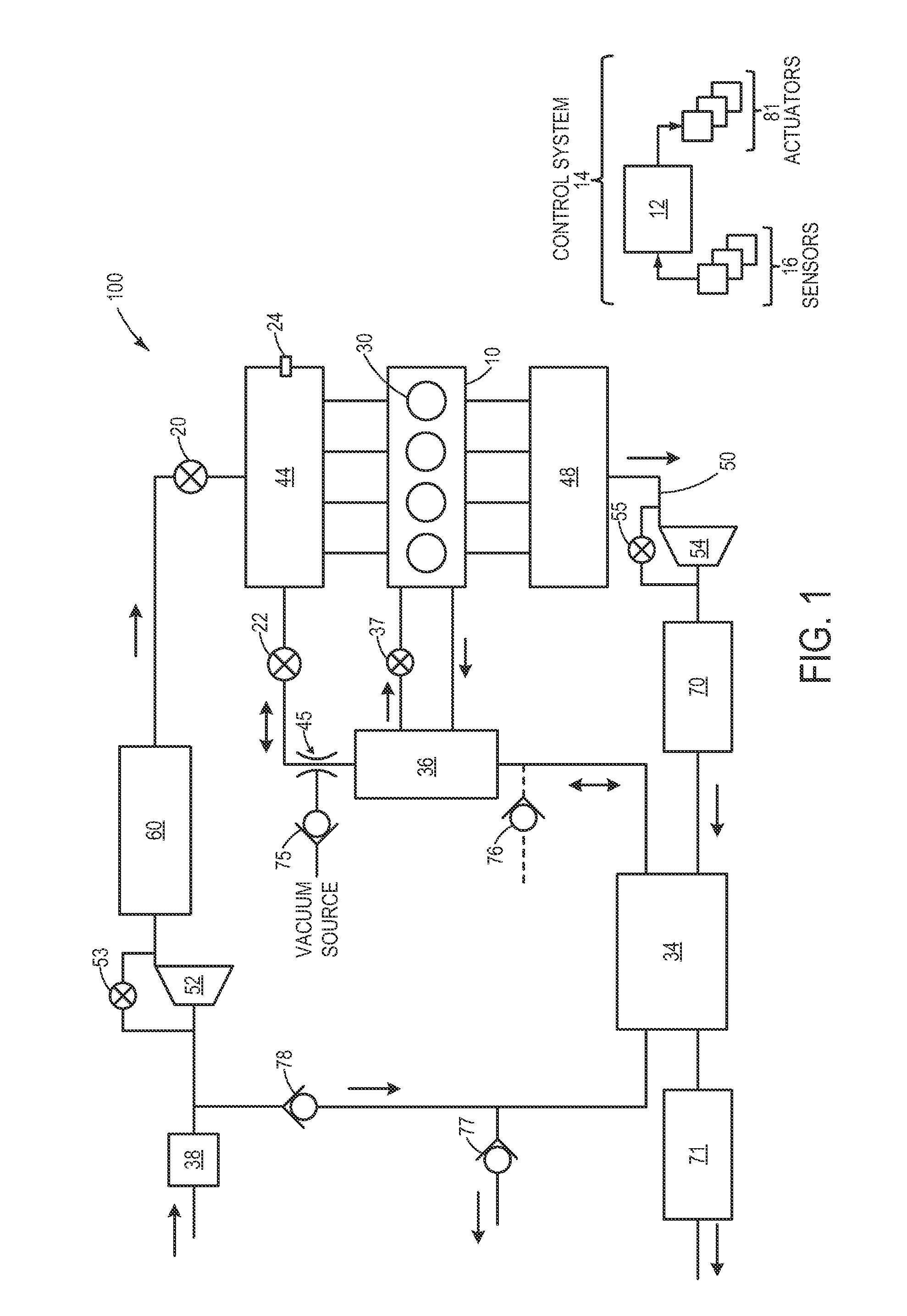

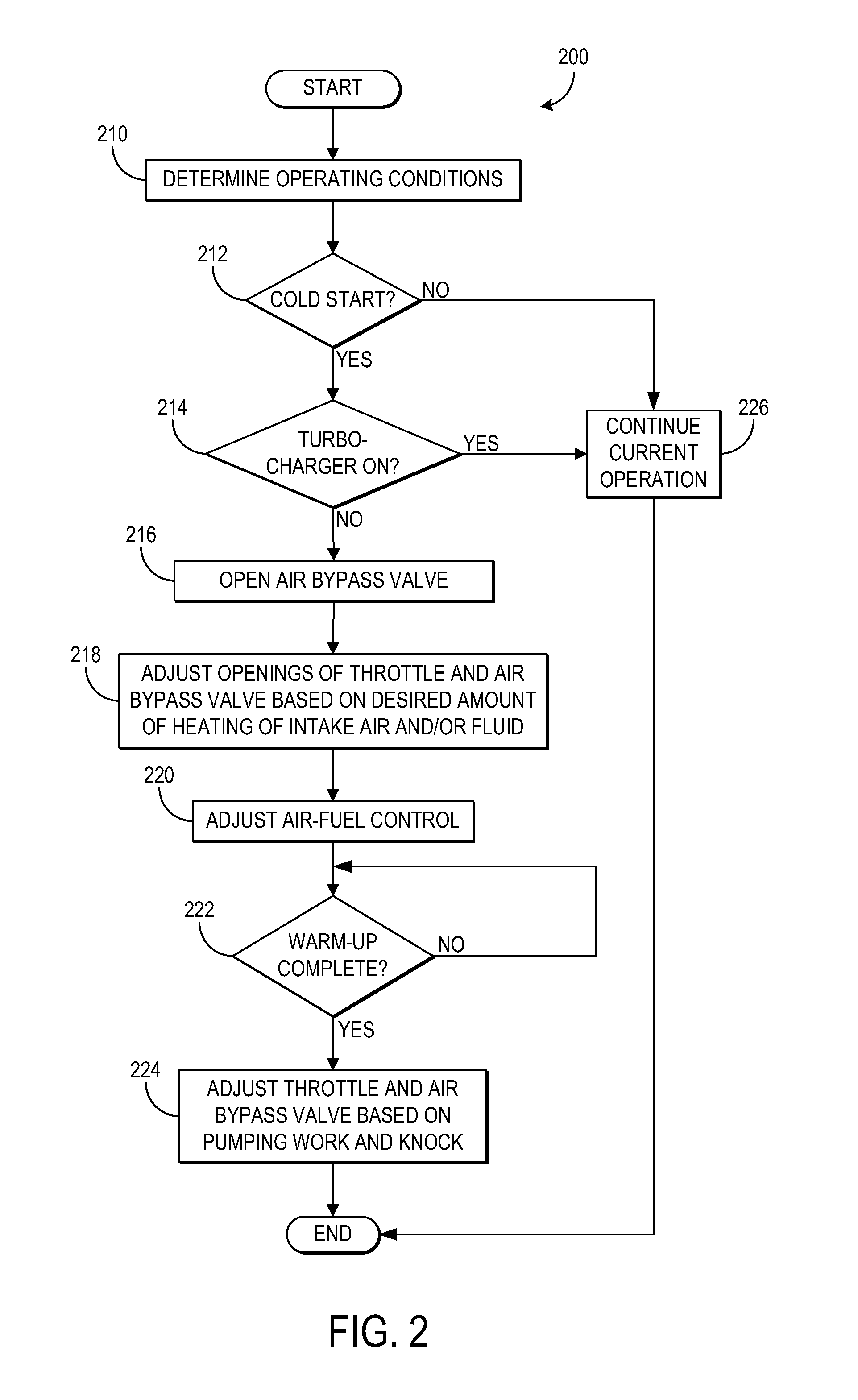

Exhaust heat recovery for engine heating and exhaust cooling

ActiveUS20110138807A1Heating fastLow fluid viscosityLiquid coolingAir-treating devicesGas to liquidsEngineering

Owner:FORD GLOBAL TECH LLC

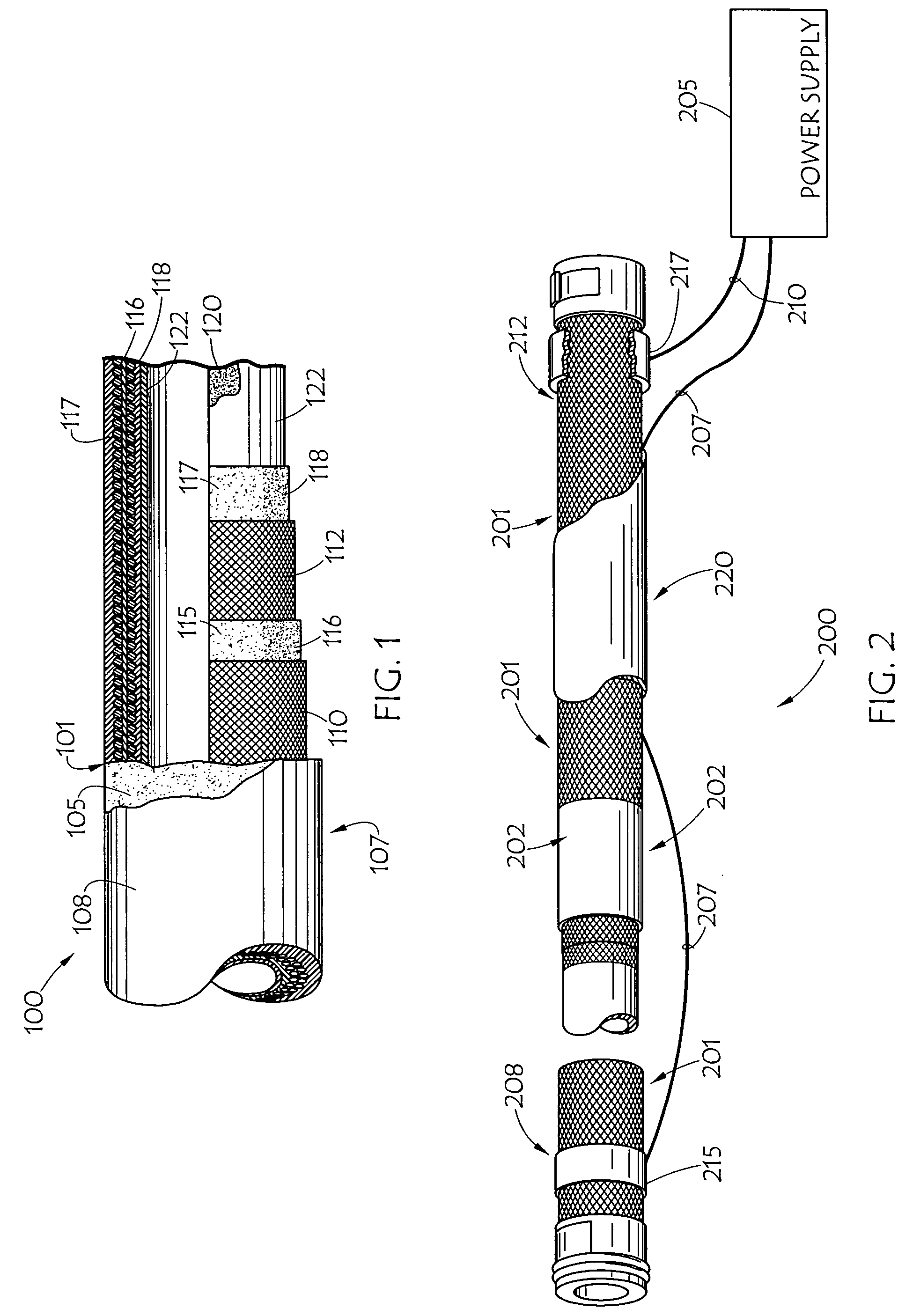

Device and method for direct delivery of a therapeutic using non-newtonian fluids

A device, system, and method for direct delivery of a therapeutic to a target site that utilizes the non-Newtonian characteristics of shear thinning and shear thickening to allow easy passage of a therapeutic through a delivery lumen yet facilitate retention of the therapeutic in the target site. The device, system, and method includes increasing the shear rate or shear stress of a non-Newtonian fluid having therapeutic properties thereby increasing or decreasing the viscosity of the non-Newtonian fluid.

Owner:BOSTON SCI SCIMED INC

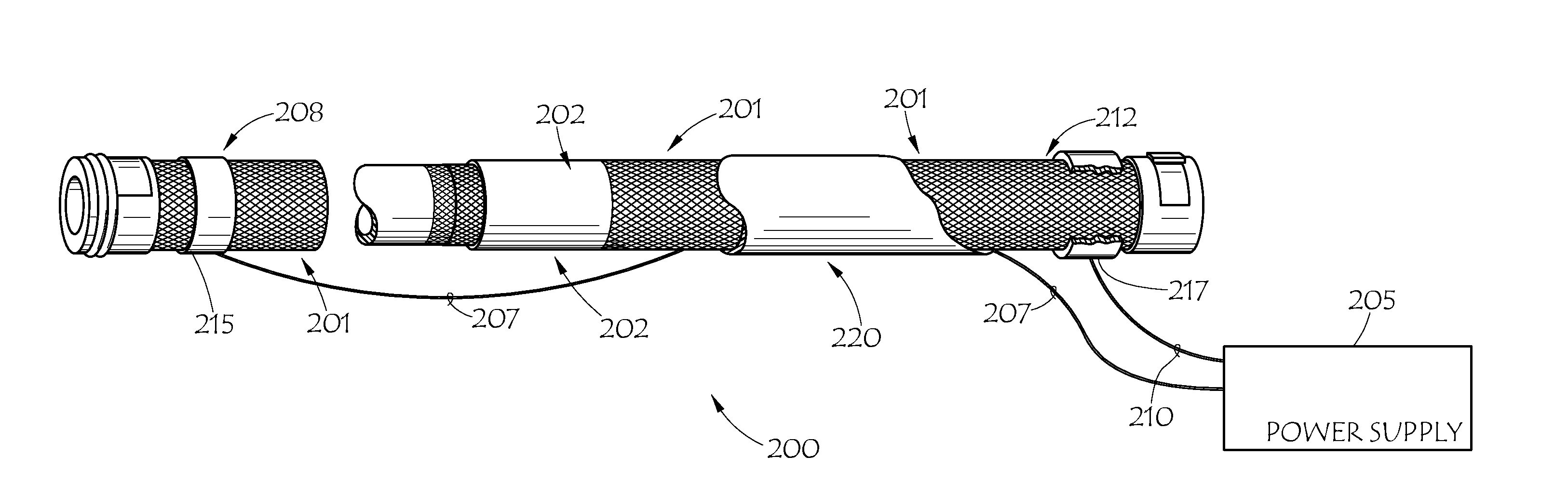

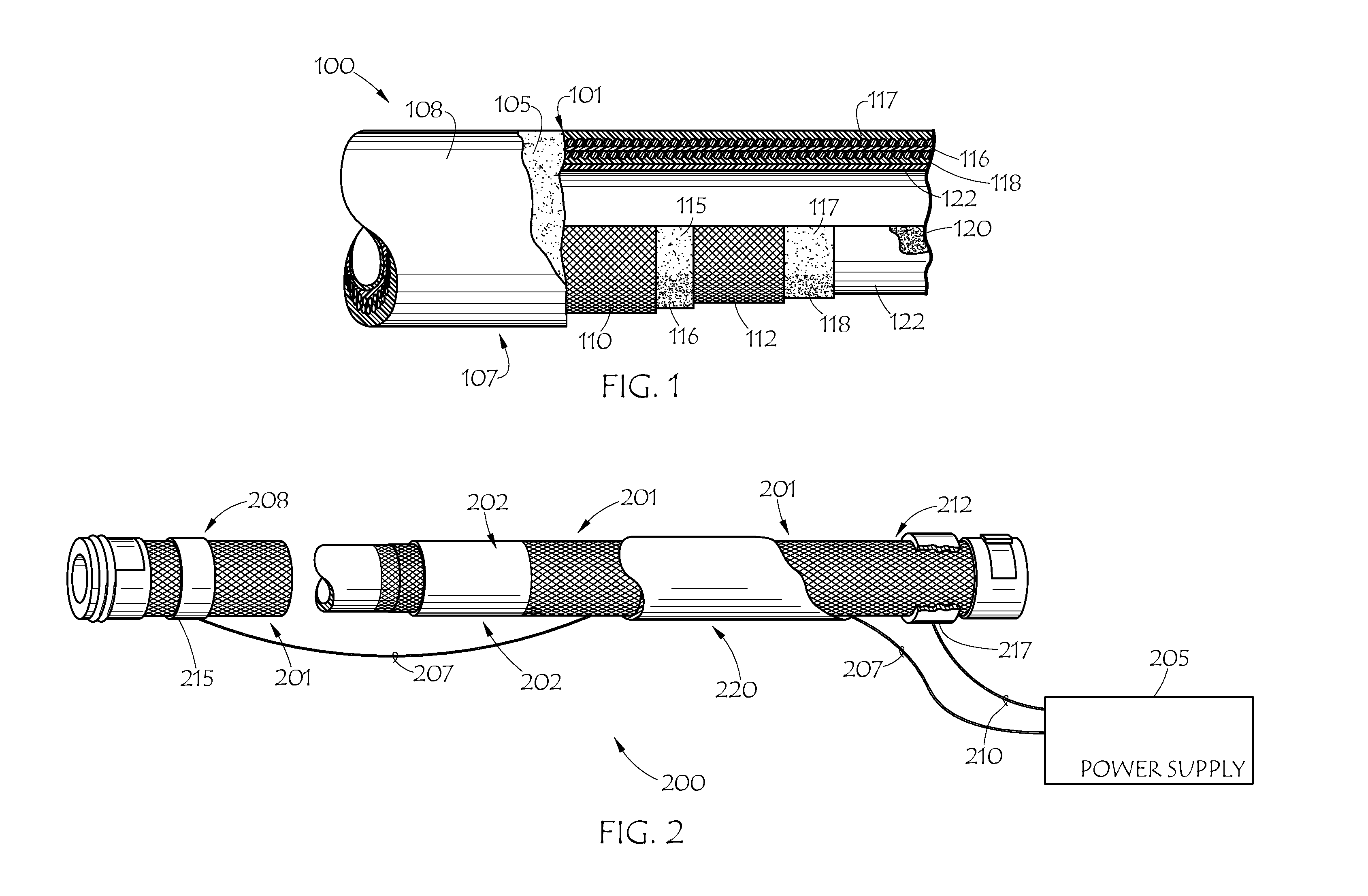

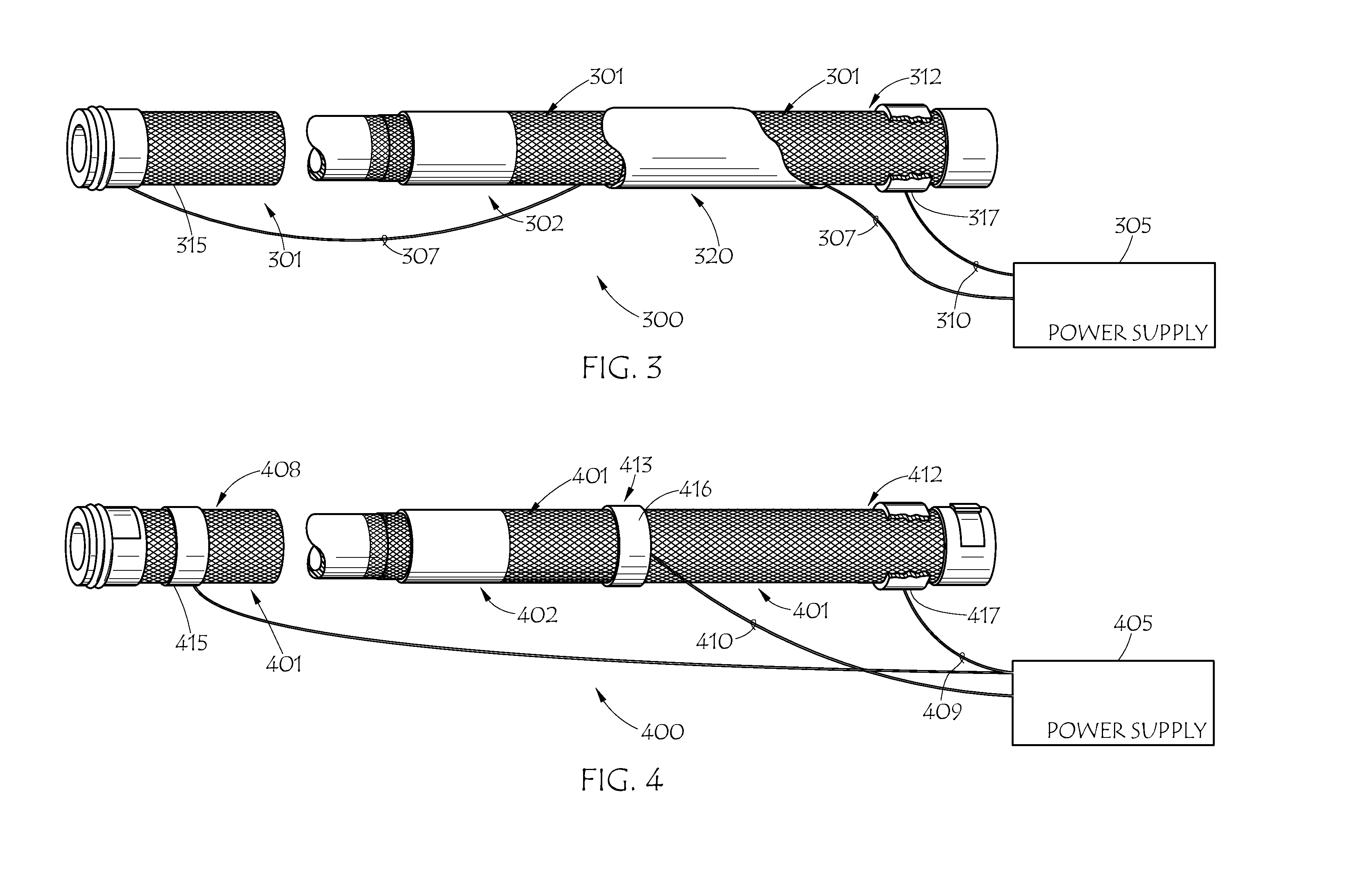

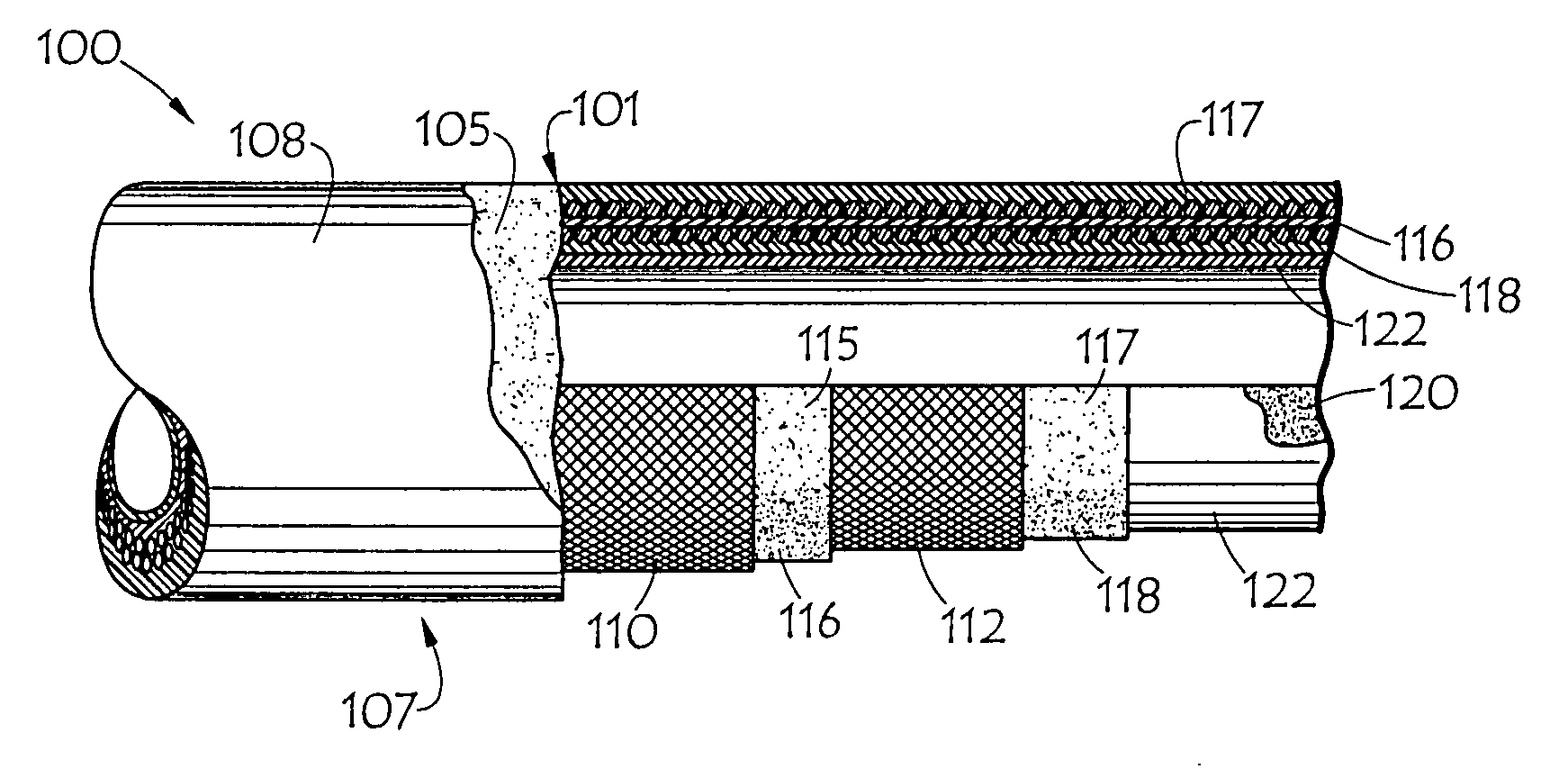

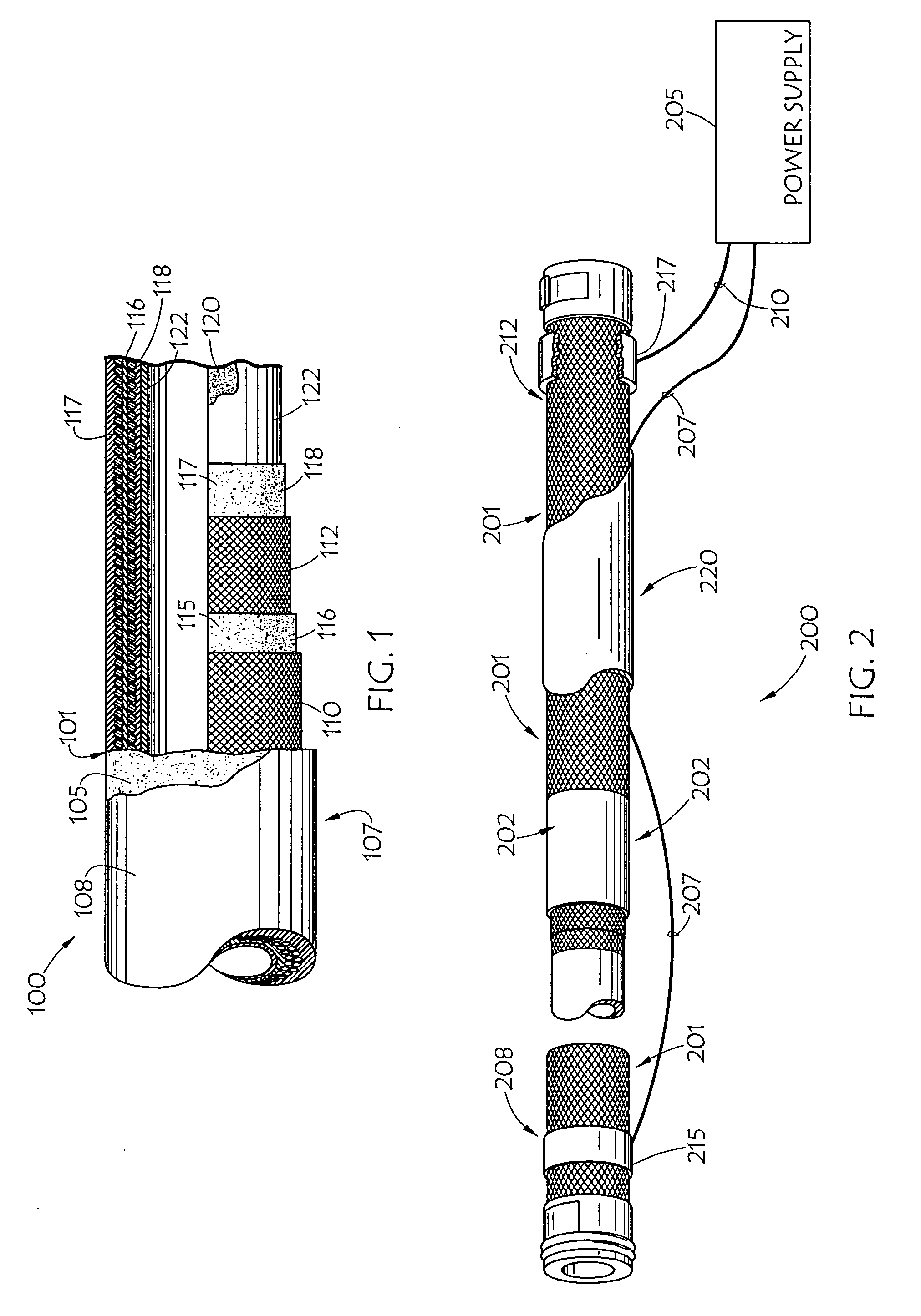

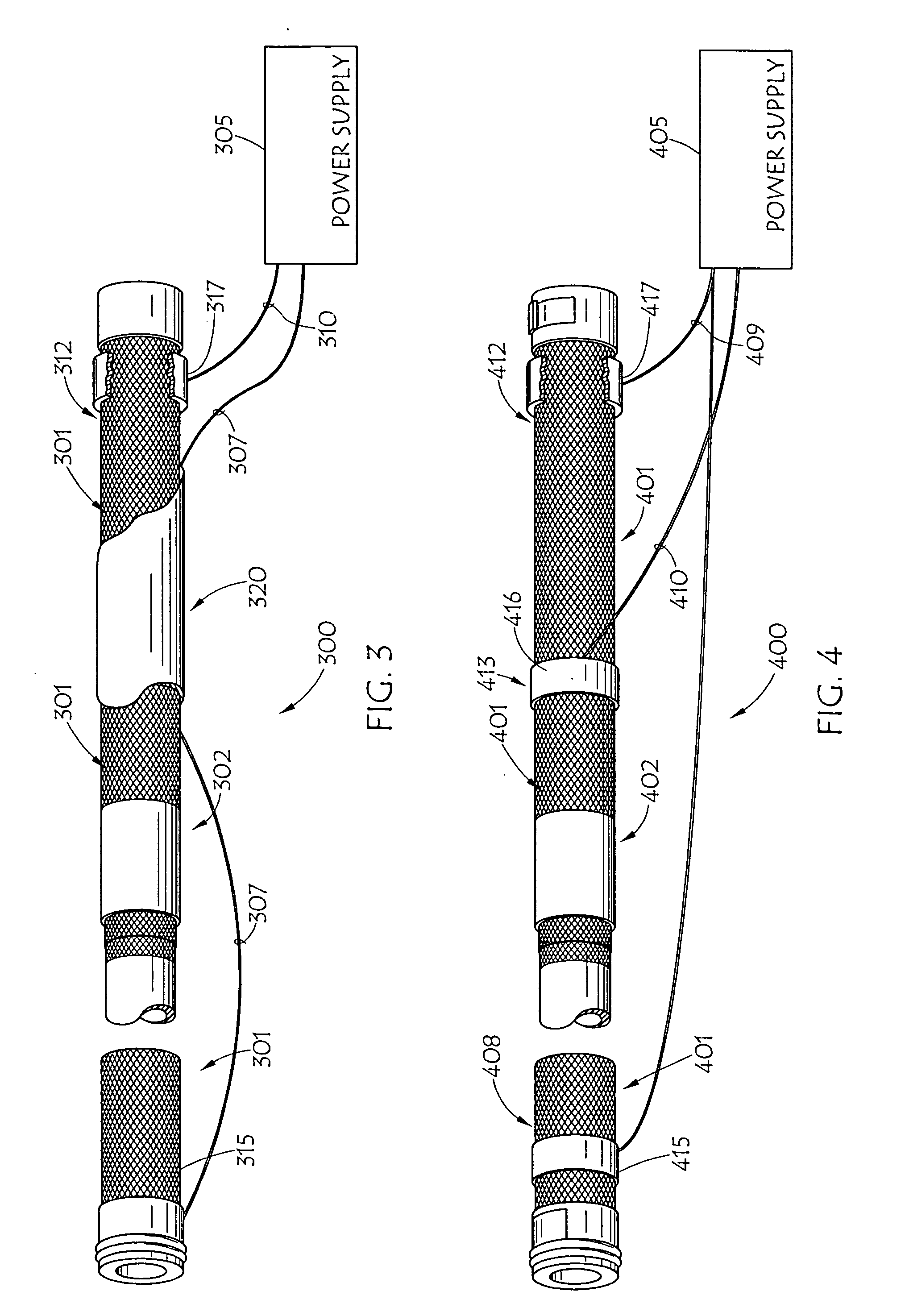

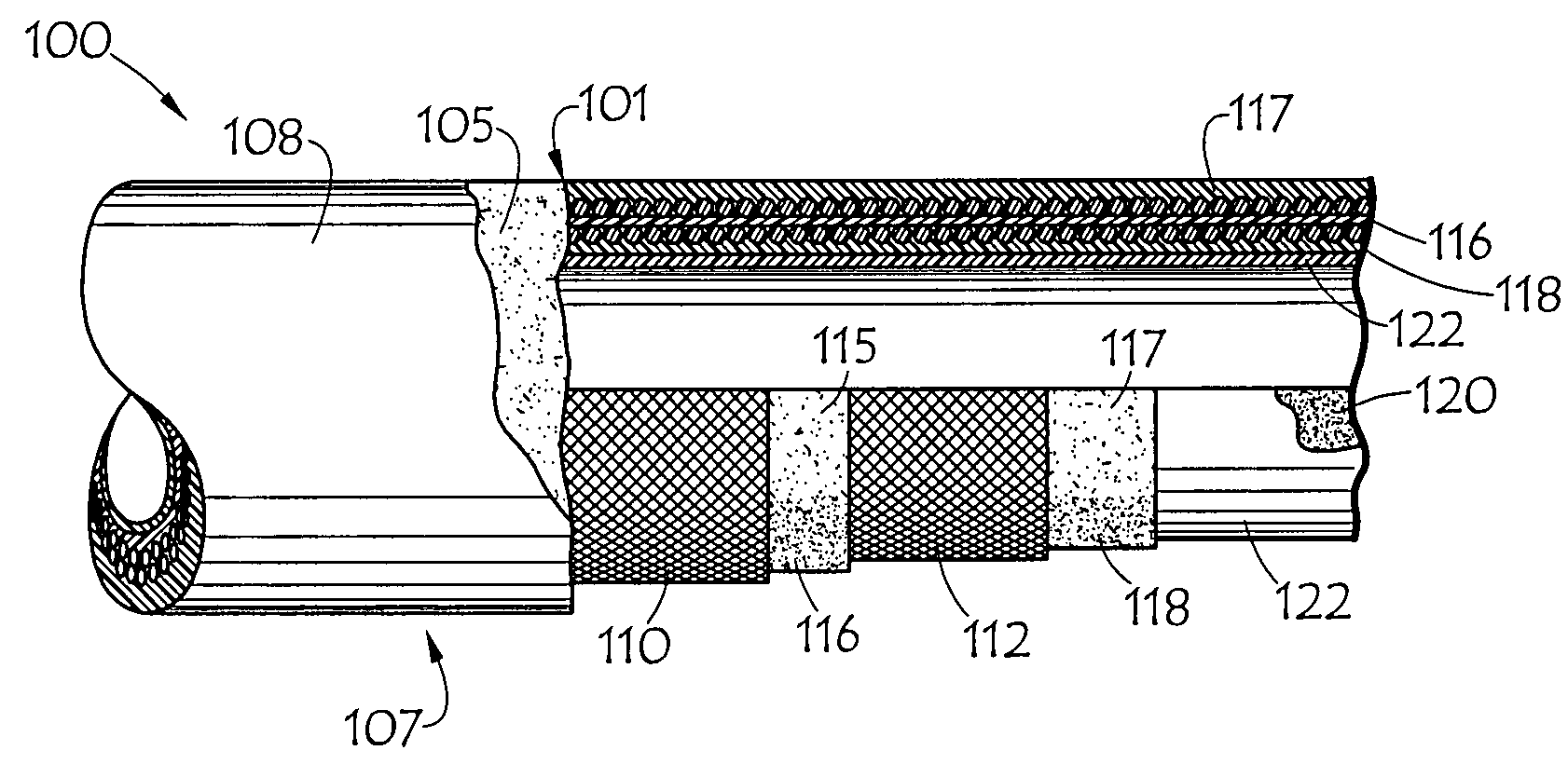

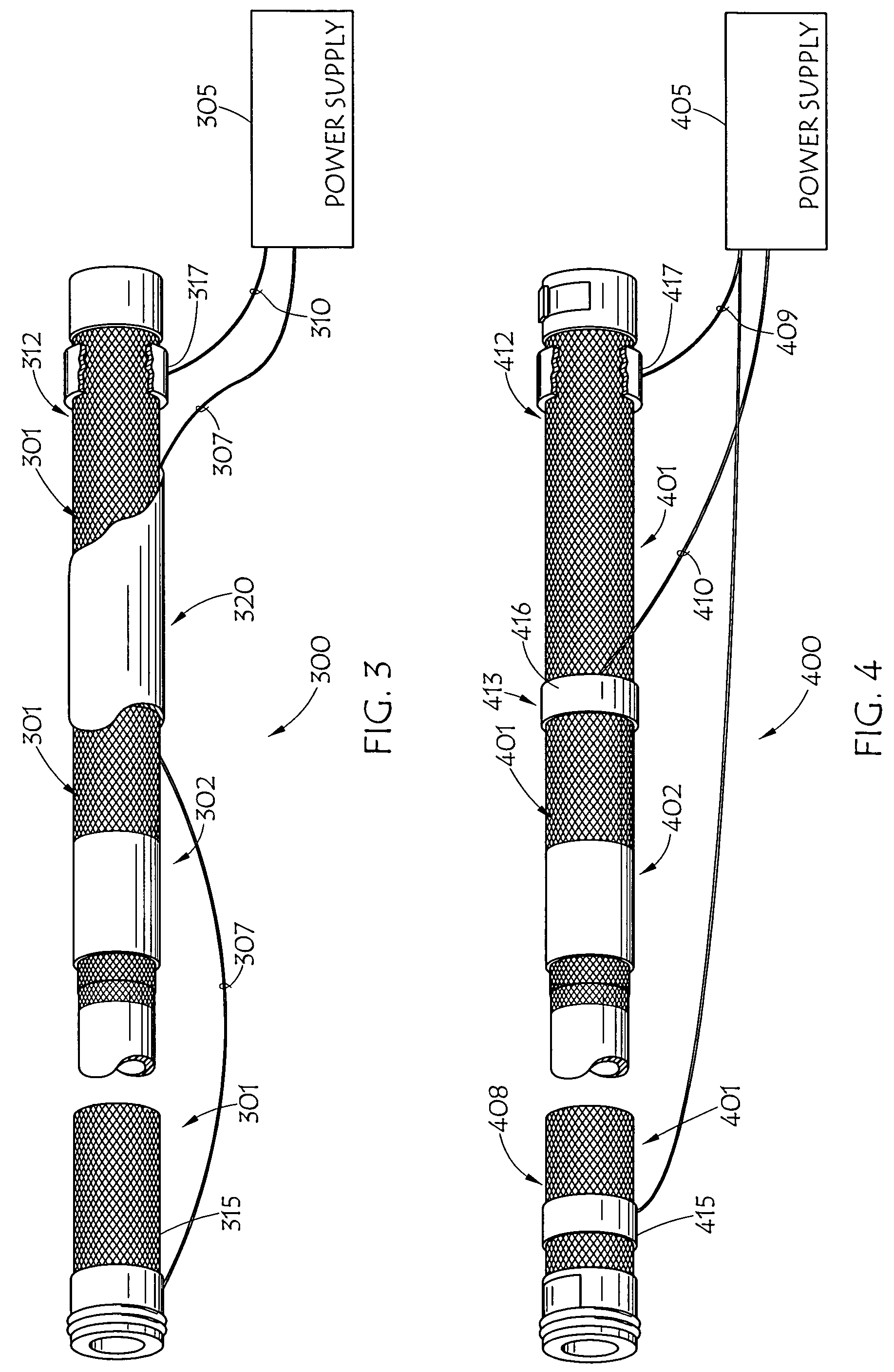

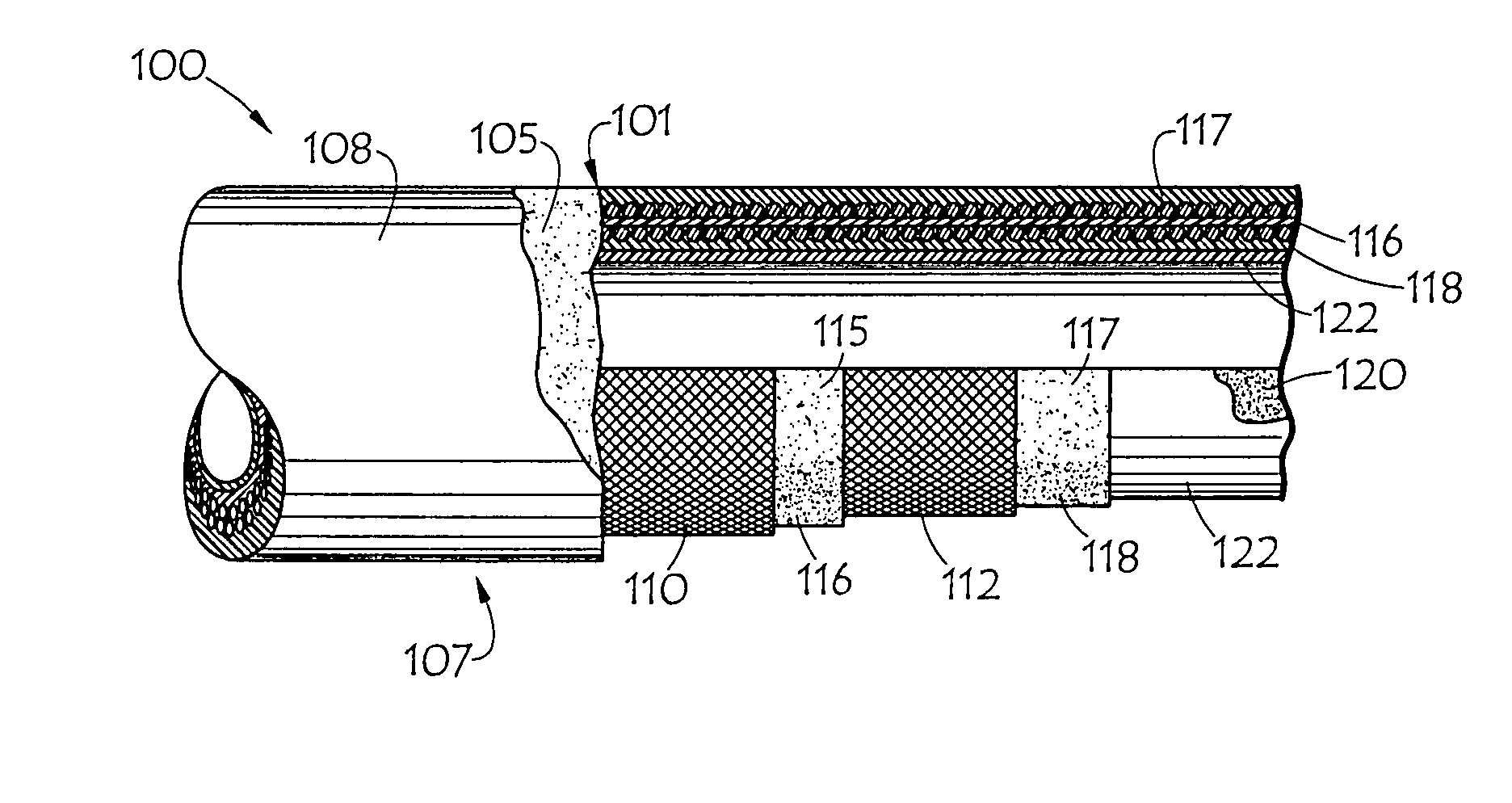

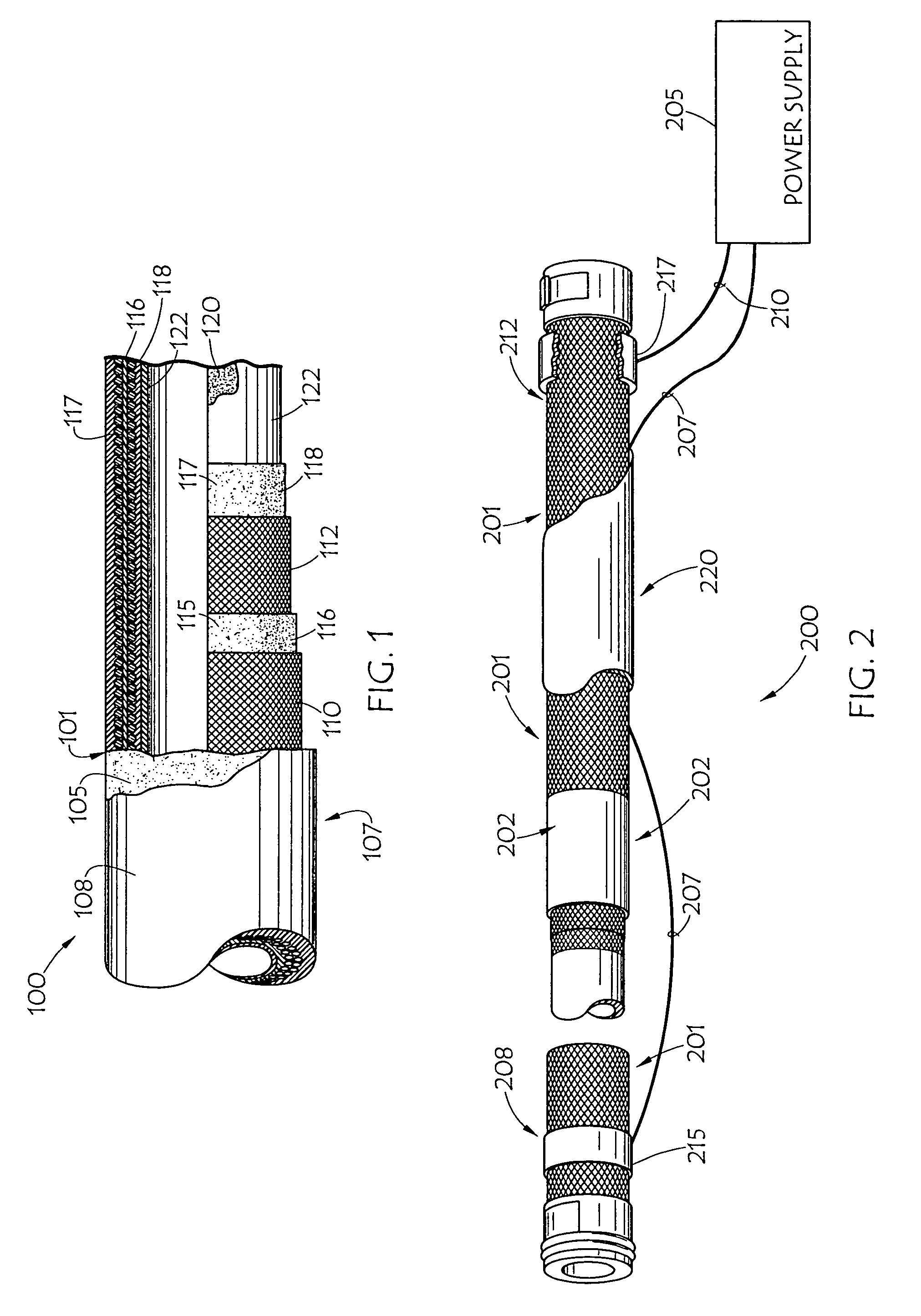

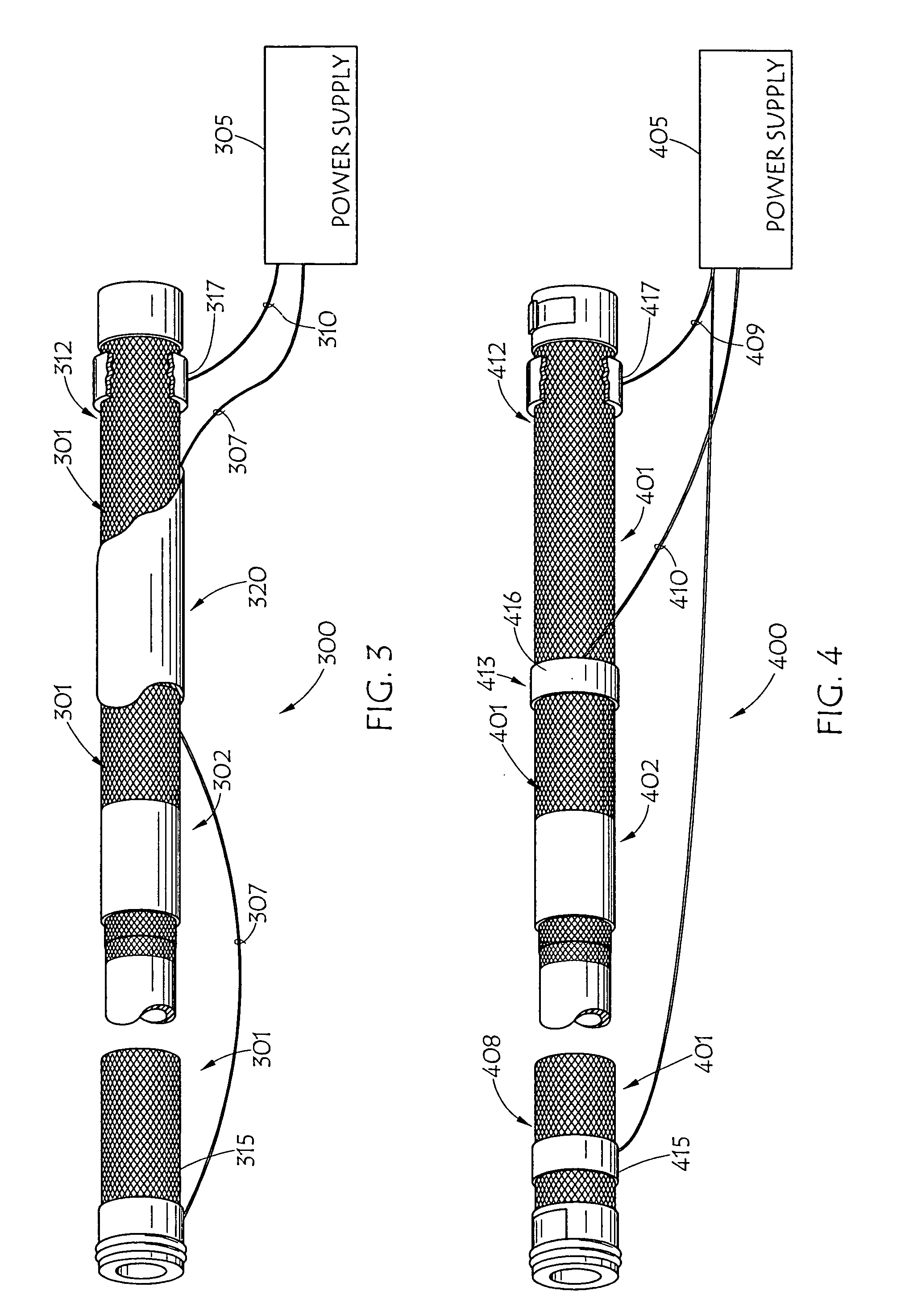

Heated fluid conduit end covers, systems and methods

ActiveUS20100206415A1Low fluid viscosityEasy to operateInternal combustion piston enginesPipe heating/coolingHeating systemBiomedical engineering

A fluid conduit body having a semi-conductive material disposed therein and at least one wire coupling an electrical power supply to the conduit to provide an electrical current therethrough to heat the fluid conduit also has an end cover molded over a fitting fitted to an end of the conduit and over an end of the wire coupling the power supply to an end of the conduit. Alternatively, a fluid conduit heating system employs a semi-conductive sleeve disposed over a fluid conduit with the sleeve extending at least partially over a fitting fitted to an end of the conduit. An electrical power supply is coupled to each end of the sleeve to provide an electrical current through the semi-conductive sleeve to heat the sleeve and the fluid conduit. An end cover is molded over at least a portion of the fitting and the sleeve extending thereover.

Owner:THE GATES CORP

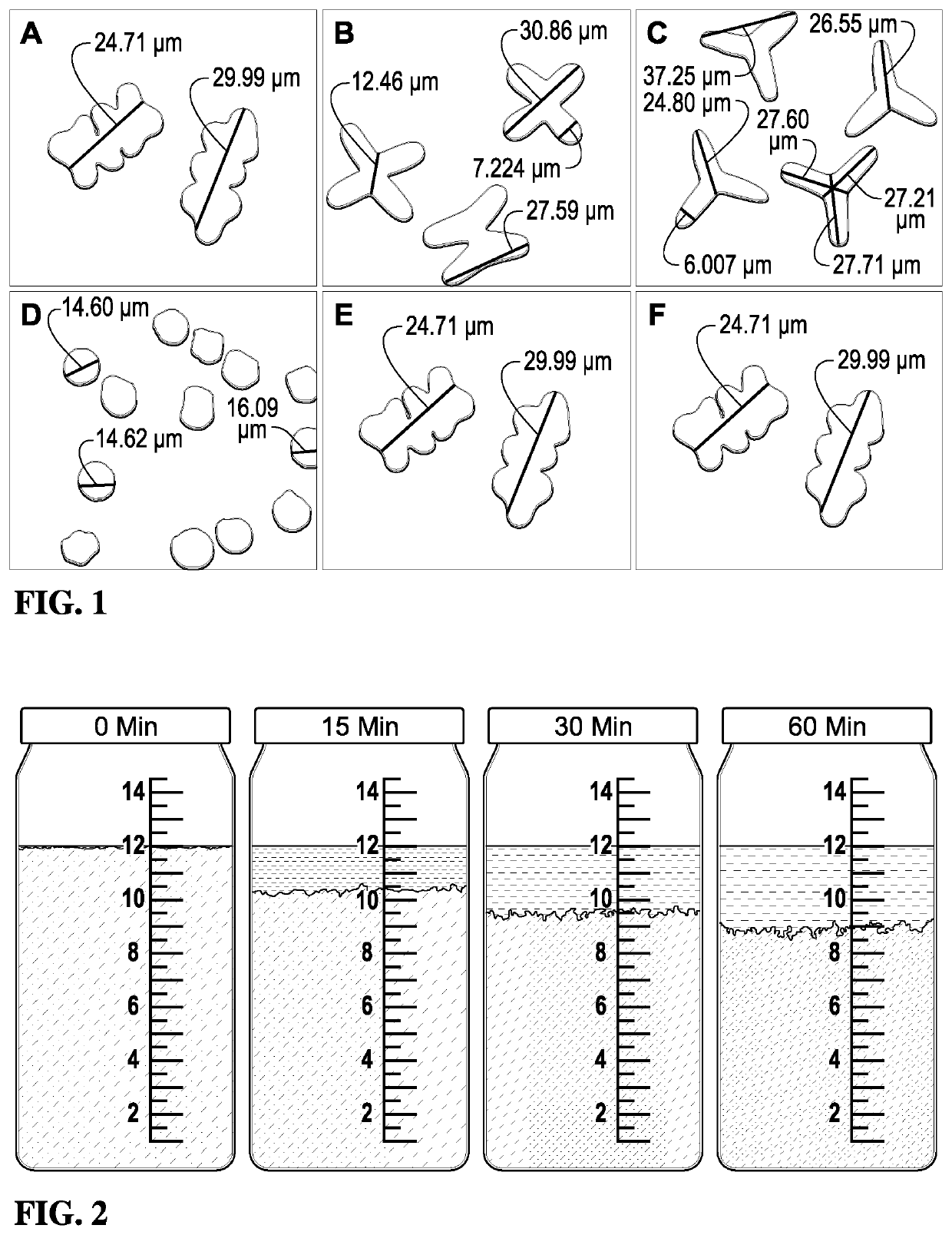

Fiber configurations for wellbore treatment compositions

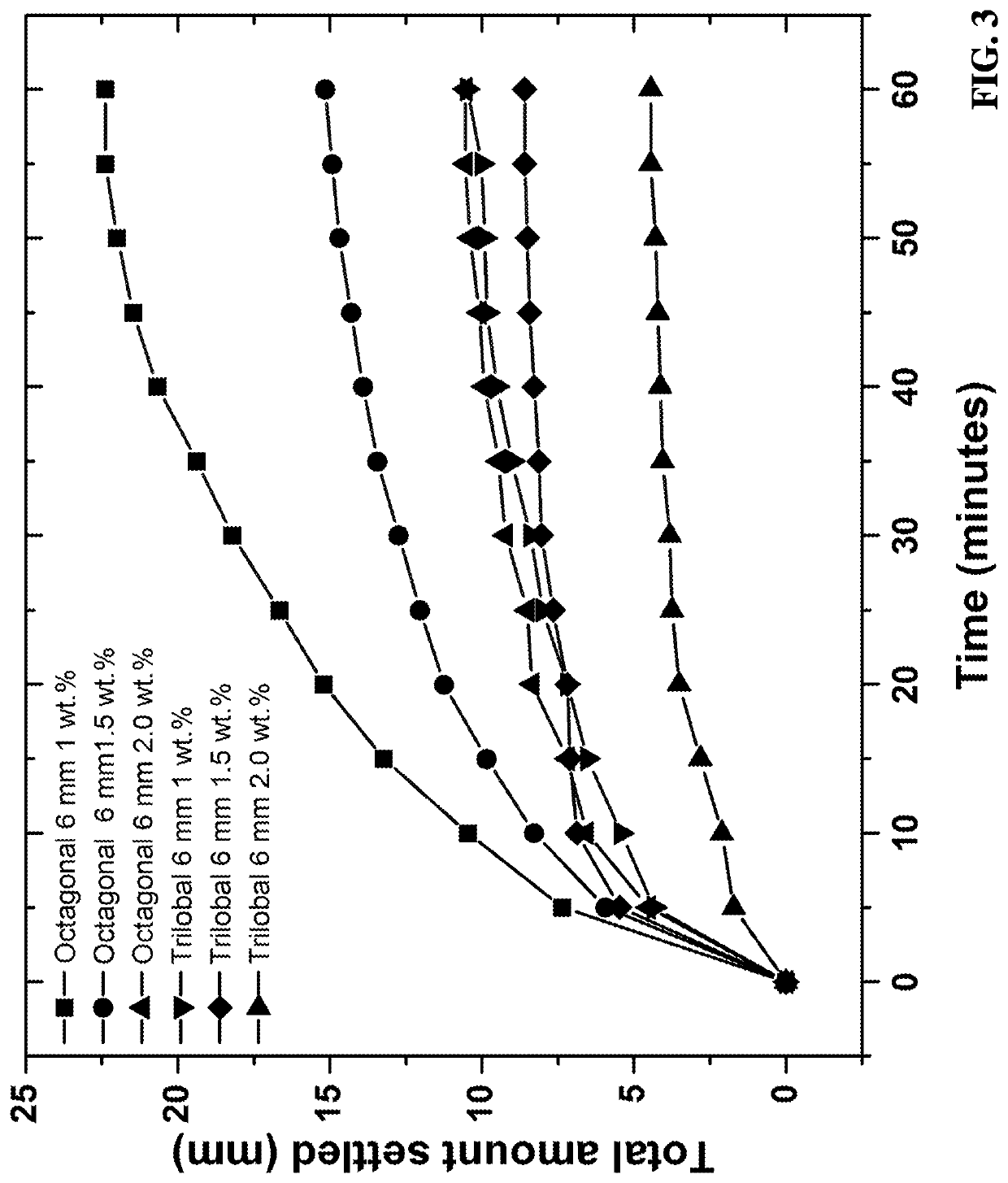

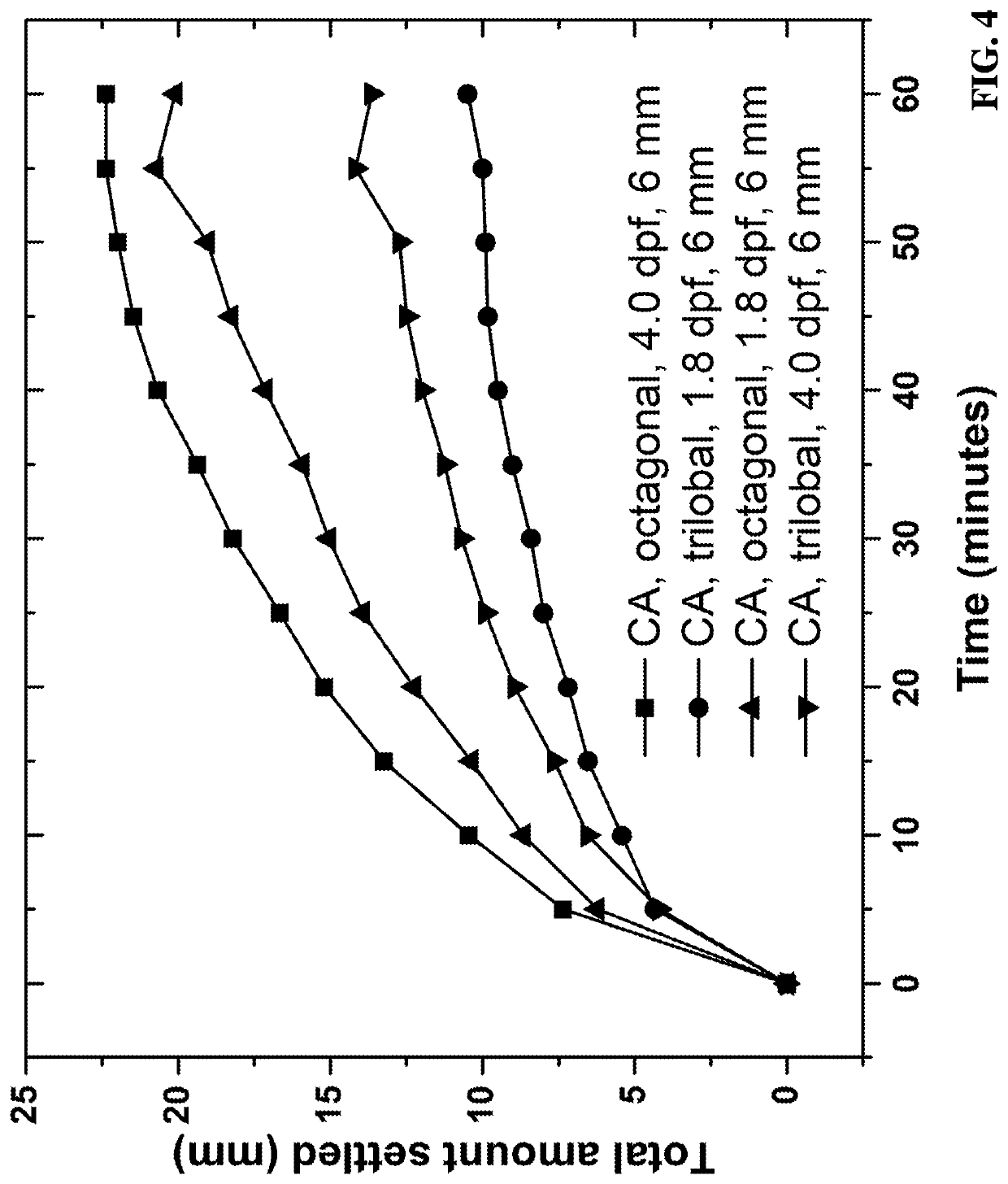

ActiveUS20200040254A1LessLow fluid viscosityFluid removalDrilling compositionCelluloseFiber structure

Suspension of proppants in hydraulic fracturing applications can be strongly affected by the cross-sectional shapes and lengths of the fibers present in the wellbore treatment compositions. For instance, it has been observed that crimped cellulose ester fibers with a trilobal cross-section and an optimized length can provide enhanced suspension of proppants in aqueous fracturing fluids. Furthermore, the present invention demonstrates that non-round cellulose ester fibers can provide superior proppant suspension properties relative to polylactic acid fibers with a round cross-section.

Owner:EASTMAN CHEM CO

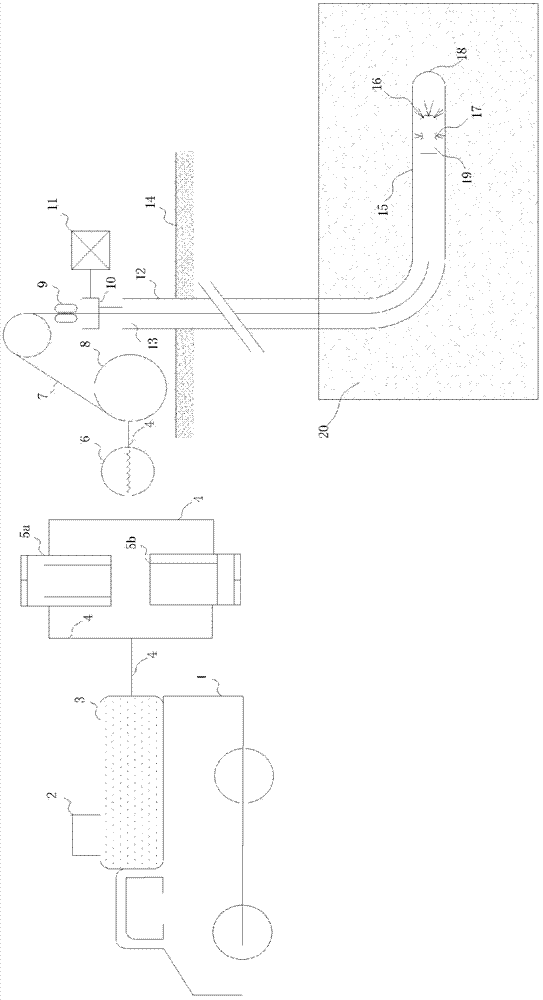

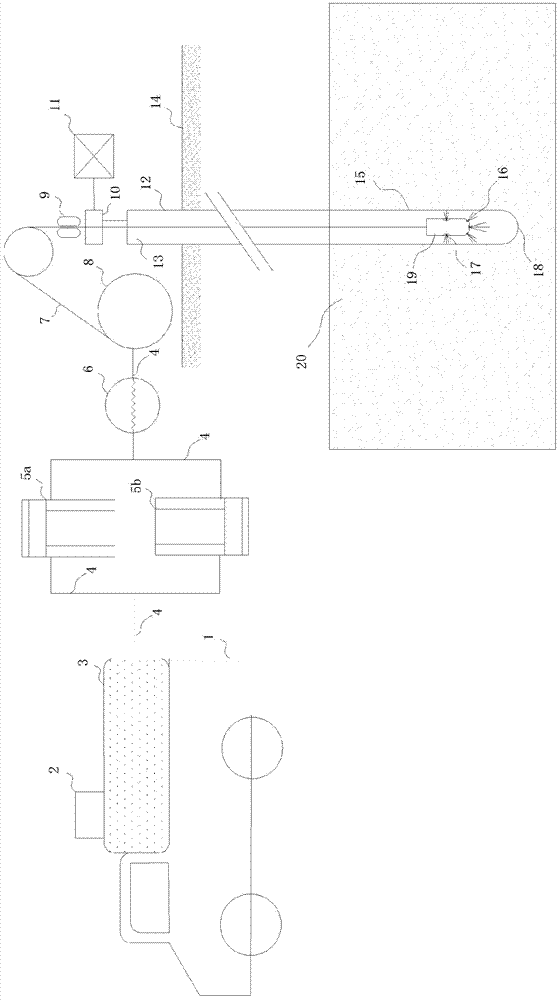

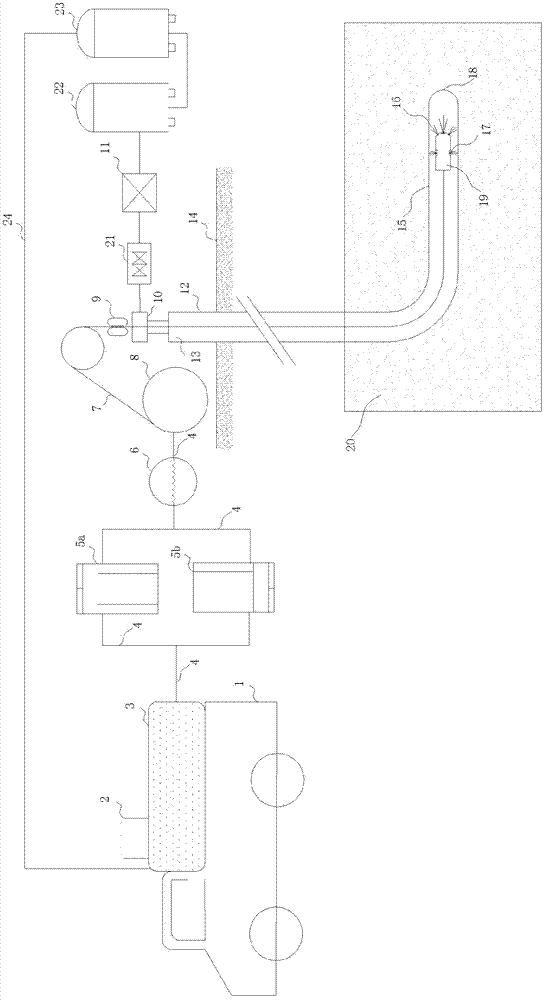

Method combining coiled tubing with supercritical CO2 for jet-flow sand washing plugging removal

The invention relates to a method combining coiled tubing with supercritical CO2 for jet-flow sand washing plugging removal. The method uses the supercritical CO2 as flushing fluid to carry out jet-flow sand washing plugging removal for a shaft or an oil casing. When a supercritical CO2 jet-flow is combined with the coiled tubing to carry out supercritical CO2 jet-flow sand washing plugging removal, pressure relief is not needed in the trip process, the coiled tubing can directly work with pressure, and the working procedure and the time are saved. The fluid viscosity of the supercritical CO2 is low, the surface tension of the supercritical CO2 is close to zero, and the diffusion coefficient of the supercritical CO2 is large, so that the supercritical CO2 can easily enter into tiny pores and cracks to dissolve polymer organic matters and other impurities, and the cleaning is more thorough. And, above all, the supercritical CO2 does not have any pollution to a reservoir, the viscosity of crude oil can also be reduced after the supercritical CO2 enters into the reservoir, the permeability of the reservoir is increased, and the yield and the recovery ratio are increased. Thus, the supercritical CO2 is especially suitable for downhole plugging removal working of unconventional oil-gas reservoirs such as low permeability oil-gas reservoirs, pressure-depleted oil-gas reservoirs, coal gas reservoirs, shale gas reservoirs, tight sandstone gas reservoirs, heavy oil reservoirs and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Electrorheological or magnetorheological compositions for treatment of subterranean formations and methods of using the same

ActiveUS20140224480A1High viscosityHigh yieldFluid removalDrilling compositionClassical mechanicsMagnetorheological fluid

The present invention relates to compositions for the treatment of subterranean formations, and methods of using the same. In various embodiments, the present invention provides a fluid for treatment of a subterranean formation, wherein the fluid is at least one of electrorheological and magnetorheological. Various embodiments also provide methods of using the electrorheological or magnetorheological fluid in a subterranean formation, including for fracturing, deposition of proppants, and combinations thereof.

Owner:HALLIBURTON ENERGY SERVICES INC

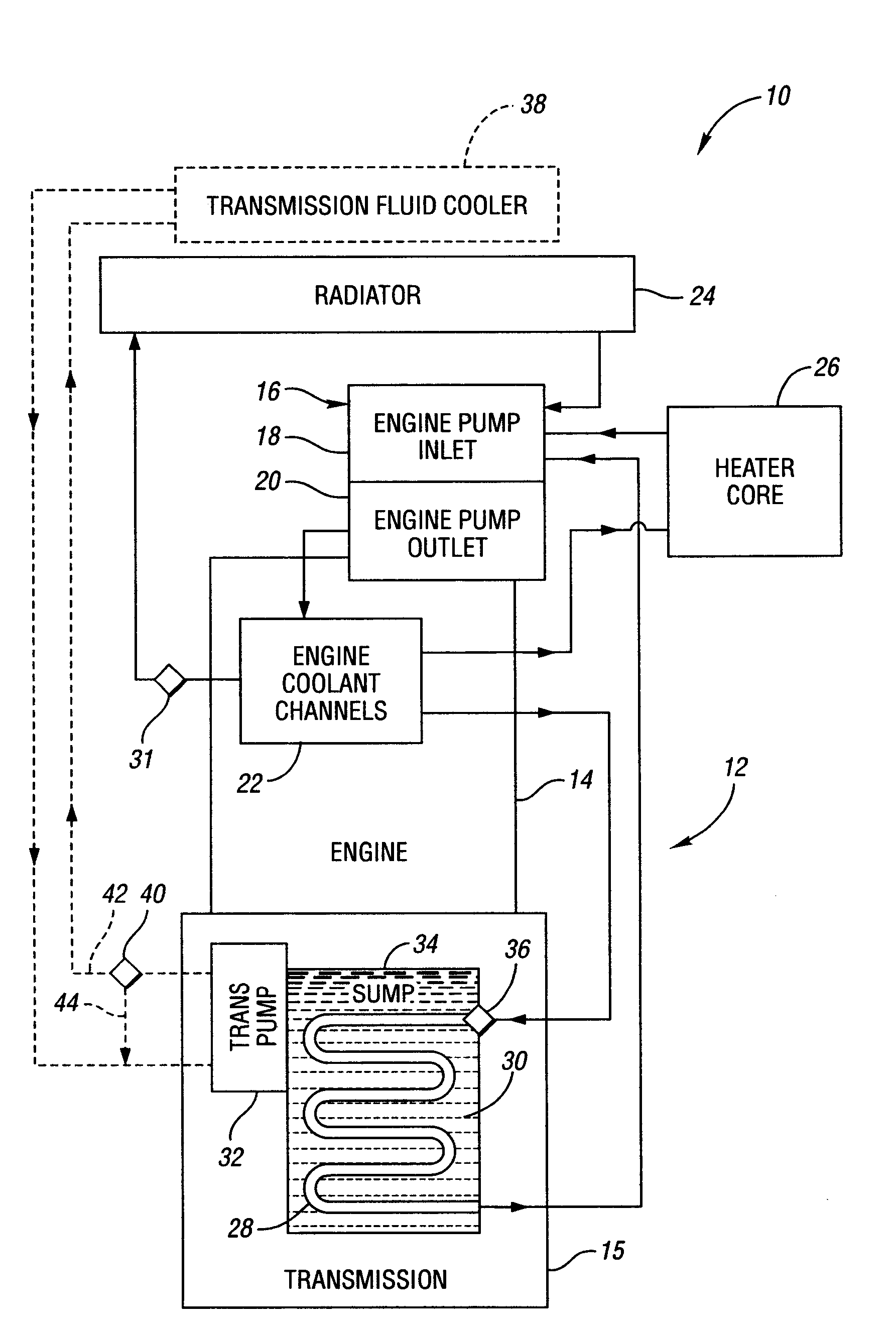

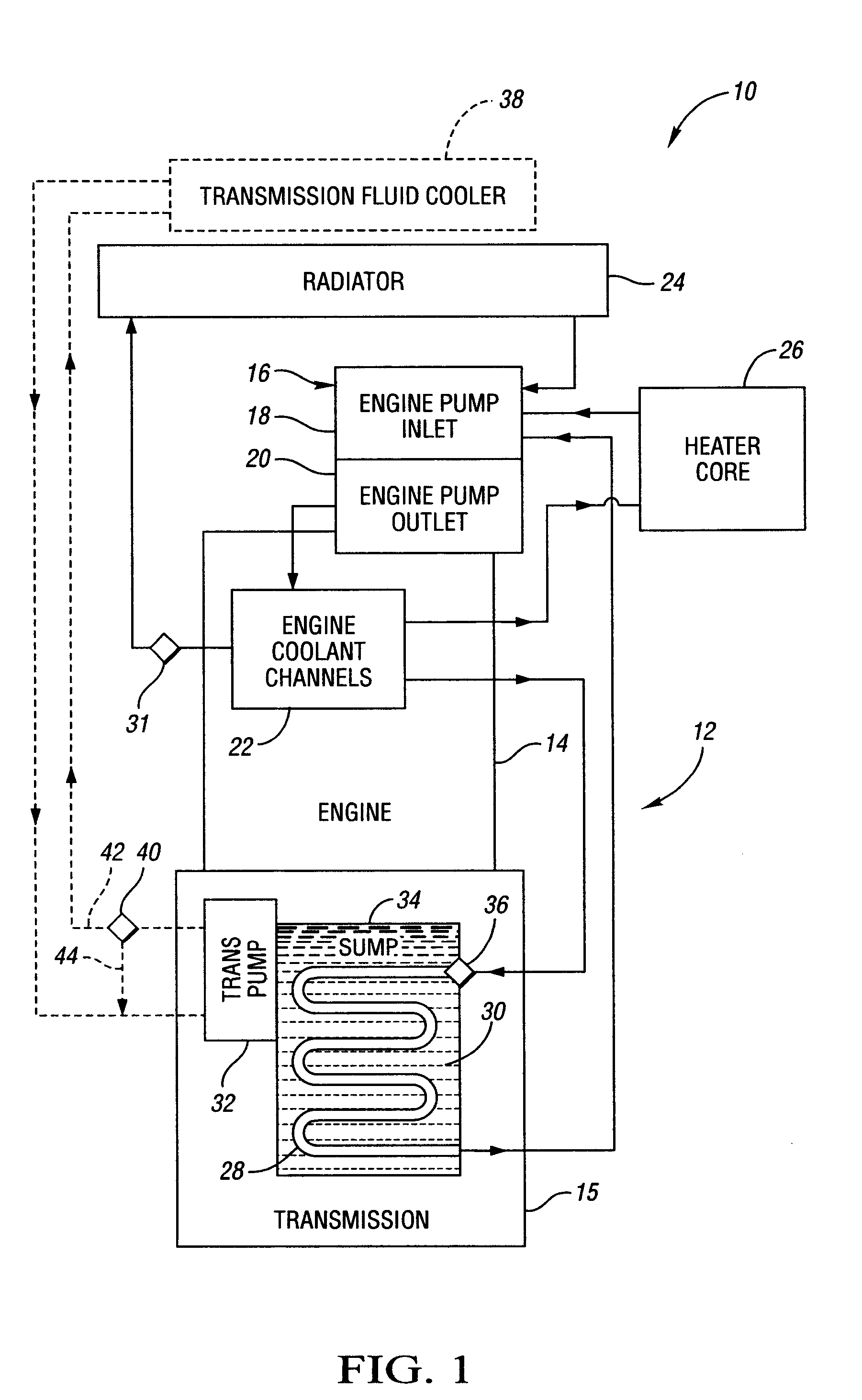

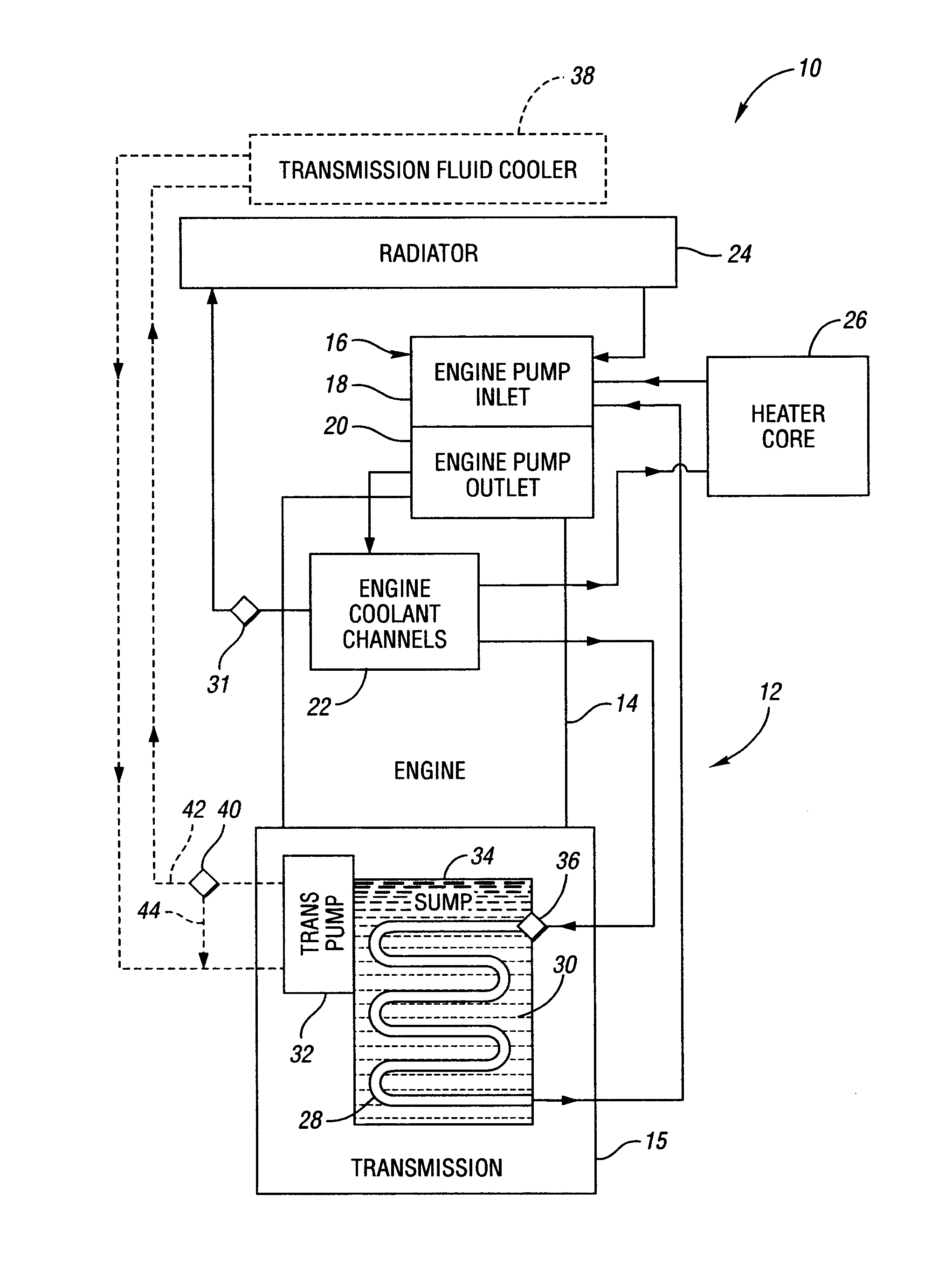

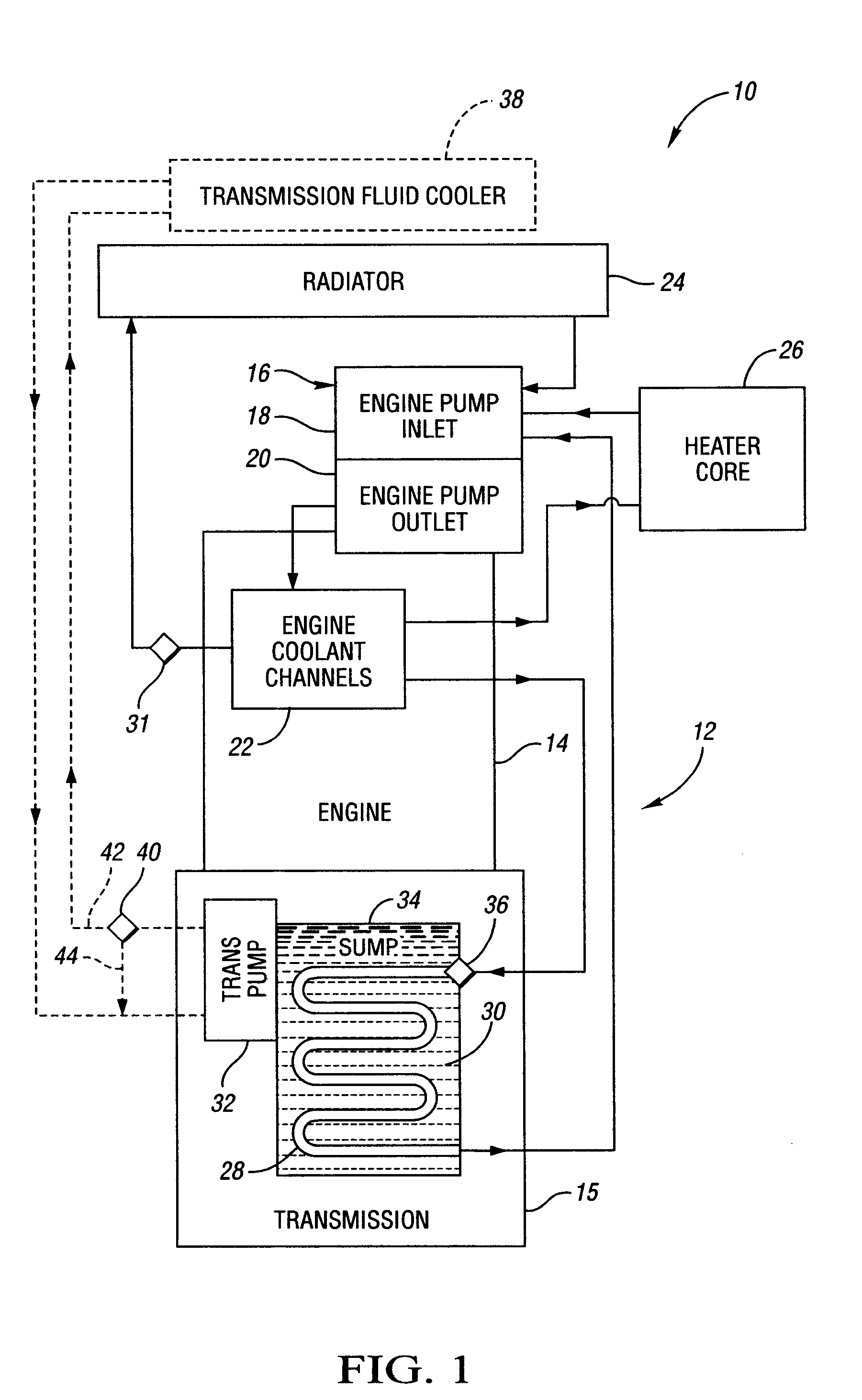

Method and Apparatus for Improving Vehicle Fuel Economy

ActiveUS20070295475A1Improve fuel economyDecrease transmission fluid viscosityAir-treating devicesRailway heating/coolingFluid viscosityCoolant channel

The present invention provides an apparatus for improving the fuel economy of a vehicle. The apparatus includes a transmission having a transmission sump that contains transmission fluid, and a heat exchanger disposed within said sump and at least partially submerged in the transmission fluid. The apparatus also includes an engine having a plurality of engine coolant channels. An engine pump is operatively connected to the engine. The engine pump is configured to transfer engine coolant through the plurality of engine coolant channels and then through the heat exchanger. Heat from the engine coolant is transferred to the transmission fluid when the engine coolant passes through the heat exchanger. The heat transferred to the transmission fluid decreases transmission fluid viscosity such that transmission spin losses are reduced and fuel economy is improved. A corresponding method for improving the fuel economy of a vehicle is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

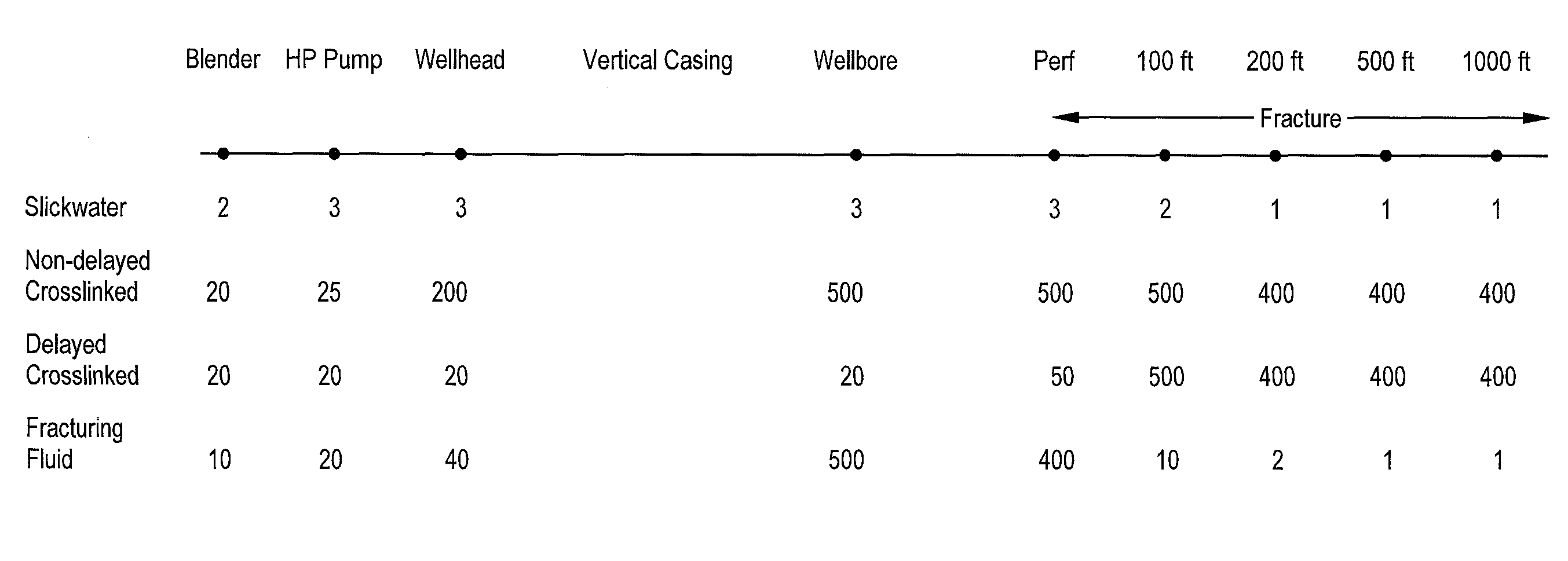

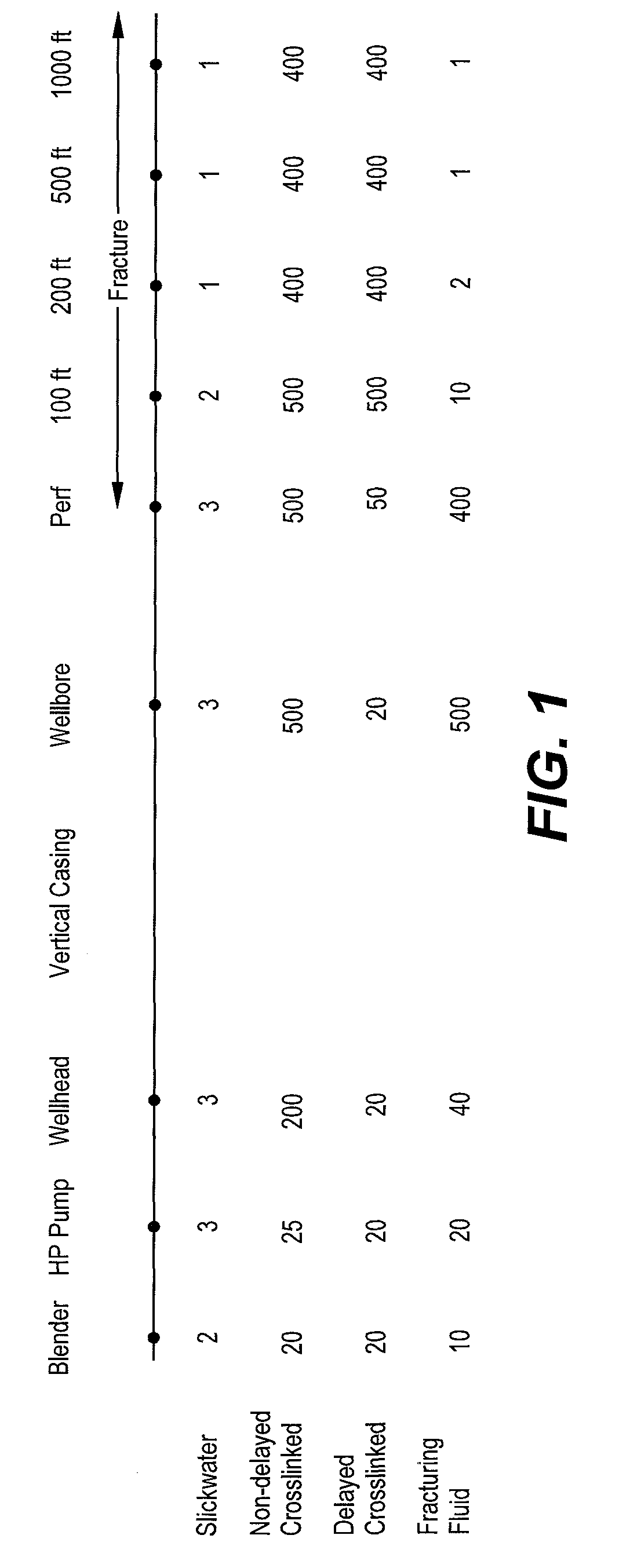

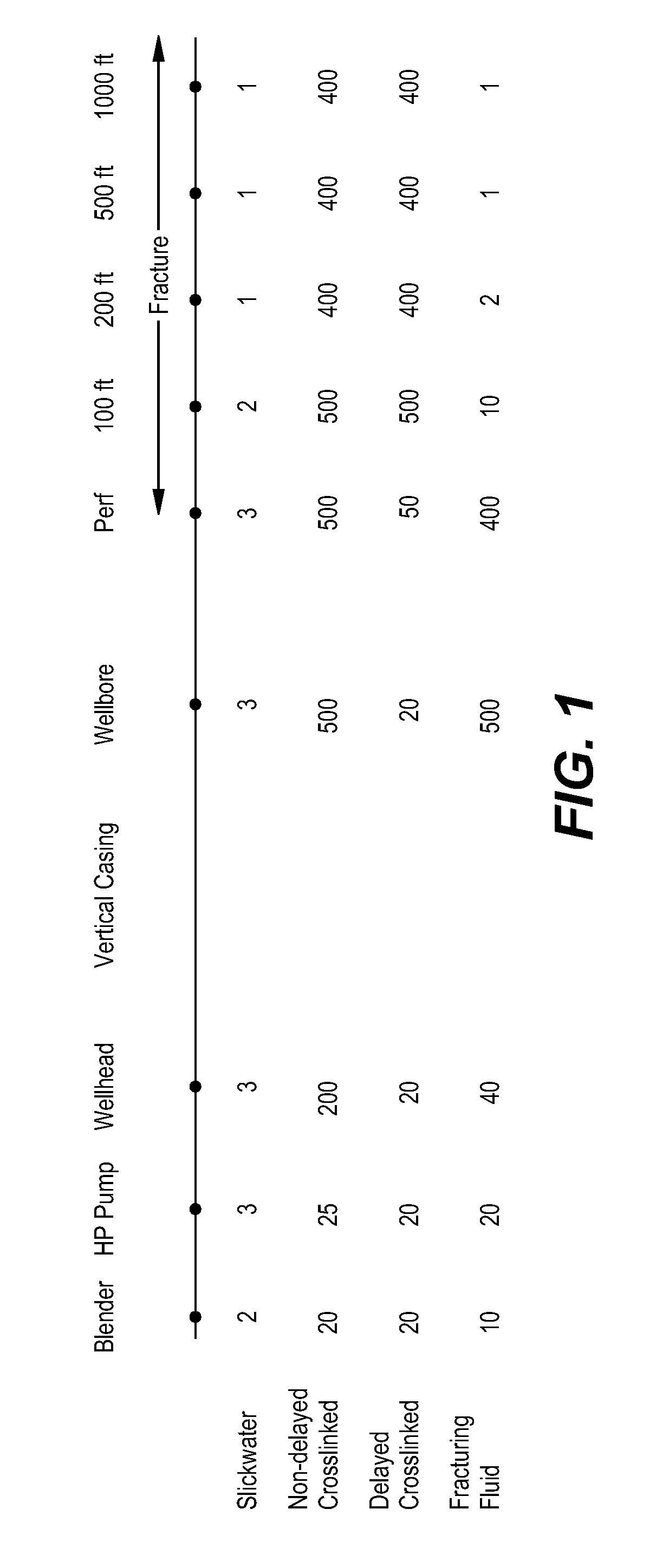

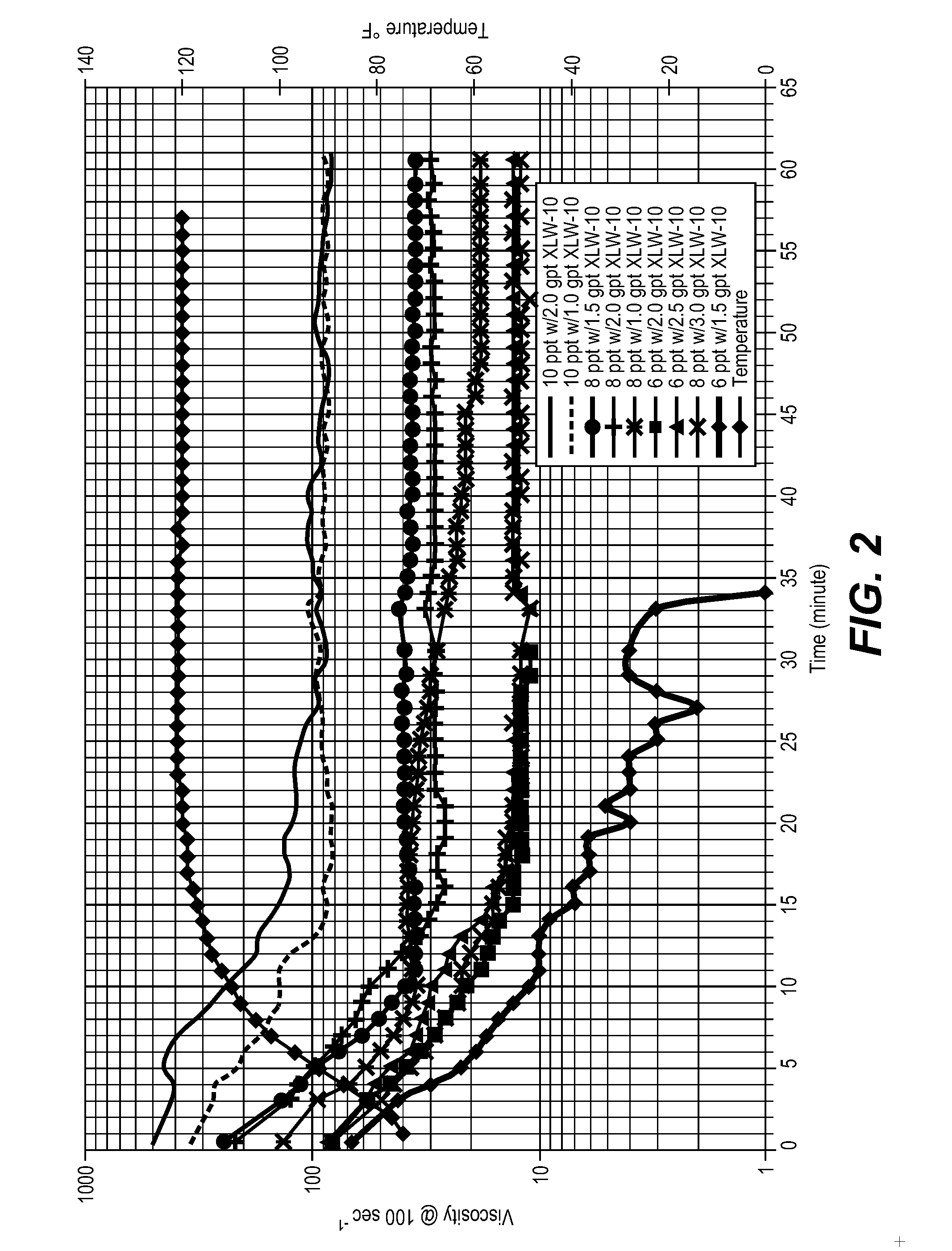

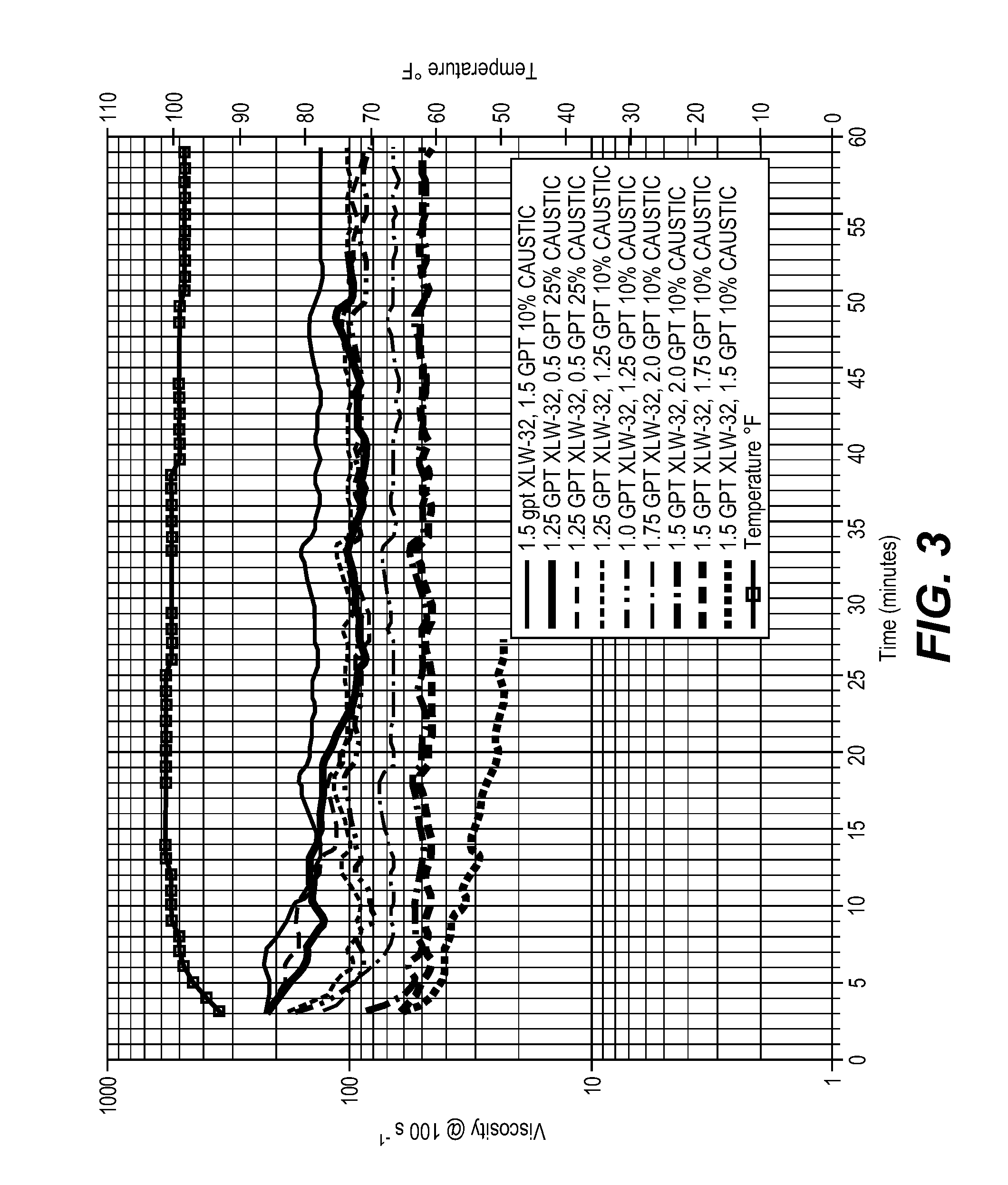

Method of fracturing subterranean formations with crosslinked fluid

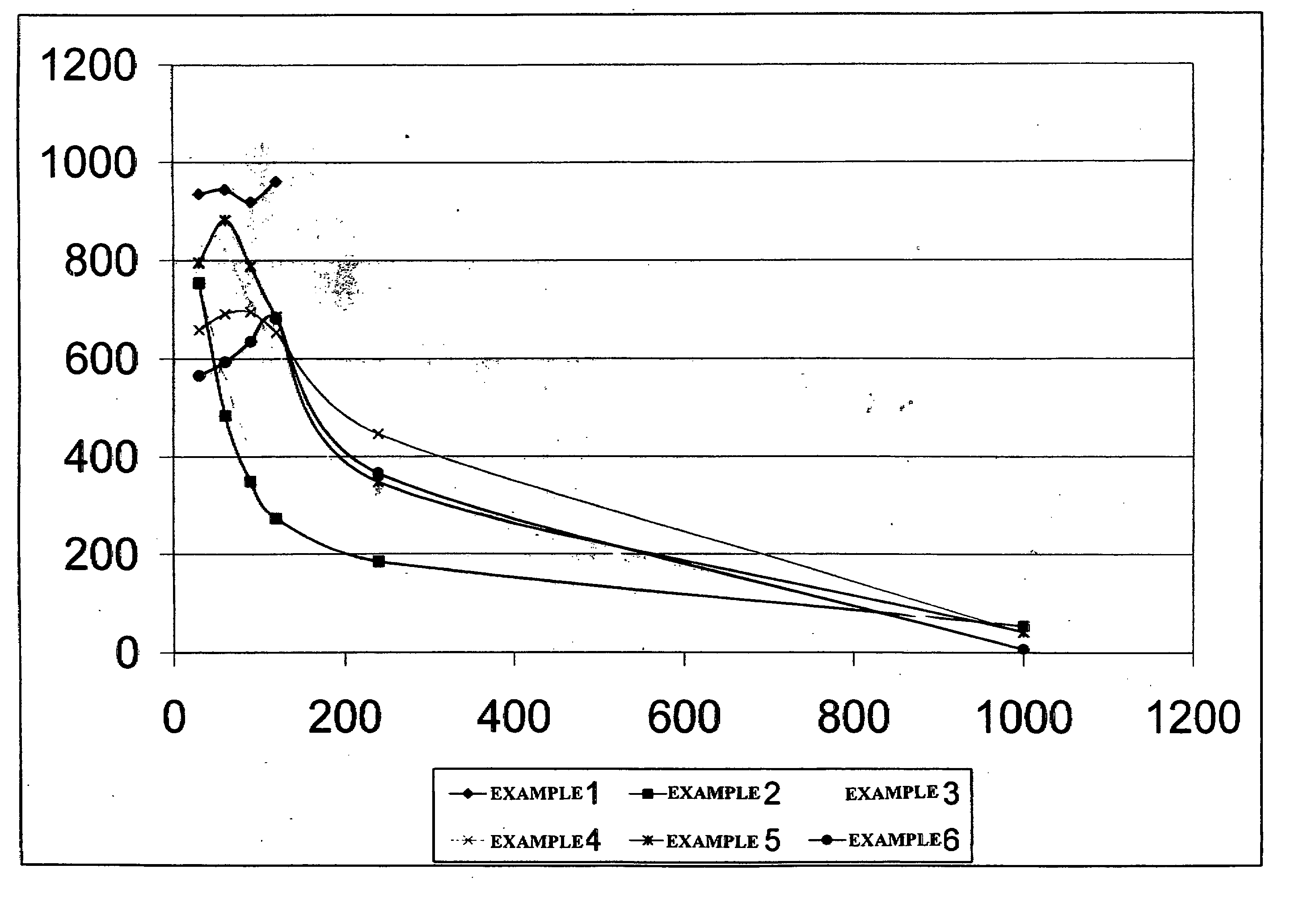

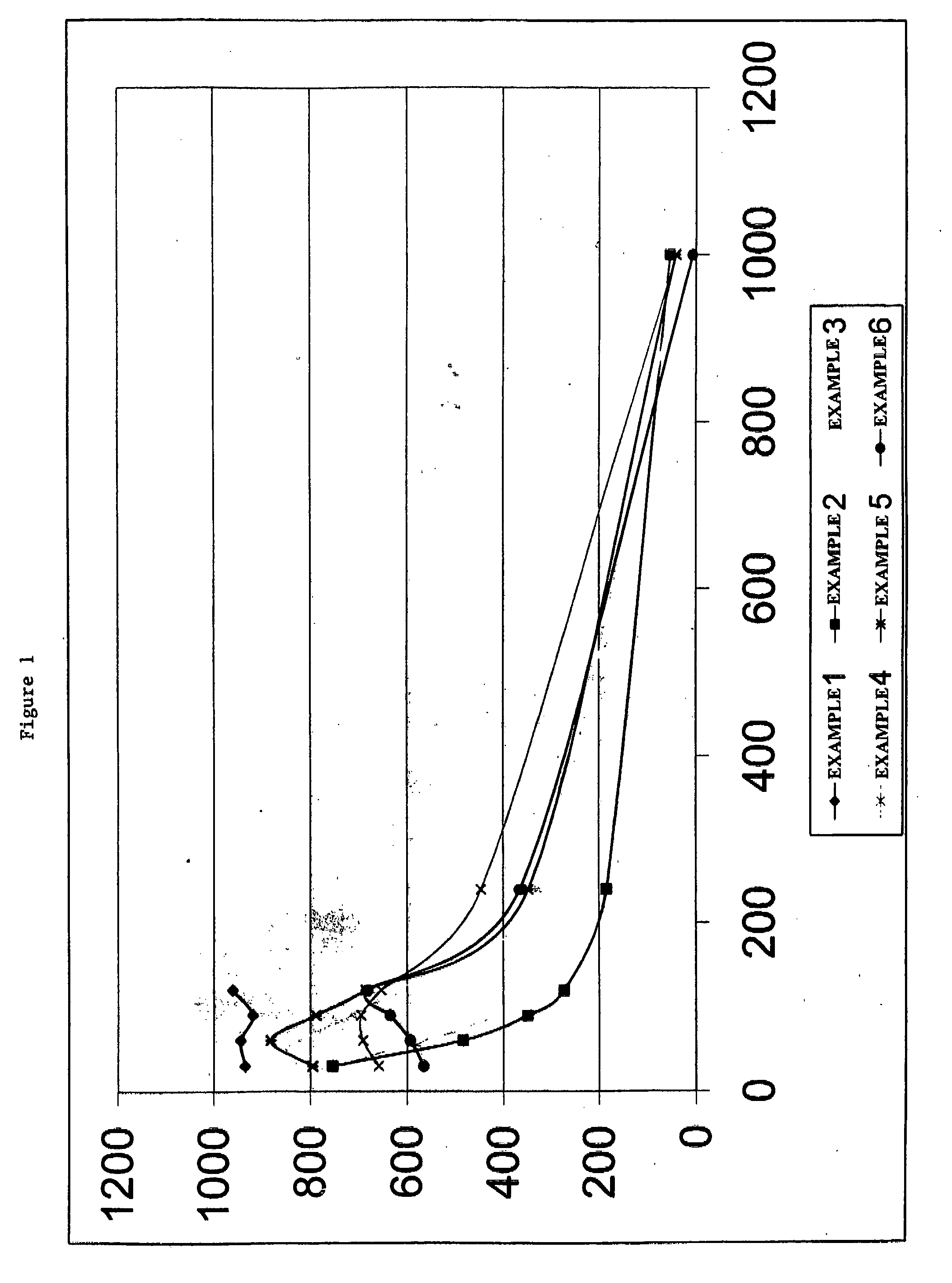

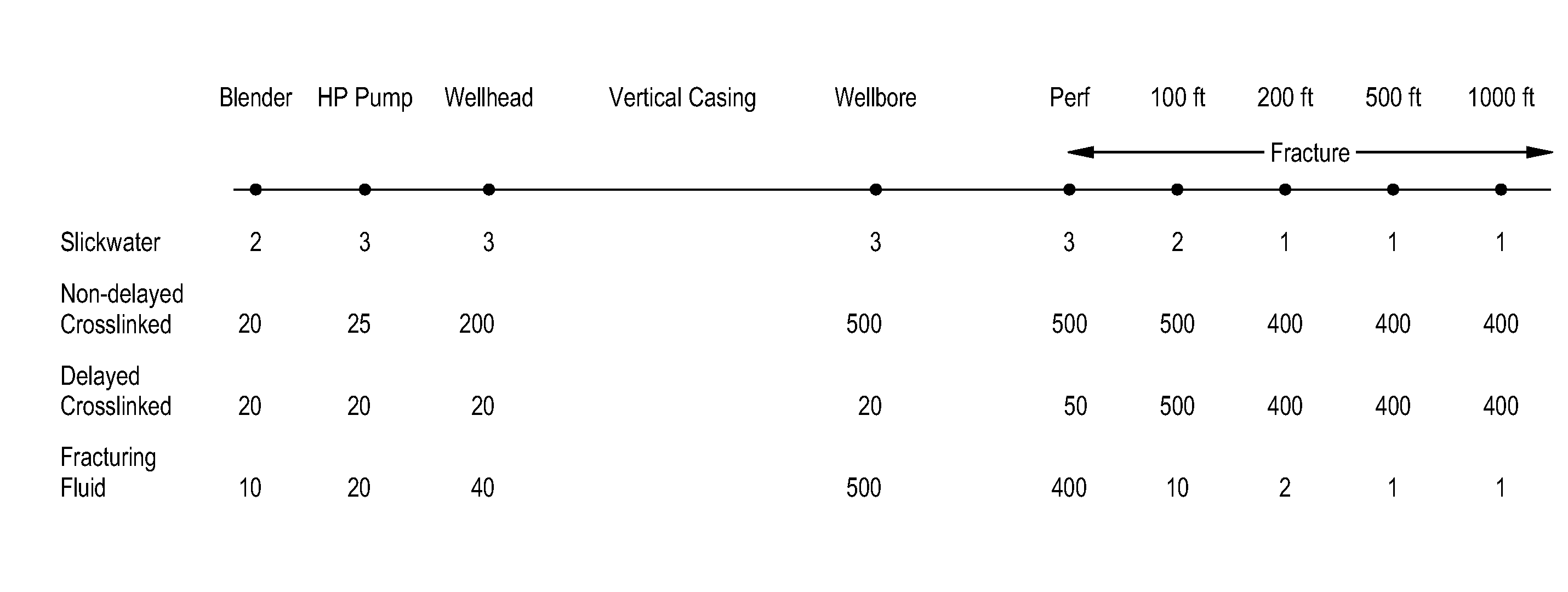

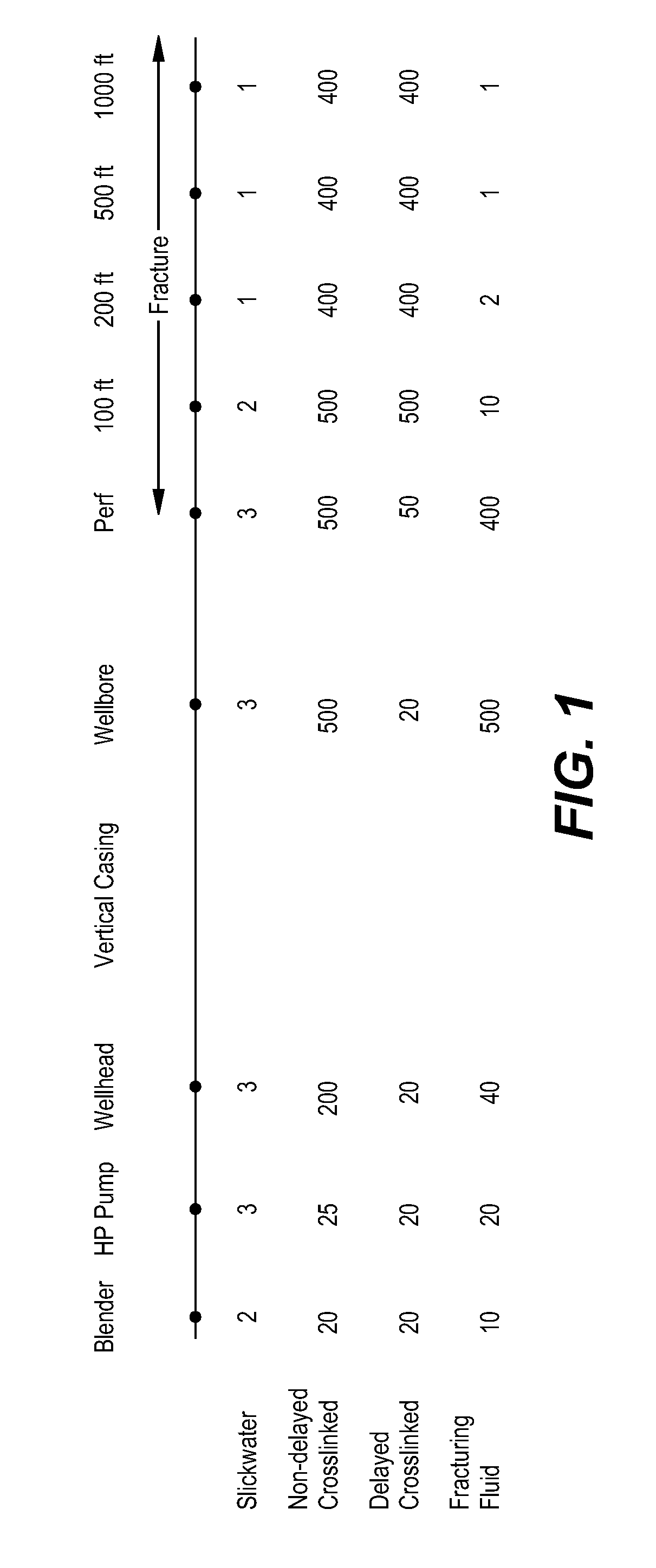

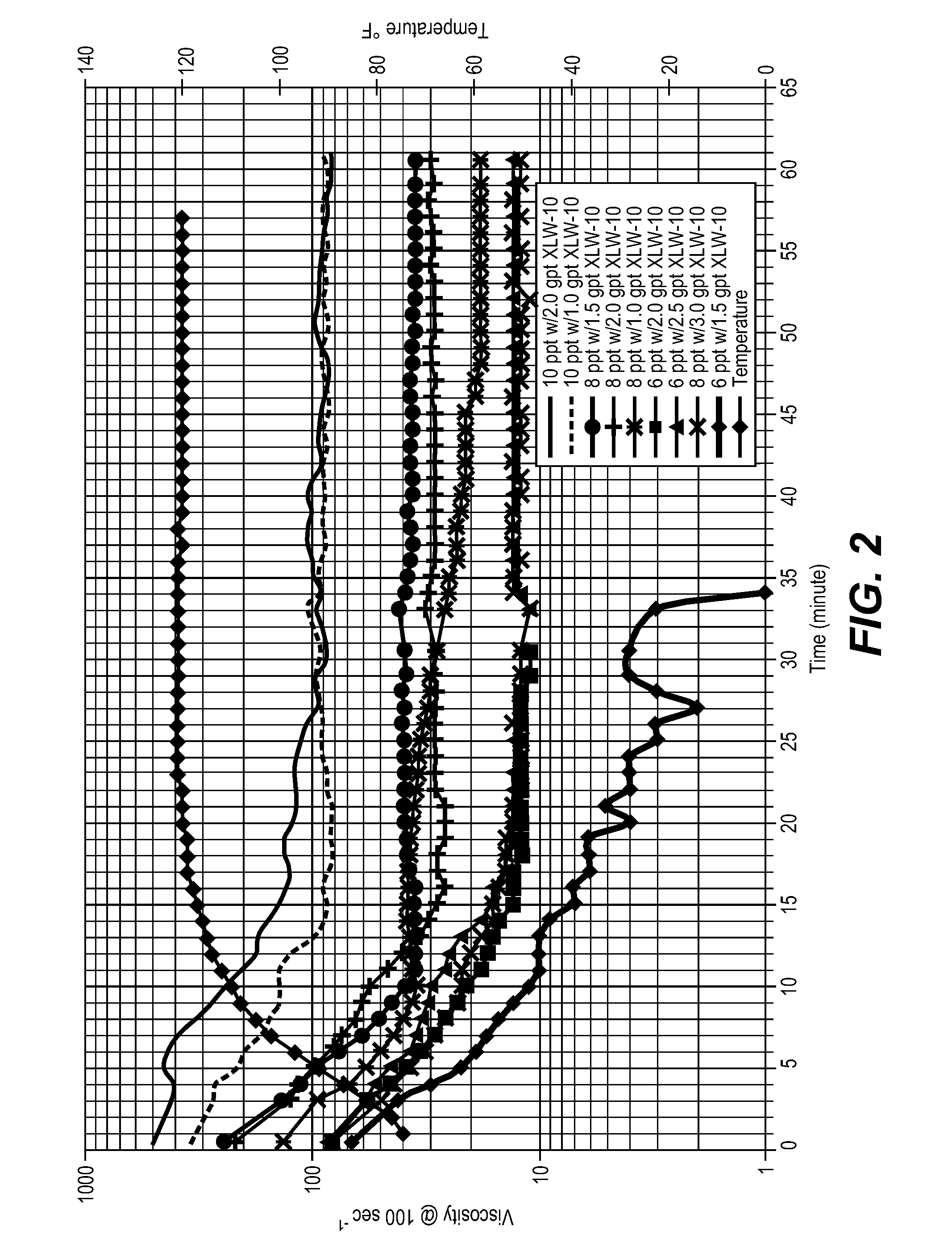

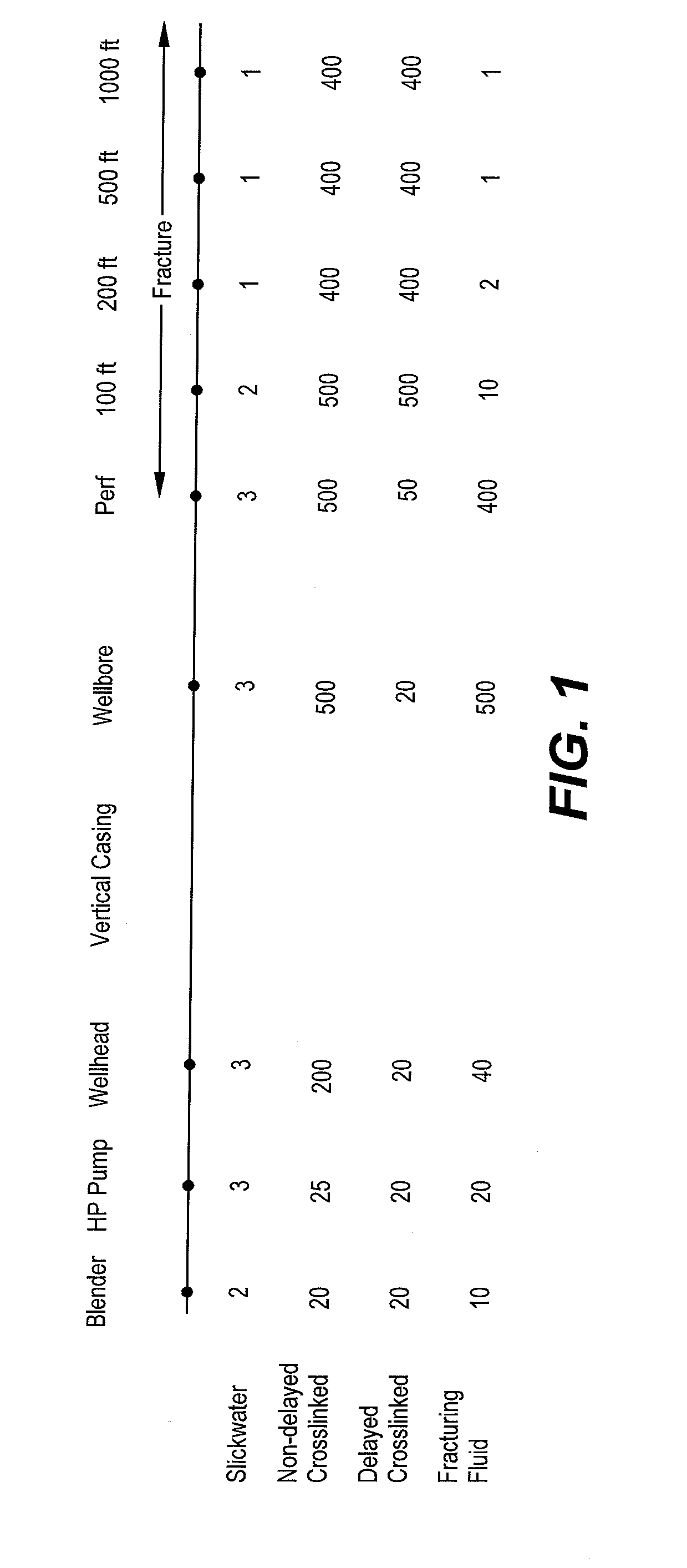

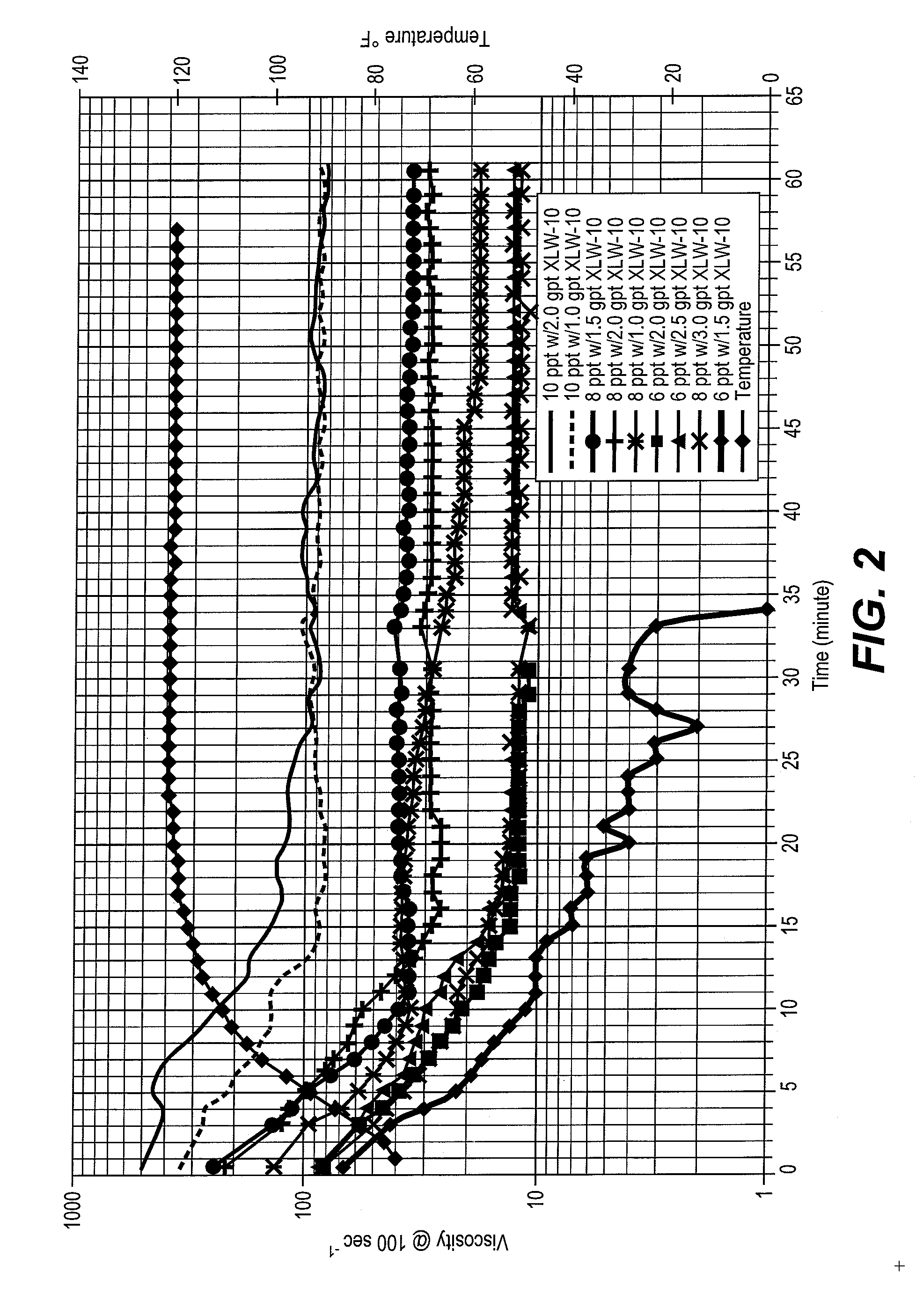

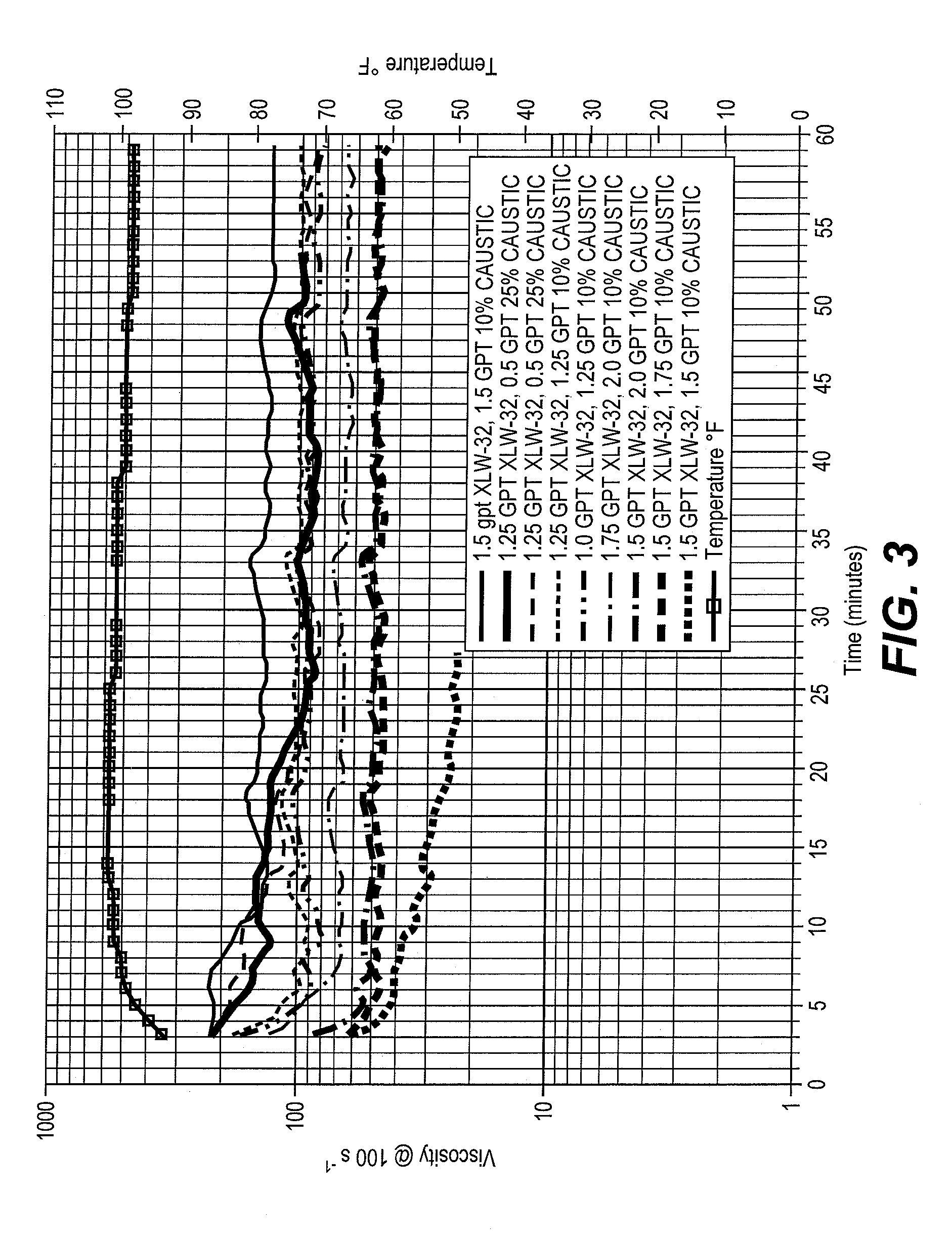

ActiveUS8371383B2Particular applicabilityHigh viscosityFluid removalDrilling compositionApparent viscosityFracturing fluid

Subterranean formations, such as tight gas formations, may be subjected to hydraulic fracturing by introducing into the formation a fracturing fluid of an aqueous fluid, a hydratable polymer, a crosslinking agent and proppant. The fracturing fluid is prepared in a blender and then pumped from the blender into the wellbore which penetrates the formation. The fluid enters the reservoir through an entrance site. The apparent viscosity of the fluid decreases distally from the entrance site such that at least one of the following conditions prevails at in situ conditions:(a) the apparent viscosity of the fracturing fluid 100 feet from the entrance site is less than 10 percent of the apparent viscosity of the fracturing fluid at the entrance site;(b) the apparent viscosity of the fracturing fluid 15 minutes after introduction into the entrance site is less than 15% of the apparent viscosity of the fracturing fluid at the entrance site; or(c) the apparent viscosity of the fracturing fluid is less than 10 cP within 15 minutes after being introduced through the entrance site.

Owner:BAKER HUGHES INC

Heated fluid conduits, systems and methods

ActiveUS20100209085A1Low fluid viscosityEasy to operateValve members for heating/coolingPipe heating/coolingSemiconductor materialsConductive materials

A heated fluid conduit has a body with a semi-conductive material disposed therein with an electrical power supply coupled to the conduit to provide a voltage across the conduit and a current therethrough, heating the fluid conduit. A fluid conduit heating system comprises a semiconductive sleeve disposed over a fluid conduit and an electrical power supply coupled to the ends of the sleeve to provide a voltage across the sleeve and a resulting current through the semiconductive sleeve, heating the sleeve and conduit Alternatively, one terminal of the electrical power supply is coupled to each end of the sleeve or conduit, and another terminal of the electrical power supply is coupled to the sleeve or conduit therebetween, to provide parallel heating circuits.

Owner:THE GATES CORP

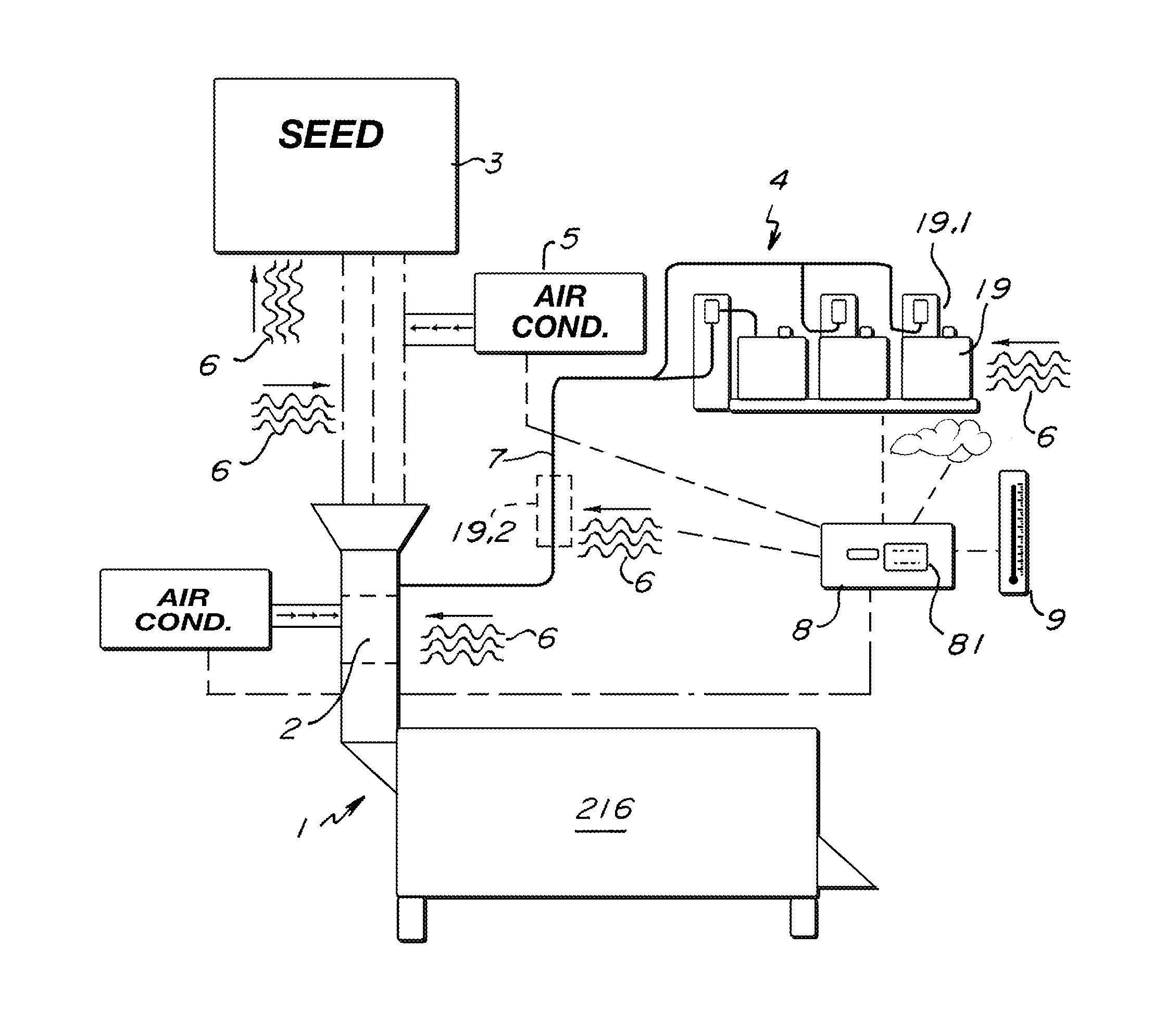

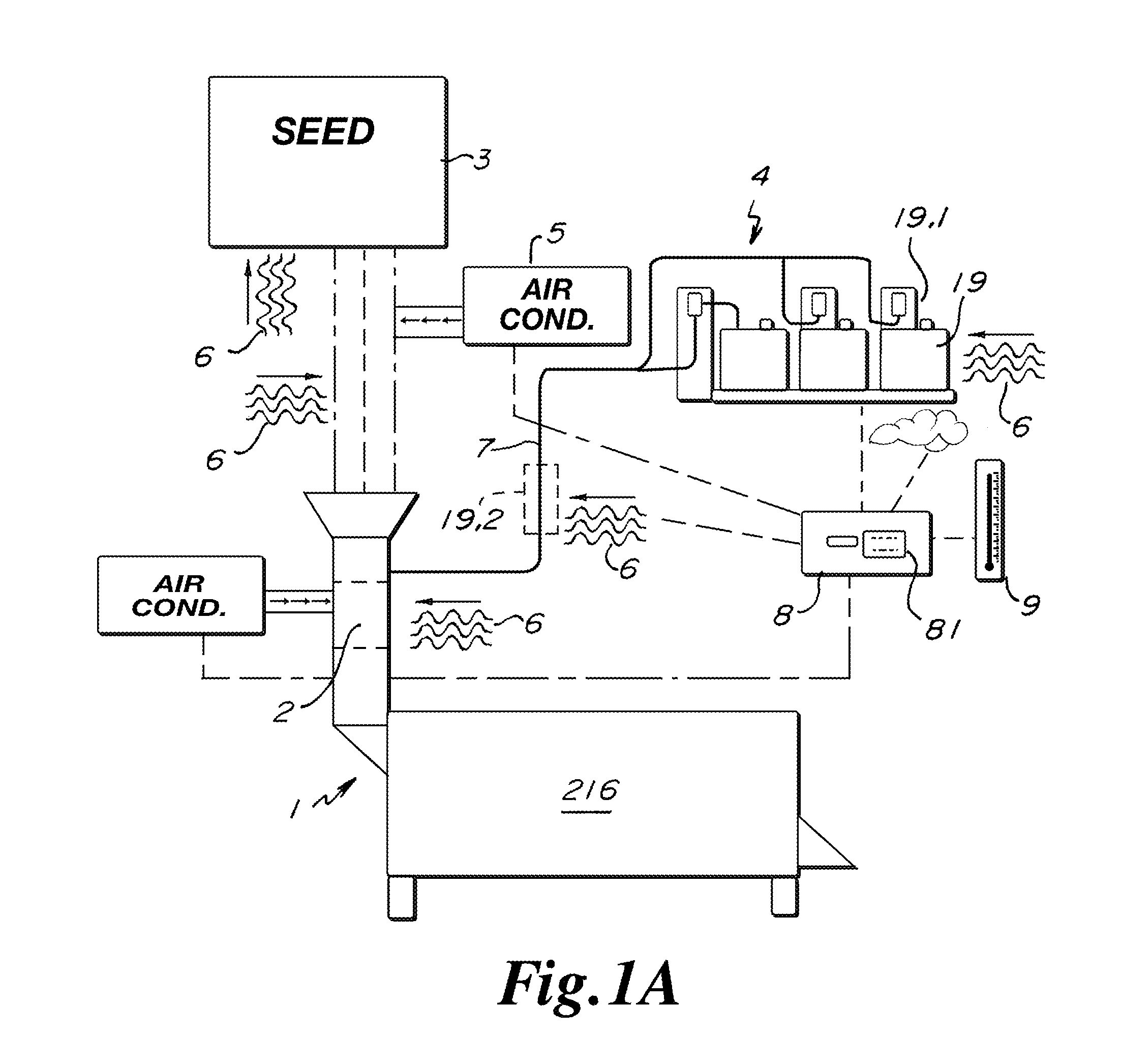

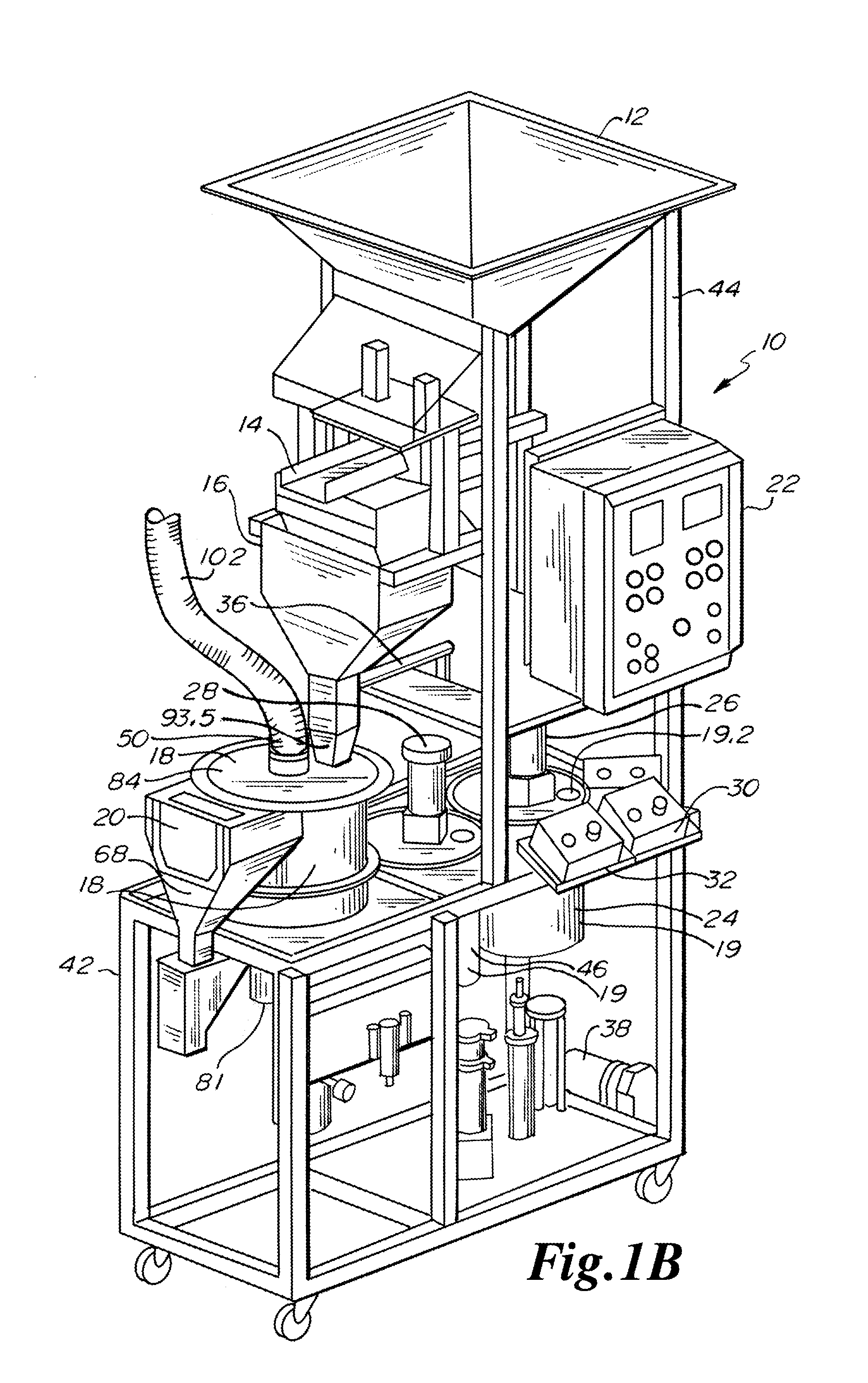

Seed treatment device with improved fluid application

InactiveUS20130273236A1Good dispersionPromote absorptionLiquid surface applicatorsDead plant preservationVaporizationEngineering

A seed treater provides enhanced seed coating capabilities and performance. The seed and / or treatment fluid may be heated for improving vaporization and absorption by the seed. Air may be injected in the seed treater to provide heat, dehumidified air, and to provide vaporization enhancement, and component cleaning functions. The functions may be controlled by a control processor based on recipes and may be changed dependent upon sensed or input environmental conditions such as temperature and humidity.

Owner:BAYER CROPSCI LP

Heated fluid conduit end covers, systems and methods

ActiveUS8559800B2Low fluid viscosityEasy to operateInternal combustion piston enginesValve members for heating/coolingPower flowSemiconductor materials

A fluid conduit body having a semi-conductive material disposed therein and at least one wire coupling an electrical power supply to the conduit to provide an electrical current therethrough to heat the fluid conduit also has an end cover molded over a fitting fitted to an end of the conduit and over an end of the wire coupling the power supply to an end of the conduit. Alternatively, a fluid conduit heating system employs a semi-conductive sleeve disposed over a fluid conduit with the sleeve extending at least partially over a fitting fitted to an end of the conduit. An electrical power supply is coupled to each end of the sleeve to provide an electrical current through the semi-conductive sleeve to heat the sleeve and the fluid conduit. An end cover is molded over at least a portion of the fitting and the sleeve extending thereover.

Owner:THE GATES CORP

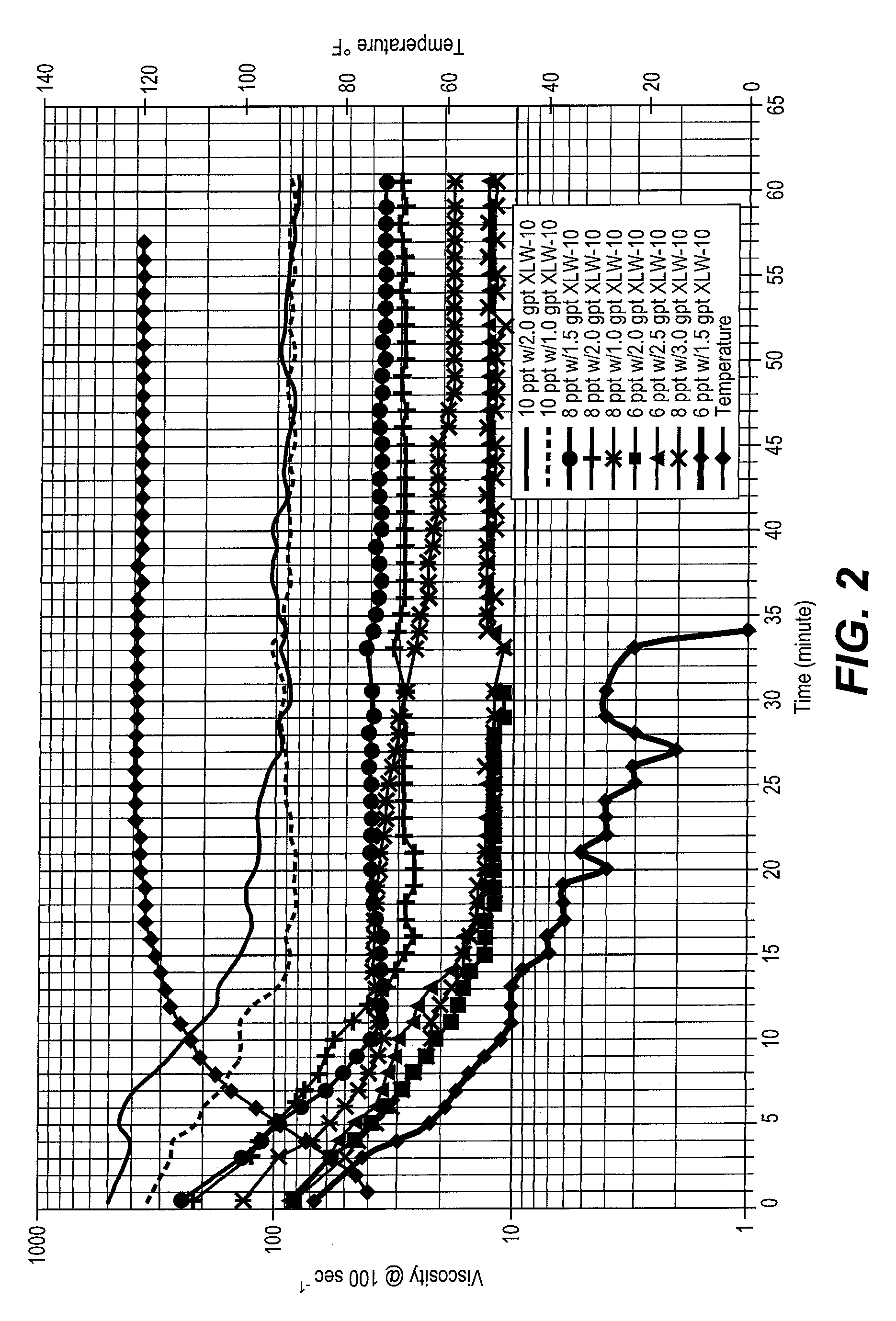

Method of fracturing subterranean formations with crosslinked fluid

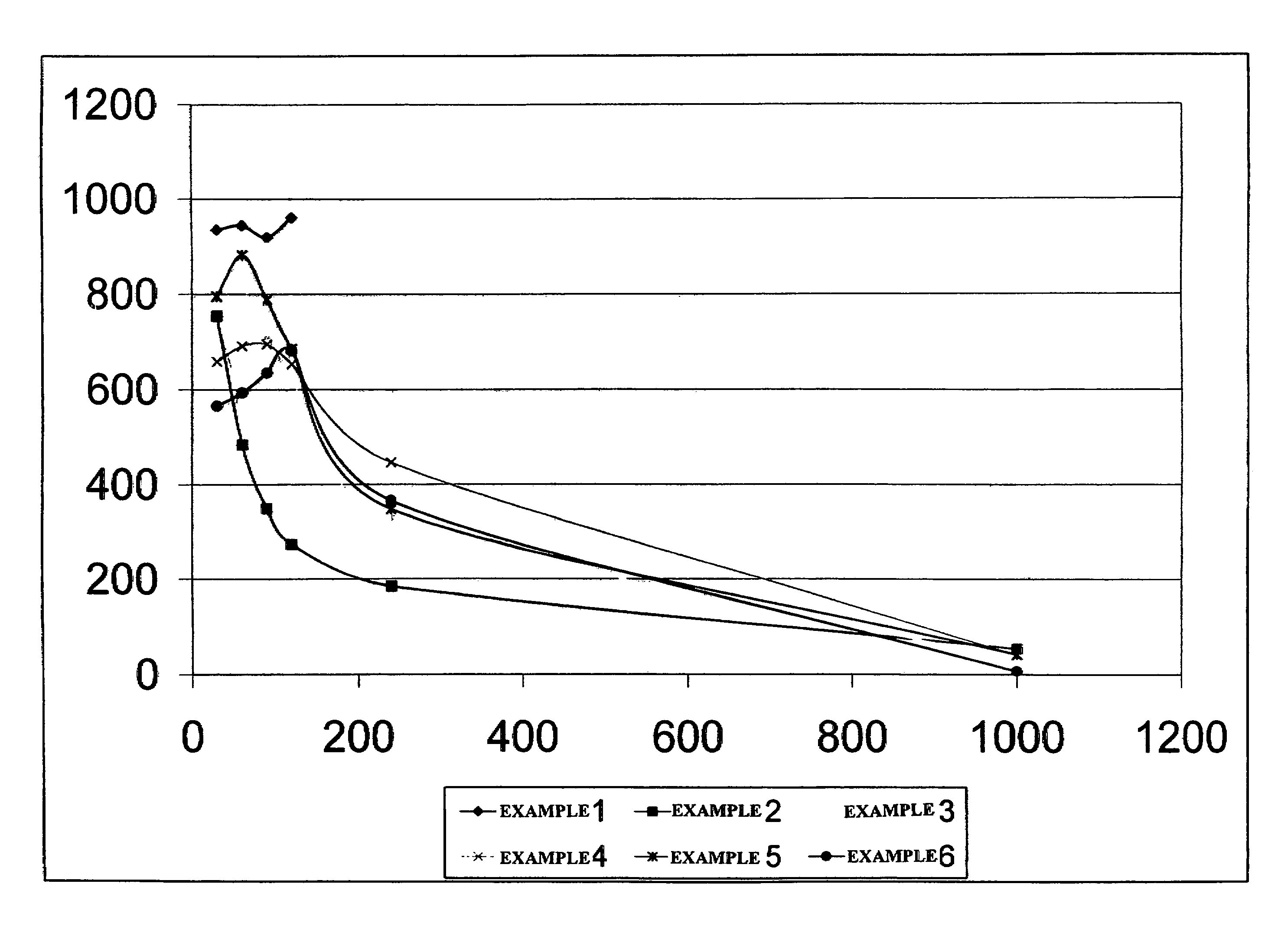

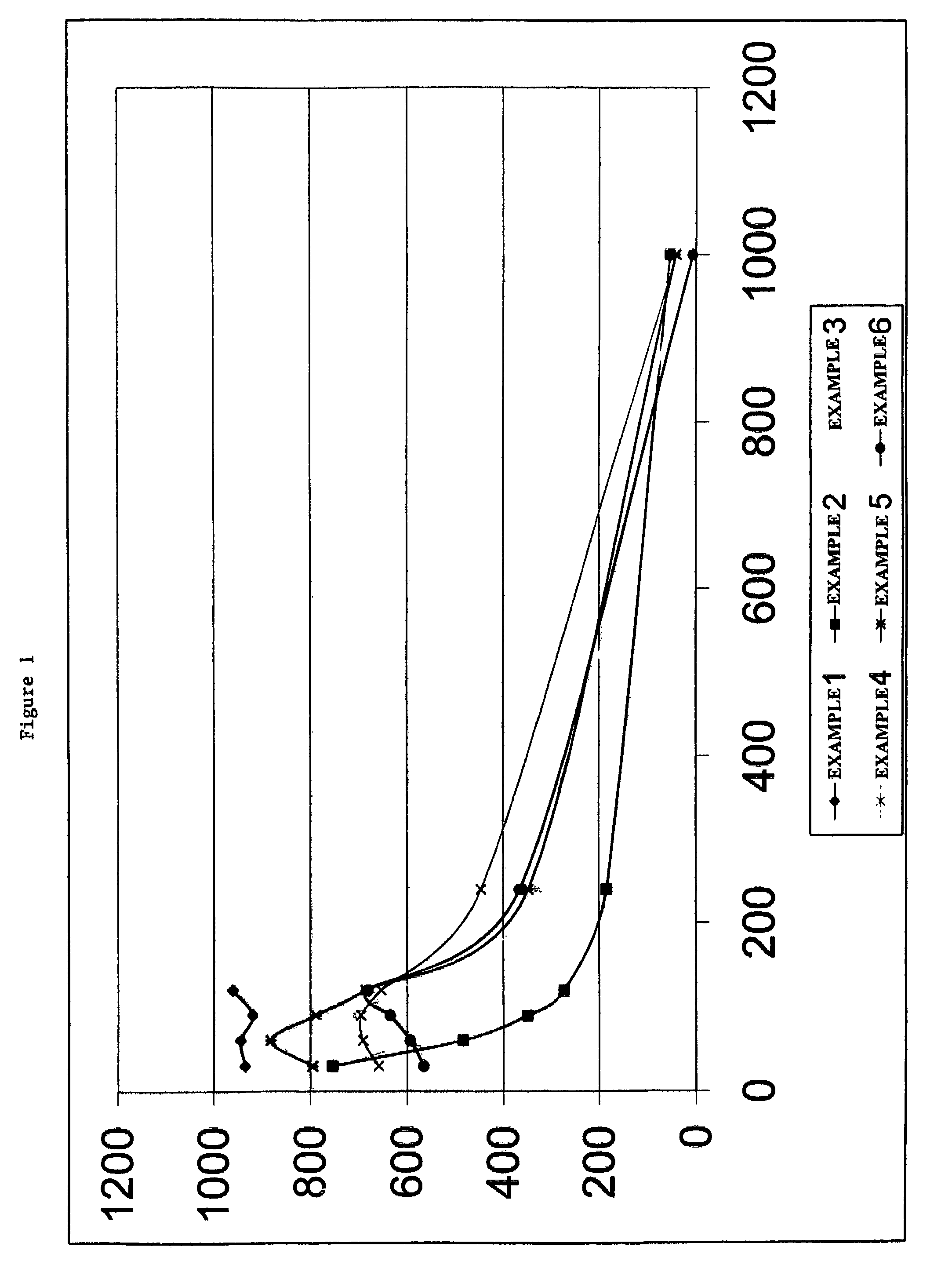

ActiveUS20130153233A1High viscosityParticular applicabilityFluid removalDrilling compositionApparent viscosityFracturing fluid

Subterranean formations, such as tight gas formations, may be subjected to hydraulic fracturing by introducing into the formation a fracturing fluid of an aqueous fluid, a hydratable polymer, a crosslinking agent and proppant. The fracturing fluid is prepared in a blender and then pumped from the blender into the wellbore which penetrates the formation. The fluid enters the reservoir through an entrance site. The apparent viscosity of the fluid decreases distally from the entrance site such that at least one of the following conditions prevails at in situ conditions:(a) the apparent viscosity of the fracturing fluid 100 feet from the entrance site is less than 10 percent of the apparent viscosity of the fracturing fluid at the entrance site;(b) the apparent viscosity of the fracturing fluid 15 minutes after introduction into the entrance site is less than 15% of the apparent viscosity of the fracturing fluid at the entrance site; or(c) the apparent viscosity of the fracturing fluid is less than 10 cP within 15 minutes after being introduced through the entrance site.

Owner:BAKER HUGHES INC

Method and apparatus for improving vehicle fuel economy

InactiveUS8042609B2Improve fuel economyLow fluid viscosityAir-treating devicesRailway heating/coolingFluid viscositySpins

Owner:GM GLOBAL TECH OPERATIONS LLC

Exhaust heat recovery for engine heating and exhaust cooling

ActiveUS8091359B2Heating fastLow fluid viscosityLiquid coolingInternal combustion piston enginesGas to liquidsExhaust fumes

Owner:FORD GLOBAL TECH LLC

Base oil for cooling of device, device-cooling oil containing the base oil, device to be cooled by the cooling oil, and device cooling method using the cooling oil

InactiveUS20120283162A1Small kinematic viscosityLarge conductivityBase-materialsEthyl phosphateOLEYL ETHER

A device-cooling base oil includes 30 mass % of at least one of an oleyl ester (e.g., oleate and oleyl alcohol ester) and oleyl ether. The oleyl ester and the oleyl ether each have 23 or more of a total number of a terminal methyl group, a methylene group and an ether group in a main chain and 1 or less of a total number of a methyl branch and an ethyl branch. The base oil has a kinematic viscosity at 40 degrees C. in a range of 4 mm2 / s to 30 mm2 / s. A device-cooling oil provided by blending the base oil is excellent in electrical insulation properties and thermal conductivity, and thus is favorably usable for cooling a motor, a battery, an inverter, an engine, an electric cell or the like in an electric vehicle, a hybrid vehicle or the like.

Owner:IDEMITSU KOSAN CO LTD

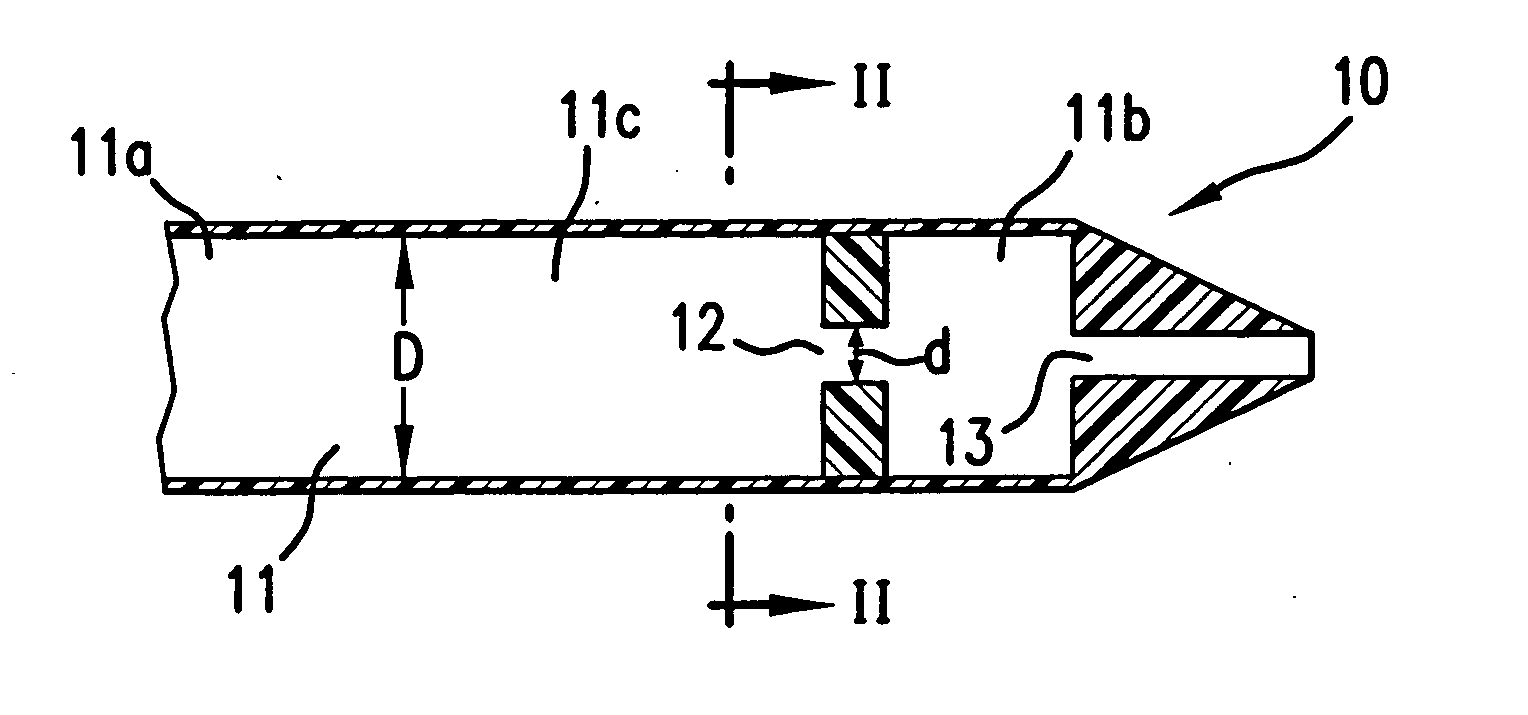

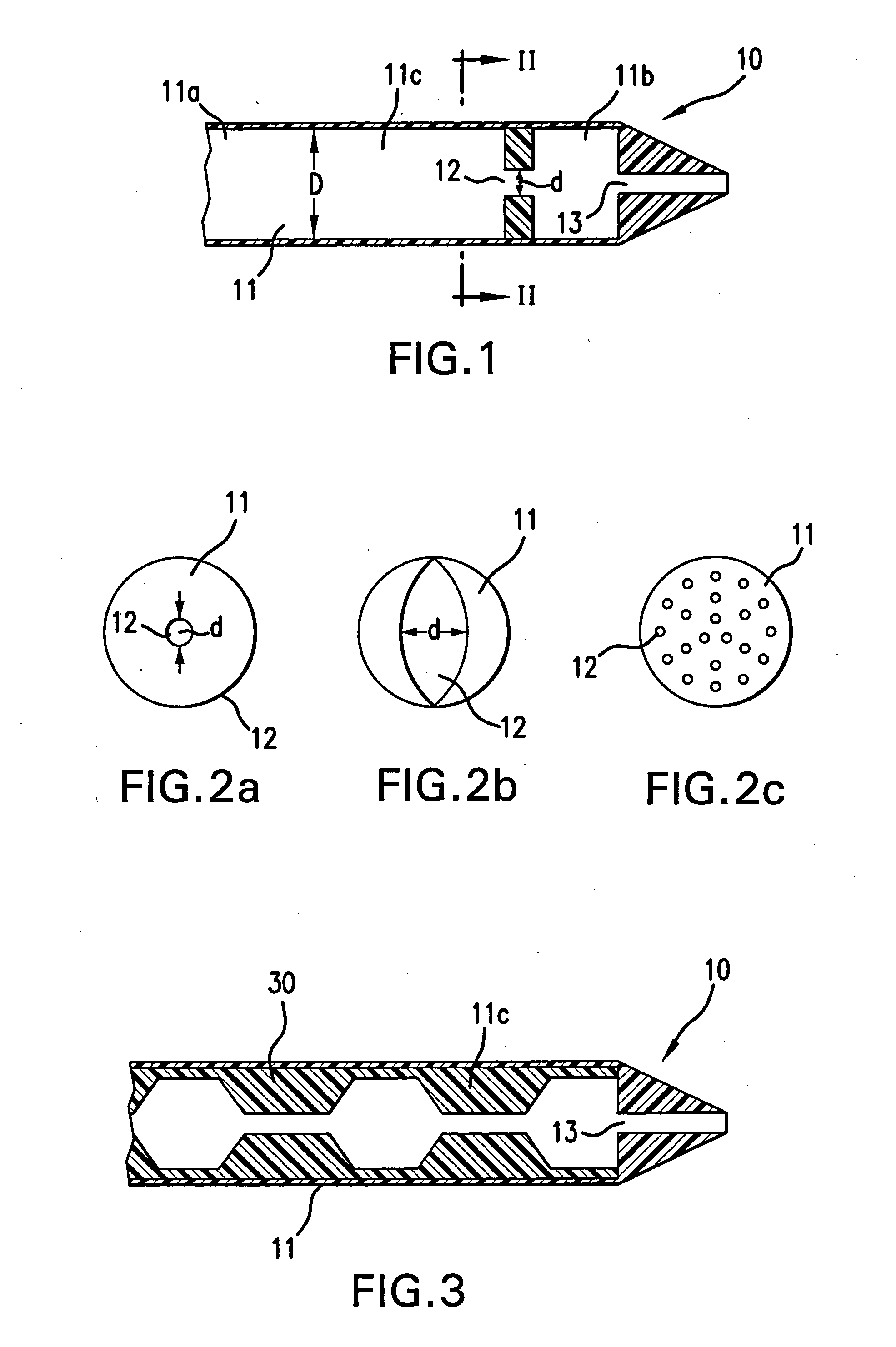

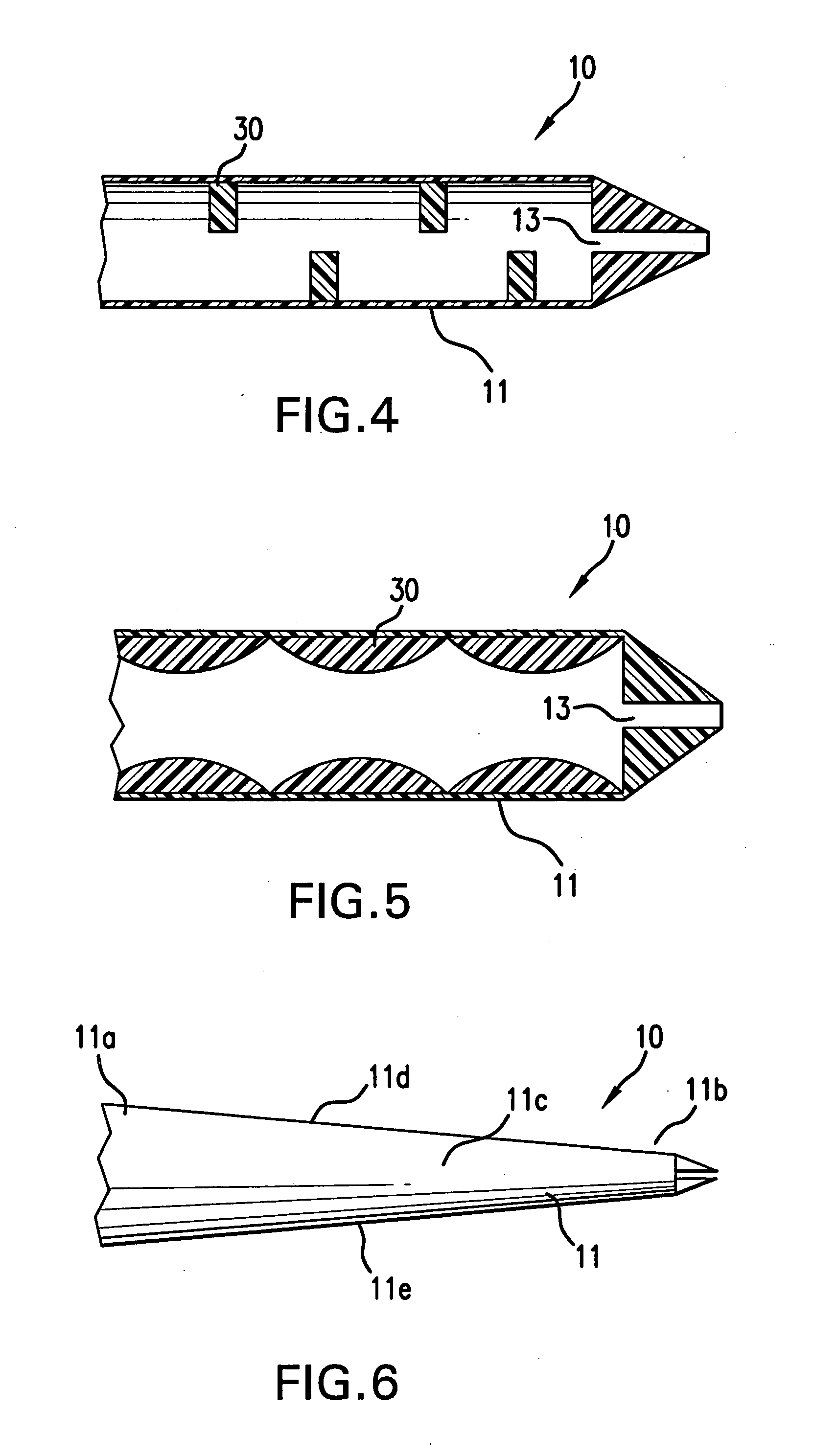

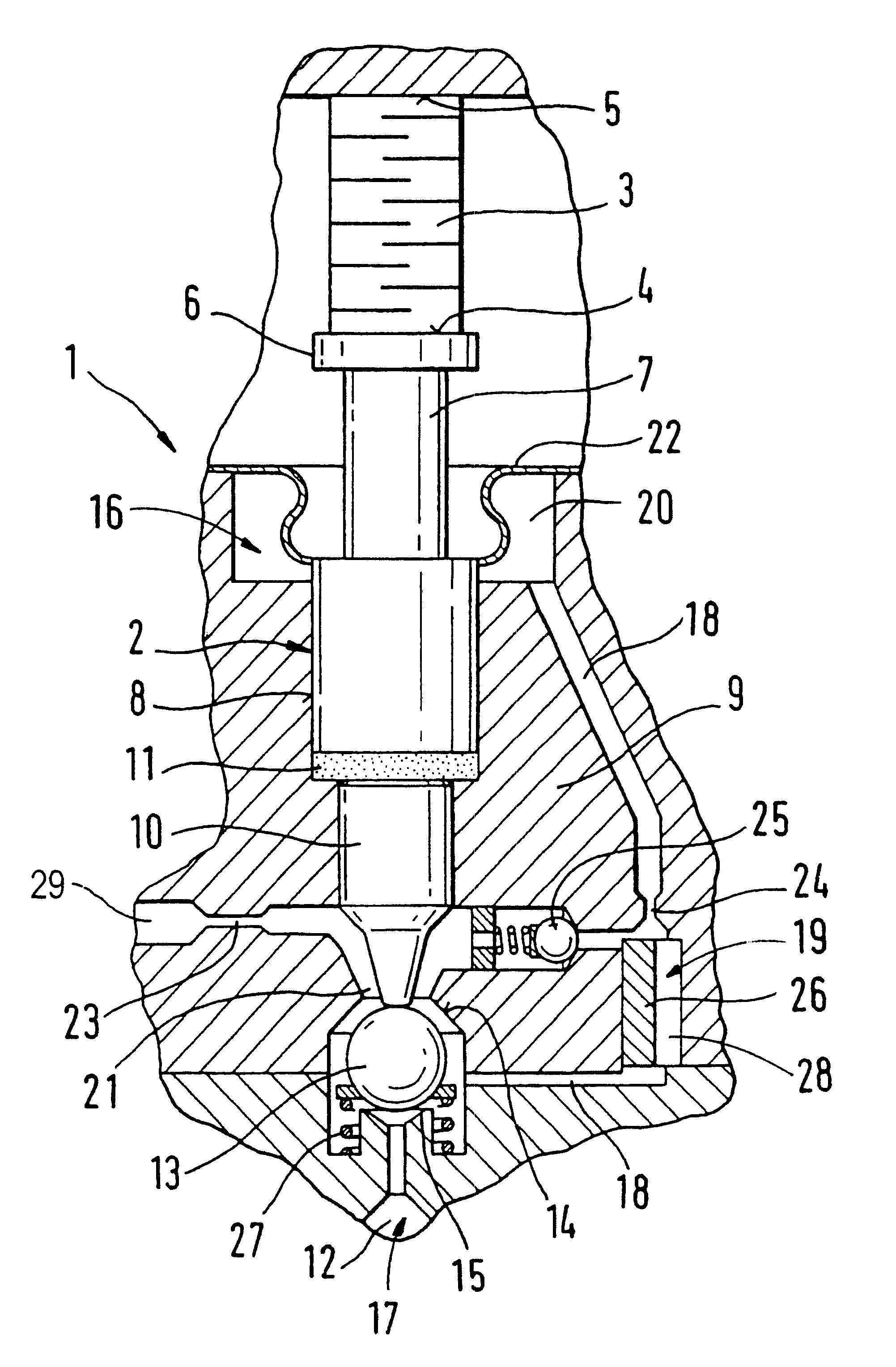

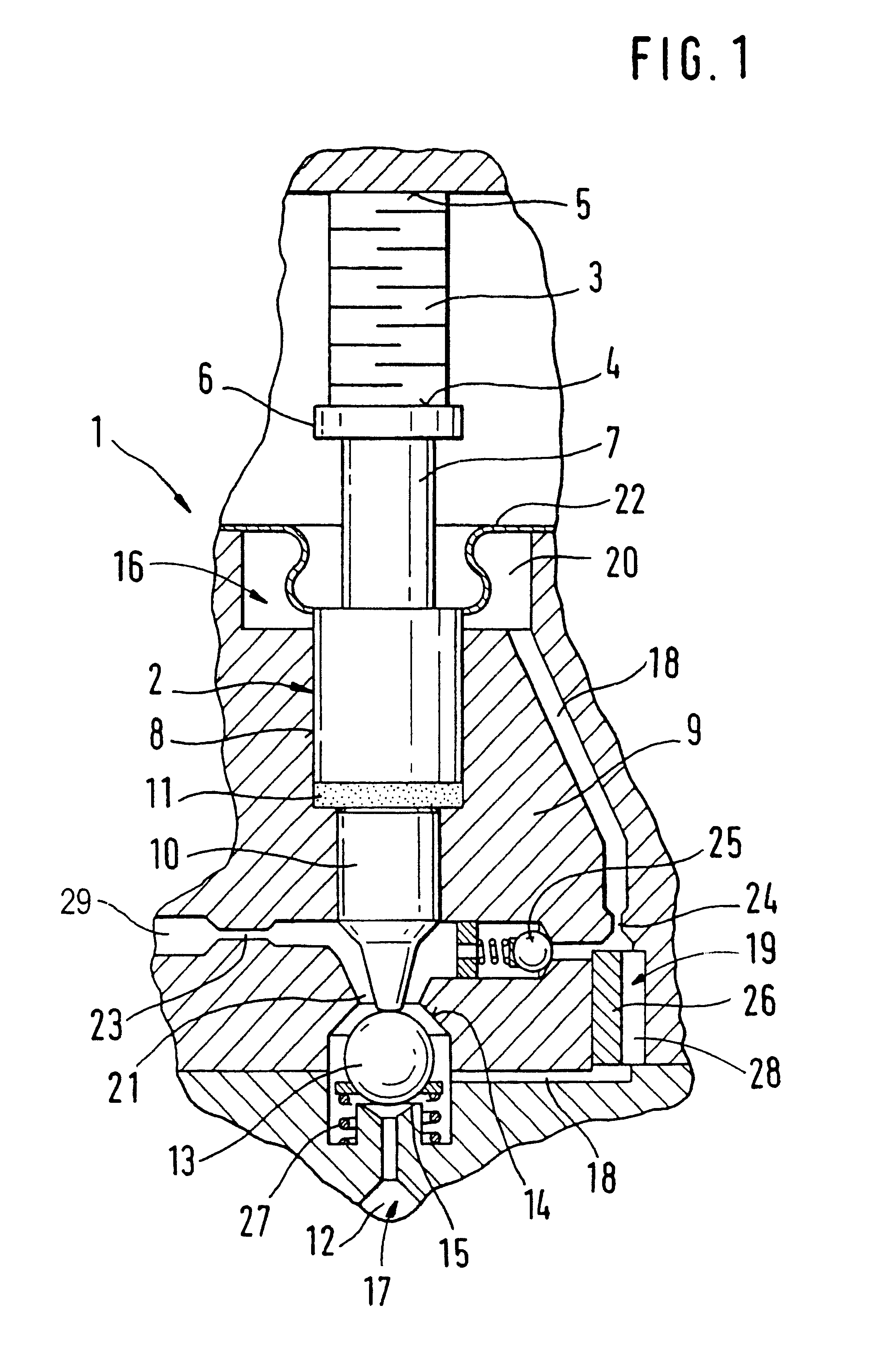

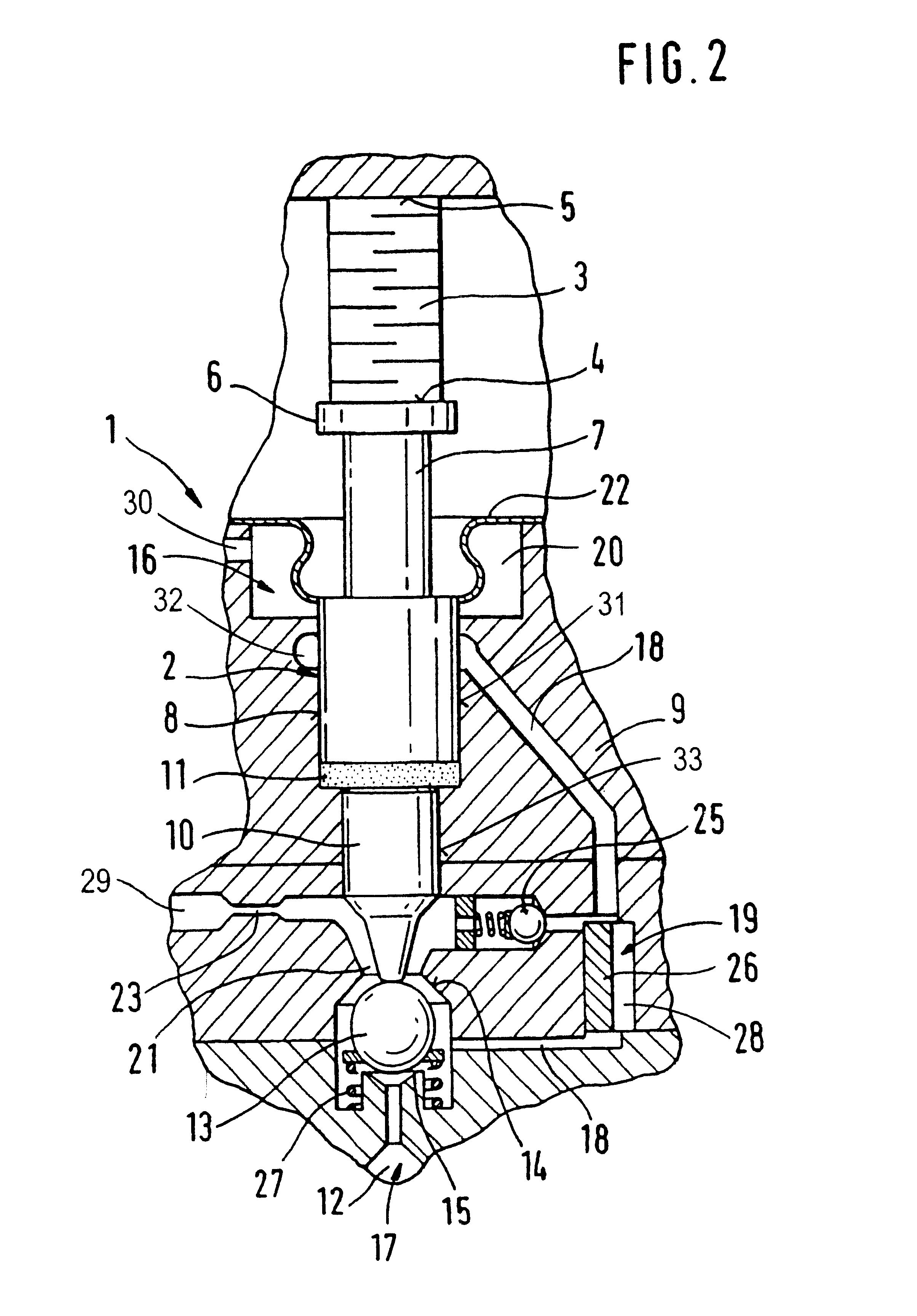

Valve for controlling liquids

InactiveUS6547213B1Increase ratingsAdequate volumetric throughputOperating means/releasing devices for valvesMovable spraying apparatusEngineeringThermal expansion

A valve for controlling fluids is described, wherein a valve closing member (13) divides a low-pressure region (16) in the valve (1) from a high-pressure region (17), and a filling device (19) is provided to compensate for a leakage quantity from the low-pressure region (16) by withdrawal of hydraulic fluid from the high-pressure region (17). The filling device (19) is embodied in a valve body (9) with a conduitlike hollow chamber (18) in which a solid body (26) is disposed in such a way that a gap (28) is formed between the solid body (26) and the valve body (9). The material of the solid body (26) has a coefficient of thermal expansion that is so much greater than that of the material of the valve body (9) that with increasing temperature, a viscosity-dictated increase in the volumetric flow around the solid body (26) is at least partly limited (FIG. 1).

Owner:ROBERT BOSCH GMBH

Heated fluid conduits, systems and methods

ActiveUS9410652B2Low fluid viscosityEasy to operatePipe heating/coolingOhmic-resistance heatingPower flowSemiconductor materials

A heated fluid conduit has a body with a semi-conductive material disposed therein with an electrical power supply coupled to the conduit to provide a voltage across the conduit and a current therethrough, heating the fluid conduit. A fluid conduit heating system comprises a semiconductive sleeve disposed over a fluid conduit and an electrical power supply coupled to the ends of the sleeve to provide a voltage across the sleeve and a resulting current through the semiconductive sleeve, heating the sleeve and conduit Alternatively, one terminal of the electrical power supply is coupled to each end of the sleeve or conduit, and another terminal of the electrical power supply is coupled to the sleeve or conduit therebetween, to provide parallel heating circuits.

Owner:THE GATES CORP

Well treatment fluid compositions and methods for their use

InactiveUS20050016733A1High viscosityIncrease volumeFluid removalFlushingAlkaline earth metalCarboxylic acid

A well treatment fluid composition comprises a solvent (such as water), a polymer soluble or hydratable in the solvent, a crosslinking agent, an inorganic breaking agent, and an ester compound. Preferably, the hydratable polymer is a polysaccharide, such as galactomannan, cellulose, or derivatives thereof. The crosslinking agent is preferably a borate, titanate, or zirconium-containing compound. The inorganic breaking agent is preferably a metal-based oxidizing agent, such as an alkaline earth metal or transition metal-based oxidizing agent. The ester compound is preferably an ester of polycarboxylic acid, such as an ester of oxalate, citrate, or ethylenediamine tetraacetate. One example of a suitable ester compound is acetyl triethyl citrate.

Owner:COMBINED SYST +1

Method of fracturing subterranean formations with crosslinked fluid

ActiveUS9194223B2Particular applicabilityHigh viscosityFluid removalDrilling compositionApparent viscosityFracturing fluid

Subterranean formations, such as tight gas formations, may be subjected to hydraulic fracturing by introducing into the formation a fracturing fluid of an aqueous fluid, a hydratable polymer, a crosslinking agent and proppant. The fluid enters the reservoir through an entrance site. The apparent viscosity of the fluid decreases distally from the entrance site such that at in situ conditions:(a) the apparent viscosity of the fracturing fluid 100 feet from the entrance site is less than 10 percent of the apparent viscosity of the fracturing fluid at the entrance site;(b) the apparent viscosity of the fracturing fluid 15 minutes after introduction into the entrance site is less than 15% of the apparent viscosity of the fracturing fluid at the entrance site; and / or(c) the apparent viscosity of the fracturing fluid is less than 10 cP within 15 minutes after being introduced through the entrance site.

Owner:BAKER HUGHES HLDG LLC

Method of fracturing subterranean formations with crosslinked fluid

ActiveUS20110146996A1Increase viscosityHigh viscosityFluid removalDrilling compositionApparent viscosityEnvironmental geology

Subterranean formations, such as tight gas formations, may be subjected to hydraulic fracturing by introducing into the formation a fracturing fluid of an aqueous fluid, a hydratable polymer, a crosslinking agent and proppant. The fracturing fluid is prepared in a blender and then pumped from the blender into the wellbore which penetrates the formation. The fluid enters the reservoir through an entrance site. The apparent viscosity of the fluid decreases distally from the entrance site such that at least one of the following conditions prevails at in situ conditions:(a) the apparent viscosity of the fracturing fluid 100 feet from the entrance site is less than 10 percent of the apparent viscosity of the fracturing fluid at the entrance site;(b) the apparent viscosity of the fracturing fluid 15 minutes after introduction into the entrance site is less than 15% of the apparent viscosity of the fracturing fluid at the entrance site; or(c) the apparent viscosity of the fracturing fluid is less than 10 cP within 15 minutes after being introduced through the entrance site.

Owner:BAKER HUGHES INC

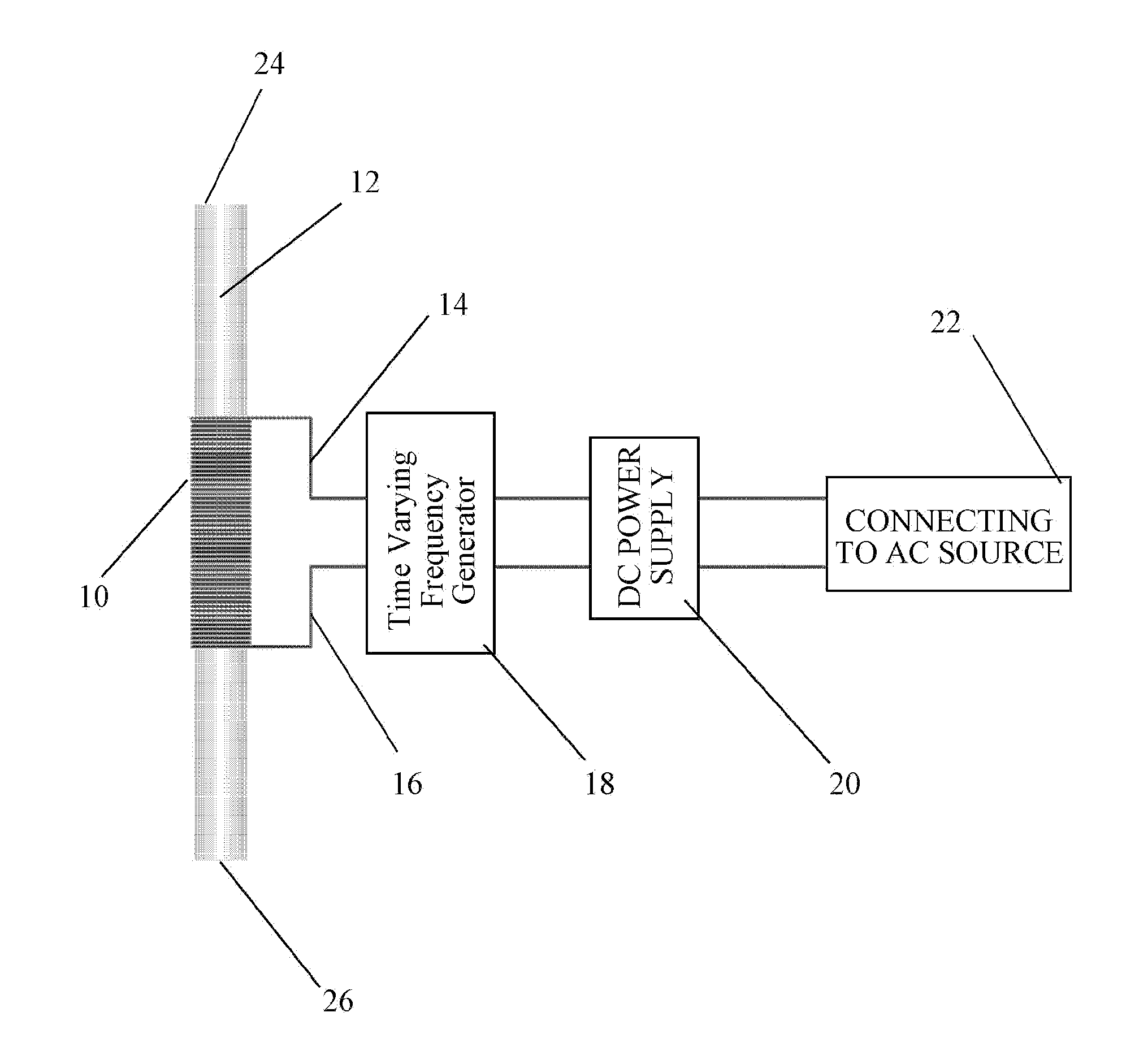

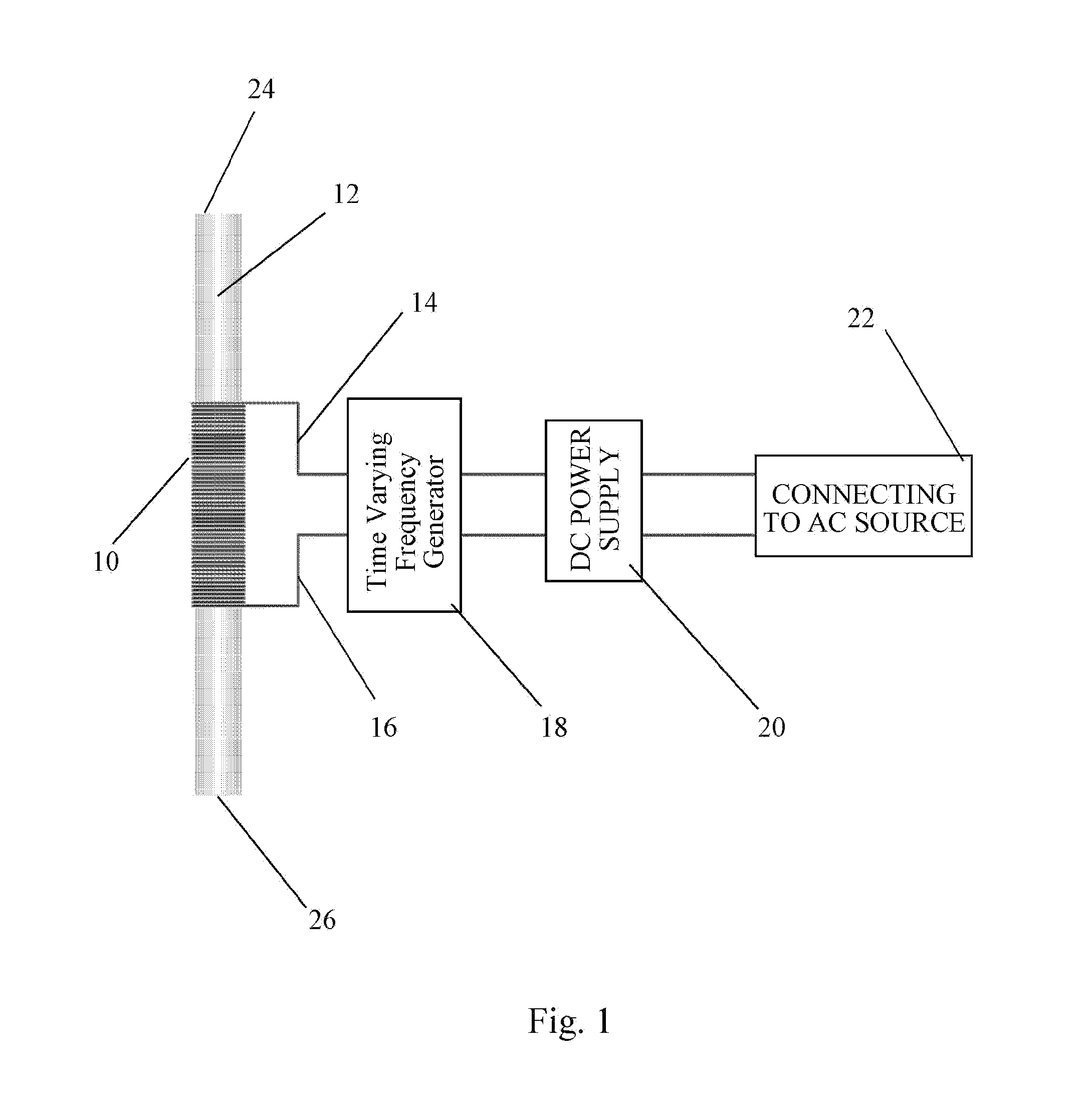

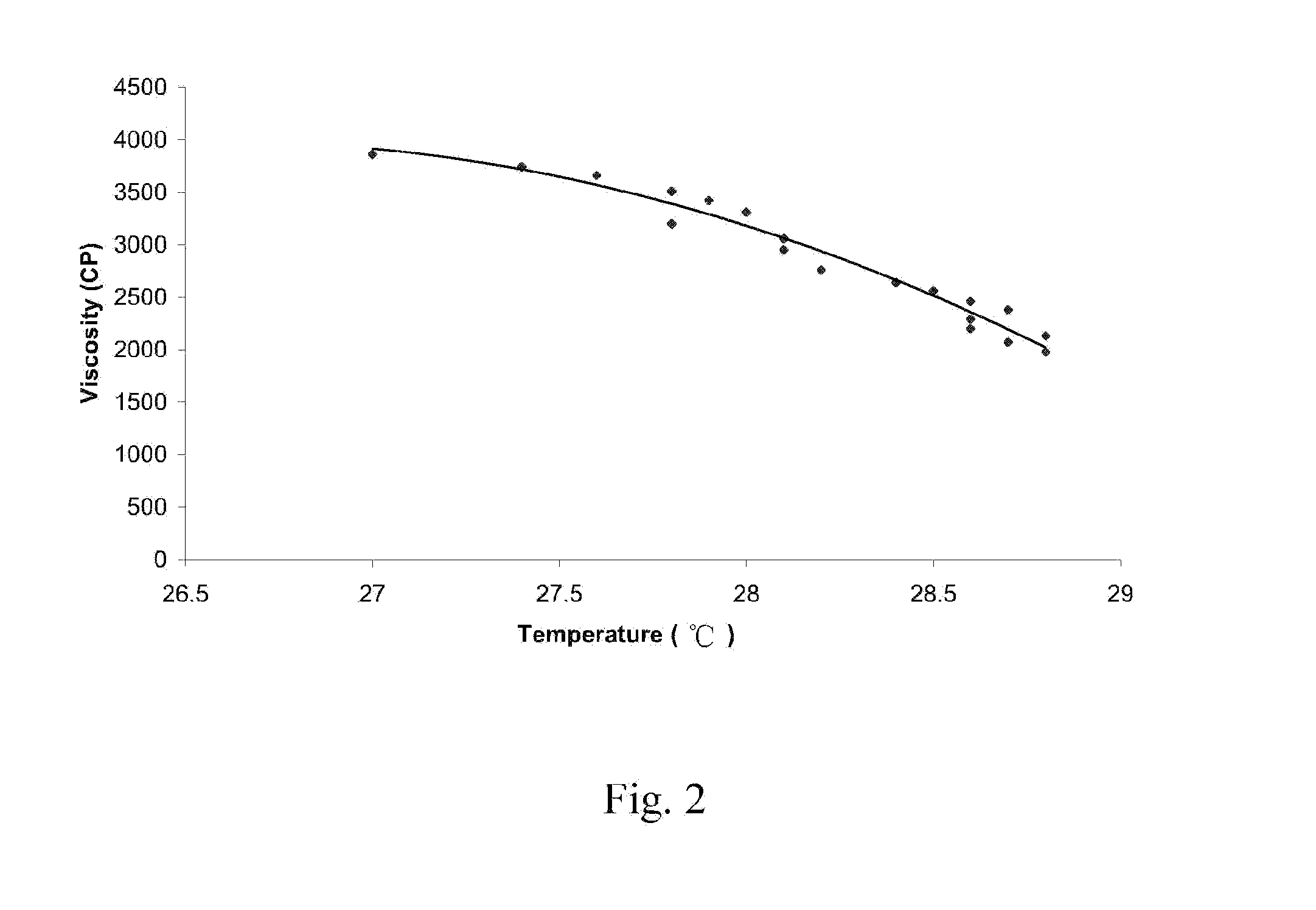

Method for treating hydrocarbon fluids using pulsating electromagnetic wave in combination with induction heating

InactiveUS20110248019A1Reduced strengthRapid productionInduction heatingPipeline systemsEngineeringElectromagnetic field

A method for treating hydrocarbon fluids using pulsating electromagnetic wave in combination with induction heating is provided, which comprise the steps of mounting an induction coil onto a conduit having a central axis from which the hydrocarbon fluid to be treated flows, the induction coil being coaxially disposed with the conduit and having an inner diameter which forms a predetermined gap with an outer periphery of the conduit; subjecting the hydrocarbon fluid through the conduit; and applying a time-varying frequency current to the induction coil to produce pulsating electromagnetic field and induction heating around the induction coil, such that the combined effect of the pulsating electromagnetic field and the induction heating is induced in the fluid to prevent and / or reduce build-up of or natural deposition of paraffin, asphaltene or the like contained in the fluid and reduce a viscosity of the fluid in production lines, flow transmission lines, pipelines and oil storage.

Owner:ECOSPEC GLOBAL TECH PTE LTD

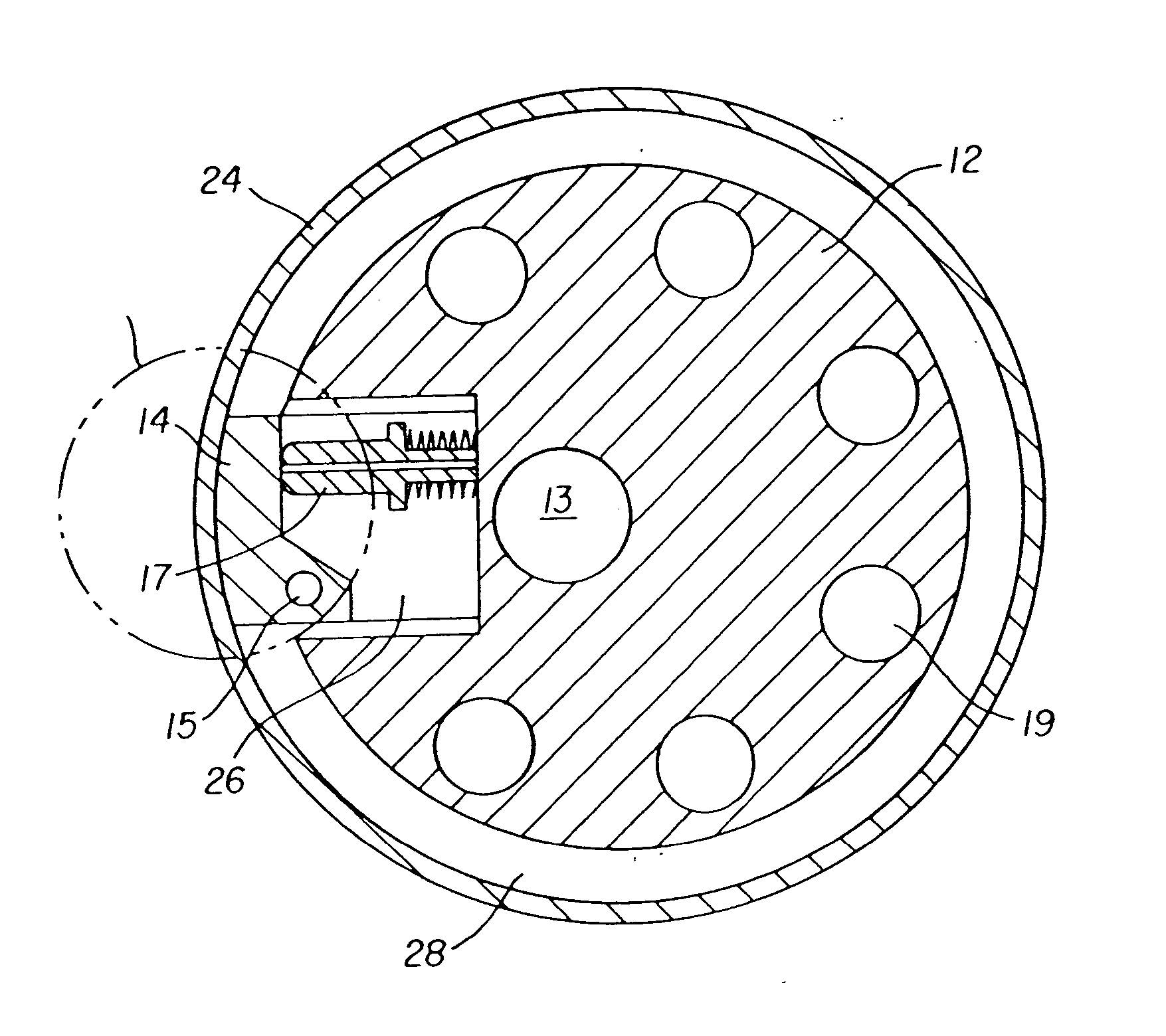

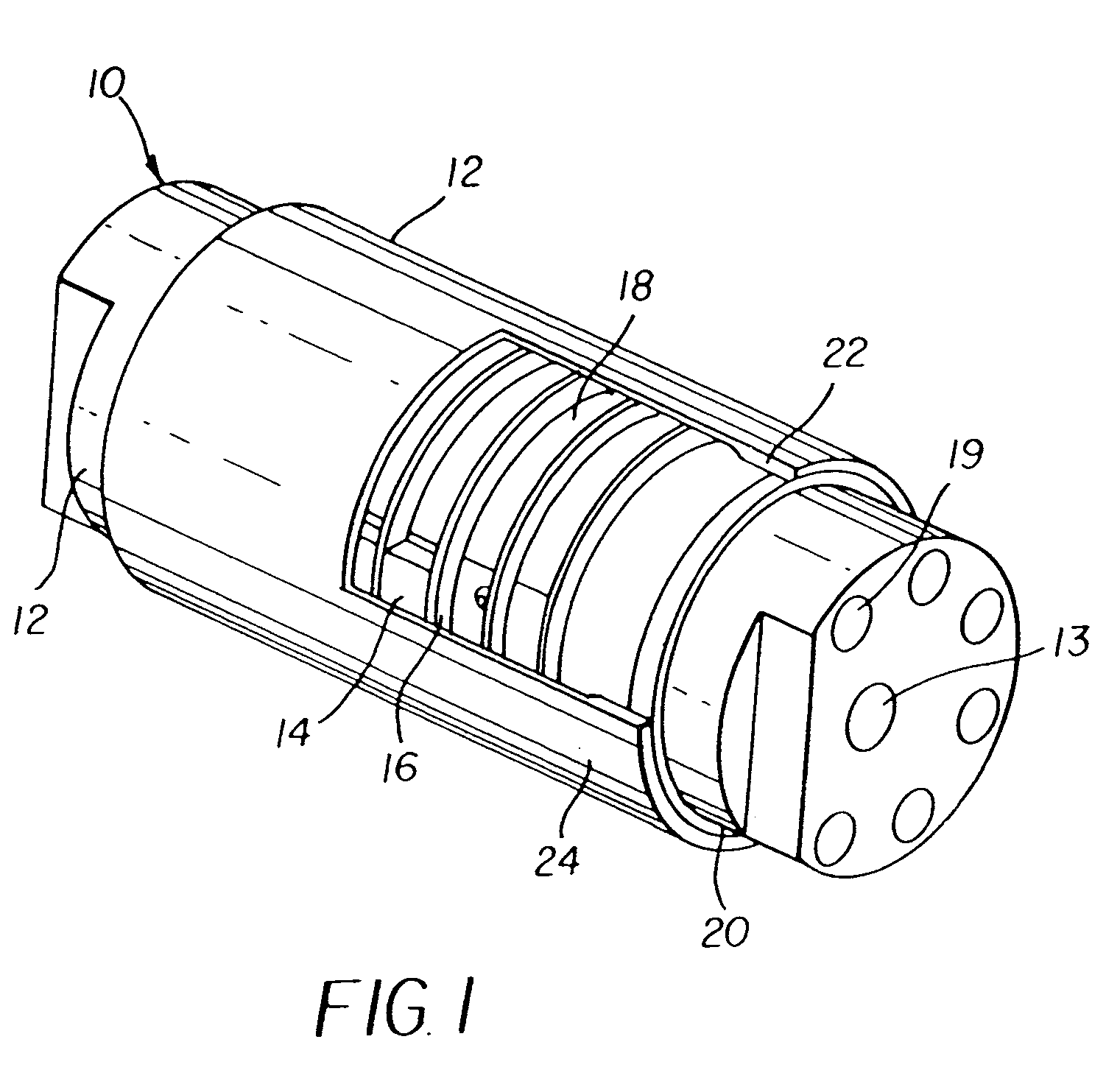

Axially compliant pressure roller utilizing non-newtonian fluid

InactiveUS20060005391A1Increase shear rateLow fluid viscosityLiquid surface applicatorsAssembly machinesEngineeringActuator

A compliant pressure roller (10) for creating uniform pressure at a nip comprises a stationary inner core (12). A plurality of shoes (14) is pivotally mounted to the stationary inner core. Dividers (16) create a plurality of annular chambers (18) wherein each of the shoes occupies one of the chambers. A non-Newtonian fluid (70) fills each of the chambers. A plurality of actuators is connected to at least one of the shoes. A thin, rotatable shell surrounds the plurality of chambers, shoes, and stationary inner core.

Owner:SKC HAAS DISPLAY FILMS CO LTD +1

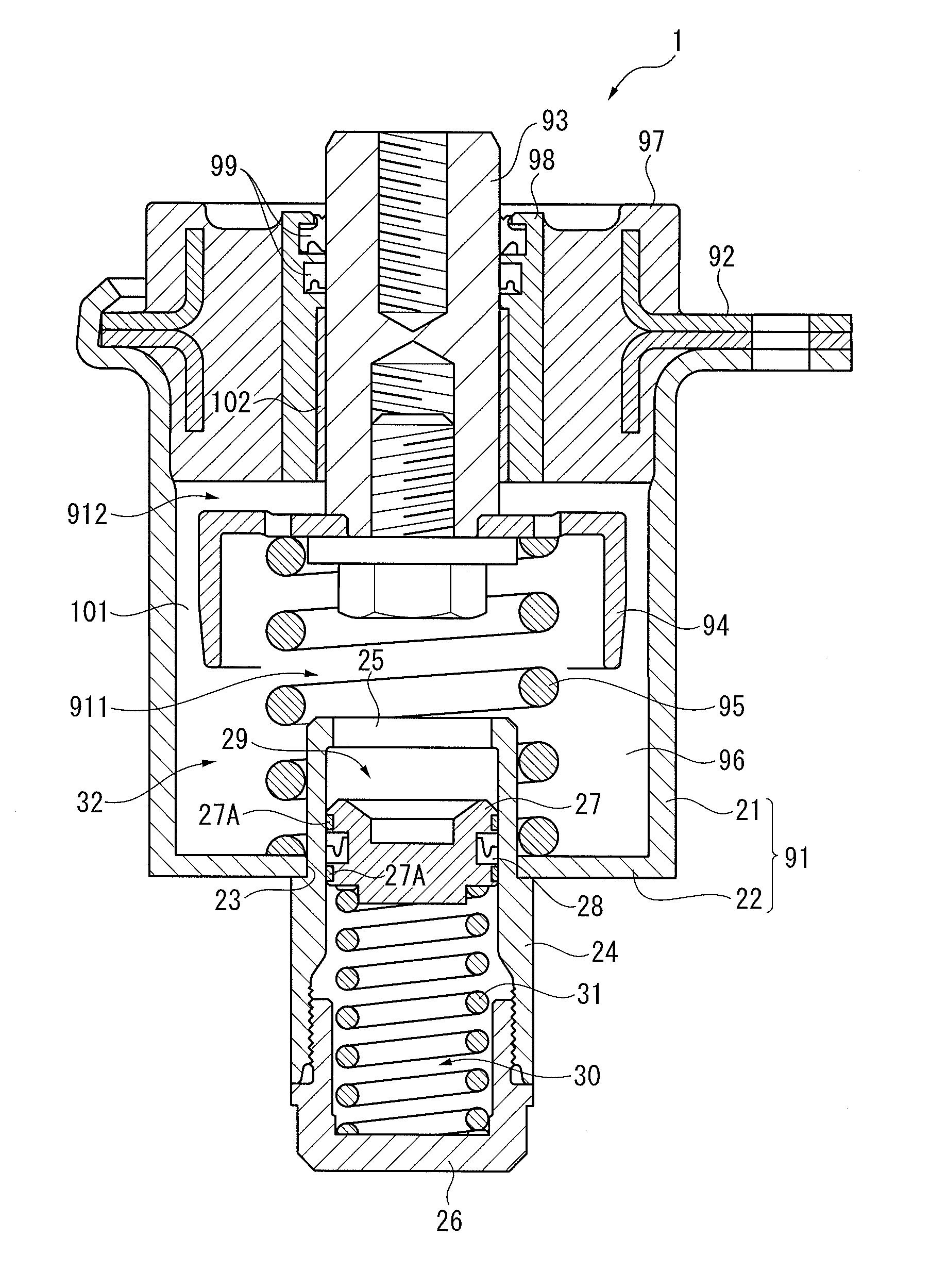

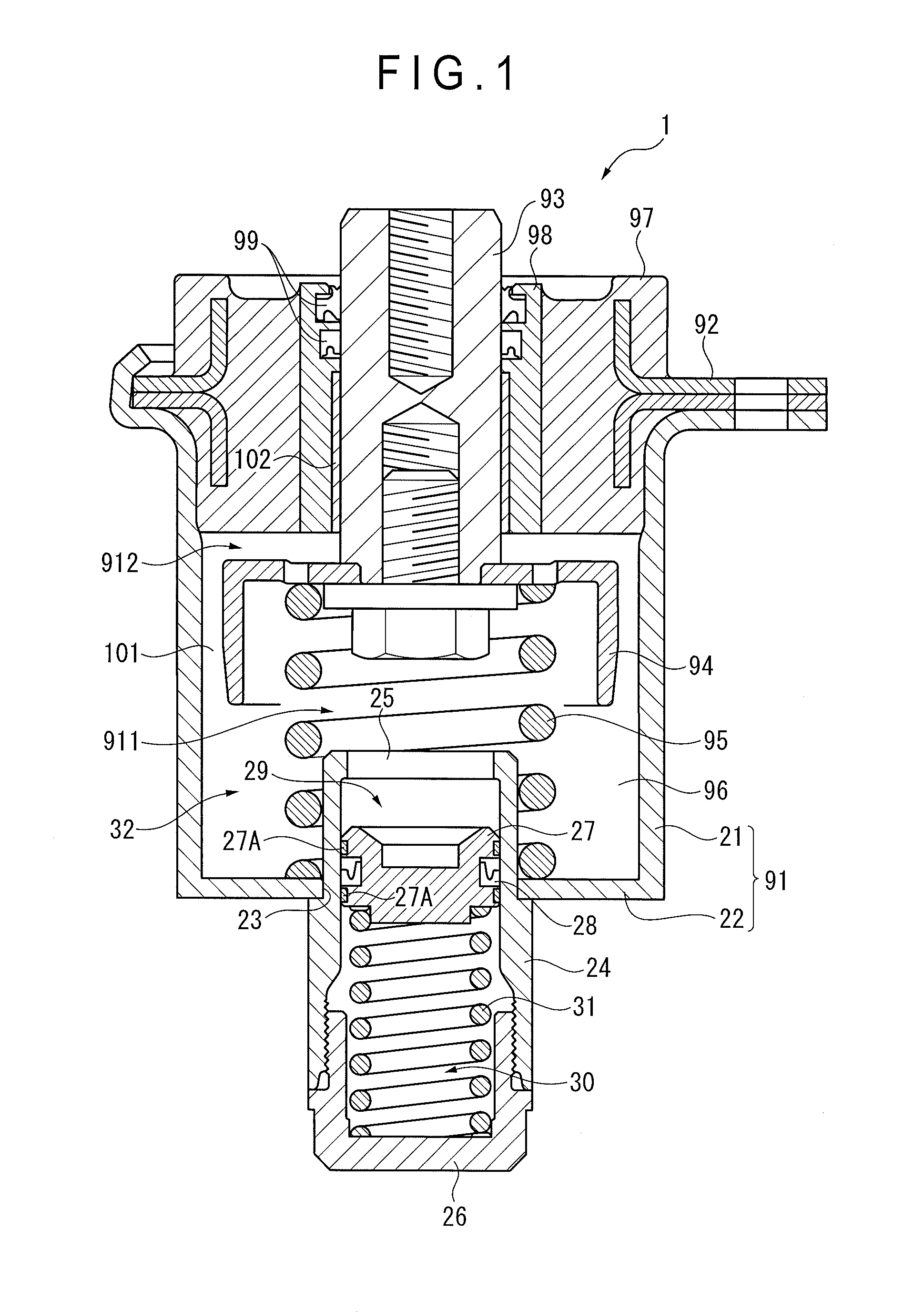

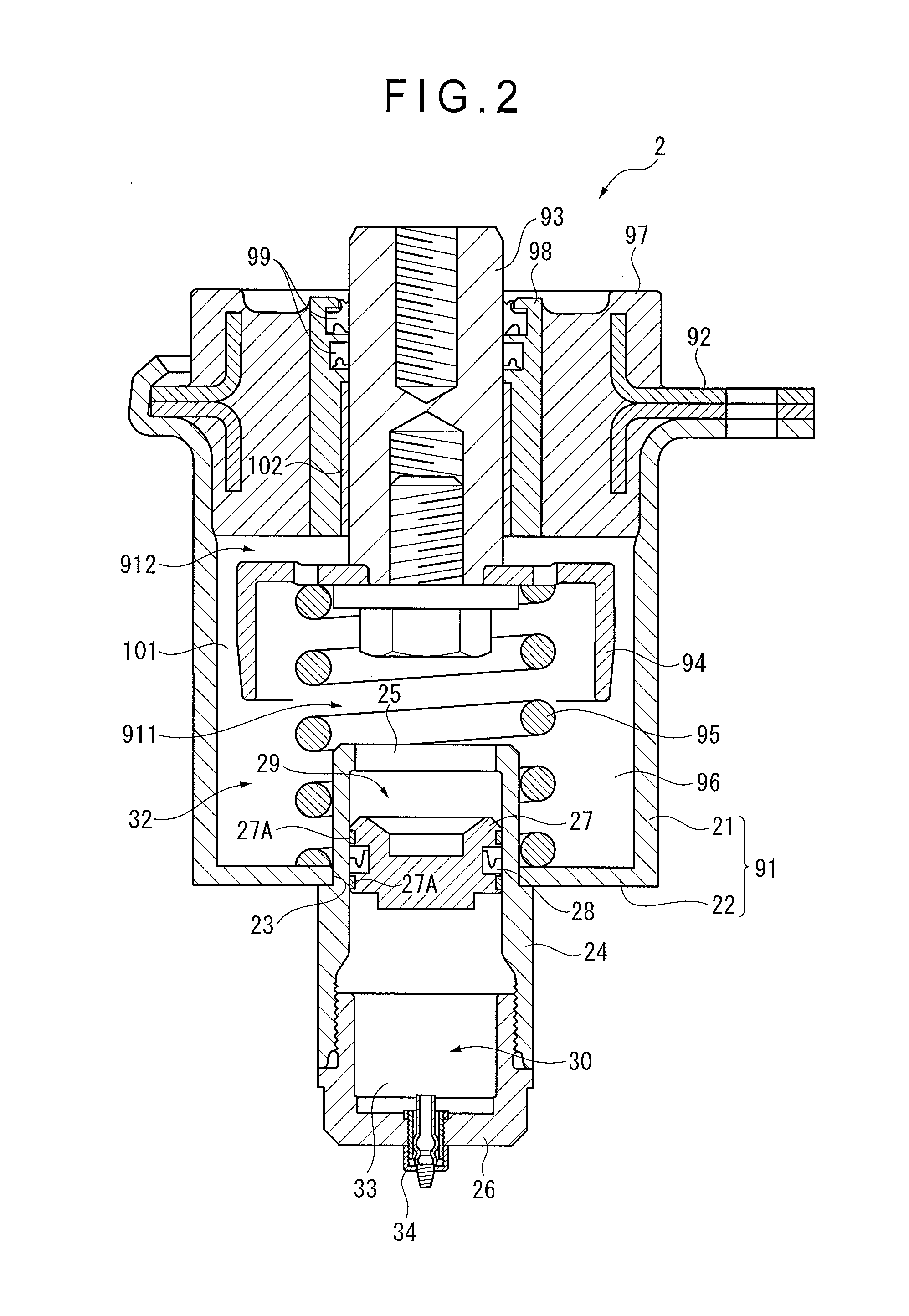

Liquid Sealed Mount

ActiveUS20110221107A1Superior anti-vibration characteristicLow fluid viscosityMachine framesLiquid springsDifferential pressureEngineering

A hydraulic mount includes: a container in which a high-viscosity fluid is liquid-tightly sealed; a rubber mount that is provided on an upper side of the container; a rod that slidably penetrates through the rubber mount; a damper plate that is provided to an end of the rod; a damping force generator that is provided by a clearance between the container and the damper plate; a main fluid chamber that includes an upper fluid chamber and a lower fluid chamber provided by dividing an interior of the container by the damper plate; a volume-variable secondary fluid chamber that communicates with the main fluid chamber; and a pressurizer that generates a differential pressure between the upper fluid chamber and the lower fluid chamber during the movement of the rod.

Owner:KOMATSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com