Method combining coiled tubing with supercritical CO2 for jet-flow sand washing plugging removal

A supercritical, CO2 technology, applied in earthwork drilling, flushing wellbore, wellbore/well parts, etc., can solve problems such as excessive scale thickness, cannot be completely removed, and difficult to control foam quality, so as to increase production and Effects of recovery factor, increase of reservoir permeability, process and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

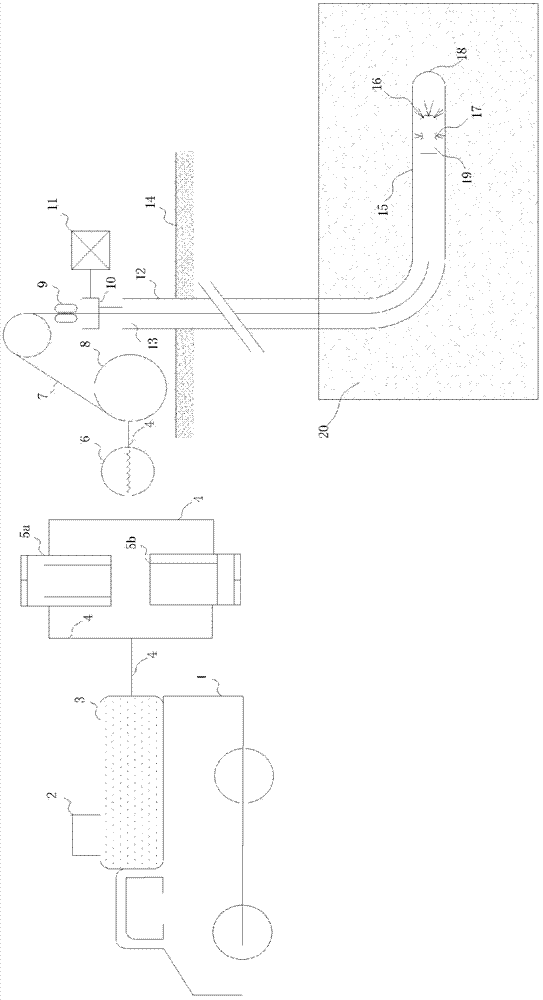

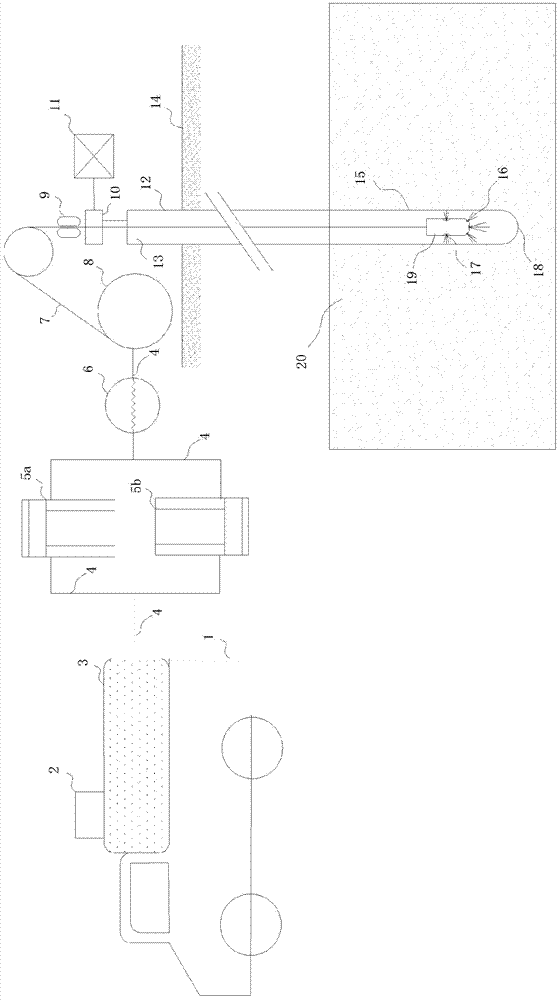

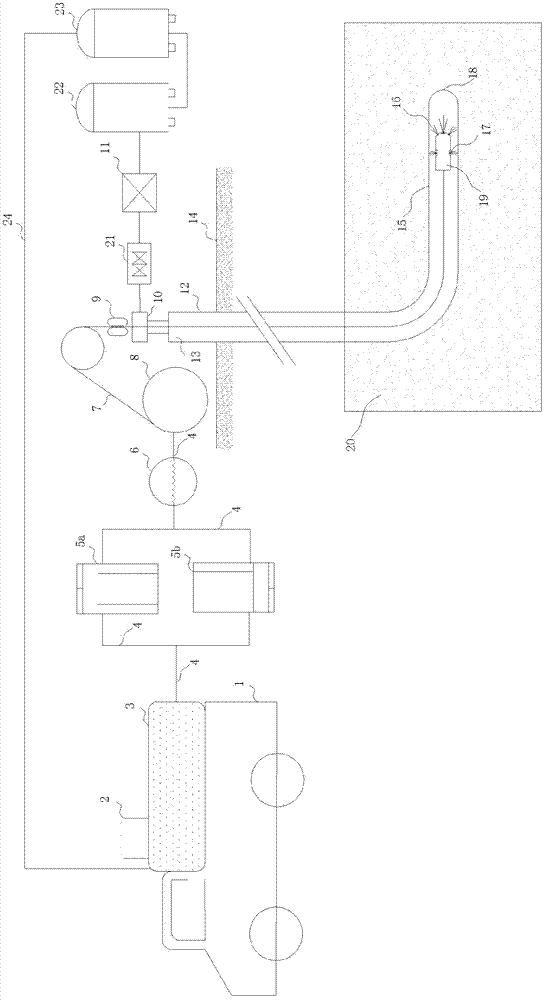

[0039] Coiled tubing supercritical CO provided by the present invention 2 Introducing supercritical CO into jet sand flushing and plugging removal method 2 The fluid is used as a well flushing fluid, which can fully utilize the supercritical CO 2 Based on the respective advantages of coiled tubing and coiled tubing, the method may include the following specific steps:

[0040] 1. Well drilling treatment: use a drift gauge to drill the well to ensure that the coiled tubing and downhole flushing tools are smoothly lowered to the upper end of the layer to be sand flushed and plugged;

[0041] 2. Sand flushing and plugging removal treatment:

[0042] figure 1 Coiled tubing supercritical CO shown 2 Schematic diagram of sand flushing and plugging removal in a jet horizontal well. Before flushing the well, lower the flushing tool to the upper end of the layer to be sand-washed and plug-removed, with an error of no more than 0.5 meters;

[0043] Liquid CO 2 By CO equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com