Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Less productive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

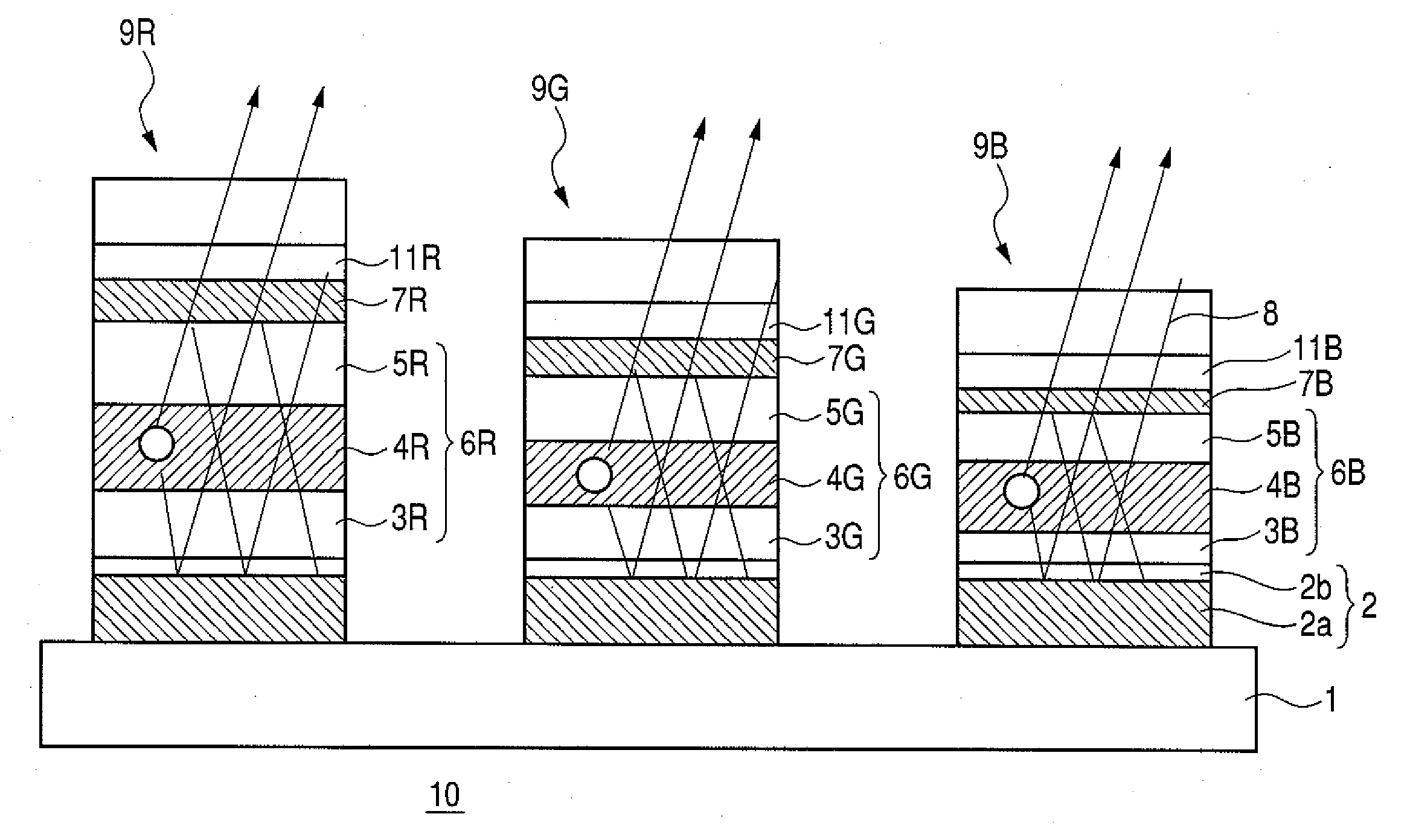

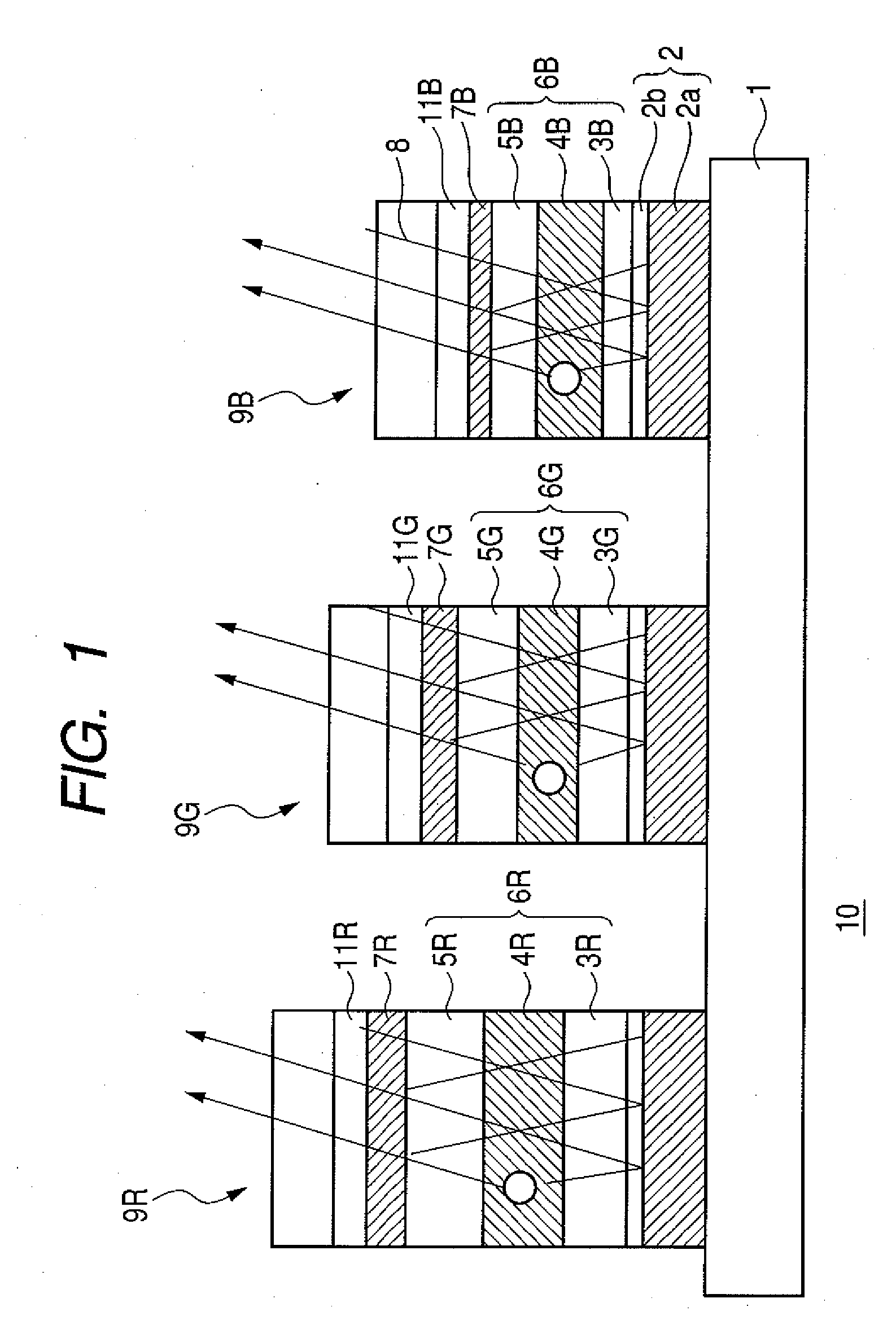

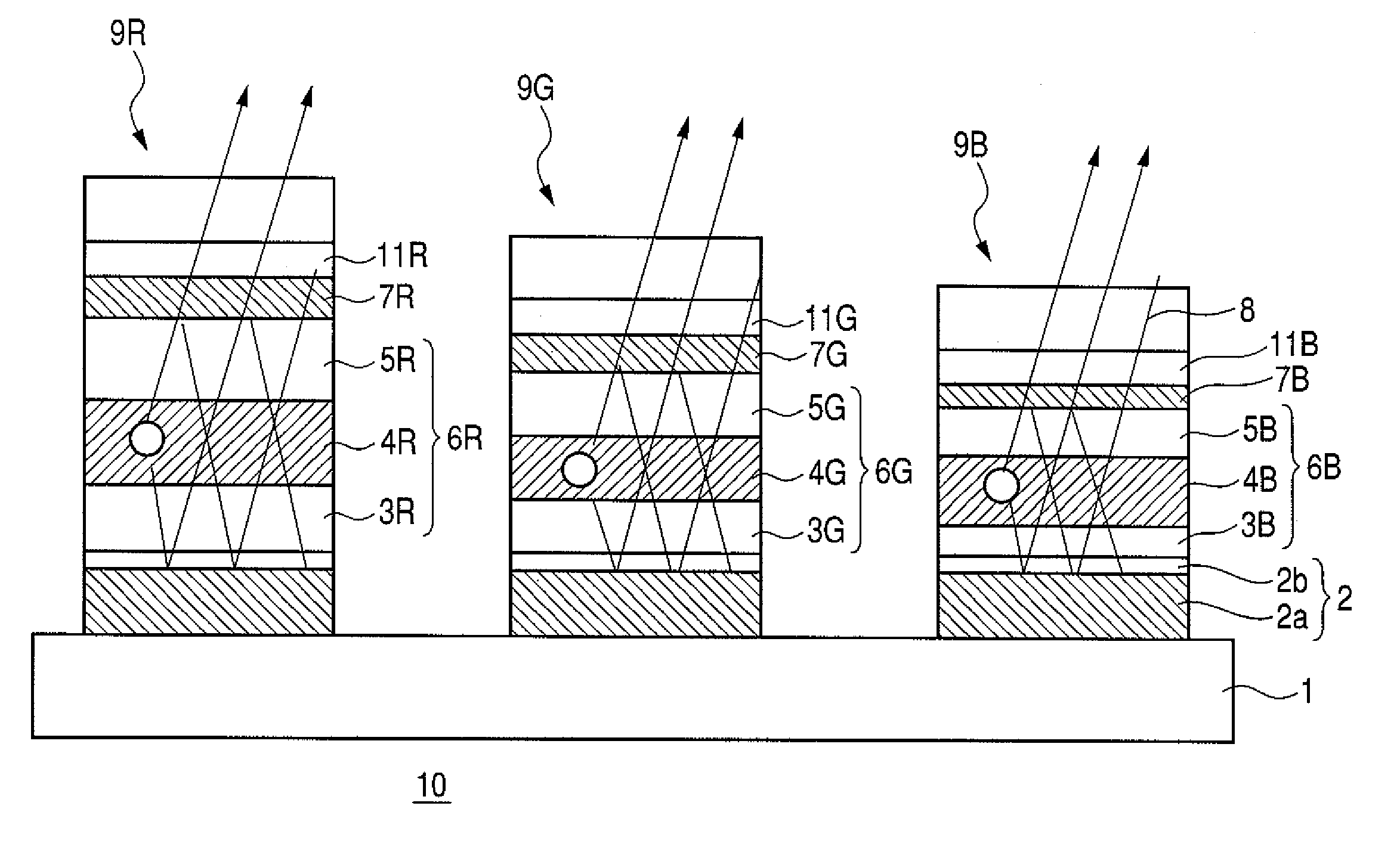

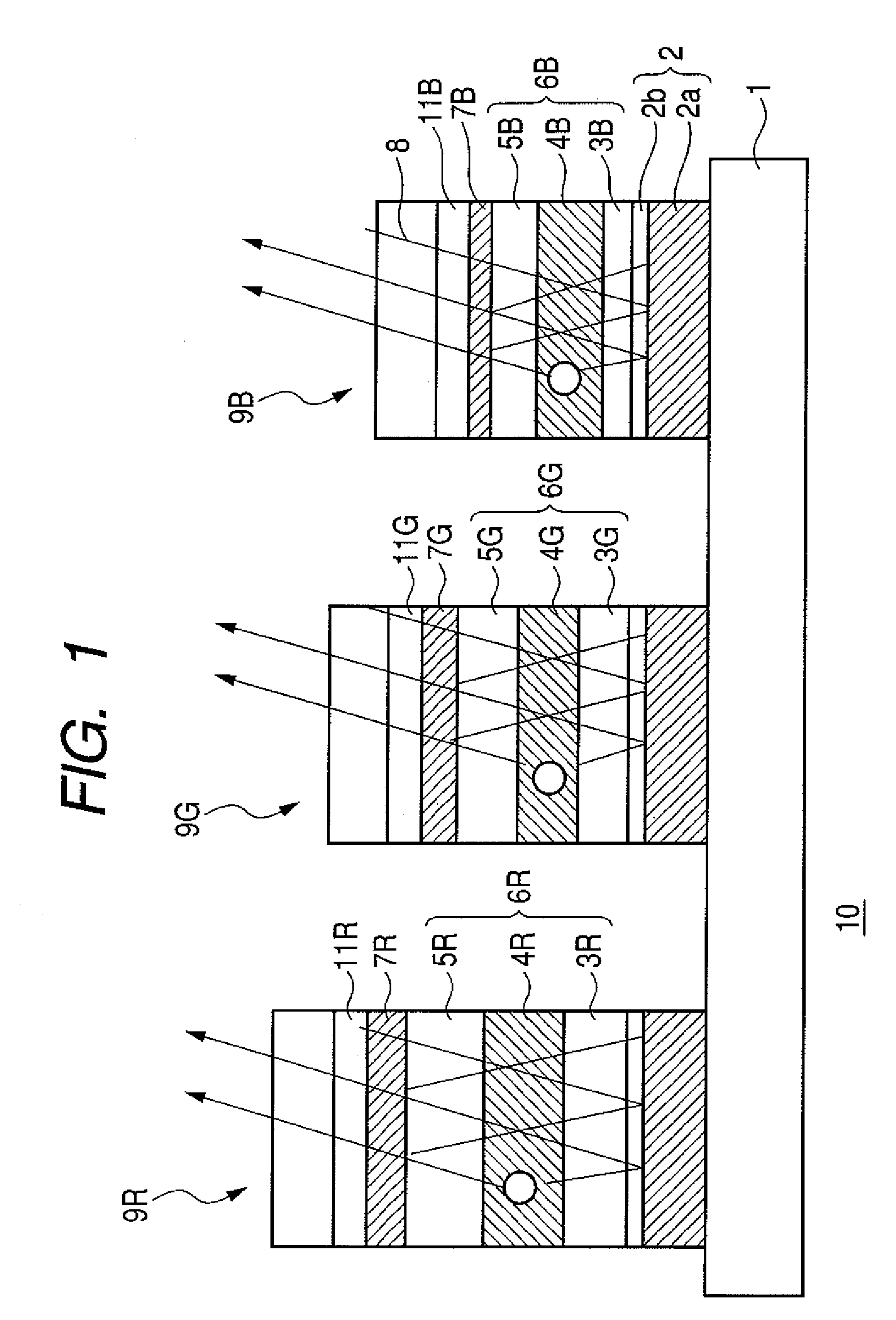

Organic light-emitting device

ActiveUS20080067926A1Improve luminous efficiencyDifference in chromaticityDischarge tube luminescnet screensElectroluminescent light sourcesChemistryOrganic compound

The organic light-emitting device of the present invention includes a plurality of organic light-emitting elements including an organic light-emitting element showing a first emission color and at least one organic light-emitting element showing a different emission color from the first emission color, each of the organic light-emitting elements including: a first electrode having a reflective surface; a second electrode placed on a light extraction side and including a semi-transparent layer; an organic compound layer including a light-emitting layer and formed between the first electrode and the second electrode; and a micro cavity structure for resonating light emitted from the light-emitting layer between the reflective surface and the semi-transparent layer, wherein the semi-transparent layer in the organic light-emitting element showing the first emission color is different in thickness and / or material from the semi-transparent layer in the at least one organic light-emitting element showing the different emission colors.

Owner:CANON KK

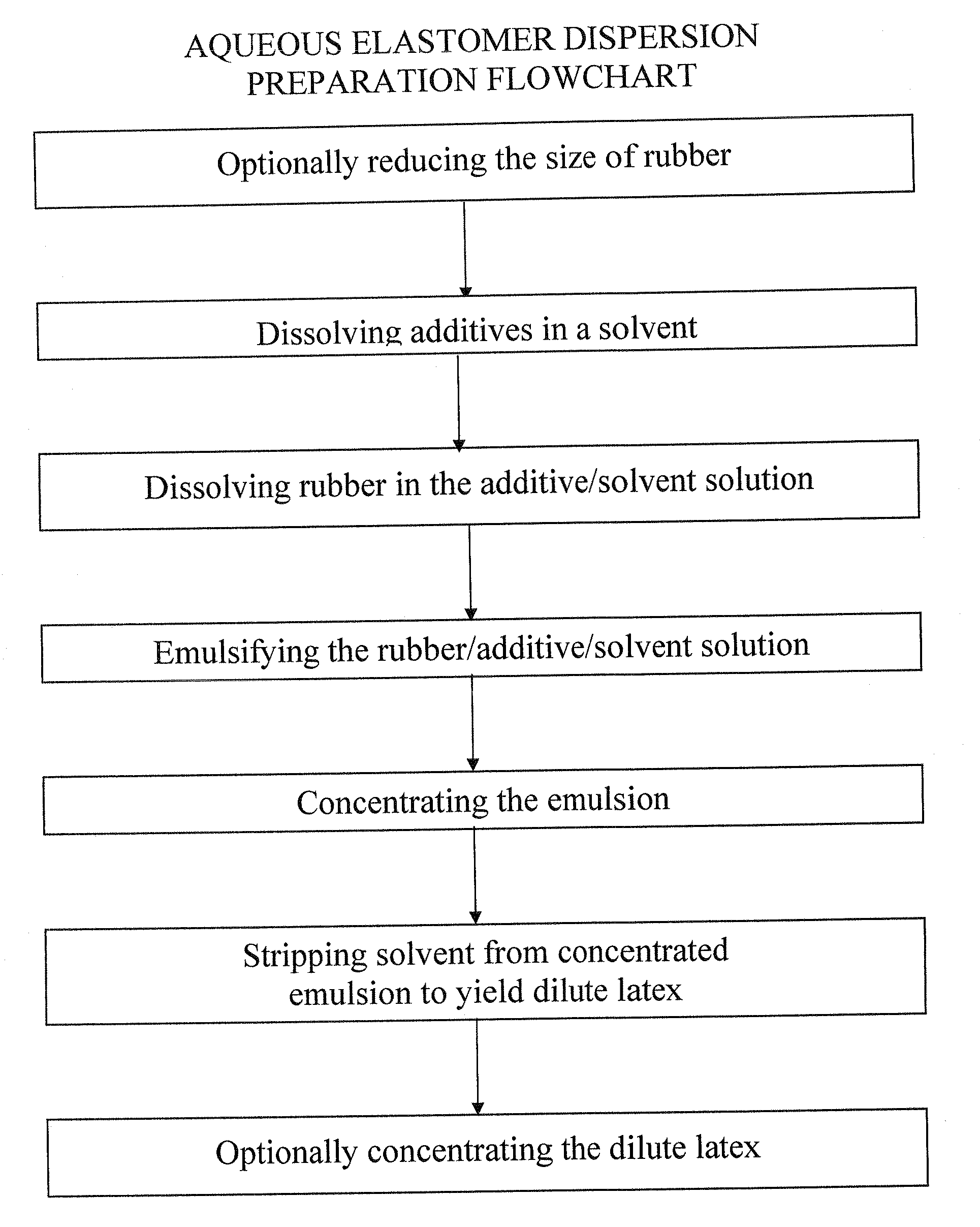

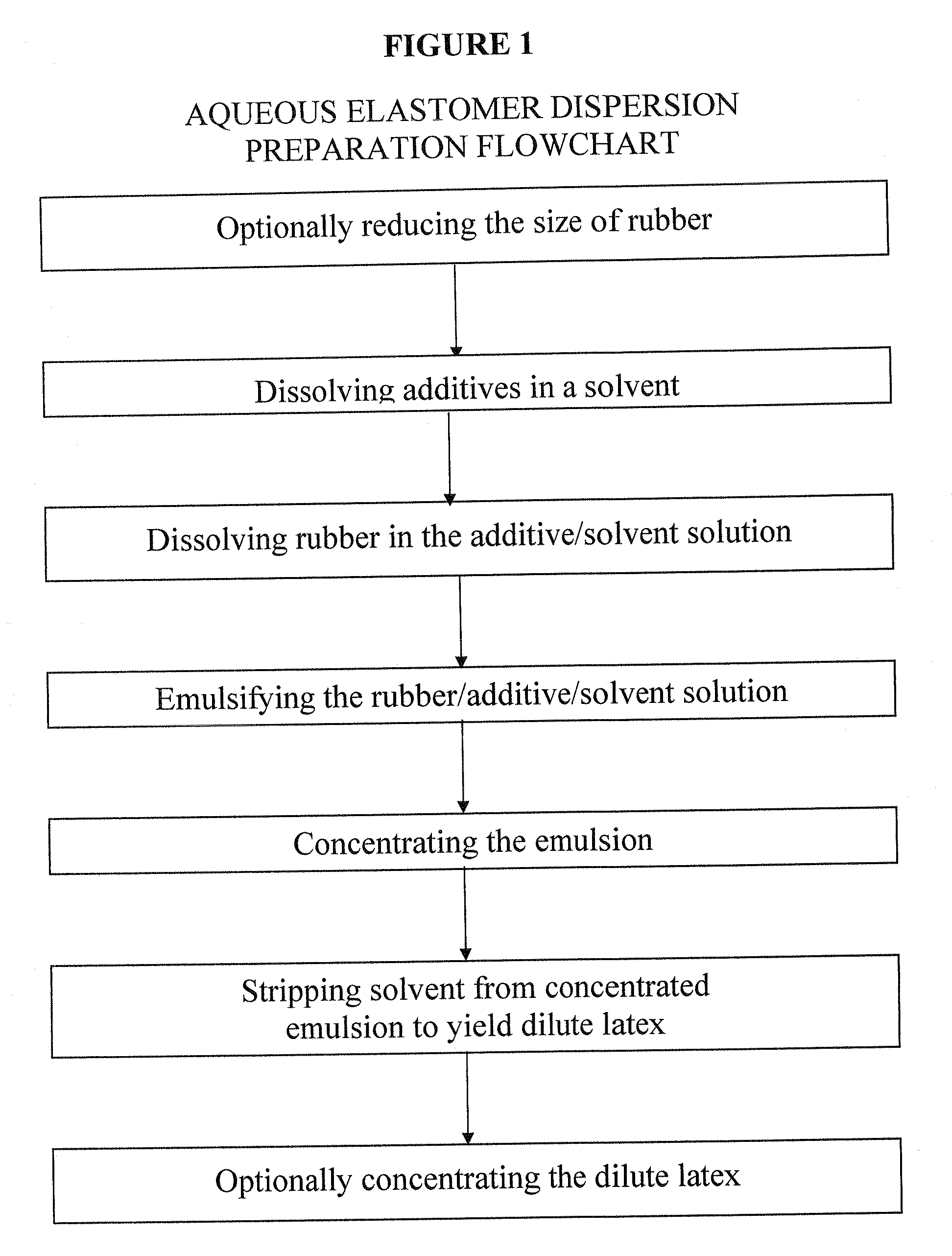

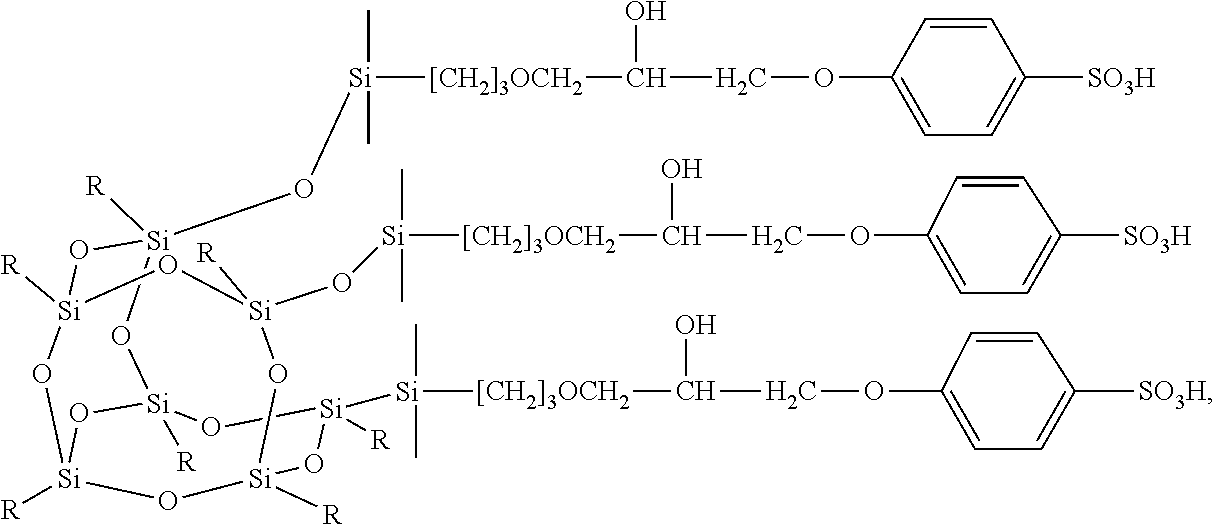

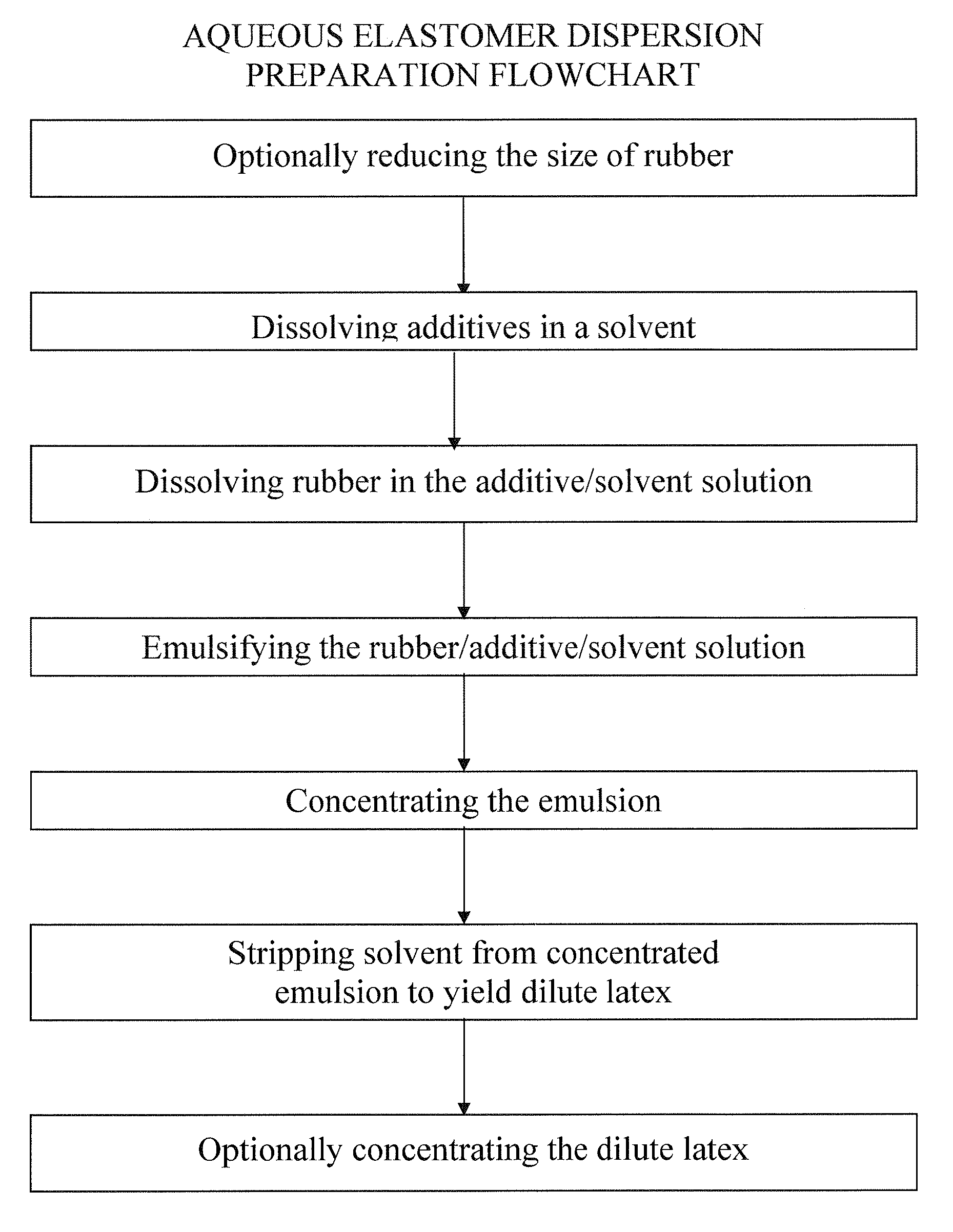

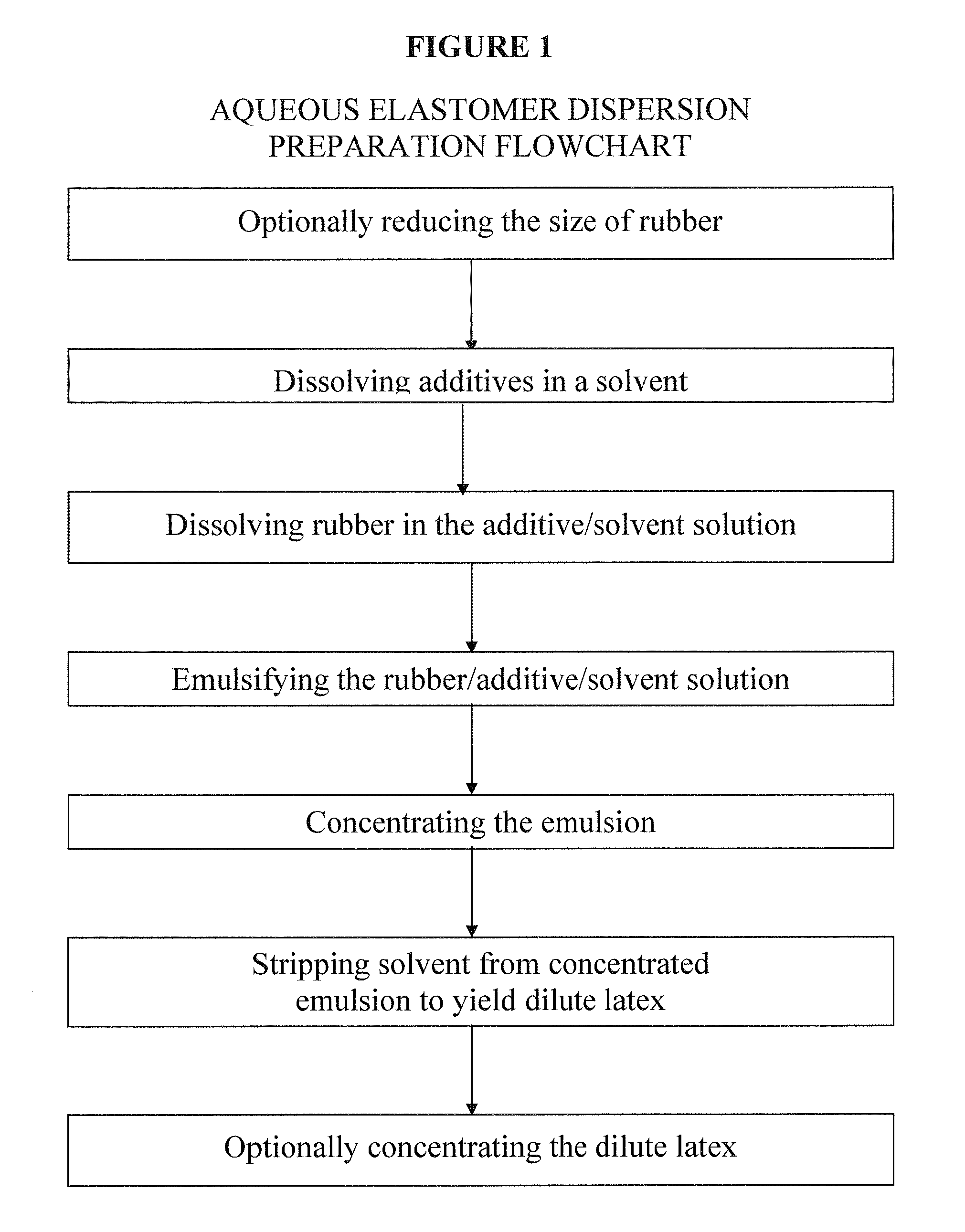

Water-based resin composition and articles made therefrom

InactiveUS20090234064A1Well formedLess surfactant/emulsifierGroup 4/14 element organic compoundsSpecial tyresElastomerWater based

An aqueous elastomer dispersion includes a dispersed phase and an aqueous phase. The dispersed phase includes an elastomer including curable aliphatic conjugated-diene elastomers, such as polyisoprene, and a minor amount of at least one additive. The aqueous phase includes water and other optional components in either a soluble state or a dispersion state. The aqueous elastomer dispersion may be prepared by dissolving an elastomer, such as rubber, and additives in a solvent mixture and then converting the resulting solution into an aqueous emulsion. The aqueous emulsion is concentrated and the solvent is stripped from it to yield a dilute latex. The dilute latex that is obtained is concentrated again. Articles made from the aqueous elastomer dispersion include medical gloves, condoms, probe covers, dental dams, finger cots, catheters and the like.

Owner:ALLEGIANCE CORP

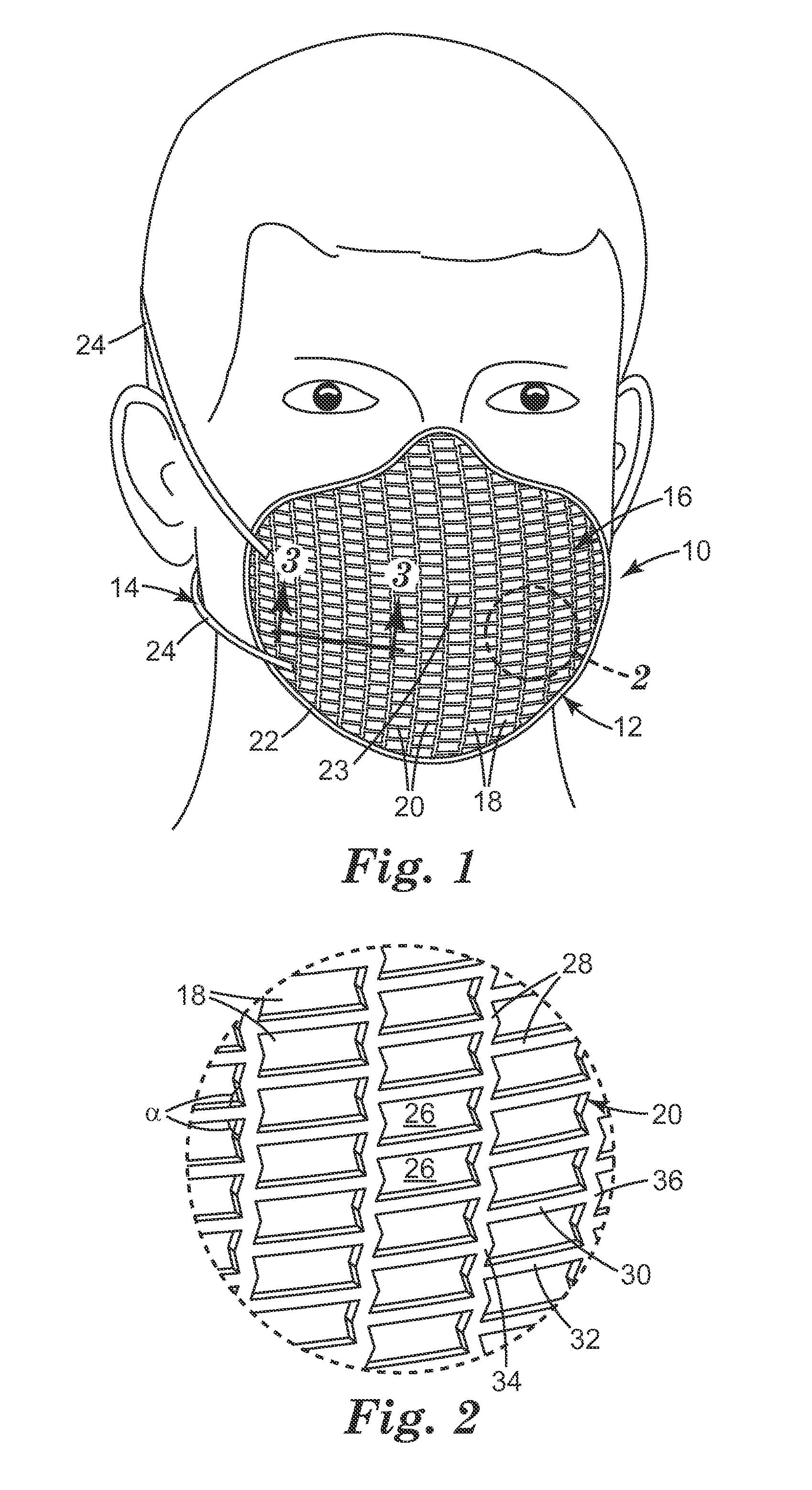

Molded auxetic mesh

Owner:3M INNOVATIVE PROPERTIES CO

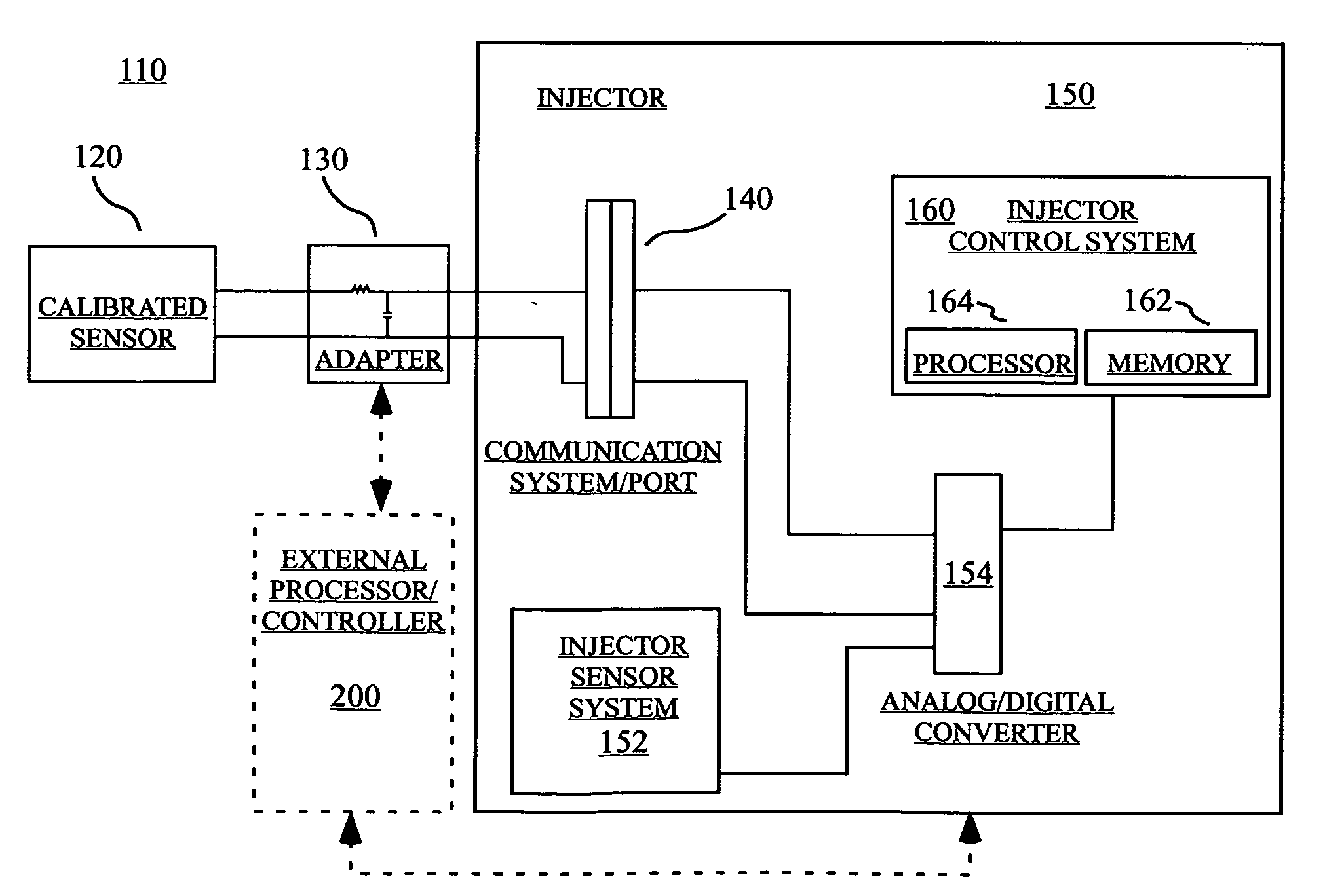

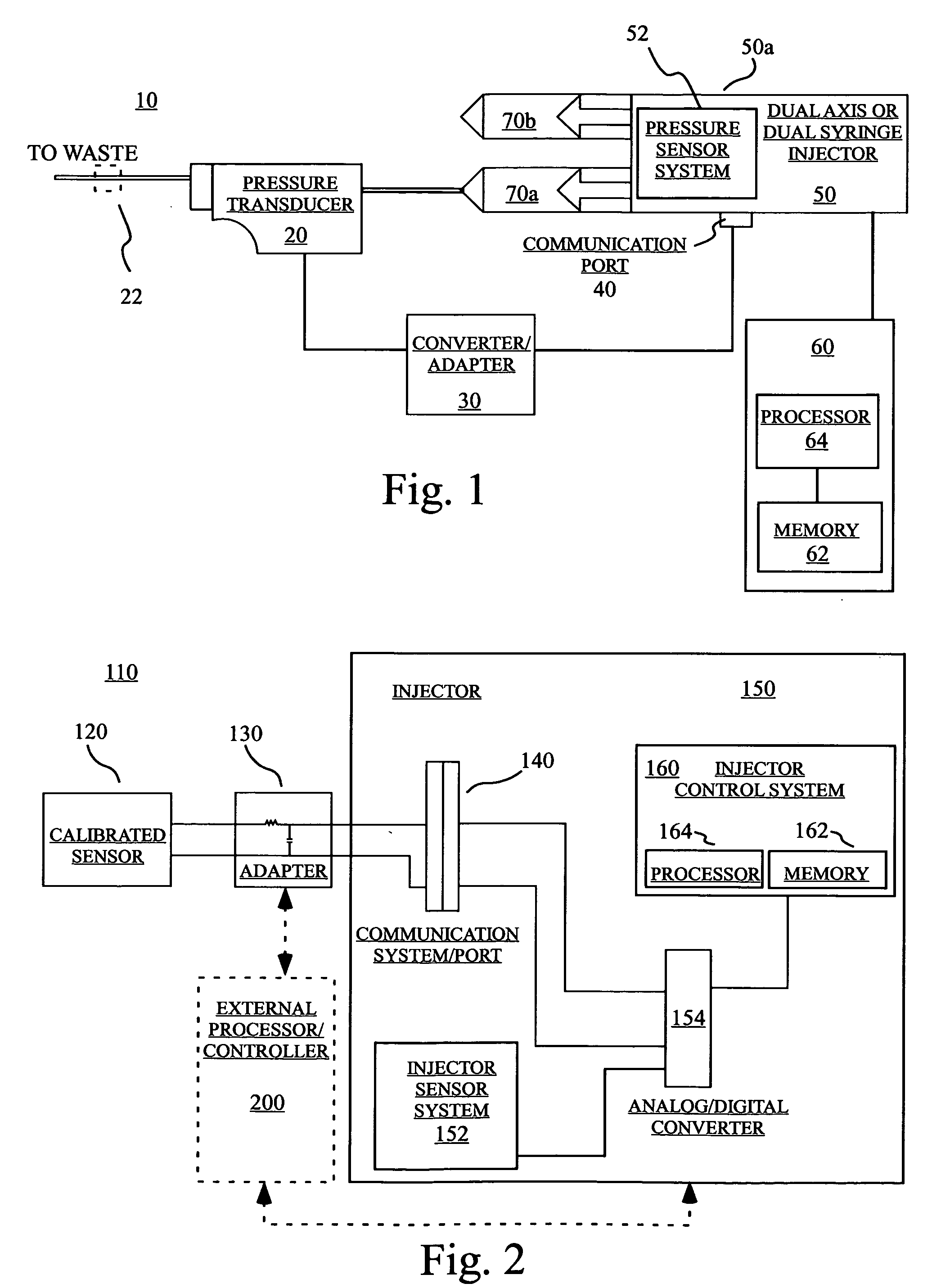

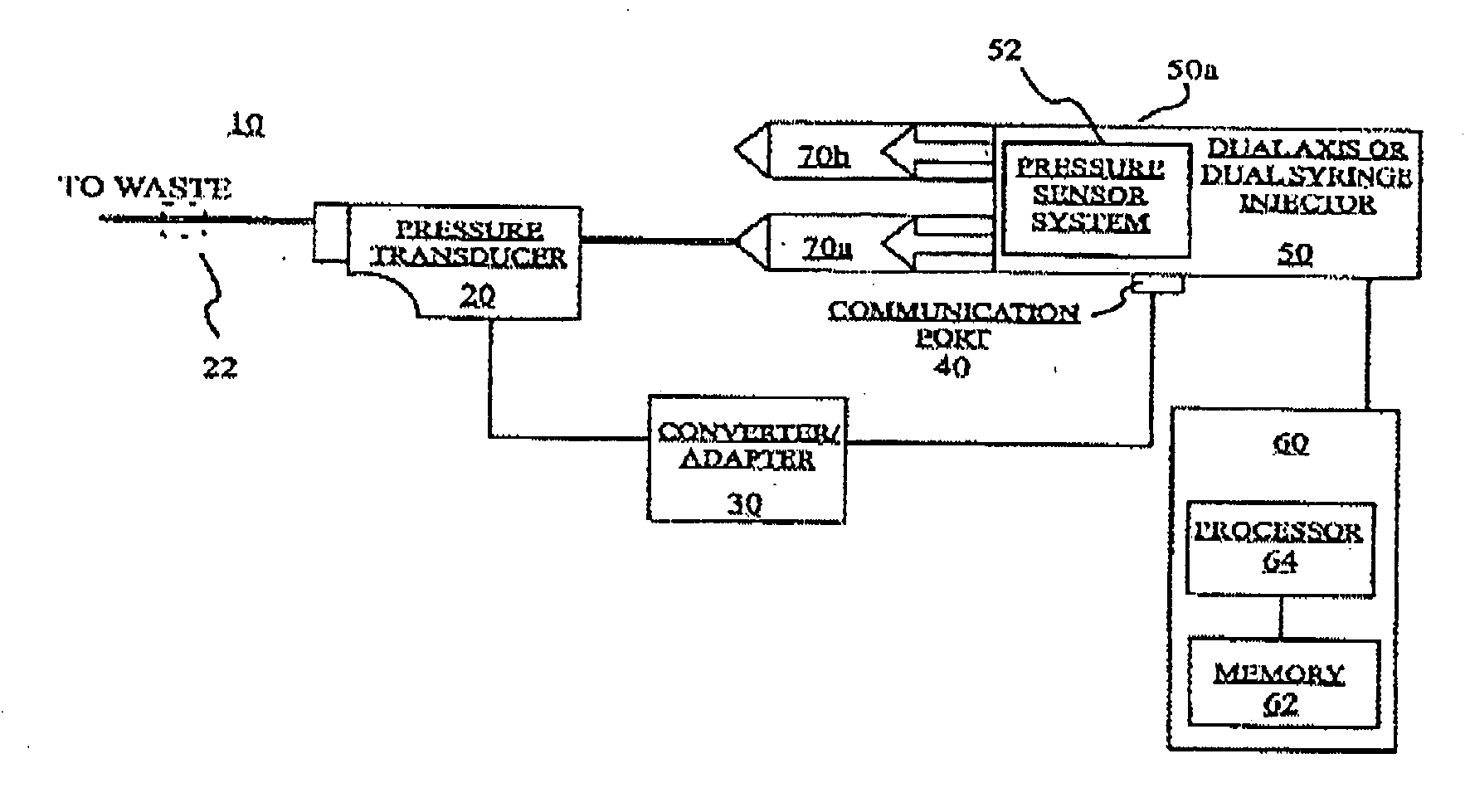

Devices, systems and method for calibration of systems

InactiveUS20060213249A1Change effectReduce downtimeMedical devicesFluid pressure measurementCommunications systemEngineering

An injector system for use in injecting a fluid into a patient includes a communication system adapted to receive data from at least a first sensor that measures a value first variable. The communication system is also adapted to receive data from a calibrated sensor that measures a value the first variable. The injector system further includes a calibration system adapted to calibrate output from the first sensor in response to output from the calibrated sensor. An injector for use in injecting a fluid into a patient, includes a first sensor that measures a value first variable, a communication port adapted to receive data from a calibrated sensor that measures the value the first variable, and a controller adapted to compare data from the calibrated sensor with data from the first sensor and to calibrate output from the first sensor. The devices, systems and methods of the present invention are applicable to systems other than injection systems. For example, a method for calibrating a system (for example, an injector system) includes: placing a calibrated sensor in communication with the system; making a measurement of the value of at least a first variable with the calibrated sensor; transmitting the measured value from the calibrated sensor to the system via a data communication system in operative connection between the calibrated sensor and the system; making a measurement of the value of the first variable with a sensor of the system at approximately the same time as the measurement made with the calibrated sensor; comparing the value of the first variable measured with the calibrated sensor with the value of the first variable measured with the system sensor; and calibrating the output of the system sensor at least in part based upon the comparison.

Owner:MEDRAD INC.

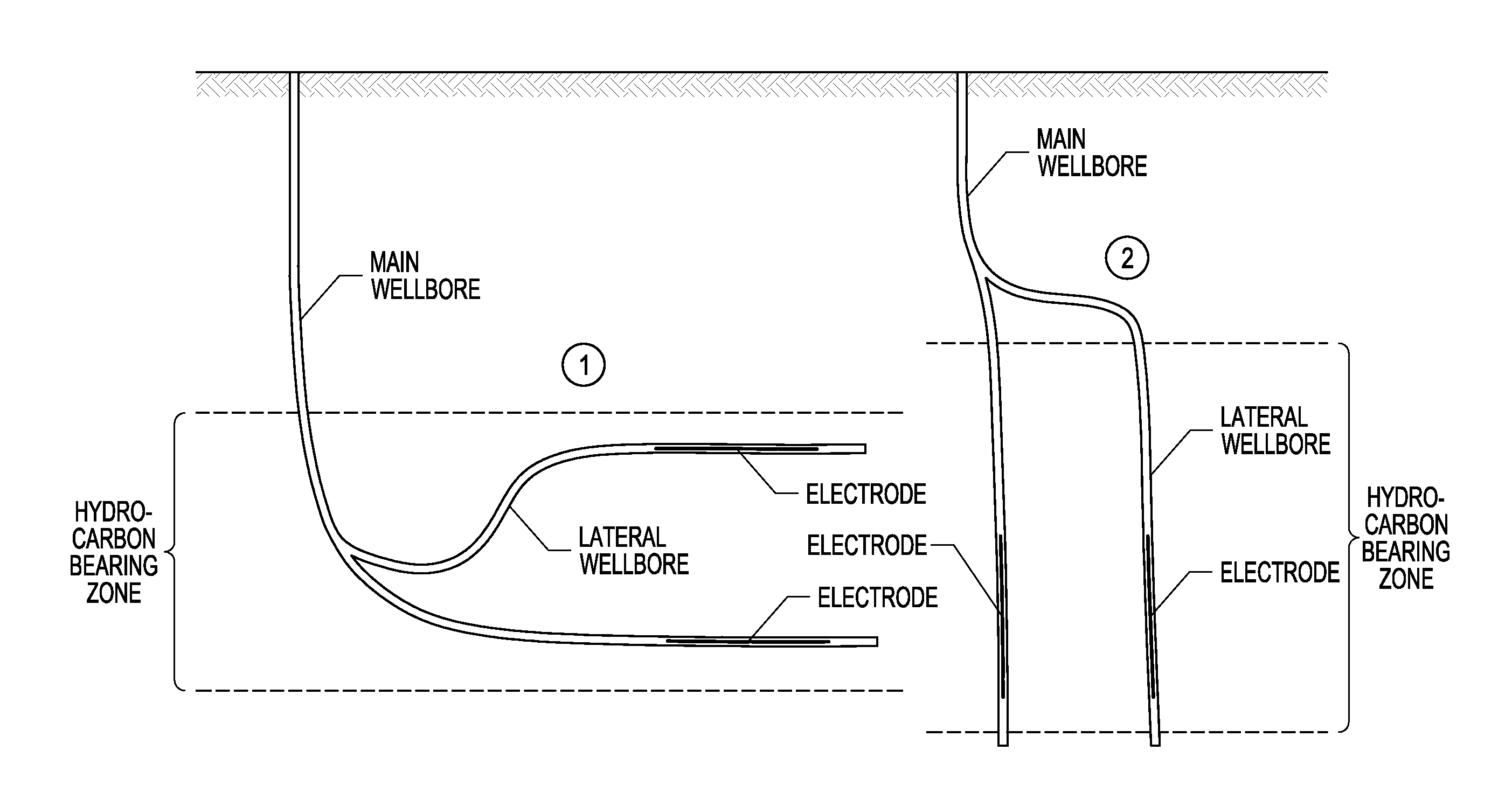

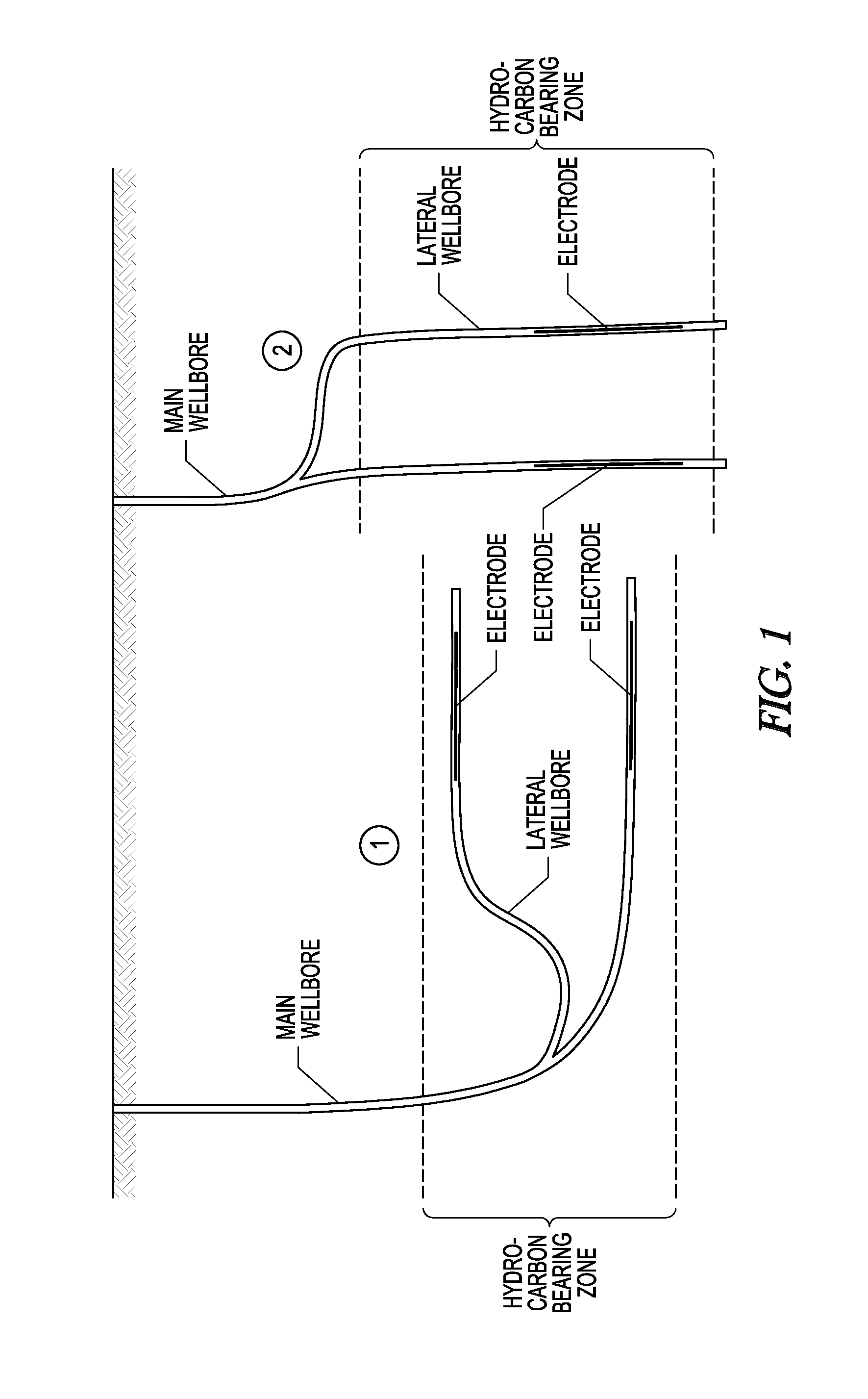

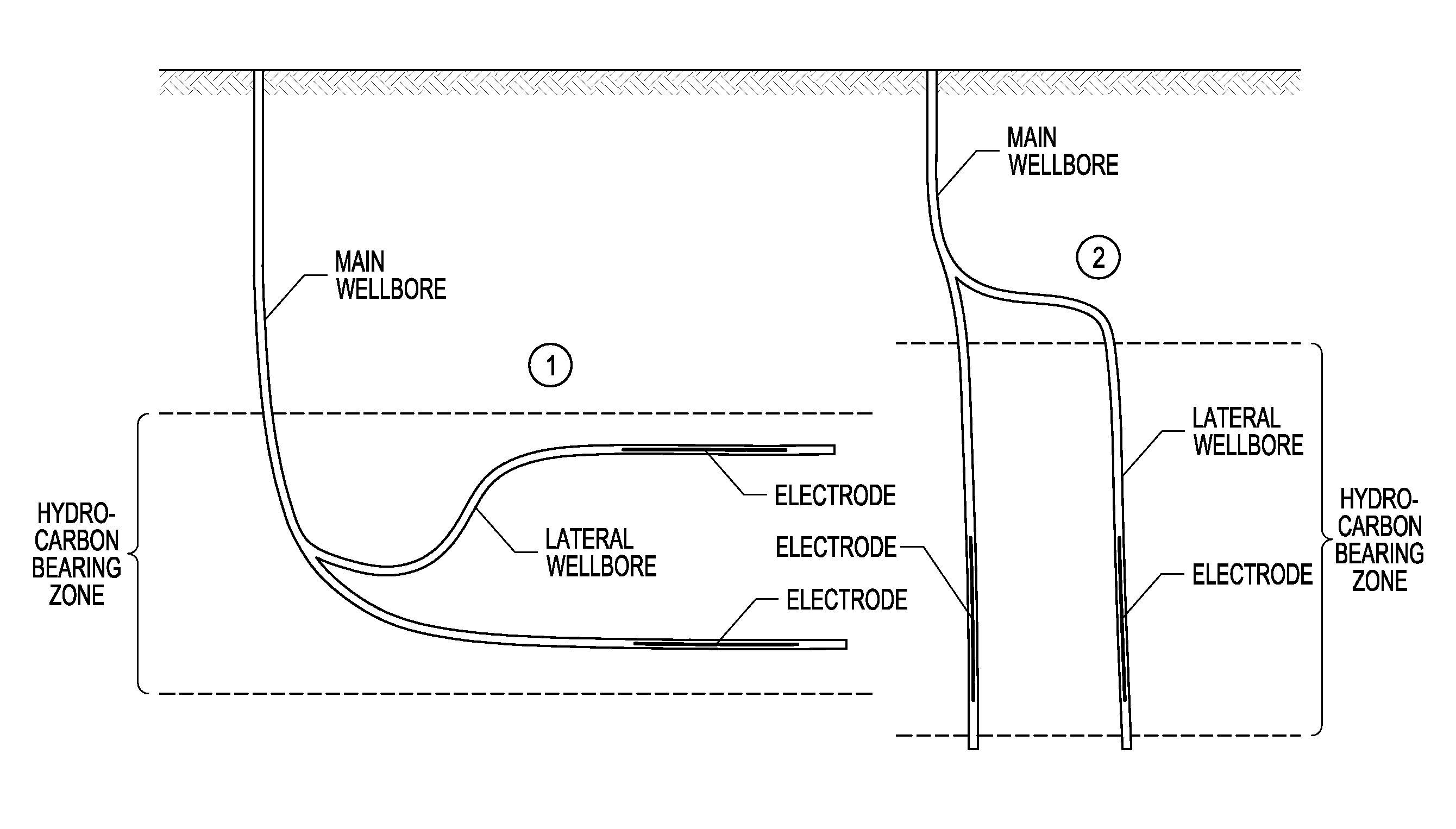

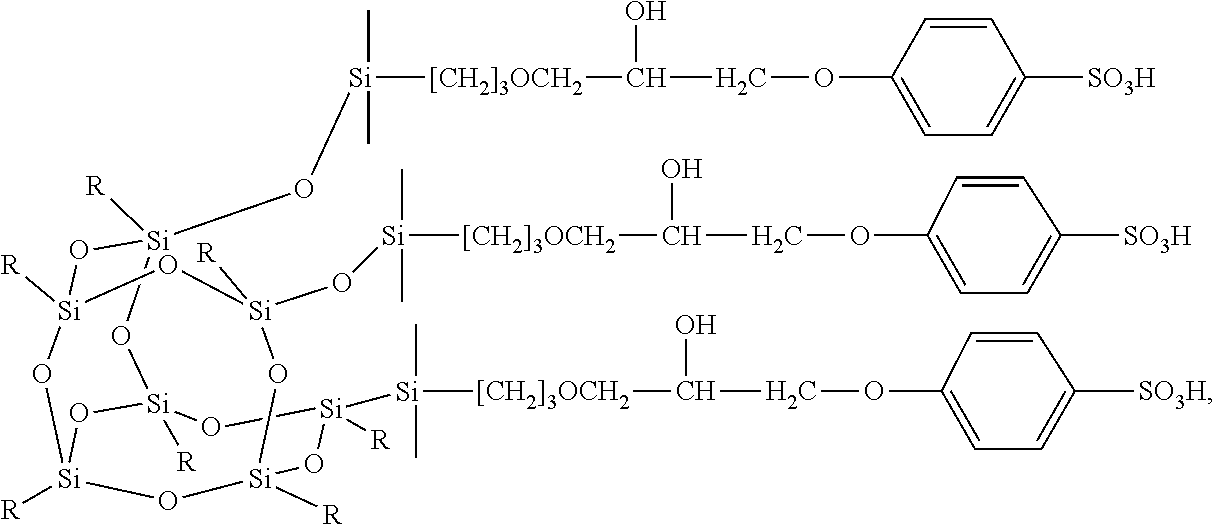

Electrorheological or magnetorheological compositions for treatment of subterranean formations and methods of using the same

ActiveUS20140224480A1High viscosityHigh yieldFluid removalDrilling compositionClassical mechanicsMagnetorheological fluid

The present invention relates to compositions for the treatment of subterranean formations, and methods of using the same. In various embodiments, the present invention provides a fluid for treatment of a subterranean formation, wherein the fluid is at least one of electrorheological and magnetorheological. Various embodiments also provide methods of using the electrorheological or magnetorheological fluid in a subterranean formation, including for fracturing, deposition of proppants, and combinations thereof.

Owner:HALLIBURTON ENERGY SERVICES INC

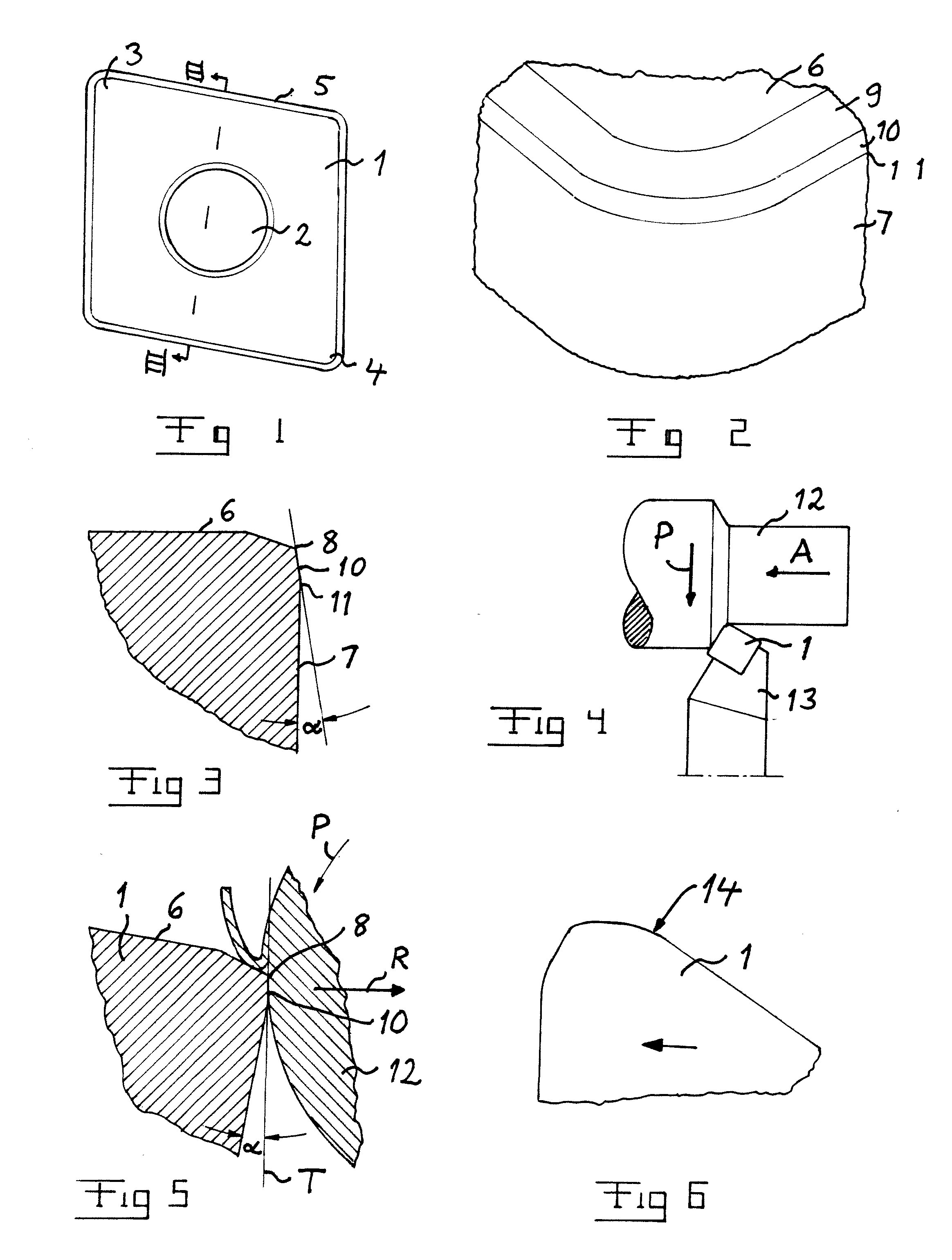

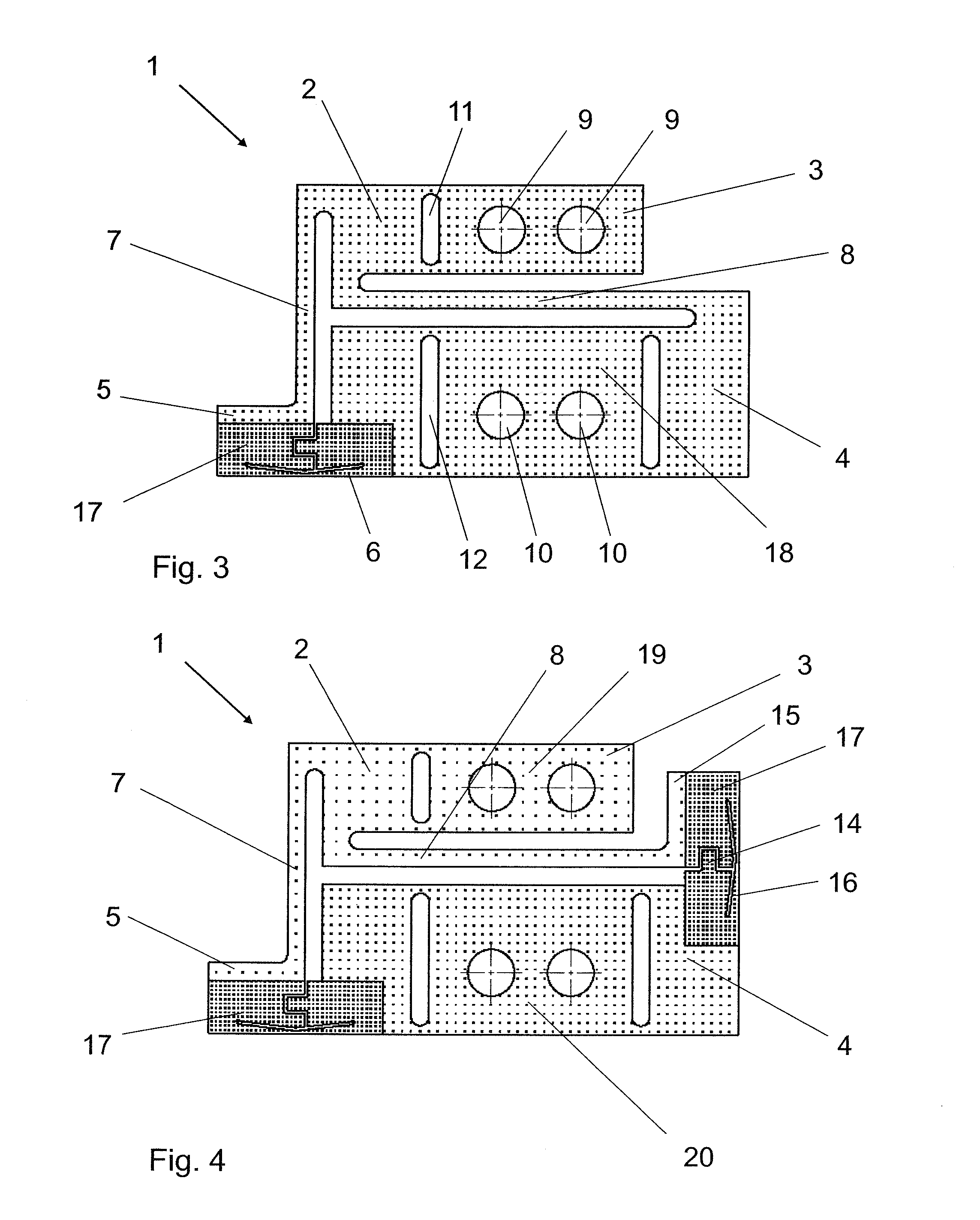

Negative insert for cutting machining

ActiveUS7758287B2Negative influence upon the result of the turning operationIncrease roughnessMilling cuttersCutting insertsEngineeringMachining

A negative insert for cutting machining has a top side, a clearance side perpendicular thereto and a cutting edge in a region interconnecting these sides and extending substantially in parallel with these sides. The insert has further a flat or rounded chamfer connecting the cutting edge to the clearance side on at least one lateral side of the insert in the region of a corner thereof. The chamfer makes an angle of 1°-15° with the clearance side for enabling application of the chamfer substantially tangentially to a work piece to be machined for bearing of the insert in two dimensions against the work piece during cutting machining operation carried out by the insert.

Owner:SECO TOOLS AB

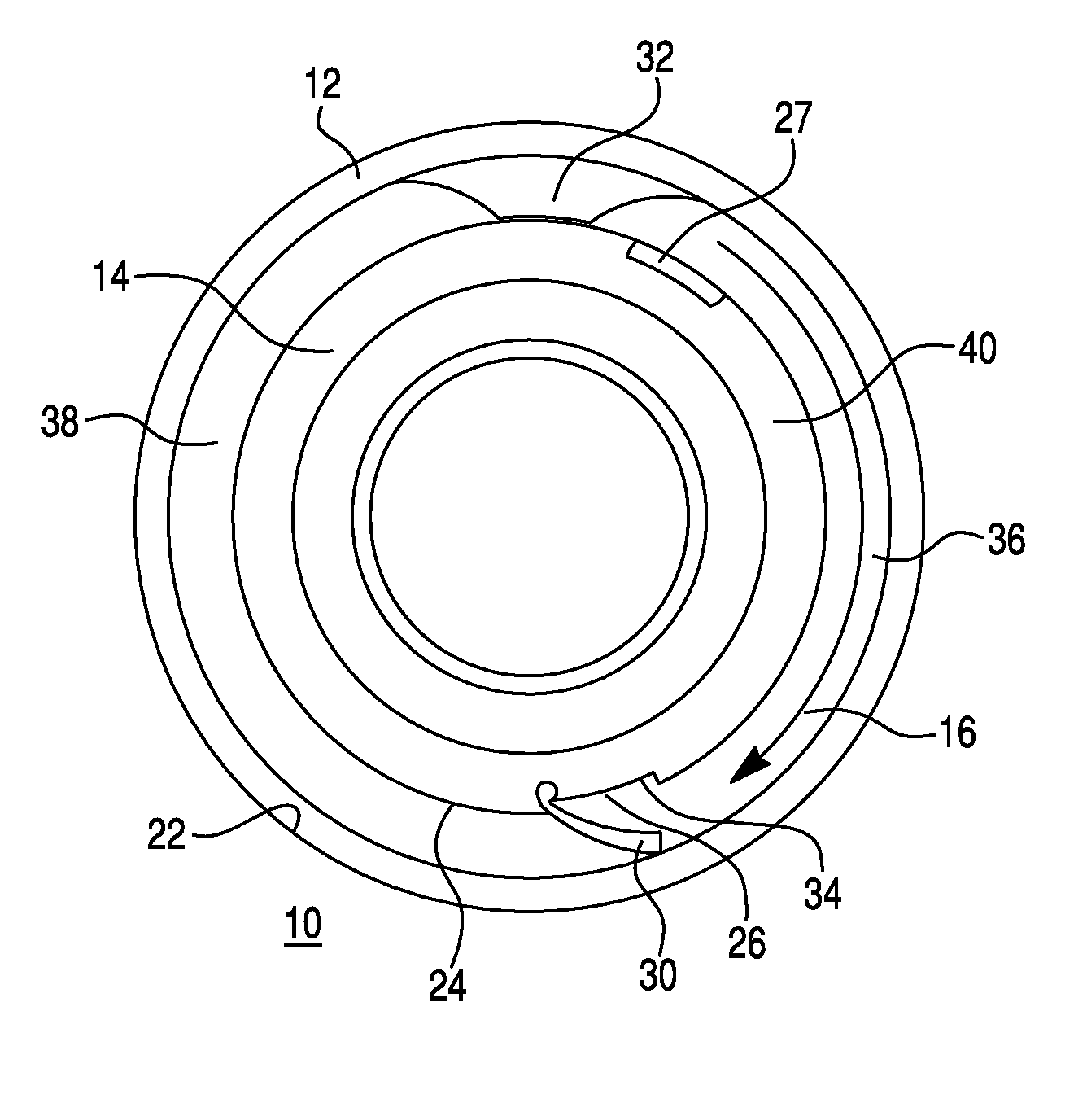

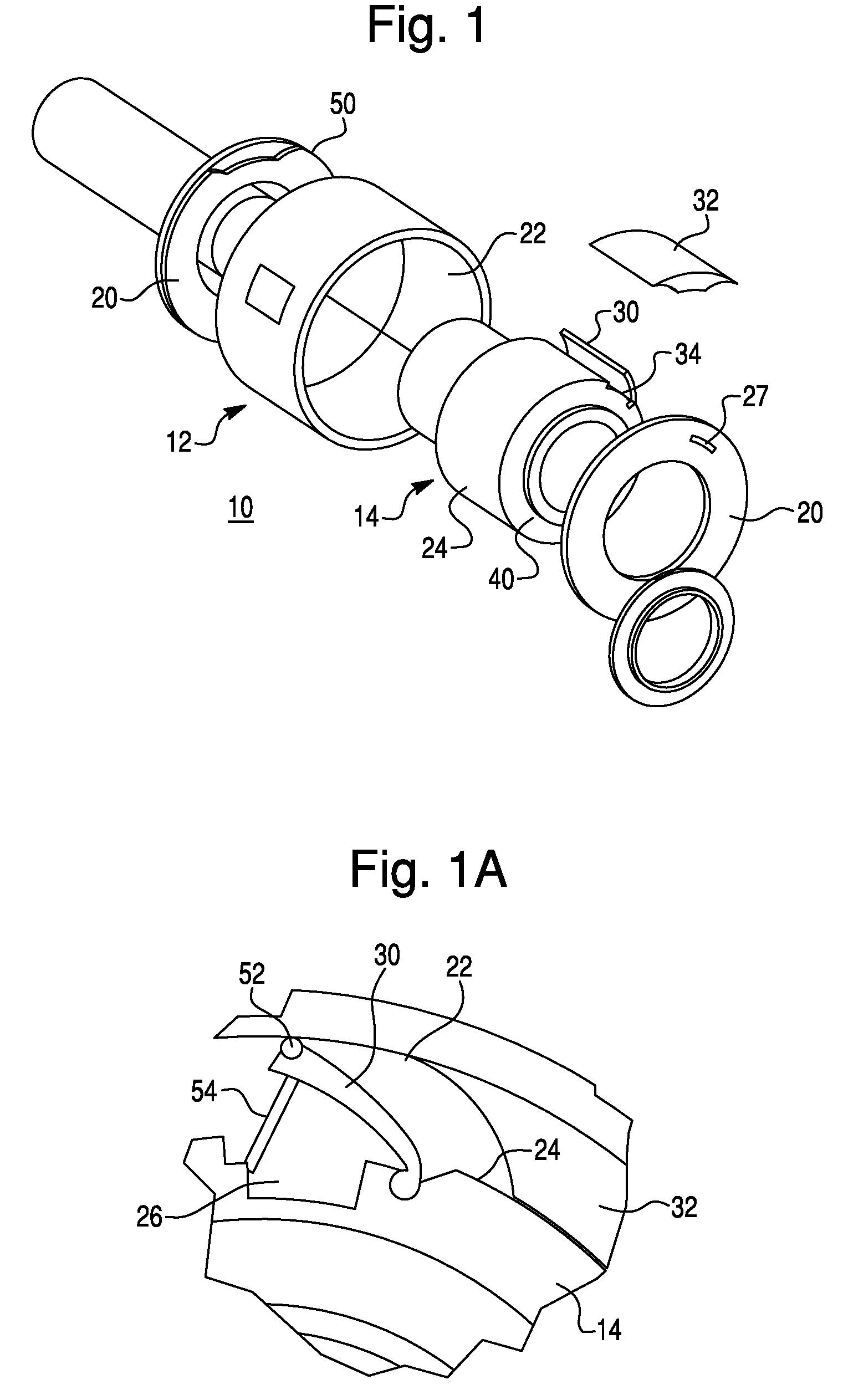

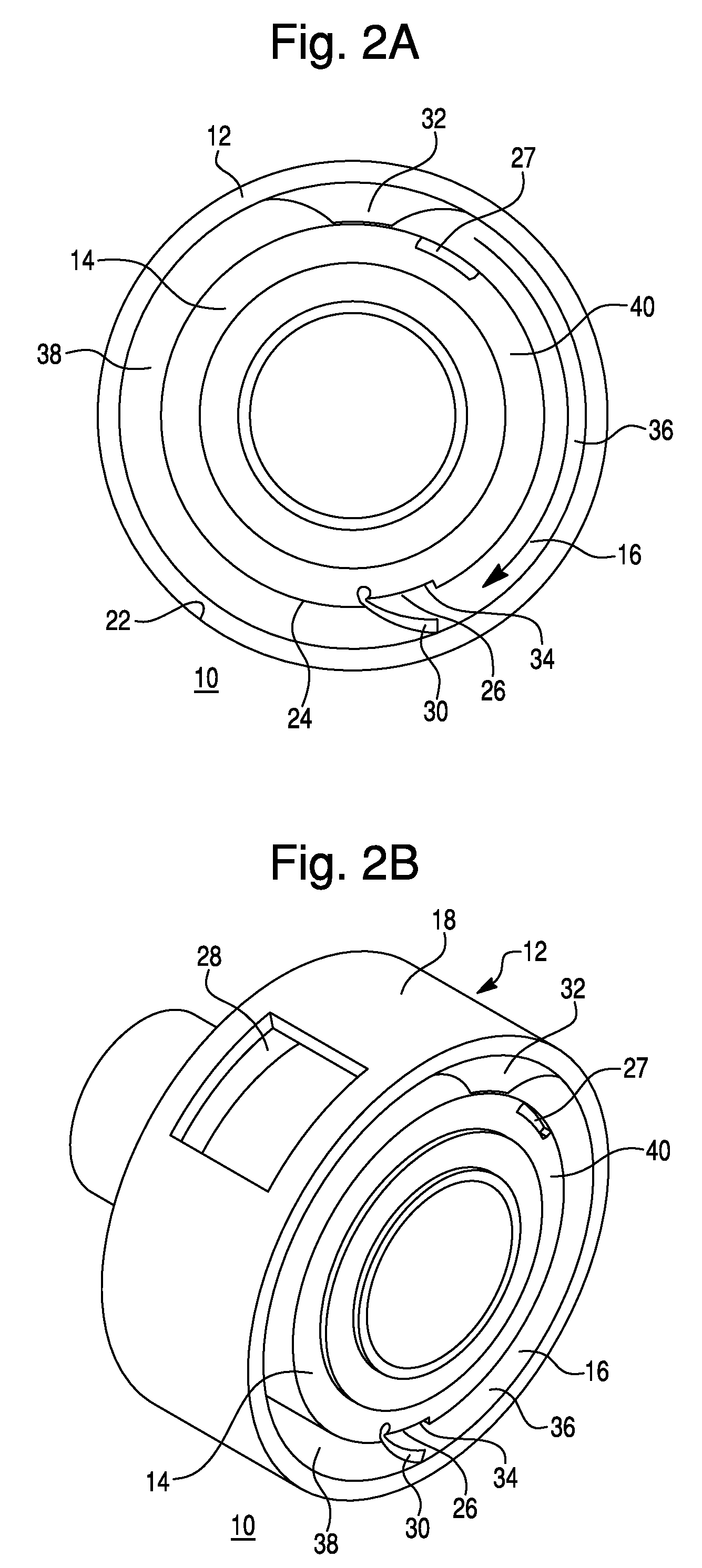

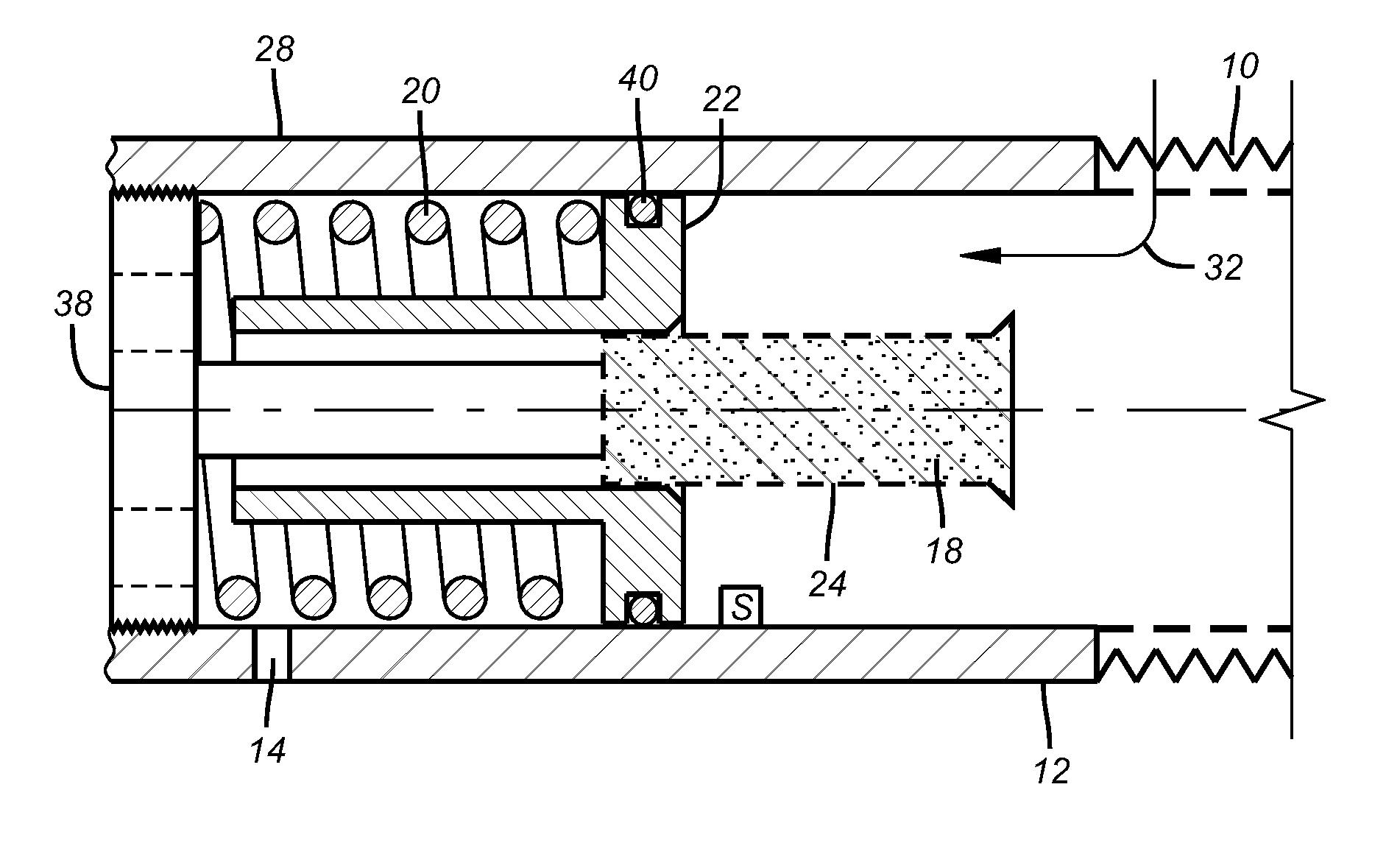

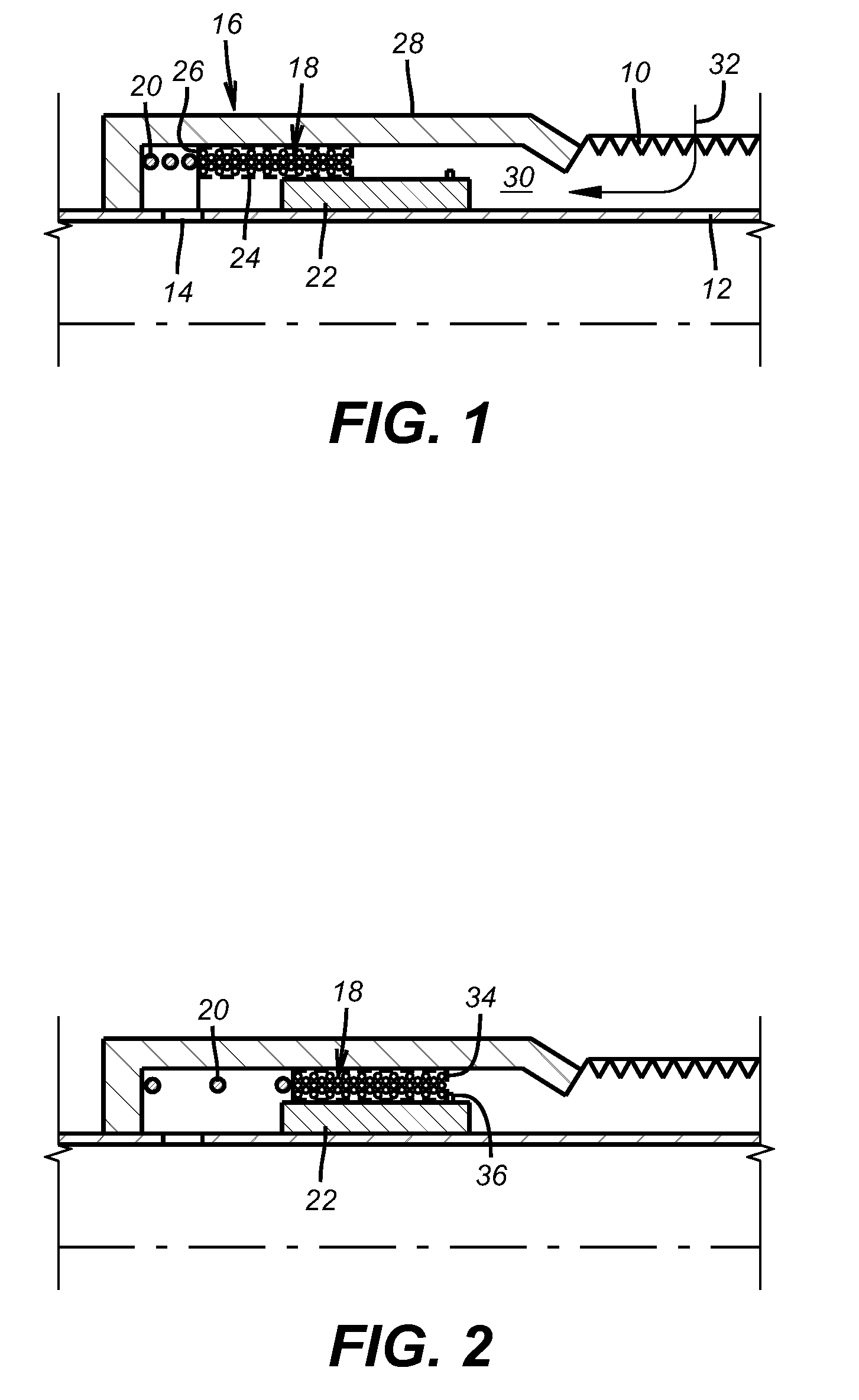

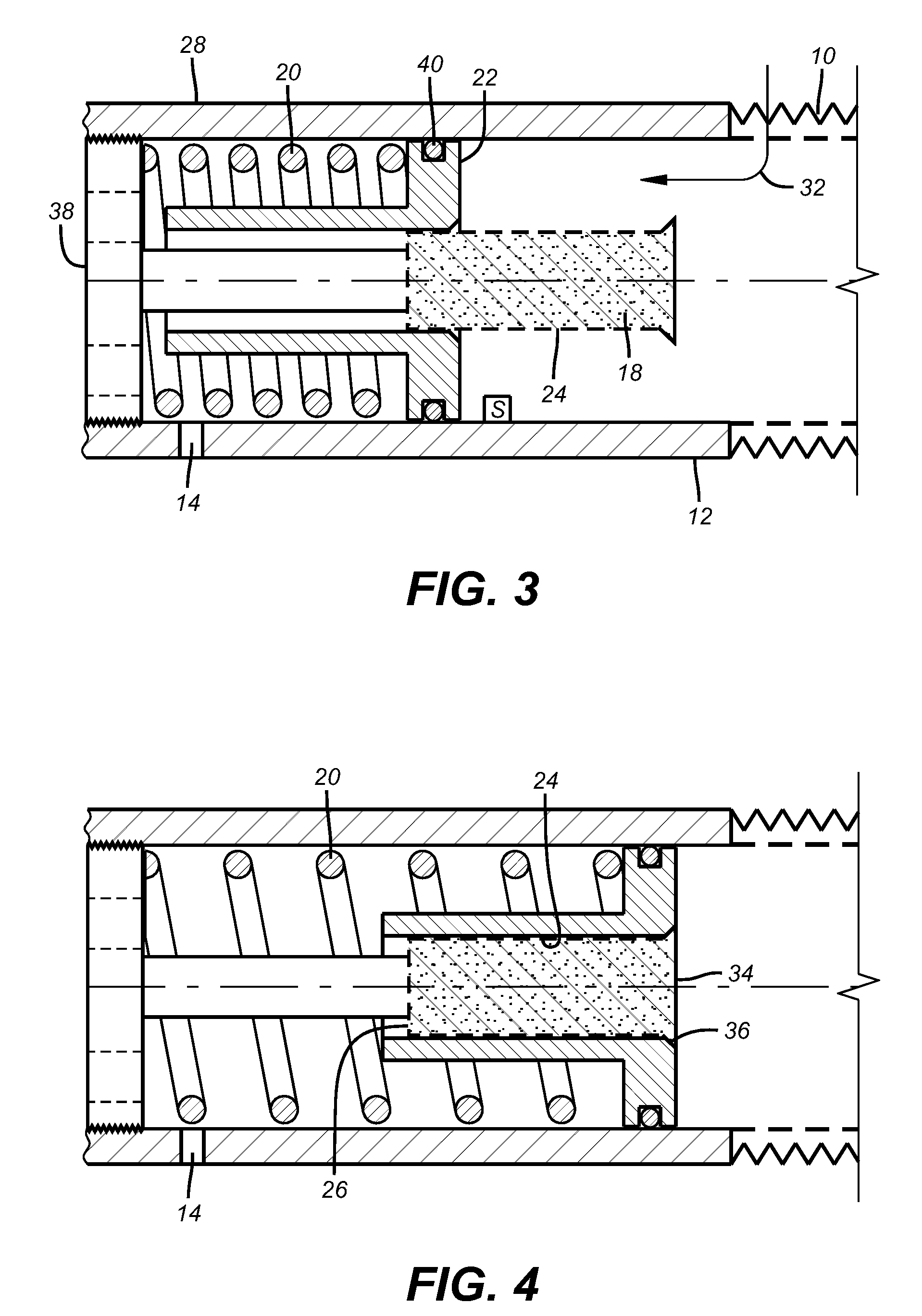

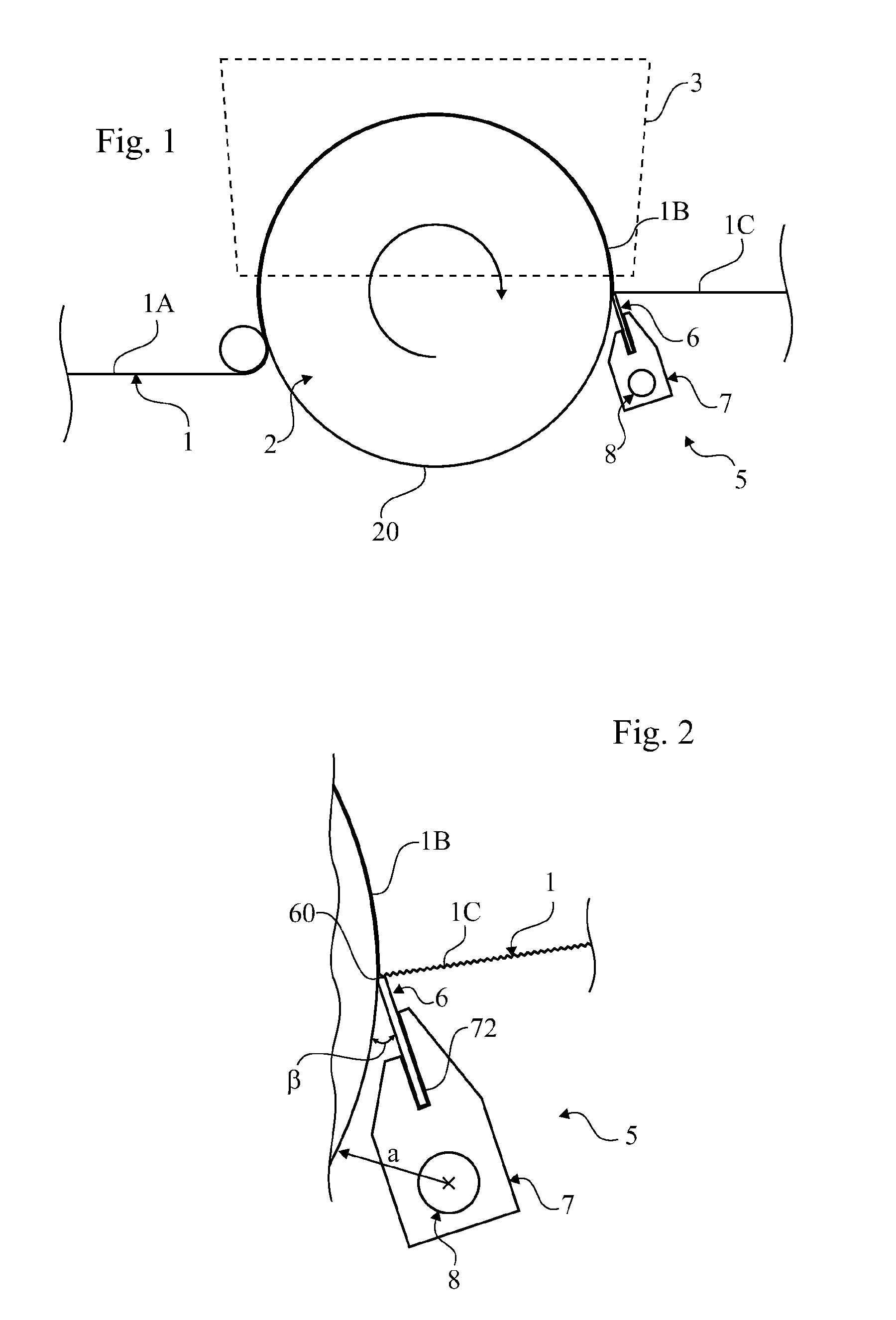

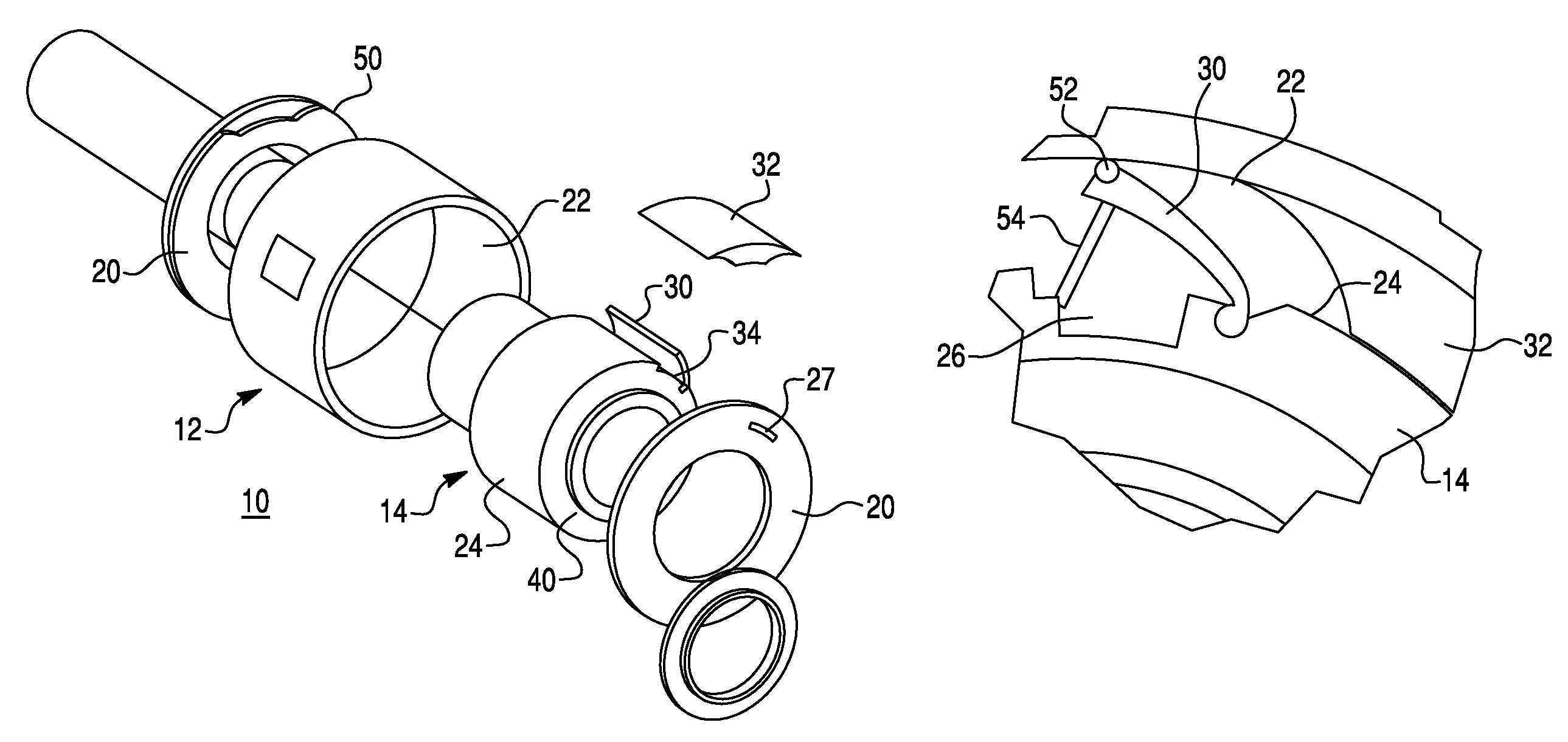

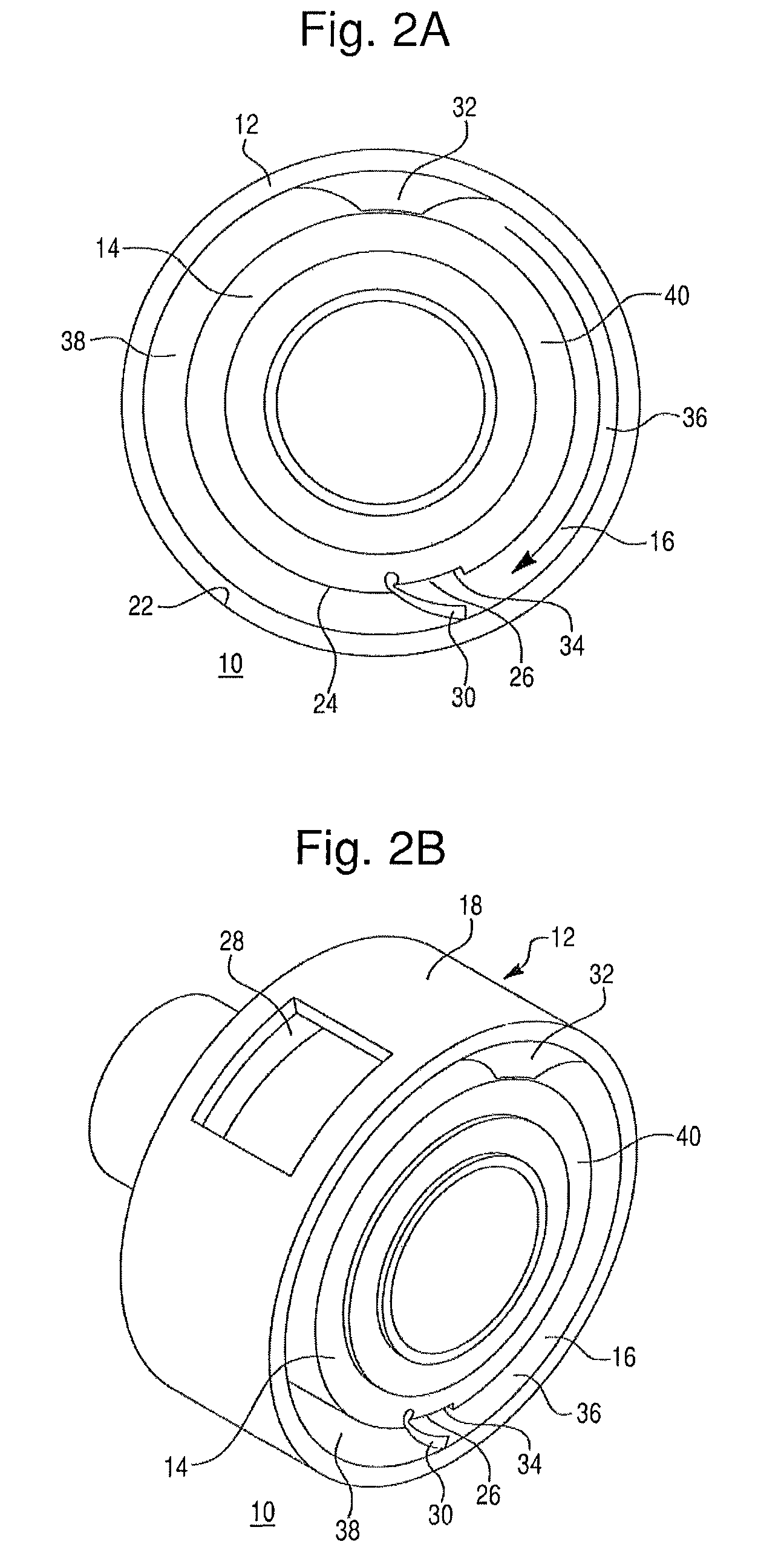

Rotary energy converter with retractable barrier

ActiveUS20100170469A1Reduced starting energyLight weight componentInternal combustion piston enginesPump componentsExternal combustion engineInternal combustion engine

A rotary internal combustion engine includes an outer housing and an inner housing and an enclosure defined therebetween. At least one of the outer and inner housings is rotatable relative to the other and at least two barriers are disposed in the enclosure and divide the enclosure into a combustion chamber and an exhaust chamber. At least one barrier is rotatable relative to at least one other barrier and at least one barrier comprises a retractable barrier mounted along a pivot axis and is pivotable between an extended position and a retracted position. An intake port, exhaust port, and ignition source are also provided. A method of combusting a fuel comprises rotating a drive member to expand a combustion chamber and substantially isolate the combustion chamber from an exhaust chamber, and introducing and combusting a combustion fluid and a fuel in the combustion chamber as the combustion chamber is expanding.

Owner:HUDSON SCOTT

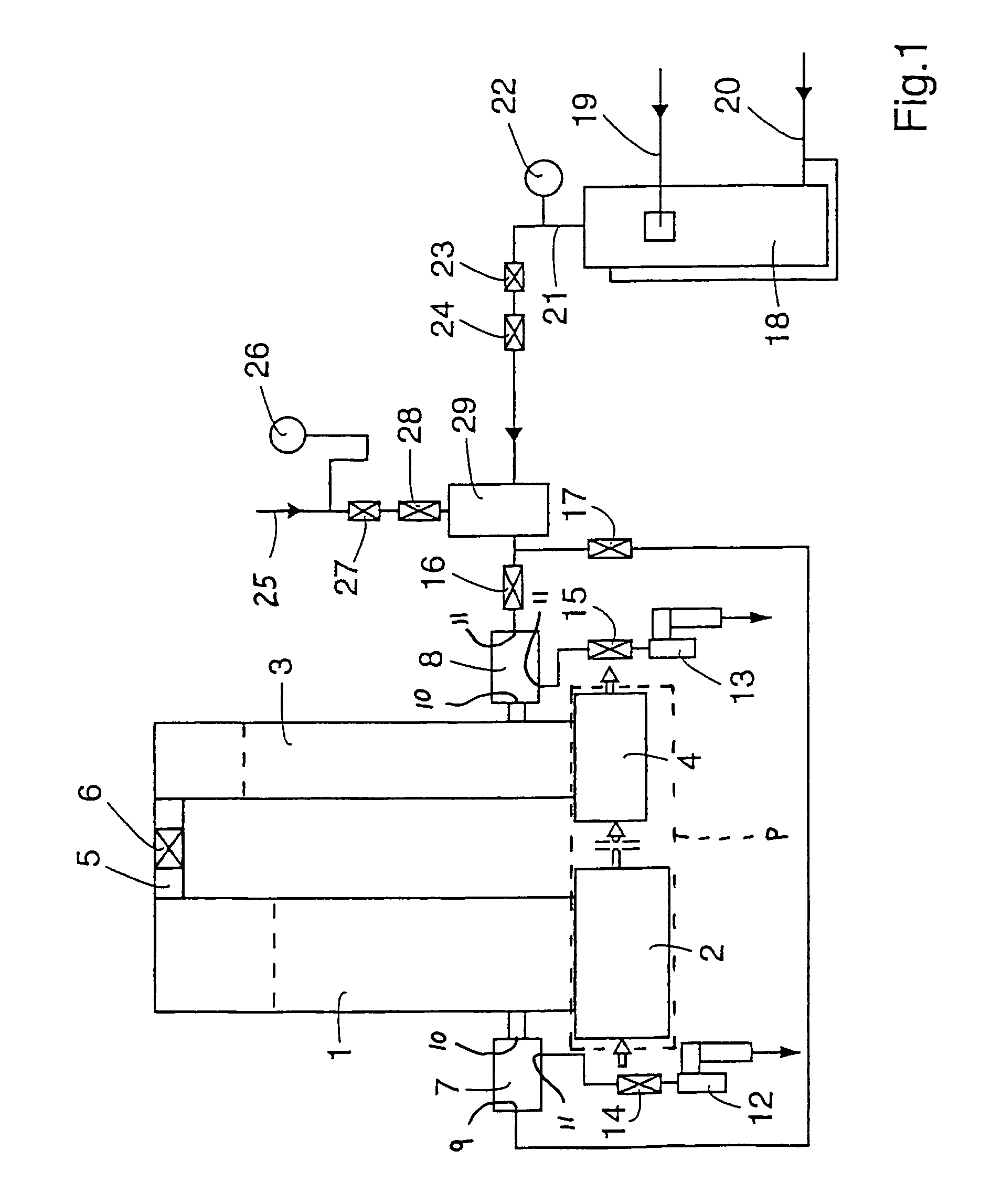

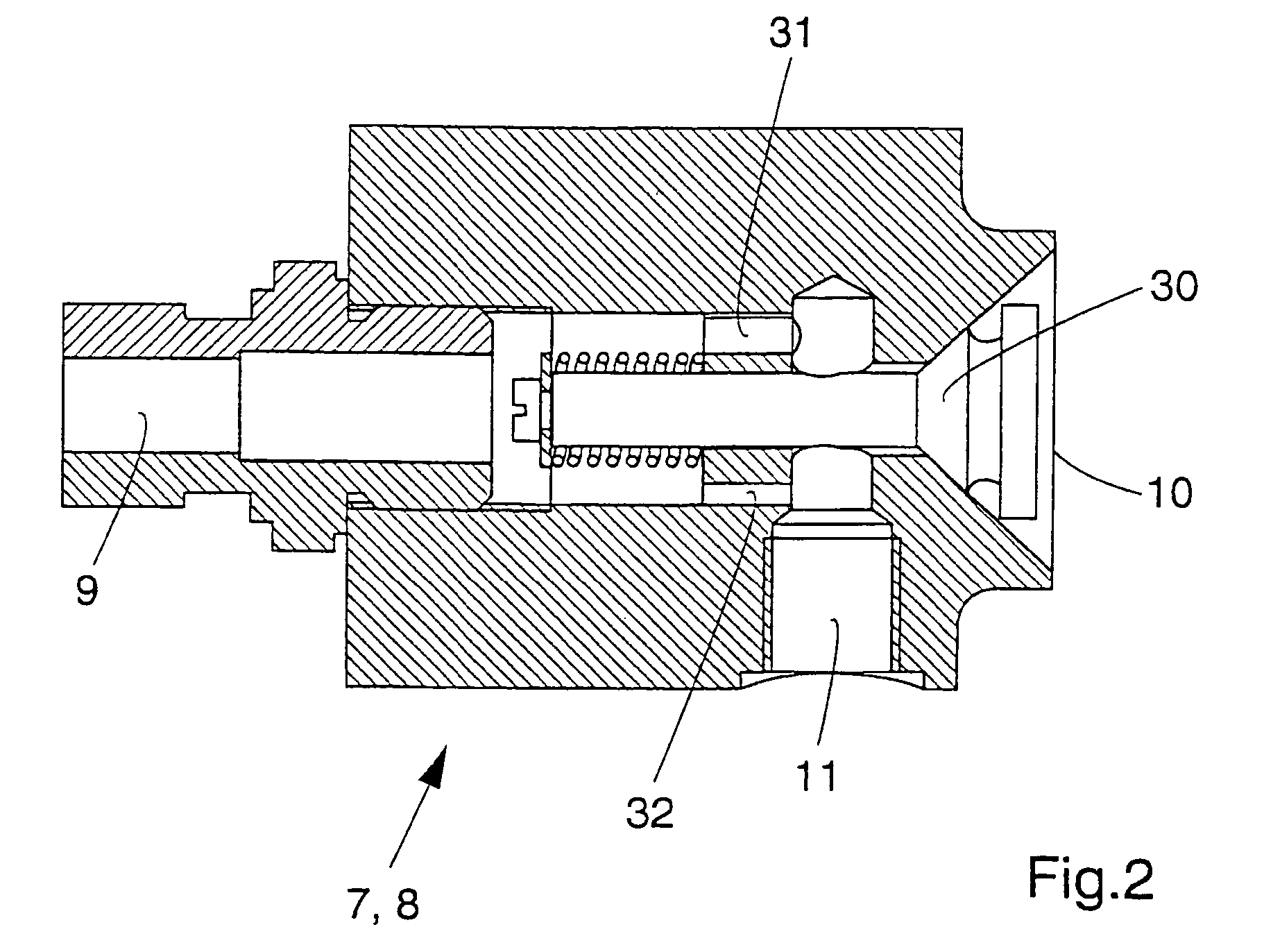

Damper device for a piston pump

InactiveUS7278837B2Less productiveReduced product lossesPositive-displacement liquid enginesPulse equalisationEngineeringGuide tube

The invention relates to a damper device for a piston pump. The device includes a partly air-filled, upright tube placed on the inlet conduit of the piston pump, and a partly air-filled, upright tube placed on the outlet conduit of the piston pump. The two upright tubes are interconnected with each other by means of a tube on which a shut-off valve is disposed. Each of the upright tubes is connected to a blower valve, respectively. Both of the blower valves are connected to a common compressed air source. The damper device may be adapted in a simple manner for aseptic operation and / or elevated product pressure.

Owner:TETRA LAVAL HLDG & FINANCE SA

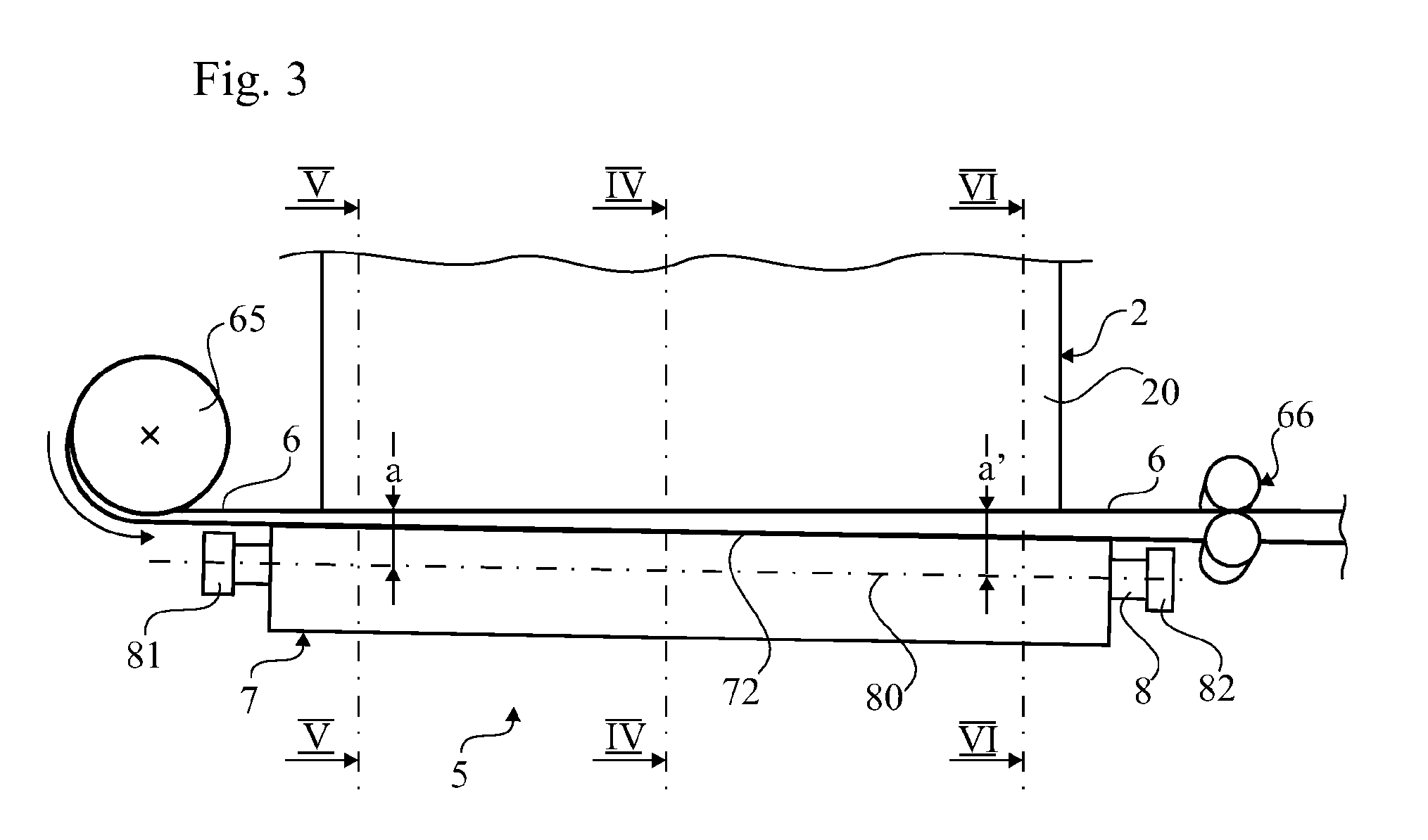

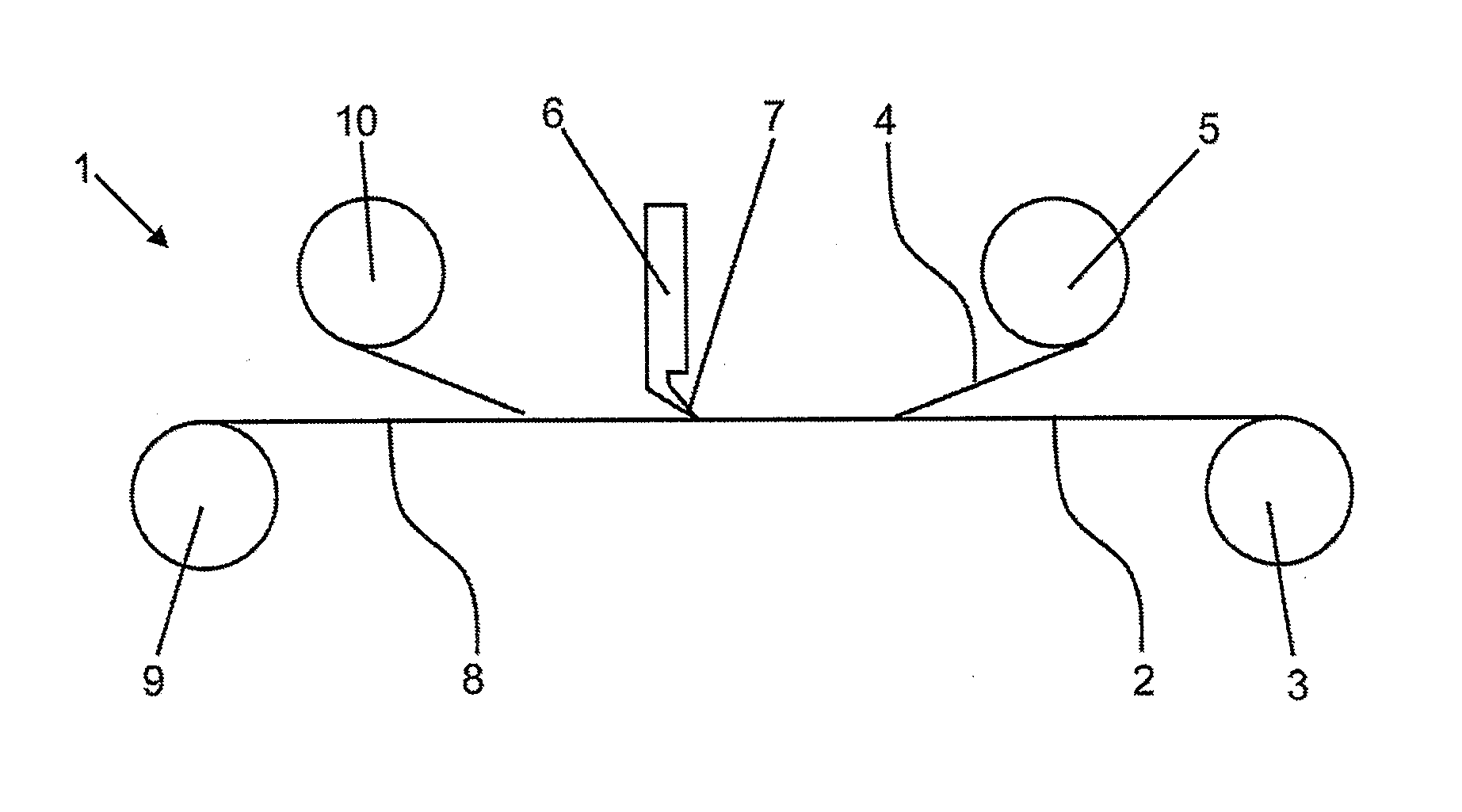

Device and method for creping of paper

ActiveUS20100032112A1Reduce production lossReduce wearNon-fibrous pulp additionNatural cellulose pulp/paperContact lineBiomedical engineering

A creping doctor device for the scraping off and creping of a running paper web from a rotating cylinder, comprising a holder device arranged to be able to support a continuous, or divided, longitudinally moveable doctor blade, which doctor blade is arranged to have a length that exceeds at least twice the length of said cylinder and is provided with a scraping surface and a contact line and / or contact surface, which contact line and / or contact surface is intended to bear against the jacket surface of said rotating cylinder at a certain linear load, said doctor blade comprising a supporting part and a wear part that is moveable in relation to the supporting part.

Owner:CS PRODN

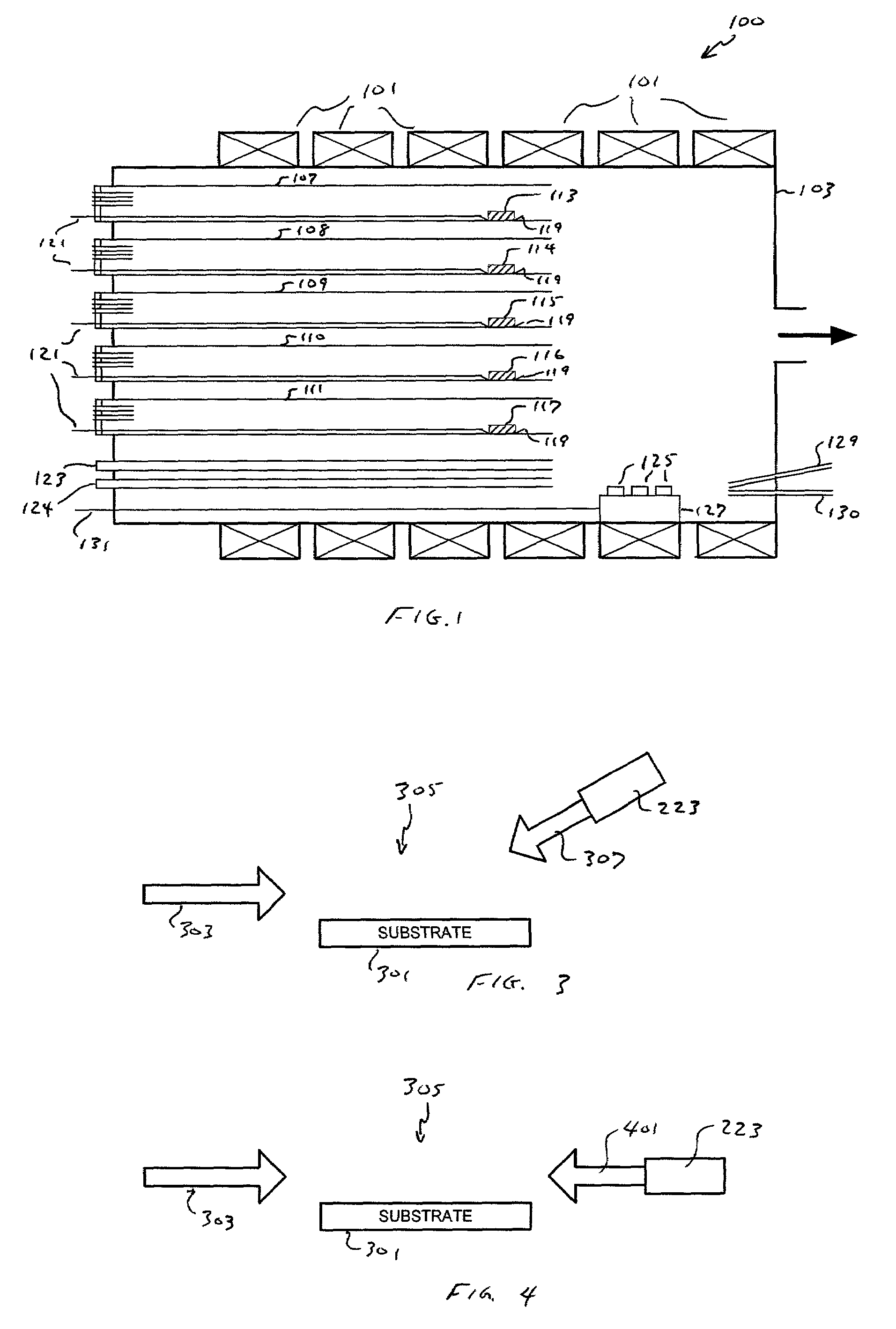

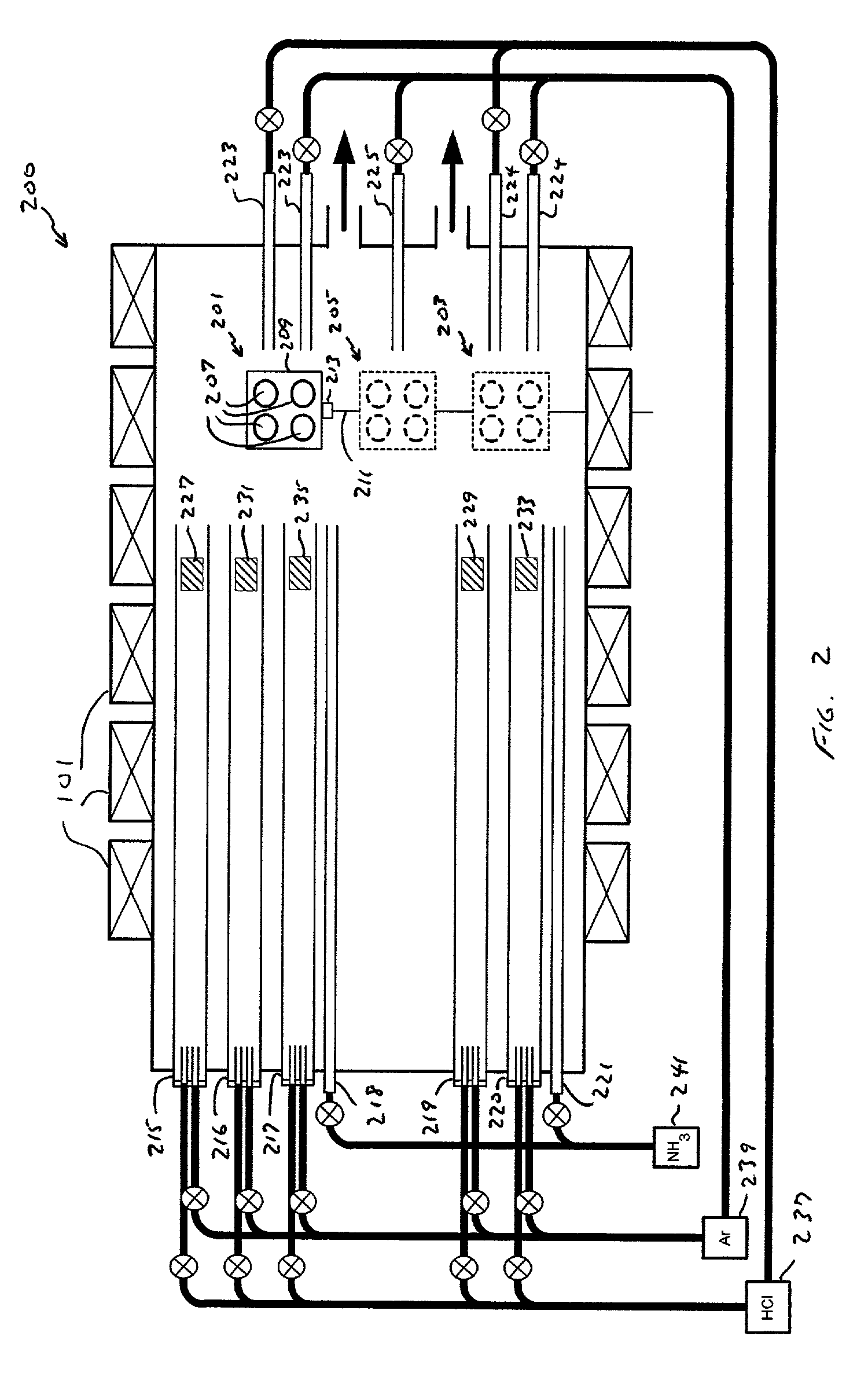

Apparatus for epitaxially growing semiconductor device structures with sharp layer interfaces utilizing HVPE

InactiveUS7670435B2Reduce conductivityPreventing thermal shockPolycrystalline material growthSemiconductor/solid-state device manufacturingLayer interfaceReactive gas

A method and apparatus for fabricating thin Group III nitride layers as well as Group III nitride layers that exhibit sharp layer-to-layer interfaces are provided. According to one aspect, an HVPE reactor includes one or more gas inlet tubes adjacent to the growth zone, thus allowing fine control of the delivery of reactive gases to the substrate surface. According to another aspect, an HVPE reactor includes both a growth zone and a growth interruption zone. According to another aspect, an HVPE reactor includes a slow growth rate gallium source, thus allowing thin layers to be grown. Using the slow growth rate gallium source in conjunction with a conventional gallium source allows a device structure to be fabricated during a single furnace run that includes both thick layers (i.e., utilizing the conventional gallium source) and thin layers (i.e., utilizing the slow growth rate gallium source).

Owner:OSTENDO TECH INC

Water-based resin compositon and articles made therefrom

An aqueous elastomer dispersion includes a dispersed phase and an aqueous phase. The dispersed phase includes an elastomer including curable aliphatic conjugated-diene elastomers, such as polyisoprene, and a minor amount of at least one additive. The aqueous phase includes water and other optional components in either a soluble state or a dispersion state. The aqueous elastomer dispersion may be prepared by dissolving an elastomer, such as rubber, and additives in a solvent mixture and then converting the resulting solution into an aqueous emulsion. The aqueous emulsion is concentrated and the solvent is stripped from it to yield a dilute latex. The dilute latex that is obtained is concentrated again. Articles made from the aqueous elastomer dispersion include medical gloves, condoms, probe covers, dental dams, finger cots, catheters and the like.

Owner:ALLEGIANCE CORP

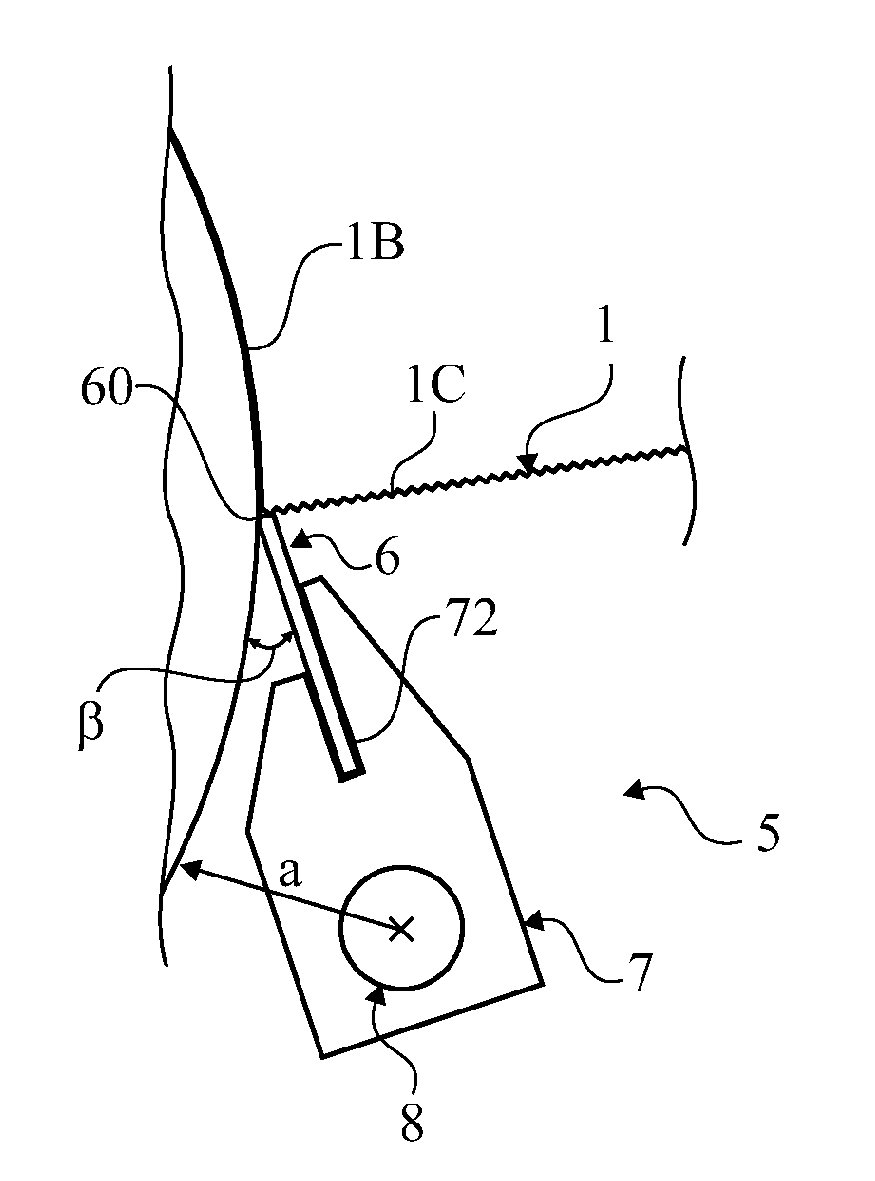

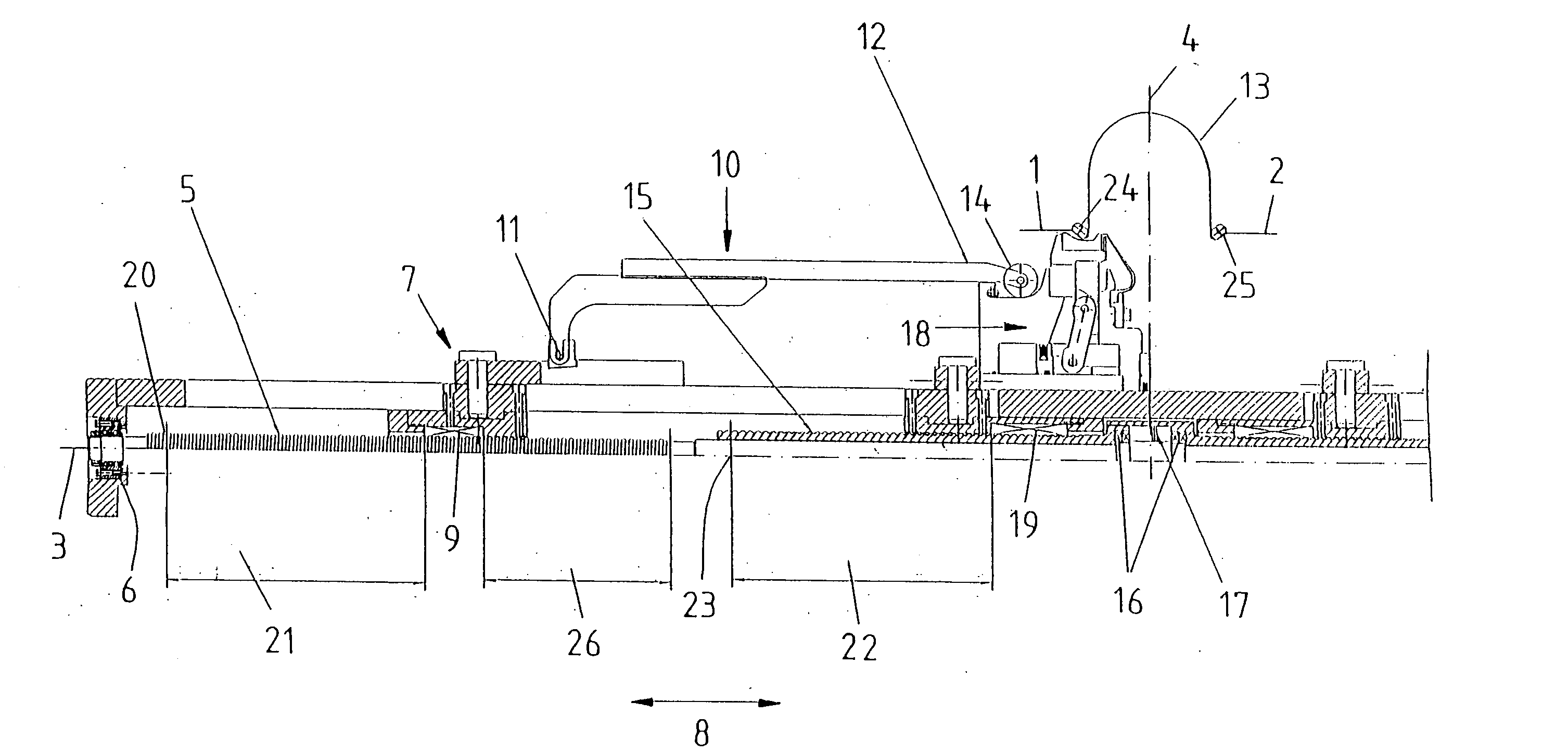

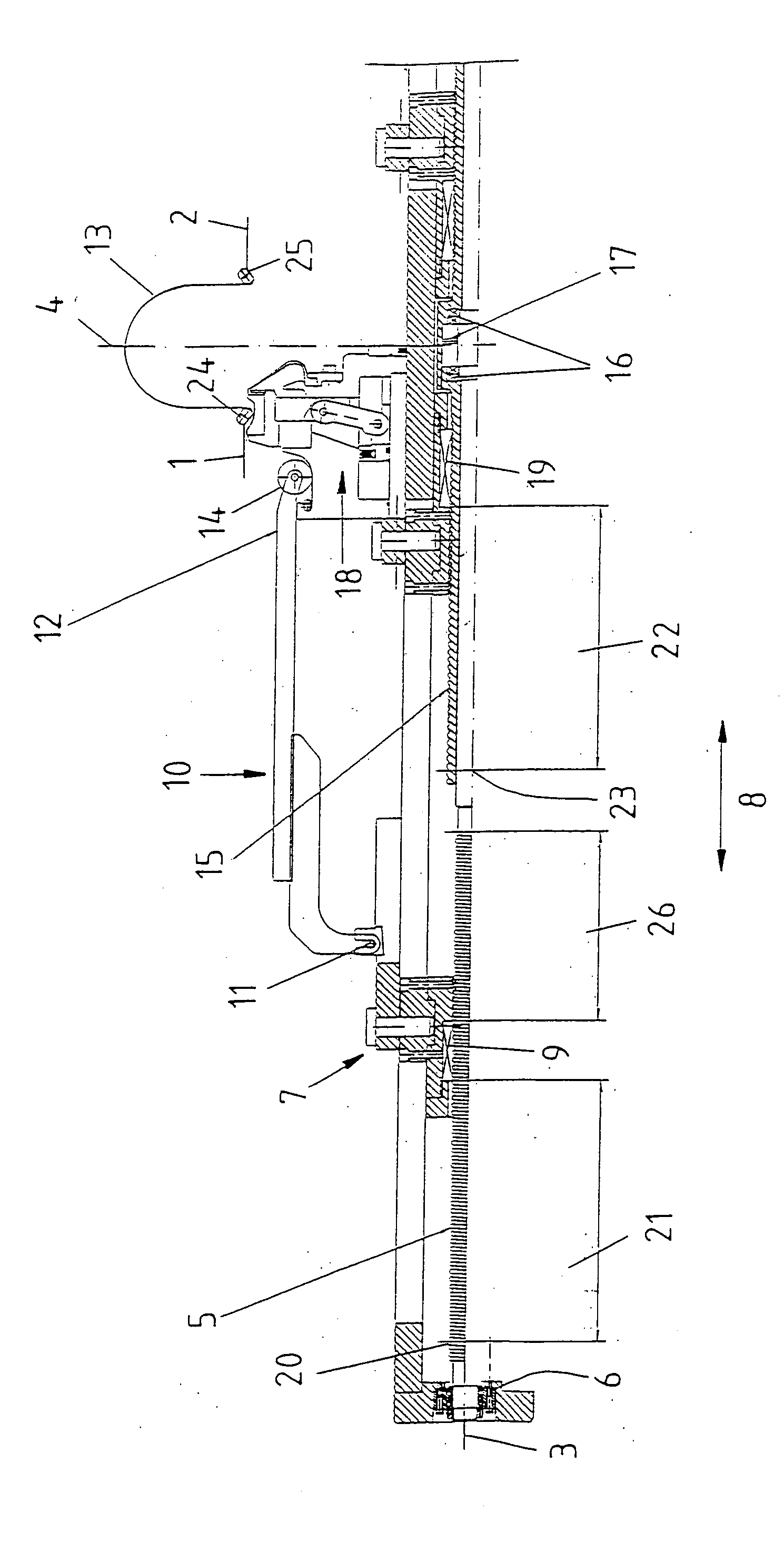

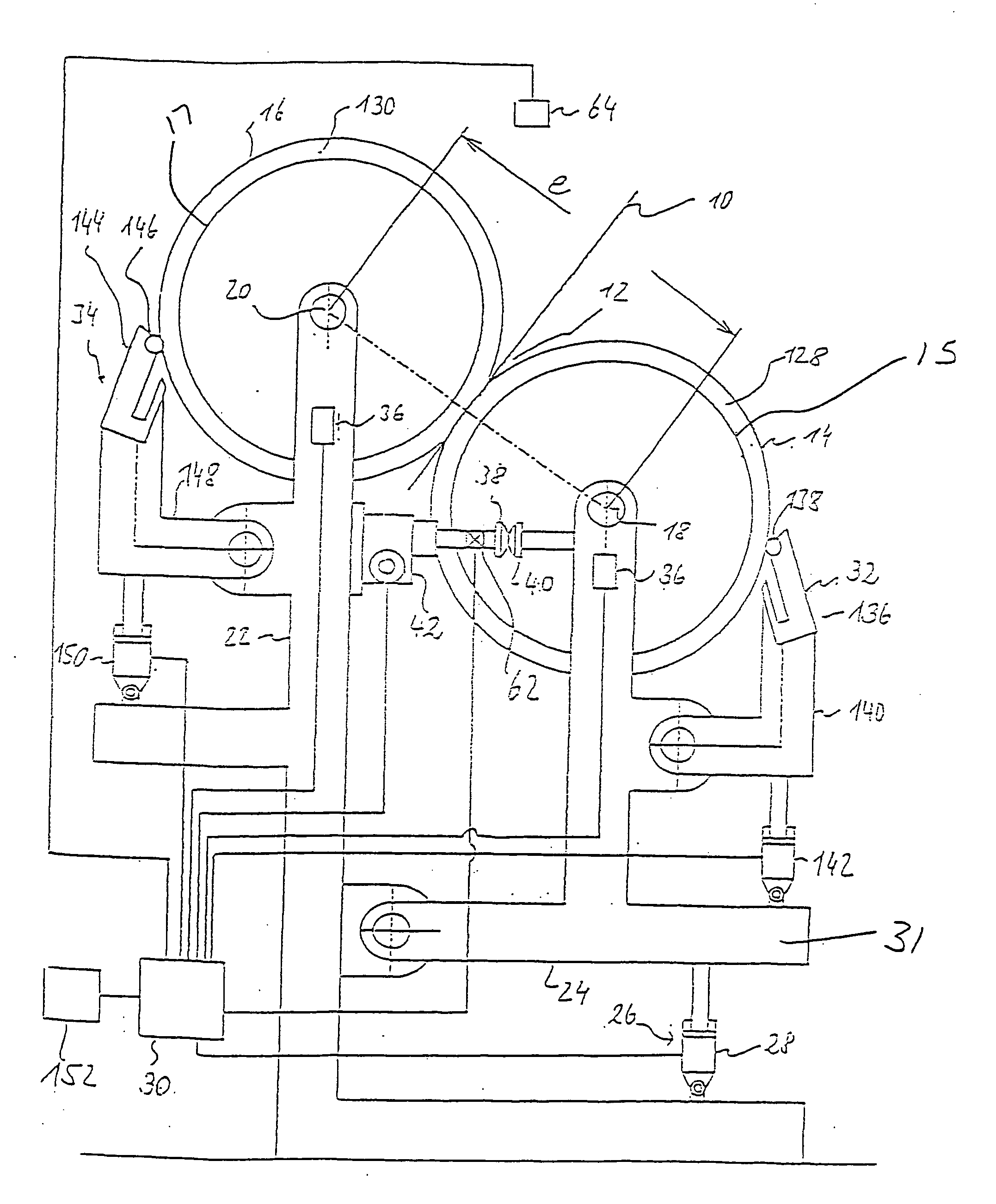

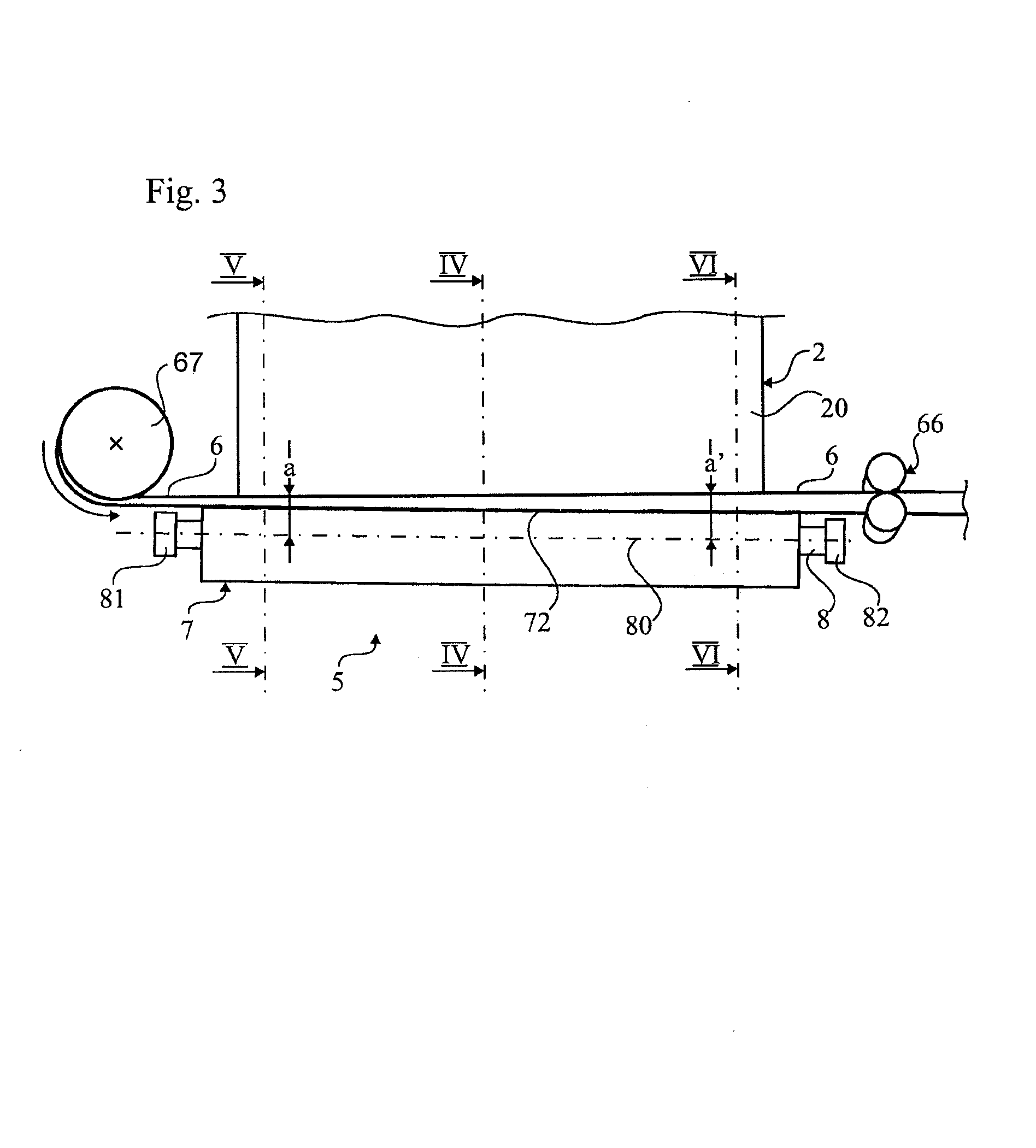

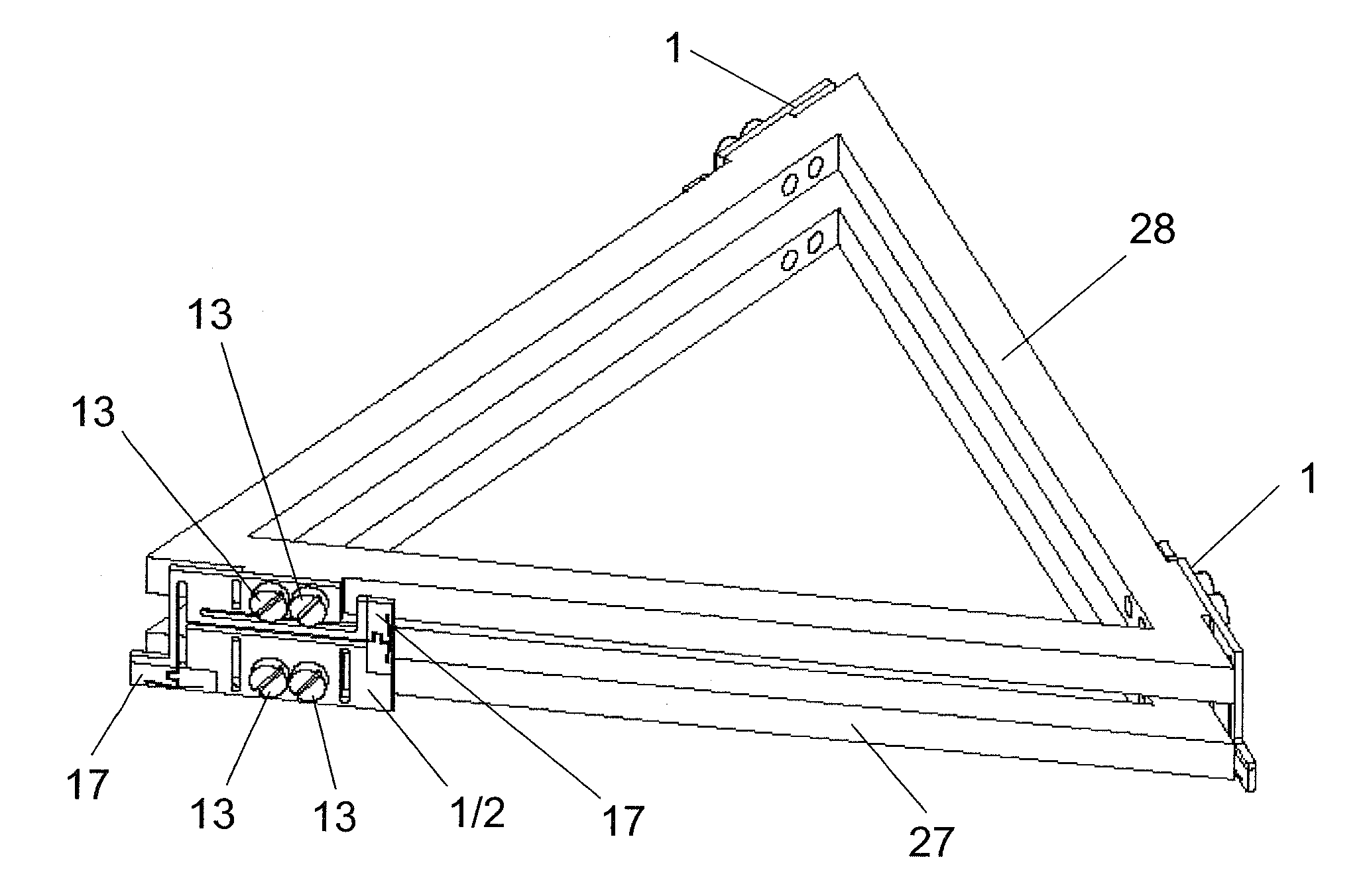

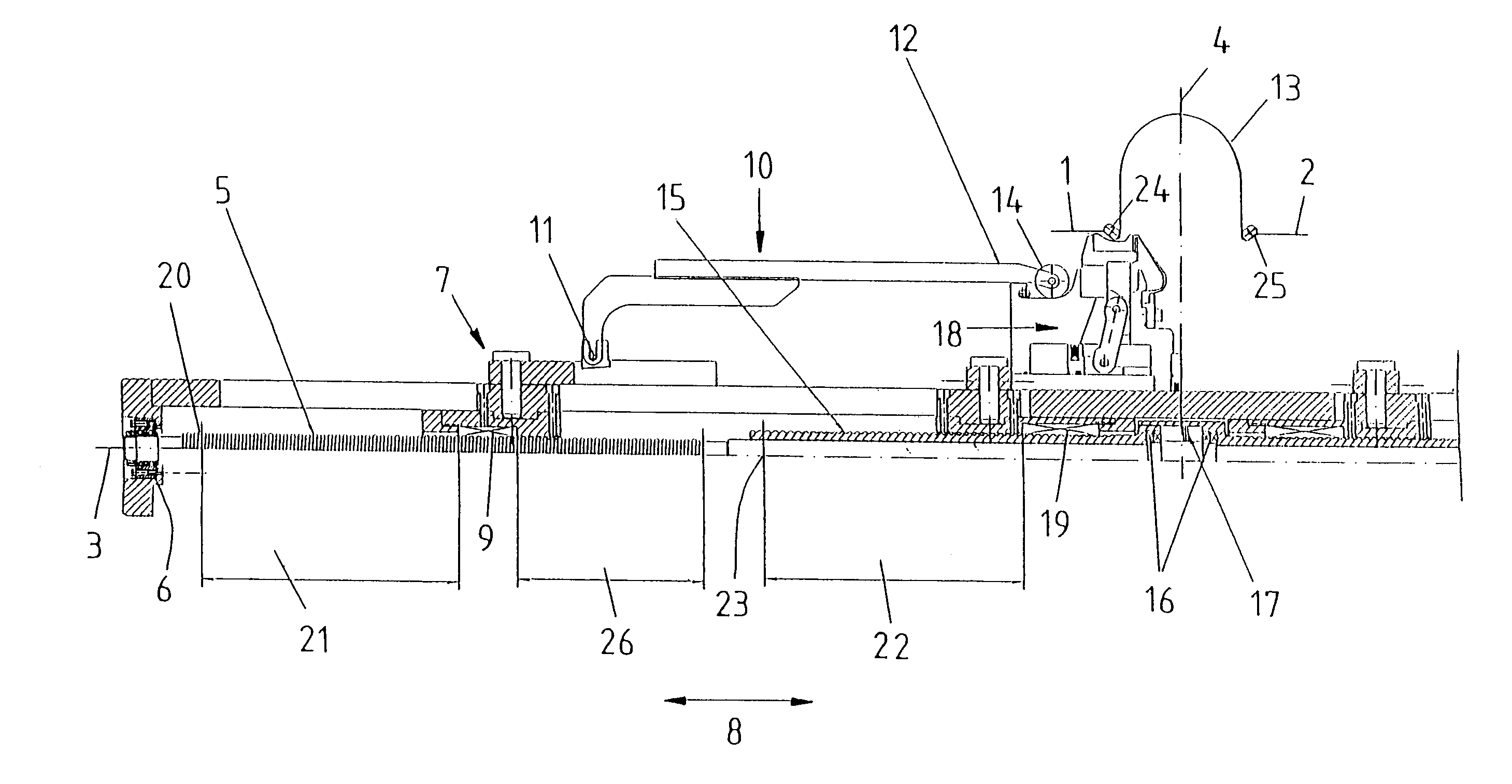

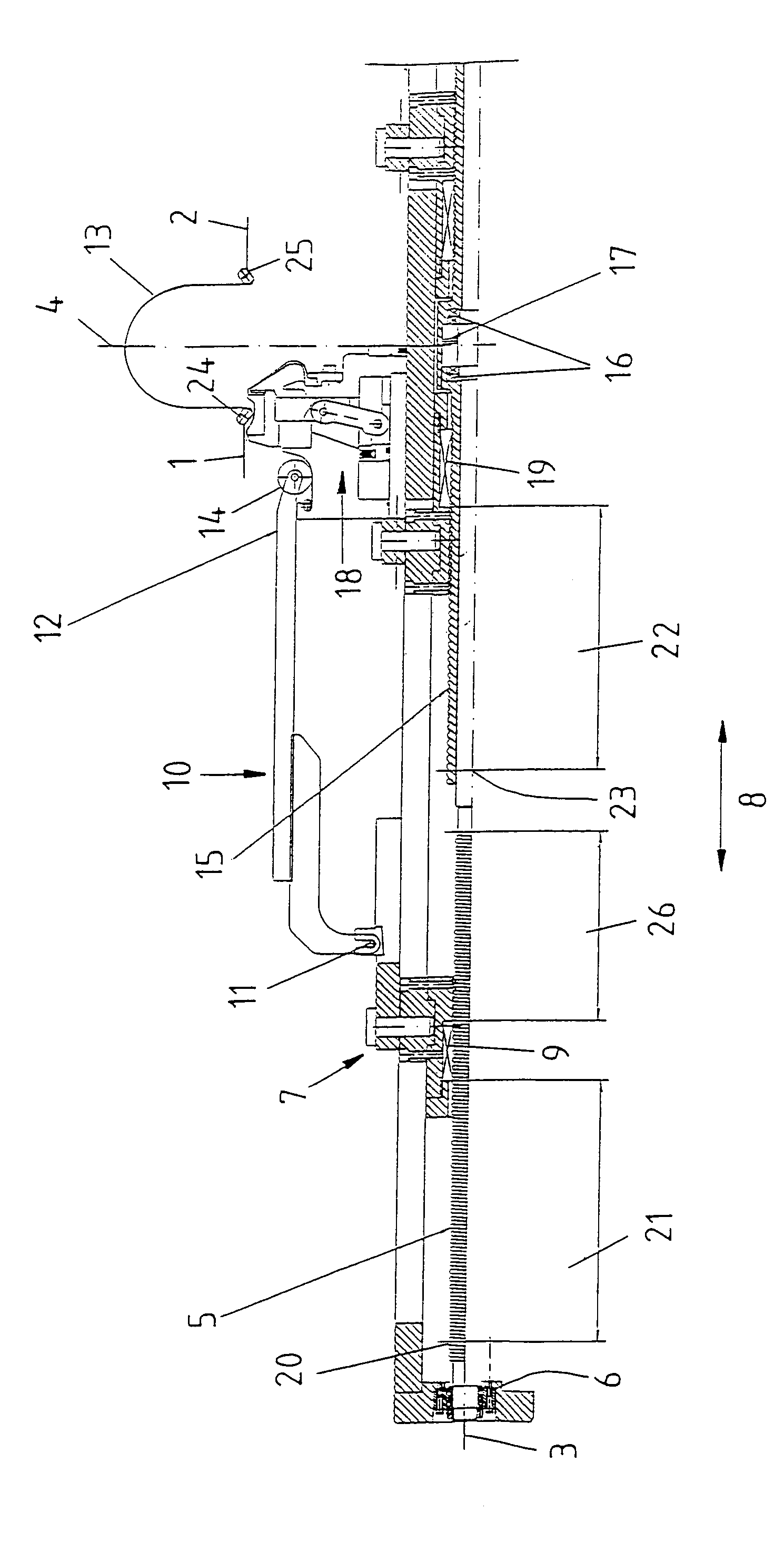

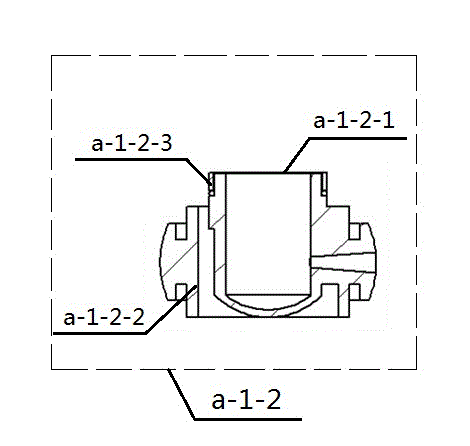

Device for turning up the tire sidewalls on a tire building drum

InactiveUS20040250941A1Improve connection qualityLess productiveTyresEngineeringMechanical engineering

Device for turning up sidewalls of a tire, wherein the device includes a first lever supporting body arranged on a first side of a drum center and being movable in an axial direction. A first lever system pivotally connected to the first lever supporting body. A second lever supporting body arranged on a second side of the drum center and being movable in an axial direction. A second lever system pivotally connected to the second lever supporting body. The first and second sides are arranged on opposite sides of the drum center. A base spindle is adapted to move the first and second lever supporting bodies in an axial synchronous manner relative to each another. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Valve responsive to fluid properties

InactiveUS7980265B2High viscosityEasy to moveCheck valvesFluid removalFluid viscosityWater production

A valve for downhole use has the ability to throttle between fully open and closed and is fully variable in positions in between. The valve is preferably responsive to flowing fluid viscosity and uses a three dimensional flow through restrictor in combination with a relatively movable cover. At a given flow, a higher viscosity fluid will create a greater relative movement and make it possible for flowing fluid to bypass more of the flow through member. In a particular application involving production from a zone, an array of such valves can allow more production where the viscosity is higher and less production where the viscosity drops due to, for example, water production.

Owner:BAKER HUGHES INC

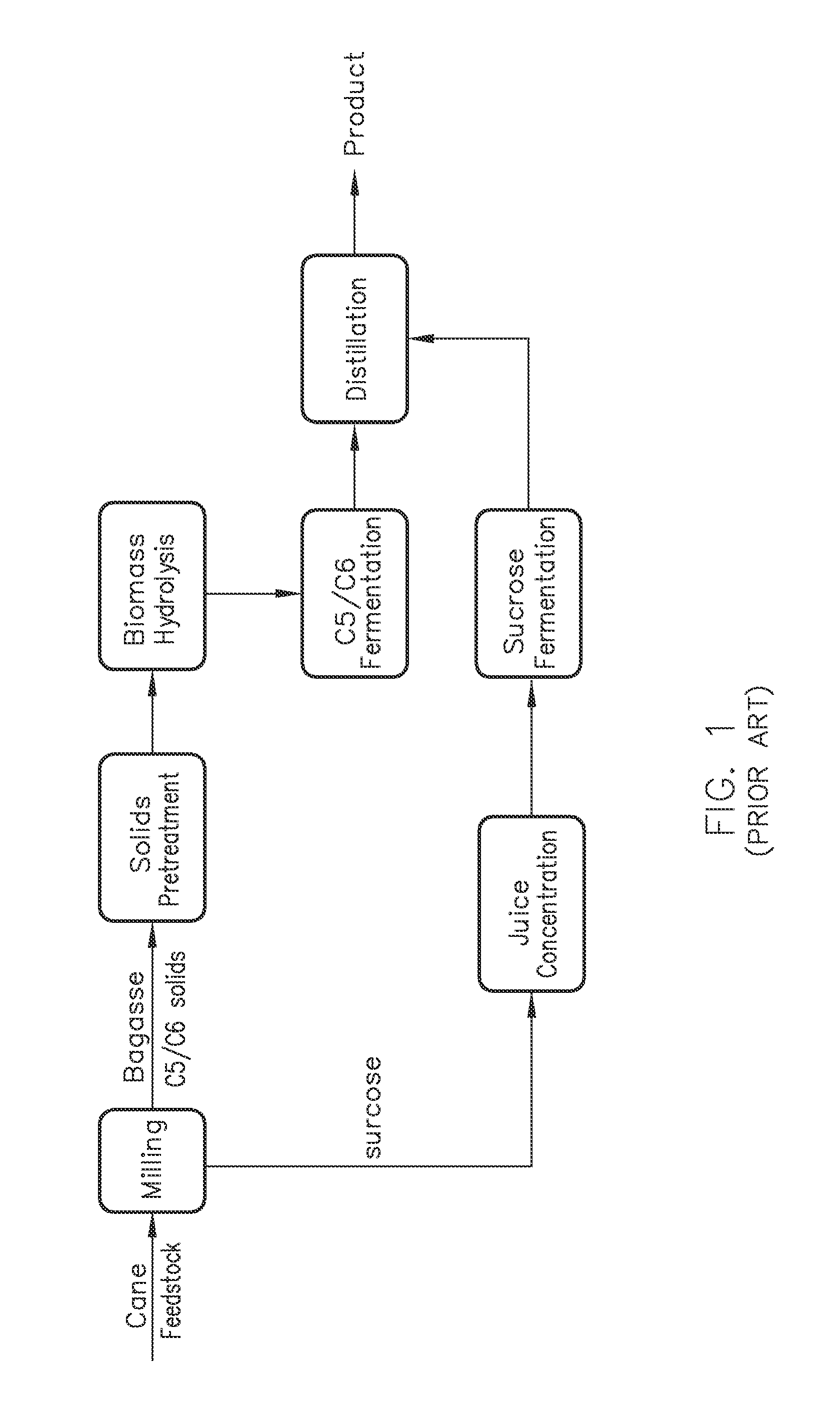

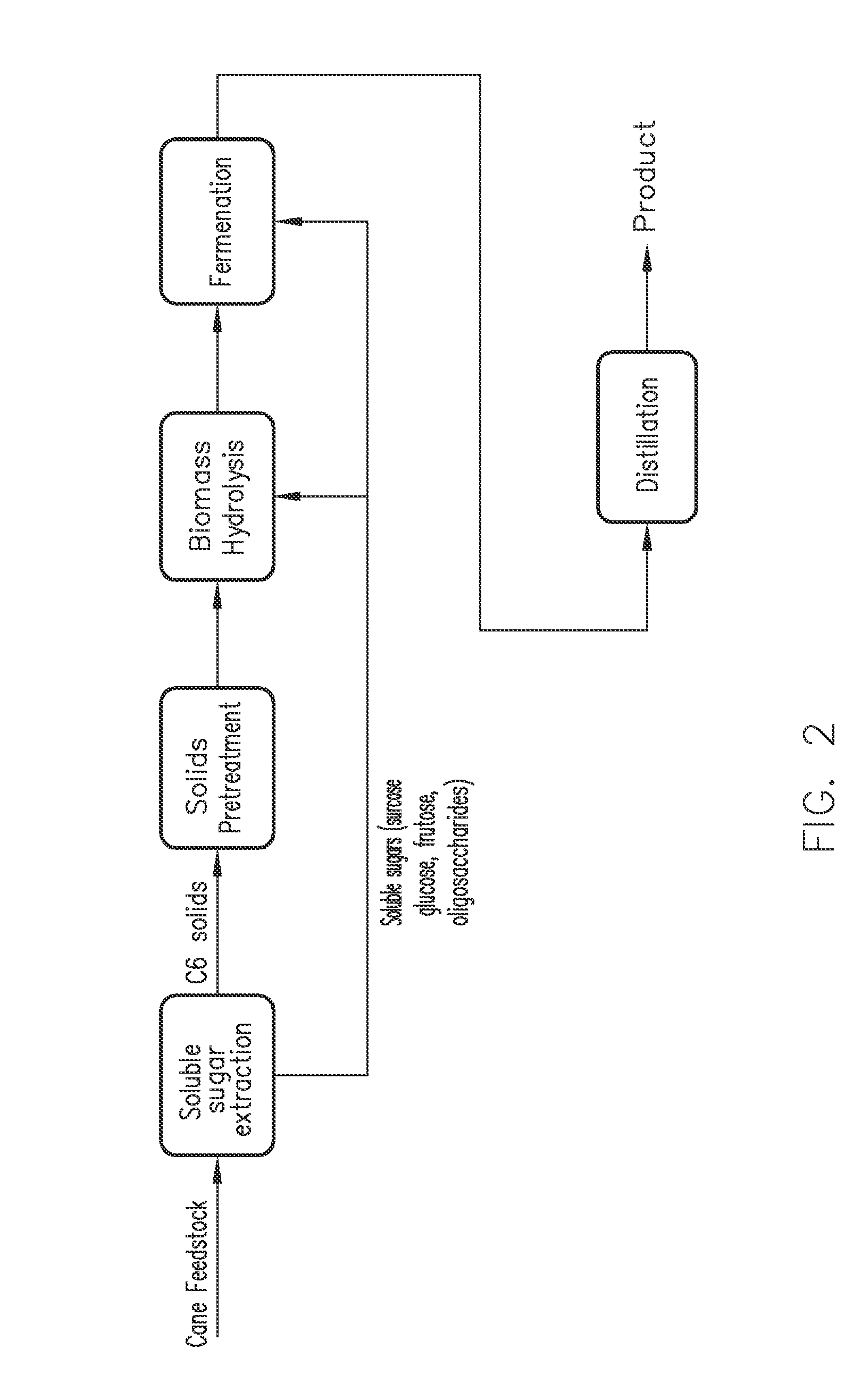

Liquid co-extraction process for production of sucrose, xylo-oligosaccharides and xylose from feedstock

InactiveUS20150307952A1Improved technicallyImproved economically viable conversion processSugar productsOrganic compound preparationSucroseSaccharophagus degradans

Owner:PRENEXUS HEALTH INC

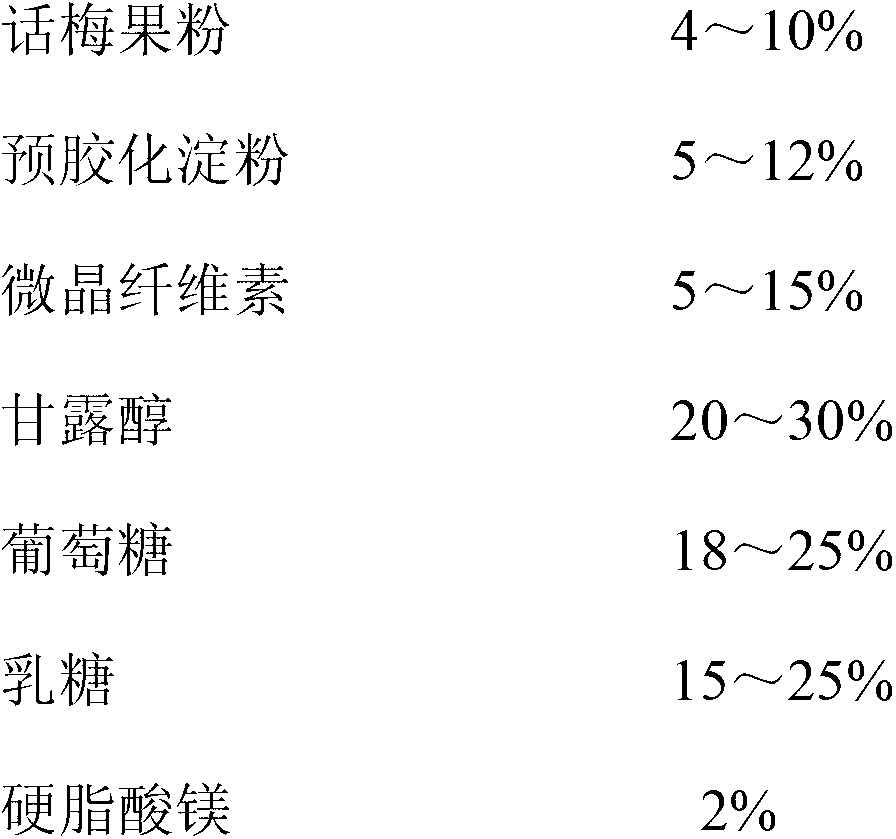

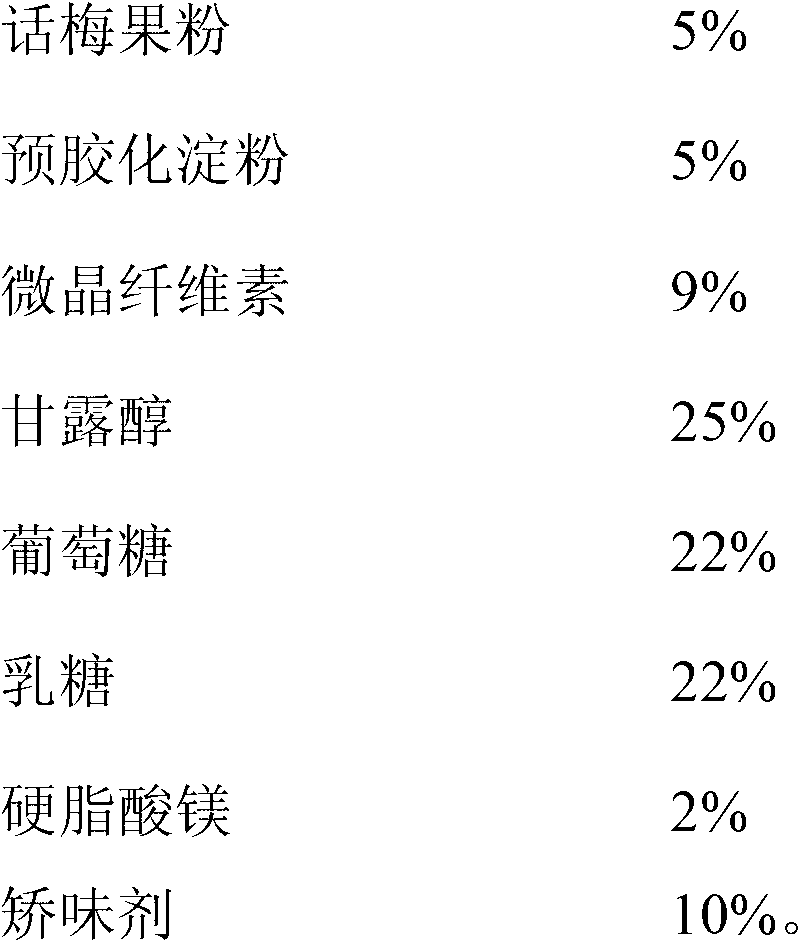

Preserved plum powder tabletting candy produced by directly tabletting complete powder, and preparation method

InactiveCN103053777AImprove powder propertiesConsidering the quality of flavorConfectionerySweetmeatsAdditive ingredientCompressibility

The invention discloses a preserved plum powder tabletting candy produced by directly tabletting complete powder, and a preparation method. The preserved plum powder tabletting candy is prepared from the following ingredients by weight: 4-10% of preserved plum powder, 5-12% of retrogradation starch, 5-15% of microcrystalline cellulose, 20-30% of mannitol, 18-25% of glucose, 15-25% of lactose, 2% of magnesium stearate and 10% of corrigent. The finished preserved plum is harmony in taste, tender in sour and sweet and sufficient in cooling feeling. Through addition of various additives and regulation in ratios, the characteristics of the powder are improved after the additives are uniformly mixed with the preserved plum powder, and the overall flowability, the compressibility and the shaping capability of the powder meet the requirements on direct powder tabletting; and the preserved plum powder tabletting candy mainly has the characteristics that a complete powder direct tabletting process is adopted, and simplicity, rapidness and convenience are obtained.

Owner:SOUTH CHINA AGRI UNIV

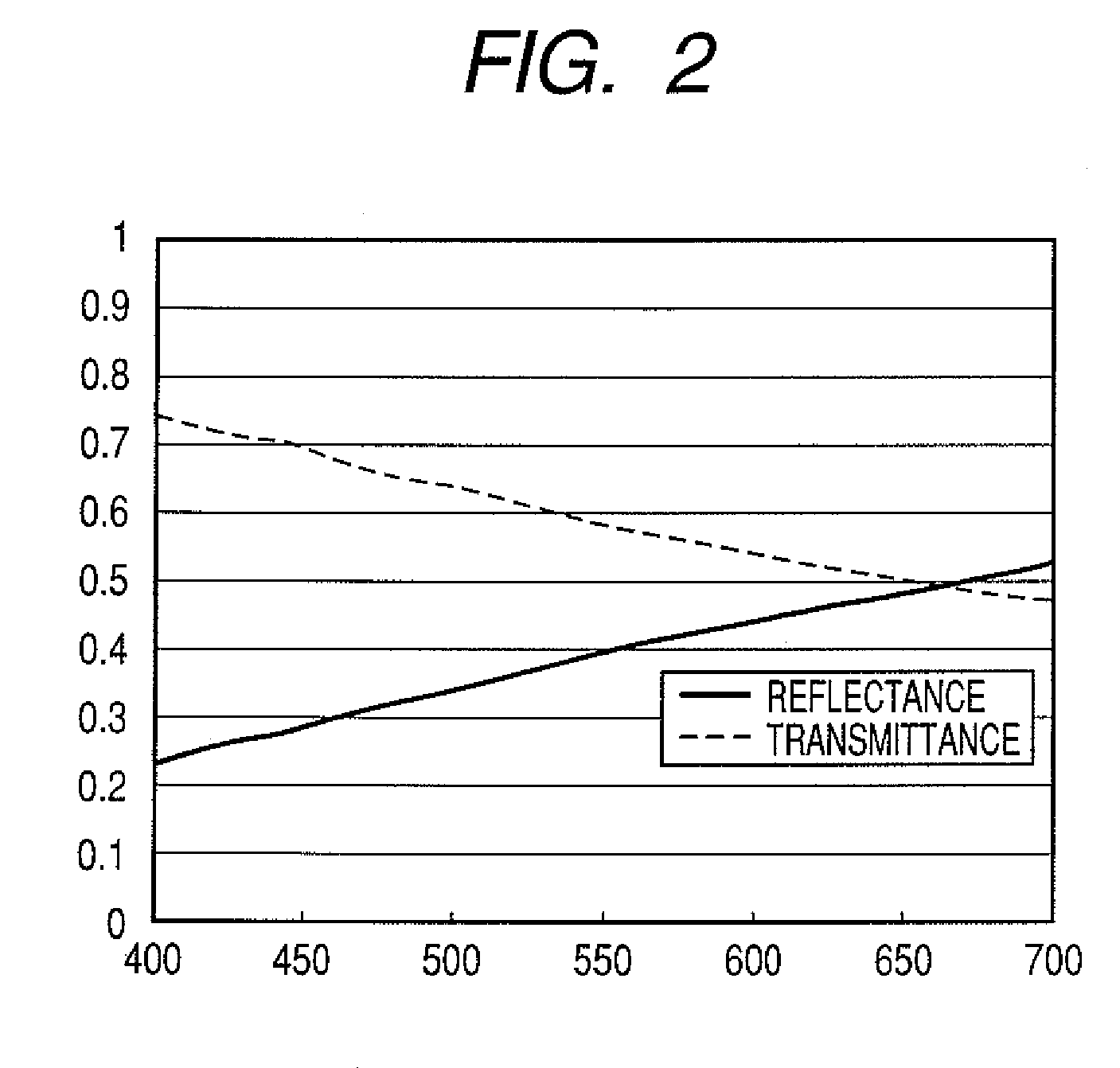

OLED with semi-transparent layer

ActiveUS7843123B2Improve luminous efficiencyDifference in chromaticityDischarge tube luminescnet screensElectroluminescent light sourcesSimple Organic CompoundsOrganic light emitting device

The organic light-emitting device of the present invention includes a plurality of organic light-emitting elements including an organic light-emitting element showing a first emission color and at least one organic light-emitting element showing a different emission color from the first emission color, each of the organic light-emitting elements including: a first electrode having a reflective surface; a second electrode placed on a light extraction side and including a semi-transparent layer; an organic compound layer including a light-emitting layer and formed between the first electrode and the second electrode; and a micro cavity structure for resonating light emitted from the light-emitting layer between the reflective surface and the semi-transparent layer, wherein the semi-transparent layer in the organic light-emitting element showing the first emission color is different in thickness and / or material from the semi-transparent layer in the at least one organic light-emitting element showing the different emission colors.

Owner:CANON KK

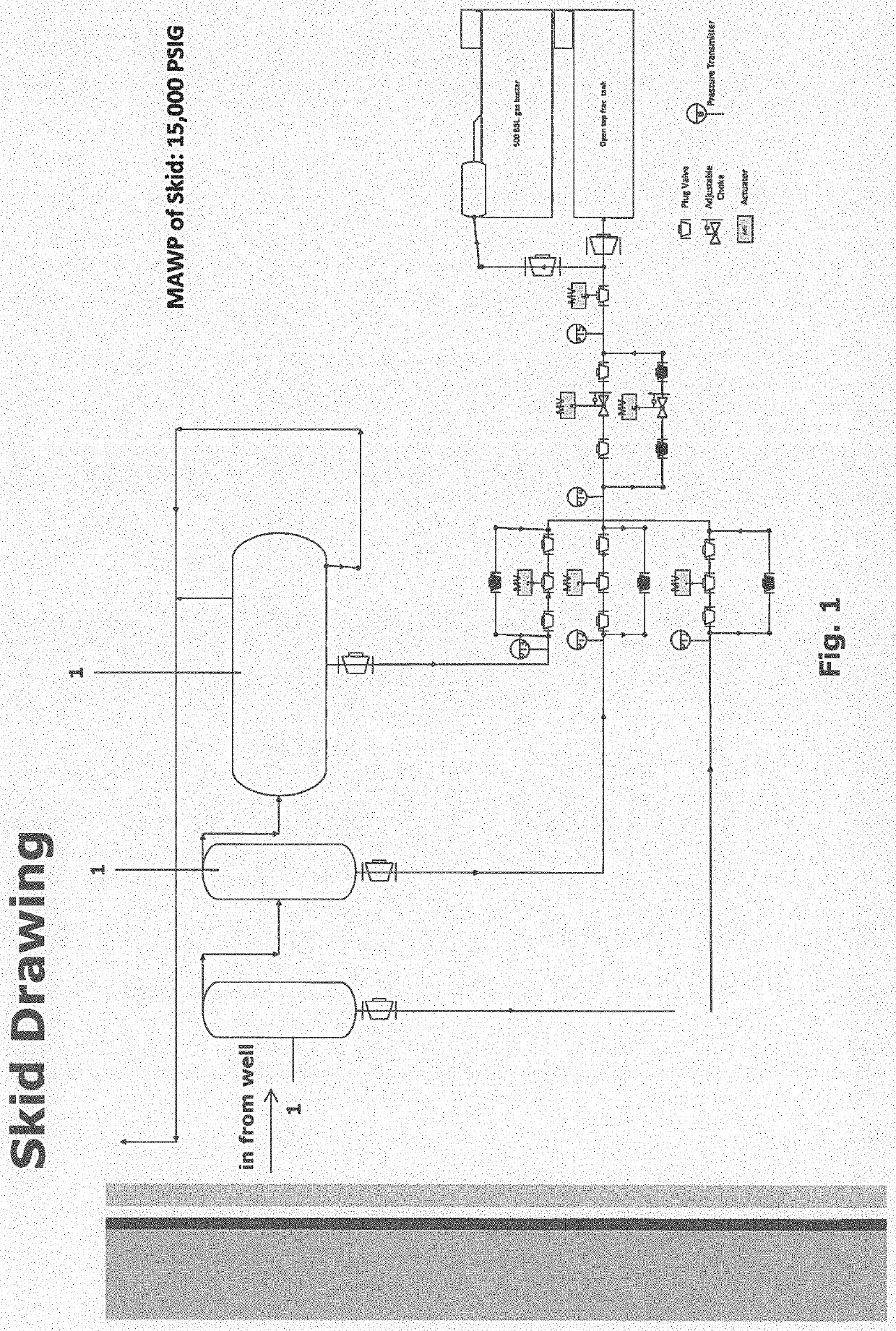

Systems and processes for automated sand separation

ActiveUS20210077923A1Labor intensive inaccurate to amountMinimize expense and laborSedimentation regulating devicesFluid removalProcess engineeringCorrosion

A sand handling system having, for example, one to three sand separators are configured to be operatively connected to a well and an inlet of a common dumping vessel. Advantageously, the dumping vessel has a sensor to measure an amount of sand in the dumping vessel and provide a signal to a programmable controller which is arranged to dump the dumping vessel when a specified amount of sand is in the dumping vessel. The system automates the sand handling process and also measures and records data associated with a number of flowback parameters. The data can then be used in well design to improve oil and / or gas production, lessen sand production, reduce well damage and / or equipment corrosion due to, for example, sand.

Owner:CHEVROU USA INC

Negative insert for cutting machining

ActiveUS20080253848A1Reduce roughnessImprove property of insertMilling cuttersCutting insertsEngineeringMachining

A negative insert for cutting machining has a top side, a clearance side perpendicular thereto and a cutting edge in a region interconnecting these sides and extending substantially in parallel with these sides. The insert has further a flat or rounded chamfer connecting the cutting edge to the clearance side on at least one lateral side of the insert in the region of a corner thereof. The chamfer makes an angle of 1°-15° with the clearance side for enabling application of the chamfer substantially tangentially to a work piece to be machined for bearing of the insert in two dimensions against the work piece during cutting machining operation carried out by the insert.

Owner:SECO TOOLS AB

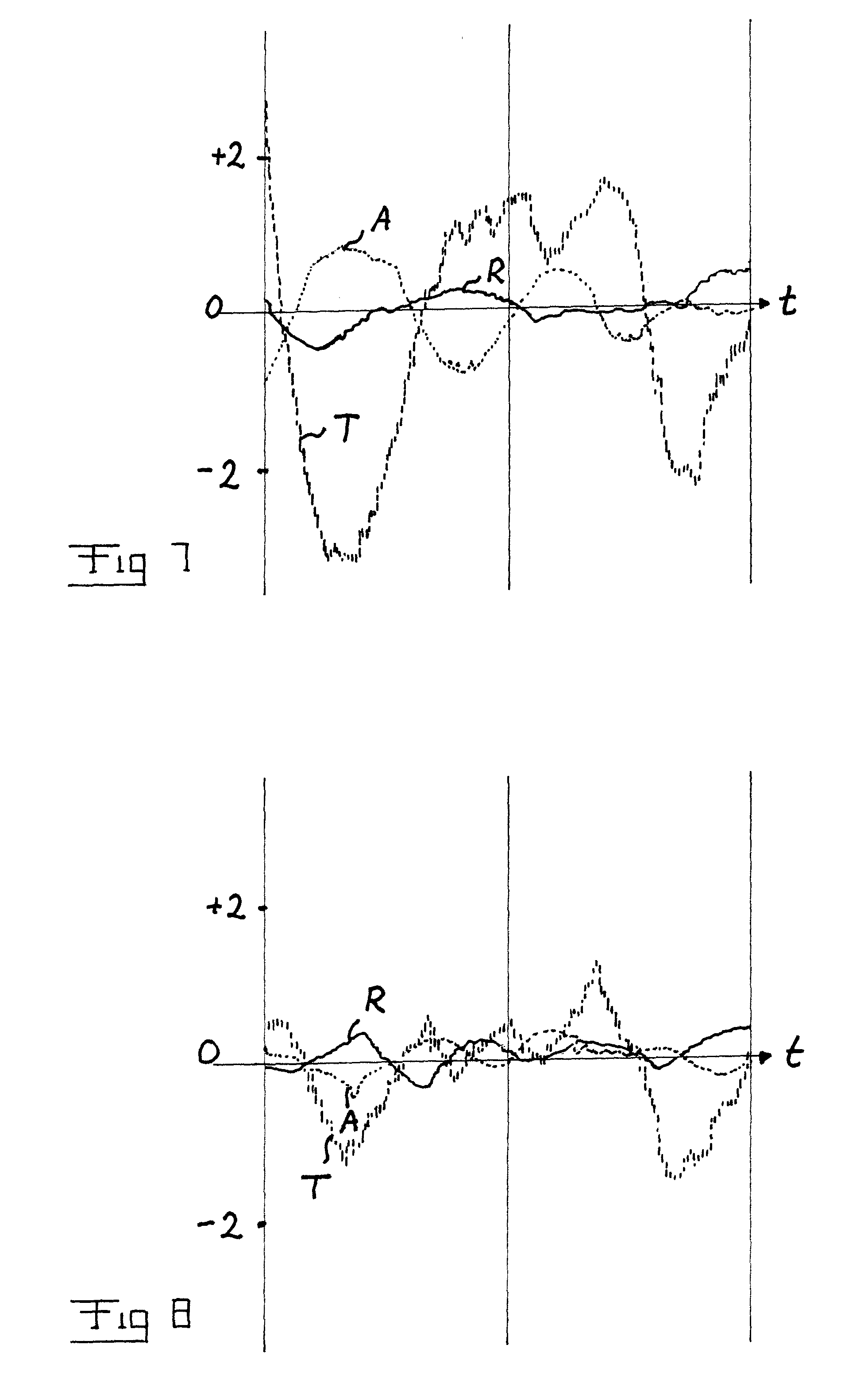

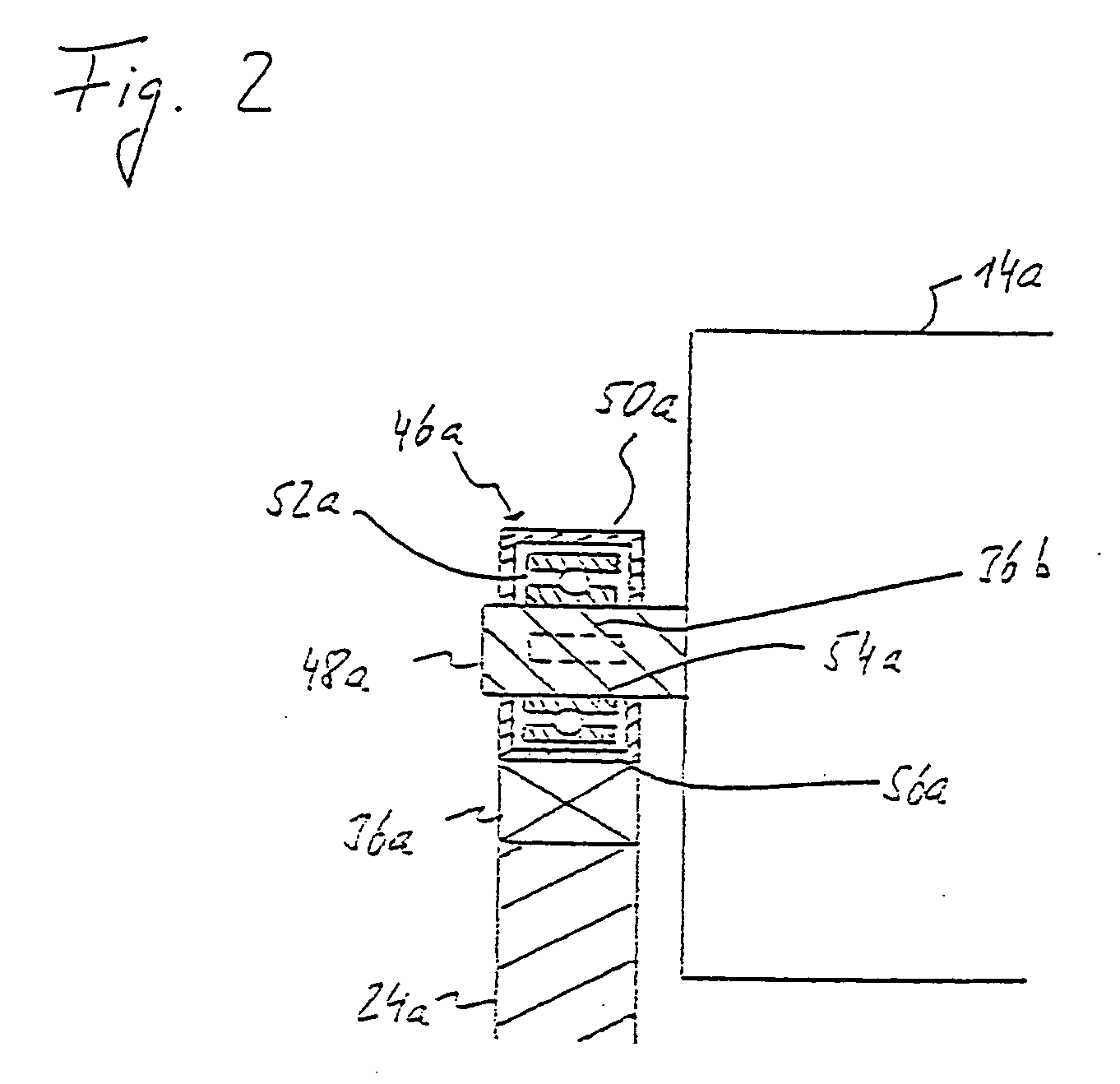

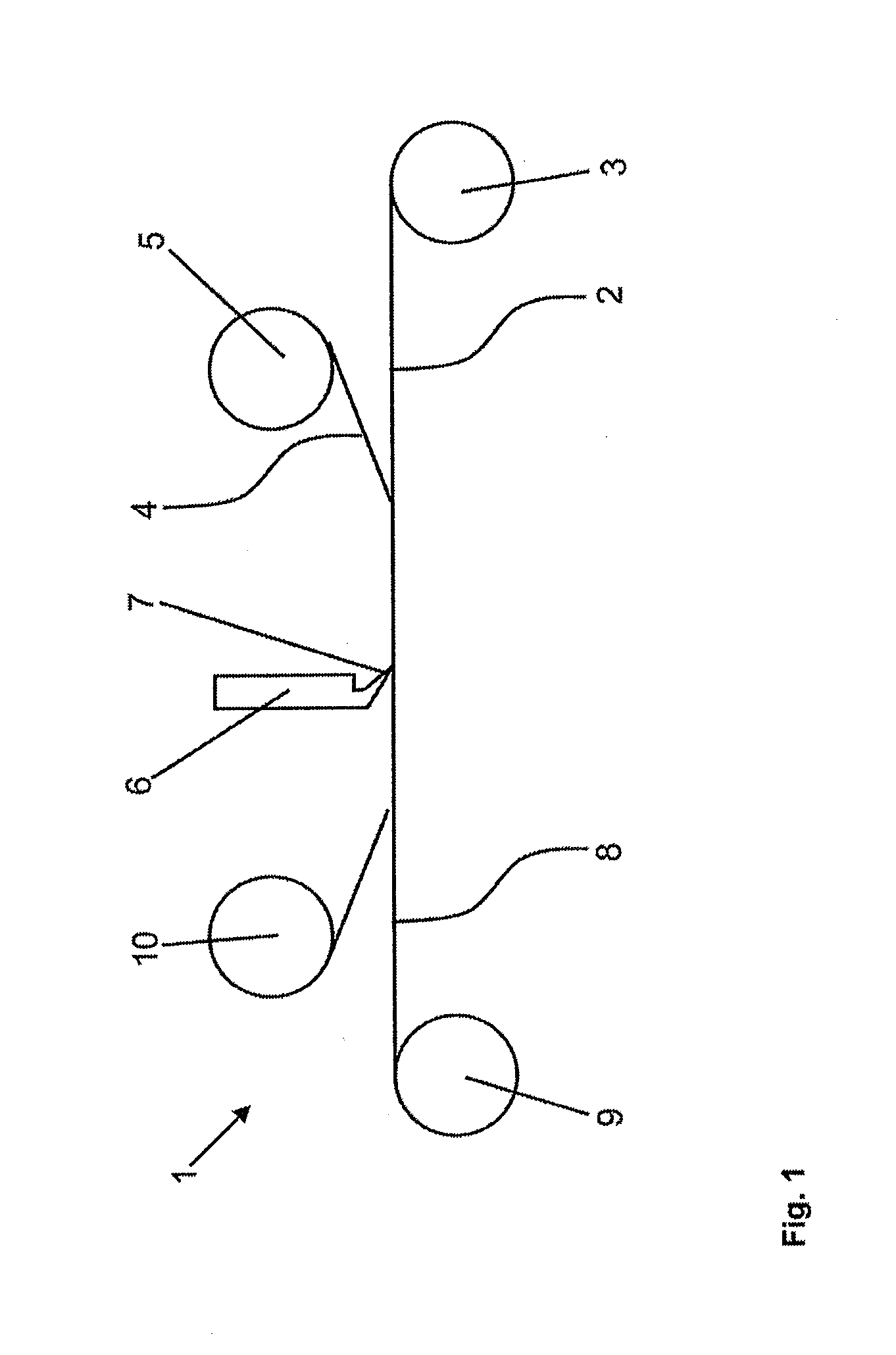

Device, method and arrangement for pressing two axis-parallel rollers approachable to one another in a device for producing and/or treating a web of material

InactiveUS20060081179A1Less productiveLess expensivePretreated surfacesCalendersEngineeringMechanical engineering

Two axially parallel rolls are pressed against each other in a device for producing and / or treating a moving material web. Sensor elements are arranged in the force transmission path running from the force-producing elements via the rolls, outside roll bodies of the two rolls. As a result of displacing the sensor elements out of the roll bodies of the rolls, the production of the rolls is less complicated and less expensive. No sensors have to be embedded in the roll bodies, which opens up the possibility of using standard rolls. In addition, the occasional grinding of the rolls can in this way be performed without any regard to the sensor elements. Nevertheless, the pressure prevailing between the rolls can continue to be measured directly, since the sensor elements are arranged in the transmission path of the pressing force.

Owner:VOITH PATENT GMBH

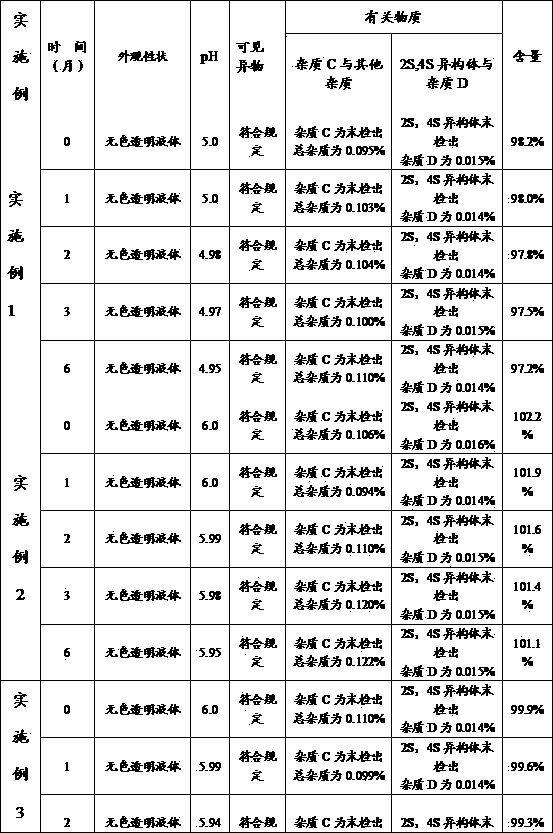

Argatroban injection and preparation method thereof

ActiveCN103463614ASimple componentsHigh liquid stabilityDipeptide ingredientsPharmaceutical delivery mechanismForeign matterActivated carbon

The invention relates to an argatroban injection and a preparation method thereof, which belong to the technical field of pharmaceutical preparations. Each 1000 ml of argatroban injection contains 0.475-0.525 g of argatroban, 50-60 g of sorbitol and the balance of injection water, and the pH value of the argatroban injection is 5.0-6.0. The argatroban injection provided by the invention has simple components, thereby effectively reducing the risk of heat source increase caused by addition of exogenous components, a heat source can be completely adsorbed by needle active carbon after adding the argatroban, the liquid medicine stability of the injection provided by the invention is high, as shown in an acceleration test result of a pilot test sample, the external properties, pH value, visible foreign matters, related substance and content of the argatroban injection prepared by the preparation method provided by the invention meet the existing provisions under an acceleration condition, and no obvious change occurs in the argatroban content with the growth of time, so that the stability of the injection is good.

Owner:ZHEJIANG TIANRUI PHARMA

Electrorheological or magnetorheological compositions for treatment of subterranean formations and methods of using the same

ActiveUS9181470B2High viscosityHigh yieldFluid removalDrilling compositionMedicineMagnetorheological fluid

The present invention relates to compositions for the treatment of subterranean formations, and methods of using the same. In various embodiments, the present invention provides a fluid for treatment of a subterranean formation, wherein the fluid is at least one of electrorheological and magnetorheological. Various embodiments also provide methods of using the electrorheological or magnetorheological fluid in a subterranean formation, including for fracturing, deposition of proppants, and combinations thereof.

Owner:HALLIBURTON ENERGY SERVICES INC

Devices, systems and method for calibration of systems

ActiveUS20070244428A1Reduce downtimeShorten the timeMedical devicesPressure infusionCommunications systemInjector

An injector system for use in injecting a fluid into a patient includes a communication system adapted to receive data from at least a first sensor that measures a value first variable. The communication system is also adapted to receive data from a calibrated sensor that measures a value the first variable. The injector system further includes a calibration system adapted to calibrate output from the first sensor in response to output from the calibrated sensor. An injector for use in injecting a fluid into a patient, includes a first sensor that measures a value first variable, a communication port adapted to receive data from a calibrated sensor that measures the value the first variable, and a controller adapted to compare data from the calibrated sensor with data from the first sensor and to calibrate output from the first sensor. The devices, systems and methods of the present invention are applicable to systems other than injection systems. For example, a method for calibrating a system (for example, an injector system) includes: placing a calibrated sensor in communication with the system; making a measurement of the value of at least a first variable with the calibrated sensor; transmitting the measured value from the calibrated sensor to the system via a data communication system in operative connection between the calibrated sensor and the system; making a measurement of the value of the first variable with a sensor of the system at approximately the same time as the measurement made with the calibrated sensor; comparing the value of the first variable measured with the calibrated sensor with the value of the first variable measured with the system sensor; and calibrating the output of the system sensor at least in part based upon the comparison.

Owner:BAYER HEALTHCARE LLC

Method for the creping of paper

ActiveUS8202395B2Cost efficientGuaranteed adjustabilityNon-fibrous pulp additionNatural cellulose pulp/paperContact lineBiomedical engineering

A creping doctor device for the scraping off and creping of a running paper web from a rotating cylinder, comprising a holder device arranged to be able to support a continuous, or divided, longitudinally moveable doctor blade, which doctor blade is arranged to have a length that exceeds at least twice the length of said cylinder and is provided with a scraping surface and a contact line and / or contact surface, which contact line and / or contact surface is intended to bear against the jacket surface of said rotating cylinder at a certain linear load, said doctor blade comprising a supporting part and a wear part that is moveable in relation to the supporting part.

Owner:CS PRODN

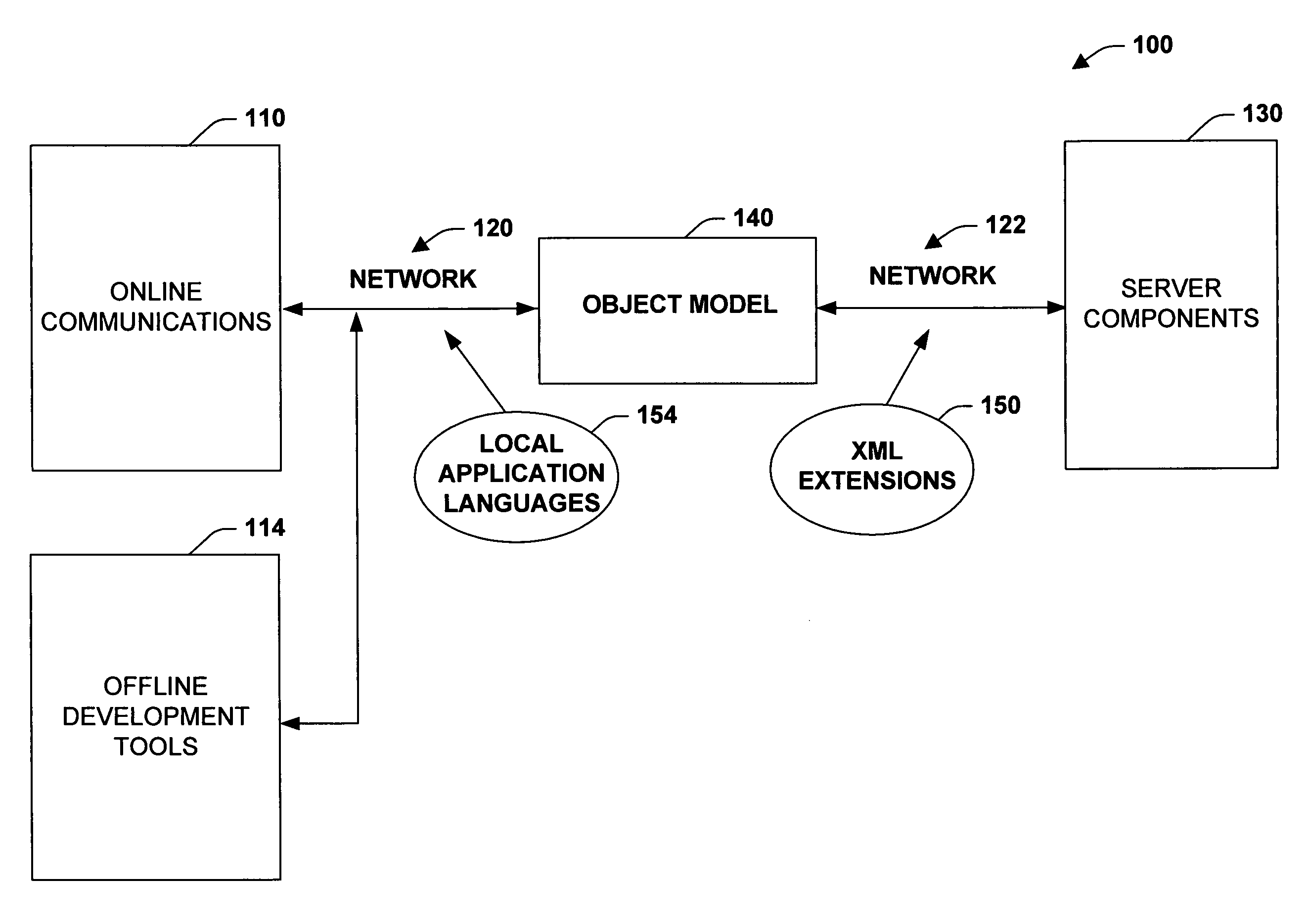

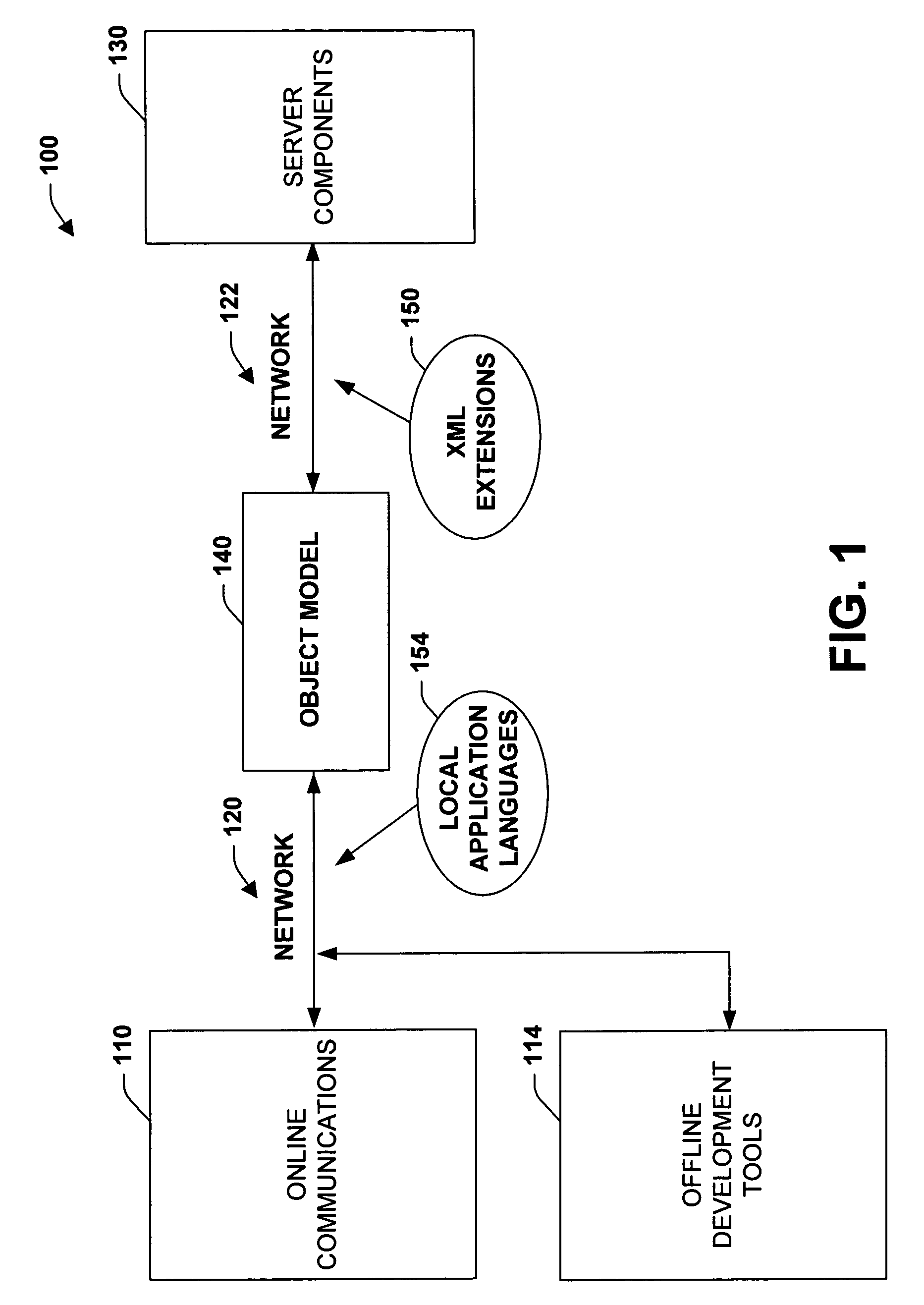

Systems and methods to facilitate utilization of database modeling

InactiveUS7885978B2Facilitate online database manipulation and offline authoring of databaseReduce needDigital data processing detailsProgramming languages/paradigmsData modelingOnline and offline

The subject invention relates to systems and methods that extend the network data access capabilities of mark-up language protocols. In one aspect, a network data modeling system is provided. The system includes a protocol component that employs a computerized mark-up language to facilitate data interactions between network components. An extension component operates with the protocol component to support the data transactions, where the extension component supplies various commands above standard network and database protocols. An object model is provided as a wrapper to the extensions in order to support various online and offline database development applications.

Owner:MICROSOFT TECH LICENSING LLC

Method for manufacturing a partially coated carrier structure

InactiveUS20120270019A1Low costSave resourcesLamination ancillary operationsDecorative surface effectsTectorial membraneEngineering

A method is provided for manufacturing a partially coated carrier structure including a carrier tape coated by a coating. A protective film is applied to at least a portion of the coating, the coating is partially removed from the carrier tape, and the protective film is removed from the coating. A device for manufacturing a partially coated carrier structure by a method of this type includes a first conveying facility for conveying a carrier tape coated by a coating, an application facility for application of a protective film to at least a portion of the coating, and at least one tool that can be used to partially remove the coating from the carrier tape.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

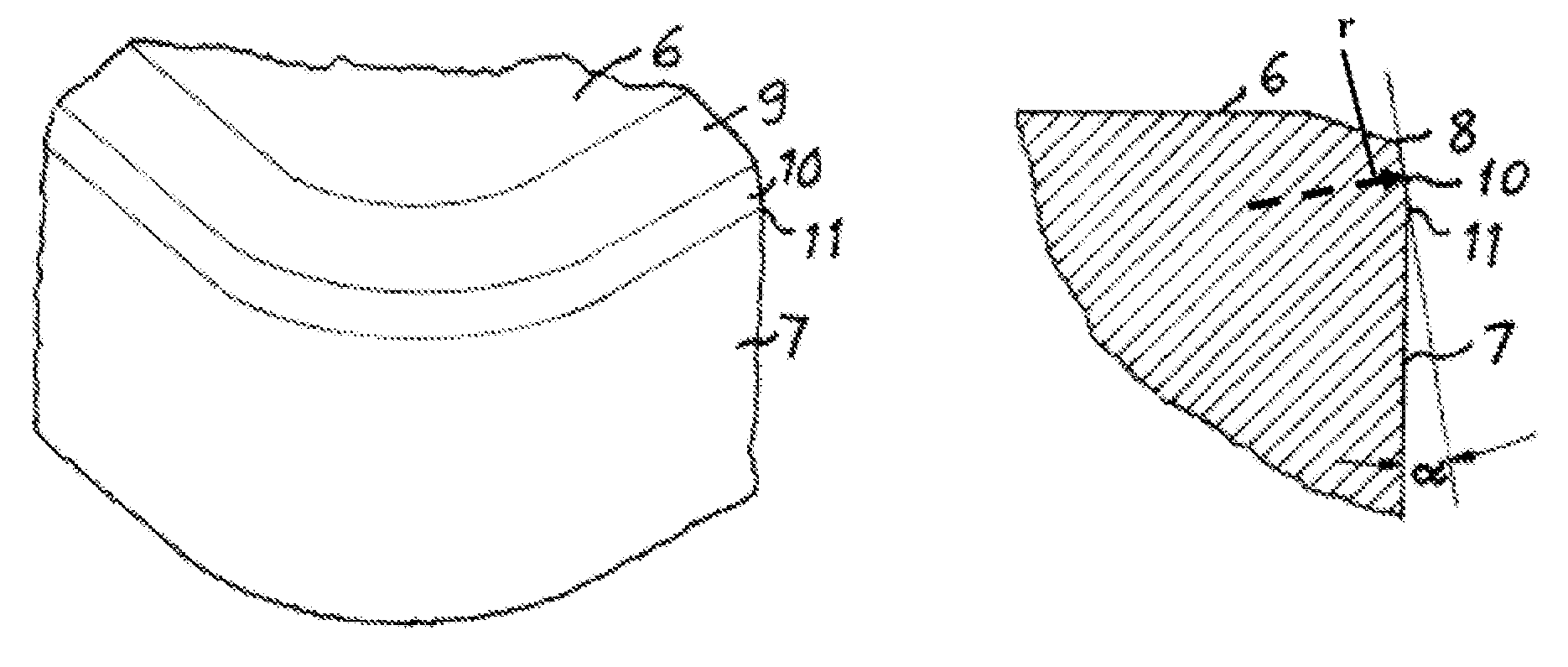

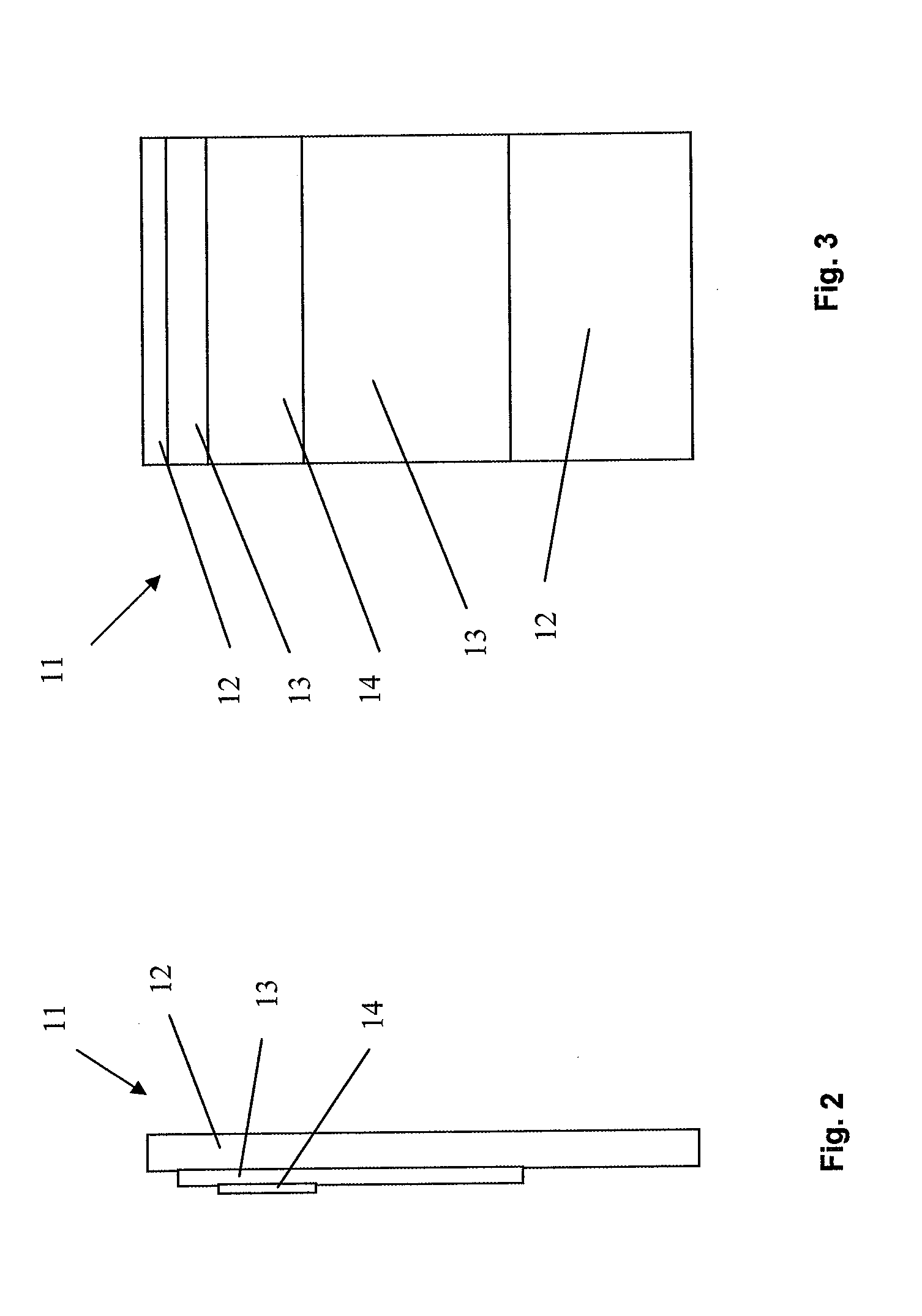

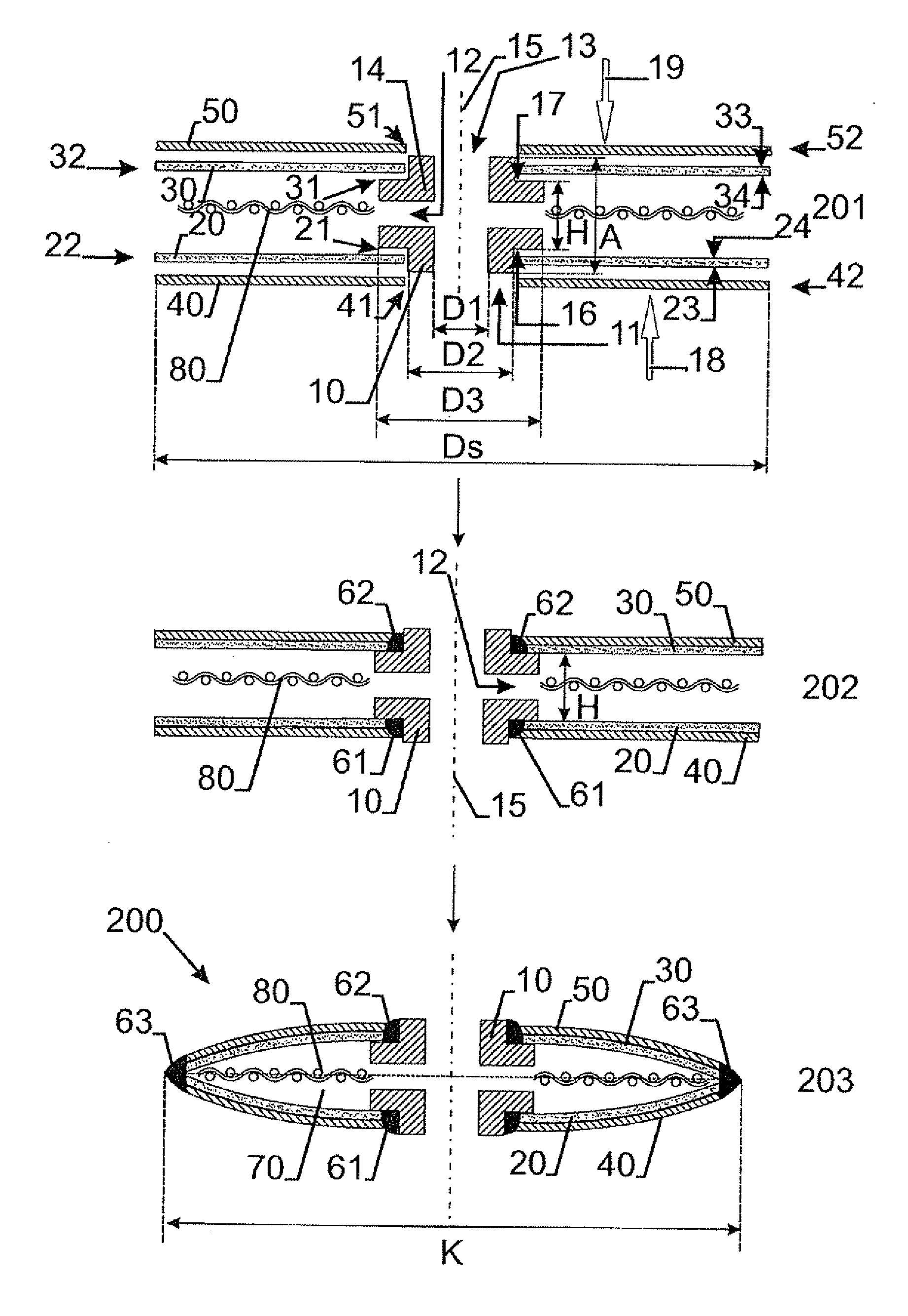

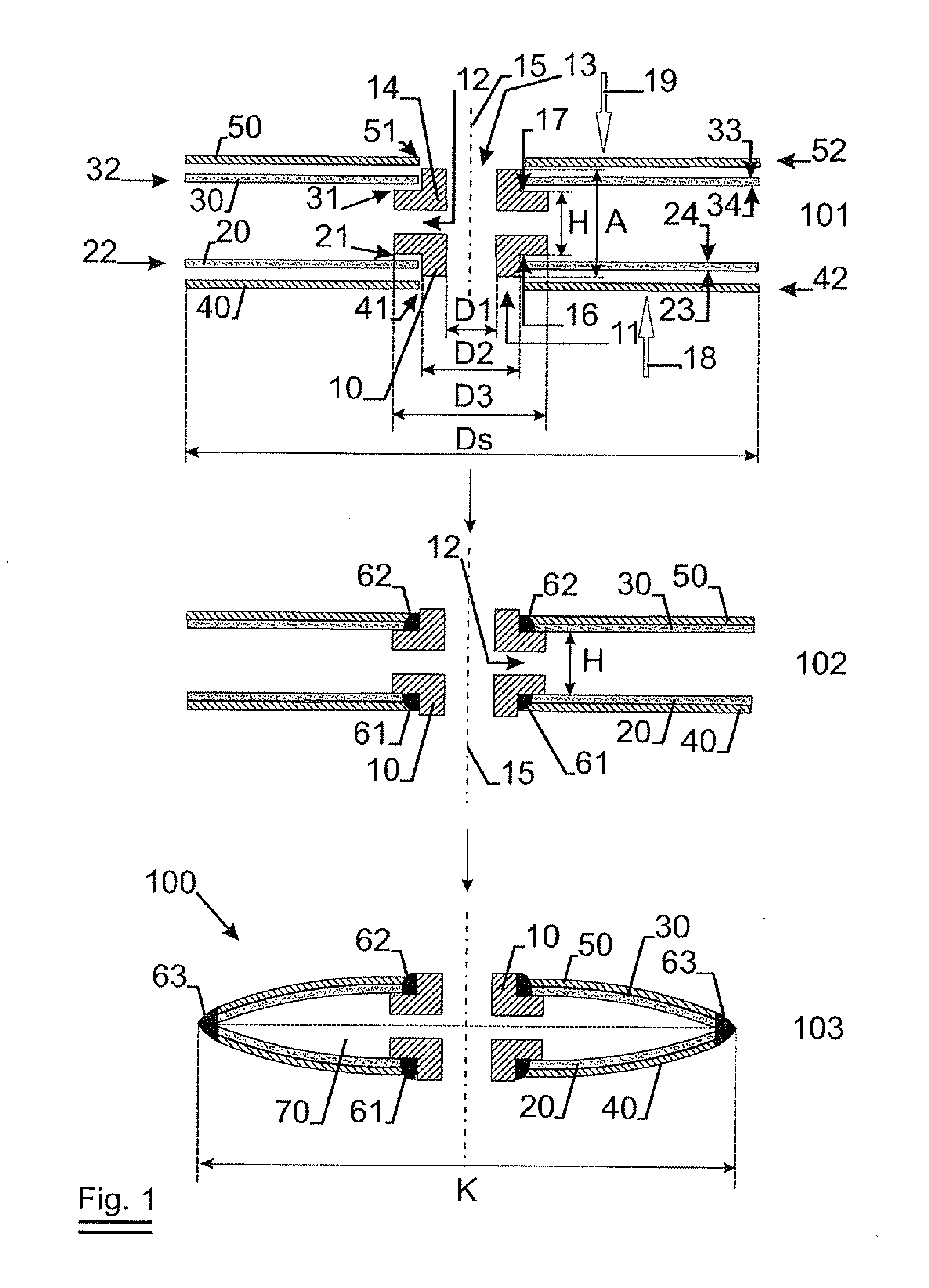

Disc-shaped filter elements and methods to provide disc-shaped filter elements

InactiveUS20100012572A1Less risk of filter membrane rupture during cleaningLess productiveLoose filtering material filtersCartridge filtersCouplingBiomedical engineering

The present invention relates to a disc-shaped filter element and to a method to provide a disc-shaped filter element. A disc-shaped filter element has a diameter K, and comprises a first and a second ring-like shaped, liquid permeable support member having an outer edge having a diameter Ds and an inner central edge, having a largest width Ws. The disc-shaped filter element comprises a first and a second ring shape-like filter membrane, the first filter membrane being in contact with the first surface of the first support member, the second filter membrane being in contact with the first surface of the second support member. The outer edges of the first filter membrane, the second filter membrane, the first support member and the second support member are liquid tight fixed to each other. The disc-shaped filter element further comprises a hub having a central void space, an outer wall, at least one channel extending from this void space to this outer wall and a coupling means. The first surface of the first support member and the second surface of the second support member are separated from each other over a distance H being different from zero at the outer wall of the hub. For each of the first support member and the second support member, the support member are provided with a radius of curvature r being smaller of equal to (K2 / 4H)+H / 4 along at least a zone of the support member, which zone is delimited by a first imaginary circle along the support member having a diameter of 0.9 DS and a second imaginary circle along the support member having a diameter of 1.1 Ws. The zone in which a radius of curvature r being smaller of equal to (K2 / 4H)+H / 4 is provided, may be delimited by the first imaginary circle along the support member may have a diameter of 0.975 Ds and a second imaginary circle along the support member may have a diameter of 1.025 Ws.

Owner:PUROLATOR ADVANCED FILTRATION

Rotary energy converter with retractable barrier

ActiveUS8286609B2Reduce stepsLight weight componentInternal combustion piston enginesPump componentsExternal combustion engineInternal combustion engine

A rotary internal combustion engine includes an outer housing and an inner housing and an enclosure defined therebetween. At least one of the outer and inner housings is rotatable relative to the other and at least two barriers are disposed in the enclosure and divide the enclosure into a combustion chamber and an exhaust chamber. At least one barrier is rotatable relative to at least one other barrier and at least one barrier comprises a retractable barrier mounted along a pivot axis and is pivotable between an extended position and a retracted position. An intake port, exhaust port, and ignition source are also provided. A method of combusting a fuel comprises rotating a drive member to expand a combustion chamber and substantially isolate the combustion chamber from an exhaust chamber, and introducing and combusting a combustion fluid and a fuel in the combustion chamber as the combustion chamber is expanding.

Owner:HUDSON SCOTT

Force plate with spring elements

InactiveUS20110209926A1Reduce and avoid cross-talkLess productiveWeighing apparatus using elastically-deformable membersApparatus for force/torque/work measurementElectrical and Electronics engineeringEngineering

Owner:SARTORIUS LAB INSTR GMBH & CO KG

Device for turning up the tire sidewalls on a tire building drum

Device for turning up sidewalls of a tire. The device includes a first lever supporting body arranged on a first side of a drum center and being movable in an axial direction. A first lever system pivotally connected to the first lever supporting body. A second lever supporting body arranged on a second side of the drum center and being movable in an axial direction. A second lever system pivotally connected to the second lever supporting body. The first and second sides are arranged on opposite sides of the drum center. A base spindle is adapted to move the first and second lever supporting bodies in an axial synchronous manner relative to each another.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Novel venous transfusion volume drip chamber

The invention provides a novel venous transfusion volume drip chamber and particularly relates to a venous transfusion volume drip chamber for amplifying, conducting, and collecting drop sounds of venous transfusion by means of a sound collection device in the drip chamber on the basis of gravity transfusion, and controlling a transfusion flow rate through an external connection system to achieve quantitative management of venous transfusion. The novel venous transfusion volume drip chamber is simple in structure, elaborate in design, safe, good in control effect of transfusion flow velocity, capable of saving energy, not only achieving a breakthrough in the field of precise transfusion, and but also providing convenience for achievement of higher-end medical management of venous transfusion.

Owner:ZHENGZHOU HAONENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com