Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Increase the pressing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

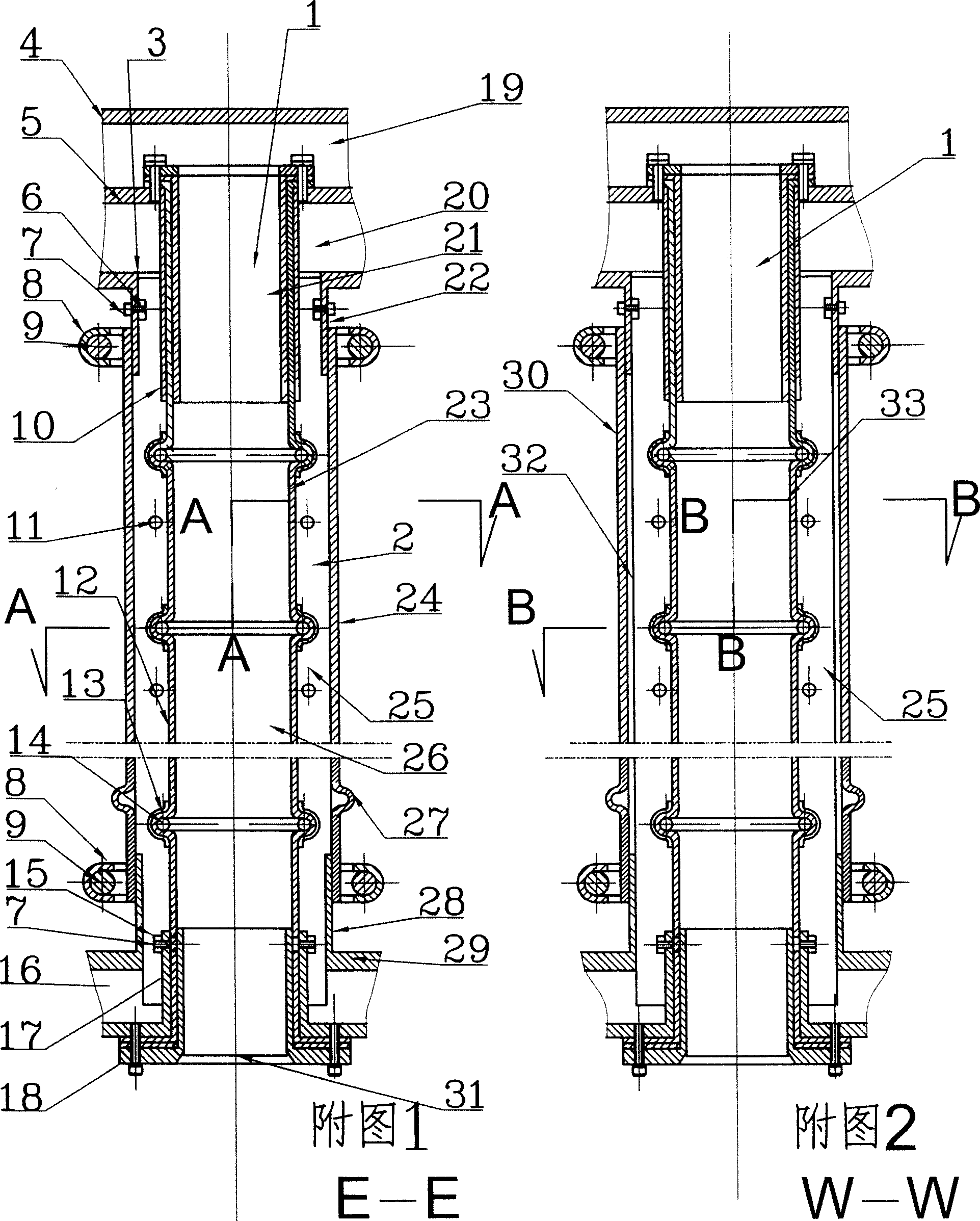

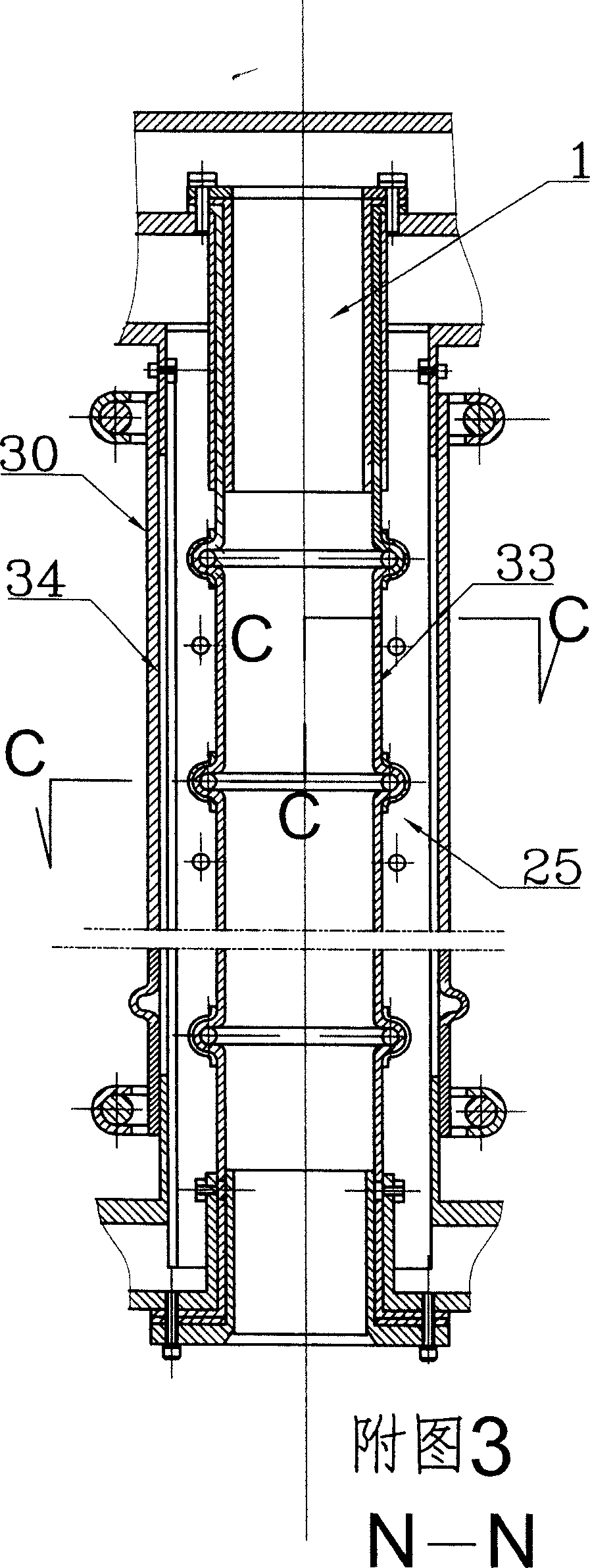

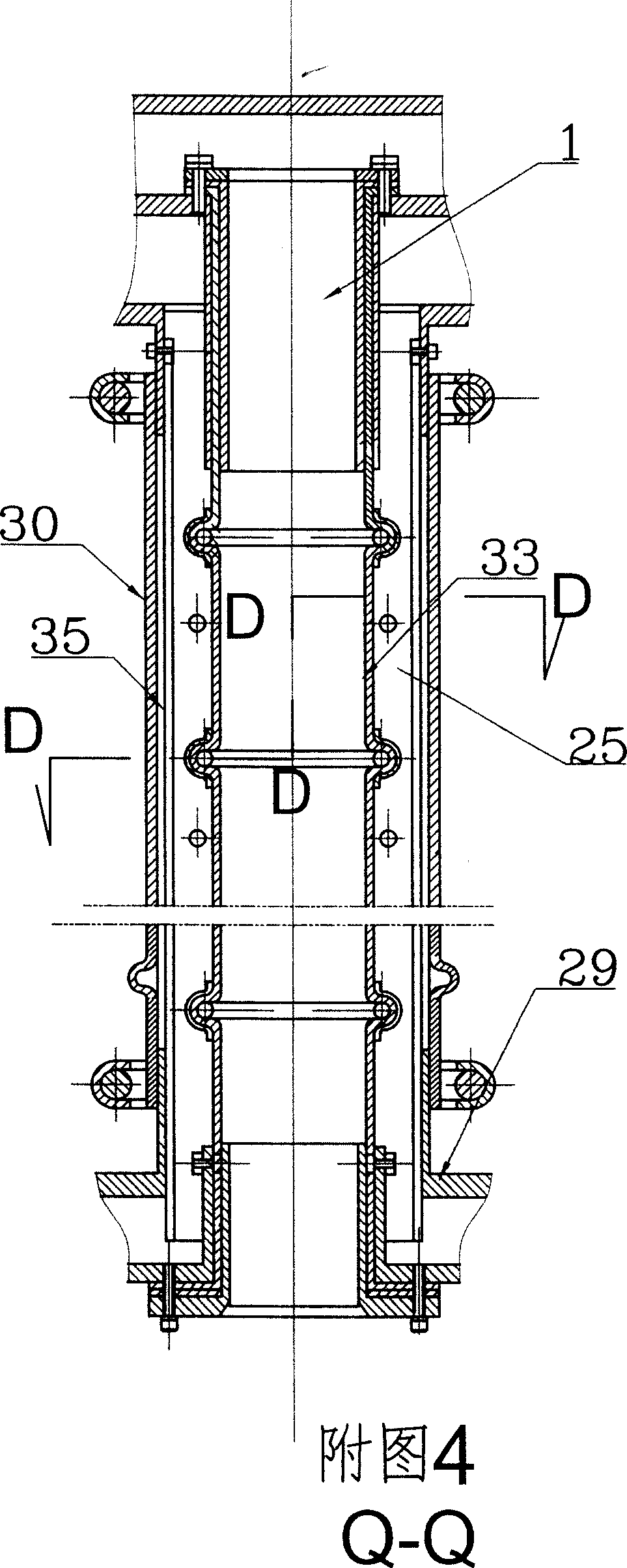

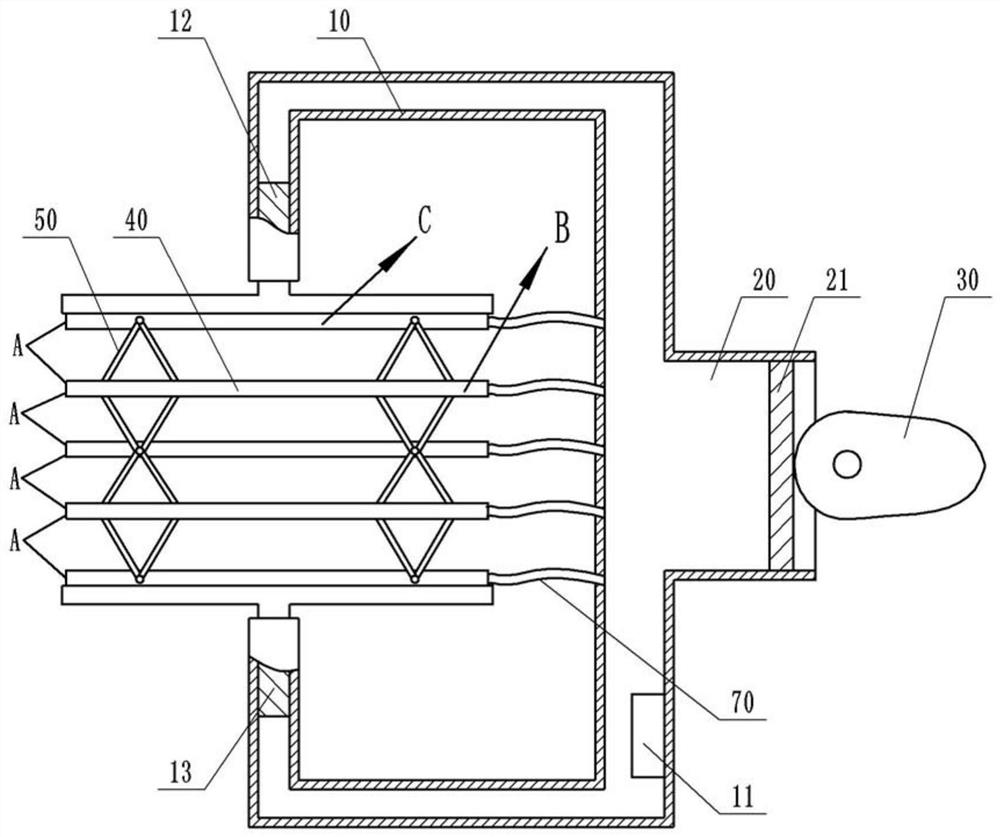

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

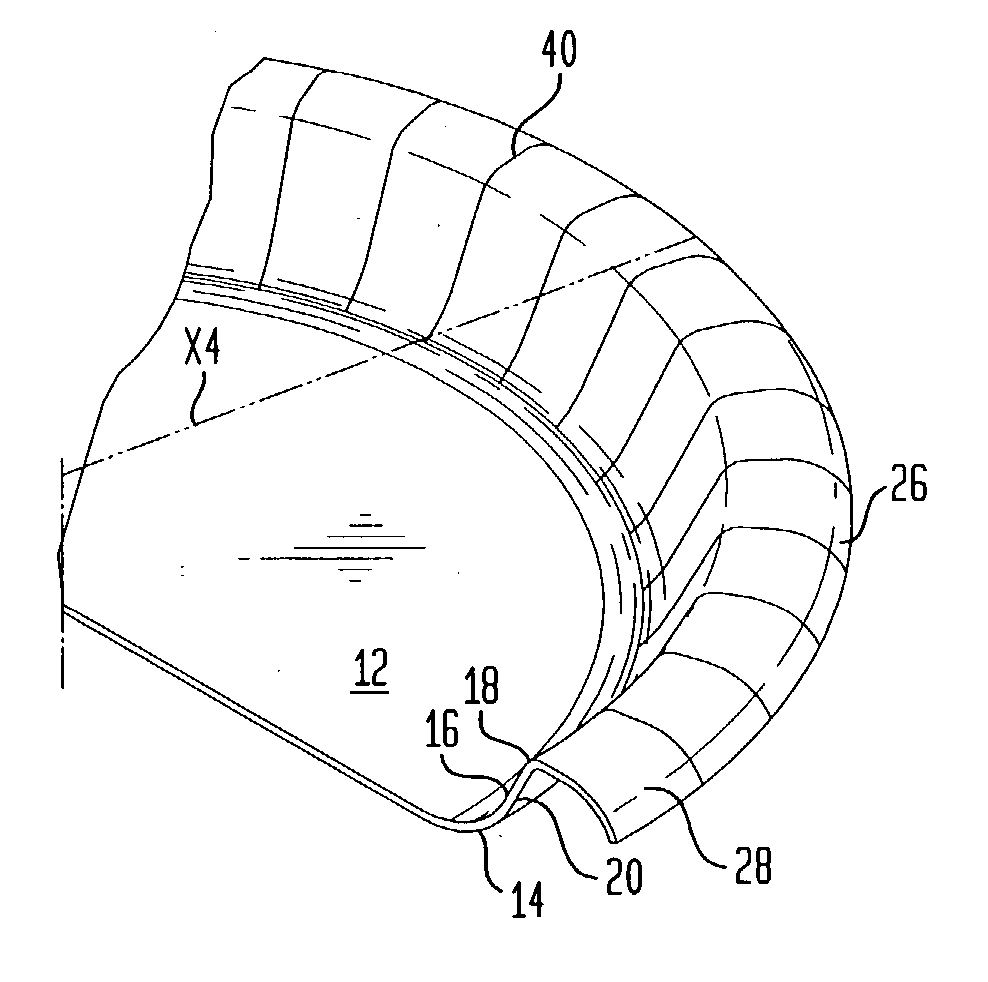

Disposable food container with a linear sidewall profile and an arcuate outer flange

InactiveUS20030173366A1Lose weightHigh strengthEnvelopes/bags making machinerySpecial paperEngineeringUltimate tensile strength

The present invention is directed to rigid disposable food containers provided with a relatively steep sidewall with a generally linear profile and an outwardly flared arcuate flange portion. The containers are further characterized by a flange outer vertical drop wherein the ratio of the length of the vertical drop to the characteristic diameter of the container is greater than about 0.01. By virtue of unique geometry, the containers of the invention exhibit improved rigidity and / or rim stiffness yet have favorable runnability in pressware manufacturing systems characteristic of plates of lower strength.

Owner:GPCP IP HLDG LLC

Adjustable steel tube joint closing device

InactiveCN104148873AWill not deviate in direction,Those who don't slip outWelding/cutting auxillary devicesAuxillary welding devicesOperation safetySteel tube

The invention provides a novel steel tube machining device, and particularly relates to an adjustable steel tube joint closing device which comprises a base, a press-fitting roller fixing seat, a first press-fitting roller, a second press-fitting roller, a third press-fitting roller and a lifting support. By means of the adjustable steel tube joint closing device, press-fitting adjustment can be carried out from multiple angles, prominent load bearing capacity and press-fitting precision are achieved, the novel press-fitting rollers can be better attached to the surfaces of tubes to be machined, press-fitting force is accurate and uniform, tube joint closing efficiency and quality can be effectively improved, operation is easy, and operation safety risks are effectively lowered.

Owner:江苏振光电力设备制造有限公司

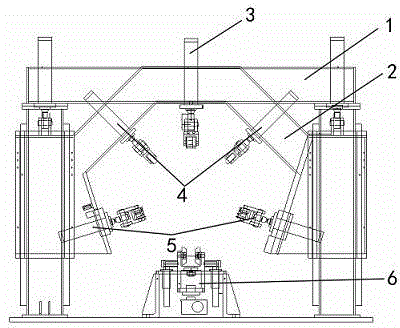

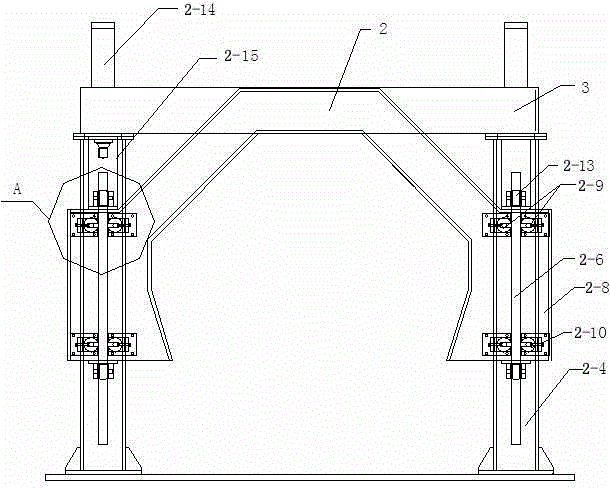

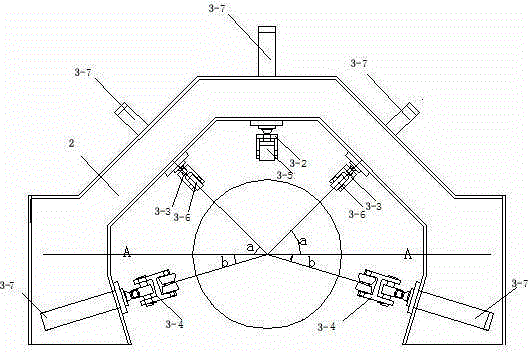

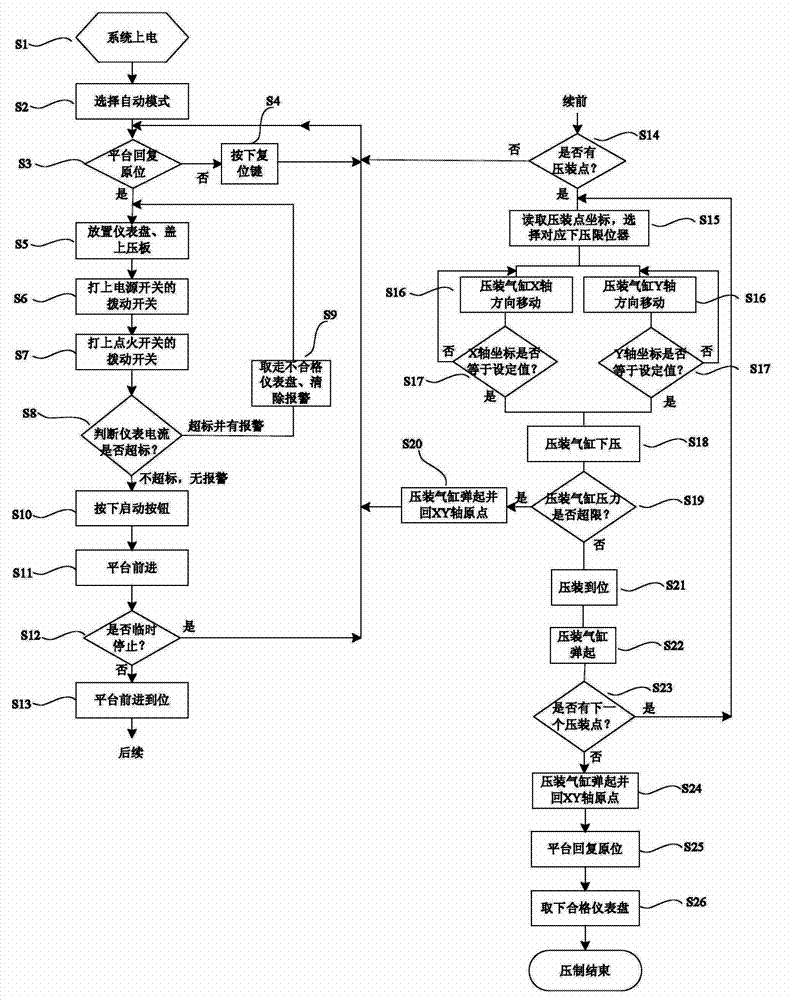

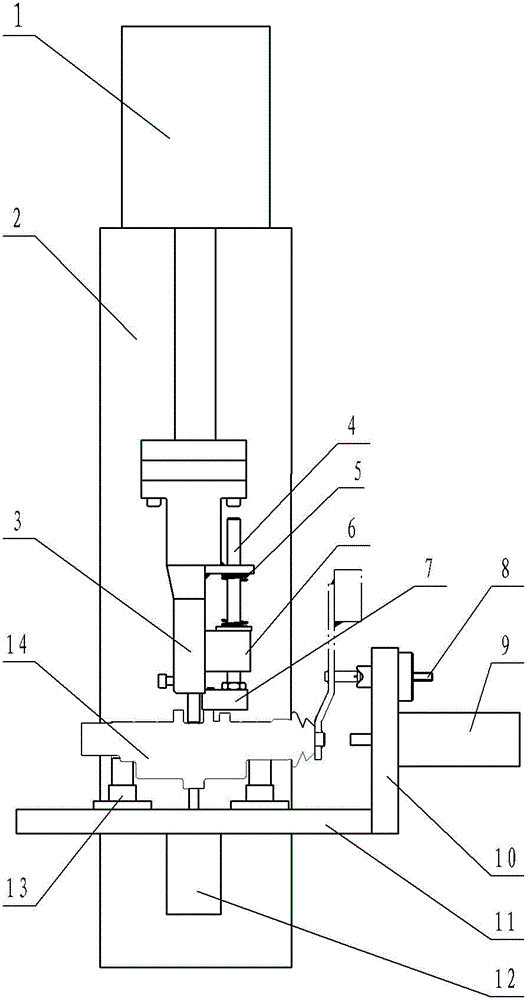

Automatic press-fitting method for automobile combination instrument needle

InactiveCN102756265AReal-time monitoring of pressing pressureReduce scrap rateMetal working apparatusPower flowGas cylinder

The invention provides an automatic press-fitting method for an automobile combination instrument needle, and relates to a press-fitting method for an instrument needle. The automatic press-fitting method comprises the following steps of: resetting a platform and a press-fitting air cylinder in position, and placing an instrument panel; electrifying an instrument and judging whether current exceeds a standard or not; moving the platform forwards, moving a press-fitting air cylinder along an XY axis, and finding out a press-fitting position; pressing down the press-fitting air cylinder after reaching a press-fitting position; judging whether press-fitting pressure exceeds a limit value or not in a pressing-down process, and if so, resetting the press-fitting gas cylinder and exiting; after a first press-fitting point is qualified in a press-fitting process, popping up the press-fitting air cylinder and moving the press-fitting gas cylinder to the next press-fitting point; after all the press-fitting points are subjected to continuous press-fitting, popping up the press-fitting air cylinder and moving back the press-fitting air cylinder to an original position of the XY axis; and exiting the platform, taking out the qualified instrument, and finishing the press-fitting process. With the adoption of the automatic press-fitting method provided by the invention, dynamic current for electrifying the instrument can be monitored, and waste products can be automatically eliminated in advance; and the press-fitting pressure is monitored in real time in the press-fitting process; and the needle is prevented from falling down when the press-fitting pressure is too low, and the instrument is prevented from being damaged when the press-fitting pressure is too high, so that the rejection rate is greatly reduced.

Owner:LIUZHOU HANGSHENG TECH +1

Locating pin press fitting device

InactiveCN104289899APrecise positioningAvoid misalignmentMetal working apparatusPunch pressEngineering

The invention relates to a locating pin press fitting device. The locating pin press fitting device comprises a base, a rack, a downwards pressing air cylinder and a fastening bolt; the rack comprises a guide rod, a clamping board, a sliding board and a fixed board; the guide rod is vertically fixed to the base; the guide rod penetrates through the fixed board, the sliding board and the clamping board in sequence from top to bottom; the fixed board is fixed to the top end of the guide rod; the sliding board, the clamping board and the guide rod are in sliding connection; the downwards pressing air cylinder with a piston rod downwards arranged is fixed to the upper surface of the fixed board; a balancing weight is fixed to the lower end of the piston rod of the downwards pressing air cylinder; a vertical pushing rod is fixed to the center of the lower surface of the sliding board. The downwards pressing air cylinder serves as pressure, the sliding board and the clamping board can only vertically move, it is avoided that due to pressure deviation, a locating pin is not accurate and staggered or the like in the press fitting process, tedious labor operations are reduced, labor intensity of workers is relieved, the press fitting speed is high, and the production efficiency and product percent of pass are improved.

Owner:NINGBO XUSHENG AUTO TECH CO LTD

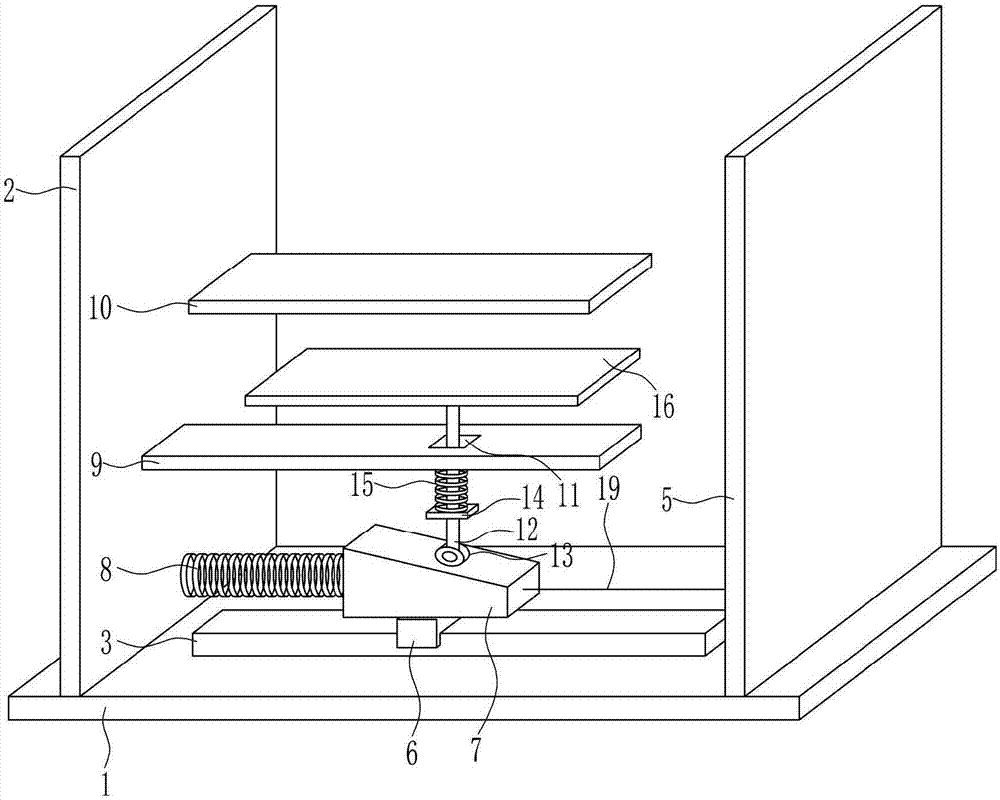

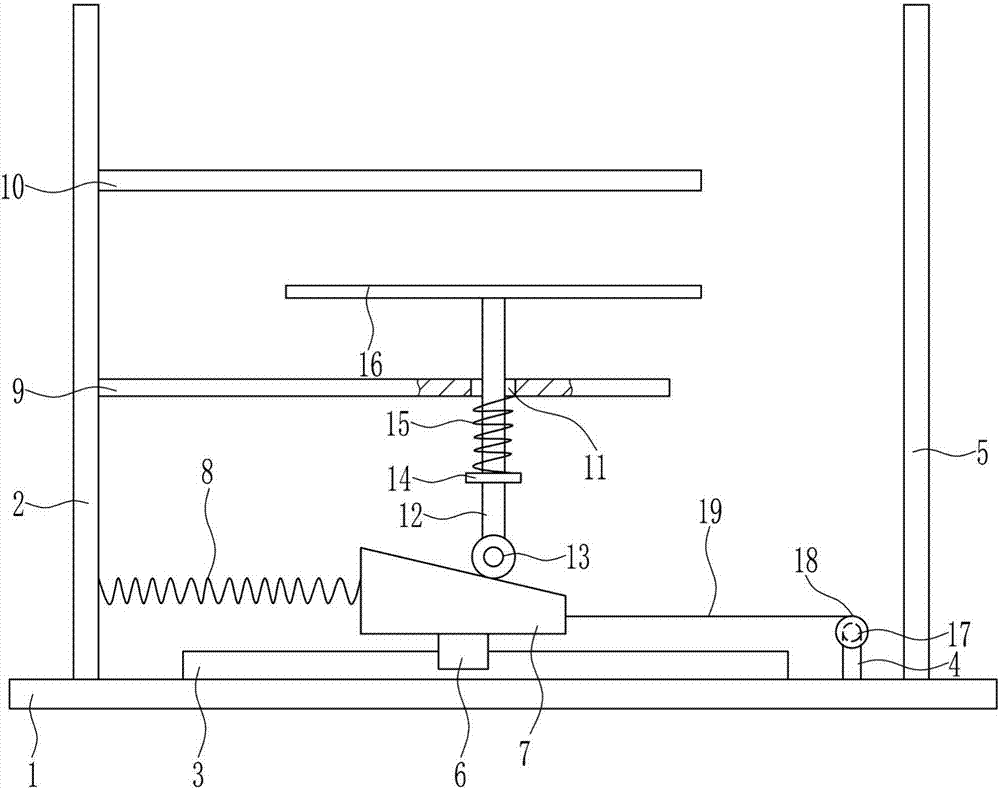

Press fit device for LED lamp bracket glue dispensing

InactiveCN106895281AWon't fallWon't shakeMaterial gluingSemiconductor devices for light sourcesEngineeringBlock match

The invention relates to a pressing device, in particular to a pressing device for dispensing glue on an LED lamp frame. The technical problem to be solved by the present invention is to provide a pressing device for dispensing glue for LED lamp holders with fast pressing speed, high working efficiency and good effect, which does not affect the use of LED lamp holders. In order to solve the above technical problems, the present invention provides such a pressing device for dispensing glue for LED lamp holders, which includes a bottom plate, a left side plate, a slide rail, a pole, a right side plate, a first slider, a wedge block, a second 1. Springs, guide plates, connecting plates, guide rods, contact rollers, etc.; the top of the bottom plate is connected by bolts from left to right in order to install a left plate, a slide rail, a pole and a right plate. Fit the first slider. In the present invention, the first pressing plate and the second pressing plate move together to press and fit the LED light frame, so that the LED light frame can be pressed faster, achieving fast pressing speed, high working efficiency and good effect.

Owner:宁波伍兹光电有限公司

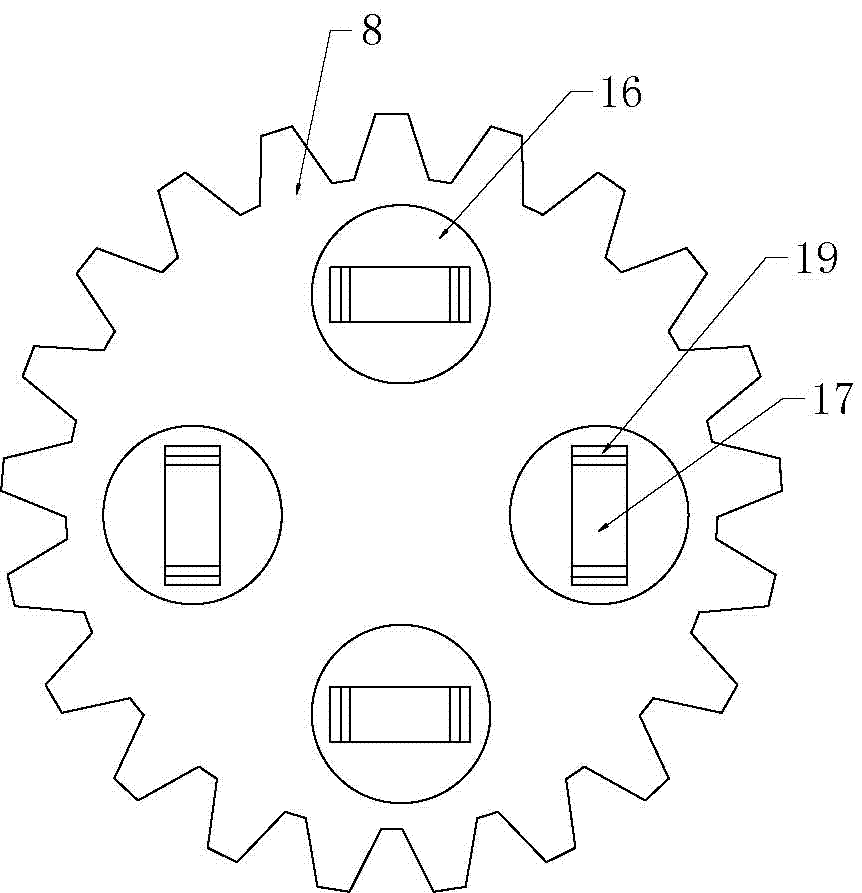

Safe efficient stamping machine

ActiveCN106864020AImprove bronzing efficiencyIncrease the pressing speedBronze printingRotary pressesRatchetCircular disc

The invention relates to the field of printing equipment and discloses a safe efficient stamping machine. The safe efficient stamping machine comprises a rack and a stamping mechanism, wherein a stamping end head is arranged at the lower end of the stamping mechanism; a mounting base is arranged below the stamping end head; a first lower pressure rod is connected on the stamping mechanism; a pawl is hinged on the first lower pressure rod; the mounting base comprises a circular disc; gear teeth are arranged in the peripheral direction of the circular disc; the rack is rotatably connected with a ratchet wheel; the ratchet wheel is engaged with the pawl; the ratchet wheel is coaxially connected with a first bevel gear; the first bevel gear is engaged with a second bevel gear; the second bevel gear is connected with a rotary shaft; a gear is connected on the rotary shaft; the gear is engaged with the gear teeth on the circular disc; a plurality of rotary plates rotatably connected on the circular disc; grooves are formed in the rotary plates; the two sides of each groove are equipped with through slots which penetrate through the corresponding rotary plate; and slide blocks are arranged in the through slots in a sliding mode. Compared with the prior art, the safe efficient stamping machine is safer to operate, and is higher in stamping speed.

Owner:广东东纳数码印刷科技有限公司

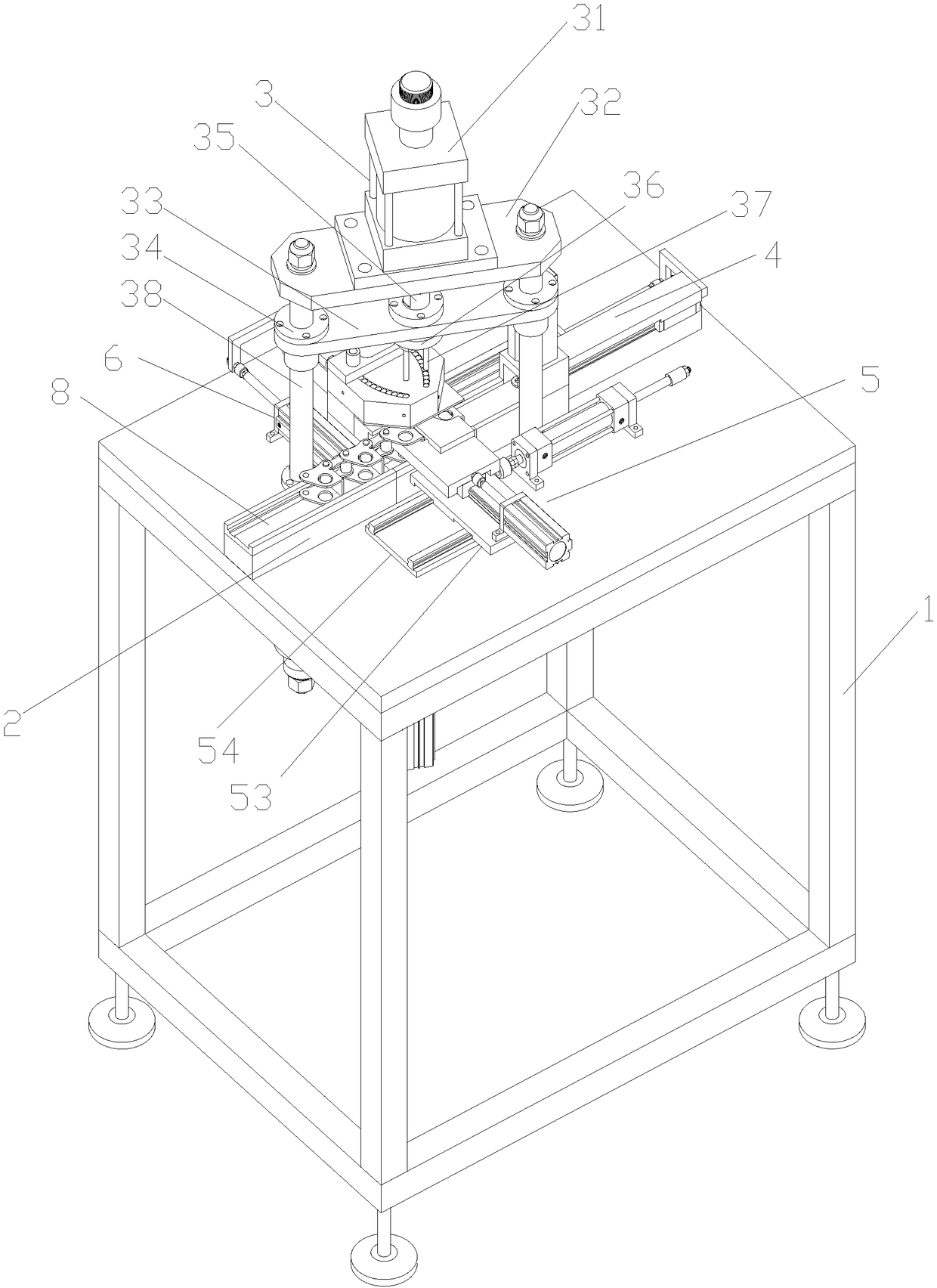

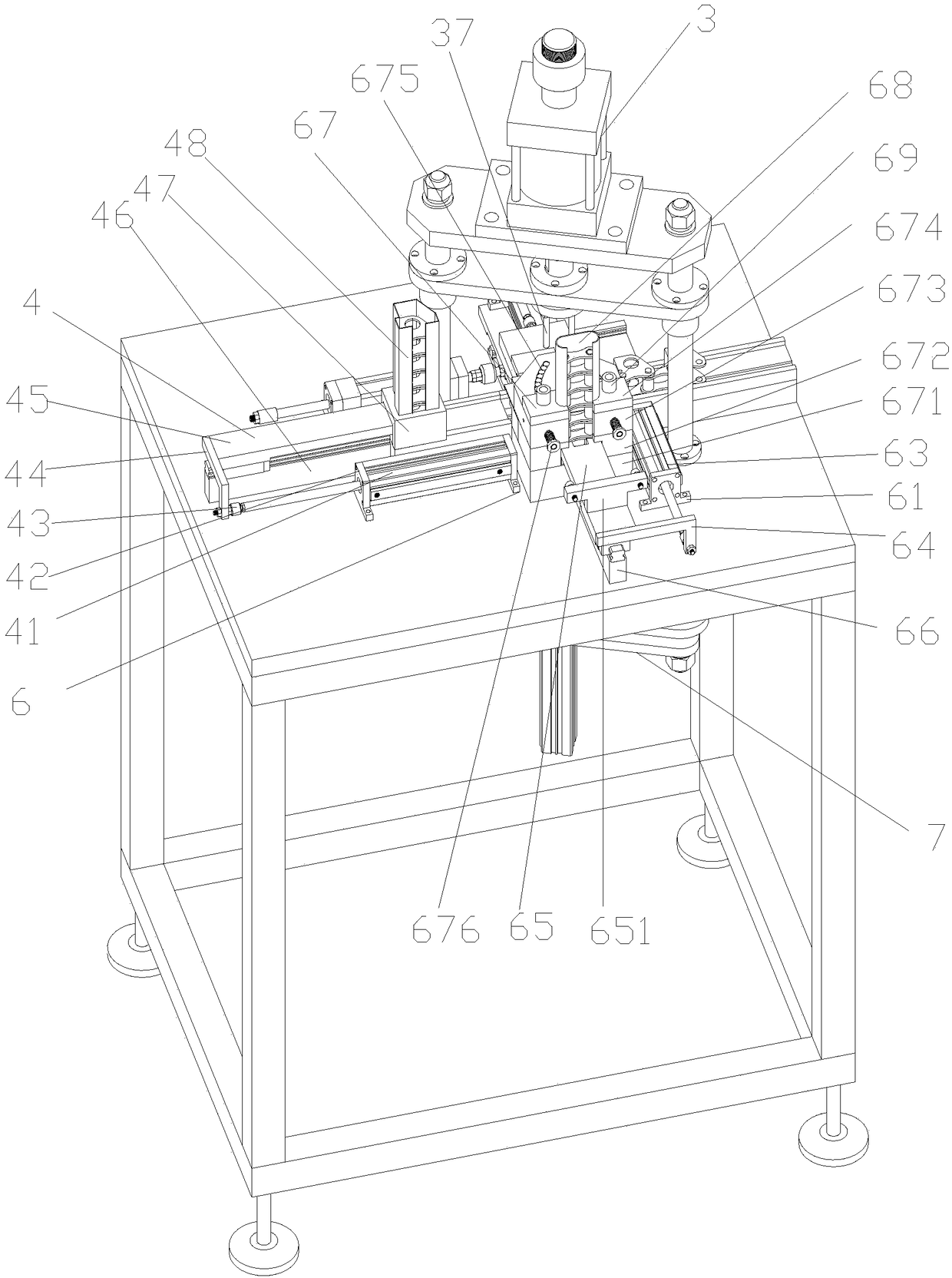

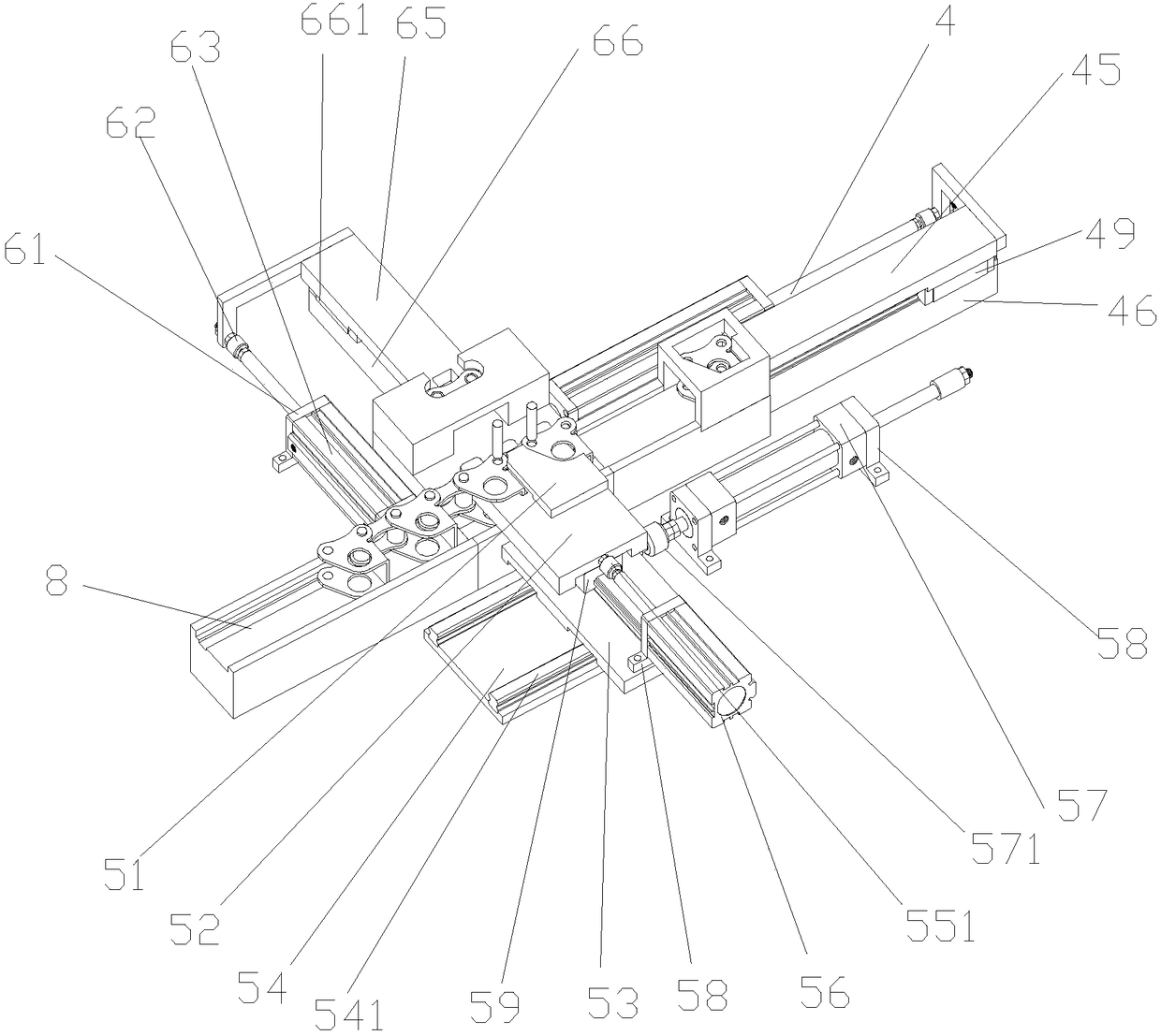

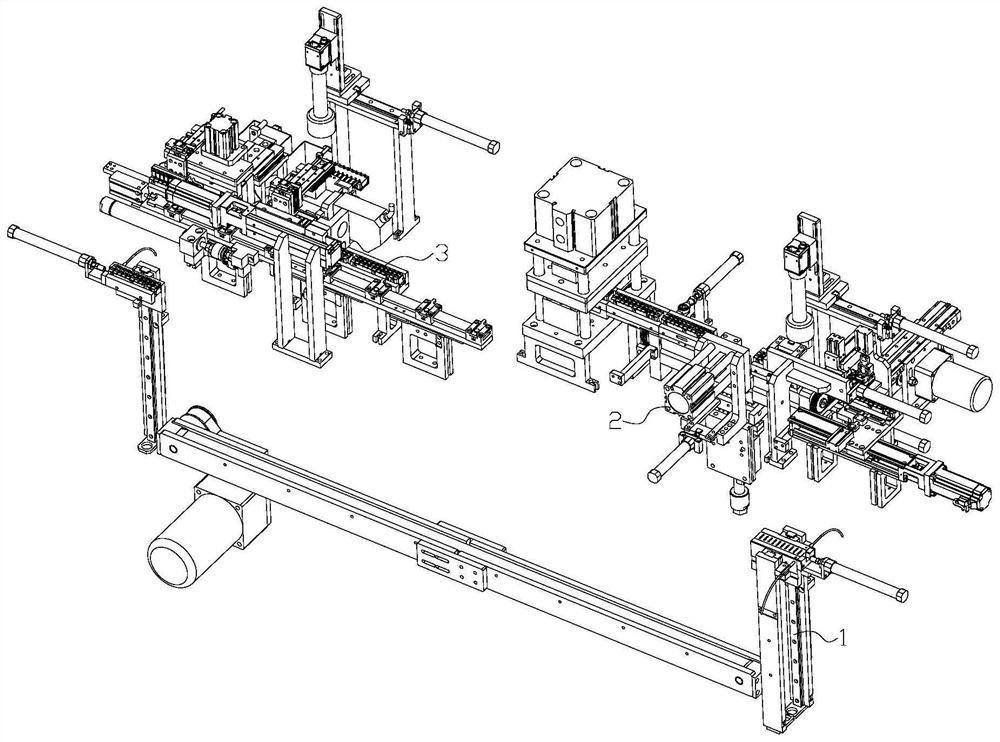

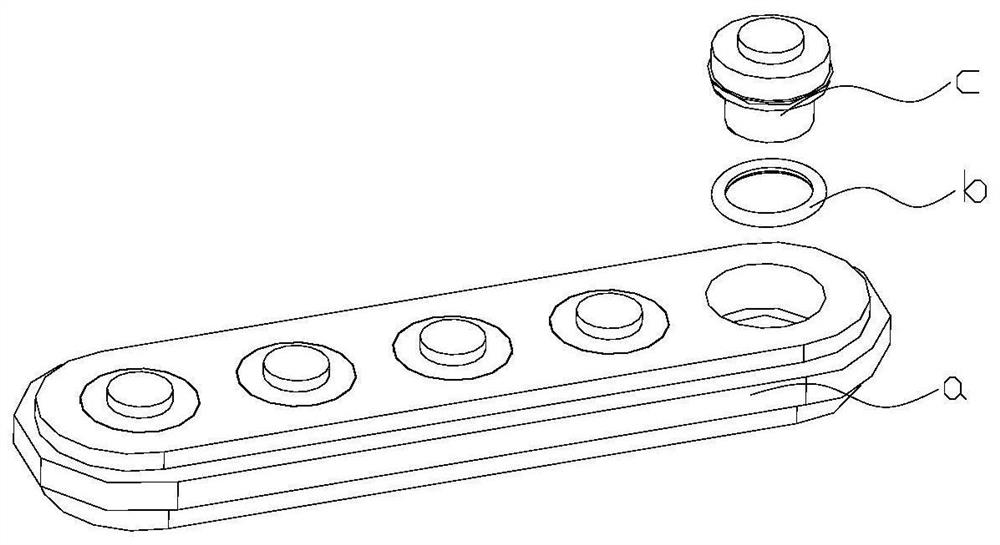

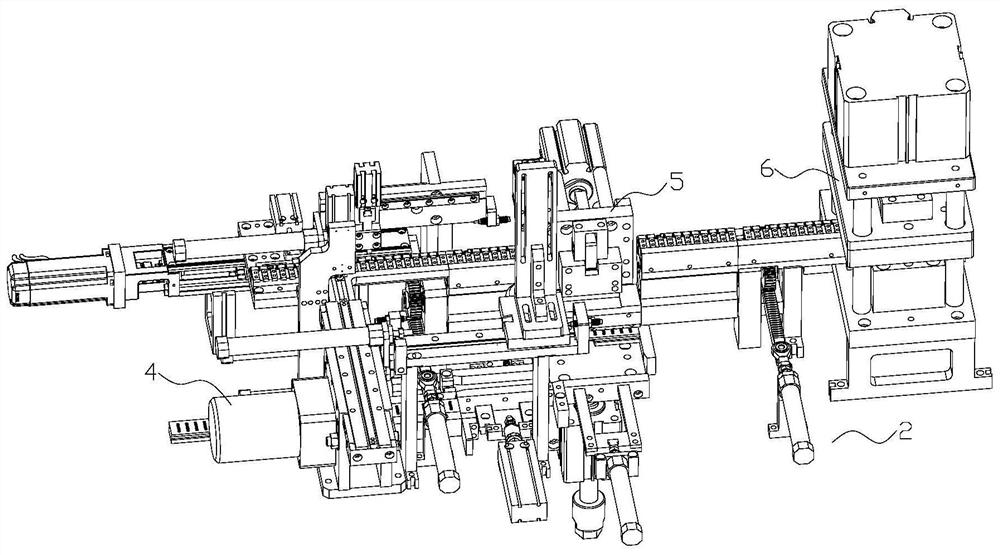

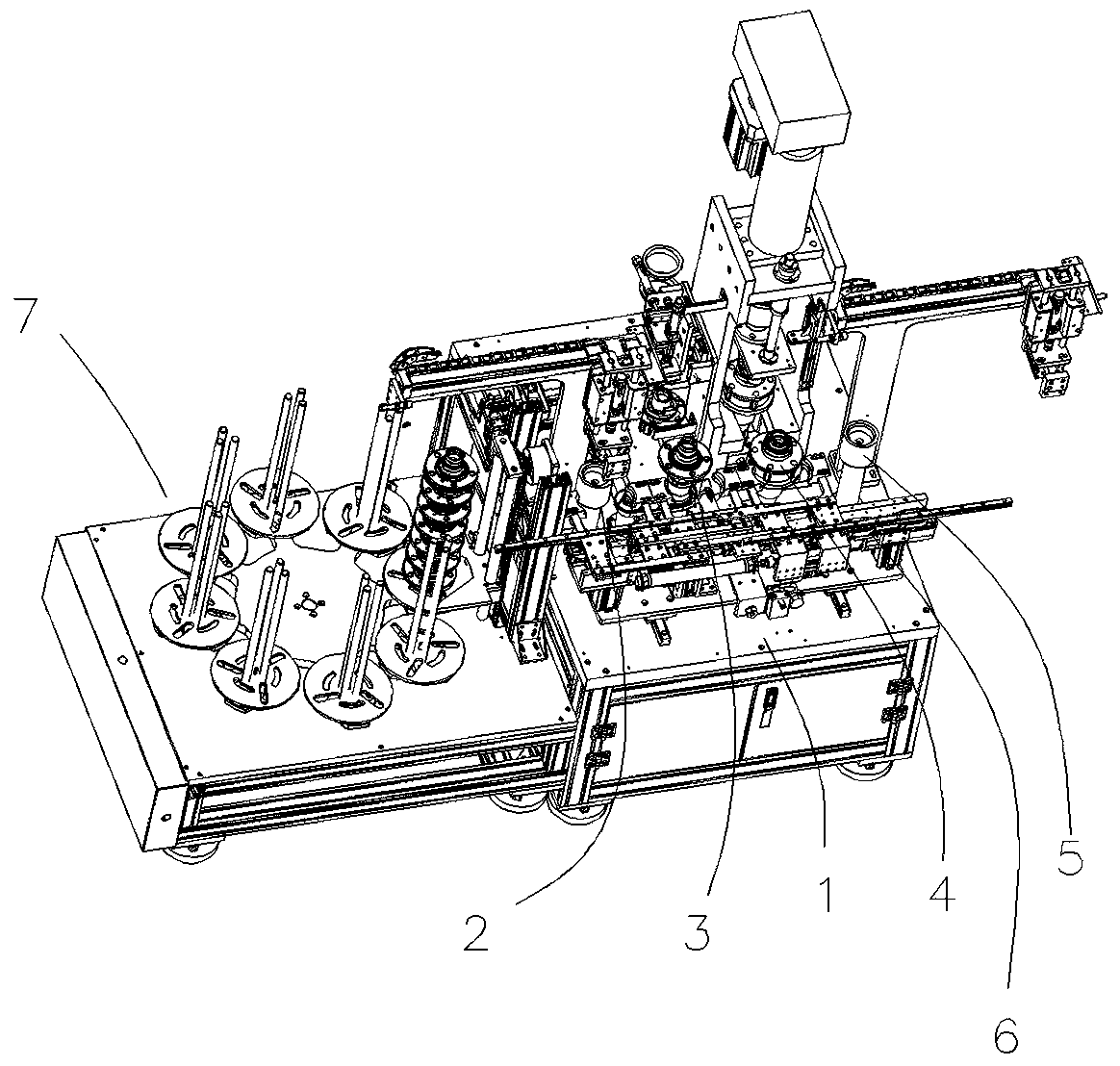

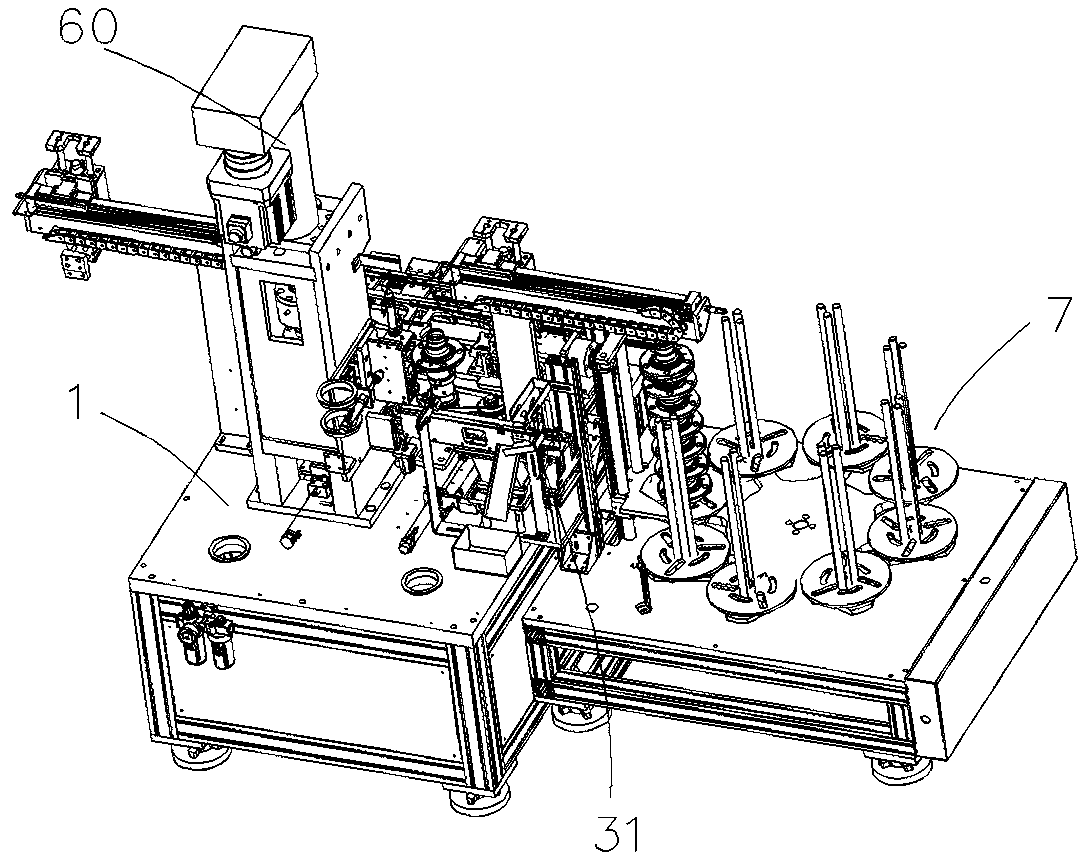

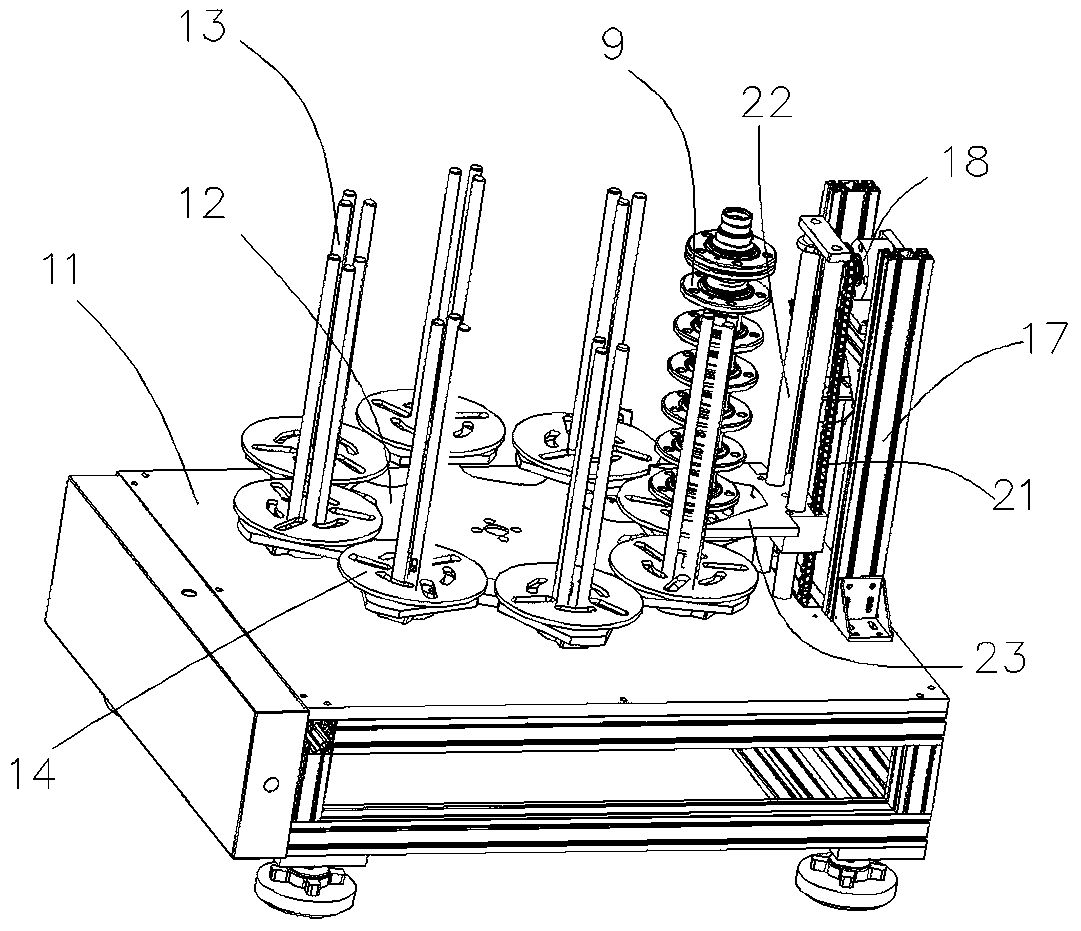

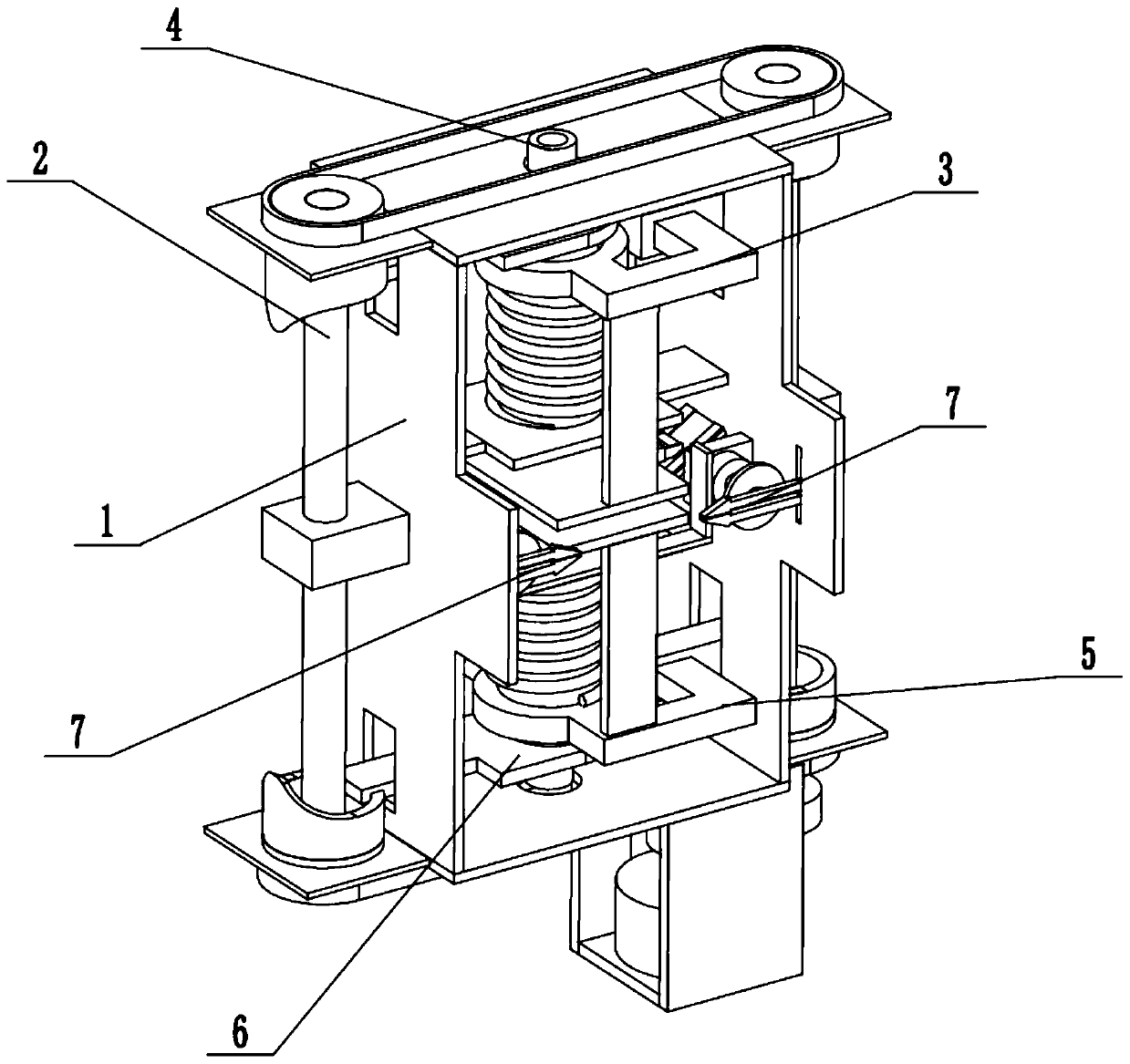

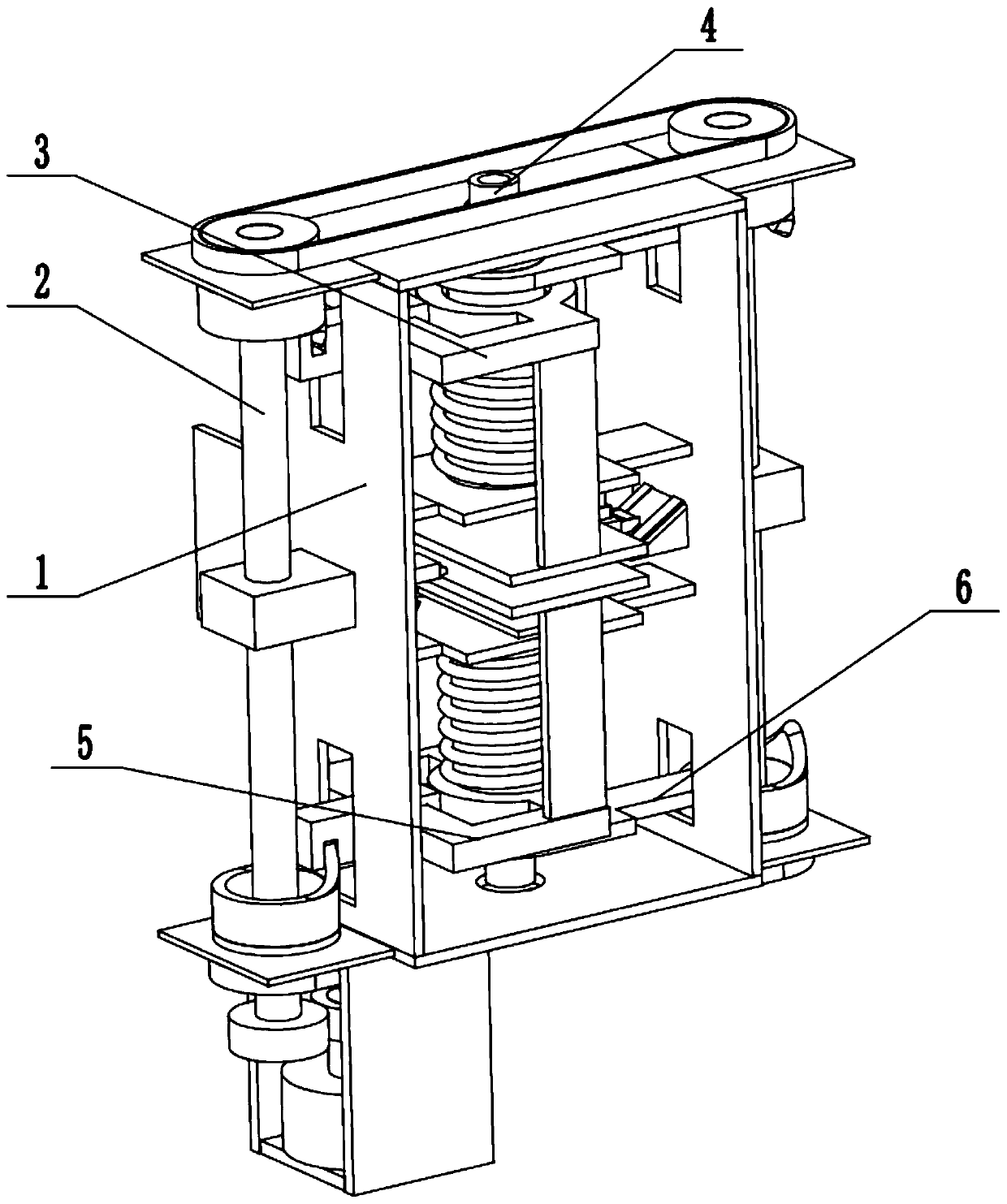

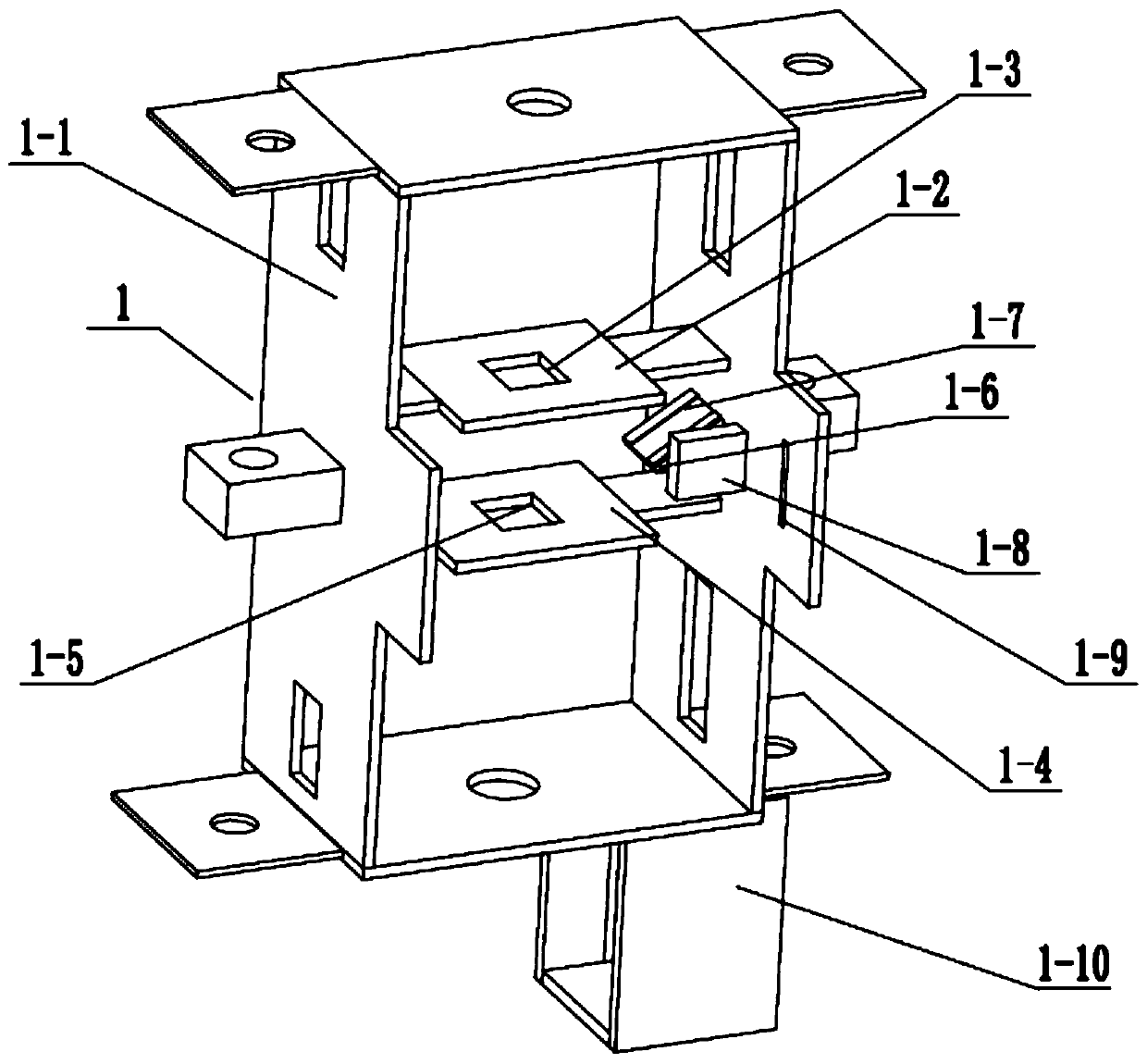

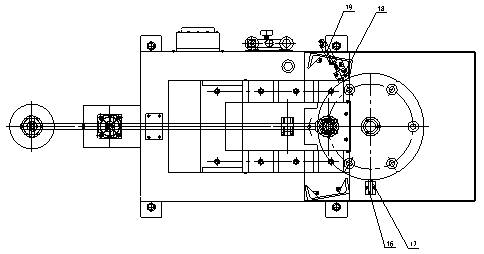

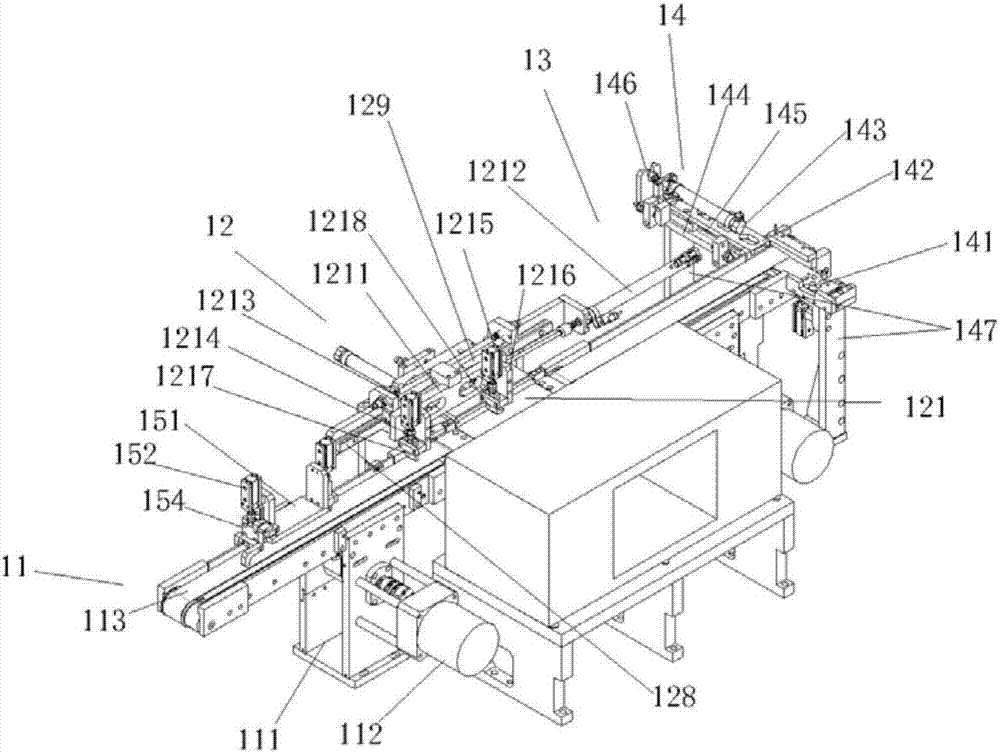

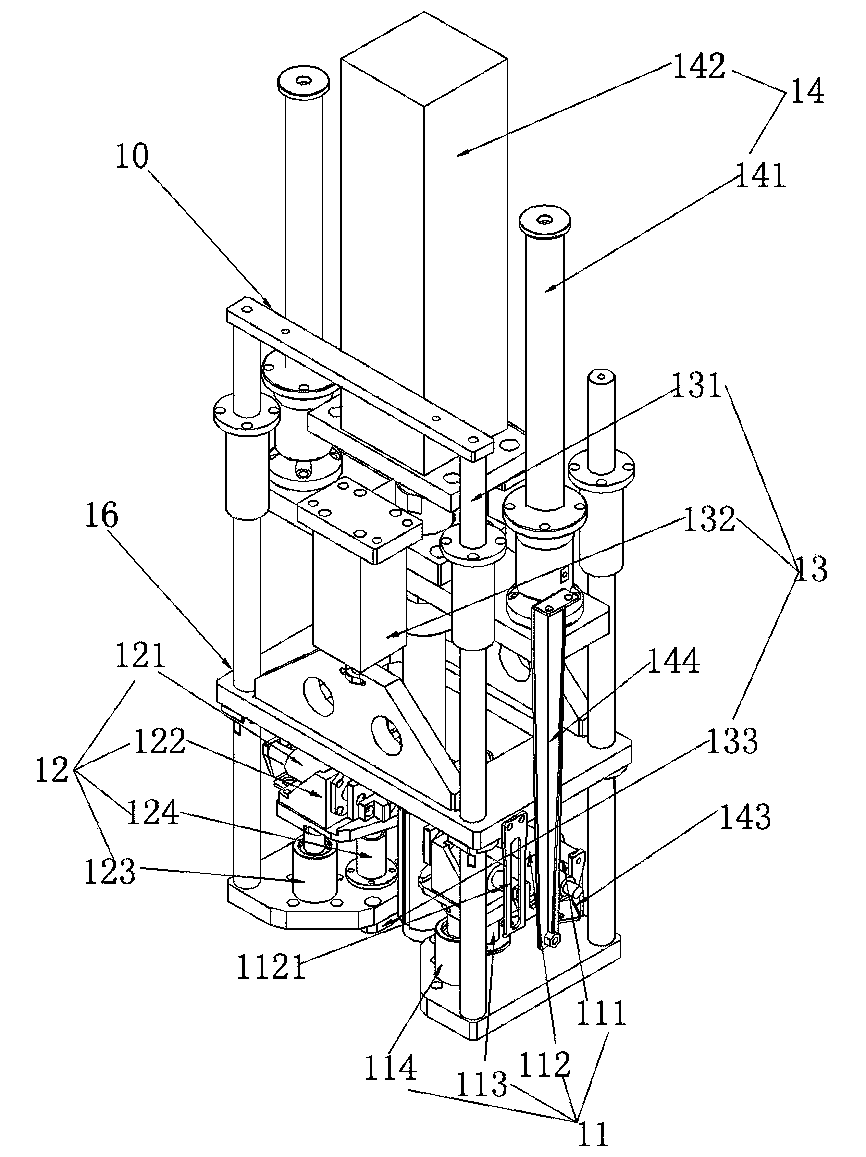

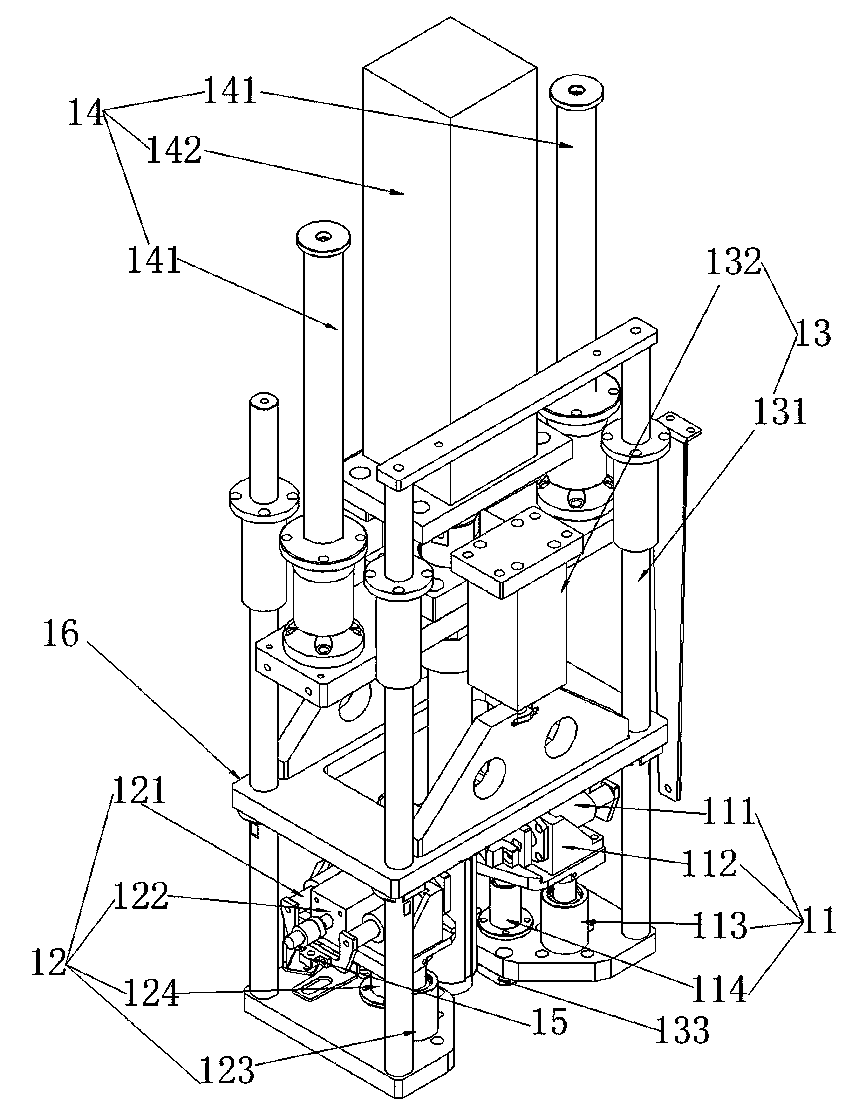

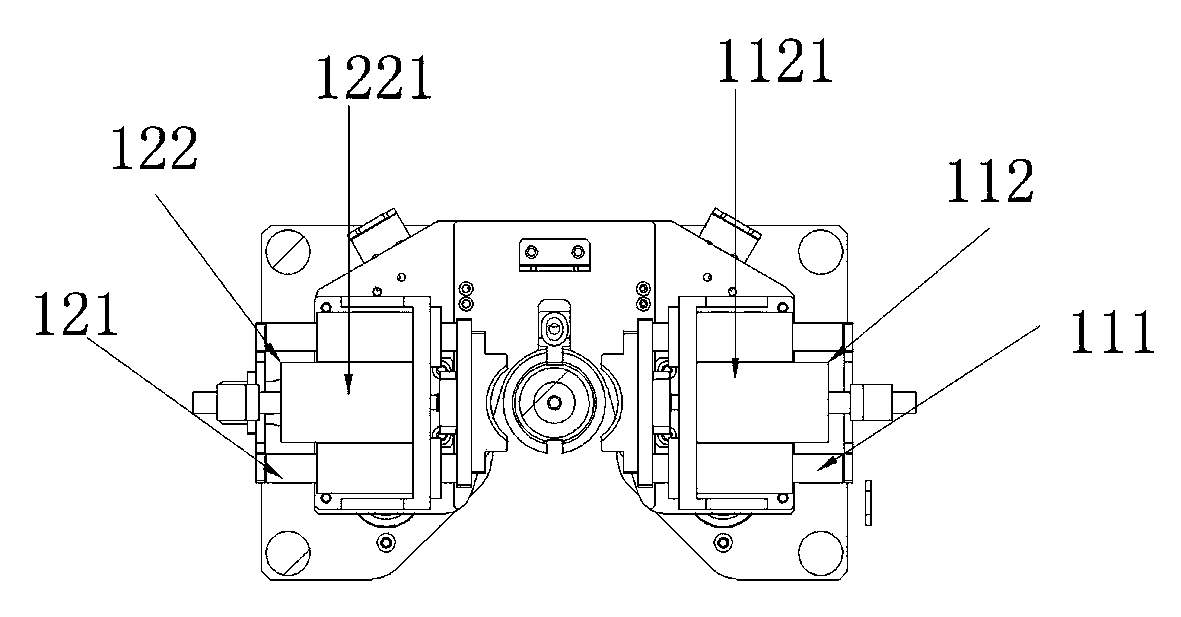

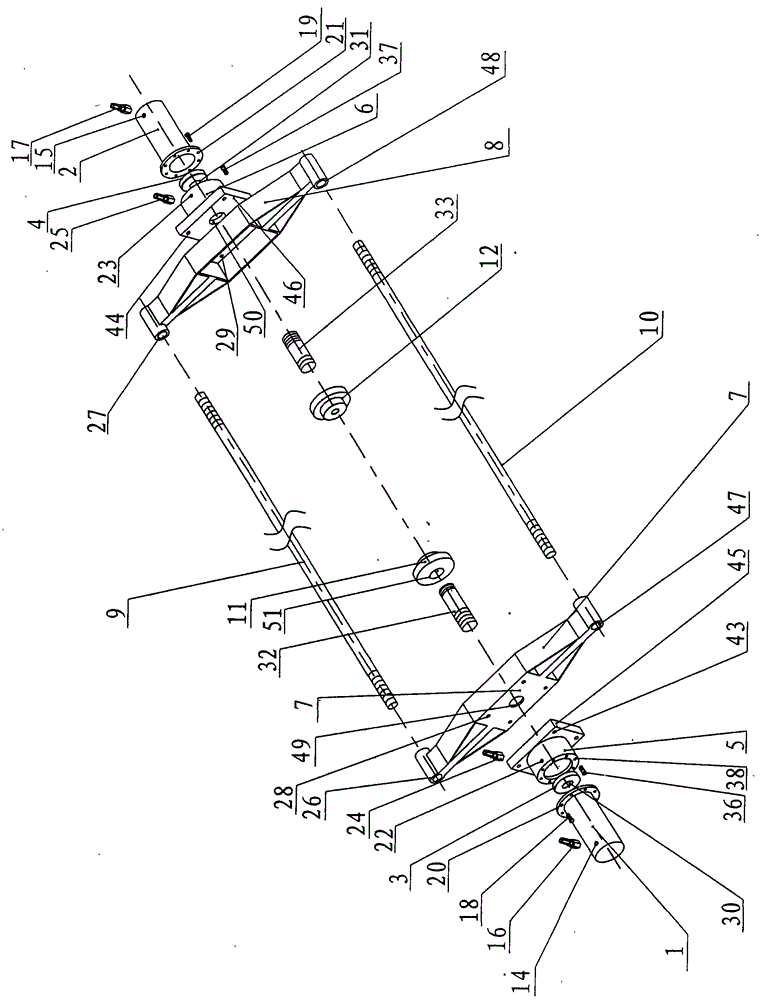

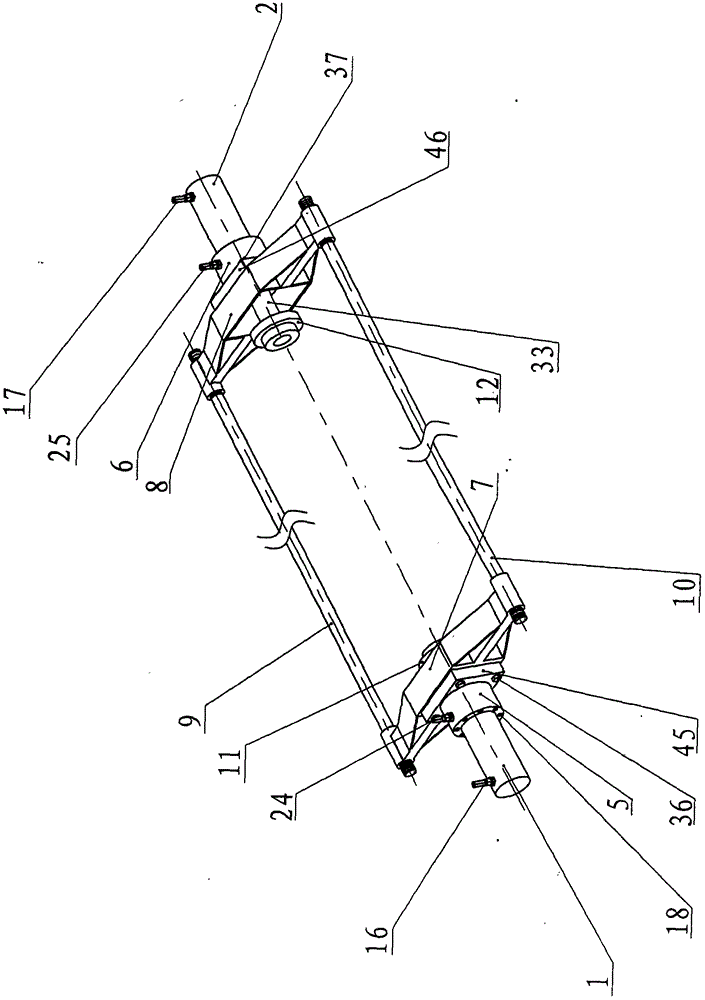

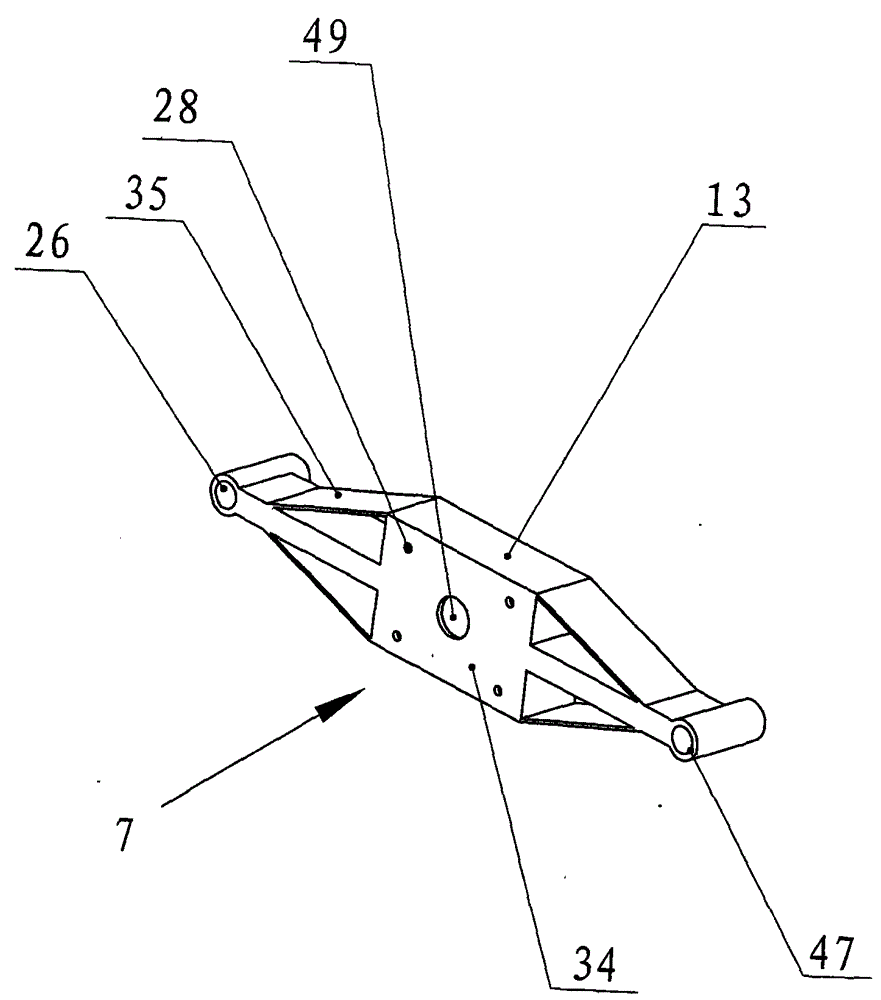

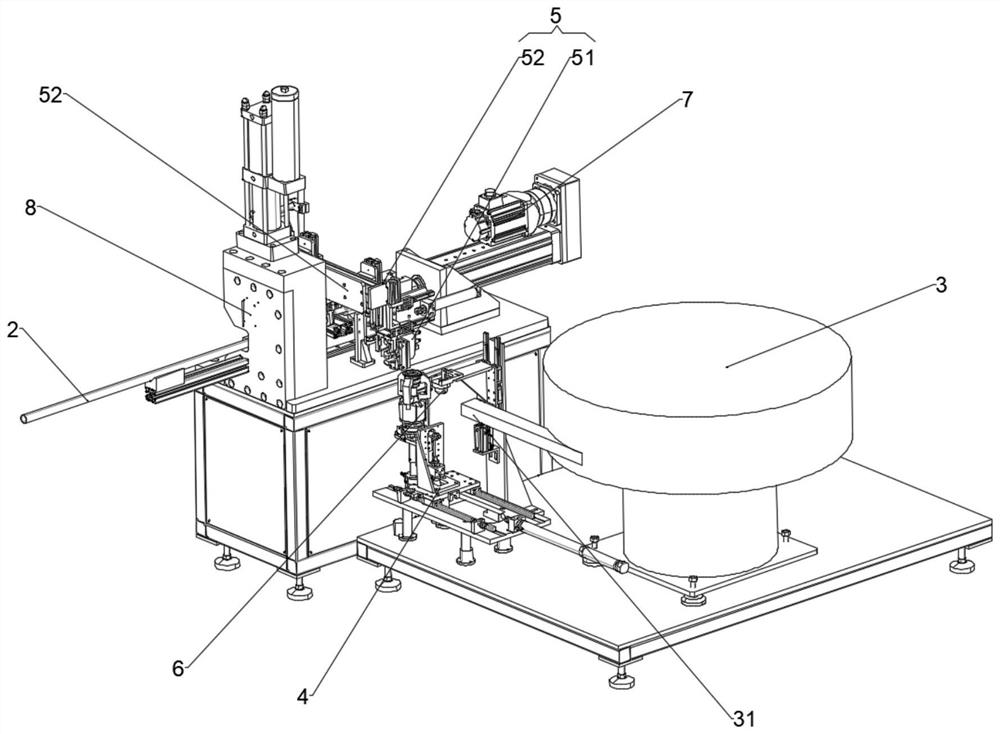

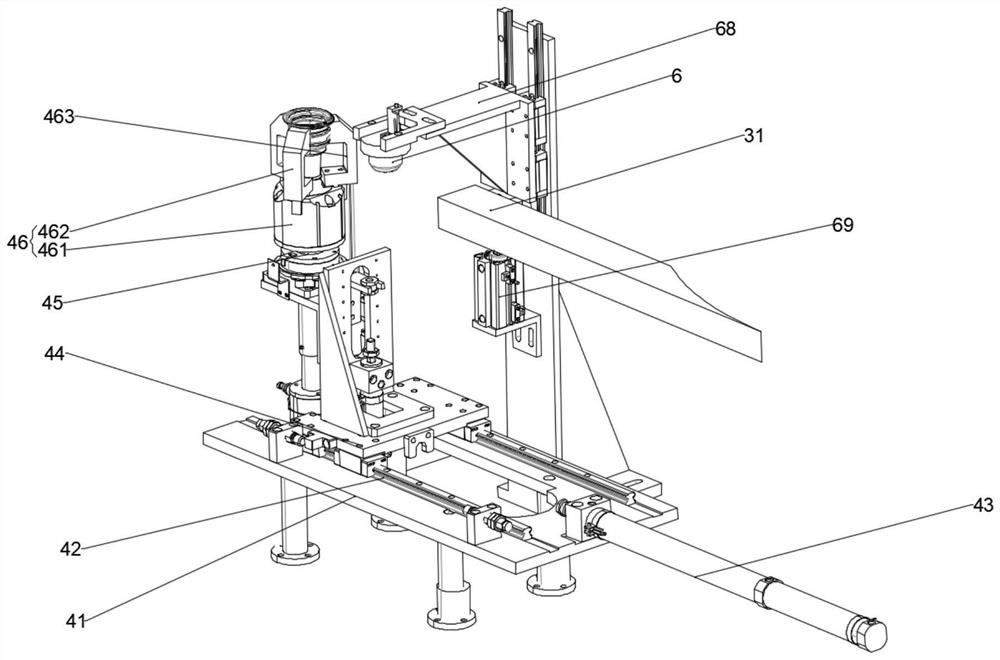

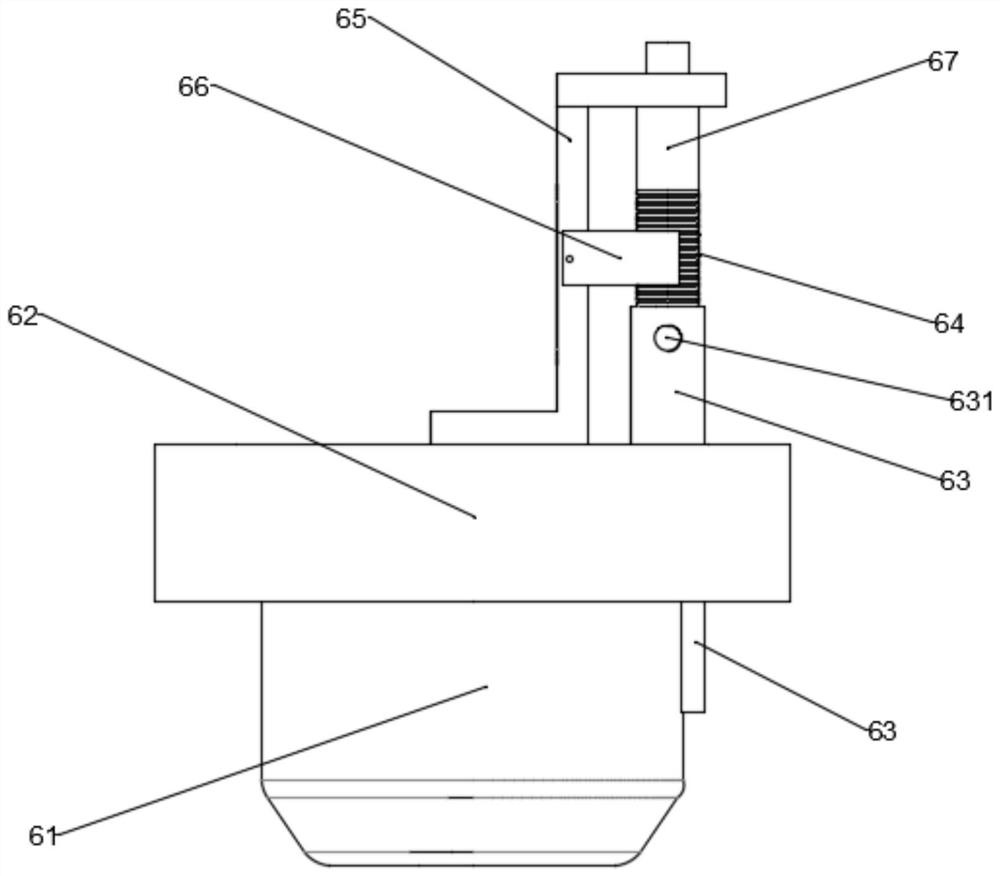

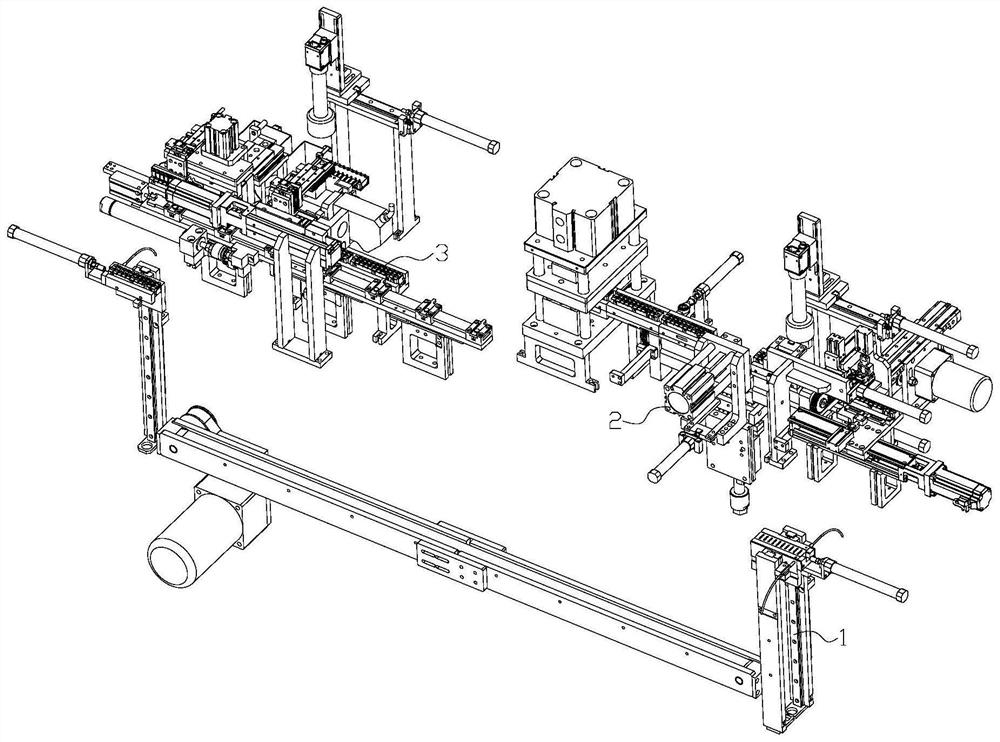

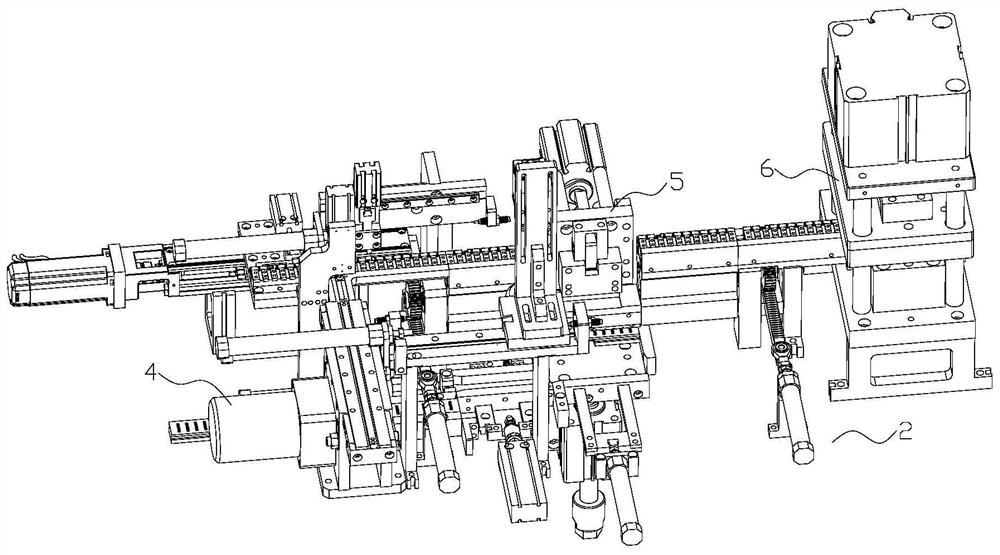

Chain assembly machine for U-shaped external single-joint agricultural machinery

ActiveCN108273955AHigh degree of automationIncrease the pressing speedMetal chainsFarm machineEngineering

The invention mainly discloses a chain assembly machine for U-shaped external single-joint agricultural machinery. The technical scheme is that a rack is included, a crossed base is arranged on a working table of the rack, a pin shaft press-fit mechanism is arranged above the crossed base, a first feeding mechanism for conveying U-shaped external single joints is arranged on one horizontal side ofthe crossed base, a base for conveying a chain out is arranged on the other horizontal side of the crossed base, a positioning and transferring mechanism is arranged on one vertical side of the crossed base and locates the U-shaped external single joints, a second feeding mechanism for conveying internal single joints and pin shafts is arranged on the other vertical side of the crossed base, theinternal single joints and the U-shaped external single joints are matched by the second feeding mechanism, a positioning mechanism is arranged below the working table and corresponds to the pin shaftpress-fit mechanism, and the pin shafts are connected to the U-shaped external single joints and the internal single joints by the positioning mechanism and the pin shaft press-fit mechanism. The chain assembly machine has the advantages of the press-fit speed is ultrahigh, and the degree of automation and the productivity are high.

Owner:HANGZHOU SHIELD CHAIN

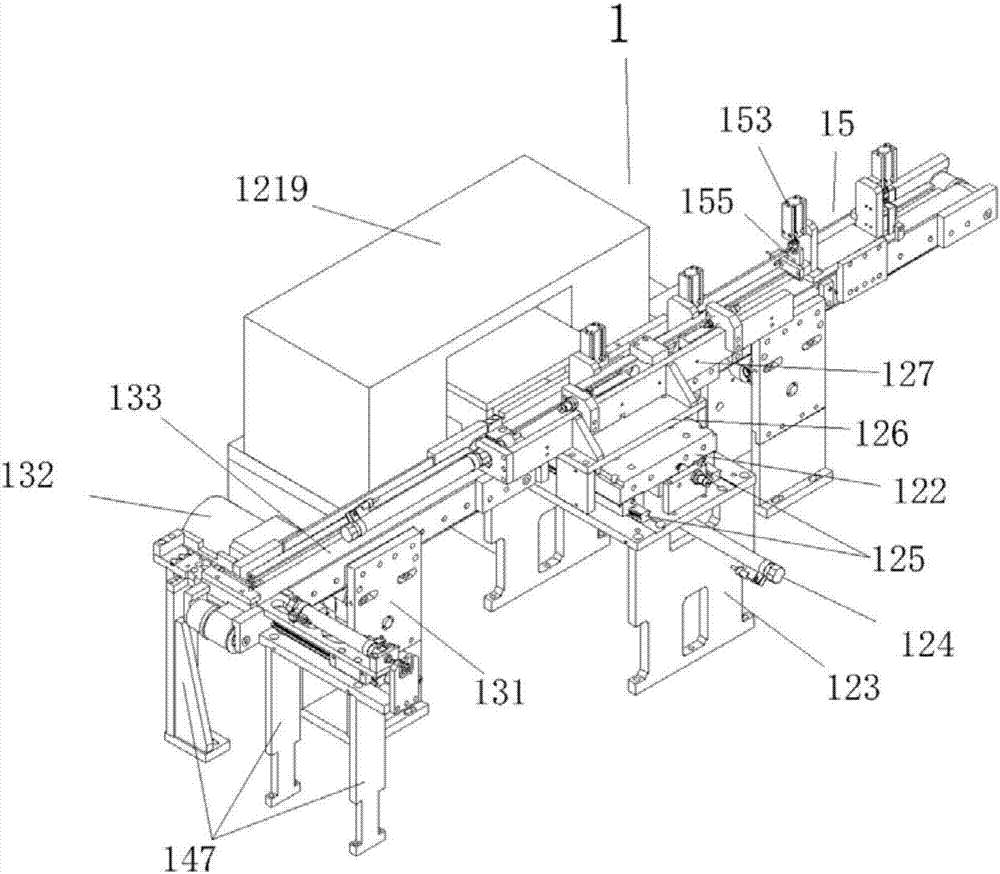

Electronic connector detection and discharging device and method

The invention relates to the field of electronic connectors, in particular to an electronic connector detection and discharging device and method and electronic connector assembling equipment. The device comprises a jig conveying mechanism, an overturning detection mechanism and a screening and discharging mechanism. The jig conveying mechanism, the overturning detection mechanism and the screening and discharging mechanism are all fixed to a workbench. The jig conveying mechanism is in sliding fit with a rubber core positioning jig, and an overturning detection station and a discharging station in the jig conveying mechanism are connected with the input end of the overturning detection mechanism and the input end of the screening and discharging mechanism correspondingly. By arranging the jig conveying mechanism, the number of air cylinders in the device is reduced, and the air cylinder cost of the device is reduced; by arranging the overturning detection mechanism, the labor intensity of workers is reduced, and the detection efficiency of electronic connectors is improved; and by arranging the screening and discharging mechanism, rapid discharging of the electronic connectors is guaranteed, and the automation degree of the device is improved.

Owner:DONGGUAN YUSEN PRECISION TERMINAL

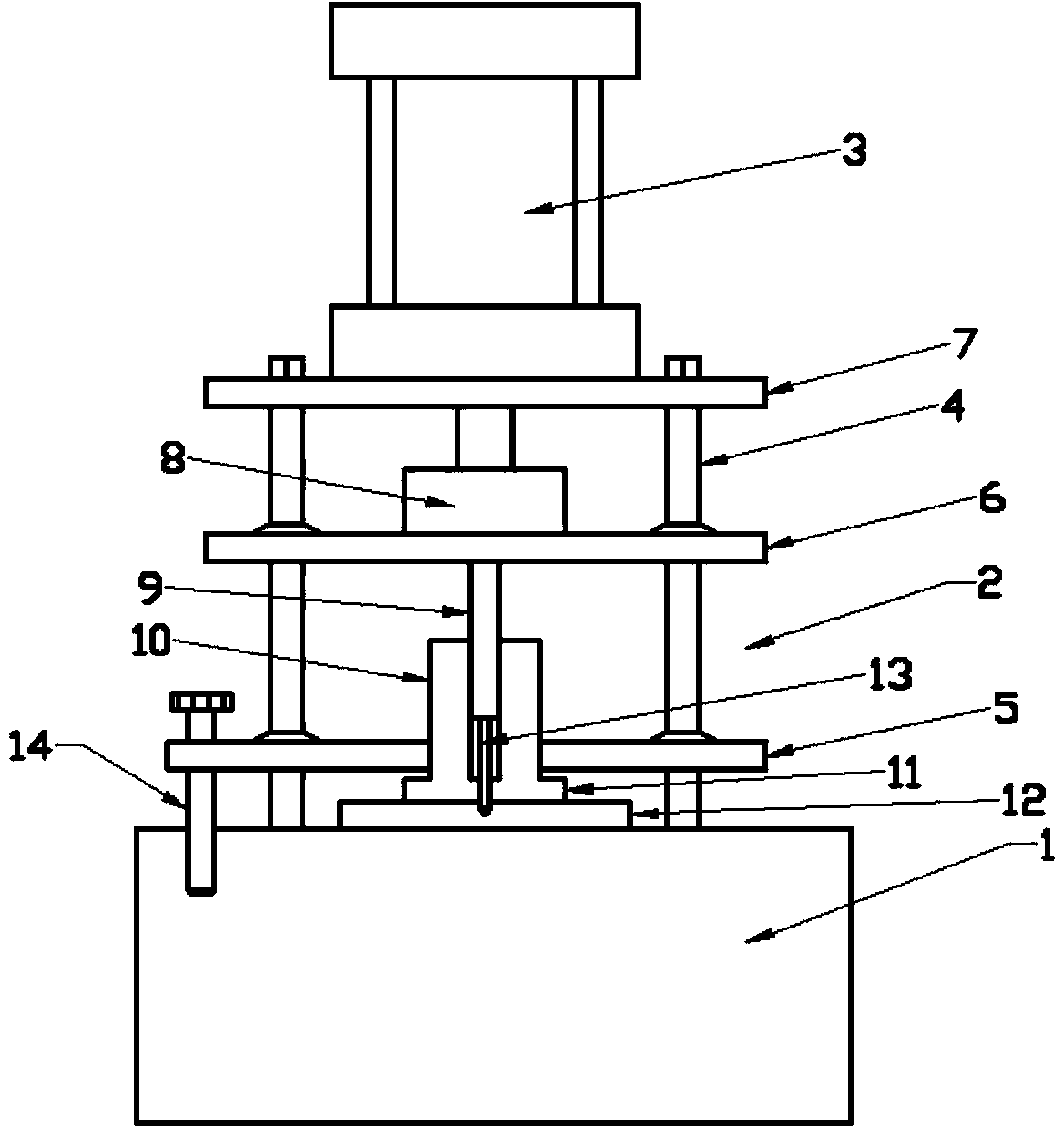

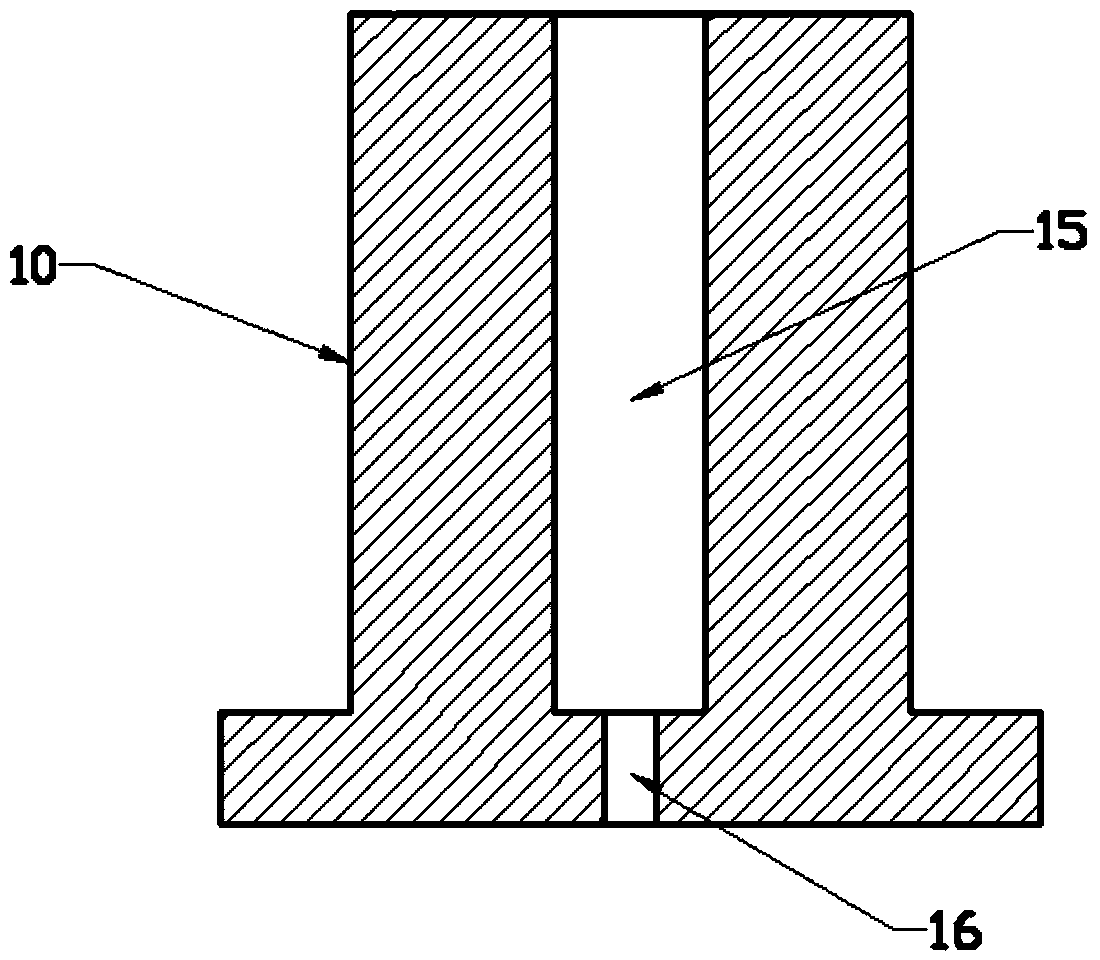

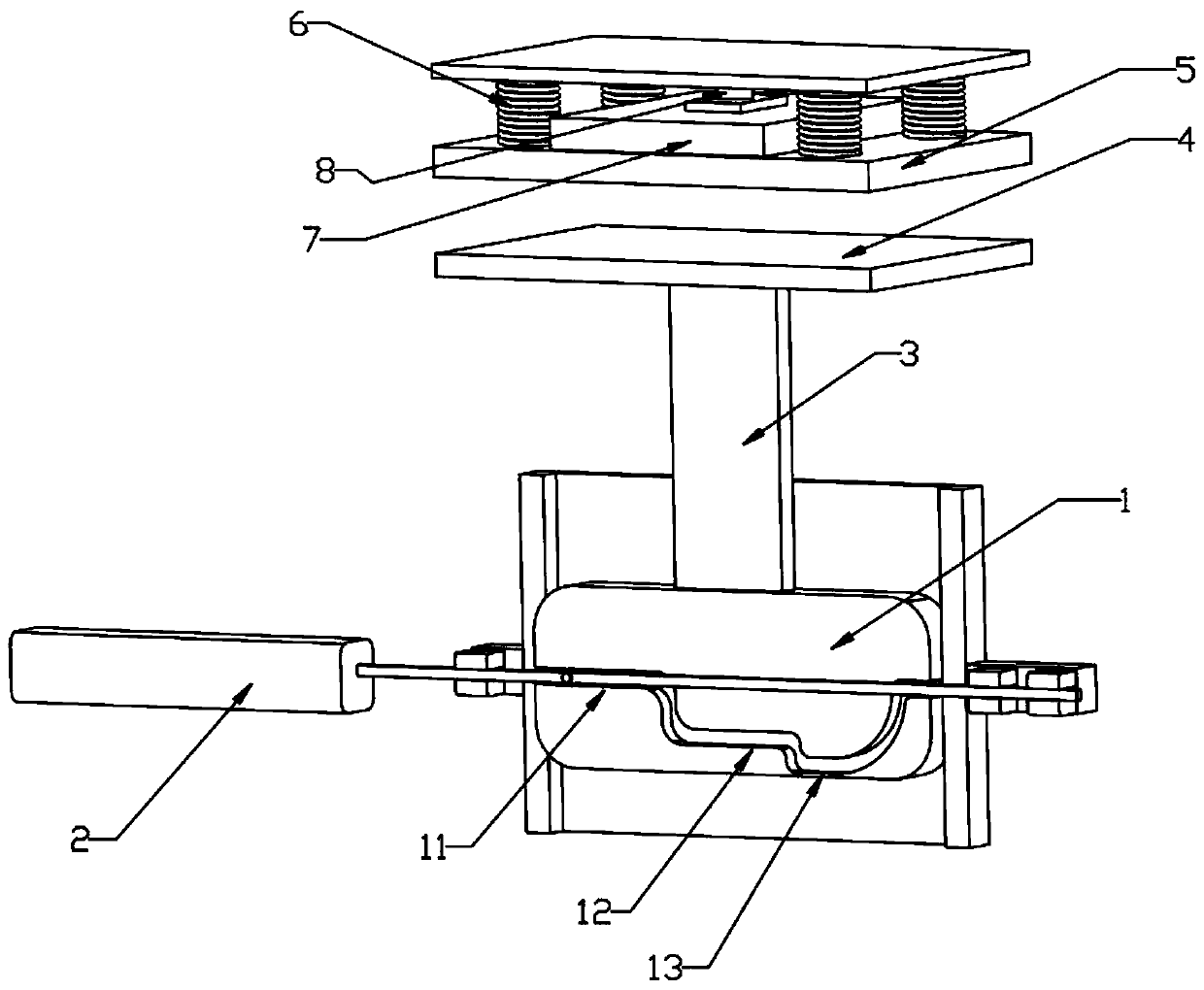

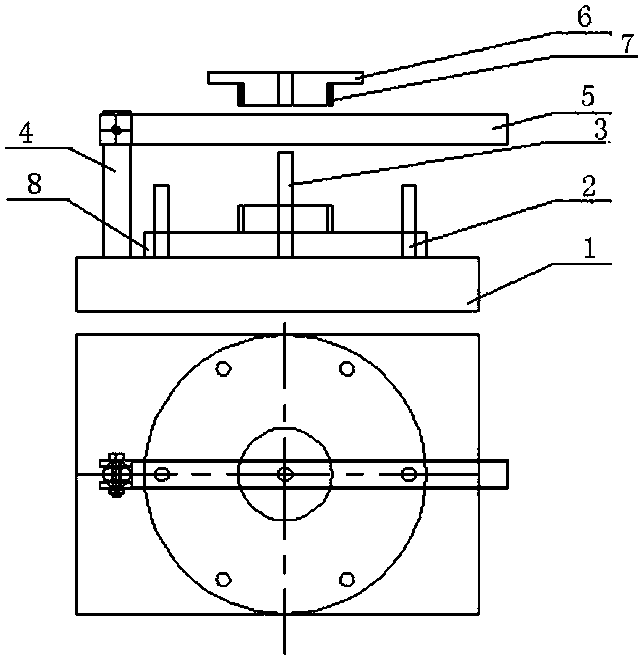

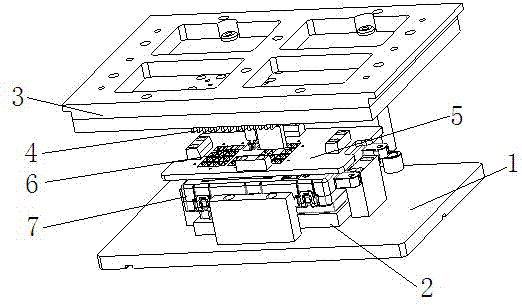

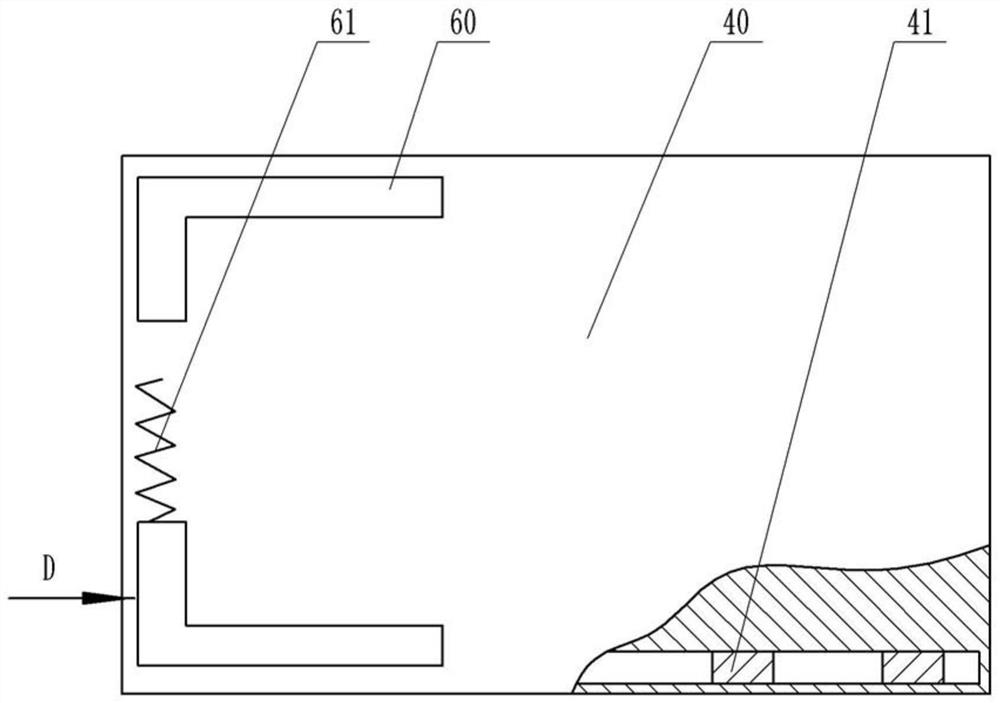

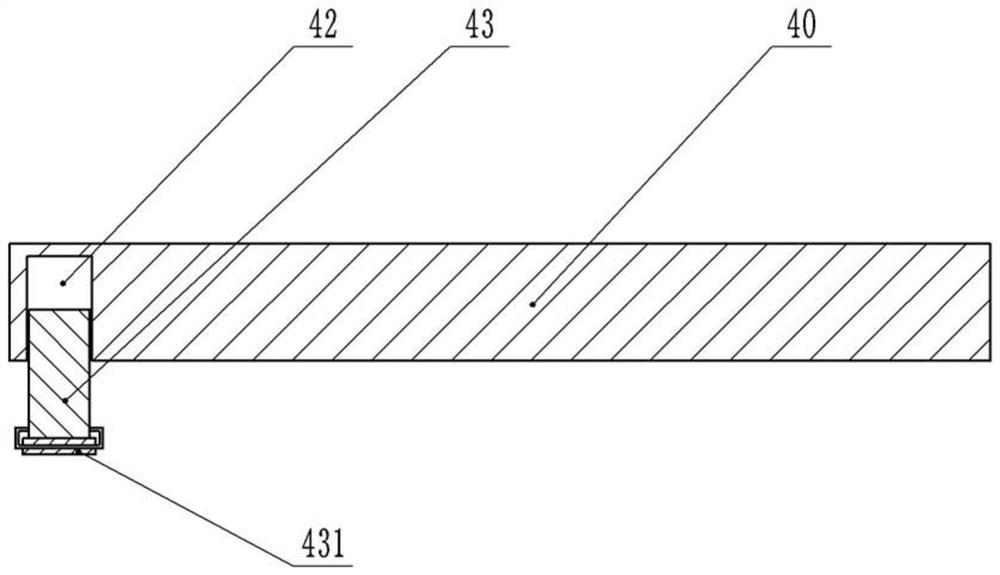

Auxiliary pressing device for rigid-flex board

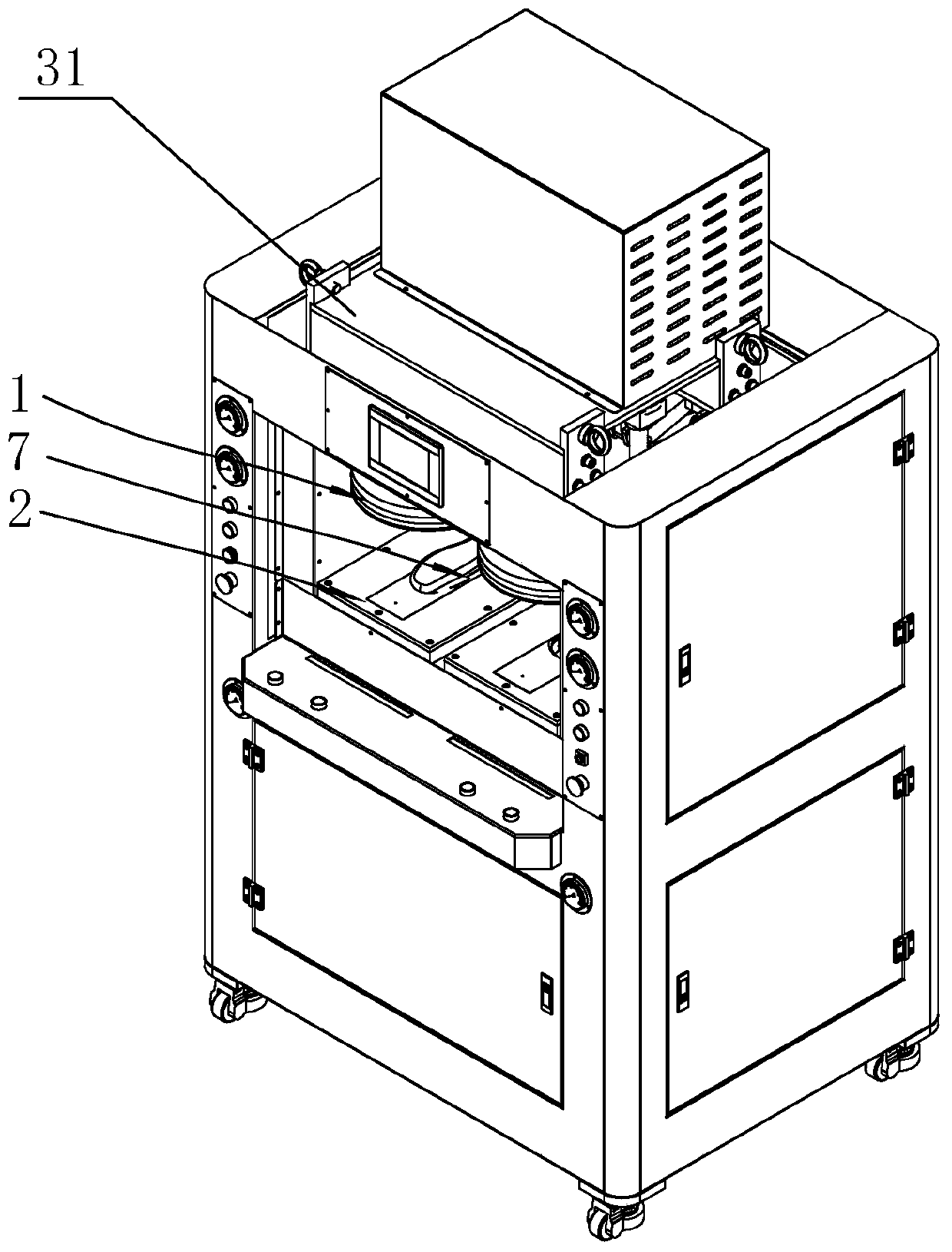

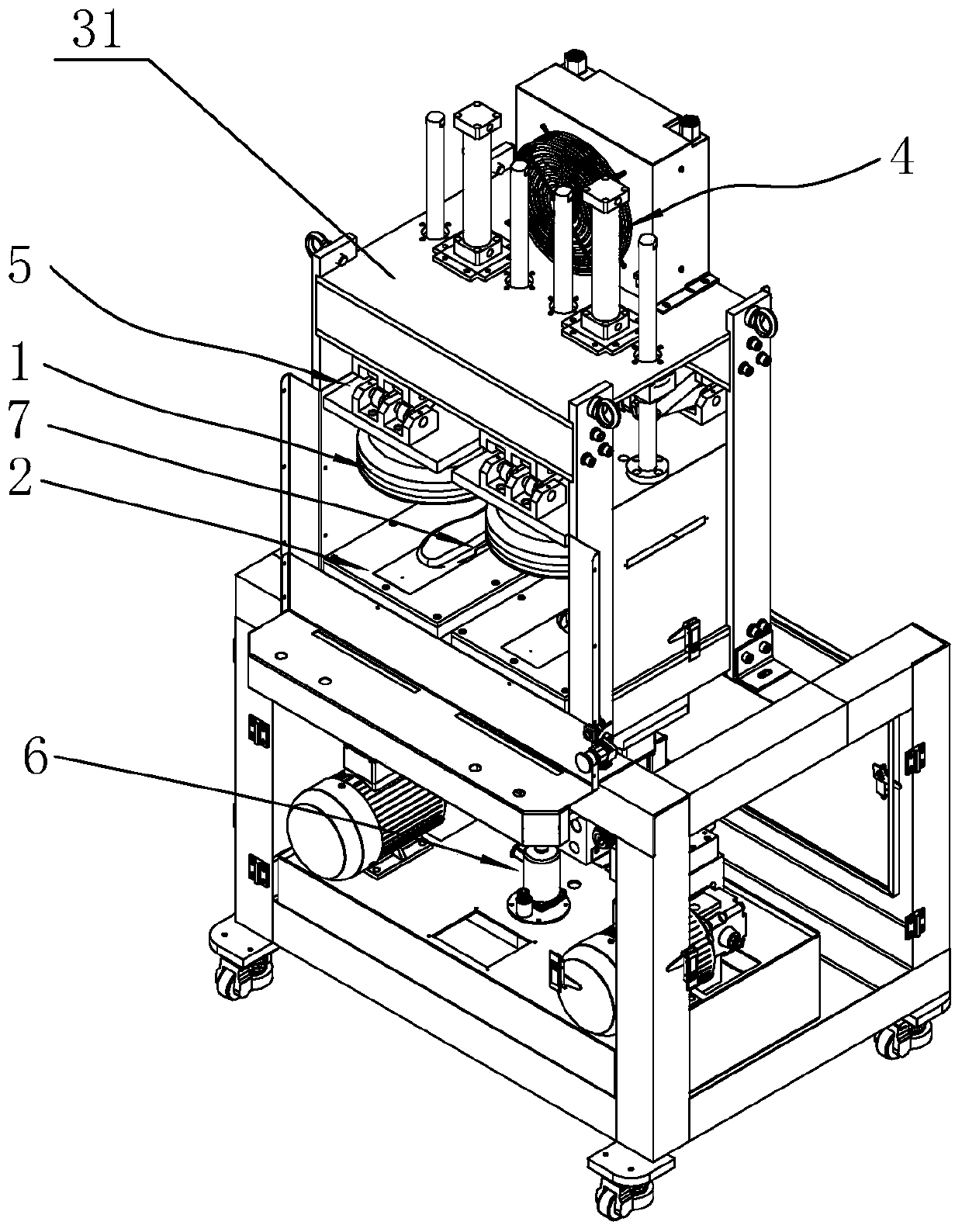

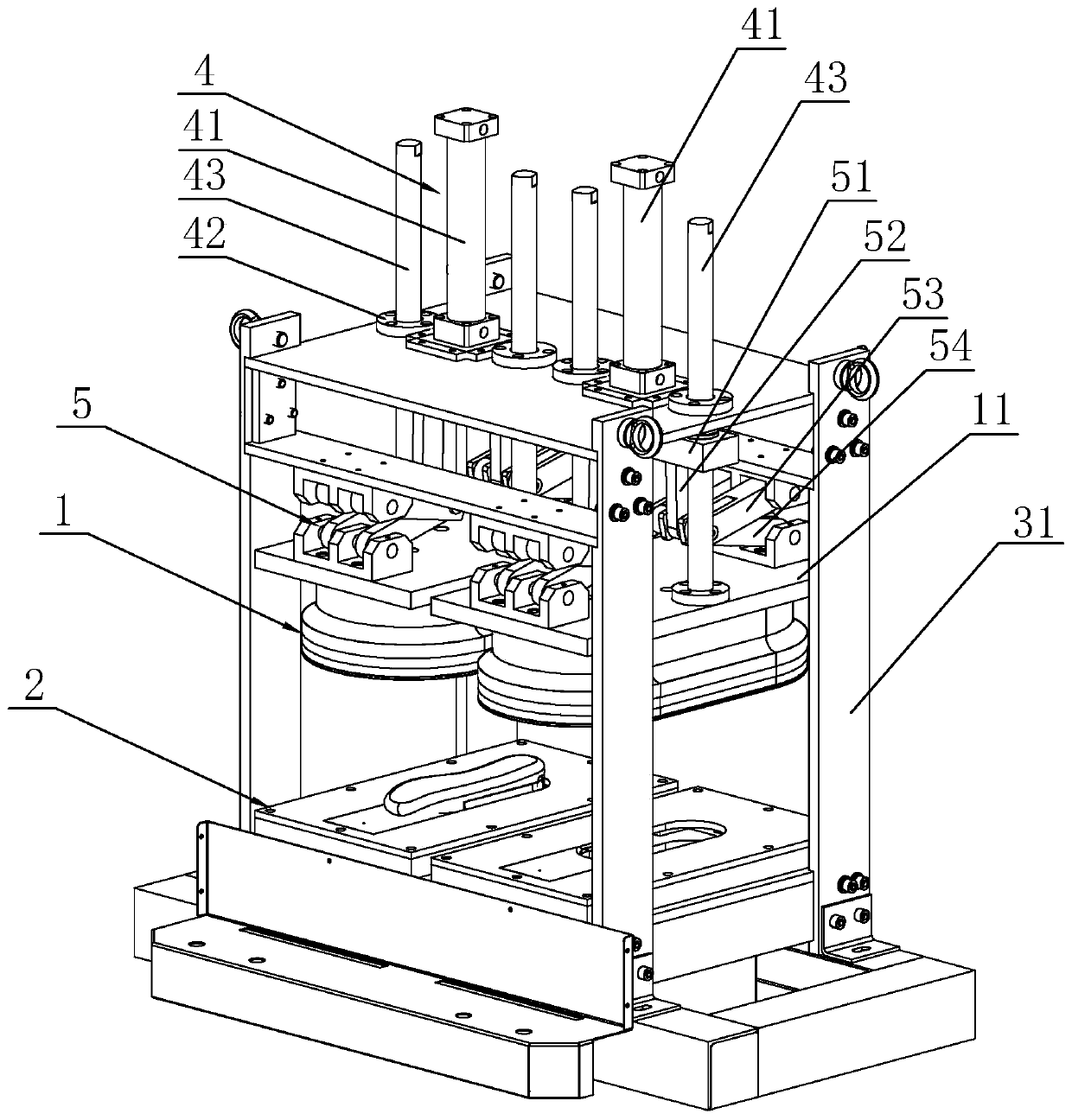

PendingCN110913610AHeating fastIncrease the pressing speedMultilayer circuit manufactureEngineeringPrinted circuit board

The invention discloses an auxiliary pressing device for a rigid-flex board. The auxiliary pressing device comprises an upper pressing plate and a lower pressing plate. The upper surface of the upperpressing plate is connected with the main frame through a plurality of springs; the lower surface of the lower pressing plate is connected with a sliding block through a connecting column, the slidingblock can move up and down along a vertical sliding rail, a horizontal air cylinder is arranged on the side face of the sliding rail, a guide rail groove set is formed in the surface of the sliding block, and the guide rail groove set comprises a first guide rail groove, a second guide rail groove and a third guide rail groove which are connected in sequence. A pulley is arranged at the front endof a push rod of the horizontal air cylinder and embedded into the guide rail groove set. Compared with a traditional air cylinder press fit mode, the mode that the sliding block, the guide rail, thespring, the upper pressing plate and the lower pressing plate are matched is adopted in the device, so that the whole heating and press fit process of the rigid-flex printed circuit board is rapidlycompleted, the machining efficiency is high, and the press fit speed is high.

Owner:江苏弘信华印电路科技有限公司

Press clamp for small commercial car assembly

ActiveCN104551618APressing speed is fastConstant pressureVehicle componentsMetal working apparatusEngineeringCar manufacturing

The invention discloses a press clamp for a small commercial car assembly and relates to the technical field of car manufacturing. The press clamp comprises a support, a vertical downward first air cylinder is arranged at the top of the support, a piston rod of the first air cylinder is connected with a pressure head which is connected with a gear shifting shifter location plate through a connection rod fixed by a limit block, a spring is assembled on the connection rod, the connection rod is disposed above the limit block, a press work table is arranged on the lower portion of the support, location pins are arranged on the upper table surface of the press work table, and a vertical upward second air cylinder is arranged on the lower table surface. A side support is arranged on the side of the press work table, a location sliding block is arranged on the upper portion of the side support, and a third air cylinder is arranged below the location block transversely. By means of the clamp, the problems of slow press speed and high reject rate of gear shifting shifter location pin pressing in an ordinary press mode can be solved.

Owner:柳州博昌汽车部件有限公司

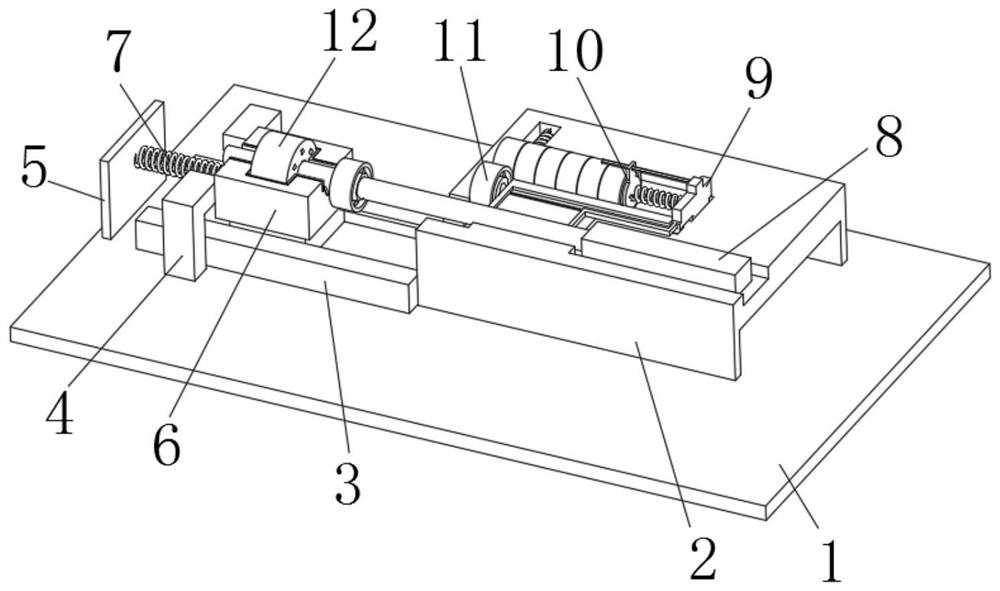

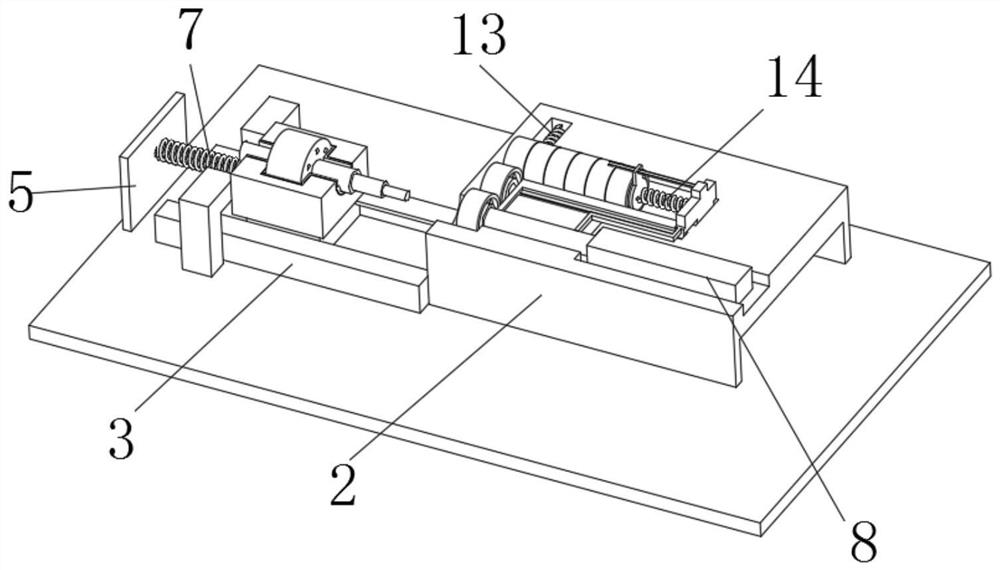

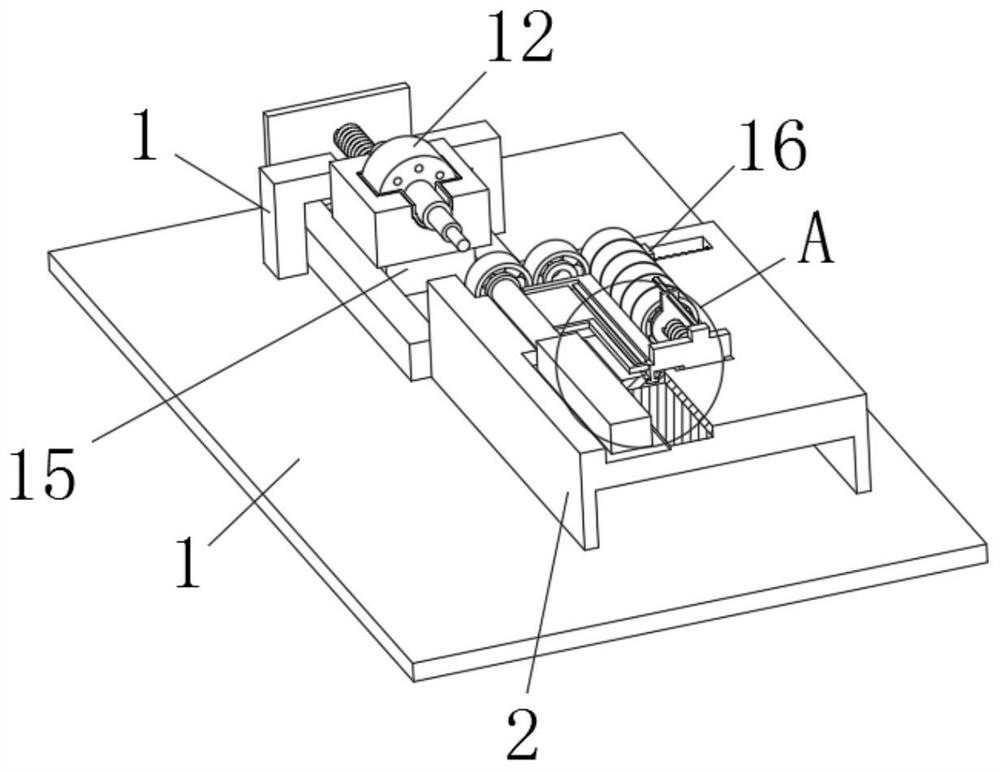

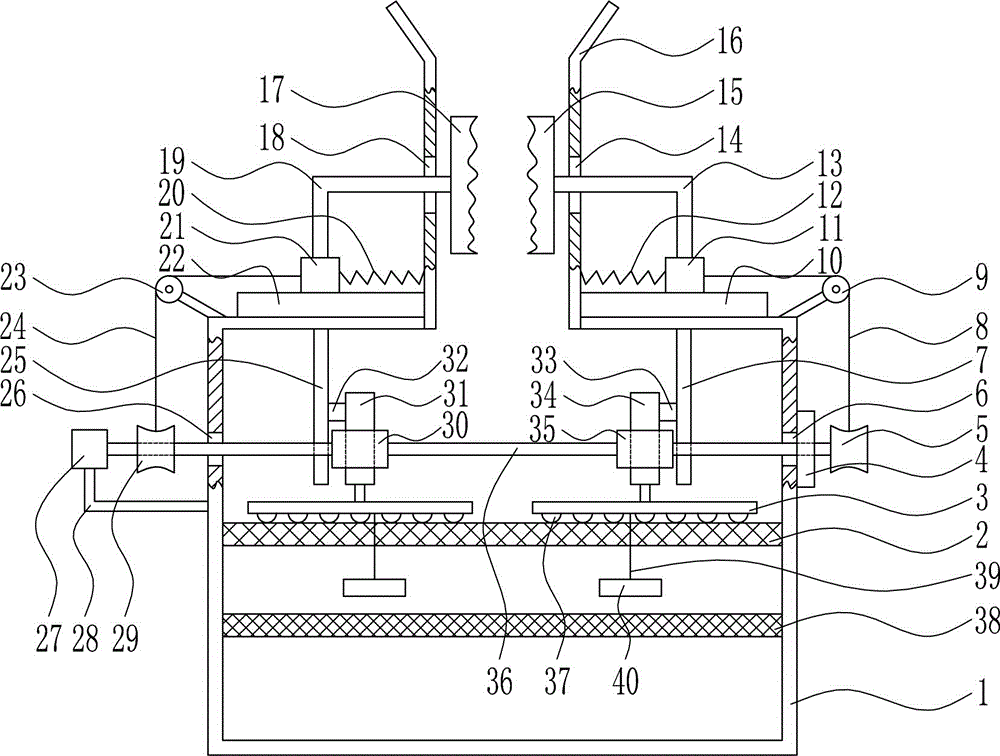

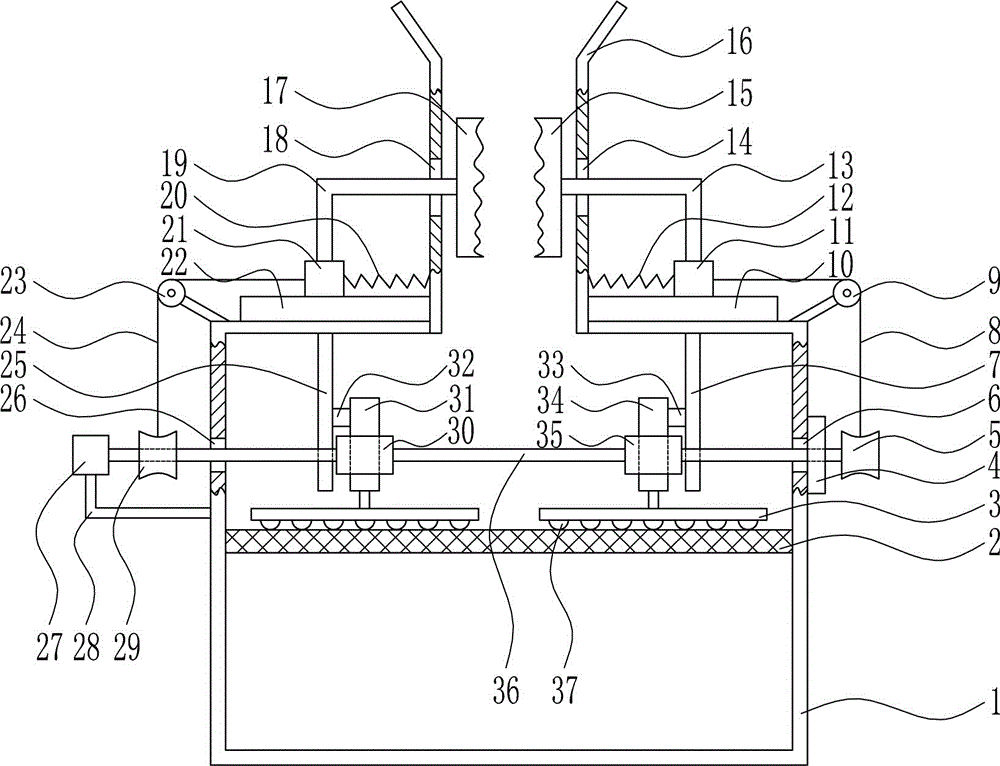

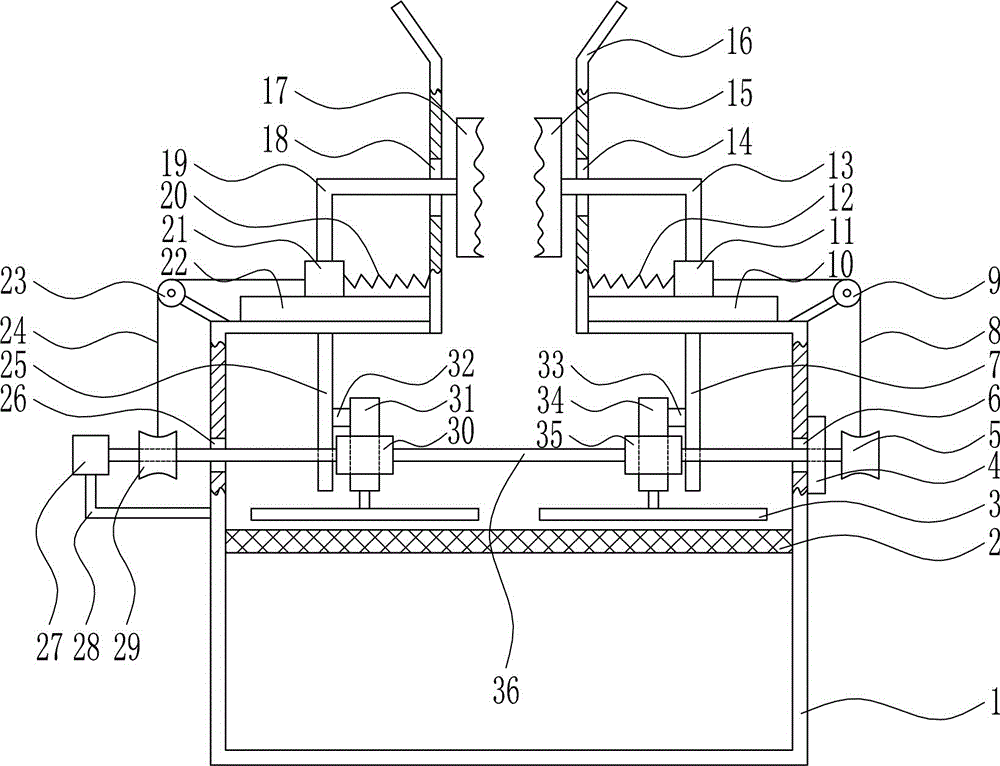

Manufacturing equipment of motor rotor

ActiveCN112039299AIncrease the pressing speedReasonable structureManufacturing stator/rotor bodiesIndustrial engineeringShaft alignment

The invention discloses manufacturing equipment of a motor rotor, and relates to the technical field of motor rotor manufacturing equipment. The manufacturing equipment comprises an operating table, wherein a U-shaped plate, a sliding rail, a pair of L-shaped baffles and a fixing plate are sequentially arranged at the top part of the operating table, and an air cylinder group is arranged at the top part of the U-shaped plate and comprises an air cylinder and a push rod, a connecting rod, a push plate, a push block, a plurality of bearings, a push spring and a push plate are arranged at the toppart of the U-shaped plate, one end of the connecting rod is installed on the push rod, and a guide rod is installed on the side wall of one side of the push plate. The manufacturing equipment is reasonable in structure, by arranging the connecting rod, the push plate, the push block, a thrust spring, the push spring and the push plate, after each bearing is press-fitted, the bearing placed on aplacement groove is automatically filled and fed, thus semi-automation is achieved, and time and labor are saved; and by arranging a placement block and a compression spring, the bearings do not needto be manually aligned with a rotor assembly shaft, and the press-fitting speed of the bearings is increased.

Owner:GUIXI HUATAI COPPER IND CO LTD

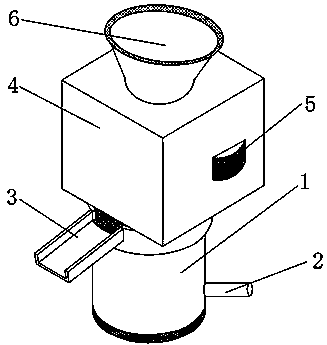

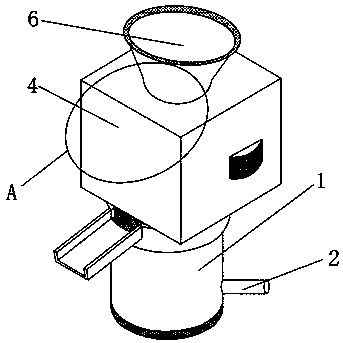

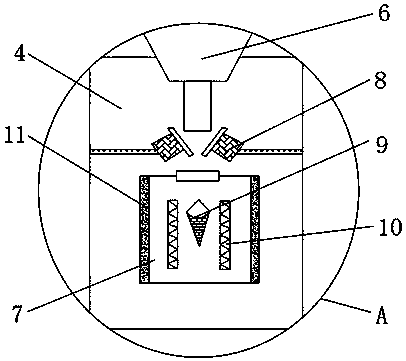

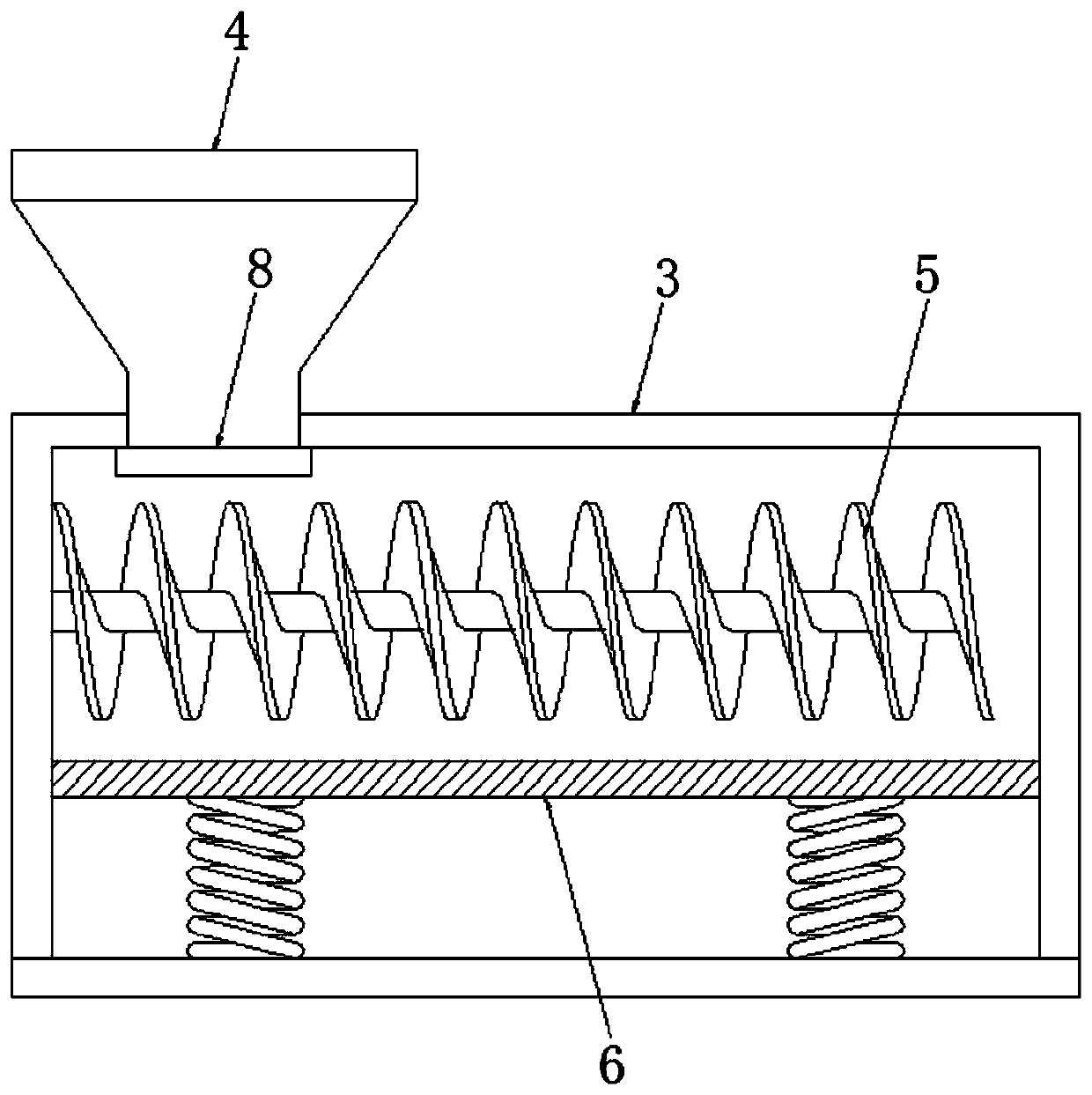

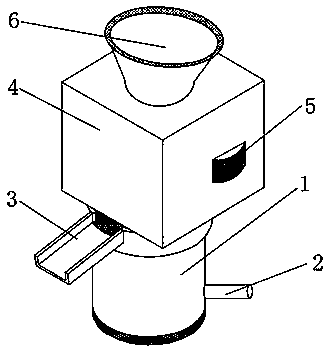

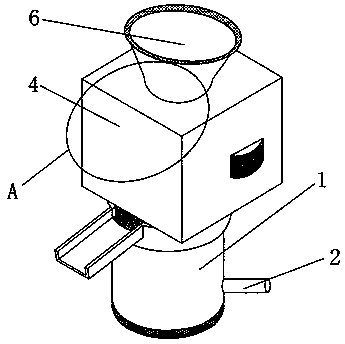

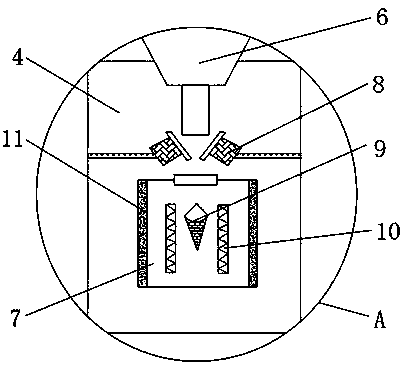

Ginseng extracting device capable of saving cost

InactiveCN108407364AClean in timeAvoid pollutionCleaning using liquidsMetal working apparatusGINSENG EXTRACTEngineering

The invention discloses a ginseng extracting device capable of saving cost. The ginseng extracting device capable of saving cost comprises an extracting tank and a waste residue collecting tank. A liquid outlet pipe is fixedly installed on the outer side of one end of the extracting tank, a double helix presser is fixedly installed on the outer side of the upper end of the extracting tank, a motoris arranged on the outer side of one end of the double helix presser, a discharging hopper is fixedly installed on the outer side of the upper end of the double helix presser, a pressing box and cutting blades are arranged in the middle in the double helix presser, and a hammer-shaped body is arranged in the pressing box. The ginseng extracting device capable of saving cost is provided with the waste residue collecting tank, the double helix presser and rotating sprayers, waste residues can be collected, profits can be increased, production cost can be saved, the speed of ginseng pressing canbe increased, extracting efficiency is improved, the interior of the device is protected against pollution, the service life is prolonged, and the ginseng extracting device capable of saving cost isapplicable to different working conditions and brings better application prospects.

Owner:安徽郁萃生物科技有限公司

Bolt pressing fit machine

PendingCN108747330ARealize press fitIncrease the pressing speedMetal working apparatusEngineeringTransfer mechanism

The invention relates to a bolt pressing fit machine which comprises a machine case. The machine case is sequentially provided with a feeding station, a bolt installing station, a bolt pressing station and a discharging station; and the machine case is further provided with a transferring mechanism for transferring a disc-shaped workpiece from a last station to a next station. The bolt pressing fit machine has the beneficial effects that press fit of bolts on the disc-shaped workpiece can be achieved in a full-automatic manner, the press fit speed is high, and the production efficiency is greatly increased.

Owner:宁波江宸智能装备股份有限公司

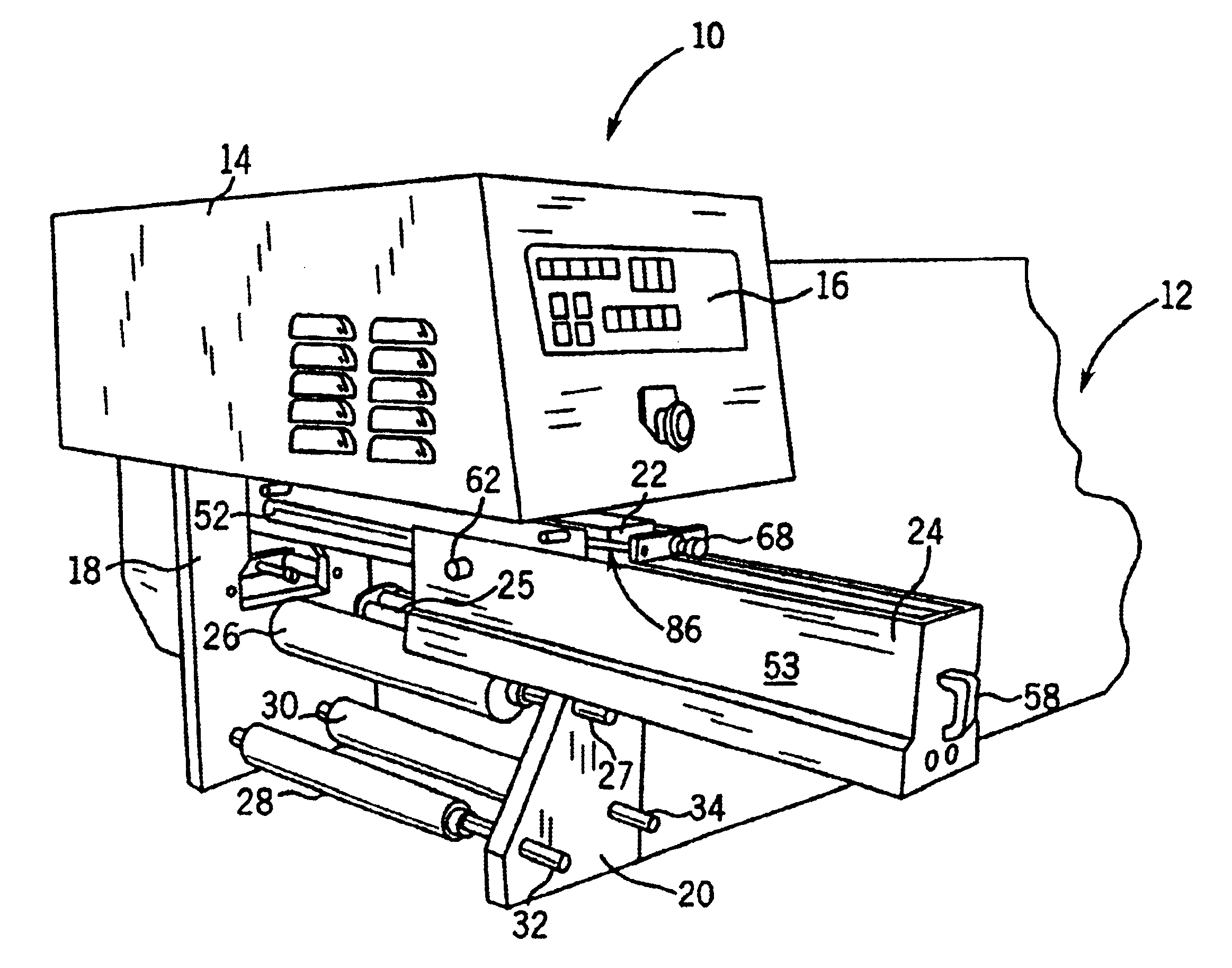

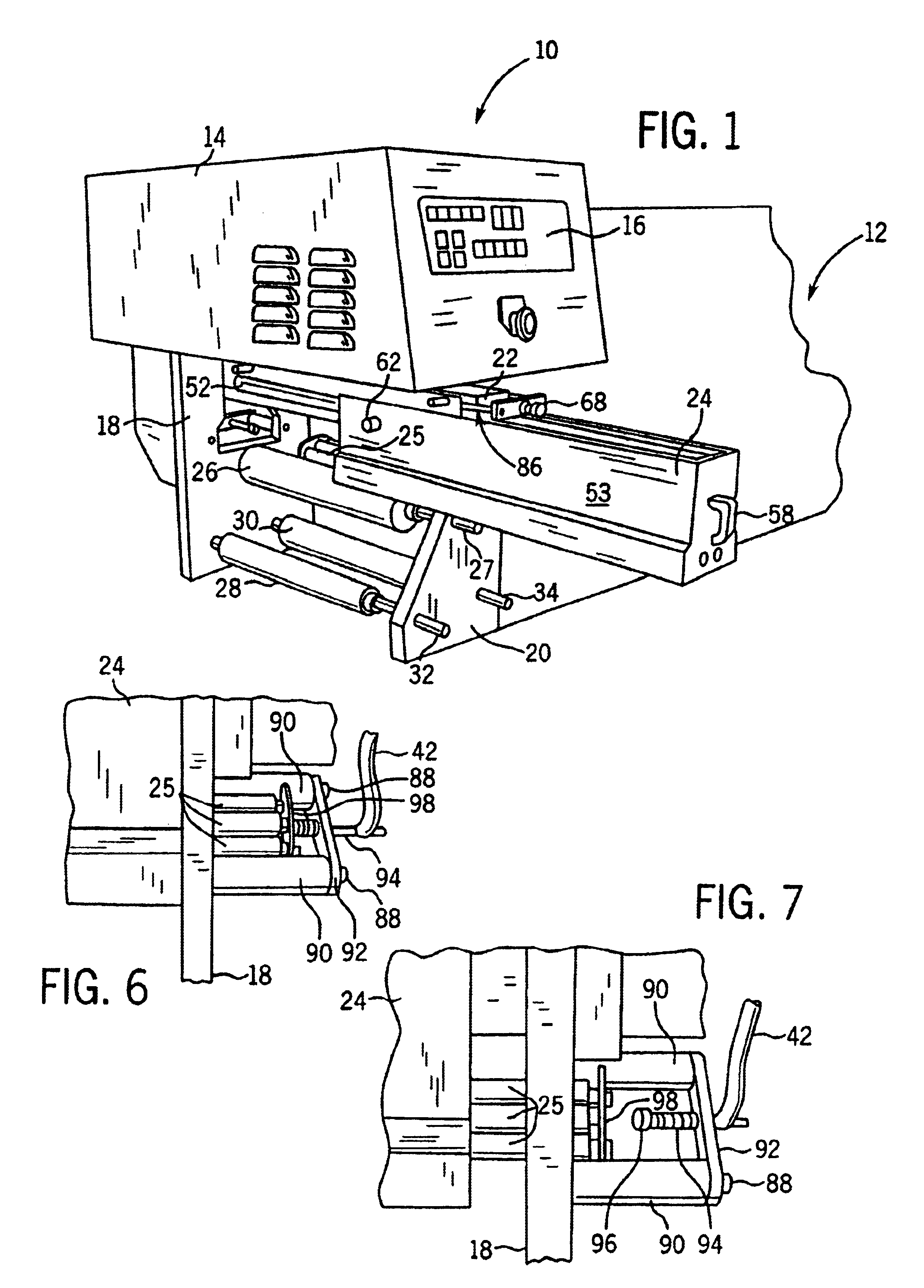

Narrow web corona treater

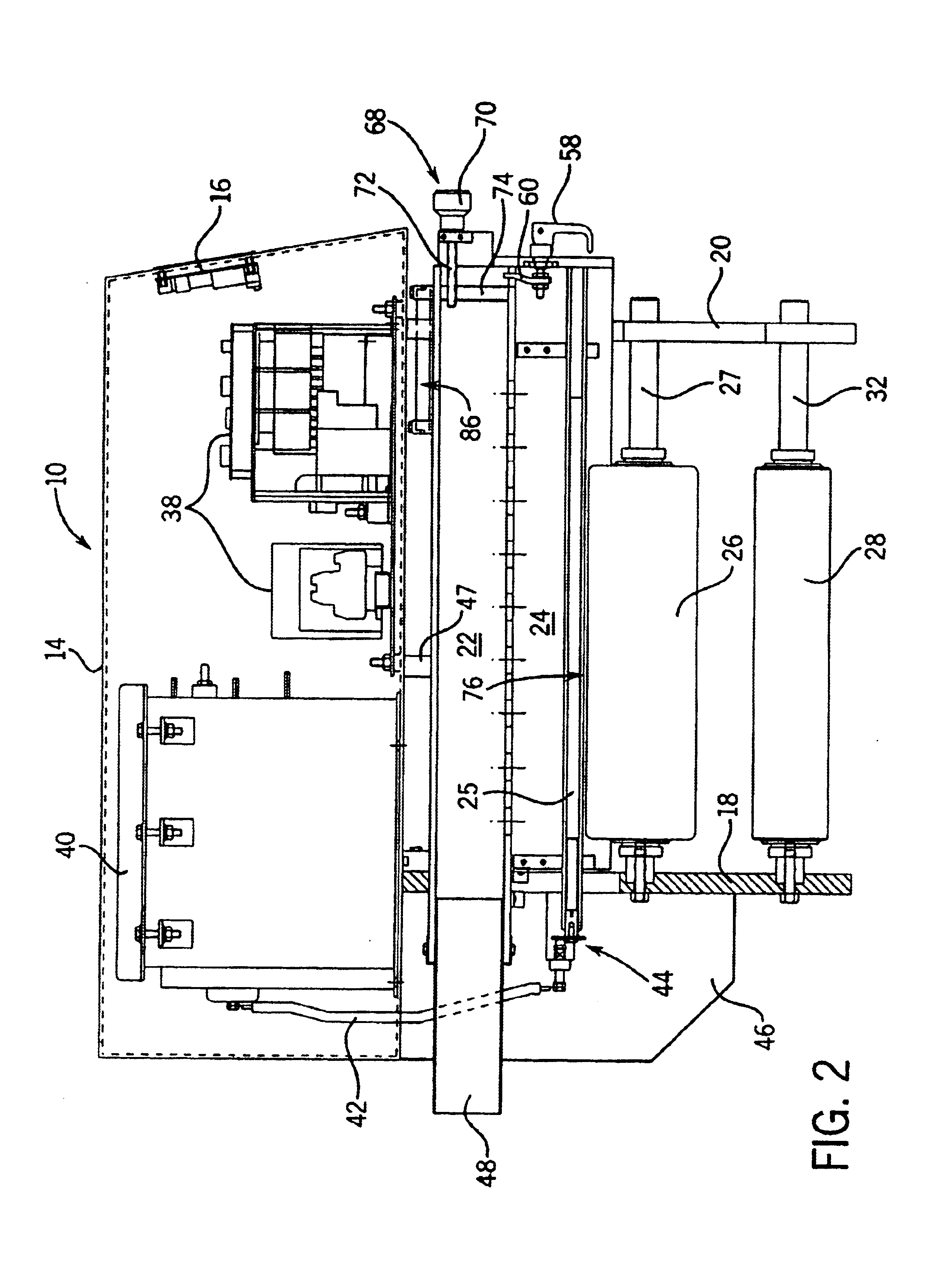

InactiveUS6894279B2High quality printingQuick installationMaterial analysis by optical meansCorona dischargeOn boardCorona discharge

A corona discharge device is adapted to be used in conjunction with a printing press. The device includes a cabinet housing an on-board power supply associated with a high voltage transformer. A rear end plate and a front end plate spaced apart in parallel relationship from the rear end plate both depend from the cabinet. An electrode support tube is fixedly mounted to the cabinet and has an electrode magazine slidably mounted on the support tube between an operative position and an inoperative position, the magazine including a series of parallel electrodes. A grounded treater roll is rotatably mounted on a first shaft between the rear end plate and the front end plate and below the support tube. A pair of spaced idler rolls is rotatably mounted on respective second and third shafts between the rear end plate and the front end plate below the treater roll such that a flexible web is guided upwardly by the idler rolls and wound about the treater roll beneath the electrodes.

Owner:ILLINOIS TOOL WORKS INC

Vacuum die-free forming sole pressing machine and using method thereof

InactiveCN111528583AImprove sealingImprove the pressing effectSolesShoe gluingEngineeringPumping vacuum

The invention relates to the field of shoemaking equipment, in particular to a vacuum die-free forming sole pressing machine and a using method thereof, and is characterized in that the vacuum die-free forming sole pressing machine comprises an upper rack, a pressing driving mechanism, a side pressurizing mechanism, a pressing assembly, a vacuum assembly, a lifting mechanism and a clamping mechanism; the vacuum assembly is fixed to the bottom of the upper rack, the pressing assembly is located over the vacuum assembly, the pressing assembly is driven by the pressing driving mechanism to be attached to or away from the vacuum assembly, and the side edge pressurizing mechanism is connected with the upper rack, the pressing driving mechanism and the pressing assembly in a pivoted mode. According to the vacuum die-free forming sole pressing machine, the pressing assembly and the vacuum assembly can be tightly matched, and the sealing performance and the pressing effect are improved; the shoe tree and the shoe body are positioned and fixed in all directions through the clamping mechanism, and the shoe sole and the vamp are prevented from deviating in the pressing process; the mode of combining hydraulic positioning and vacuumizing positioning is adopted, the operation steps are simple, positioning is accurate, and meanwhile the pressing speed is increased.

Owner:福建中泰德玛智能设备有限公司

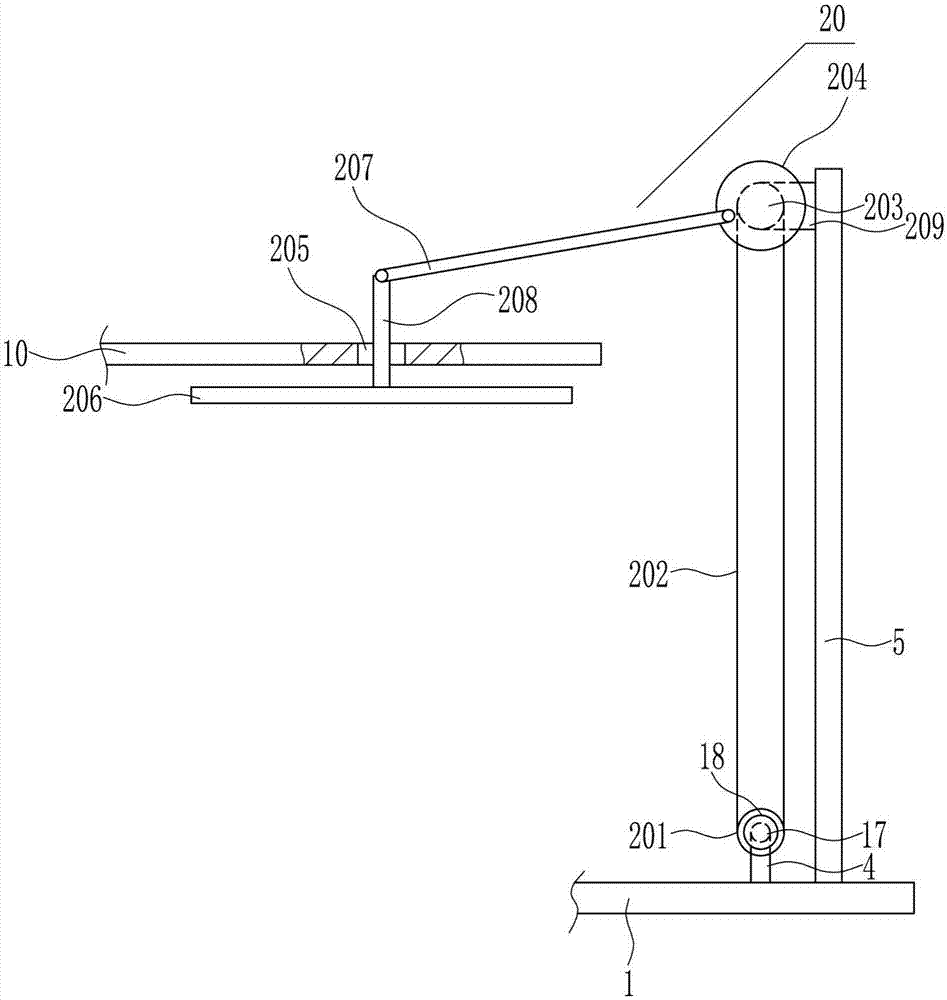

Processing system for garments

ActiveCN110239193AImprove work efficiencyCloth pressing speed is fastLaminationLamination apparatusEngineeringMechanical engineering

The invention relates to the field of garment processing, and more particularly relates to a cutting system for garments. The system comprises a fabric unwinding roller, a machine frame, a fabric intermittent unwinding and winding driver, a style cutter, a fabric receiver, a fabric aligner and a recycling box; and the fabric unwinding roller is rotatably connected to the front end of the machine frame, the fabric intermittent unwinding and winding driver is rotatably connected in the machine frame, the style cutter is meshed with the fabric intermittent unwinding and winding driver, and the fabric intermittent unwinding and winding driver drives the style cutter to have reciprocating displacement on the machine frame in the vertical direction. The system provided by the invention has the beneficial effects of quickly and automatically cut batch-shaped and roller-shaped fabrics into a specified demand shape without manual operation, saving manpower, changing cutters with different shapes according to actual production requirements and being very convenient and quick.

Owner:贵州雨林服饰有限公司

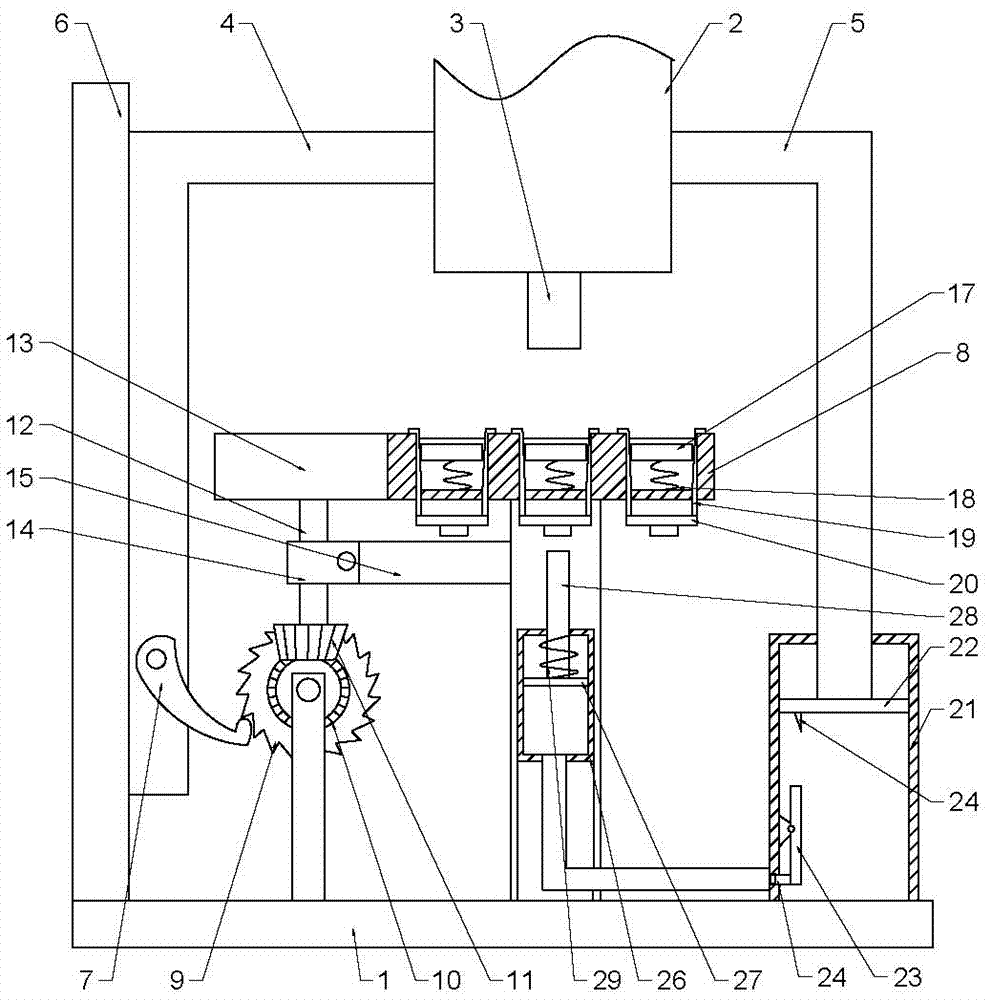

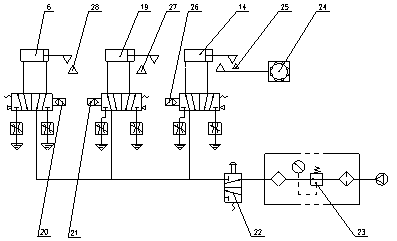

Pneumatic control rotary multi-station automatic lever powder pressing machine

ActiveCN109318520ASuitable for pressing medicineImprove securityPress ramShaping pressEngineeringMechanical engineering

The invention discloses a pneumatic control rotary multi-station automatic lever powder pressing machine, and relates to the technical field of special equipment of initiating explosive device powderpressing for fuze. The pneumatic control rotary multi-station automatic lever powder pressing machine comprises a lever powder pressing machine body, and a rotating mechanism, a locating mechanism anda pressure mechanism are mounted on the lever powder pressing machine body. According to the pneumatic control rotary multi-station automatic lever powder pressing machine, safety is high, after a conventional lever powder pressing machine is transformed, powder pressing action is automatically carried out in a shielding cavity, and even though accidents occur, operating personnel can be isolatedfrom explosion and are not hurt; a powder pressing die stably rotates and presses powder under the action of a cylinder, shock and electrostatic interference are avoided during the process, and the machine is quite suitable for initiating explosive device powder pressing; if accidents occur, operating personnel can press an explosion-proof hand valve to make the equipment stop running; efficiencyis high, the conventional lever powder pressing machine only has one station, the pneumatic control rotary multi-station automatic lever powder pressing machine can have multiple stations, the powderpressing speed is greatly increased, and labor intensity of operating personnel is reduced as well; and selected components are easy to obtain, and transformation cost is low.

Owner:江西星火军工工业有限公司

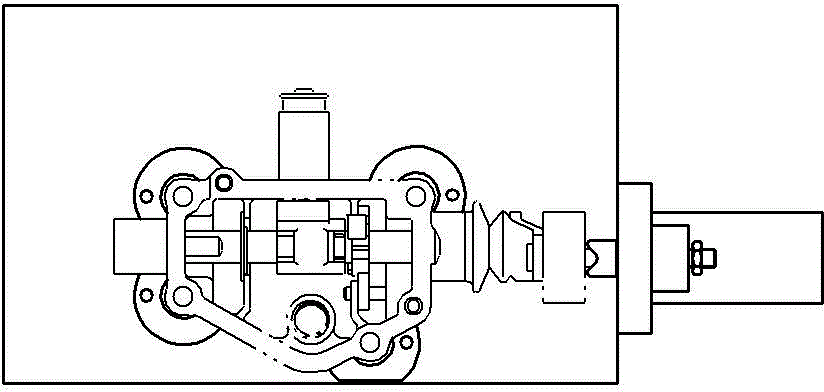

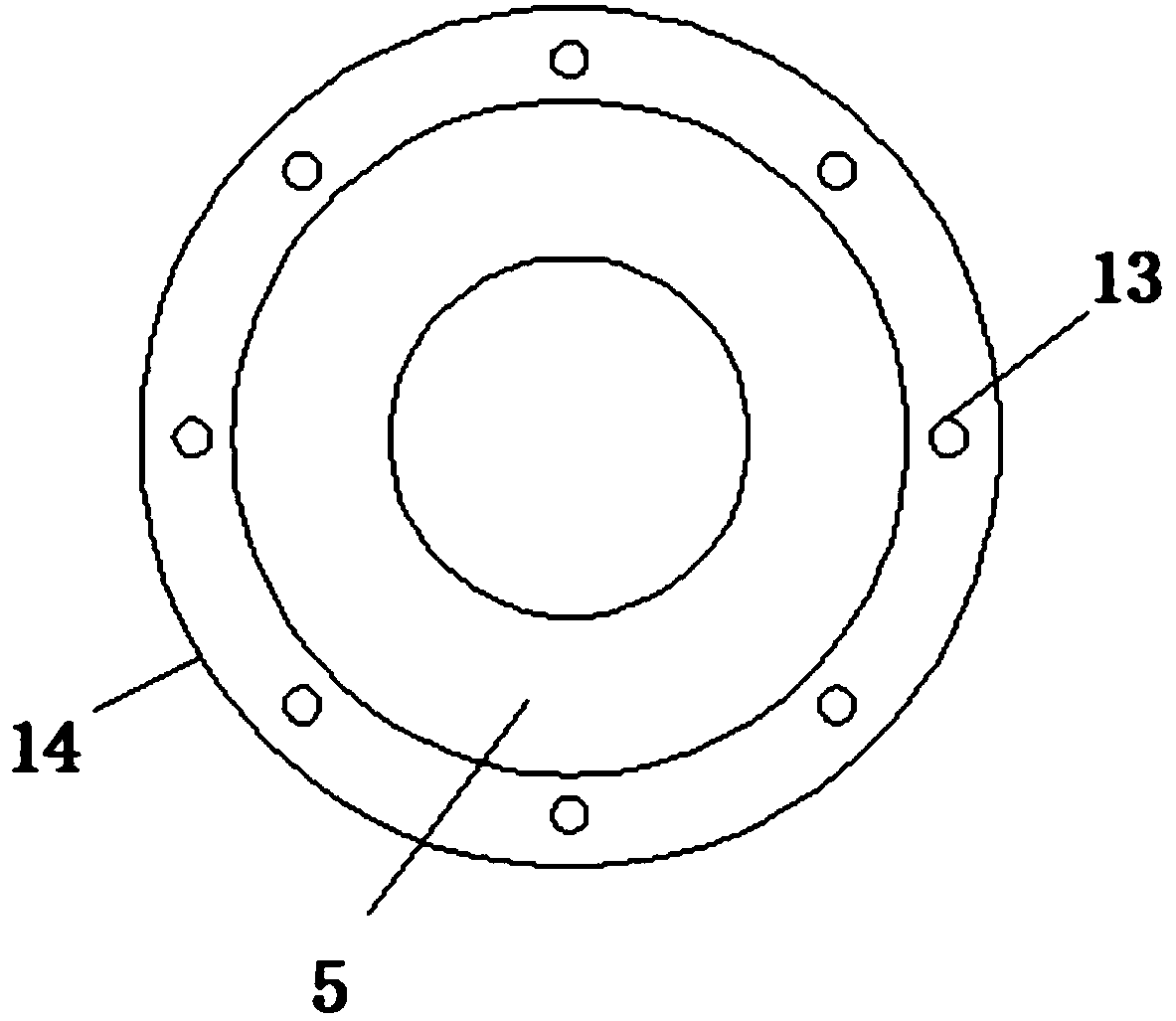

Static hydraulic pump motor oil seal packaging technology apparatus

The name of the invention is hydrostatic pump motor oil seal assembly tool, which relates to an oil seal assembly tool. It mainly solves the problem that when the oil seal is assembled, the hammer is used to knock back and forth along the edge of the oil seal back and forth, the force is uneven, and the oil seal is easily cracked by directly hitting the oil seal. In the present invention, an oil seal upper end cover positioning shaft and a central positioning shaft are fixed perpendicular to the base on the upper end surface of the base, a handle support plate is fixed perpendicular to the base on the side of the end surface of the base, and a handle support plate is fixed on the end of the handle support plate. The handle arranged parallel to the base, and the oil seal fixing seat are connected to the central positioning shaft through clearance fit. When the present invention is in use, the oil seal fixing seat is positioned through the central positioning shaft on the base, and the end cover is positioned through the two end cap positioning shafts and the central positioning shaft, so that the operation is convenient, safe and reliable; the handle support plate of the present invention and The handle adopts a lever principle, which is easy to operate, labor-saving and high in work efficiency.

Owner:CRRC LUOYANG CO LTD

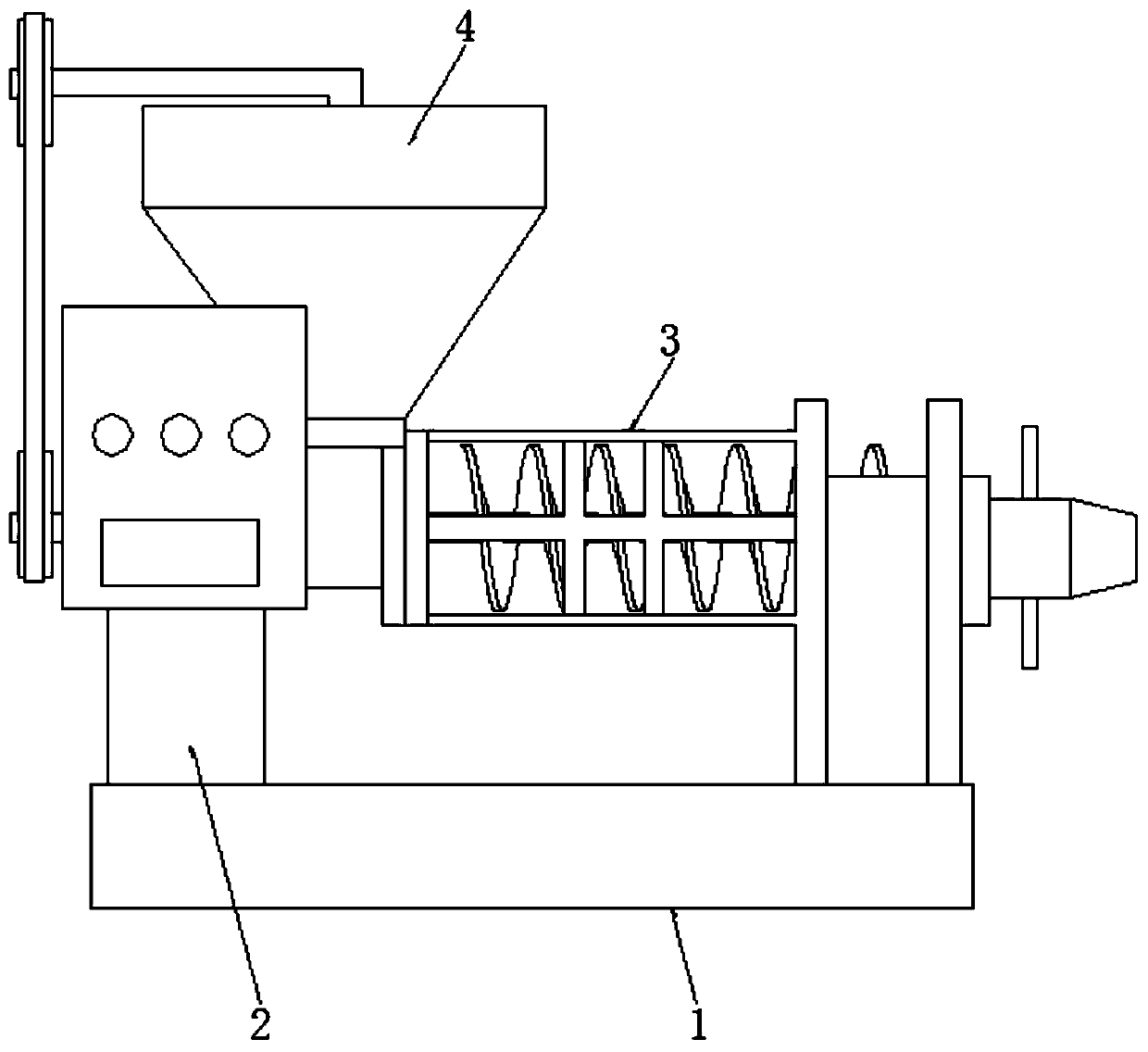

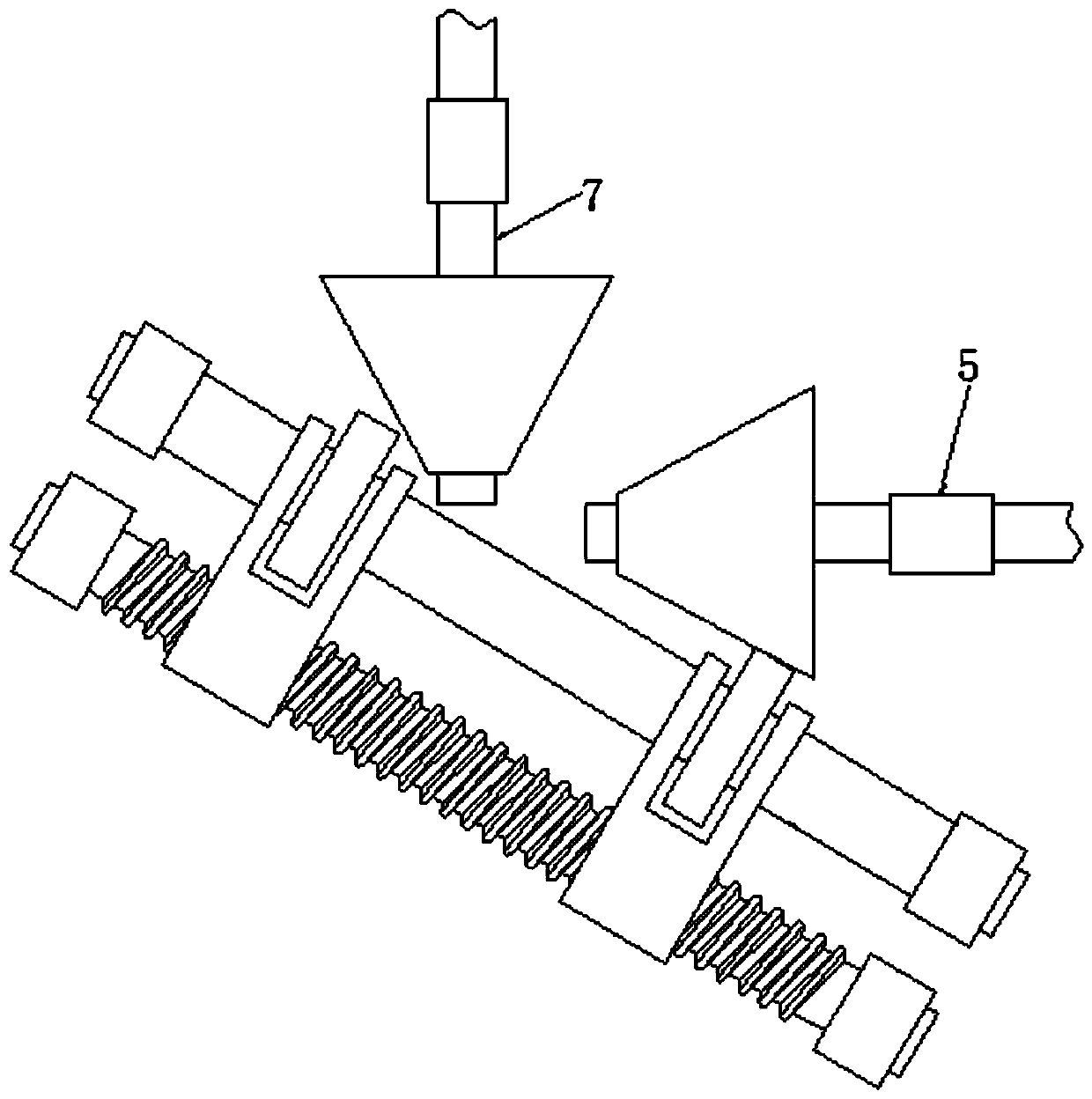

Oil expeller capable of changing expelling speed and preventing blockage based on gravity variation

InactiveCN111055525AChange the pressing speedAvoid cloggingFatty-oils/fats productionPressesMechanical engineeringThreaded rod

The invention relates to the technical field of agriculture and discloses an oil expeller capable of changing the expelling speed and preventing blockage based on gravity variation. The oil expeller comprises a base. The upper portion of the base is movably connected with a supporting column used for supporting and stabilizing the oil expeller. A shell is fixed to the upper portion of the supporting column to isolate a rotary roll. The surface of the shell is provided with a feed port, and a raw material is fed into the oil expeller along the feed port. The rotary roll is movably connected tothe interior of the shell. The an oil expeller capable of changing the expelling speed and preventing blockage based on gravity variation conducts scraping on the inner wall in the expelling process through a sliding block to prevent blockage due to the fact that expelling skin is closely attached to the inner wall. The rotating speed of the rotary roll is automatically changed by gravity variation through a threaded rod and movable blocks, so that the oil expelling speed is increased. A baffle and a vertical rod are used in linkage to facilitate implementation of follow-up steps. The linkageperformance of the whole oil expeller is improved.

Owner:蒲军

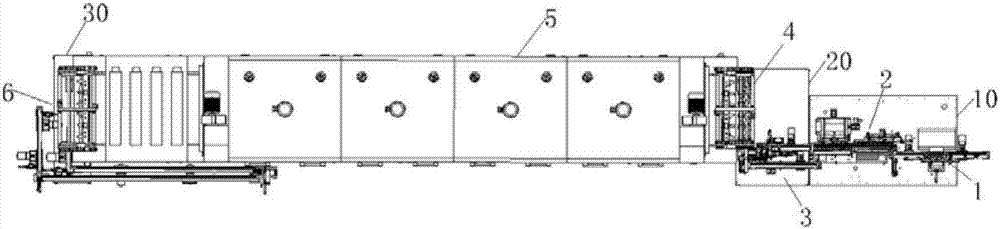

Lamination screening device for detecting dispersion gluing and baking of relay

ActiveCN107146740AIncrease the pressing speedImprove yieldRelaysMechanical engineeringCooking & baking

The invention relates to a lamination screening device for detecting dispersion gluing and baking of a relay, and mainly solves the problems of low efficiency and various defective products due to manual loading and unloading. The lamination screening device for detecting dispersion gluing and baking of the relay is employed and comprises a third conveying belt, wherein the third conveying belt is corresponding to a third passage, is fixed on a second workbench by a seventh base and is driven by a third motor, the third motor is fixed on the seventh base, the other end of the third conveying belt is connected with a third push device, the third push device comprises a second push plate, and the second push plate moves above the third conveying belt. With the technical scheme that the lamination screening device is arranged on the second workbench, the problem is solved very well.

Owner:泰州市津专知识产权服务有限公司

Cost-saving ginseng extracting device

InactiveCN108481783AClean in timeAvoid pollutionHollow article cleaningMetal working apparatusSlagGINSENG EXTRACT

The invention discloses a cost-saving ginseng extracting device which comprises an extracting tank and a waste slag collecting groove. A liquid outlet pipe is fixedly installed on the outer side of one end of the extracting tank, a double helix presser is fixedly installed on the outer side of the upper end of the extracting tank, a motor is arranged on the outer side of one end of the double helix presser, a discharging hopper is fixedly installed on the outer side of the upper end of the double helix presser, a pressing box and a cutting blade are arranged in the middle position in the double helix presser, and a hammer-shaped body is arranged inside the pressing box. The cost-saving ginseng extracting device is provided with a waste slag collecting groove, the double helix presser and arotary spraying head, waste slag can be collected, profits are improved, the production cost is saved, the ginseng extracting speed can be increased, the extracting efficiency is improved, the deviceinterior is prevented from being polluted, the service life is prolonged, the device is suitable for different working conditions, and the better using prospect is achieved.

Owner:HEFEI FENGJIE BIOLOGICAL TECH CO LTD

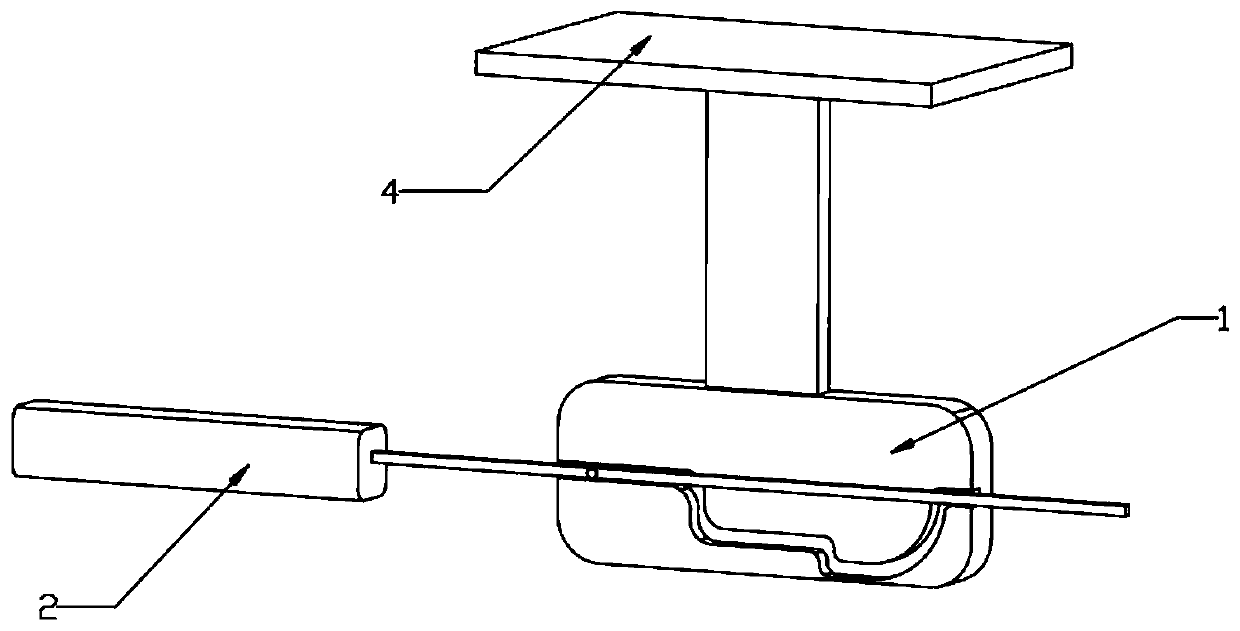

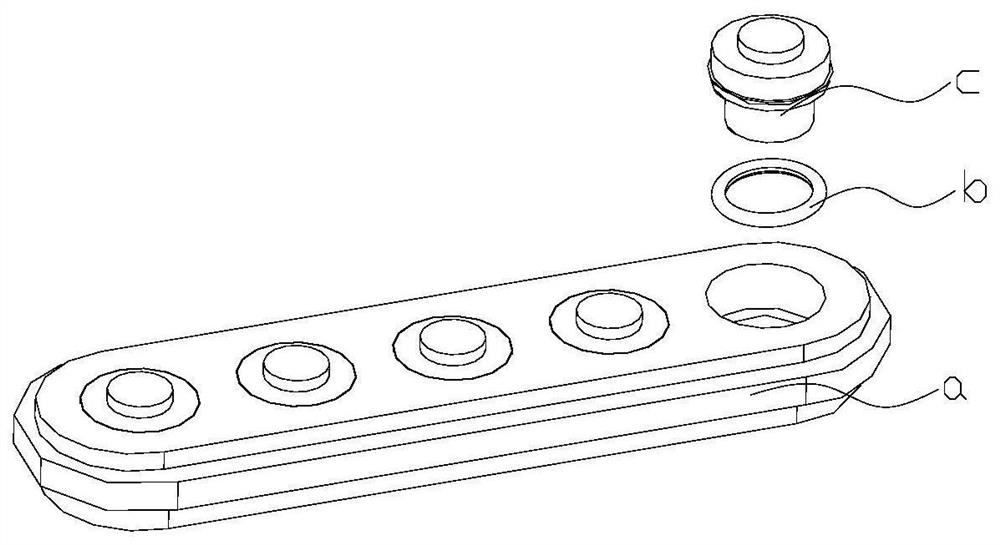

Press fitting device of automobile connector

ActiveCN102931563AIncrease the pressing speedImprove processing qualityLine/current collector detailsEngineeringElectronic component

The invention discloses a press fitting device of an automobile connector. The press fitting device comprises a base. The press fitting device is characterized by comprising a pressure plate and a plurality of pressure heads, wherein the base is provided with a boss, and the boss is internally provided with a groove used for placing the automobile connector; the pressure plate is arranged above the boss, and the bottom of the pressure plate is provided with a plurality of pressure heads used for pressing an electronic component on the automobile connector; and a base plate is arranged between the boss and the pressure heads, the base plate is provided with a plurality of locating holes used for limiting the position of the electronic component, and each pressure head can stretch into the corresponding locating hole. The press fitting device provided by the invention solves the problems that a manual work manner is adopted to crimp the electronic component on the automobile connector, the working efficiency is lower, the localization is difficult, the press fitting accuracy is lower, the quality of a product can not be better guaranteed, and the defective fraction of the product is higher so as to bring large loss for enterprises; and the press fitting device of the automobile connector provided by the invention has the advantages that the structure is simple, the electronic component is rapidly exactly pressed on the electronic component arranged on the automobile connector.

Owner:KUNSHAN LEAGUE AUTOMECHANISM

Clamp for press fitting of short-axis pipe

The invention discloses a clamp for press fitting of a short-axis pipe. The clamp for press fitting of the short-axis pipe comprises a clamp frame, an electrical controller, a first clamping mechanism, a second clamping mechanism, a pressing mechanism, a press fitting mechanism and a clamping sensor, wherein the first clamping mechanism and the second clamping mechanism respectively comprise a clamping guide rod and a clamping oil cylinder, and the pressing mechanism comprises a pressing guide rod and a pressing oil cylinder, the press fitting mechanism comprises multiple press fitting guide rods, a press fitting oil cylinder and a downward-pressing sensor. According to the clamp for press fitting of the short-axis pipe fitting, the two clamping oil cylinders are controlled by the electrical controller to fix the pipe through clamping, and the pipe fit is arranged on a workpiece in a press fitting mode through the cooperation between the pressing mechanism and the press fitting mechanism after being fixed. According to the clamp for press fitting of the short-axis pipe, the press fitting process is simple, operation is convenient, manual participation is not needed, the automation degree is high, and the effects that press fitting positioning is accurate, pressing fitting speed is high and press fitting efficiency is high are achieved due to the fact that position signals are detected through the clamping sensors and the downward-pressing sensor; the clamp can be used for press fitting of short-axis pipes with various sizes, and the application range is widened.

Owner:SHENZHEN NARI TECH

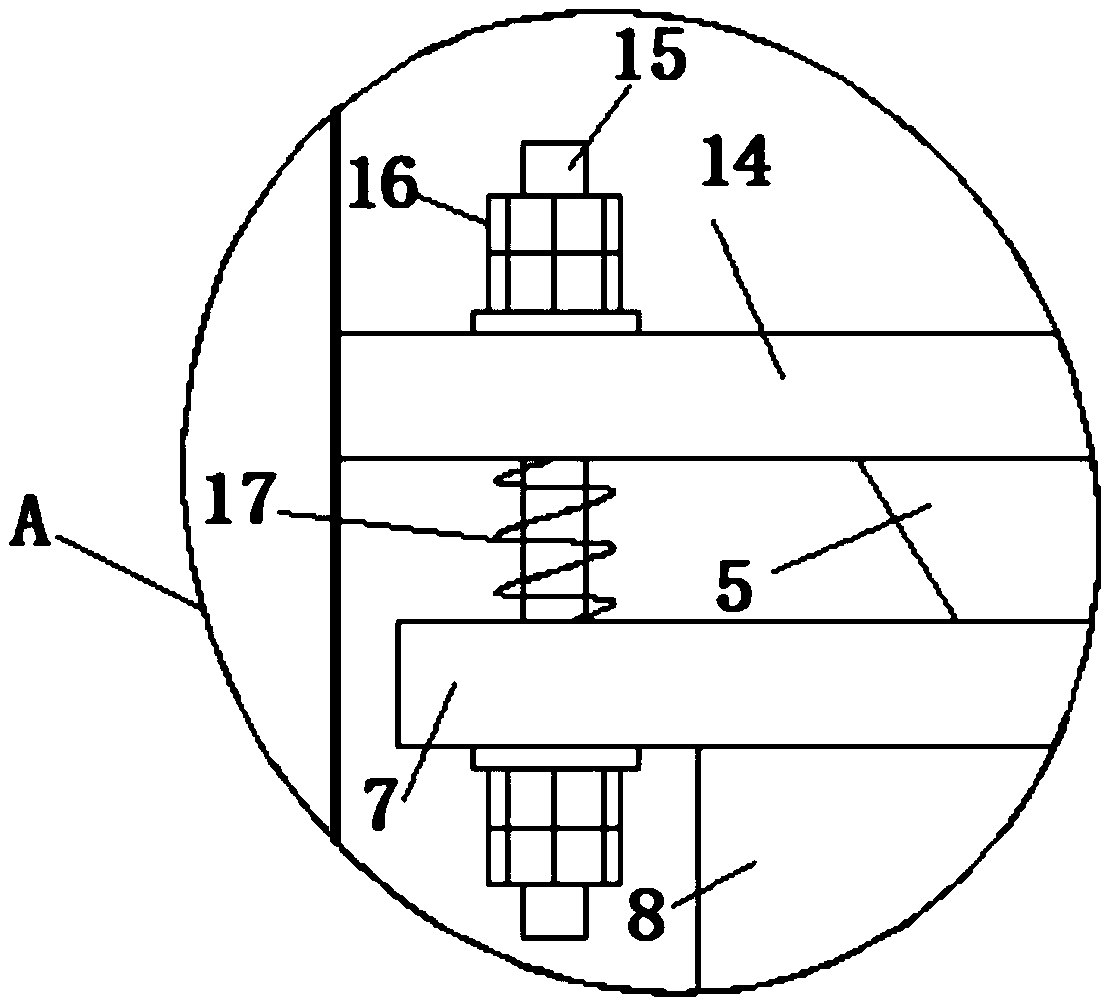

Hub bearing for engineering trucks and special press-fitting assembly for races

InactiveCN103817513ASimple structureIncrease the pressing speedMetal working apparatusMetal-working hand toolsTruckEngineering

The invention discloses a hub bearing for engineering trucks and a special press-fitting assembly for races and relates to the field of special press-fitting assemblies for mounting hub bearings and hub bearing races on rear-axle hub shaft tubes. A left cylinder work oil nozzle (16) and a left cylinder block return oil nozzle (24) are respectively arranged on a left cylinder (1) and a left cylinder block (5) which are connected with each other, and a right cylinder work oil nozzle (17) and a right cylinder block return oil nozzle (25) are respectively arranged on a right cylinder (2) and a right cylinder block (6) which are connected with each other; a front support rod (9) and a rear support rod (10) are connected between a left support rod holder (7) provided with the left cylinder block (5) and a right support rod holder (8) provided with the right cylinder block (6); a left cylinder piston (3), a left thrust connecting rod (32) and a left pressure tool (11) are integrally connected, and a right cylinder piston (4), a right thrust connecting rod (33) and a right pressure tool (12) are integrally connected. The special press-fitting assembly for the races is simple in structure and high in press-fitting speed.

Owner:TAIZHOU SHENZHOU TRANSMISSION TECH

Special squeezer for grape wine brewing

InactiveCN109536326AAvoid cloggingEasy to separateWine preparationHydraulic cylinderHydraulic equipment

The invention relates to the technical field of grape processing, in particular to a special squeezer for grape wine brewing. The special squeezer for grape wine brewing comprises a housing, wherein the housing is a unilaterally closed trough body; a flow-guiding pipe is connected to the bottom of the housing; a bottom support is fixedly connected to the outer wall of the housing; a support is vertically arranged at an opening in the upper end of the housing; a hydraulic cylinder is tightly mounted on the support through bolts; the hydraulic cylinder is connected with external hydraulic equipment through an oil pipe; a pressing plate is fixedly connected to the end part of a power rod of the hydraulic cylinder; a second fixing ring is welded to the inner wall of the housing; an inner container is arranged at the bottom of the inner cavity of the housing; a first fixing ring is welded to an opening in the upper end of the inner container. The special squeezer for grape wine brewing canpromote rapid separation of grape juice in the inner container, so that the squeezing speed is greatly increased; moreover, meshes can be effectively prevented from being blocked, so that working staff conveniently clean a whole machine.

Owner:银川瑞海陈技术咨询服务有限公司

Device used for quickly squeezing peanut oil in factory

The invention relates to a squeezing device, in particular relates to a device used for quickly squeezing peanut oil in a factory, and aims to solve the technical problem to provide the device used for quickly squeezing the peanut oil in the factory and quick in squeezing speed. For solving the technical problem, the invention provides the device used for quickly squeezing the peanut oil in the factory; the device comprises a squeezing box, a first filter screen, a squeezing plate, a bearing seat, a right reel, a first slide rail, a right pull rope, a right pulley, a right slide rail, a right slider, a right spring and the like; the left wall of a feeding funnel is provided with a fourth through hole, the right wall of the feeding funnel is provided with a first through hole, the first through hole and the fourth through hole are located on the same height, the left side of the top of the squeezing box is provided with a left pulley and a left slide rail, and the left pulley is located on the left of the slide rail. The device has the effects of quick squeezing speed, high squeezing efficiency and simple operation.

Owner:刘道发

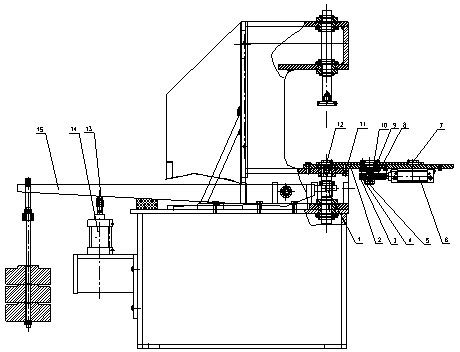

Automatic press-fitting process for flow guiding pipe

ActiveCN113290520AHigh degree of automationIncrease the pressing speedMetal-working hand toolsConveyor partsElectric machineryEngineering

The invention particularly relates to an automatic press-fitting process for a flow guiding pipe. The automatic press-fitting process for the flow guiding pipe is characterized by sequentially comprising the following steps that S1, a pipe body is placed in a clamping mechanism to be positioned and clamped; S2, a flow guide connector is selected out through a vibration disc; S3, a transverse moving device clamps the flow guide connector and transfers the flow guide connector to a positioning station for positioning; S4, after positioning is completed, the transverse moving device transfers the flow guide connector to a material transferring device for material transferring; S5, the material transferring device moves the flow guide connector to a press-fitting station, and a pushing motor pushes a material taking device to move forwards to sleeve the flow guide connector at the moment; S6, photographing inspection is conducted by a high-definition camera; S7, if a thread position of the flow guide connector is not qualified, an operator is prompted to conduct a reset operation to the material taking device, and the steps S2 to S6 are repeated; if the thread position is qualified, the step S8 is carried out; S8, the pushing motor pushes the material taking device to press the flow guide connector into the pipe body. The automatic press-fitting process for the flow guiding pipe is convenient automatically to find a thread starting position of the flow guiding pipe, and the beneficial effect of improving the flow guiding pipe press-fitting speed is achieved.

Owner:CHANGZHOU BAODUN ELECTRONICS MACHINERY

Sheet metal stamping machine

InactiveCN108127764BImprove processing efficiencyAvoid offsetWood working apparatusFlat articlesPunchingWood machining

The invention belongs to the technical field of wood processing and treatment, and particularly discloses a plank punching machine. The machine includes a pressing mechanism, a transmission mechanismand a power mechanism; the pressing mechanism includes multiple pressing plates, every two adjacent pressing plates form a pressing unit, and a power transmission structure is arranged on each pressing unit; a groove is formed in the pressing plate on the upper portion of each pressing unit, and a fixing structure is arranged on the upper surface of each pressing plate below and includes two L-shaped clamping plates which are arranged opposite to each other and define a semi-square shape; the transmission mechanism includes a hydraulic column, and a first piston column is movably connected tothe interior of the upper portion of the hydraulic column and fixedly connected to the pressing plate positioned at the top; a second piston column is movably connected to the interior of the lower portion of the hydraulic column and fixedly connected to the pressing plate at the lowest position; a piston cylinder is connected to the side wall of the hydraulic column and internally and movably connected with a piston. By using the punching machine to press wood planks, multiple wood planks can be pressed at a time and effectively prevented from sliding.

Owner:重庆仁实商贸有限公司

An electronic connector detection and blanking device and method

ActiveCN112777302BReduce in quantityLow costSortingConveyor partsControl engineeringElectrical connector

The invention relates to the field of electronic connectors, in particular to an electronic connector detection and blanking device and method, and electronic connector assembly equipment. The device includes a jig conveying mechanism, an overturning detection mechanism and a screening and unloading mechanism; the jig conveying mechanism, the overturning detection mechanism and the screening and unloading mechanism are all fixed on the workbench; the jig conveying mechanism is slidably matched with the rubber core positioning jig, In addition, the overturn detection station and the blanking station in the jig conveying mechanism are respectively connected with the input end of the overturn detection mechanism and the input end of the screening and unloading mechanism; the device reduces the number of cylinders in the equipment by setting the jig conveying mechanism, and reduces the The cost of the cylinder is reduced; the manual labor intensity is reduced by setting the flip detection mechanism, and the detection efficiency of the electronic connector is improved; the electronic connector is quickly unloaded by setting the screening and unloading mechanism, and the automation degree of the equipment is improved.

Owner:DONGGUAN YUSEN PRECISION TERMINAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com