Bolt pressing fit machine

A press-fitting machine and bolt technology, which is applied in the field of bolt-pressing machines, can solve problems such as slow efficiency and increased workload, and achieve the effects of reducing defective rate, increasing production efficiency, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

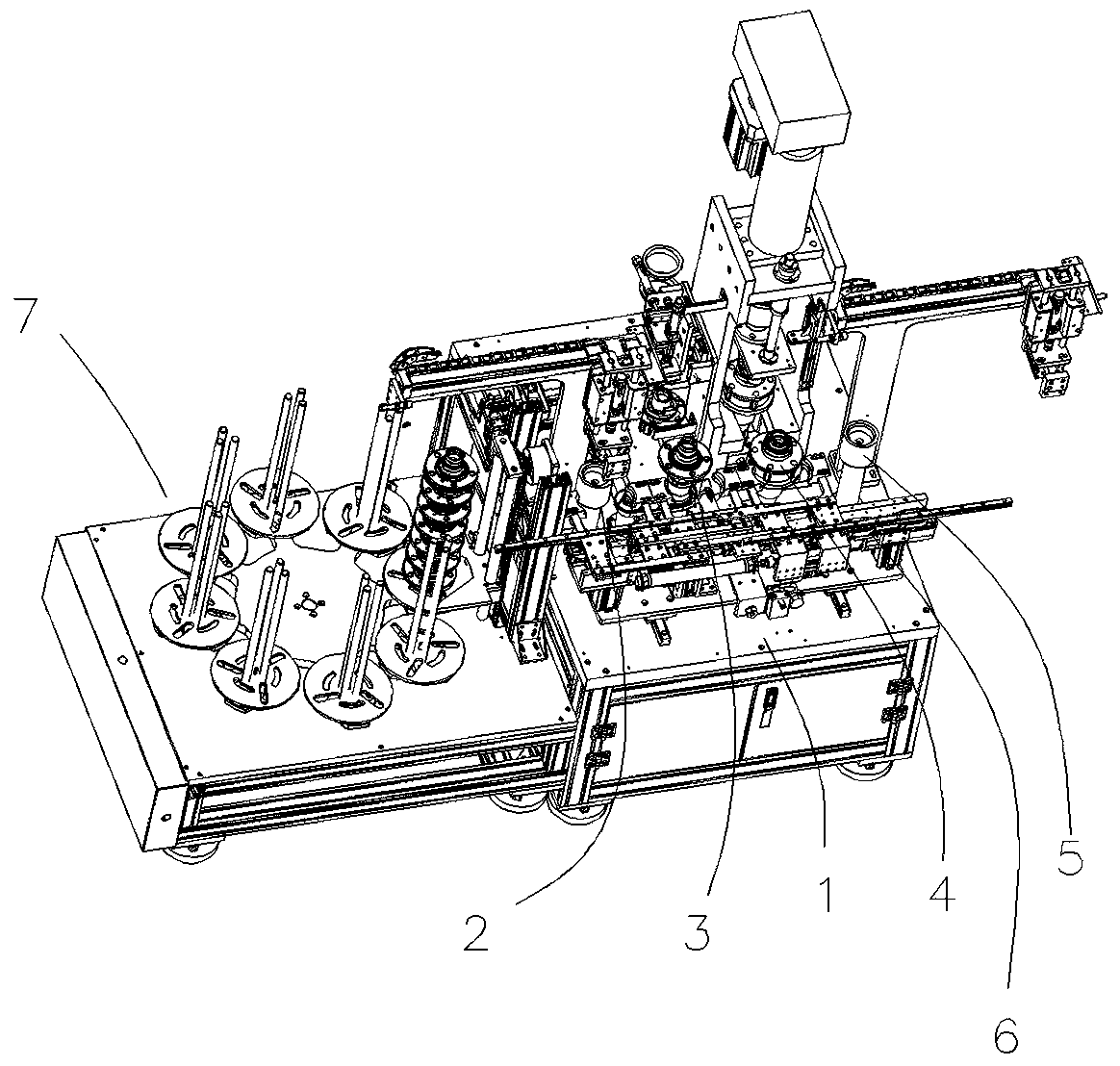

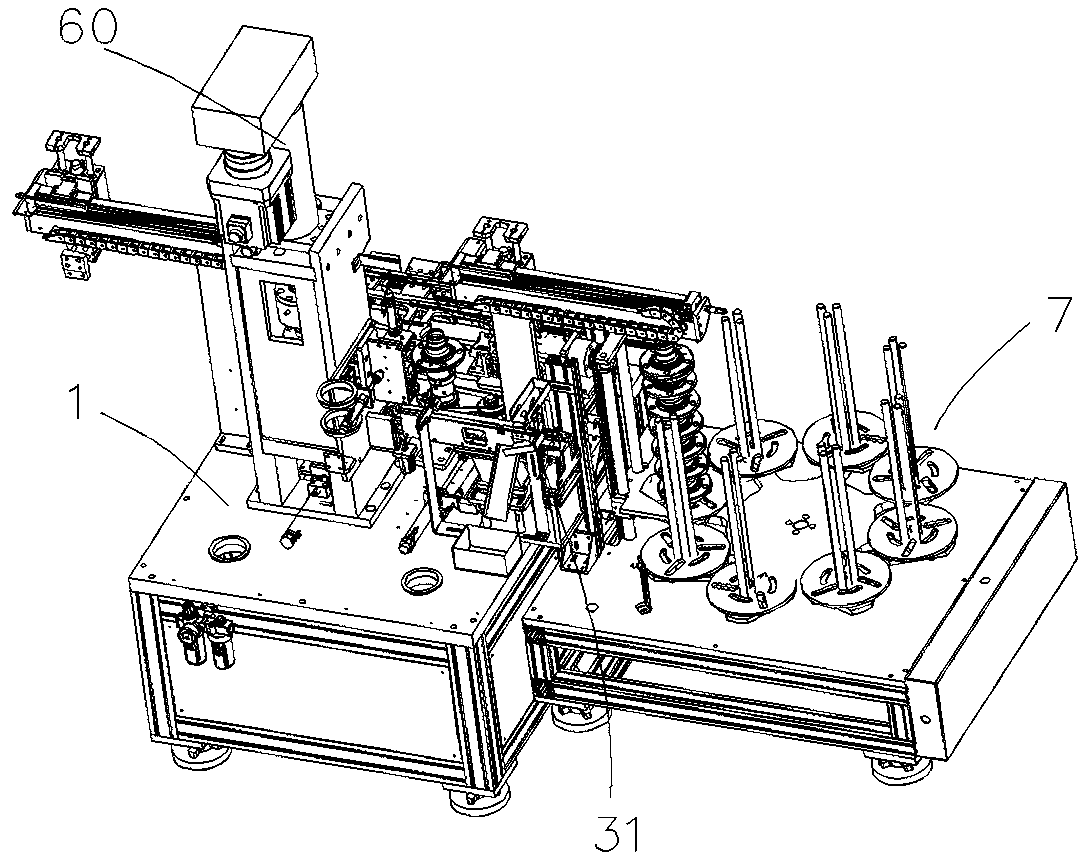

[0045] combined with Figures 1 to 9 , a bolt pressing machine, comprising a cabinet 1, the cabinet 1 is provided with a feeding station 2, a bolt loading station 3, a bolt pressing station 4, and a blanking station 5 in sequence; the cabinet 1 is also provided with There is a material shifting mechanism 6 for transferring the disc-shaped workpiece from the previous station to the next station;

[0046] The feeding station 2 includes a disc-shaped workpiece storage device 7, a feeding base 8 fixed on the cabinet 1, and a disc-shaped workpiece 9 transferred from the disc-shaped workpiece storage device 7 to the feeding base 8. The reclaiming manipulator 10;

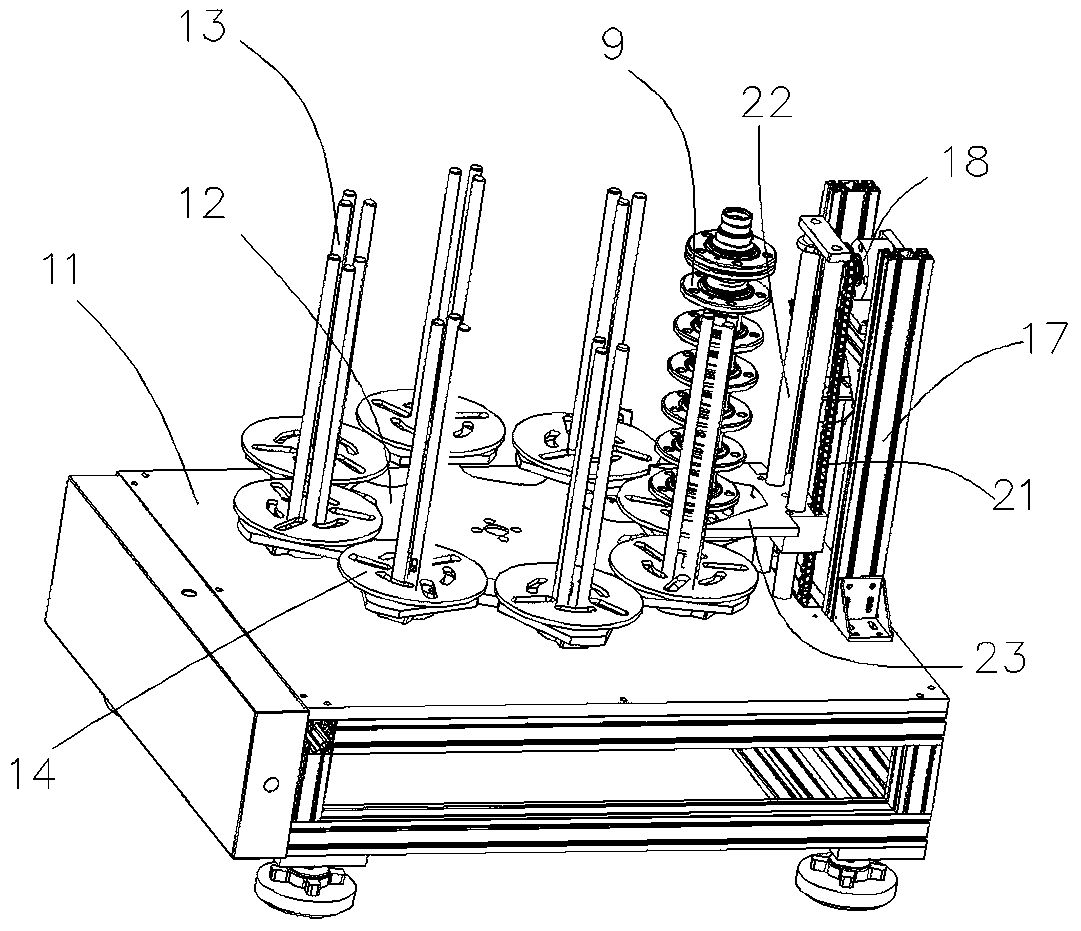

[0047] The optimal design of the disc-shaped workpiece storage device 7, the disc-shaped workpiece storage device 7 includes a material box 11, and a rotatable transfer disc 12 is provided on the material case 11, and the edge of the transfer disc 12 There are several material levels, and the material level is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com