A kind of installation device and installation method of ultra-thin-wall bushing

A mounting device and ultra-thin-wall technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as difficulty in ensuring shape and position, difficult installation success, and tolerance, so as to ensure coaxiality and low overall manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

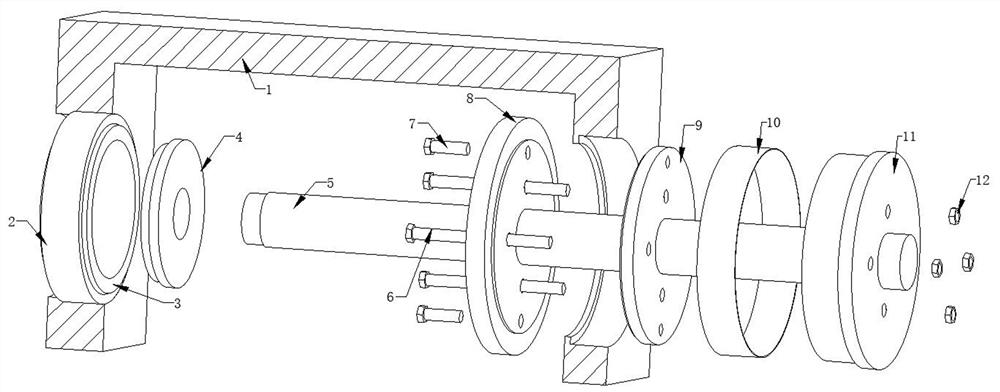

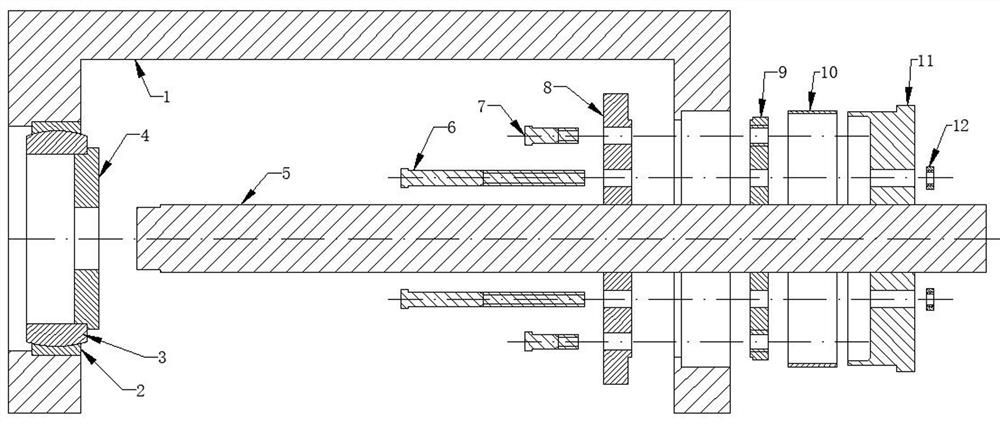

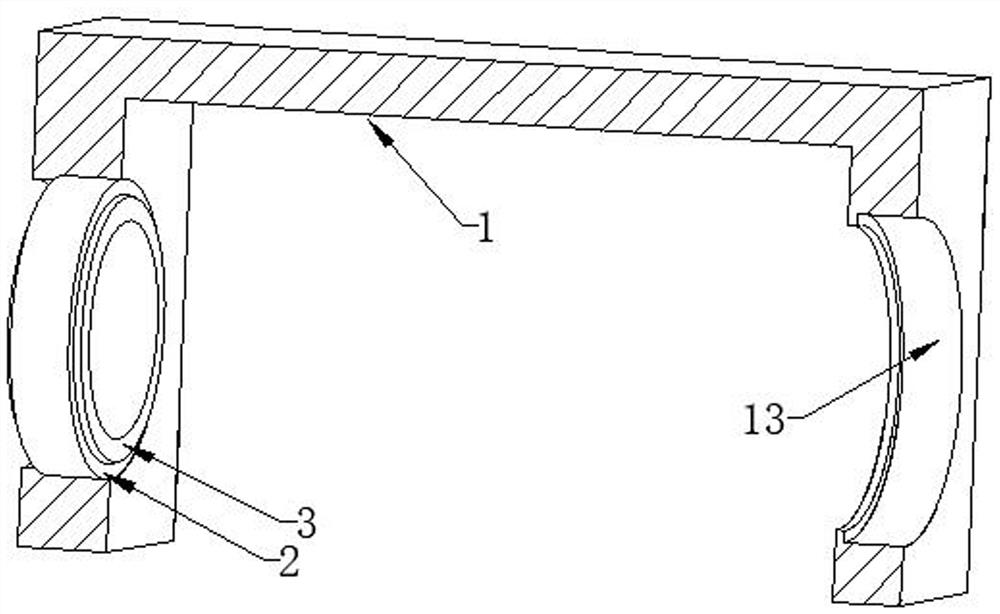

[0038] The main structure of this embodiment, such as figure 1 , figure 2 As shown, it includes a frame beam 1, a centering rod 5 is interspersed in the middle of the frame beam 1, the left end of the centering rod 5 is detachably embedded in the beam column on the left side of the frame beam 1, and the right end of the centering rod 5 penetrates the frame On the beam column on the right side of the beam 1, the centering rod 5 is embedded with a supporting plate 8, a pressing plate 9, and a thrust plate 11 from left to right; the supporting plate 8, the pressing plate 9, and the thrust plate 11 are all provided There are through holes with matching positions, the number of said through holes is at least three, and the centers of any three through holes are not on the same straight line, a long screw 6 is embedded in the through hole, and one end of the long screw 6 is set There is a compression nut 12, through the cooperation of the long screw rod 6 and the compression nut 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com