Automatic box assembly device

An assembly device and automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as uncoordinated movements, complicated operations, poor stability and reliability of equipment, and achieve the effect of improving the beat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

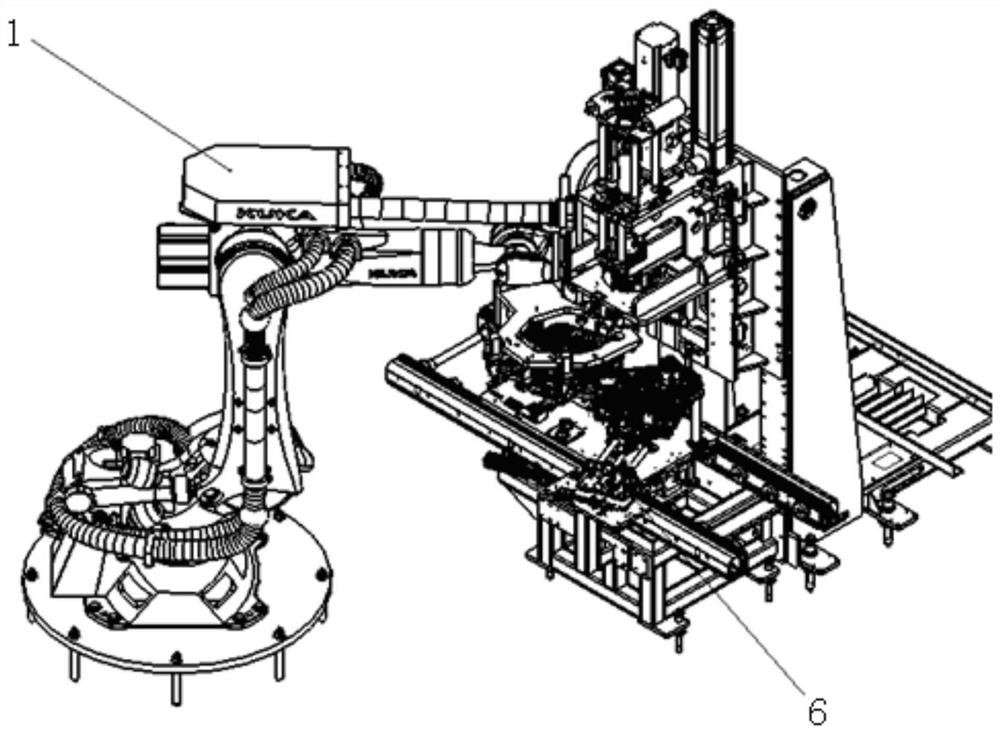

[0031] like Figure 1-10 Shown, for a kind of automatic case-closing assembly device provided by the present invention, it comprises:

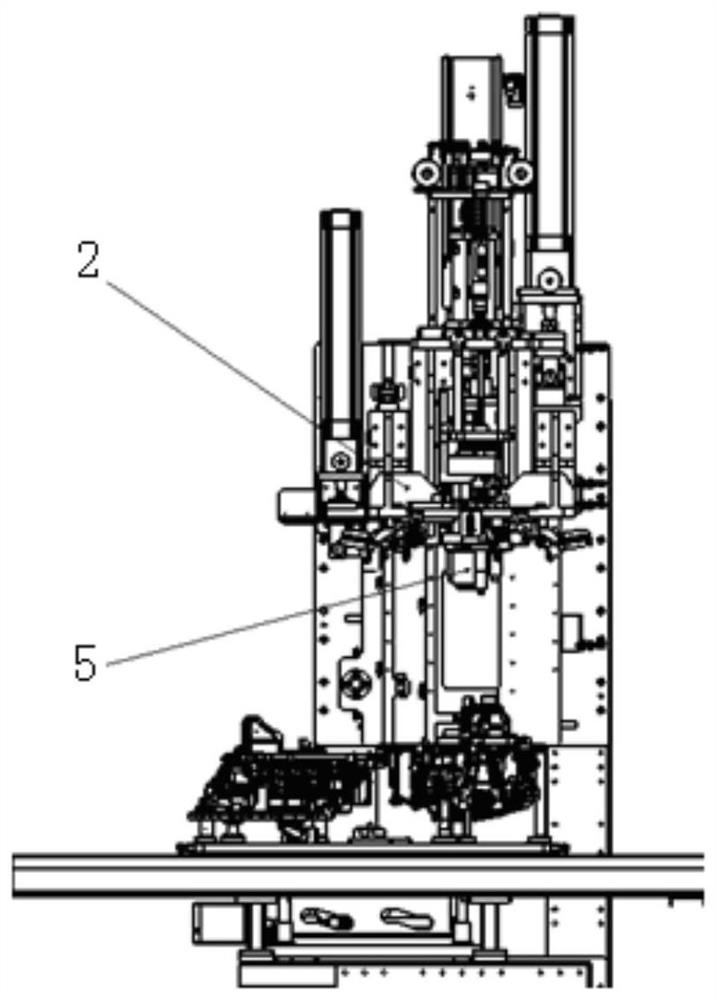

[0032] An automatic feeding mechanism, including a robot gripper 2 for feeding and a robot 1 for driving the robot gripper 2;

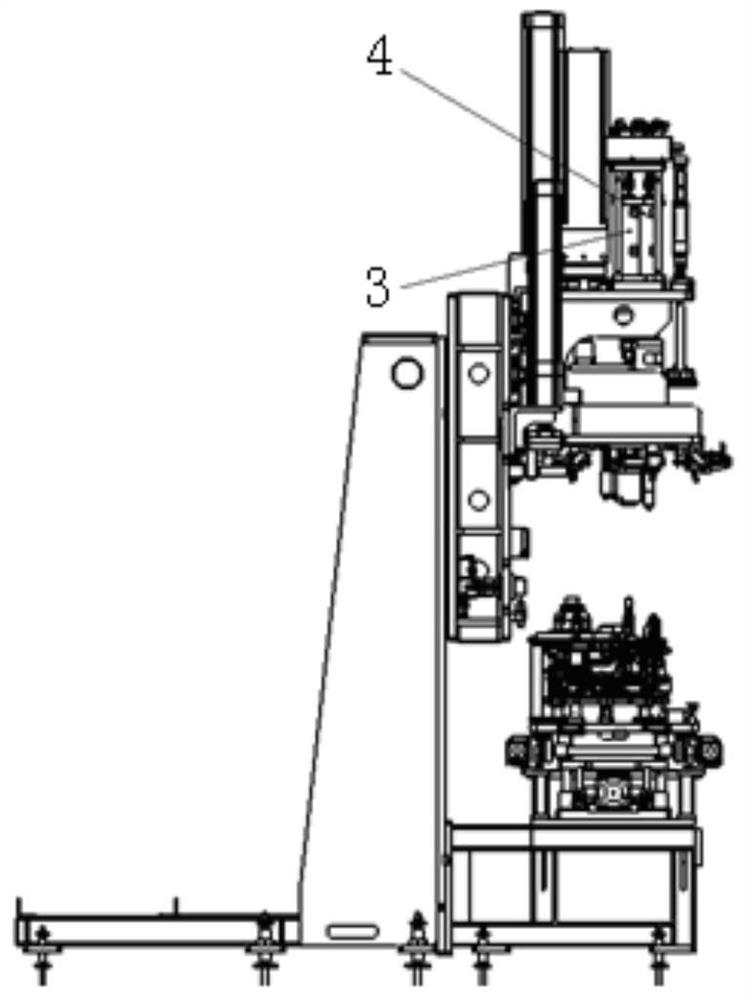

[0033] The press-fitting main mechanism of the lifter includes a servo press 3 fixed on the lifting cylinder 4 at the press-fitting position, a clutch housing lifting cylinder 5 and a support;

[0034] The input shaft clamping mechanism includes a four-petal clamping mechanism with a spring 12 in the middle at the output end of the shaft lifting cylinder 11. There is a hydraulic clamping sleeve 10 on the upper part of the component, which is connected to the tension sensor 9 sequentially from top to bottom to clamp the driving cylinder. The output end of 8 is connected to the clamping jaw 7, which is arranged in the clamping clamp 6, and the clamping jaws are connected by a spring 12, and the clamping jaw 7 can be lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com