Press clamp for small commercial car assembly

A commercial vehicle and manipulator technology, which is applied in the manufacture of tools, vehicle parts, transportation and packaging, etc., can solve the problems of slow press-fitting speed and high rate of unqualified products, and achieve the effect of increased press-fitting speed and constant pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

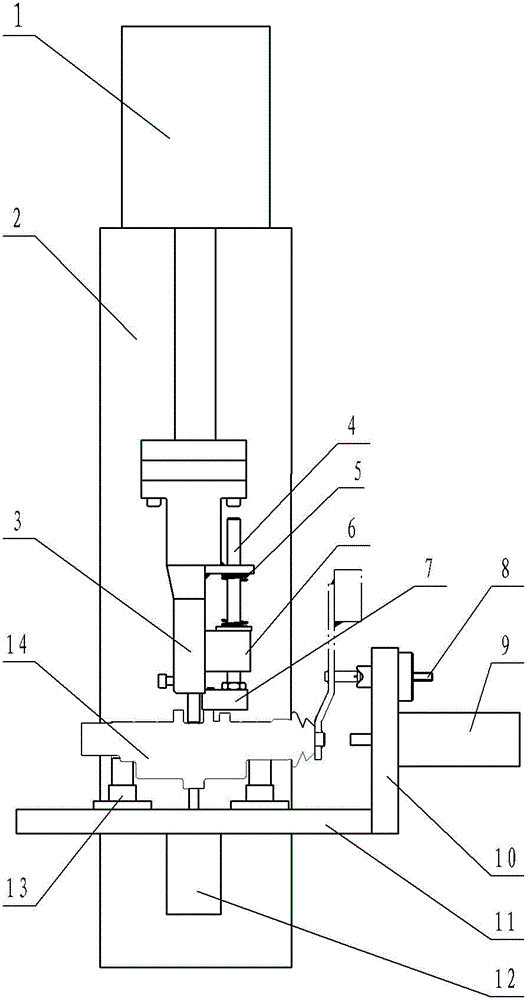

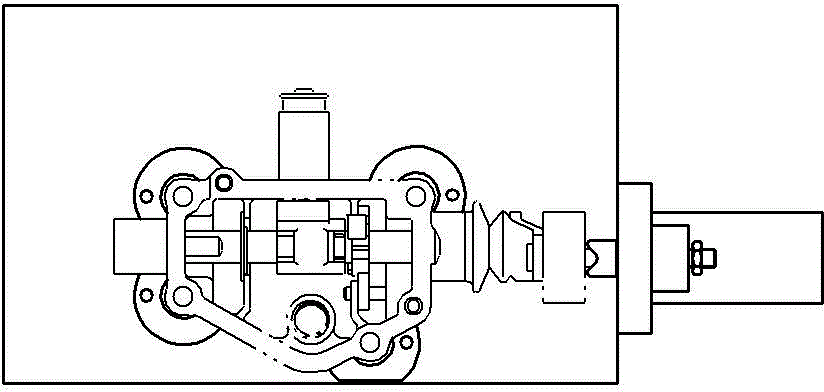

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail: as Figure 1~Figure 2 as shown,

[0015] This small commercial vehicle manipulator cover assembly press-fitting fixture includes a "["-shaped bracket 2, and the top of the bracket 2 is arranged side by side with the first cylinder 1 vertically downward, and the piston rod of the first cylinder 1 is connected with a pressure head. 3. The pressure head 3 is aligned downward to the position of the shift block positioning pin of the manipulator cover assembly 14. The shift pad positioning plate 7 is connected to the connecting rod 4 and fixed to the pressure head through the limit block 6. 3, a spring 5 is assembled above the limit block 6, and the connecting rod 4 can make the shifting head positioning plate 7 realize the automatic return function through the spring 5 when the pressure head 3 is returned, and the shifting head positioning plate 7 Through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com