Automatic press-fitting method for automobile combination instrument needle

A combined instrument pointer and automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of easily crushed instruments, unqualified products, and product scrapping, so as to improve production efficiency and reduce scrap rate, method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

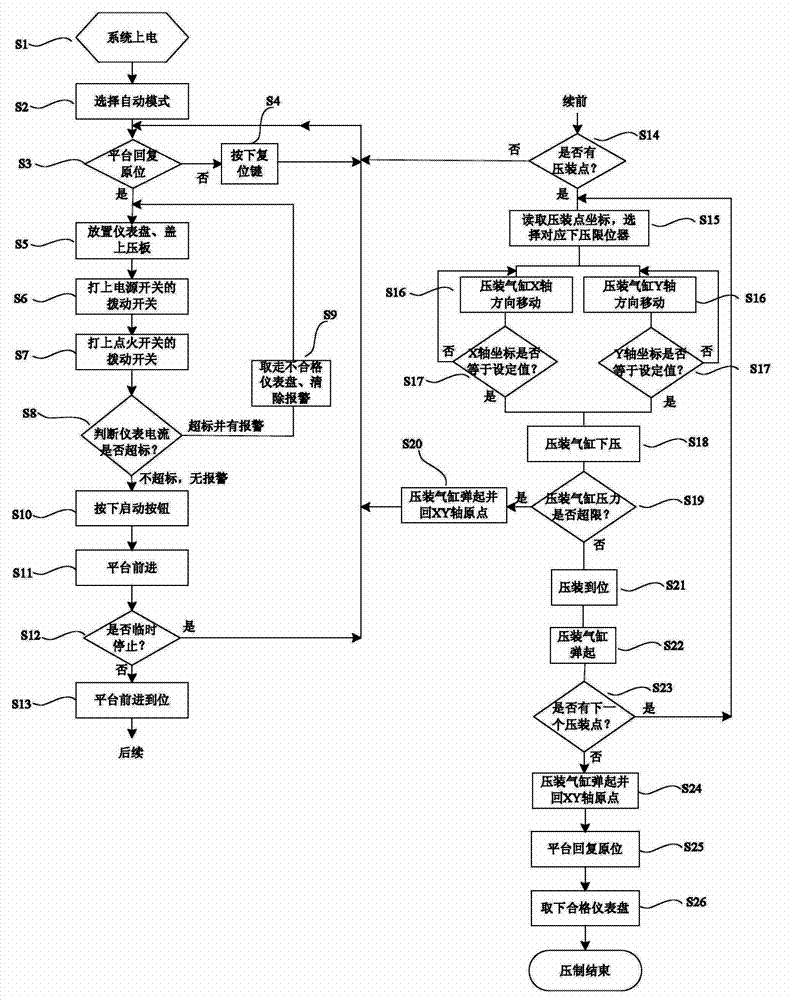

[0044] A method for automatic press-fitting of a combination instrument pointer of an automobile, the method comprising: resetting the platform and the press-fitting cylinder to their positions, and placing the instrument panel; powering on the instrument, and judging whether the current exceeds the standard; When the press-fitting cylinder reaches the press-fitting point, the press-fitting cylinder is pressed down; in the process of pressing down, it is judged whether the press-fitting pressure exceeds the limit value. When the press-fitting pressure exceeds the limit value, the press-fitting cylinder resets and exits; The loading cylinder pops up and moves to the next press-fitting point; after all the press-fitting points are continuously pressed, the press-fitting cylinder pops up and moves back to the origin of the XY axis; the platform exits, and the qualified instrument is taken out, and the instrument press-fitting process ends.

[0045] The above-mentioned metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com