Automatic press-fitting system for pointers of vehicle-mounted pointer-type electronic clock

An electronic clock and pointer-type technology, which is applied in the field of automatic press-fitting system of vehicle-mounted pointer-type electronic clock hands, can solve problems such as product reliability and consistency cannot be guaranteed, pointer accuracy cannot be guaranteed during pressing, and quality cannot be guaranteed. Reduce the scrap rate, avoid pointer falling off, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

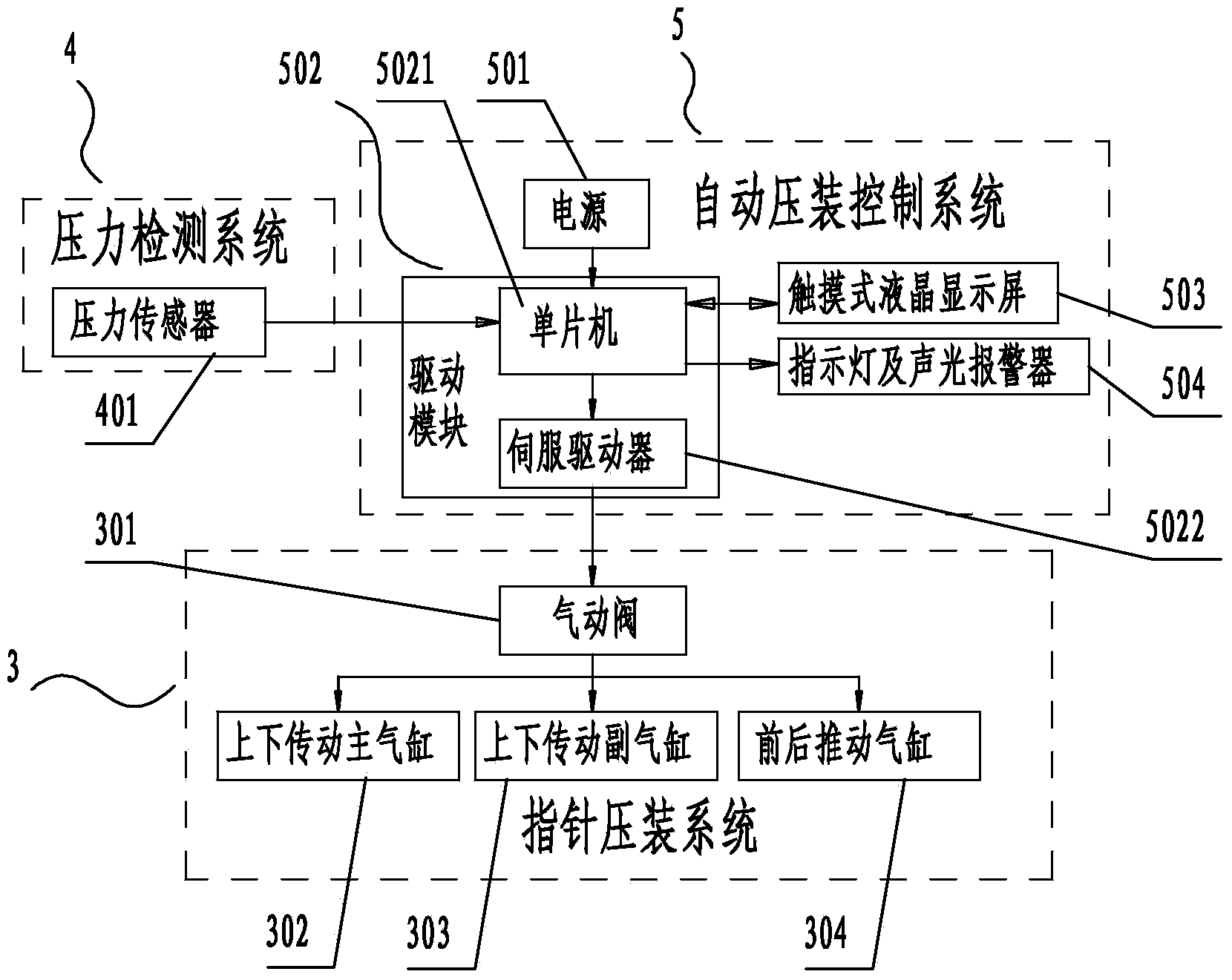

[0033] Embodiment 1: The pressure detection system 4 is installed on the pointer press-fit system 3, the input end of the automatic press-fit control system 5 is connected with the output end of the pressure detection system 4, and the output end of the automatic press-fit control system 5 is connected with the pointer Input connection of press fitting system 3.

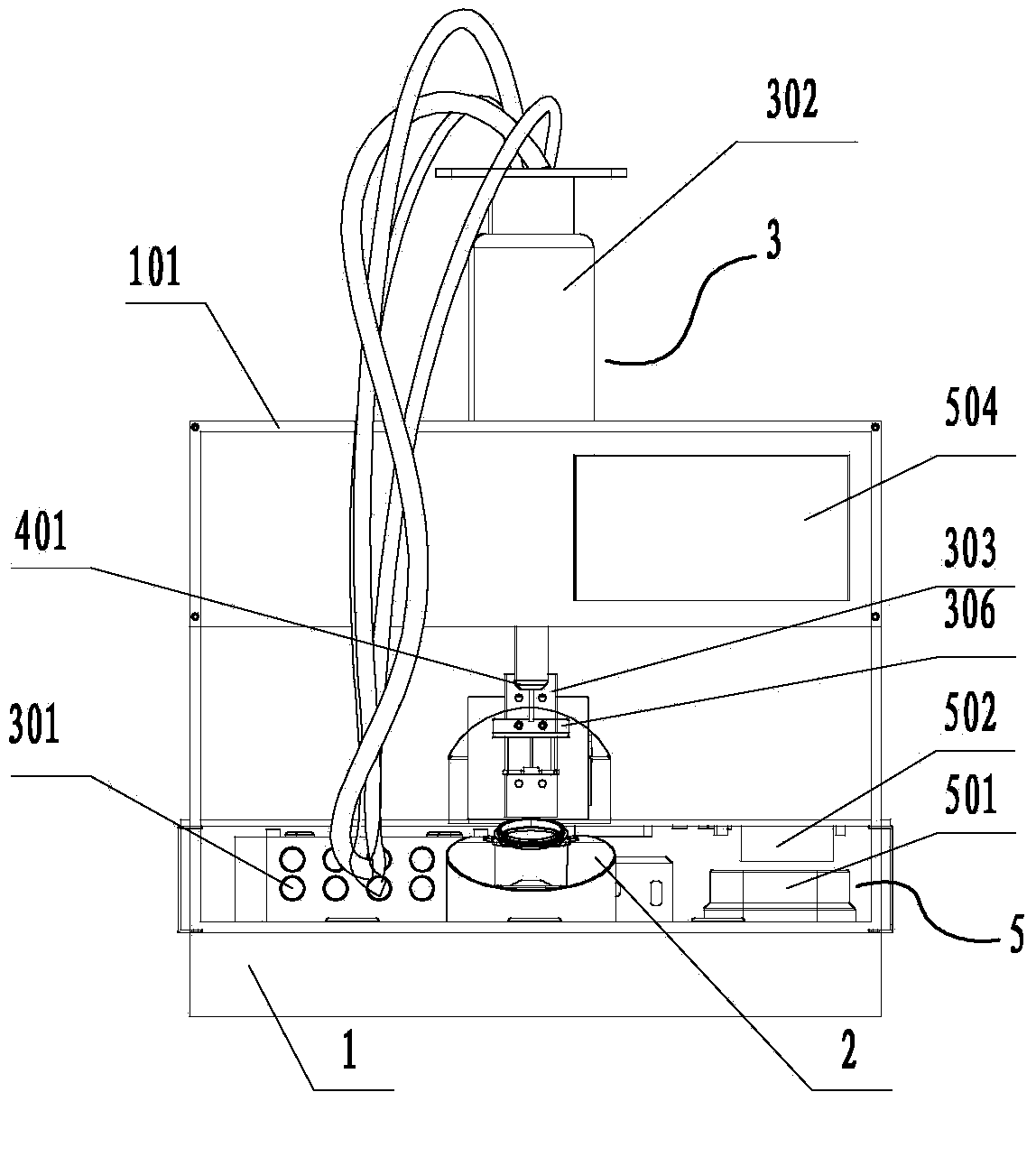

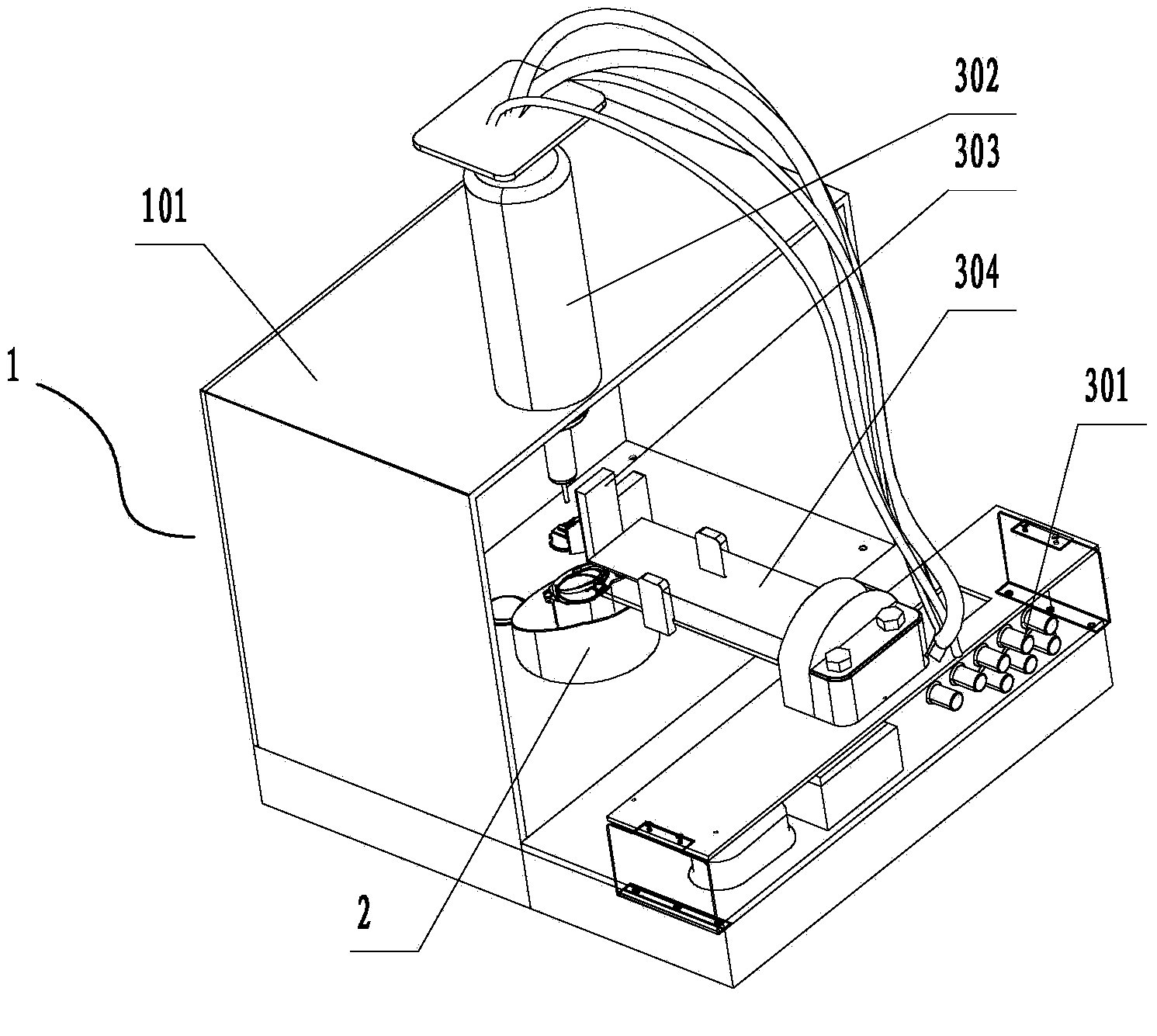

[0034] A vehicle-mounted pointer-type electronic clock pointer automatic press-fitting system, the system includes a fixed platform 1, a mold cavity 2 for horizontally fixing and translationally fixing the electronic clock, and a pointer press-fitting system for pressing the hands of the electronic clock 3. A pressure detection system for real-time detection of the pressure of the press-fit pointer 4. An automatic press-fit control system 5 for controlling the current, pressure and press-fit process; the mold cavity 2 is installed on the fixed platform 1 ;

[0035] The pointer pressing system 3 includes a pneuma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com