Pneumatic control rotary multi-station automatic lever powder pressing machine

A pneumatic control and multi-station technology, applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve problems such as low production efficiency, accidents that hurt personnel, and inadequate protection, so as to reduce labor intensity and increase pressure. The effect of drug speed and low transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

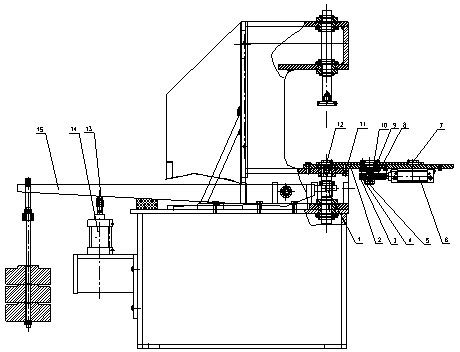

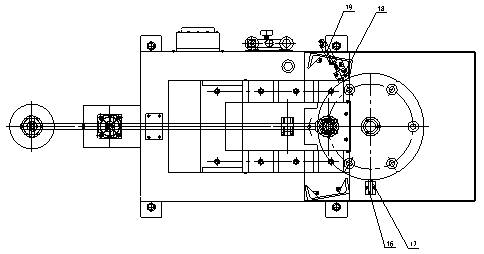

[0024] A pneumatically controlled rotary multi-station automatic lever medicine press, please refer to Figure 1-3 , comprising a lever medicine pressing machine body, on which an indexing mechanism, a positioning mechanism and a pressure mechanism are installed, and the indexing mechanism includes a workbench supporting plate 2, an overrunning clutch push-pull plate 3, and an ordinary flat key 4 , overrunning clutch 5, ordinary double-acting cylinder 6, lower mold body cover 7, bearing cover 8, tapered roller bearing 9, indexing shaft 10, indexing table 11 and electromagnetic reversing valve C20, the workbench supporting plate 2. It is fixed on the body of the lever medicine press by screws. The indexing table 11 is connected with the indexing shaft 10 through the hexagon socket head screw. The tapered roller bearing sleeve 9 is installed on the indexing shaft 10. The tapered roller bearing sleeve 9 The overrunning clutch 5 is connected with the index shaft 10 through the ord...

Embodiment 2

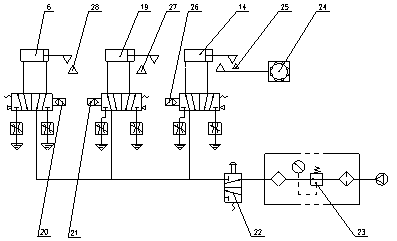

[0028] On the basis of Example 1, please refer to Figure 1-3 , the pressure mechanism includes a lower ejector rod 1, a lower ejector rod sleeve 12, a cap nut 13, a double-acting cylinder 14, an electromagnetic reversing valve A26, an explosion-proof manual valve 22, an air filter combination triple piece 23 and a double-setting repeating cycle Digital display time relay 24; the port of the double-acting cylinder 14 is connected to the cap nut 13 and supported on the lever 15, one end of the lower ejector rod 1 is connected to the lever 15, and the other end of the lower ejector rod 1 is placed on the lower ejector rod Below the sleeve 12; it should be noted that the lever medicine press includes but not limited to six working positions, preferably six working positions.

[0029] After the ordinary double-acting cylinder 6 moves in place, it will touch its built-in signal magnetic ring C28, so that the electromagnetic reversing valve C20 will be reset, and the electromagnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com