Chain assembly machine for U-shaped external single-joint agricultural machinery

An assembly machine and single-section technology, applied in the direction of metal chains, etc., can solve the problems of low degree of automation, slow press-fitting speed, and long processing procedures, and achieve the effects of high degree of automation, fast press-fitting speed, and fast production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

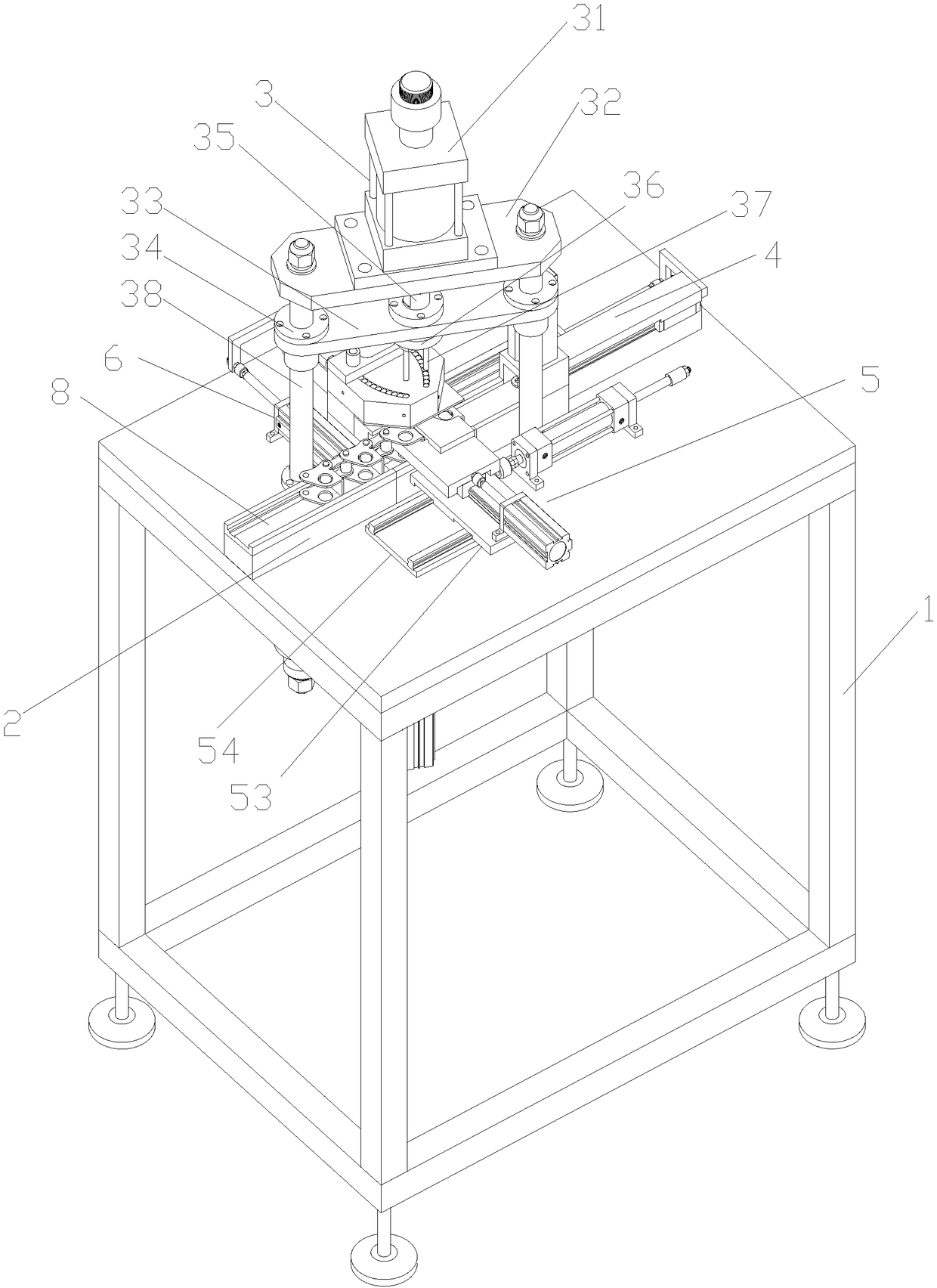

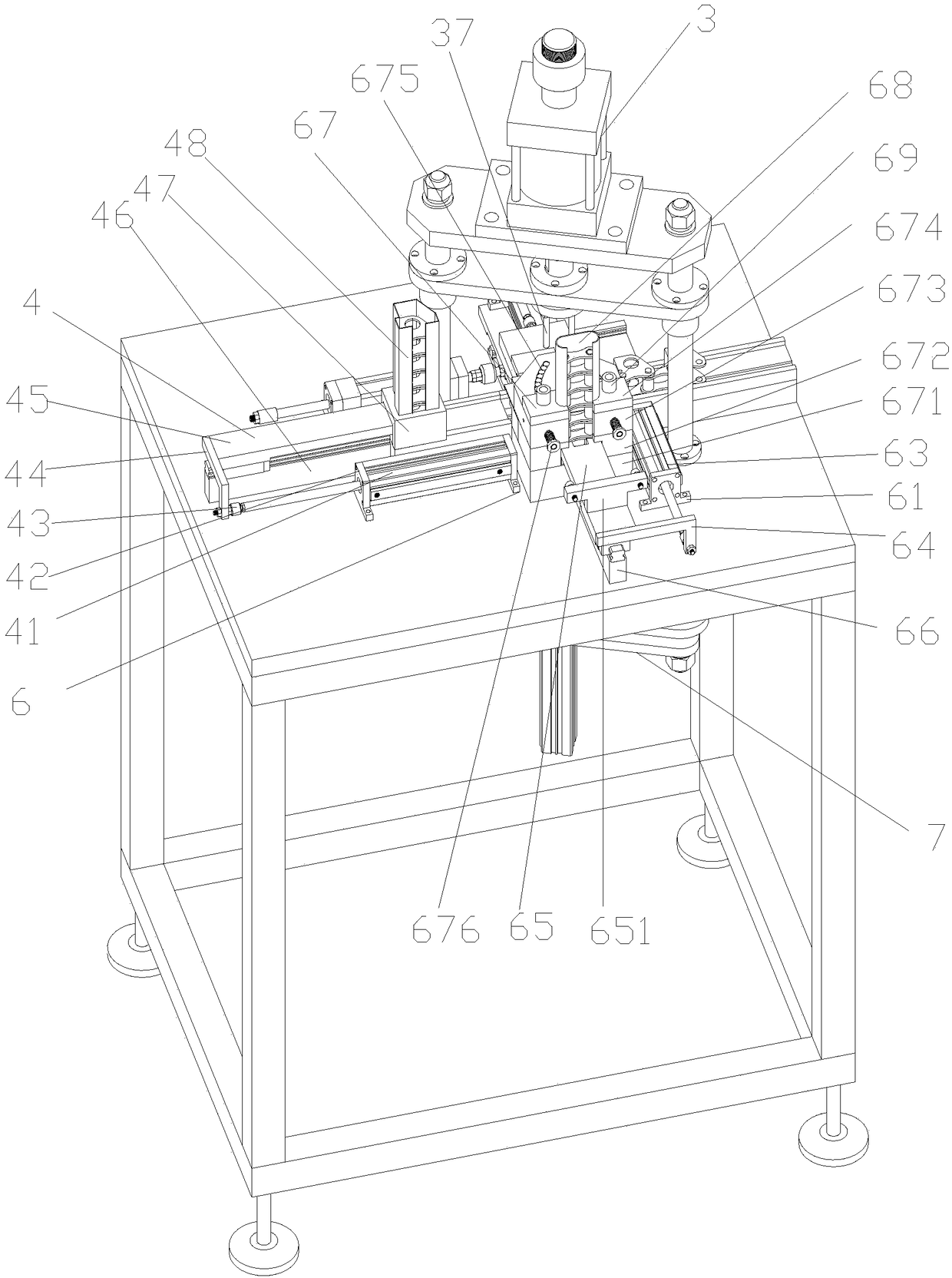

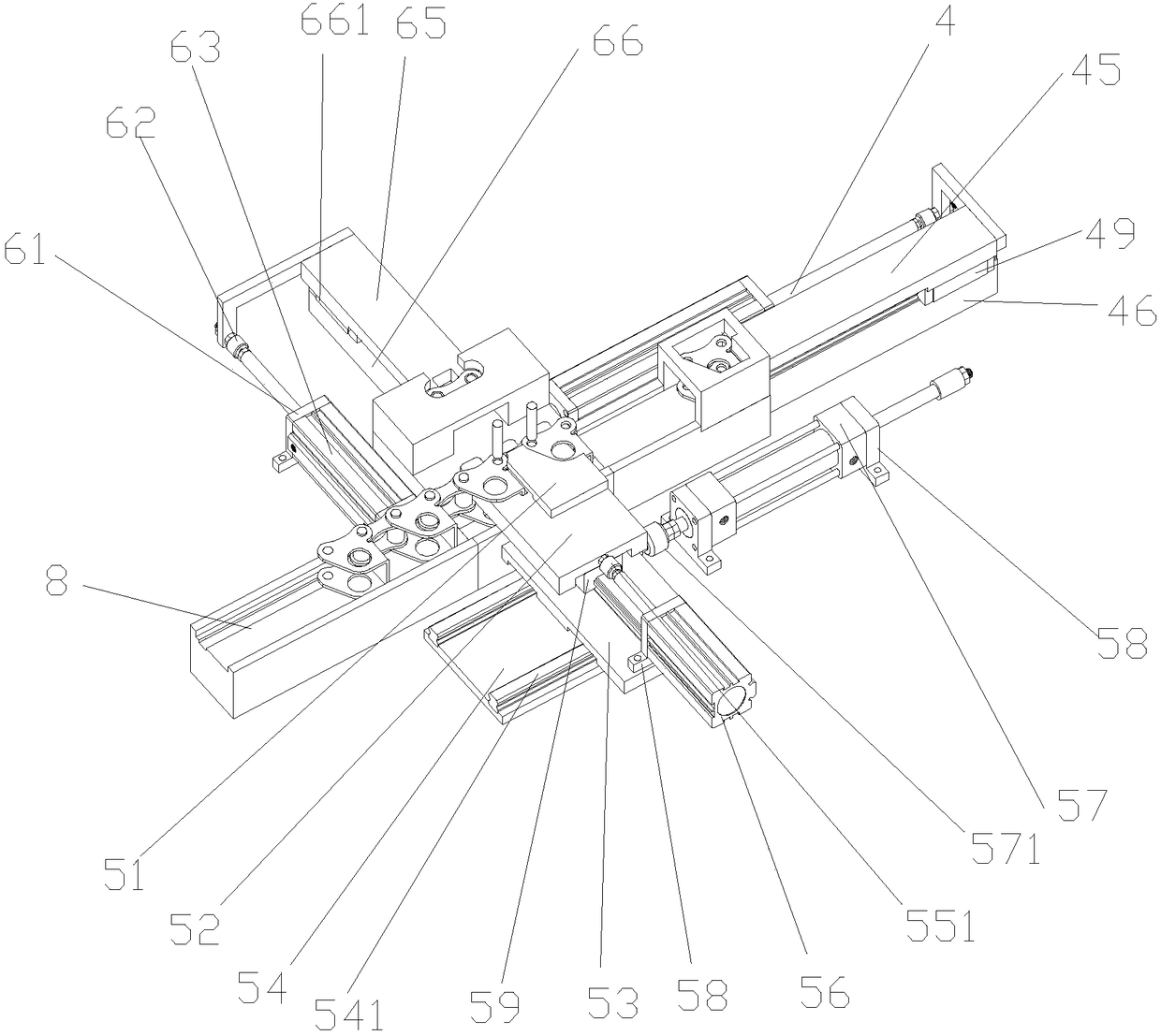

[0030] Such as Figure 1-12 The U-shaped outer single-section agricultural machinery chain assembly machine includes a frame 1, a base 2 is arranged on the work surface of the frame 1, and a pin press-fitting mechanism 3 is arranged above the base 2, and the base 2 One lateral side is provided with the first feeding mechanism 4 for conveying the U-shaped outer single section, and the other lateral side of the base 2 is provided with a base for conveying the chain out of the chain, and the base includes a chain out guide rail 8, a chain out guide rail 8 Installed on the upper side of the base 2, the chain-out guide rail 8 is adapted to the assembled chain. The length of the chain-out guide rail 8 can be determined according to the actual situation. The vertical side of the base 2 is provided with a positioning transfer mechanism 5. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com