Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Increase the flow cross section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

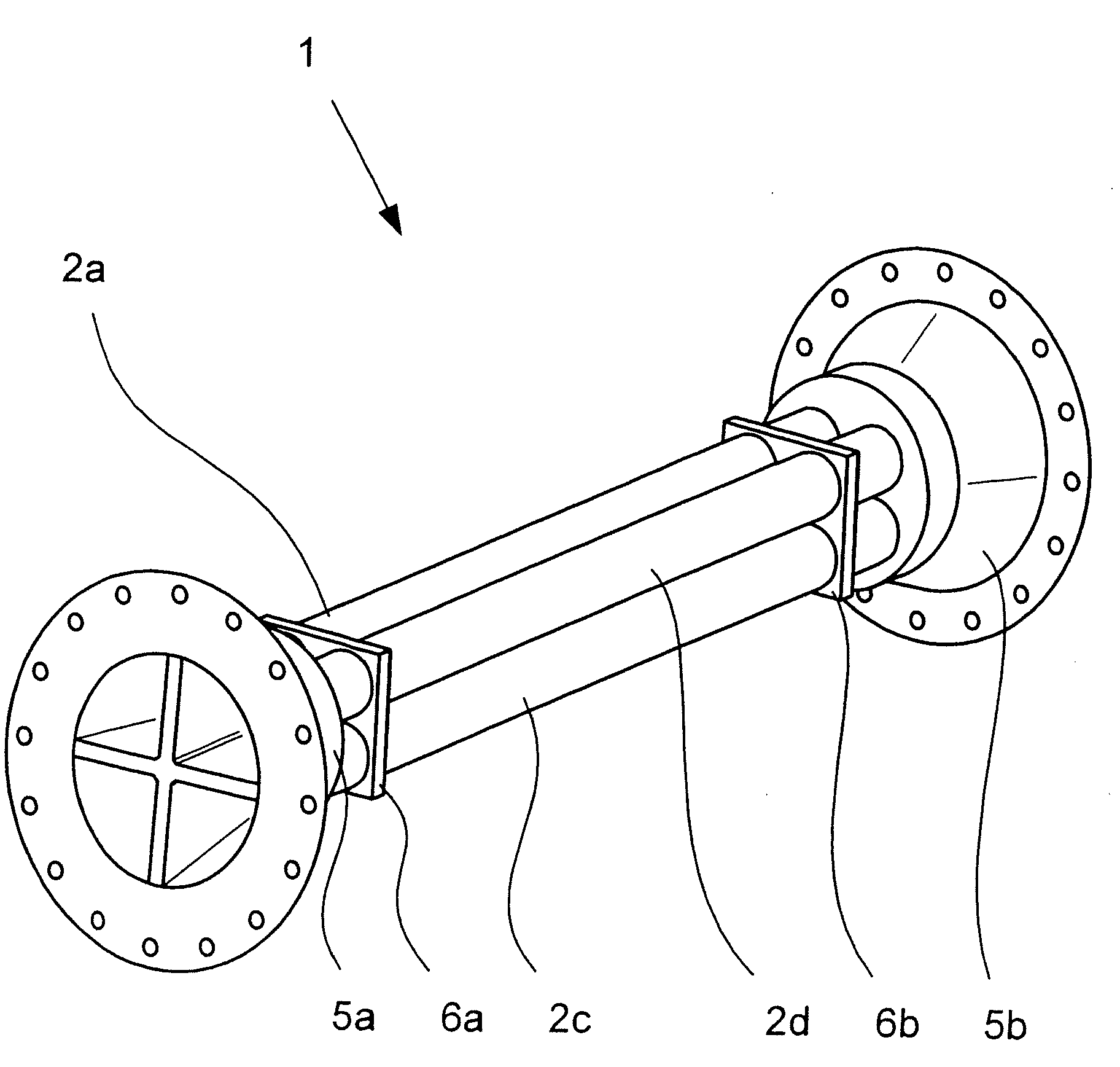

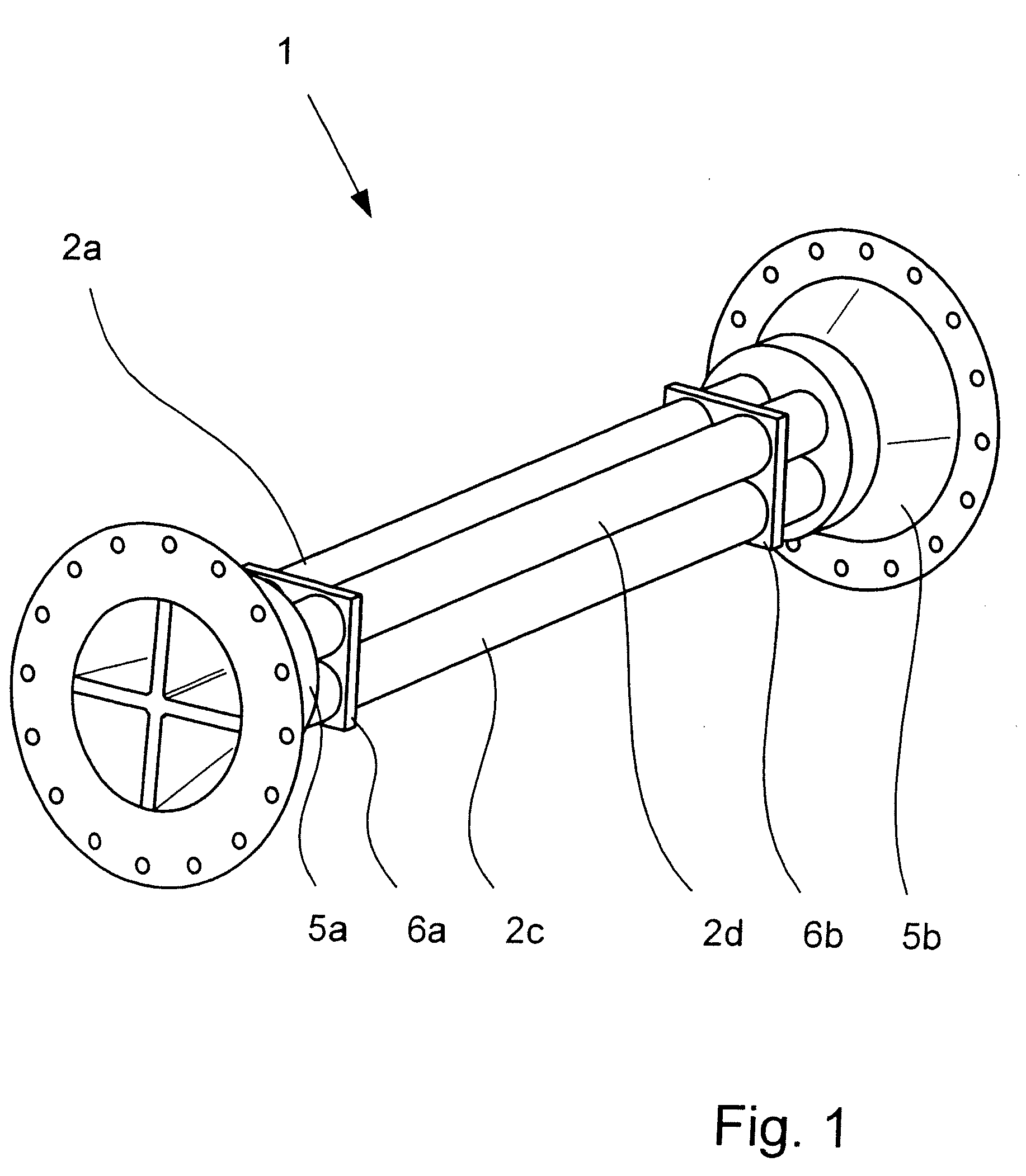

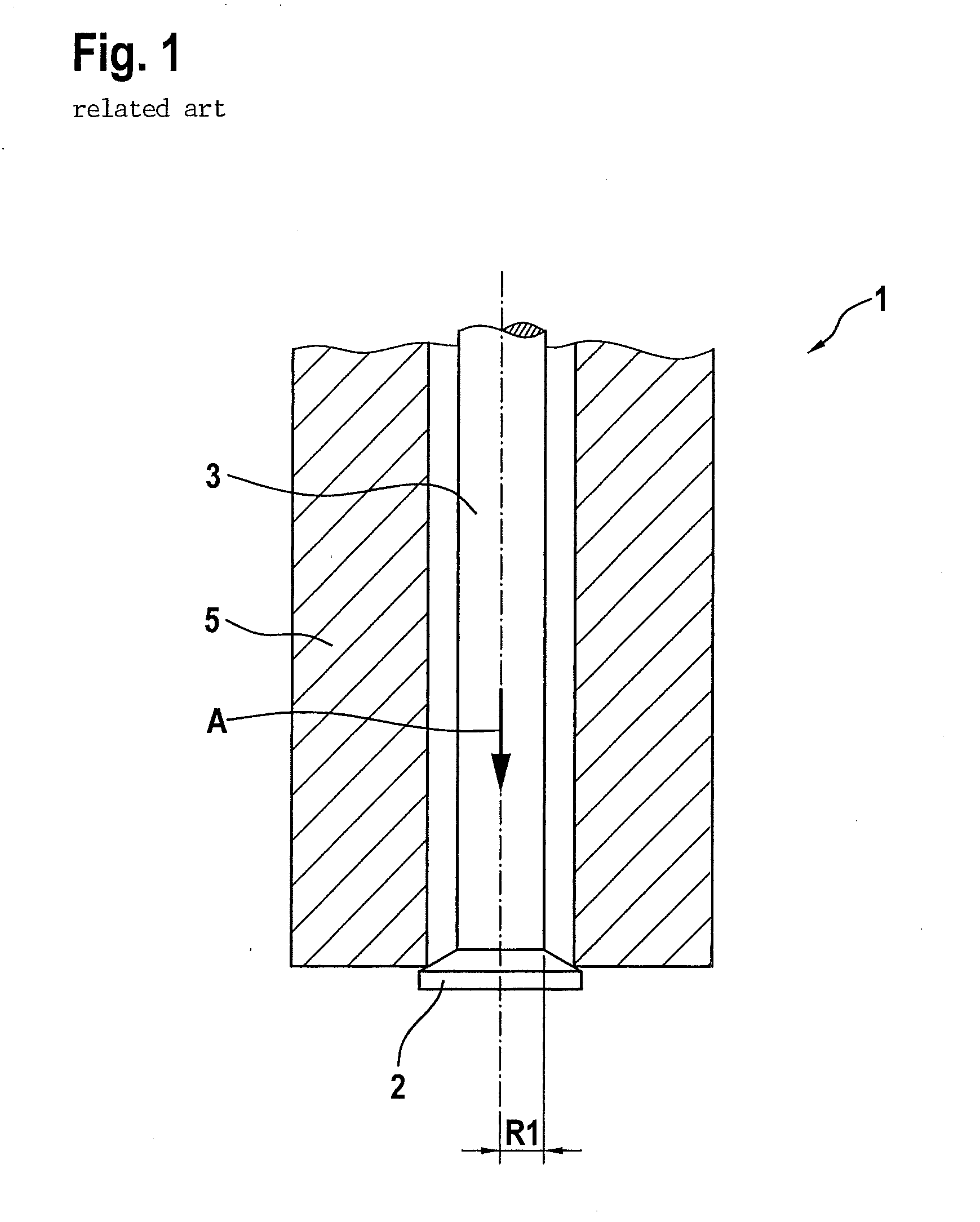

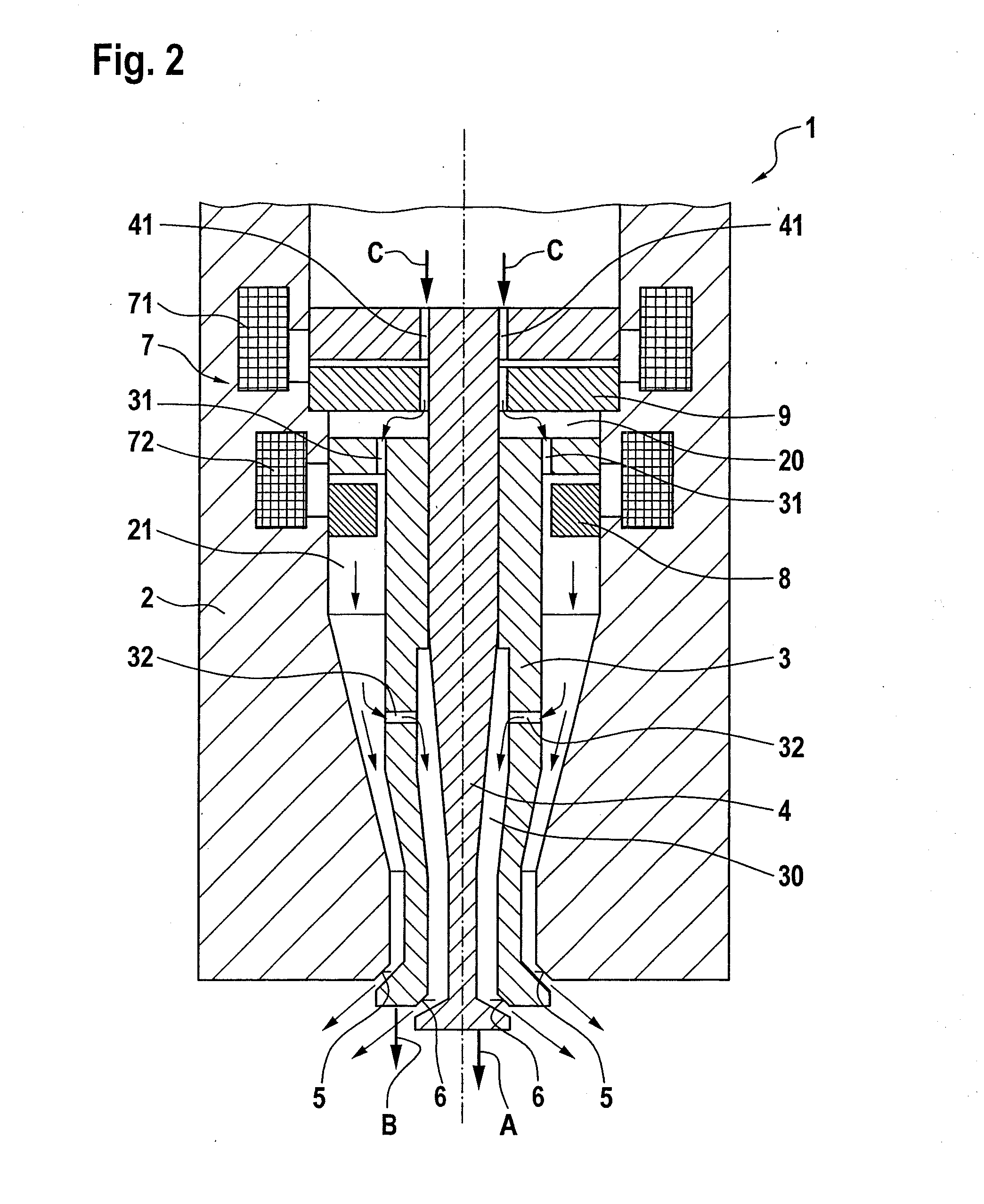

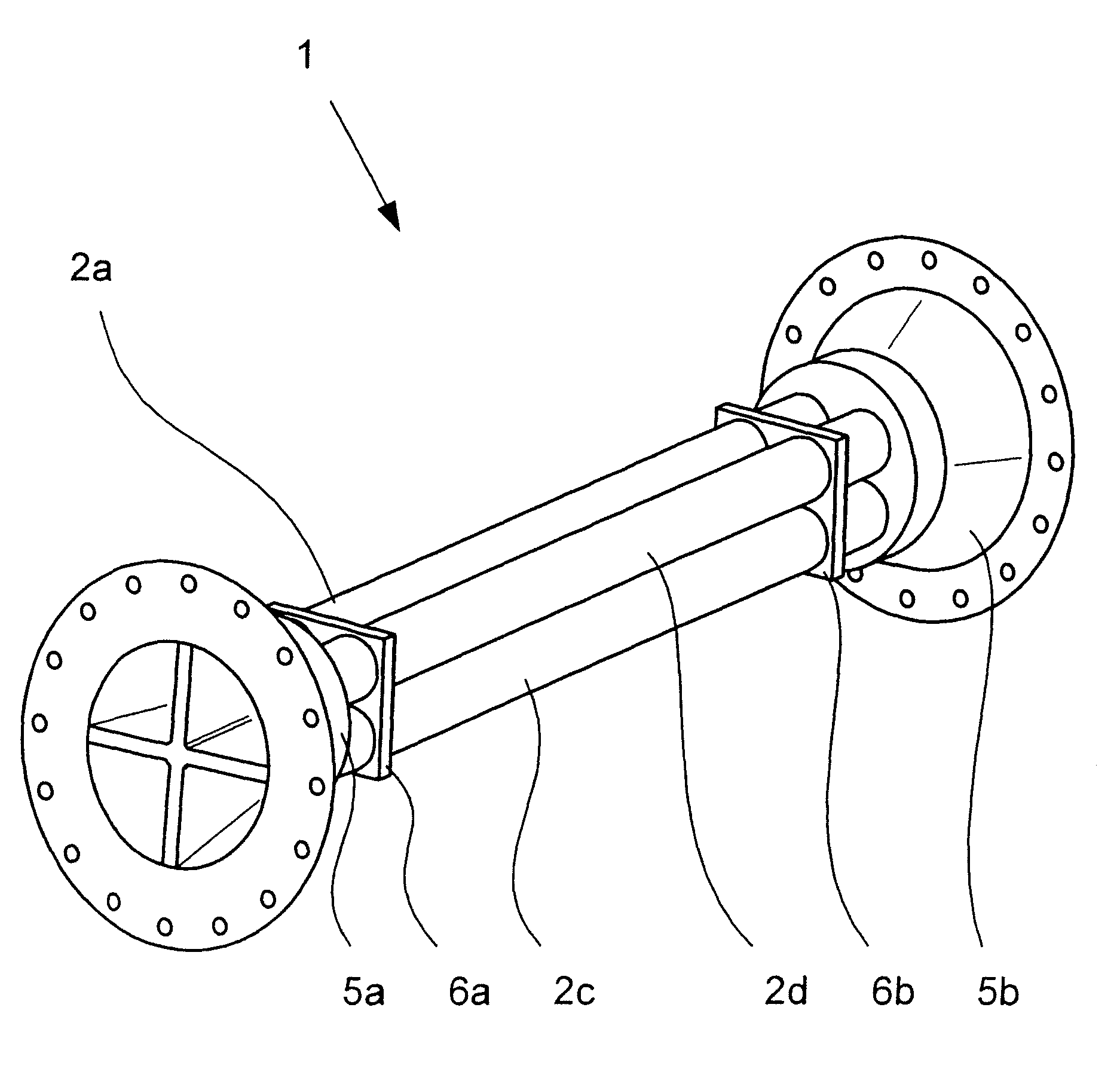

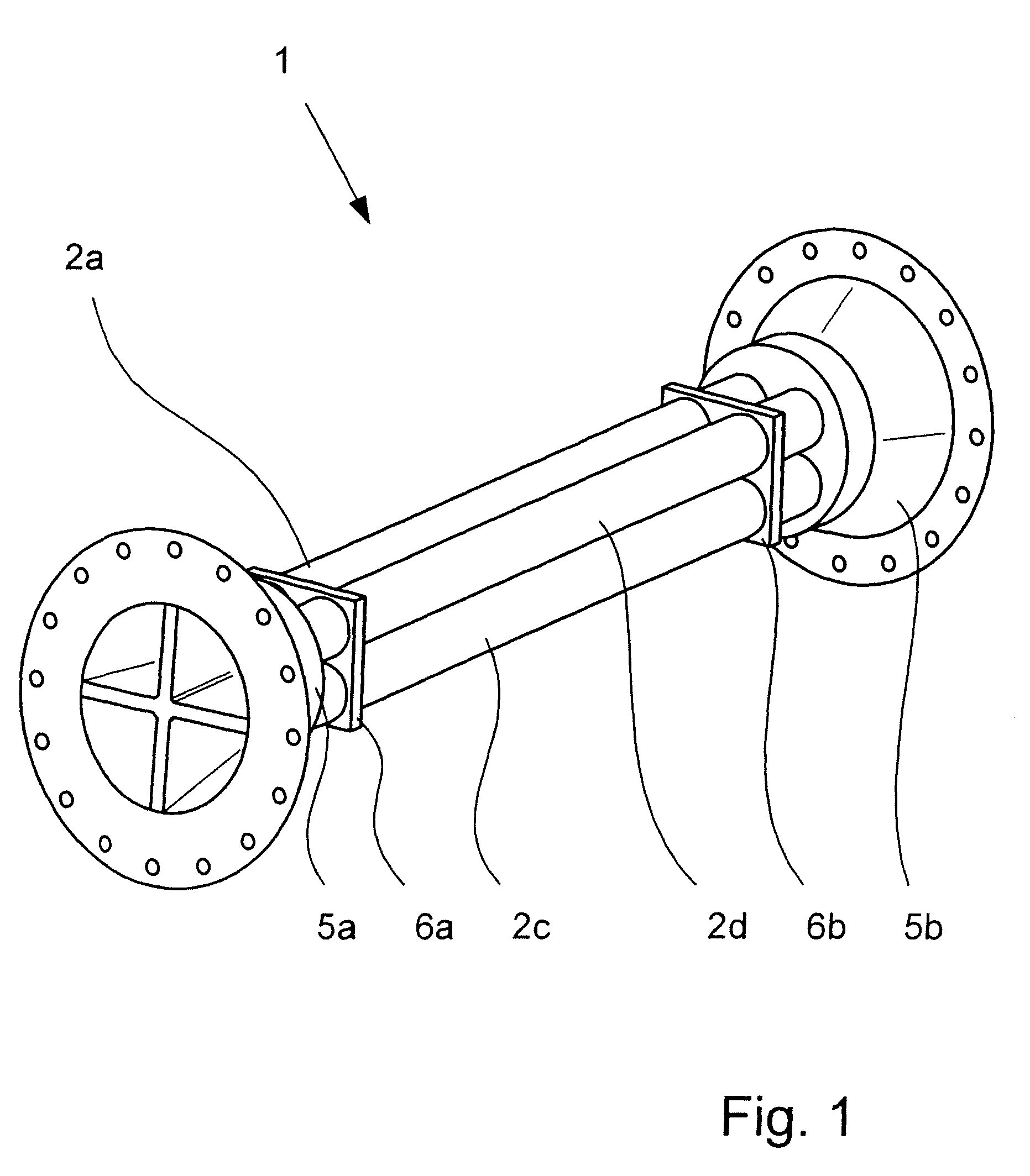

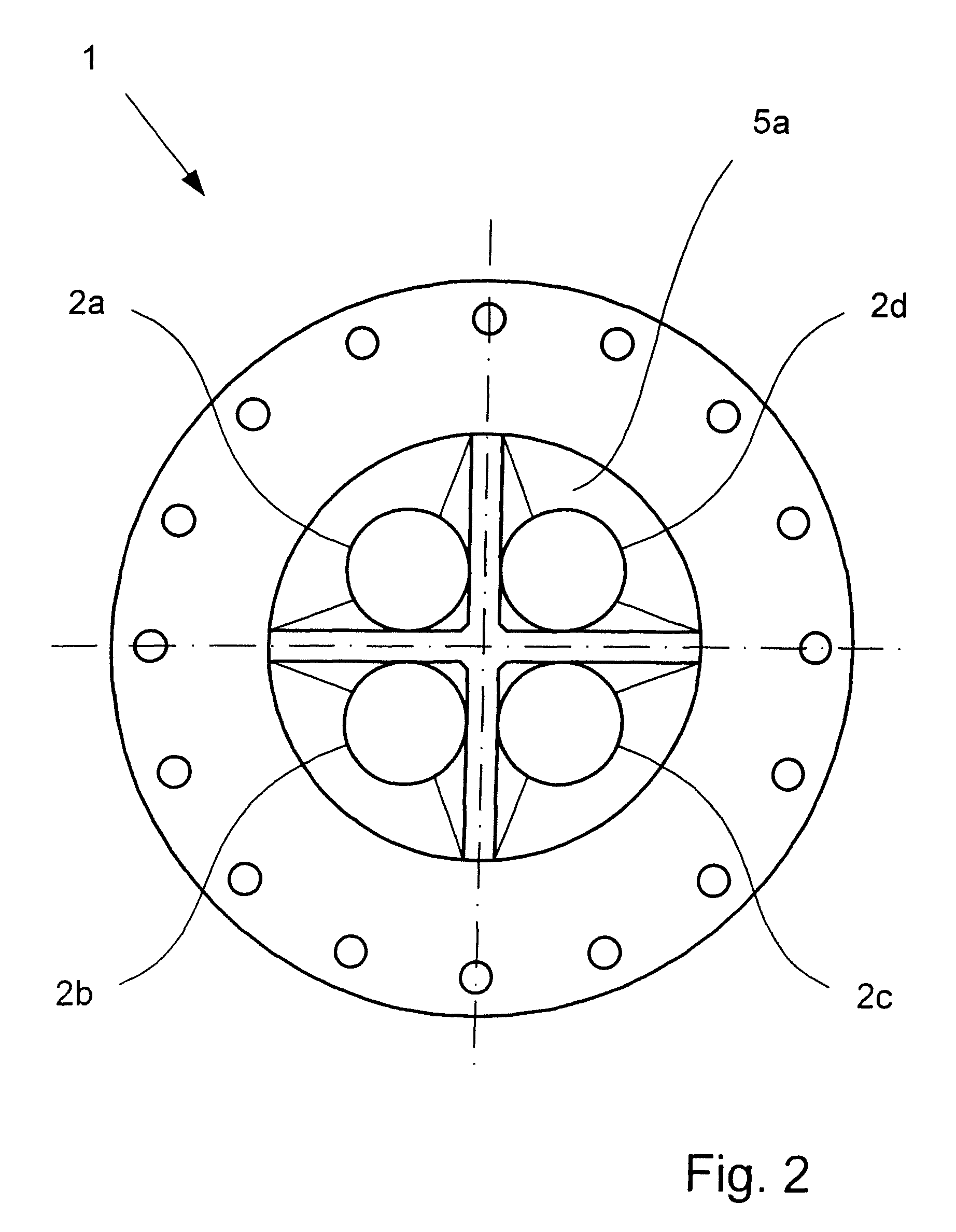

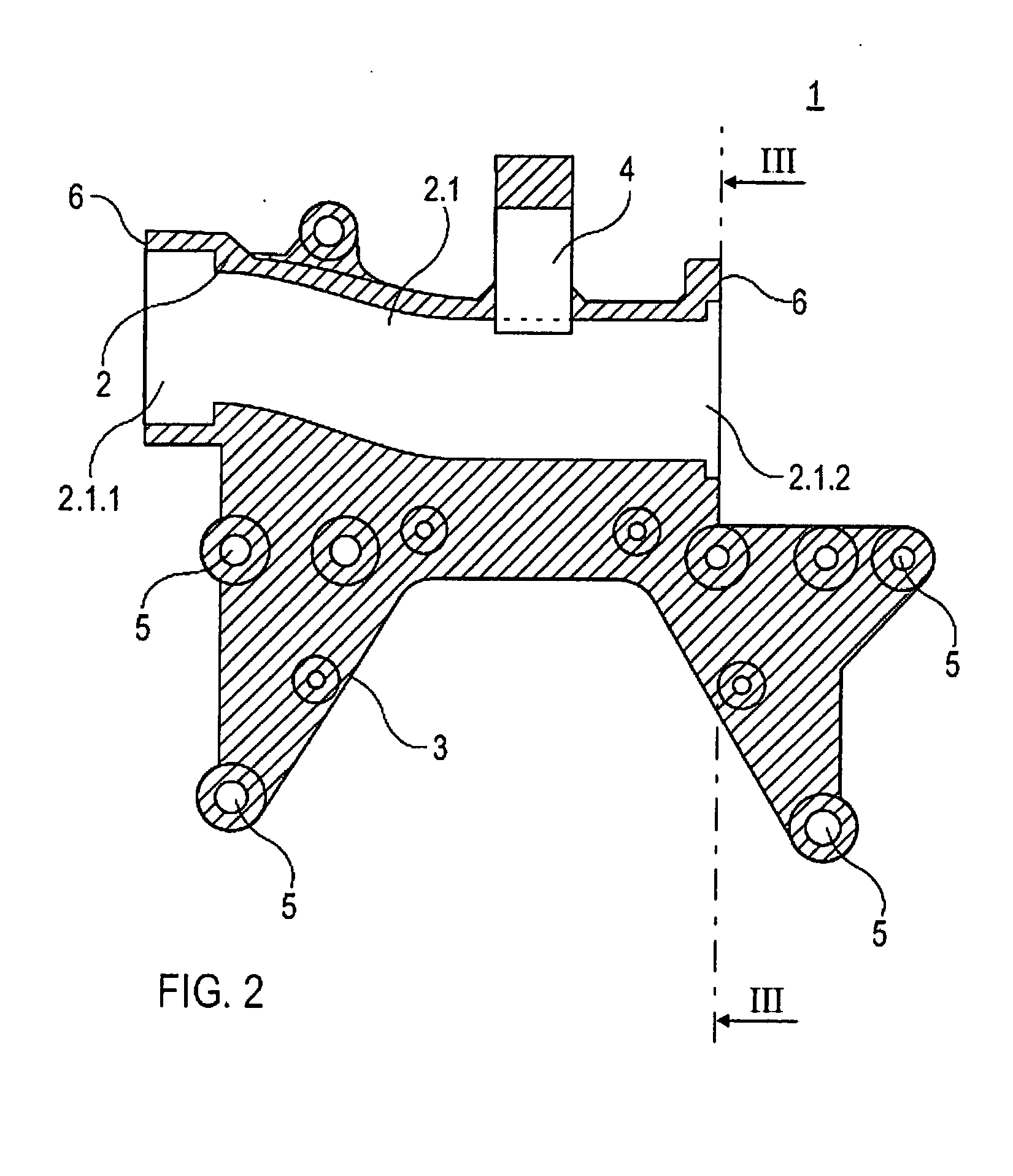

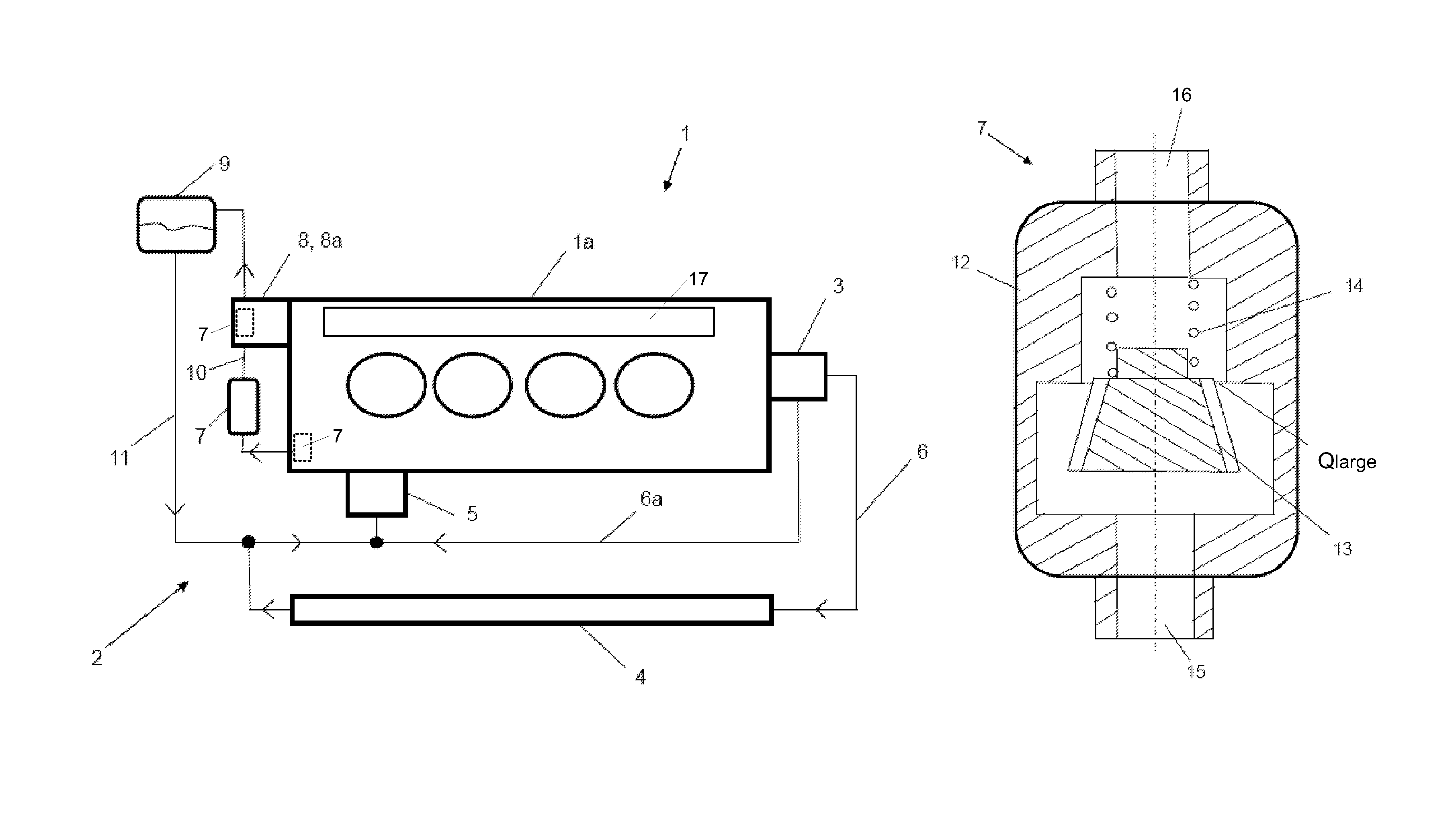

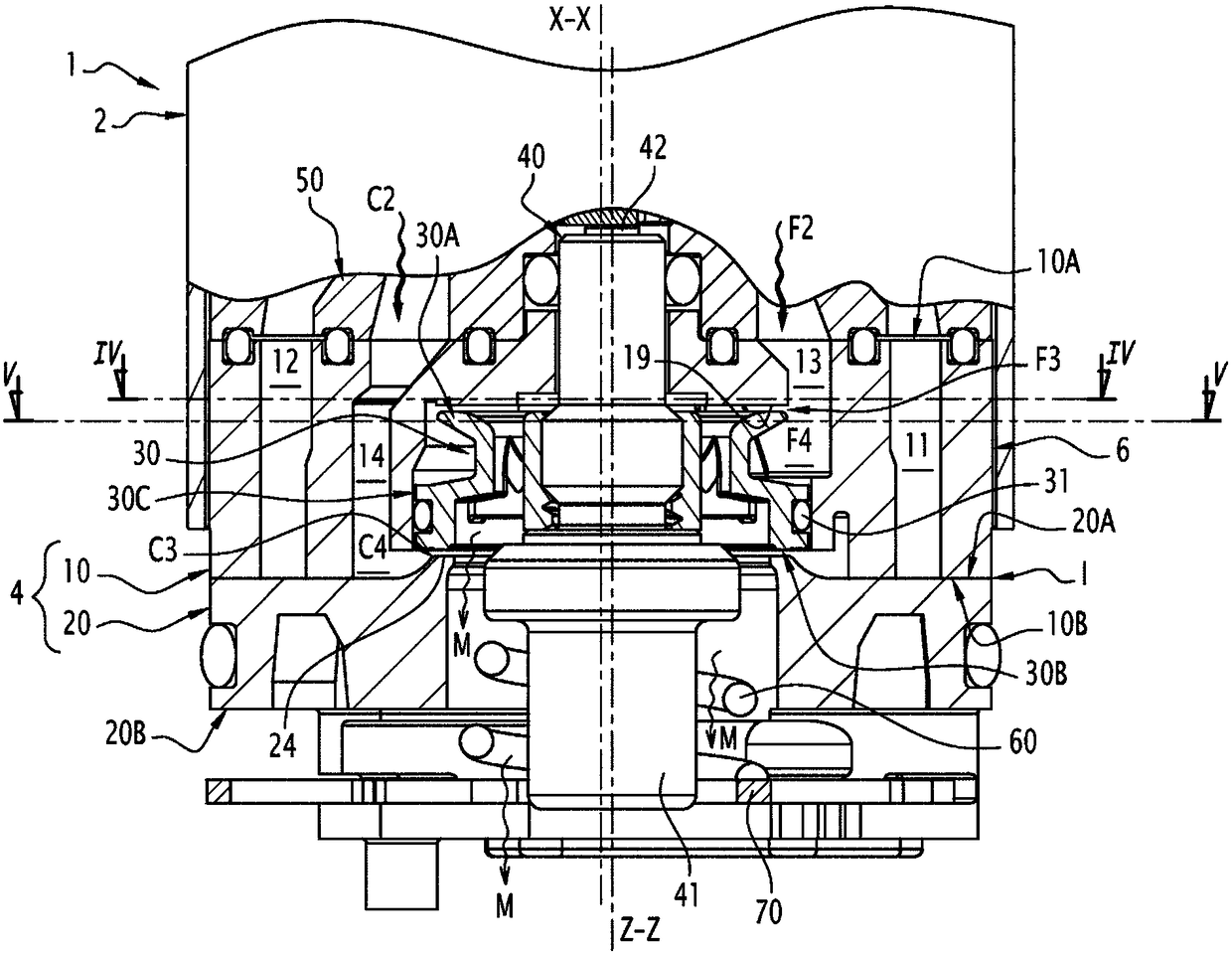

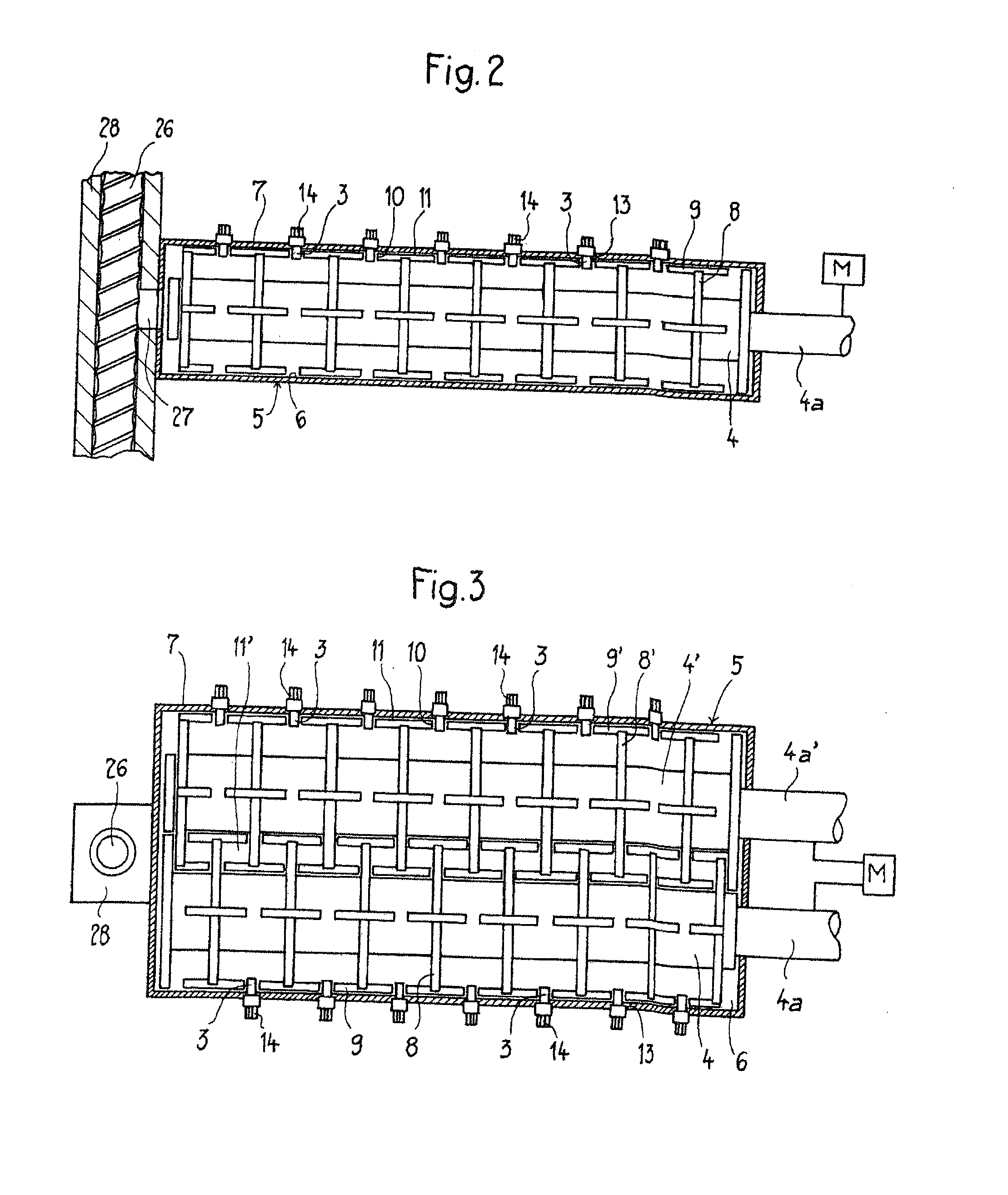

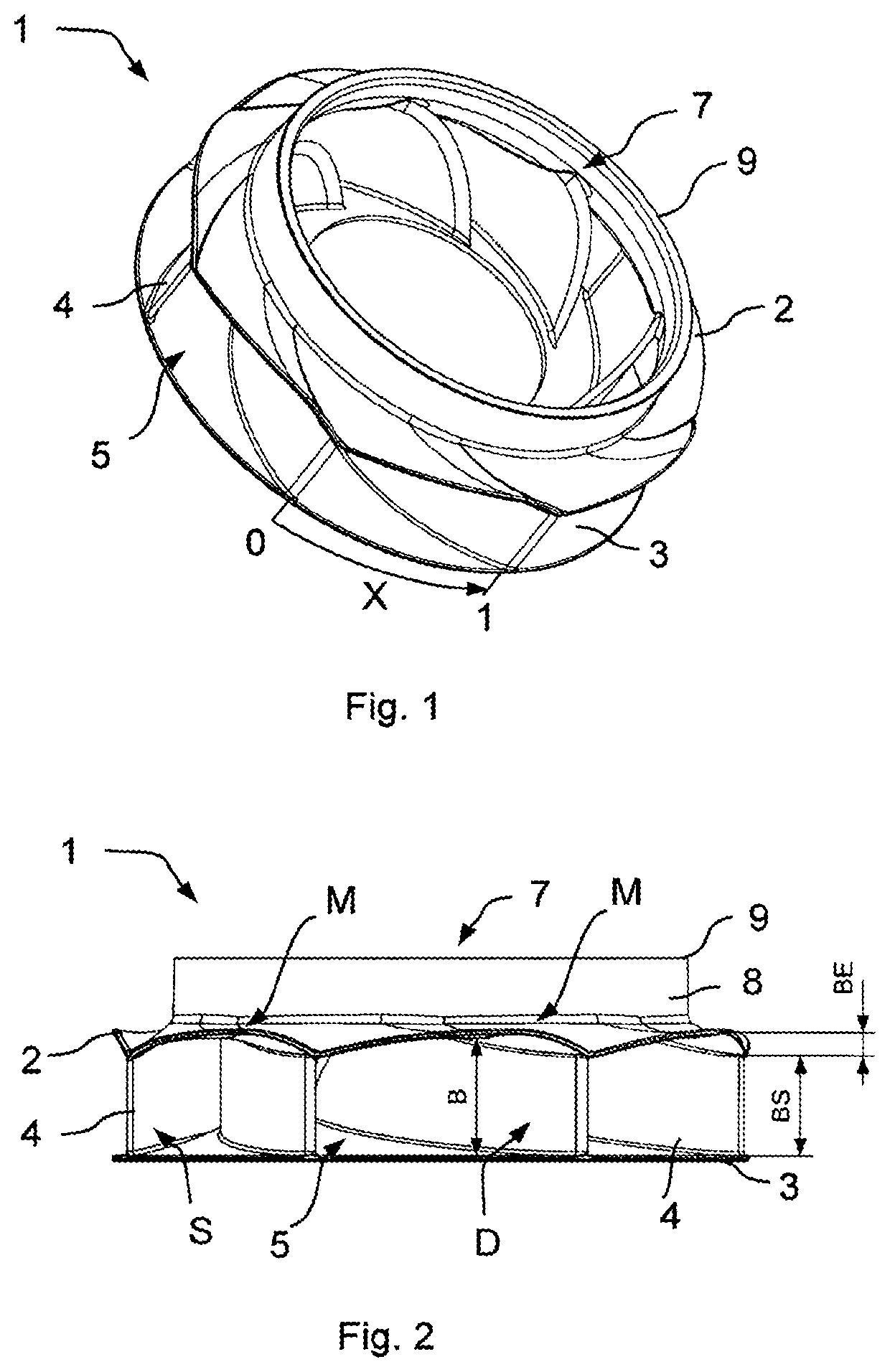

Mass flowmeter

A mass flowmeter is provided which operates on the Coriolis principle, having (1) at least four measurement tubes which can oscillate and through which a medium can flow, (2) at least one oscillation generator for excitation of the oscillations of the measurement tube, and (3) at least one oscillation sensor for detection of the excited oscillations of the measurement tubes. The measurement tubes are preferably arranged closely in parallel such that the flow cross section covered by the measurement tubes covers as small an area as possible. The use of four or more compactly arranged measurement tubes advantageously allows for the measurement of a high mass flow rate with measurement tubes having a relatively small cross section and length, resulting in a mass flowmeter having compact length and width dimensions, and which requires only a relatively low energy oscillation generator for excitation of the oscillations of the measurement tubes.

Owner:KRONE GMBH

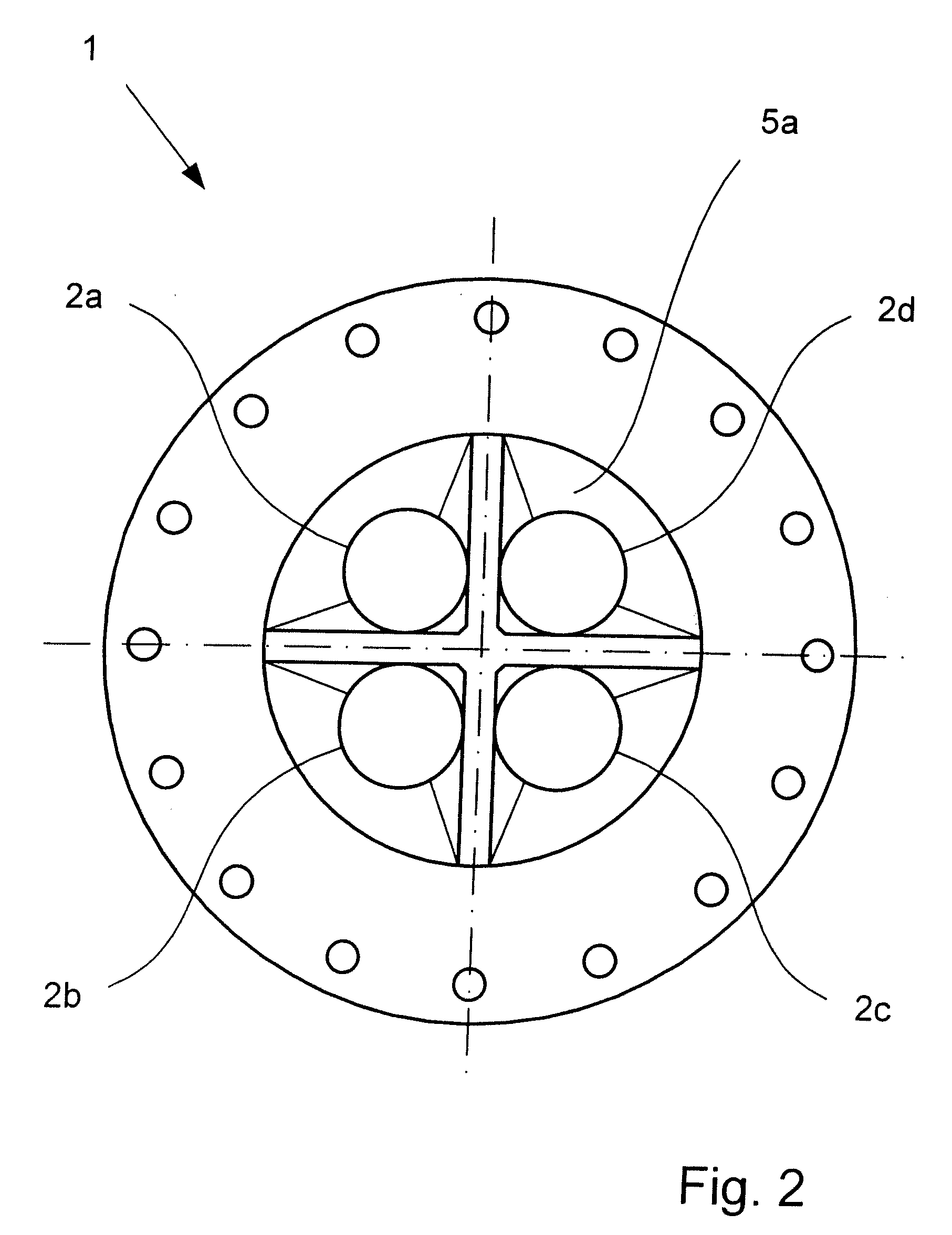

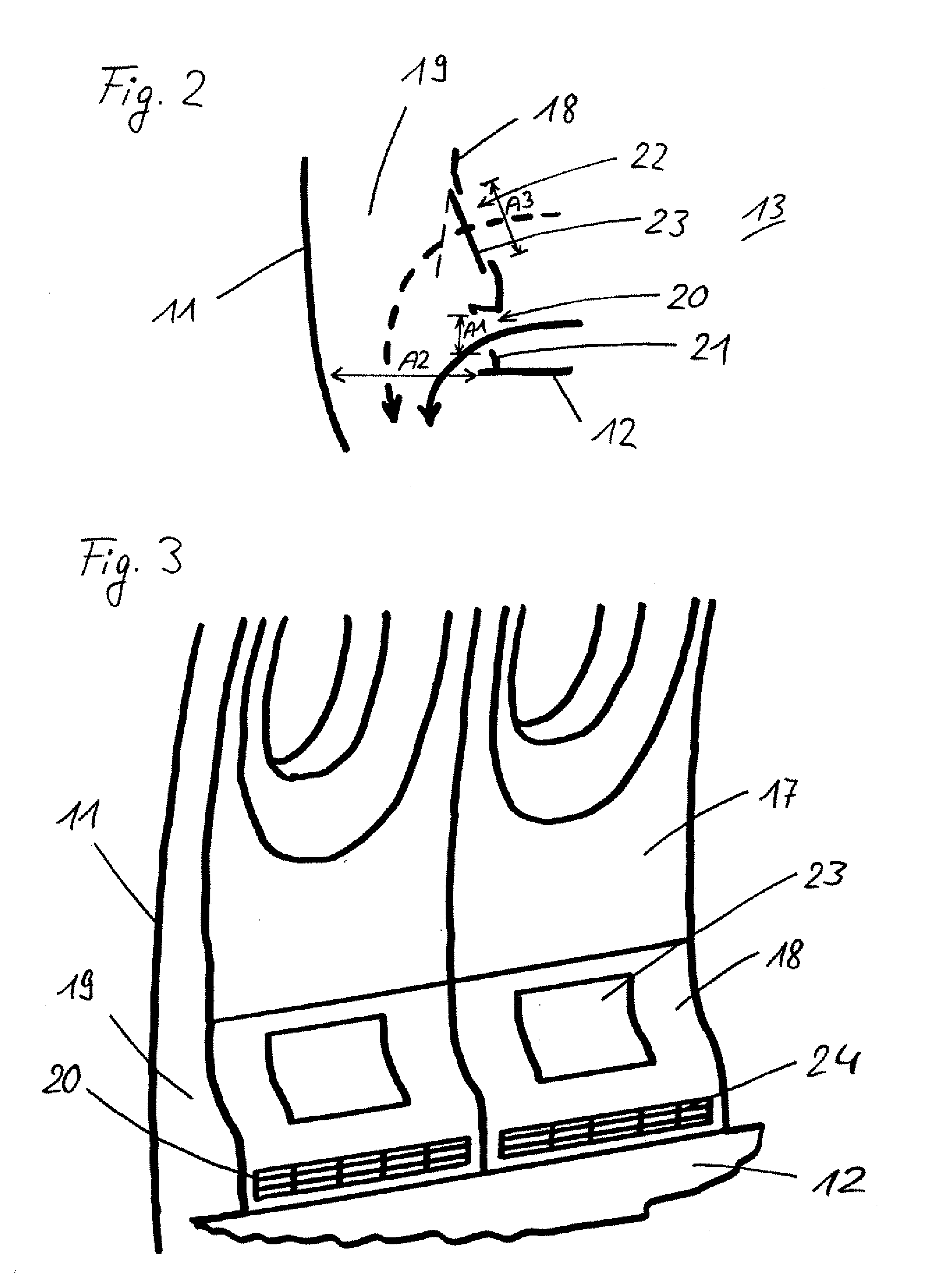

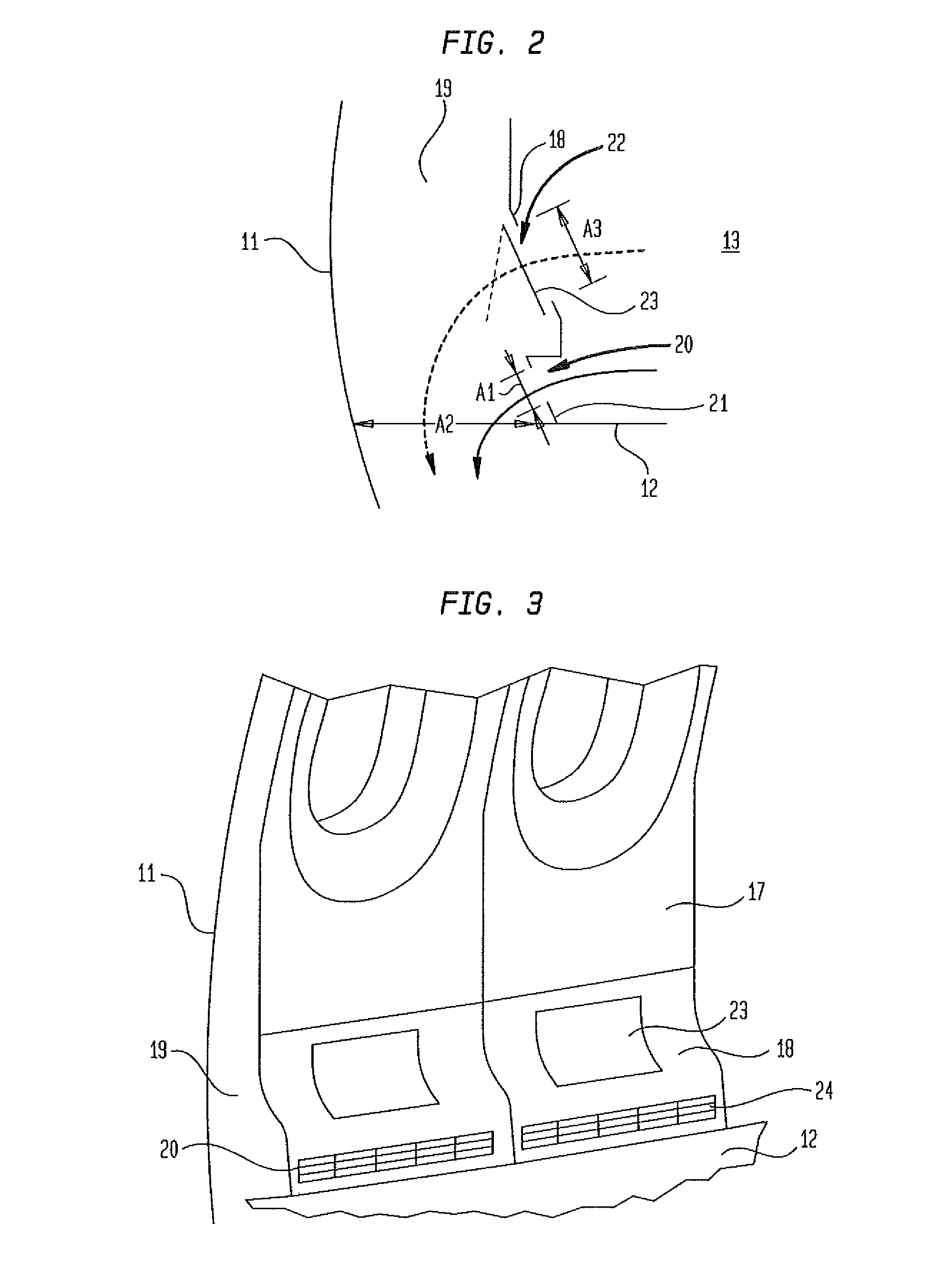

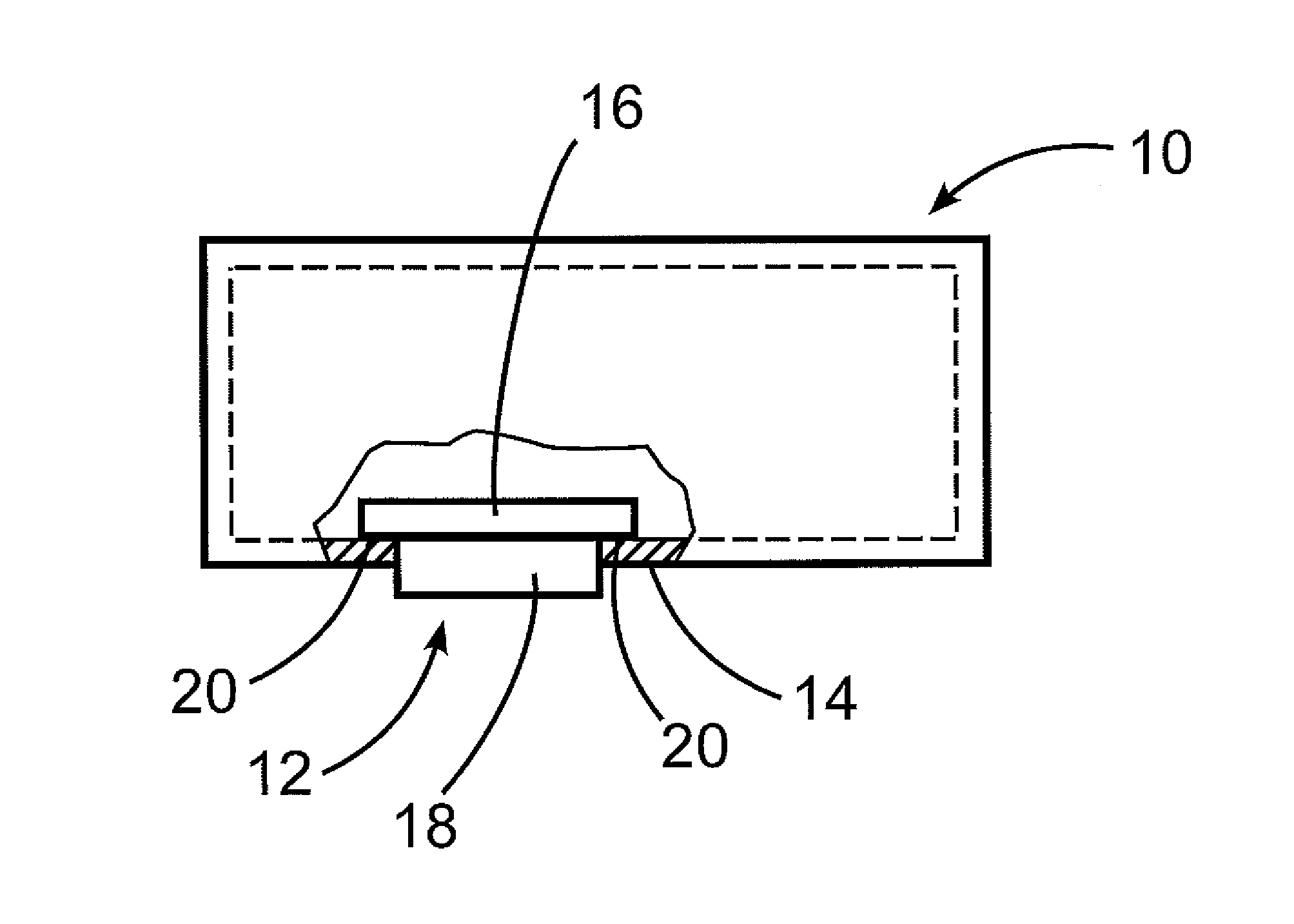

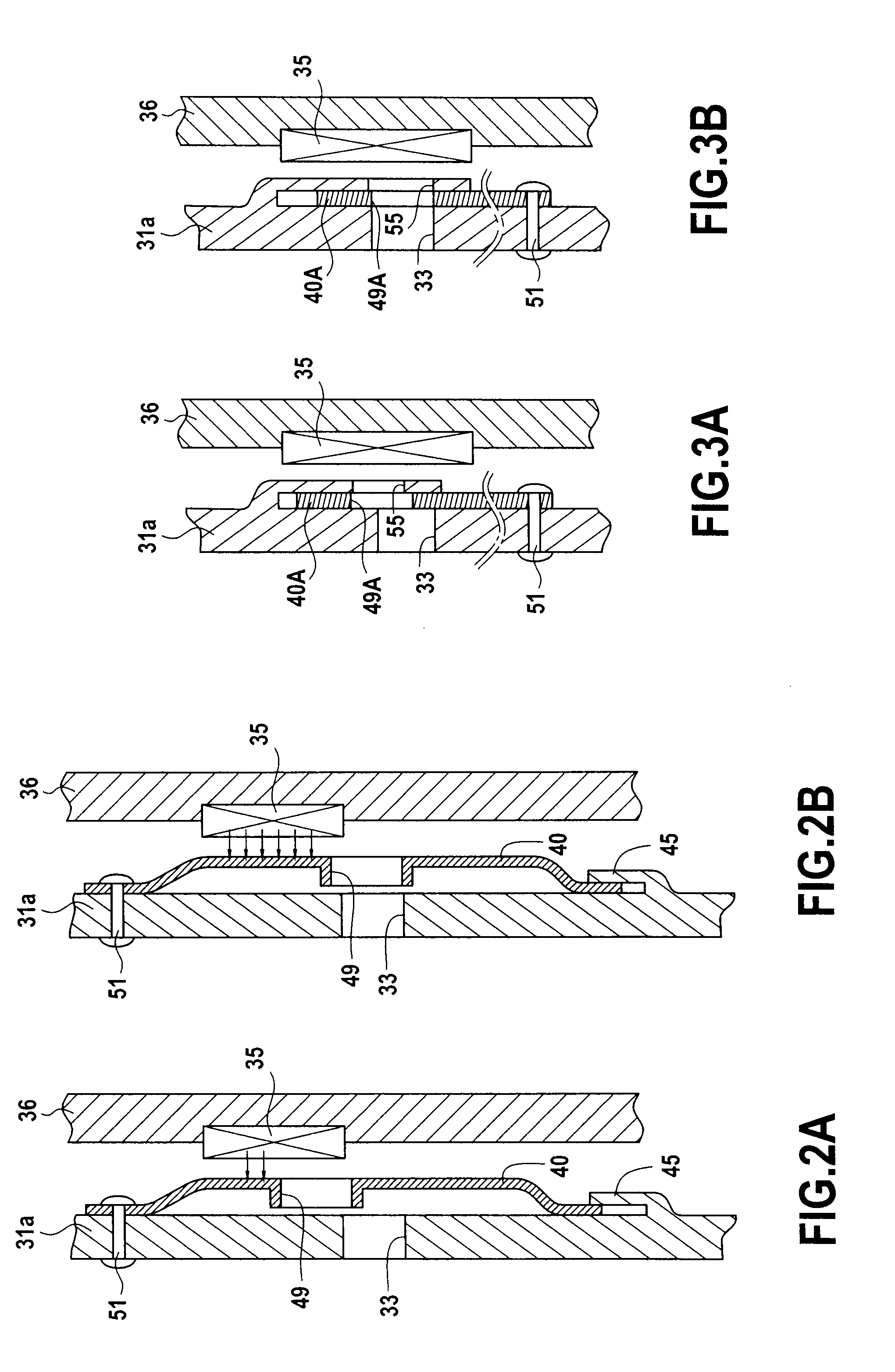

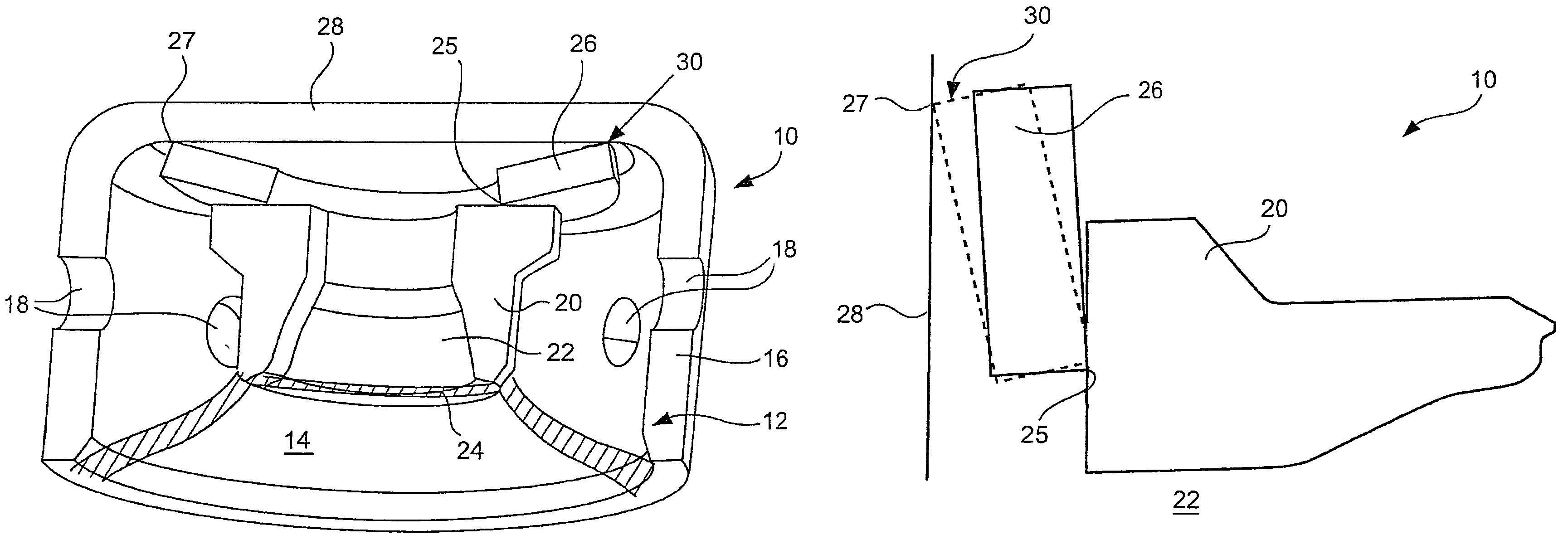

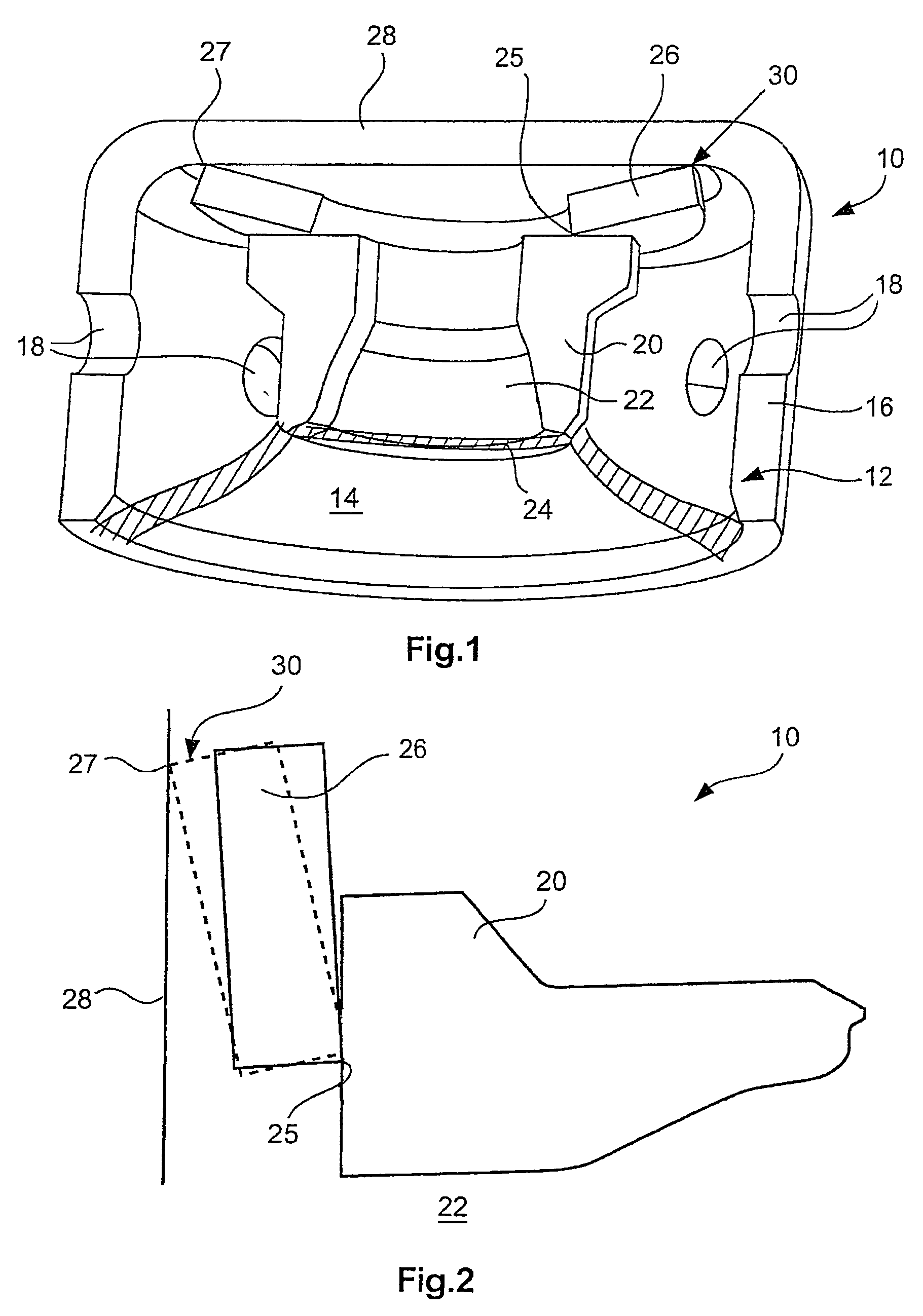

Decompression device for an aircraft

ActiveUS20100187358A1Simply designQuick pressure compensationAir-treatment apparatus arrangementsFuselagesAirplaneFuselage

The invention relates to a cover panel for an aircraft, comprising a decompression opening that can be closed by a decompression flap that comprises a membrane, and a ventilation opening that is provided separately in the cover panel and that is permanently open. Furthermore, the invention relates to an aircraft fuselage comprising such a cover panel.

Owner:AIRBUS OPERATIONS GMBH

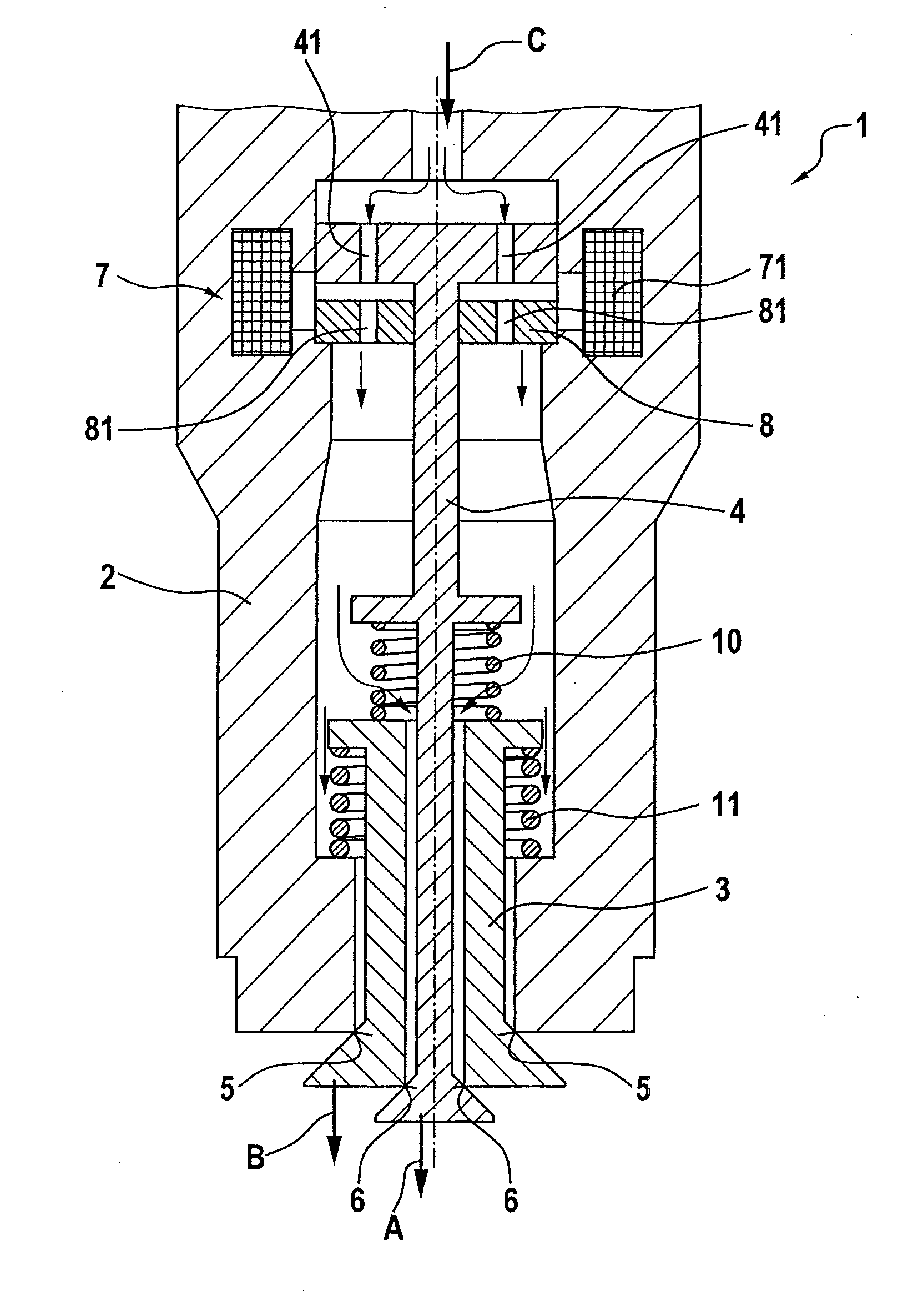

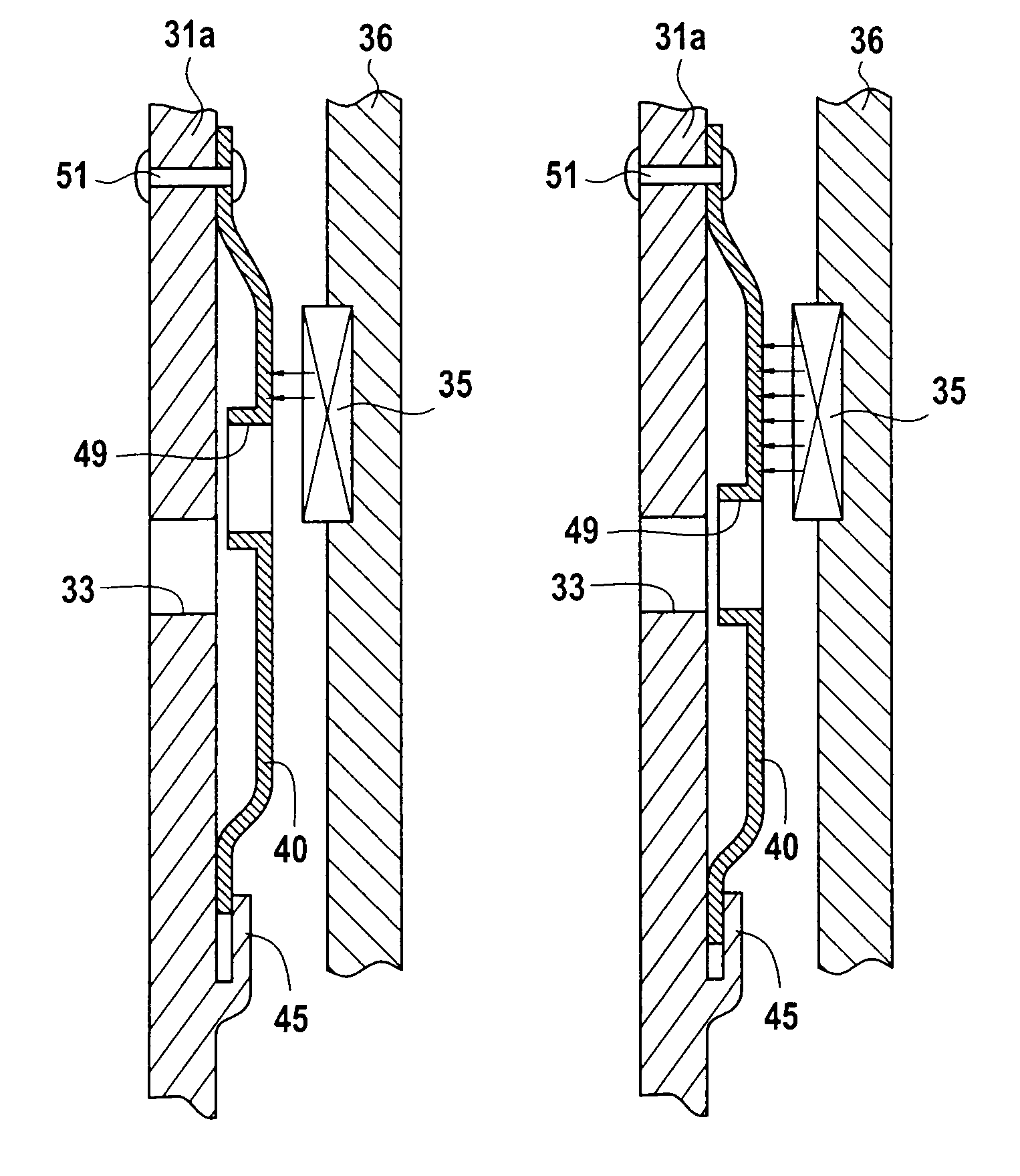

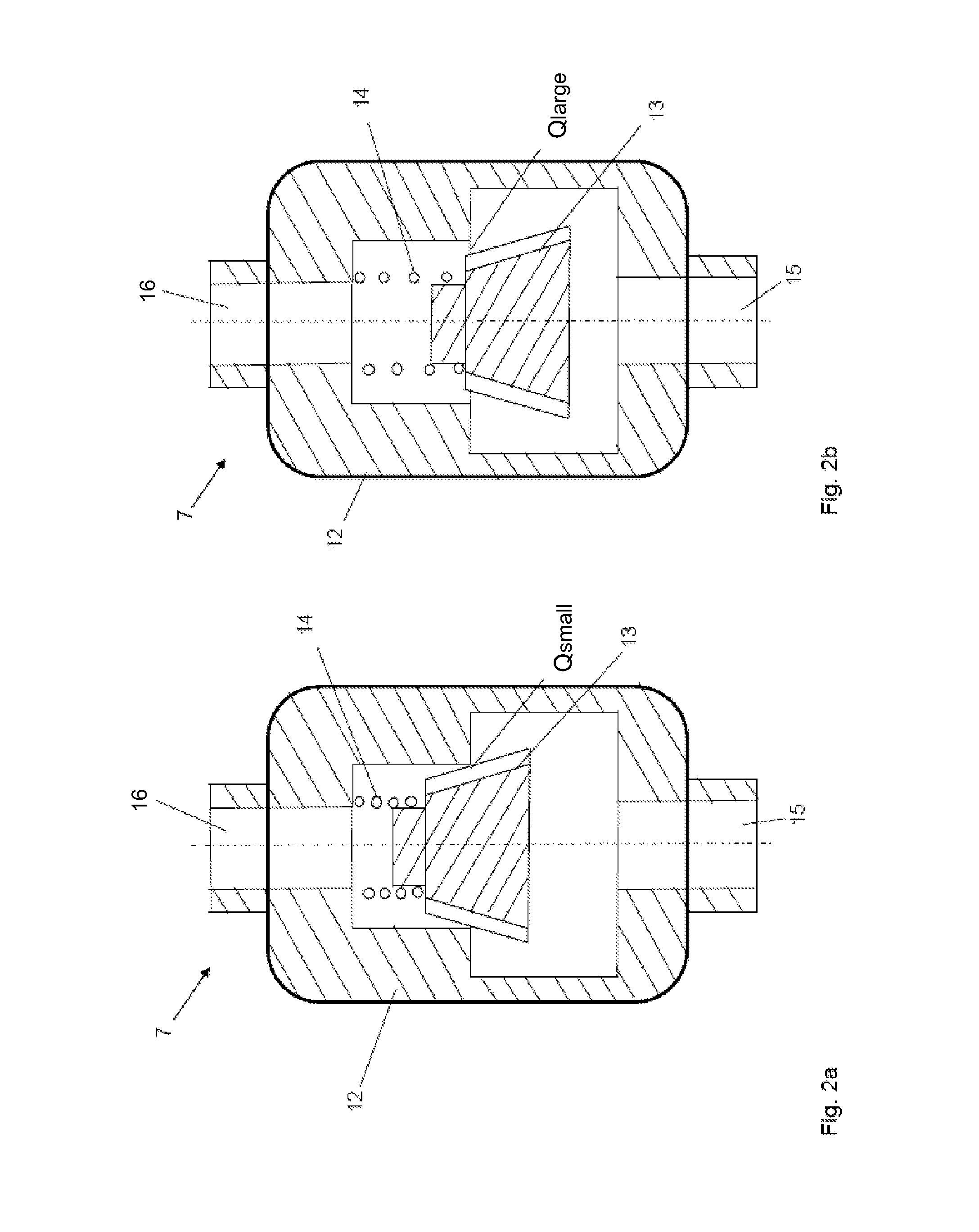

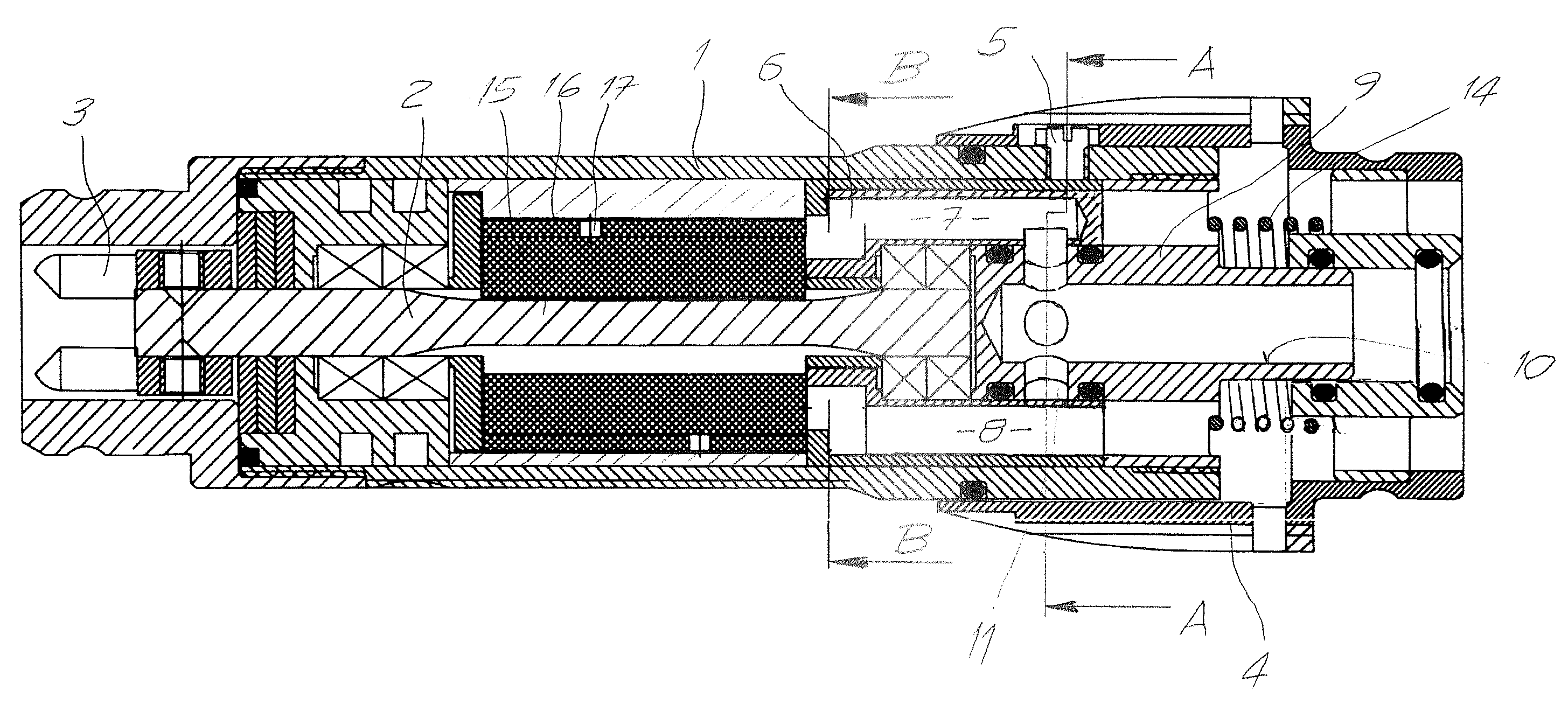

Gas injector having a dual valve needle

ActiveUS20150267659A1Compact and small designCompact designInternal combustion piston enginesFuel supply apparatusInjectorEngineering

A gas injector for injecting gaseous fuel includes: a valve body; an outer needle which is a hollow needle; an inner needle disposed in a hollow region of the outer needle; and an actuator system configured to actuate the outer needle and the inner needle independently of each other in each case. A first sealing seat is provided between the valve body and the outer needle, and a second sealing seat is provided between the outer needle and the inner needle.

Owner:ROBERT BOSCH GMBH

Decompression device for an aircraft

ActiveUS8567721B2Avoid excessive depthSave installation spaceAir-treatment apparatus arrangementsFuselagesFuselageAirplane

The invention relates to a cover panel for an aircraft, comprising a decompression opening that can be closed by a decompression flap that comprises a membrane, and a ventilation opening that is provided separately in the cover panel and that is permanently open. Furthermore, the invention relates to an aircraft fuselage comprising such a cover panel.

Owner:AIRBUS OPERATIONS GMBH

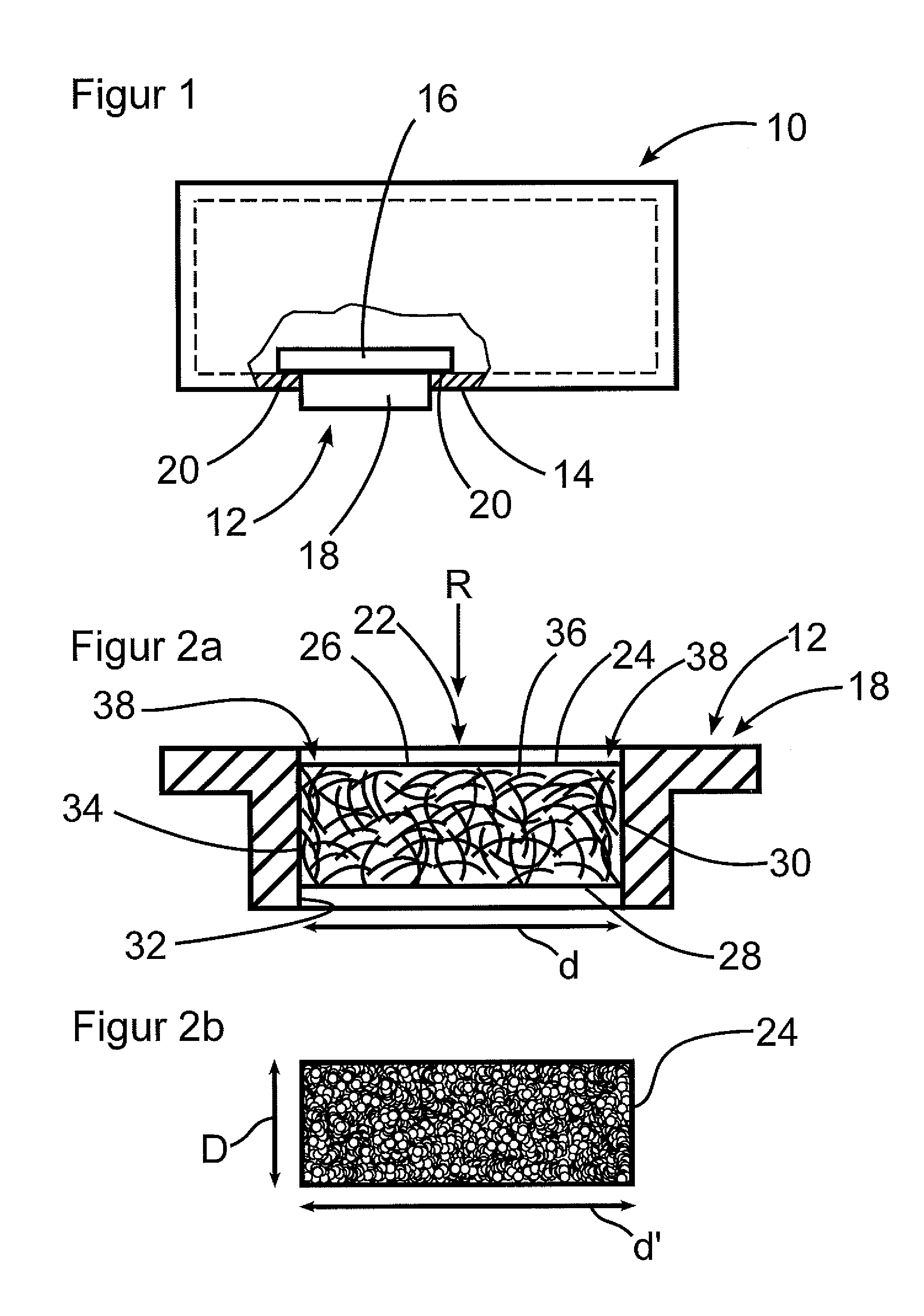

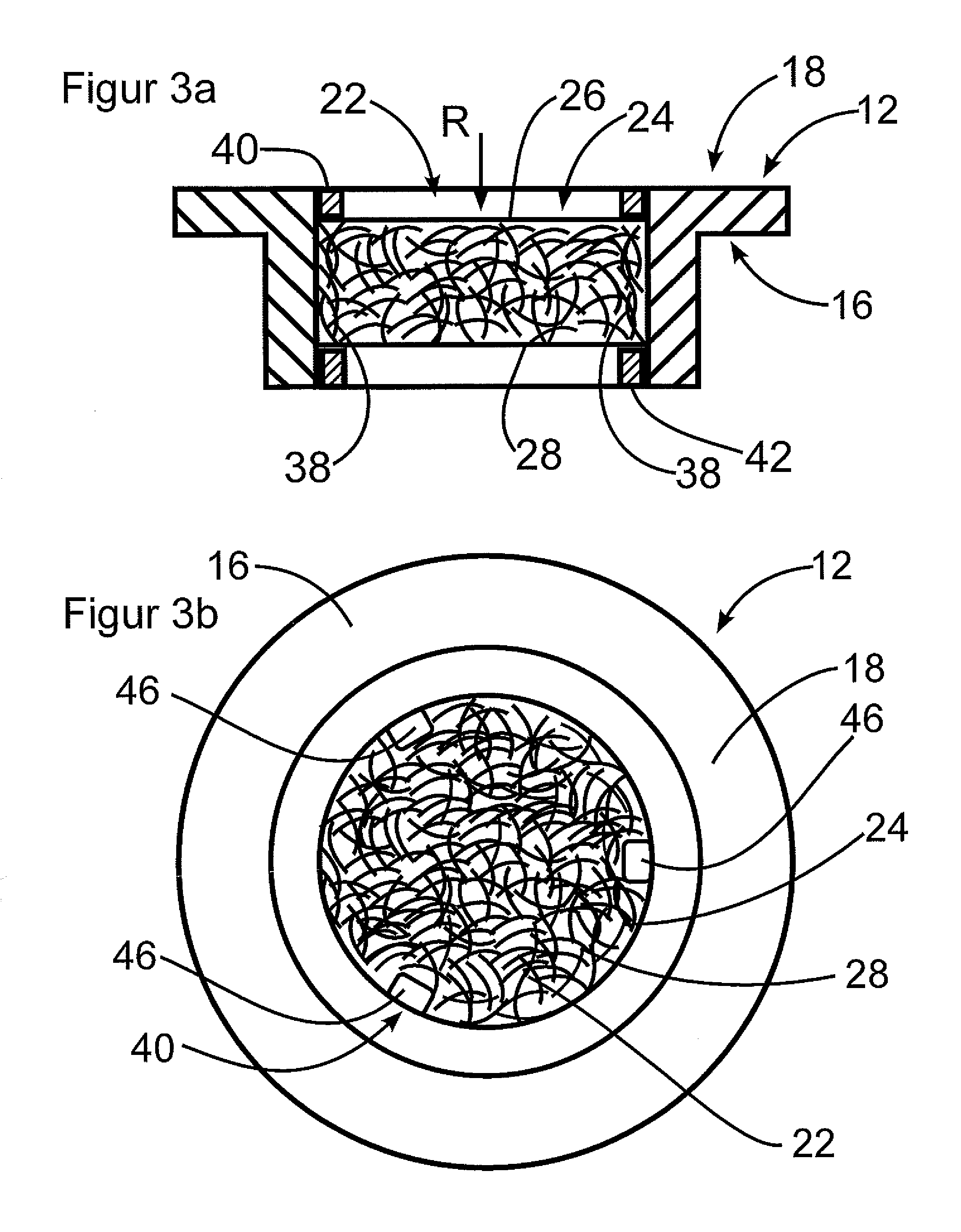

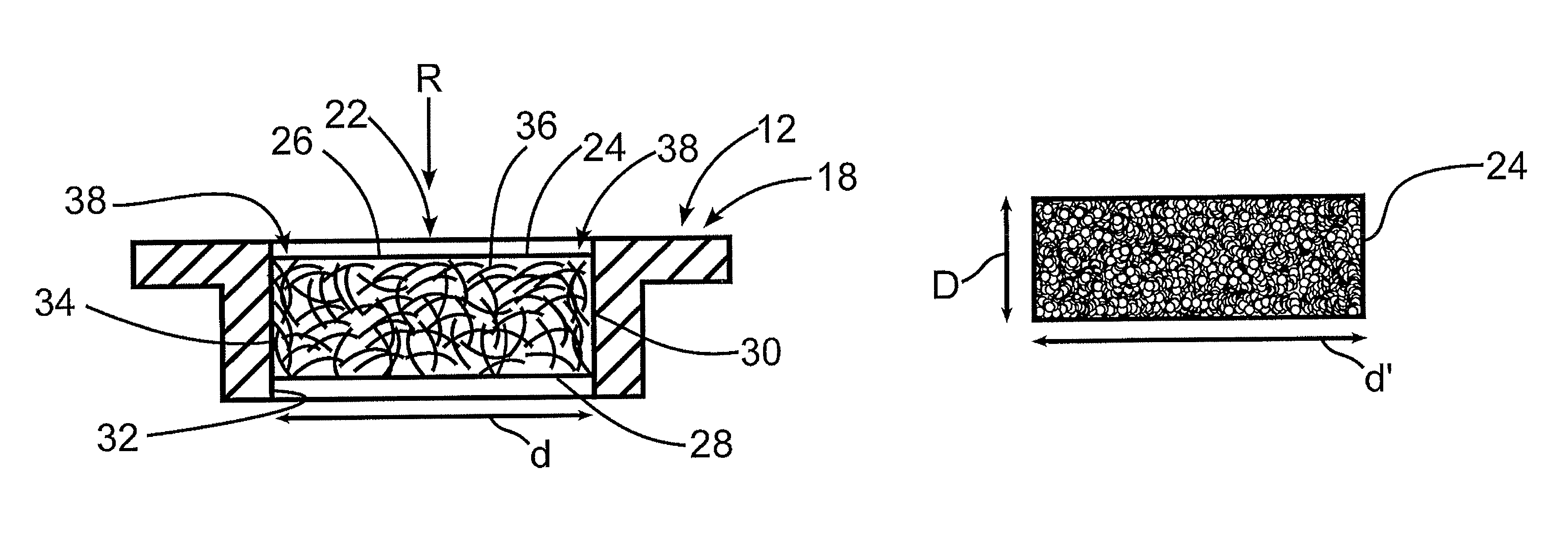

Pressure release device for housings with flameproof encapsulation with porous body having interference fit

ActiveUS20150060445A1Increased gas flow cross sectionEasy to manufactureLarge containersFire rescueEngineeringInterference fit

A pressure release device for a protective housing for flameproof enclosure of electrical operating means. The device includes an accommodating body (18) having a passage (22), and a porous body (24) arranged in the passage (22). The porous body (24) is elastically deformed by means of an interference fit in the passage (22), and thus, reliably supported therein free of flame or spark exiting gaps.

Owner:R STAHL SCHALTGERATE

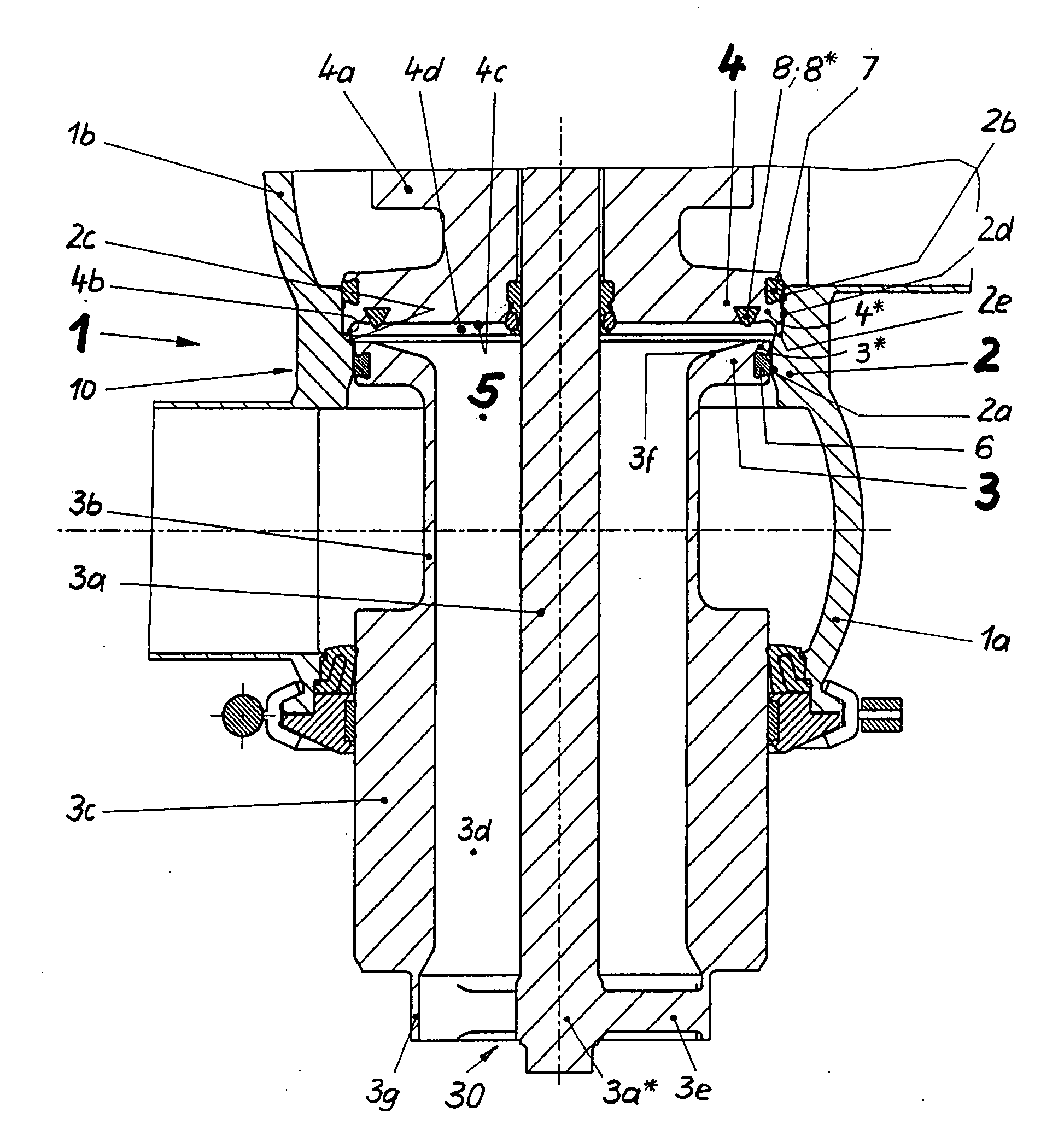

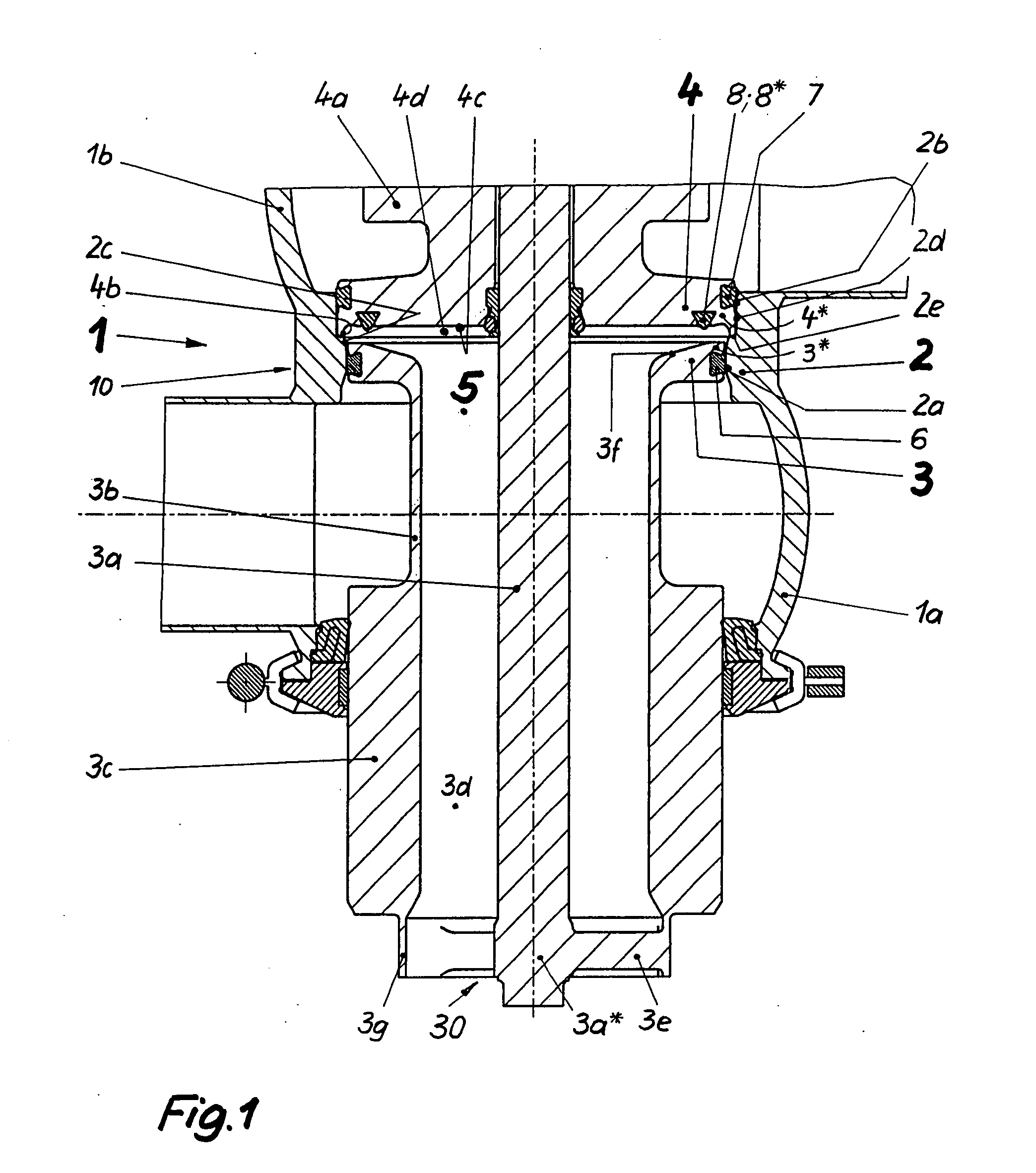

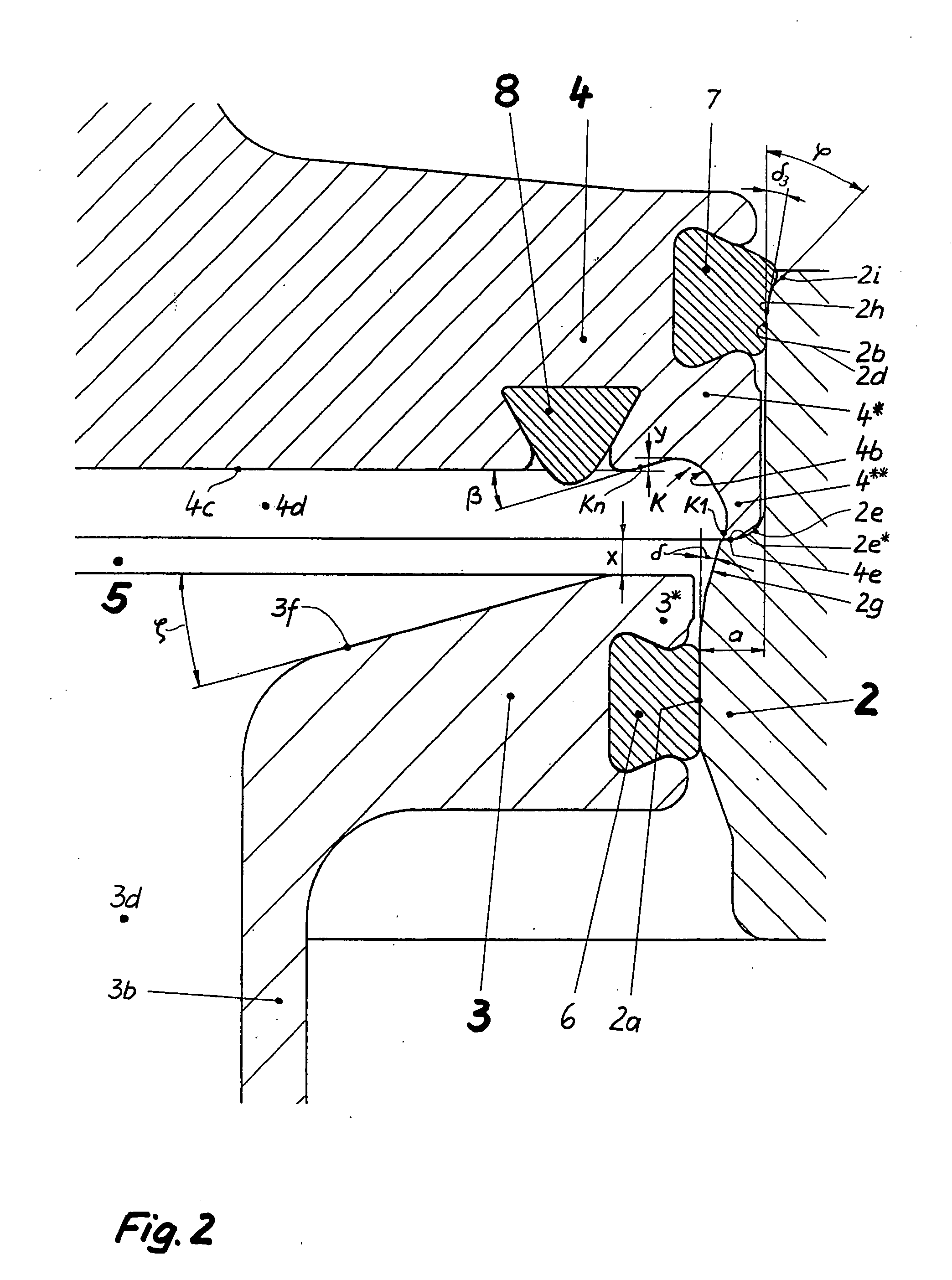

Double seat valve

ActiveUS20090008594A1Reduce trafficSmooth diversionPlug valvesMultiple way valvesEngineeringMechanical engineering

The invention relates to a double seat valve with cleanable seats, which is improved with regard to the prior art in that a discharge possibly free of turbulence of the seat cleaning flow into and out of the leakage cavity is ensured and a direct admission of the seat areas, which would increase pressure, is safely avoided. This is achieved in that the second closing element (4) abuts in its closed position at the transition area (2e; 2e*) with a stop face (4e) arranged at a front face of its cylindrical lug (4*) and that directly adjacent to the first seat (2a, 2g), that a central recess (4d) is provided in the front face of the second cylindrical lug (4*), which starts radially on the outside with a rotationally symmetrical diversion area (4b) (starting point of the contour (K)) and is bounded at the front by a front face (4c) oriented substantially vertically towards the longitudinal axis of the second closing element (4), the diversion area (4b) leading out into the front face (4c) (leading out point of the contour (K)), that the diversion area (4b) and the stop face (4e) form a second circumferential edge (U2), which is directly adjacent to a first end section (2g) of the first seat (2a) in the closed position of the second closing element (4), that, viewed in vertical centre section, the diversion area (4b) comprises a contour (K) with unbent shape, wherein a direction vector in the leading out point of the diversion area (4b) points into a discharge bore (3d) centrally arranged in the first closing element (3), without colliding with the first closing element (3) in the area of its areas bounding the leakage cavity (5) or of the intermediate seal (8; 8*) and without forming impact pressure thereby, and that a frontal boundary of the first closing element (3) directed towards the leakage cavity (5) has an axial safety distance (x) from the direction vector at an outlet point of the transition area (2e) formed as a first circumferential edge (U1) into the first end section (2g).

Owner:TUCHENHAGEN GMBH

Rotor nozzle for a high-pressure cleaning appliance

ActiveUS20120138706A1Easy to cleanLarge lengthBurnersMovable spraying apparatusSpray nozzleHigh pressure

A rotor nozzle for a high-pressure cleaning appliance is provided. The rotor nozzle has a housing, which comprises at least one inlet opening tangentially, and which is provided in a front wall with a pan-shaped depression with a central opening. A nozzle body is arranged in the housing and supported with a spherical end in the pan-shaped depression. A longitudinal axis of the nozzle body is inclined to the longitudinal axis of the housing, it being possible for liquid in the housing to be caused to rotate about the longitudinal axis, and the nozzle body rotating together with the rotating liquid. In order to reduce flow losses in the rotor nozzle, without the operation of the rotor nozzle (in particular, start-up behavior of the nozzle body) being noticeably impaired, the nozzle body is provided with an outer contour deviating from the circular shape in a rear end area.

Owner:ALFRED KARCHER GMBH & CO KG

Low-pressure valve with an inner and outer throughflow cross section

InactiveUS8616523B2Function increaseReduce surface pressureOperating means/releasing devices for valvesPositive displacement pump componentsPre stressEngineering

An electromagnetically actuated valve with a valve body which is assigned to a valve seat, is mechanically prestressed in a first direction toward a first switching position and can be adjusted by means of a magnetic actuator in a second, opposite direction into a second switching position is disclosed. The valve body has a planar contact surface which can be brought into sealing contact with a surface of the valve seat, which surface is planar at least in sections.

Owner:ROBERT BOSCH GMBH

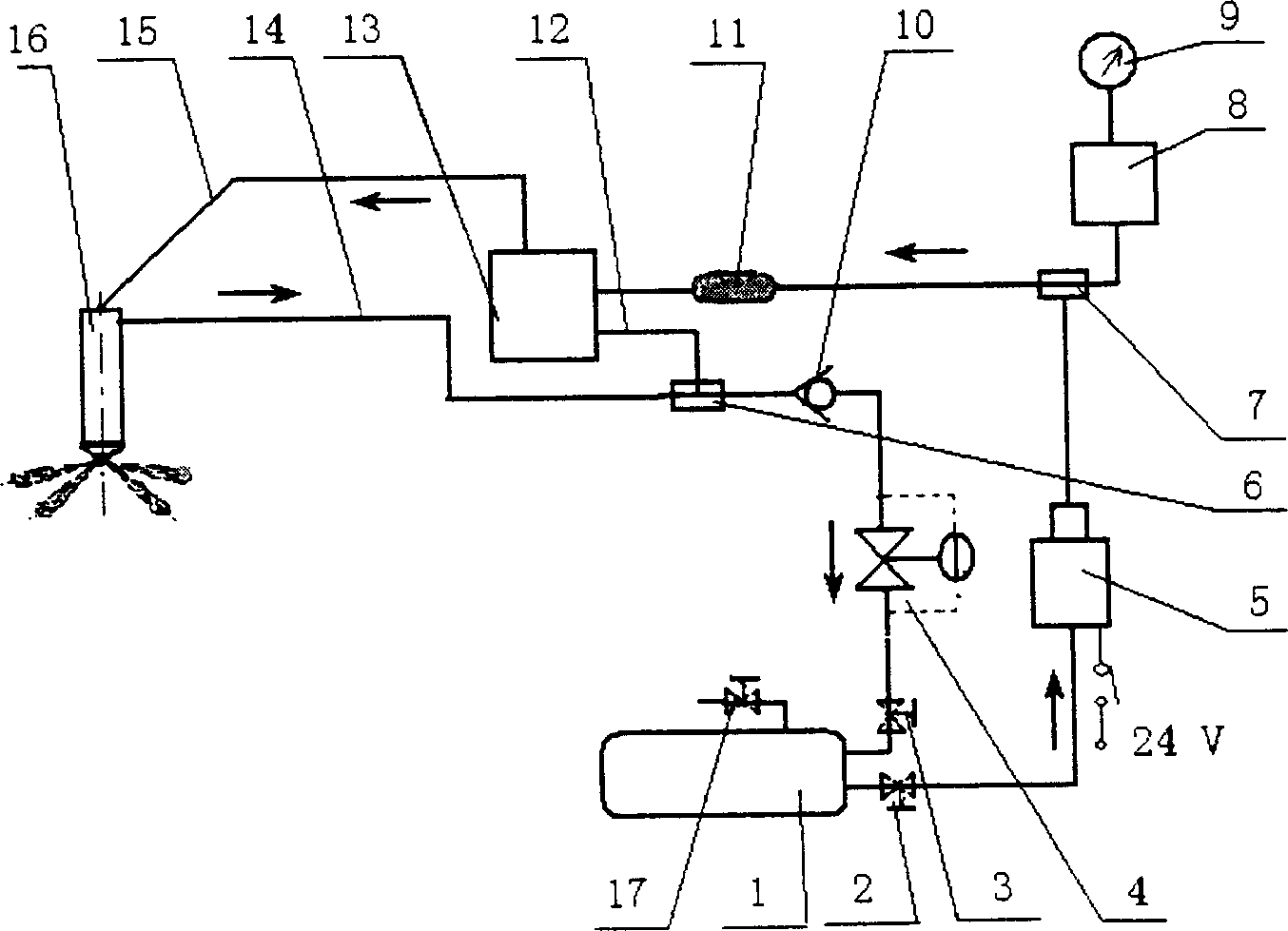

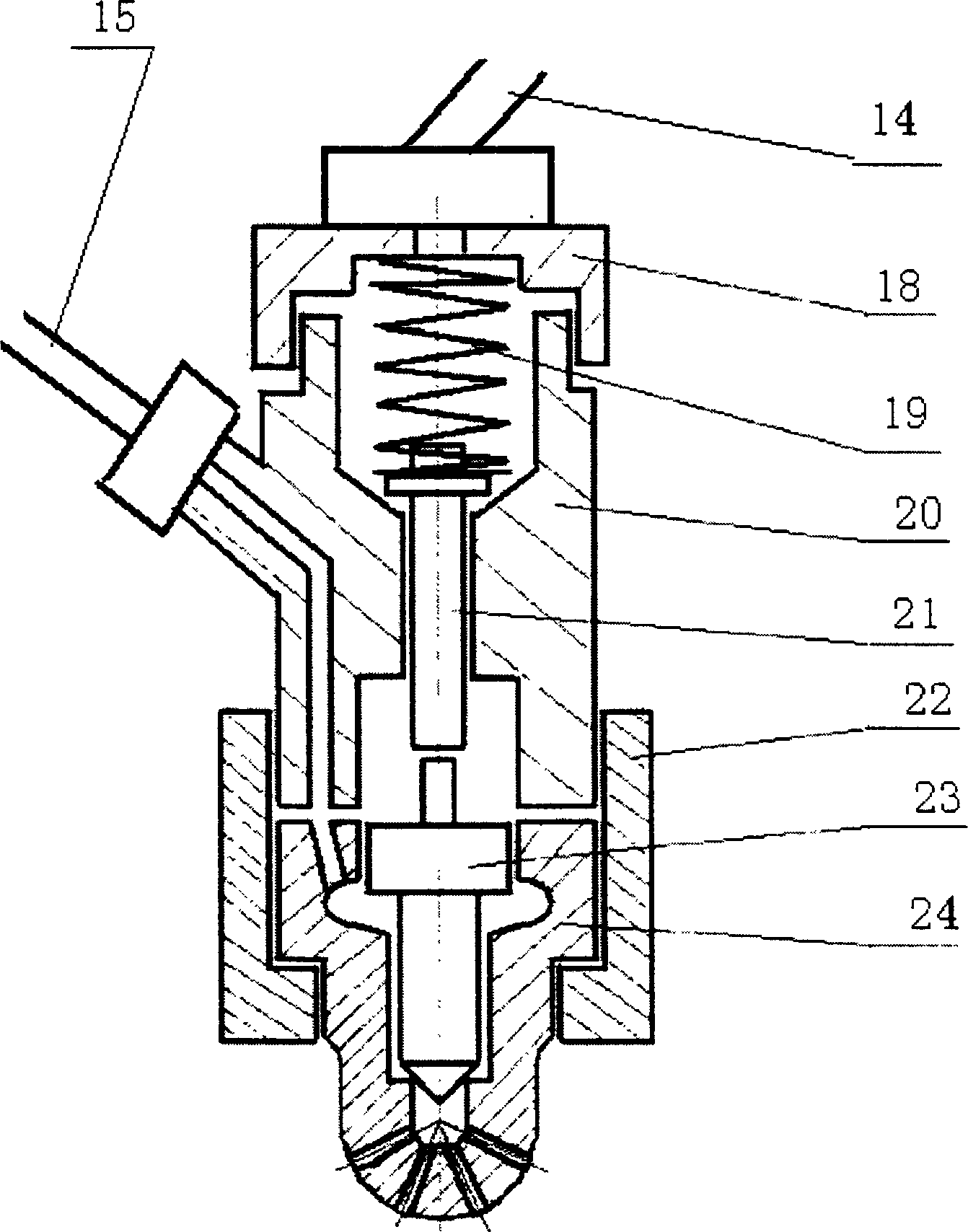

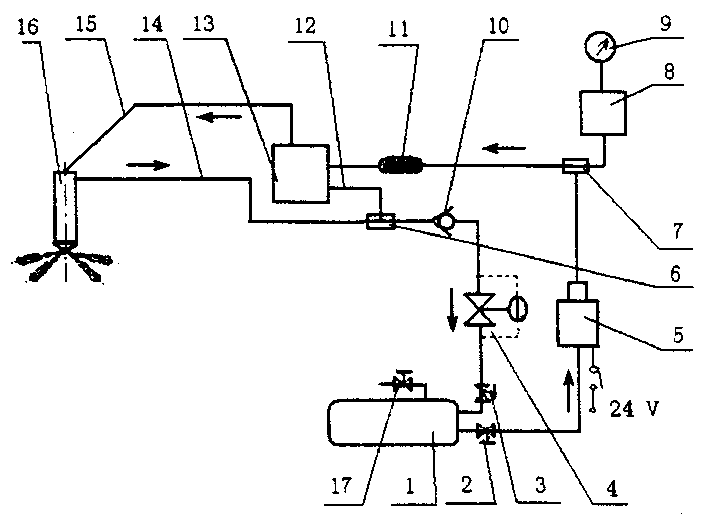

Dimethyl ether fuel hypermulti orifice forced injection system

InactiveCN1470757AEasy to spreadAccelerate emissionsInternal combustion piston enginesFuel supply apparatusReflux valveFuel filter

The present invention relates to a dimethylether fuel ultramultinozzle intensified spray system. The DME storage tank is connected with low-pressure fuel conveying pump via liquid outlet value, the outlet of the low-pressure fuel conveying pump is connected with intensified fuel-spraying pump through one end of T-junctor via fuel filter, an other end of T-junctor is connected with pressure-storing device on which the pressure gauge is mounted, the outlet of intensified fuel-spraying pump is connected with ultramultinozzle fuel-spraying device through high-pressure fuel pipe. Besides, said system also contains other several components of locking cap, needle valve, regulating nut, pressure-regulating spring, non-return valve and pressure control valve, etc. Said system can make engine obtain high efficiency and ultralow discharge.

Owner:SHANGHAI JIAO TONG UNIV

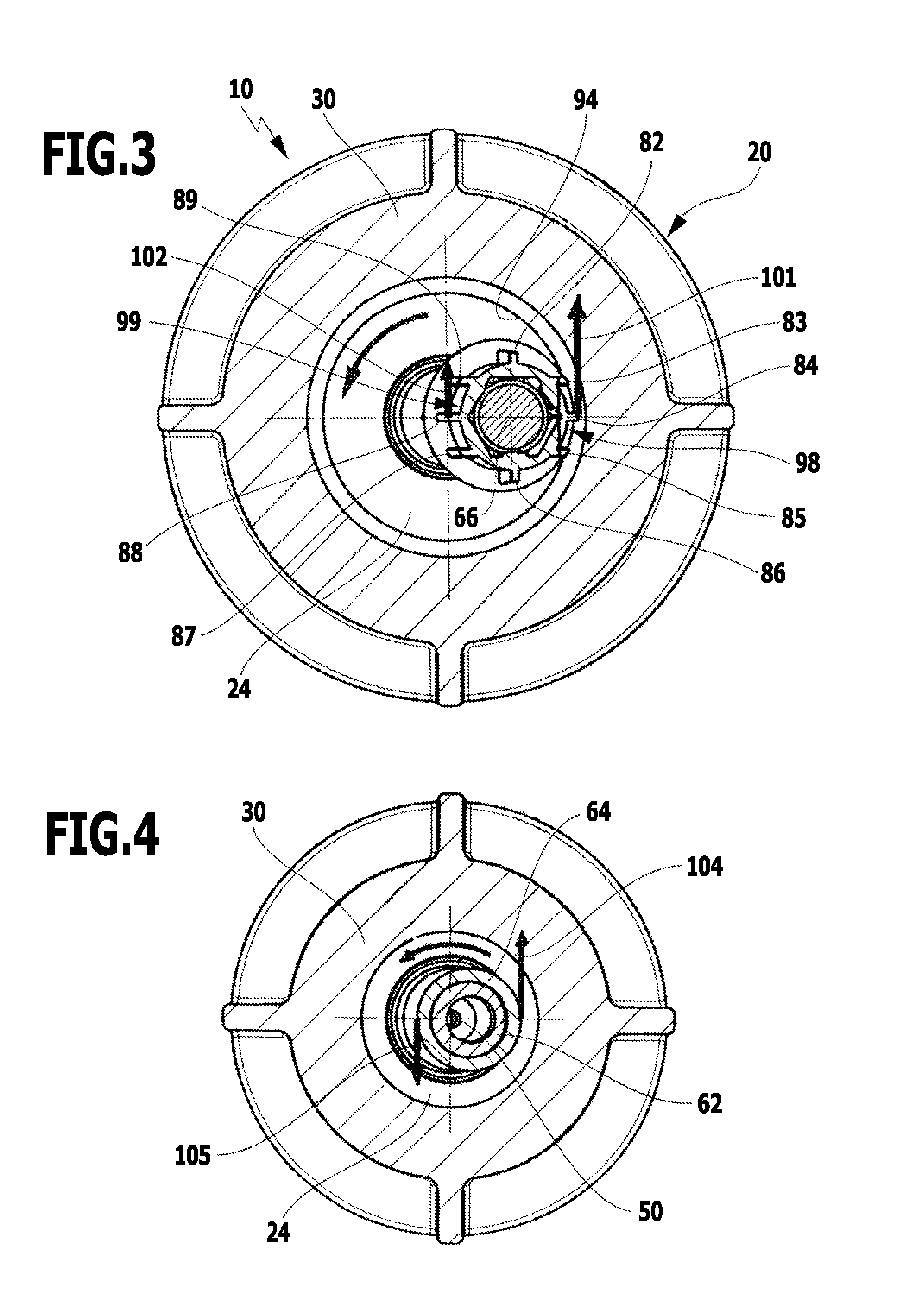

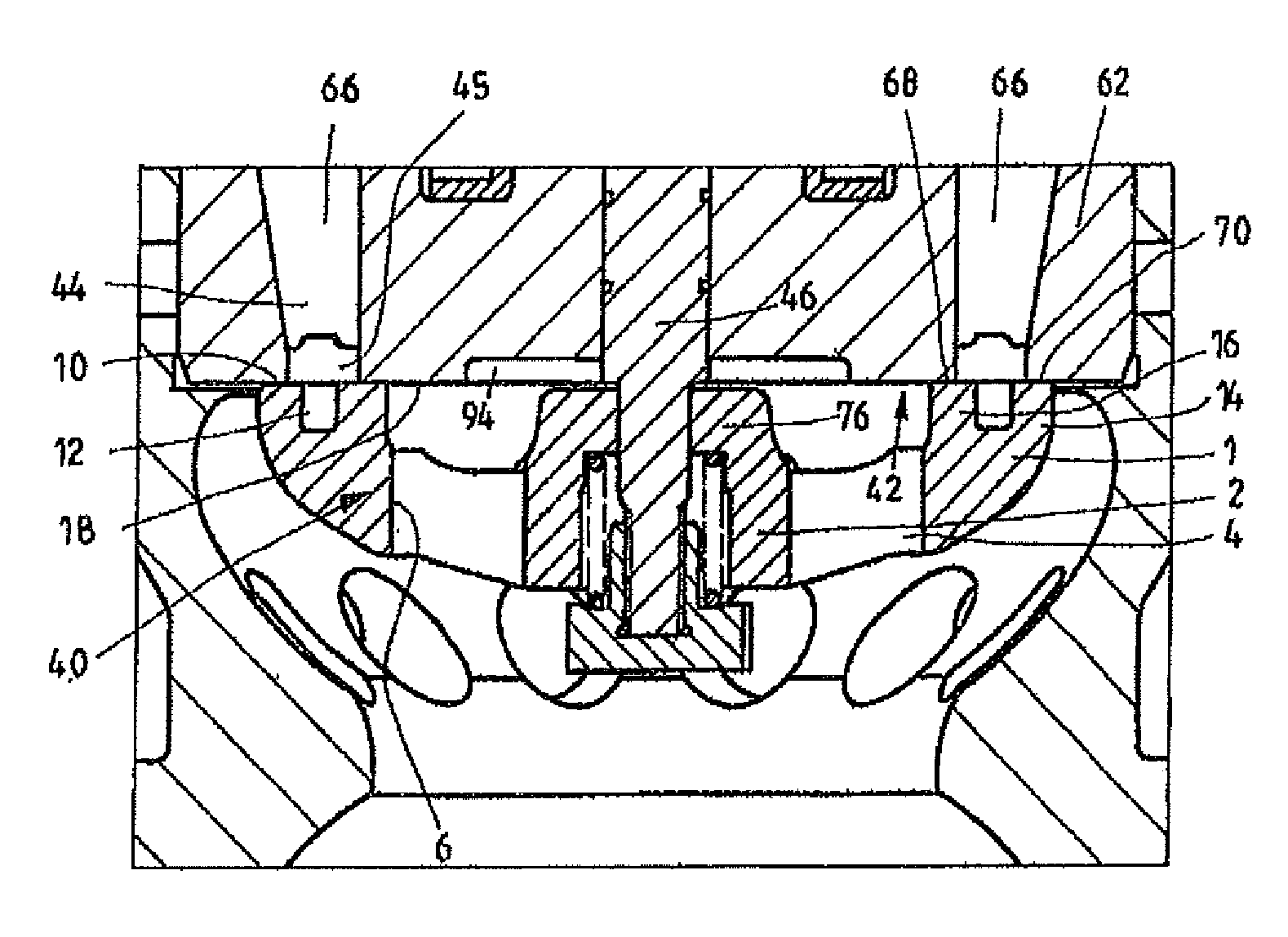

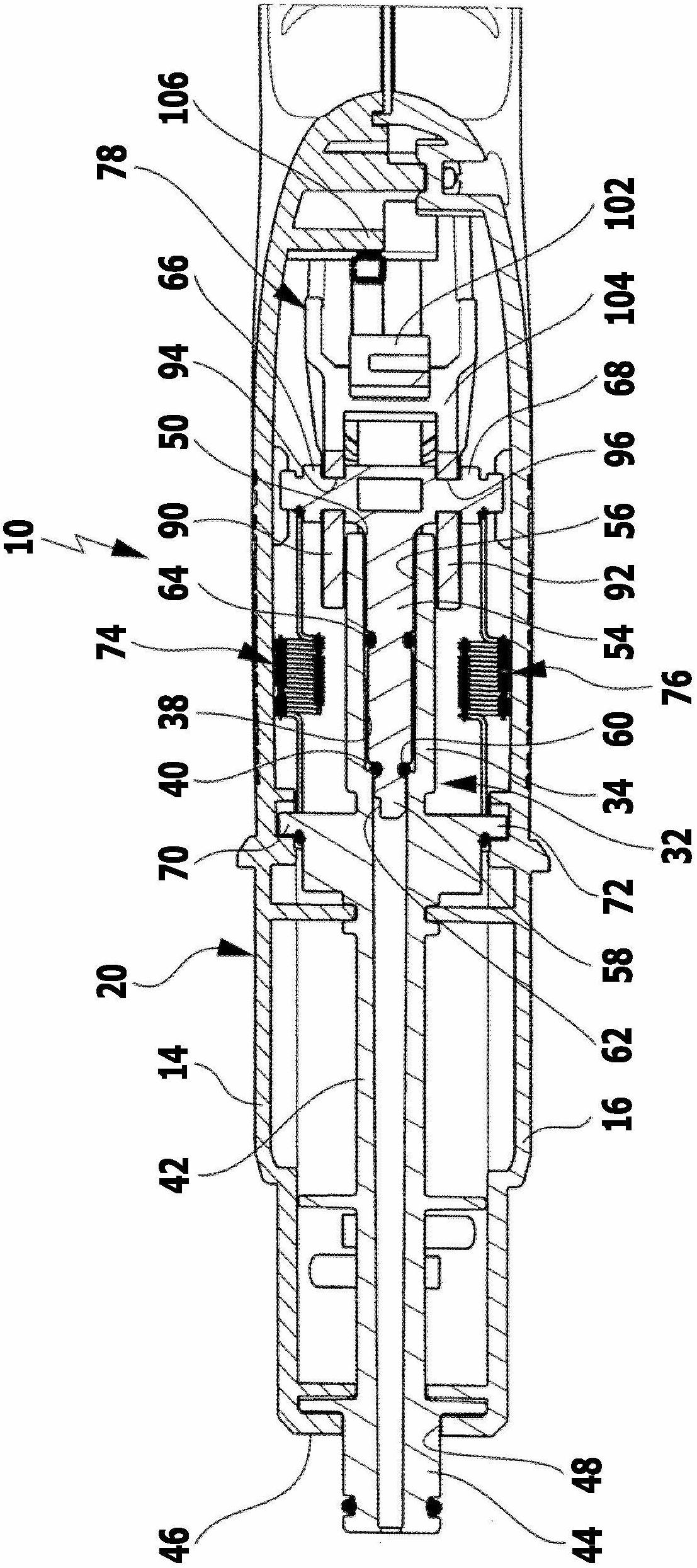

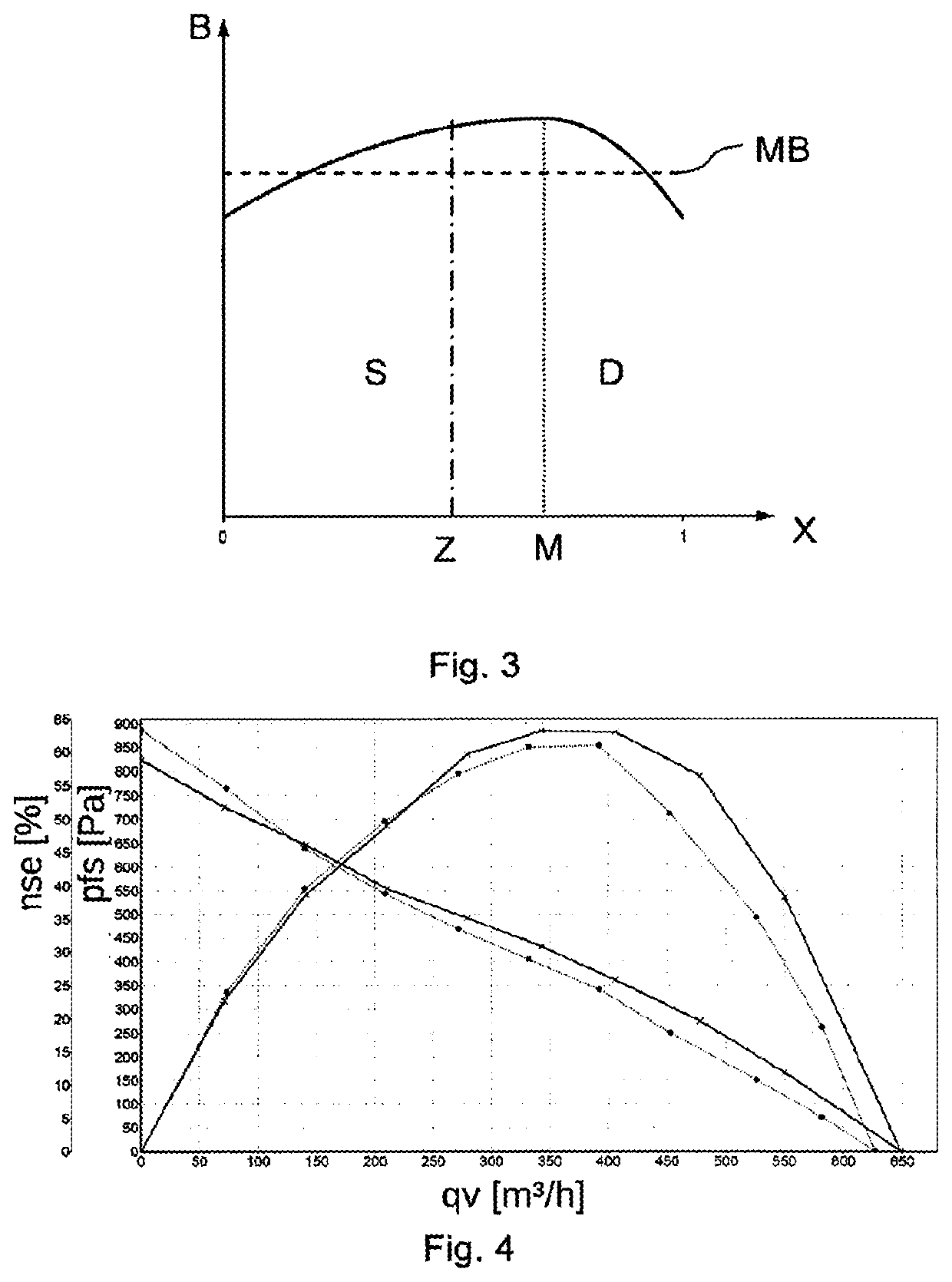

Mass flowmeter

ActiveUS7946187B2Increase the flow cross sectionIncrease mass flowDirect mass flowmetersStreamflowAtomic physics

A mass flowmeter is provided which operates on the Coriolis principle, having (1) at least four measurement tubes which can oscillate and through which a medium can flow, (2) at least one oscillation generator for excitation of the oscillations of the measurement tube, and (3) at least one oscillation sensor for detection of the excited oscillations of the measurement tubes. The measurement tubes are preferably arranged closely in parallel such that the flow cross section covered by the measurement tubes covers as small an area as possible. The use of four or more compactly arranged measurement tubes advantageously allows for the measurement of a high mass flow rate with measurement tubes having a relatively small cross section and length, resulting in a mass flowmeter having compact length and width dimensions, and which requires only a relatively low energy oscillation generator for excitation of the oscillations of the measurement tubes.

Owner:KRONE GMBH

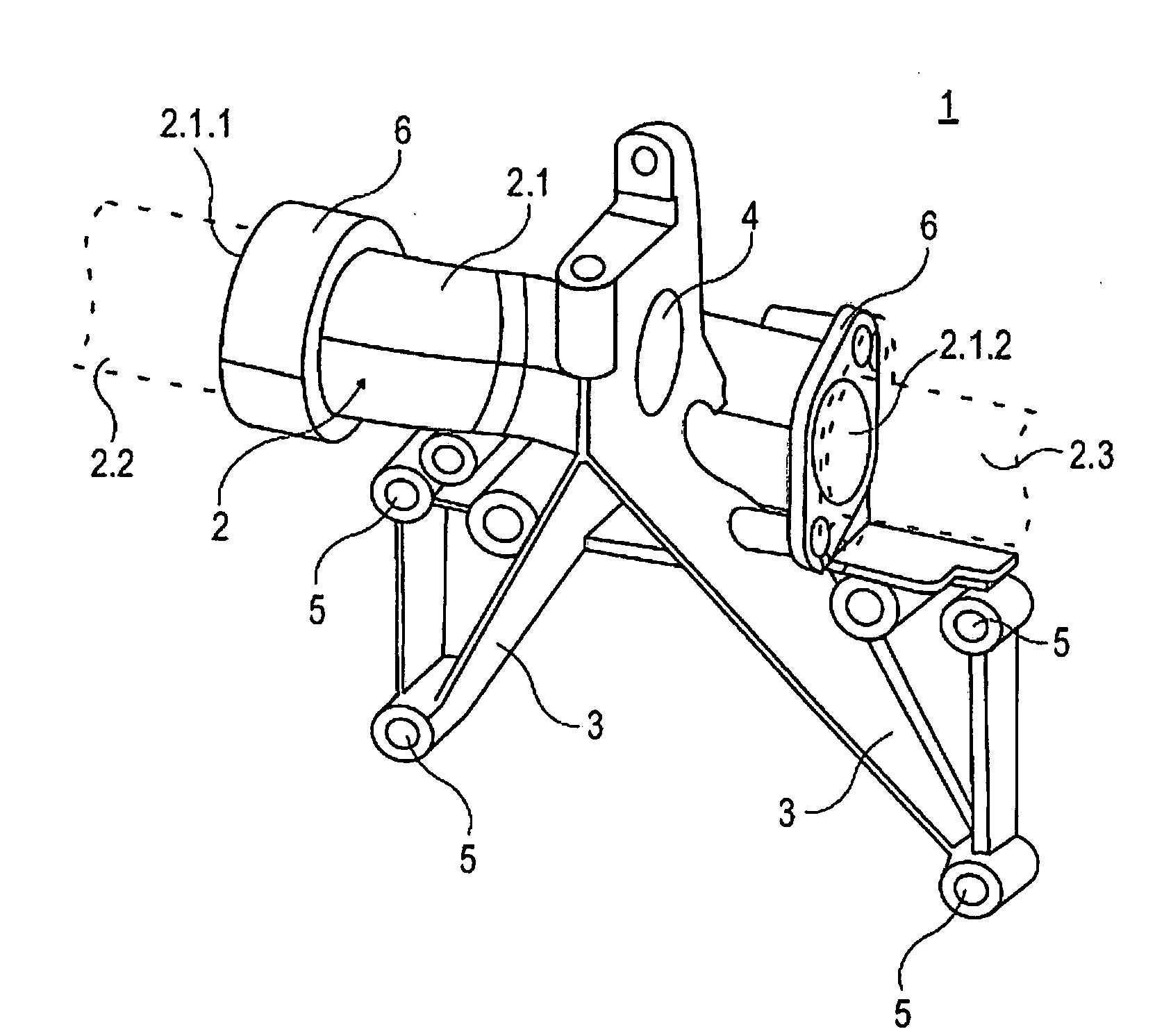

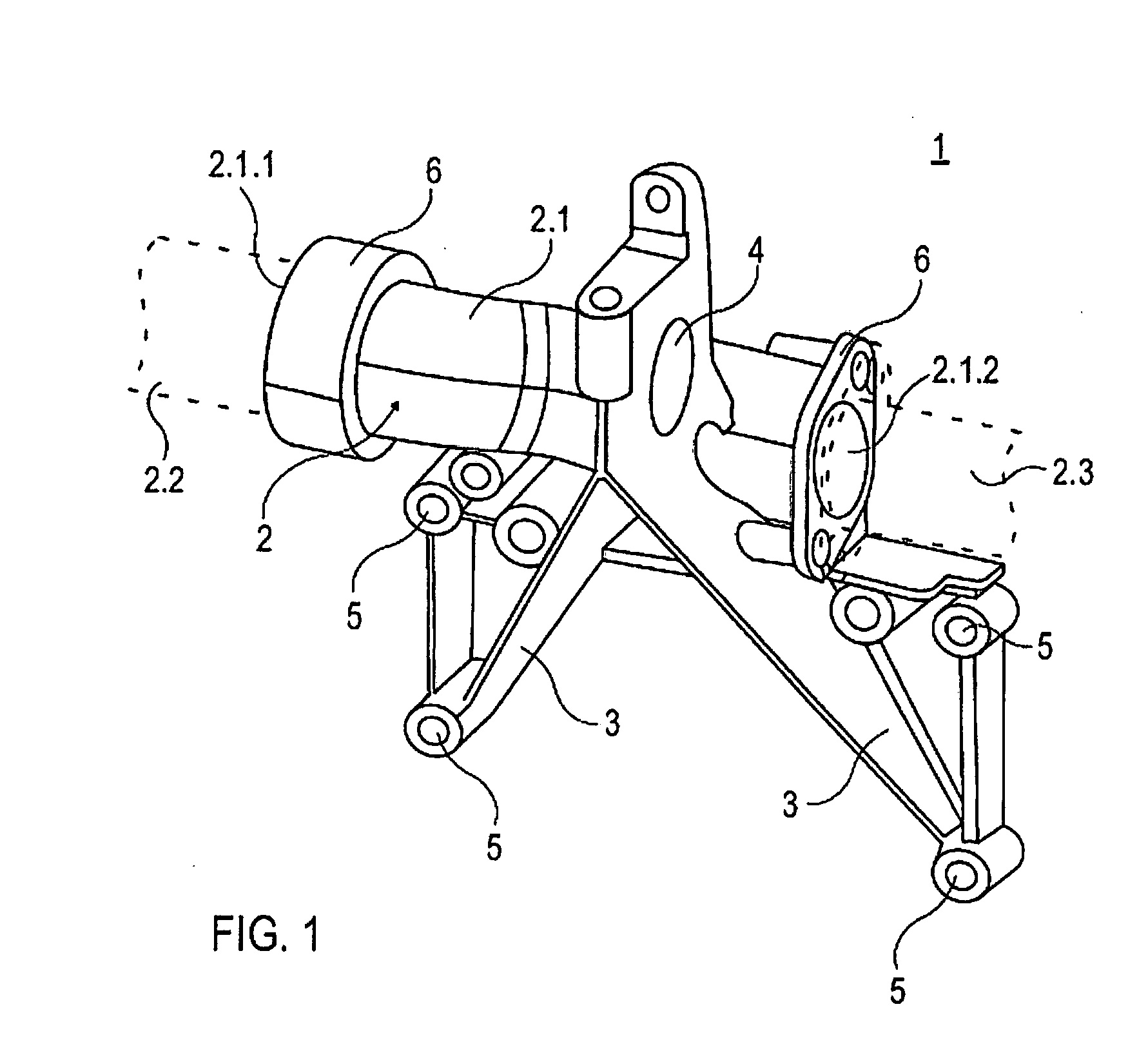

Exhaust gas recirculation line holder

InactiveUS20090084920A1Reduce weightReduced pressure dropExhaust gas recirculationMachines/enginesExhaust fumesVehicle frame

In an exhaust gas recirculation line holder of an internal combustion engine wherein a line section of an exhaust gas recirculation line is integrated into the holder which is supported on the engine block and / or the vehicle frame, the holder is provided with a shaped part, in particular a cast part, with the line section of the exhaust gas recirculation line formed therein and a support structure also being formed integrally with the holder so that manufacturing costs, assembly time and assembly expenditure are reduced.

Owner:DAIMLER AG

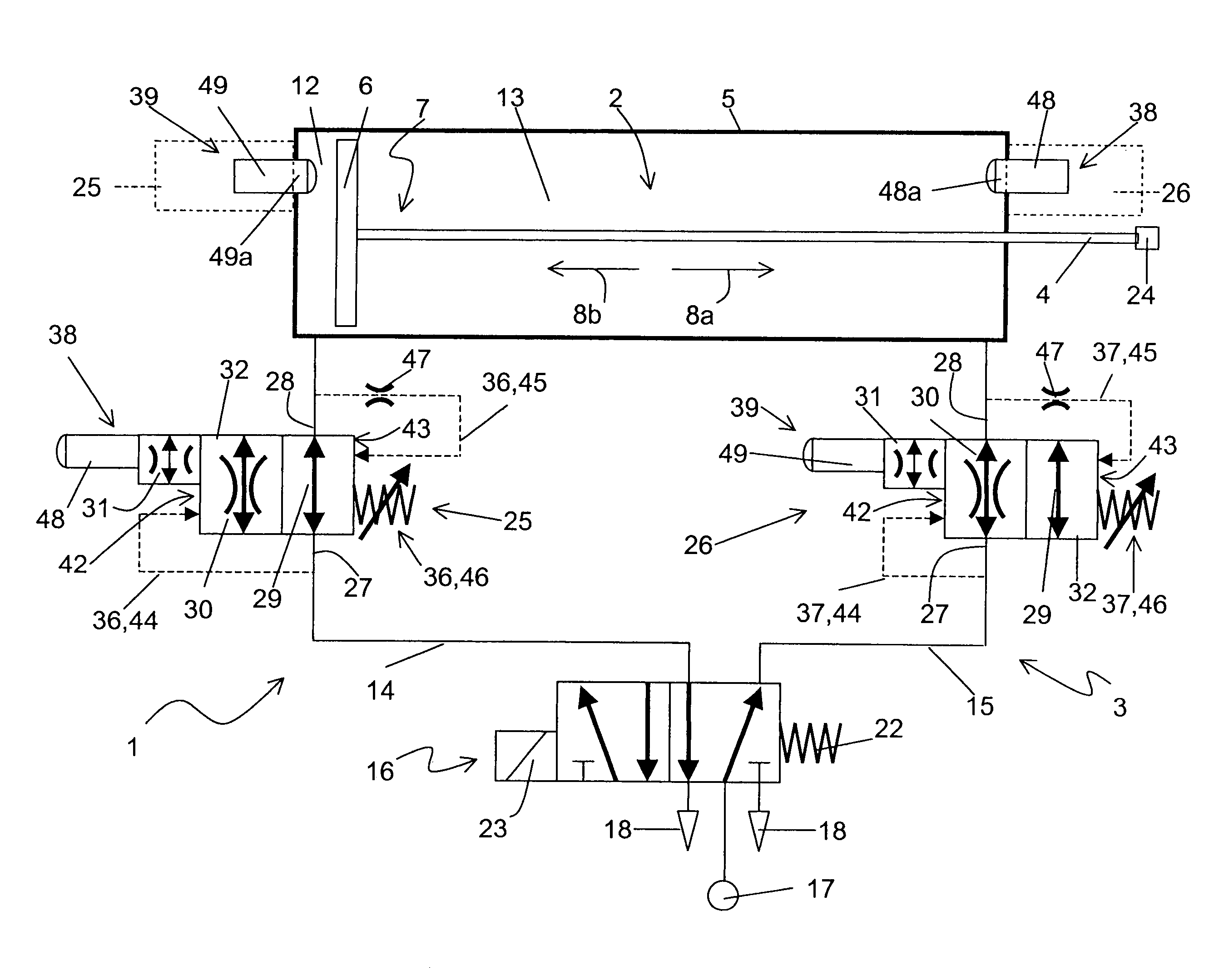

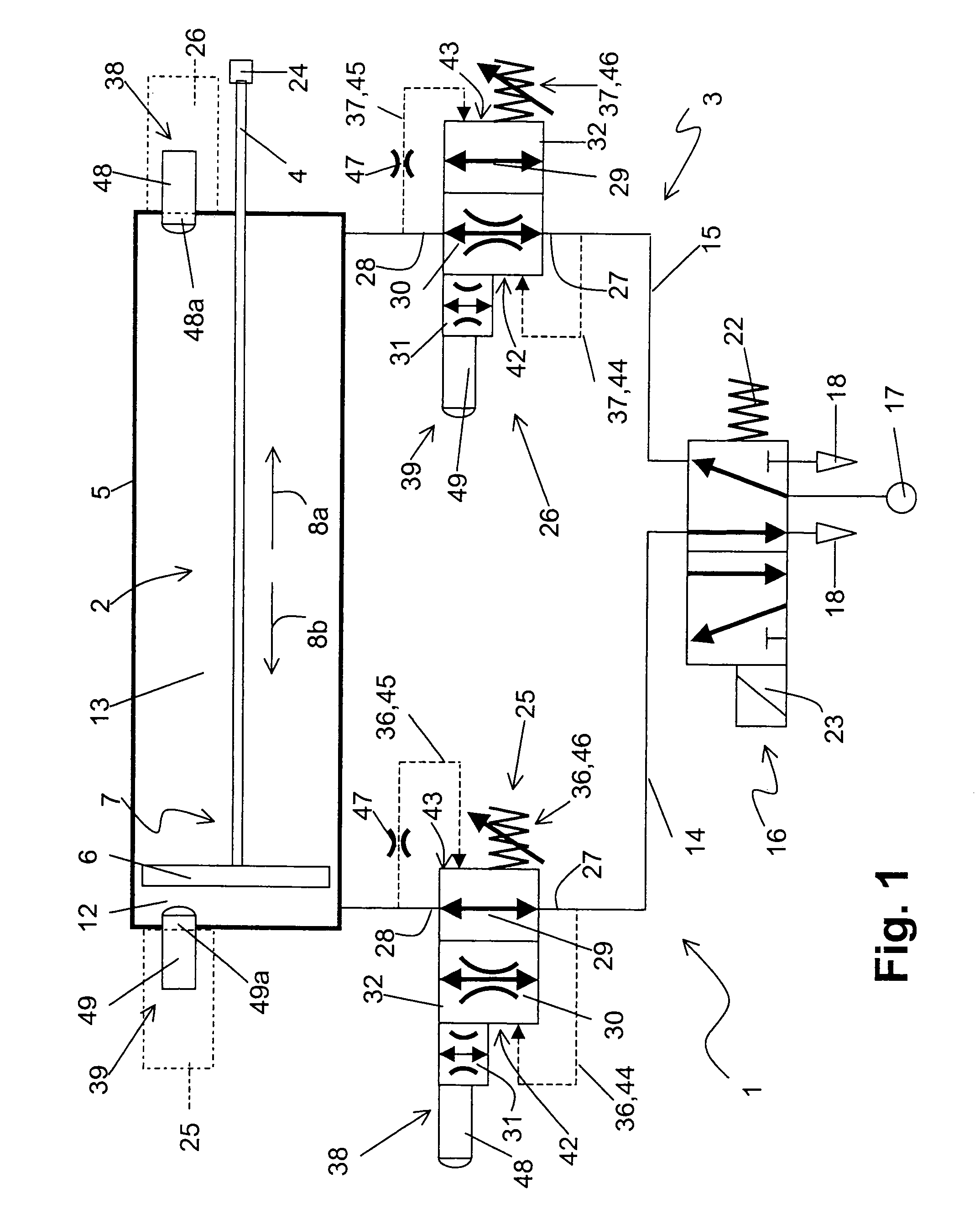

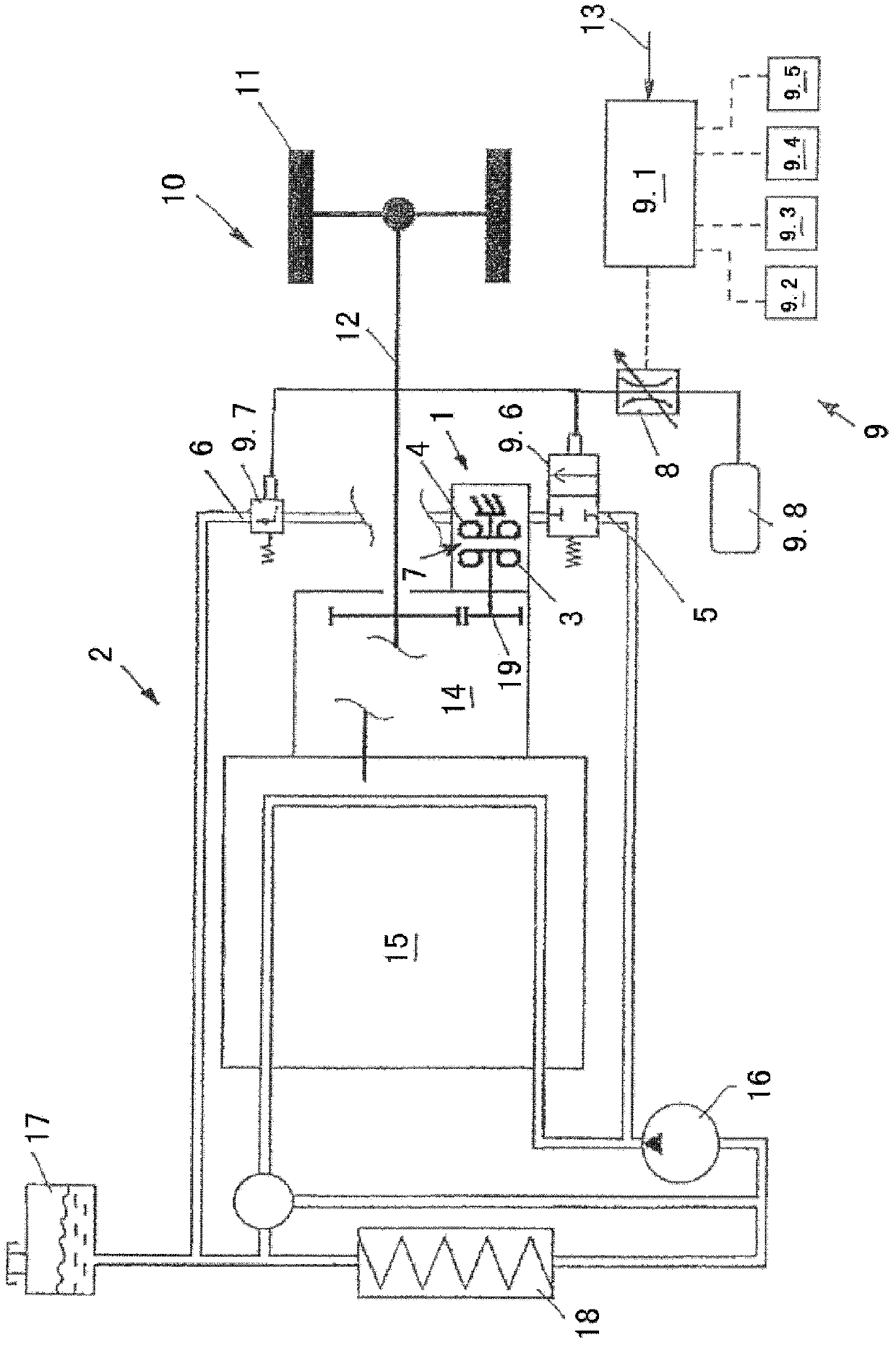

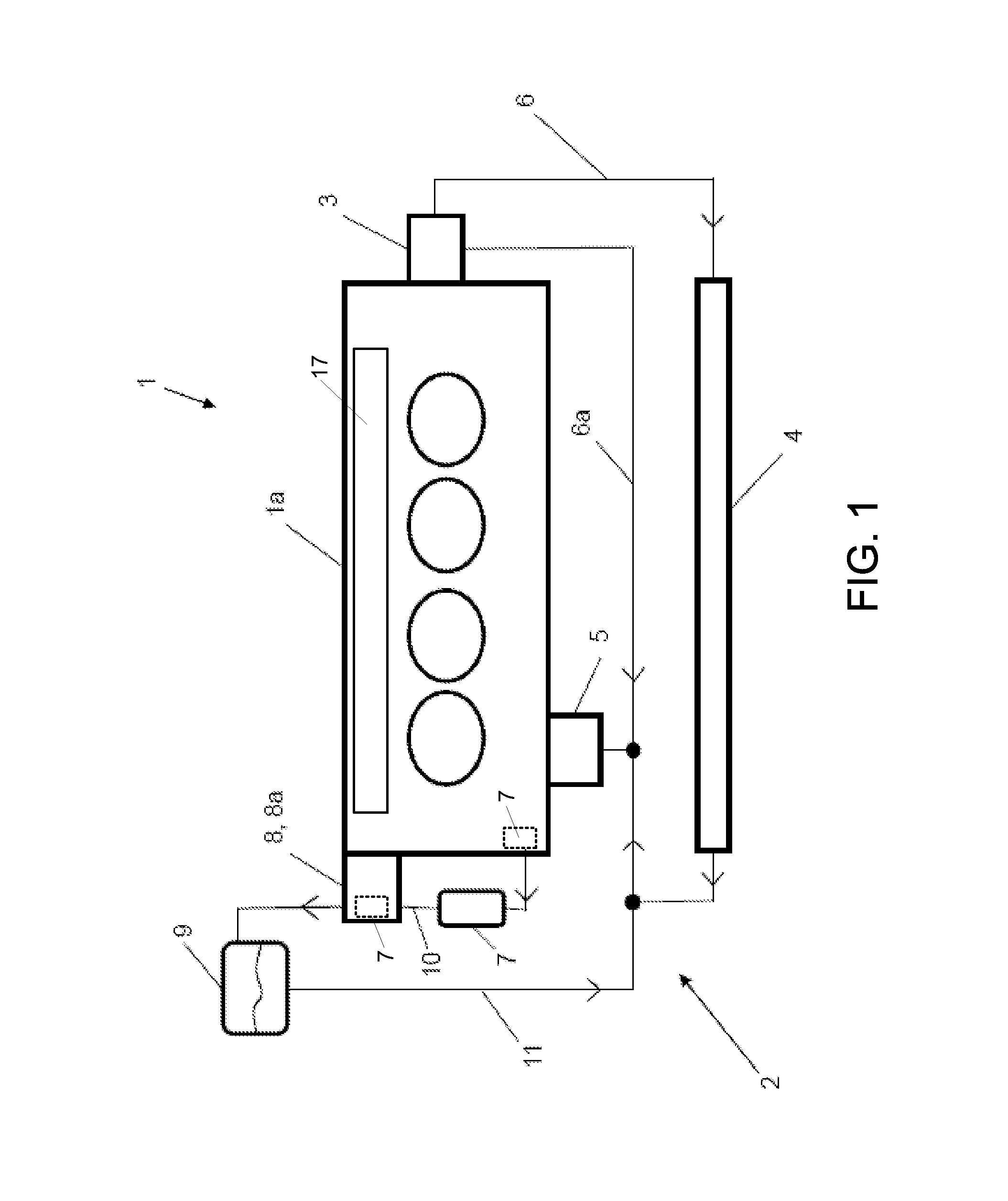

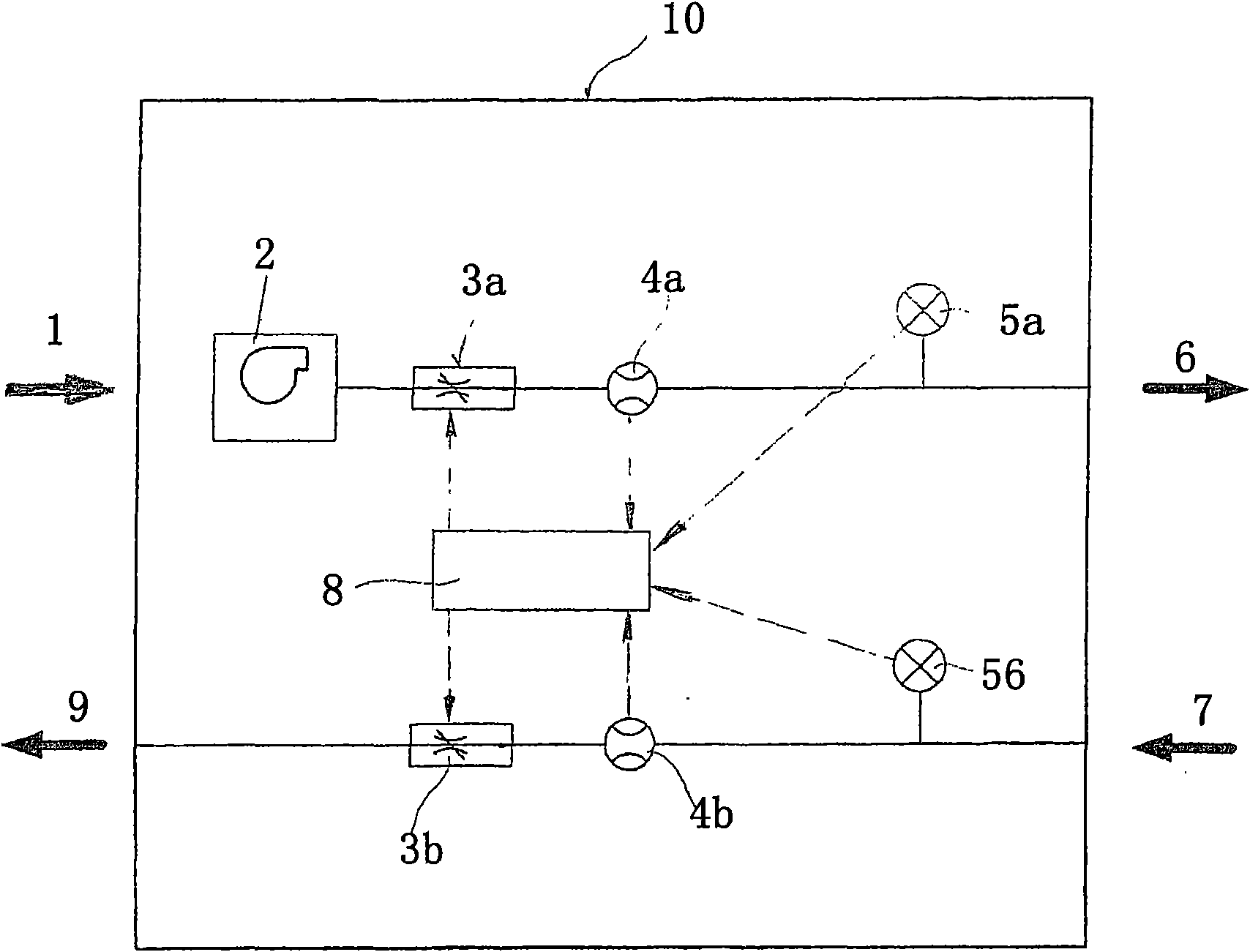

Pneumatic drive system

InactiveUS7896102B2Reduced flow cross sectionSmall flow cross-sectionConstructionsServomotor componentsActuatorControl valves

A pneumatic drive system (1) in which the movement of an output drive unit (7) of a pneumatic drive (2) is controlled by a control valve (25 and 26) which is connected with the working chambers (12 and 13) of the pneumatic drive (2). The control valve (25 and 26) comprises least one air economy setting (30) setting a choke cross section and a high power setting (29) defining a flow cross section larger than it. An actuator serves to ensure that the control valve is switched over, in a fashion dependent on the air pressure obtaining in the at least one working chamber (12 and 13) from the normally assumed air economy setting (30) into the high power setting (29), when the output drive unit (7) meets with an increased resistance to motion.

Owner:FESTO AG & CO KG

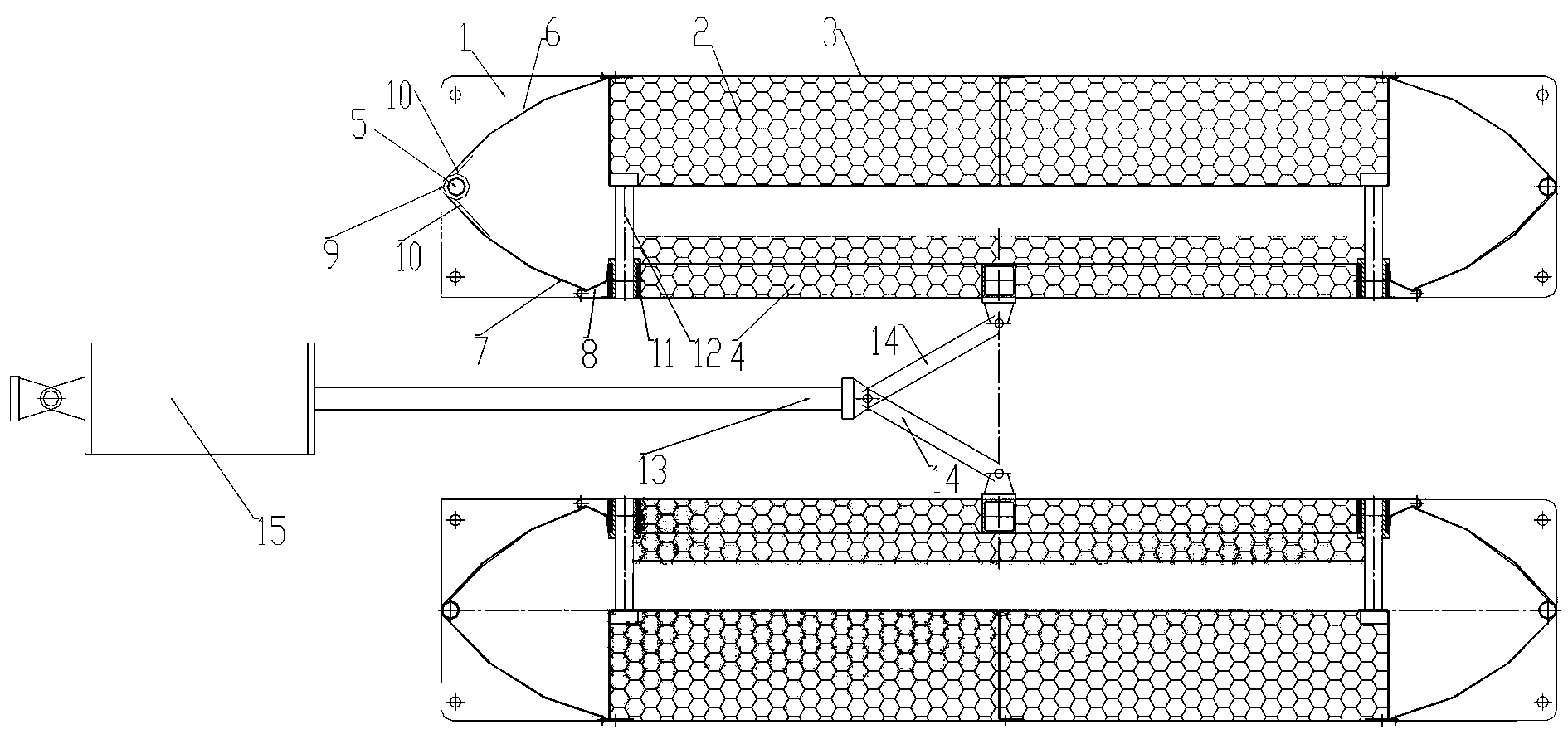

Sheet type silencer with adjustable through-flow area

ActiveCN103256830AChange flow cross sectionIncrease the flow cross sectionSound producing devicesEngineeringAnnual average

The invention discloses a sheet type silencer with an adjustable through-flow area. The sheet type silencer comprises a plurality of silencer units. Each silencer unit comprises a fixed silencer body, a movable silencer body, as well as a rectangular cavity which is surrounded by a back plate and an upper-lower cover plate, wherein the fixed silencer body is fixed inside the cavity; the back plate is provided with a plurality of guide shafts which are perpendicular to the back plate and run through the fixed silencer body; the movable silencer body is provided with guide sleeves matched with the guide shafts; and the movable silencer body can slide along the guide shafts by virtue of the guide sleeves. The sheet type silencer also comprises two rotating shafts which are respectively arranged at the front end and the rear end of the cover plate and are vertical to the guide shafts, two arc-shaped fixed flow guide plates, two arc-shaped movable flow guide plates, and a driver capable of driving the movable silencer body to move along the guide shafts. The through-flow area of the silencer with the structure can be adjusted, i.e., the sheet thickness and the sheet spacing of the silencer are determined according to the annual average temperature, and therefore, a fan with appropriate power can be selected.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

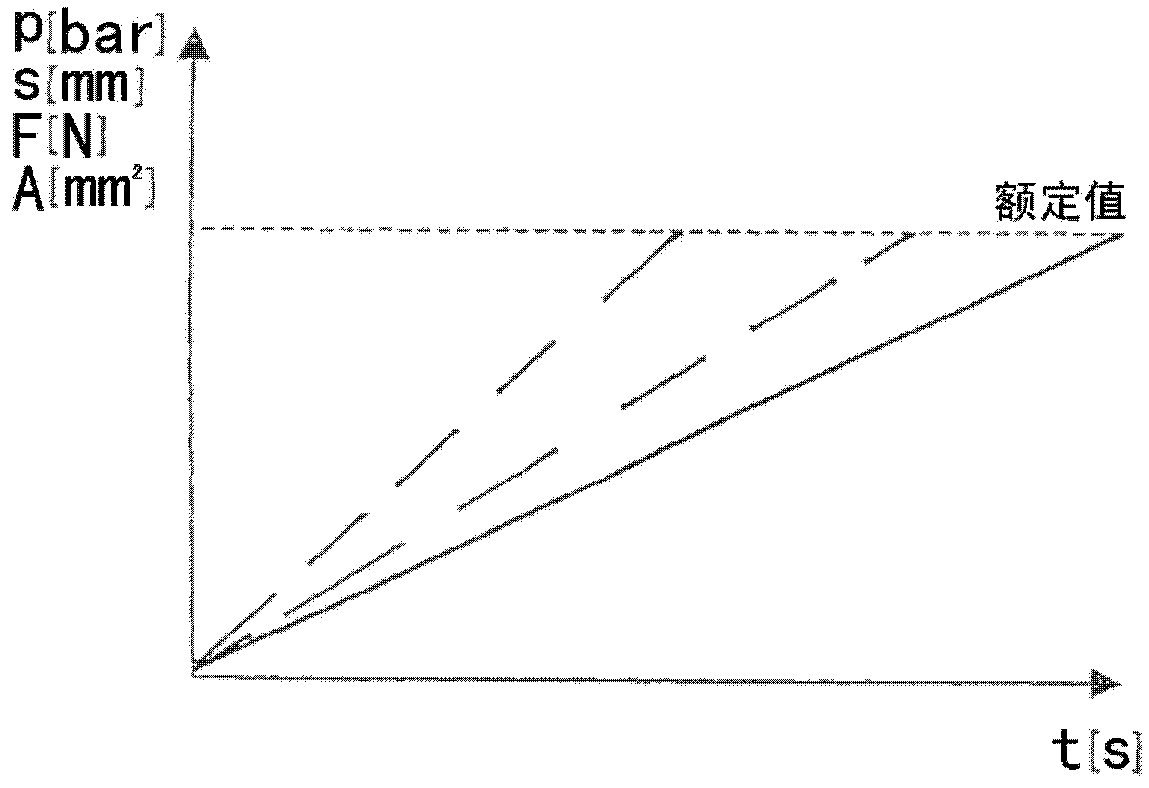

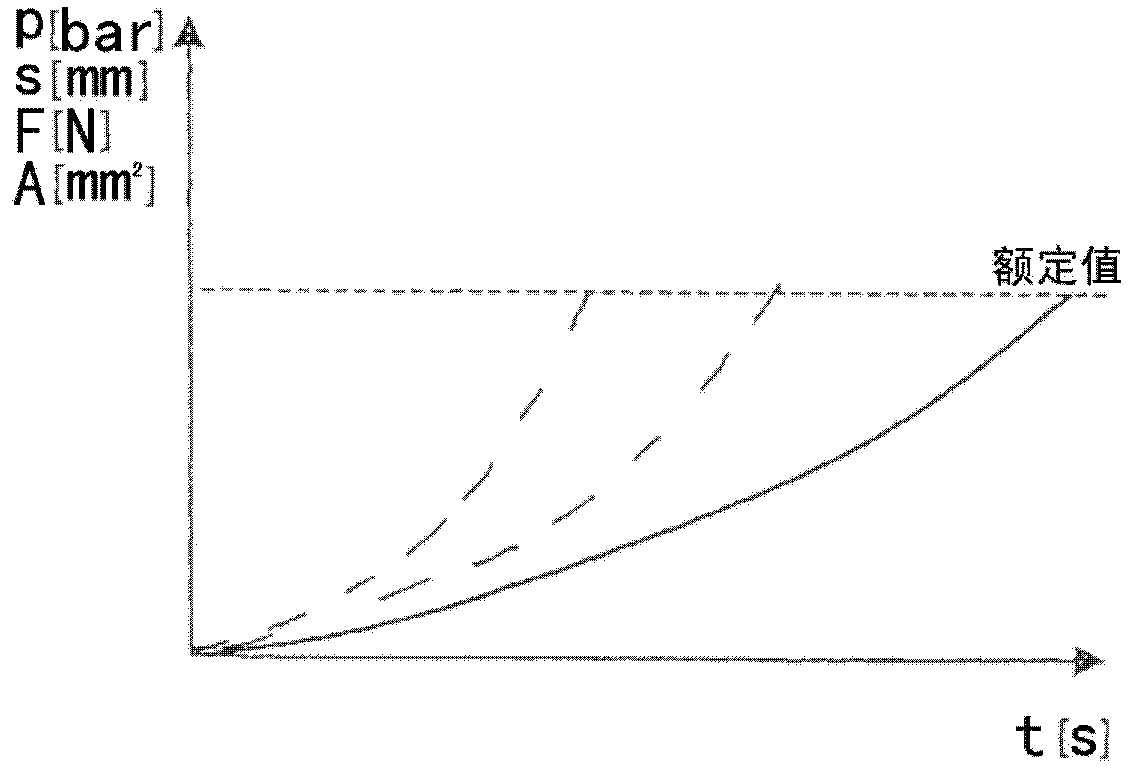

Method for preventing pressure peaks in a working medium cycle having a hydrodynamic machine

InactiveCN102387948AReduce loadAvoid pressure spikesLiquid resistance brakesHydrodynamic brakesEngineeringMechanical engineering

The invention relates to a method for preventing pressure peaks in a working medium cycle in which a hydrodynamic machine is operated, wherein the hydrodynamic machine comprises a primary wheel and a secondary wheel which together form a toroidal working chamber that can be filled and emptied via a working medium inlet and working medium outlet in order to hydrodynamically transmit torque from the primary wheel to the secondary wheel. The invention is characterized in that the rate of change of the flow cross-section for the working medium that flows into and / or out of the working chamber is changed depending on a predetermined input variable when connecting and disconnecting the hydrodynamic machine.

Owner:VOITH PATENT GMBH

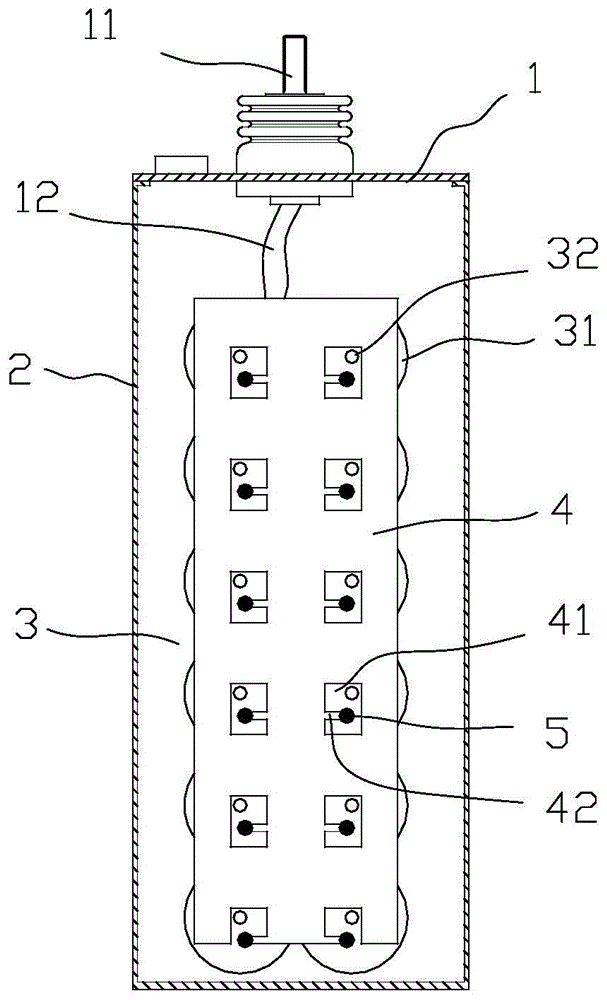

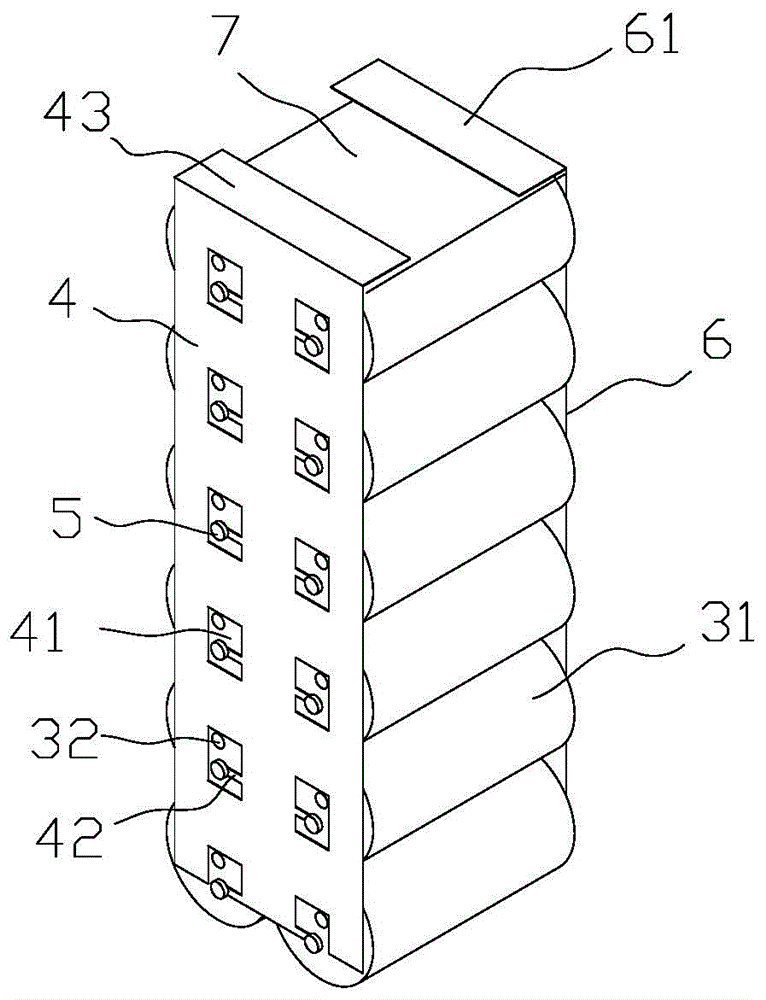

Power capacitor high in heat dissipation performance

ActiveCN104465095AIncrease the flow cross sectionLow calorific valueMultiple fixed capacitorsFixed capacitor housing/encapsulationCapacitanceElectricity

The invention relates to a power capacitor high in heat dissipation performance. The power capacitor high in heat dissipation performance comprises a cover plate assembly, a shell and a capacitor core assembly, wherein the capacitor core assembly is formed by overlaying a plurality of cylindrical capacitor cores, leading-out copper belts are arranged on the metal-sprayed surface of the capacitor core assembly, the two sides of each leading-out copper belt at least extend to the central areas of the metal-sprayed surfaces of the capacitor cores located on the two sides of the capacitor core assembly, a through hole or a groove is formed in the portion, corresponding to the center of the metal-sprayed surface of each capacitor core, of each leading-out copper belt, an opening of each groove is located on one side of the corresponding leading-out copper belt, and elastic fins which extend to the through holes or the grooves and are used for being electrically connected with the metal-sprayed surfaces through welding are arranged on the leading-out copper belts. According to the power capacitor high in heat dissipation performance, by increasing the widths of the leading-out copper belts, current can evenly pass through the power capacitor, and the amount of heat can be reduced; in addition, the areas of the leading-out copper belts are increased in a multiplied mode, and thus the heat dissipation performance is greatly improved.

Owner:ANHUI TONGFENG ELECTRONICS

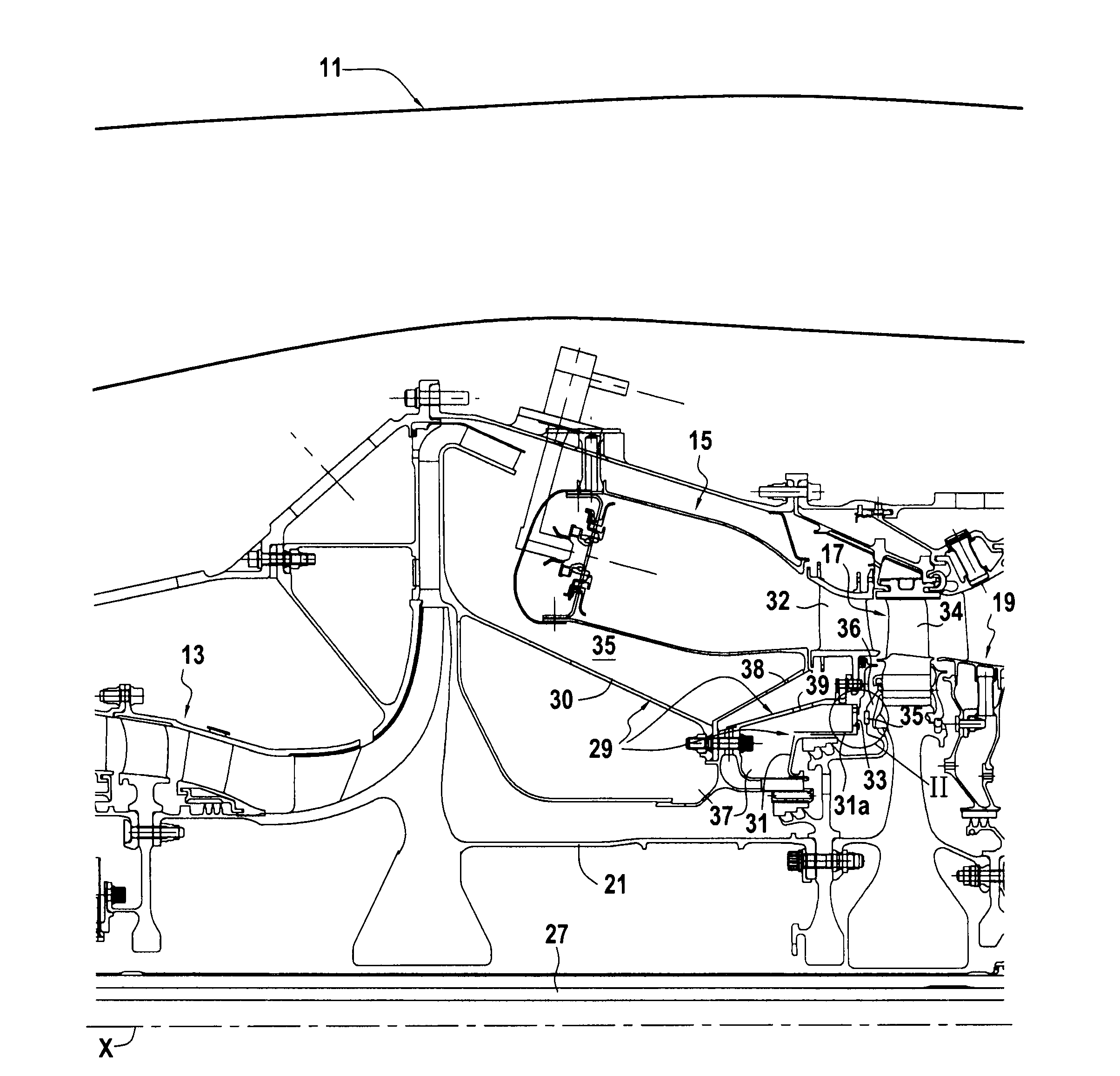

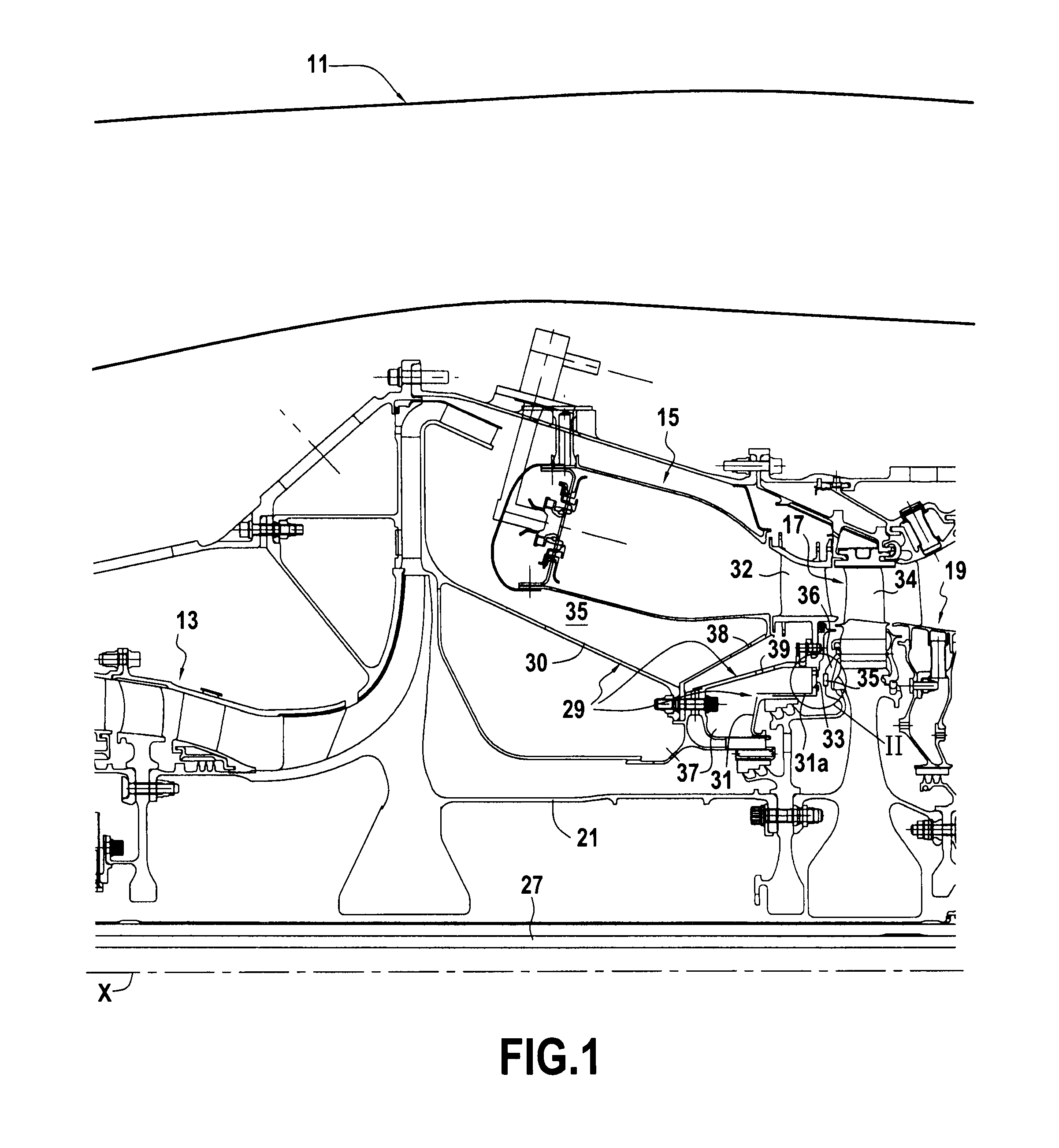

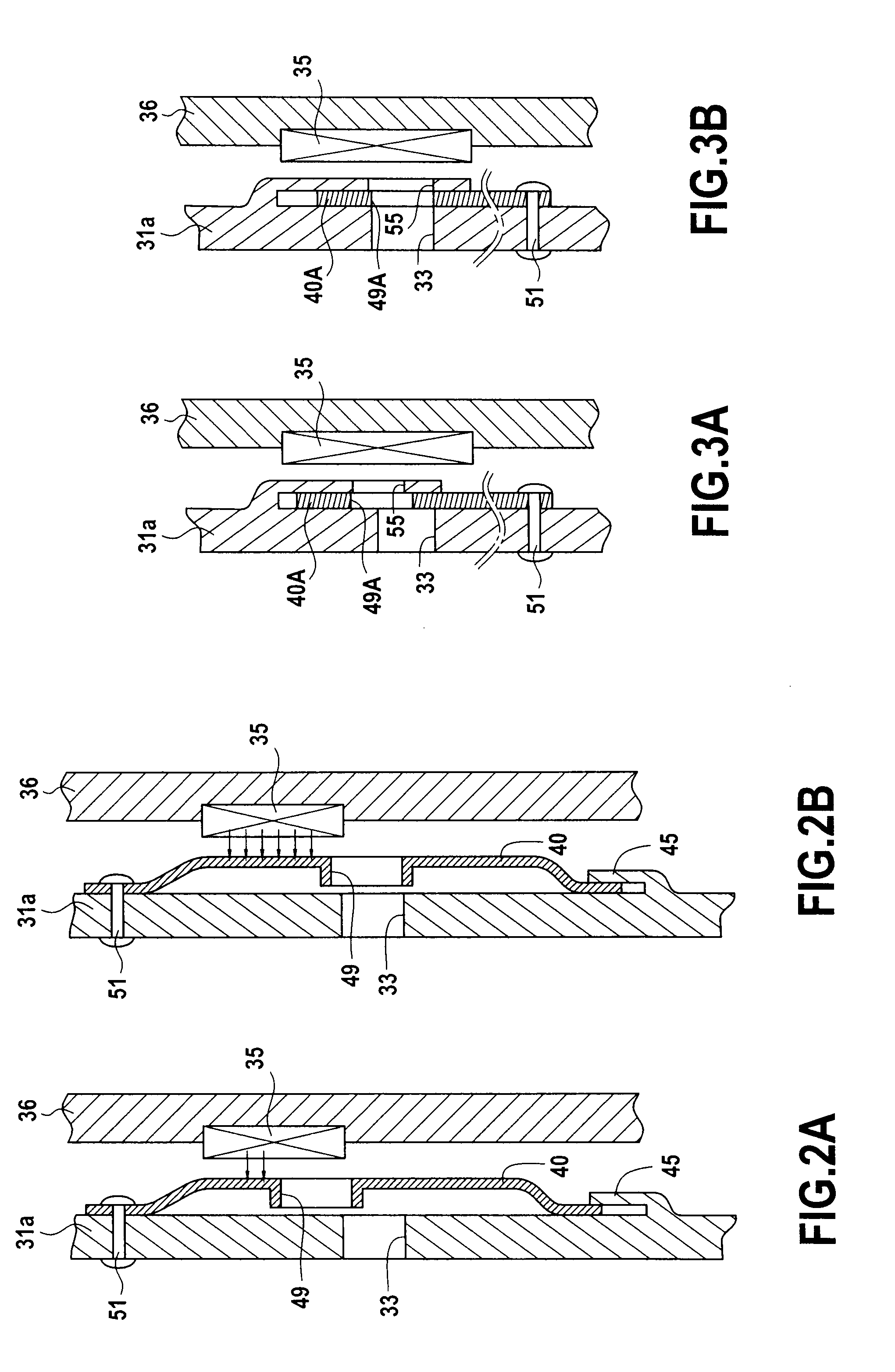

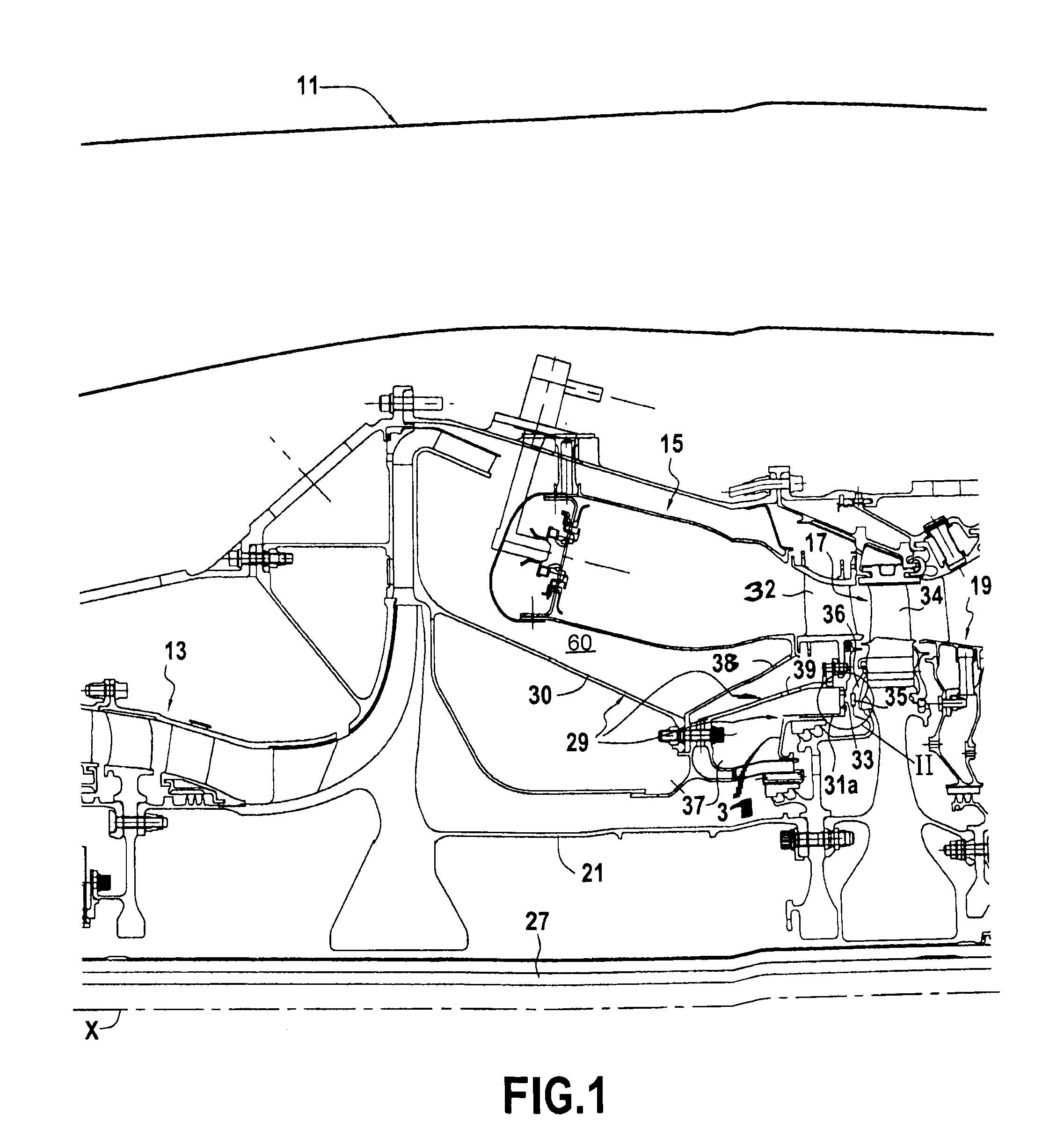

Turbojet including an automatically variable flow rate bleed circuit for cooling air

ActiveUS20120151936A1Quick upgradeIncrease rotation speedTurbine/propulsion engine coolingBlade accessoriesEddy currentTurbine

Bleeding cooling air to cool a subassembly, e.g. such as a turbine, with automatic adjustment of the air flow section as a function of the speed of the engine. According to the invention, a shutter element is fastened to co-operate with a bleed hole, with the material that constitutes either the shutter element or the wall in which the hole is formed being of a type in which it is possible to create eddy currents, and a magnet is mounted to move past said arrangement.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

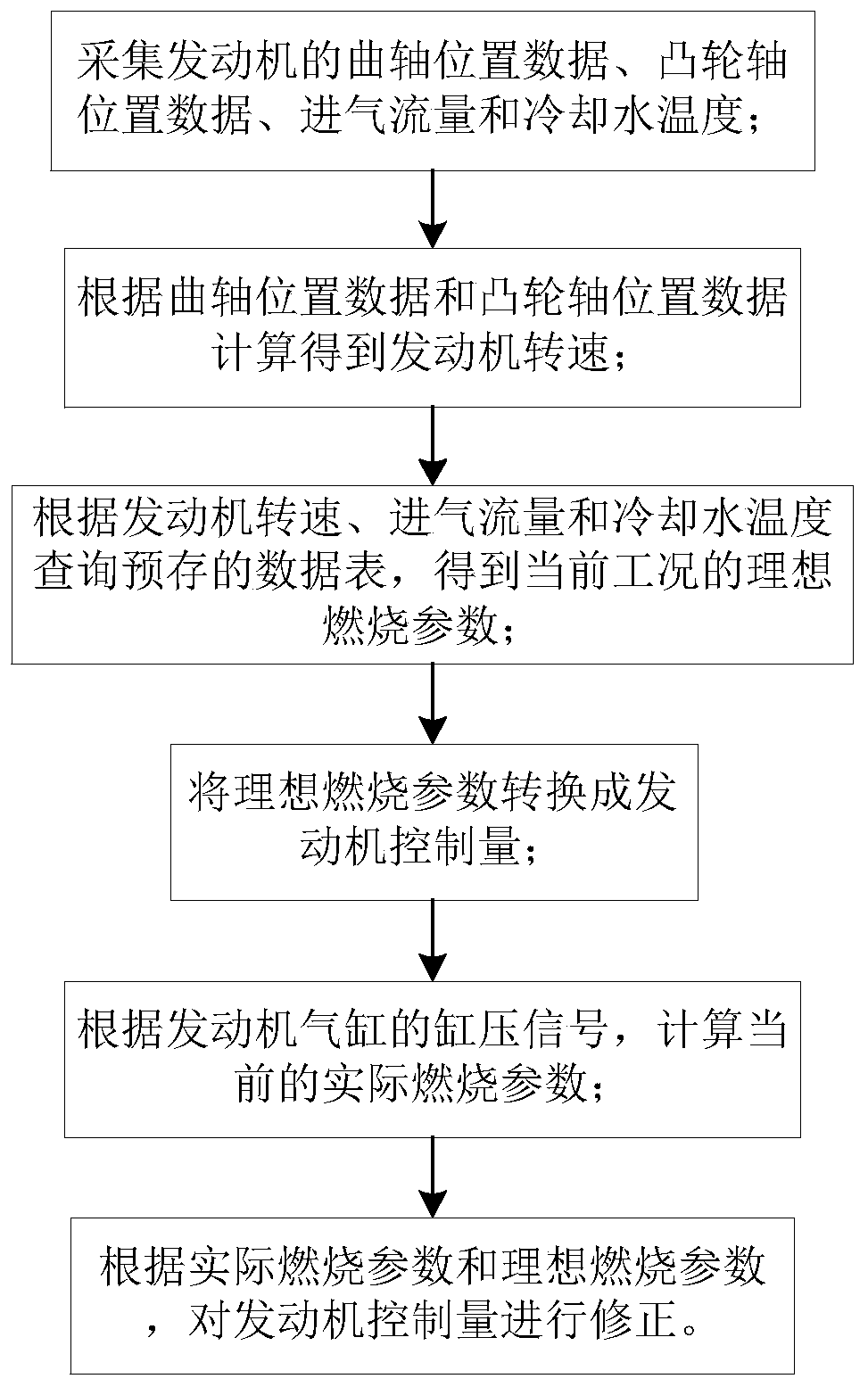

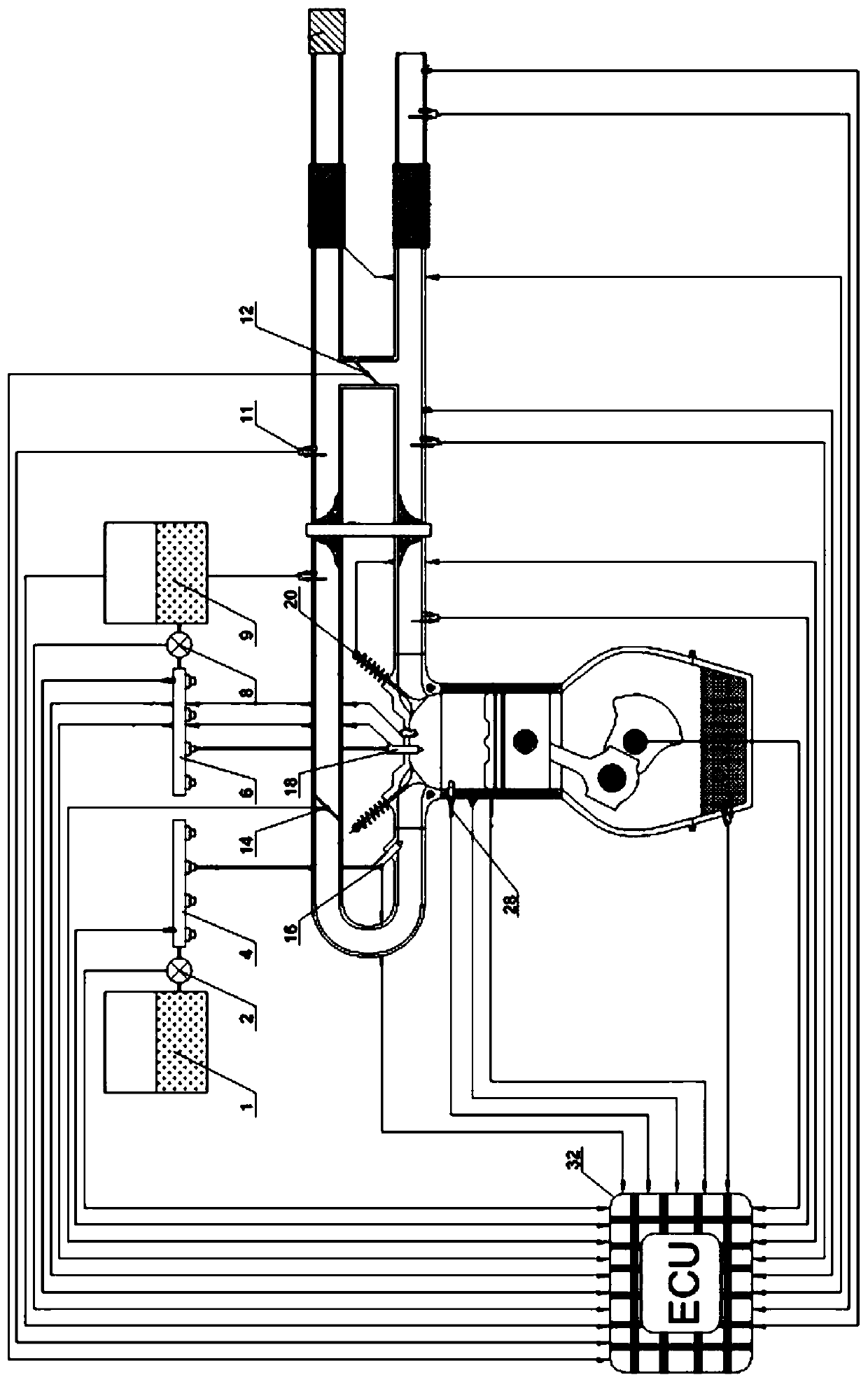

Double injection gasoline lean burning engine with porous oil nozzle

InactiveCN110145405AHigh thermal efficiencyEmission reductionElectrical controlInternal combustion piston enginesInlet channelGasoline

The invention provides a double injection gasoline lean burning engine with a porous oil nozzle. According to the double injection gasoline lean burning engine, the crankshaft position data, cam shaftposition data, air intake flow and cooling water temperature of the engine are collected; the rotating speed of the engine is calculated according to the crankshaft position data and the cam shaft position data; a prestored data sheet is inquired according to the rotating speed of the engine, the air intake flow and the cooling water temperature, and ideal burning parameters of the current work condition are obtained; the ideal burning parameters are converted into the engine control quantity; current actual burning parameters are calculated according to a cylinder pressure signal of an engine air cylinder; and the engine control quantity is corrected according to the actual burning parameters and the ideal burning parameters. By optimizing the injection moment of air inlet channel injection and a direct injection system, the injection pulse width and the proportion, feedback control over the burning phase and the burning rate is achieved, and therefore layered lean burning achieves ultralow emissions proportionable with homogeneous charge ignition burning, and the engine has the full load range work capacity.

Owner:SHANGHAI JIAO TONG UNIV

Turbojet including an automatically variable flow rate bleed circuit for cooling air

ActiveUS9062605B2Simple and inexpensive solutionQuick upgradeTurbine/propulsion engine coolingBlade accessoriesEddy currentTurbine

Bleeding cooling air to cool a subassembly, e.g. such as a turbine, with automatic adjustment of the air flow section as a function of the speed of the engine. According to the invention, a shutter element is fastened to co-operate with a bleed hole, with the material that constitutes either the shutter element or the wall in which the hole is formed being of a type in which it is possible to create eddy currents, and a magnet is mounted to move past said arrangement.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Liquid-cooled internal combustion engine with afterrun cooling, and method for operating an internal combustion engine of said type

ActiveUS9222400B2Small sectionReduced flow cross sectionCoolant flow controlCylinder headsLine tubingExternal combustion engine

An engine comprises a cylinder head connected to a cylinder block; a cooling circuit including a pump, a heat exchanger, and a ventilation vessel; a liquid-cooled component, connected into the cooling circuit by a connecting line and arranged between the pump and the ventilation vessel, which is cooled when the engine is not in operation; and a valve which is self-controlling as a function of coolant pressure arranged in the connecting line between the pump and the ventilation vessel, the valve adjustable between a first working position having a first, relatively small cross section of the connecting line, and a second working position, having a second, relatively large cross section of the connecting line, the valve controlling coolant throughput, wherein when the engine is not in operation and coolant pressure is reduced, the valve is in the second working position to provide an enlarged flow cross section.

Owner:FORD GLOBAL TECH LLC

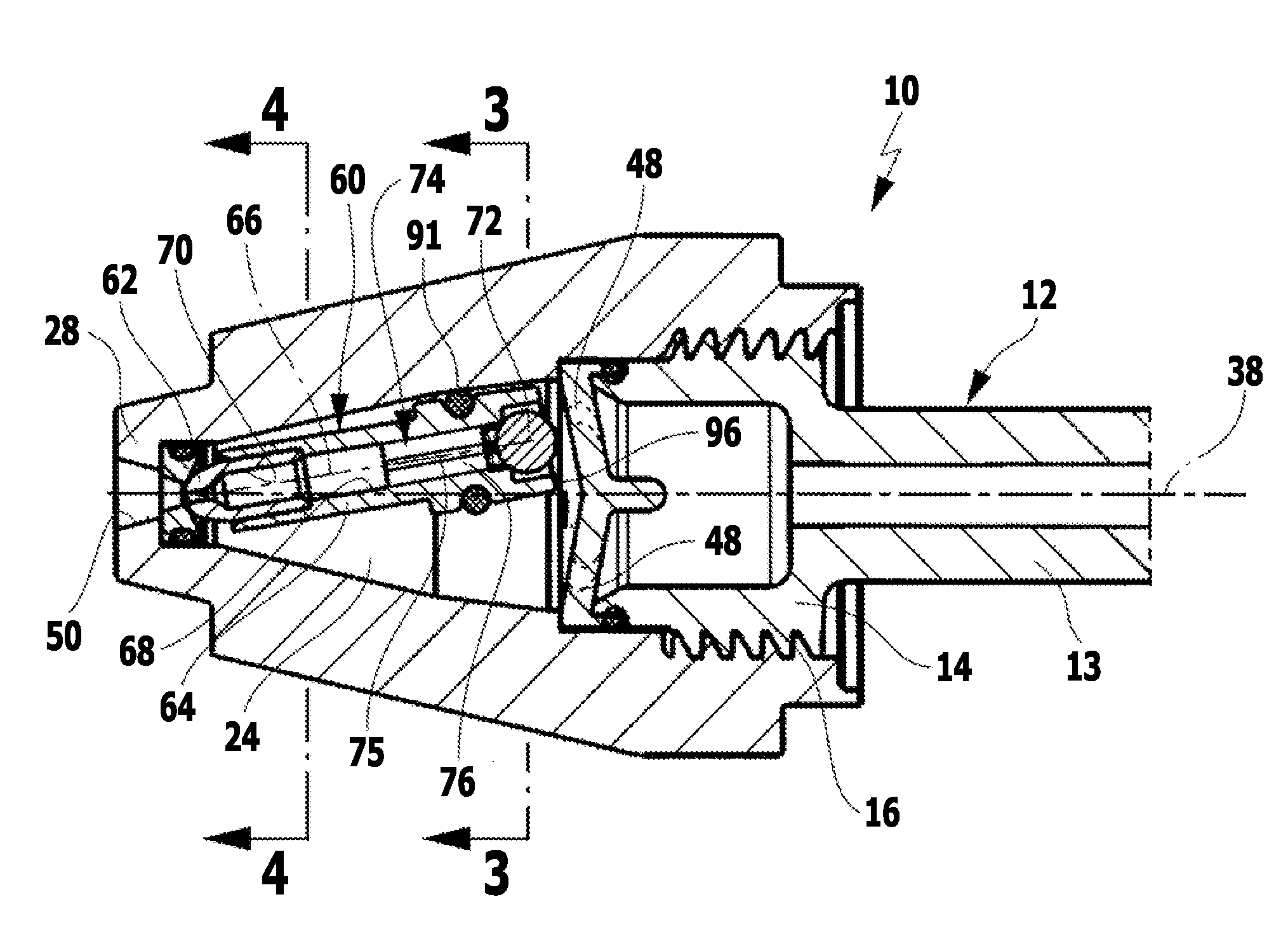

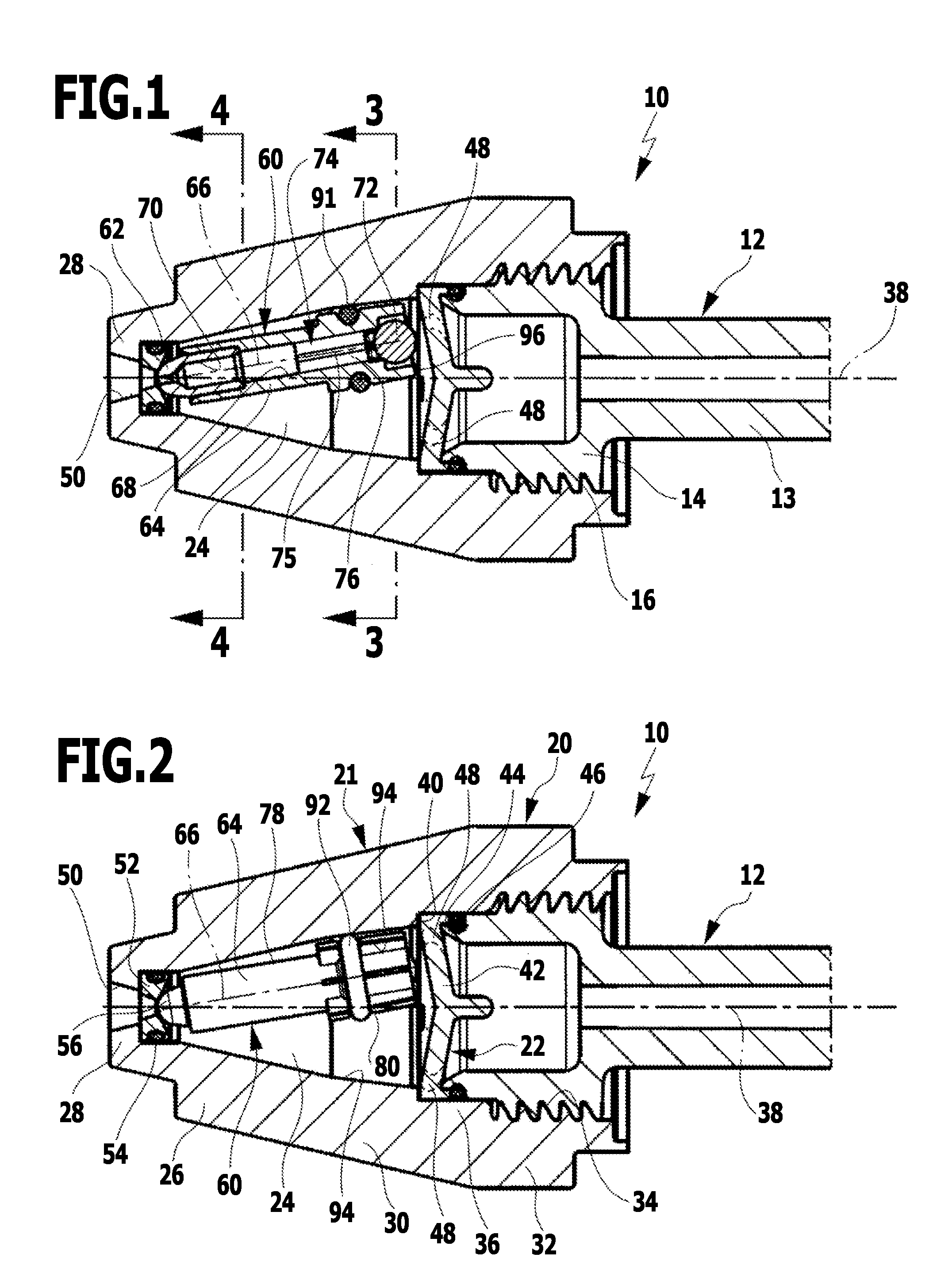

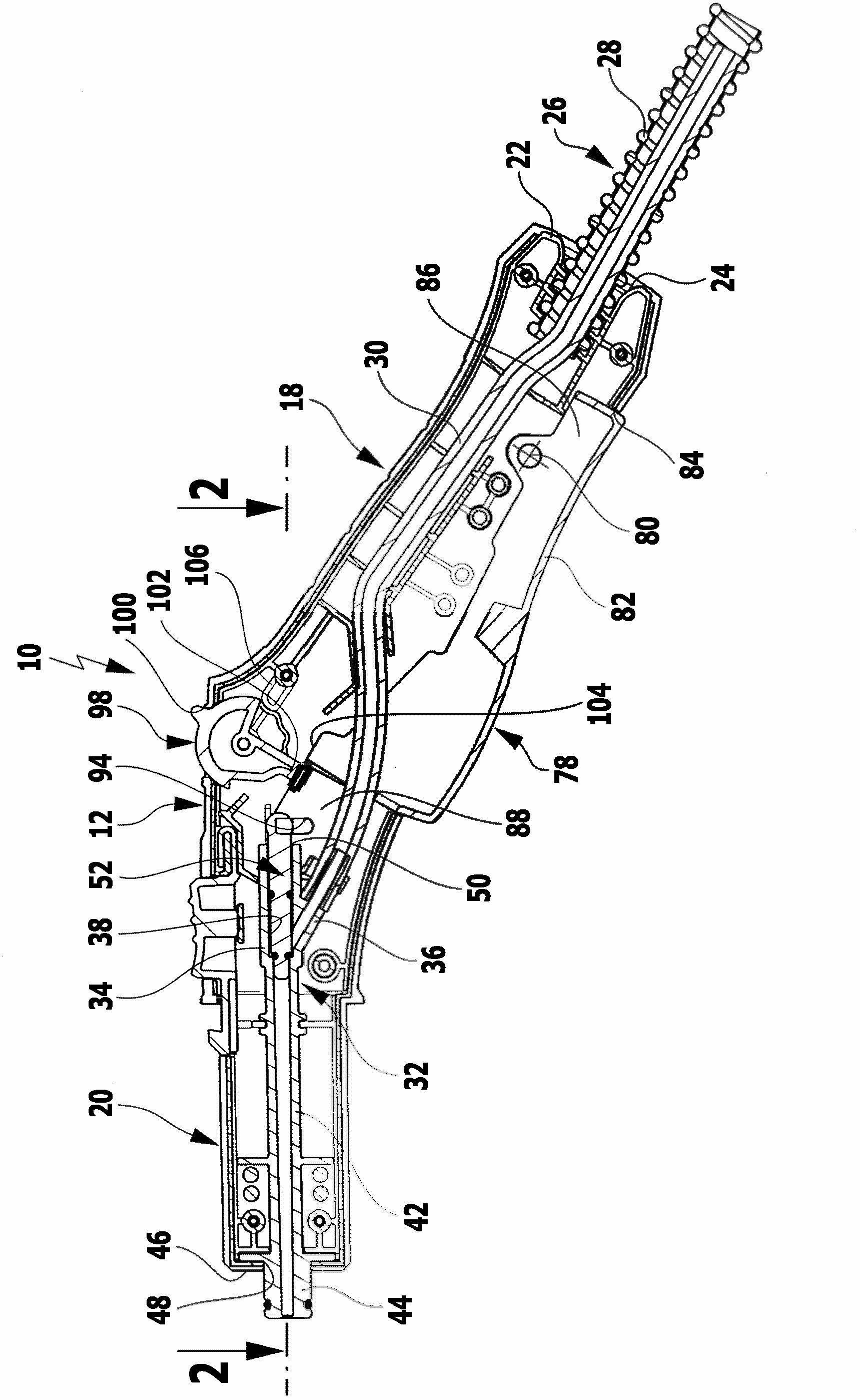

Handpiece for steam jet device

ActiveCN102655952ALess risk of getting stuckIncrease the flow cross sectionCleaning using liquidsSpring force

The invention relates to a handpiece (10) for a steam jet device having a housing (12) which has an inlet (24) for a feed line and an outlet (48) for a discharging line and in which a metering valve (32) is arranged with a valve housing (34), in which a valve body (52) is mounted which can be displaced to and fro linearly in a displacement direction, wherein the valve body is coupled to an actuating member (78) which is held movably on the housing and can be moved by the user counter to the action of a spring force. In order to develop the handpiece in such a way that it makes particularly sensitive metering of the steam discharge possible, it is proposed according to the invention that at least one spring element is arranged laterally next to the valve housing (34), which at least one spring element loads the valve body (52) with a spring force which is oriented parallel to the displacement direction.

Owner:ALFRED KARCHER GMBH & CO KG

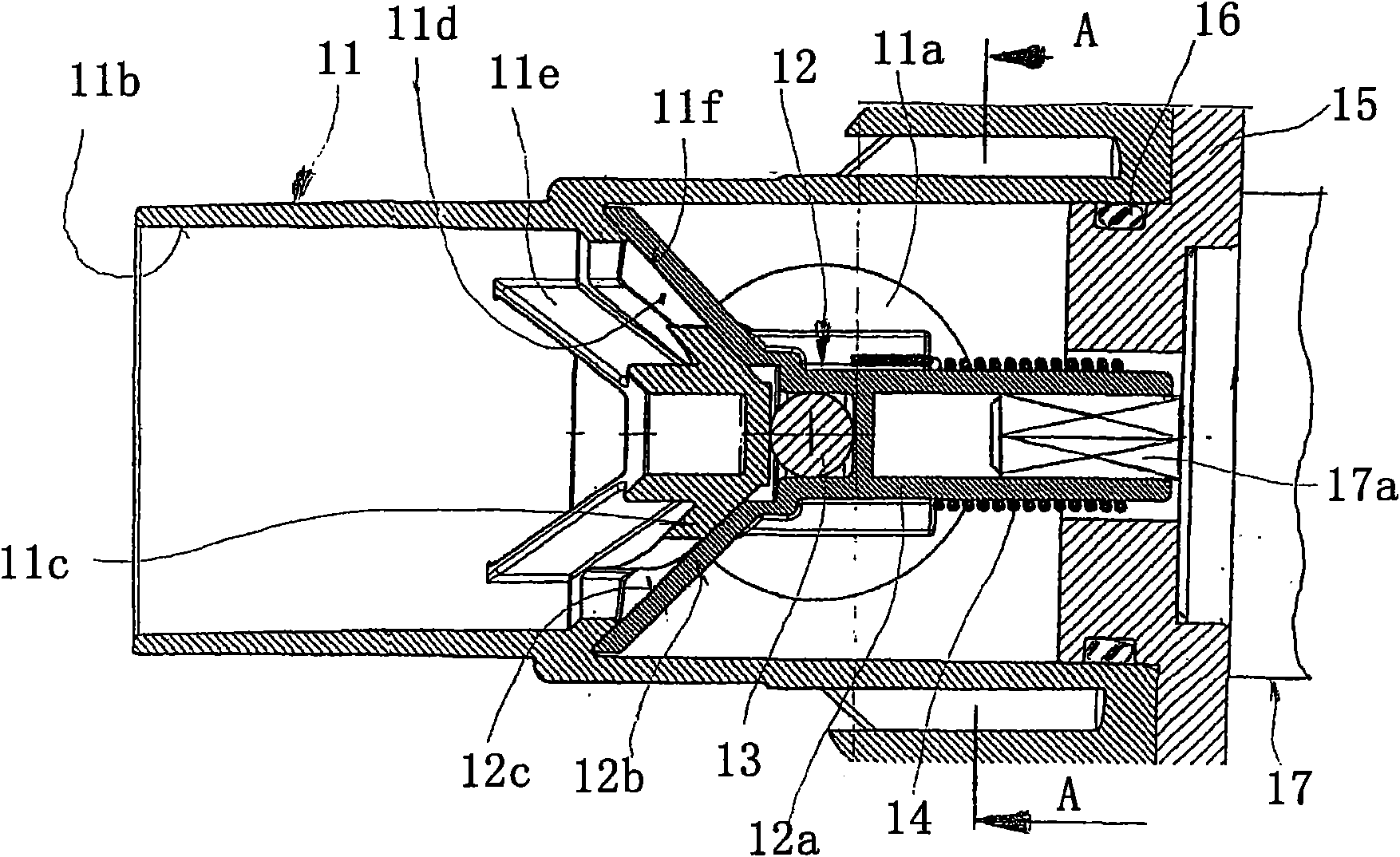

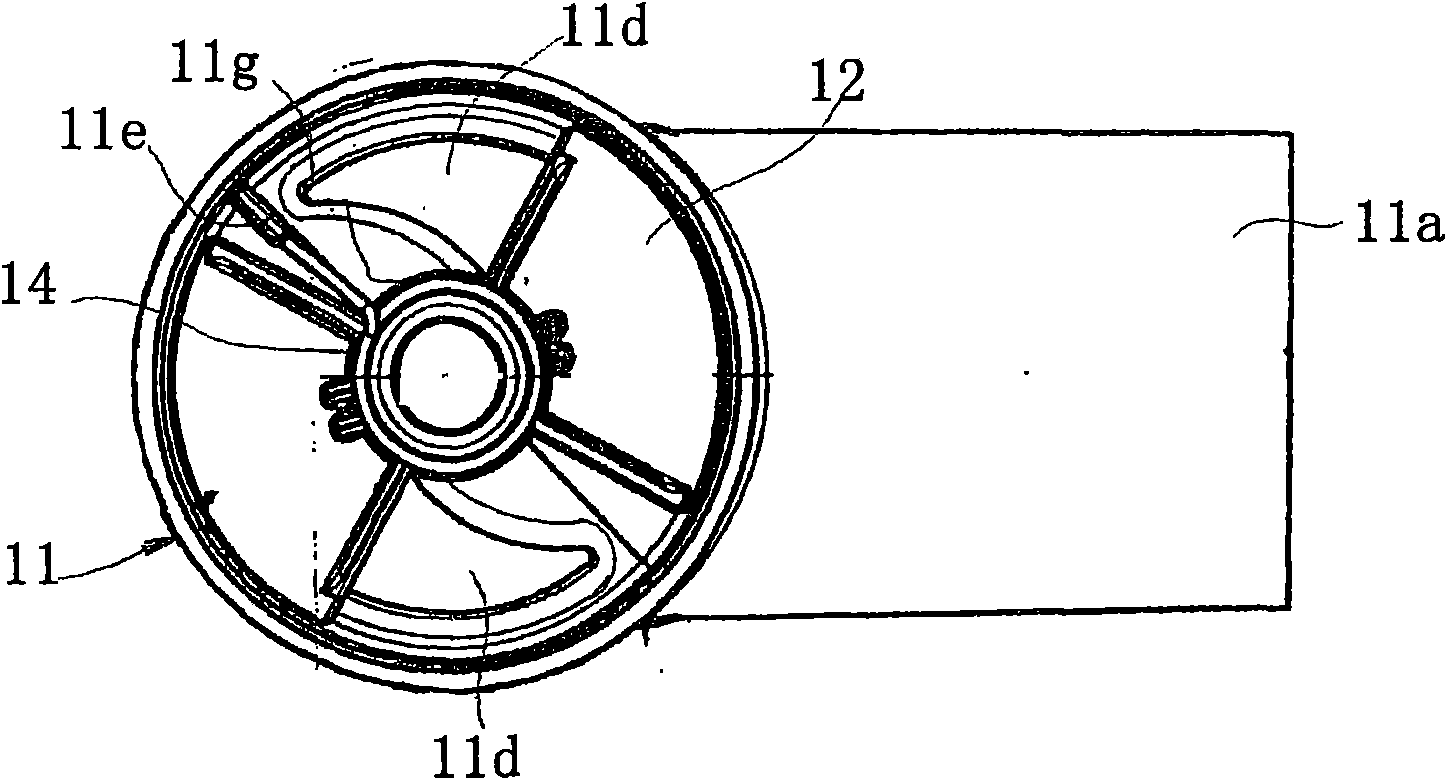

Control valve for respiratory devices

The invention relates to a respiratory device for keeping a patient breathing artificially or support his or her breathing naturally. Said respiratory device comprises an air inlet, an air source, and at least one proportionally adjustable control valve. The control valve is provided with a housing (11) and a rotary valve (12) which is arranged in the housing so as to be twistable about the longitudinal axis thereof and which allows through-holes (11d) of the housing (11) to be entirely or partially closed by twisting the rotary valve (12). The rotary valve (12) and a corresponding support surface (11f) of the housing (11) have a conical shape, the support surface (11f) cooperating with the rotary valve (12). The through-holes (11d) are disposed in the area of the support surface (11f).

Owner:IMTMEDICAL

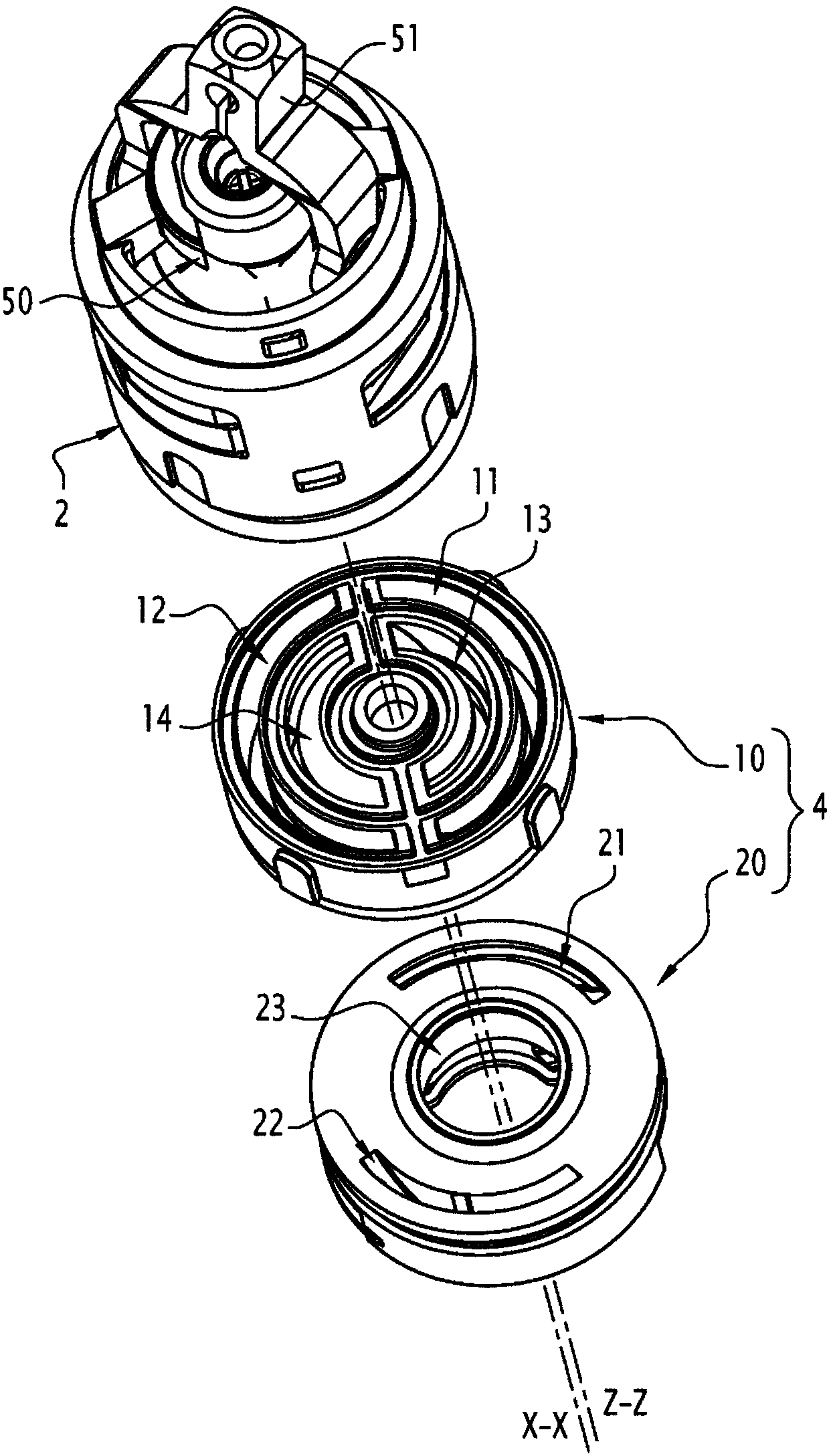

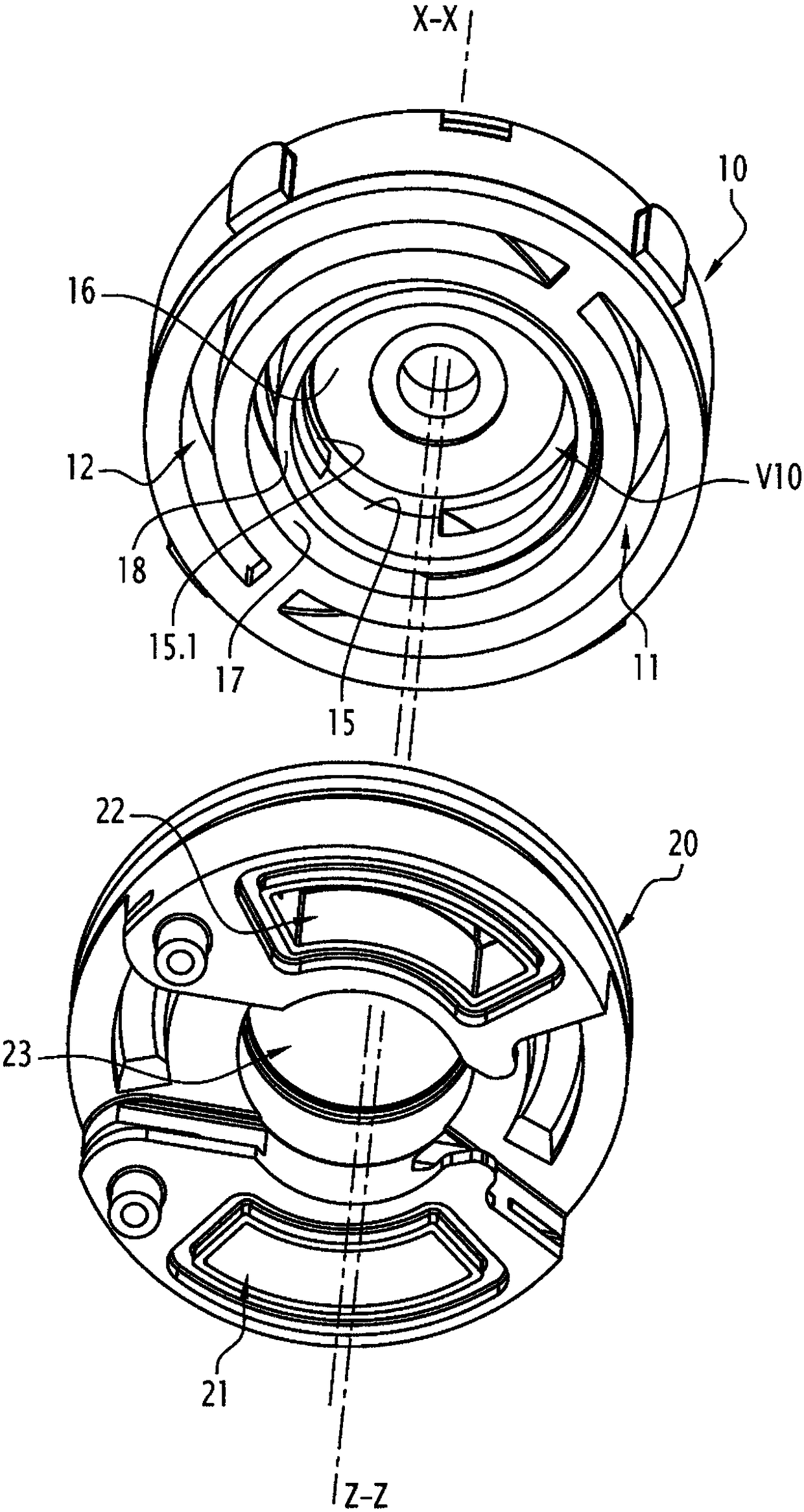

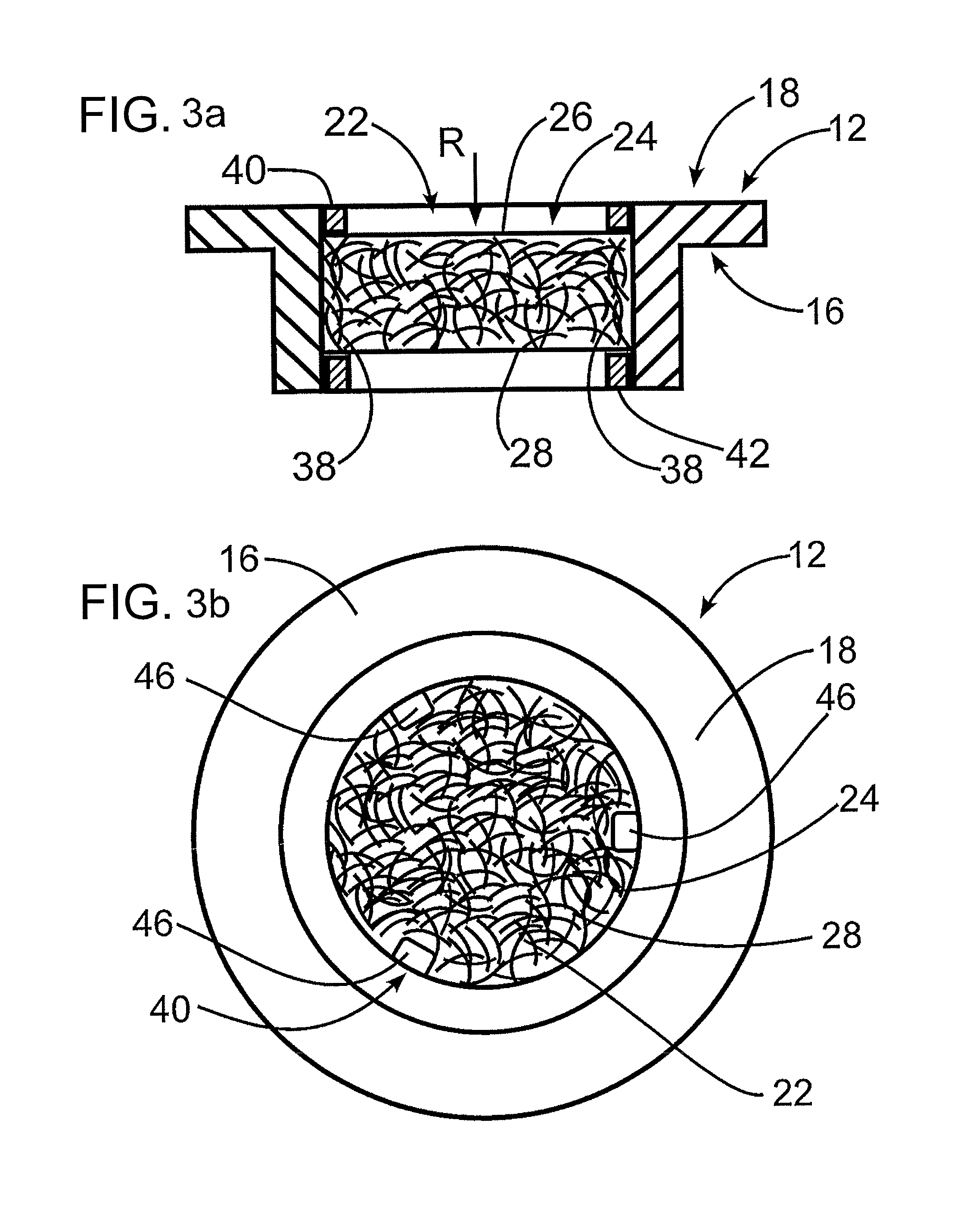

Thermostatic cartridge for controlling hot and cold fluids to be mixed

ActiveCN108369426ASpool outer diameter increasedFlow Section OptimizationTemperature control without auxillary powerOperating means/releasing devices for valvesEngineeringMechanical engineering

This cartridge (1) comprises a base (4), that defines a base axis (X-X) on which an outer peripheral face (6) of the base is centred, and that includes first (10) and second (20) base portions that follow one another along the base axis, the first base portion delimiting a first inlet opening (13) for a first of the cold and hot fluids to be mixed, and a second inlet opening (14) for the second fluid, while the second base portion delimits an outlet opening for a mixture of the cold and hot fluids. The cartridge also comprises a thermostatic element(40), as well as a control spool (30) for controlling the temperature of the mixture, which defines a spool axis (Z-Z) parallel to the base axis and is linked to the body (41) of the thermostatic element so as to be moved along the spool axis insuch a way as to vary, in an inverse manner, the respective flow sections of a first passage (F3) for the first fluid and a second passage (C3) for the second fluid, said passages being respectivelysupplied by the first inlet opening and the second inlet opening, extending around the spool axis while being centred on said spool axis, and being delimited axially between the spool and the first and second base portions. In order to maximise the flow sections of the fluids through the base, the spool axis is offset relative to the base axis.

Owner:VERNET SA

Micro-Air Motor

InactiveUS20080298960A1Different cross-sectionEasy to adaptPump componentsReaction enginesNeutral positionCompressed air

A micro-air motor comprises a collector rotatably mounted in a casing for the compressed air supply and discharge to or from the rotor. By twisting the collector as far the end positions a direction of rotation reversal as well as continuous speed regulation is possible. In a neutral position of the collector the rotor can be additionally stopped and locked.

Owner:ROTOMED

Pressure release device for housings with flameproof encapsulation with porous body having interference fit

ActiveUS9492694B2Increase the flow cross sectionEasy to manufactureLarge containersSubstation/switching arrangement casingsInterference fitEngineering

A pressure release device for a protective housing for flameproof enclosure of electrical operating means. The device includes an accommodating body (18) having a passage (22), and a porous body (24) arranged in the passage (22). The porous body (24) is elastically deformed by means of an interference fit in the passage (22), and thus, reliably supported therein free of flame or spark exiting gaps.

Owner:R STAHL SCHALTGERATE

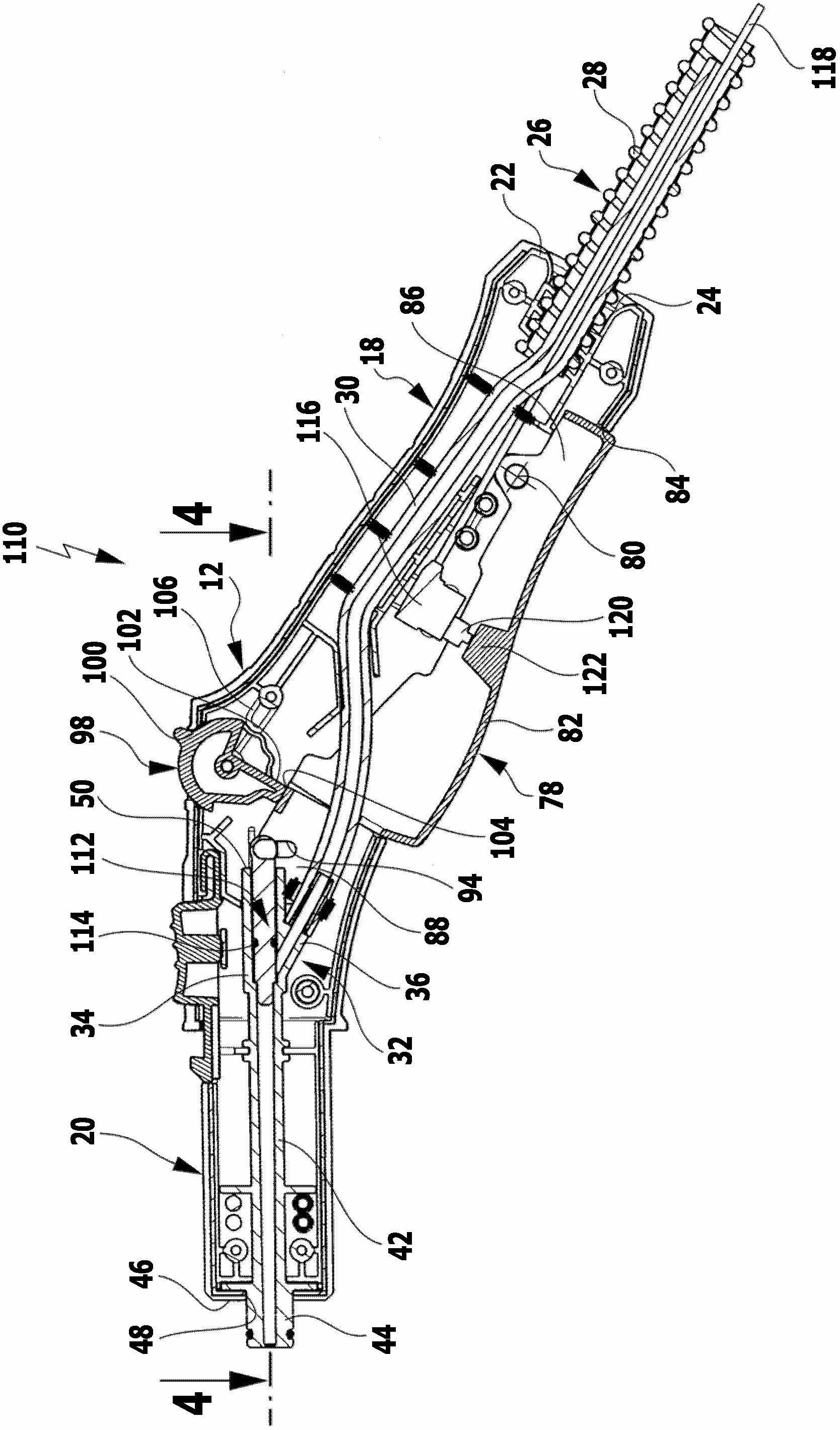

Double shaft reactor/mixer and system including an end cap for a reactor/mixer and a discharge screw connector block

ActiveUS20140321232A1Avoid condensationInhibition formationLiquid degasificationRotary stirring mixersEngineeringMechanical engineering

An at least two shaft reactor / mixer, in particular for process engineering treatment of highly viscose, elastic and / or solid containing reaction substance and mixture, in which at the housing inner wall inwardly directed static mixing elements are arranged, which interact with scrapers of the at least two shafts in such a way, that in the area of the spaces between the scrapers the static mixing elements and the housing inner wall sheer forces, in particular a flow disturbance, are generated in an enhanced manner. In addition, there is a system including an end cap for a one or multiple shaft reactor / mixer and a discharge screw connector block being connectable with the end cap in a detachable manner.

Owner:BUSS SMS CANZLER

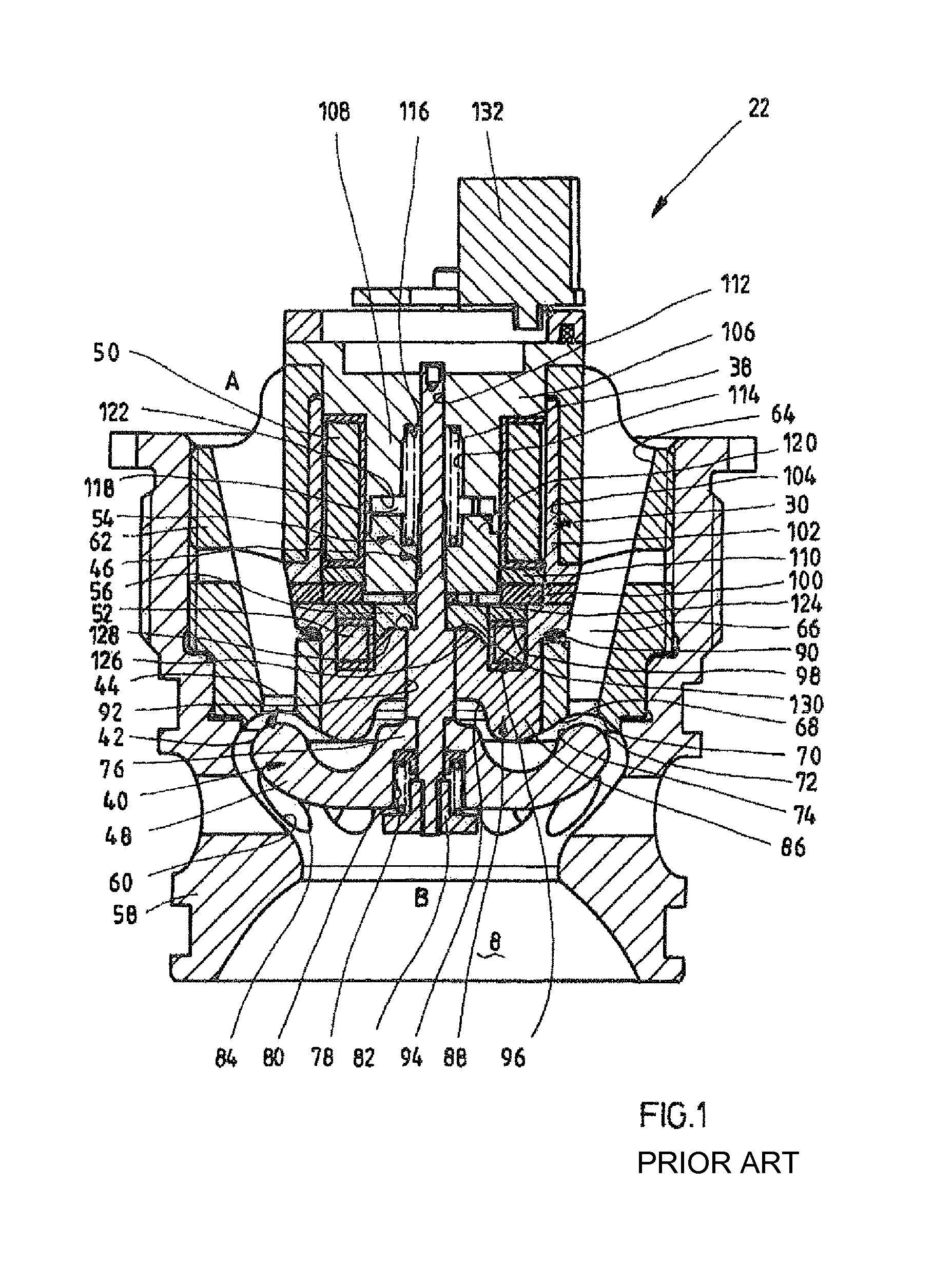

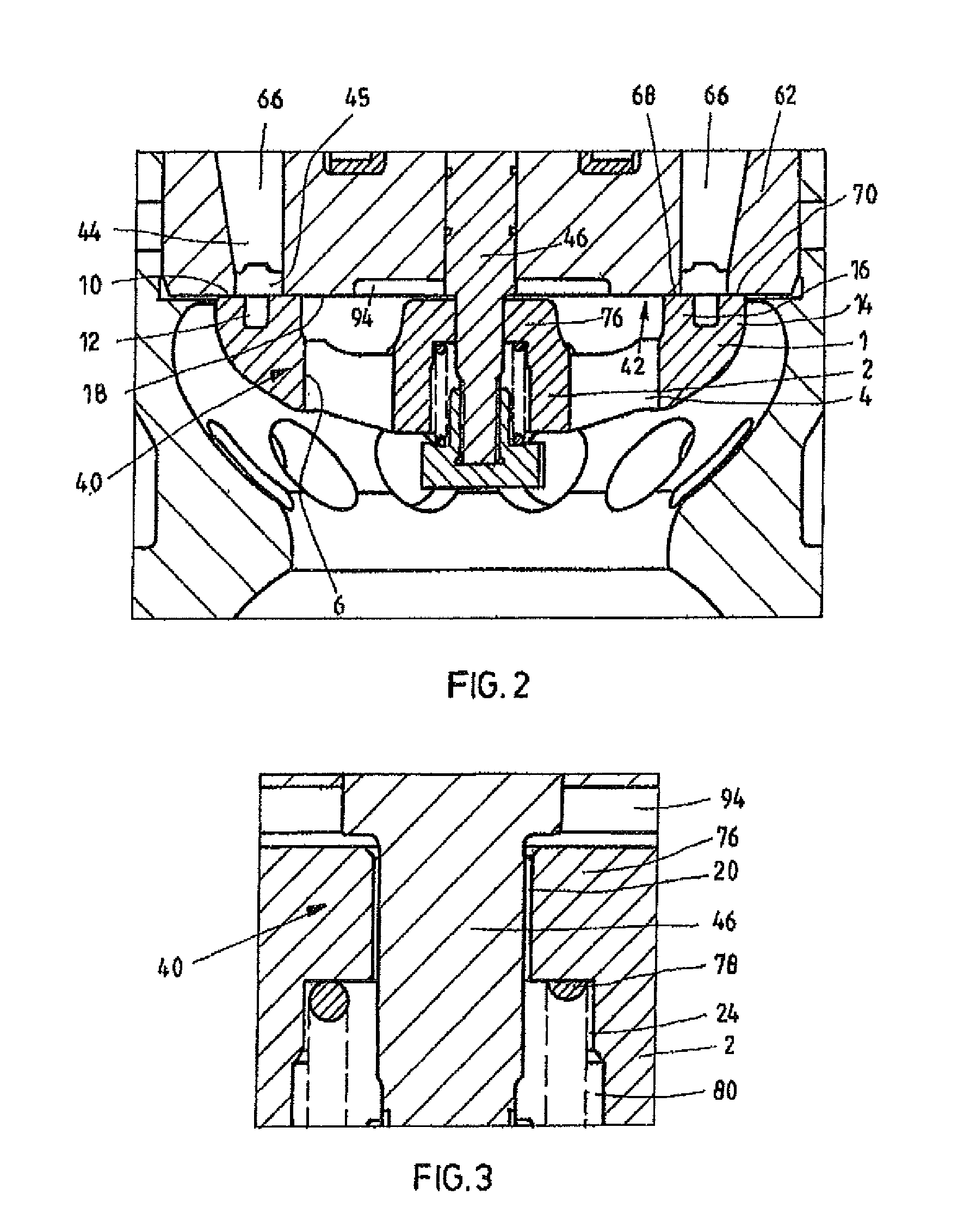

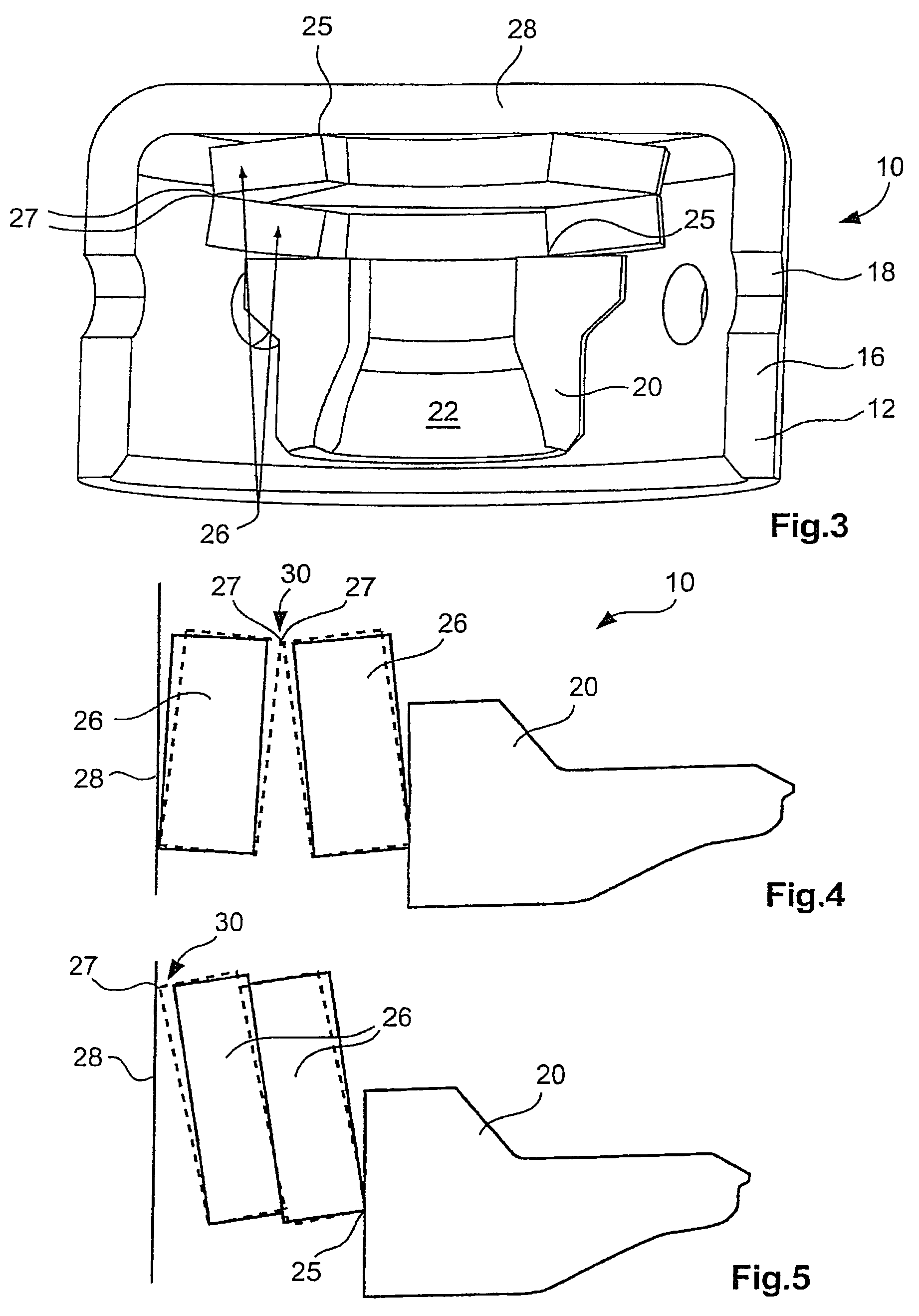

Gas generator

ActiveUS7665762B2Simple designIncrease the flow cross sectionPedestrian/occupant safety arrangementNuclear engineeringNormal position

A gas generator for a vehicle occupant restraint system a rigid outer housing (12), a chamber (14) formed in the outer housing (12), in which a compressed gas is present at least upon activation of the gas generator (10), a component immovable (20; 34; 62) relative to the outer housing (12), at least one outflow opening (22) formed in the immovable component (20; 34; 62), and a least one resilient element (26), which is clamped inside the outer housing (12) and rests against the immovable component (20; 34; 62) at least in its normal position. In its normal position, the resilient element (26) closes a flow path between the chamber (14) and external surroundings of the gas generator (10) and is deformed elastically under the influence of compressed gas, whereby it clears a flow cross-section (30) whose size is increasing with increasing pressure.

Owner:TRW AIRBAG SYST

PVC (polyvinyl chloride) profile for anti-cracking impact-resistant back net reinforcing ribs and treatment technique thereof

The invention discloses a PVC (polyvinyl chloride) profile for anti-cracking impact-resistant back net reinforcing ribs, which comprises a PVC substrate and a reinforcing agent. The reinforcing agent is composed of the following components in parts by weight: 5-10 parts of high-efficiency impact modifier based on acrylic ester polymer, 0.5-1 part of organotin stabilizing agent, 1-1.5 parts of light calcium carbonate, 0-0.5 part of active calcium, 0.05-0.1 part of toughener, 3 parts of chlorinated polyethylene, 0.08 part of oxidized wax, 0.3 part of polyethylene wax, 0.6-0.9 part of organic wax and 0.1-0.3 part of modifier. Ethyl silicate and heat-resistant pigment and filler are added into the modifier. The heat-resistant pigment and filler comprises nano smectite silicate and blocking functional filler in a mass ratio of 1.5:1:1. Compared with the prior art, the PVC profile for anti-cracking impact-resistant back net reinforcing ribs effectively reduces the problem of cracking of the reinforcing ribs due to long-time usage, and enhances the cracking resistance and impact resistance of the reinforcing ribs.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

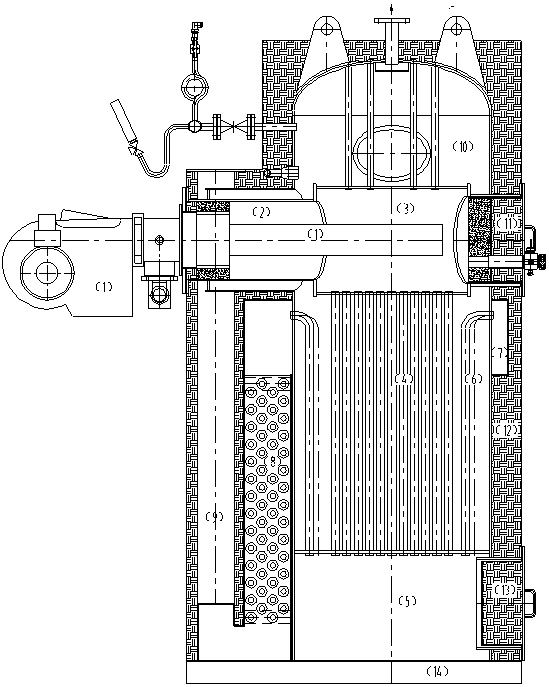

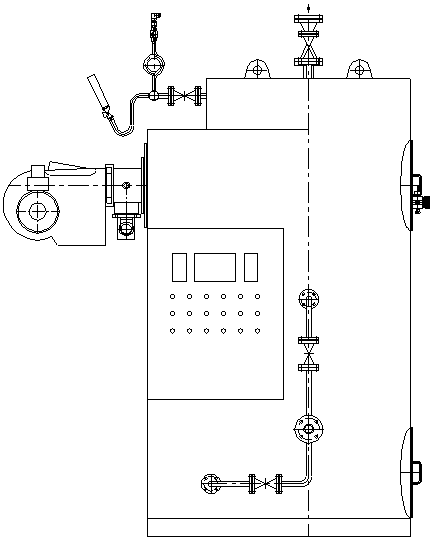

Vertical full premix gas steam or hot water boiler

PendingCN107559810AIncrease the flow cross sectionReduce the temperatureCombustion chambersCombustorPipe Tobacco

The invention discloses a vertical full premix gas steam or hot water boiler. The boiler comprises a full premix combustor (1) transversely penetrating a vertical boiler shell (10) in a connected manner, the full premix combustor (1) comprises a racket-shaped front segment handle hearth (2) and a racket-shaped rear segment racket face hearth (3), the racket-shaped front segment handle hearth (2) is located on the outer side of the vertical boiler shell (10), the racket-shaped rear segment racket face hearth (3) is located in the vertical boiler shell (10), the top of a vertical two-return-stroke straight smoke tube (4) is communicated with the racket-shaped rear segment racket face hearth (3), and the bottom of the two-return-stroke straight smoke tube (4) is communicated with a bottom smoke box (5). The vertical full premix gas steam or hot water boiler is compact in structure and high in heat efficiency.

Owner:JIANGSU SHUANGLIANG BOILER

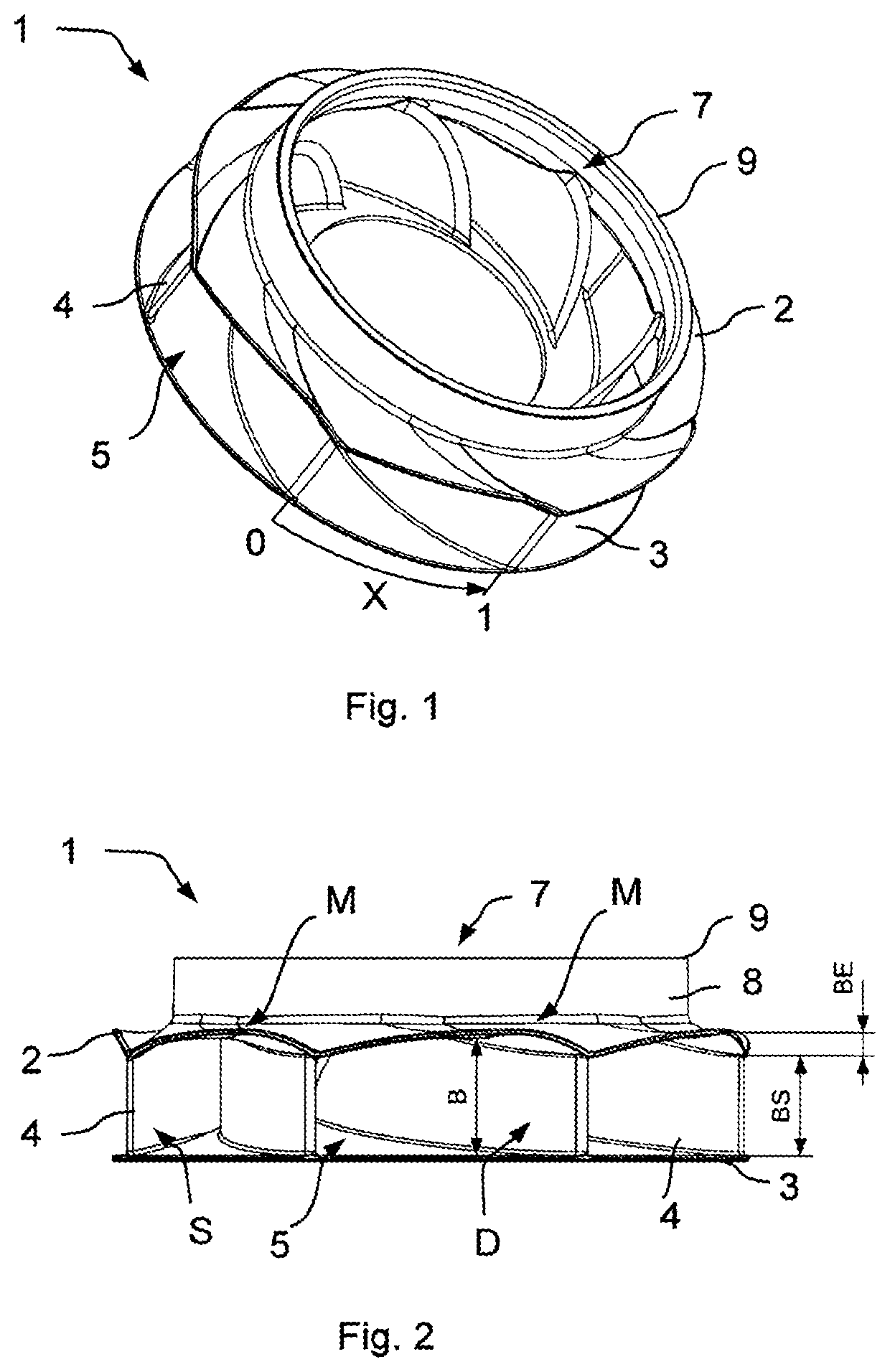

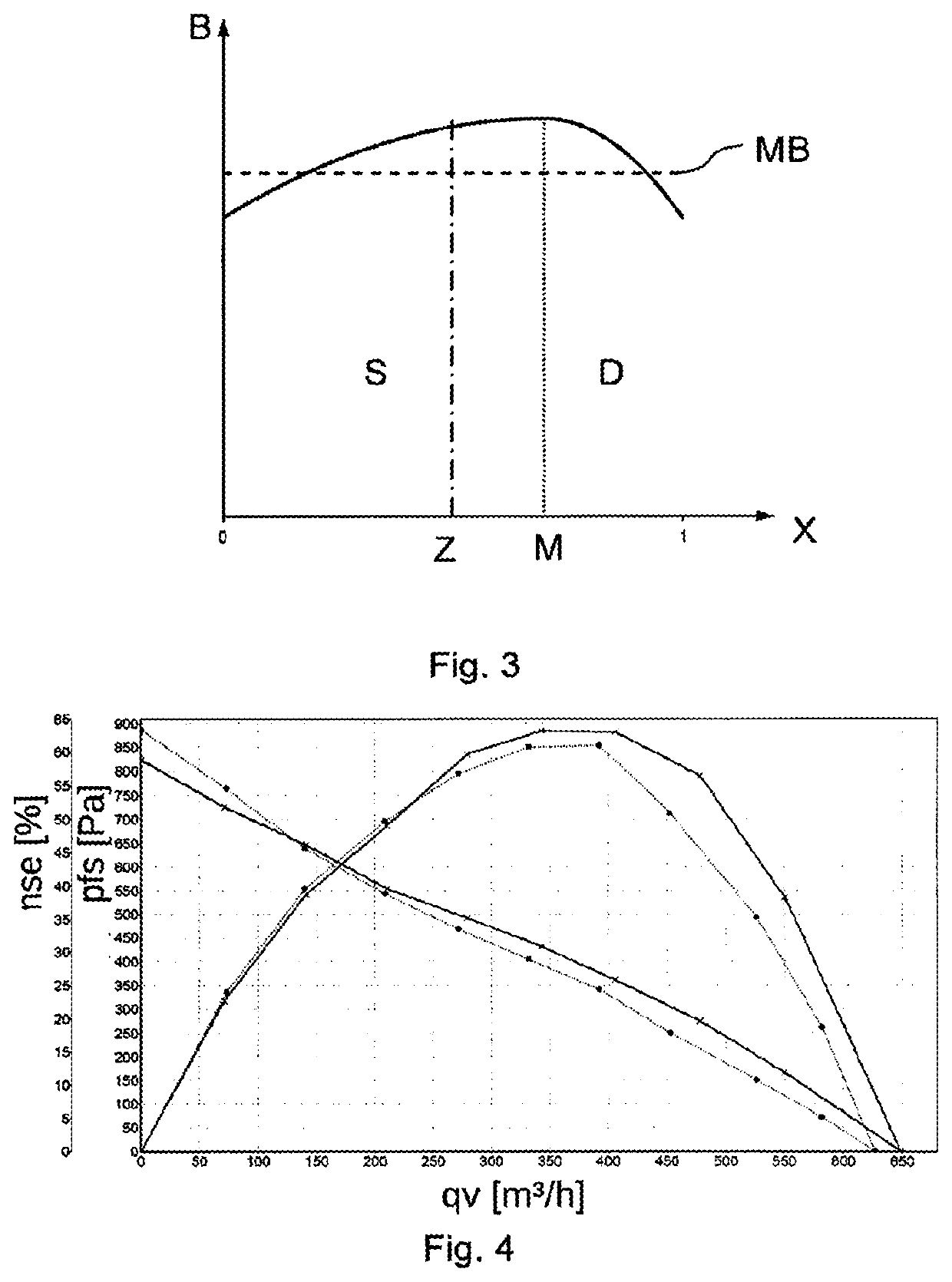

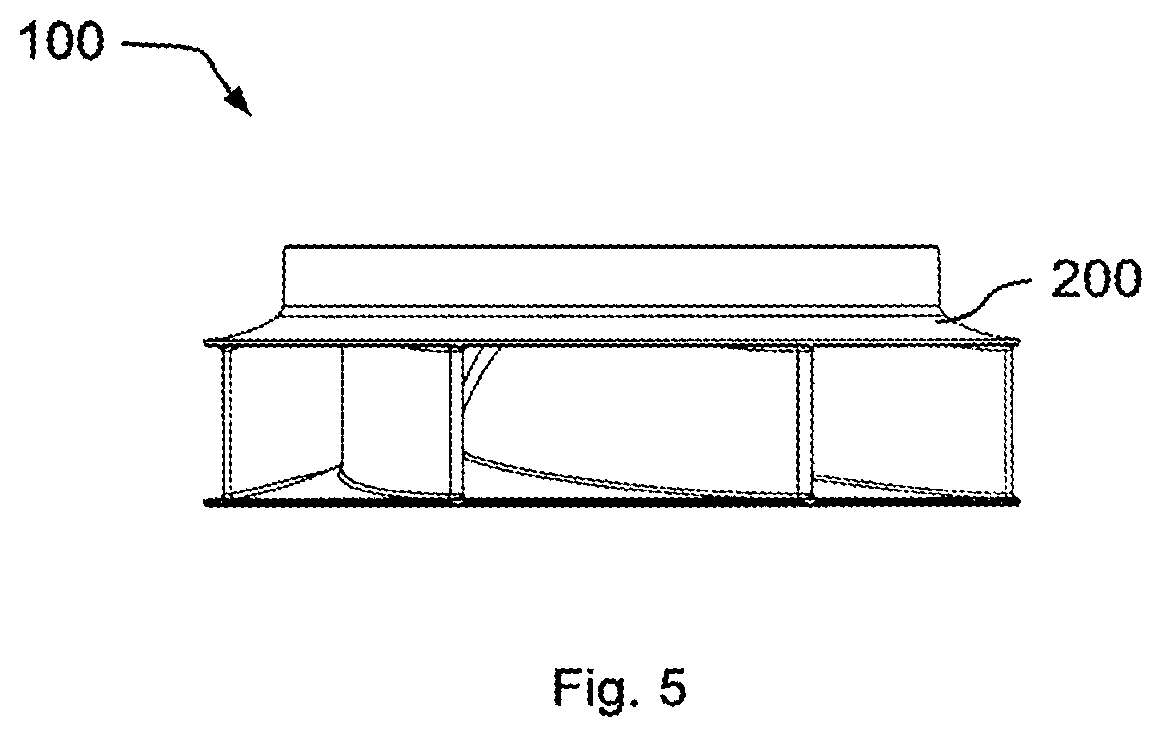

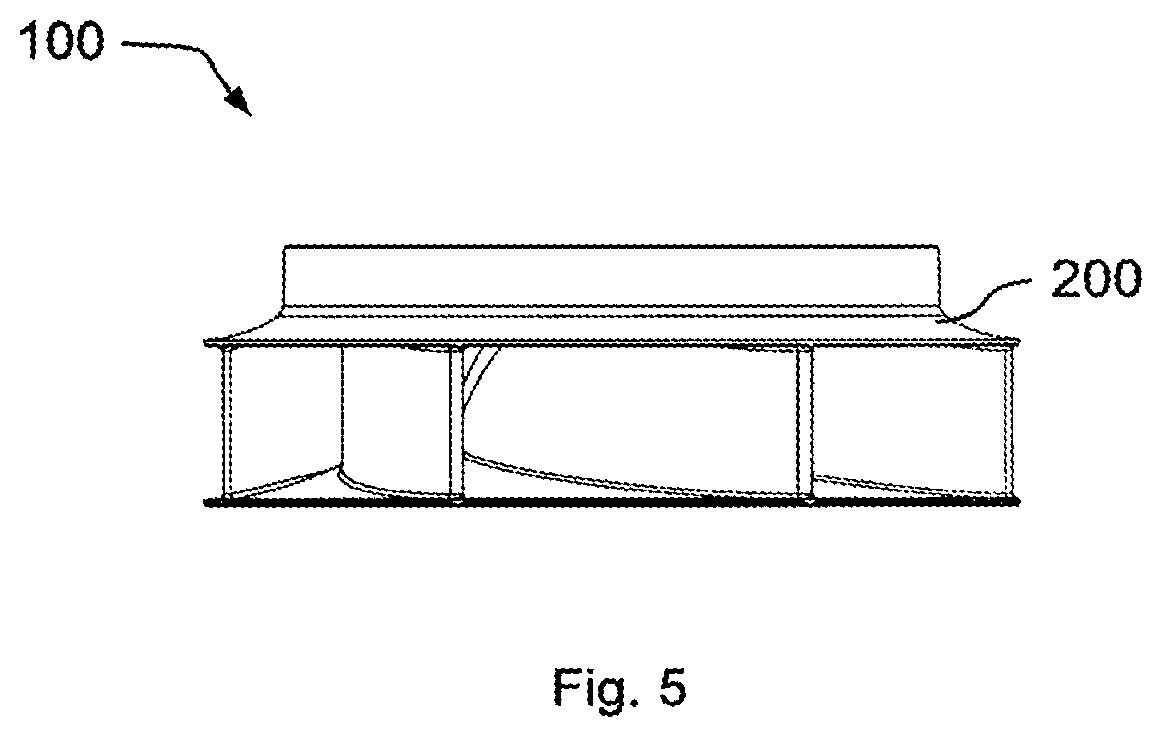

Covered radial fan wheel with a periodically and asymmetrically shaped plate

ActiveUS20200080565A1Improve efficiencyImproved noise behaviorEngine manufacturePump componentsImpellerSuction force

Owner:EBM PAPST MULFINGEN GMBH & CO KG

Covered radial fan wheel with a periodically and asymmetrically shaped plate

ActiveUS11143197B2Improve efficiencyImprove noiseEngine manufacturePump componentsImpellerSuction force

Owner:EBM PAPST MULFINGEN GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com