Thermostatic cartridge for controlling hot and cold fluids to be mixed

A technology of constant temperature spool and thermal fluid, applied in temperature control, engine cooling, non-electric variable control, etc., can solve the problem of limited outer diameter and achieve the effect of increasing the outer diameter of the slide valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

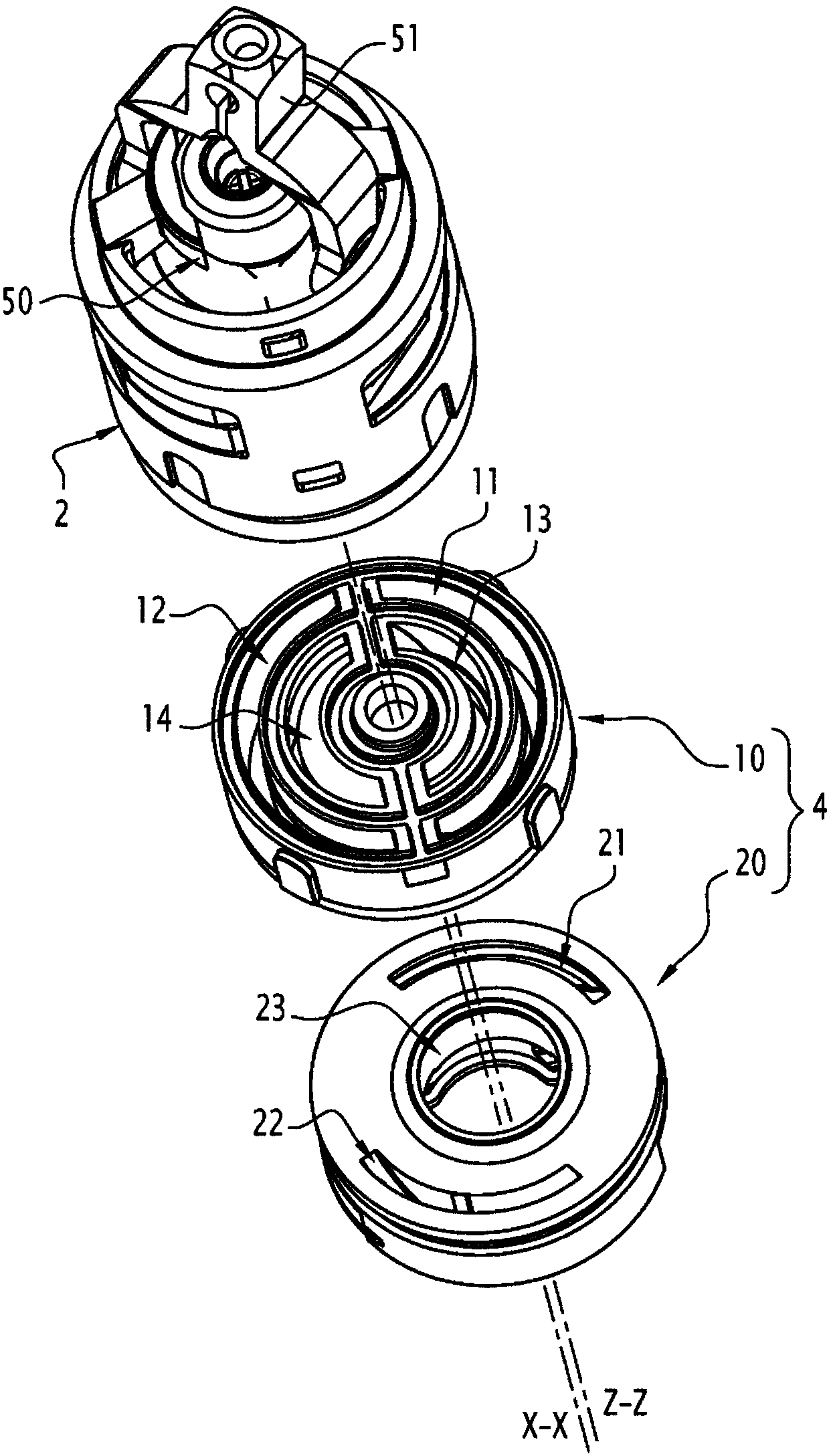

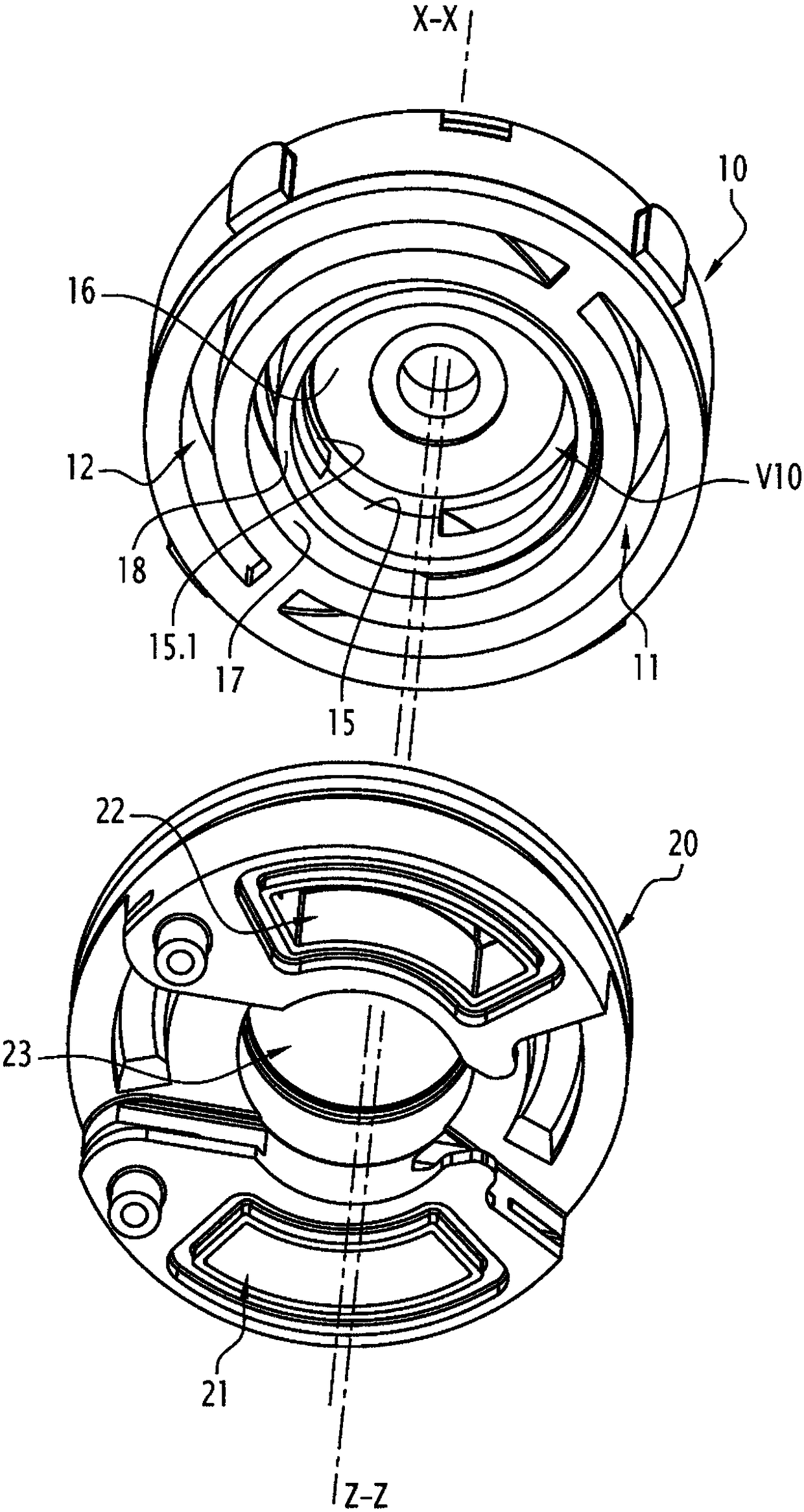

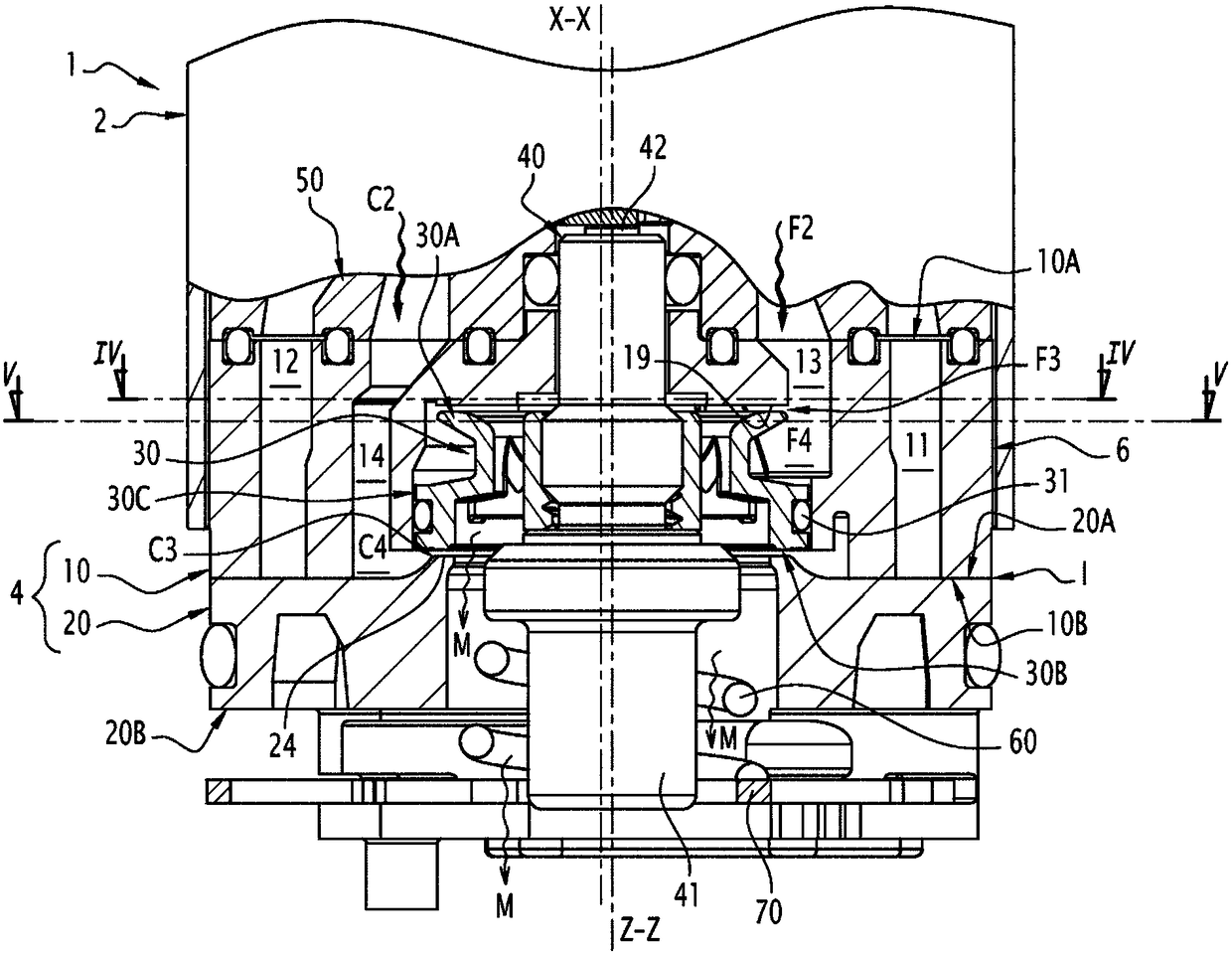

[0017] Figure 1 to Figure 7 A thermostatic spool 1 arranged along the main axis X-X is shown. This cartridge is suitable for equipping taps (not shown in the figures) for mixing hot and cold water, or more generally for equipping sanitary facilities.

[0018] For convenience, the remainder of the description is oriented relative to the axis X-X, considering that the terms "upper" and "top" etc. image 3 , 6 and 7 are the axial direction of the upper part, while the terms "lower" and "bottom" etc. correspond to the axial direction in the opposite sense.

[0019] The thermostatic valve core 1 comprises an upper housing 2 and a lower base 4 which are fixedly assembled to each other in the assembled state of the valve core.

[0020] The base 4 has a generally cylindrical external shape, with a cylindrical peripheral surface 6 centered on the axis X-X. The axis X-X is thus defined by the periphery of the base and can therefore be described as the base axis. In the example cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com