Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Increase structural viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight aggregate high-performance concrete and preparation method thereof

InactiveCN106830988AImproved particle size distributionGood adhesivenessCeramicwareOperabilityUltimate tensile strength

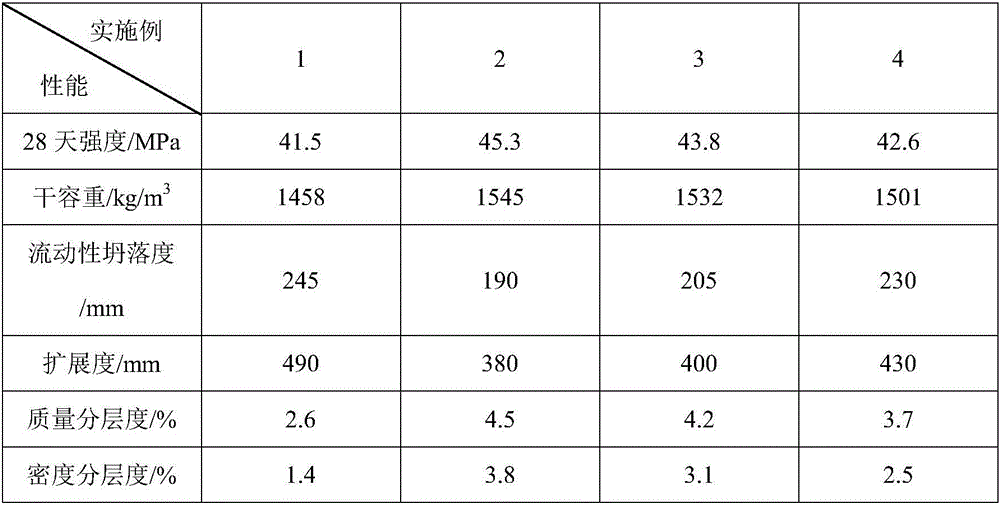

The invention discloses a lightweight aggregate high-performance concrete and a preparation method thereof. The lightweight aggregate high-performance concrete contains the following raw materials: 180-310 parts of cement, 580-650 parts of ceramsite, 420-500 parts of pottery sand, 0-80 parts of sand regenerated from construction waste, 100-130 parts of coal ash, 100-210 parts of mineral powder, 130-160 parts of water, 4.5-6.5 parts of water reducer, 1-1.5 parts of enhanced modified material and 0.45-0.60 part of anti-separation material. The lightweight aggregate high-performance concrete has the advantages of light unit weight (1450-1550kg / m3), high 28-day strength (40-50MPa), separation resistance, capability of being pumped, slump of 190-250mm, divergence of 400-550mm, no aggregate floating, simple preparation method, high operability and low cost.

Owner:JIANGSU UNIV OF SCI & TECH

High-performance lightweight aggregate concrete

InactiveCN101747006AImprove the way of forceImprove mechanical propertiesSolid waste managementSlagExpanded clay aggregate

The invention discloses high-performance lightweight aggregate concrete. The high-performance lightweight aggregate concrete is characterized in that: high-performance porcelain granules are taken as lightweight aggregate; and the high-performance lightweight aggregate concrete is prepared by mixing the following raw materials in proportion: 400 to 430 kg / m<3> of cement, 500 to 570 kg / m<3> of high-performance porcelain granule, 40 to 55 kg / m<3> of fly ash, 40 to 55 kg / m<3> of grounded furnace slag, 540 to 565 kg / m<3> of sand, 180 to 185 kg / m<3> of water and 6 to 10 kg / m<3> of water reducing agent, wherein the performance indexes of the high-performance porcelain granule is that stacking density is less than and equal to 700 kg / m<3>, cylinder pressure strength is greater than and equal to 6.0 MPa, strength mark is greater than and equal to 35 MPa and water absorbing capacity is less than and equal to 1.0 percent. The high-performance lightweight aggregate has the advantages that the strength is high, and workability and pumpability can meet design and construction requirements.

Owner:NINGBO UNIV

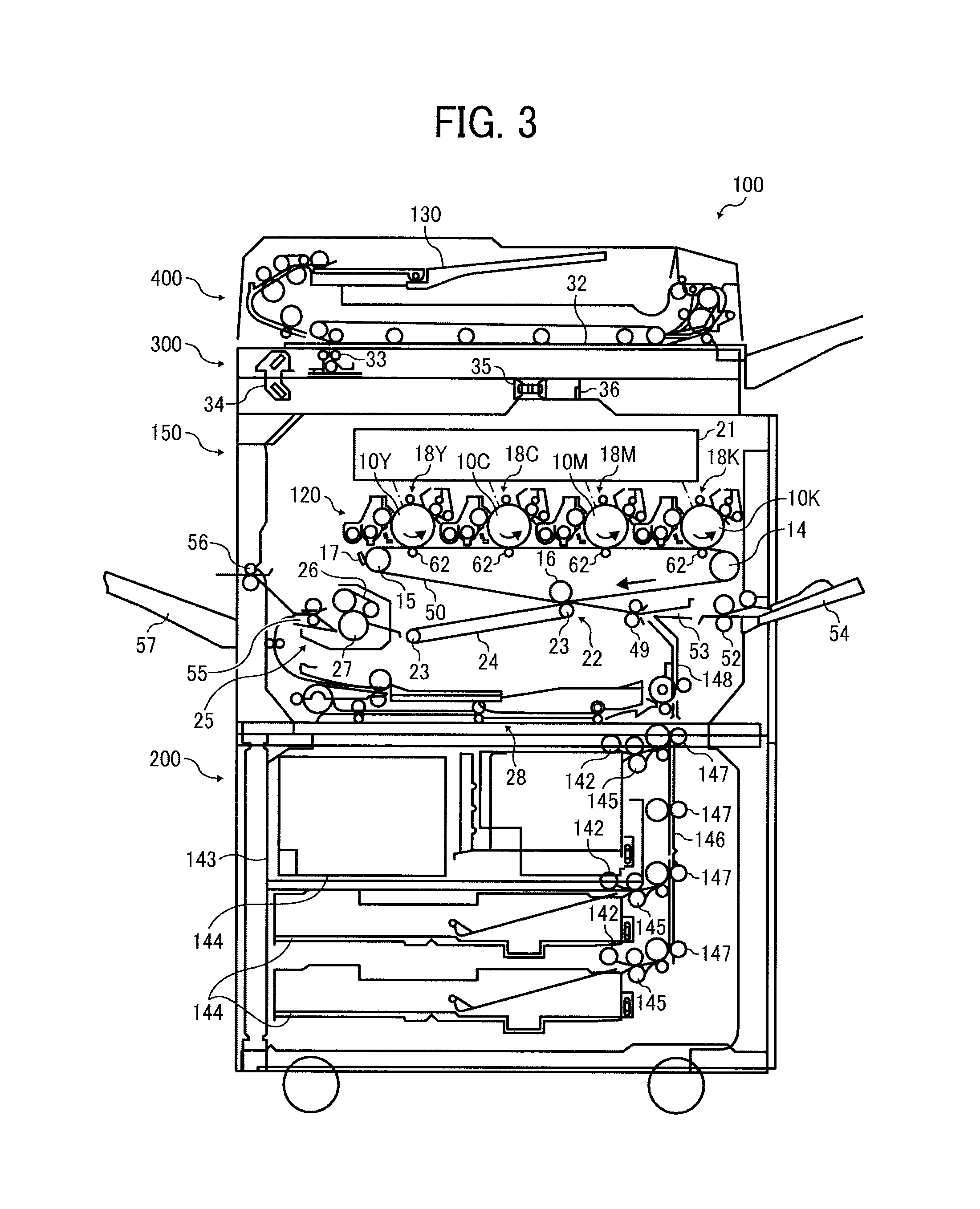

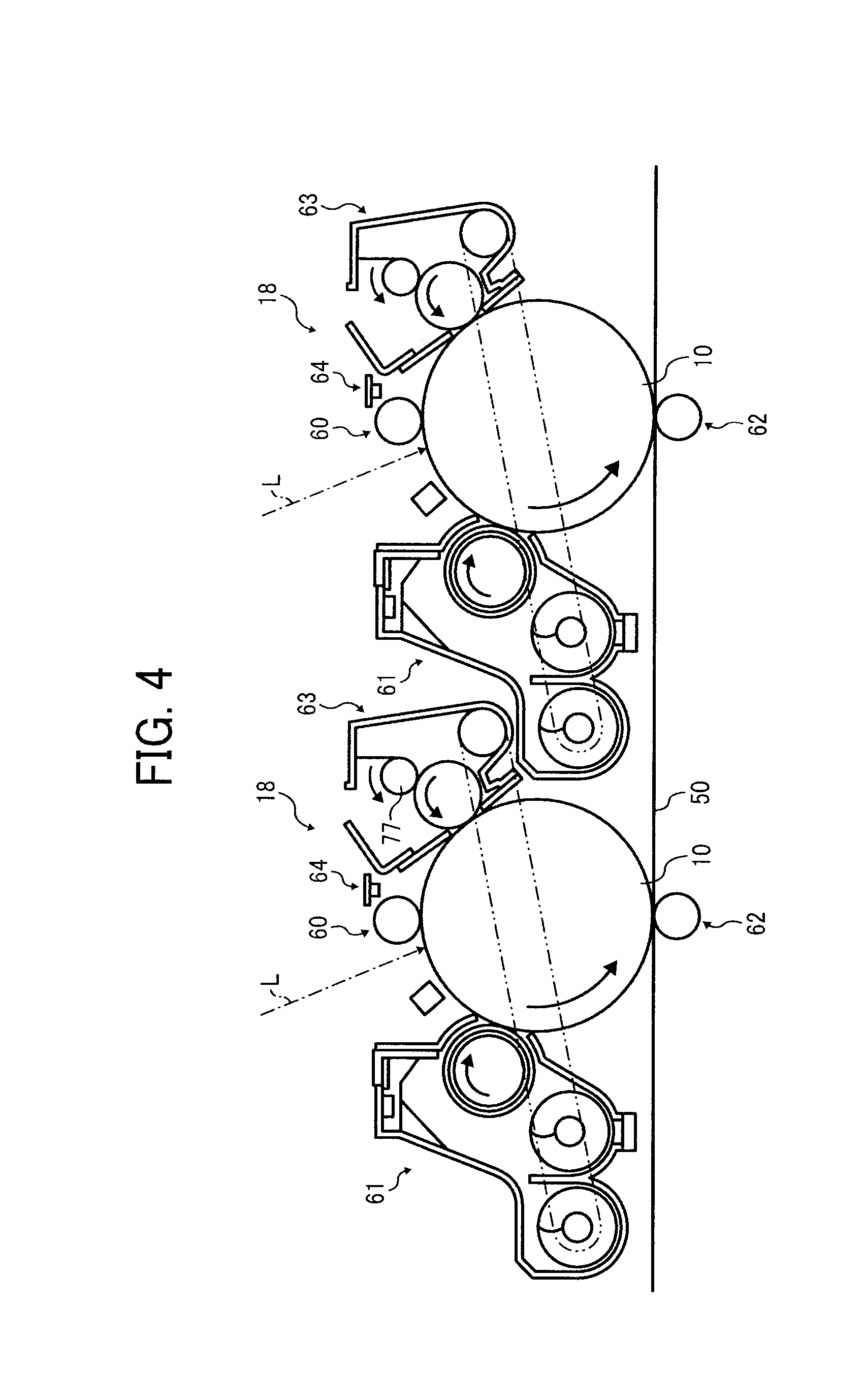

Toner for electrophotography, developer and method of preparing the toner

InactiveUS20130236826A1Improve low-temperature fixabilityAvoid it happening againDevelopersOrganic solventOil phase

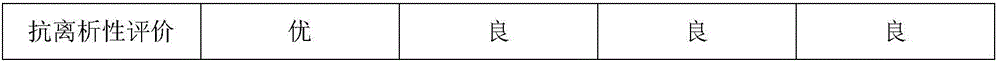

A toner for electrophotography, which is prepared by a method including dissolving or dispersing a toner composition including at least a binder resin, or binder resin and a binder resin precursor as a resin component; and a colorant in an organic solvent to form an oil phase; emulsifying or dispersing the oil phase in an aqueous medium to form an emulsion dispersion comprising emulsified particles; converging the emulsified particles to granulate mother toner particles, including controlling a temperature of the emulsion dispersion to control a circularity of the mother toner particles; and removing the organic solvent, wherein the resin component includes a crystalline resin in an amount not less than 50% by weight, and the mother toner particles have an average circularity of from 0.940 to 0.980.

Owner:RICOH KK

Acrylate emulsifying thickening agent and production process thereof

InactiveCN100999875AIncrease steric hindranceSpace and Amplitude ReductionDyeing processMethacrylamideSolvent

The present invention is one kind of emulsified acrylate thickener for paint printing. It consists of acrylic acid 160-170 weight portions, vinyl benzene sulfonic acid 90-95 weight portions, 2-acrylamido-2-methypropyl sulfonic acid 18-19 weight portions, chlorotrimethylamino propyl acrylamide 22-24 weight portions, 20 % concentration ammonia water 300-320 weight portions, glyceryl dimethcrylate 2.5-3.5 weight portions, No. 200 solvent oil or aviation kerosene 100-150 weight portions, hydrogenated polyoxyethylene castor oil ether 22-28 weight portions, and ammonium persulfate 5-7 weight portions, which are reverse emulsion polymerized and mixed with linear organosilicon body in 4-6 weight portions. It has high water combining capacity, great electrolysis capacity, good handle and high color brightness.

Owner:LIAONING FIXED STAR FINE CHEM

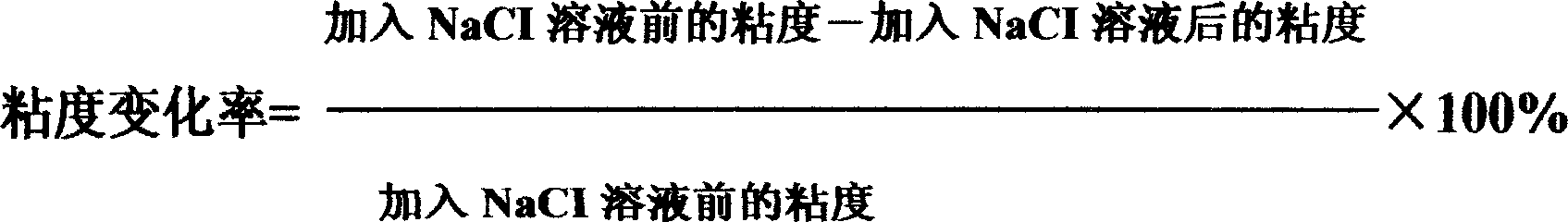

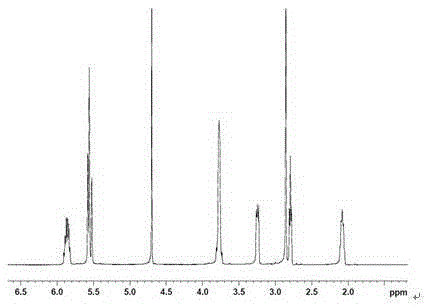

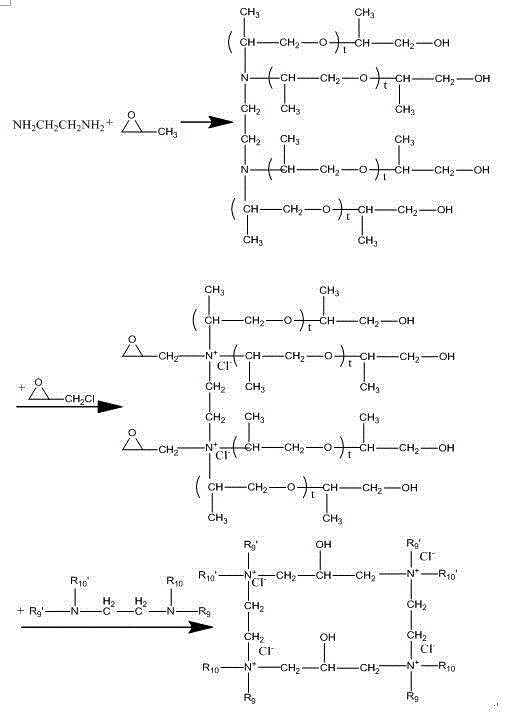

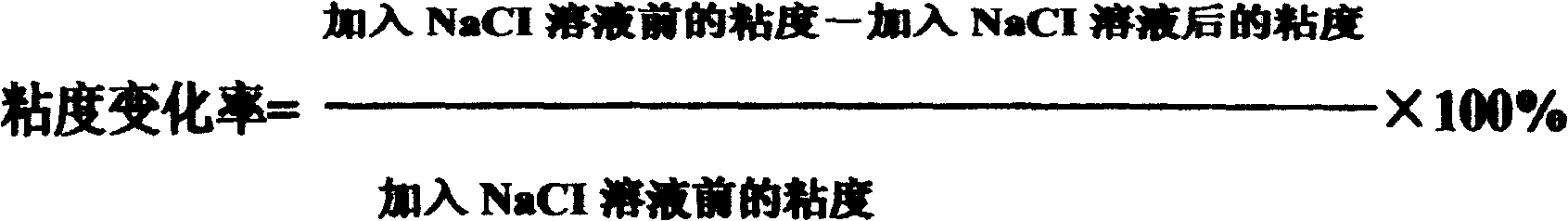

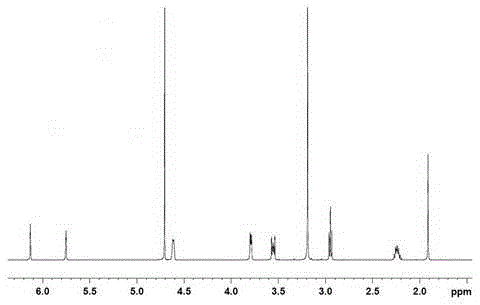

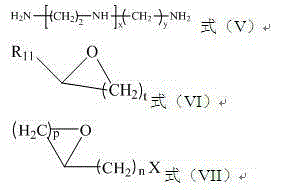

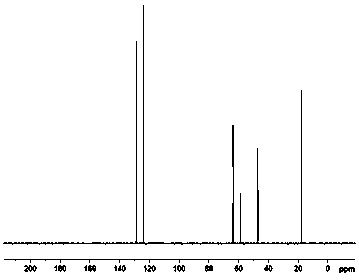

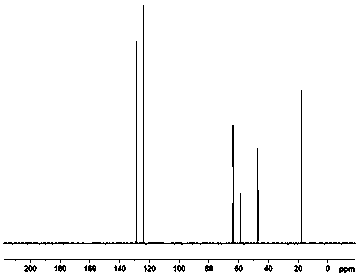

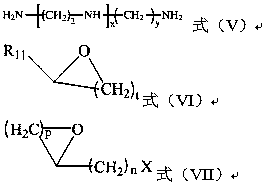

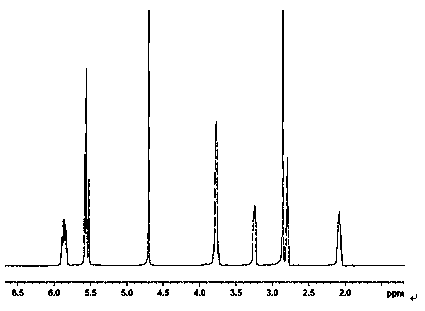

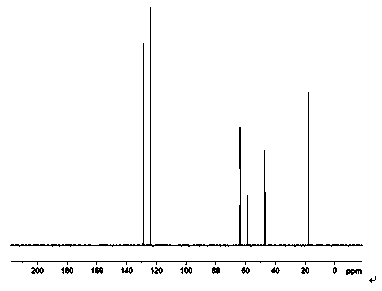

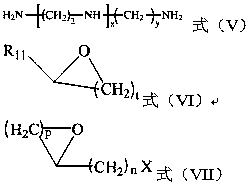

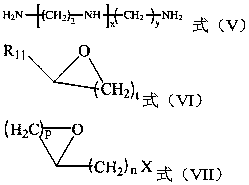

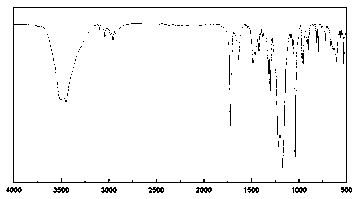

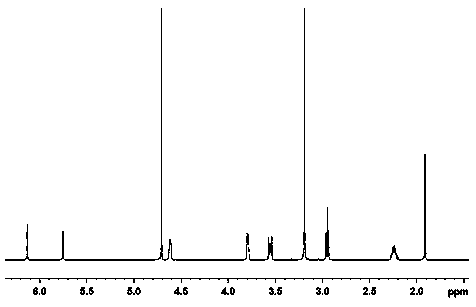

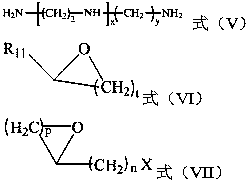

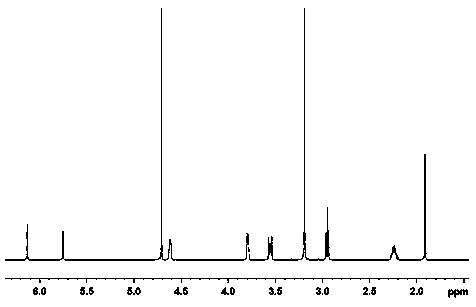

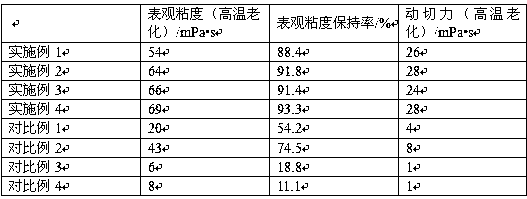

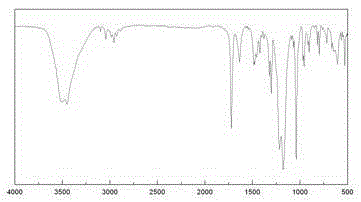

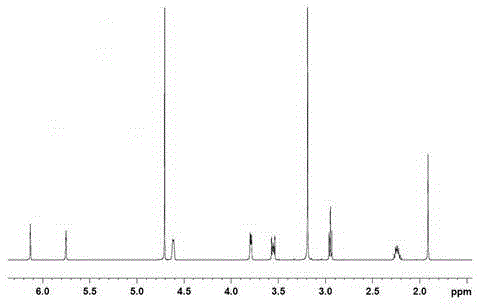

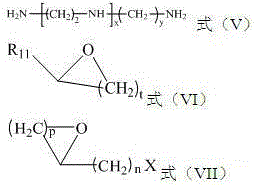

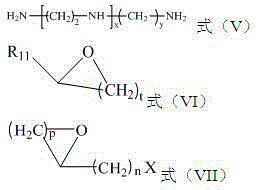

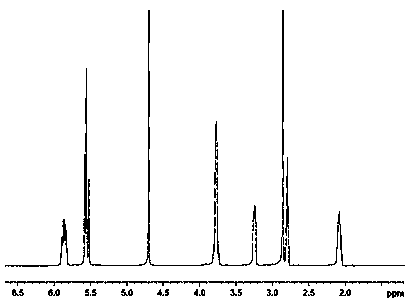

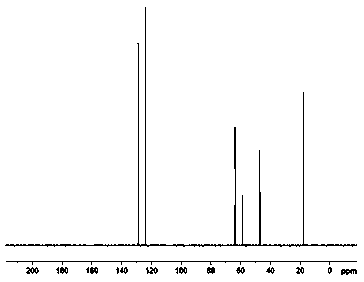

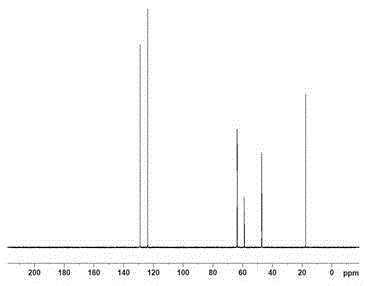

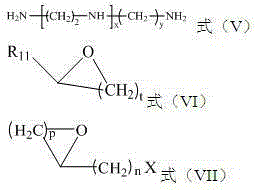

Tackifier copolymerization associate used for drilling fluid and preparation method of tackifier copolymerization associate

ActiveCN106608946AHigh temperature and salt resistanceHigh apparent viscosityDrilling compositionMethacrylamideChemistry

The invention discloses a tackifier copolymerization associate used for a drilling fluid and a preparation method of the tackifier copolymerization associate. The copolymerization associate comprises a constitutional unit A, a constitutional unit B, a constitutional unit C and a constitutional unit D. The constitutional unit A is N, N-dimethylacrylamide, the constitutional unit B is N-methyl diallyl propylsulfonate (MAPS) which is an amphoteric ionic monomer, the constitutional unit C is an ionic associate of the constitutional unit B and cationic polyamine, and the constitutional unit D is starch. Based on the total amount of the copolymerization associate, the copolymerization associate comprises 6-45% by weight of N, N-dimethylacrylamide, 5-35% by weight of the N-methyl diallyl propylsulfonate which is an amphoteric ionic monomer, 2-30% by weight of the cationic polyamine, and 5-35% by weight of starch. A tackifier obtained through the preparation method can resist temperature as high as 180 DEG C, can resist a saturated NaCl solution, and resist a CaCl2 solution with the concentration being 20%. The tackifier is excellent shale inhibition and filtrate reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of salt-resistant carboxymethyl starch

The invention relates to a preparation method of salt-resistant carboxymethyl starch. A mixed solvent of ethanol and isopropyl alcohol serves as a reaction medium, and multi-step modification of cassava starch is performed in slurry taking the mixed solvent as a medium. The method comprises the following specific steps: swelling the starch to prepare starch milk; adding a surfactant and performing modification such as alkalization and etherification by an 'acid pretreatment process'; and adding a crosslinking agent for a micro-crosslinking reaction. In the method provided by the invention, the surfactant is added as a penetrant, the reagent molecules are promoted to penetrate and spread into the starch particles, and the alkalization efficiency and etherification efficiency are improved; the generation of side reactions can be reduced by adding an etherifying agent before an alkalizer, thus the alkalization and etherification are carried out at the same time, and more thorough etherification reaction is guaranteed; finally, the starch is subjected to micro-crosslinking so as to improve the structure viscosity and enhance the salt resistance; the product viscosity 4% exceeds 40,000, the substitution degree is over 1.0, the salt-viscosity ratio goes beyond 0.5, and the product can be applied to multiple technical fields instead of CMC.

Owner:HANGZHOU HONGBO NEW MATERIALS

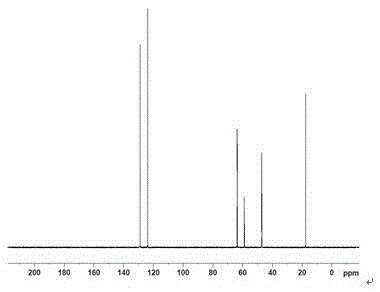

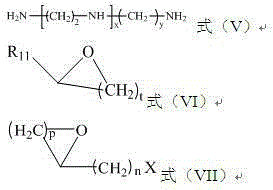

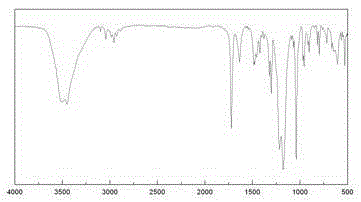

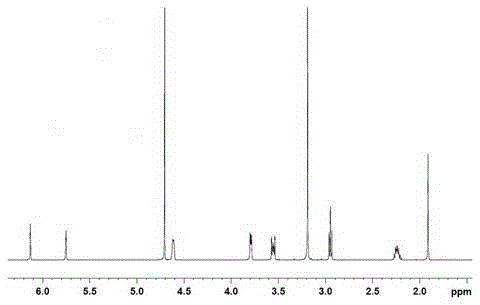

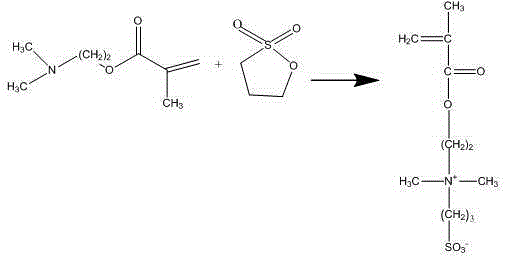

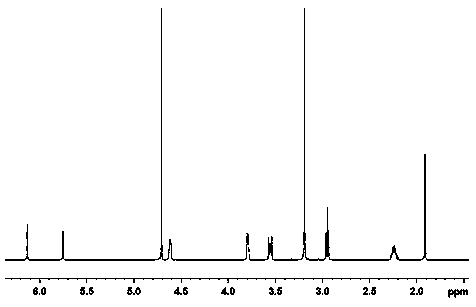

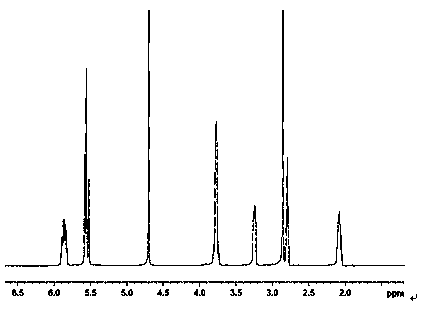

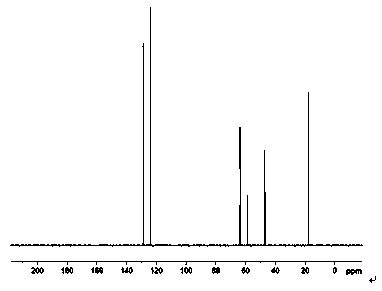

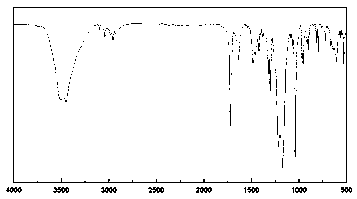

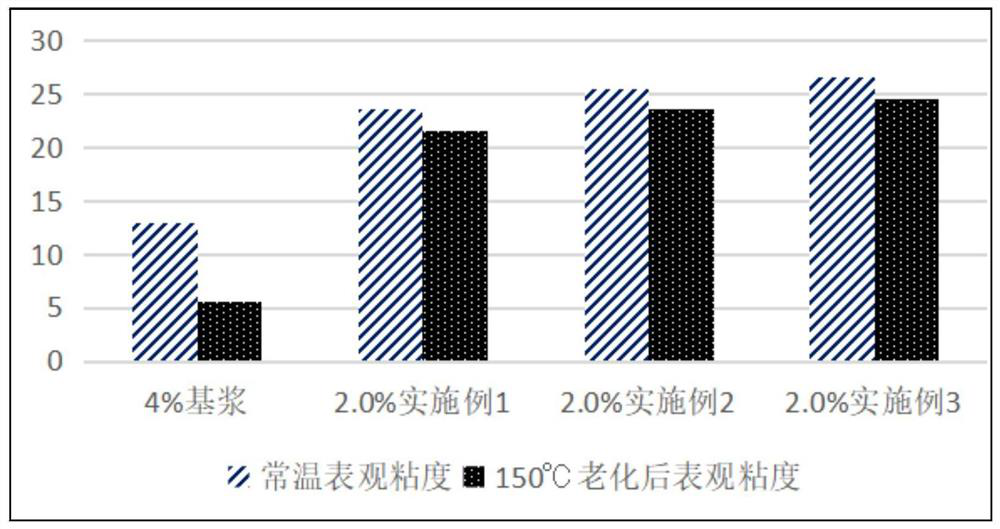

Grafted starch thickening agent copolymerization association compound and preparation method thereof

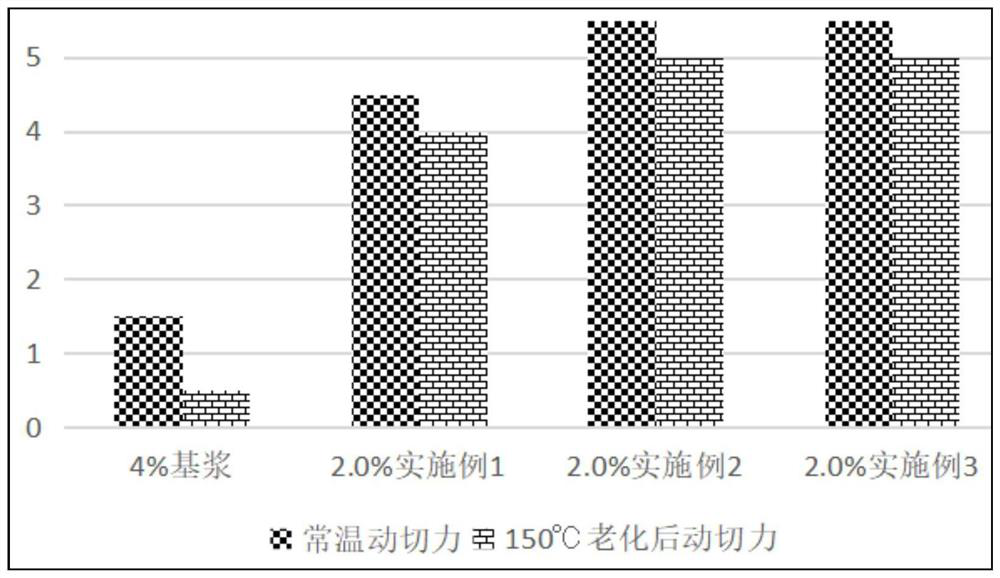

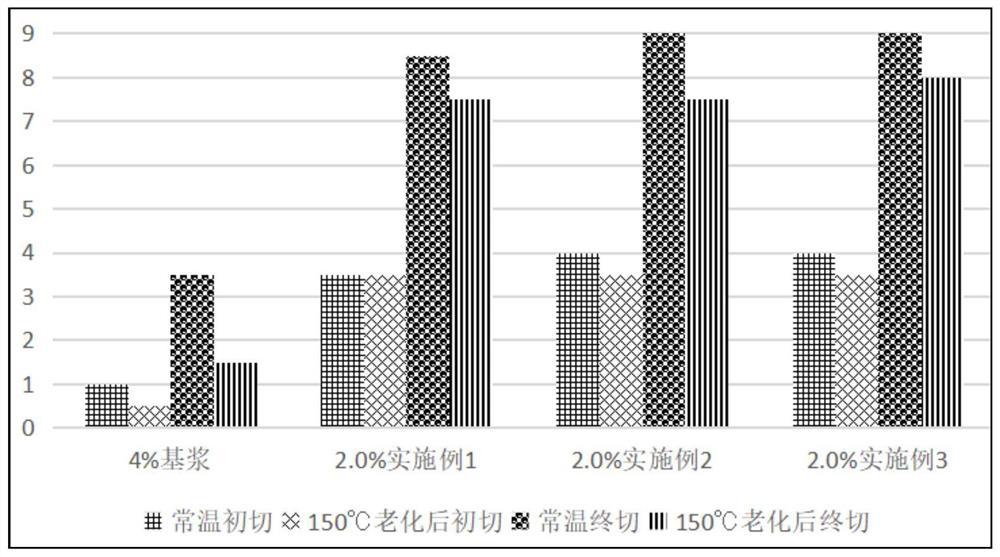

ActiveCN106608975AIncrease shear forceImprove heat and salt resistanceDrilling compositionStructural unitPolyamine

The invention discloses a grafted starch thickening agent copolymerization association compound and a preparation method thereof. The copolymerization association compound contains a structural unit A, a structural unit B, a structural unit C and a structural unit D, the structural unit A is acrylamide, the structural unit B is an amphoteric monomer methacryloyloxyethyl-N,N-dimethylpropanesulfonate (DMAPS), the structural unit C is an ion association body of the structural unit B and cationic polyamine, and the structural unit D is starch; and based on the total amount of the copolymerization association compound, the content of the acrylamide is 6-45wt%, the total content of the amphoteric monomer methacryloyloxyethyl-N,N-dimethylpropanesulfonate is 5-35wt%, the content of the cationic polyamine is 2-30wt%, and the content of the starch is 5-35wt%. Temperature resistance of the thickening agent prepared by the method can reach 150 DEG C, anti-NaCl concentration is saturated, and anti-CaCl2 concentration reaches 20%; and meanwhile, excellent shale inhibition performance and filtrate loss controllability are furthermore achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylate emulsifying thickening agent and production process thereof

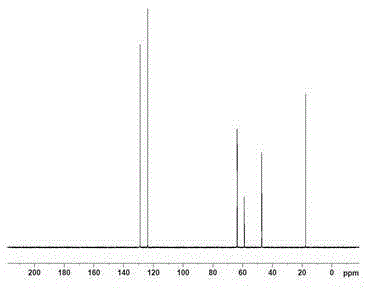

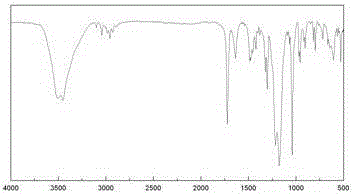

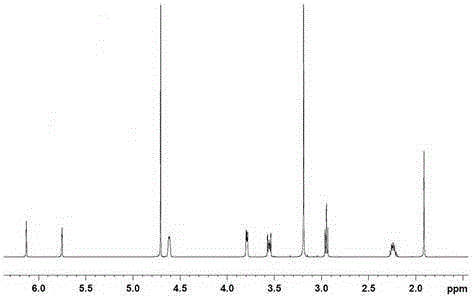

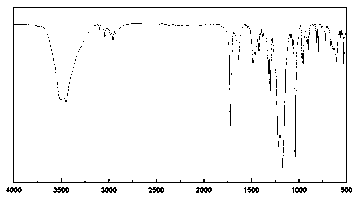

InactiveCN100418990CIncrease structural viscosityIncrease steric hindranceDyeing processPolyoxyethylene castor oilSolvent

The present invention is one kind of emulsified acrylate thickener for paint printing. It consists of acrylic acid 160-170 weight portions, vinyl benzene sulfonic acid 90-95 weight portions, 2-acrylamido-2-methypropyl sulfonic acid 18-19 weight portions, chlorotrimethylamino propyl acrylamide 22-24 weight portions, 20 % concentration ammonia water 300-320 weight portions, glyceryl dimethcrylate 2.5-3.5 weight portions, No. 200 solvent oil or aviation kerosene 100-150 weight portions, hydrogenated polyoxyethylene castor oil ether 22-28 weight portions, and ammonium persulfate 5-7 weight portions, which are reverse emulsion polymerized and mixed with linear organosilicon body in 4-6 weight portions. It has high water combining capacity, great electrolysis capacity, good handle and high color brightness.

Owner:LIAONING FIXED STAR FINE CHEM

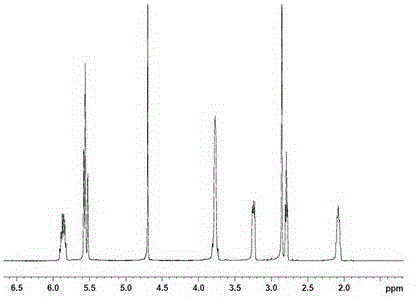

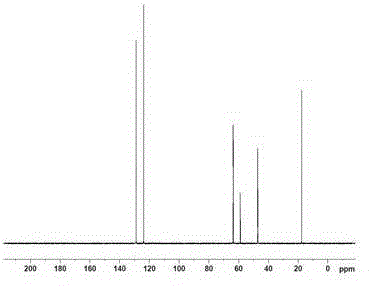

Aqueous resin dispersion and method for producing the same

InactiveCN1492886AExcellent alkali thickening performanceIncrease structural viscosityAcid groupEmulsion

The present invention provides an aqueous resin dispersion having a relatively low acid value and high viscosity and structural viscosity after alkali neutralization, and a method for producing the same. A core / shell-type aqueous resin dispersion comprising a core / shell-type resin including: a core part comprising a resin (C) having an acid value of not more than 20 and a hydroxyl group value of not more than 100 and being emulsion-polymerized from a polymerizable unsaturated monomer (c) containing neither acid group nor hydroxyl group, and optionally a hydroxyl group-containing polymerizable unsaturated monomer (b), and optionally an acid group-containing polymerizable unsaturated monomer (a), and a shell part comprising a resin (S) having an acid value of 30 to 150 and a hydroxyl group value of 10 to 100 and being emulsion-polymerized from the acid group-containing polymerizable unsaturated monomer (a), the hydroxyl group-containing polymerizable unsaturated monomer (b), and the polymerizable unsaturated monomer (c) containing neither acid group nor hydroxyl group.

Owner:DAICEL CHEM IND LTD

Starch-containing thickening agent copolymerization association compound and preparation method thereof

ActiveCN106608976AIncrease shear forceImprove heat and salt resistanceDrilling compositionTemperature resistanceStructural unit

The invention discloses a starch-containing thickening agent copolymerization association compound and a preparation method thereof. The copolymerization association compound contains a structural unit A, a structural unit B, a structural unit C and a structural unit D, the structural unit A is N,N-dimethylacrylamide, the structural unit B is an amphoteric monomer methacryloyloxyethyl-N,N-dimethylpropanesulfonate (DMAPS), the structural unit C is an ion association body of the structural unit B and cationic polyamine, and the structural unit D is starch; and based on the total amount of the copolymerization association compound, the content of the N,N-dimethylacrylamide is 6-45% by weight, the total content of the amphoteric monomer methacryloyloxyethyl-N,N-dimethylpropanesulfonate is 5-35% by weight, the content of the cationic polyamine is 2-30% by weight, and the content of the starch is 5-35% by weight. Temperature resistance of the thickening agent prepared by the method can reach 150 DEG C, anti-NaCl concentration is saturated, and anti-CaCl2 concentration reaches 20%; and meanwhile, excellent shale inhibition performance and filtrate loss controllability are furthermore achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

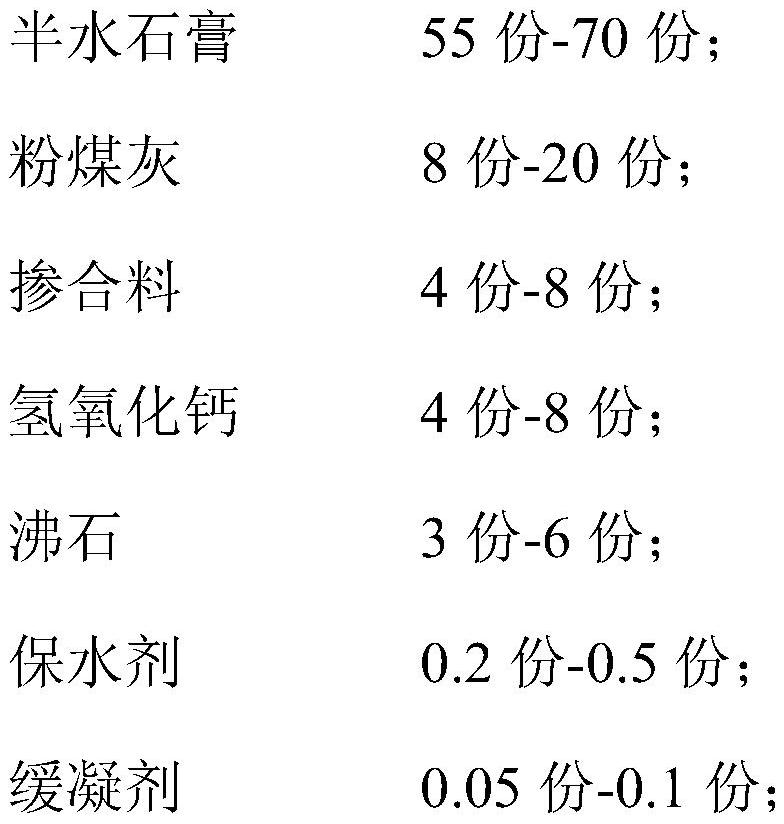

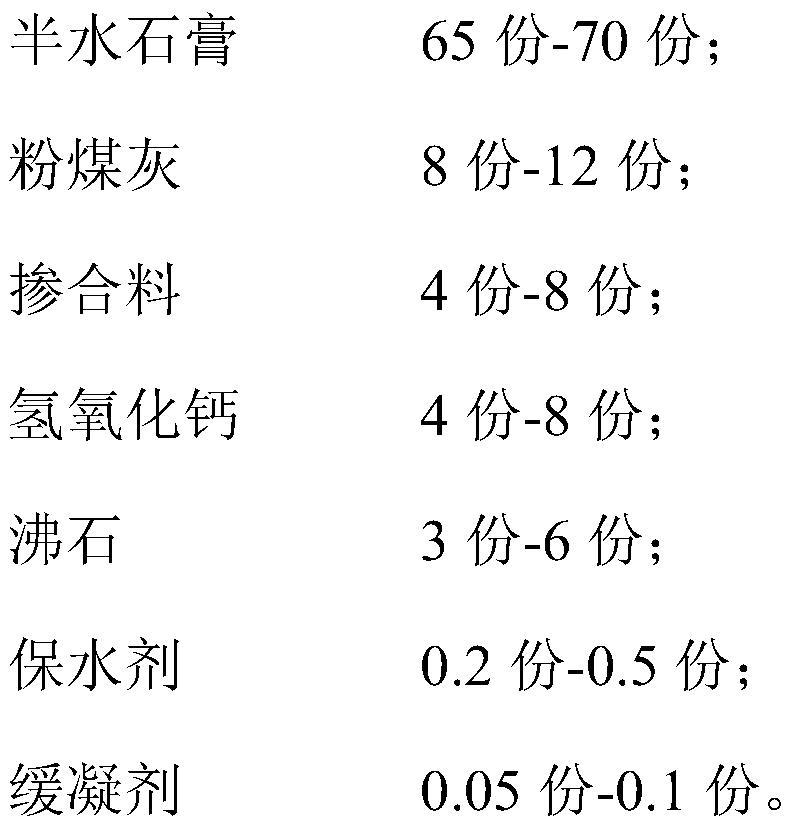

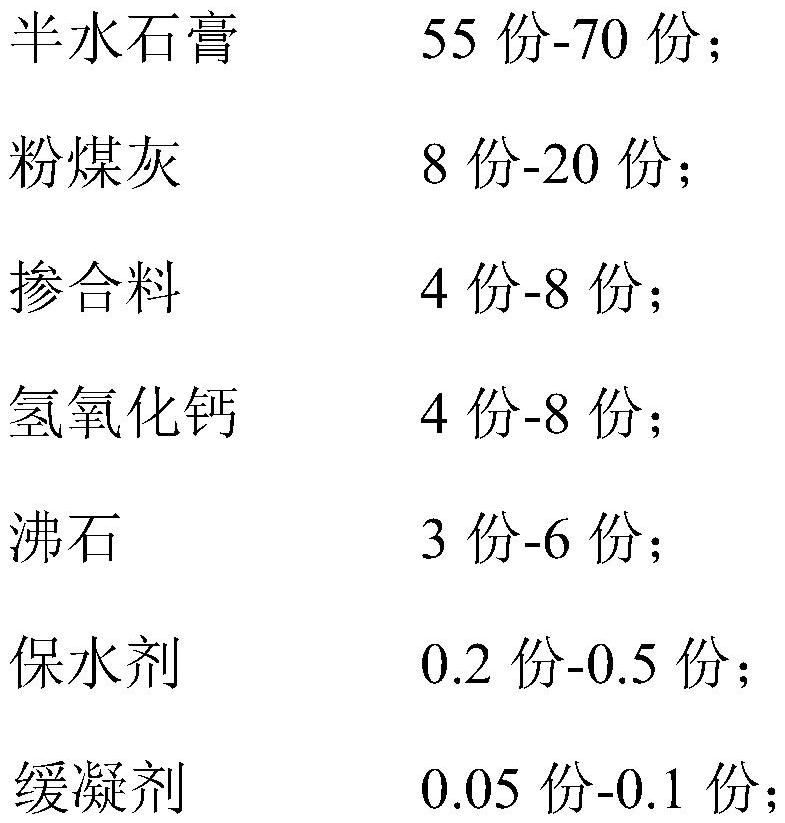

Gypsum-based wall leveling material as well as preparation method and use method thereof

The invention relates to a gypsum-based wall leveling material as well as a preparation method and a use method thereof. The wall leveling material is prepared from the following raw materials in parts by mass: 55-70 parts of semi-hydrated gypsum; 8-20 parts of fly ash; 4-8 parts of an admixture; 4-8 parts of calcium hydroxide; 3-6 parts of zeolite; 0.2-0.5 part of a water retaining agent; and 0.05-0.1 part of a retarder; wherein the admixture is selected from one or two of silica fume or metakaolin. The gypsum-based wall leveling material provided by the invention does not need cement, redispersible rubber powder and a water repellent, can also have good water resistance, can maintain good mechanical properties in a high-humidity environment, can also solve the problems of hollowing and cracking of a wall surface, and is low in cost and easier to apply and popularize.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Tackifier copolymerization associate used for drilling fluid and preparation method of tackifier copolymerization associate

ActiveCN106608974AIncrease shear forceImprove heat and salt resistanceDrilling compositionTackifierPolyamine

The invention discloses a tackifier copolymerization associate used for a drilling fluid and a preparation method of the tackifier copolymerization associate. The copolymerization associate comprises a constitutional unit A, a constitutional unit B, a constitutional unit C and a constitutional unit D. The constitutional unit A is acrylamide, the constitutional unit B is N-methyl diallyl propylsulfonate (MAPS) which is an amphoteric ionic monomer, the constitutional unit C is an ionic associate of the constitutional unit B and cationic polyamine, and the constitutional unit D is starch. Based on the total amount of the copolymerization associate, the copolymerization associate comprises 6-45% by weight of acrylamide, 5-35% by weight of the N-methyl diallyl propylsulfonate which is an amphoteric ionic monomer, 2-30% by weight of the cationic polyamine, and 5-35% by weight of starch. A tackifier obtained through the preparation method can resist temperature as high as 180 DEG C, can resist a saturated NaCl solution, and resist a CaCl2 solution with the concentration being 20%. The tackifier is excellent shale inhibition and filtrate reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

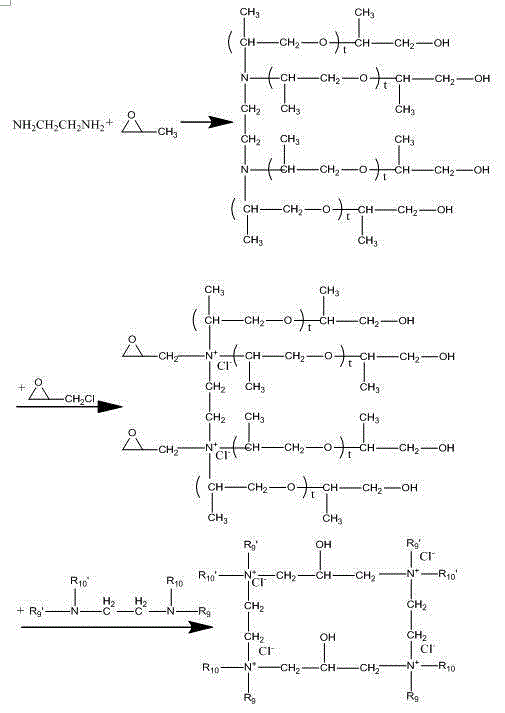

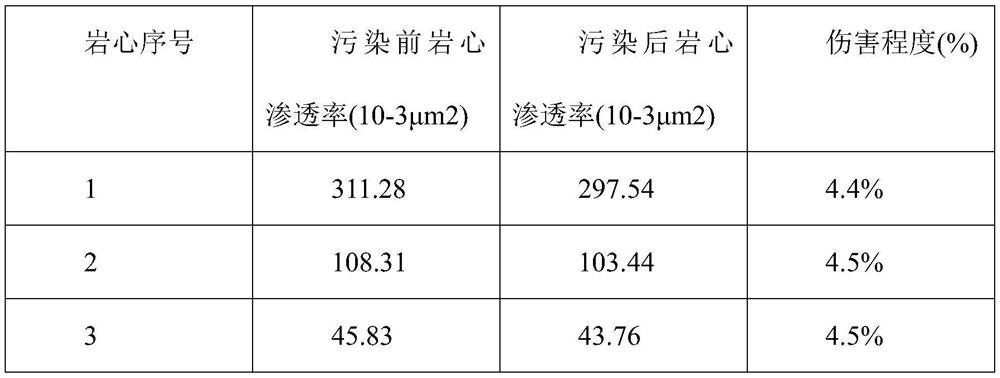

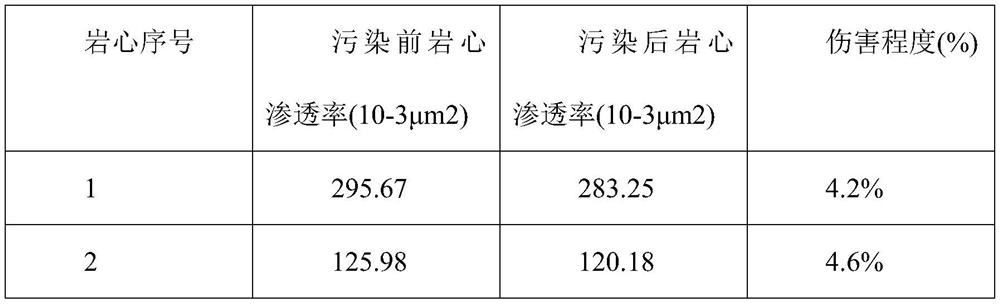

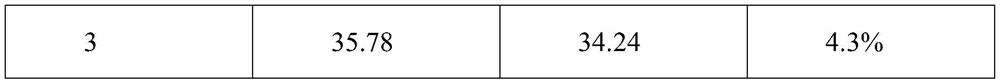

Solid-phase-free clean low-damage well killing fluid and preparation method thereof

The invention discloses a solid-phase-free clean low-damage well killing fluid and a preparation method thereof. The solid-phase-free clean low-damage well killing fluid comprises 1.5%-2.5% of a tackifier, 0.8%-1.2% of a filtrate reducer, 0.05%-0.2% of an inorganic salt crystallization inhibitor, 8%-30% of a weighting agent, 0.5%-2% of a clay stabilizer and the balance of water. The well killing fluid is used for well drilling, well repairing and other well killing operation in downhole operation, and is good in compatibility with strata, low in damage, free of pollution, adjustable in densityand good in mobility.

Owner:蒲城驭腾新材料科技有限公司

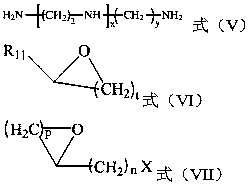

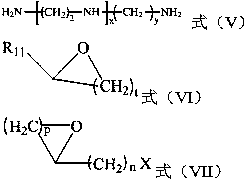

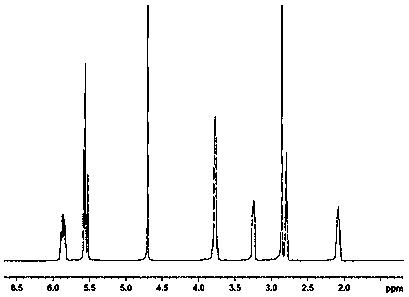

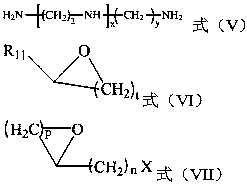

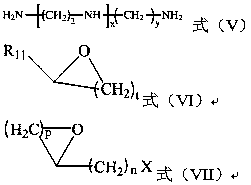

Anti-calcium tackifier copolymerization complex and preparation method thereof

ActiveCN106608971AIncrease shear forceImprove heat and salt resistanceDrilling compositionFiltrationStructural unit

The invention discloses an anti-calcium tackifier copolymerization complex and a preparation method thereof. The anti-calcium tackifier copolymerization complex comprises a structural unit A, a structural unit B and a structural unit C. The structural unit A is acrylamide, the structural unit B is a zwitterionic monomer methacryloyloxyethyl-N, N-dimethylpropanesulfonate (DMAPS), and the structural unit C is an ionic complex of the structural unit B and cationic polyamine. The copolymerization complex comprises, by weight, 10 to 75% of the structural unit A, 8 to 55% of the zwitterionic monomer and 1 to 50% of the cationic polyamine, and preferably, comprises 30 to 65% of the structural unit A, 20 to 60% of the zwitterionic monomer and 3 to 40% of the cationic polyamine. The tackifier obtained by the preparation method can resist a temperature of 150 DEG C, has a saturated anti-NaCl concentration and an anti-CaCl2 concentration of 20% and has excellent shale inhibition performances and de-filtration performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

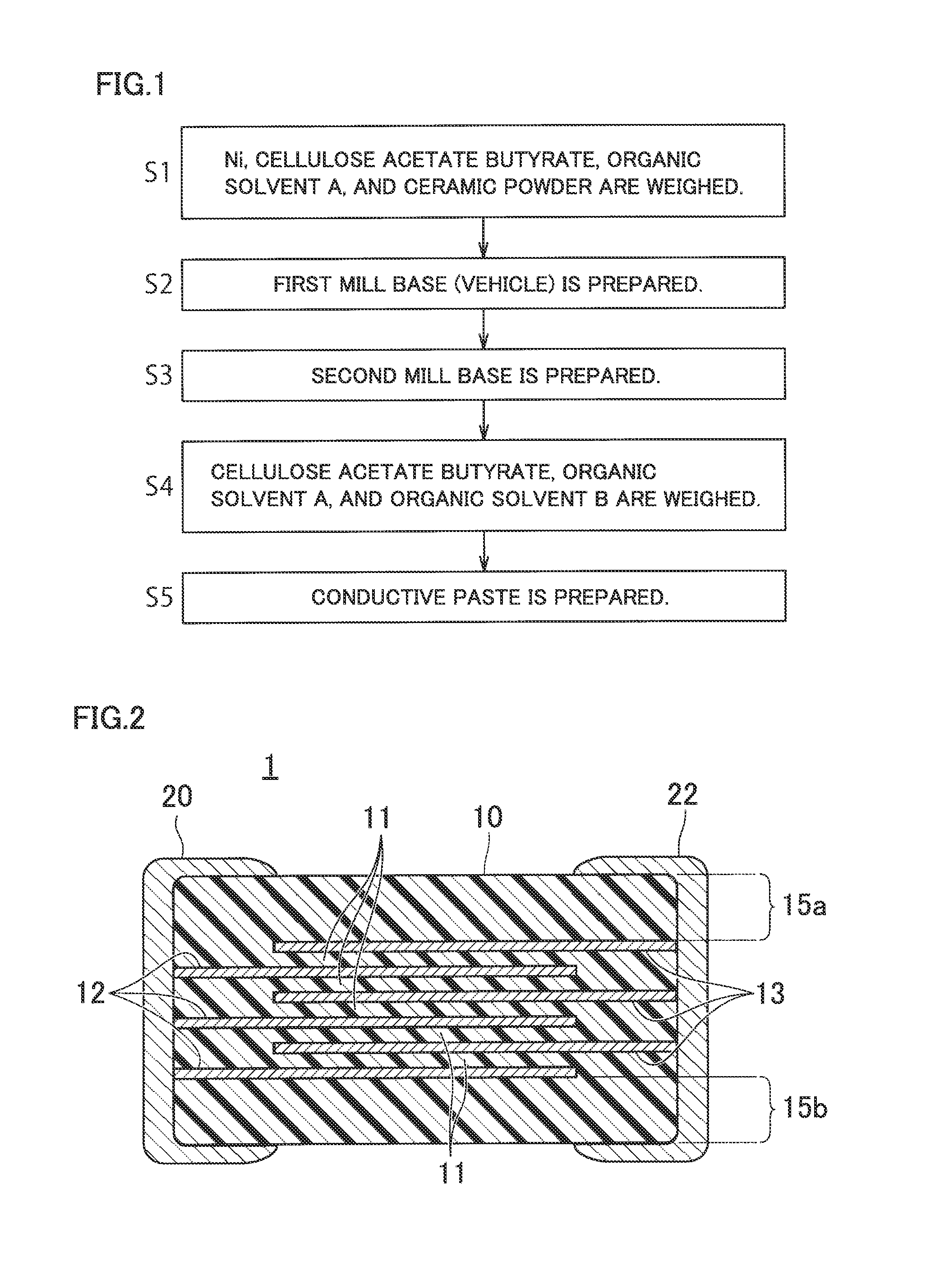

Conductive paste and ceramic electronic component

ActiveUS20160194504A1Excellent print characteristicMaintain it fluidityFixed capacitor dielectricStacked capacitorsSolventOrganic solvent

A conductive paste obtained by adding an organic solvent B to a vehicle containing a Ni powder, a binder resin component, and an organic solvent A. The Ni powder has an average primary particle size of 30 to 400 nm. The binder resin component is cellulose acetate butyrate. Organic solvent A is a solvent having a Δδ value of 11.5 or less with the cellulose acetate butyrate. Organic solvent B is a solvent having a Δδ value from 11.5 to 25.0 with the cellulose acetate butyrate. A ratio of the organic solvent B relative to a total of the organic solvent A and the organic solvent B is 5.0 to 40.0 wt %.

Owner:MURATA MFG CO LTD

A kind of anti-calcium thickening agent copolymerized association and preparation method thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of tackifier copolymerized association

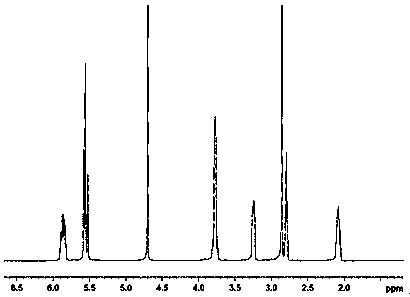

ActiveCN106608972BHigh apparent viscosityEasy to cutDrilling compositionTemperature resistanceStructural unit

The invention discloses a preparation method of a thickening agent copolymerization association compound. The copolymerization association compound contains a structural unit A, a structural unit B and a structural unit C, the structural unit A is acrylamide, the structural unit B is amphoteric monomer N-methyldiallyl propanesulfonate (MAPS), and the structural unit C is an ion association body of the structural unit B and cationic polyamine; and based on the total amount of the copolymerization association compound, the content of the structural unit A is 10-75wt%, the total content of the amphoteric monomer is 8-55wt%, and the content of the cationic polyamine is 1-50wt%. Temperature resistance of the thickening agent prepared by the method can reach 200 DEG C, anti-NaCl concentration is saturated, and the anti-CaCl2 concentration reaches 20%; and meanwhile, excellent shale inhibition performance and filtrate loss controllability are furthermore achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of viscosifier copolymer association for drilling fluid and preparation method thereof

The invention discloses a tackifier copolymerization associate used for a drilling fluid and a preparation method of the tackifier copolymerization associate. The copolymerization associate comprises a constitutional unit A, a constitutional unit B, a constitutional unit C and a constitutional unit D. The constitutional unit A is acrylamide, the constitutional unit B is N-methyl diallyl propylsulfonate (MAPS) which is an amphoteric ionic monomer, the constitutional unit C is an ionic associate of the constitutional unit B and cationic polyamine, and the constitutional unit D is starch. Based on the total amount of the copolymerization associate, the copolymerization associate comprises 6-45% by weight of acrylamide, 5-35% by weight of the N-methyl diallyl propylsulfonate which is an amphoteric ionic monomer, 2-30% by weight of the cationic polyamine, and 5-35% by weight of starch. A tackifier obtained through the preparation method can resist temperature as high as 180 DEG C, can resist a saturated NaCl solution, and resist a CaCl2 solution with the concentration being 20%. The tackifier is excellent shale inhibition and filtrate reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Copolymer for drilling fluid tackifier and preparation method thereof

The invention discloses a tackifier copolymerization associate used for a drilling fluid and a preparation method of the tackifier copolymerization associate. The copolymerization associate comprises a constitutional unit A, a constitutional unit B, a constitutional unit C and a constitutional unit D. The constitutional unit A is N, N-dimethylacrylamide, the constitutional unit B is N-methyl diallyl propylsulfonate (MAPS) which is an amphoteric ionic monomer, the constitutional unit C is an ionic associate of the constitutional unit B and cationic polyamine, and the constitutional unit D is starch. Based on the total amount of the copolymerization associate, the copolymerization associate comprises 6-45% by weight of N, N-dimethylacrylamide, 5-35% by weight of the N-methyl diallyl propylsulfonate which is an amphoteric ionic monomer, 2-30% by weight of the cationic polyamine, and 5-35% by weight of starch. A tackifier obtained through the preparation method can resist temperature as high as 180 DEG C, can resist a saturated NaCl solution, and resist a CaCl2 solution with the concentration being 20%. The tackifier is excellent shale inhibition and filtrate reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of flocculant and its preparation method and application

ActiveCN113121002BGood flocculation effectIncreased association pointsSustainable biological treatmentWater/sewage treatment by flocculation/precipitationFlocculationCross linker

The invention discloses a flocculant, a preparation method and application thereof. The flocculant comprises a starch structural unit, a zwitterionic monomer structural unit, a polyether structural unit and a cross-linking agent structural unit. In the preparation method, the amphoteric ion graft copolymerization modified starch, polyether and water are mixed, and the cross-linking agent is added dropwise to carry out cross-linking reaction after mixing evenly; . The modified starch flocculant prepared by the invention has the advantages of fast flocculation effect, low biological toxicity, low cost and the like, and the removal rate of COD, turbidity and suspended solids can reach more than 90% at a low usage amount.

Owner:CHINA PETROLEUM & CHEM CORP +1

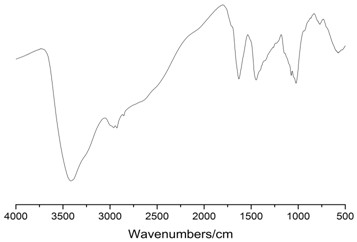

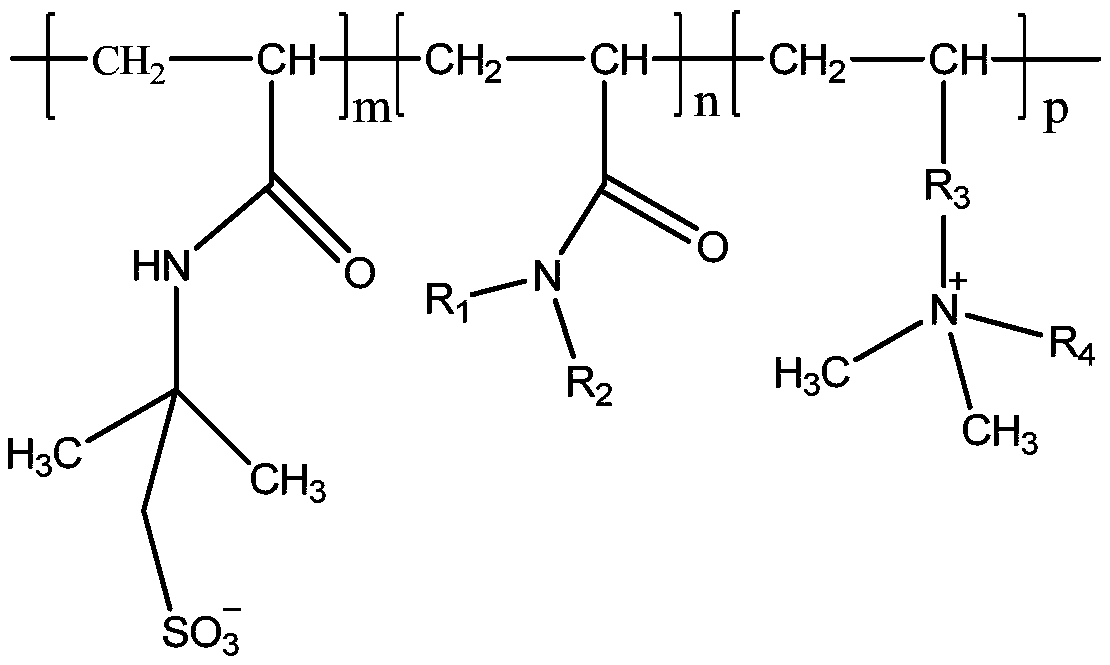

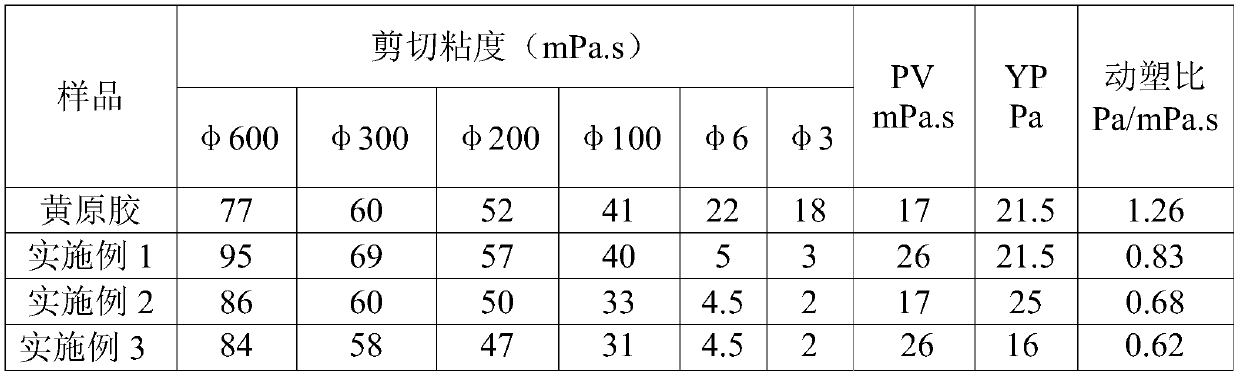

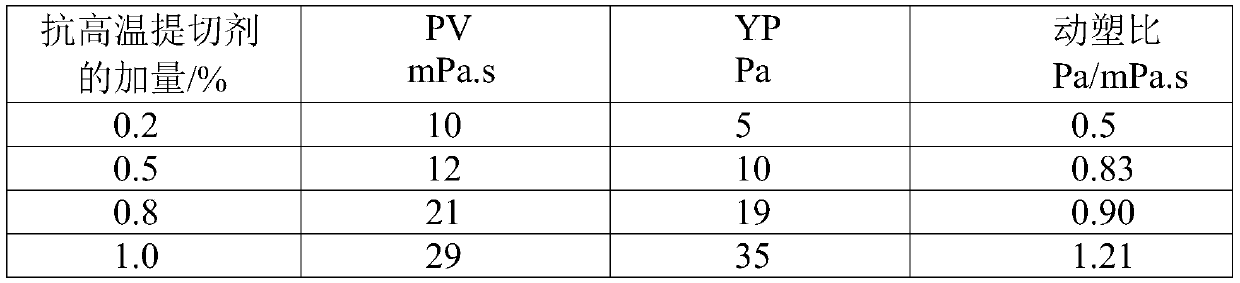

Anti-high temperature shearing agent for solid-free drilling fluid and preparation method thereof

ActiveCN107163184BShear thinningEffective resistance to high temperature and saltDrilling compositionSaline waterBiopolymer

The invention discloses a high temperature resistant rheological modifier for a solid-free drilling fluid and a preparation method of the high temperature resistant rheological modifier. According to the rheological modifier, three monomers with different functional groups are polymerized under the condition of a redox system through the reasonable molecular design, molecular chains of a correspondingly generated polymer is fully extended and mutually act in the space to form a space net structure, other assistants mutually matched with the polymer are also used, so that the prepared rheological modifier has the shearing dilutability similar to that of a biopolymer and effectively resists high temperature and salinity, the highest tolerable temperature is up to 170 DEG C, and the rheological modifier is an efficient rheological modifier suitable for fresh water and saline water solid-free drilling fluid system; in addition, the preparation method of the rheological modifier is simple and feasible, the cost is also lower than that of the foreign like product, and the rheological modifier is quite favorable for market popularization and application.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

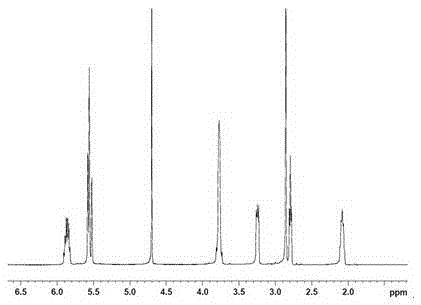

A kind of tackifier copolymerized association and preparation method thereof

The invention discloses a copolymerization and association complex used as a tackifier and a preparation method thereof. The copolymerization and association complex contains a constitutional unit A, a constitutional unit B and a constitutional unit C, wherein the constitutional unit A is acrylamide; the constitutional unit B is an amphion monomer N-methyldiallyl propanesulfonate (MAPS); and the constitutional unit C is an ion association complex of the constitutional unit B and cationic polyamine. On the basis of the total amount of the copolymerization and association complex, the content of acrylamide is 10 to 75 wt%, preferably 30 to 65 wt%; the total content of the amphion monomers is 8 to 55 wt%, preferably 20 to 60 wt%; and the content of cationic polyamine is 1 to 50 wt%, preferably 3 to 40wt%. The tackifier prepared by using the preparation method in the invention can resist a temperature as high as 200 DEG C, NaCl with a saturation concentration and CaCl2 with a concentration of 20%, and has superior shale inhibition performance and fluid loss reduction performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of temperature-resistant tackifier copolymerized association and preparation method thereof

ActiveCN106608944BHigh apparent viscosityEasy to cutDrilling compositionTemperature resistanceControllability

The invention discloses a temperature-resistant thickening agent copolymerization association compound and a preparation method thereof. The copolymerization association compound contains a structural unit A, a structural unit B and a structural unit C, the structural unit A is N,N-dimethylacrylamide, the structural unit B is an amphoteric monomer methacryloyloxyethyl-N,N-dimethylpropanesulfonate (DMAPS), and the structural unit C is an ion association body of the structural unit B and cationic polyamine; and based on the total amount of the copolymerization association compound, the content of the N,N-dimethylacrylamide is 10-75% by weight, preferably 30-65% by weight, the total content of the amphoteric monomer is 8-55% by weight, preferably 20-60% by weight, and the content of the cationic polyamine is 1-50% by weight, preferably 3-40% by weight. Temperature resistance of the thickening agent prepared by the method can reach 150 DEG C, anti-NaCl concentration is saturated, and anti-CaCl2 concentration reaches 20%; and meanwhile, excellent shale inhibition performance and filtrate loss controllability are furthermore achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of grafted starch tackifier copolymerized association and preparation method thereof

ActiveCN106608975BHigh apparent viscosityEasy to cutDrilling compositionTemperature resistanceTackifier

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of starch-containing tackifier copolymerized association and preparation method thereof

ActiveCN106608976BHigh apparent viscosityEasy to cutDrilling compositionTemperature resistanceTackifier

The invention discloses a starch-containing thickening agent copolymerization association compound and a preparation method thereof. The copolymerization association compound contains a structural unit A, a structural unit B, a structural unit C and a structural unit D, the structural unit A is N,N-dimethylacrylamide, the structural unit B is an amphoteric monomer methacryloyloxyethyl-N,N-dimethylpropanesulfonate (DMAPS), the structural unit C is an ion association body of the structural unit B and cationic polyamine, and the structural unit D is starch; and based on the total amount of the copolymerization association compound, the content of the N,N-dimethylacrylamide is 6-45% by weight, the total content of the amphoteric monomer methacryloyloxyethyl-N,N-dimethylpropanesulfonate is 5-35% by weight, the content of the cationic polyamine is 2-30% by weight, and the content of the starch is 5-35% by weight. Temperature resistance of the thickening agent prepared by the method can reach 150 DEG C, anti-NaCl concentration is saturated, and anti-CaCl2 concentration reaches 20%; and meanwhile, excellent shale inhibition performance and filtrate loss controllability are furthermore achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nanofiber-xanthan gum composite viscosity-increasing and cutting agent for drilling fluid and preparation method

ActiveCN110157393BImprove temperature resistanceEnhance the lift effectDrilling compositionFiberInorganic salts

The nanofiber-xanthan gum compound viscosity and shearing agent for drilling fluid is composed of 55-60% cationic nano-cellulose, 13-15% dispersant, 6.5-11% inorganic salt, and 18-20% xanthan gum; In the present invention, the sugarcane residue is firstly dried, pulverized, purified, strongly acidified, and dialyzed to prepare cationic nanofibers; on this basis, it is combined with xanthan gum and inorganic salts to form a composite viscosity-extracting fiber and spherical natural polymer. The shearing agent has a certain synergistic effect and can increase the viscosity and shearing force of the drilling fluid at the same time.

Owner:BINZHOU UNIV

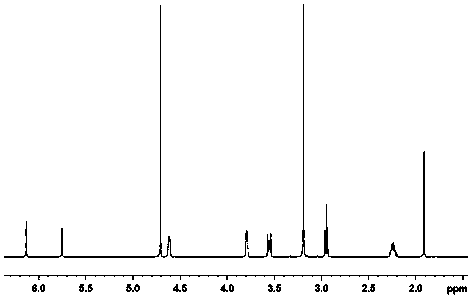

Temperature-resistant thickening agent copolymerization association compound and preparation method thereof

ActiveCN106608944AHigh apparent viscosityEasy to cutDrilling compositionTemperature resistanceControllability

The invention discloses a temperature-resistant thickening agent copolymerization association compound and a preparation method thereof. The copolymerization association compound contains a structural unit A, a structural unit B and a structural unit C, the structural unit A is N,N-dimethylacrylamide, the structural unit B is an amphoteric monomer methacryloyloxyethyl-N,N-dimethylpropanesulfonate (DMAPS), and the structural unit C is an ion association body of the structural unit B and cationic polyamine; and based on the total amount of the copolymerization association compound, the content of the N,N-dimethylacrylamide is 10-75% by weight, preferably 30-65% by weight, the total content of the amphoteric monomer is 8-55% by weight, preferably 20-60% by weight, and the content of the cationic polyamine is 1-50% by weight, preferably 3-40% by weight. Temperature resistance of the thickening agent prepared by the method can reach 150 DEG C, anti-NaCl concentration is saturated, and anti-CaCl2 concentration reaches 20%; and meanwhile, excellent shale inhibition performance and filtrate loss controllability are furthermore achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tackifier copolymerization association compound, and preparation method thereof

ActiveCN106608947AIncrease shear forceImprove heat and salt resistanceDrilling compositionFiltrationReduced properties

The invention discloses a tackifier copolymerization association compound, and a preparation method thereof. 100wt% of the tackifier copolymerization association compound comprises 10 to 75wt%, preferably 30 to 65wt% of a structure unit A, 8 to 55wt%, preferably 20 to 60wt% of a structure unit B, and a structure unit C; the structure unit A is N,N-dimethylacrylamide; the structure unit B is amphoteric monomer N-methyl diallyl propanesulfonate (MAPS), the structure unit C is an ionic association compound of the structure unit B with cationic polyamine; and the amount of cationic polyamine accounts for 1 to 50wt%, preferably 3 to 40wt% of the total amount of the tackifier copolymerization association compound. The tackifier prepared via a preparation method in the invention is capable of tolerating a temperature as high as 200 DEG C, tolerating NaCl concentration as high as the saturation concentration, and tolerating CaCl2 concentration as high as 20%, and also possesses excellent shale inhibition and filtration reducing properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method for preparing tackifier copolymerized association

The invention discloses a method for preparing a tackifier copolymerization associate. The copolymerization associate comprises a constitutional unit A, a constitutional unit B and a constitutional unit C. The constitutional unit A is N, N-dimethylacrylamide, the constitutional unit B is N-methyl diallyl propylsulfonate (MAPS) which is an amphoteric ionic monomer, and the constitutional unit C is an ionic associate of the constitutional unit B and cationic polyamine. Based on the total amount of the copolymerization associate, the copolymerization associate comprises 10-75% by weight of the constitutional unit A, 8-55% by weight of the amphoteric ionic monomer, and 1-50% by weight of the cationic polyamine. A tackifier obtained through the preparation method can resist temperature as high as 200 DEG C, can resist a saturated NaCl solution, and resist a CaCl2 solution with the concentration being 20%. The tackifier is excellent shale inhibition and filtrate reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of thickening agent copolymerization association compound

ActiveCN106608972AIncrease shear forceImprove heat and salt resistanceDrilling compositionTemperature resistanceControllability

The invention discloses a preparation method of a thickening agent copolymerization association compound. The copolymerization association compound contains a structural unit A, a structural unit B and a structural unit C, the structural unit A is acrylamide, the structural unit B is amphoteric monomer N-methyldiallyl propanesulfonate (MAPS), and the structural unit C is an ion association body of the structural unit B and cationic polyamine; and based on the total amount of the copolymerization association compound, the content of the structural unit A is 10-75wt%, the total content of the amphoteric monomer is 8-55wt%, and the content of the cationic polyamine is 1-50wt%. Temperature resistance of the thickening agent prepared by the method can reach 200 DEG C, anti-NaCl concentration is saturated, and the anti-CaCl2 concentration reaches 20%; and meanwhile, excellent shale inhibition performance and filtrate loss controllability are furthermore achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com