Lightweight aggregate high-performance concrete and preparation method thereof

A high-performance concrete and lightweight aggregate technology, applied in the field of concrete, can solve the problems that affect the popularization and application of lightweight aggregate concrete, do not comply with low-carbon environmental protection, and poor constructability, so as to improve uniformity and compactness, light bulk density, and reduce The effect of bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

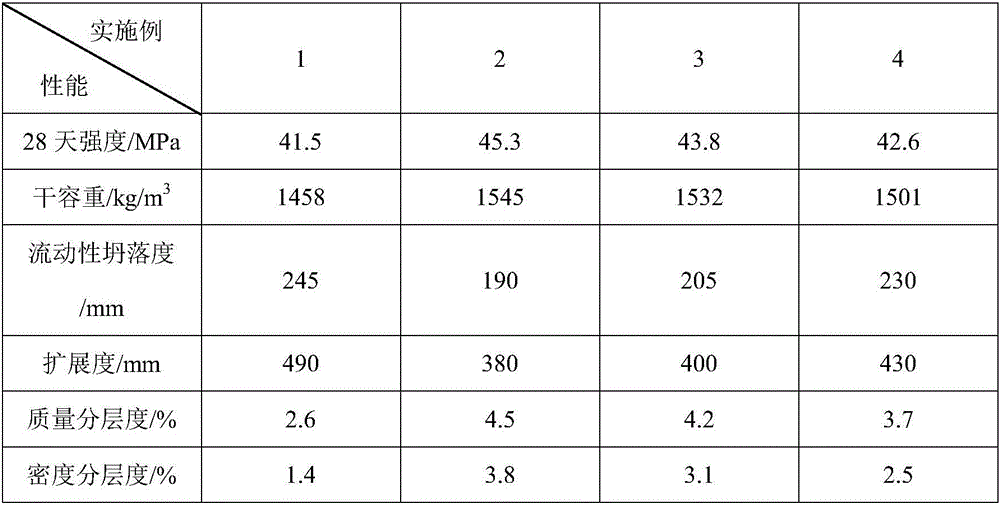

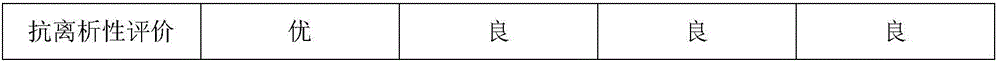

Examples

Embodiment 1

[0019] Cement: 42.5 general purpose Portland cement.

[0020] Lightweight aggregate: Ceramsite is 5-19mm crushed shale ceramsite, density grade is 800, cylinder compression strength is 6.5Mpa, and 1h water absorption rate is 3%.

[0021] Sand: shale ceramic sand, density grade 700, 1~5mm, medium coarse sand with fineness modulus 2.6~3.3, bulk density 750~850kg / m 3 .

[0022] Reclaimed sand: construction waste reclaimed sand, medium sand in Zone II with a fineness modulus of 2.6 to 3.3, and a bulk density of 1450 to 1550 kg / m 3 .

[0023] Fly ash: Zhenjiang Jianbi Power Plant Class I fly ash, with a specific surface area of 400m 2 / kg above, density is 2.2~2.4g / cm 3 .

[0024] Ground slag powder: Shanghai Baosteel S95 slag powder with a specific surface area of 450m 2 / kg above, the density is 2.5~2.9g / cm 3 .

[0025] Water reducing agent: polycarboxylic acid superplasticizer, solid content is more than 20%, water reduction rate is more than 25%.

[0026] Raw materials: 180 parts of ce...

Embodiment 2

[0029] Raw materials: 309 parts of cement, 619 parts of high-performance ceramsite, 103 parts of fly ash, 103 parts of mineral powder, 458 parts of ceramic sand, 50 parts of construction waste reclaimed sand, 145 parts of water, 6.5 parts of water reducing agent, reinforced modified materials 1.0 part and 0.56 part of anti-segregation material. Among them, the reinforced modified material is sodium silicate, sodium sulfate and organic alcohol amine with a weight ratio of 65:30:5; the organic alcohol amine is 50% by mass of diethanol monoisopropanolamine and 50% of three A mixture of isopropanolamine; the anti-segregation material is a mixture of modified methyl cellulose and carboxymethyl cellulose with a weight ratio of 75:25.

[0030] Preparation process: Using a forced mixer, first premix the light aggregate ceramsite ceramsite in the mixing drum for 30 seconds, add additional water according to the pre-tested water absorption rate of the ceramsite and ceramsite, mix well and ...

Embodiment 3

[0032] Raw materials: 258 parts of cement, 619 parts of high-performance ceramsite, 103 parts of fly ash, 154 parts of mineral powder, 458 parts of ceramic sand, 50 parts of construction waste reclaimed sand, 135 parts of water, 5.2 parts of water reducing agent, reinforced modified materials 1.2 parts and 0.60 parts of anti-segregation materials. Among them, the reinforced modified material is sodium silicate, sodium sulfate and organic alcohol amine with a weight ratio of 60:30:10; the organic alcohol amine is 60% by mass of diethanol monoisopropanolamine and 40% of triisopropanol. Isopropanolamine mixture; the anti-segregation material is a mixture of modified methylcellulose and carboxymethylcellulose with a weight ratio of 70:30.

[0033] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cylinder compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com