Solid-phase-free clean low-damage well killing fluid and preparation method thereof

A technology without solid phase and killing fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems such as the large influence of brine density and the large filtration loss of brine killing fluid, and achieve good fluidity , adjustable density, to meet the effect of on-site construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a solid-free clean low-damage well killing fluid, comprising the following steps:

[0032] Add the weighting agent into the water, stir evenly to prepare well killing fluid preparation fluid, add viscosifier, fluid loss reducer, inorganic salt crystallization inhibitor, clay stabilizer in sequence, after stirring evenly, you can get clean low damage pressure without solid phase well fluid.

Embodiment 1

[0049] During the workover process, the filtrate in the killing fluid may enter the oil and gas layers and cause certain damage to the oil layer. In order to evaluate the damage degree of the solid-free clean and low-damage killing fluid to the formation, the core flow experiment was used to select Comparative experiments were conducted on cores with different high and low permeability to investigate the degree of damage caused by the killing fluid to the cores, and the results are shown in the table below.

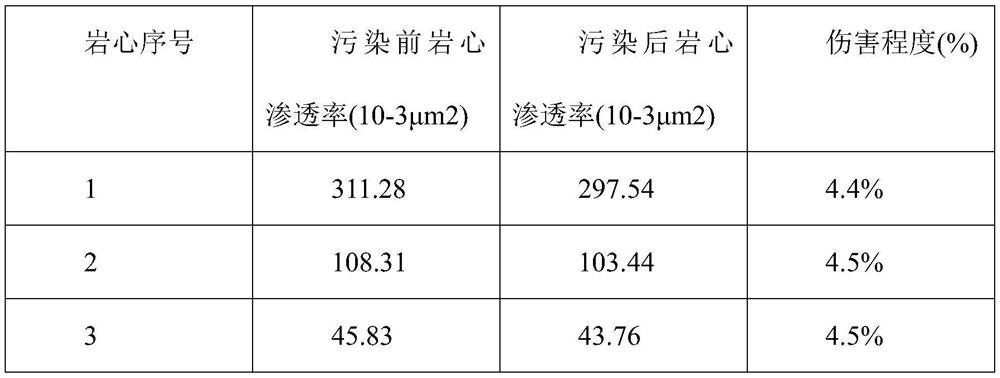

[0050] Tackifier 20g, fluid loss reducer sulfomethyl phenolic resin SMP6g, inorganic salt crystallization inhibitor 1g, weighting agent 200g (water-soluble organic acid salt sodium formate and CaCl The mass ratio is 1:3), clay stabilizer 10g, water It is 763g. After mixing and stirring at room temperature for 30 minutes, a solid-free, clean and low-damage killing fluid can be obtained. Do the killing fluid to pollute the core, the results are shown in Table 1.

[0051] ...

Embodiment 2

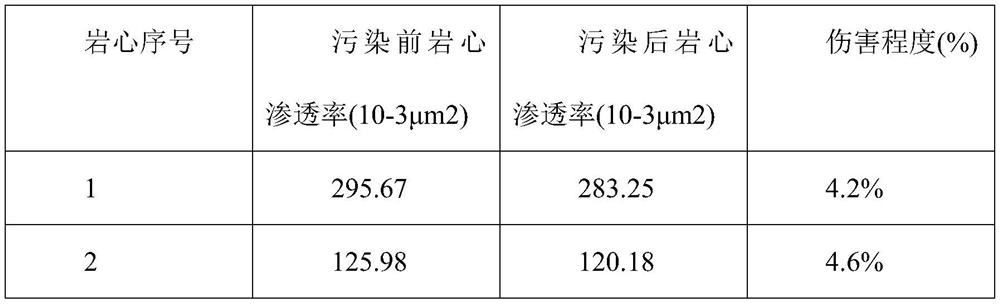

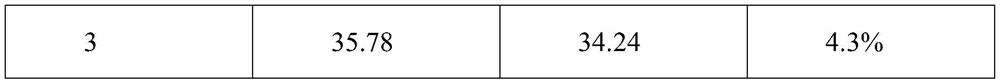

[0055]Configure solid-free clean killing fluid: viscosifier (weak gel formed by chromium acetate and partially hydrolyzed polyacrylamide cross-linking agent) 2.0%, fluid loss reducer (sulfomethyl phenolic resin SMP) 0.6%, Inorganic salt crystallization inhibitor 0.1%, weighting agent (the mass ratio of water-soluble organic acid salt sodium formate to CaCl2 is 1:2) 30%, clay stabilizer 1%, and the balance is water, and the pollution test of well killing fluid on core is done. The results are shown in Table 2.

[0056] Table 2 Experimental data of killing fluid on core contamination

[0057]

[0058]

[0059] From Table 2, it can be found that the low-damage killing fluid with no solid phase cleaning in the ring has a good effect of protecting the oil layer, has good compatibility with the formation, and can meet the requirements of on-site construction with low damage and no pollution. Its popularization and application has extensive economic and social benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com