Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Improved meshing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

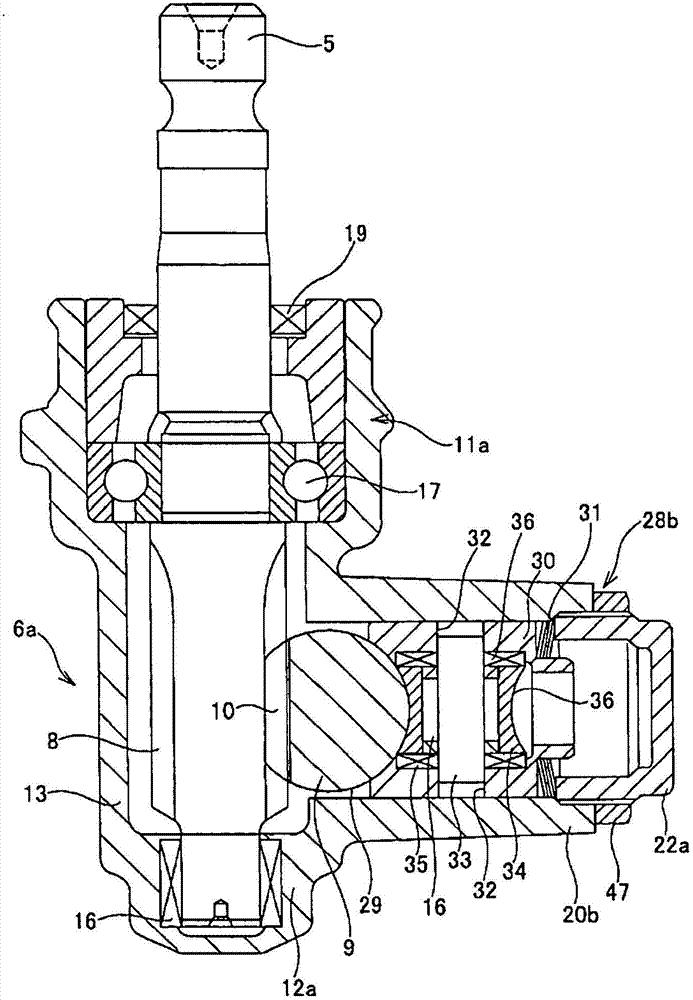

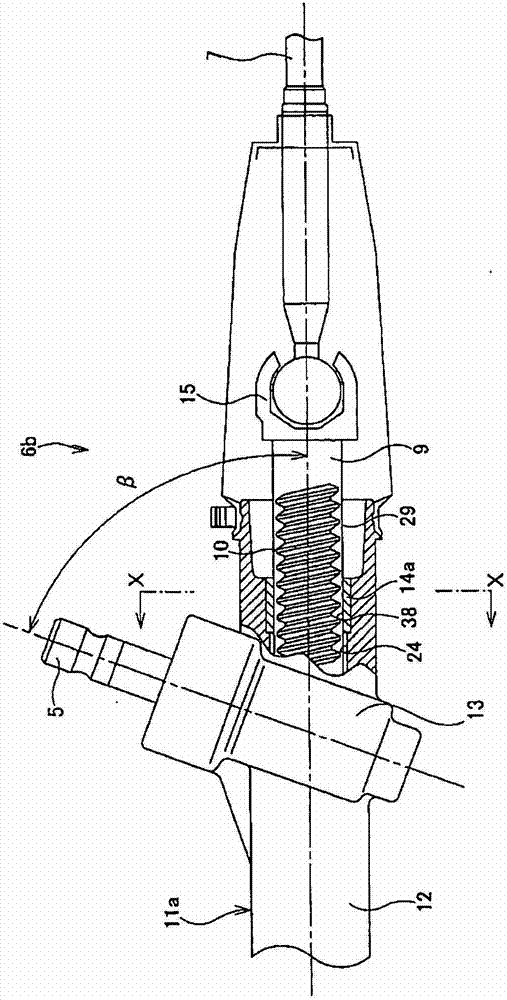

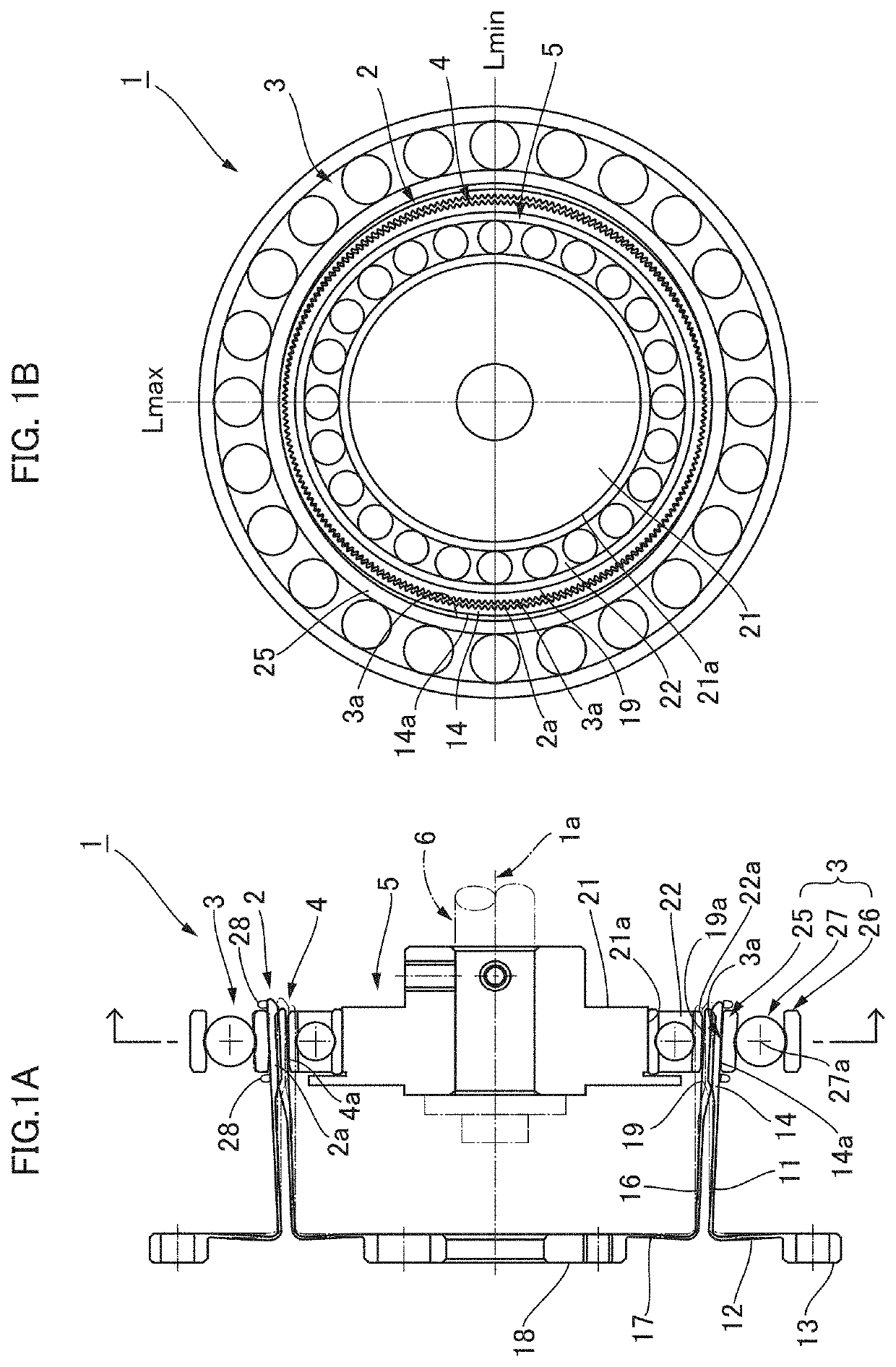

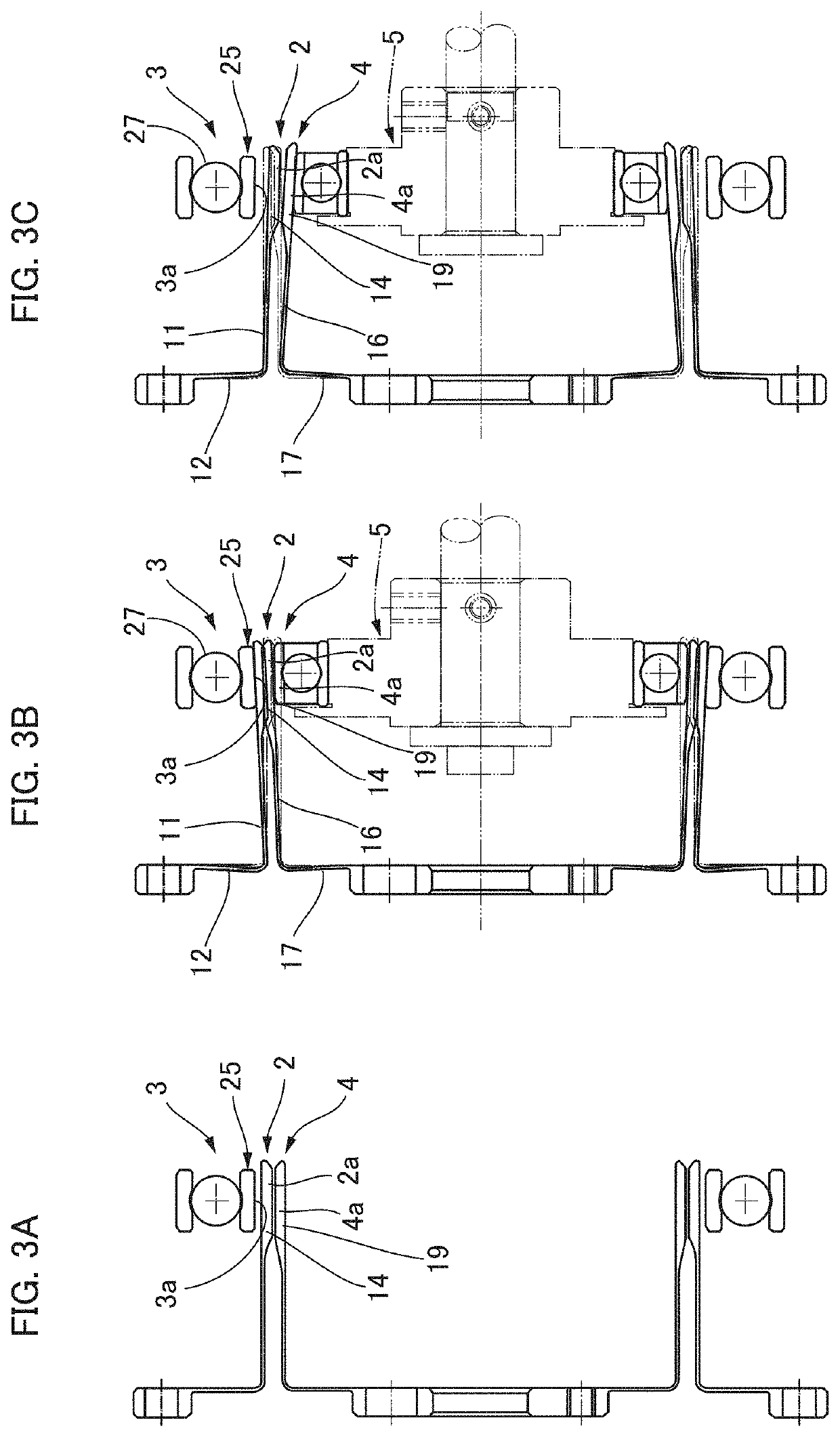

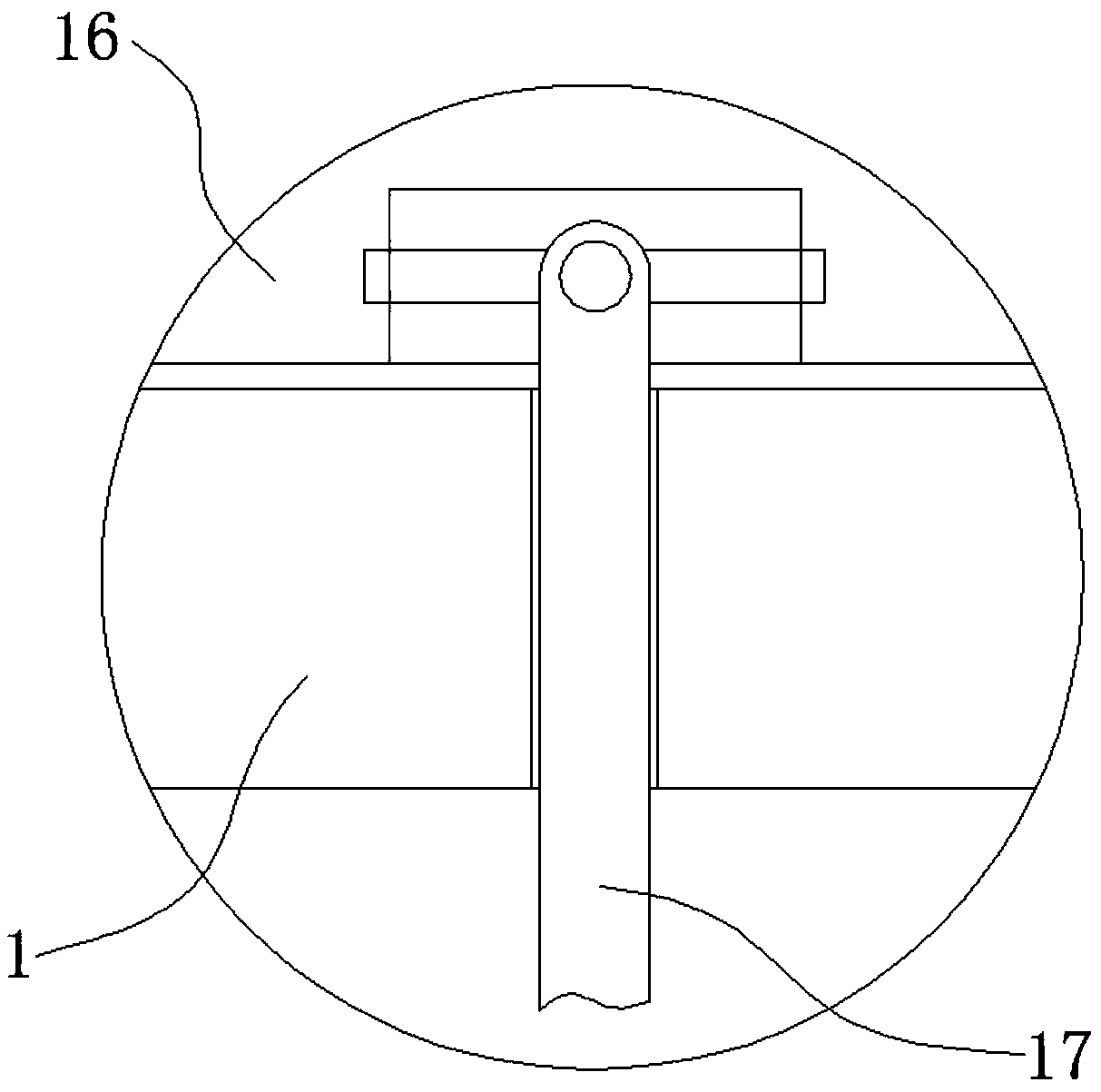

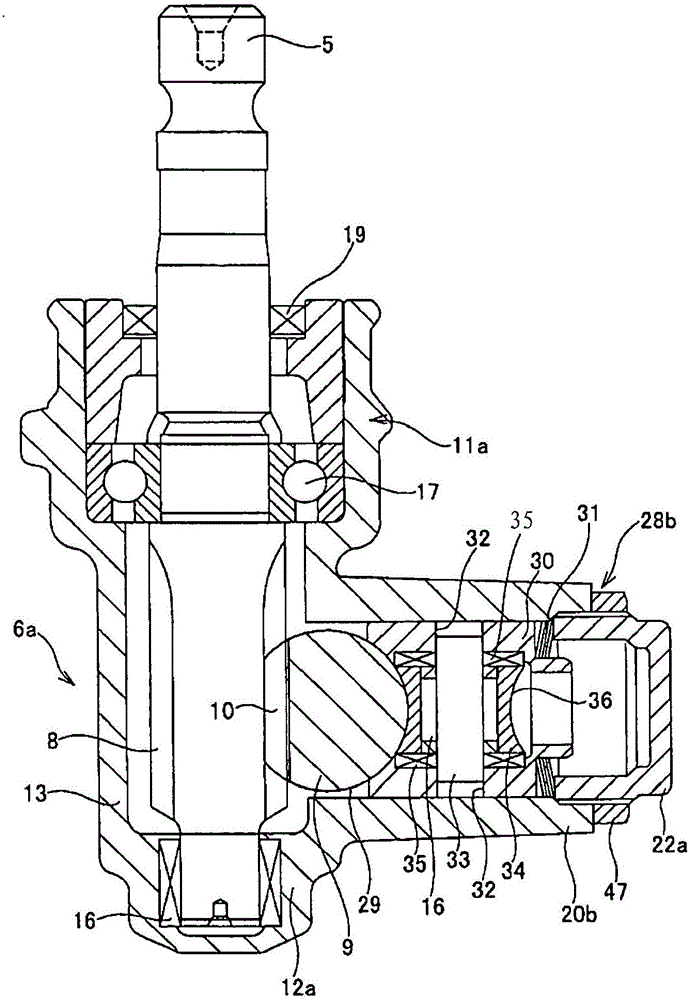

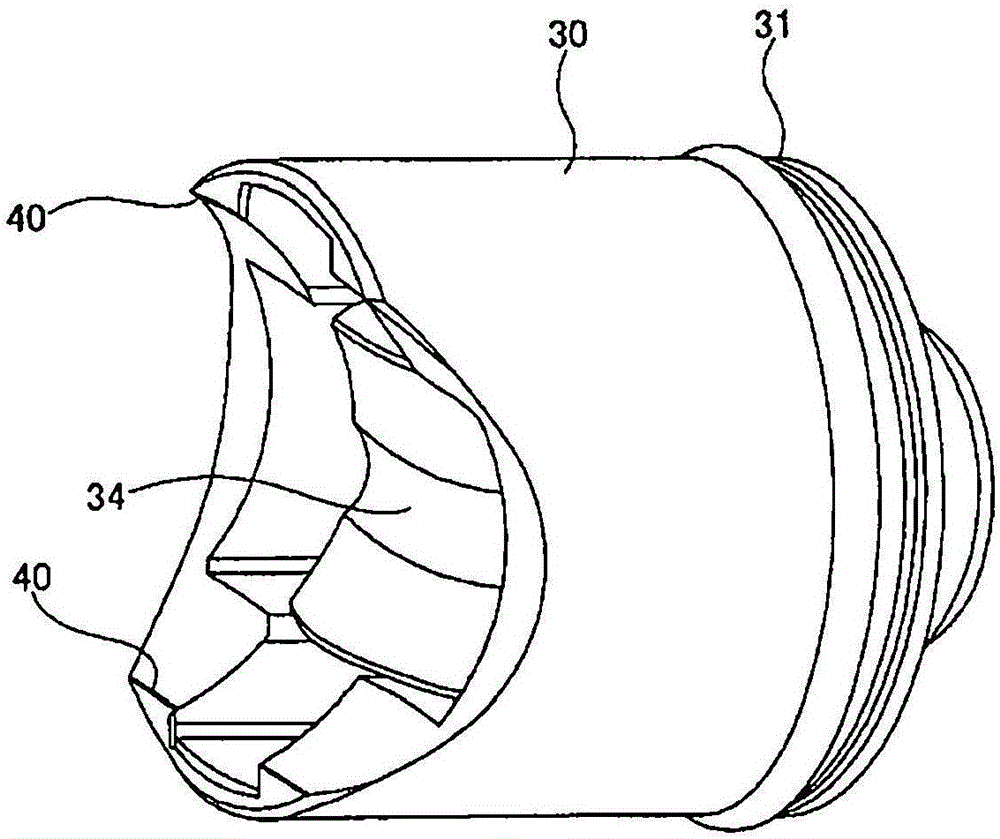

Rack-and-pinion steering gear unit

InactiveCN102892663APrevent operating forceImprove responsivenessMechanical steering gearsFriction gearingsNeedle roller bearingRack and pinion

The present invention provides a rack-and-pinion steering gear unit whereby the operating force of a steering wheel or the operating assist force of an electric motor can be prevented from increasing, and whereby response can be improved in fine operations during forward travel and the like. A back surface (29) of a rack shaft (9) is elastically pressed toward a pinion shaft (5) by a pressing roller (34). The pressing roller (34) is rotatably supported, via a radial needle bearing (16a), on a support shaft (33) supported on and fixed to a holder (30). A thrust needle bearing (35) for bearing a thrust load applied by the pressing roller (34) is provided between an inner side surface of the holder (30) and two side surfaces of the pressing roller (34) in the axial direction.

Owner:NSK LTD

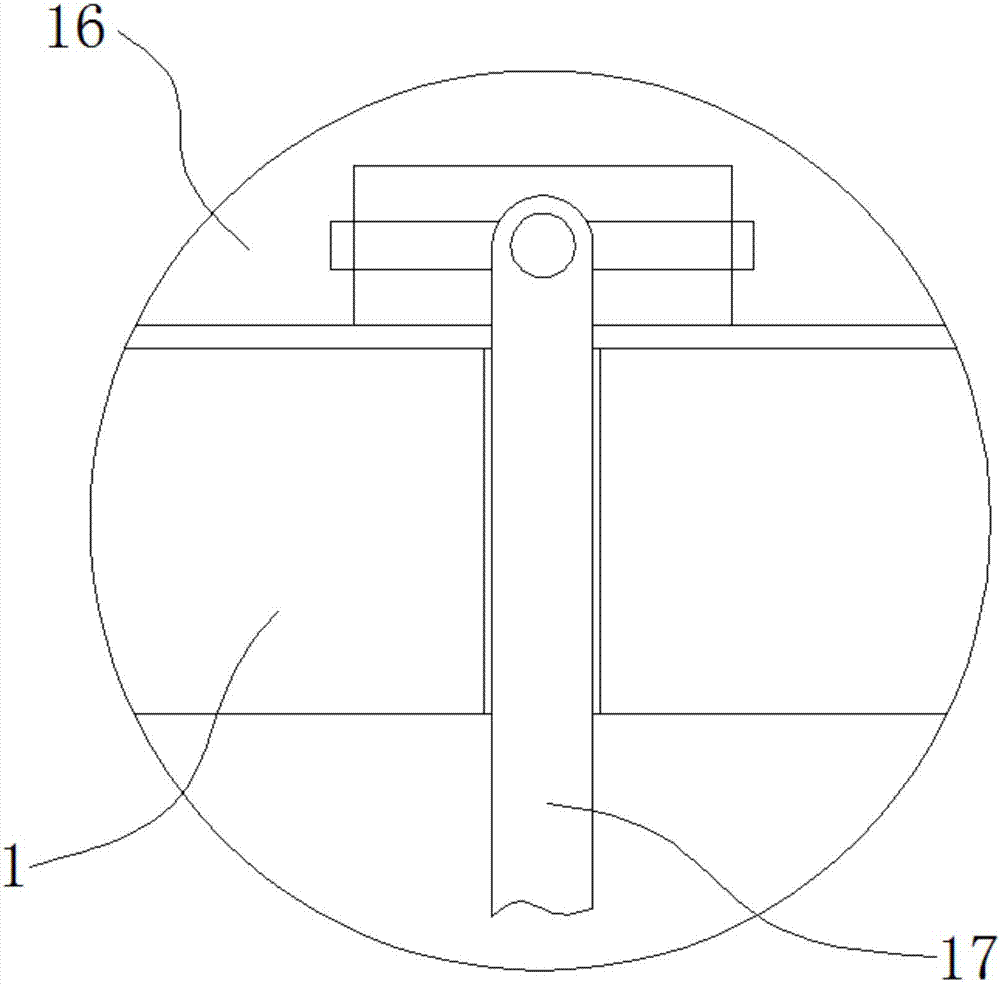

Clamp Device for Connection

InactiveUS20070283538A1Increase meshing areaTightly woundSnap fastenersFlexible elementsEngineeringElectrical and Electronics engineering

Owner:TAKAGI MFG

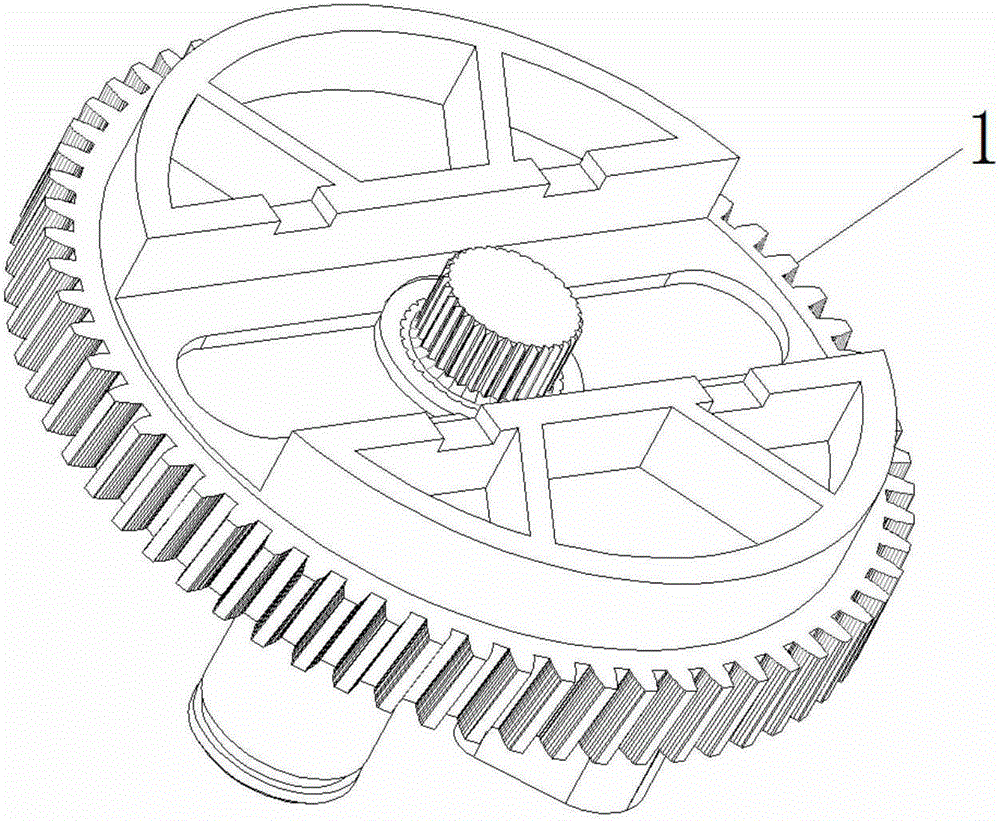

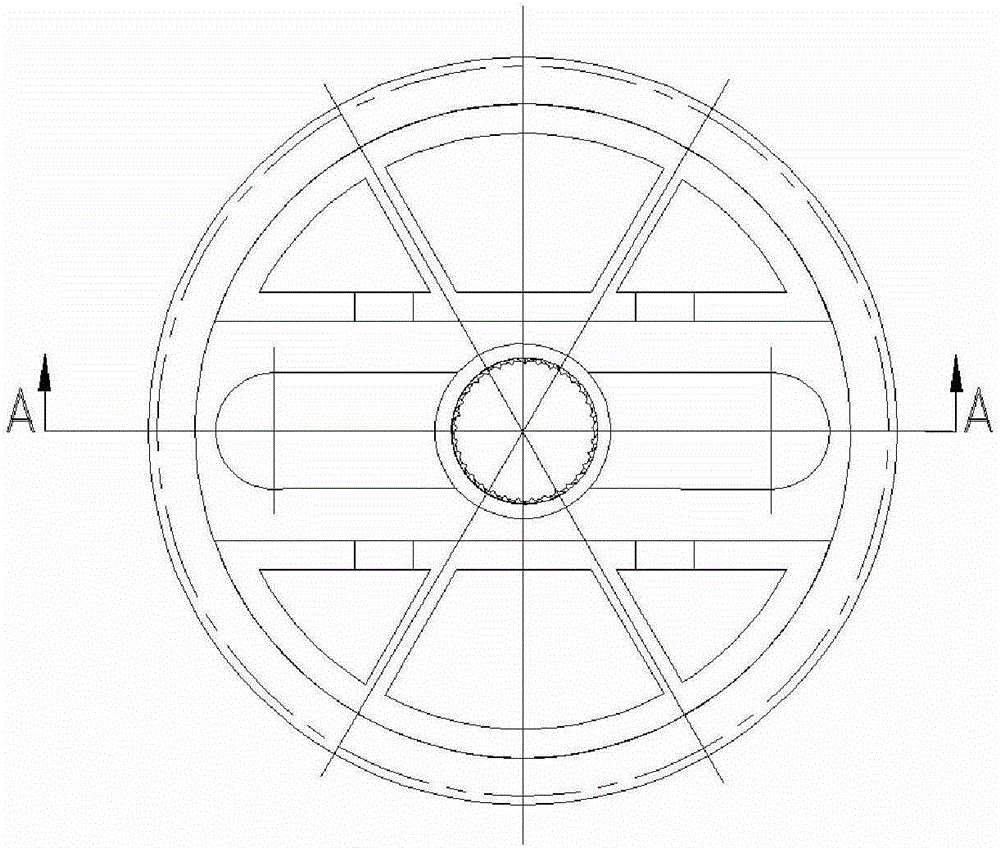

Worm and helical gear transmission pair based on variable pressure angle and application of worm and helical gear transmission pair

PendingCN105179601AImprove machining accuracyReduce noisePortable liftingToothed gearingsGear transmissionEngineering

The invention discloses a worm and helical gear transmission pair based on a variable pressure angle and application of the worm and helical gear transmission pair. The worm and helical gear transmission pair is reliable in transmission, durable and easy to manufacture. In order to achieve the purposes, the worm and helical gear transmission pair based on the variable pressure angle comprises a worm and a helical gear which are engaged with each other, wherein the transverse module (Mt2) of the helical gear is equal to the shaft surface module (Ma1) of the worm; the tooth profile angle alpha n2 of the end face reference circle of the helical gear is larger than the tooth profile angle alpha n1 of the shaft surface reference circle of the worm; the swing angle beta 2 of the reference circle of the helical gear is equal to the lead angle lambda 1 of the shaft surface reference circle of the worm; the difference between the tooth profile angle alpha n2 of the end face reference circle of the helical gear and the tooth profile angle alpha n1 of the shaft surface reference circle of the worm is smaller than 10 degrees.

Owner:SHENZHEN POWER MOTOR IND

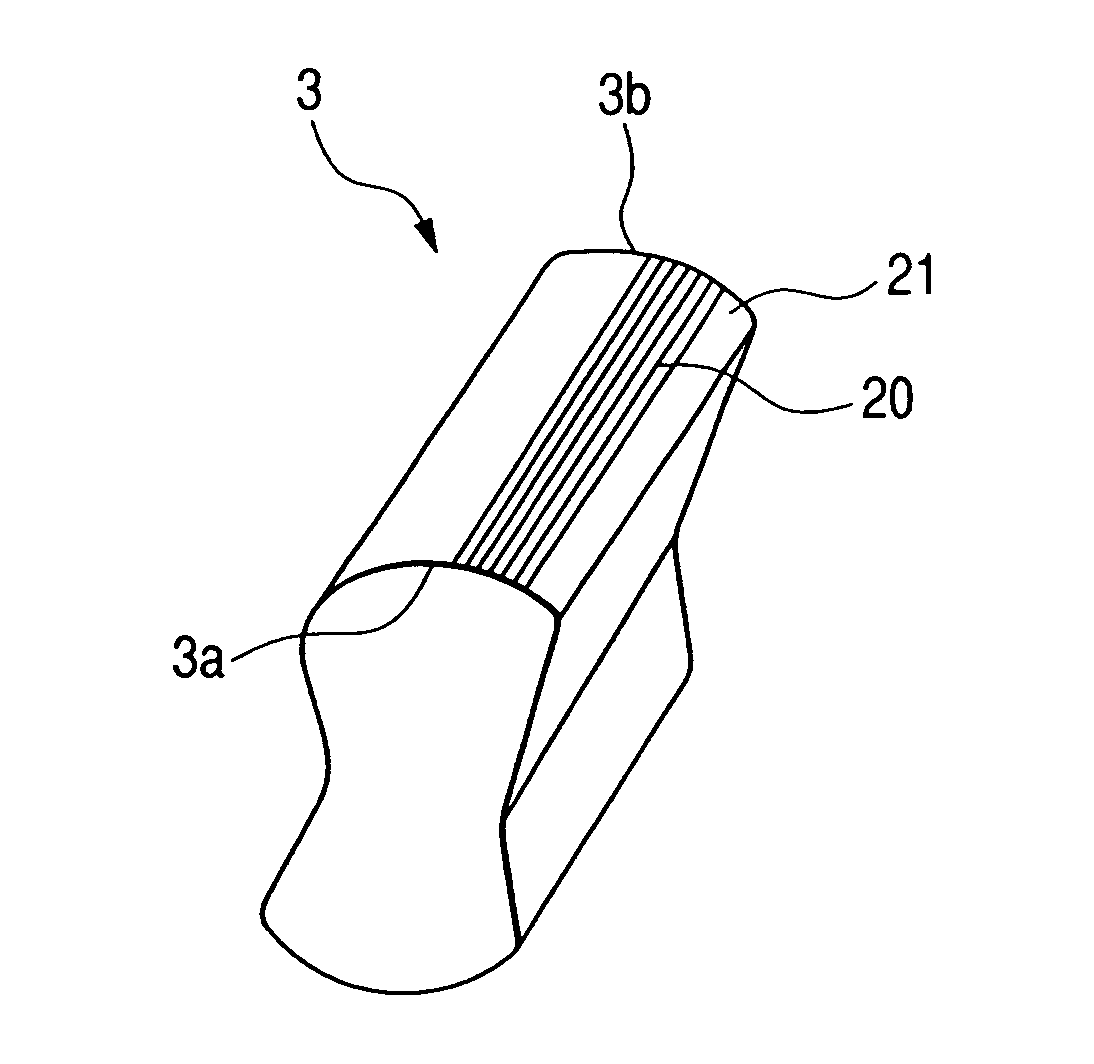

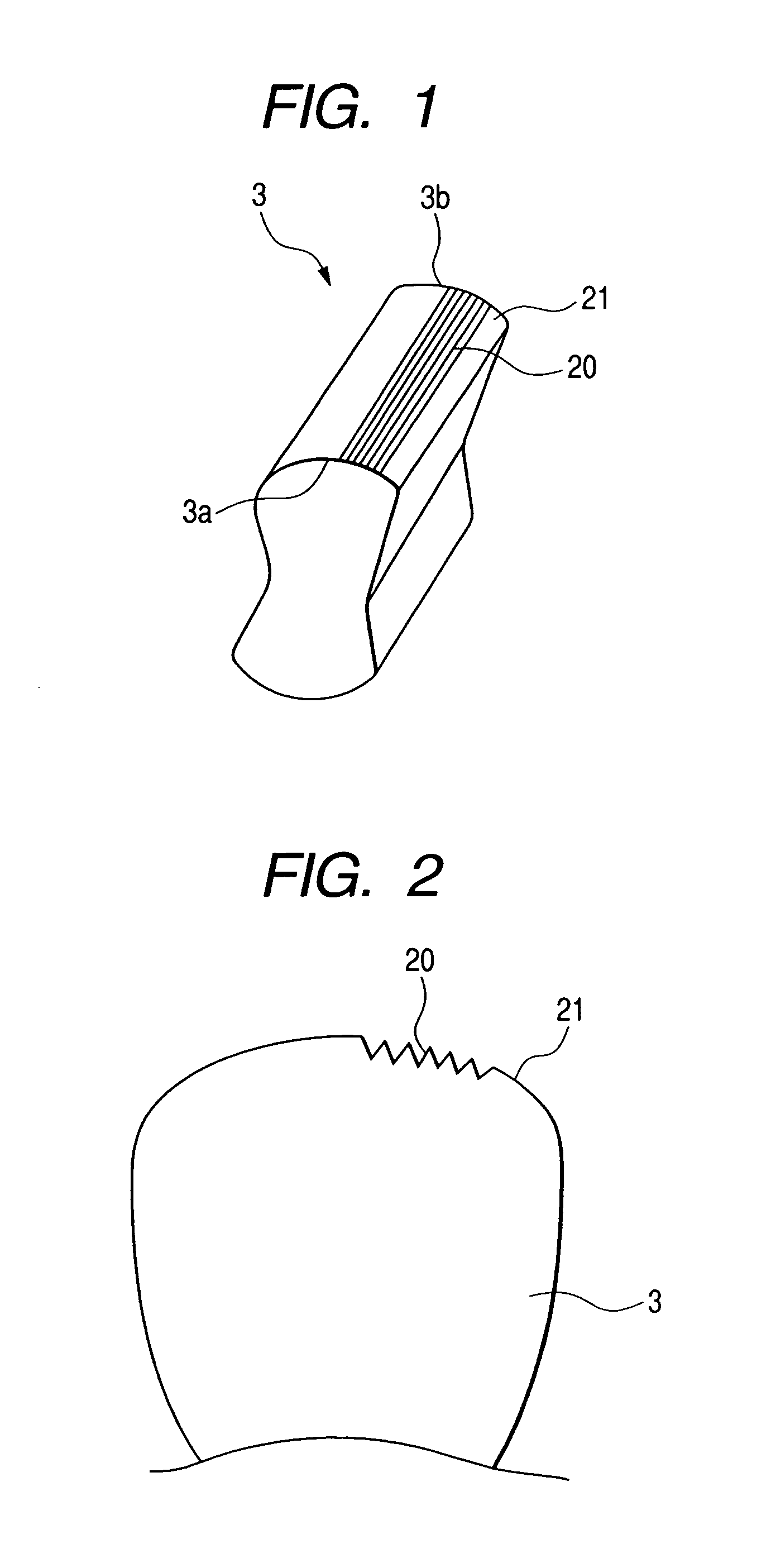

One-way clutch and sprag for the one-way clutch

InactiveUS20060076205A1High viscositySufficient propertyMechanical actuated clutchesCouplingsEngineeringCam

A one-way clutch comprising an inner race and an outer race radially spaced apart from each other and concentrically disposed for rotation relative to each other, and a spray disposed between the inner race and the outer race for transmitting torque is characterized in that the cam surface of the sprag which contacts with the outer peripheral surface of the inner race is formed with a plurality of axially extending grooves.

Owner:NSK WARNER

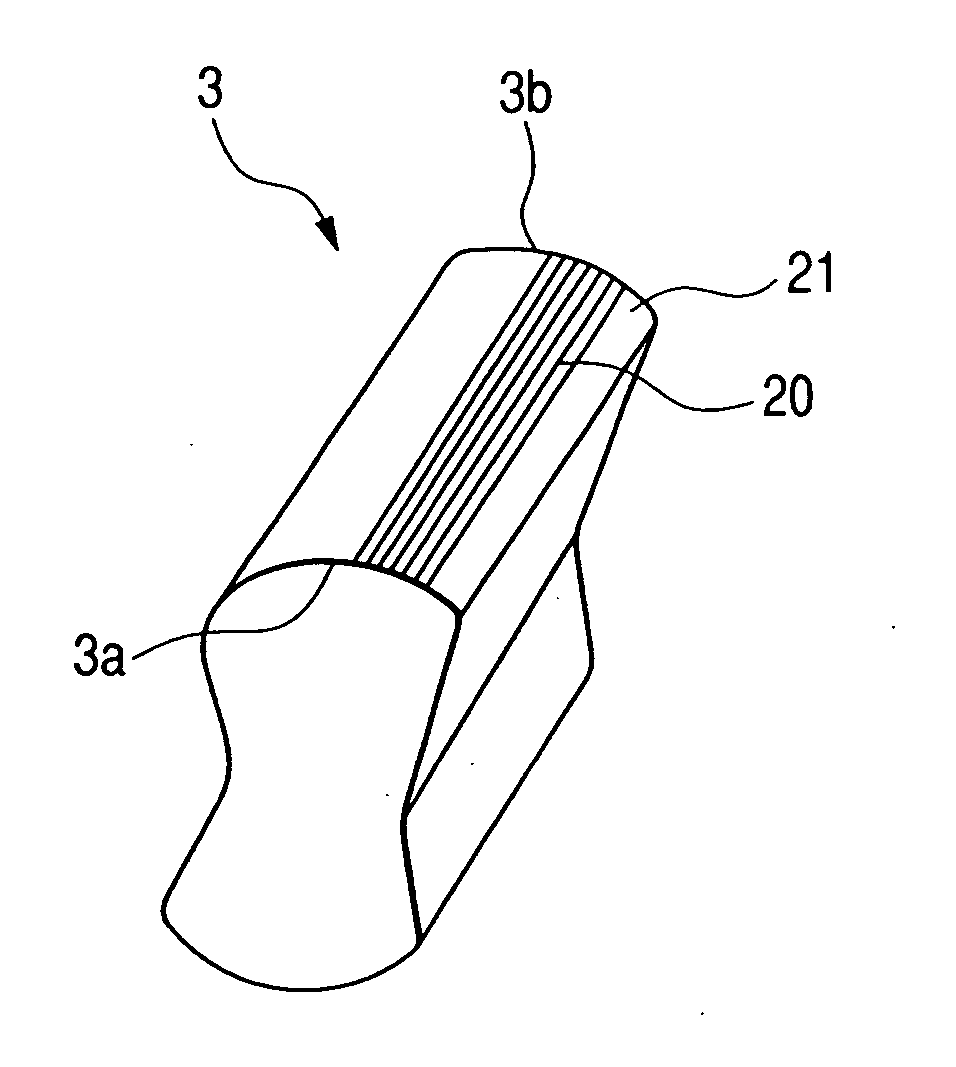

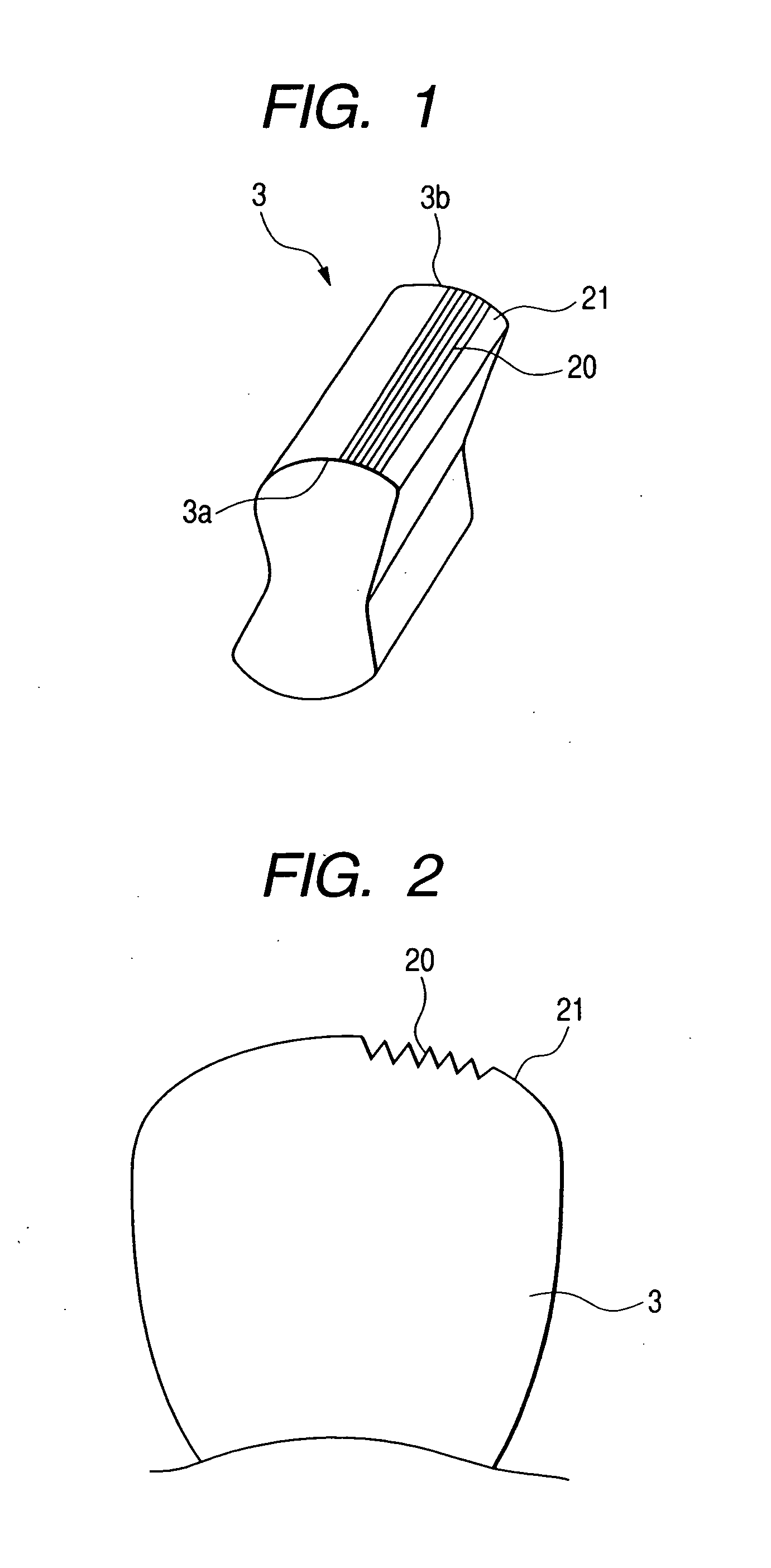

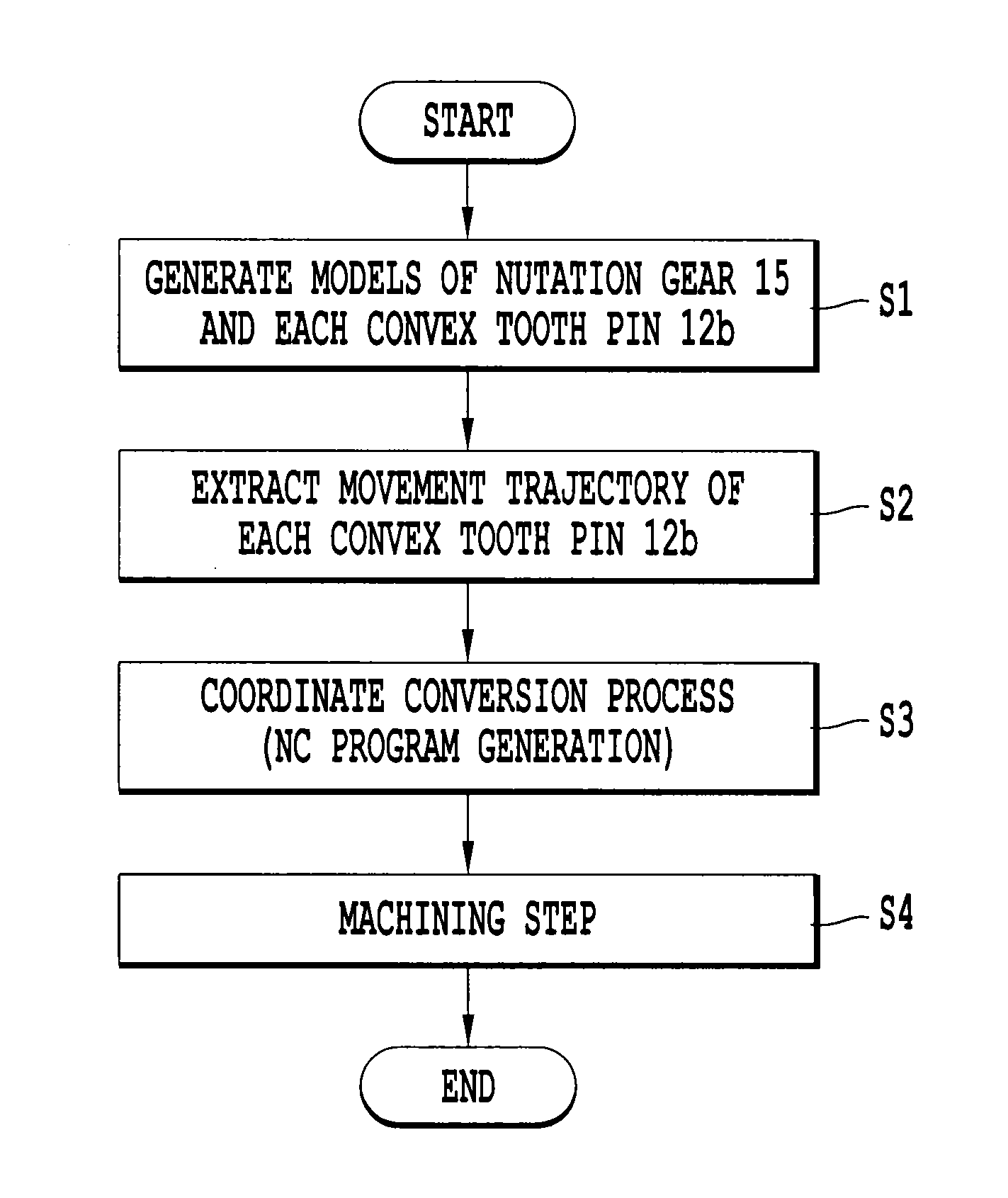

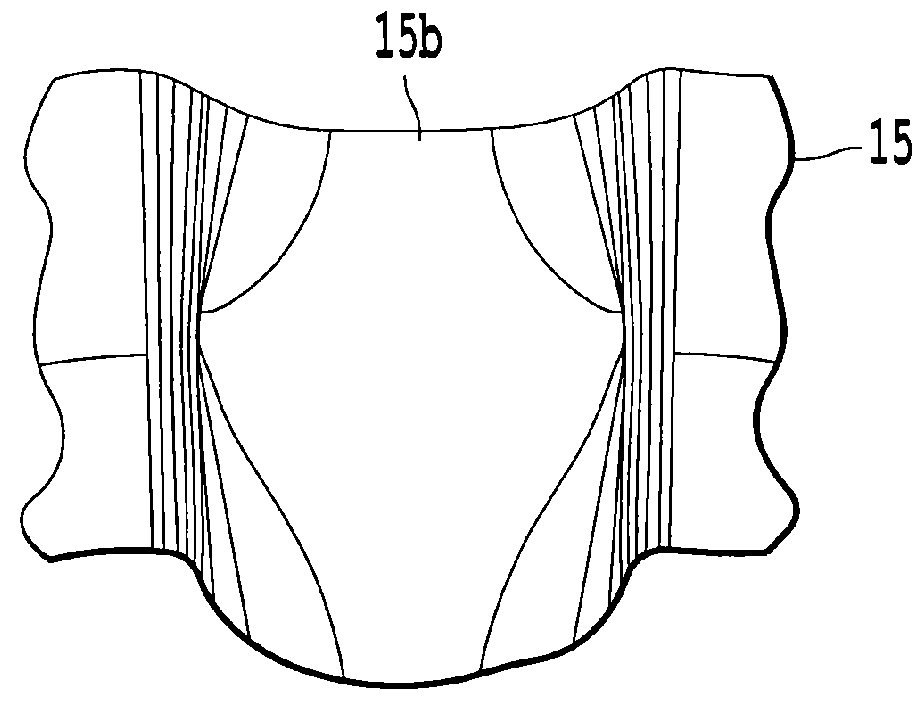

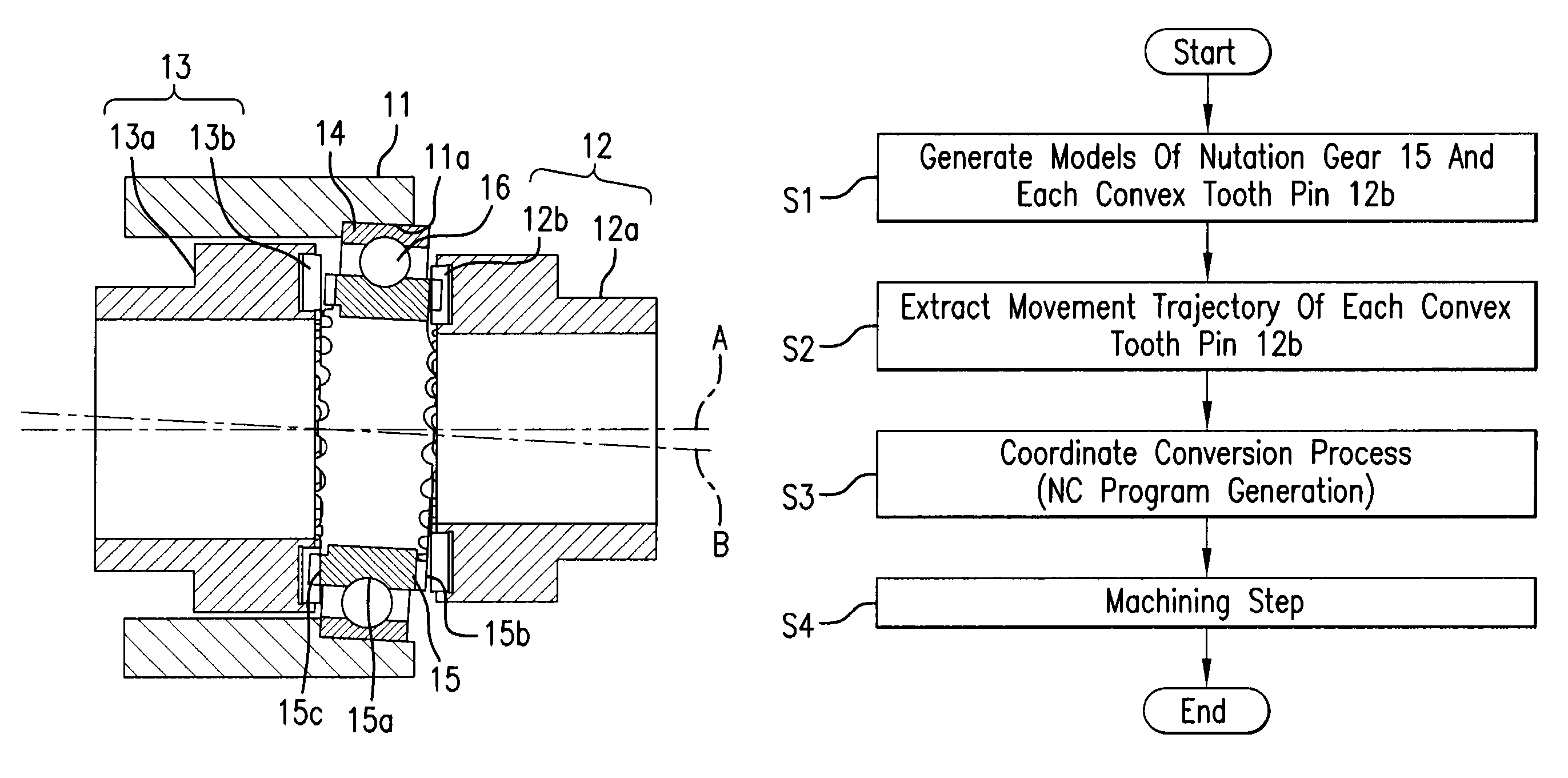

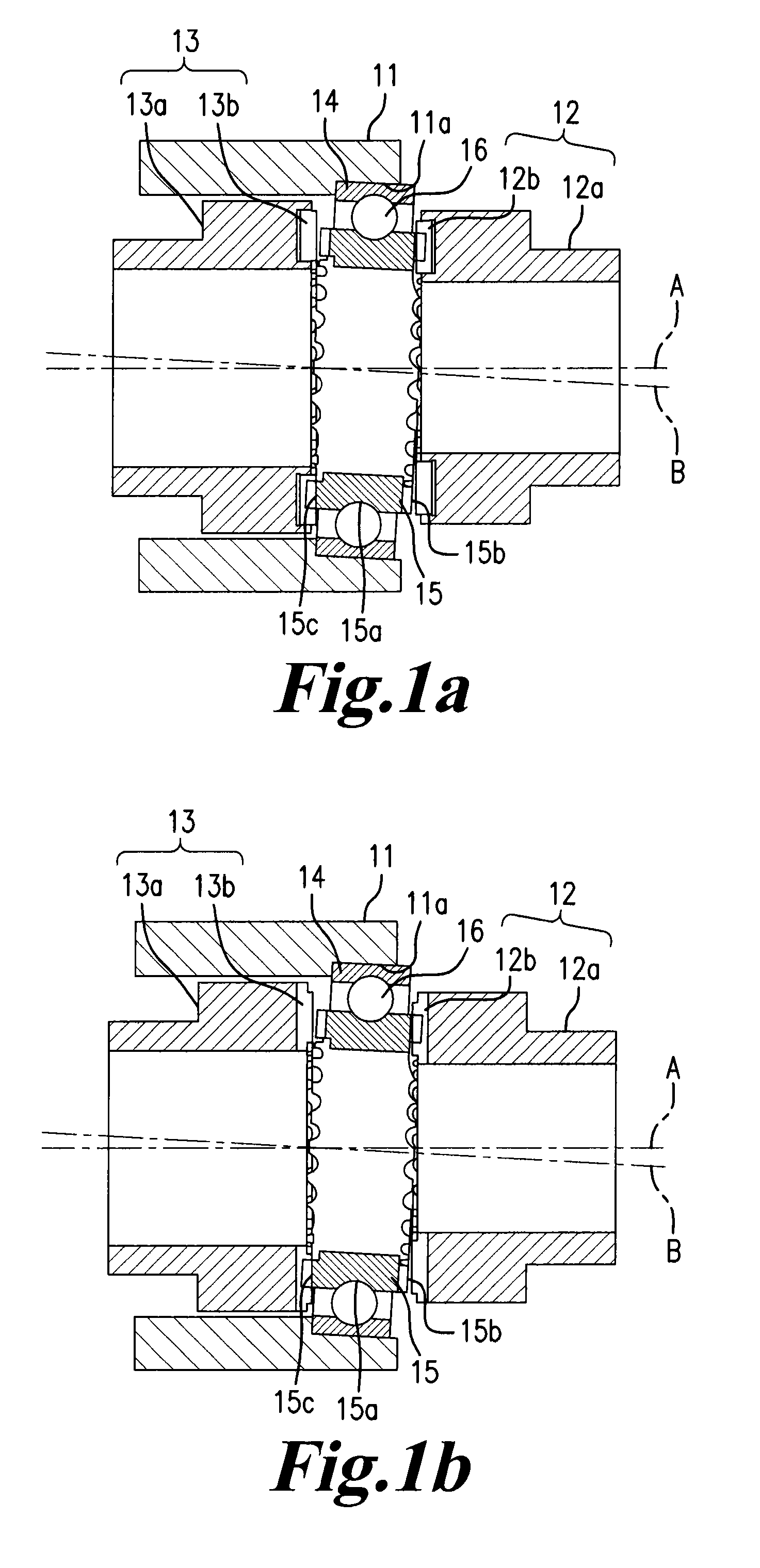

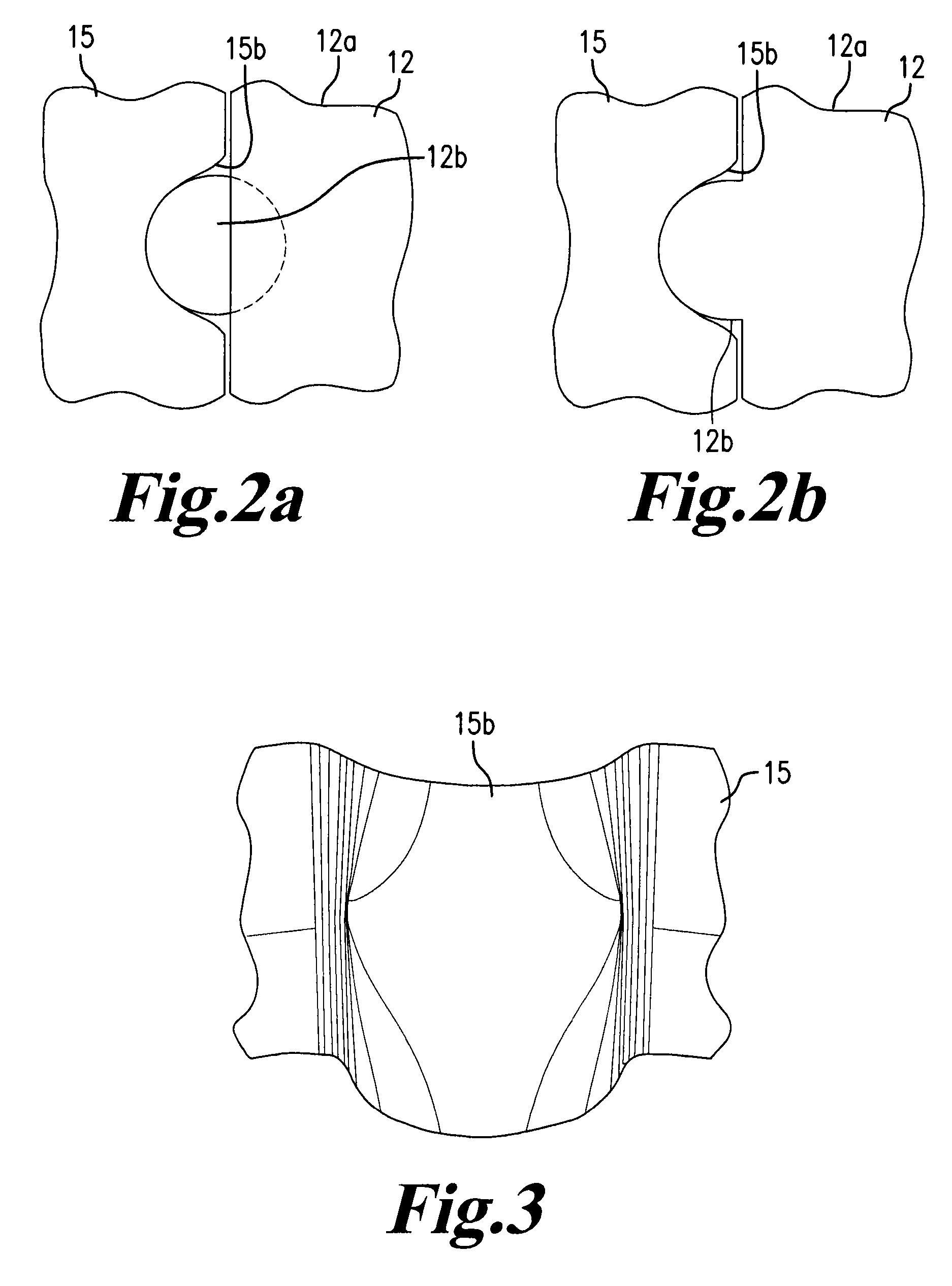

Processing method and processing device for concave-convex gear

A trajectory extracting step of extracting a relative movement trajectory of each convex tooth pin of a mating gear with respect to a concave-convex gear at the time when torque is transmitted between the mating gear (fixed shaft) and the concave-convex gear (nutation gear) and a machining step of, when the concave-convex gear is machined on a concave tooth forming face of a disc-shaped workpiece on which the concave teeth have not been machined, moving at least one of the disc-shaped workpiece and a working tool such that a relative movement trajectory of the working tool with respect to the disc-shaped workpiece coincides with the relative movement trajectory of each convex tooth pin with respect to the concave-convex gear, extracted in the trajectory extracting step, are included.

Owner:JTEKT CORP

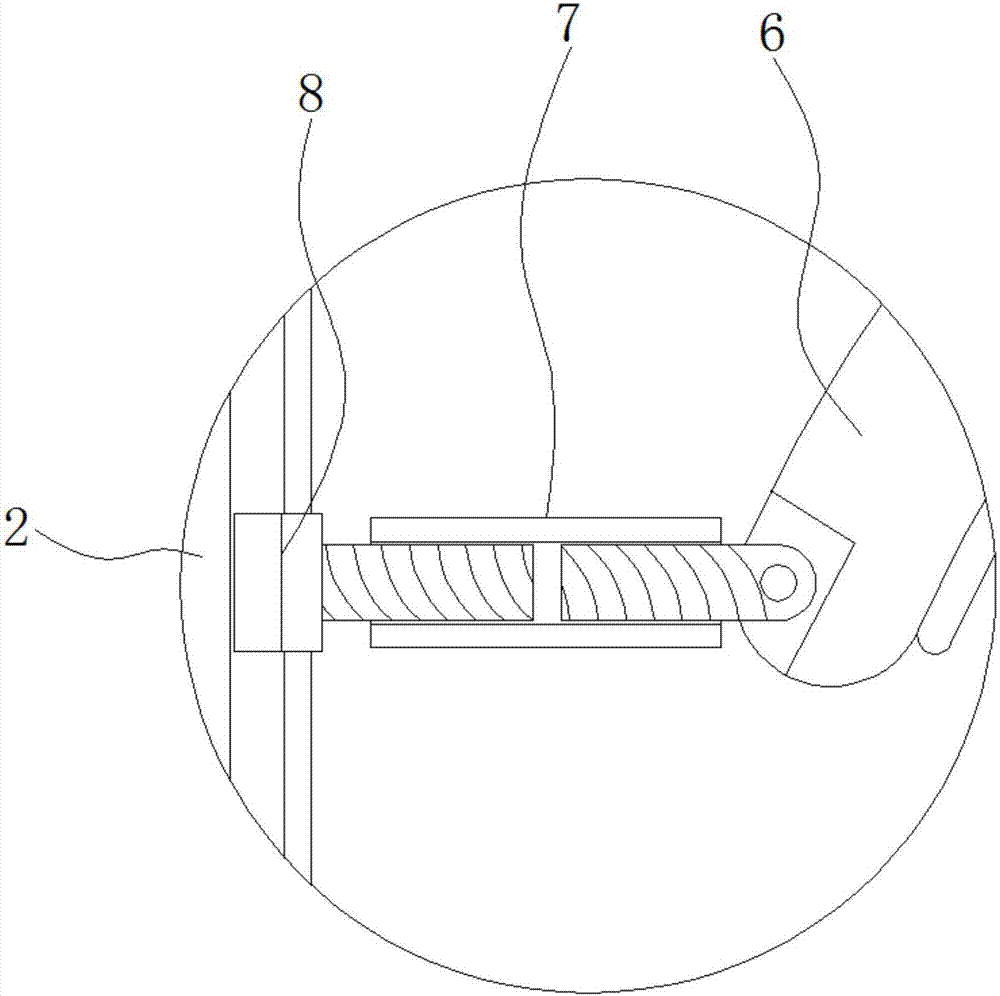

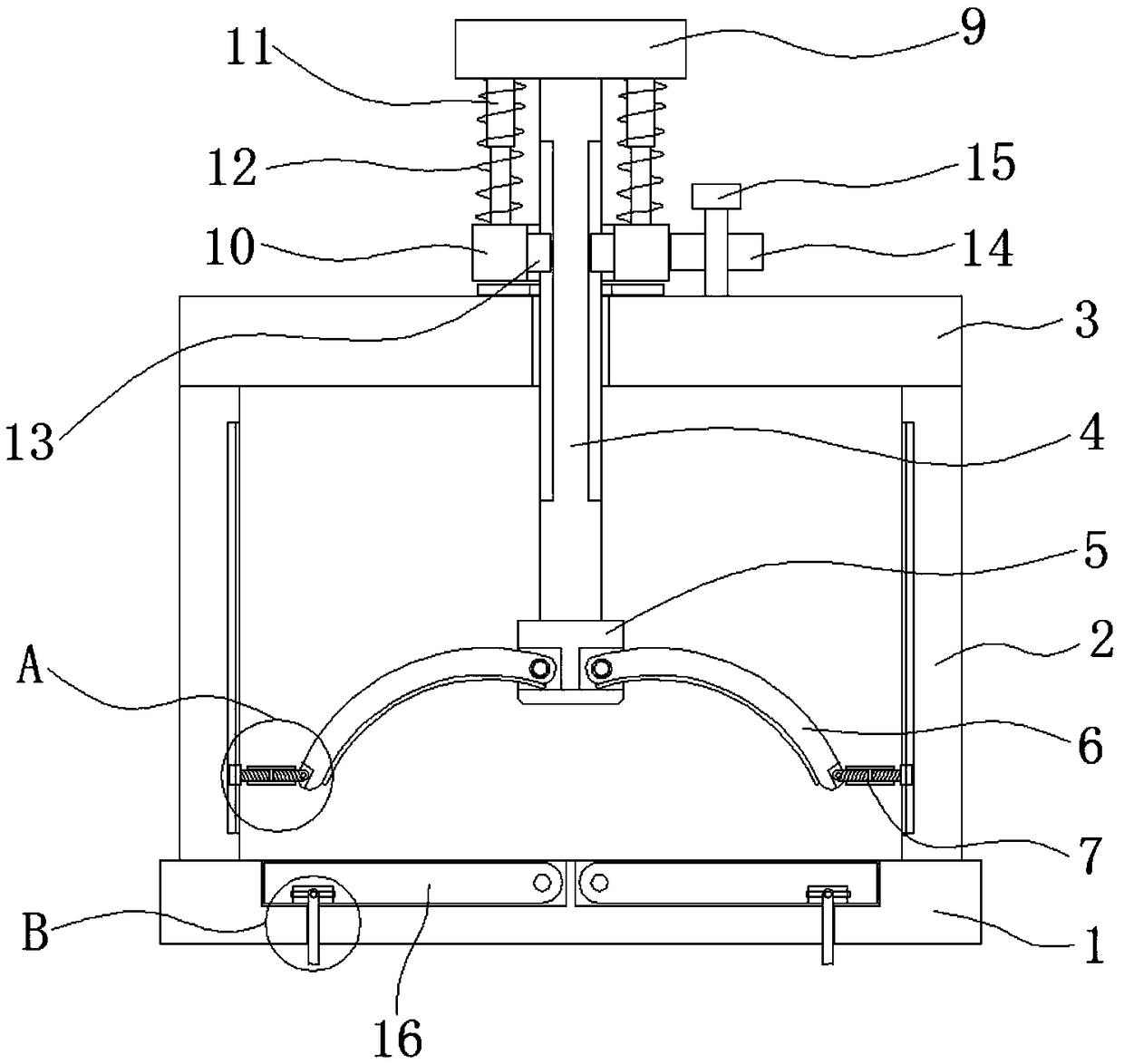

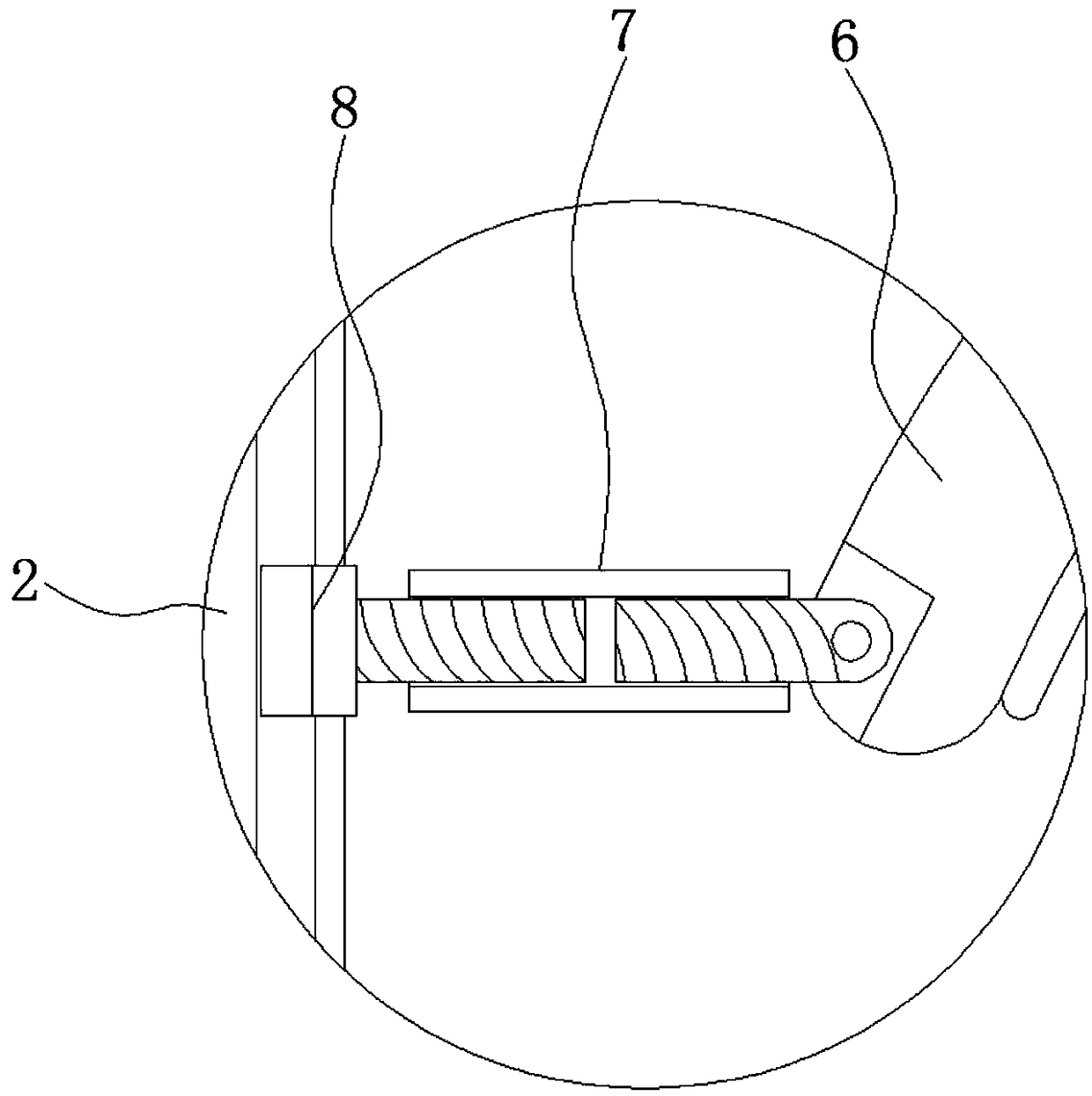

Fixing device used in operation

InactiveCN106943198AEasy to changeImproved meshingInstruments for stereotaxic surgeryEngineeringTorso

The invention discloses a fixing device used during operation, which belongs to the technical field of medical equipment. It includes a placement plate, one side of the placement plate is symmetrically provided with two support plates, and the ends of the two support plates away from the placement plate are connected by a mounting plate, and a first screw is inserted on the mounting plate, and the installation A socket corresponding to the first screw is provided on the board, and the first screw is threadedly connected to the inner wall of the socket, and an installation block is fixedly connected to the end of the first screw close to the placement plate, and the installation block is far away from the side of the first screw. One side is symmetrically provided with installation grooves, and the inner side wall of the installation groove is connected with an arc-shaped splint through the rotation of the first rotating shaft. A first chute corresponding to the first slider is provided on the support plate. The present invention is simple in structure, easy to use, can guarantee the fixation effect on the patient's trunk, and can avoid pinching the patient at the same time.

Owner:谷新运

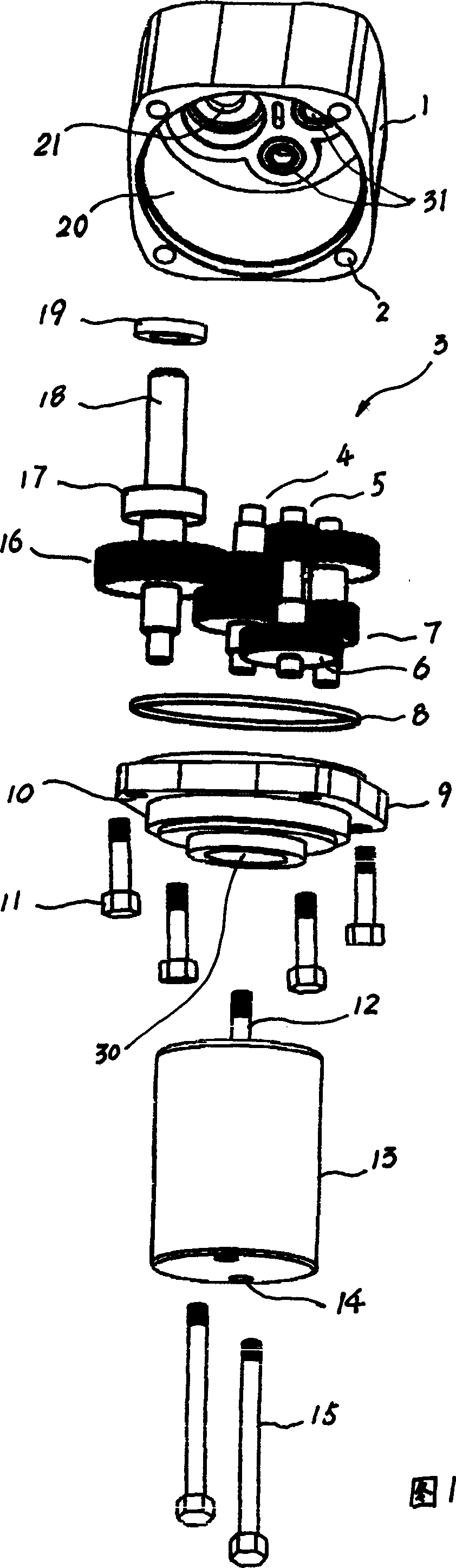

Reduction gear box of electric machine

InactiveCN1525083AGuaranteed running performanceEasy to installToothed gearingsMechanical energy handlingElectric machineDrive shaft

The invention relates to a reduction gear box in electric machine, including electric machine, reduction box and reduction gear; the reduction gear is set in the reduction box and the first driving component of the reduction gear is connected to the driving shaft of the electric machine, and the electric machine is directly connected to the reduction box by an end cover. Thus, the reduction box and the electric machine share the same end cover, largely simplifying the whole structure to make it simpler and more convenient to manufacture and assemble; synchronously, beneficial to control the sealing and working properties of the whole machine. It sets seal washer between the reduction box and the end cover and sets oil seal at the shaft-outlet stop mouth of the reduction box, reducing the leakage of gear lubricant in the reduction box as far as possible and enhancing the sealing property. The reduction and the end cover are made by precision manufacturing device, ensuring the precise installation driving shafts at all levels of the reduction gear.

Owner:ZHEJIANG LINIX MOTOR

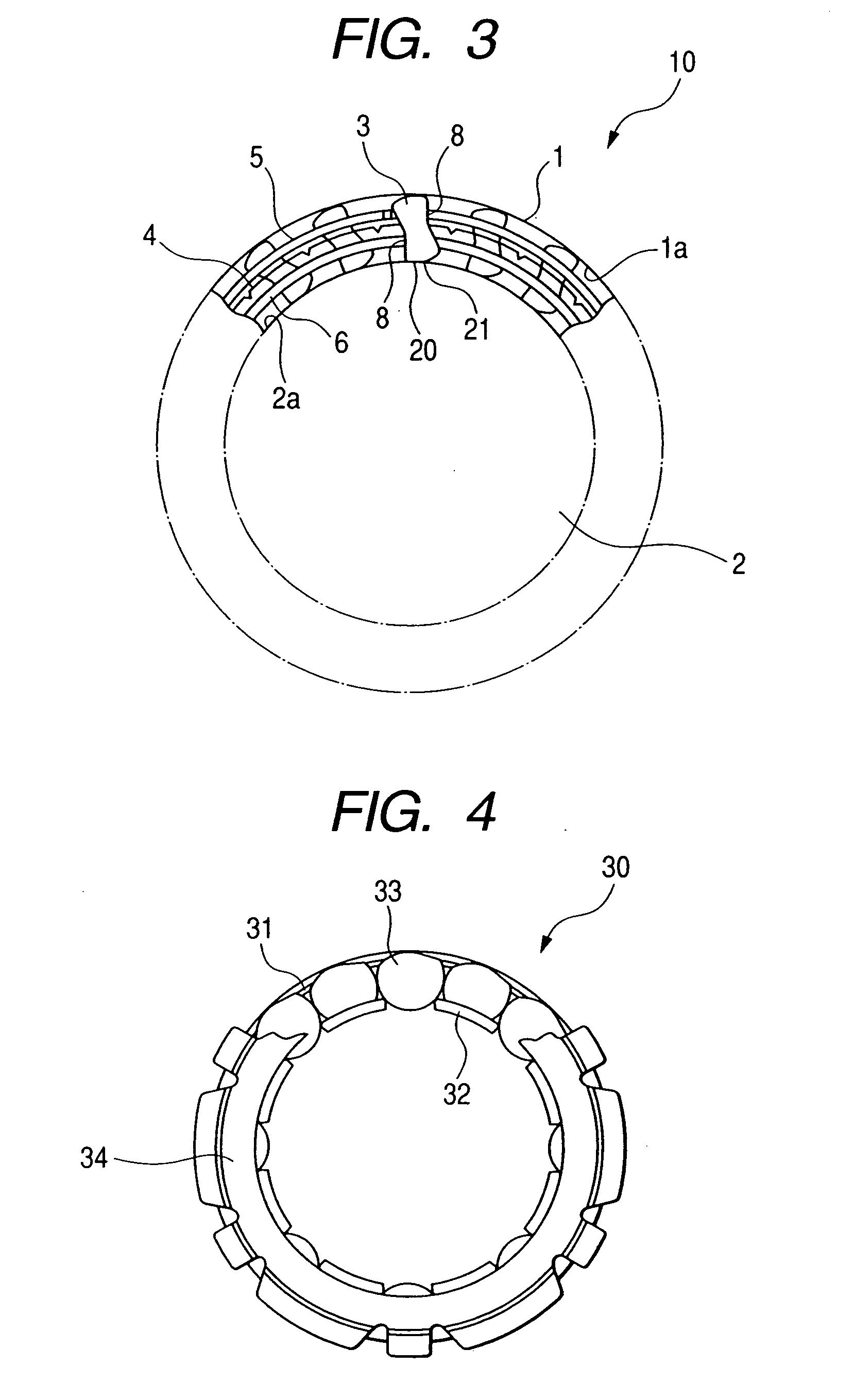

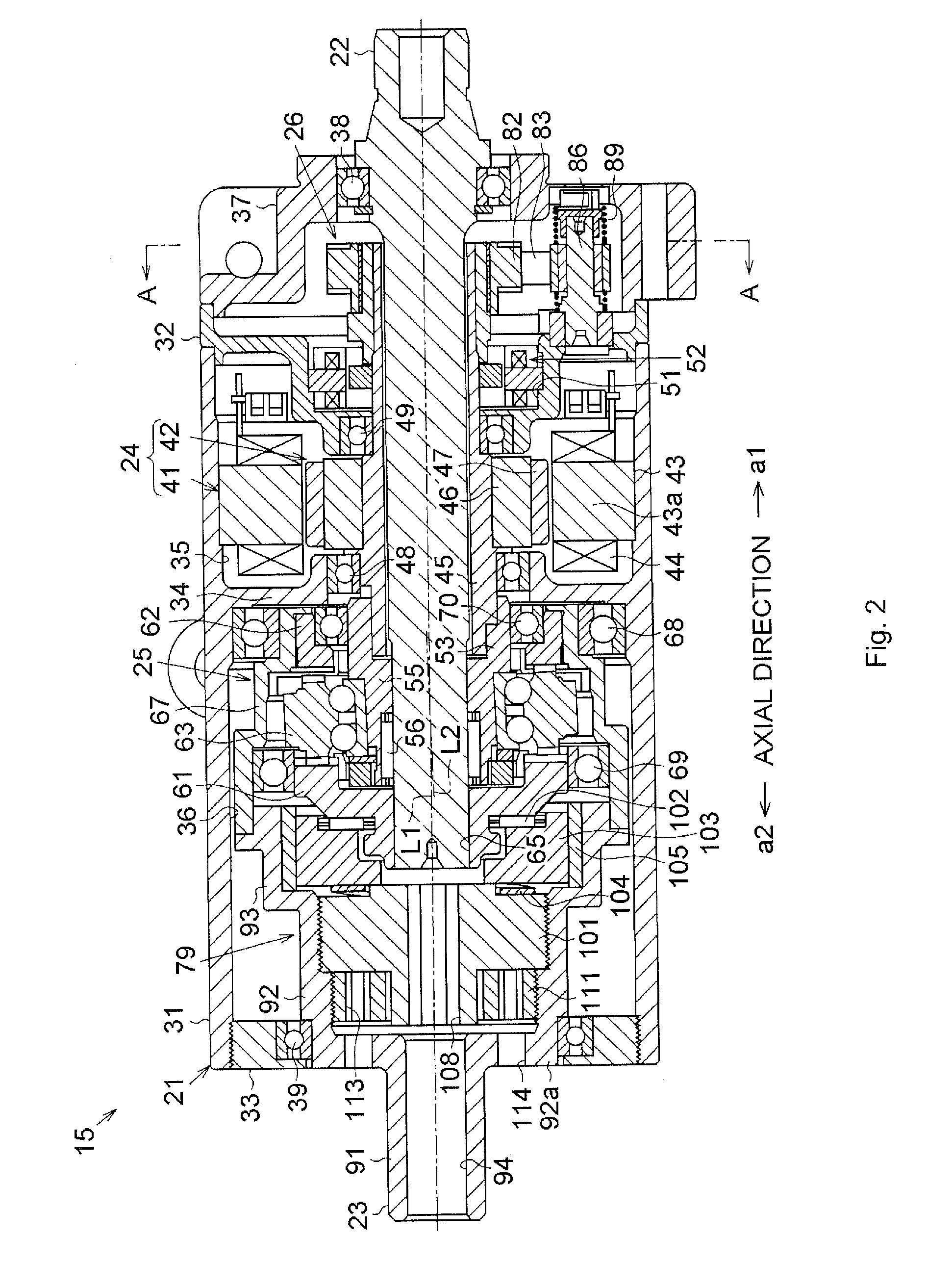

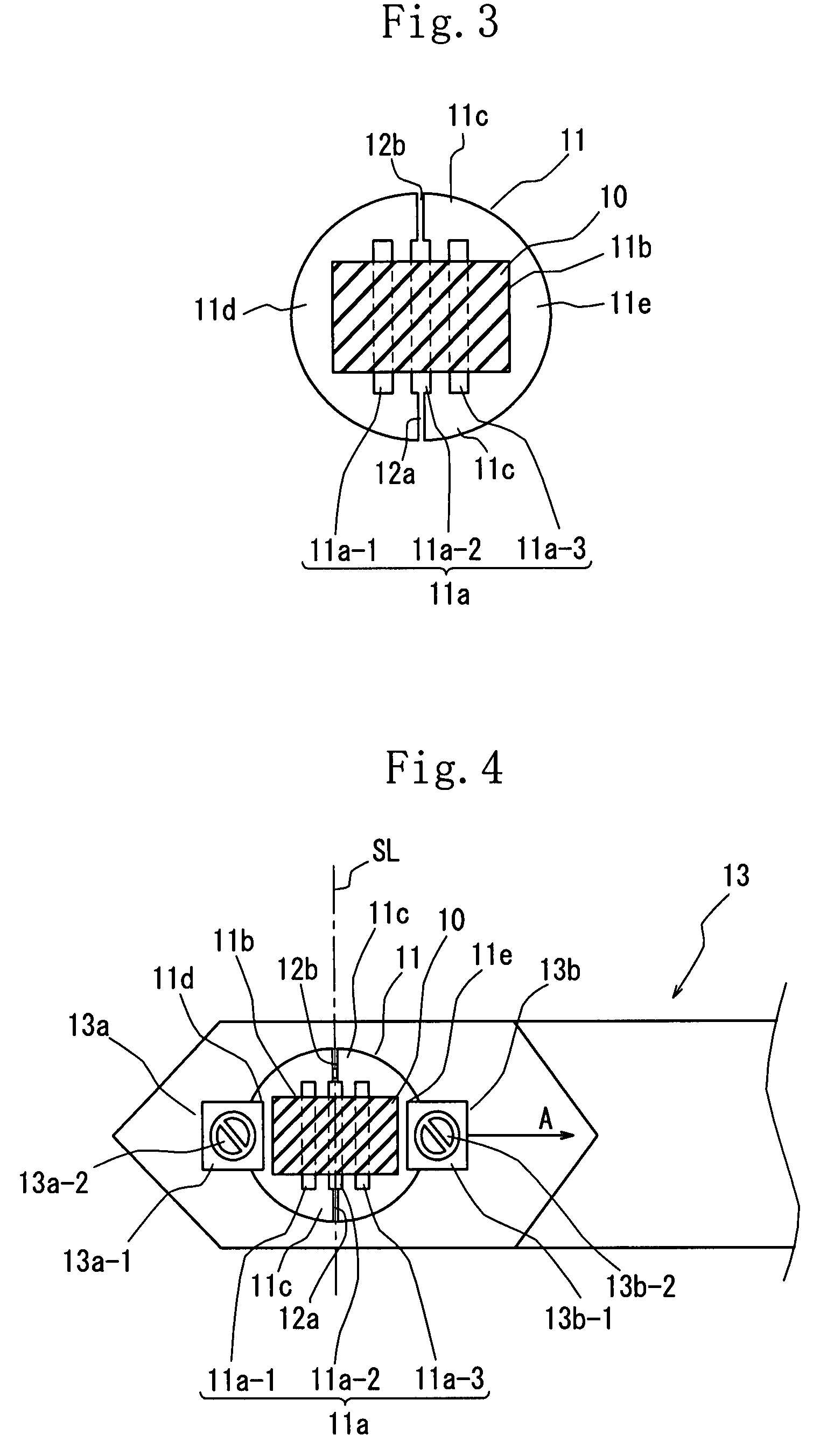

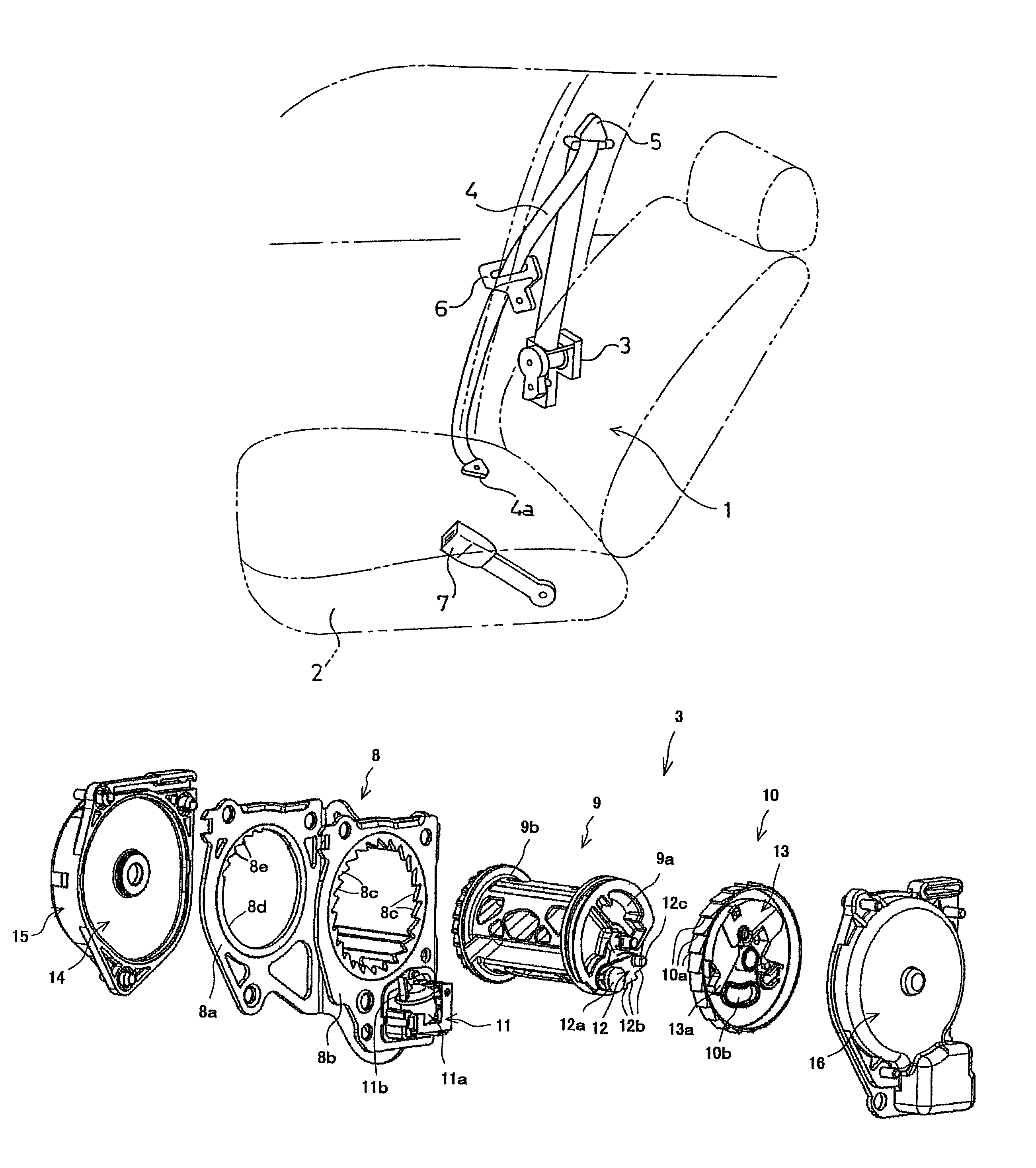

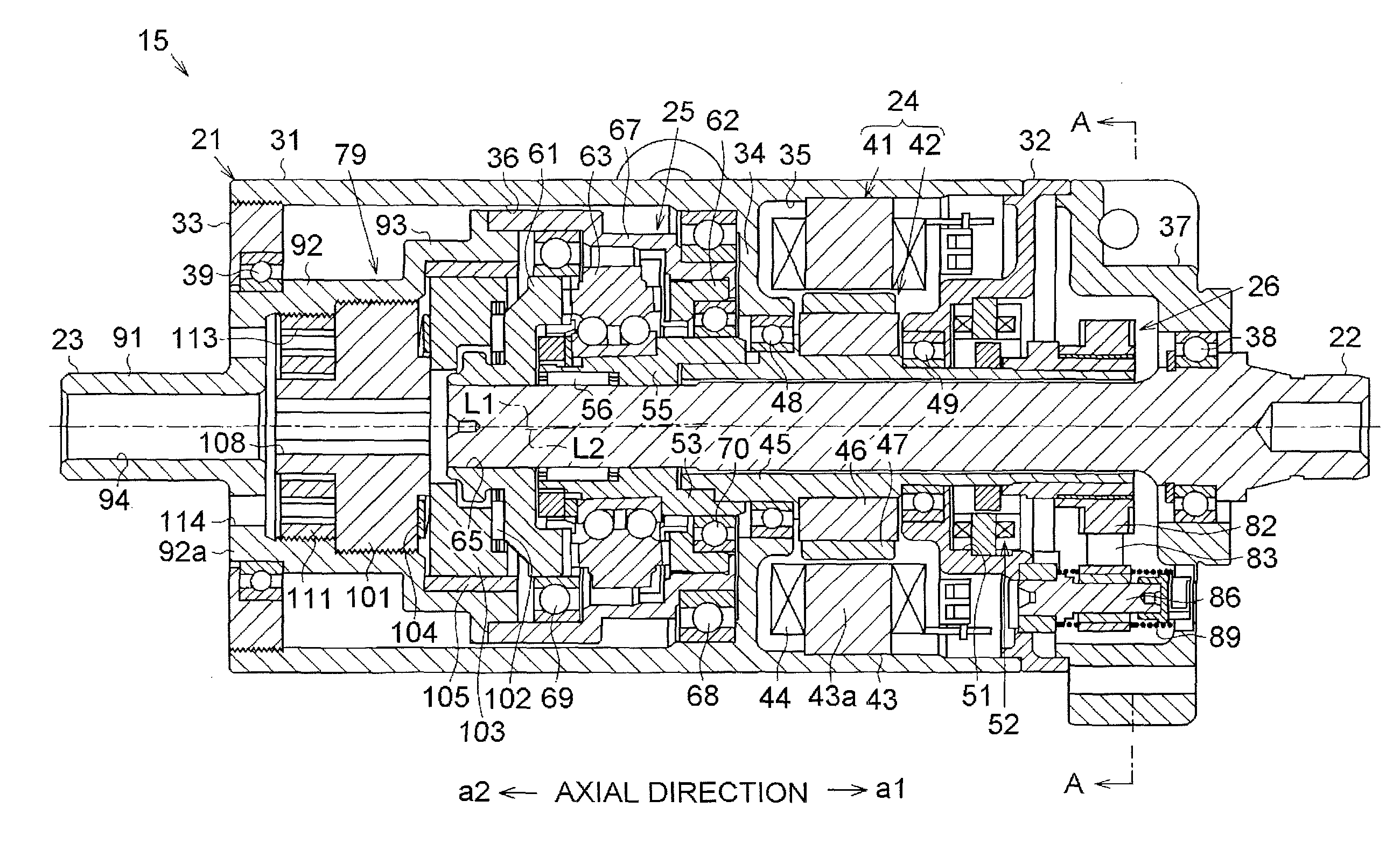

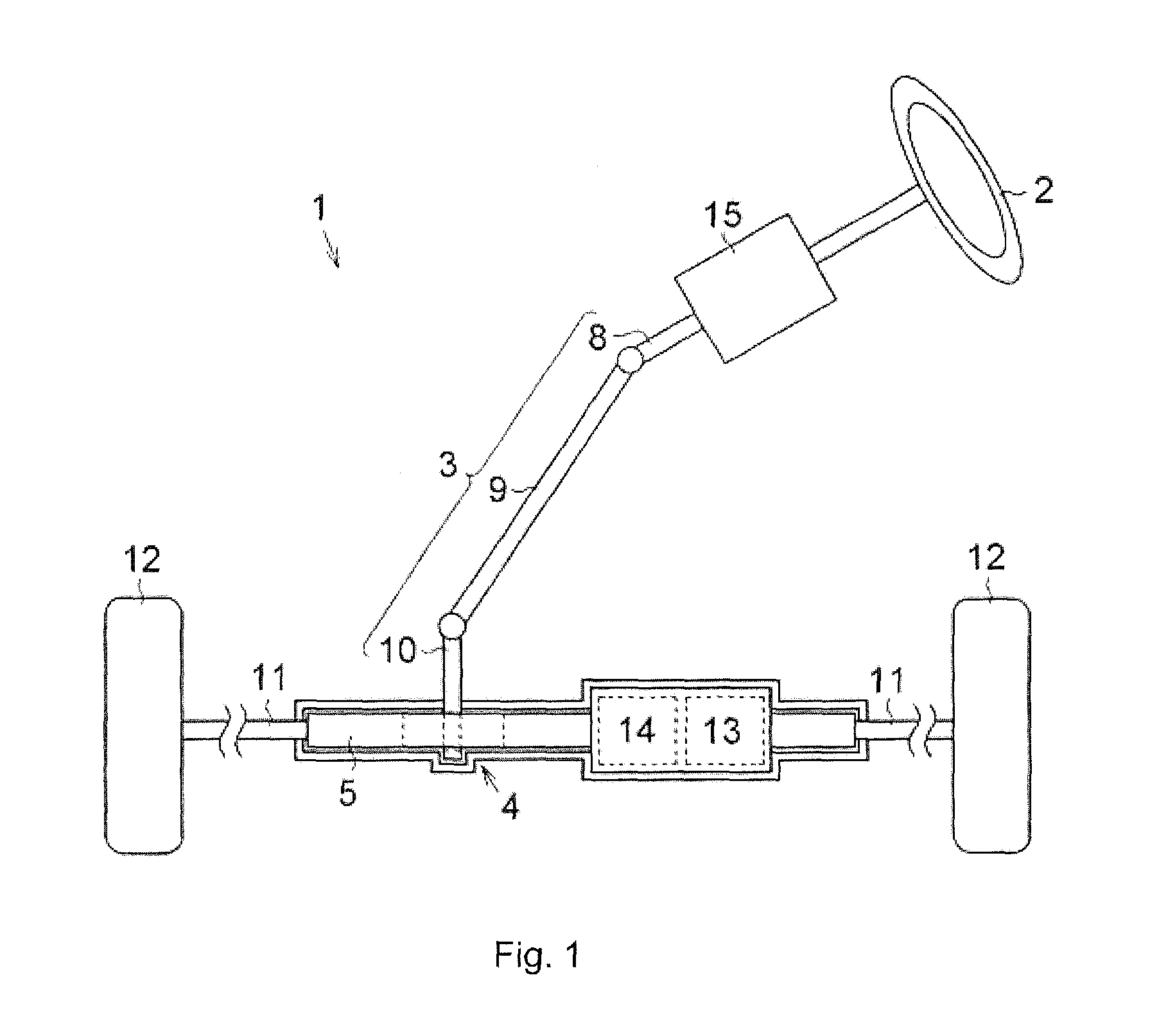

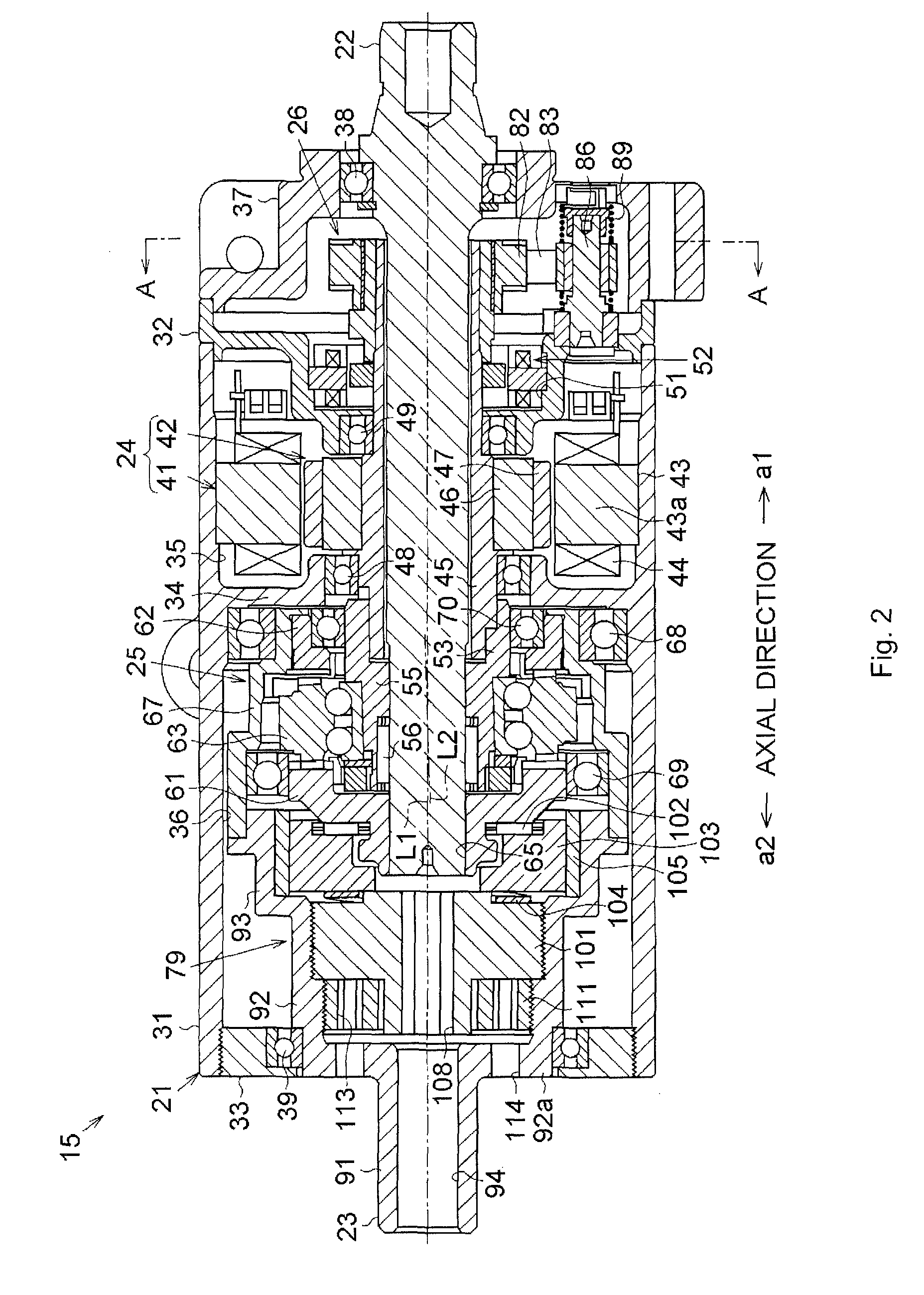

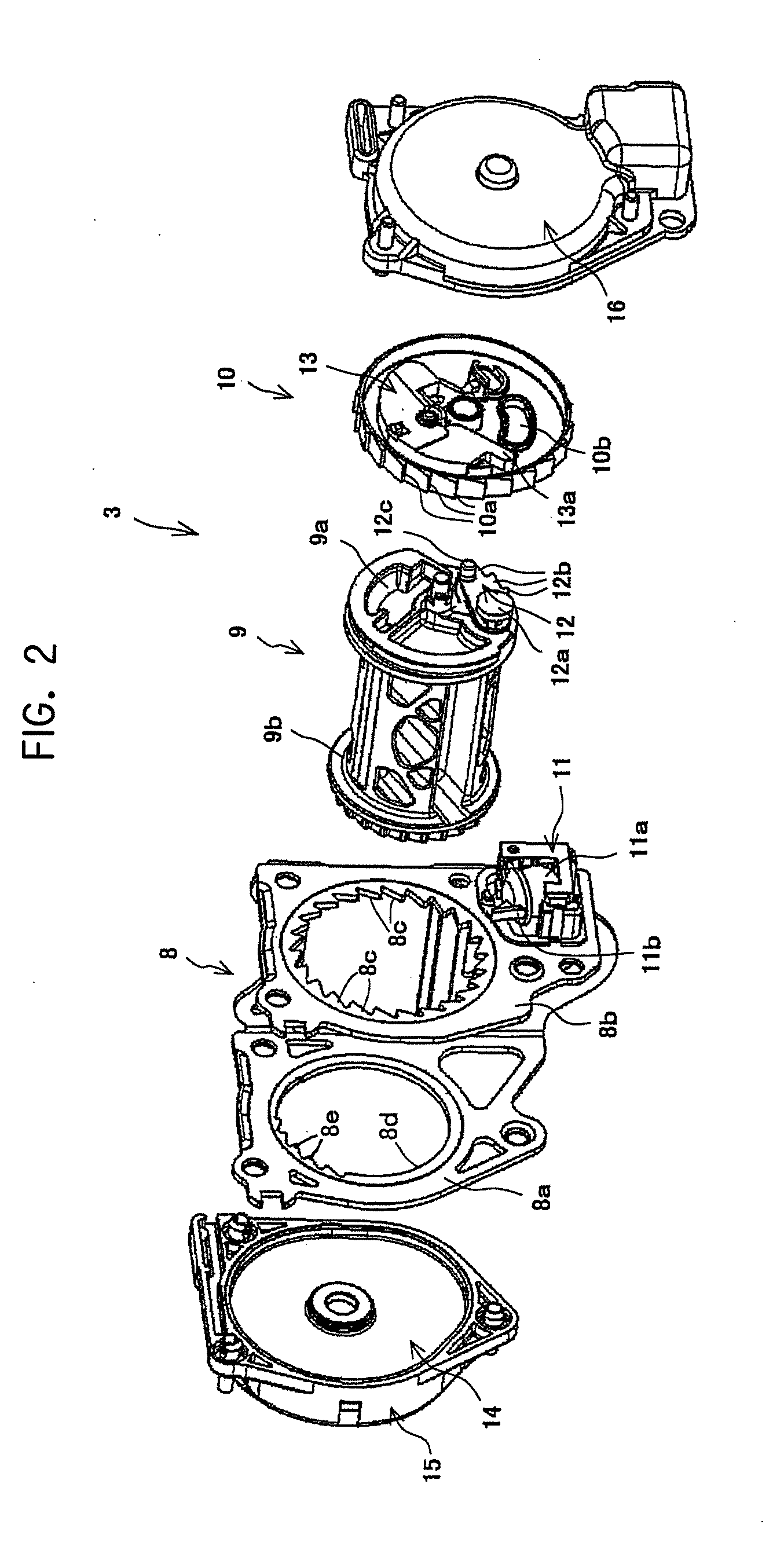

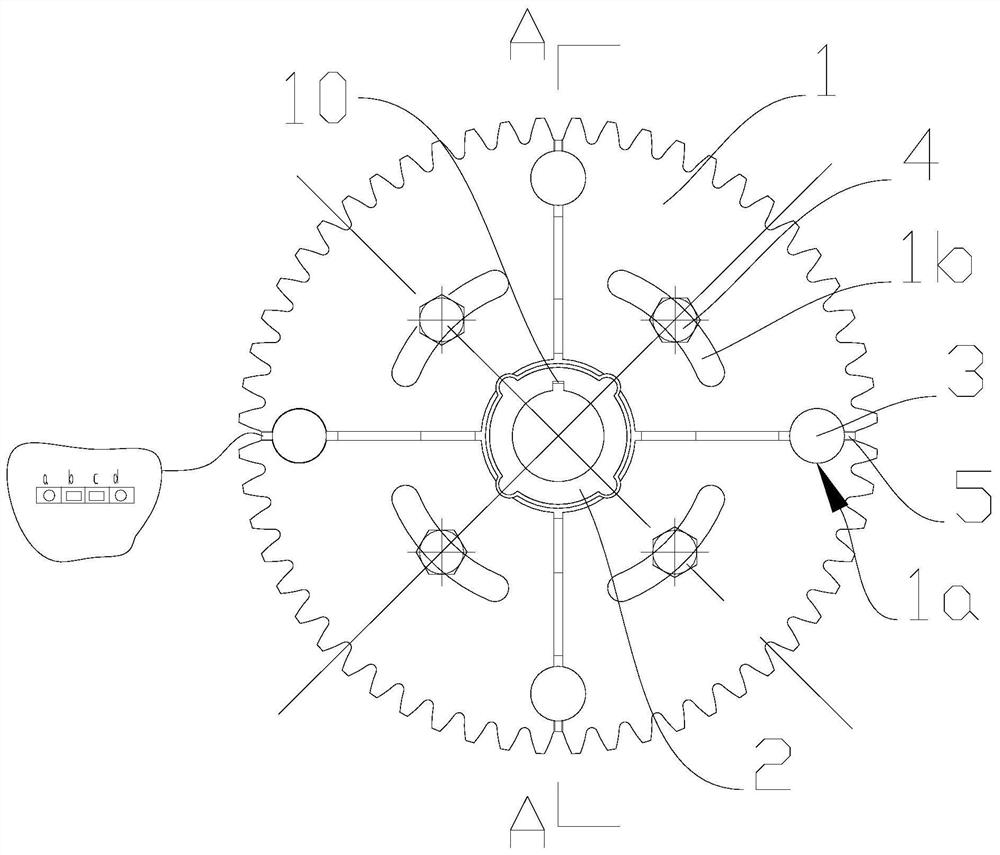

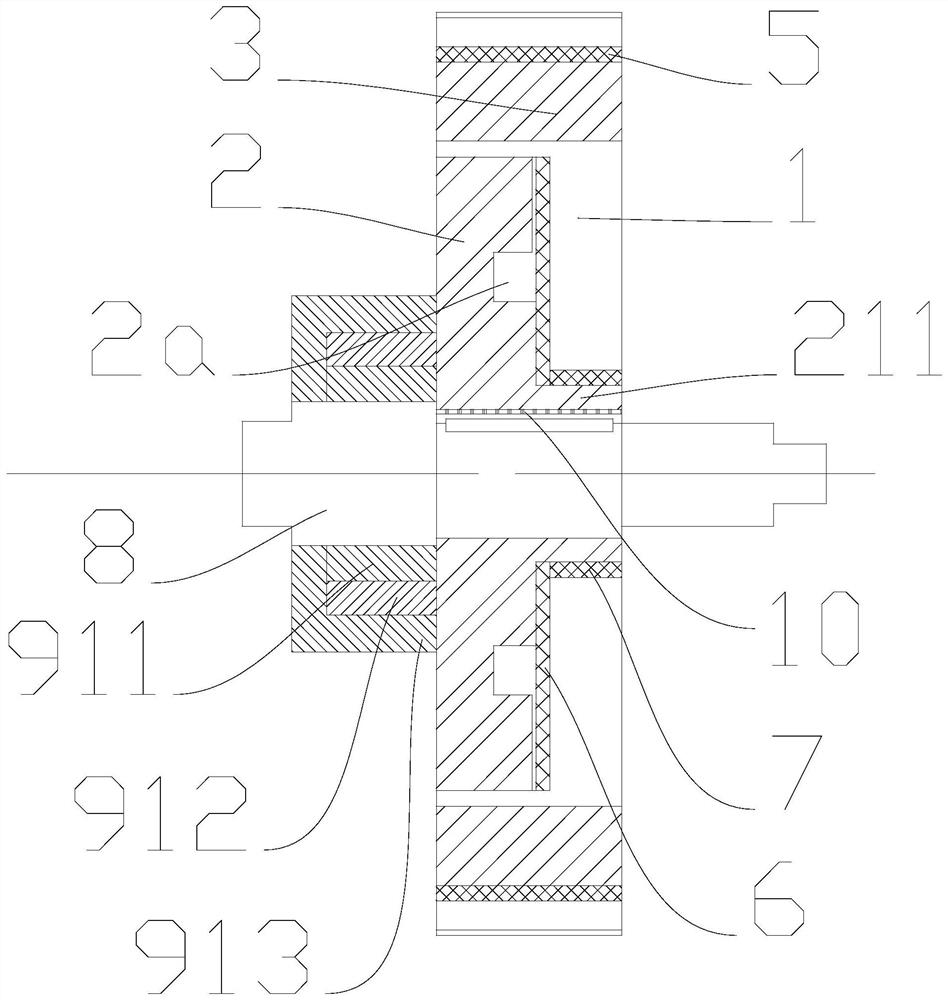

Transmission ratio variable device

InactiveUS20140045636A1Improved meshingReduce variationToothed gearingsPower driven steeringNutationEngineering

A second shaft is configured by a shaft portion extending outside a housing in which a nutation gear mechanism is housed, a housing portion, and a cylindrical portion. A communicating hole, through which an outside and an inside of the housing portion communicate with each other, is formed in the shaft portion. A preload applying mechanism includes a preload adjusting plug that is screwed to the housing portion and is able to be operated from outside through the communicating hole, a wave washer compressed in accordance with a position of the preload adjusting plug, and a lock nut that is screwed to the housing portion of the second shaft so as to press the preload adjusting plug toward the nutation gear mechanism.

Owner:JTEKT CORP

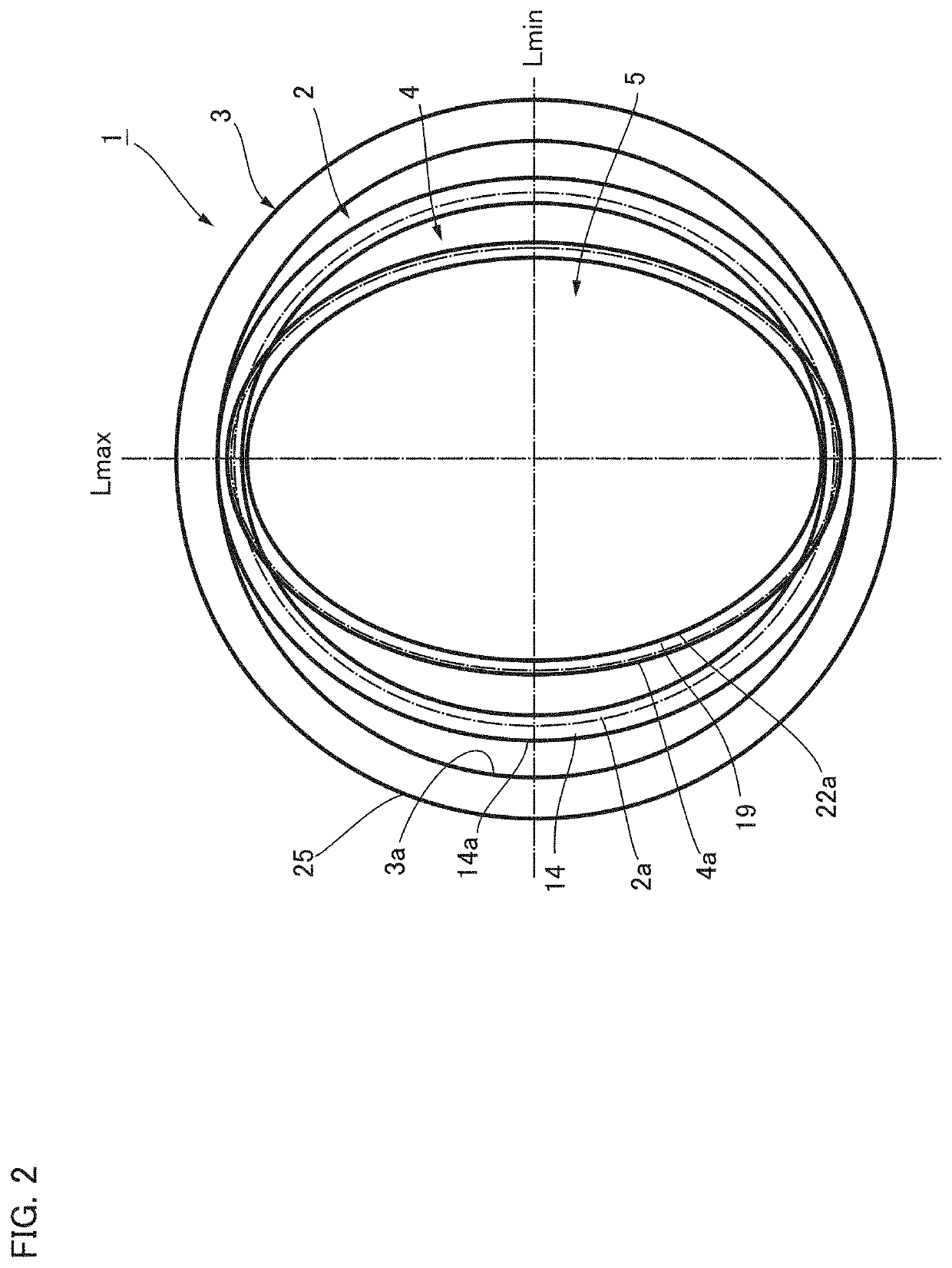

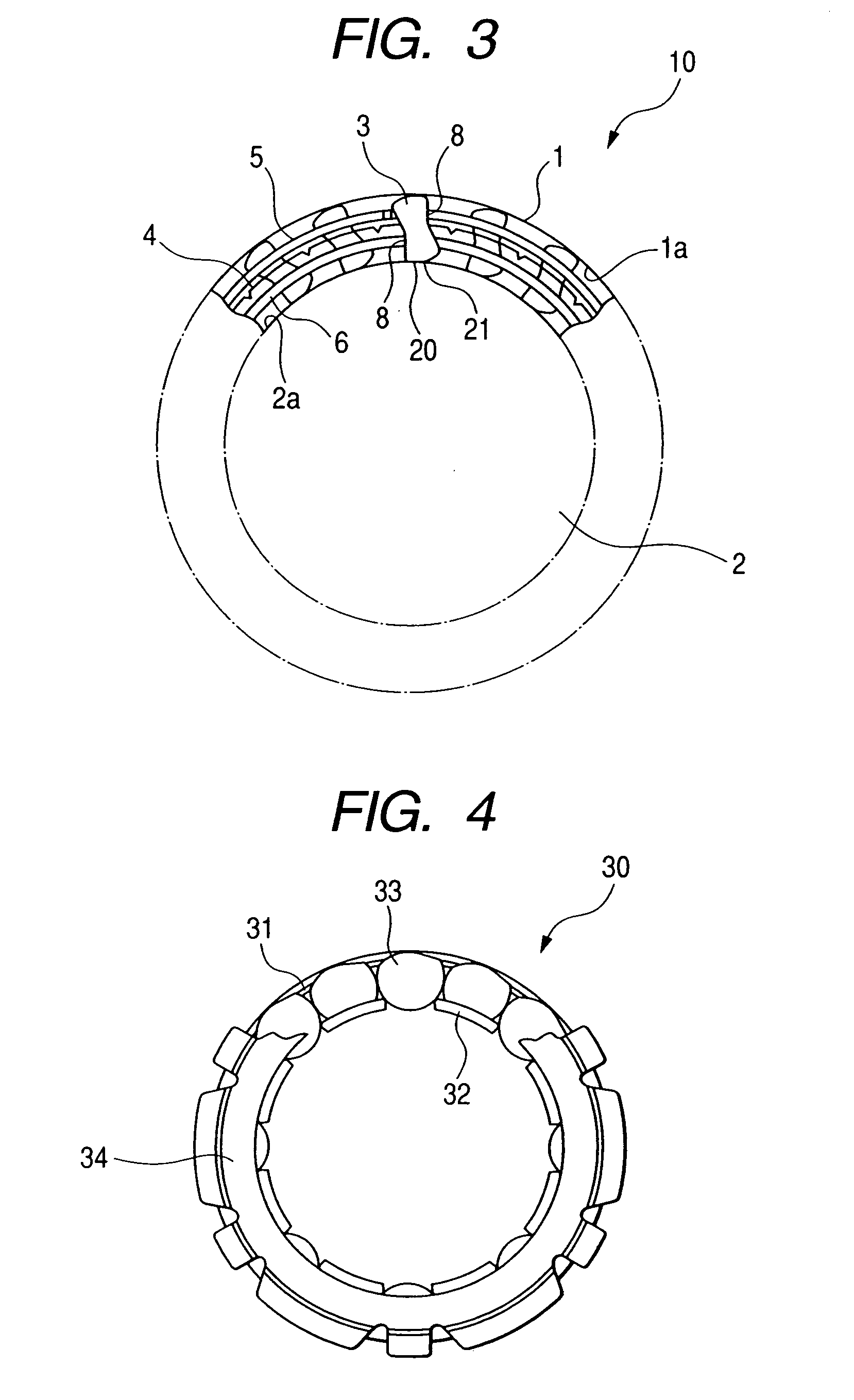

Strain wave gearing

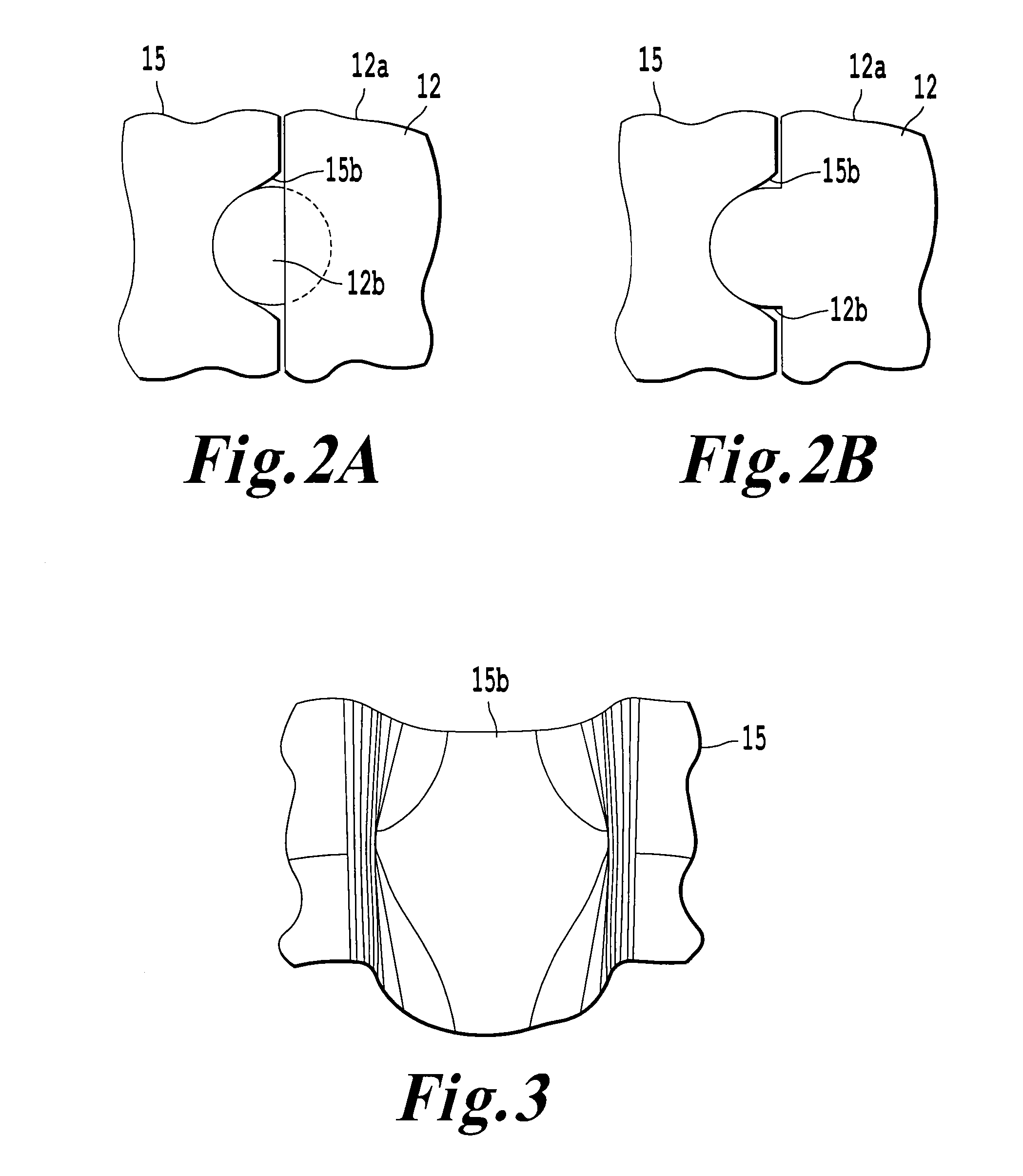

In a strain wave gearing, a flexible externally toothed gear flexed by a wave generator meshes with a flexible internally toothed gear while in an overlapping meshing state. A floating ring, which supports the internally toothed gear from the outer circumferential side, maintains the overlapping state of the meshing and supports the internally toothed gear in a floating state that allows displacement following a state of radial flexion in the tooth trace direction of the internal teeth of the internally toothed gear. Differences between the meshing states of both gears can be alleviated at each position in the tooth trace direction. Degradation in the transmission characteristics and the strength characteristics of the strain wave gearing caused by manufacturing dimensional accuracy of each component and assembly accuracy can be suppressed.

Owner:HARMONIC DRIVE SYST IND CO LTD

New energy street lamp with quick mounting structure

ActiveCN112879858AFixedImproved meshingMechanical apparatusLighting support devicesNew energyEngineering

The invention discloses a new energy street lamp with a quick mounting structure, and belongs to the technical field of new energy, the new energy street lamp comprises a mounting rod, a mounting seat and an adjusting rod, a base is fixedly mounted on the lower surface of the adjusting rod, a sliding groove is formed in the inner wall of one side of the mounting rod, and the base is slidably mounted in the sliding groove. According to the street lamp, adjustment is conducted according to the actual use height of the street lamp through an arranged first threaded column, the adjusting rod is driven to move upwards under the limitation of the base installed at the bottom when the first threaded column rotates through a first threaded groove in the adjusting rod, the base slides in the sliding groove in the mounting rod, and the street lamp is adjusted to the proper height; the rod body can be stored, the height of the rod body can be adjusted, and the problems that due to the fact that an existing street lamp is integrally designed, the length is large, transportation and installation are not convenient, adjustment cannot be conducted according to the actual situation of an installation site, and the street lamp cannot well illuminate the site needing illumination are solved.

Owner:广东顺腾照明科技有限公司

Mesh and method of observing rubber slice technical field

InactiveUS7675043B2Well formedStretch smoothlyMaterial analysis using wave/particle radiationElectric discharge tubesMechanical engineeringMesh grid

Owner:SUMITOMO RUBBER IND LTD

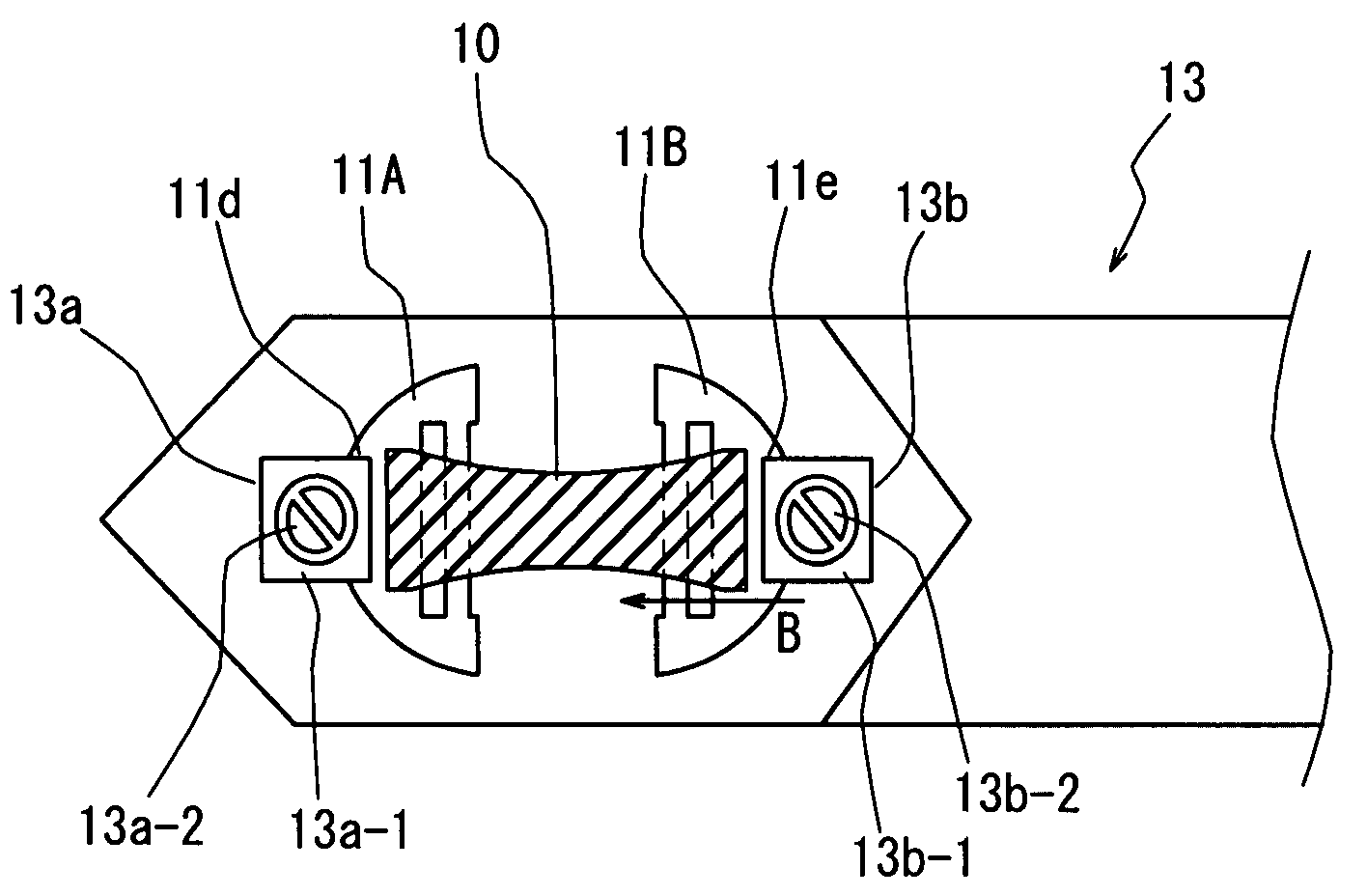

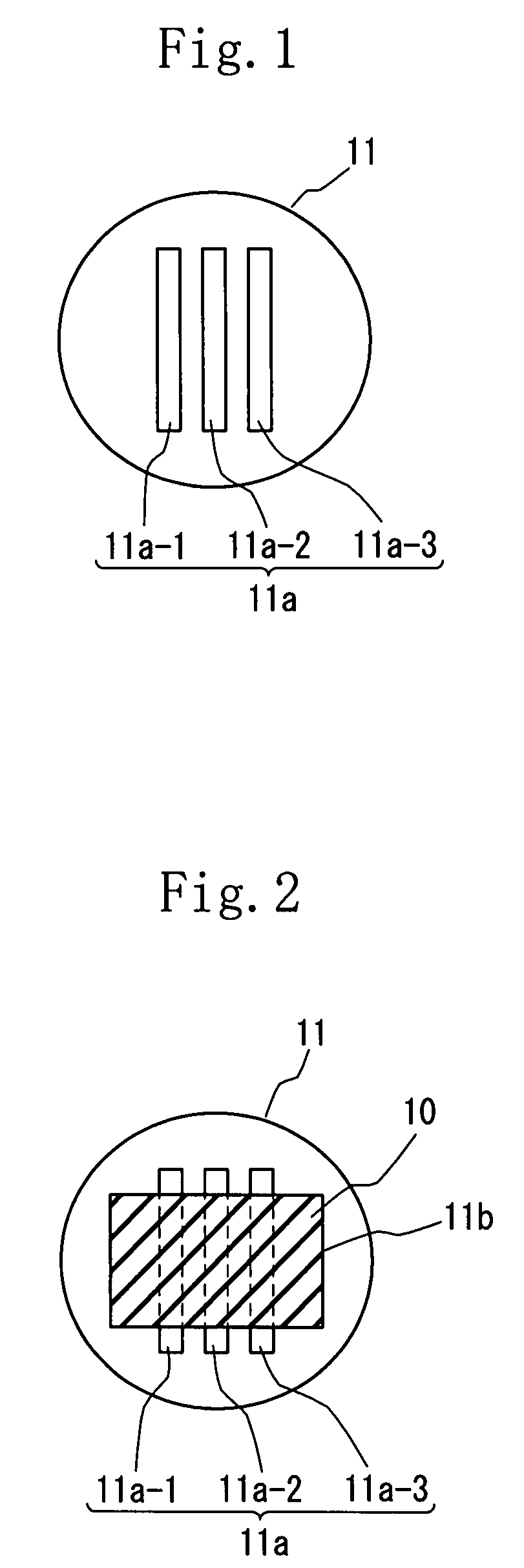

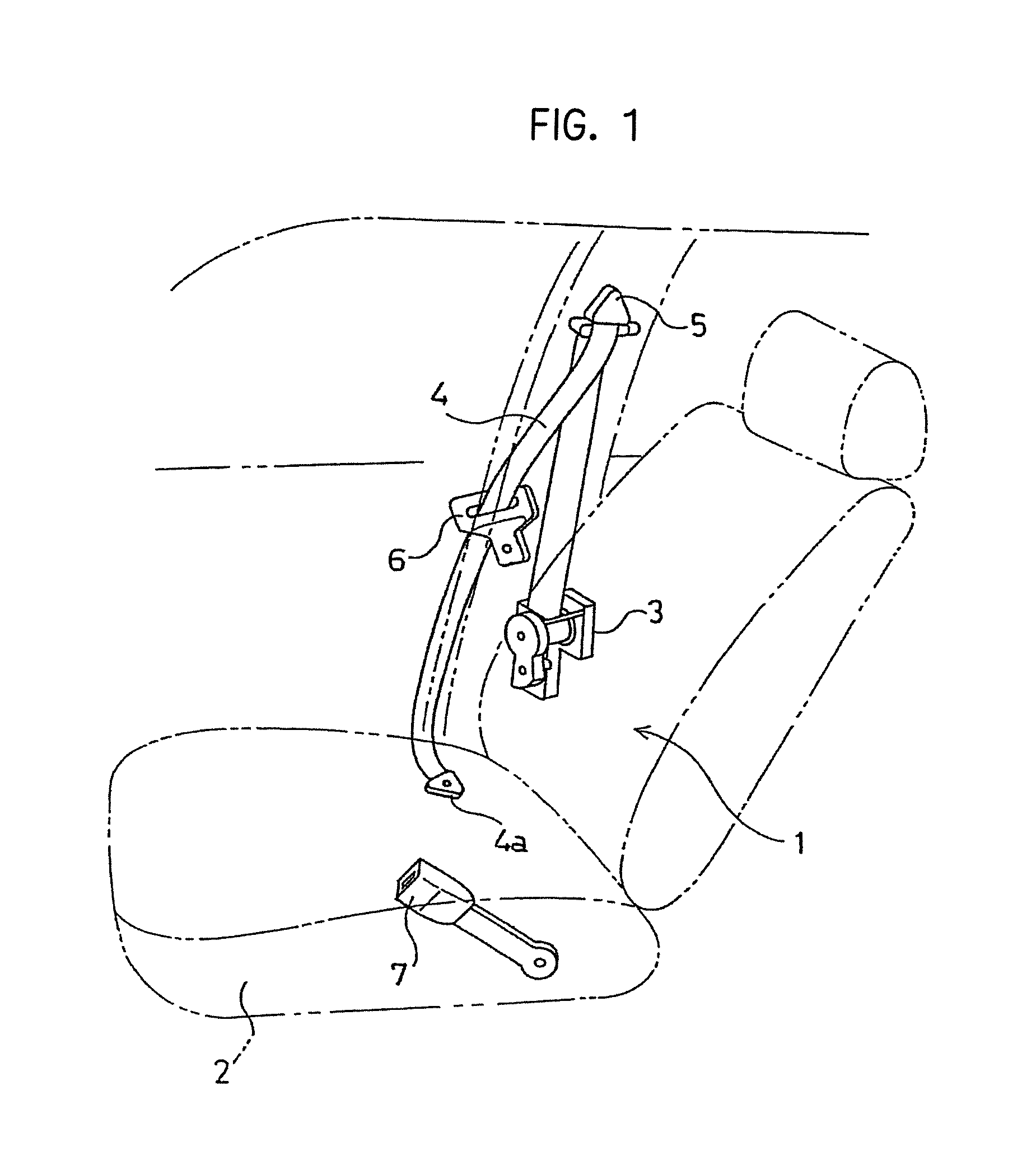

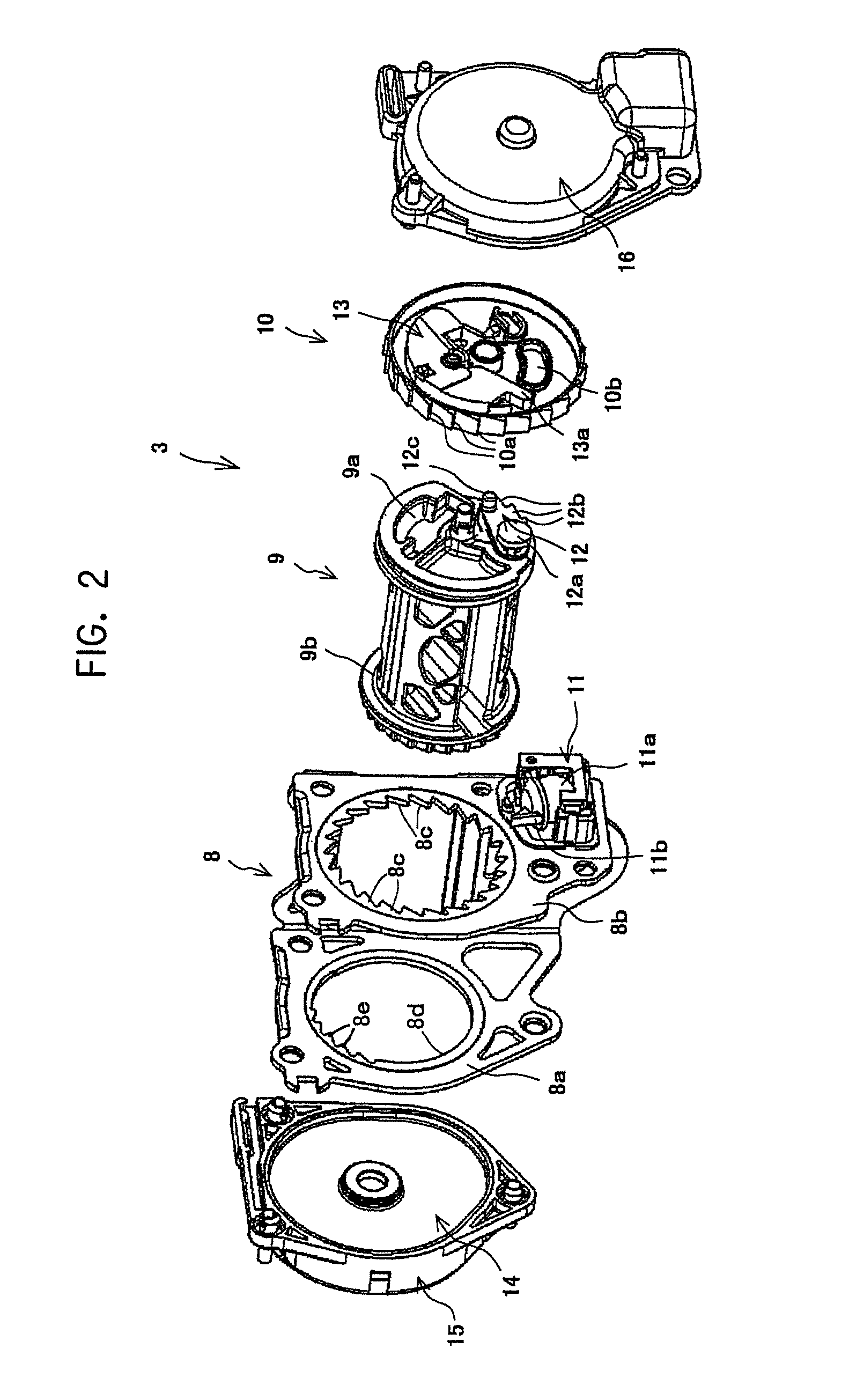

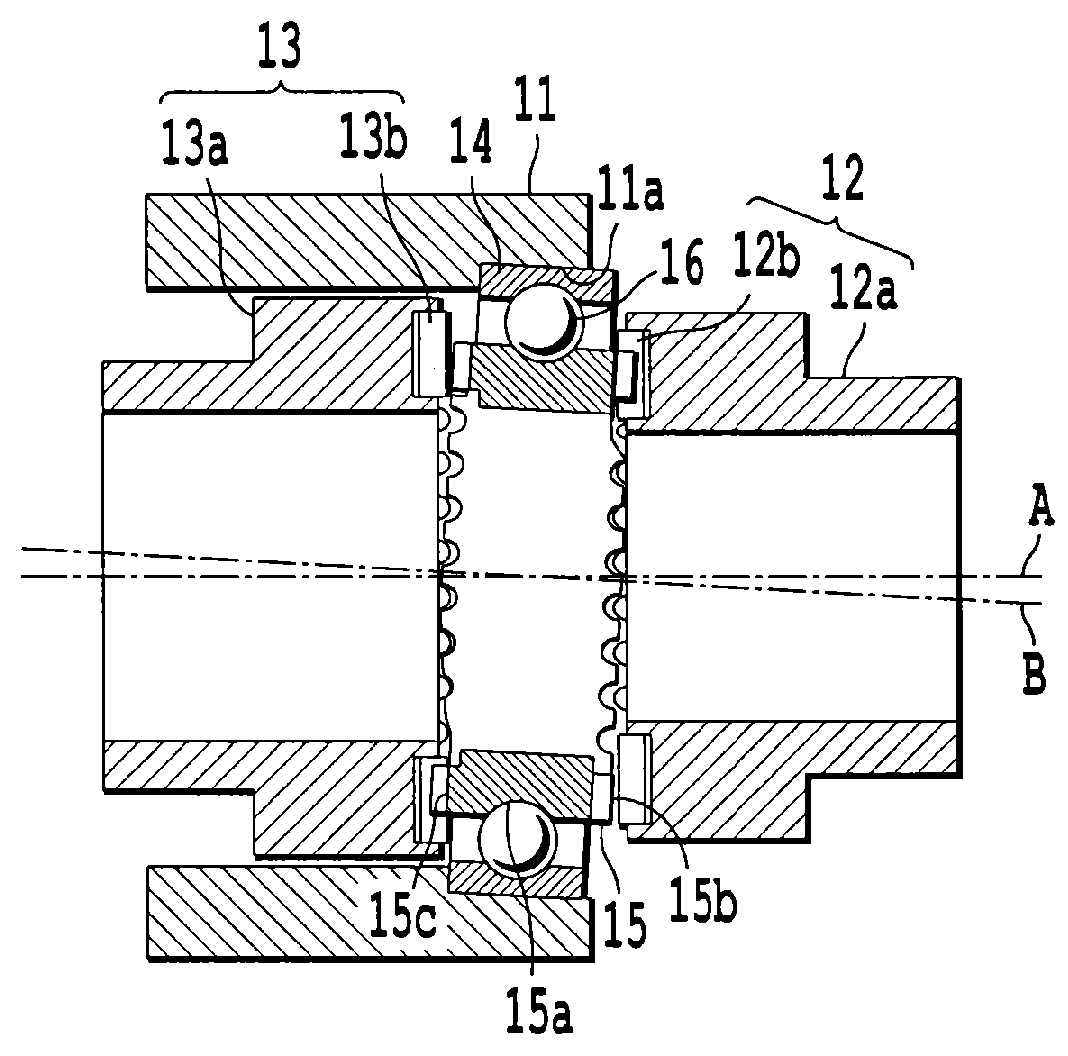

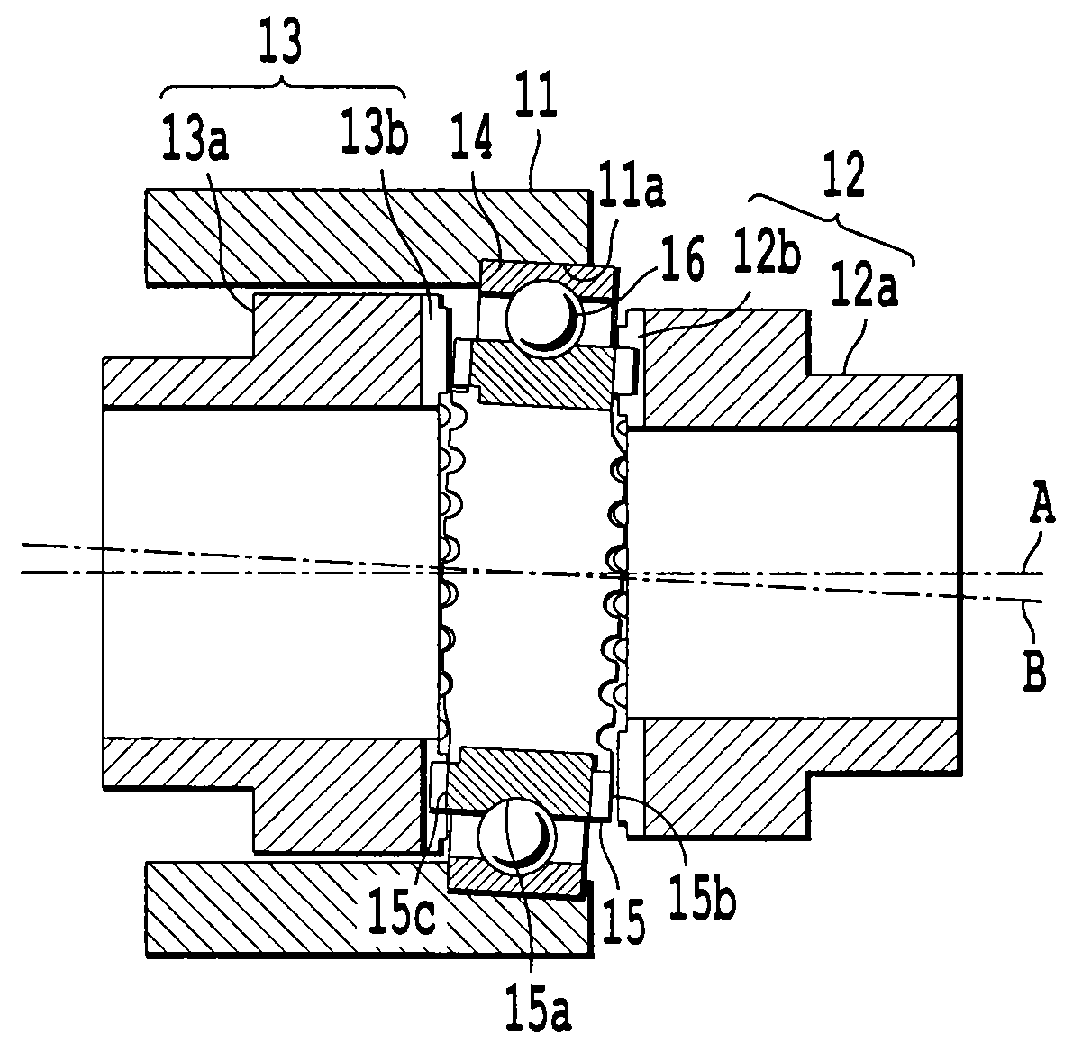

Seat belt retractor and seat belt apparatus including the same

InactiveUS8950819B2Effective engagementEfficient implementationSafety beltsBelt retractorsSeat beltSTI Outpatient

During an emergency, in one form of a retractor having a spool, external teeth of a pawl provided at a spool right side end are made to mesh with some of internal teeth provided on a frame, and, with load acting on a seat belt, a spool left side end is brought into contact with a spool pushing portion. Since the spool left side end tends to be moved further in a direction of seat belt load with the load acting on the seat belt, the spool pushing portion pushes the spool left side end, whereby some of external teeth come into contact with internal teeth provided on the frame and fit deeply into gaps between adjacent ones of the internal teeth. Thus, some of the external teeth of the spool effectively come into mesh with the respective internal teeth of the frame with a simple movement of the spool.

Owner:JOYSON SAFETY SYST JAPAN KK

Processing method and processing device for concave-convex gear

ActiveUS9339879B2Improved meshingEasy to processToothed gearingsGear wheelsTorque transmissionControl theory

Owner:JTEKT CORP

Processing method for concave-convex gear

InactiveUS8777696B2Increase ratingsSmall sizeToothed gearingsGear-cutting machinesNutationEngineering

A relative movement trajectory of each convex tooth pin of a mating gear with respect to a concave-convex gear at the time when torque is transmitted between the mating gear and the concave-convex gear (nutation gear) may be expressed by a first linear axis, a second linear axis, a third linear axis, a fourth rotation axis, a fifth rotation axis and a sixth indexing axis. Then, a relative movement trajectory of each convex tooth pin of the mating gear, expressed by the first linear axis, the second linear axis, the third linear axis, the fifth rotation axis and the sixth indexing axis in the case where the fourth rotation axis is brought into coincidence with the sixth indexing axis, is calculated, and at least one of a disc-shaped workpiece and a working tool is moved on the basis of the calculated relative movement trajectory.

Owner:JTEKT CORP

Transmission ratio variable device

InactiveUS8784253B2Improved meshingReduce variationToothed gearingsDifferential gearingsNutationEngineering

A second shaft is configured by a shaft portion extending outside a housing in which a nutation gear mechanism is housed, a housing portion, and a cylindrical portion. A communicating hole, through which an outside and an inside of the housing portion communicate with each other, is formed in the shaft portion. A preload applying mechanism includes a preload adjusting plug that is screwed to the housing portion and is able to be operated from outside through the communicating hole, a wave washer compressed in accordance with a position of the preload adjusting plug, and a lock nut that is screwed to the housing portion of the second shaft so as to press the preload adjusting plug toward the nutation gear mechanism.

Owner:JTEKT CORP

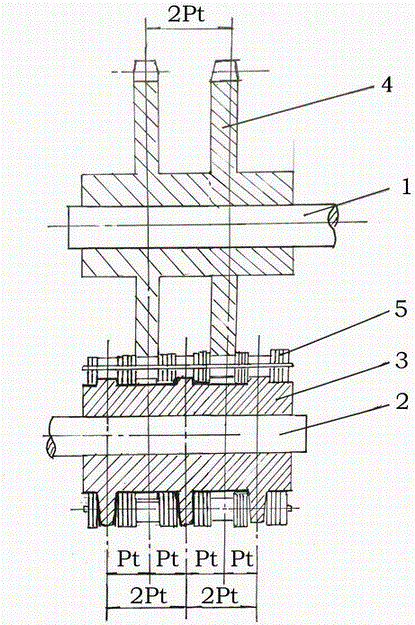

High-bearing coal mining machine walking system

PendingCN110644989AImprove carrying capacityImprove reliabilityPropulsionMining engineeringGear wheel

The invention relates to a high-bearing coal mining machine walking system which comprises a guide sliding shoe, a walking gear and a pin row. The walking gear and the pin row are engaged with each other. The walking gear is provided with double rows of gear teeth, and the structure parameters of the double rows of gear teeth are the same. The pin row is provided with double rows of tooth grooves,and the structure parameters of the double rows of tooth grooves are the same. The gear teeth and the tooth grooves are correspondingly engaged according to rows. The tooth faces of the gear teeth are outwards convex surfaces in the tooth width direction, correspondingly, the groove walls of the tooth grooves are inwards concave surfaces in the tooth width direction, and the walking gear and thepin row are in a mutually concave-convex embedded state on the normal sections of all engagement positions of the tooth profile of any gear tooth. The high-bearing coal mining machine walking system is high in bearing capability, high in reliability and capable of adapting to horizontal bending of the pin row, stress concentration cannot be generated on the edge of a gear of the walking gear, andthe high-bearing coal mining machine walking system can better meet the requirements for large-mining-height and large-powder direction development of coal mining machines.

Owner:SHANGHAI BRANCH TIANDI SCI&TECH CO LTD +1

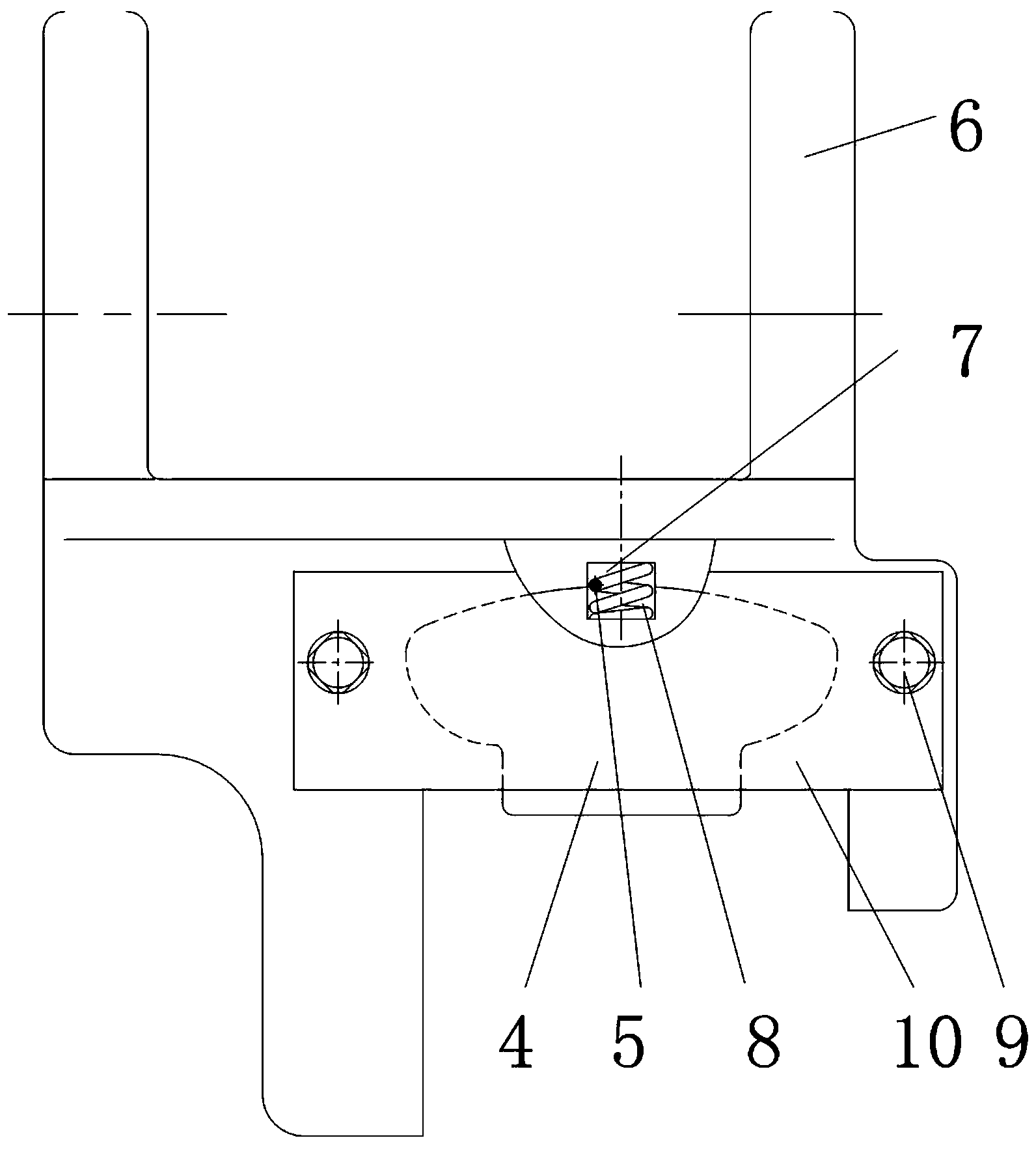

Non-guide foot of coal cutter

The invention provides a non-guide foot of coal cutter. The non-guide foot comprises a non-guide foot body, wherein two side surfaces, which are contacted with two sides of a scraper conveyor cogged rail, of the non-guide foot are a plate type structure, wear-resistant plate mounting slots are formed in two ends of the non-guide foot body, wear-resistant devices are arranged in the wear-resistant plate mounting slots and are positioned by baffles which are arranged in the ends of the non-guide foot body, each wear-resistant device consists of wear-resistant plates and springs, grooves are formed in the wear-resistant plate, one ends of the spring are arranged in the grooves of the wear-resistant plate, grooves corresponding to those on the wear-resistant plates are formed at the wear-resistant plate mounting slots on the non-guide foot body, and the other ends of the springs are arranged in the grooves in the wear-resistant plate mounting slots on the non-guide foot body. According to the non-guide foot, the walking part of the coal cutter can be prolonged, the coal cutting production efficiency can be further increased, the equipment loss and fault rate can be reduced, the change is convenient and the production cost can be lowered.

Owner:HARBIN ENG UNIV

Seat belt retractor and seat belt apparatus including the same

InactiveUS20130154337A1Efficient implementationSimple actionSafety beltsBelt retractorsSeat beltEngineering

During an emergency, in one form of a retractor having a spool, external teeth of a pawl provided at a spool right side end are made to mesh with some of internal teeth provided on a frame, and, with load acting on a seat belt, a spool left side end is brought into contact with a spool pushing portion. Since the spool left side end tends to be moved further in a direction of seat belt load with the load acting on the seat belt, the spool pushing portion pushes the spool left side end, whereby some of external teeth come into contact with internal teeth provided on the frame and fit deeply into gaps between adjacent ones of the internal teeth. Thus, some of the external teeth of the spool effectively come into mesh with the respective internal teeth of the frame with a simple movement of the spool.

Owner:JOYSON SAFETY SYST JAPAN KK

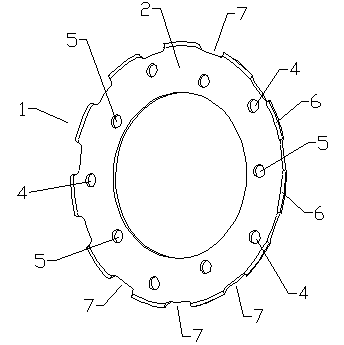

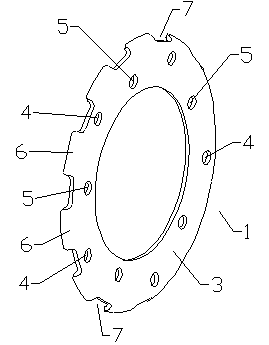

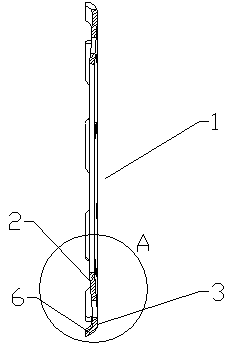

Gear adjusting gasket and differential

The invention relates to a gear adjusting gasket and a differential. The gear adjusting gasket is provided with an inner side surface, an outer side surface and inclinations alpha which incline towards the outer side surface, the adjusting gasket is provided with a plurality of first lubrication holes and a plurality of second lubrication holes, the first lubrication holes and the lubrication holes are arranged in a staggered mode, the centers of the first lubrication holes and the centers of the second lubrication holes are respectively arranged on circumferences with different radii, the outer edge of the adjusting gasket is provided with extending portions, every extending portion is bent towards the inner side surface of the adjusting gasket to form a cambered surface, and the outer edges of the extending portions are evenly provided with notches which are arranged at intervals. The gear adjusting gasket is arranged between a differential shell and gears, enables the gears to restrict towards the center along an axis all the time, and guarantees gear clearance, so that the gear clearance can be adjusted anytime during the operation of the gears to guarantee two pairs of gears of the differential are in a good engagement state.

Owner:SHENGRUI TRANSMISSION

Strain wave gearing

Owner:HARMONIC DRIVE SYST IND CO LTD

Novel intelligent gear

ActiveCN111828591AImproved meshingEasy meshRotating vibration suppressionMachine part testingGear wheelControl engineering

The invention discloses a novel intelligent gear. The gear comprises a fixing disc and multiple gear modules evenly distributed in the circumferential direction, all the gear modules are fixedly connected with the fixing disc, the outer edges of the gear modules are spliced to form a complete wheel flange, an adjusting body is arranged at the joint between every two adjacent gear modules, and theadjusting bodies are made of variable-rigidity flexible materials; and the gear further comprises a sensor module and an intelligent control system, wherein the sensor module is used for directly sensing and measuring meshing state parameters of the gear and sending the parameters to the intelligent control system, and the intelligent control system is used for processing the parameters sent by the sensor module and controlling the variable-rigidity flexible materials of the adjusting bodies to be subjected to rigidity-flexibility and deformation conversion according to an optimization instruction obtained through processing. According to the provided novel intelligent gear, real-time gear meshing performance monitoring and dynamic gear meshing performance adjusting are integrated, and a closed loop, from meshing performance monitoring to meshing performance adjusting, of the gear is achieved.

Owner:CHONGQING UNIV

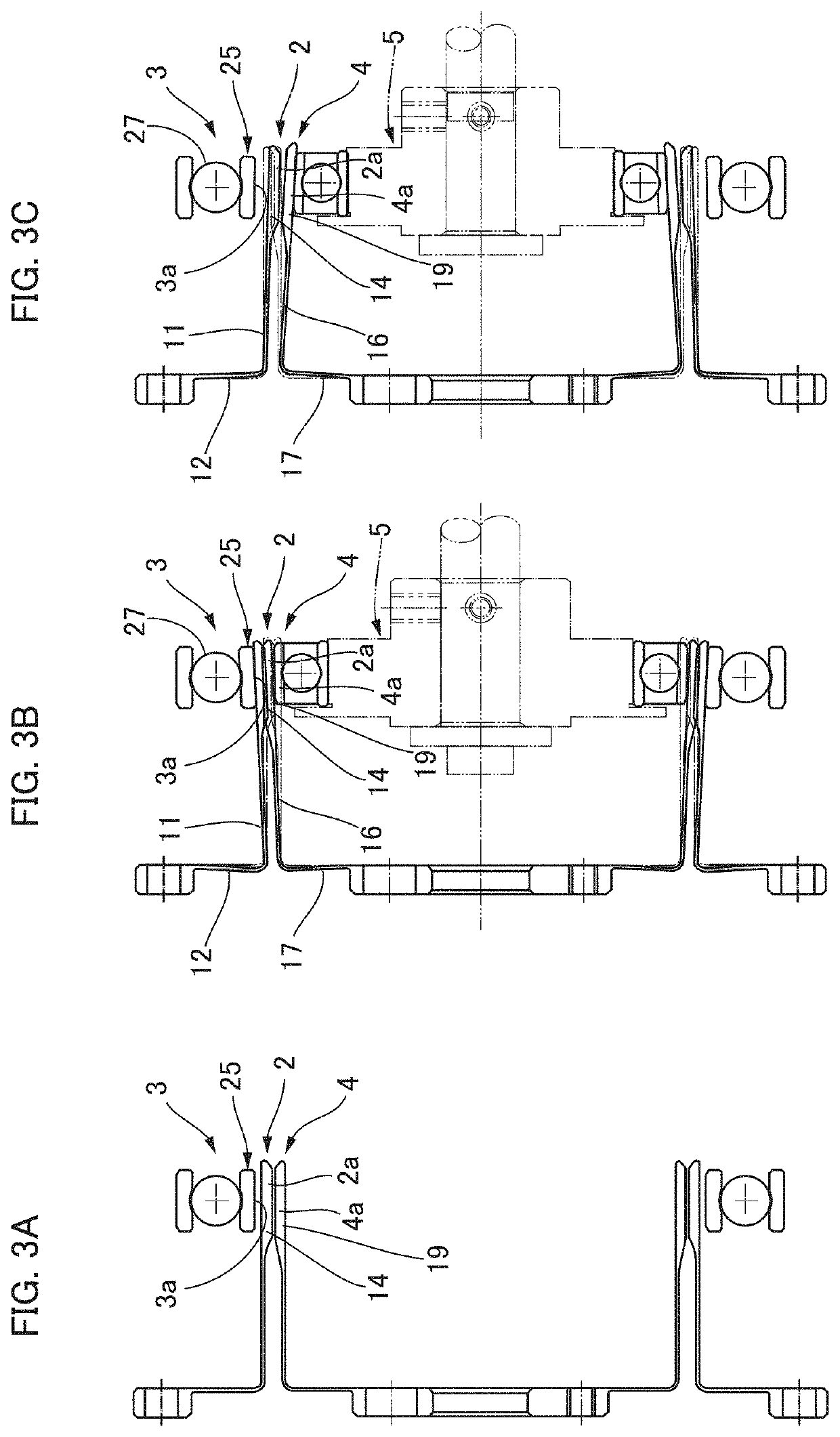

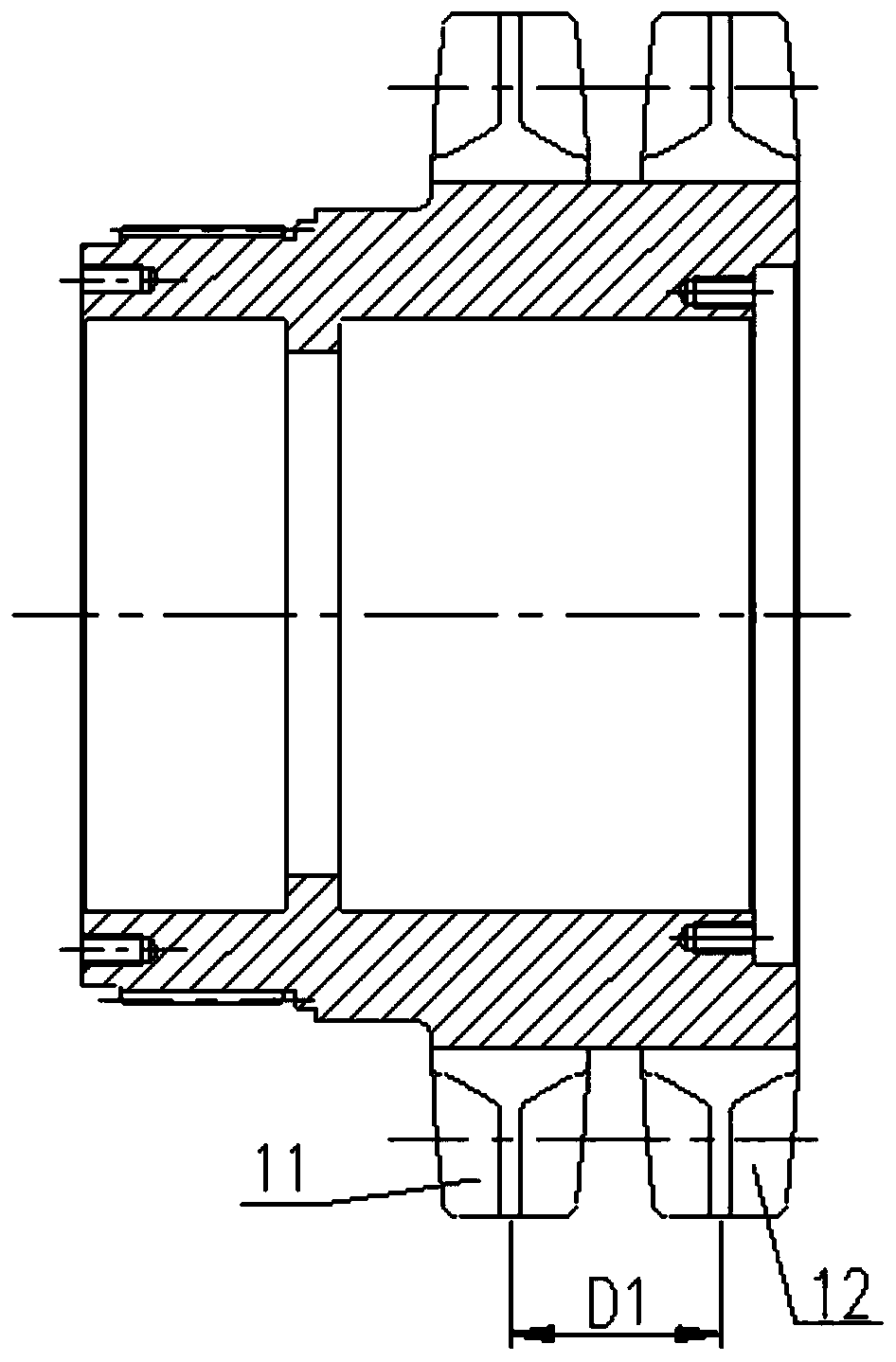

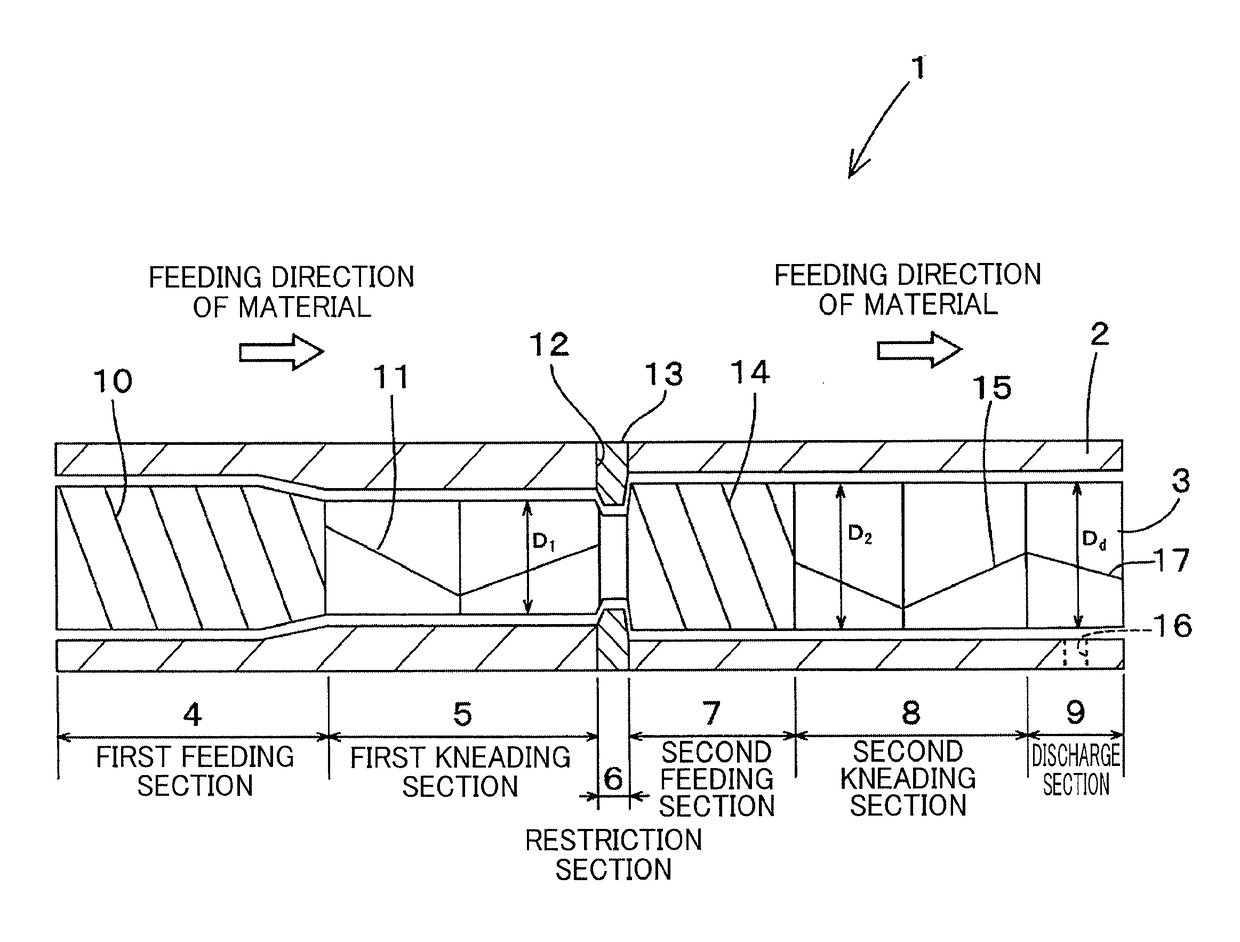

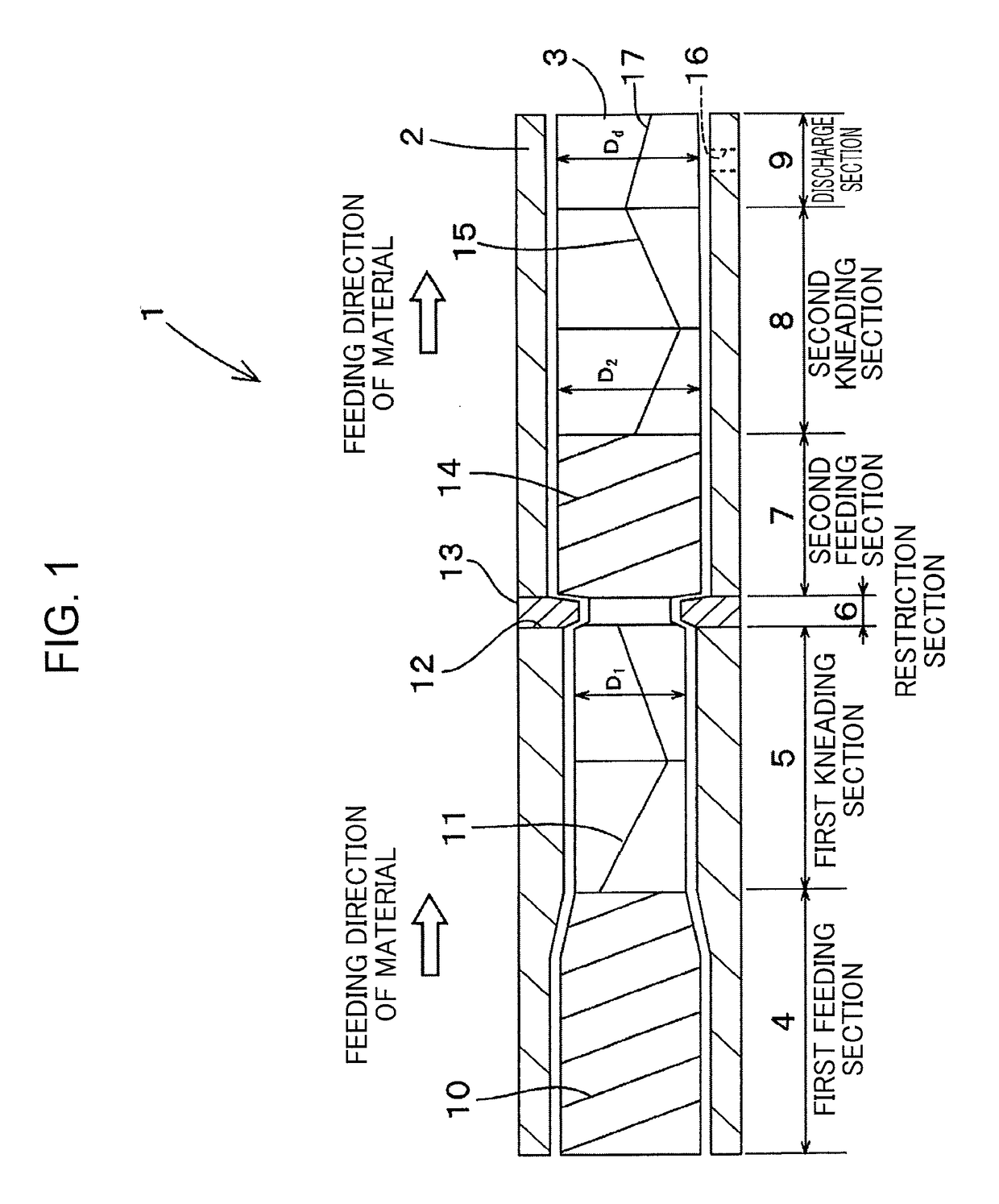

Continuous kneading device

ActiveUS20170173543A1Improved meshingSufficiently kneading evenRotary stirring mixersTransportation and packagingEngineeringMaterial supply

A continuous kneading device (1) includes a pair of kneading rotors (3), being capable of increasing mesh between the kneading rotors (3) while suppressing a kneading load applied to the kneading rotors (3). The continuous kneading device (1) includes a barrel (2) and a pair of kneading rotors (3) housed in the barrel (2) and rotating in mesh in directions different from each other. Each kneading rotor (3) includes a plurality of kneading flights (11, 15) for kneading a material supplied into the barrel (2). The kneading flights (11, 15) and respective portions of the barrel (2) housing the kneading flights (11, 15) respectively configure a plurality of kneading sections aligned axially of the kneading rotors (3). The material is fed axially from the upstream kneading section to the downstream kneading section to be sequentially kneaded. The kneading flight (15) constituting the downstream kneading section has a rotational outer diameter (D2) larger than a rotational outer diameter (D1) of the kneading flight (11) constituting the upstream kneading section.

Owner:KOBE STEEL LTD

Fixing device used during operation

InactiveCN108635063AGuaranteed fixed effectImprove the fixed effectInstruments for stereotaxic surgeryEngineeringThreaded rod

The invention discloses a fixing device used during operation. The fixing device comprises a placement plate, wherein one side of the placement plate is symmetrically provided with two supporting plates, the ends, away from the placement plate, of the two supporting plates are connected through a mounting plate, a first threaded rod is inserted in the mounting plate, the mounting plate is providedwith an insertion port corresponding to the first threaded rod, the first threaded rod is in threaded connection with the inner side wall of the insertion port, one end, close to the placement plate,of the first threaded rod is rotationally connected with a mounting block, one side, away from the first threaded rod, of the mounting block is symmetrically provided with mounting grooves, the innerside walls of the mounting grooves are rotationally connected with arc-shaped clamping plates through first rotating shafts, the sides, away from the first rotating shafts, of the arc-shaped clampingplates are rotationally connected with first sliding blocks through turnbuckles, and the supporting plate is provided with first sliding grooves corresponding to the first sliding blocks. The fixingdevice used during the operation has the advantages that the structure is simple, the use is convenient, the fixing effect on the trunk of a patient is ensured, and it can be avoided that the patientis hurt by clamping.

Owner:谷新运

One-way clutch and sprag for the one-way clutch

Owner:NSK WARNER

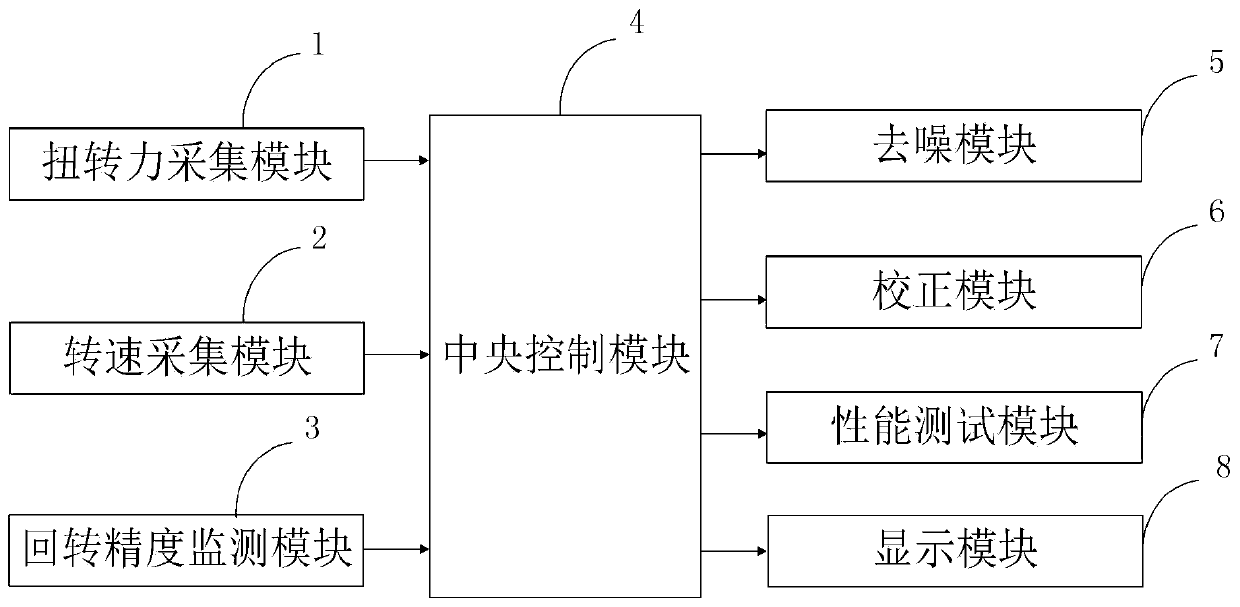

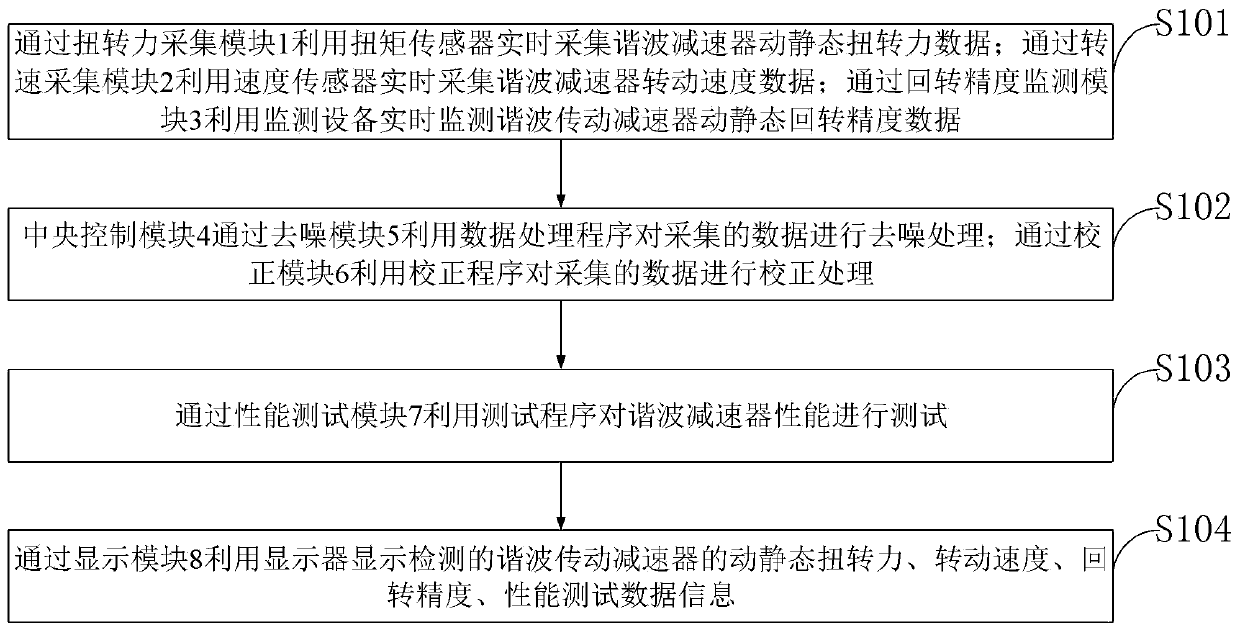

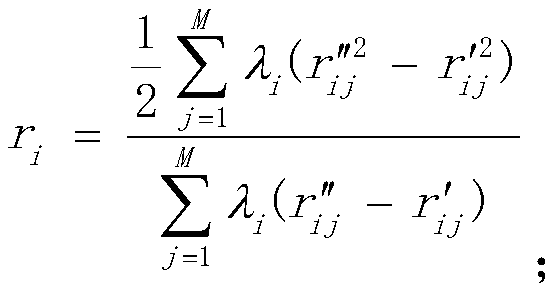

Dynamic and static rotation precision detection system of harmonic reducer

InactiveCN110108482AHigh precisionReduce machining accuracyMachine gearing/transmission testingReduction driveHarmonic

The present invention relates to the technical field of harmonic reducers, and discloses a dynamic and static rotation precision detection system for a harmonic reducer. The dynamic and static rotation precision detection system for a harmonic reducer comprises: a torsion force acquisition module, a torsion speed acquisition module, a rotation precision monitoring module, a central control module,a denoising module, a correction module, a performance test module, and a display module. The detection system adopts the rotation precision monitoring module to be simpler, is more convenient to use, has a higher precision test method, and is particularly suitable for detection and use of the harmonic reducer before leaving factory; adopts the performance test module to test the transmission performance of the harmonic reducer, controls processing and assembly precision of flexible wheels, also helps to improve meshing state and lubrication state of a working surface of the harmonic reducer,and improves transmission performance of the space lubrication harmonic reducer.

Owner:YANCHENG INST OF TECH

Rack and pinion steering unit

InactiveCN102892663BLarge operating forceIncrease the operating assist forceMechanical steering gearsGearing elementsNeedle roller bearingSteering wheel

A rack and pinion steering gear unit is achieved that is capable of preventing an increase in operating force of the steering wheel and auxiliary operating force from a motor, and improving the response performance to minute operation when traveling straight. A pressing roller 34 elastically pushes the rear surface 29 of a rack shaft 9 toward a pinion shaft 5. This pressing roller 34 is supported by way of a radial needle bearing 16a by a support shaft 33 that is supported by and fastened to a holder 30 so as to be able to rotate freely. A thrust needle bearing 35 that receives a thrust load that is applied to the pressing roller 34 is provided between both side surfaces in the axial direction of the pressing roller 34 and the inside surface of the holder 30.

Owner:NSK LTD

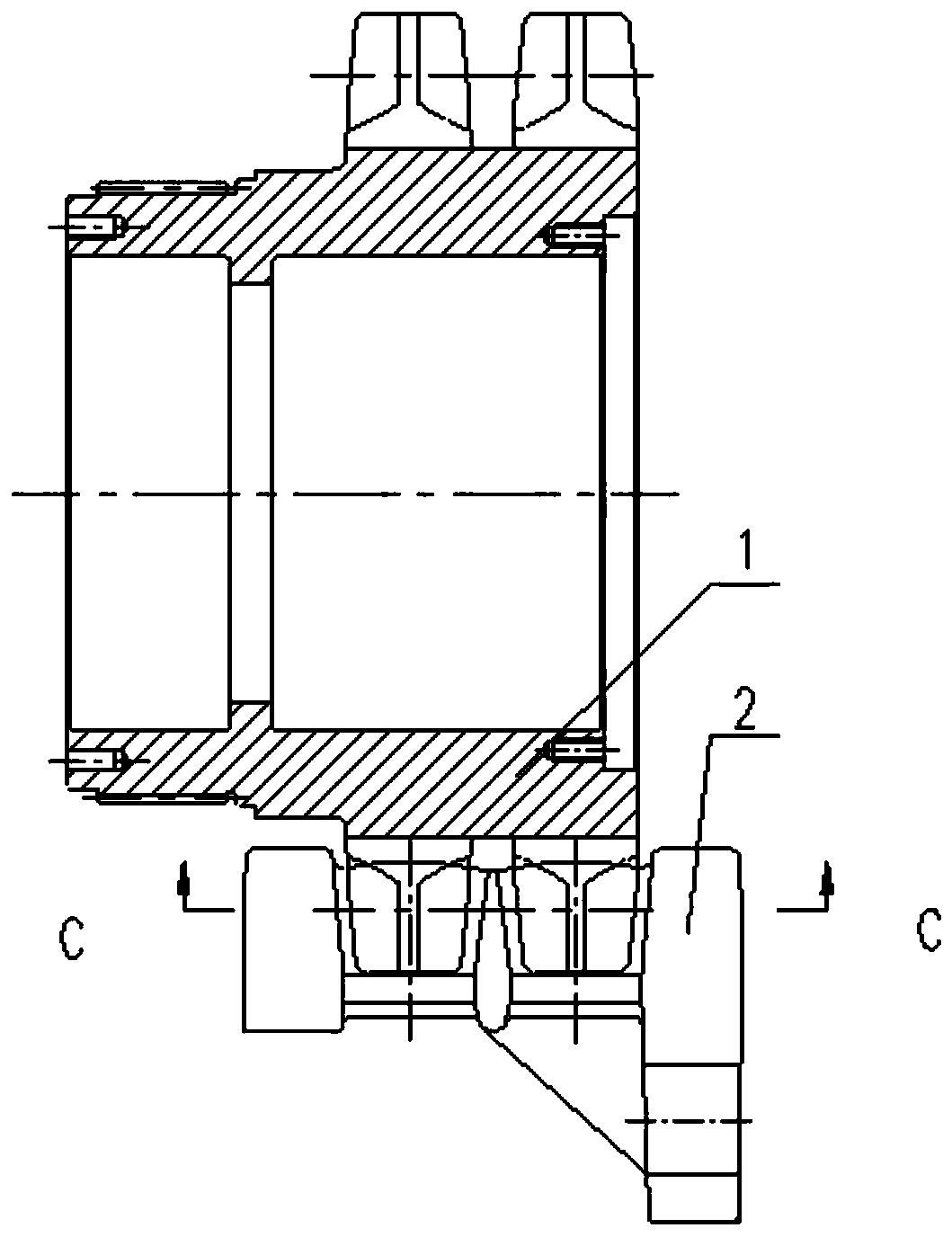

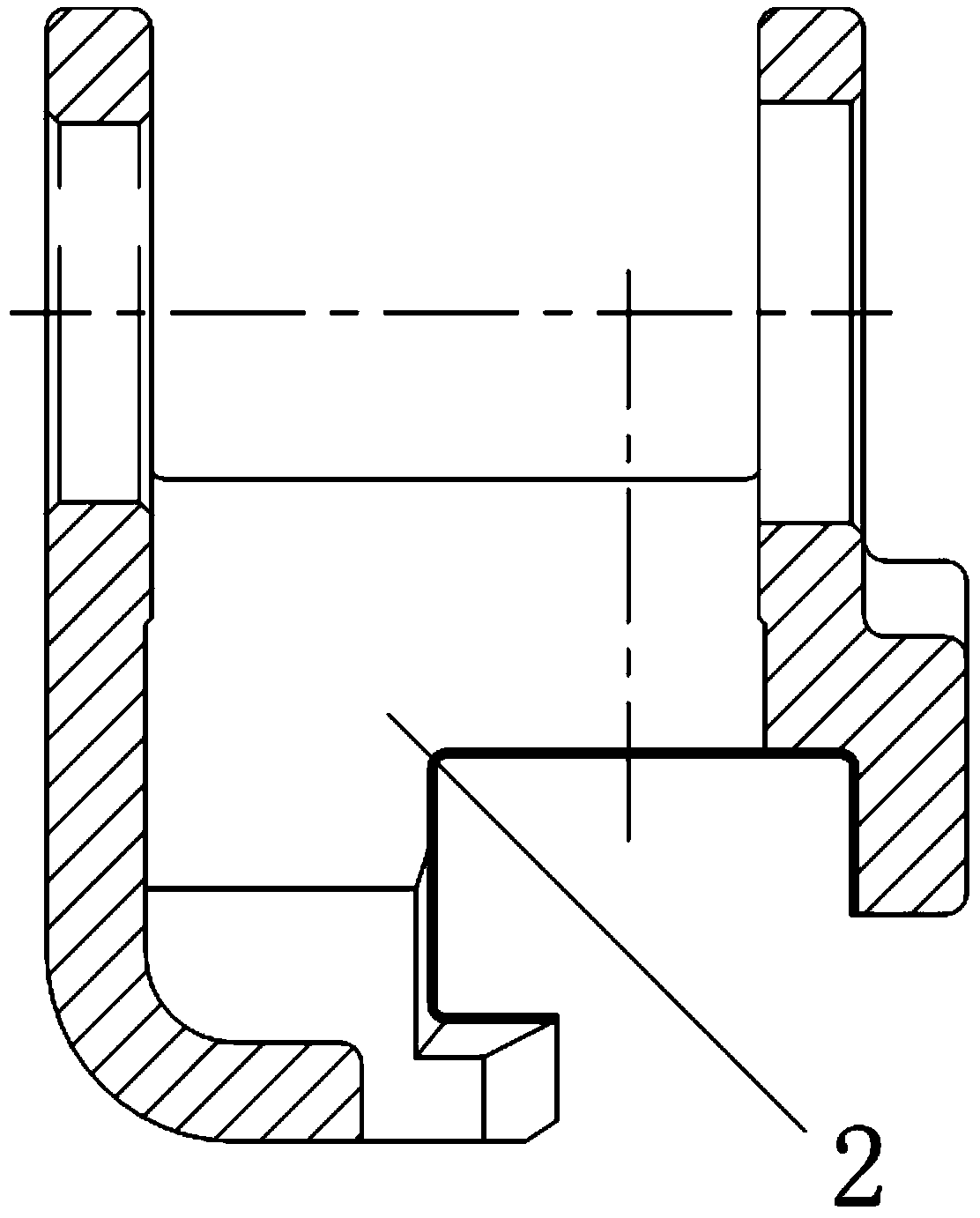

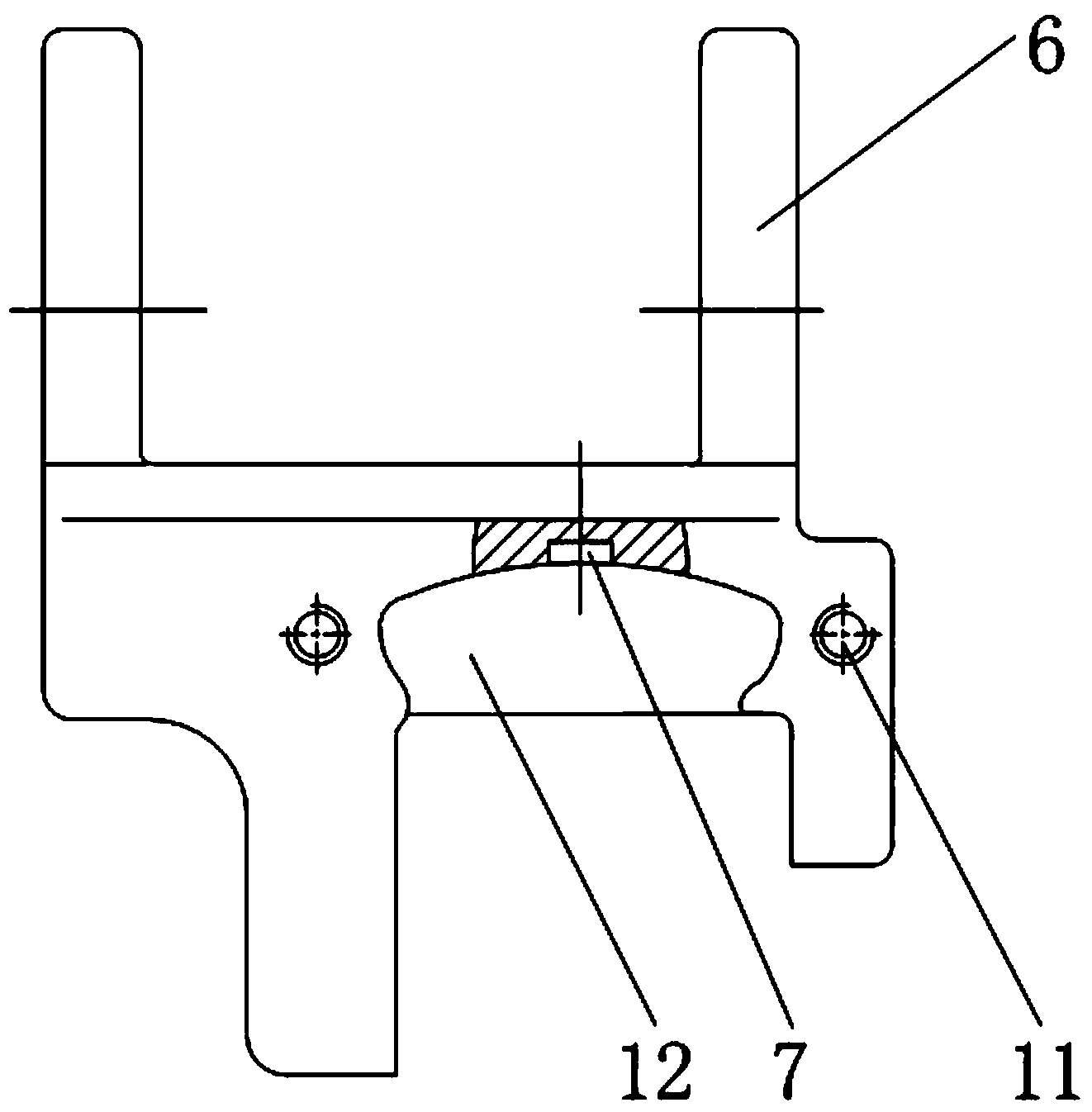

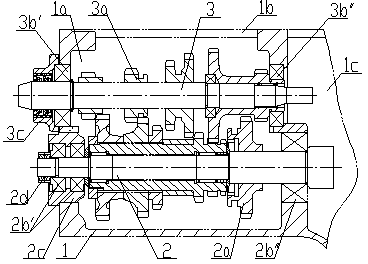

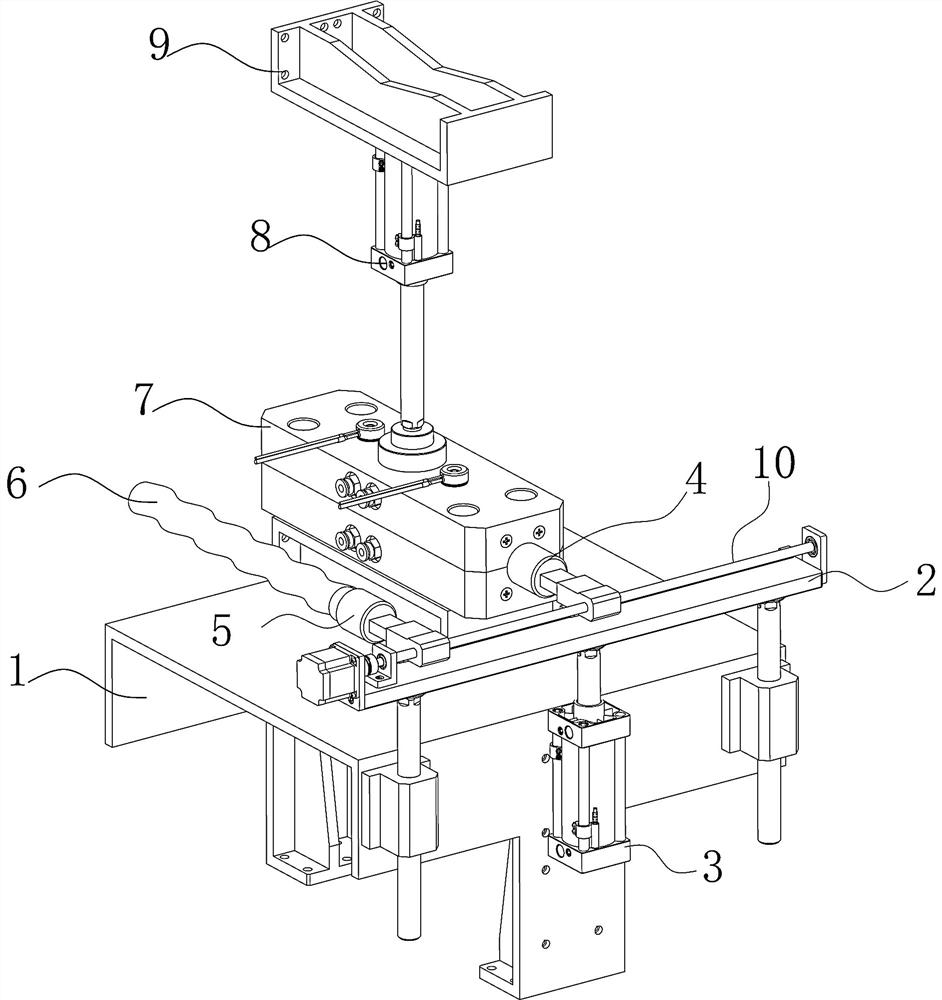

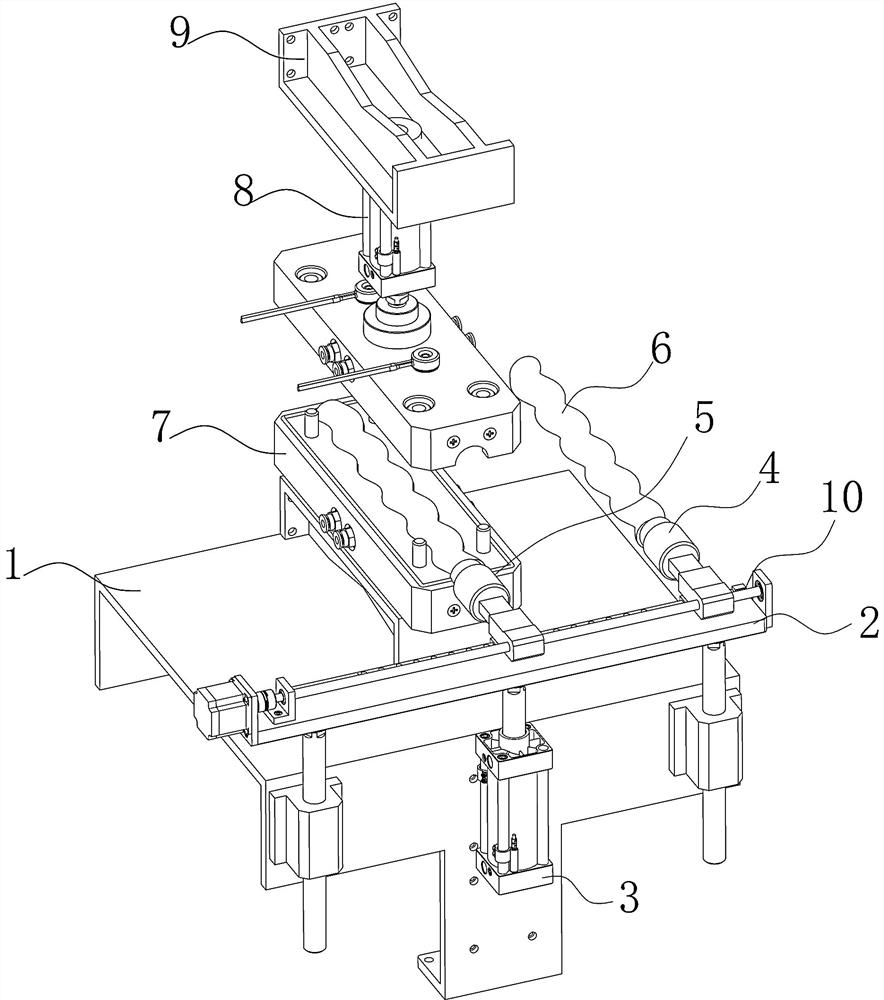

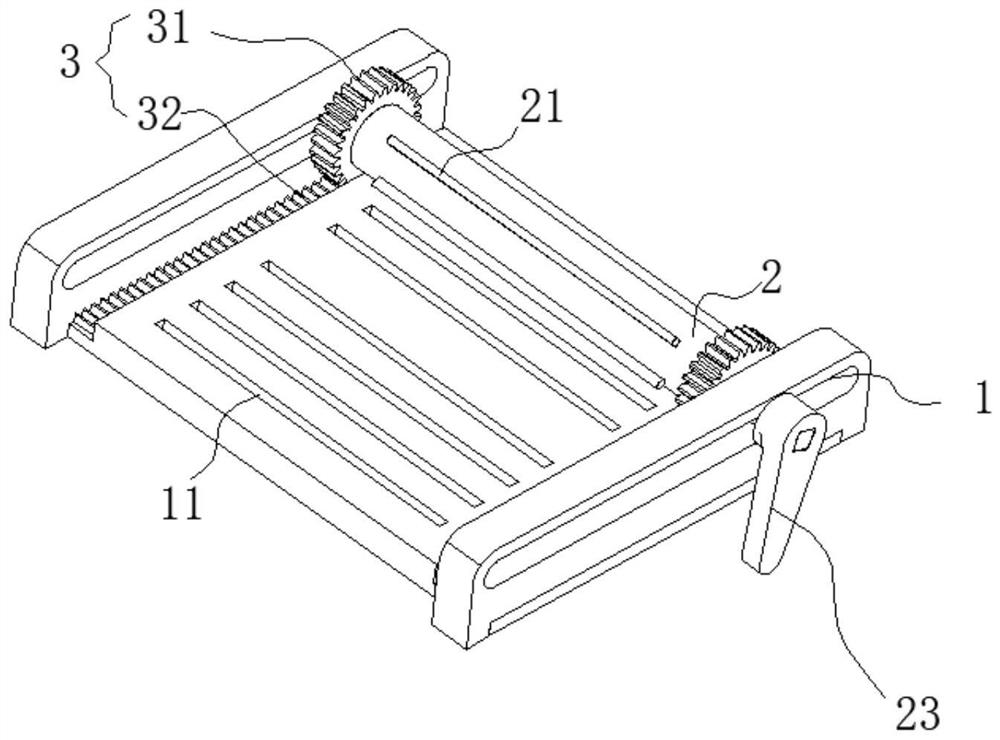

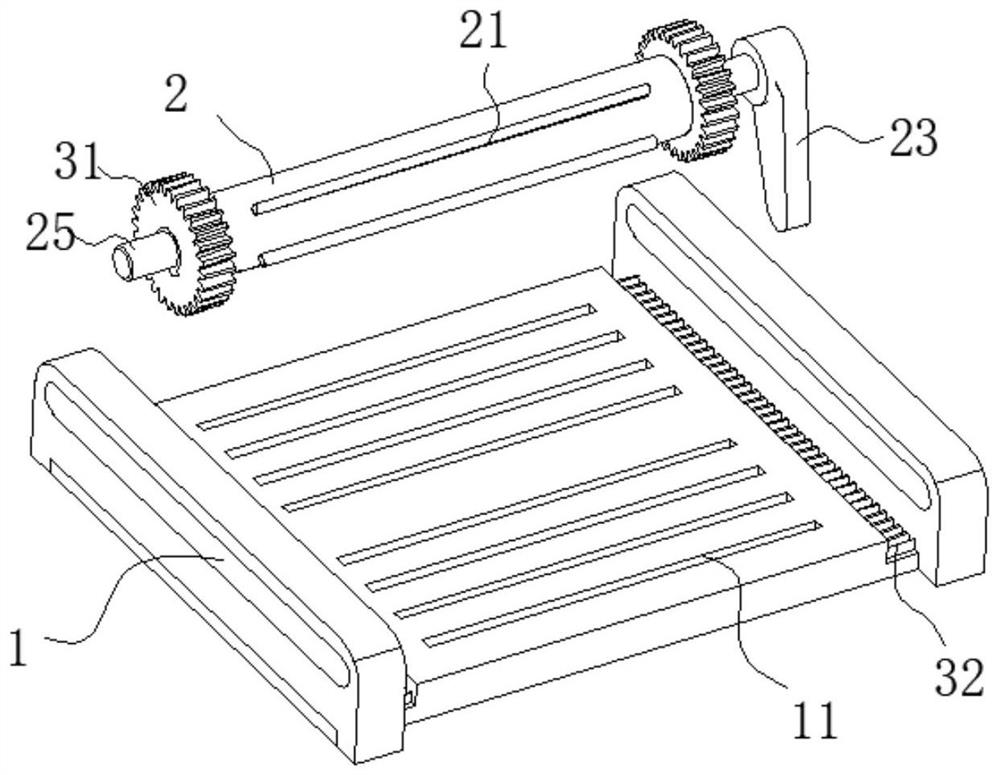

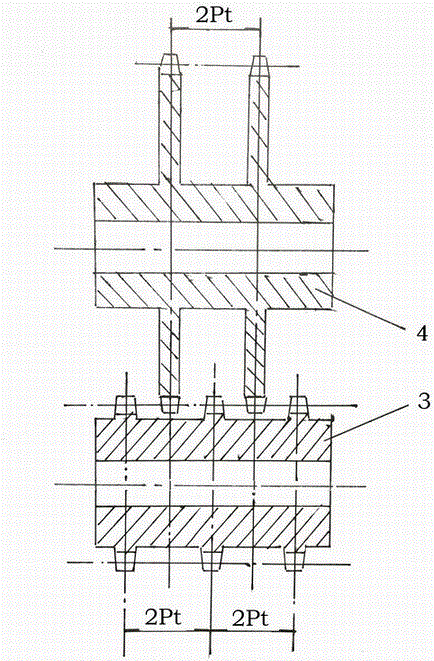

Assembling device and assembling method for gearbox double-shaft assembly of tractor

The invention belongs to the field of mechanical manufacture and relates to an assembling device and an assembling method for gearbox double-shaft assemblies of a tractor. The assembling device comprises a body component (9), two sets of guide components (10), a locating component (11), a hoisting hook component (12) and a pre-installing component (13). The locating component (11), the guide components (10) and the hoisting hook component (12) are fixedly connected to the body component (9) to form a fixedly connected 'integral assembly'. According to the assembling device and the assembling method for gearbox double-shaft assemblies of the tractor, when the double-shaft assemblies conduct assembly in a casing of a power shifting gearbox in an arranging mode, mesh gears between the double-shaft assemblies are in the normal mesh state, collision mechanical damage produced on the mesh faces of the gears is avoided, and it is further ensured that the double-shaft assemblies are accurately aligned when the double-shaft assemblies fall down, so that seal rings at the shaft ends are prevented from being cut, scratched and damaged. In addition, the assembling device is novel in structure, the assembling method is easy to implement and has good use value.

Owner:FIRST TRACTOR

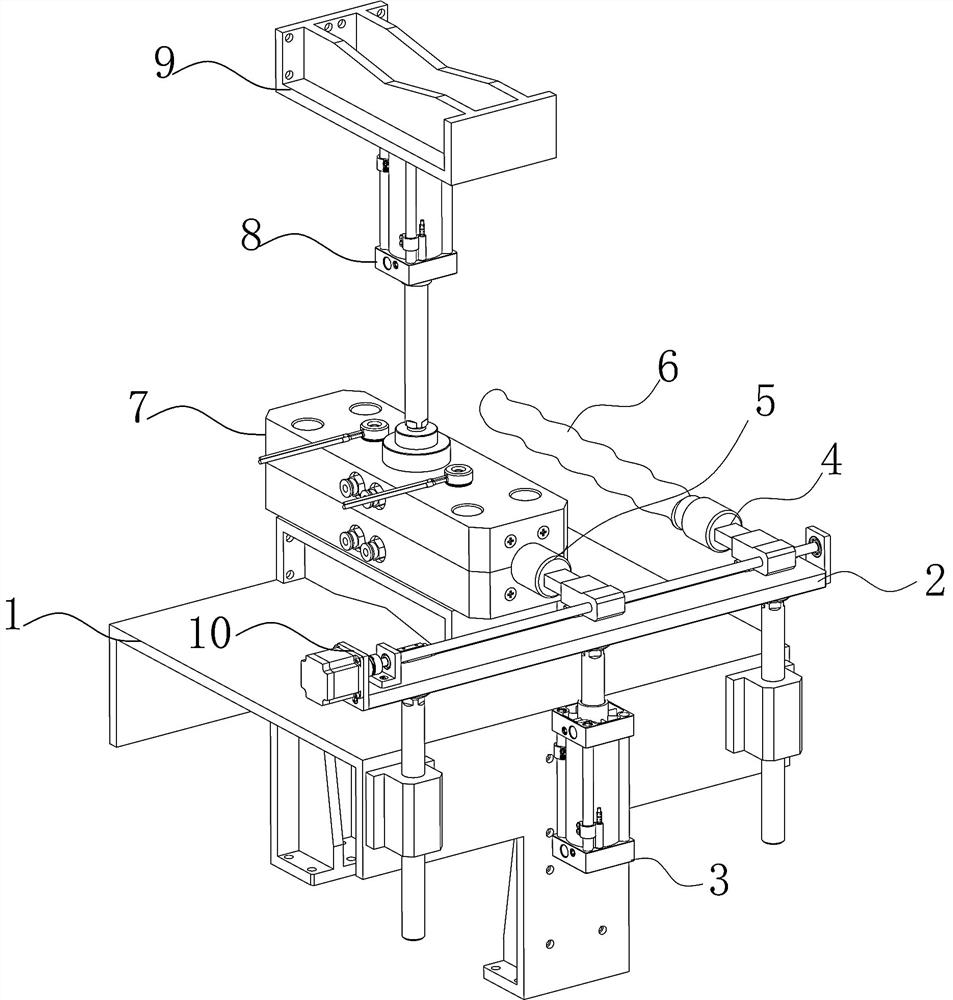

Screw motor rotor surface dressing device and machining method thereof

The invention provides a screw motor rotor surface dressing device and a machining method thereof. The screw motor rotor surface dressing device comprises a dressing mold; the dressing mold comprisesan upper mold plate and a lower mold plate, groove bodies are arranged inside the upper mold plate and the lower mold plate, a rotor is arranged inside the groove bodies, hot runners are arranged above the upper mold plate, and the hot runners are in communication with the groove bodies; the outer surface of the rotor is provided with a plurality of cutter grooves with crossed spiral lines, protruding blocks are formed between the cutter grooves, dressing is injected into the cutter grooves (601) between the protruding blocks through the hot runners, the machining method comprises the steps that crossed spiral groove bodies are machined through a CNC, a plurality of protrusions arranged along the spiral lines are formed, only edges of the protrusions are chamfered, and tops of the protrusions are not chamfered, the machining method is used for increasing the contact area between dressing and the outer surface of the rotor, improving the adhesion strength and prolonging the service lifeof the whole rotor.

Owner:SINOPEC OILFIELD EQUIP CORP +1

Silk screen groove roller rolling forming press

PendingCN114871364AMeet displacement needsAvoid pulling damageFinal product manufactureMetal-working apparatusGear wheelEngineering

Owner:NUCLEAR POWER INSTITUTE OF CHINA +1

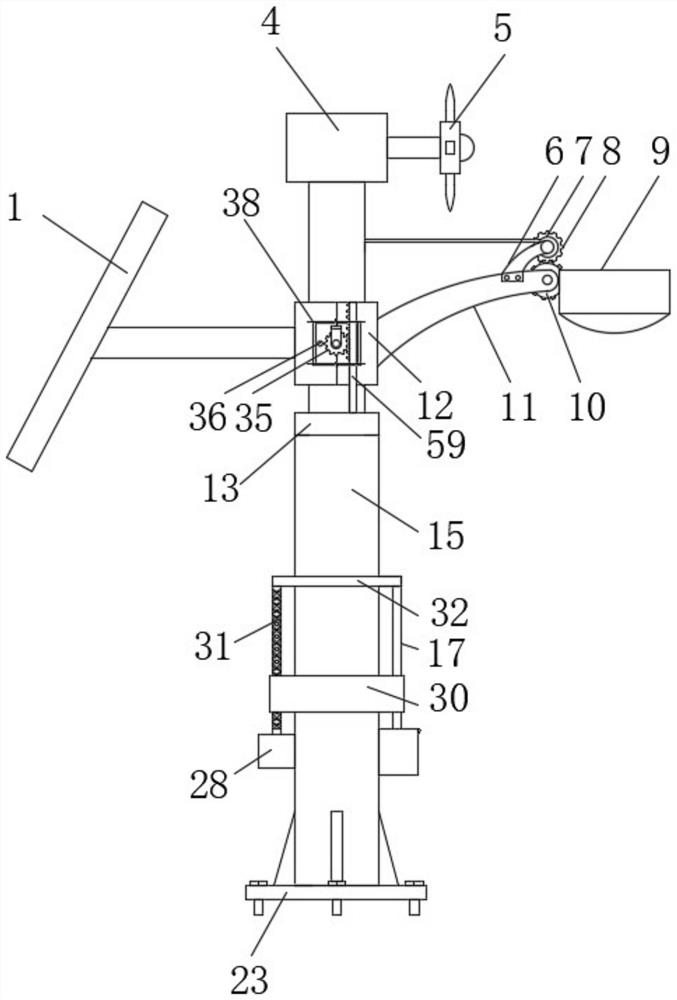

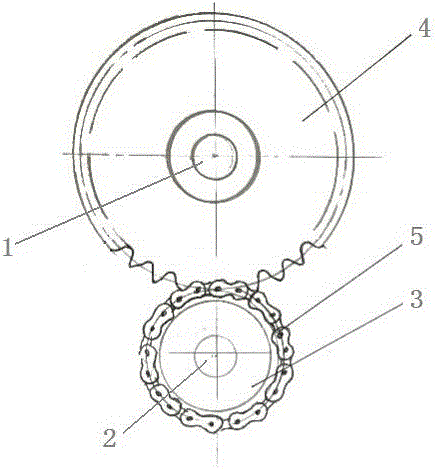

Wind driven generator transmission mechanism adopting chain wheels for speed increasing

ActiveCN106402297AReduce manufacturing costsReduce complexityFinal product manufactureGearingWind drivenLow speed

The invention discloses a wind driven generator transmission mechanism adopting chain wheels for speed increasing, and belongs to the field of wind driven generators. The wind driven generator transmission mechanism structurally comprises a high-speed shaft, a low-speed shaft, multi-row small chain wheels, multi-row large chain wheels and the like; multi-row sleeve roller chains are arranged between the multi-row small chain wheels and the multi-row large chain wheels, wheel teeth of the multi-row small chain wheels are surrounded by odd-number-row engaging circumferences of the multi-row sleeve roller chains, the even-number-row sleeve roller chains of the multi-row sleeve roller chains are in the mid-air suspending state on the multi-row small chain wheels, and therefore the multi-row small chain wheels are mounted on the high-speed shaft, the multi-row large chain wheels are mounted on the low-speed shaft, and the speed increasing transmission relation is formed by engaging of the multi-row large chain wheels and the even-number-row chains of the multi-row sleeve roller chains; through the chains, the transmission mechanism with the wind driven generator high-rotating-speed requirement is achieved, the engaging state is good, and on the basis of keeping the use advantages of chain transmission, the beneficial effects of being simple in structural design, capable of reducing complexity of the wind driven generator speed increasing transmission mechanism and the manufacturing cost of a wind driven generator, convenient to maintain and the like are achieved.

Owner:张国欣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com