Worm and helical gear transmission pair based on variable pressure angle and application of worm and helical gear transmission pair

A technology of variable pressure angle and helical gears, which is applied to gear transmissions, transmissions, belts/chains/gears, etc., and can solve problems such as long processing cycles, different thicknesses of gears, and easy deformation of tooth shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

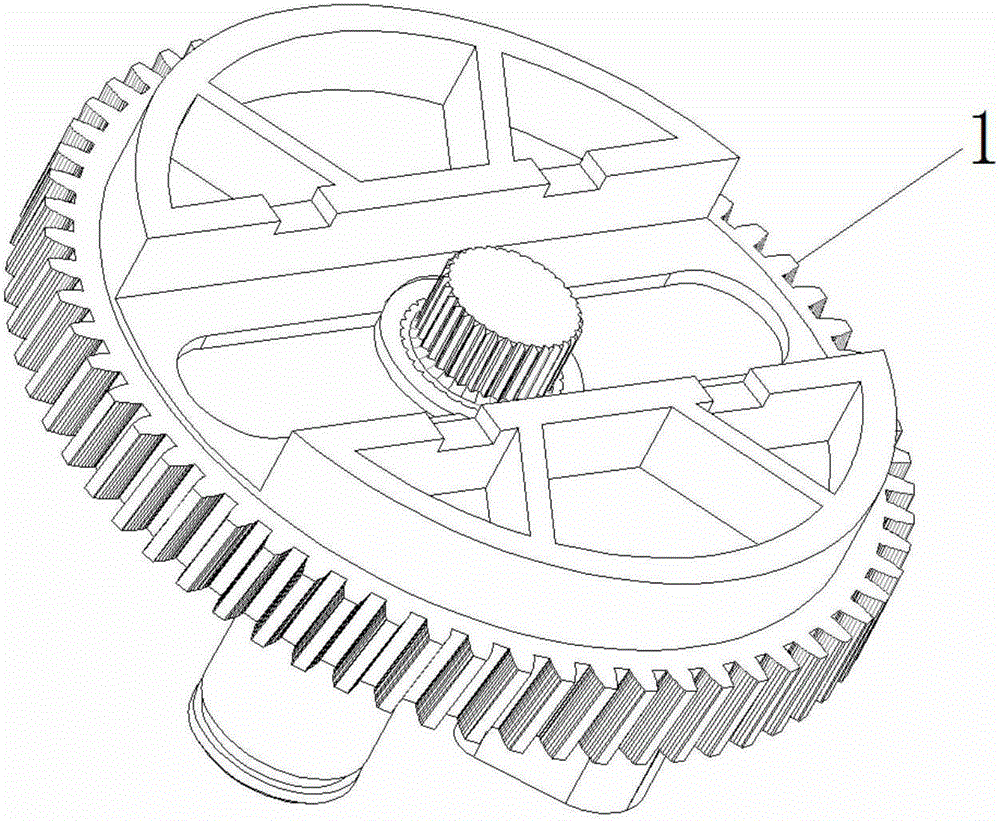

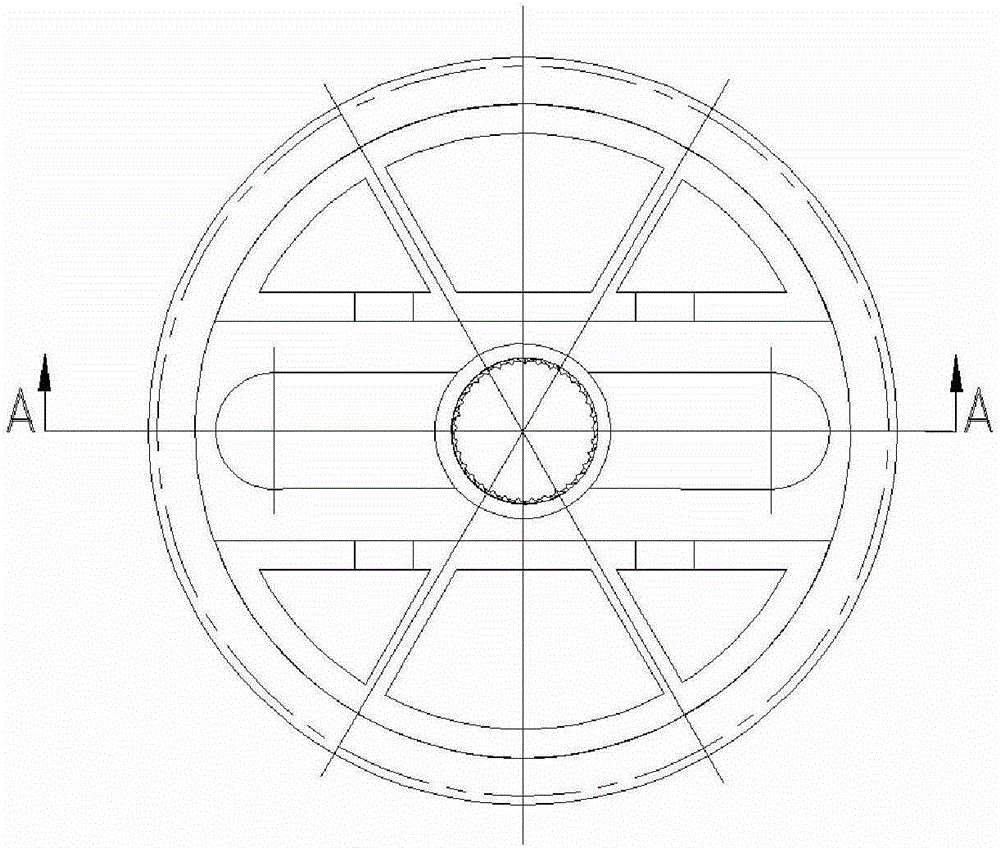

[0050] Such as Figure 1-7 Shown, it has shown the specific embodiment of the present invention, and the present invention is based on the worm helical gear transmission pair of variable pressure angle, comprises the worm screw and helical gear that meshes with each other; It is characterized in that:

[0051] Described helical gear end surface modulus (Mt2)=worm shaft surface modulus (Ma1);

[0052] Helical gear end face indexing scalloped angle (αn2) > worm shaft face indexing scalloped angle (αn1);

[0053] Helical gear indexing circle helix angle (β2) = worm shaft surface indexing circle lead angle (λ1);

[0054] The indexing crenated angle (αn2) on the end surface of the helical gear-the indexing crenated angle (αn1) on the worm shaft surface is less than 10°.

[0055] In some specific examples:

[0056]When, the helical gear end face modulus (Mt2)=worm shaft face modulus (Ma1); helical gear end face indexing crenated angle (αn2)=worm shaft face indexing crenated angle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch circle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com