Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Improve uneven force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

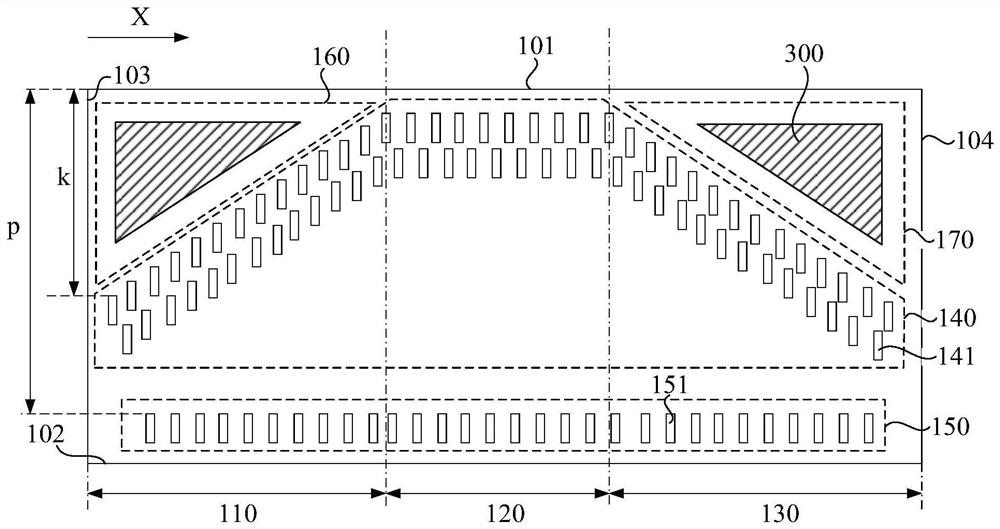

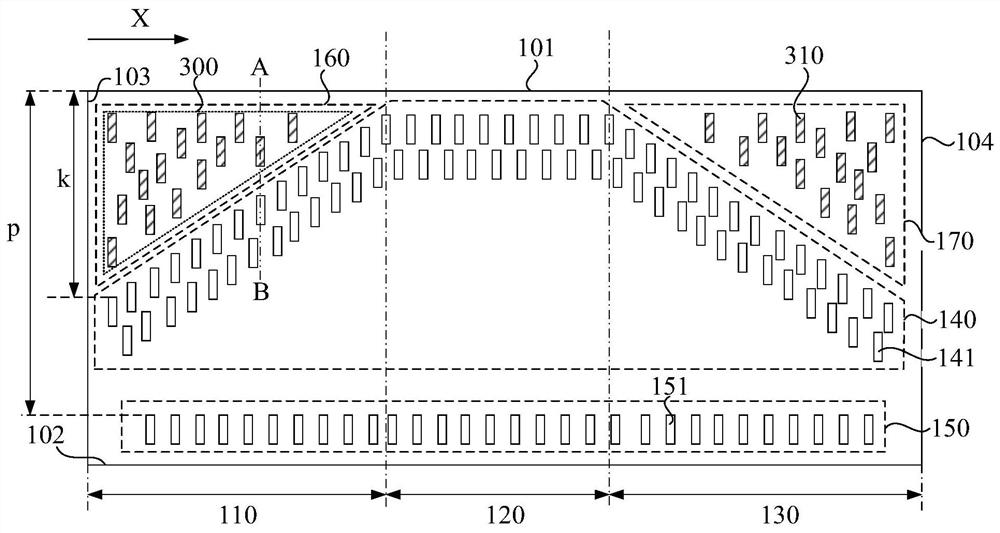

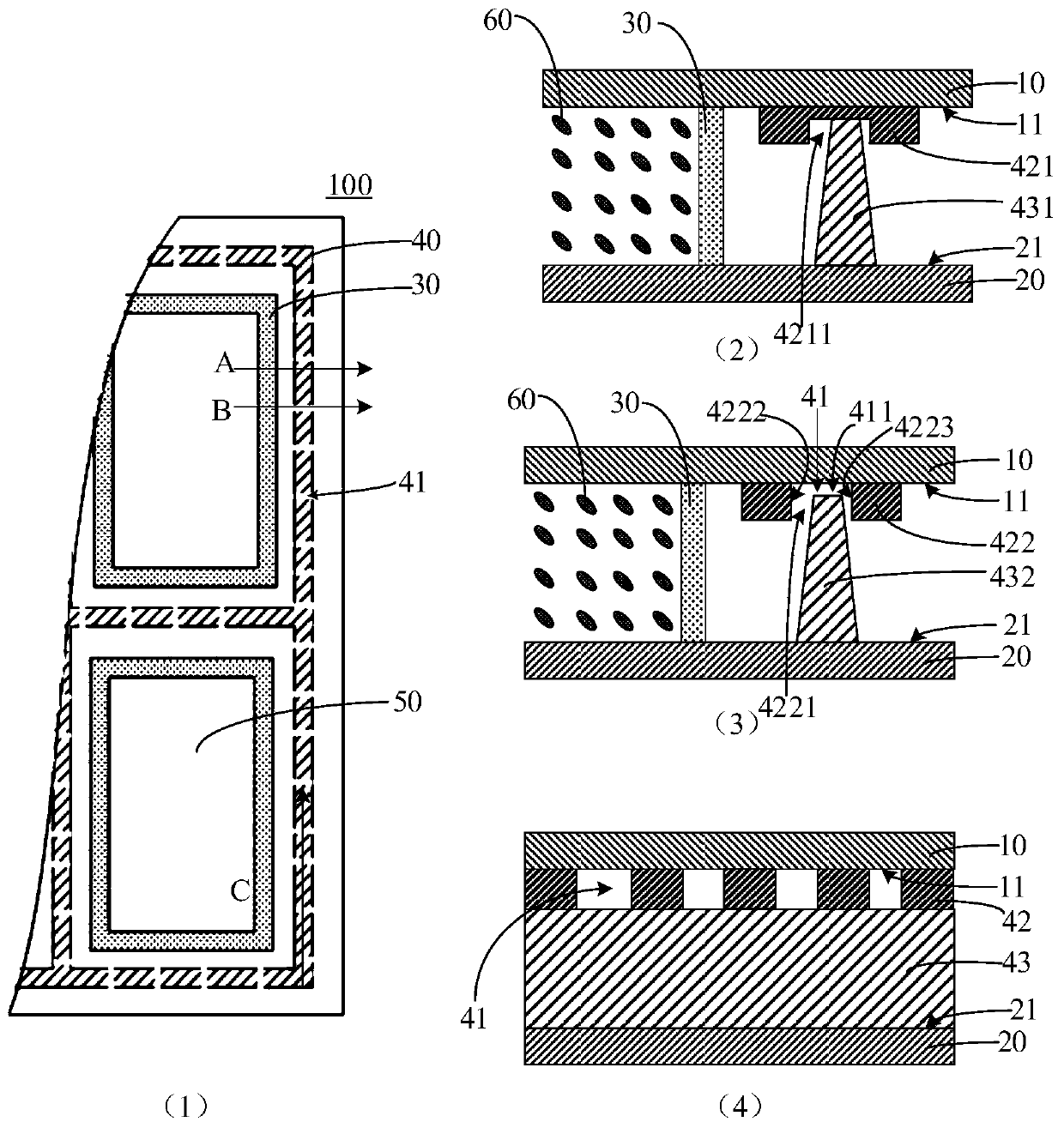

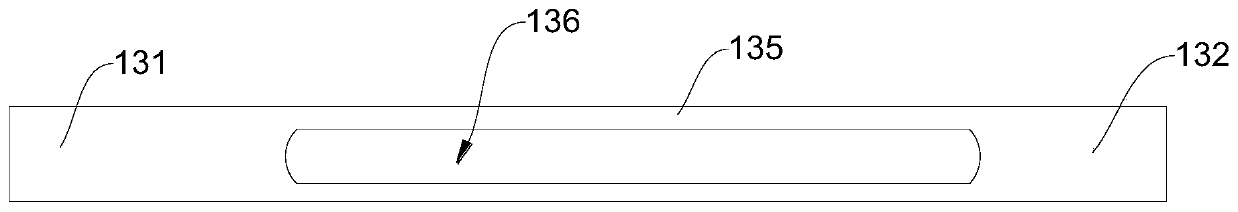

Driving chip and display device

ActiveCN111883039AImprove uneven forceAvoid damageStatic indicating devicesDisplay deviceStructural engineering

The invention discloses a driving chip and a display device. The driving chip comprises a first region, a second region and a third region; in the first direction, the distance between each output terminal located in the first area and the first edge is gradually reduced, and the distance between each output terminal located in the third area and the first edge is gradually increased; the distances between the output terminals in the second area and the first side are equal and are less than the distances between the first area and the first side of the output terminals in the second area; thedistances between the input terminals and the first side are equal; the output terminal group is located between the input terminal group and the first side; heightening layers are arranged in an area surrounded by the output terminal, the first edge and the third edge of the first area and an area surrounded by the output terminal, the first edge and the fourth edge of the third area, wherein the first direction is parallel to the plane where the driving chip is located and the first edge of the driving chip. According to the technical scheme provided by the embodiment of the invention, theproblem of uneven stress of the driving chip is improved, and the driving chip is prevented from being damaged.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Printed board open hole printing ink filling method and hole filling breathable board

InactiveCN103763871AImprove qualityStable supportPrinted circuit detailsPrinted element electric connection formationPrinting inkOpen hole

The invention provides a printed board open hole printing ink filling method and a hole filling breathable board. The printed board open hole printing ink filling method includes the following steps that the hole filling breathable board is manufactured, a blind hole corresponding to an open hole to be filled in a printed board is formed in a resin base material board, wherein the blind hole does not penetrate through an epoxy base material board, and the aperture of the blind hole in the breathable board is larger than the aperture of the corresponding open hole to be filled in the printed board; the boards are stacked, wherein the resin base material board provided with the blind hole, the printed board provided with the open hole to be filled and a hole filling template provided with an opening corresponding to the open hole to be filled are sequentially arranged on a machine table in an aligning mode; filling of printing ink is performed, wherein the printing ink is pushed to the other side of the open hole to be filled from one side of the open hole to be filled, and therefore the open hole to be filled can be filled with the printing ink.

Owner:JIANGNAN INST OF COMPUTING TECH

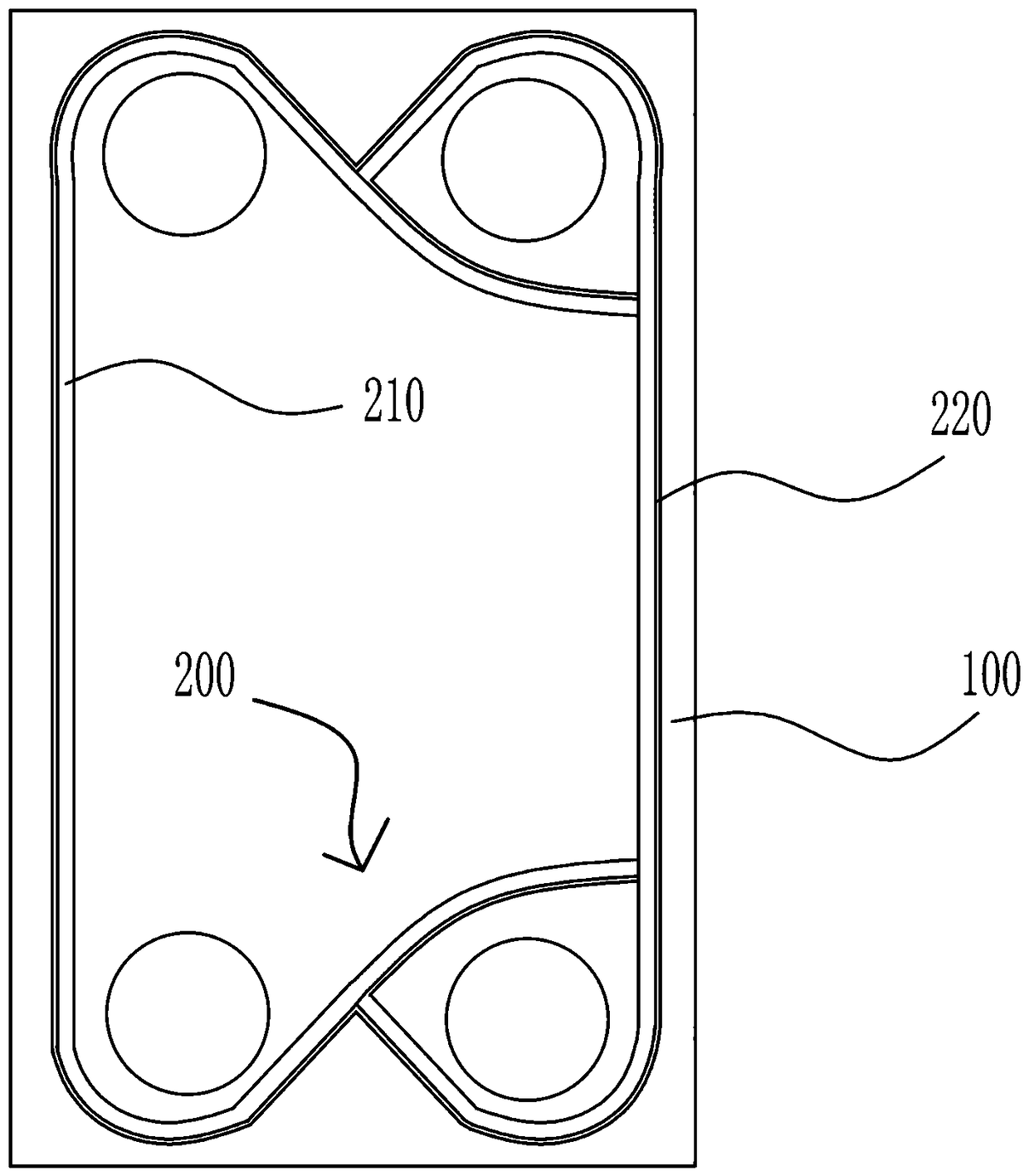

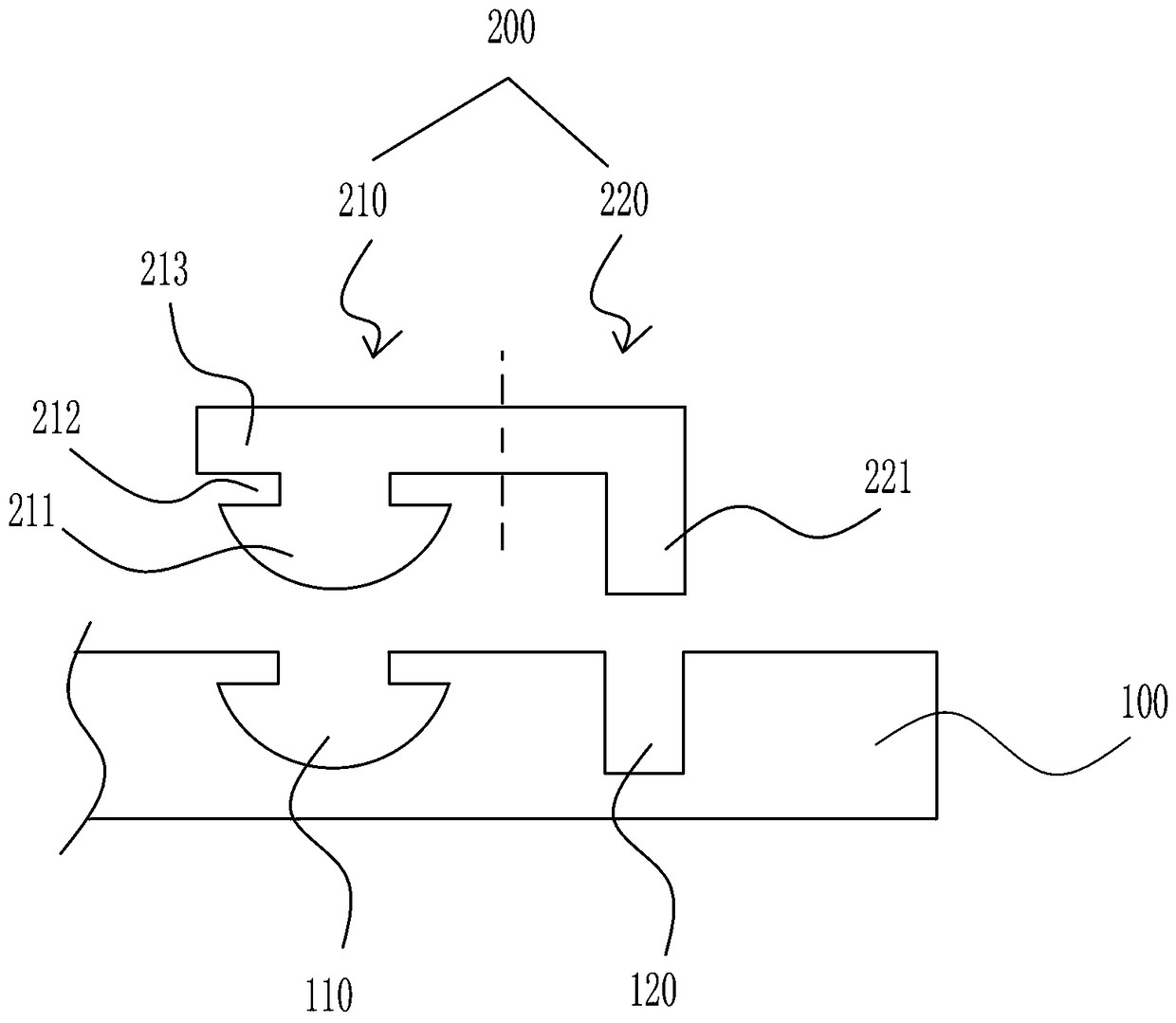

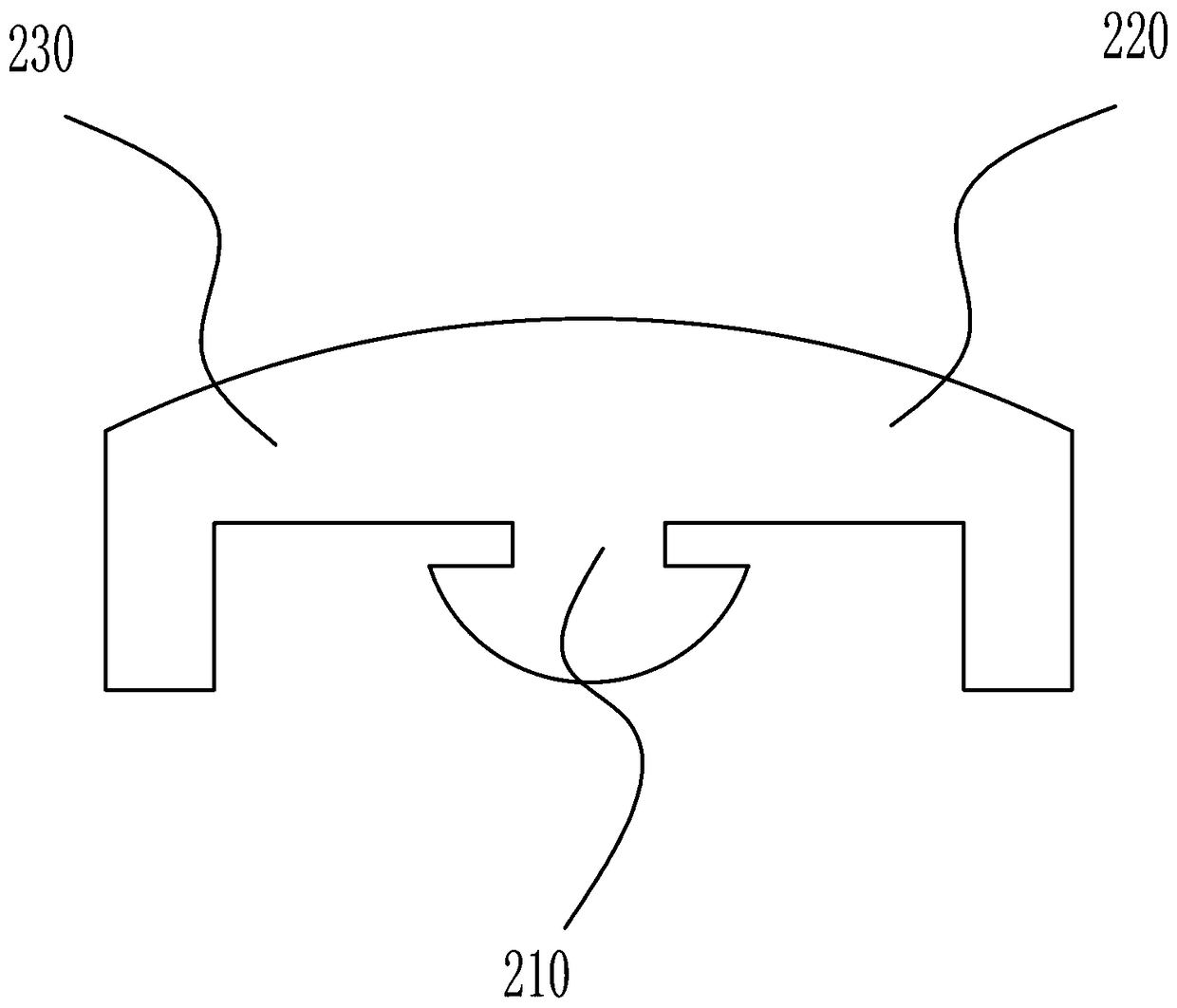

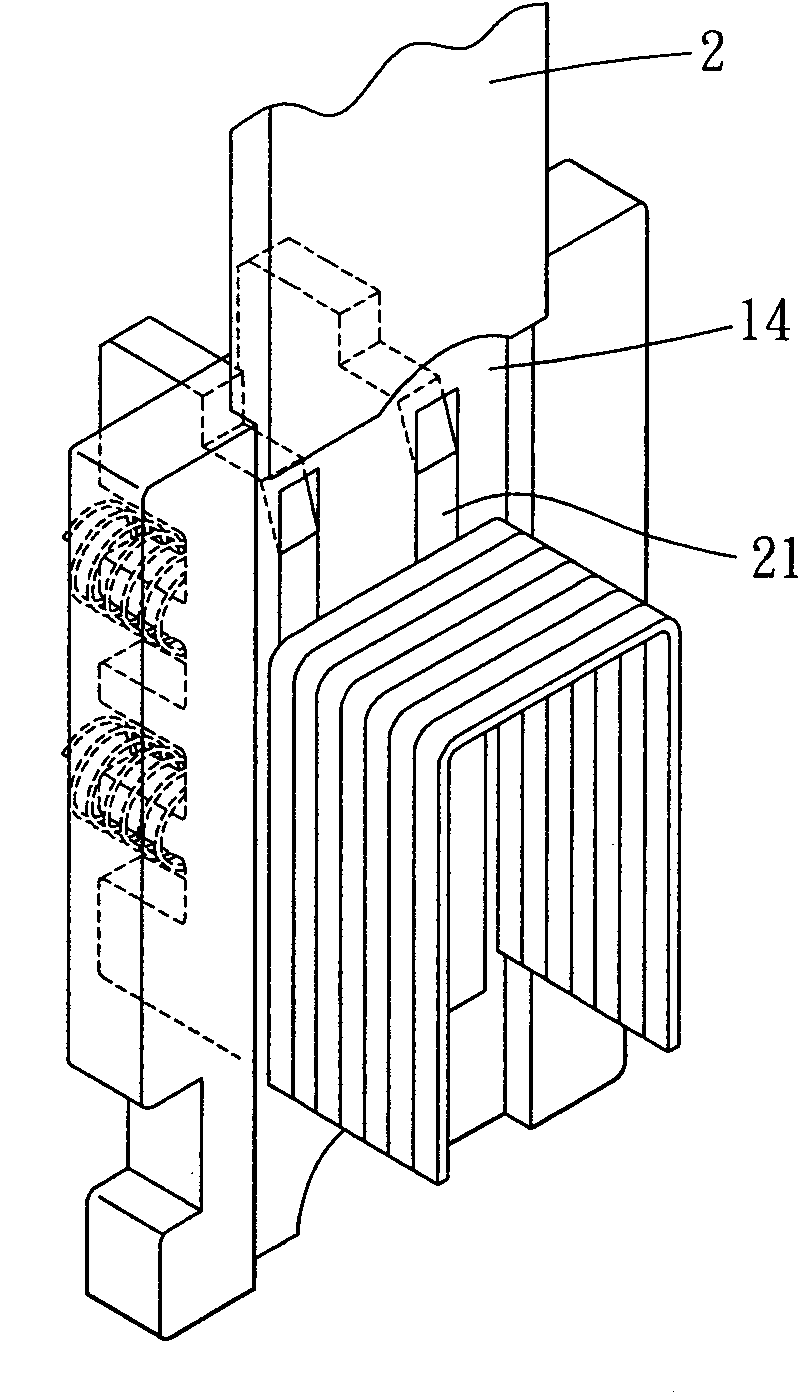

Plate type heat exchanger with good sealing property

PendingCN109141095AImprove rigidityIncrease tightnessHeat exhanger sealing arrangementHeat exchanger fasteningPlate heat exchangerButt joint

The invention relates to the technical field of plate type heat exchangers, and discloses a plate type heat exchanger with a good sealing property. The plate type heat exchanger includes a plurality of heat exchanging plate pieces alternately flipped and stacked with each other and sealing gaskets located between every adjacent heat exchanging plate pieces, each sealing gasket comprises a first sealing part and a second sealing part which is located on one side of the first sealing part and integrally formed with the first sealing part, and each first sealing part comprises an embedded arc-shaped bottom, a clamping groove part and a flow stopping top from bottom to top; and one sides of the second sealing parts are in butt joint with one sides of the flow stopping tops and formed integrally, the other sides, opposite to the flow stopping tops, of the second sealing parts are downwardly provided with flanges, and each heat exchanging plate piece is provided with an embedded arc-shaped groove matched with the correspondingly first sealing part and a positioning sealing groove matched with the correspondingly flange. According to the plate type heat exchanger with the good sealing property, installation is simple, the tightness between the heat exchanging plate pieces is good, the sealing gaskets are easier to suffer stress evenly, and sealing is firm.

Owner:ZHEJIANG HUALI INTELLIGENT EQUIP CO LTD

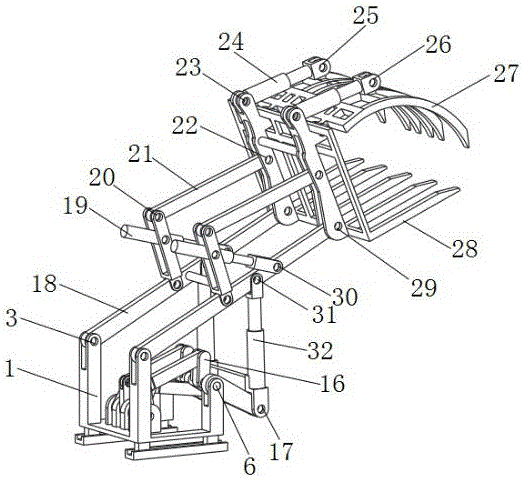

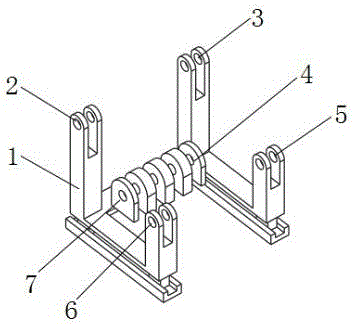

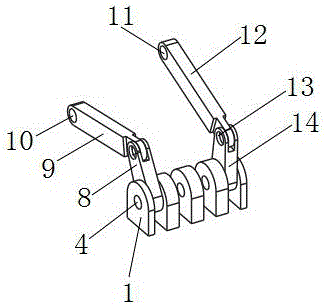

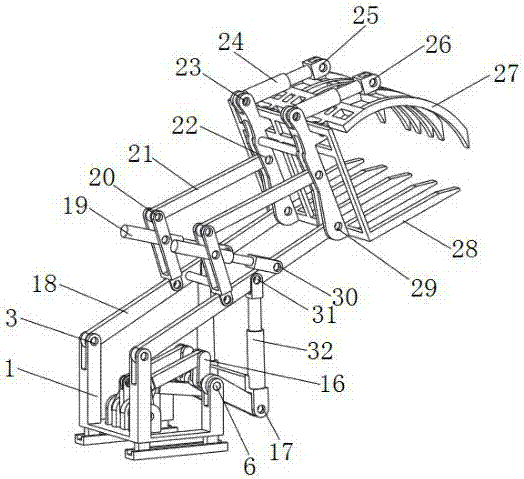

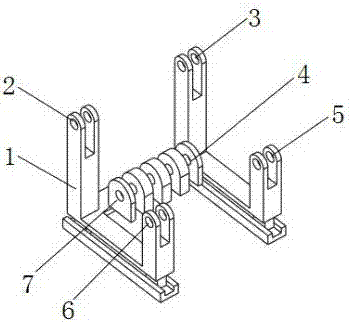

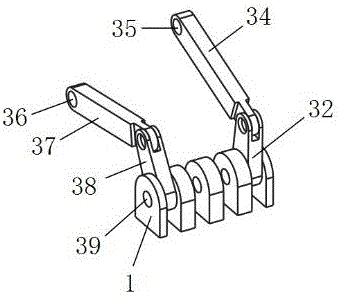

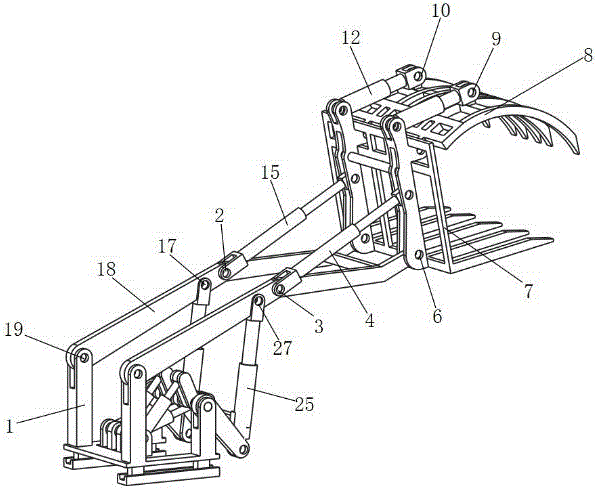

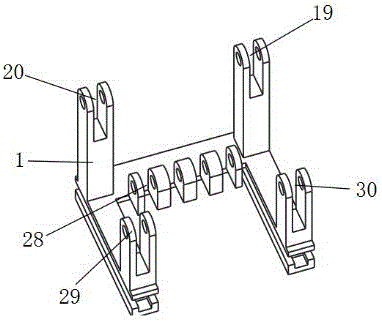

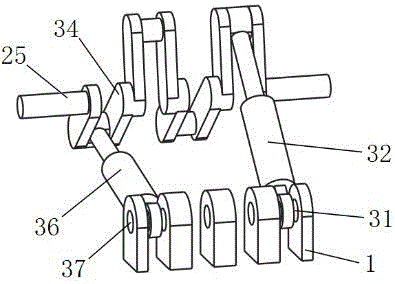

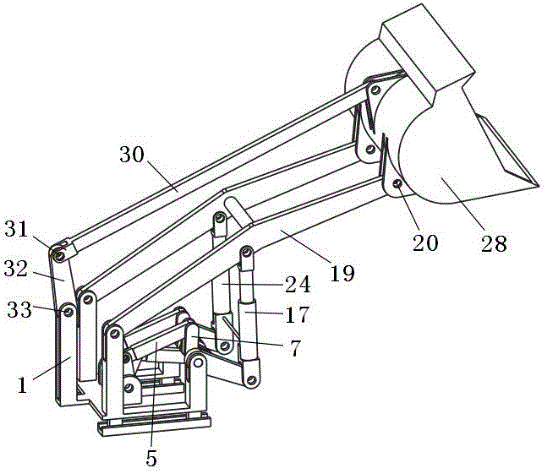

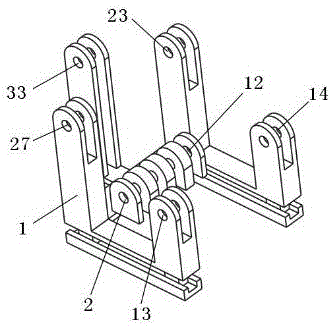

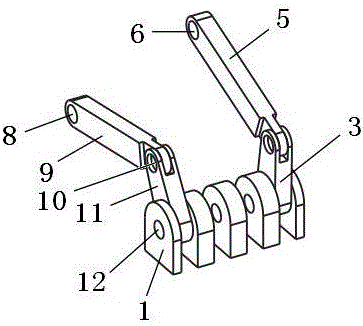

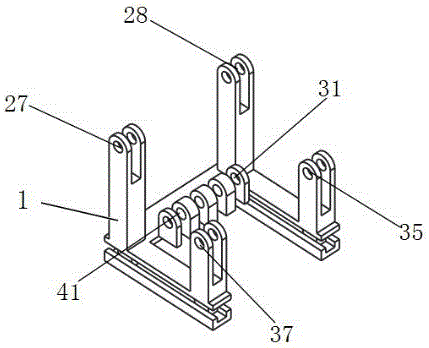

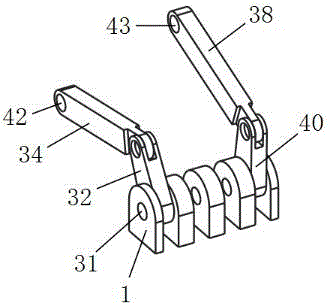

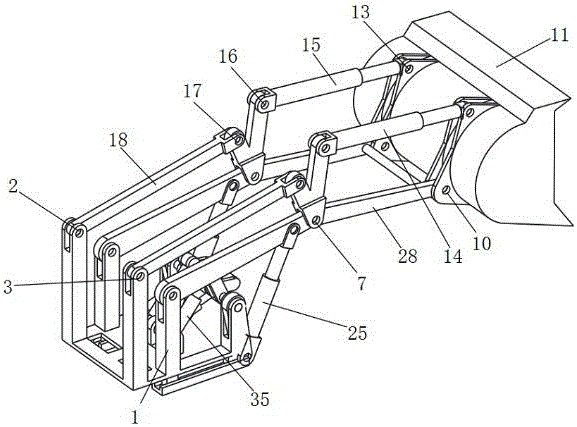

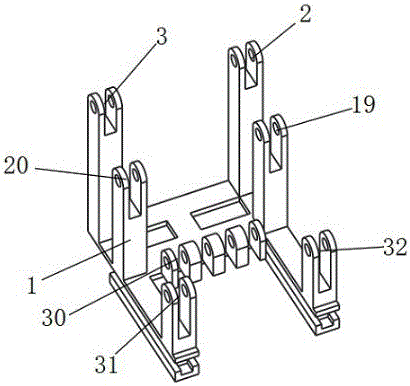

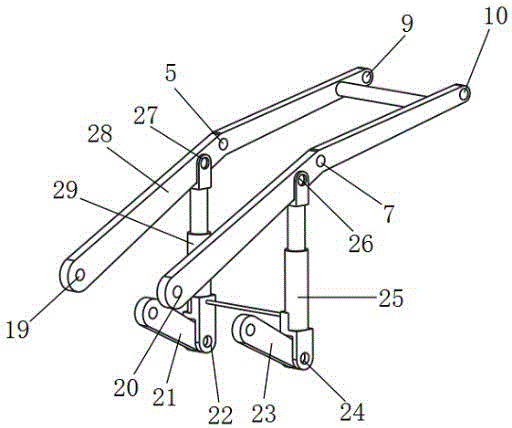

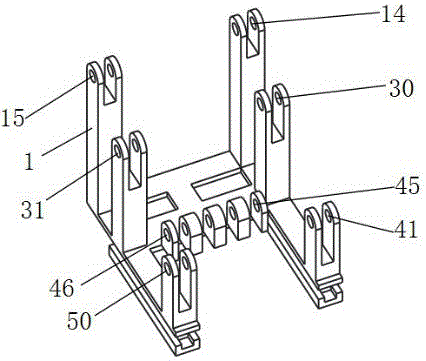

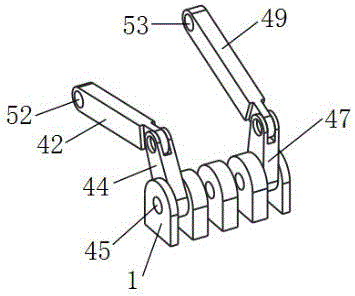

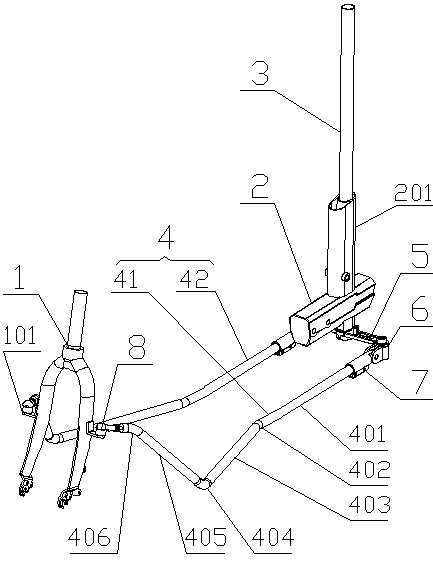

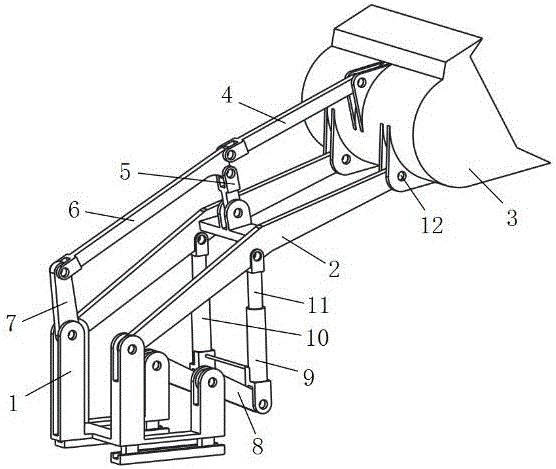

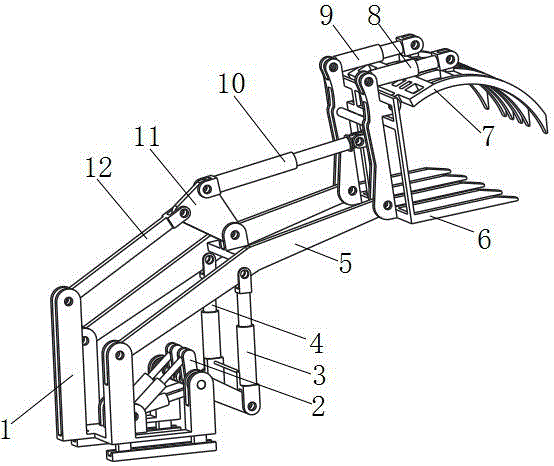

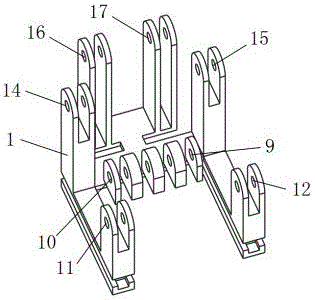

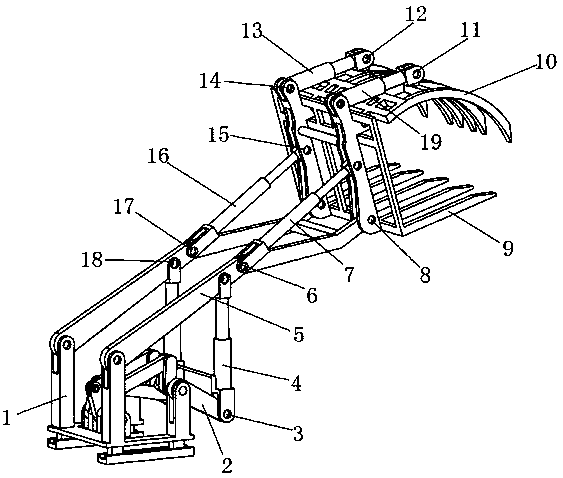

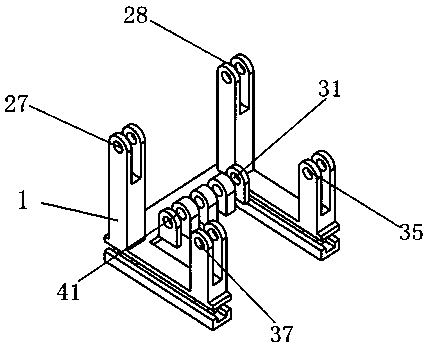

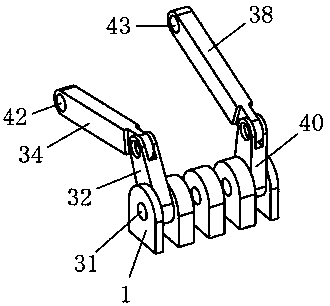

Planar controllable slippage type wood forklift with multi-unit connection rod driving function

InactiveCN106081932AImprove mechanical propertiesImprove rigidityFluid-pressure actuator safetyLoad-engaging elementsHydraulic cylinderMulti unit

A planar controllable slippage type wood forklift with a multi-unit connection rod driving function comprises a multi-unit connection rod driving mechanism, a movable arm lifting mechanism, a fork bucket control mechanism and the like. Under control of a computer, the multi-unit connection rod driving mechanism achieves driving of multiple small-power motors and high-power and high-torque power output, and meets the power requirement of high-load operation of the slippage type wood forklift. A hydraulic cylinder is applied to the configuration design of the wood forklift as a connection rod on the basis of the Pascal principle, the problem that in the prior art, stress on two driving chains for lifting a movable arm is unbalanced is effectively solved, and the bearing stability is improved. The slippage type wood forklift not only has the characteristics of being high in transmission efficiency, high in response speed, high in motion precision, good in controllability, capable of saving energy, environmentally friendly and the like as a controllable mechanism, but also has better bearing performance and shock resistance through introduction of the multi-unit connection rod driving mechanism and a hydraulic element, can achieve the overload protection function easily and has great engineering application prospects and development potential.

Owner:SHANDONG JIAOTONG UNIV

A Multi-Unit Connecting Rod Drive Plane Controllable Sliding Forklift

InactiveCN106081932BImprove mechanical propertiesImprove rigidityFluid-pressure actuator safetyLoad-engaging elementsMulti unitHydraulic cylinder

A planar controllable slippage type wood forklift with a multi-unit connection rod driving function comprises a multi-unit connection rod driving mechanism, a movable arm lifting mechanism, a fork bucket control mechanism and the like. Under control of a computer, the multi-unit connection rod driving mechanism achieves driving of multiple small-power motors and high-power and high-torque power output, and meets the power requirement of high-load operation of the slippage type wood forklift. A hydraulic cylinder is applied to the configuration design of the wood forklift as a connection rod on the basis of the Pascal principle, the problem that in the prior art, stress on two driving chains for lifting a movable arm is unbalanced is effectively solved, and the bearing stability is improved. The slippage type wood forklift not only has the characteristics of being high in transmission efficiency, high in response speed, high in motion precision, good in controllability, capable of saving energy, environmentally friendly and the like as a controllable mechanism, but also has better bearing performance and shock resistance through introduction of the multi-unit connection rod driving mechanism and a hydraulic element, can achieve the overload protection function easily and has great engineering application prospects and development potential.

Owner:SHANDONG JIAOTONG UNIV

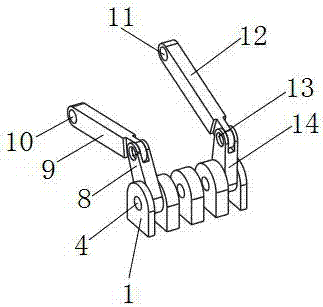

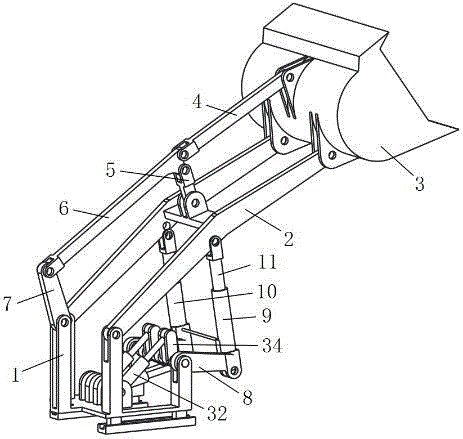

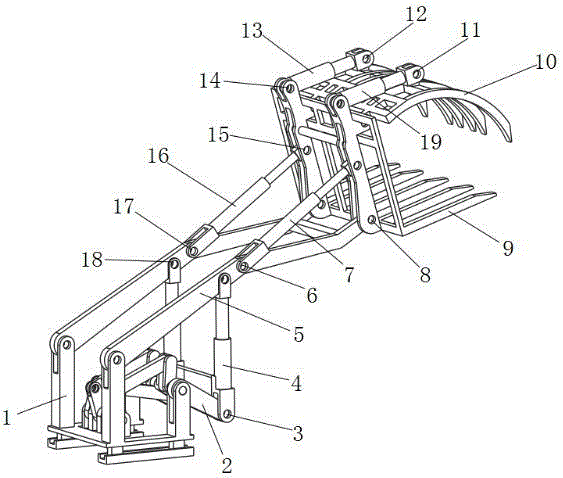

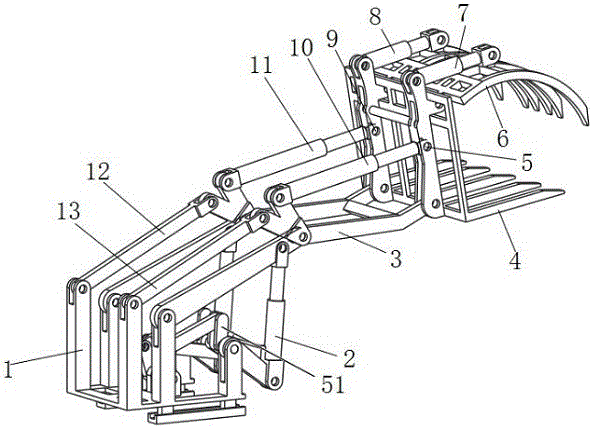

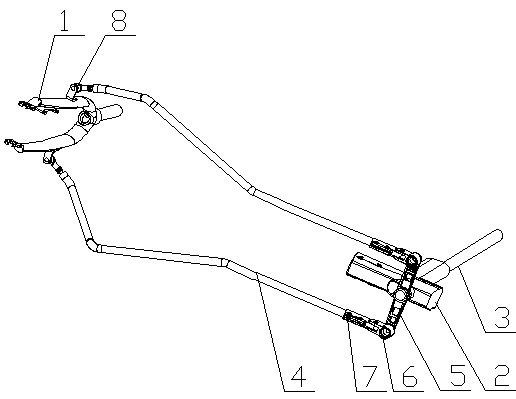

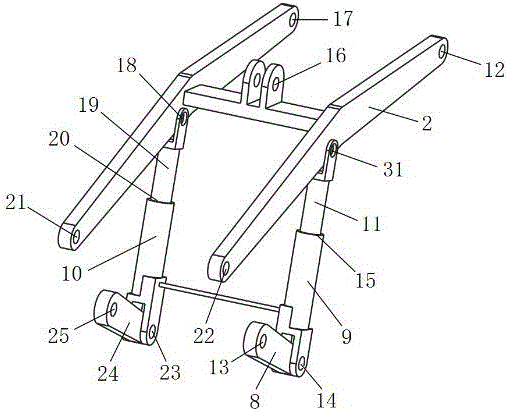

Planar three-range-of-motion loading robot with multi-unit connection rod driving function

InactiveCN106088182AImprove power adaptabilitySolve power problemsMechanical machines/dredgersMulti unitRange of motion

A planar three-range-of-motion loading robot with a multi-unit connection rod driving function comprises a multi-unit connection rod driving mechanism, a movable arm lifting mechanism, a fork bucket control mechanism and the like. Under control of a computer, the multi-unit connection rod driving mechanism achieves driving of multiple small-power motors and high-power and high-torque power output, and meets the power requirement of high-load operation of the slippage type loading robot. On the basis of the Pascal principle, a hydraulic element is introduced to the movable arm lifting mechanism, equal in-cylinder pressure is achieved, the problem that stress on two driving chains for driving a movable arm of an original controllable loading mechanism is unbalanced is effectively solved, and the bearing stability is improved. The loading robot has the characteristics of being high in transmission efficiency, high in response speed, high in motion precision, good in controllability and the like as the original controllable loading mechanism, but also has better bearing performance and vibration resistance through introduction of the multi-unit connection rod driving mechanism and the hydraulic element, can achieve the overload protection function easily, and is quite suitable for manufacturing of large, intermediate and small-sized loading robots.

Owner:SHANDONG JIAOTONG UNIV

Carbon fiber reinforced gypsum board and preparation method thereof

The invention relates to a carbon fiber reinforced gypsum board and a preparation method thereof. The technical problem that a gypsum board is low in rupture strength, poor in compressive strength andpoor in waterproof performance in the prior art is solved. The carbon fiber reinforced gypsum board provided by the invention is prepared from the following raw material components: 70-110 parts of agypsum powder, 20-30 parts of diatomite, 5-10 parts of glucose, 4-12 parts of an admixture, 160-200 parts of water and 20-30 parts of chopped carbon fibers. Moreover, the invention further provides apreparation method of the carbon fiber reinforced gypsum board. The carbon fiber reinforced gypsum board disclosed by the invention is widely applied to the technical field of building materials.

Owner:威海南海碳材料科技研究院有限公司

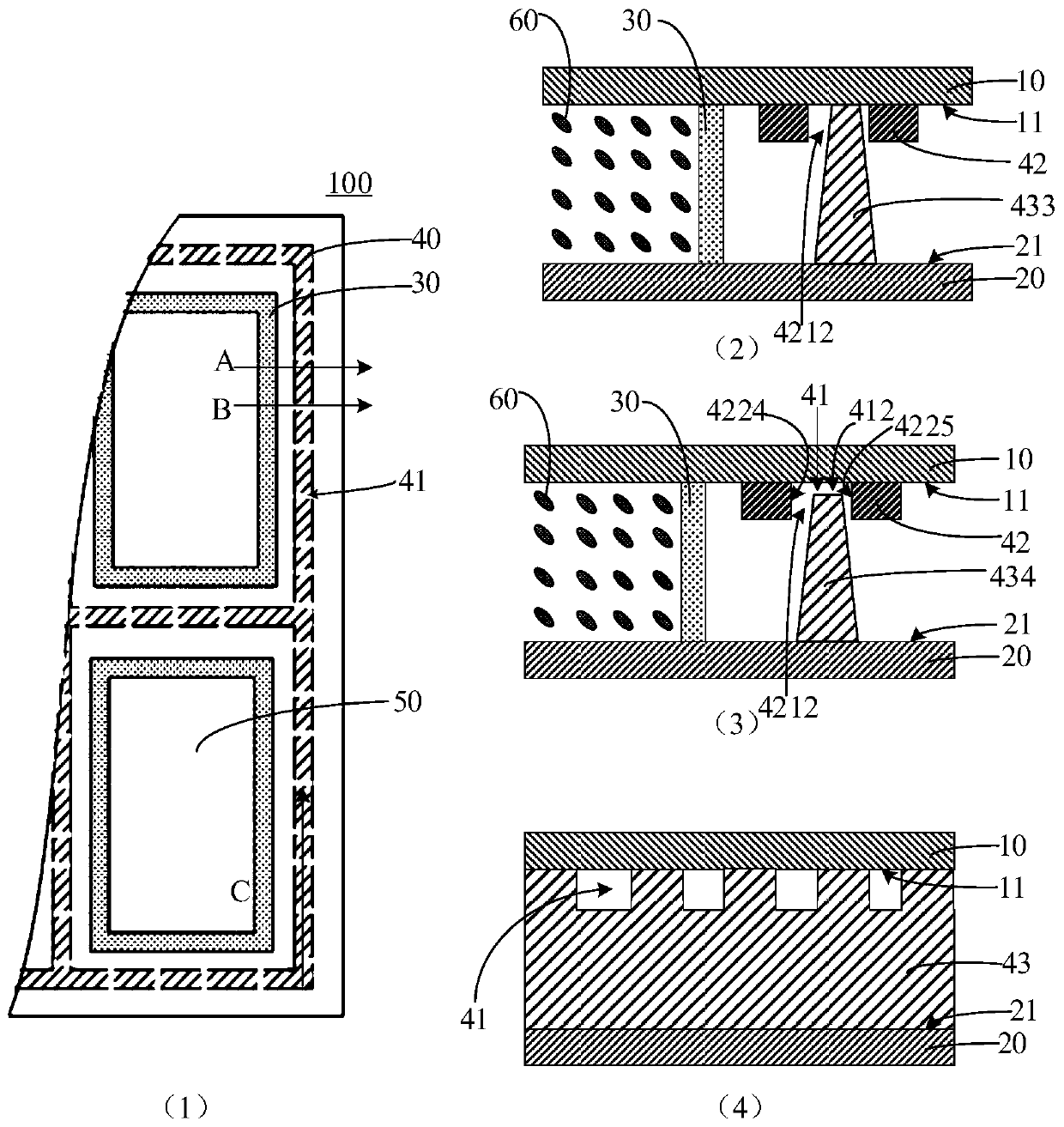

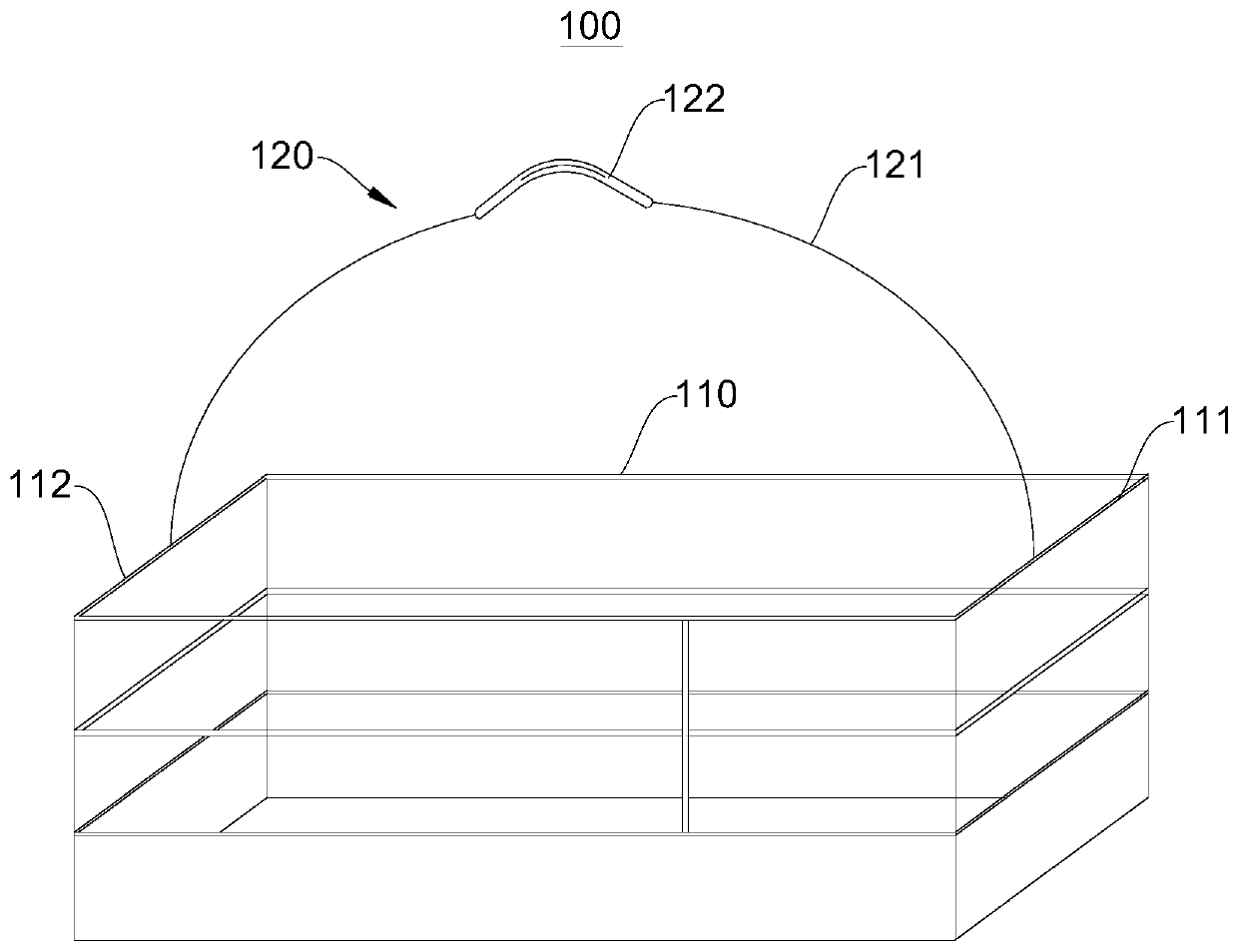

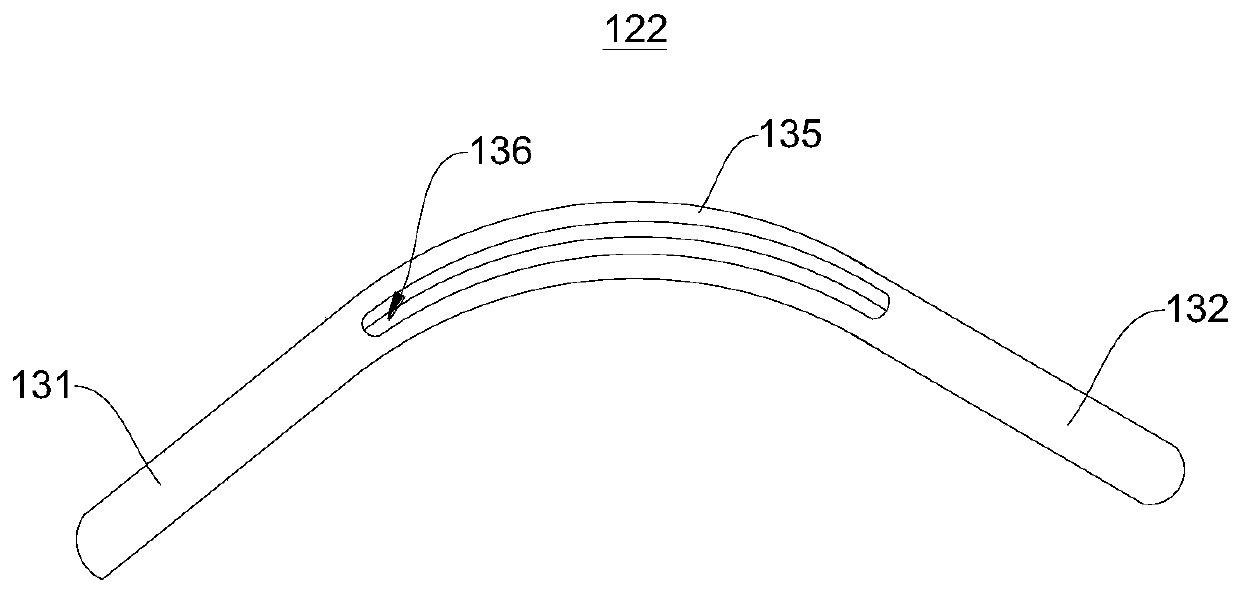

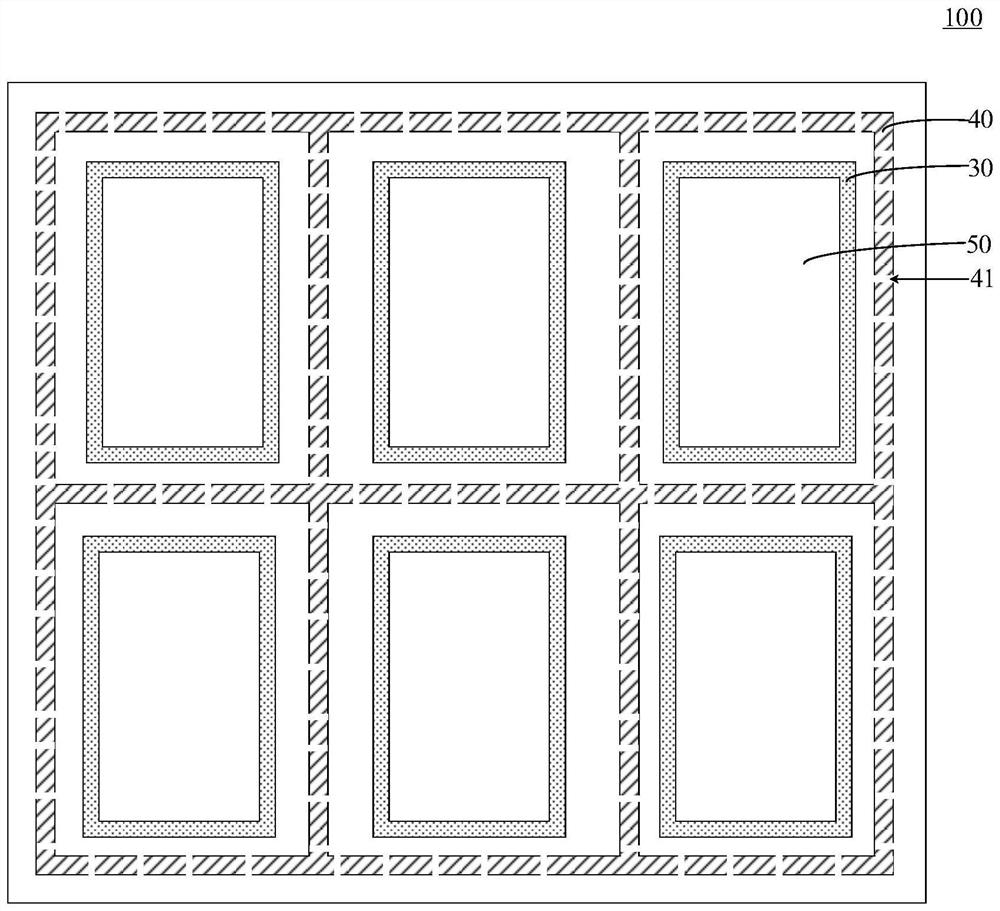

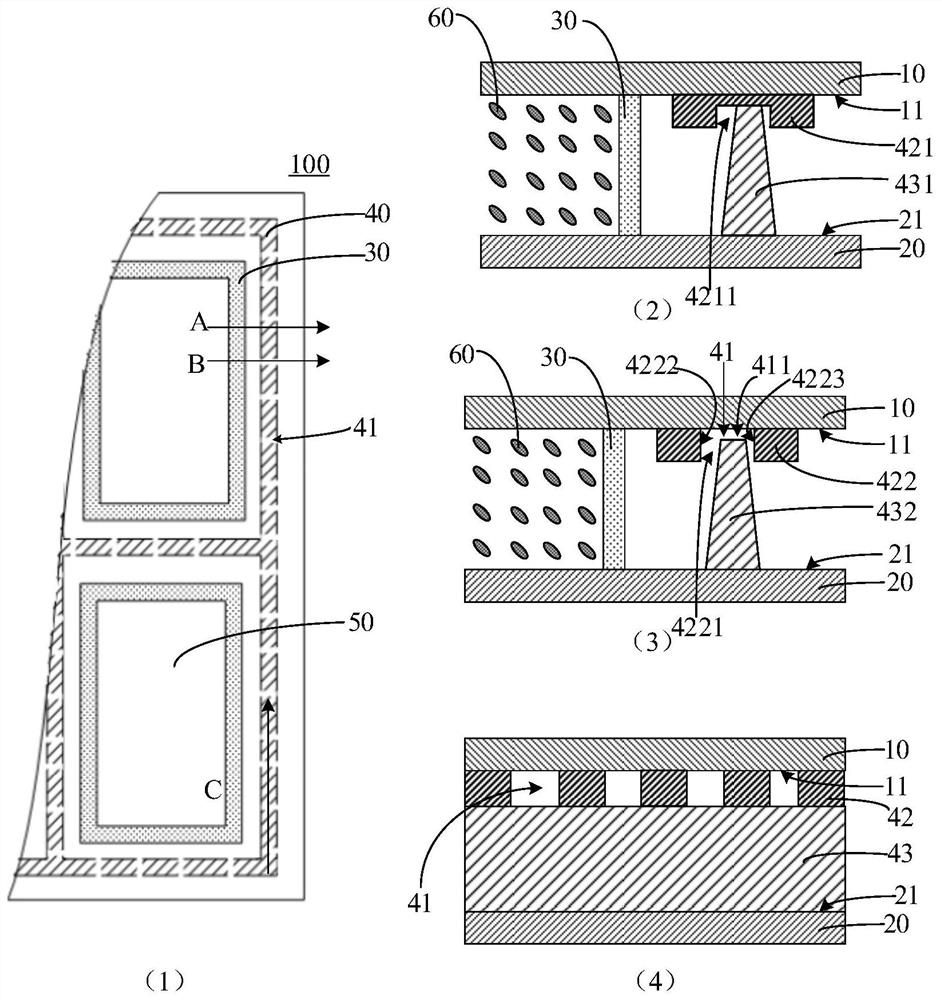

Display component

The embodiment of the application discloses a display component. The display component comprises a first substrate, a second substate, a main frame sealant and a first retaining wall, wherein the first substrate comprises a first surface, the second substrate comprises a second surface, the first surface and the second surface are arranged in an opposite manner, the main frame sealant is arrangedbetween the first surface and the second surface, the first surface, the second surface and the main frame sealant are enclosed to form a plurality of display panels, the first retaining wall is arranged around the display panel, and the first retaining wall comprises an airflow channel. According to the scheme, the airflow intensity can be alleviated, puncture or deformation caused by airflow impact is prevented, and the problem of non-uniform stress during cutting of the display component can be effectively improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

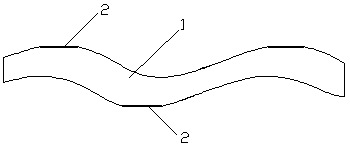

High-performance wave spring

Owner:SUZHOU CITY HUQIU DISTRICT HUSHUGUAN SPRING FACTORY

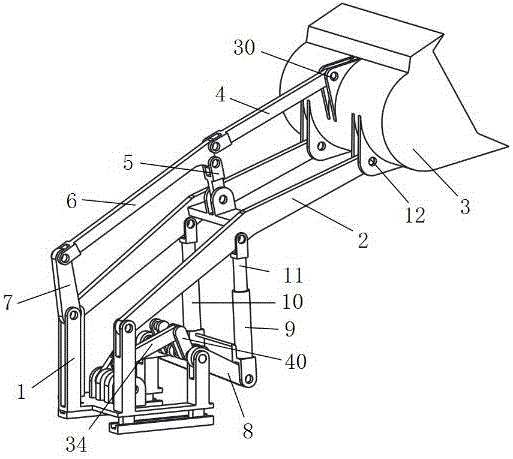

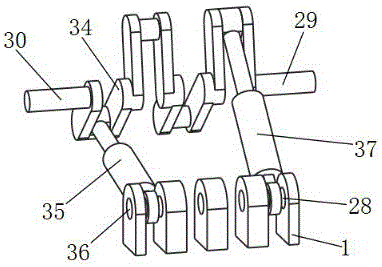

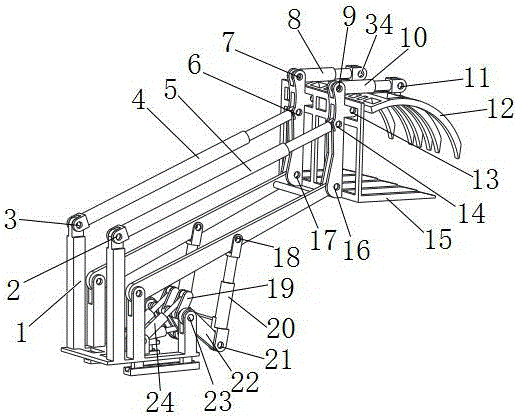

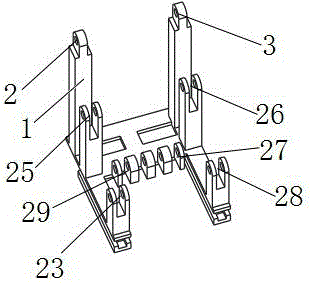

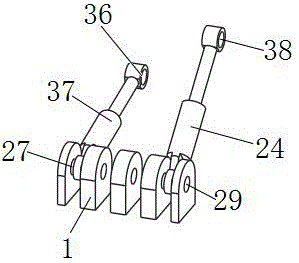

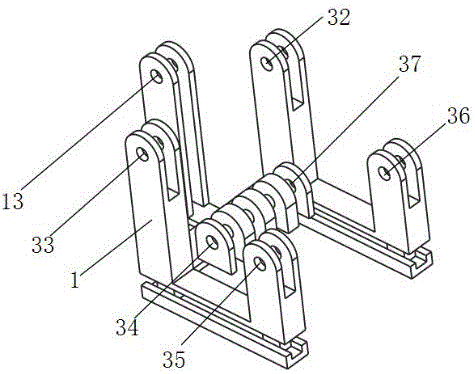

Four-range-of-motion sliding type wood forklift with multi-unit linear driving function

InactiveCN106120892AImprove carrying capacityGuaranteed carrying capacityMechanical machines/dredgersHydraulic cylinderMulti unit

A four-range-of-motion sliding type wood forklift with a multi-unit linear driving function comprises a multi-unit linear driving mechanism, a movable arm lifting mechanism, a fork bucket control mechanism and the like. The multi-unit linear driving mechanism is driven by multiple sets of linear drivers, high-power and high-torque power output is achieved through a crankshaft, and the power requirement for high-load operation of the sliding type wood forklift is met. A hydraulic cylinder is applied to the configuration design of the wood forklift as a connection rod, and a hydraulic element is introduced into the movable arm lifting mechanism, so that pressures in the cylinder are equal, the problem that in the prior art, stress on two driving chains for lifting a movable arm is unbalanced is effectively solved, and the bearing stability is improved. The sliding type wood forklift not only has the characteristics of being high in transmission efficiency, high in response speed, high in motion precision, good in controllability, capable of saving energy, environmentally friendly and the like as a controllable mechanism, but also has better bearing performance and vibration resistance through introduction of the multi-unit linear driving mechanism and the hydraulic element, can achieve the overload protection function easily and has great engineering application prospects and development potential.

Owner:SHANDONG JIAOTONG UNIV

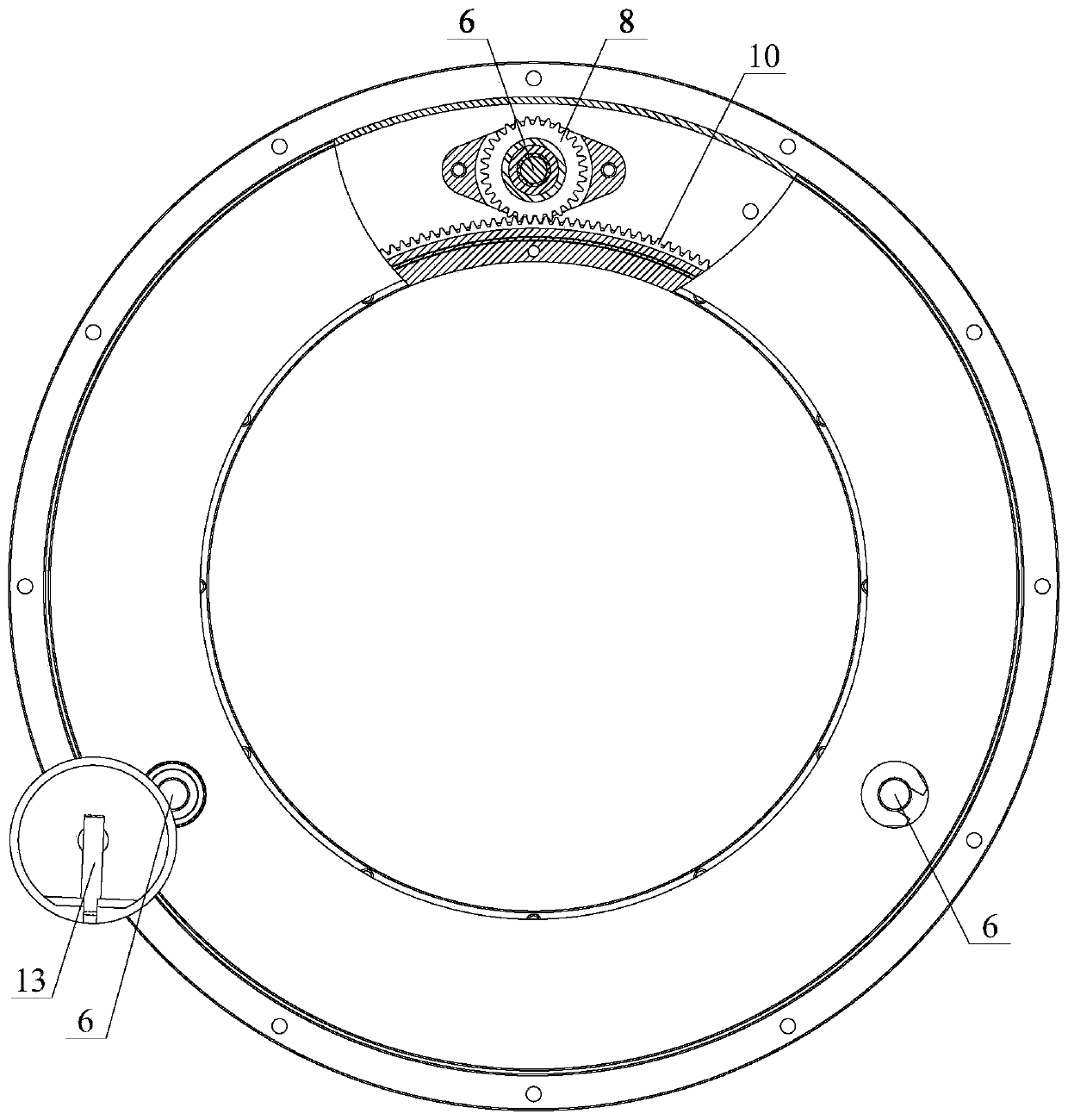

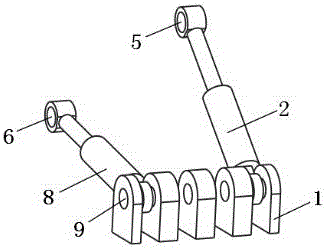

Belted layer attached drum with fast attachment diameter adjusting mechanism

ActiveCN110481074AImprove uneven forceIncrease productivityFinal product manufactureTyresEngineeringDrive shaft

The invention discloses a belted layer attached drum with a fast attachment diameter adjusting mechanism. The belted layer attached drum comprises a radial plate, a polyhedral cone and a drum core which are coaxially arranged from outside to inside. The peripheral face of the drum core is sleeved with a limiting ring in an axial moving manner, and the limiting ring is axially connected with multiple driving screw rods. An inner ring and an outer ring of small gear are engaged with the corresponding driving screw rod and a large gear ring correspondingly. The outer ring of one small gear is engaged with a driving gear, and the driving gear is connected with a rocking handle through a transmission shaft coaxially arranged in a penetrating manner. According to the belted layer attached drum,a device with the rocking handle for driving the limiting ring is additionally arranged, so that the limiting position of the belted layer attached drum adjusting polyhedral cone is easier to operate,the situation that stress is ununiform when the polyhedral cone and a limiting point are in contact is relieved through limiting of the limiting ring, the production efficiency is effectively improved, and the labor force of workers is greatly reduced.

Owner:TIANJIN SAIXIANG TECH +1

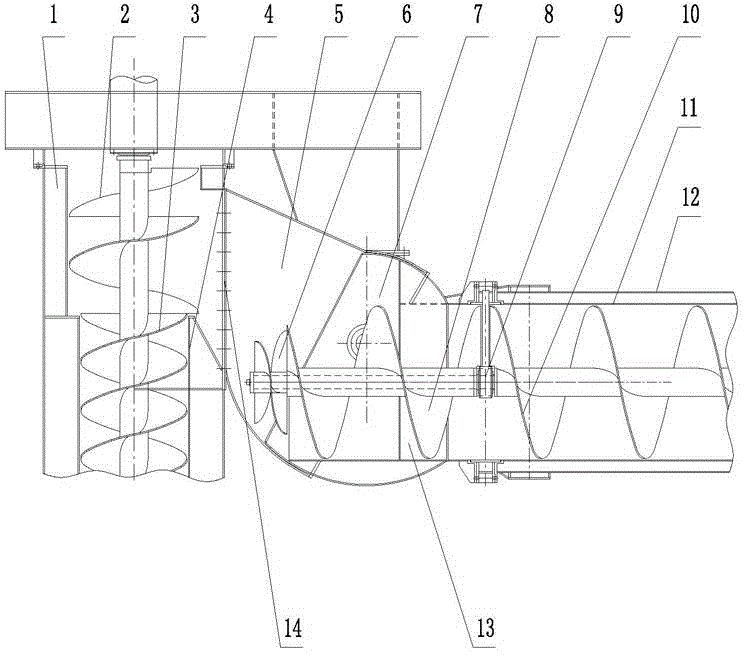

Coaxial ring-shaped material groove material transferring device

ActiveCN104627701ALarge transfer spaceImprove smooth performancePackagingLoading/unloadingEngineeringScrew conveyor

The invention discloses a coaxial ring-shaped material groove material transferring device which can improve the fluency of material flowing of a conveying system, improve the force bearing of a supporting structure, lower the energy consumption of a perpendicular screw conveyor and a horizontal screw conveyor at the transferring position, and remove a dead angle at a joint position. The coaxial ring-shaped material groove material transferring device comprises the perpendicular screw conveyor provided with a discharging port and a perpendicular supporting pipe, the horizontal screw conveyor provided with a horizontal supporting pipe, a ring-shaped discharging groove and a ring-shaped feeding groove. The ring-shaped discharging groove is connected with the discharging port through a flange, the ring-shaped feeding groove is connected with the horizontal screw conveyor through a flange, the ring-shaped discharging groove is hinged to the ring-shaped feeding groove, and the ring center of the ring-shaped discharging groove and the ring center of the ring-shaped feeding groove are hinge points of the ring-shaped discharging groove and the ring-shaped feeding groove. By means of the scheme, the purposes of improving the fluency of material flowing of the conveying system, improve the force bearing of the supporting structure, lower the energy consumption of the perpendicular screw conveyor and the horizontal screw conveyor at the transferring position, and remove the dead angle at the joint position are achieved.

Owner:WUHAN UNIV OF TECH +1

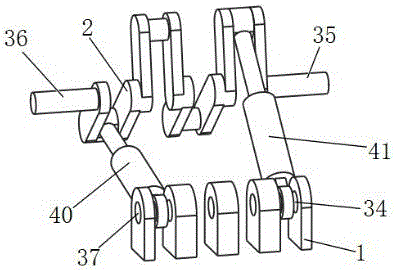

Multi-unit-linear-driven loading robot with three planar ranges of motion

InactiveCN106013285AKinesiology is goodImprove mechanical propertiesMechanical machines/dredgersMulti unitRange of motion

A multi-unit-linear-driven loading robot with three planar ranges of motion comprises a multi-unit-linear-driving mechanism, a movable arm lifting mechanism, a bucket control mechanism and the like. Multiple linear drivers are adopted by the multi-unit-linear-driving mechanism for driving, high-power and high-torque power output is achieved through cranks, and the power requirement of an executing mechanism is met. Hydraulic elements are introduced in the movable arm lifting mechanism, equal pressure in two cylinders is achieved, the problem of unbalanced stress on two driving chains for lifting movable arms in original controllable loading mechanisms is effectively solved, and the bearing stability of the movable arms is improved. the loading robot not only has the characteristics of high mechanical efficiency, high response speed, high moving precision, good controllability and the like of the original controllable loading mechanisms, but also has better bearing and shock-resisting performance due to introduction of the multi-unit-linear-driving mechanism and the hydraulic elements, an overload protection function can be easily achieved, and the technical scheme is quite suitable for manufacturing of large, medium and small loading robots.

Owner:SHANDONG JIAOTONG UNIV

Multiunit linear driving simple high-load electro-hydraulic controllable sliding wood forking machine

InactiveCN106049570AImprove carrying capacityGuaranteed carrying capacityMechanical machines/dredgersHydraulic cylinderElectro hydraulic

The invention relates to a multiunit linear driving simple high-load electro-hydraulic controllable sliding wood forking machine. The multiunit linear driving simple high-load electro-hydraulic controllable sliding wood forking machine comprises a multiunit linear driving mechanism, a movable arm lifting mechanism, a fork bucket control mechanism and the like, wherein the multiunit linear driving mechanism is driven by a plurality of groups of linear drivers, high-power and high-torque power output is realized by virtue of a crankshaft, and the power requirement of high-load operation of the sliding wood forking machine is satisfied. On the basis of the Pascal's principle, hydraulic cylinders are used as connecting rods so as to be introduced into the configuration of the wood forking machine, so that the problem of unbalanced stress of two driving chains for lifting movable arms in the existing design is effectively solved, and the bearing stability is increased. The sliding wood forking machine has the characteristics of high transmission efficiency, high response speed, high moving accuracy, good controllability, energy conservation, environmental friendliness and the like of a controllable mechanism, and the multiunit linear driving mechanism and hydraulic elements are introduced, so that the sliding wood forking machine has good bearing and antivibration performance, an overload protection function is easy to realize, and the sliding wood forking machine has good engineering application prospects and development potential.

Owner:SHANDONG JIAOTONG UNIV

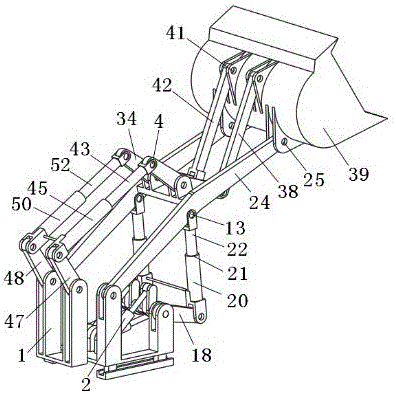

Multi-unit linkage-drive planar 3-acitivity face-shovel loading robot

InactiveCN105951903AImprove power adaptabilityGood kinematics and dynamicsMechanical machines/dredgersHigh torqueControllability

A multi-unit linkage-driven planar 3-acitivity face-shovel loading robot comprises a multi-unit linkage-drive mechanism, a movable arm lifting mechanism, a bucket control mechanism, and the like. Under the control of a computer, the multi-unit linkage-drive mechanism is driven by a plurality of low-power motors, the high-power and high-torque power output is achieved, and then the high-loading operation power demand of the loading robot is met; based on the Pascal's law, the same in-cylinder pressure is achieved by introduction of hydraulic elements into the movable arm lifting mechanism, thereby effectively solving the problem that two drive chains of lifting movable arms of a conventional controllable loading mechanism are subjected to uneven pressure and improving the bearing stability; the loading robot has not only the high-transmission-efficiency, high-response-speed, high-motion-accuracy, high-controllability and other characteristics of the conventional controllable loading mechanism, but also better bearing and anti-vibration properties by introduction of the multi-unit linkage-drive mechanism and the hydraulic elements; meanwhile, the overload protection function is easy to achieve; and such technical scheme is very suitable for manufacturing of large-, medium- and small-sized loading robots.

Owner:SHANDONG JIAOTONG UNIV

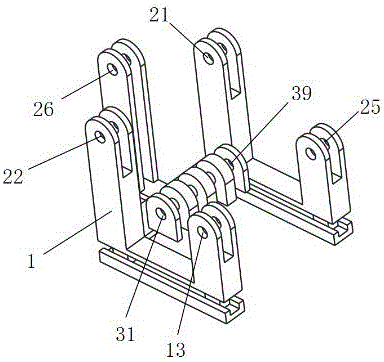

Simple high-load wood forklift with multi-unit connection rod driving function

InactiveCN106115557AImprove power adaptabilitySolve power problemsLifting devicesMulti unitHydraulic cylinder

A simple high-load wood forklift with a multi-unit connection rod driving function comprises a multi-unit connection rod driving mechanism, a movable arm lifting mechanism, a fork bucket control mechanism and the like. Under the control of a computer, the multi-unit connection rod driving mechanism achieves driving of multiple low-power motors and high-power and high-torque power output, and meets the power requirement for high-load operation of the wood forklift. A hydraulic cylinder is applied to the configuration design of the wood forklift as a connection rod on the basis of the Pascal principle, through introduction of a hydraulic element, the problem that in the prior art, stress on two driving chains for lifting a movable arm is unbalanced is effectively solved, and the bearing stability is improved. The wood forklift not only has the characteristics of being high in transmission efficiency, high in response speed, high in motion precision, good in controllability, capable of saving energy, environmentally friendly and the like as a controllable mechanism, but also has better bearing performance and shock resistance through introduction of the multi-unit connection rod driving mechanism and the hydraulic element, can achieve the overload protection function easily and has great engineering application prospects and development potential.

Owner:SHANDONG JIAOTONG UNIV

Planar three-degree-of-freedom sliding type loading robot with multi-unit linear driving function

InactiveCN106120894AGood lift and translationImprove rigidityMechanical machines/dredgersMulti unitHydraulic cylinder

A planar three-degree-of-freedom sliding type loading robot with a multi-unit linear driving function comprises a multi-unit linear driving mechanism, a movable arm lifting mechanism, a bucket control mechanism and the like. Under control of a computer, the multi-unit linear driving mechanism achieves driving of multiple low-power linear drivers and high-power and high-torque power output, and meets the power requirement for the sliding type loading robot. A hydraulic cylinder is applied to the configuration design of the loading robot as a connection rod, through introduction of a hydraulic element, the problem that stress on two driving chains for lifting a movable arm of an original controllable sliding loading mechanism is unbalanced is effectively solved, and the bearing stability is improved. The sliding type loading robot not only has the characteristics of being high in transmission efficiency, high in response speed, high in motion precision, good in controllability and the like as the original controllable sliding loading mechanism, but also has better bearing performance, shock resistance and lifting translation performance through the novel configuration design, can achieve the overload protection function easily and is quite suitable for manufacturing of large, intermediate, and small-sized sliding type loading robots.

Owner:SHANDONG JIAOTONG UNIV

Multi-unit connecting rod driving high-stability electro-hydraulic controllable sliding type wood forking machine

InactiveCN106120907AImprove mechanical propertiesImprove rigidityMechanical machines/dredgersMulti unitHydraulic cylinder

The invention provides a multi-unit connecting rod driving high-stability electro-hydraulic controllable sliding type wood forking machine. The multi-unit connecting rod driving high-stability electro-hydraulic controllable sliding type wood forking machine comprises a multi-unit connecting rod driving mechanism, a movable arm lifting mechanism, a fork bucket control mechanism and the like. Driving of a plurality of small-power motors and large-power and high-torque power output are achieved through the multi-unit connecting rod driving mechanism under control of a computer, and the high-load operation power requirements of the sliding type wood forking machine are met. Based on the Pascal principle, a hydraulic cylinder is used as a connecting rod to be applied to the type design of a wood forking mechanism, the problem that two driving chains of a lifting movable arm are unbalanced in stress in the previous design is effectively solved, and the bearing stability is improved. The sliding type wood forking machine not only has the characteristics of being high in transmission efficiency, response speed and moving precision, good in controllability, savable in energy, environmentally friendly and the like of a controllable mechanism, but also has better bearing performance and better anti-vibration performance by introducing the multi-unit connecting rod driving mechanism and a hydraulic element; an overload protection function is easy to achieve; and the engineering application prospects and the development potential are high.

Owner:SHANDONG JIAOTONG UNIV

Bicycle steering link mechanism

The invention discloses a bicycle steering connecting rod mechanism, and belongs to the field of mechanical steering transmission. The mechanism is a bilateral pull rod structure with an angle limit function. The bicycle steering link mechanism is mounted between a frame and a front fork of a front wheel and used for steering the front wheel of a bicycle, and is characterized by comprising a steering vertical pipe, a steering pull rod, a steering linkage piece, a first transmission connecting piece, a second transmission connecting piece and a universal shaft. The mechanism is particularly suitable for a middle-mounted carrying bicycle. On one hand, the defects that a traditional single-side single-pull-rod structure is unbalanced in stress and poor in rigidity are overcome, and on the other hand, the arranged steering angle limiting piece can ensure that the steering connecting rod mechanism can operate safely and reliably, and motion interference is avoided.

Owner:天津市路士美科技发展有限公司

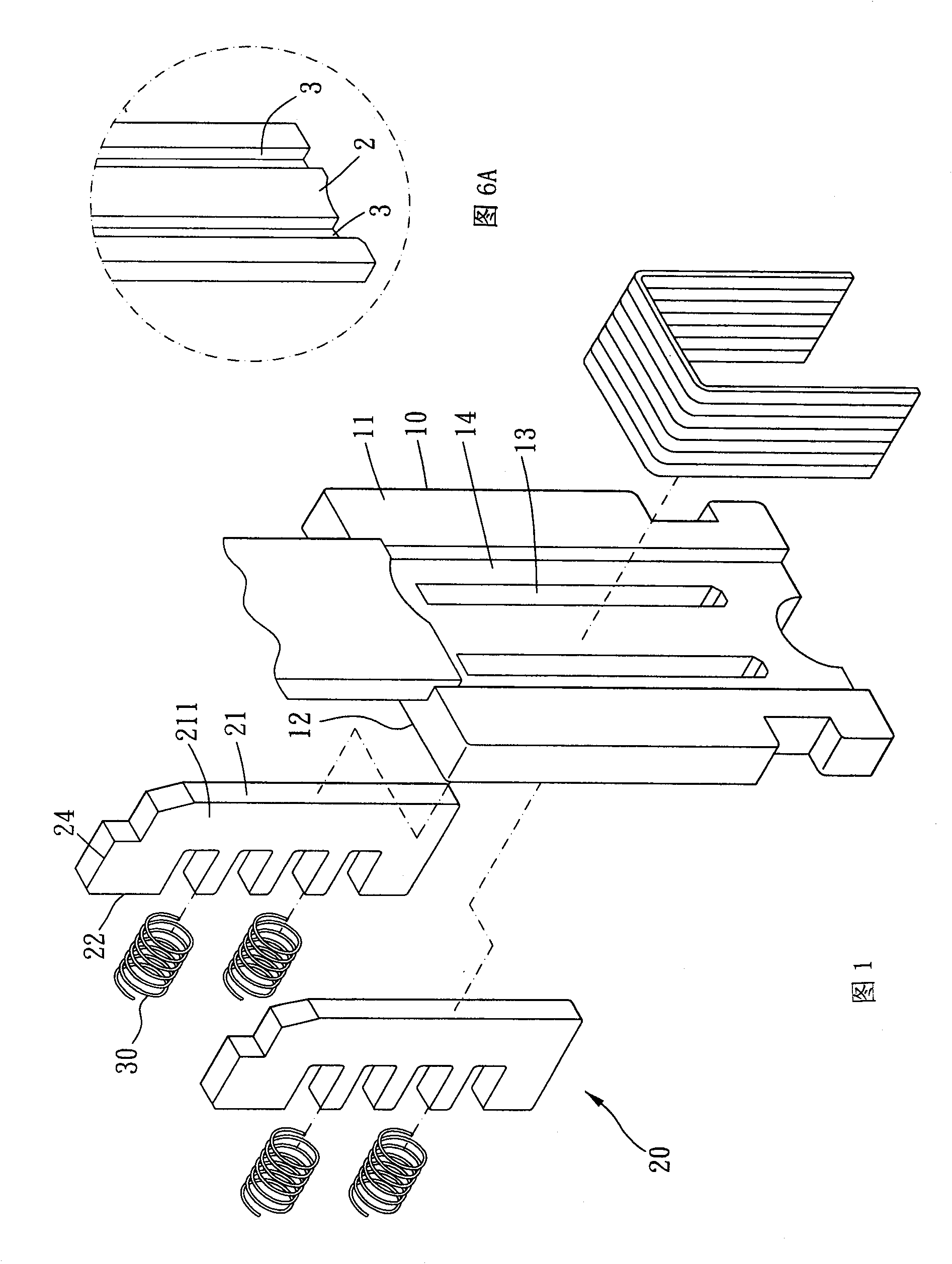

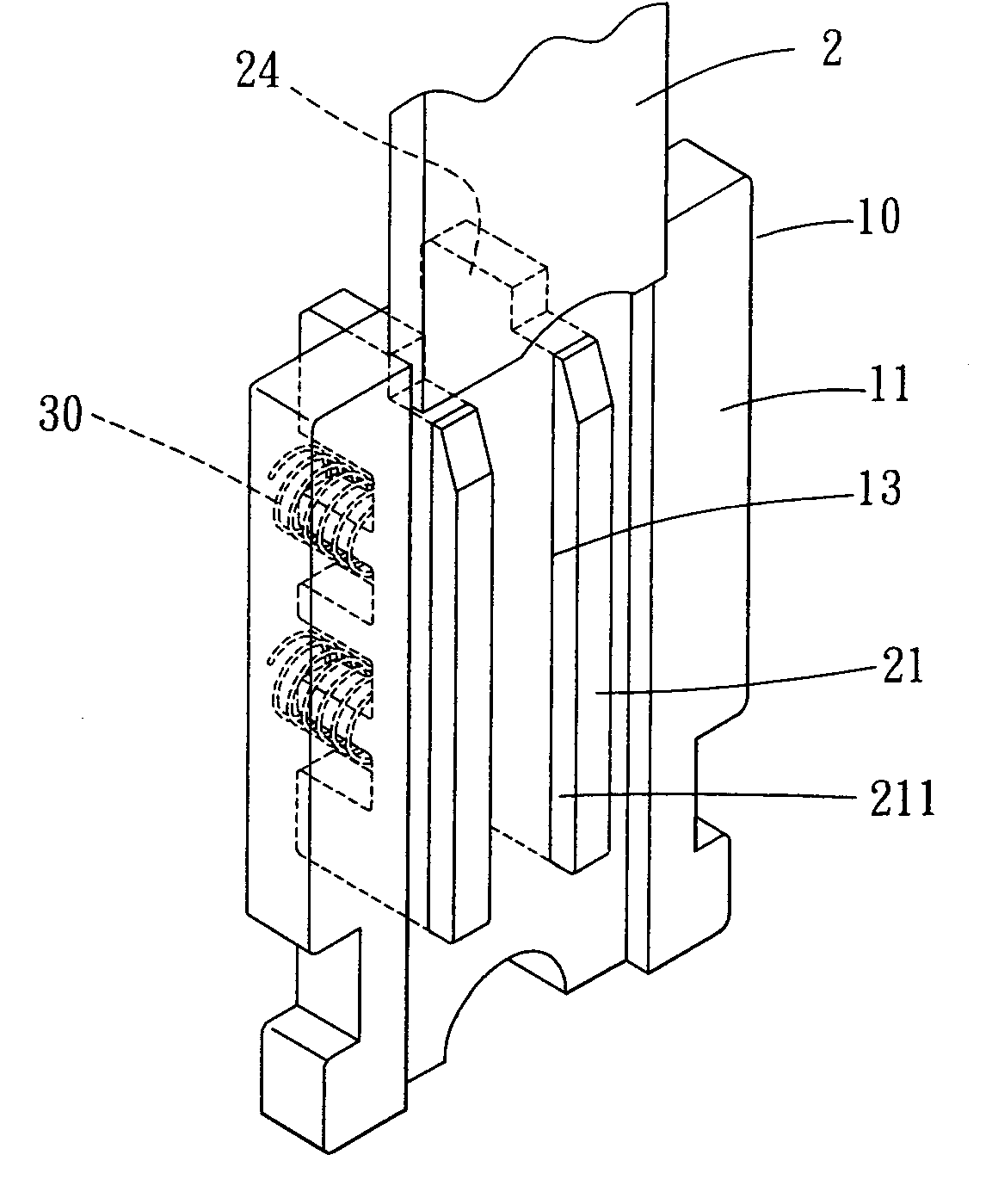

Guide nail structure and nail gun with the same

InactiveCN102371572BImprove uneven forceImprove work efficiencyStapling toolsEngineeringNail structure

The invention discloses a nail guiding structure, comprising a guiding plate, at least one supporting member and a pushing and butting means. The guiding plate is vertically arranged in front of a nail rail and is provided with a first face and a second face, the first face of the guiding plate faces to the nail rail, the guiding plate is provided with at least one vertical penetration groove which penetrates through the first face and the second face of the guiding plate, the supporting member penetrates into the penetration groove in a manner of sliding back and forth, the supporting member is provided with a supporting end and a pushing and butting end, the supporting end selectively protrudes and extends outside the first face, the pushing and butting end is located at the side with the second face, the supporting member is further provided with at least one supporting face which is parallel to the extending direction of the nail rail and is used for supporting and righting a nail pin, and the pushing and butting means is used for elastically pushing and butting the pushing and butting end, and thus, the supporting end is endowed with a trend of protruding and extending to the outside of the first face.

Owner:APEX MFG

Plane three-activity electro-hydraulic controllable face shovel loading robot

InactiveCN106120890AKinesiology is goodImprove mechanical propertiesMechanical machines/dredgersElectro hydraulicControllability

The invention provides a plane three-activity electro-hydraulic controllable face shovel loading robot. The plane three-activity electro-hydraulic controllable face shovel loading robot comprises a movable arm lifting mechanism, a bucket control mechanism and the like. A hydraulic element is introduced into the movable arm lifting mechanism, so that the in-cylinder pressure is equal, the problem that two lifting branched chains of a movable arm of the loading robot are unbalanced in stress is solved, and the bearing stability is improved. According to the plane three-activity electro-hydraulic controllable face shovel loading robot, the characteristics of being high in transmission efficiency, response speed and moving precision, good in controllability and the like of an existing controllable loading mechanism are achieved; and in addition, the bearing capability and the anti-vibration performance of the loading robot are greatly improved by introducing the hydraulic element, an overload protection function is easy to achieve, the reliability and the practicability of the loading robot are greatly improved so that operation in places where the construction environments are bad can be achieved through the loading robot, and the hydraulic element is suitable for manufacturing large-size, medium-size and small-size loading robots.

Owner:SHANDONG JIAOTONG UNIV

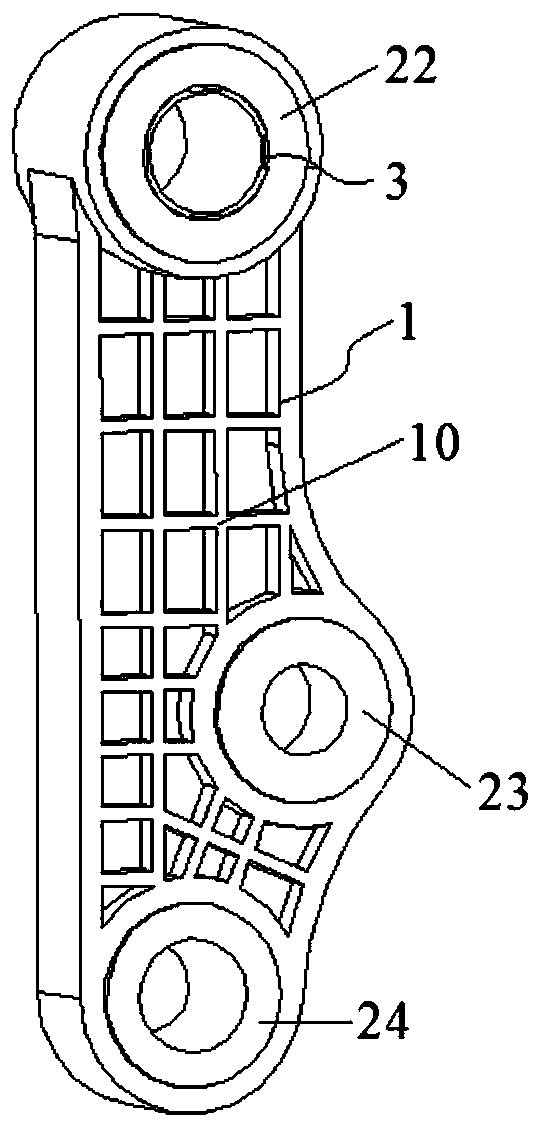

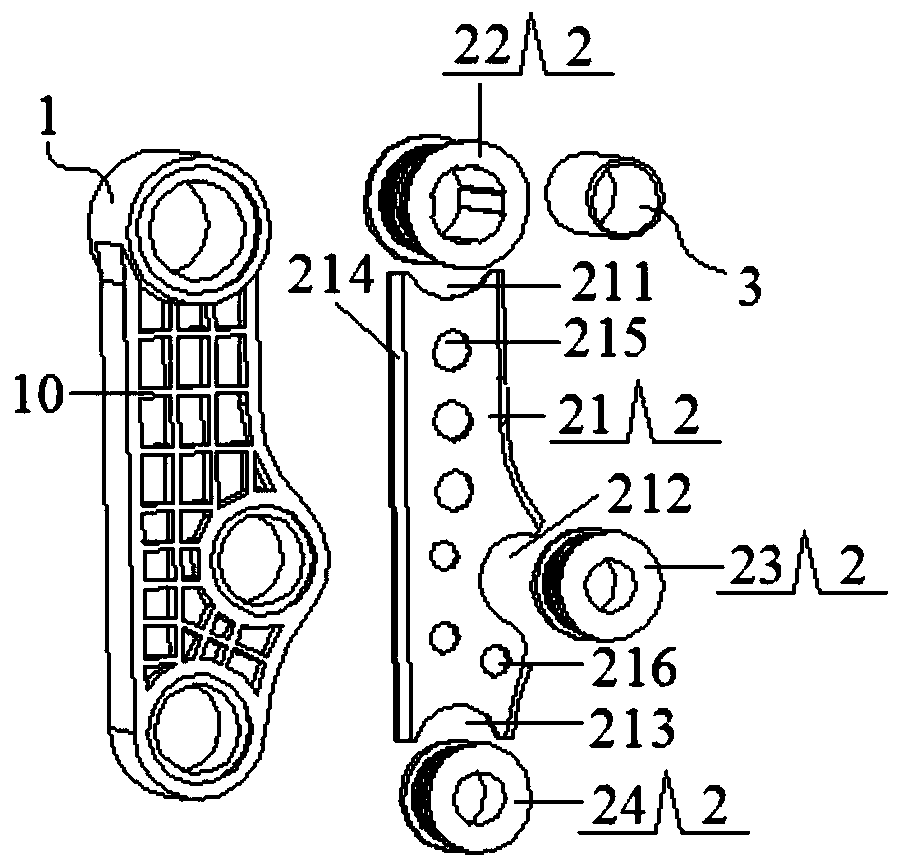

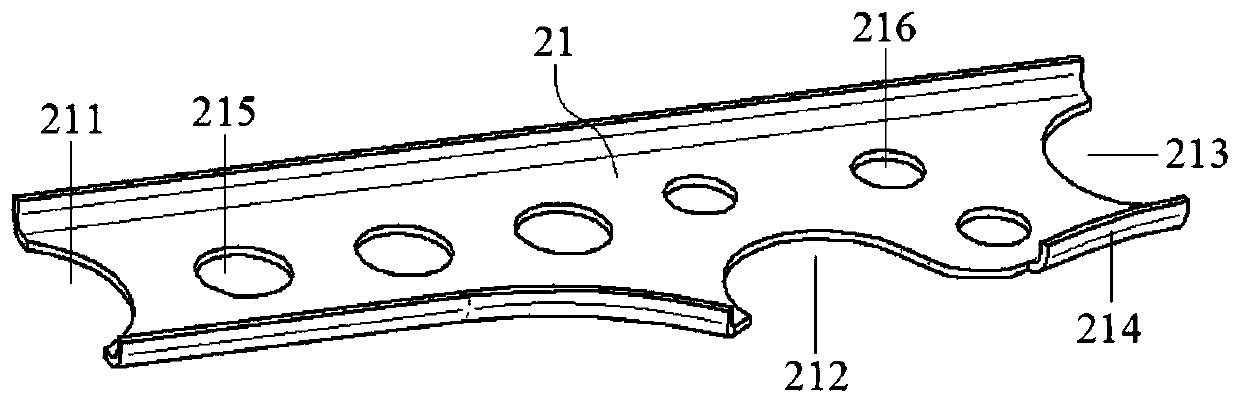

A steering rod swing arm

The invention discloses a steering pull rod swinging arm comprising a swinging arm body, a skeleton and a sliding bearing. The swinging arm body and the skeleton are subjected to insert injection molding; the skeleton comprises a skeleton main body, a sliding bearing seat, a first steering pull rod lining and a second steering pull rod lining; the gravity center of a triangle constituted by geometric centers of a sliding bearing seat notch, a first steering pull rod lining notch and a second steering pull rod lining notch coincides with the gravity center of the skeleton; and the sliding bearing is fixed into the sliding bearing seat in an embedded mode. According to the steering pull rod swinging arm, the swinging arm body is formed on the skeleton through an insert injection molding technology, and the cost is low; and through all the notches in the skeleton main body, the problem of uneven force bearing of the steering pull rod swinging arm is solved advantageously, and thus the service life of the steering pull rod swinging arm is prolonged.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

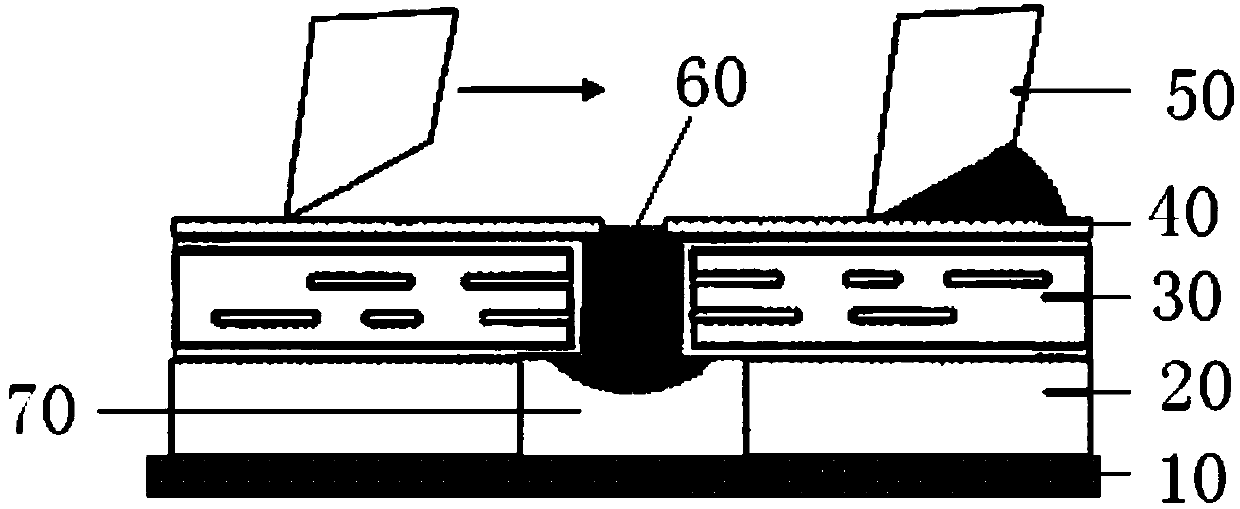

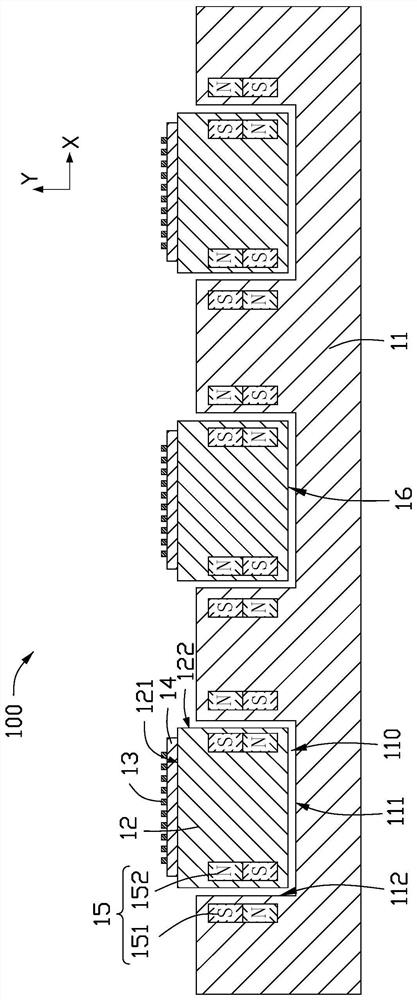

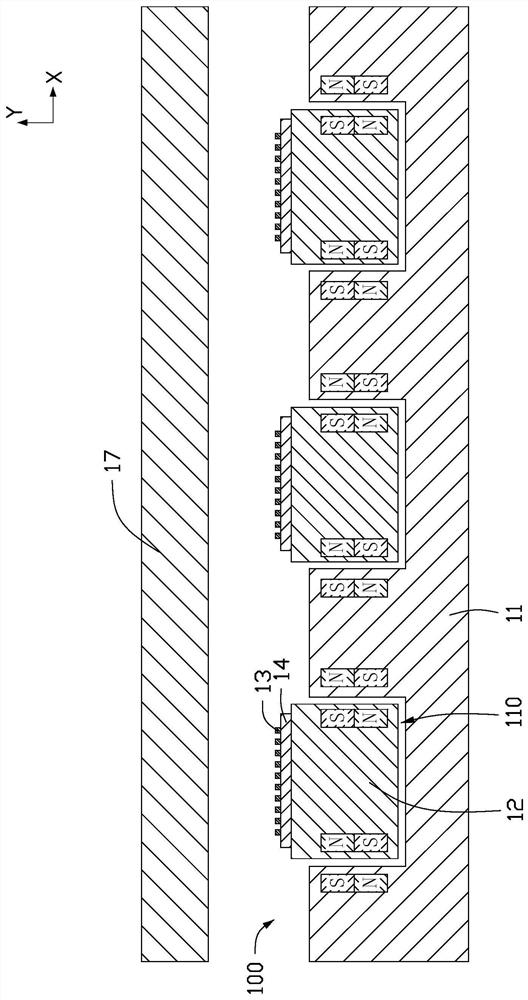

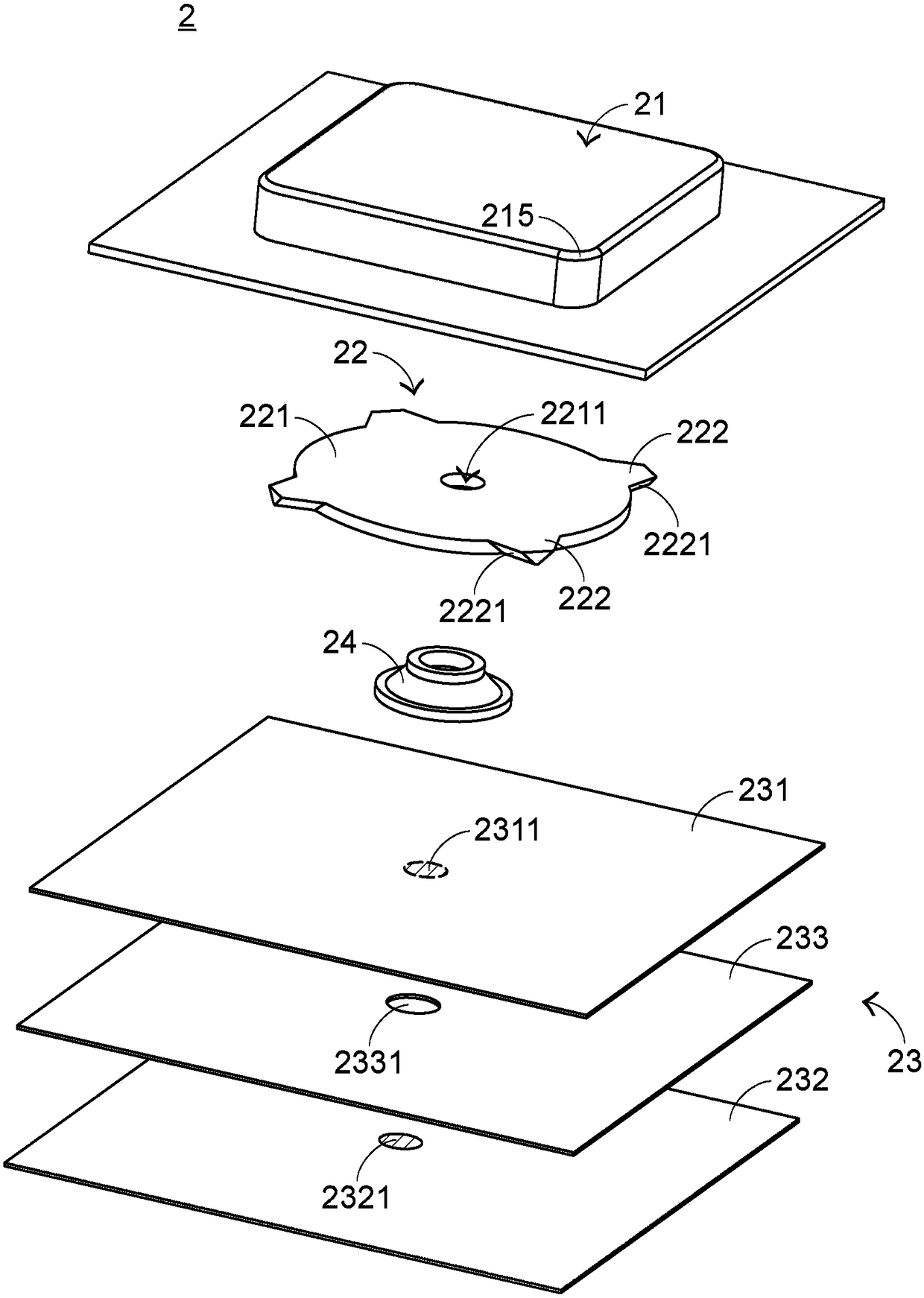

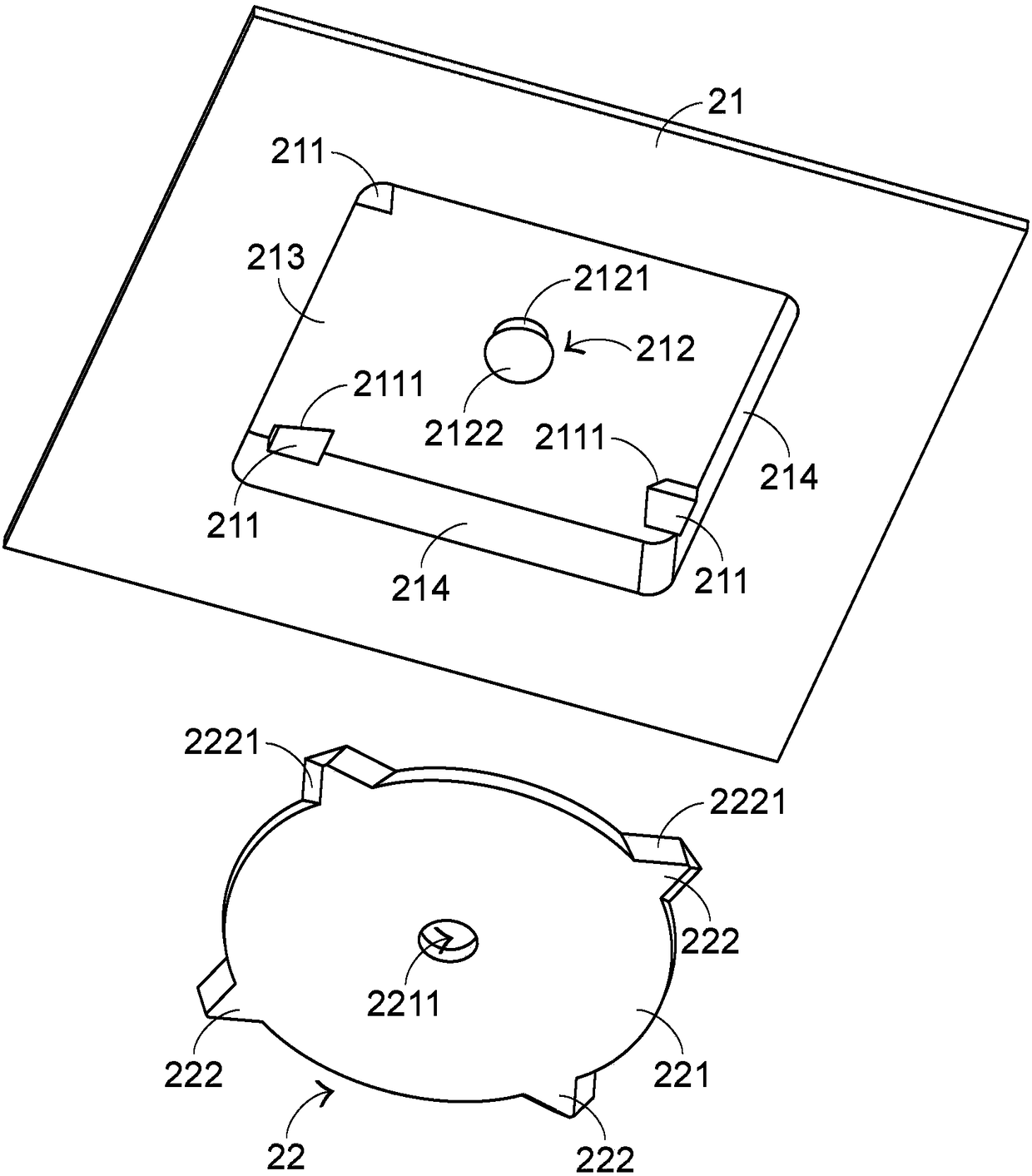

Micro device transfer device and micro device transfer method

ActiveCN110707016BImprove uneven forceHeight adjustableSolid-state devicesSemiconductor/solid-state device manufacturingMicro devicesEngineering

The present invention provides a transfer device for a micro device, comprising: a first base; a transfer base, the transfer base is formed on the first base, and the transfer base is used to carry a plurality of micro devices; the first base At least one cushioning element is also included between the transfer substrate and the transfer substrate. The transfer device of the micro device of the present invention can provide a buffer force when transferring the micro device, so as to prevent the micro device from being damaged.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Four-range-of-motion electrical-hydraulic mechanism type wood forklift with multi-unit linear driving function

InactiveCN106082037AImprove rigidityImprove job stabilityLifting devicesConfiguration designRange of motion

A four-range-of-motion electrical-hydraulic mechanism type wood forklift with a multi-unit linear driving function comprises a multi-unit linear driving mechanism, a movable arm lifting mechanism, a fork bucket control mechanism and the like. The multi-unit linear driving mechanism is driven by a multi-set linear driver, achieves high-power and high-torque power output through a crankshaft and meets the power requirement of high-load operation of the wood forklift. A hydraulic cylinder is applied to the configuration design of the wood forklift as a connection rod on the basis of the Pascal principle, the problem that in the prior art, stress on two driving chains for lifting a movable arm is unbalanced is effectively solved through introduction of a hydraulic element, and the bearing stability is improved. The wood forklift not only has the characteristics of being high in transmission efficiency, high in response speed, high in motion precision, good in controllability, capable of saving energy, environmentally friendly and the like as a controllable mechanism, but also has better bearing performance and shock resistance through introduction of the multi-unit connection rod driving mechanism and the hydraulic element, can achieve the overload protection function easily and has great engineering application prospects and development potential.

Owner:SHANDONG JIAOTONG UNIV

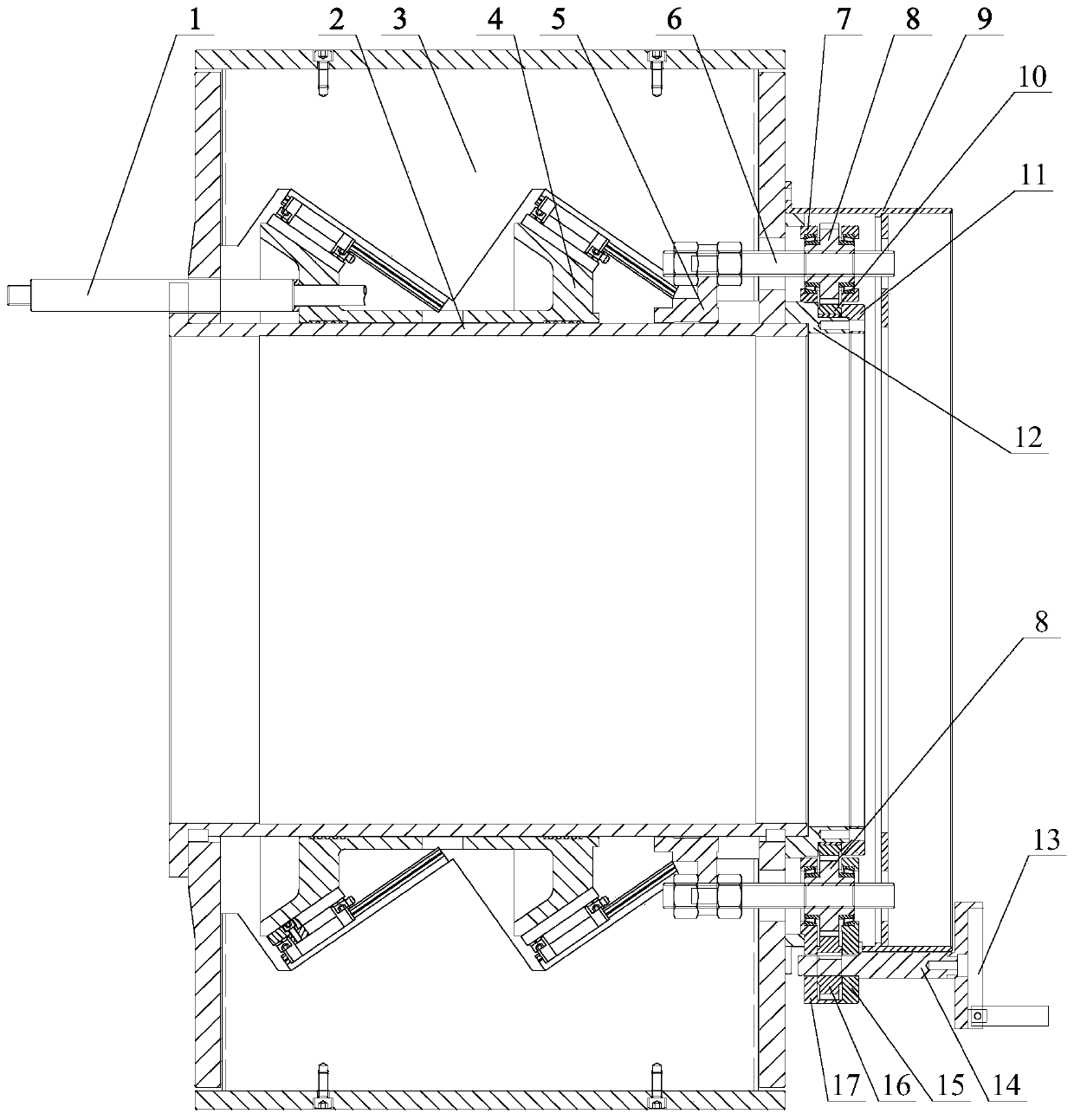

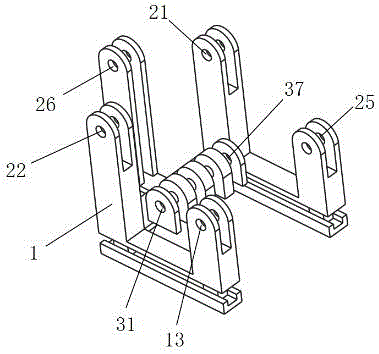

Sixteen-rod four-range-of-motion heavy-duty loading robot with multi-unit linear driving function

A multi-unit linear drive sixteen-rod four-degree-of-motion heavy-duty loading robot includes a multi-unit linear drive mechanism, a boom lifting mechanism, a bucket control mechanism, and the like. The multi-unit linear drive mechanism is driven by multiple sets of linear drives, and realizes high-power, high-torque power output through the crankshaft to meet the power requirements of the actuator. By introducing hydraulic components into the boom lifting mechanism and bucket control mechanism, the pressure in the cylinder is equalized, the problem of unbalanced force on the two drive chains of the loading robot bucket and boom is improved, and the load stability is improved. The loading robot not only has the characteristics of high transmission efficiency, fast response, high motion precision, and good controllability, but also the planar parallel design of the bucket control mechanism and the introduction of multi-unit linear drive mechanism and hydraulic components have greatly improved its carrying capacity. And anti-vibration performance, and easy to achieve overload protection function, especially suitable for manufacturing heavy-duty high-load loading robots.

Owner:SHANDONG JIAOTONG UNIV

Basket and architectural basket equipment

InactiveCN109695343AEven by forceReduce security risksBuilding support scaffoldsHanging basketEngineering

The invention relates to the field of buildings and in particular relates to a basket and architectural basket equipment. The basket comprises a basketry and a suspension assembly, wherein the basketry comprises a first end and a second end opposite to each other; the suspension assembly comprises a traction rope and a suspension body; the traction rope is connected with the first end, the suspension body and the second end in sequence; the suspension body comprises a first extension part and a second extension part which are connected with each other and between which an included angle is formed; a first hole is formed in the first extension part; a second hole communicated with the first hole is formed in the second extension part; the traction rope penetrates through the first hole andthe second hole in sequence; the hole diameter of the first hole and the second hole is greater than the diameter of the traction rope. The included angle is formed between the first extension part and the second extension part, and the hole diameter of the first hole and the second hole is greater than the diameter of the traction rope. When a worker walks in the basket, the center of gravity istransferred, and the traction rope slides relative to the suspension body under constraint of the first hole and the second hole, so that the stress of the traction rope on two sides of the suspensionbody is uniform, and potential safety hazards are reduced.

Owner:浙江恒鸿建设有限公司

A simple high-load forklift driven by multi-unit connecting rods

InactiveCN106115557BImprove mechanical propertiesImprove rigidityLifting devicesMulti unitHydraulic cylinder

A simple high-load wood forklift with a multi-unit connection rod driving function comprises a multi-unit connection rod driving mechanism, a movable arm lifting mechanism, a fork bucket control mechanism and the like. Under the control of a computer, the multi-unit connection rod driving mechanism achieves driving of multiple low-power motors and high-power and high-torque power output, and meets the power requirement for high-load operation of the wood forklift. A hydraulic cylinder is applied to the configuration design of the wood forklift as a connection rod on the basis of the Pascal principle, through introduction of a hydraulic element, the problem that in the prior art, stress on two driving chains for lifting a movable arm is unbalanced is effectively solved, and the bearing stability is improved. The wood forklift not only has the characteristics of being high in transmission efficiency, high in response speed, high in motion precision, good in controllability, capable of saving energy, environmentally friendly and the like as a controllable mechanism, but also has better bearing performance and shock resistance through introduction of the multi-unit connection rod driving mechanism and the hydraulic element, can achieve the overload protection function easily and has great engineering application prospects and development potential.

Owner:SHANDONG JIAOTONG UNIV

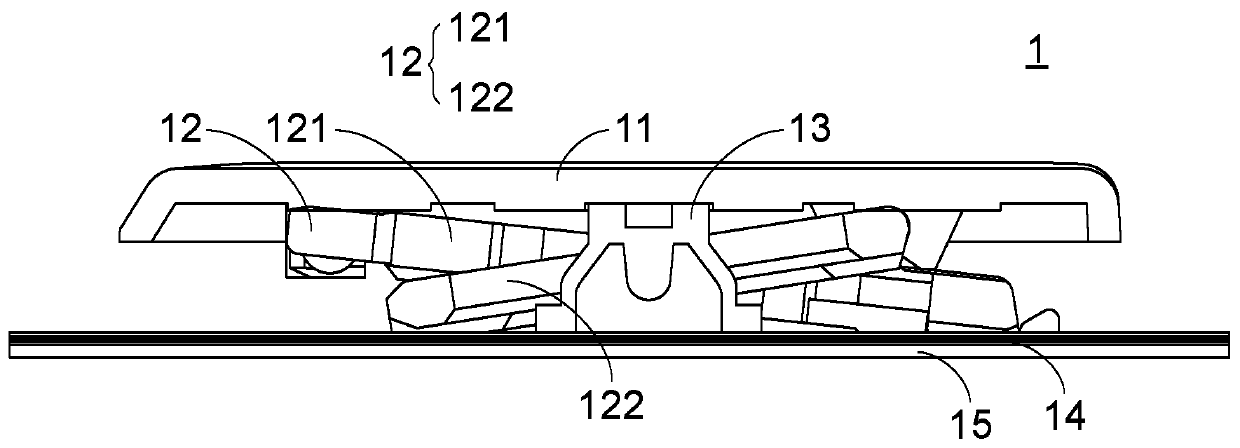

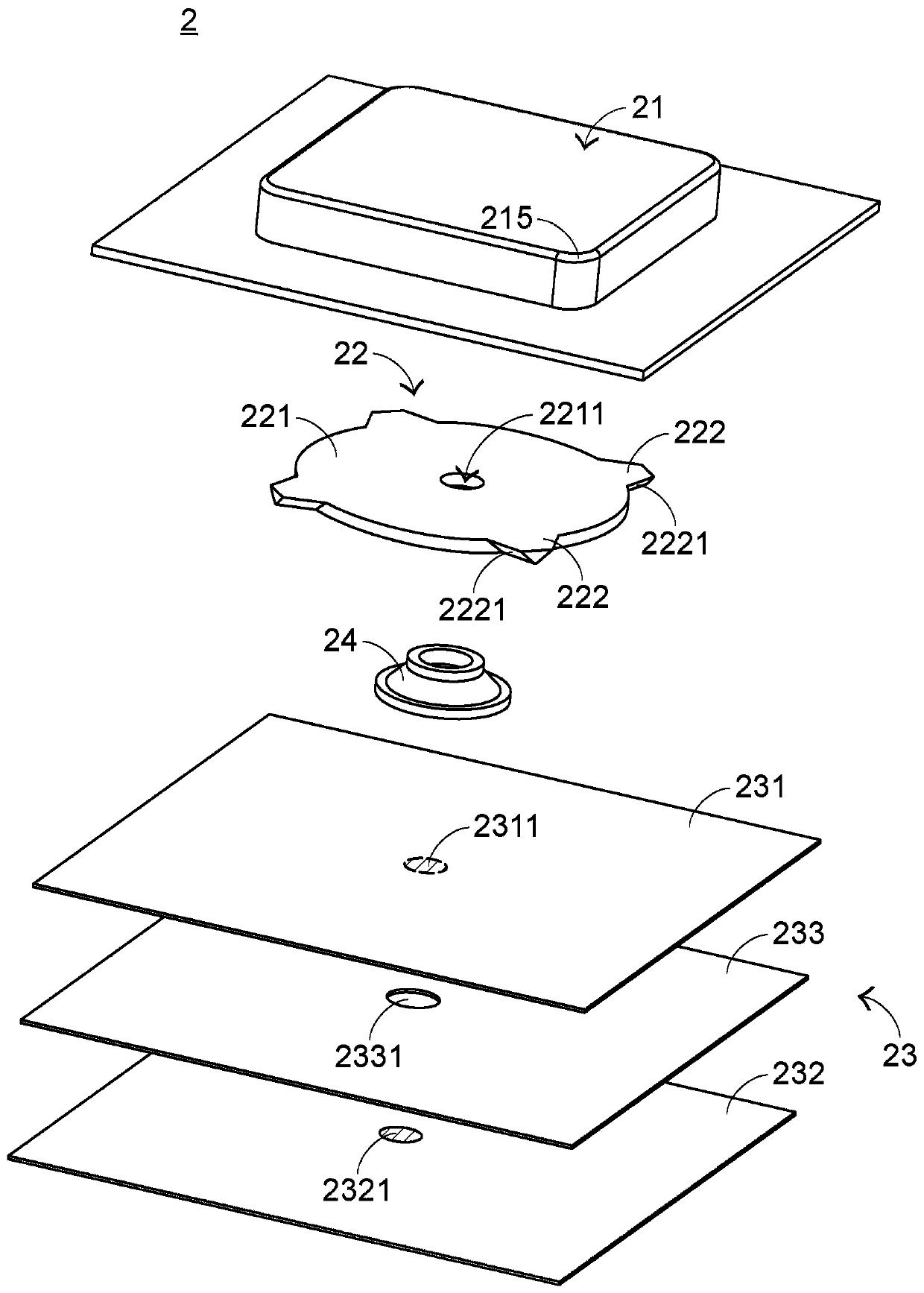

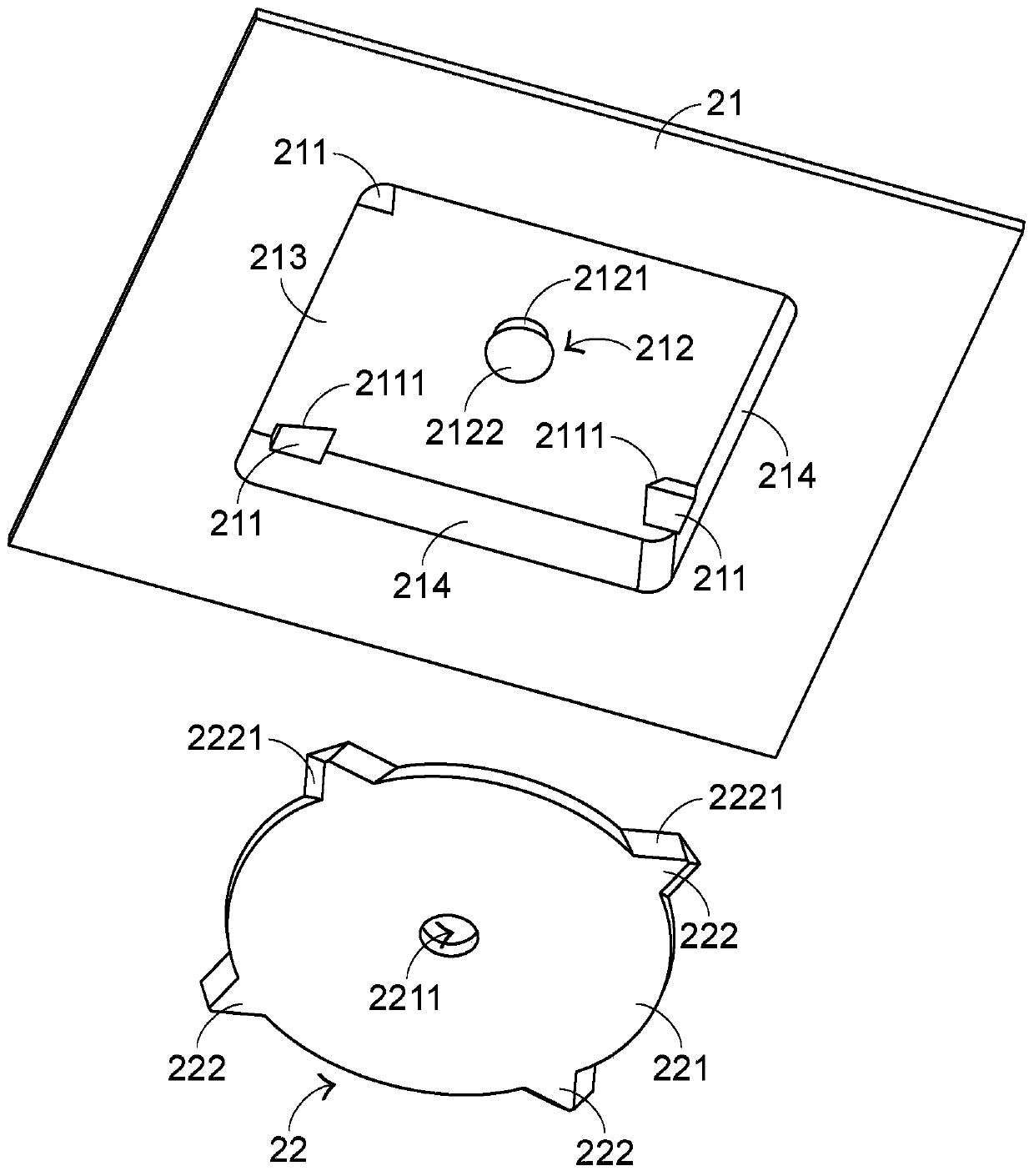

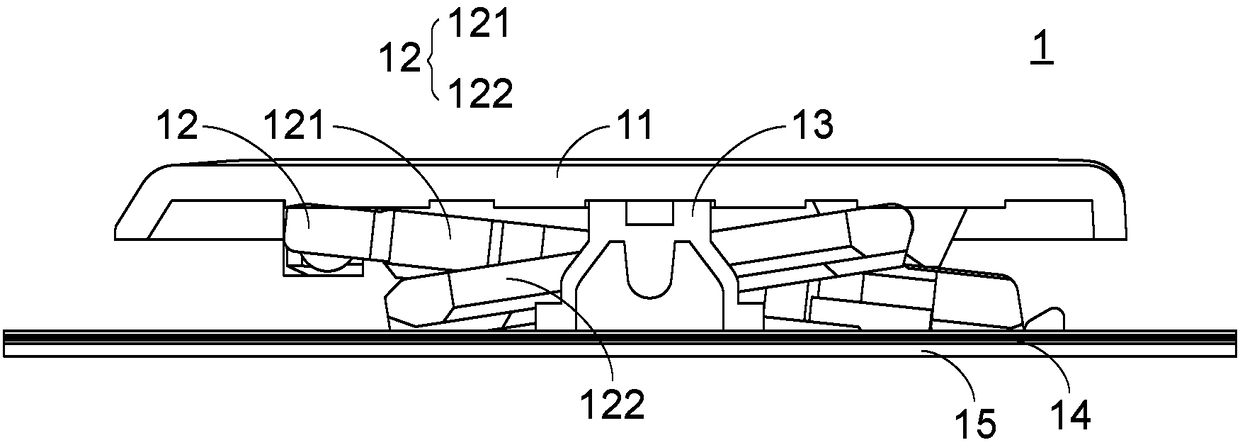

key structure

ActiveCN109509667BImprove uneven forceAvoid uneven forceEmergency actuatorsElectric switchesSoft keyKey pressing

The invention discloses a key structure, which comprises a soft key cap, a conduction disc, a switching circuit board capable of generating key signals and an elastic element. The conduction disc is fixed on the inner surface of the soft key cap, and is in contact with multiple inner walls of the soft key cap. The switching circuit board is arranged below the conduction disc, and the elastic element is arranged between the conduction disc and the switching circuit board. When the soft key cap is under contact pressure, the conduction disc is twisted due to the deformation of the soft key cap and pushes the inner walls of the soft key cap to transmit contact pressure to the corners of the soft key cap.

Owner:PRIMAX ELECTRONICS LTD

Display components

The embodiment of the present application discloses a display assembly, which includes a first substrate, a second substrate, a main frame glue, and a first retaining wall. Wherein, the first substrate has a first surface; the second substrate has a second surface, and the first surface is arranged opposite to the second surface; the main seal sealant is arranged on the first surface and the second surface. Between the second surfaces, the first surface, the second surface and the main sealant are surrounded by several display panels; the first retaining wall is arranged around the display panel, and the first retaining wall There is an airflow channel on it. This solution can slow down the strength of the airflow, prevent the puncture or deformation of the main sealing frame glue caused by the impact of the airflow, and can effectively improve the problem of uneven force when the display component is cut.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Key structure

ActiveCN109509667AImprove uneven forceAvoid uneven forceEmergency actuatorsElectric switchesKey pressingContact pressure

The invention discloses a key structure, which comprises a soft key cap, a conduction disc, a switching circuit board capable of generating key signals and an elastic element. The conduction disc is fixed on the inner surface of the soft key cap, and is in contact with multiple inner walls of the soft key cap. The switching circuit board is arranged below the conduction disc, and the elastic element is arranged between the conduction disc and the switching circuit board. When the soft key cap is under contact pressure, the conduction disc is twisted due to the deformation of the soft key cap and pushes the inner walls of the soft key cap to transmit contact pressure to the corners of the soft key cap.

Owner:PRIMAX ELECTRONICS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com