Multi-unit linkage-drive planar 3-acitivity face-shovel loading robot

A link-driven, three-degree-of-motion technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem of lack of overload protection and vibration absorption means, and poor stability of the boom lifting mechanism , weak load capacity and other issues, to achieve the effect of realizing numerical control of operations, strong overload protection performance, and improved rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

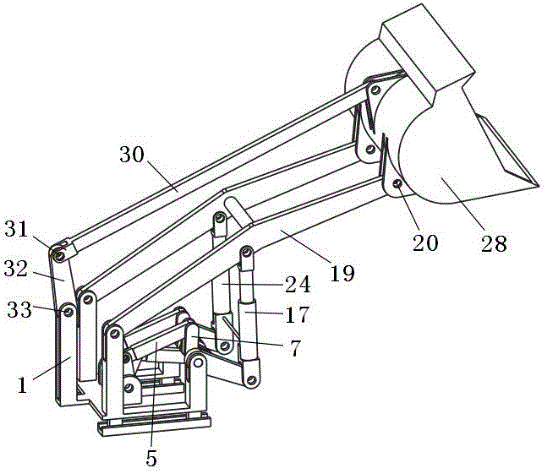

[0028] control figure 1 , a multi-unit link-driven planar three-activity front shovel loading robot according to the present invention includes a multi-unit link drive mechanism, a boom lifting mechanism, a bucket control mechanism and a frame 1 .

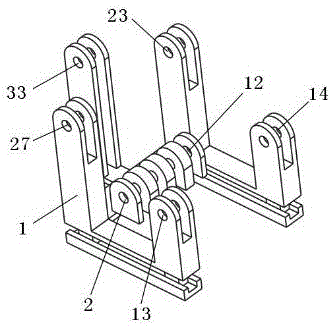

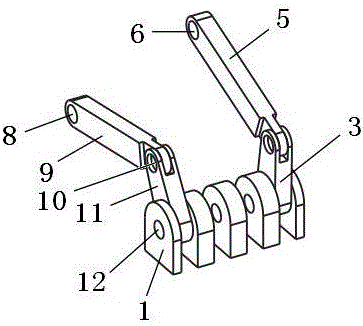

[0029] control figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the multi-unit connecting rod drive mechanism includes a frame 1, a first active rod 3, a second active rod 11, a first connecting rod 5, a second connecting rod 9, and a crankshaft 7, and one end of the first active rod 3 passes through The first rotating pair 2 is connected to the frame 1, and the other end is connected to one end of the first connecting rod 5 through the second rotating pair 4, and the other end of the first connecting rod 5 is connected to the crankshaft 7 through the third rotating pair 6. One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com