Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Improve sieving efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

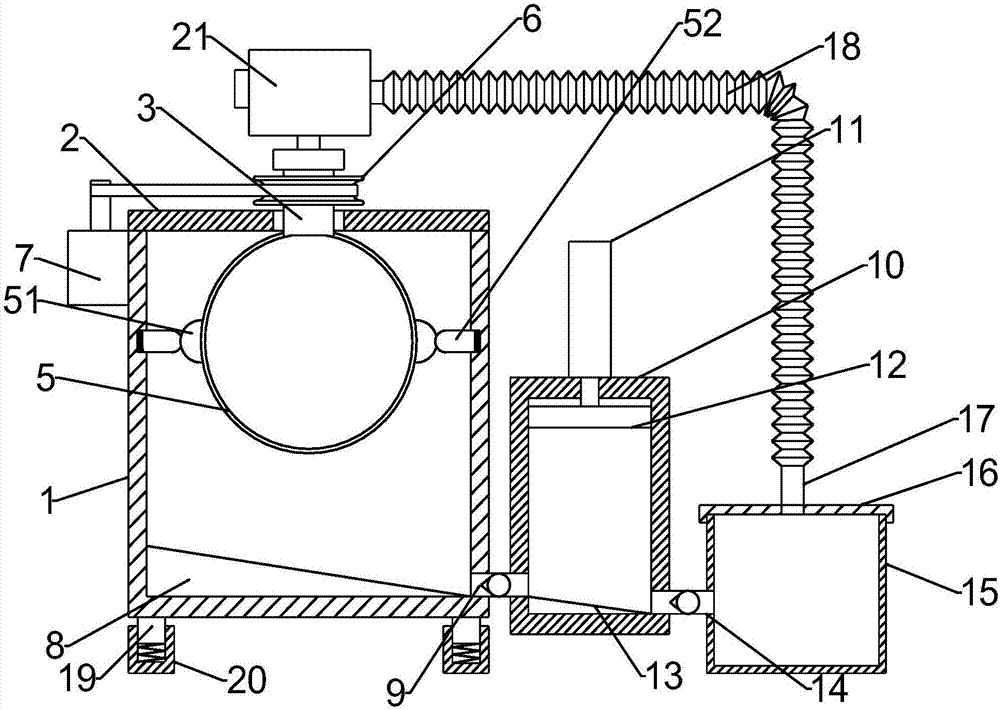

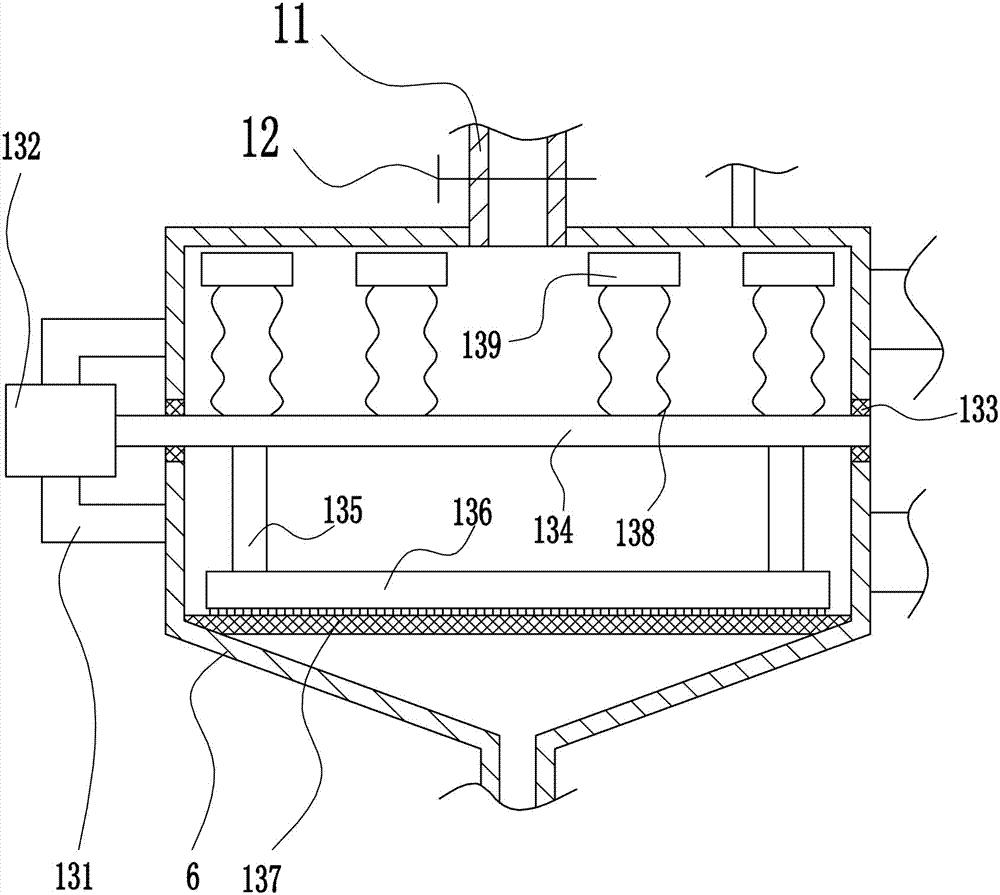

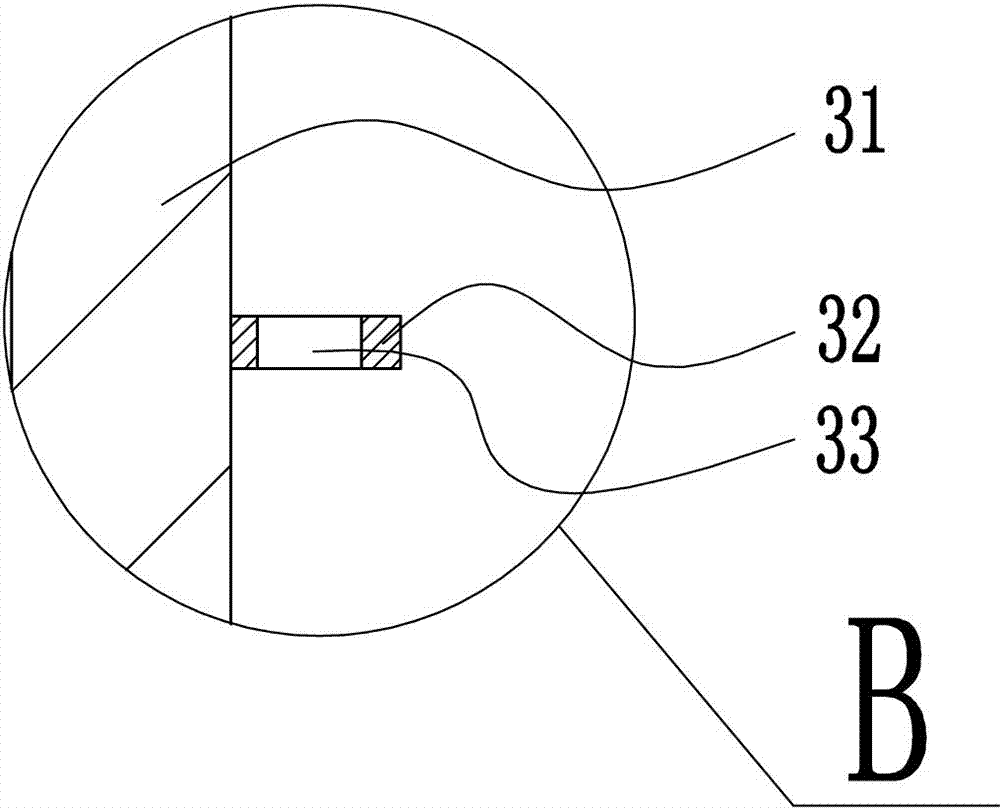

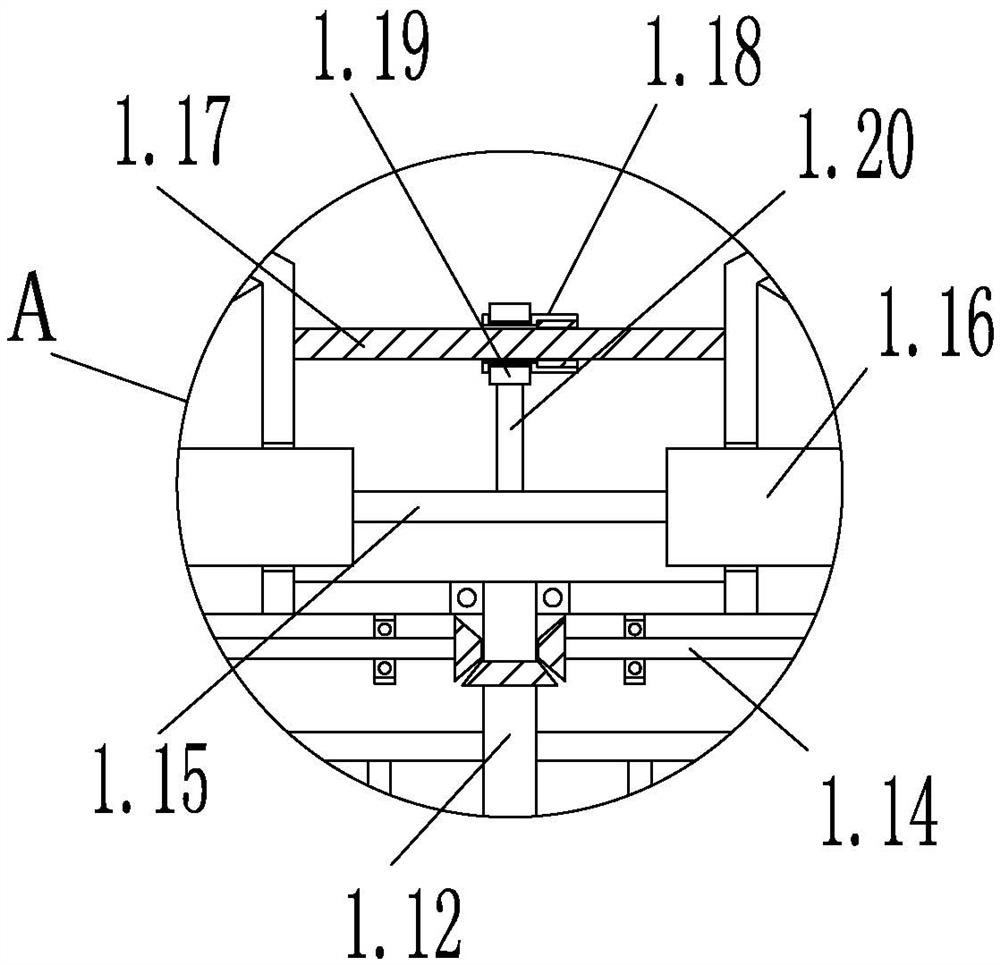

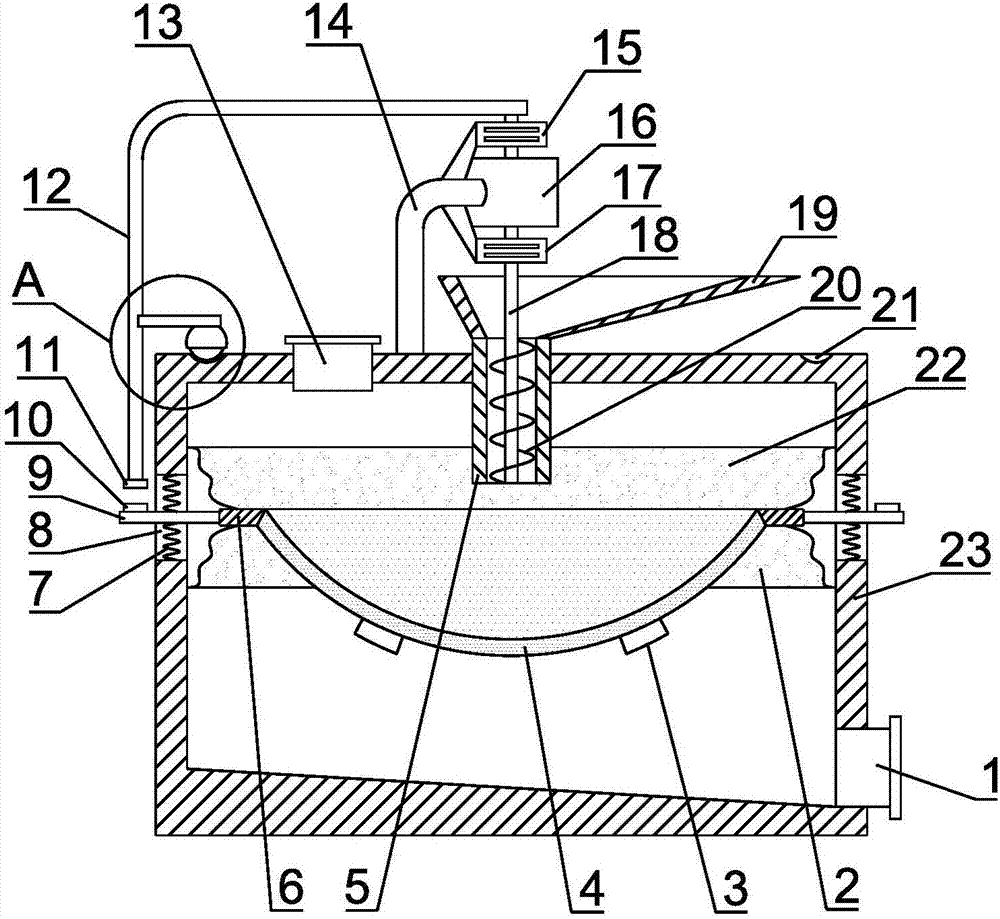

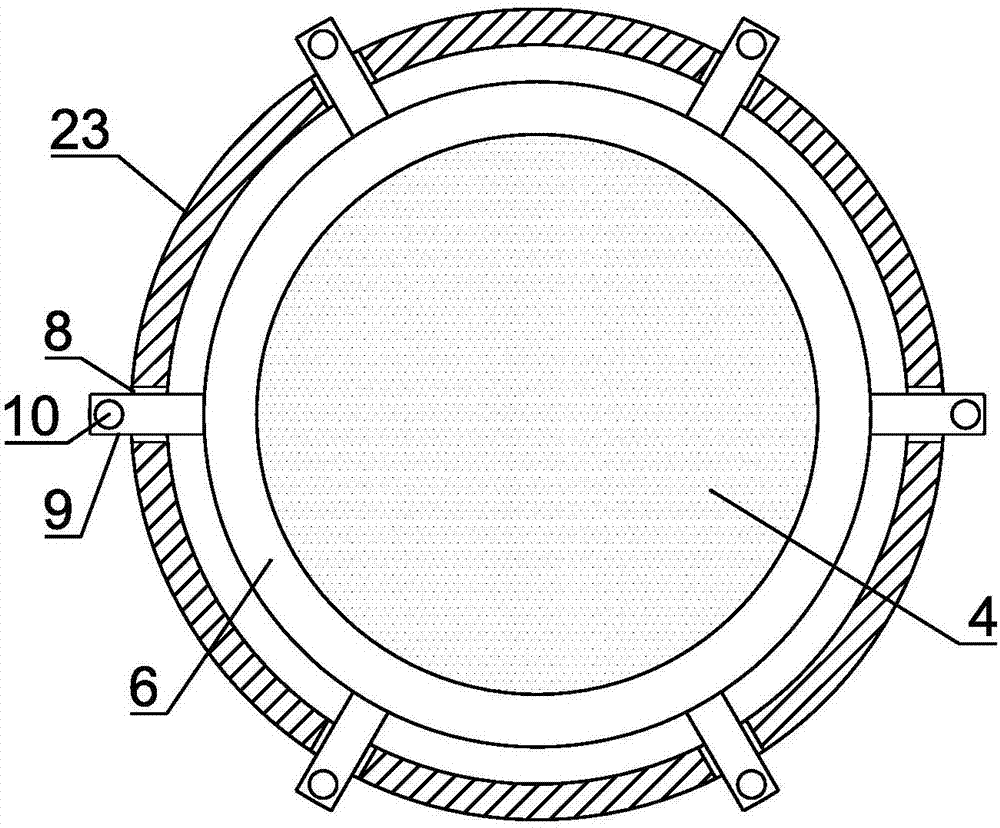

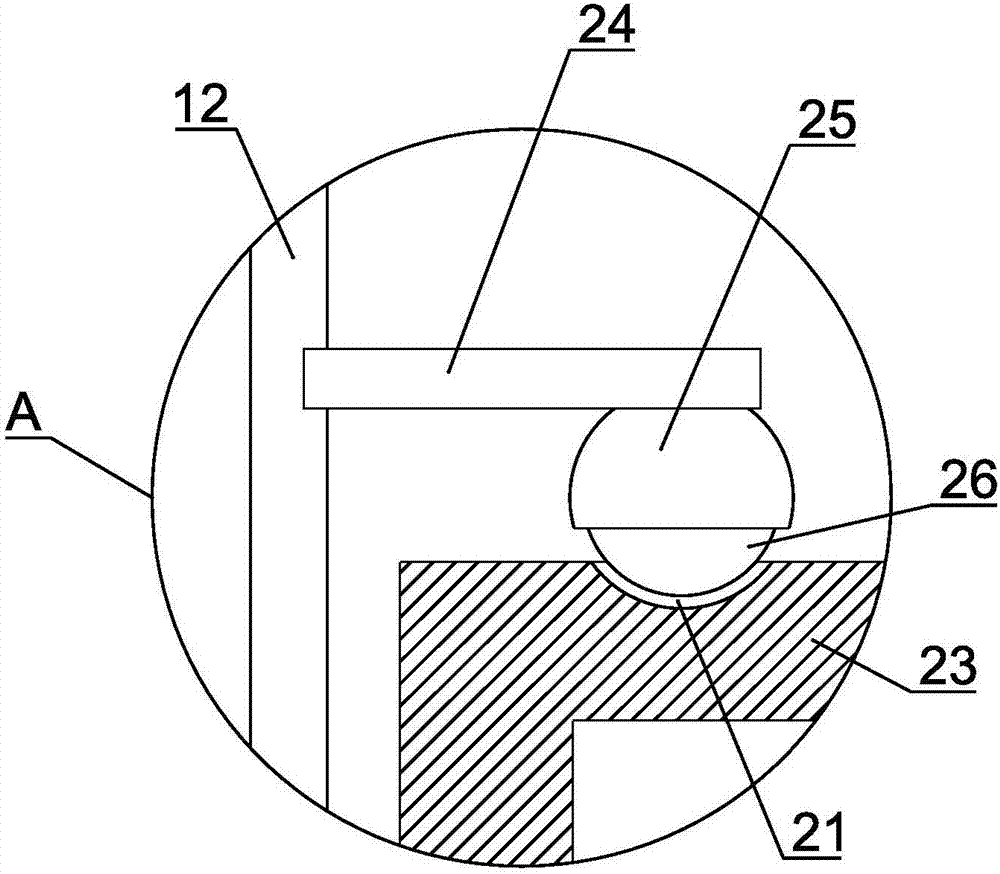

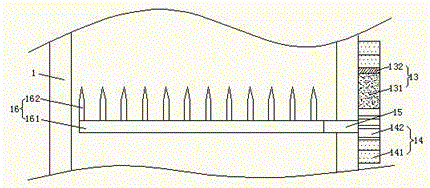

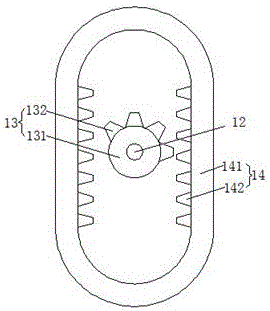

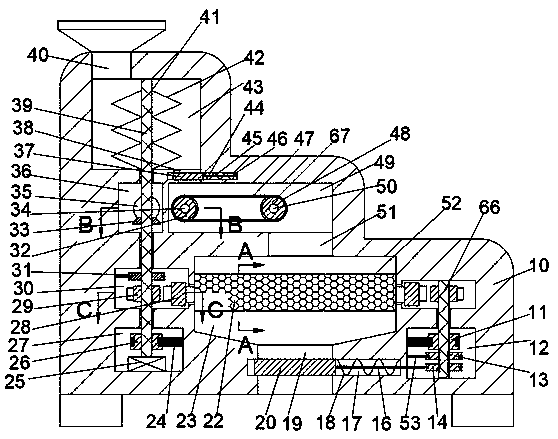

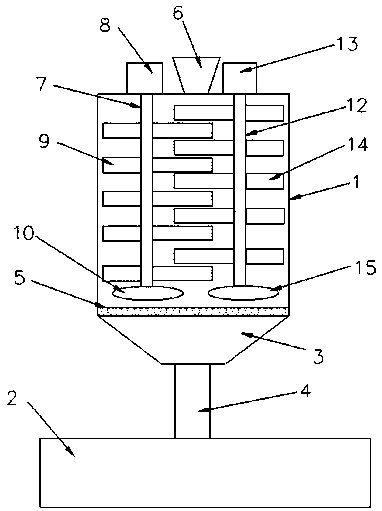

Drying and sieving device for soft magnetic material powder

InactiveCN107127148AEasy to siftImprove sieving efficiencySievingScreeningEngineeringMechanical engineering

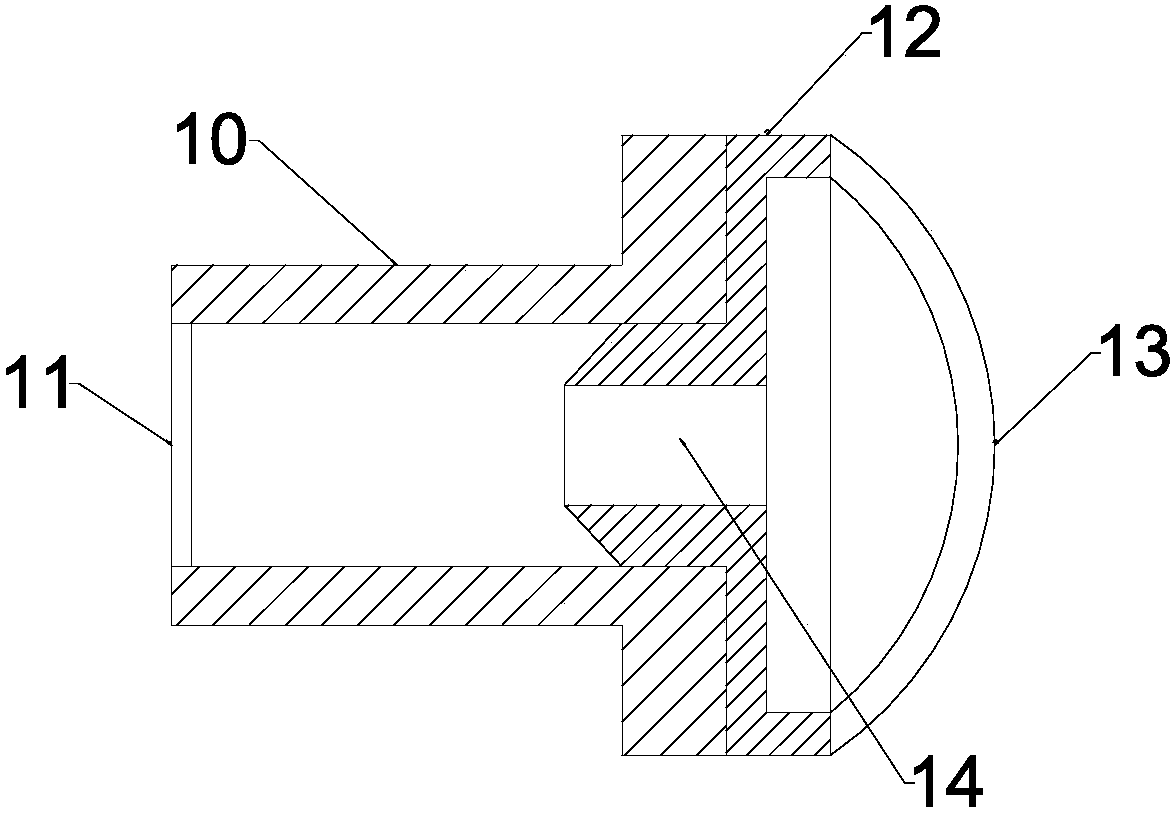

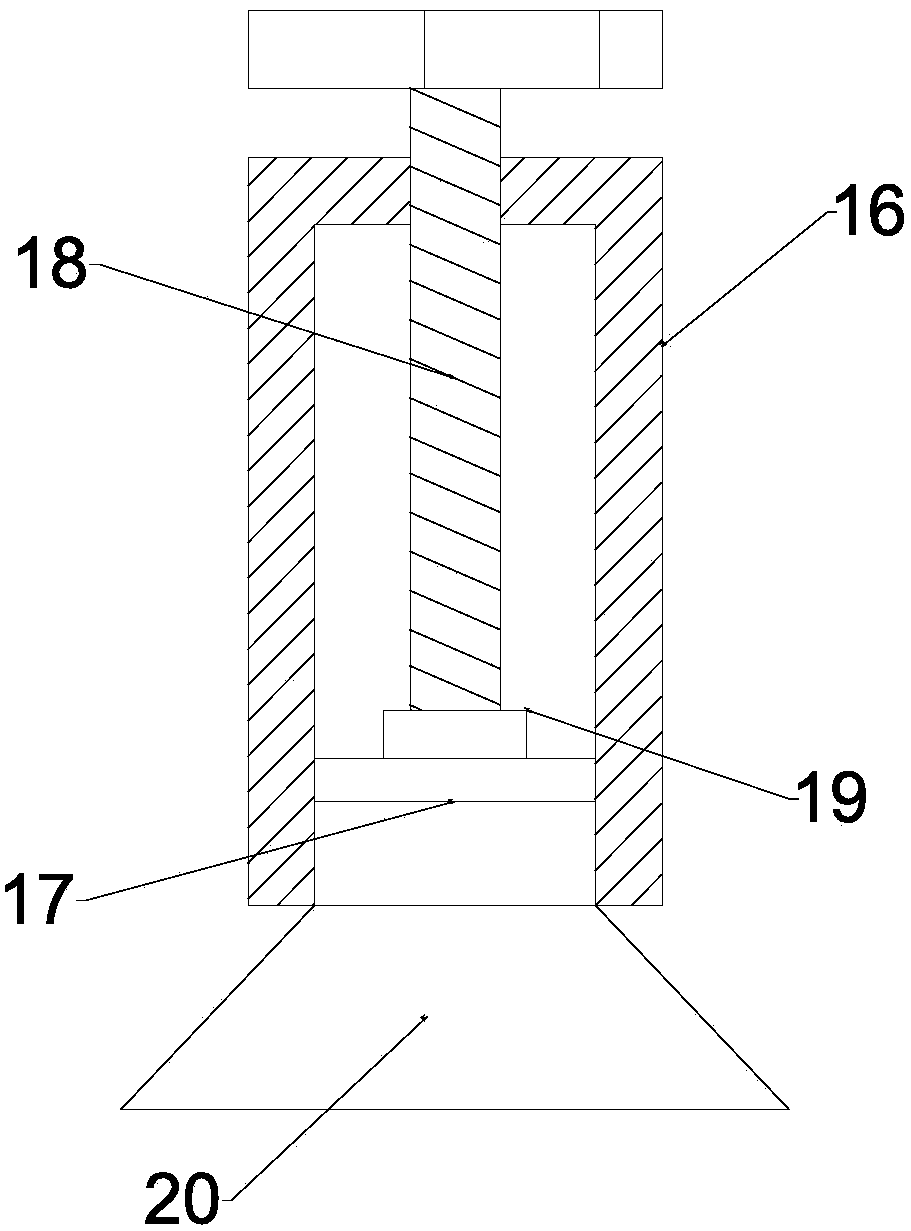

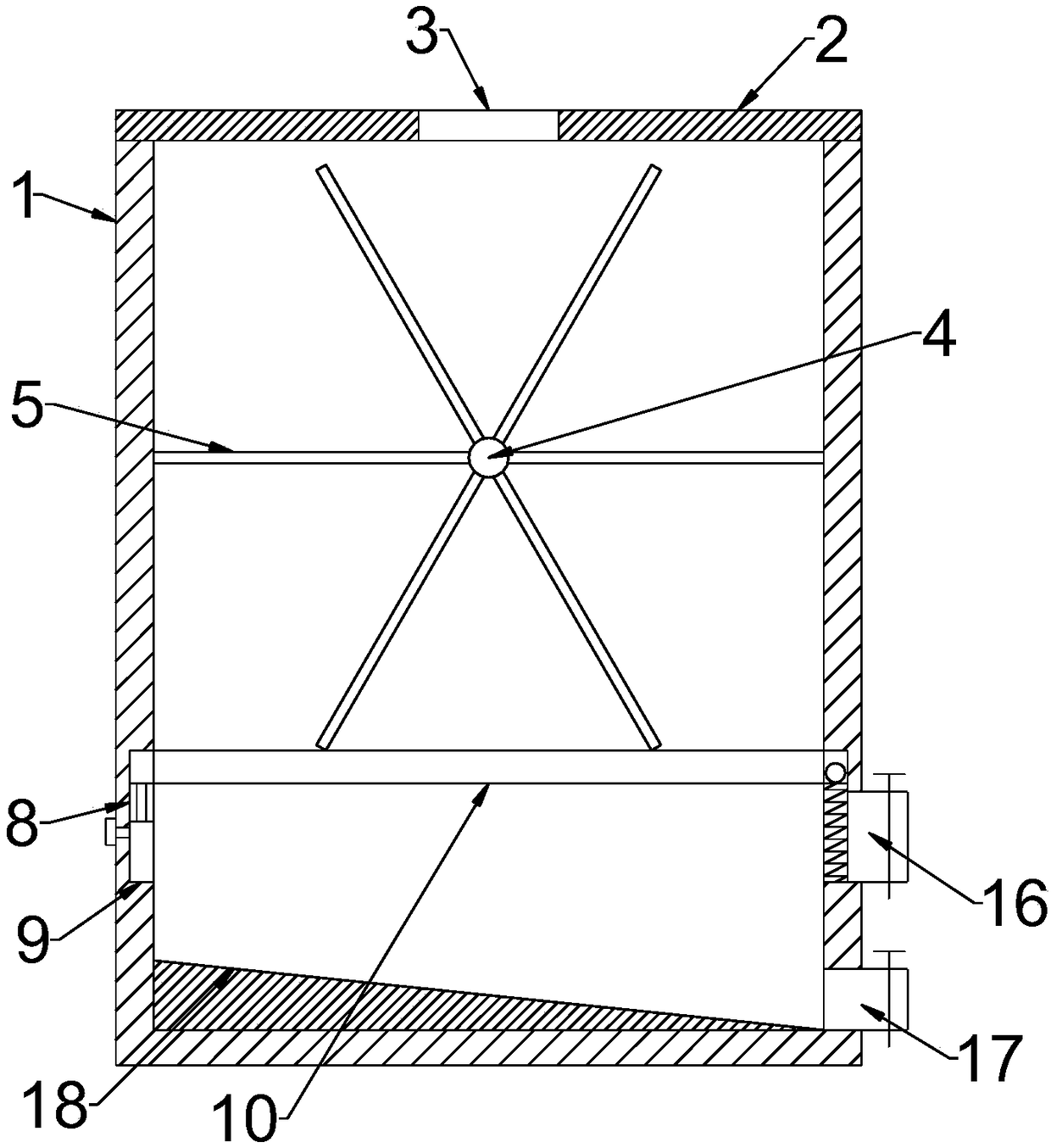

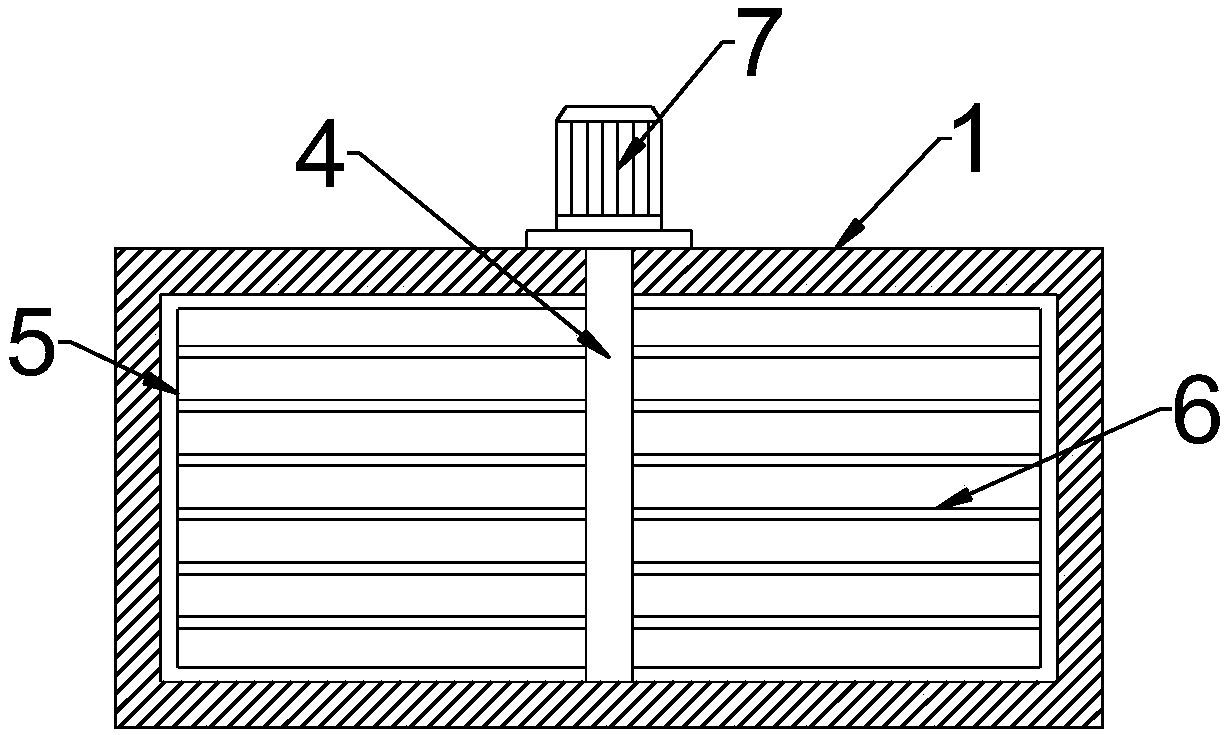

The invention discloses a drying and screening device for soft magnetic material powder, which comprises a screening box, a material guide cylinder, a material storage tank and a heating box. The screening box is provided with a movable upper cover, a feeding pipe, a threaded connection cover, Sealed bearing, air pipe, filter bag, collision protrusion, telescopic protrusion, transmission wheel, motor, first guide bottom plate and first material guide pipe; the material guide cylinder is equipped with electric telescopic rod, piston plate, second guide The bottom plate and the second material guide pipe; the storage tank is provided with a threaded sealing cover, an exhaust pipe and a connecting hose; the lower end of the screening box is provided with a support rod and a support sleeve; There are heating pipes, air intake holes and air guide pipes. In the present invention, through the filter bag, the collision protrusion and the telescopic protrusion, the passing efficiency is improved by collision and friction during rotation, the piston is driven by the electric telescopic rod to produce a circulation effect, and the air is heated by the heating tube, thereby drying the powder and improving the screening efficiency.

Owner:许晶

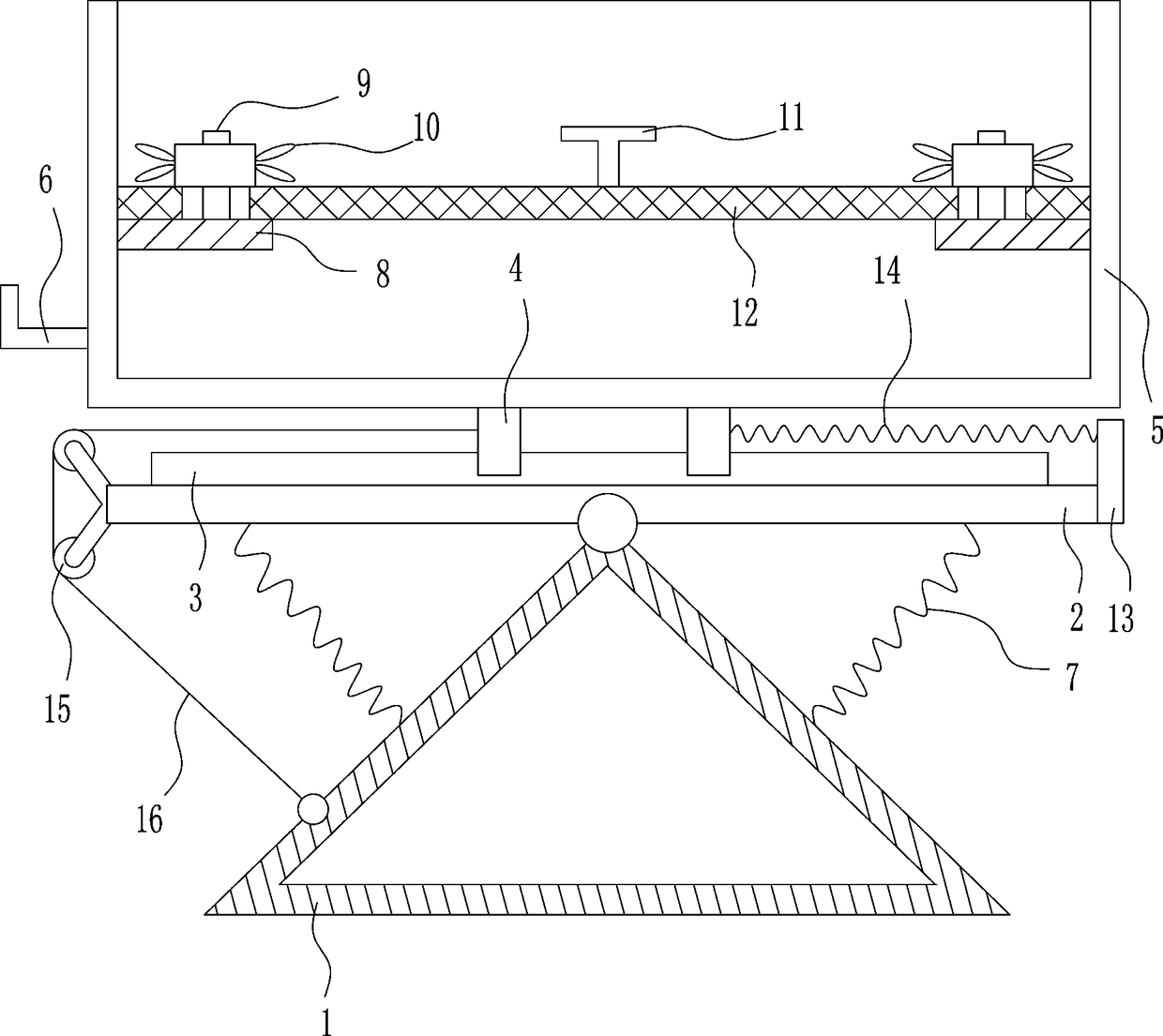

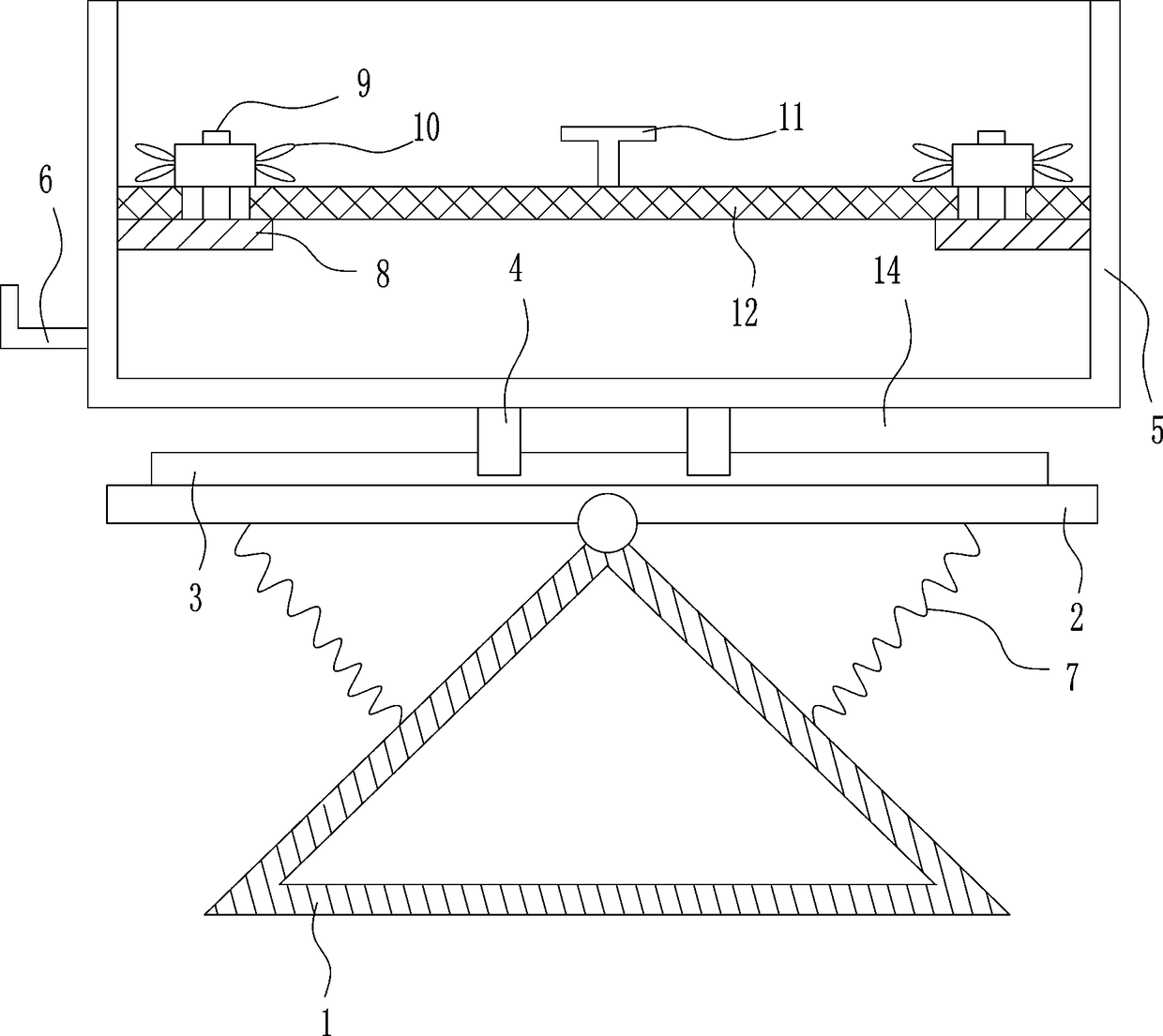

Screening equipment for powder cosmetic production

InactiveCN106984531AImprove sieving efficiencyExtended service lifeSievingScreeningBiochemical engineeringCosmetics

The invention relates to screening equipment, in particular to screening equipment for powder cosmetic production, which achieves the effects that uniform fine particles can be can obtained and the screening efficiency is high. The screening equipment for the powder cosmetic production comprises a bottom plate, a collection mechanism, a right rack, a first sliding rail, a screening box, connecting rods, a lifting mechanism and the like; a containing groove is formed in the middle of the top of the bottom plate; the collection mechanism is arranged in the containing groove; the right rack is arranged at the right end of the top of the bottom plate; the first sliding rail is arranged in the middle of the left side of the right rack, and is slidingly connected with a first sliding block; and the left side of the first sliding block is connected with the screening box. A powder cosmetic is screened through the matching of the lifting mechanism, a striking mechanism and a screening mechanism, so that the screening efficiency is improved. The collection mechanism can allow collection work of the powder cosmetic to be more convenient.

Owner:陈涛

Vibrating-type screening device of chemical raw materials

ActiveCN109604154AImprove uniformityImprove adsorption capacitySievingGas current separationCouplingPulp and paper industry

The invention discloses a vibrating-type screening device of chemical raw materials. The vibrating-type screening device comprises a screening cavity, a first filter net plate, a collecting cavity, asecond filter net plate, a motor, a rotating shaft and an impact rod; mounting grooves are embedded in the two sides of the screening cavity, and the first filter net plate is connected between the mounting grooves; the output end of the motor is in connection transmission with the rotating shaft through a coupling, and the tail end of the rotating shaft is connected with the impact rod through aconnecting rod; an incomplete gear is welded to the periphery of the rotating shaft, and the periphery of the incomplete gear is connected with a swinging frame; and a sliding rod is welded to the left end of the swinging frame and movably penetrates through the left wall of the screening cavity, and the tail end of the sliding rod is connected with a brush rod. The impact rod continuously makes contact with the first filter net plate to enable the first filter net plate to shake, thus the screening efficiency is improved, the brush rod is in attachment contact with the second filter net platein a horizontal reciprocating mode, thus the passing efficiency of the second filter net plate is improved, and blockage is effectively avoided.

Owner:江西绿川生物科技实业有限公司

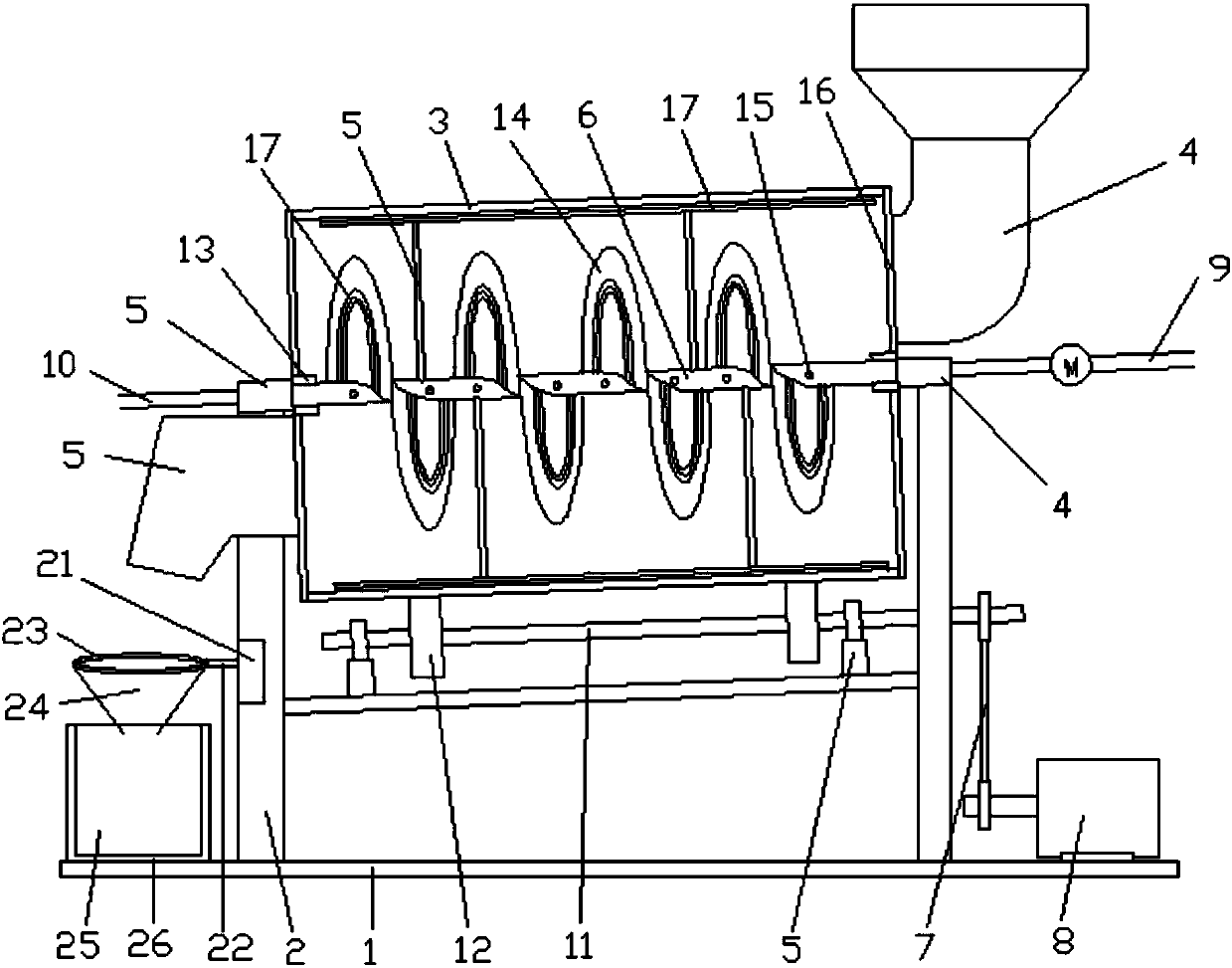

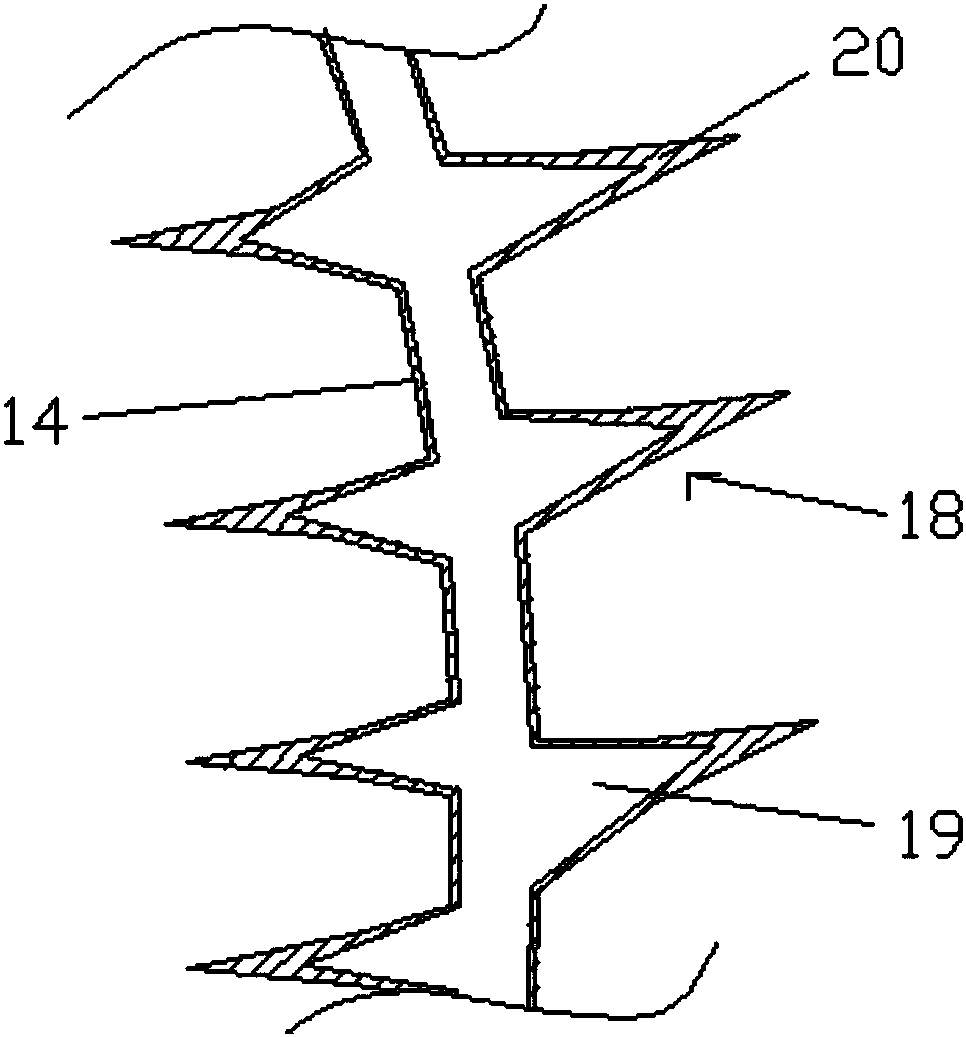

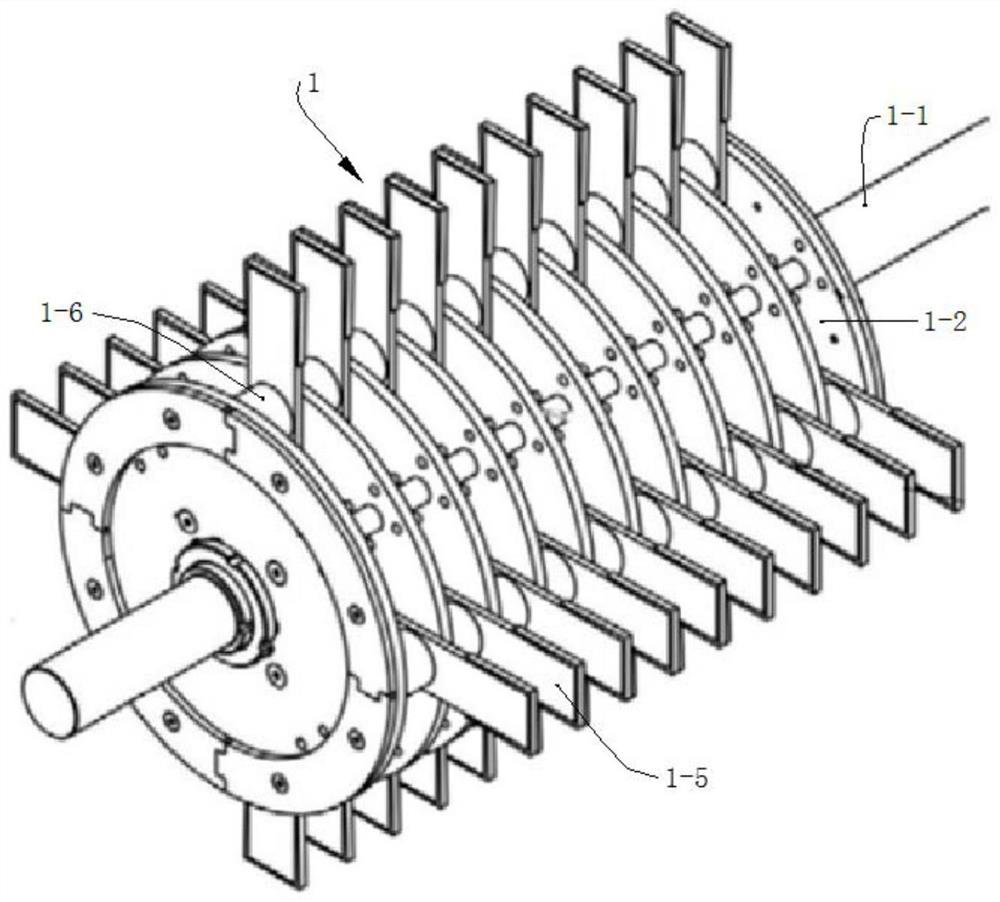

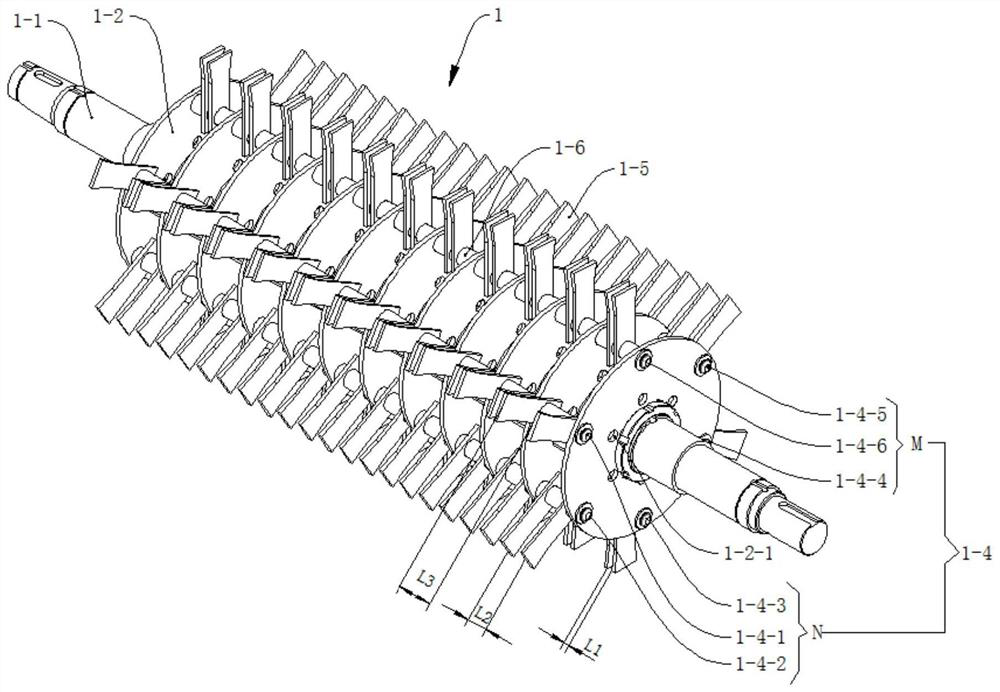

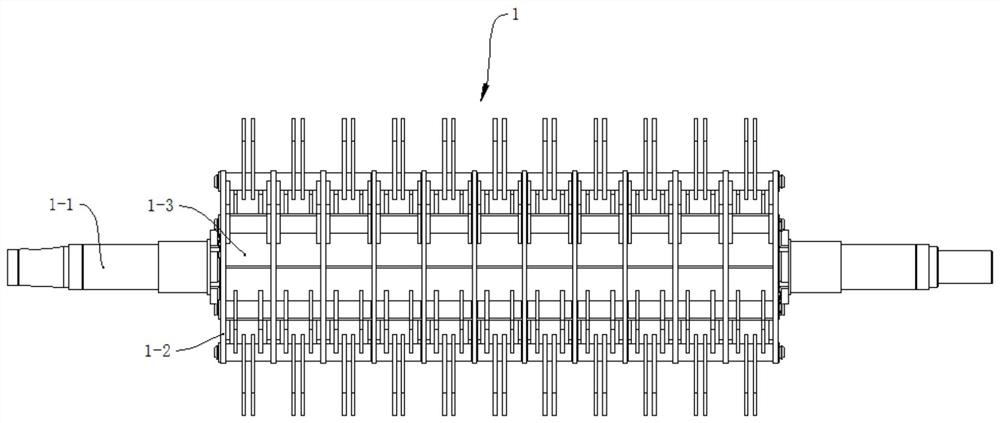

Rotary drum rotary-type drying granulating device

The invention discloses a rotary drum rotary-type drying granulating device. The rotary drum rotary-type drying granulating device comprises a base, supports, a rotary drum and a strip-type scraping plate, wherein the two ends of the rotary drum are arranged on the supports; a feed port is formed in the side surface of the high end of the rotary drum; a discharge port is formed in the side surfaceof the low end of the rotary drum; the lower ends of the two supports are fixed on the bottom surface through the base; a center shaft fixing heat conducting pipe is arranged in the center of the rotary drum in a penetration manner; hollow helical blades communicated with the fixing heat conducting pipe are arranged on the part, inside the rotary drum, of the fixing heat conducting pipe; a plurality of hot air outlets are also formed in the fixing heat conducting pipe; the parts, outside the rotary drum, of the fixing heat conducting pipe are communicated to a steam input pipe and a steam output pipe in a sealing manner; a plurality of fins are also arranged on the helical blades along the helical direction of the helical blades; and one side of the strip-type scraping plate is leaned against the inner wall of the rotary drum, and the other side of the strip-type scraping plate is fixedly connected to the fixing heat conducting pipe by at least two supporting rods. The rotary drum rotary-type drying granulating device is simple in structure and reasonable in design, has a good drying effect and high drying efficiency and is capable of grading dried materials; and materials are less likely to bond by adopting the rotary drum rotary-type drying granulating device.

Owner:四川旭瑞达机电设备有限公司

Biomass granular fuel crushing device with material pressing function

ActiveCN110976005AReduce energy consumptionAvoid accumulationSievingScreeningElectric machineCoupling

The invention discloses a biomass granular fuel crushing device with a material pressing function. The device comprises a crushing device; the crushing device comprises a first crushing chamber and asecond crushing chamber; a crushing motor is mounted at the bottom of the second crushing chamber; the output shaft of the crushing motor is connected with a first rotating shaft through a coupling; hammer plate frames are correspondingly arranged outside the first rotating shaft; the two hammer plate frames are respectively positioned in the first crushing chamber and the second crushing chamber;crushing parts are uniformly arranged on the hammer plate frames; a middle screen is arranged between the first crushing chamber and the second crushing chamber; a feeding hole is formed in the top of the first crushing chamber; the crushing parts are an L-shaped blades; the corners of the tail ends of the L-shaped blades are obtuse angles; the first rotating shaft is sleeved with a rotating scraping piece; the rotating scraping piece is located at the top of the middle screen; and the rotating scraping piece is in the shape of a fan blade. With the device of the invention adopted, material deposition can be avoided, and high working efficiency can be realized.

Owner:湖南农福来生物质科技股份有限公司

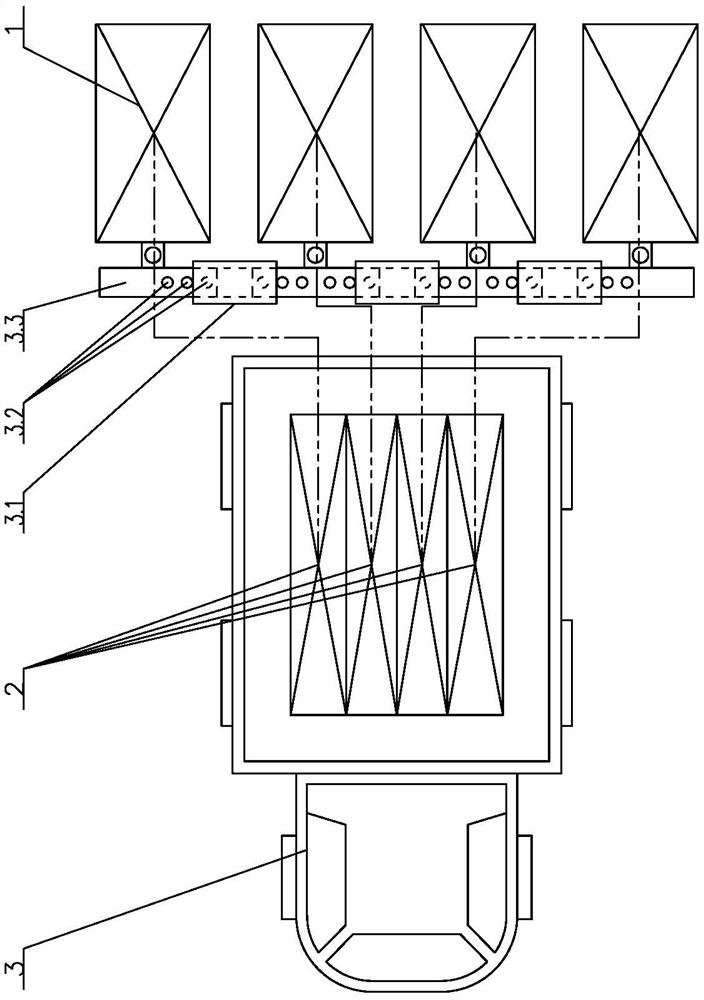

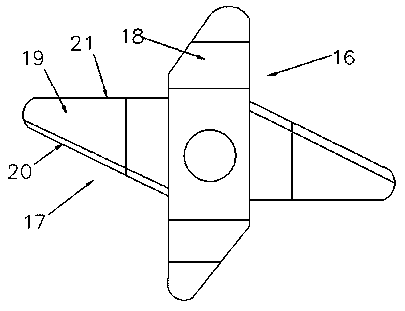

Mixed planting integrated sowing equipment of ensiled Zea mays L. and Glycine max (Linn.) Merr., and mixed planting method

ActiveCN112913376ASow evenlyGood energy saving effectRegular seed deposition machinesGrain treatmentsSeederAgricultural engineering

The invention discloses mixed planting integrated sowing equipment of ensiled Zea mays L. and Glycine max (Linn.) Merr., and a mixed planting method, and belongs to the technical field of ensiled Zea mays L. and Glycine max (Linn.) Merr. planting. The mixed planting integrated sowing equipment is characterized by comprising fertilizer smashing, vibrating and sieving equipment, a sower installation traverse frame and at least two groups of sower bodies, wherein the sower installation traverse frame is horizontally fixed on the rear part of an agricultural vehicle, each group of sower bodies is horizontally hinged and fixed to the sower installation traverse frame in parallel, and the fertilizer smashing, vibrating and sieving equipment is installed and fixed on the hopper of the agricultural vehicle. The mixed planting integrated sowing equipment is provided with a seed and fertilizer pre-mixing mechanism and an automatic material-mixing type sower, so that while sowing operation efficiency is effectively improved, the texture and the fertility of the soil can be improved, a yield is further improved, and labor intensity is lowered.

Owner:MAIZE RES INST SHANDONG ACAD OF AGRI SCI

Superfine wollastonite powder magnetic-attraction vibrating screening device

InactiveCN107876383AImprove screening effect and efficiencyImprove sieving efficiencySievingScreeningDual axisMagnet

The invention discloses a superfine wollastonite powder magnetic-attraction vibrating screening device comprising a machine body. A screen net is arranged inside the machine body. Multiple vibrators are arranged at the bottom of the screen net. A reinforcing ring plate is fixedly arranged on the outer ring of the screen net. Multiple extension plates are circumferentially arranged on the outer ring of the reinforcing ring plate. The tops of the extension plates are provided with first permanent magnets. A feeding pipe is installed in the middle of the top of the machine body. A hopper is arranged at the upper end of the feeding pipe. A material conveying shaft is arranged in the middle of the inner side of the feeding pipe. The inner side of the feeding pipe is further provided with a spiral blade located on the material conveying shaft. The upper end of the material conveying shaft is connected with an output shaft of a second transmission. The input end of the second transmission isconnected with a lower output shaft of a double-extension motor. An upper output shaft of the double-extension motor is connected with an input shaft of a first transmission. An L-shaped support rod is installed on an output shaft of the first transmission. A second permanent magnet is installed at the lower end of the L-shaped support rod. The superfine wollastonite powder magnetic-attraction vibrating screening device is novel in structure, good in screening and filtering effect, high in efficiency, so that the wollastonite powder can be reliably used.

Owner:李姗姗

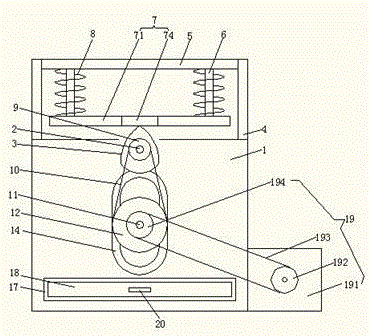

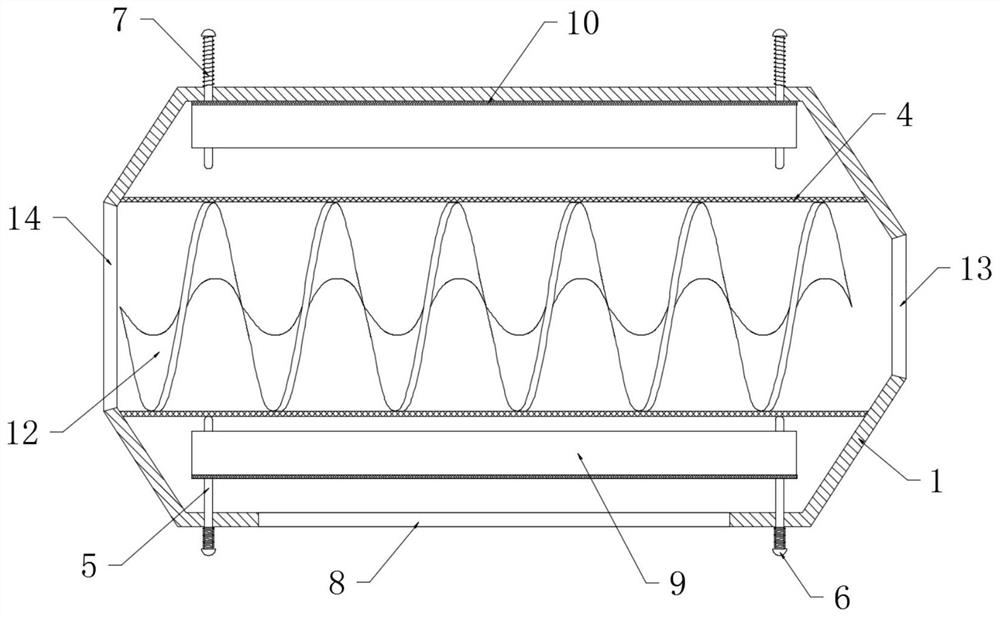

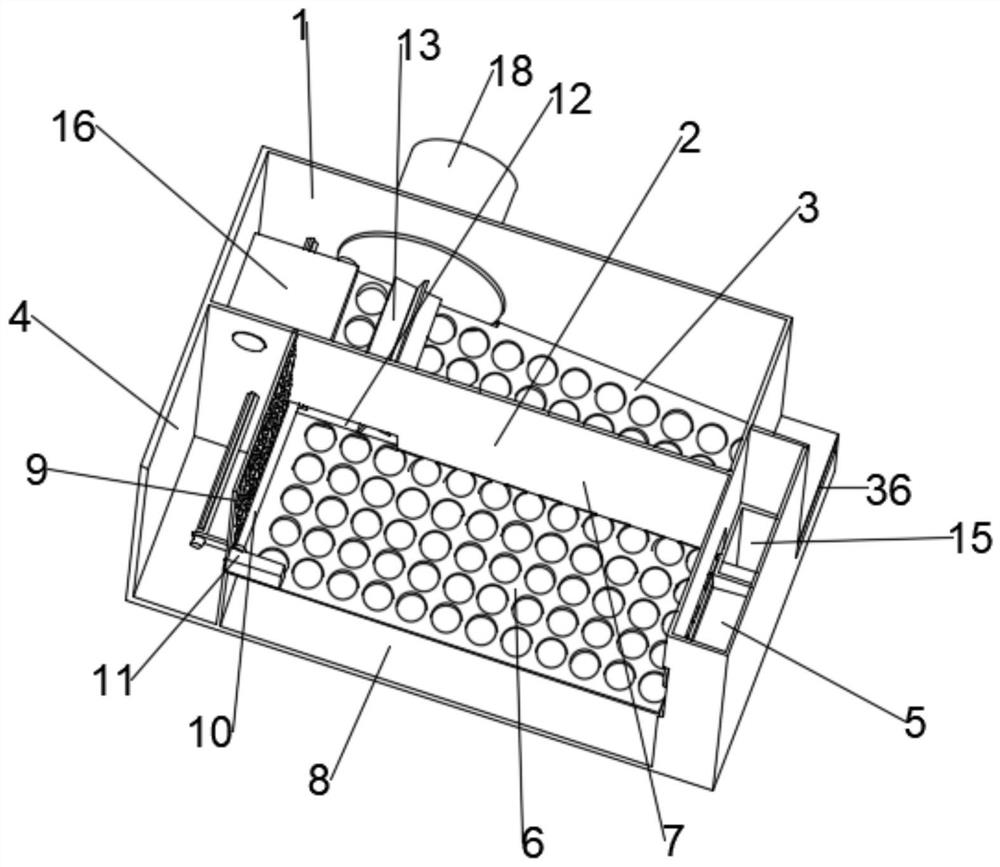

Sieving and mixing device for poultry breeding feed

InactiveCN107712979AImprove sieving efficiencyHigh speed impact effectSievingFeeding-stuffEngineeringCam

The invention discloses a sieving and mixing device for a poultry breeding feed. The sieving and mixing device comprises a housing, wherein clamping sleeves are arranged on two sides of the housing; asliding connecting rod and a compression spring are arranged in each clamping sleeve; a metal ring and a filter screen bag are arranged between the sliding connecting rods; a stirring shaft is arranged at the middle part of the filter screen bag; elastic rods and a base plate are arranged at the upper end of the stirring shaft; the stirring shaft is provided with stirring brackets, vertical connecting rods, ripple stirring blades and stirring bottom plates; upper covers are arranged at the upper end of the housing; a feeding pipe, a gear sleeve, a discharging hopper, a supporting plate, a sliding rod, a rack and a limiting baffle are arranged on the upper covers; a motor and a discharging pipeline are arranged on the right wall of the housing; and a cam is arranged at the output end of the motor. According to the sieving and mixing device disclosed by the invention, the feed can be uniformly and quickly sieved, the mixed feed can be stirred, the sieving efficiency of materials is improved in a swinging manner, and the mixing of the materials is promoted, so that the processing efficiency is effectively improved.

Owner:怀化市神通农牧科技有限公司

Straw recycling device with fermentation function for agricultural production

InactiveCN108990564AEasy to recycleEasy to moveBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringFermentation

The invention belongs to the technical field of agricultural production, and particularly relates to a straw recycling device with a fermentation function for agricultural production. According to theproblems that existing straw recycling device is inconvenient to use, is relatively single in function, and cannot further improve the utilization rate of straw, the following scheme is provided. Thestraw recycling device comprises a base; four corners of the outer wall of the top of the base are respectively and fixedly provided with supports through screws; the outer walls of the tops of the four supports are respectively fixed with a same crushing box through screws; a solar cell panel is fixed on one side of the outer wall of the top of the crushing box through screws; the solar cell panel is connected with a solar controller through wires; and the solar controller is connected with a storage battery through wires. The device provided by the invention can be moved to a field conveniently, and has the advantage of conveniently recycling straw. Crushed straw can be conveniently fermented, the utilization rate of the straw is increased, and the fermentation efficiency of the strawis accelerated through mutual match of an arranged second servo motor and arranged stirring rods.

Owner:郑州希硕物联科技有限公司

Pulse crusher

InactiveCN101574676AImprove work efficiencyIncrease the sieving speedGrain treatmentsEngineeringCrusher

The invention discloses a pulse crusher in the field of material crushing devices, which comprises a shell, wherein the upper part of the shell is provided with a feed opening, a rotor is arranged in the shell, a sieving plate is arranged on the periphery of the rotor in a half surrounded mode to form a crushing room, and the upper part of the sieving plate is connected with the lower side of the feed opening transitionally; and the upper side of the extended periphery of the sieving plate in the feed opening is provided with a plurality of nozzles blowing towards a circulation layer directly. When the pulse crusher works, pulse airflow can generate instant impact force to impact large particles directly so that the large particles get into a beating area of the rotor, and small particle materials have more sifting opportunities; and the pulse airflow can improve the sifting speed of the materials, and the pulse air flow is ensured to have excellent impact effect. The pulse crusher breaks through the inherent prejudice in the prior art and breaks the circulation layer in the feed opening, and the breaking effect is more direct and efficient, thus the pulse crusher can promote the sifting of the small particle materials and the re-striking and the re-crushing of the large particle materials, and improve the working efficiency of the crusher.

Owner:JIANGSU MUYANG GRP CO LTD

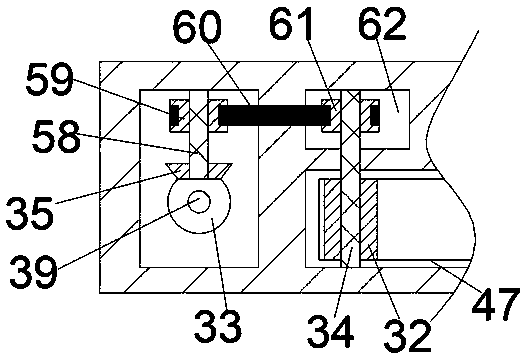

Vibratory screening combined chemical powder screening device

InactiveCN108144840AEasy to cleanEnsure internal and external connectivitySievingScreeningEngineeringCam

The invention discloses a vibratory screening combined chemical powder screening device. The vibratory screening combined chemical powder screening device comprises a shell. Electric push rods are arranged on the two sides of the shell. An upper cover is arranged at the upper ends of the electric push rods. The upper cover is provided with an elastic mounting plate, a feed pipe, a motor, a cam anda filter screen cylinder. A bottom plate is arranged at the internal bottom of the shell. The right wall of the shell is provided with a discharge pipe. Filter cloth, a screw cap, a rubber ball sleeve and an air injection cavity are arranged on the discharge pipe. The two sides of the shell are provided with notches. A sleeve is arranged on the sidewall of the shell and located below the notches.The sleeve is provided with a piston plate, a threaded rod, a rotary bearing and suction cups. According to the vibratory screening combined chemical powder screening device, the elastic mounting plate vibrates up and down to screen and intercept powder with different mesh numbers onto corresponding filter screens. In this way, screening and collection can be conducted rapidly. The vibratory screening combined chemical powder screening device can conduct exhausting and collect high-mesh powder through the design of the discharge pipe, the filter cloth, the screw cap, the rubber ball sleeve and the air injection cavity and improve the stability through the sleeve, the piston plate, the threaded rod, the rotary bearing and the suction cups.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

Shaking type screening device for drug processing

ActiveCN109317404AImprove sieving efficiencyEasy to recycleSievingScreeningPulp and paper industryDrug

The invention discloses a shaking type screening device for drug processing. The screening device comprises a casing, a stirring structure, a telescopic supporting rod and a screen plate; perpendicular sliding grooves are symmetrically embedded in the lower parts of the two sides of the casing; two ends of the screen plate movably extend into the perpendicular sliding grooves; the screen plate isglidingly connected with the perpendicular sliding grooves; the stirring structure comprises a rotating shaft, rotating frames and a motor; the rotating shaft is radially rotationally arranged betweenthe front side wall and the back side wall inside the casing; six groups of the rotating frames distributed at equal angles are welded on the periphery of the rotating shaft; and when the rotating frames are symmetric on two sides and are kept horizontal, the upper surface of the screen plate and the lower end of the rotating frames movably fit each other. According to the screening device, the lower ends of the rotating frames fit and press the screen plate continuously and then leave to withdraw the pressure during rotation, so that the screen plate shakes continuously, the screening efficiency of medicinal materials can be further improved, the effect one-way rotation for residue discharging can be formed, and the screening device is convenient to use.

Owner:泗水泗河源文化旅游开发有限责任公司

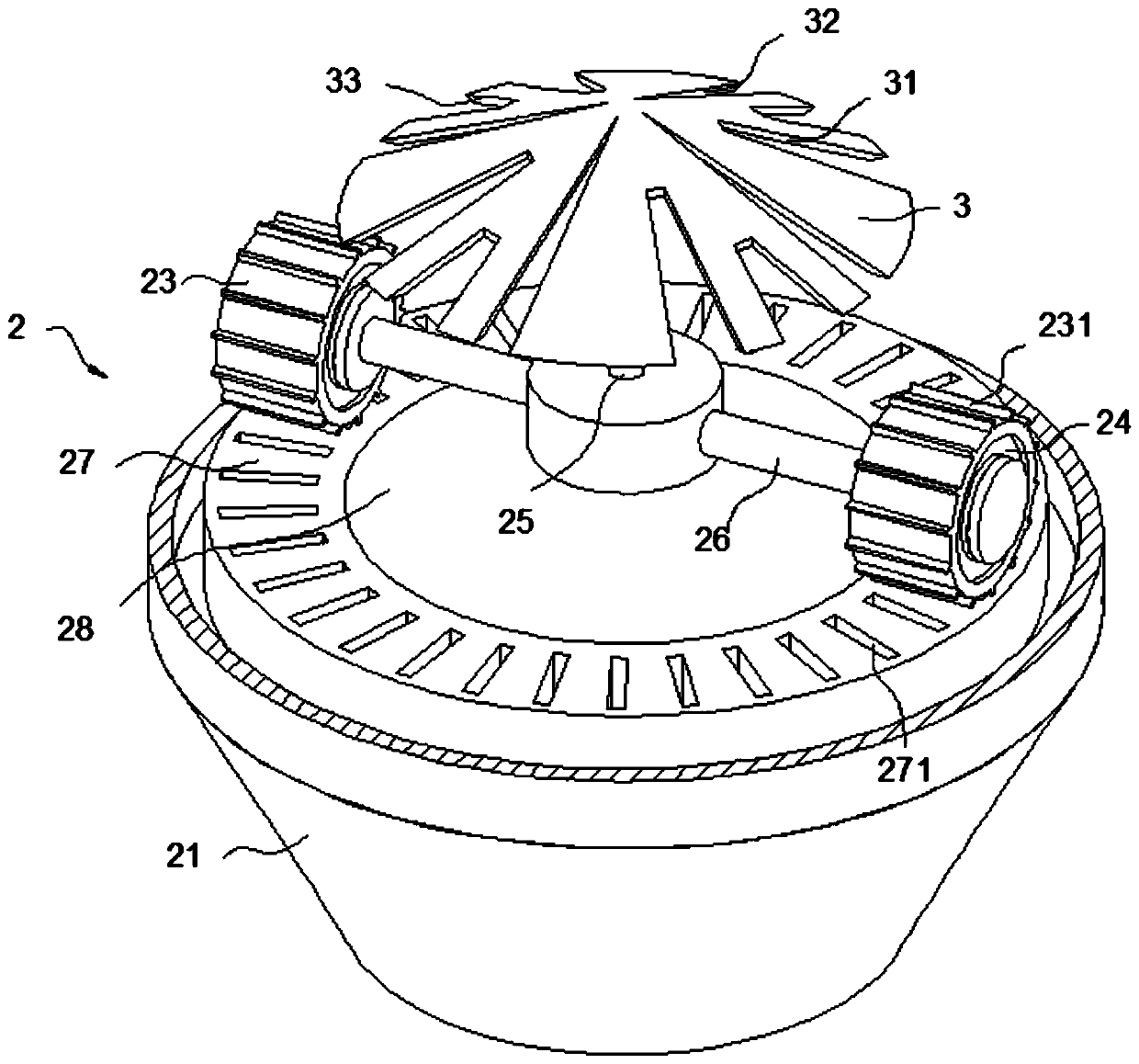

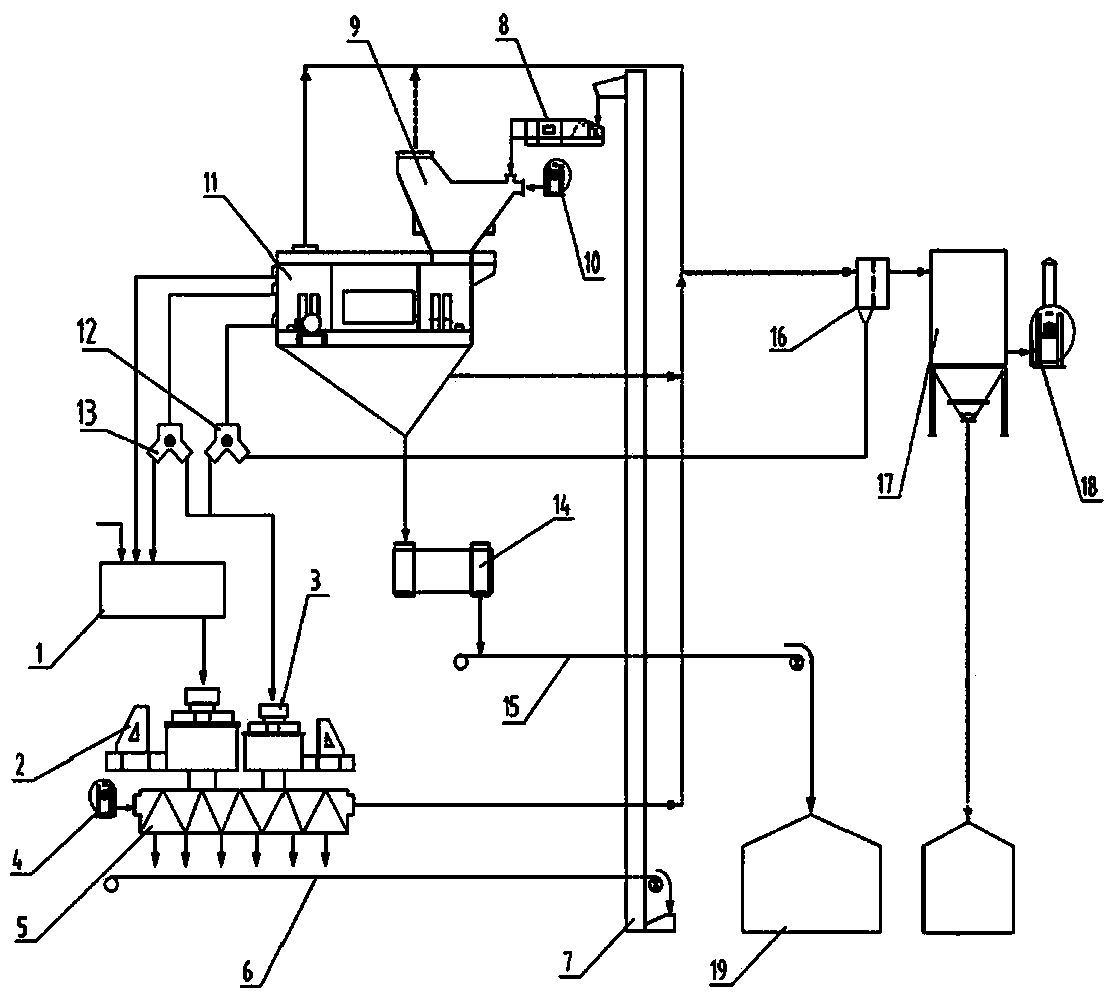

Environment-friendly high-quality sand making building station system

PendingCN109127086APrecise screeningCompact structureGrain treatmentsProduction rateEnvironmental resistance

The invention discloses an environment-friendly high-quality sand making building station system. A discharging port of a feeding and collecting bin is connected with a feeding port of a spill waterfall type vertical shaft through a pipeline, a discharging port of the spill waterfall type vertical shaft is connected with a feeding port of a primary powder concentrator, and a plate conveyor is placed below a discharging port of the primary powder concentrator. The system has the benefits as follows: 1, the gradation and fineness can be controlled according to demands of clients, so that different selling prices of products in different specifications can be obtained, and better economic effects can be obtained; 2, the capacity is high, finished products have superior granule shapes and thesand production rate is high; 3, the stone powder content and moisture content of sand can be controlled as required.

Owner:NANTONG UNION MACHINERY ELECTRONTCS TECH CO LTD

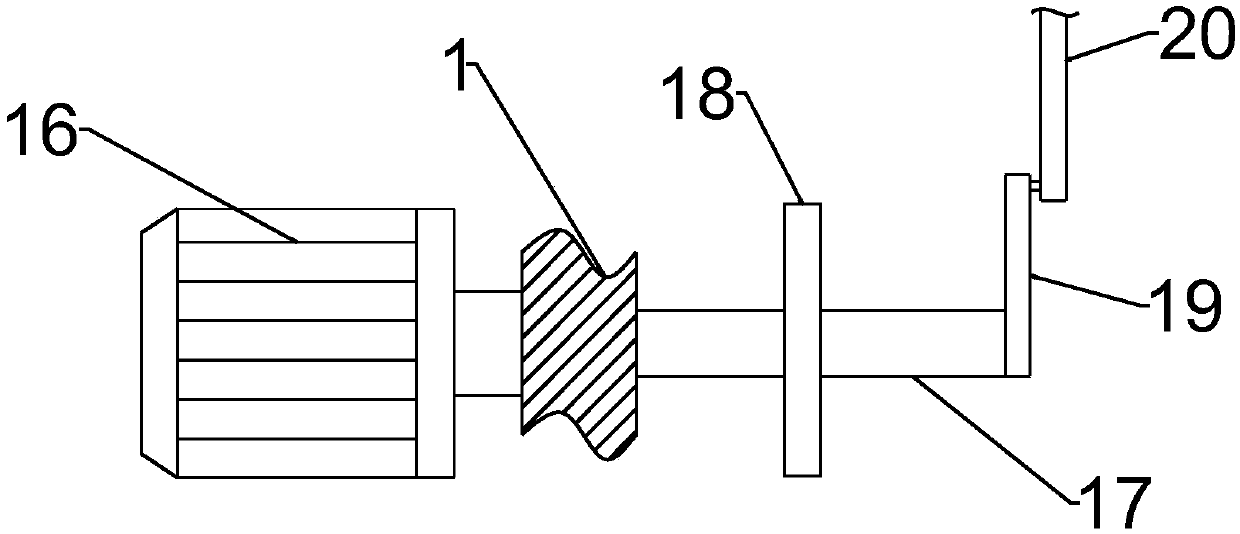

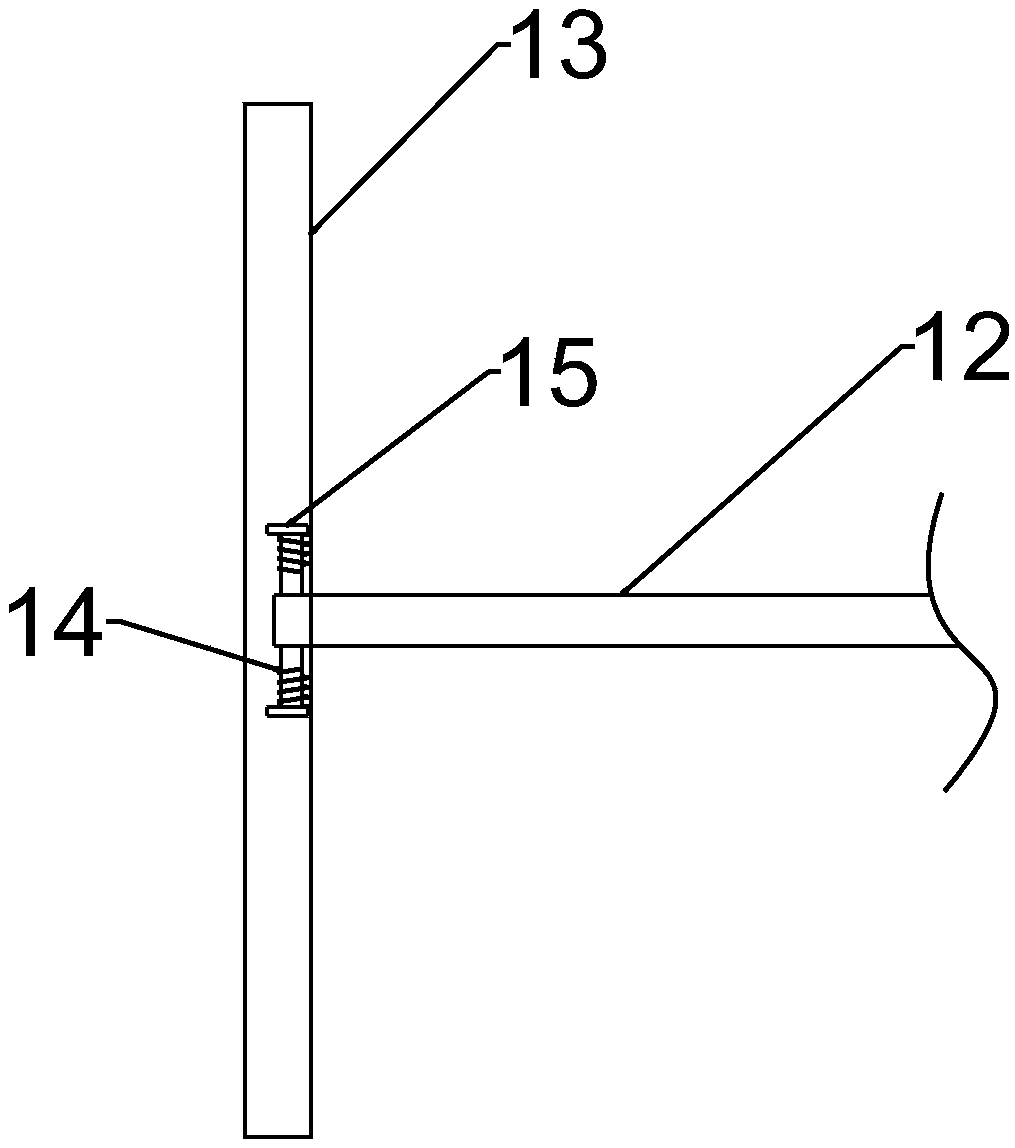

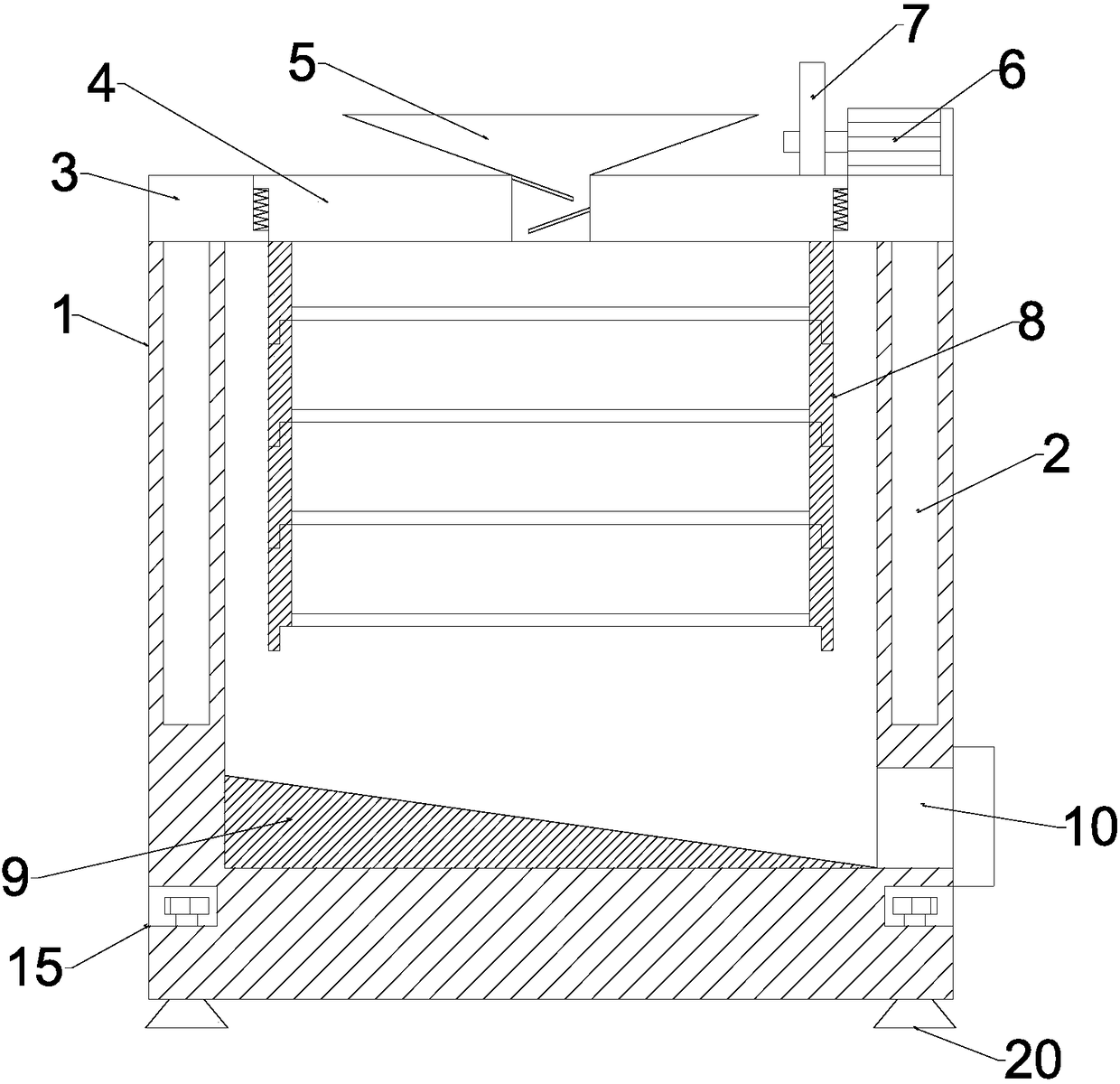

Drying and pelletizing device for chemical engineering

InactiveCN107816857AEvenly heatedImprove drying effectSievingScreeningEngineeringMechanical engineering

The invention discloses a drying and pelletizing device for chemical engineering. The drying and pelletizing device comprises two supporting bases, a rotary barrel, a steam pipe coil and a motor; thetwo ends of the rotary barrel are each provided with a connecting end, and the rotary barrel are rotationally connected with the two supporting bases through the two connecting ends; the steam pipe coil is tightly attached to the inner wall of the rotary barrel and is arranged in the axis direction of the rotary barrel spirally, and the two ends of the steam pipe coil are communicated with a steam inlet pipe and a steam outlet pipe corresponding; a plurality of fins are arranged on the steam pipe coil in the spiral direction, the roots of the fins are internally provided with fin cavities communicated with hollow runners, and the ends of the fins are fin blades with the isosceles triangle cross sections; the rotary barrel is provided with a material inlet and a material outlet; and the output end of the motor is connected with the connecting end of a chain, and the rotary barrel is further driven to rotate. The drying device is simple in structure, reasonable in design, even in material heating, and capable of conducting cutting and pelletizing while drying operation is carried out; and the equipment is high in systematicness, good in drying effect and high in production efficiency.

Owner:四川旭瑞达机电设备有限公司

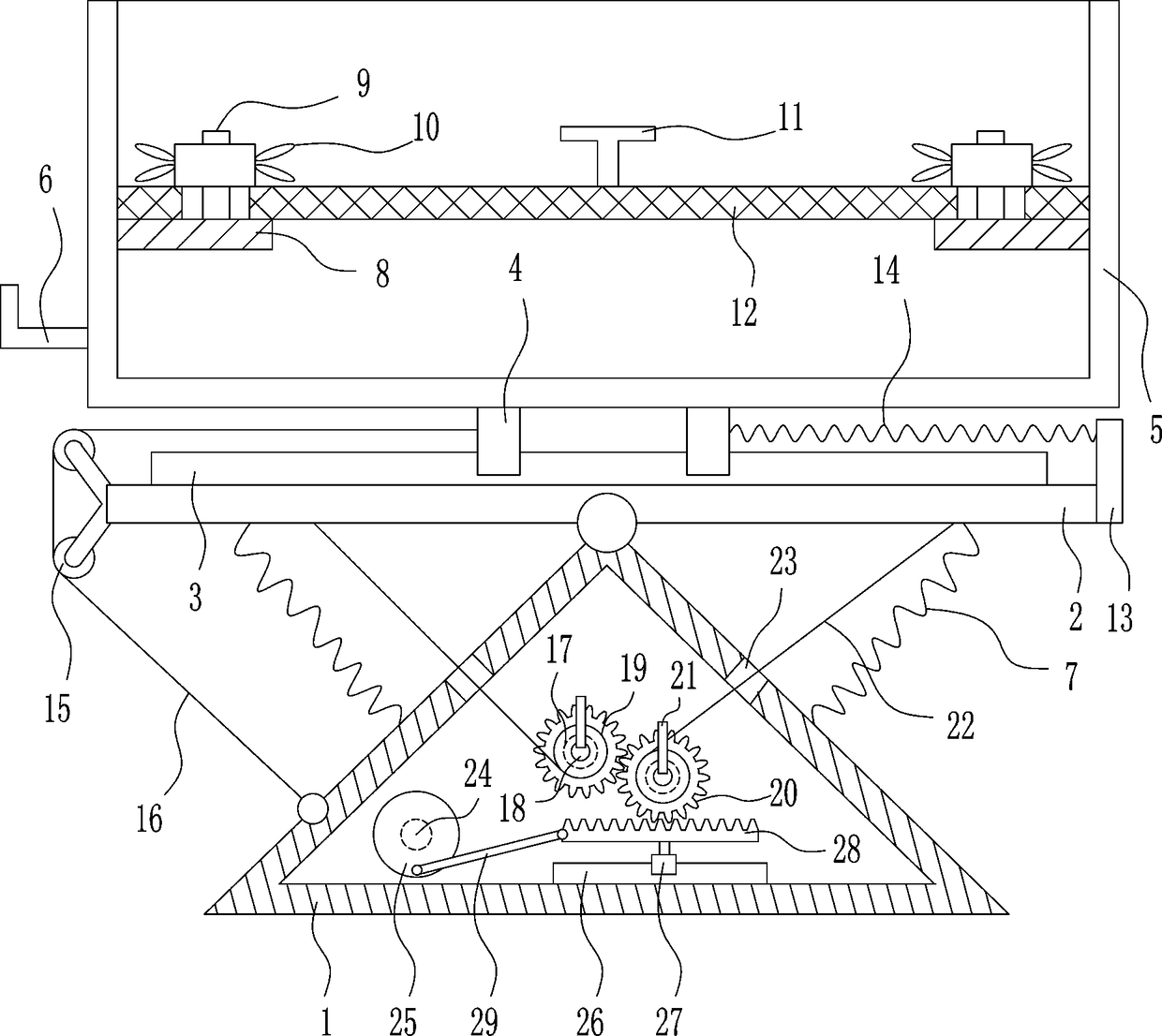

Orthopedical traditional Chinese medicinal material oscillating sieving device

The invention provides a sieving device, in particular to an orthopedical traditional Chinese medicinal material oscillating sieving device. The invention aims to provide the orthopedical traditionalChinese medicinal material oscillating sieving device which can improve the sieving efficiency effectively to sieve traditional Chinese medicinal materials which are uniform in size. The invention provides the orthopedical traditional Chinese medicinal material oscillating sieving device which comprises a mounting box, an oscillating plate, a first slide rail, a first slide block, a sieving box, afirst handle, a first spring, a mounting rod, a threaded rod, a butterfly nut and the like, wherein the oscillating plate is rotatably connected to the top of the mounting box; the first slide rail is arranged in the middle of the top of the oscillating plate; and the first slide rail is slidably connected to a first slide block. The orthopedical traditional Chinese medicinal material oscillatingsieving device provided by the invention achieves the effect of improving the sieving efficiency effectively to sieve traditional Chinese medicinal materials which are uniform in size. The sieving box which swings clockwise and anticlockwise will also move left and right, so that the medicinal materials are fully sieved and the sieved medicinal materials are uniform in particle.

Owner:朱宁生

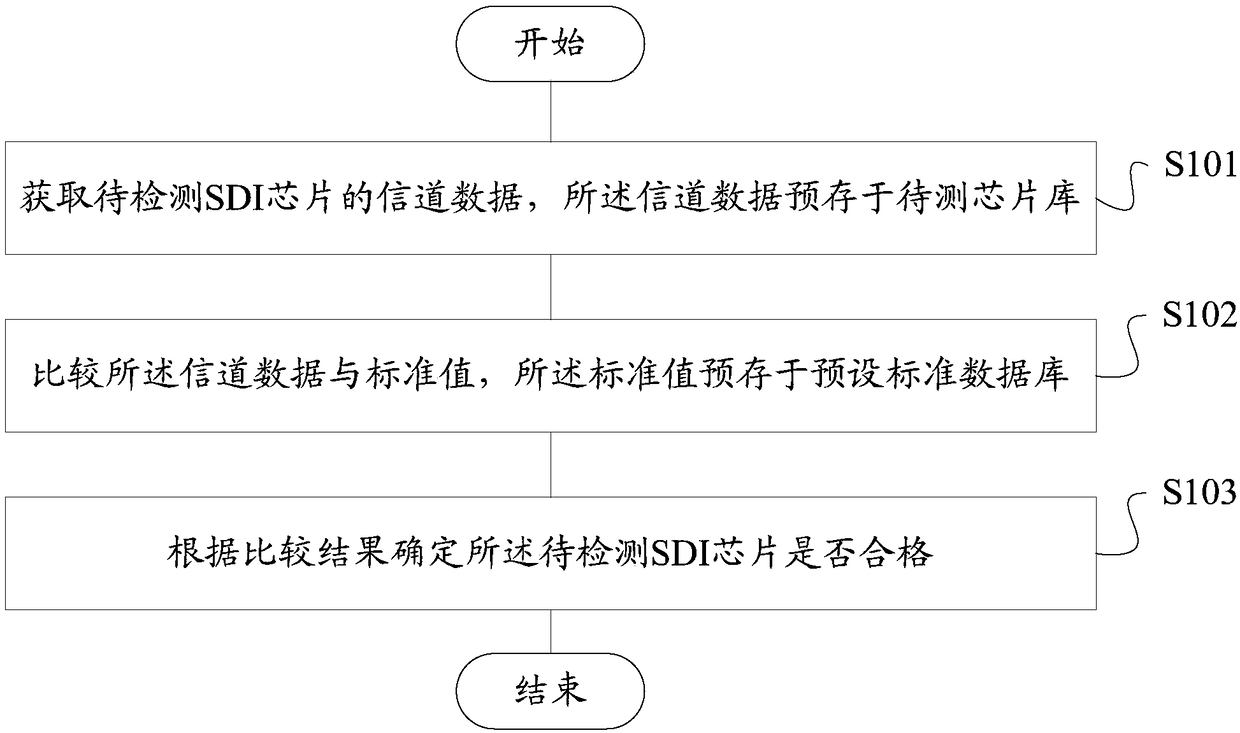

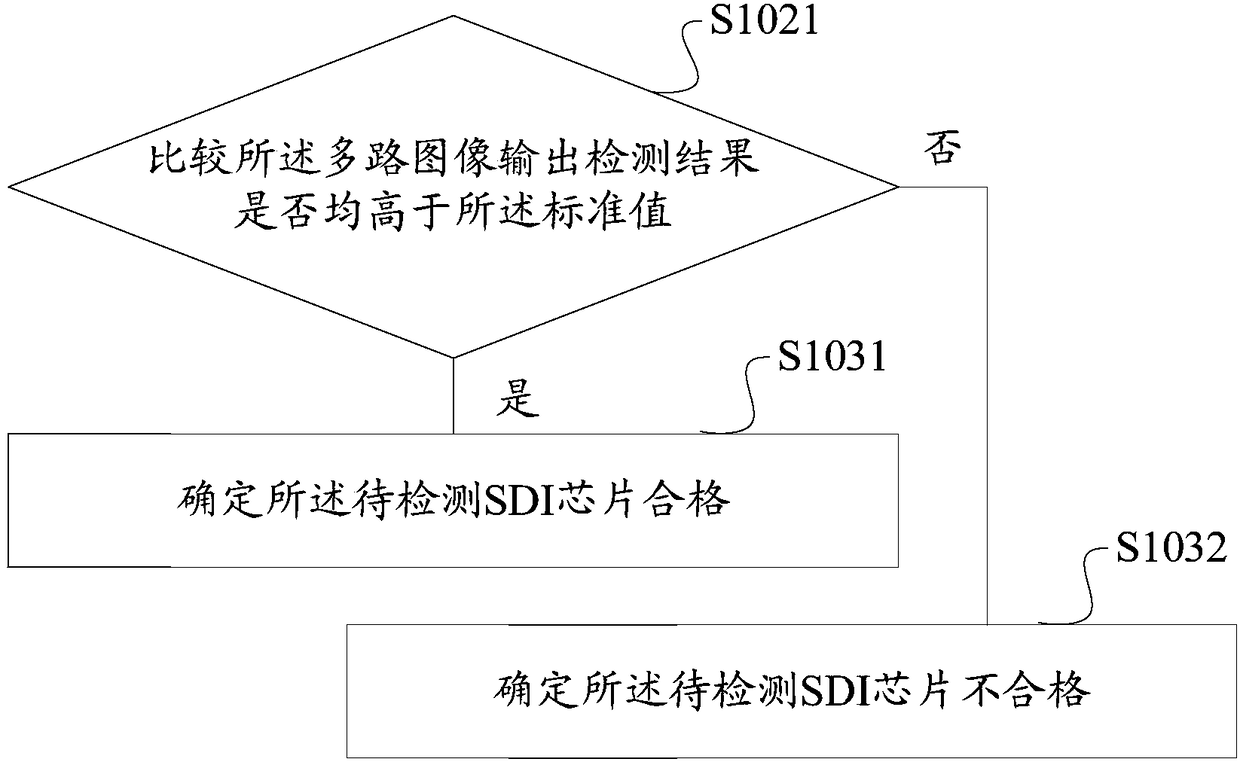

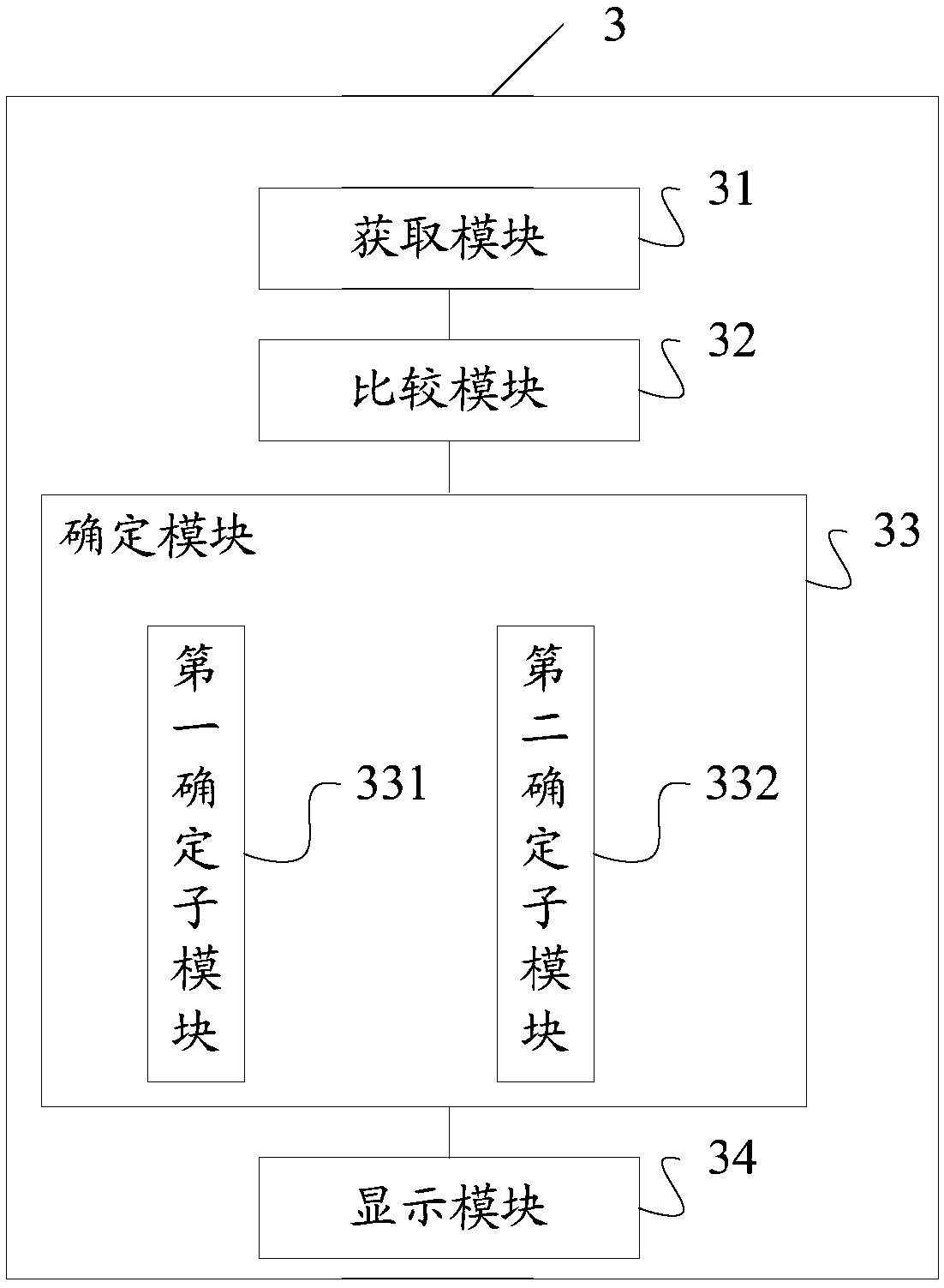

Automatic detection method and device of SDI chip, storage medium and terminal

InactiveCN108521571AImplement automatic detectionImprove sieving efficiencyTelevision systemsChannel dataTime cost

The invention provides an automatic detection method and device of an SDI chip, a storage medium and a terminal. The method comprises the following steps: obtaining channel data of the SDI chip to bedetected, wherein the channel data are pre-stored in a chip library to be tested; comparing the channel data with a standard value, wherein the standard value is pre-stored in a preset standard database; and determining whether the SDI chip to be tested is qualified according to the comparison result. By adoption of the scheme provided by the invention, the screening efficiency of the SDI chips inthe production process can be improved, and the time cost is reduced.

Owner:SHANGHAI XIAOYI TECH CO LTD

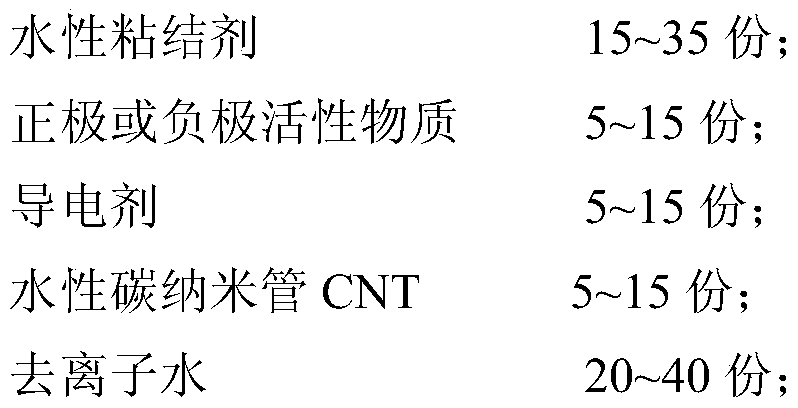

CNT-containing aqueous lithium battery paste and preparation method thereof

ActiveCN109713308ASolve the problem of fragmentationAvoid stabilityCell electrodesViscosityLithium battery

A CNT-containing aqueous lithium battery paste is characterized by comprising the following components, by mass, 15 to 35 parts of aqueous binder; 5 to 15 parts of positive electrode or negative electrode active material; 5 to 15 parts of conductive agent; 5 to 15 parts of aqueous CNT, and 20 to 40 parts of deionized water, wherein the aqueous CNT has a diameter of 10 to 54 nm. The invention alsodiscloses a method for preparing the aqueous lithium battery paste. The method comprises adding a CNT dispersion liquid for stirring after high-viscosity stirring. Thus, the CNT can be uniformly dispersed into a paste system to prevent the secondary agglomeration of the CNT dispersion liquid with other conductive agents or main materials, thereby well solving the dispersion problem of CNT and thepaste stability. In addition, since the paste prepared by the invention is uniformly dispersed, the sieving efficiency of the paste can be improved, the sieving time can be reduced, the production efficiency can be improved, and the production cost can be reduced. The lithium battery paste of the invention is simple in ingredients and simple in preparation method.

Owner:ZHEJIANG CASNOVO MATERIALS

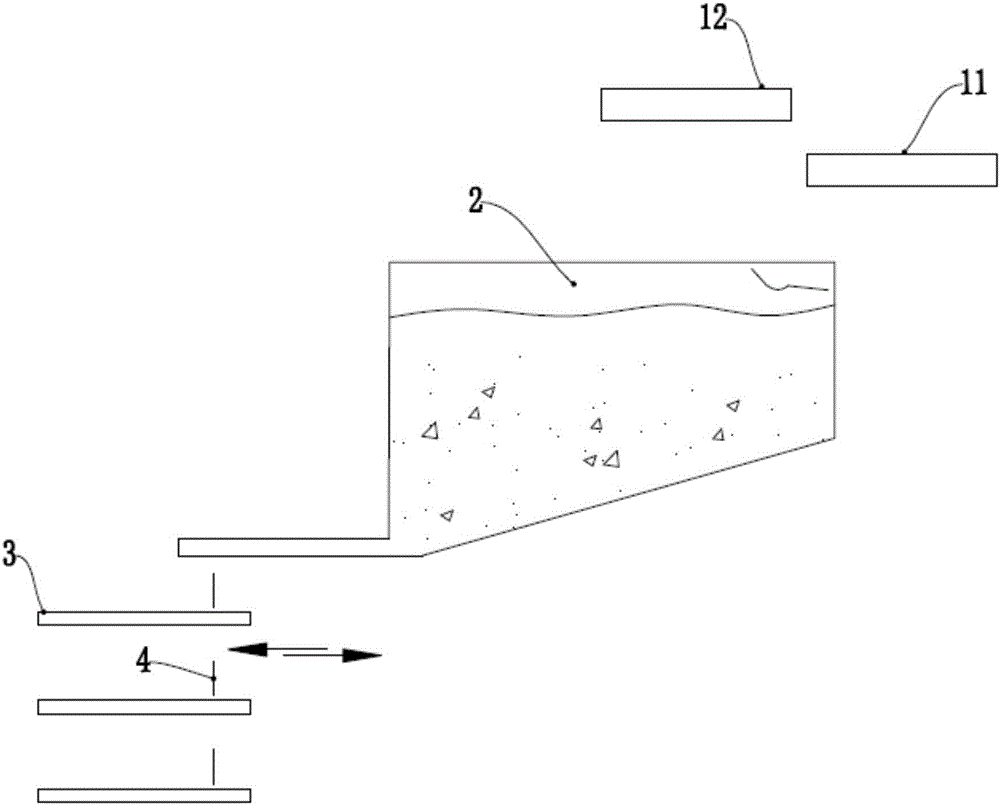

Polishing waste slag recycling method and facility used by method

ActiveCN106348406AAvoid cloggingAchieve maximum fitnessSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationSludgeFiltration

The invention discloses a polishing waste slag recycling method which comprises the following steps: settling, screening, pressure filtration and utilizing, wherein the screening step comprises the process of sequentially passing the settled slurry through a 6-20-mesh screen, a 40-60-mesh screen and a 110-130-mesh screen. The polishing waste slag recycling facility comprises a polishing wastewater output tube, a flocculant output tube, a settling tank, filter screens, scrapers and a filter press. By using the polishing waste slag recycling method, the flocculant added into the settling tank accelerates the solid-liquid separation of the polishing wastewater; the settled slurry is subjected to layered screening, thereby enhancing the screening efficiency and avoiding the problem of screen blockage caused by the settled slurry; and the settled slurry is recycled for different purposes by different screening ways, thereby implementing the maximum-applicability reutilization on the waste.

Owner:QINGYUAN NAFUNA CERAMICS +2

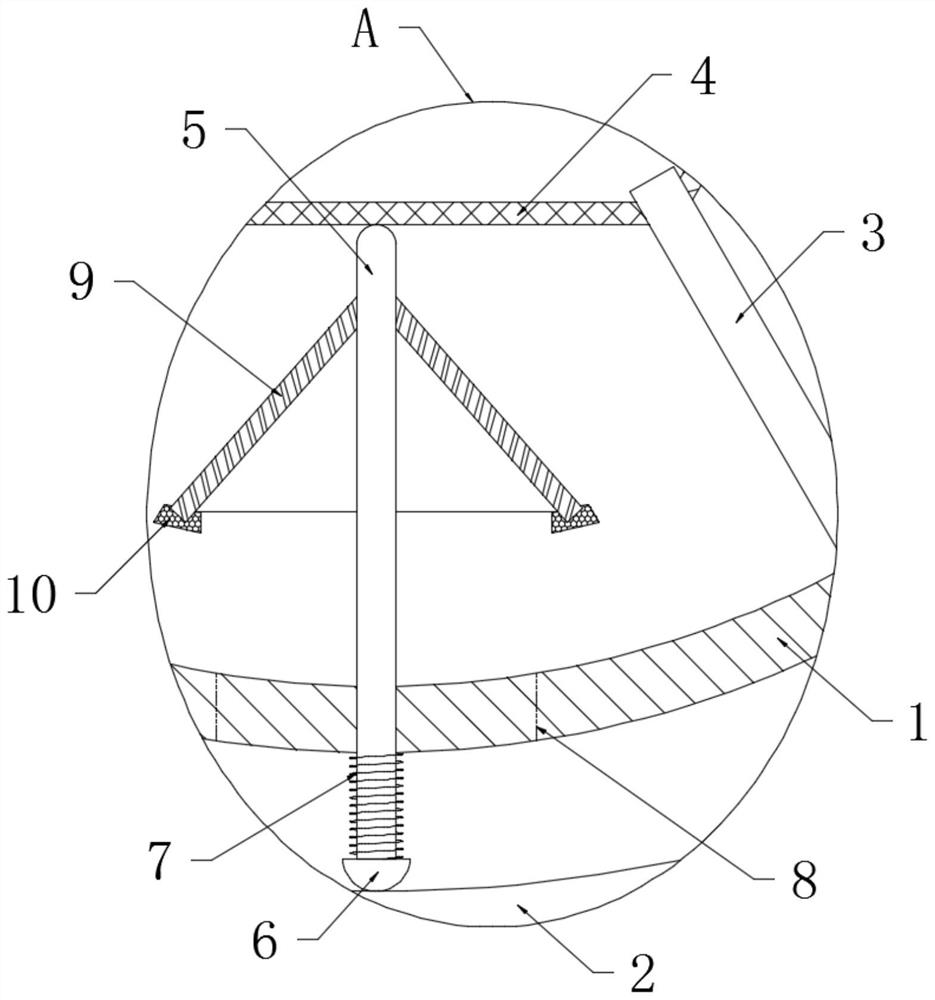

Medicament sieving device

The invention discloses a medicament sieving device. The medicament sieving device comprises a housing, wherein a first rotating rod is inserted in the surface of the housing; two ends of the first rotating rod respectively penetrate through the front side and the rear side of the housing; eccentric wheels are respectively connected to two ends of the first rotating rod; vertical shafts are respectively and fixedly connected to two edges of the housing; an upper beam is fixedly connected to top ends of the vertical shafts; two fixing rods are fixedly connected to the lower part of the upper beam; and a medicinal sieve sleeves bottom ends of the two fixing rods. According to the medicament sieving device disclosed by the invention, through the arrangement of the upper beam, the fixing rods and pressure springs, the medicinal sieve can only move in the longitudinal direction; the medicinal sieve is pushed down by the pressure springs, so that the joggling effect of the medicament sieving device is enhanced; the joggling effect is enhanced, so that partial medicament embedded in holes can be shaken out through joggling; through the arrangement of a toothed half wheel, a toothed ring and a dredging plate, and when the toothed half wheel rotates, the dredging plate is driven to make reciprocating movement in the longitudinal direction along with the toothed half plate, so that a mesh screen is regularly dredged.

Owner:广州念泽环保科技有限公司

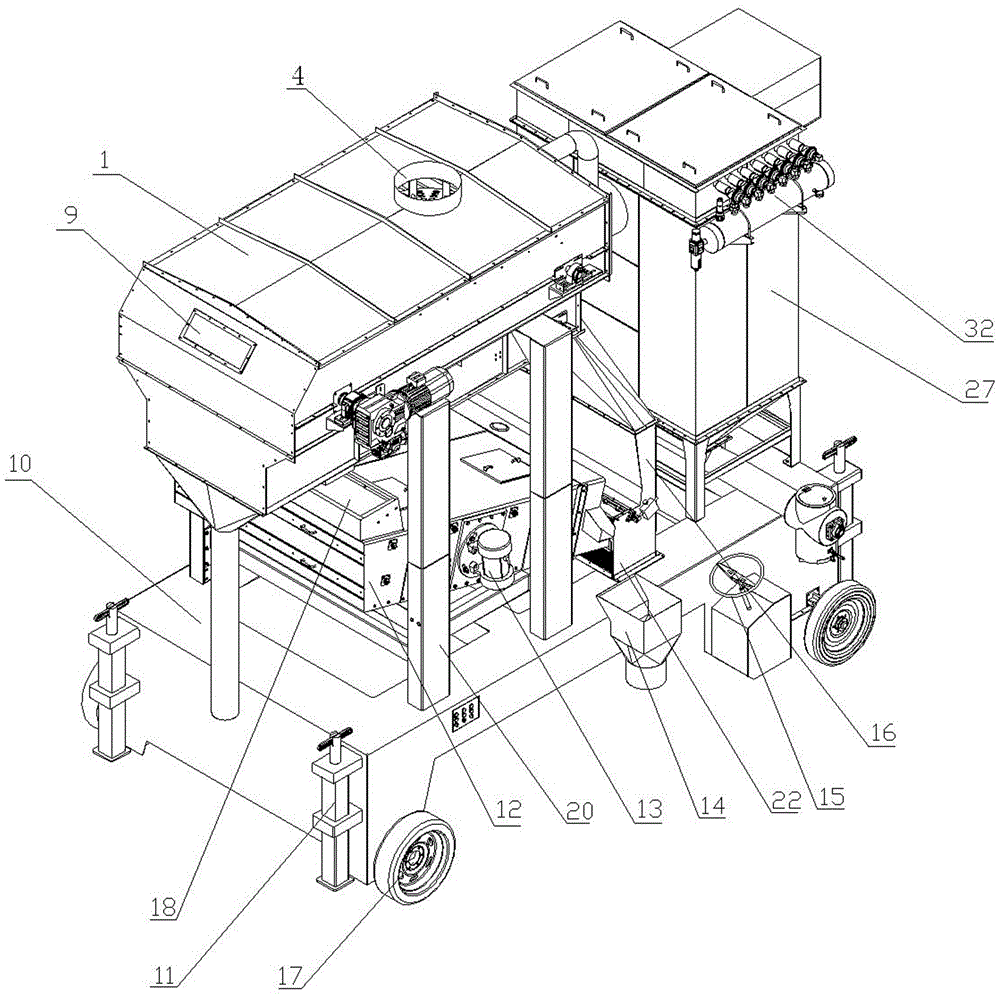

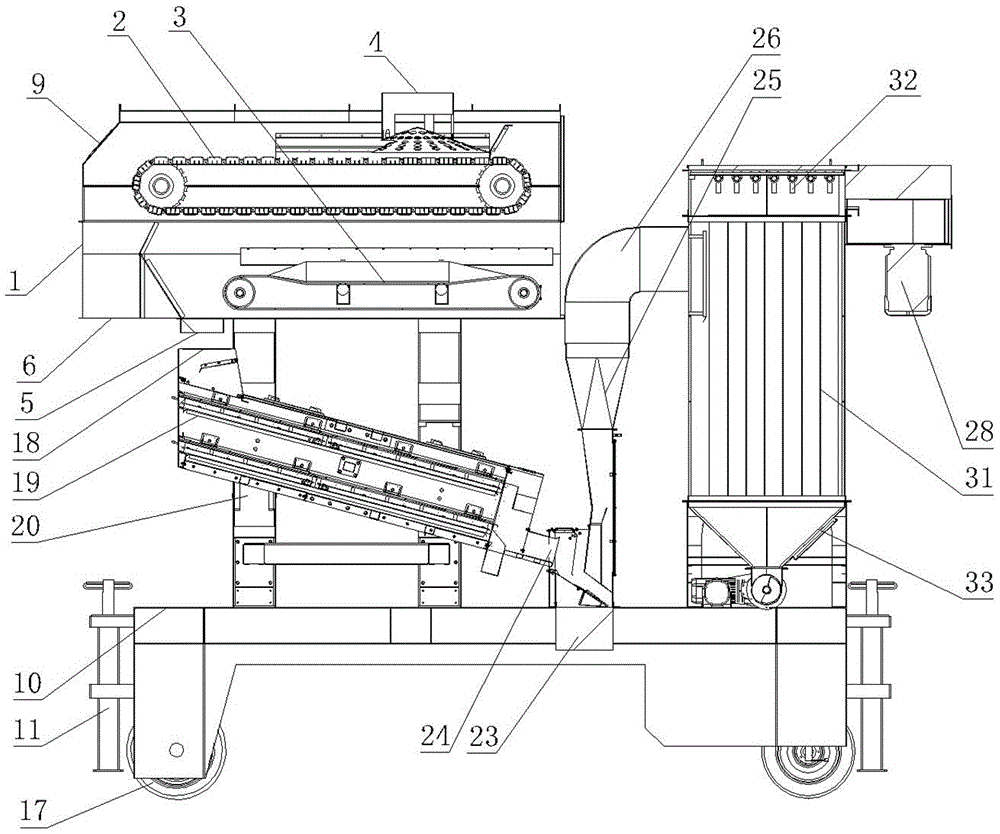

Efficient integrated cleaning equipment

InactiveCN105583157AImprove sieving efficiencyEasy to handleSievingGas current separationMaterial removalPrimary screening

The invention discloses efficient integrated cleaning equipment. The efficient integrated cleaning equipment comprises a self-walking platform, a support arranged on the self-walking platform, an endless screen precleaner arranged on the support, a self-balancing vibration screen arranged on the support and a dust removal device arranged on the self-walking platform. The efficient integrated cleaning equipment combines primary screening, deep screening and material dust removal through a reasonable and compact structure, the operation sequence of repeated screening is shortened, time and labor are saved, and material bolting and screening efficiency is improved; larger impurities are screened preliminarily through the precleaner, light impurities in materials are removed through the self-balancing vibration screen, a great amount of dust generated by mutual striking and impact is sucked away through an air suction opening in the material discharging process, the material treatment effect is better, the content of the material impurities is low, and quality is high; and the sucked away dust is treated in the pulse dust removal device, dust and other impurities are discharged and collected through a dust outlet, clean air is discharged through an air outlet of a draught fan, and the whole production process is free of dust and pollution.

Owner:HEBEI PINGLE FLOUR MACHINERY GROUP

Efficient building sand sieving device capable of preventing meshes from being blocked

PendingCN112742692AGood sand screening effectImprove sieving efficiencySievingScreeningEnvironmental geologyWaste material

The invention discloses an efficient building sand screening device capable of preventing meshes from being blocked. The device comprises a sand screening tank body and an arc-shaped track plate, the sand screening tank body is of a cylindrical structure, and the arc axis of the track plate and the rotation center line of the sand screening tank body are parallel and located on the same vertical plane; and a plurality of vertical supporting legs are welded to the bottom of the track plate, a collecting opening is formed at the bottom of the track plate, and a feeding opening and a waste opening are formed at the two ends of the sand screening tank body respectively. The efficient building sand screening device has the beneficial effects that in the rotating process of the sand screening tank body, sand always makes contact with two to three screens for screening, meanwhile, the axial size of the sand screening tank body is larger, a large amount of sand can be screened at the same time, and impurities such as gravel and garbage blocked by the screens in the sand can be conveyed through auger blades and finally leave the sand screening tank body from the waste opening; and the sand can be screened without shutdown, the screening efficiency and the sand screening thoroughness are greatly improved, and the efficient building sand screening device is particularly suitable for screening requirements of building construction.

Owner:李伟

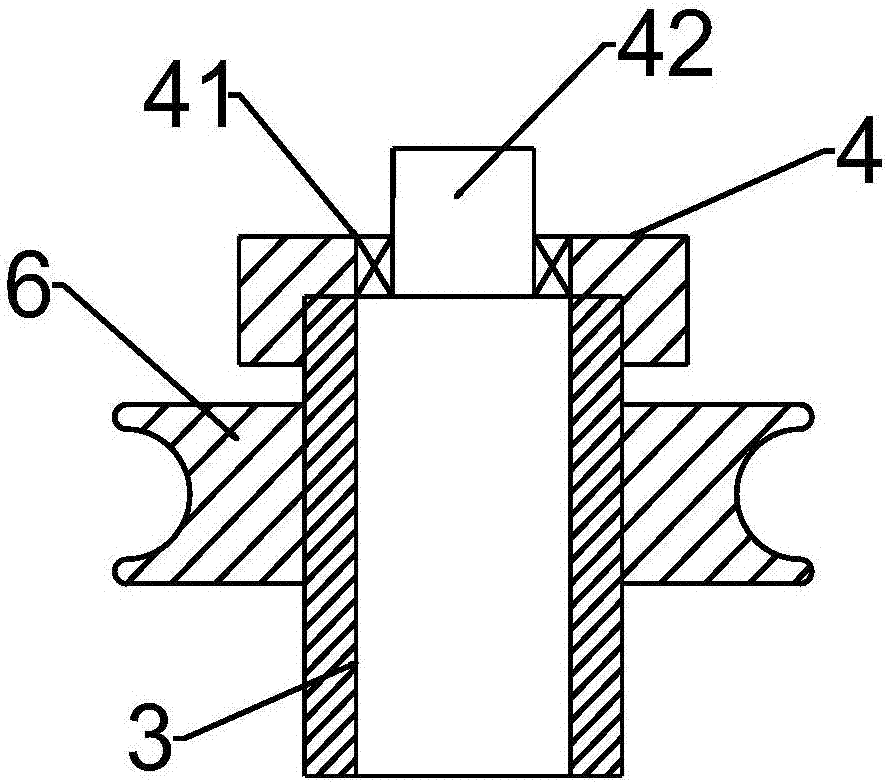

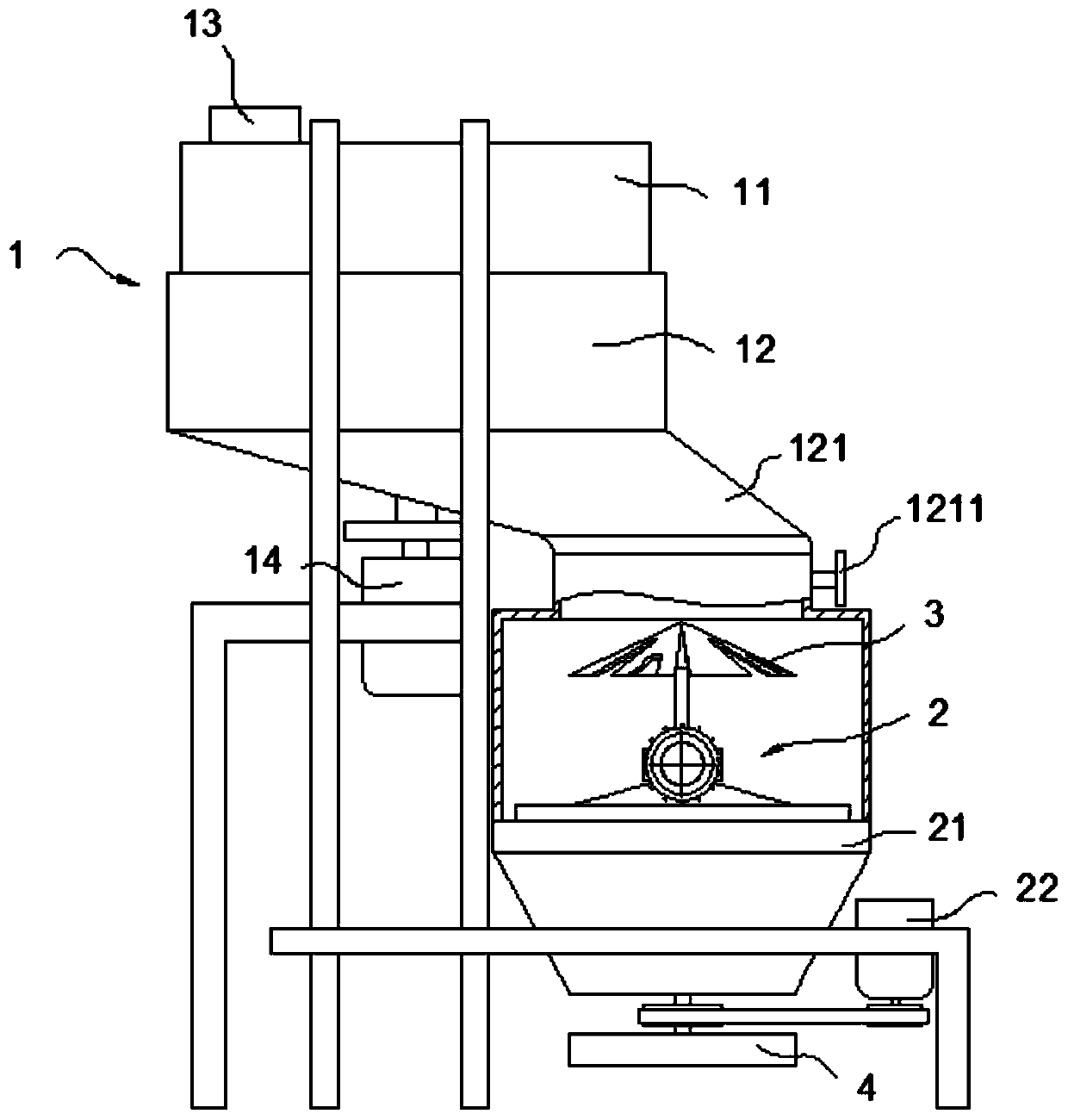

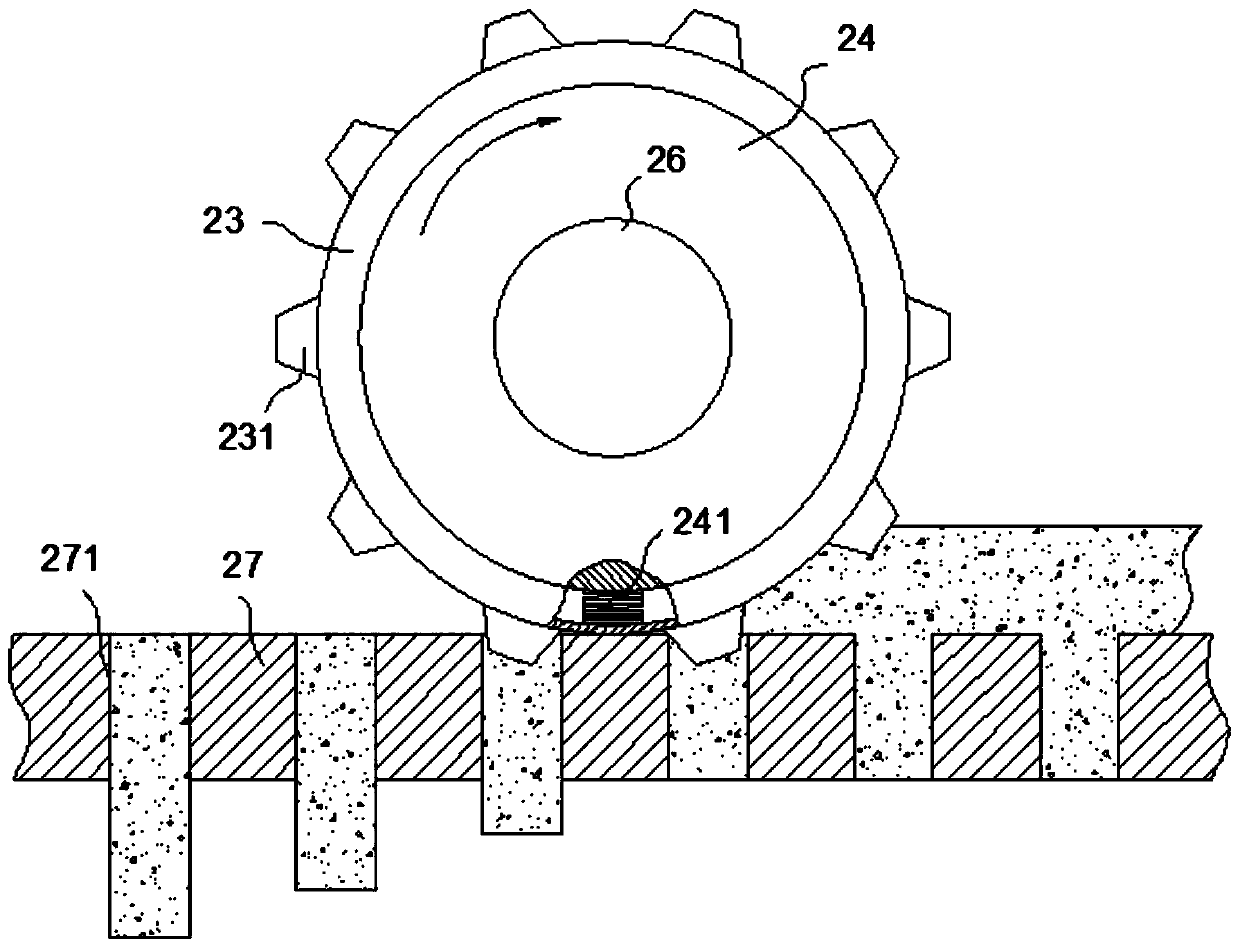

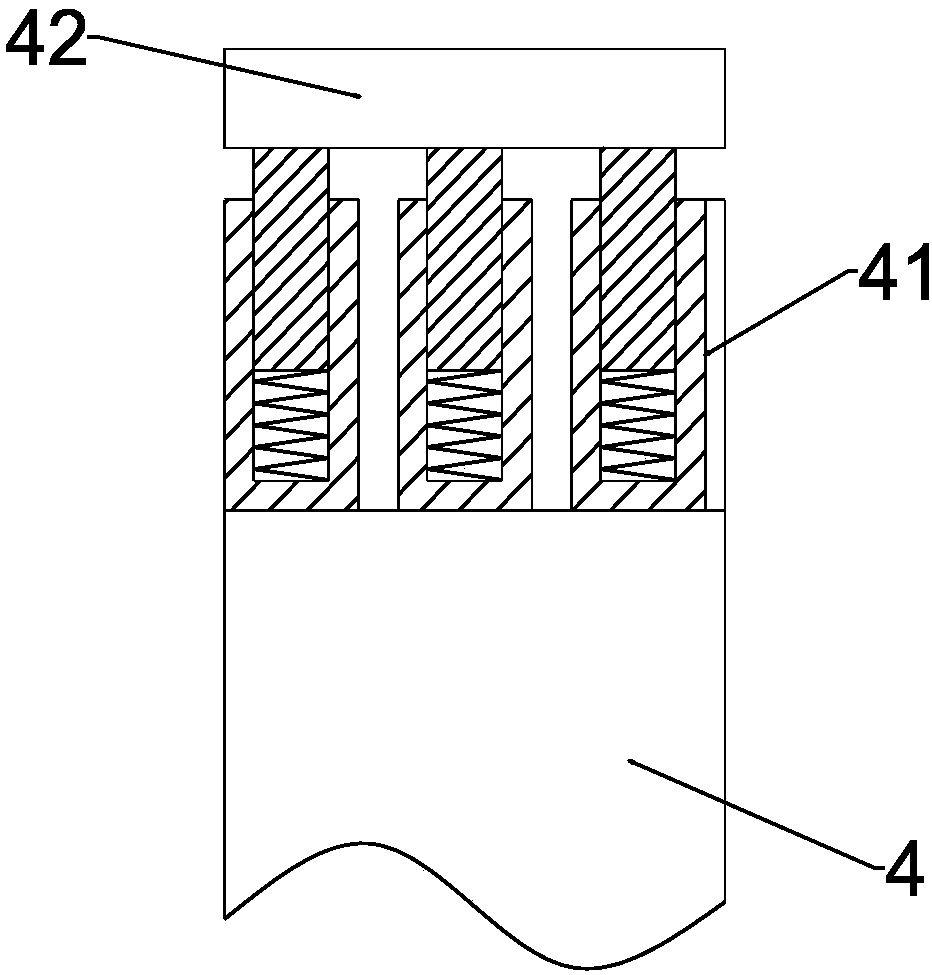

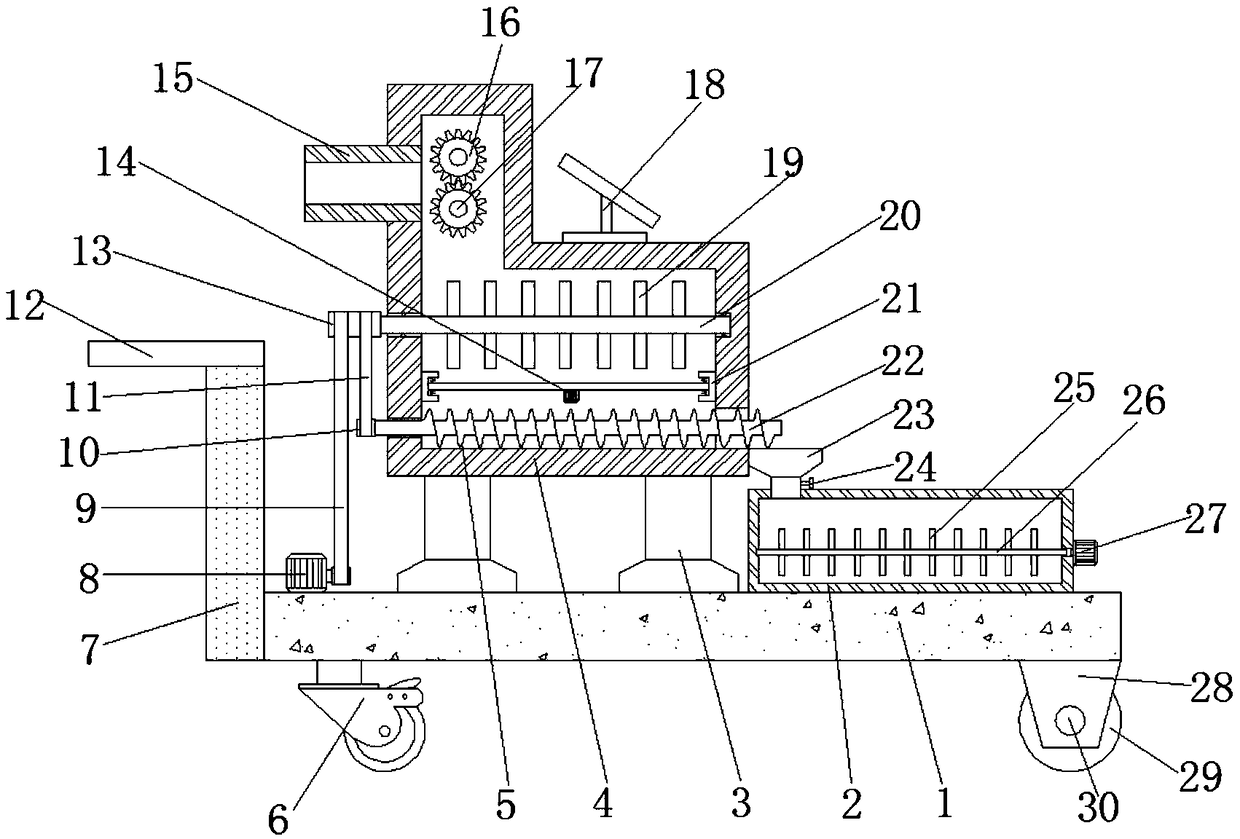

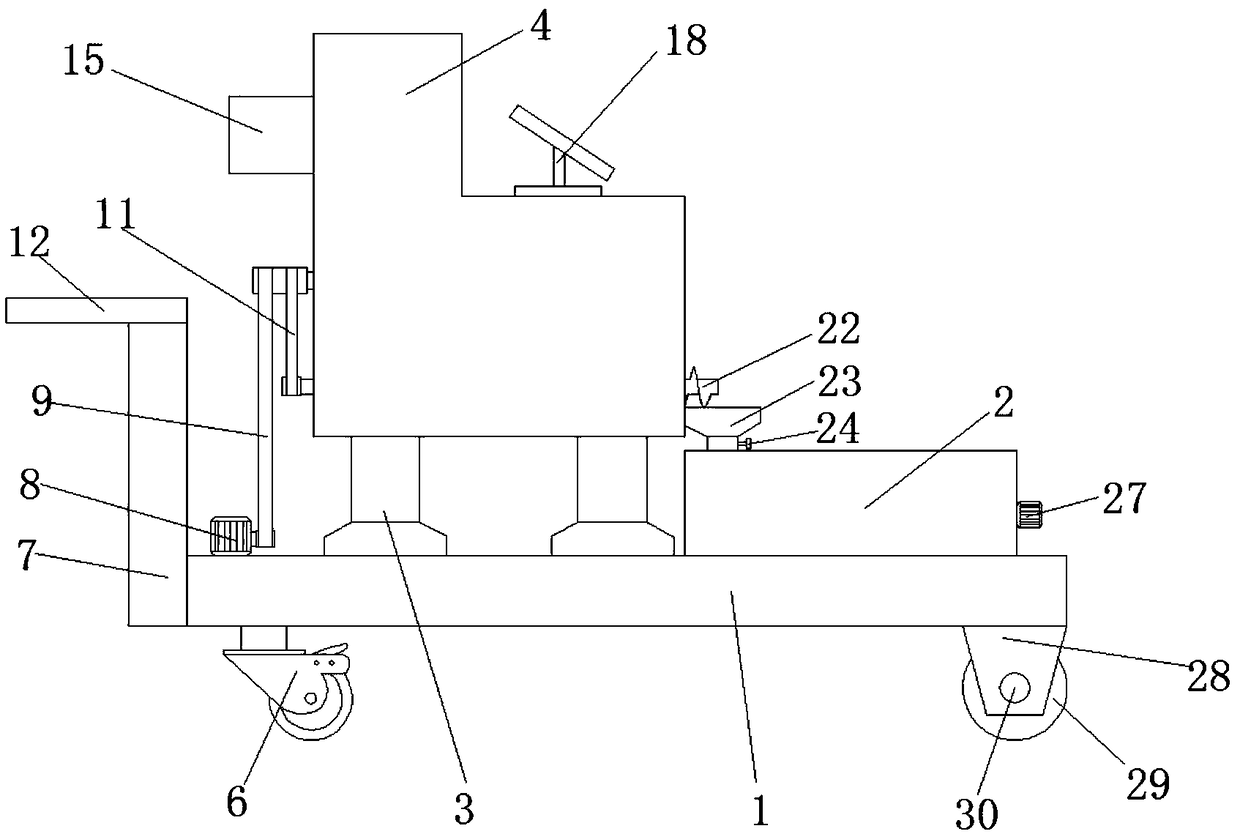

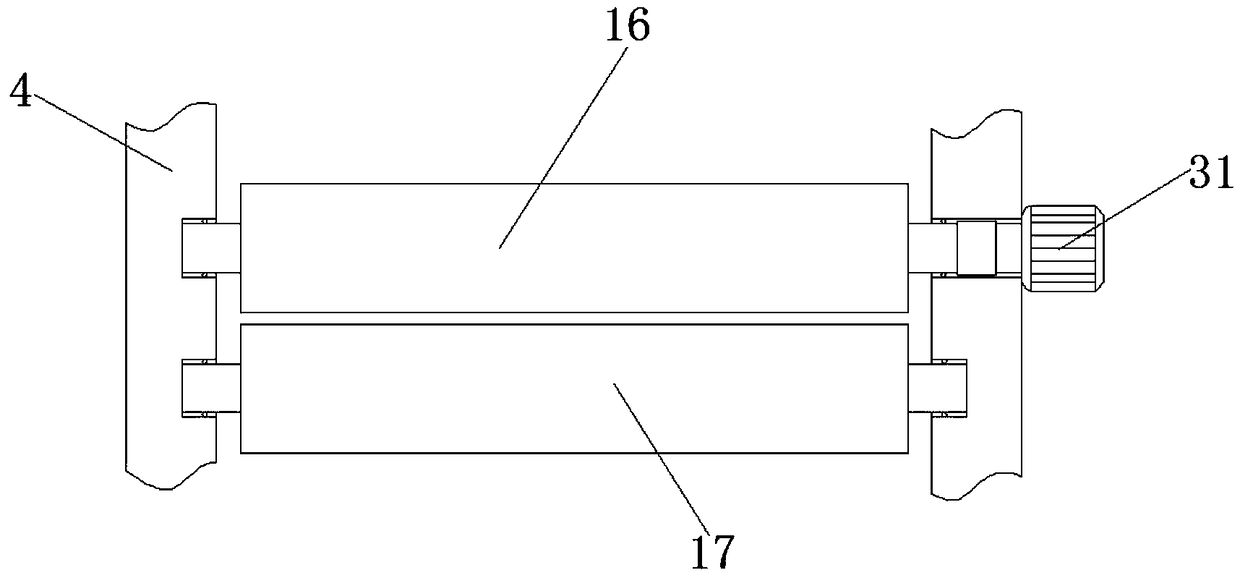

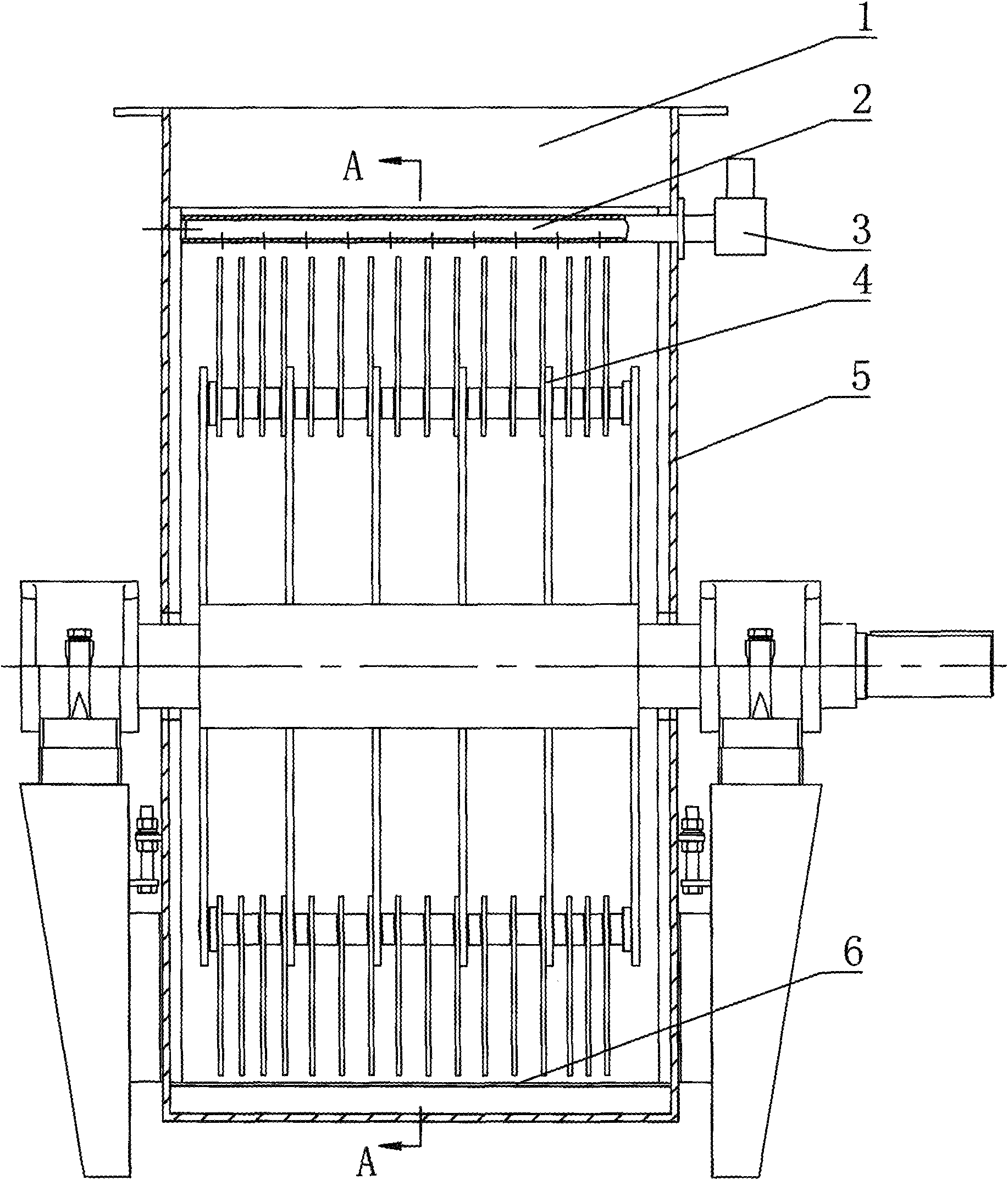

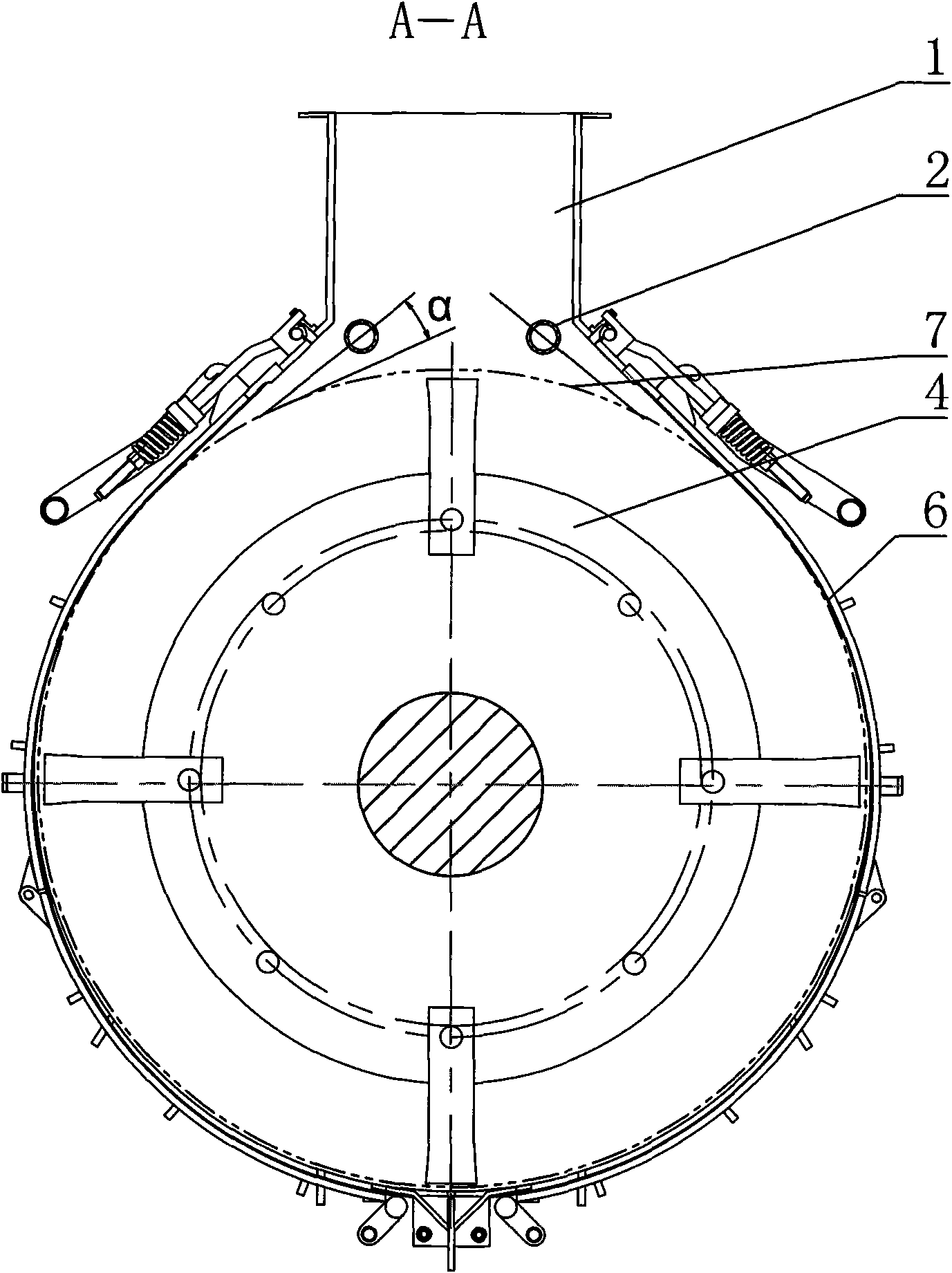

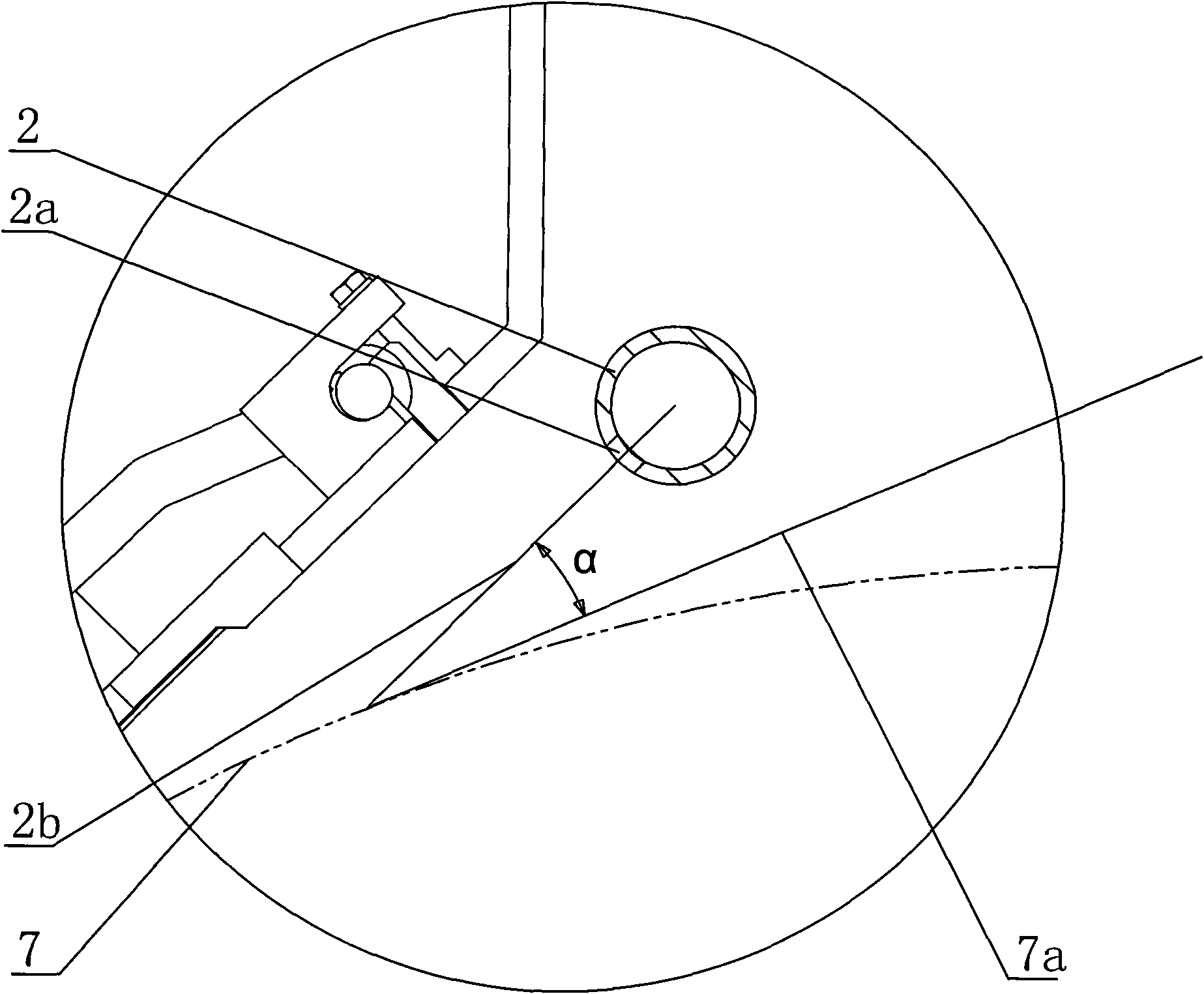

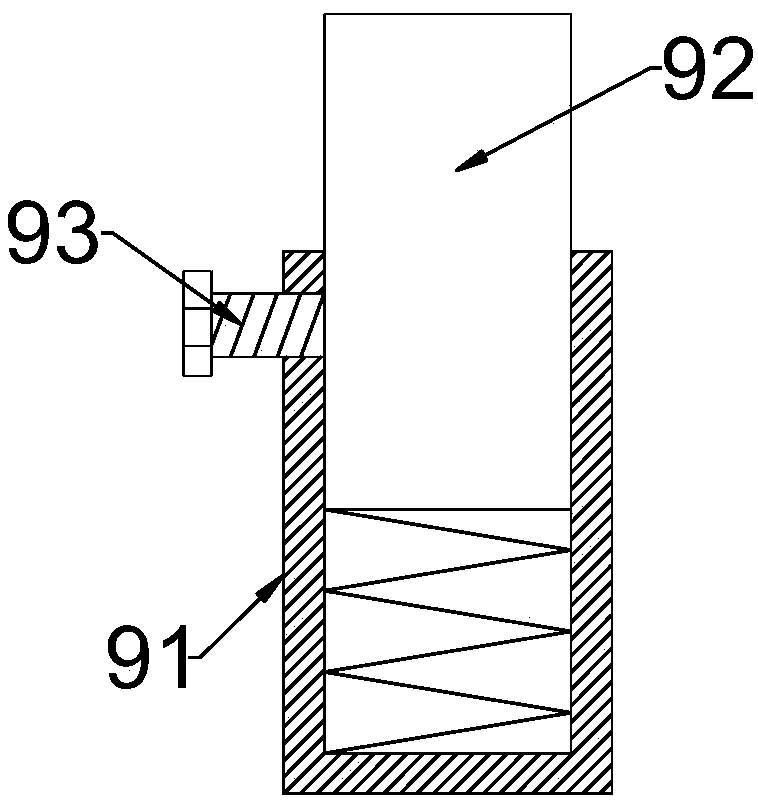

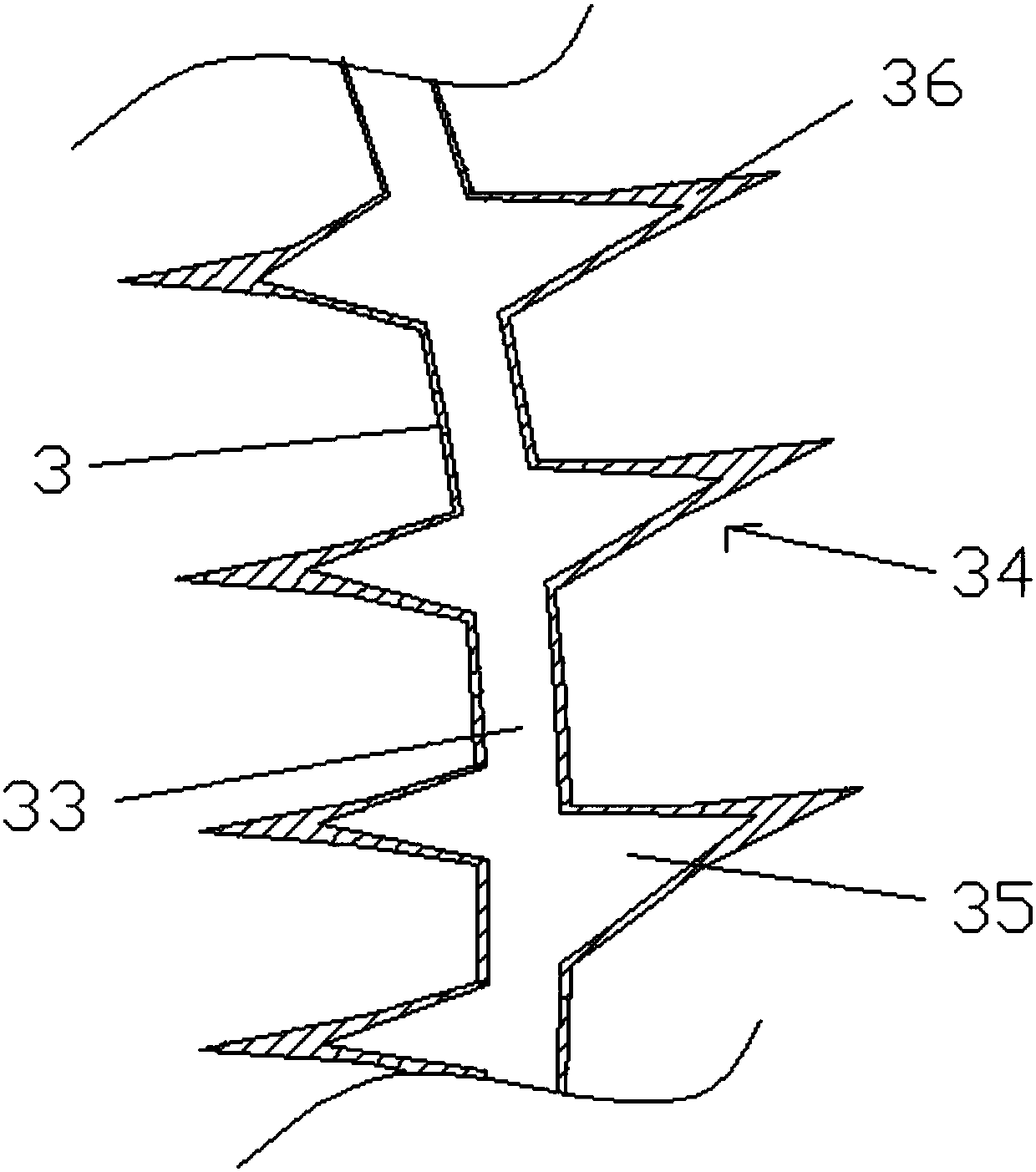

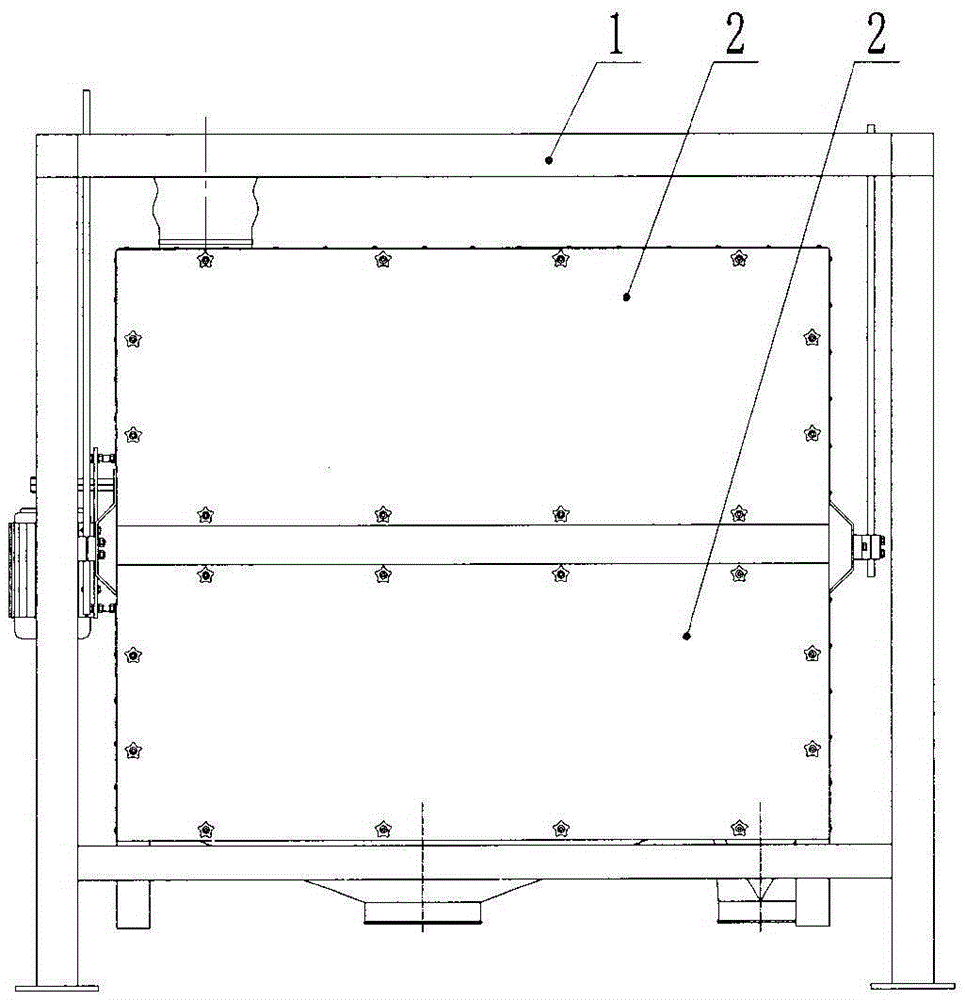

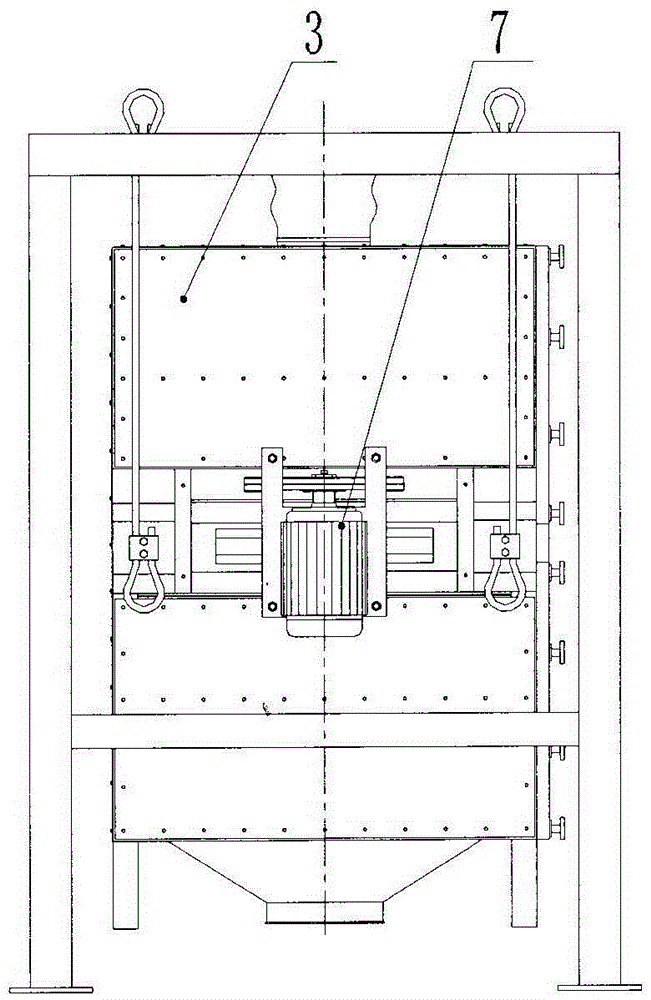

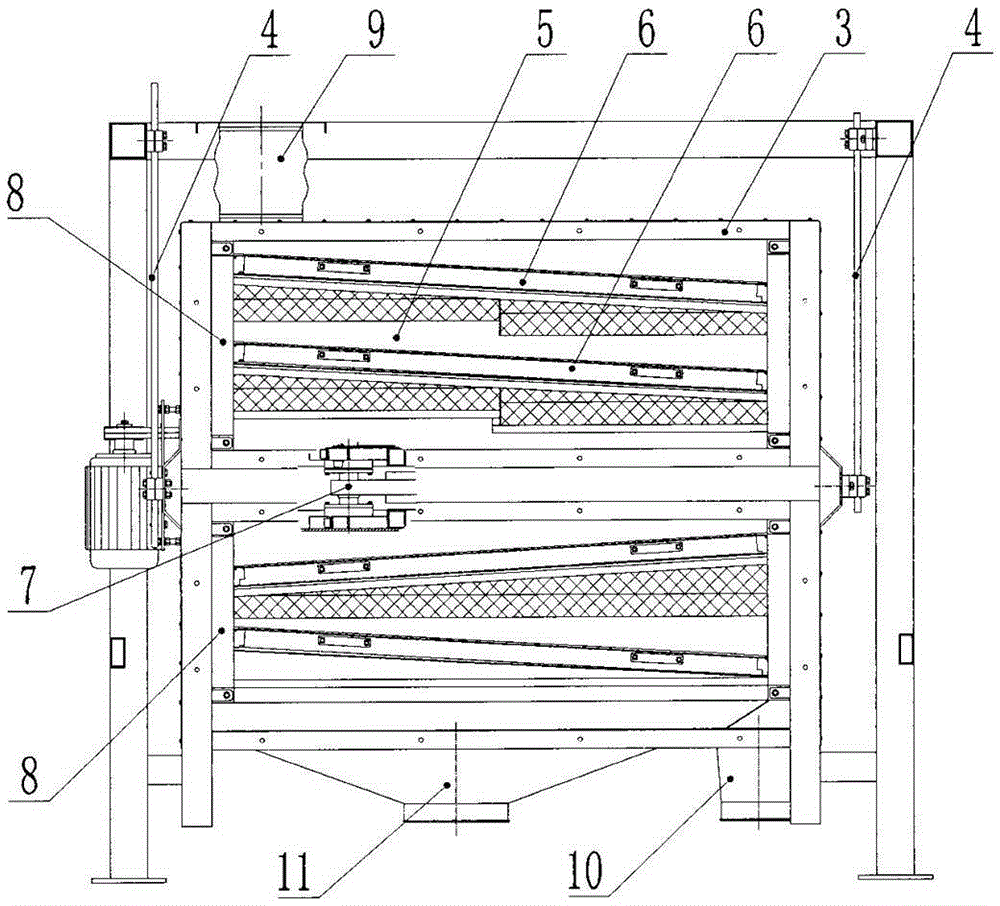

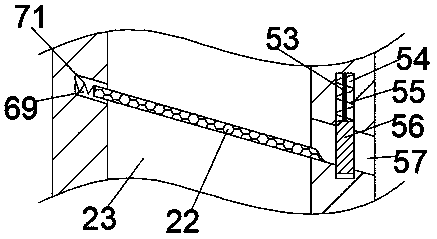

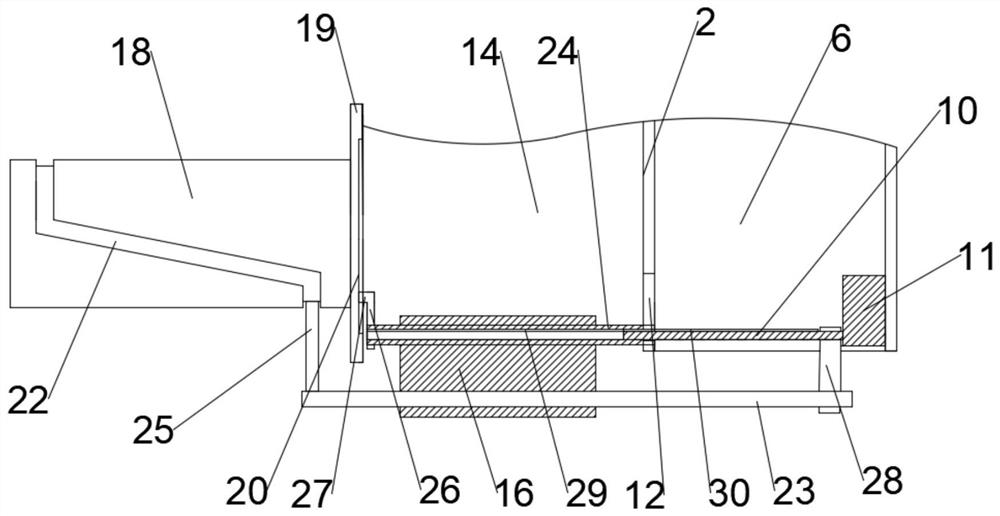

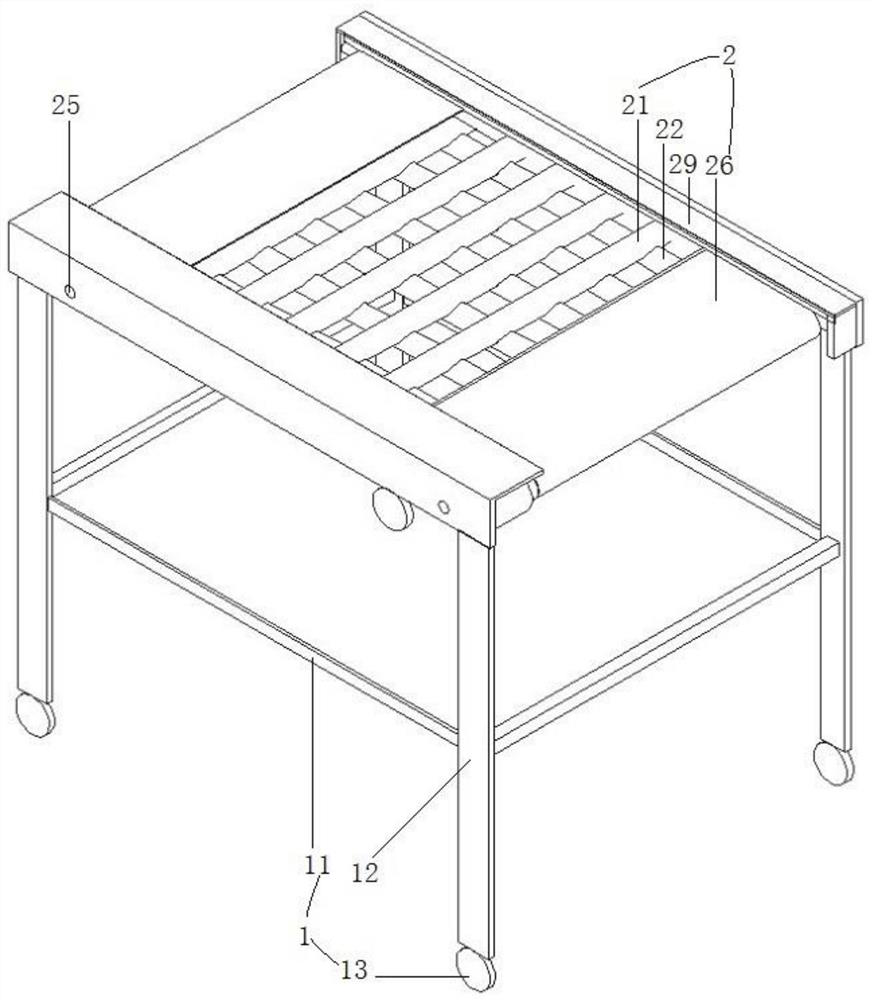

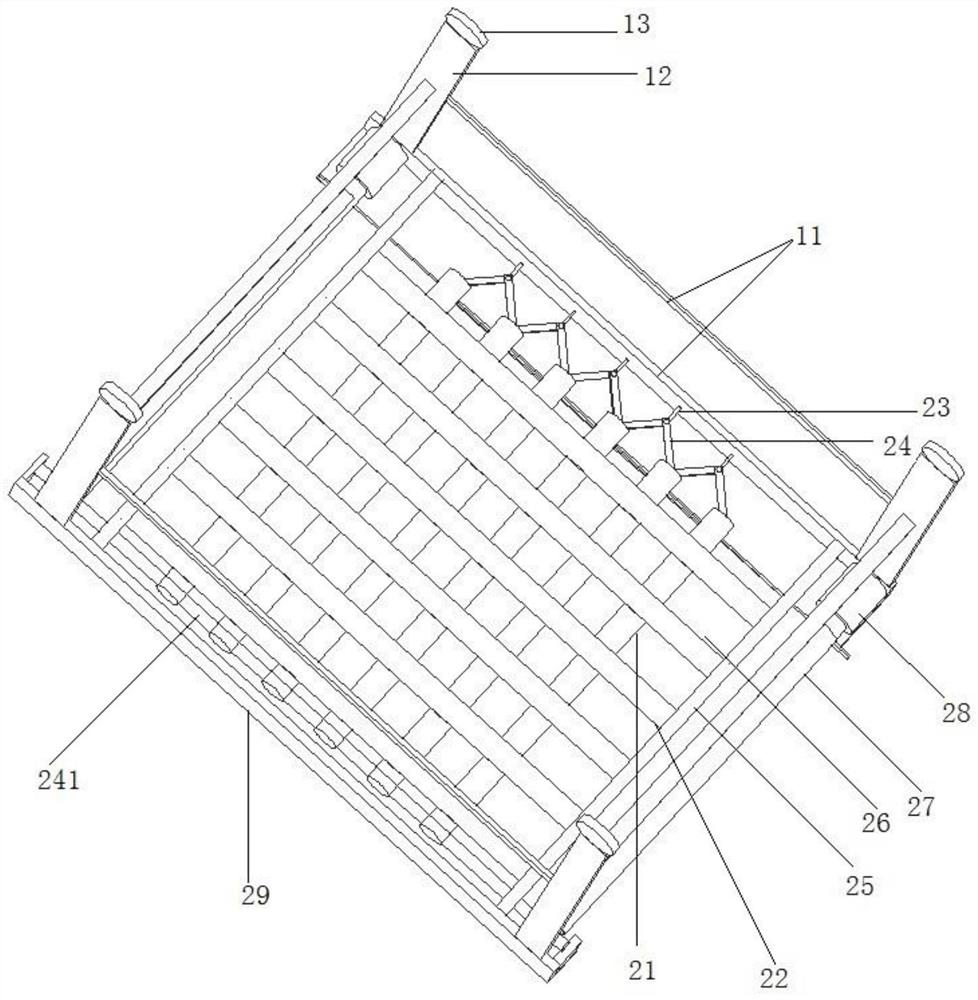

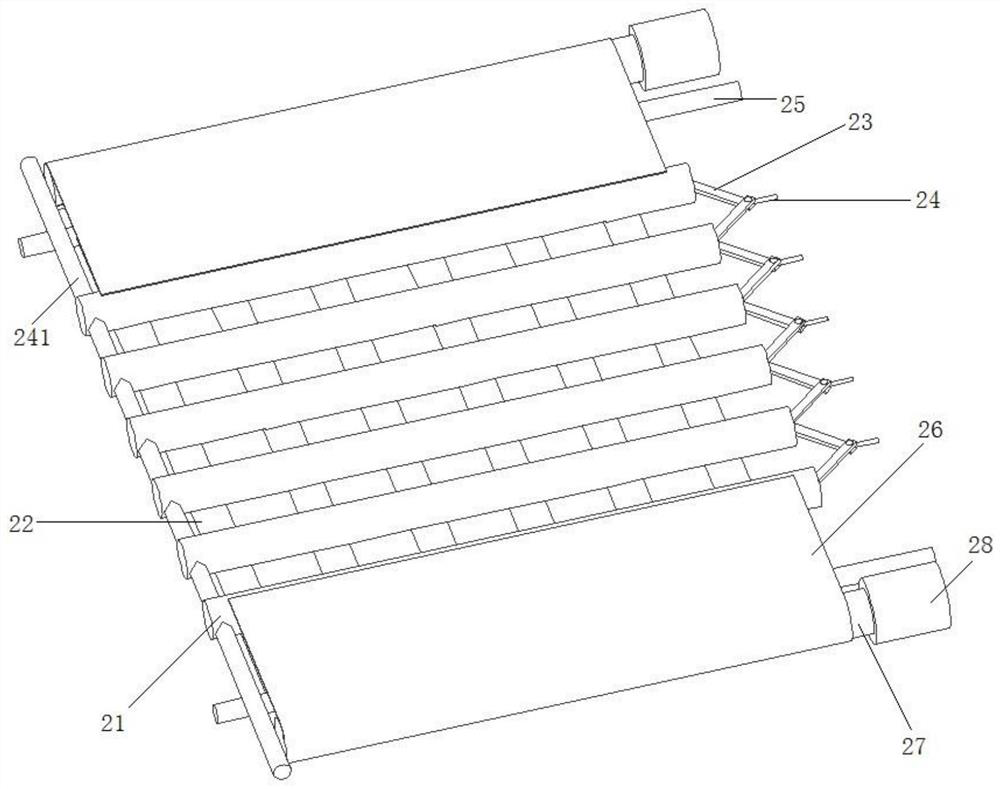

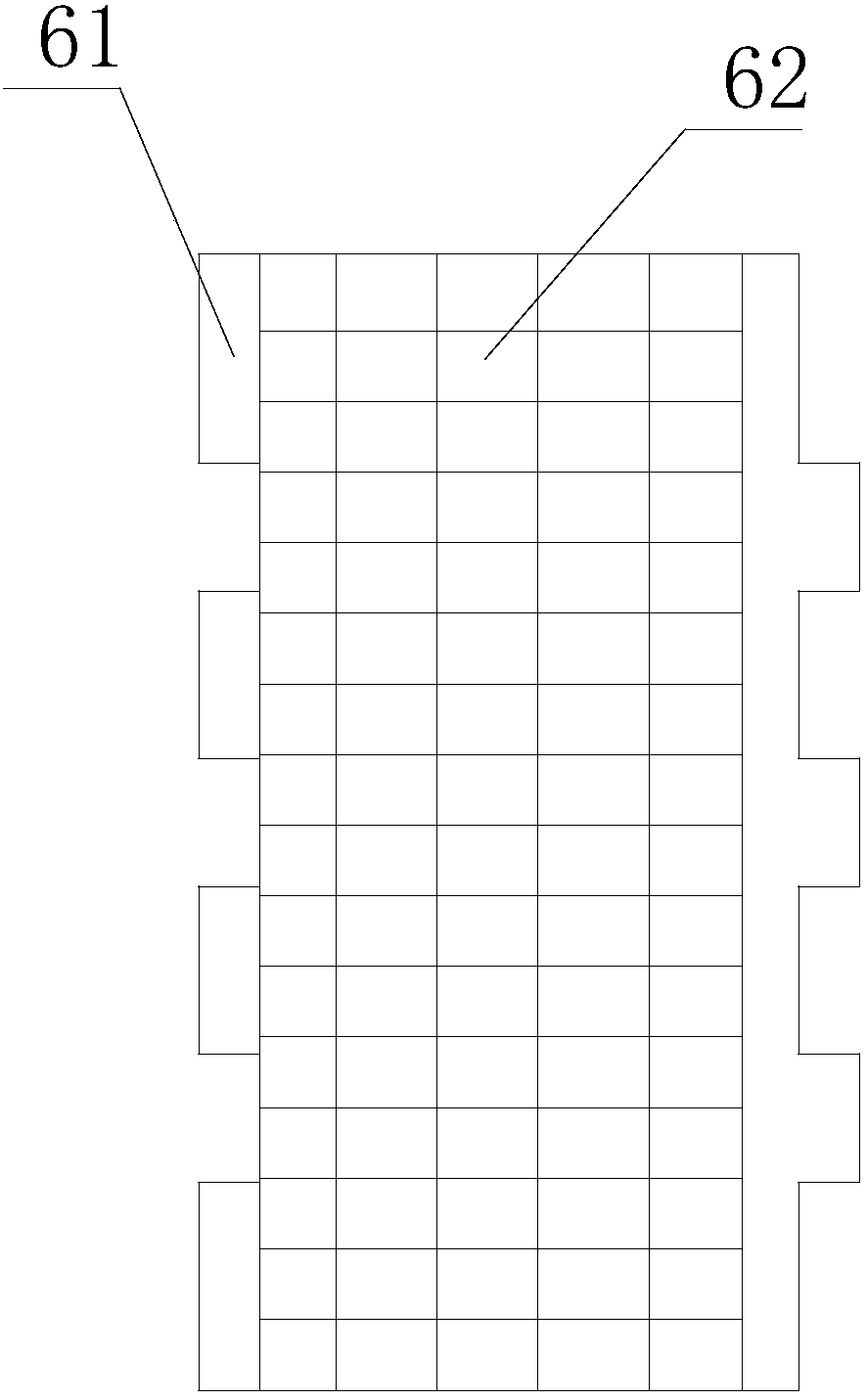

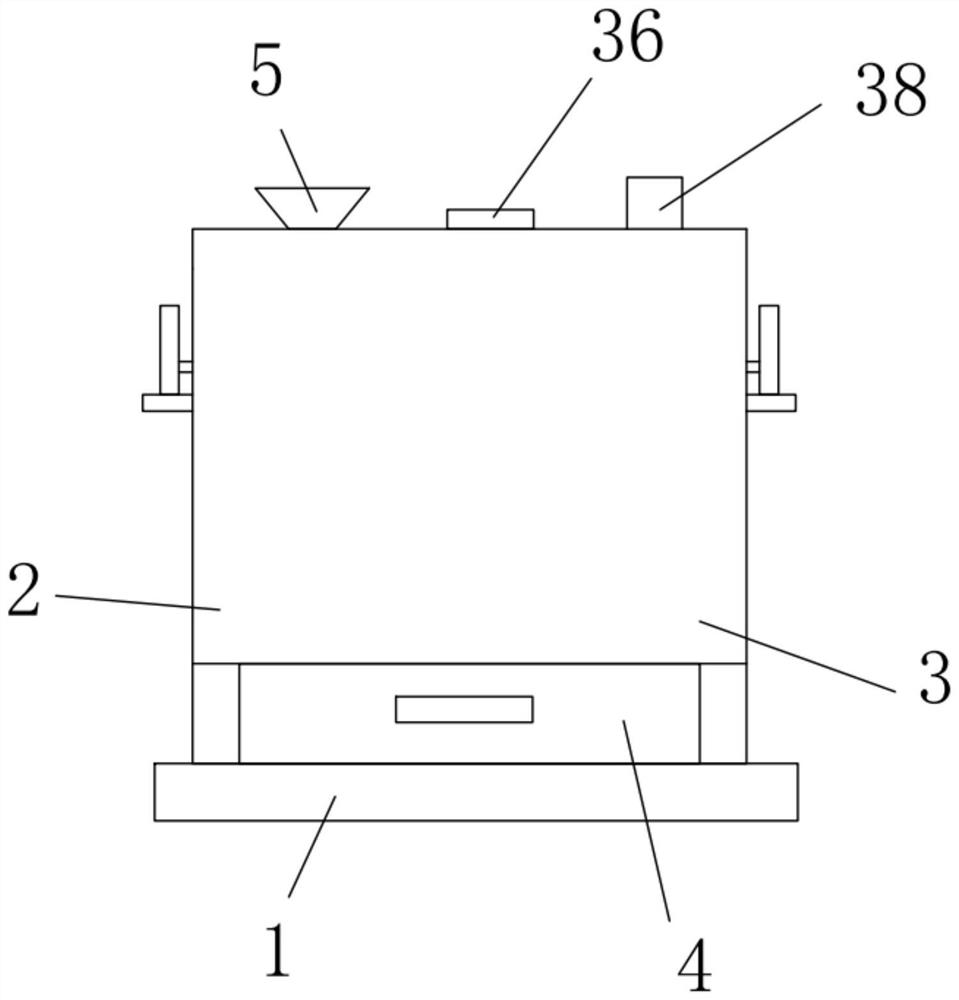

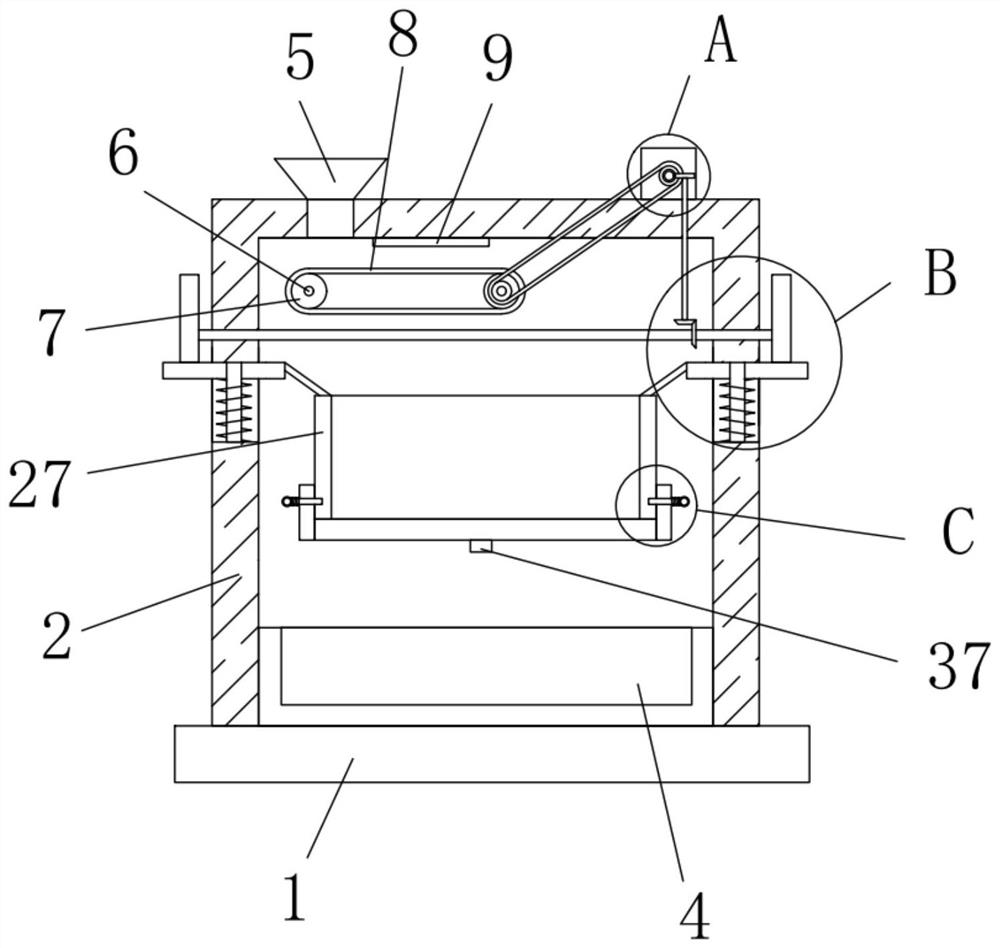

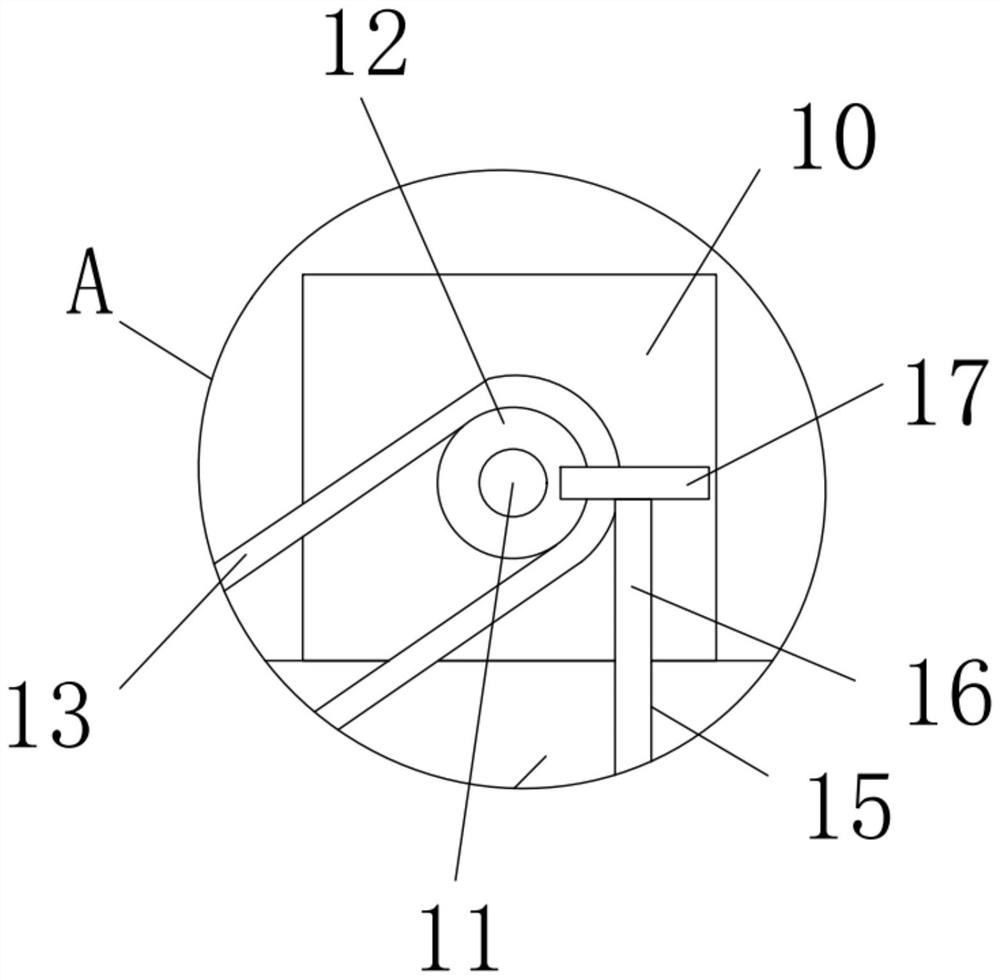

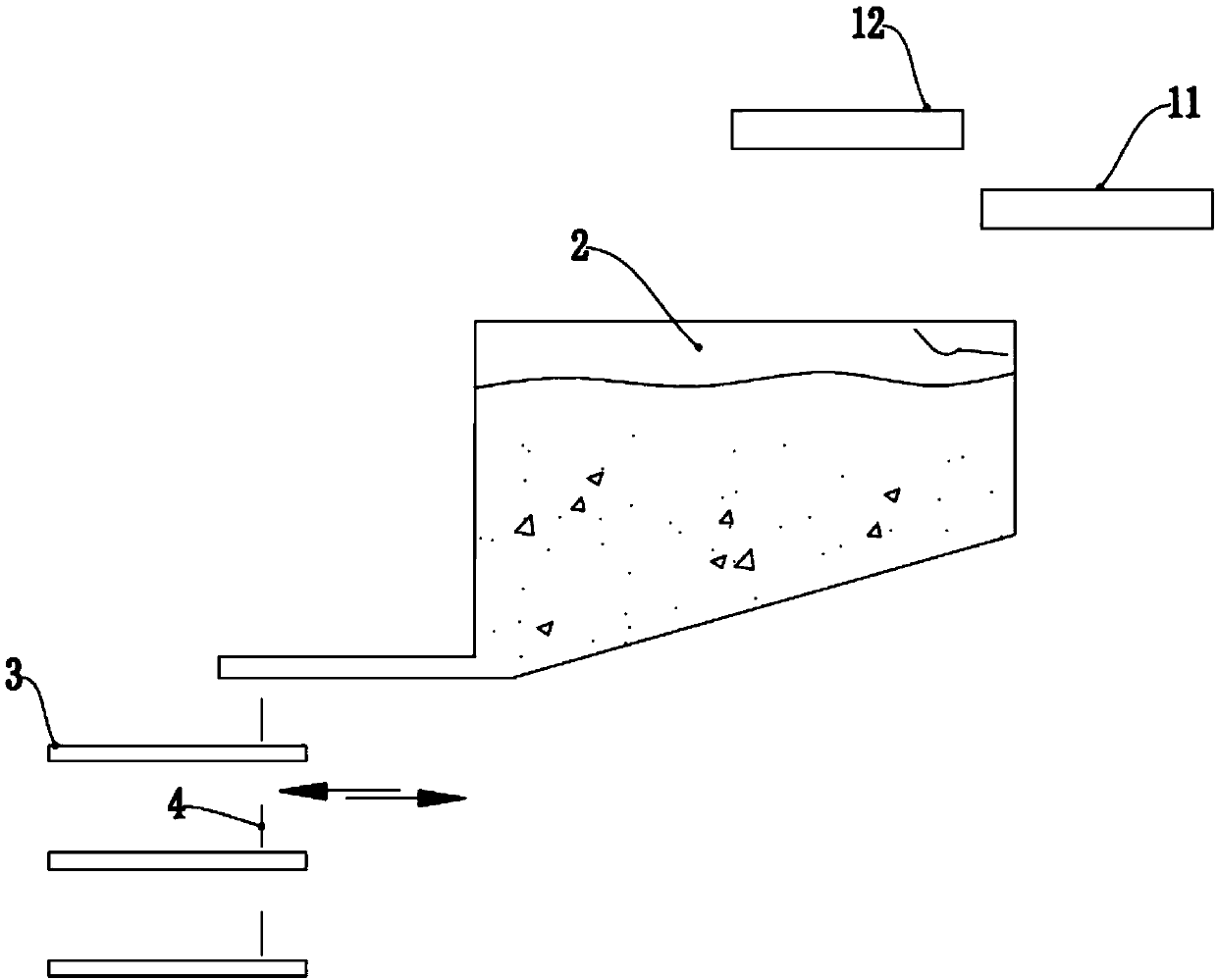

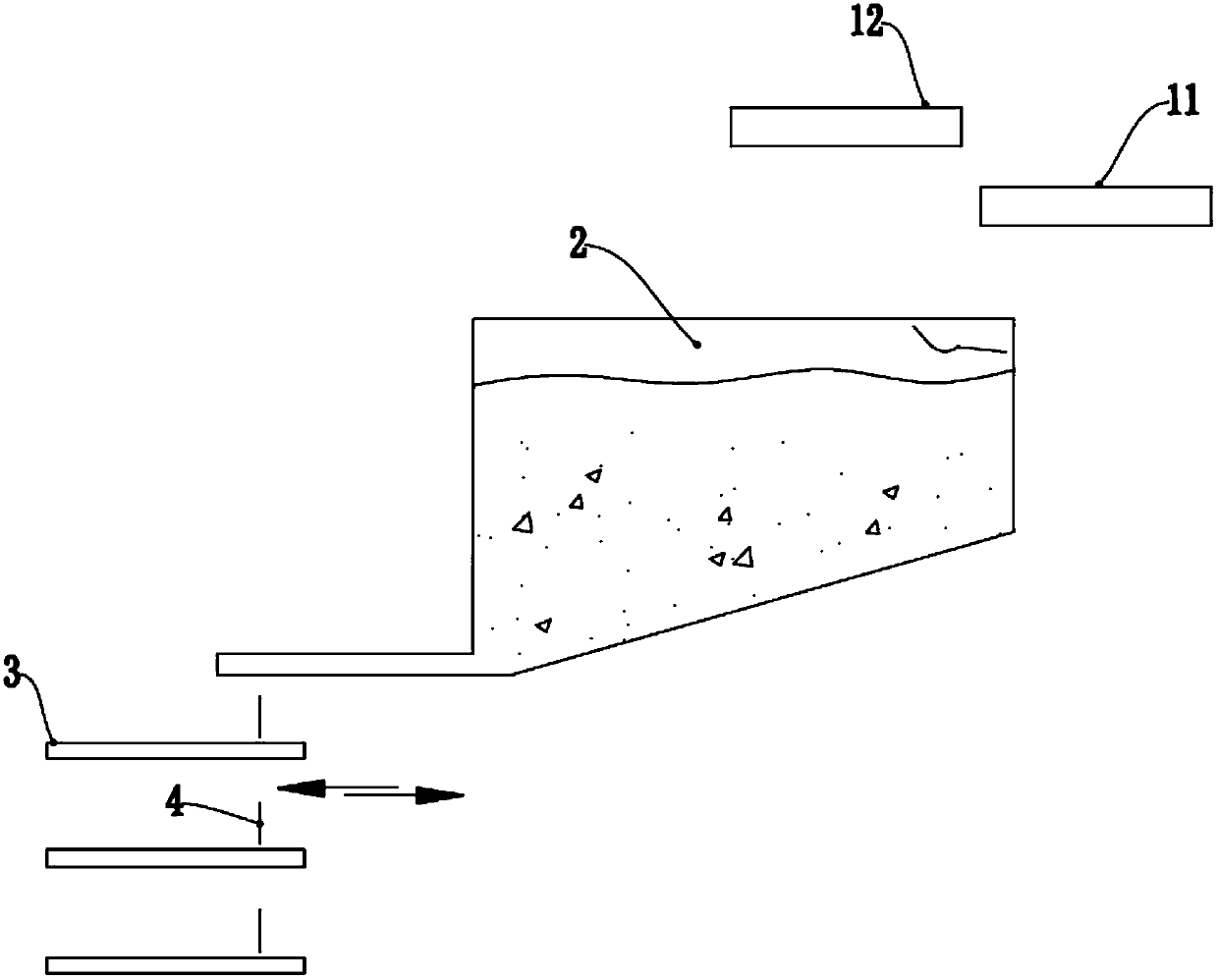

Drawer type powder inspection sieve

The invention discloses a drawer type powder material inspection sieve which comprises a machine frame (1), a sieve door (2), a sieve body (3), a hanging mechanism (4), a transmission mechanism (7) and a pressing mechanism (8). The sieve body is hung on the machine frame through the hanging mechanism, and the sieve door is fixed on one side of the machine frame, so that a channel is formed among lateral walls of a sieve frame, the sieve door and the sieve body. The transmission mechanism is fixed on the machine frame, the hanging mechanism for hanging the sieve body is of a combined structure, a hanger at the material inlet end of the sieve body is hung through a steel wire rope, and a hanger at the tail end of the sieve body is hung through glass reinforced plastic (GRP). The transmission mechanism is of a structure capable of being drawn out integrally, and an output shaft of the transmission mechanism is fixed on the sieve body through a clamper assembly (15). The multilayer sieve frame (5) is arranged in the sieve body, each layer of the sieve frame is movably connected with the sieve body, and sieve lattices (6) movably connected with the multilayer frame are arranged in each layer of the sieve frame.

Owner:ZHENGZHOU ZHAOFENG COMPLETE SETS OF EQUIP

Flour screening equipment based on mechanical vibration

The invention discloses flour screening equipment based on mechanical vibration. The flour screening equipment comprises a machine shell, a screening cavity is formed in the lower end of the interiorof the machine shell, a conveying cavity is formed in the upper side of the screening cavity, a discharging mechanism for feeding flour to be screened is arranged at the upper end of the interior of the machine shell, a conveying mechanism for evenly discharging the flour to be screened is arranged in the conveying cavity, and a screening mechanism for screening flour is arranged in the screeningcavity. The flour screening device is simple in structure and convenient to operate, flour to be screened can be evenly conveyed during work so as to prevent the flour from being accumulated during screening, the flour screening efficiency is improved by adopting the mechanical vibration principle during flour screening, and the screened flour falls off from different outlets, so that the flour isconvenient to collect.

Owner:象山侧风电子技术有限公司

Building stone pulverizing machine

ActiveCN109513499ASmooth millingIncrease contact areaGrain treatmentsMechanical engineeringEngineering

The invention discloses a building stone pulverizing machine. The building stone pulverizing machine comprises a pulverizing box and a powder collecting box. Two pulverizing assemblies are arranged inthe pulverizing box. A discharging bin is arranged at the bottom of the pulverizing box and communicates with the powder collecting box through a discharging pipe. A filter screen is arranged in thedischarging bin. The top of the pulverizing box is provided with a feeding port. The two pulverizing assemblies are divided into the first pulverizing assembly and the second pulverizing assembly. Thebuilding stone pulverizing machine is novel in structure design, convenient to operate, capable of achieving uniform building stone pulverizing, high in pulverizing quality and capable of sieving thepulverized stone powder, and the later machining quality of the stone powder is improved.

Owner:QINGDAO HAIDE ROAD & BRIDGE ENG

Screening device for flour processing

ActiveCN113275231AAvoid clogging the meshImprove stability and sieving efficiencySievingGas current separationStructural engineeringSieve

The invention discloses a screening device for flour processing. The screening device comprises a material distributing and filtering bin and a coarse material filtering bin which are separated by a partition plate, a fine material filtering bin and a feeding box are arranged at the two ends of the material distributing and filtering bin correspondingly, the material distributing and filtering bin is divided into a first bin and a second bin through a first filtering sieve, and the first bin and the second bin are vertically arranged. The first bin and the fine material filtering bin are separated through a second filtering sieve, a turnover telescopic rod with a turnover scraper at the front end is arranged at the junction of the first filtering sieve and the second filtering sieve, a material passing opening formed in the partition plate corresponds to the turnover scraper, and propeller blades driven by a power mechanism to rotate are arranged in the coarse material filtering bin. The power mechanism can synchronously drive a turnover telescopic rod to alternately and horizontally move and turn over along the surface of the first filter sieve, the coarse material filtering bin and the fine material filtering bin are in airflow communication, a third filtering sieve is arranged in the coarse material filtering bin, the lower portion of the third filtering sieve communicates with the second bin, and a material returning mechanism connected with a feeding box is arranged in the second bin. The wheat screening efficiency can be improved.

Owner:ANHUI NORMAL UNIV +1

Gravel classifying and screening machine and gravel classifying and screening construction process

ActiveCN112934692ASolve the problem of taking outImprove sieving efficiencySievingScreeningElectric machineryStructural engineering

The invention discloses a gravel classifying and screening machine and a gravel classifying and screening construction process. The gravel classifying and screening machine comprises a rack and a mesh assembly. Gravel is slowly poured on meshes formed by multiple upper-layer cross rods and multiple lower-layer cross rods, and the gravel is classified and screened under periodic movement and swaying of braking universal wheels. When the gravel is clamped in meshes, telescopic rods are controlled to stretch out of top hinge rods, the distance between the telescopic rods and the top hinge rods is increased, then the gravel is naturally loosened and automatically falls off, at the moment, sealing bodies are flexibly folded, a motor rotates to wrap the sealing bodies on a reel, and the gravel cannot fall off from the front end and the rear end of the upper-layer cross rods; and then the telescopic rods are controlled to contract and pull back the hinge rods to reduce the spacing distance between the telescopic rods and the top hinge rods, the motor rotates reversely to release the sealing bodies from the reel to the upper-layer cross rods, rapid resetting is achieved, then the gravel is classified and screened again, and the problem that the gravel needs to be taken out through tools such as a crowbar after shutdown is solved. The screening efficiency of gravel classification is improved.

Owner:SINOHYDRO BUREAU 9

Fiber regeneration machine

PendingCN112844656AConvenient continuous cuttingIncrease cutting frequencyGrain treatmentsFiberEngineering

The invention discloses a fiber regeneration machine. The fiber regeneration machine comprising a machine shell, wherein a rotor is arranged in the machine shell and comprises a rotor shaft, cutter heads, shaft pins and blades; the multiple cutter heads are arranged on the rotor shaft; each of the multiple shaft pins is connected with all the cutter heads; all the shaft pins are evenly distributed along the outer rings of the cutter heads; two blades are arranged on the shaft pin located between every two adjacent cutter heads; at least every two adjacent shaft pins form a group; the two blades on the shaft pin, located between every two adjacent cutter heads, in each group of shaft pins gradually approach the cutter heads in the clockwise direction; and the blades, located between every two adjacent cutter heads, on the same shaft pin are arranged in the same mode. According to the fiber regeneration machine, the crushing effect can be improved, the production efficiency is improved, and the energy consumption is reduced.

Owner:SHANDONG JIEFENG MACHINERY MFG

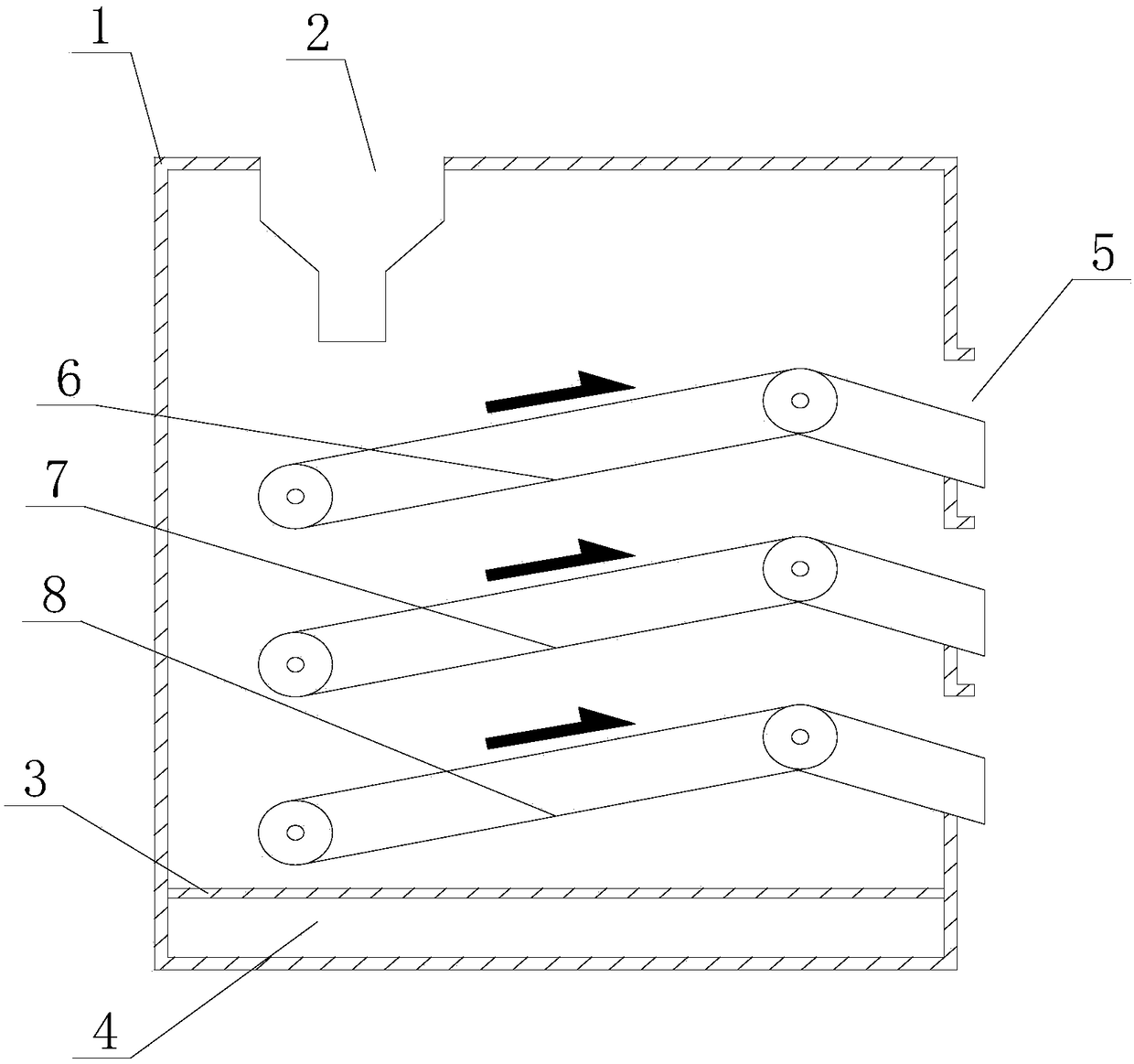

Screening device beneficial for improving efficiency

InactiveCN108380477AImprove efficiencyImprove sieving efficiencySievingScreeningEngineeringMechanical engineering

The invention discloses a screening device beneficial for improving efficiency. Conveying belts are arranged inside a screening room; the downstream height of each conveying belt is higher than the downstream height; each feeding opening is formed in the upper top of a machine body and is toward the corresponding conveying belt; each discharging hole is formed in the sidewall of the machine body;each discharging opening is connected with the downstream end of the corresponding conveying belt; when each conveying belt runs, aggregates on the conveying belt are discharged via the discharging opening; each conveying belt adopts a crawler-type conveying belt; each screen is arranged on the corresponding crawler plate and penetrates through the corresponding crawler plate; the quantity of theconveying belts is two or higher; all conveying belts are sequentially arranged from top to bottom; the diameter of screen holes of the conveying belts is sequentially reduced from top to bottom; thequantity of the discharging openings is the same as the quantity of the conveying belts; each conveying belt is matched with one discharging opening; and each partition plate is provided with an openhole. Through the structure, the screening device beneficial for improving the efficiency disclosed by the invention can realize simultaneous discharging of the aggregates which are different in particle size, and effectively improves the screening efficiency.

Owner:成都神智电子科技有限公司

Medicine powder filtering pharmaceutical device and using method thereof

ActiveCN112620099AImprove filtration efficiencyAvoid cloggingSievingScreeningEngineeringMechanical engineering

The invention relates to the technical field of pharmaceutical equipment, and discloses a medicine powder filtering pharmaceutical device and a using method thereof. The medicine powder filtering pharmaceutical device comprises a base; a box body is fixedly mounted at the top of the base; a first hole is arranged on the inner wall of one side of the box body; a collecting box is placed at the top of the base; a feeding port is formed at the top of the box body; two symmetrically-arranged first rotating rods are rotatably installed on the inner walls of the two sides of the box body; transmission rollers are fixedly installed on the first rotating rods; a same transmission belt is fixedly installed on the two transmission rollers; a heating pipe is fixedly installed at the top of the box body and located above the transmission belt; and a servo motor is fixedly installed at the top of the box body. The medicine powder filtering pharmaceutical device provided by the invention is reasonable in design, medicine powder can be heated conveniently, the filtering efficiency of the medicine powder can be improved by moving a filtering net up and down, the filtering net can be prevented from being blocked, and the filtering net can be disassembled and cleaned conveniently.

Owner:湖北济安堂药业股份有限公司

Method for recycling polishing waste slag and equipment used therefor

ActiveCN106348406BAvoid cloggingAchieve maximum fitnessSludge treatmentWater/sewage treatment by flocculation/precipitationSludgeFiltration

Owner:QINGYUAN NAFUNA CERAMICS +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com