Shaking type screening device for drug processing

A screening device and drug technology, applied in the fields of sieving, grain processing, solid separation, etc., can solve the problems of difficulty in discharging drugs that cannot be screened, low efficiency, etc., and achieve the effects of improving screening efficiency, convenient use, and easy recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

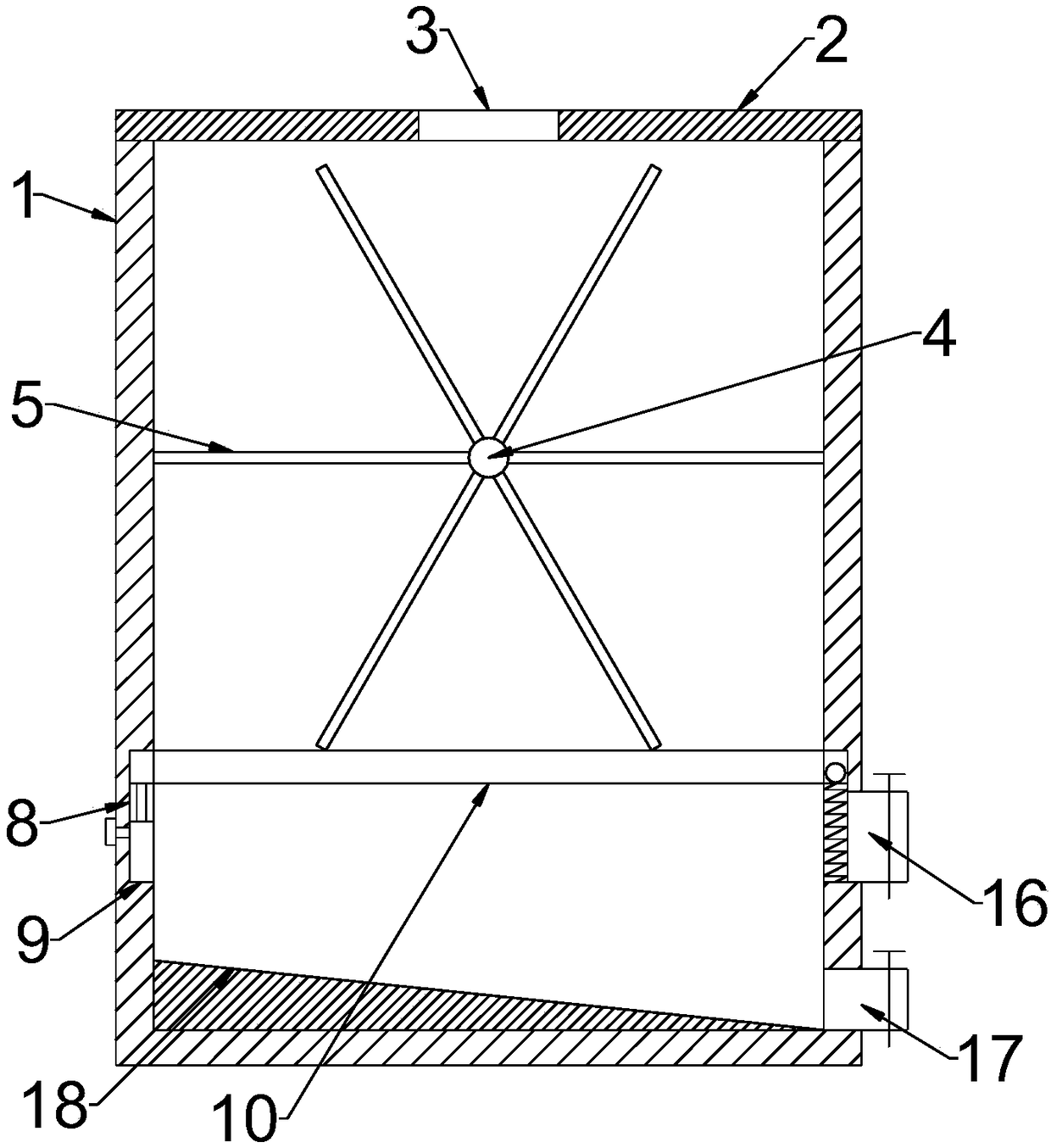

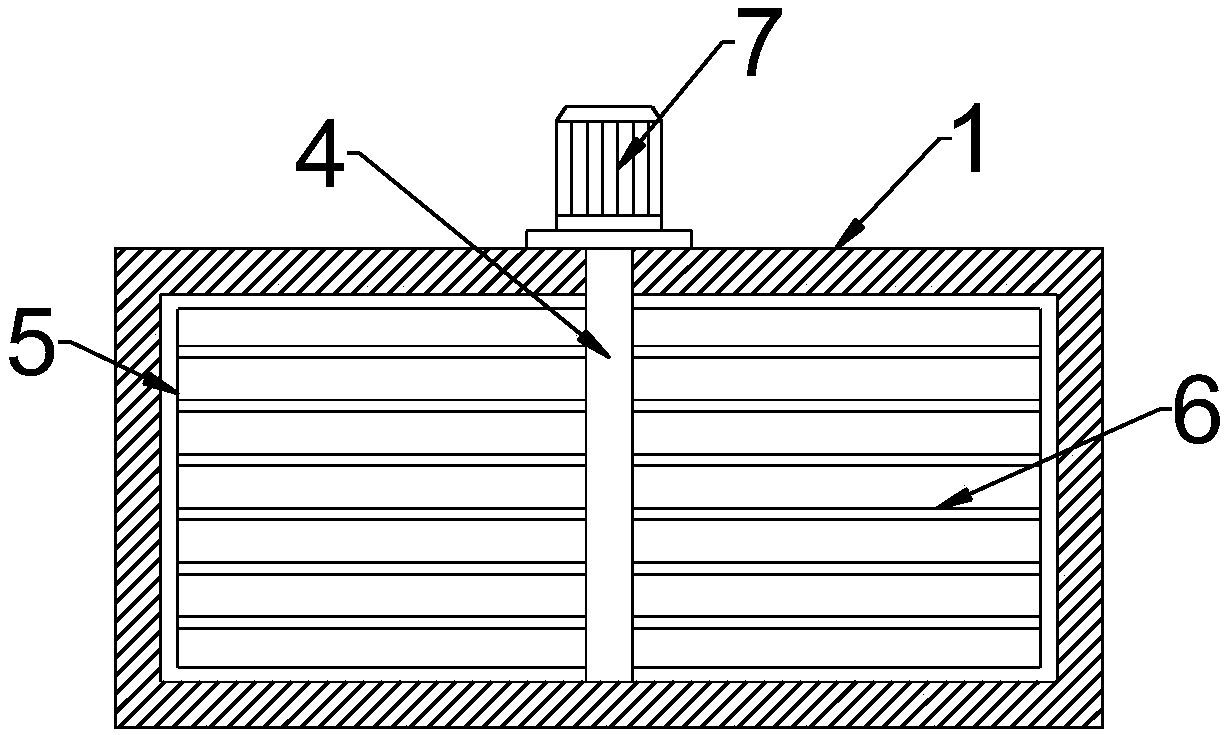

[0019] see Figure 1~3 , in an embodiment of the present invention, a shaking type drug processing and screening device includes a housing 1, a stirring structure, a telescopic support rod 9 and a screen plate 10, and the lower parts of both sides of the housing 1 are symmetrically embedded with vertical chutes 8 , the two ends of the screen plate 10 move deeply into the vertical chute 8, the screen plate 10 is slidably connected with the vertical chute 8, and the stirring structure is composed of the rotating shaft 4, the rotating frame 5 and the motor 7 The rotating shaft 4 is arranged radially between the front and rear side walls of the housing 1, and the outer periphery of the rotating shaft 4 is welded with six sets of rotating frames 5 arranged in an equiangular distribution. The rotating frames 5 have two When the lateral symmetry is kept horizontal, the upper surface of the screen plate 10 and the lower end of the rotating frame 5 are movably attached.

[0020] The u...

Embodiment 2

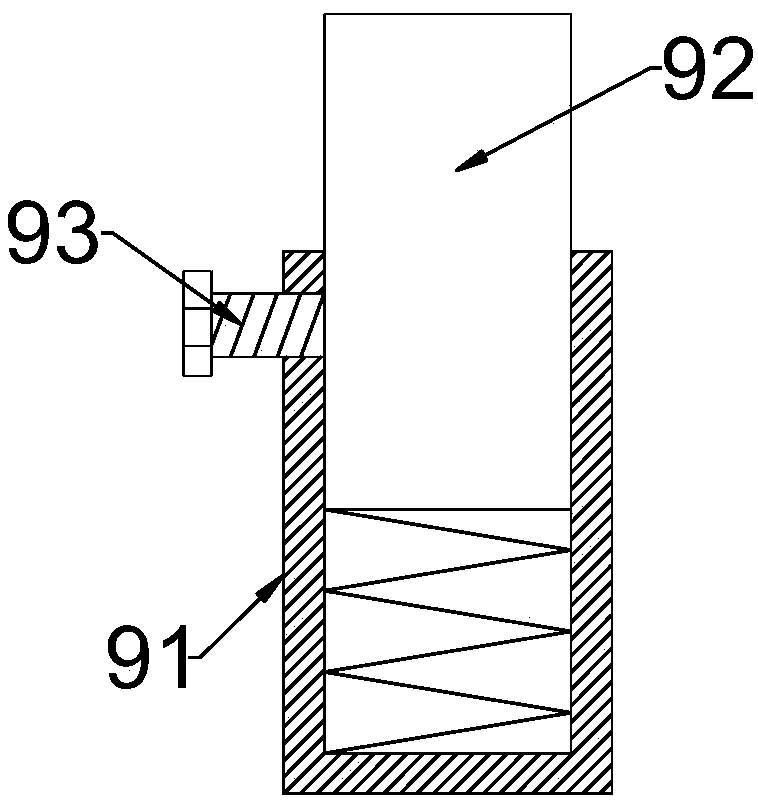

[0024] see Figure 4 , in the embodiment of the present invention, a shaking type drug processing and screening device, on the basis of embodiment 1, the screen plate 10 is composed of a frame 11, a first filter 12, a horizontal chute 13, a second filter 14 Composed of sliding protrusions 15, the vertical chute 8 on the right side is symmetrically embedded with sliding grooves front and rear, and the two ends of the frame 11 are slidably matched with the vertical chute 8 on both sides respectively, and the frame 11 The left side of the lower end is rotatably connected with the upper end of the telescopic support rod 9 through a hinged joint, the upper surface of the frame 11 is inlaid with a first filter screen 12, and the front and rear sides of the frame 11 are symmetrically embedded with a horizontal chute 13, The horizontal chute 13 is located at the right part of the frame 11 and the right end of the horizontal chute 13 runs through the right side of the frame 11, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com