Drawer type powder inspection sieve

A drawer-type, powder technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of accelerating material flow speed, high overall height of sieve grid, increasing sieving efficiency, etc., to achieve accelerated flow speed, good The cleaning effect and the effect of increasing the screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail by means of embodiments in conjunction with the accompanying drawings, however, the present invention is not limited to the following embodiments.

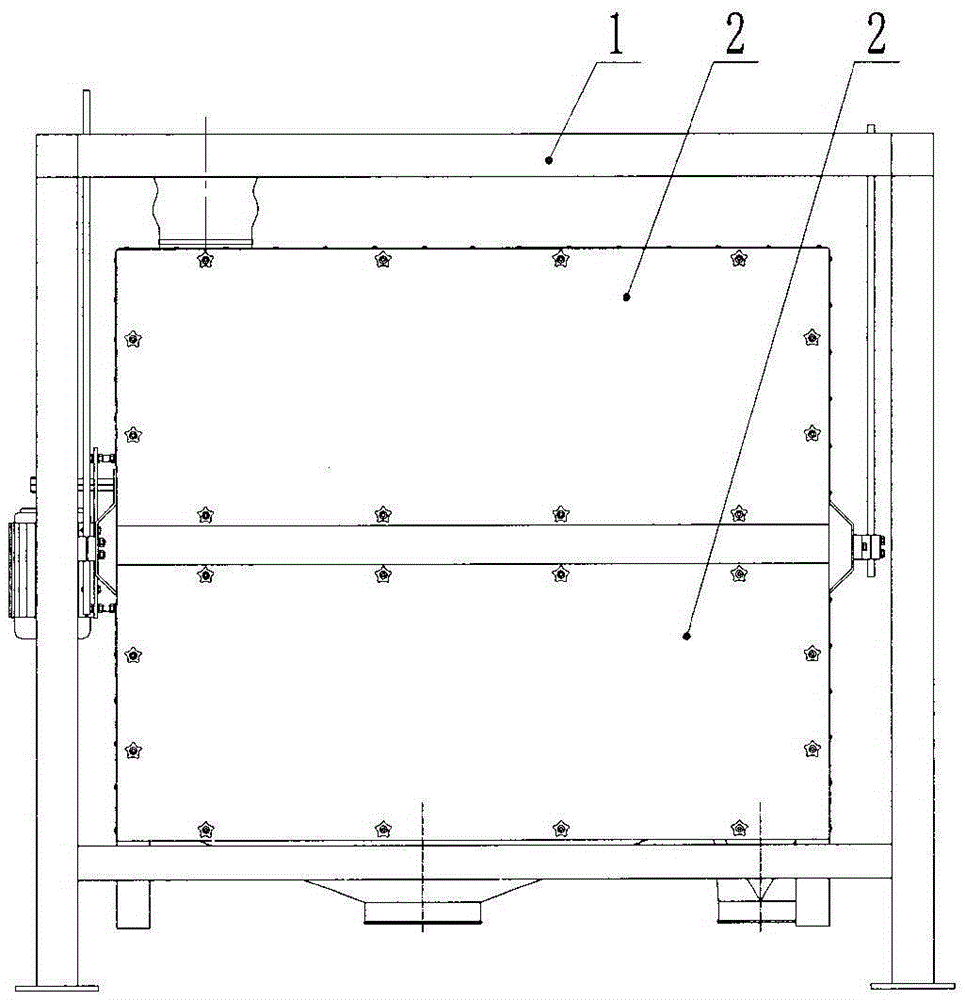

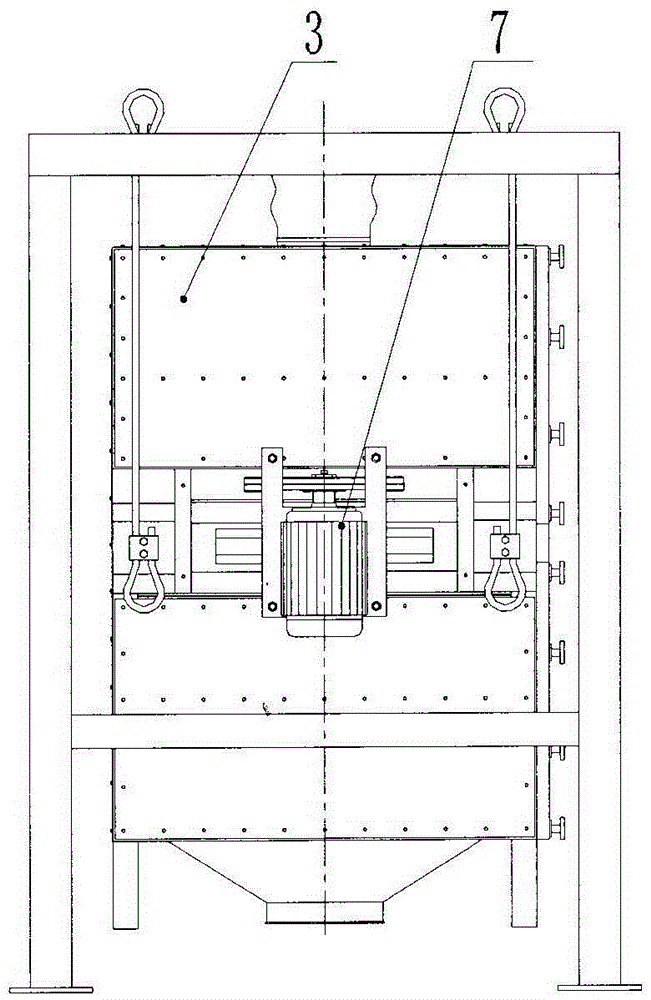

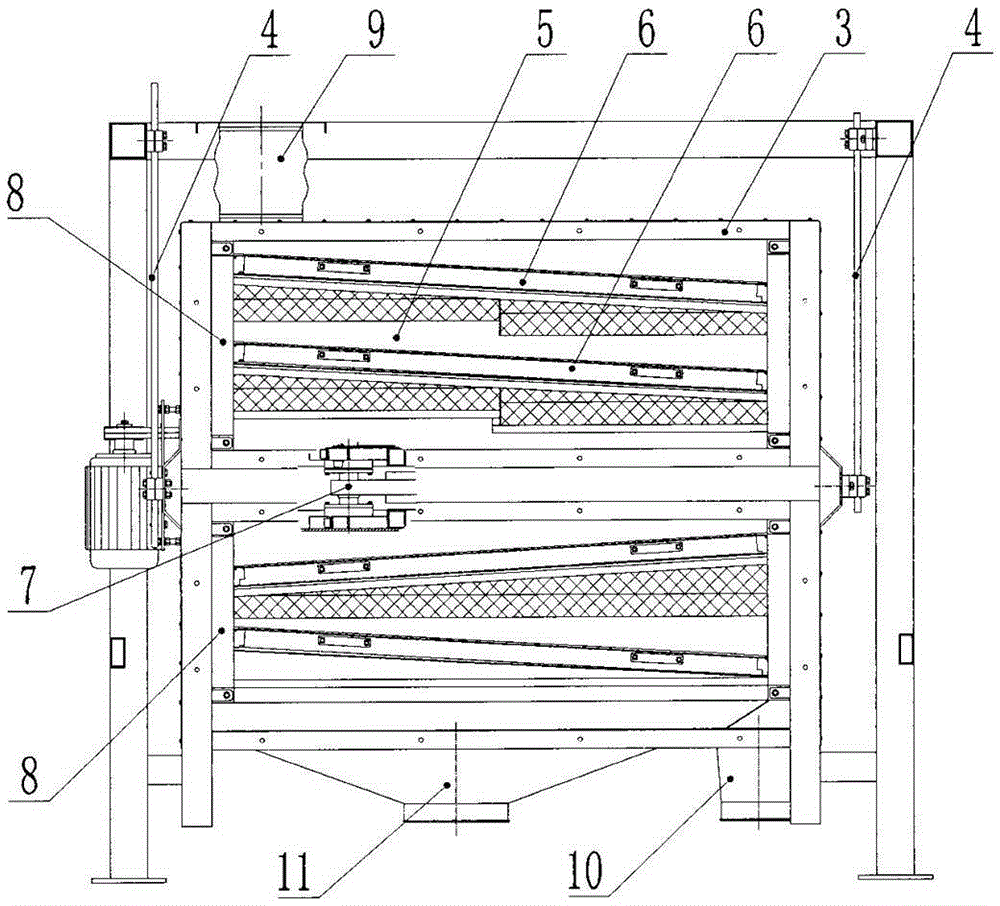

[0036] Such as Figure 1 ~ Figure 3 As shown: the drawer-type powder inspection sieve described in this embodiment is mainly composed of a frame 1, a sieve door 2, a sieve body 3, a hanging mechanism 4, a transmission mechanism 7 and a pressing mechanism 8. Frame 1 is a frame structure, which is welded by square steel pipes, and is used for fixing equipment and hanging the screen body. The sieve body 3 is the main working part, which is hung on the frame 1 by the hanging mechanism. The amplitude at the end; the suspension at the end of the screen body is suspended by a glass fiber reinforced plastic boom, which can make the swimming distance and swimming time of the screen body small when starting and stopping. The hanging method of FRP suspenders and wire rope suspenders is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com