Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Improve potting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

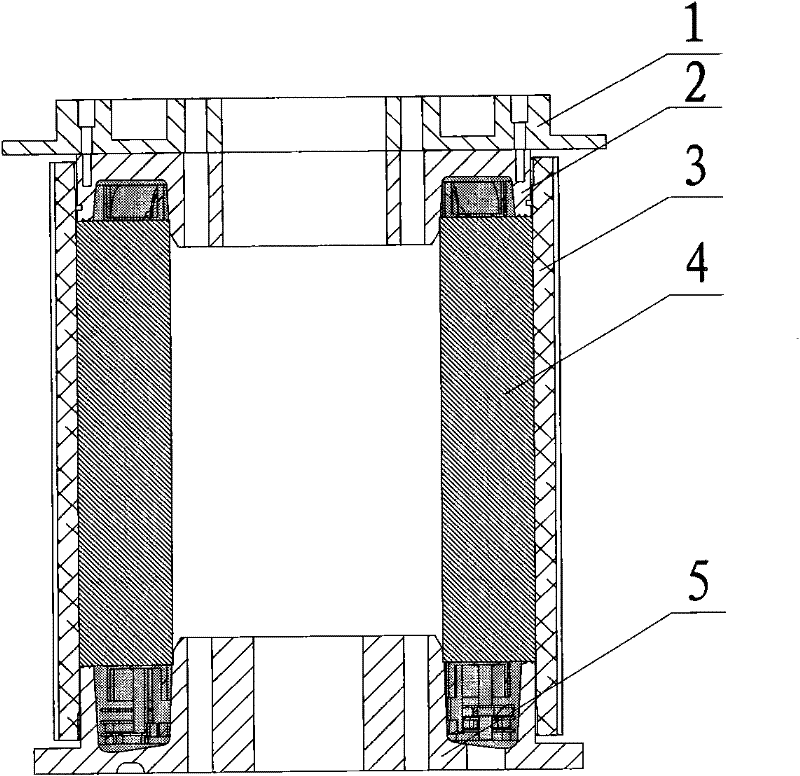

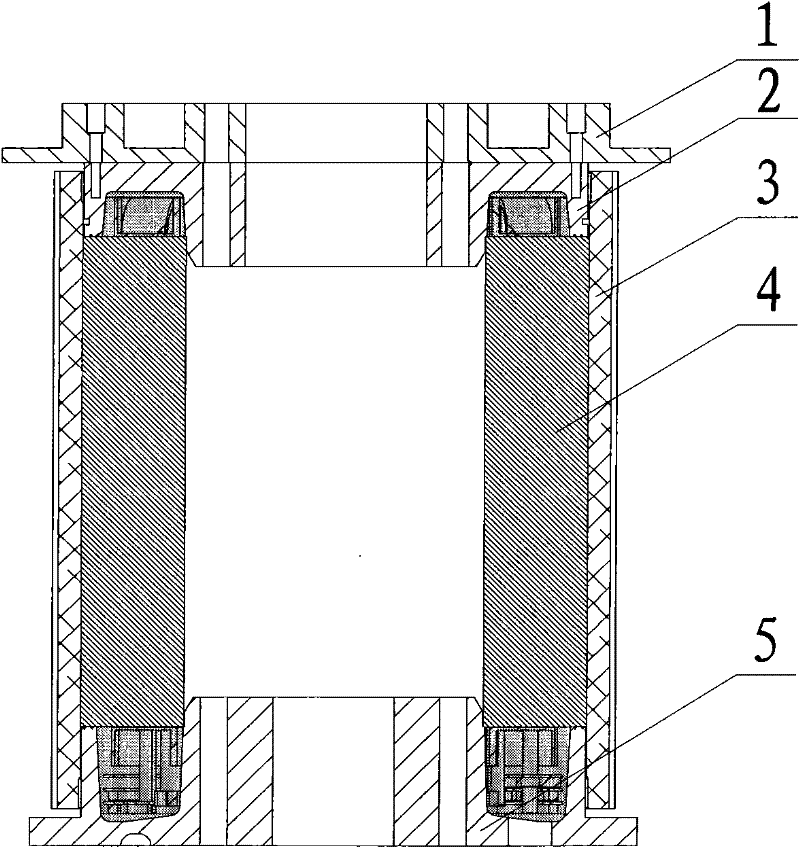

Motor stator core potting process

InactiveCN102280975AImprove potting efficiencyEasy to remove the moldManufacturing stator/rotor bodiesEpoxyEngineering

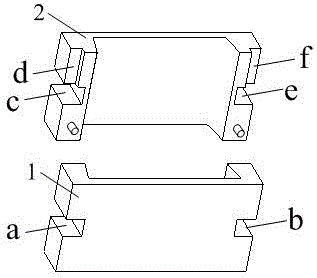

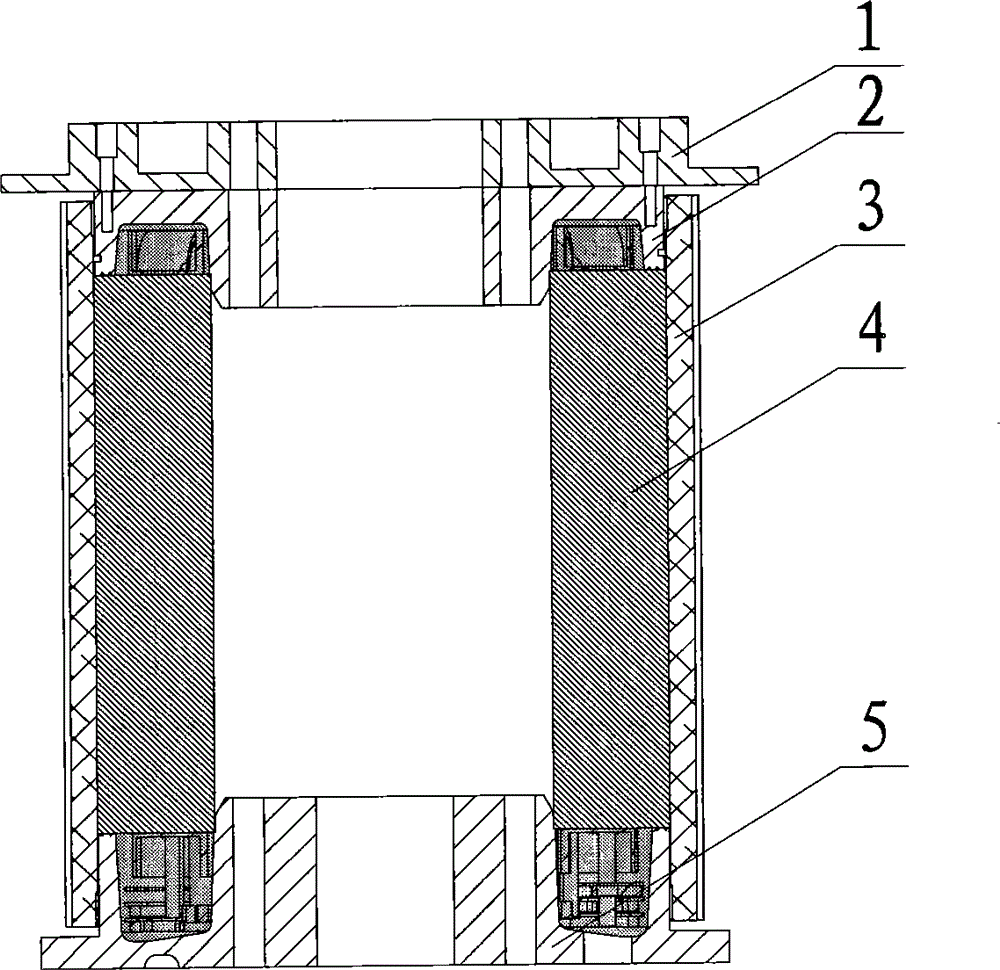

The invention provides a filling and sealing process of a motor stator core. The filling and sealing process comprises the following steps of: (1) preparing a filling and sealing material; (2) arranging an upper die filling and sealing die and a lower die filling and sealing die on a motor stator and positioning; (3) injecting the prepared filling and sealing material from an upper die plate; and (4) curing at 75-85 DEG C for 20-40 percent. The filling and sealing material is prepared from the following raw materials, such as epoxy resin, a diluting agent, a curing agent, a flexibilizer, silicon micropowder, and the like according to certain proportions. Compared with the prior art, the invention has the advantages that the filling and sealing time is greatly shortened, the operation is convenient, the filing and sealing efficiency of a motor is effectively improved, and energy consumption is saved; the stator has high surface finish quality and good insulation and waterproofing property; meanwhile, the mechanical property of the motor is improved, and the running stability of the motor is better ensured.

Owner:NANJING GAOQI ELECTRIC

Transformer shell gluing device and gluing method with same

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

Hollow fiber membrane filtration core potting mold and use method thereof

The present invention discloses a hollow fiber membrane filtration core potting mold and a use method thereof. The potting mold is made from a hydrophobic organic material and has advantages of simple structure, easy processing and easy use, wherein the hydrophobic organic material has a low surface energy so as to effectively reduce the adhesion between the potting glue and the potting mold, such that the potted and casted filtration core can be completely demolded, the demolding difficulty is reduced, the damage on the work-piece during the demolding process is avoided, and the potting efficiency is effectively improved. According to the use method of the potting mold, with the pre-treatment process on the potting mold, the demolding difficulty is further reduced, and the potting efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

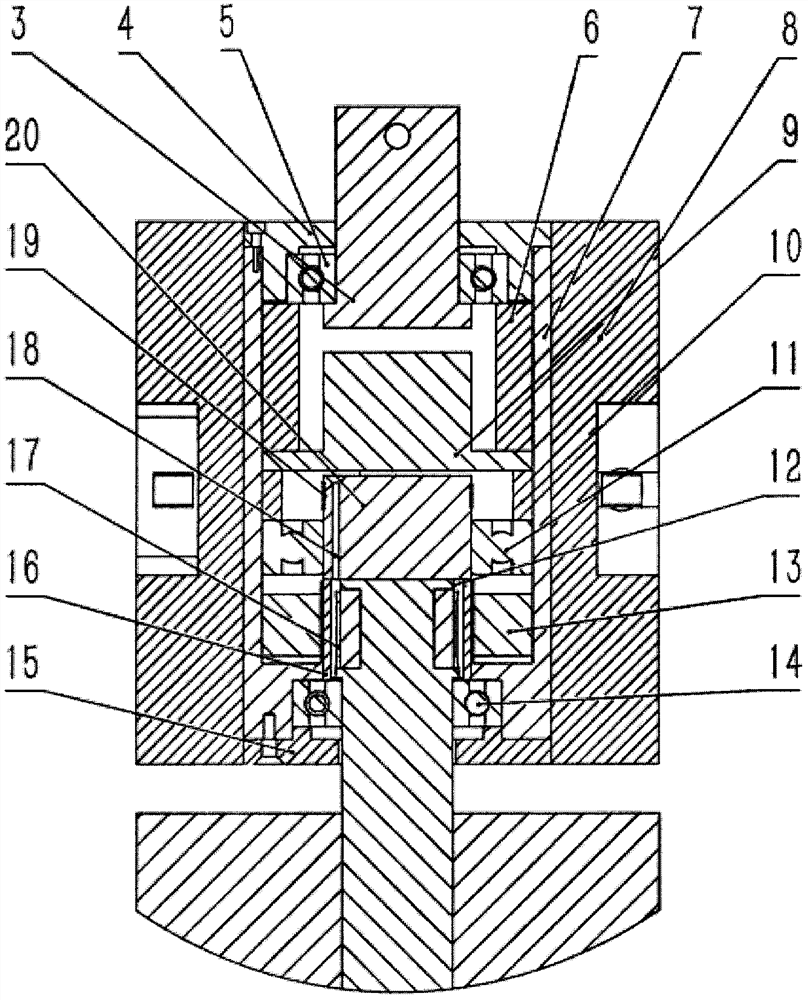

Quick dismounting and filling-sealing apparatus for electric connector

InactiveCN106207711AImprove potting efficiencyEasy to operateContact member cases/bases manufactureElectricityMachine parts

Owner:BEIJING MECHANICAL EQUIP INST

Silica gel preparation method

InactiveCN102641698AHigh quality consistencyGood defoaming effectColloidal chemistry detailsSilica gelMechanical engineering

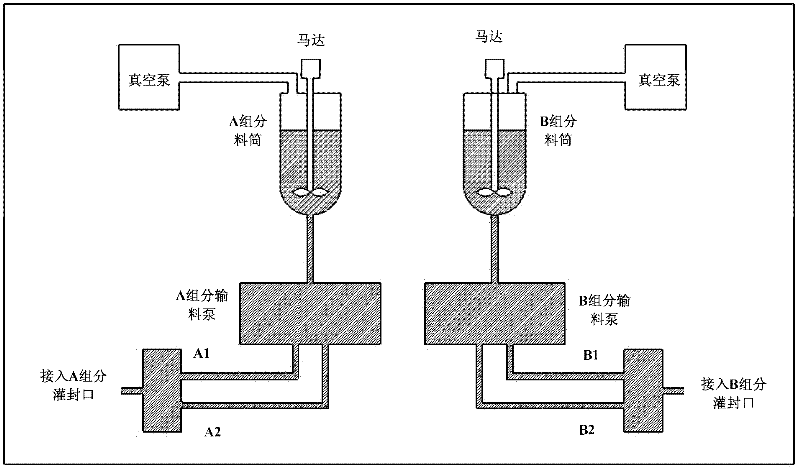

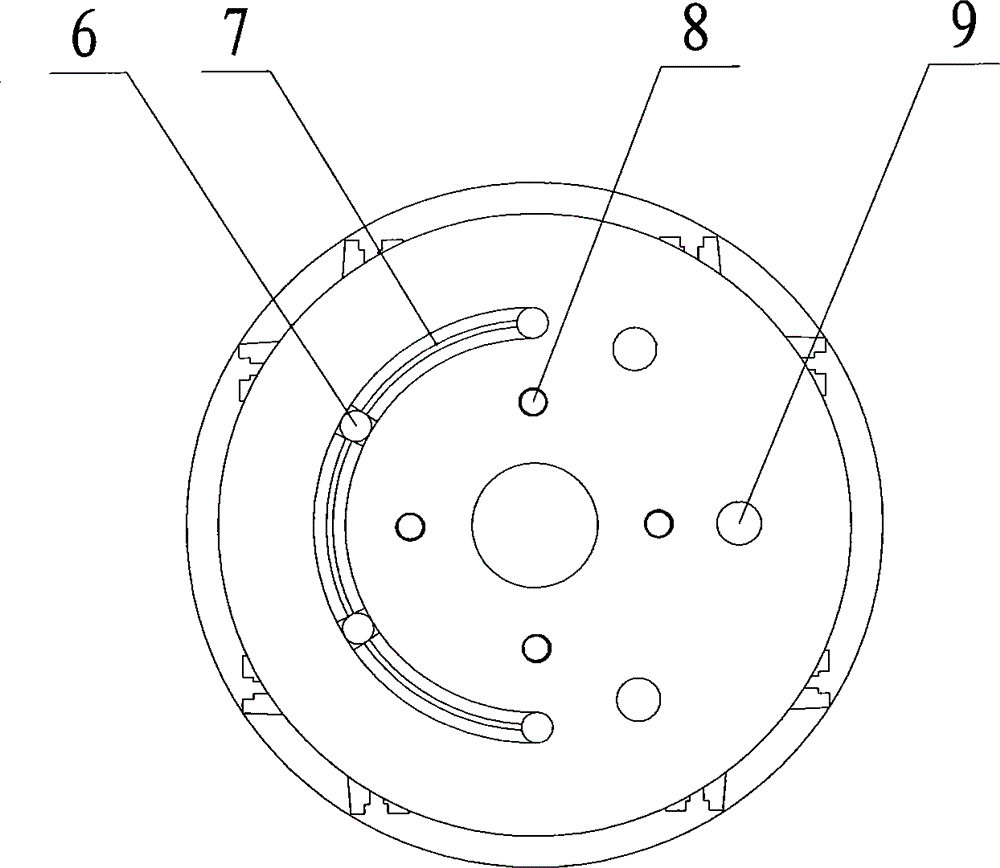

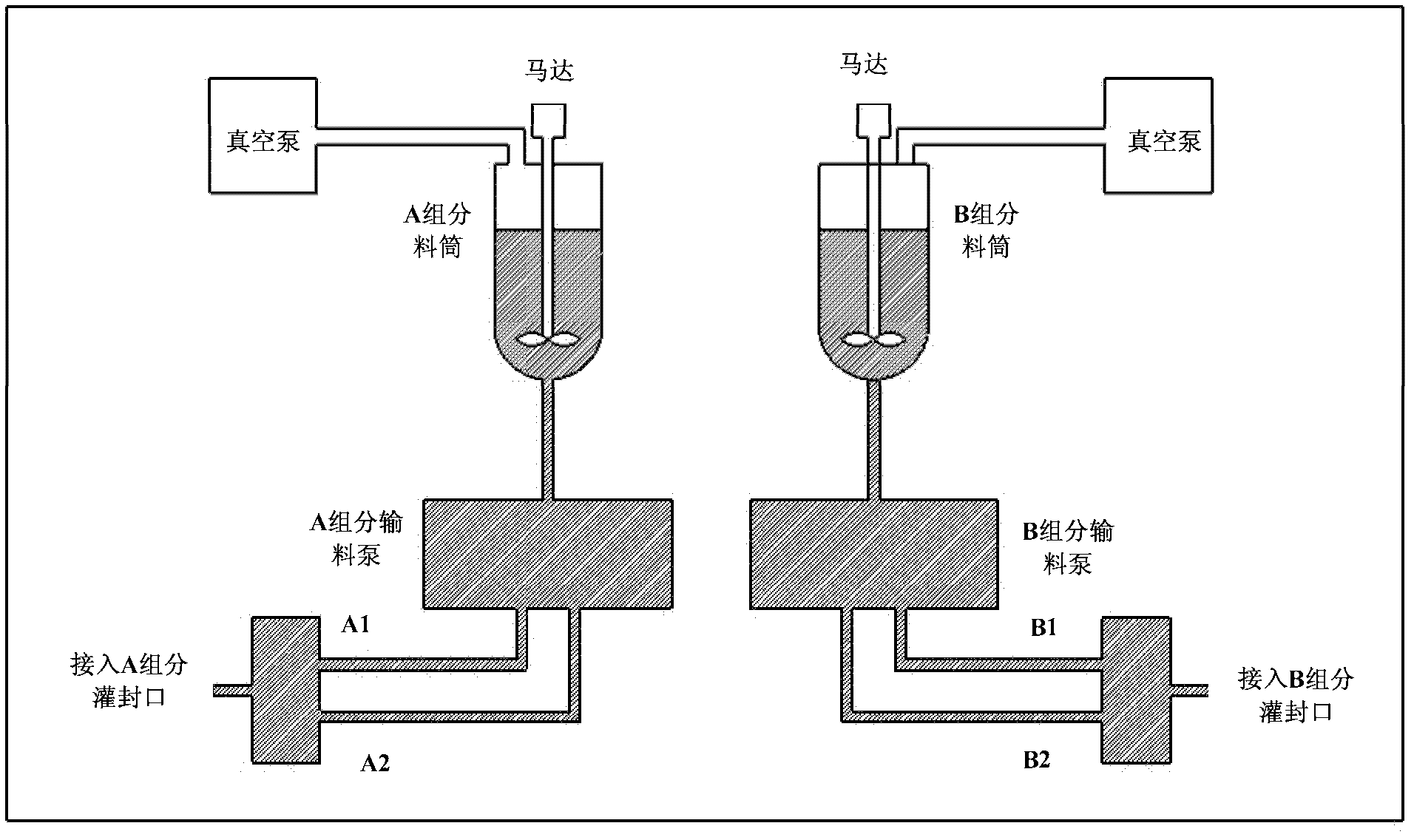

The invention provides a silica gel preparation method which comprises the following steps of: respectively placing more than two aged raw material components for preparing silica gel in barrels of a stirring mechanism, maintaining in the vacuum state and respectively intermittently stirring the raw material components of the silica gel for foam discharging; arranging discharging holes in the barrels, communicating with transporting pipelines through transporting pumps, connecting the transporting pipelines with filling and sealing openings of the raw material components, arranging reflow pipelines capable of being closed between the filling and sealing openings and the transporting pumps, and sending the raw material components subjected to the foam discharging into respective transporting pipelines; and closing the filling and sealing openings of the transporting pipelines, and enabling the raw material components to return to the barrels through reflow pipelines to form reflow, and controlling the reflow states of the materials until the whole transporting pipelines of all components are in the vacuum state. The preparation method meets the requirements of an IGBT (Insulated Gate Bipolar Transistor) module for consistency and reliability of products produced massively and in batches.

Owner:XIAN YONGDIAN ELECTRIC

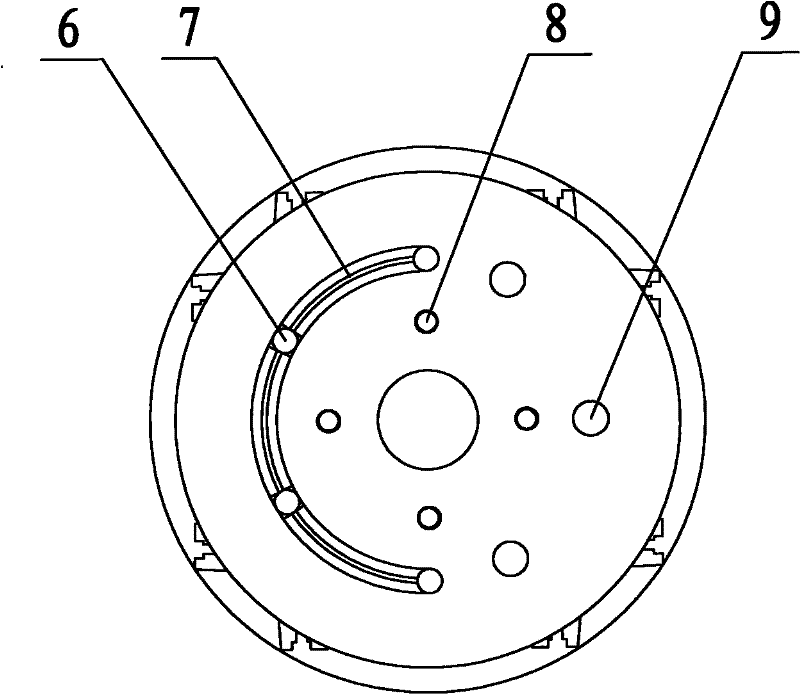

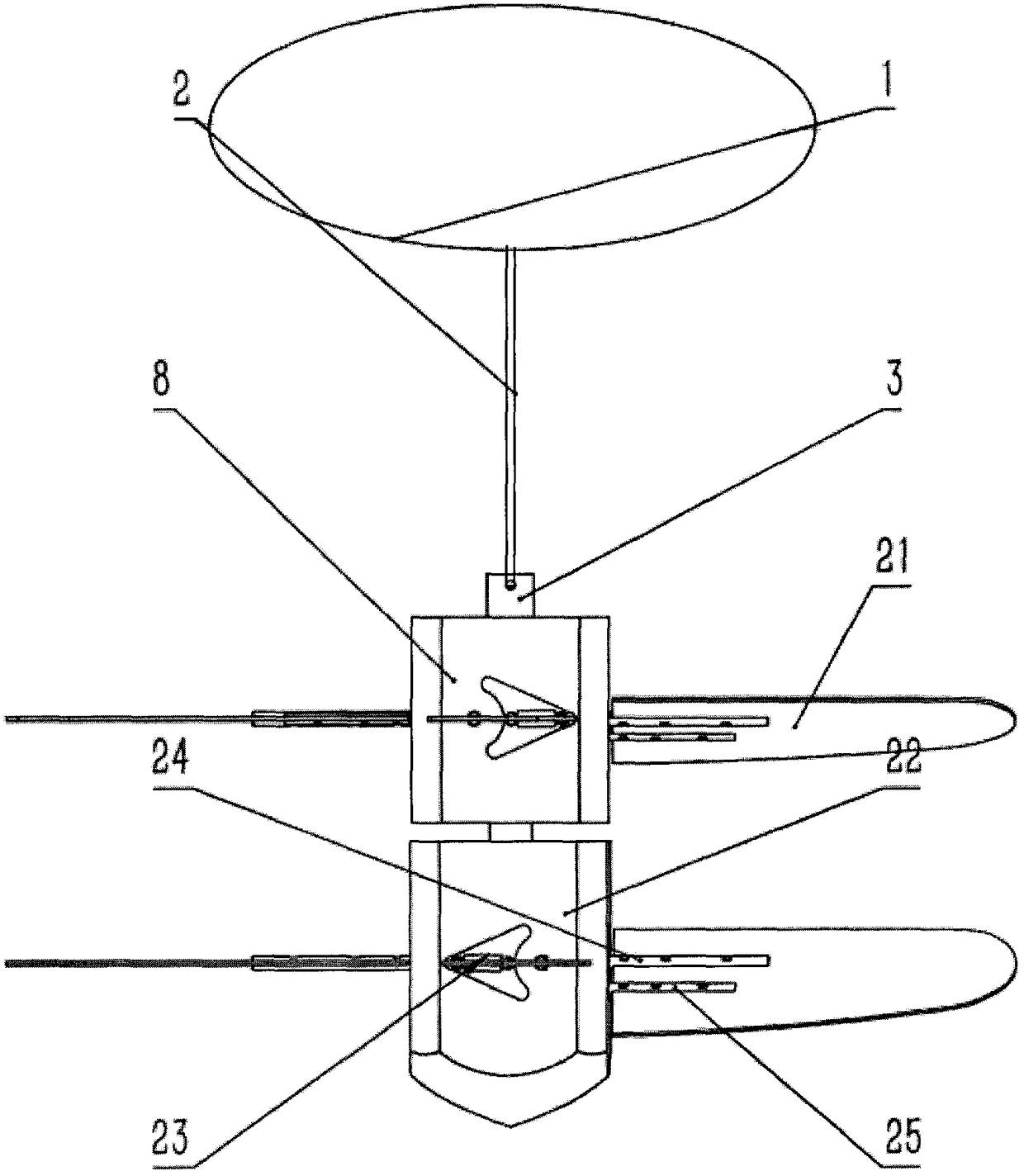

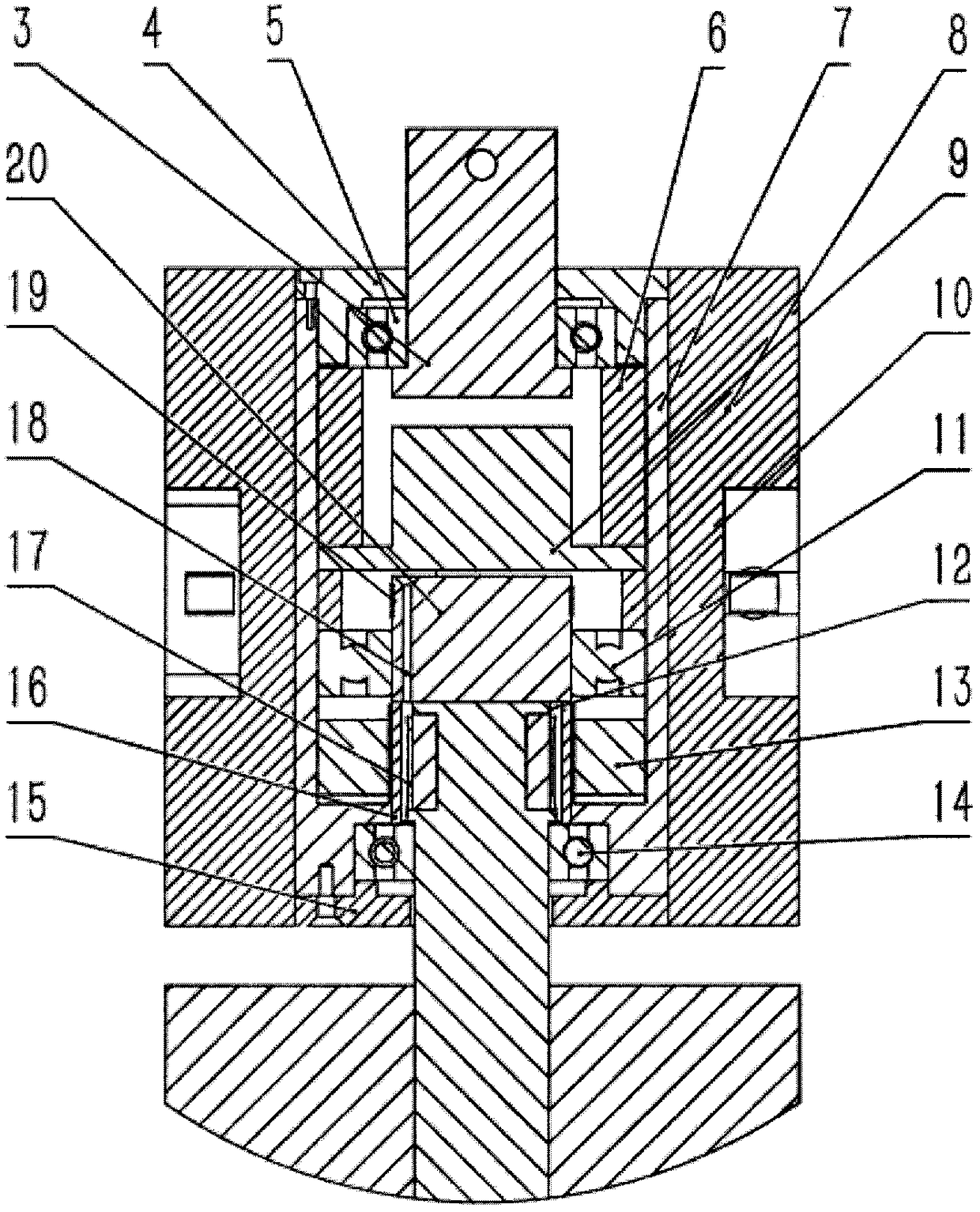

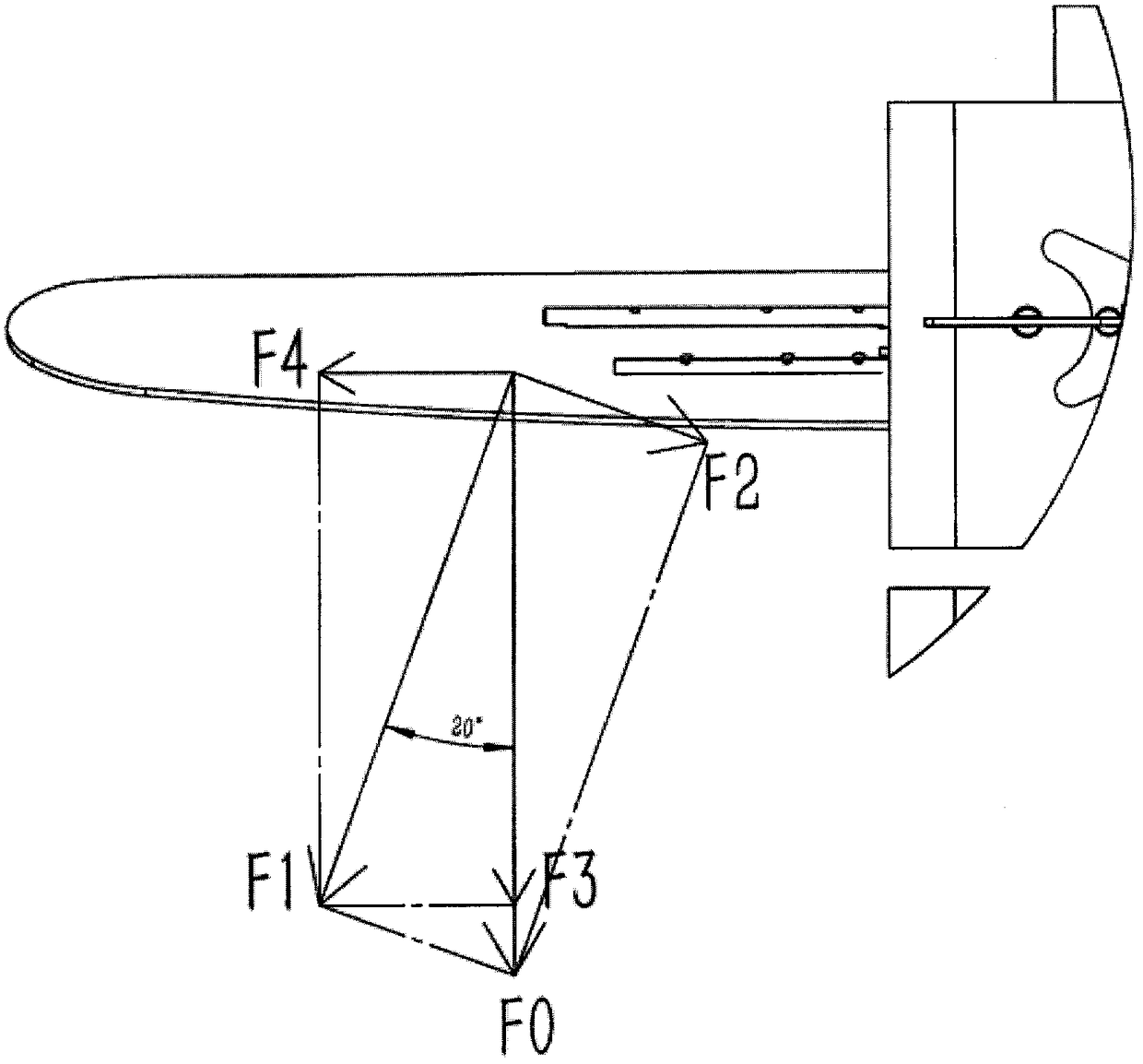

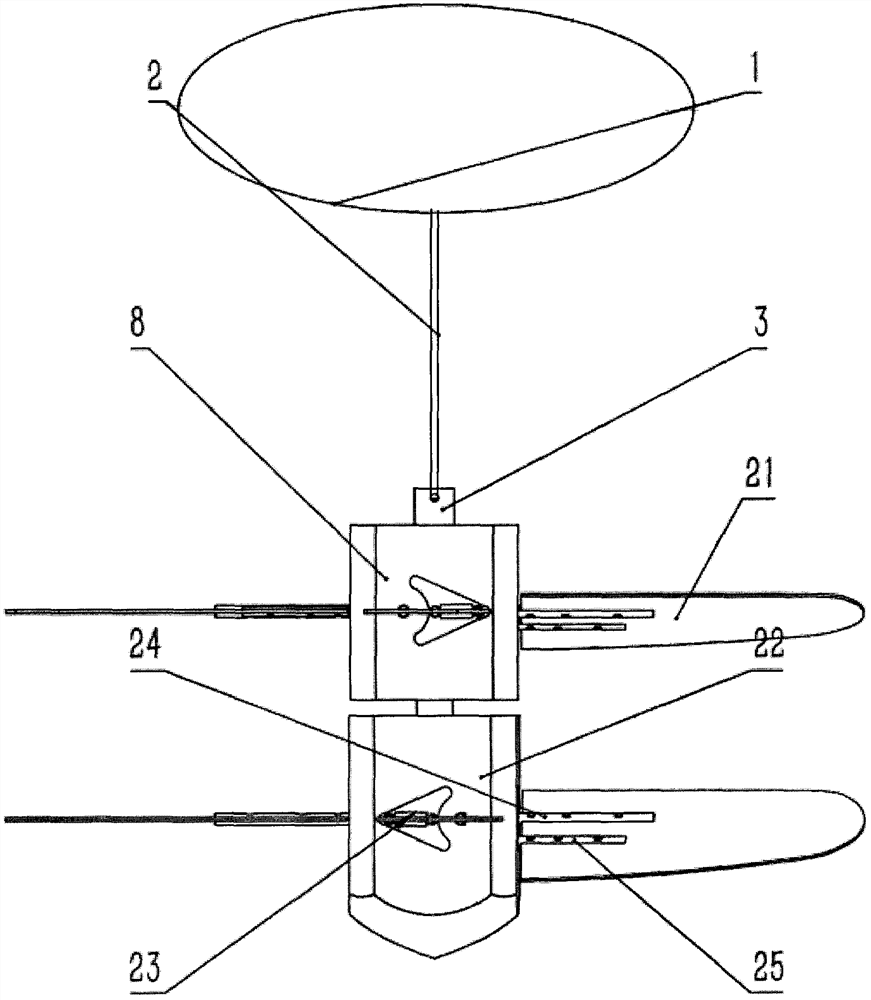

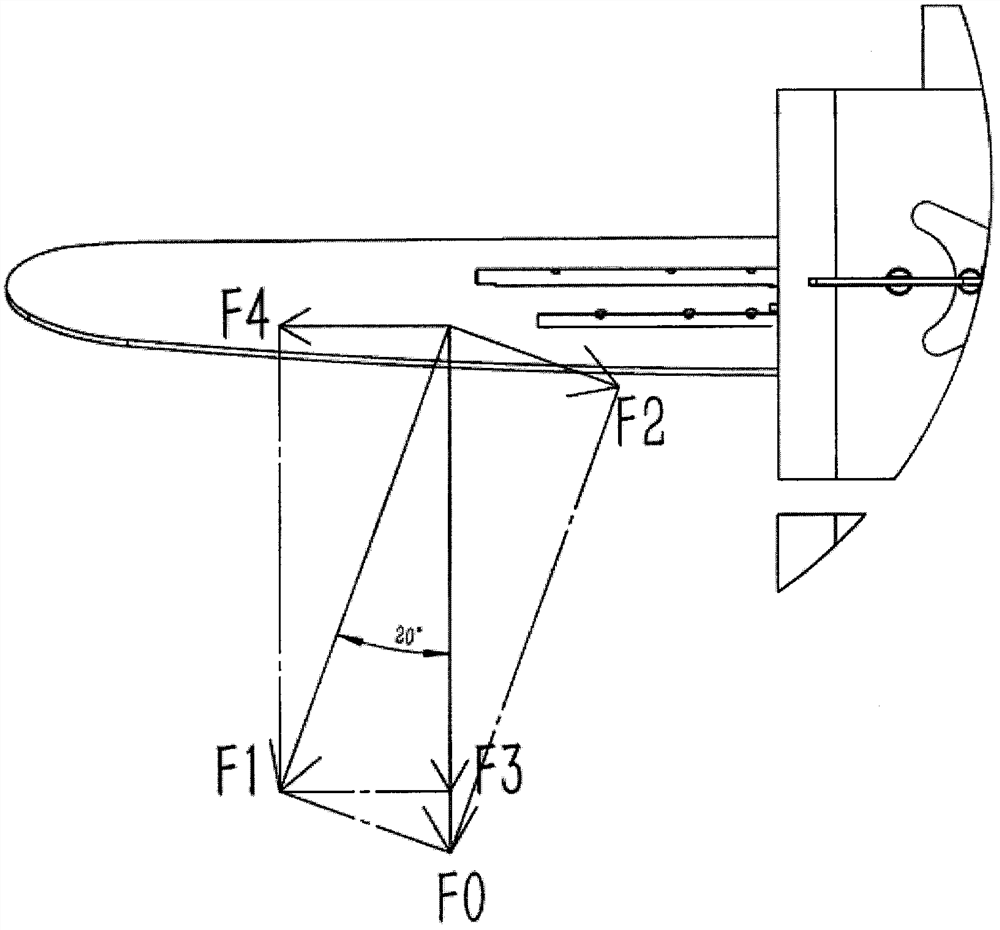

Novel efficient sealing type wave power generation device

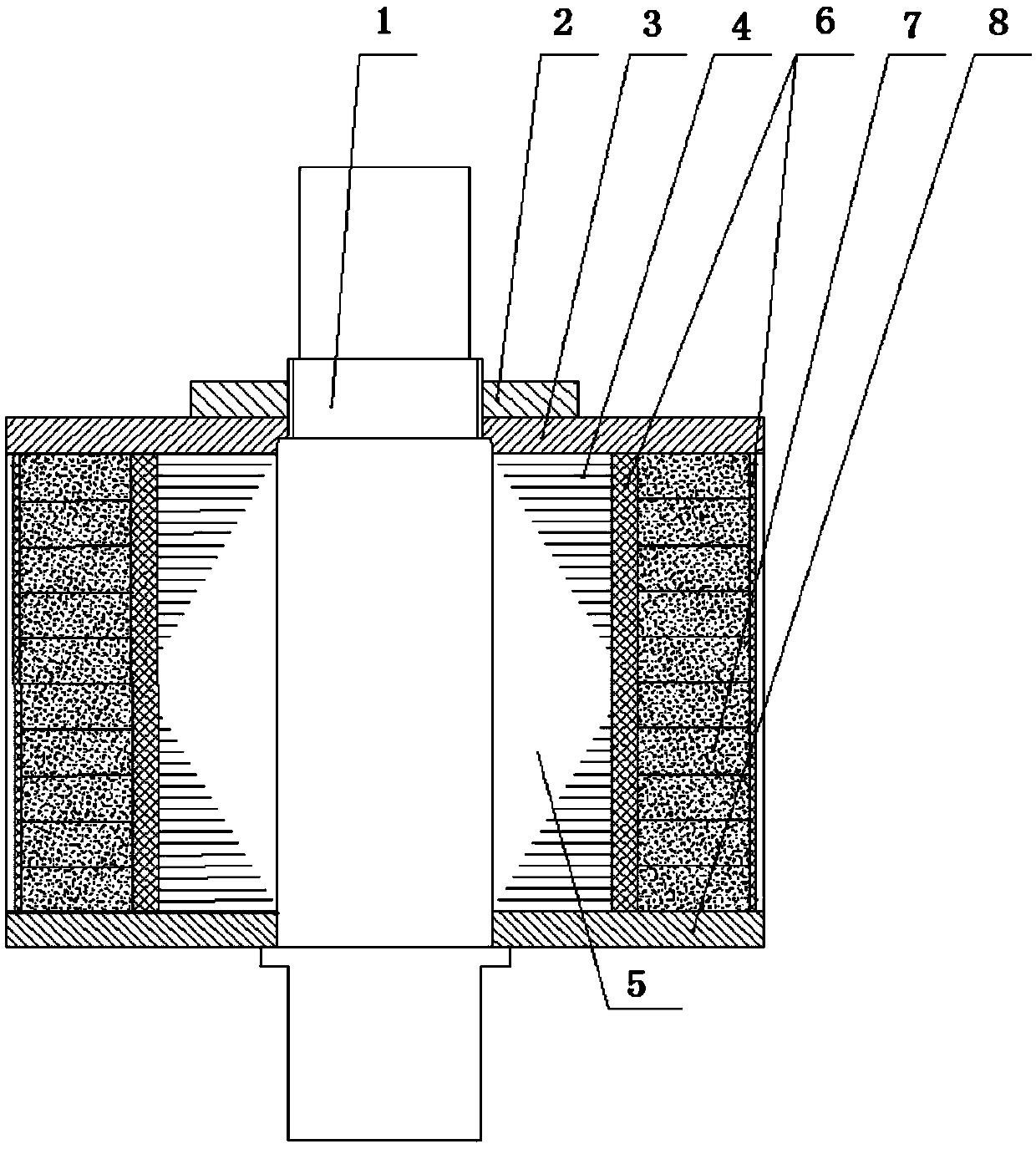

ActiveCN108443051AImprove potting efficiencyImprove power generation efficiencyHydro energy generationMachines/enginesMagnetCounterbore

The invention discloses a novel efficient sealing type wave power generation device. The device comprises three parts, namely, a generating body, an upper rotating body and a lower rotating body, wherein the upper rotating body and the generating body are coaxially arranged; and the upper rotating body and the lower rotating body form a rotating pair. The device has the advantages that a gum flowing groove is formed, and all magnet grooves in a shaft can be conveniently potted through a counterbore hole, and thus the potting efficiency is technically improved; the upper rotating body and the lower rotating body swing wing plates up and down and regularly circumferentially move in opposite directions, so that the rotating speed is increased, and the power generation efficiency is improved;magnets and coils are all sealed into potting gum when the device generates power, so that the sealing performance is high, and the service life is long; in addition, the mounting and maintaining costis low; the energy utilization efficiency is high; the structure is simple; and the integrated ideal is easily achieved.

Owner:TIANJIN POLYTECHNIC UNIV

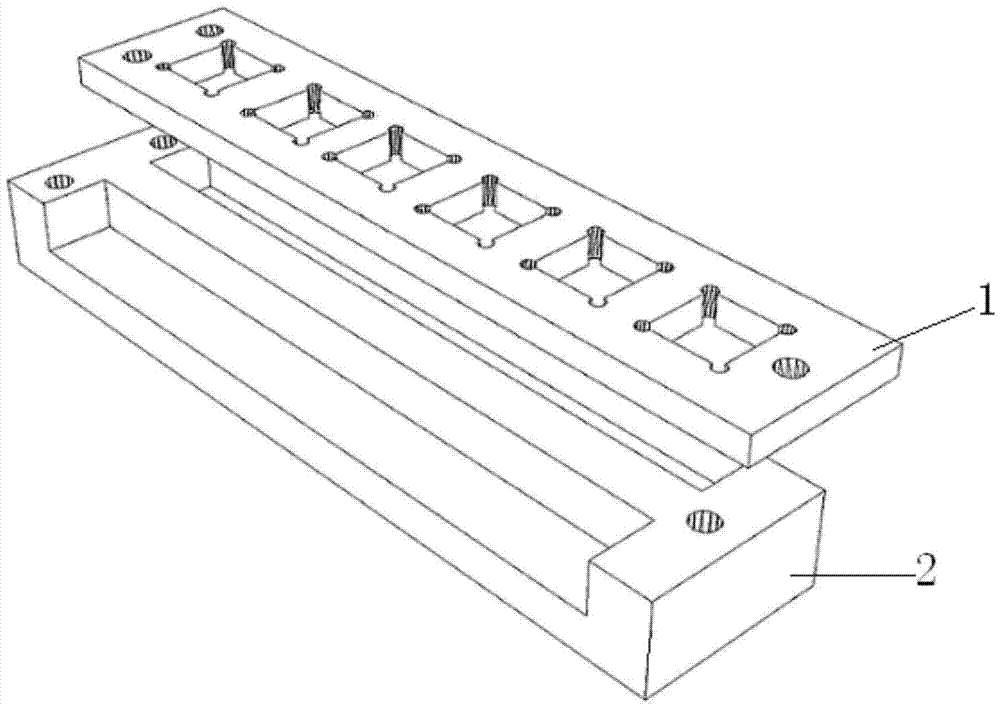

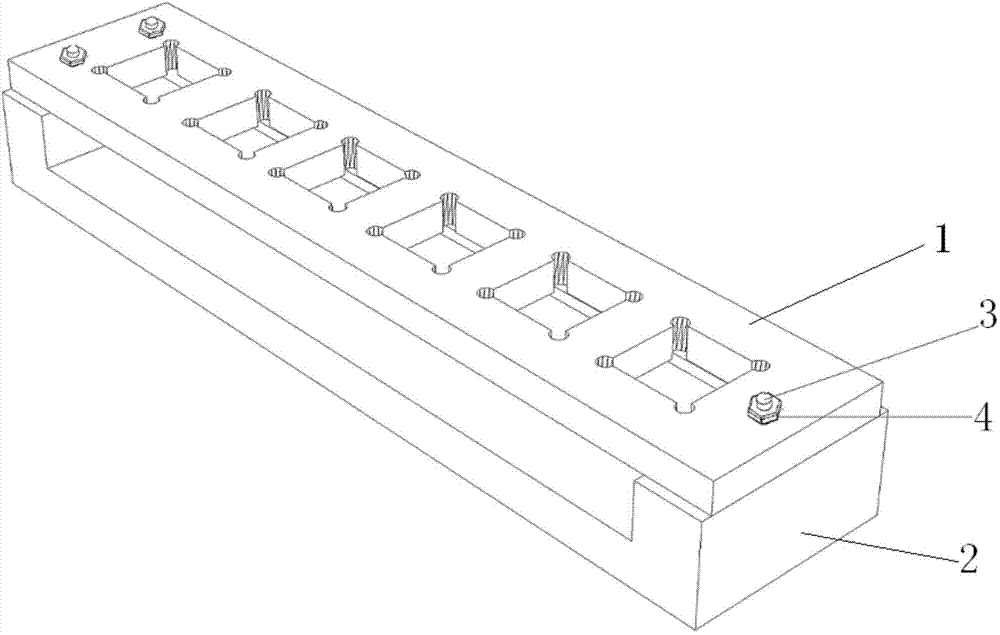

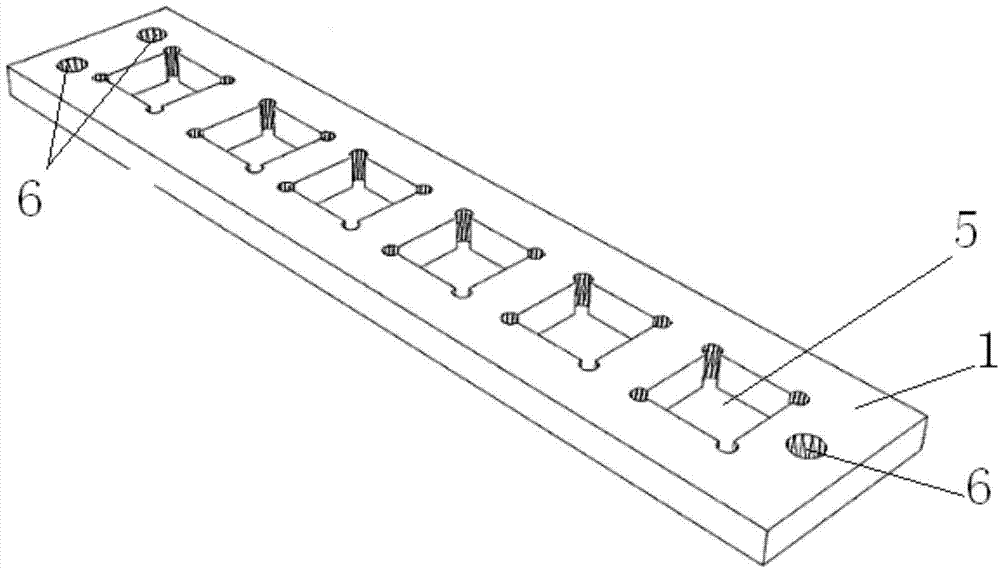

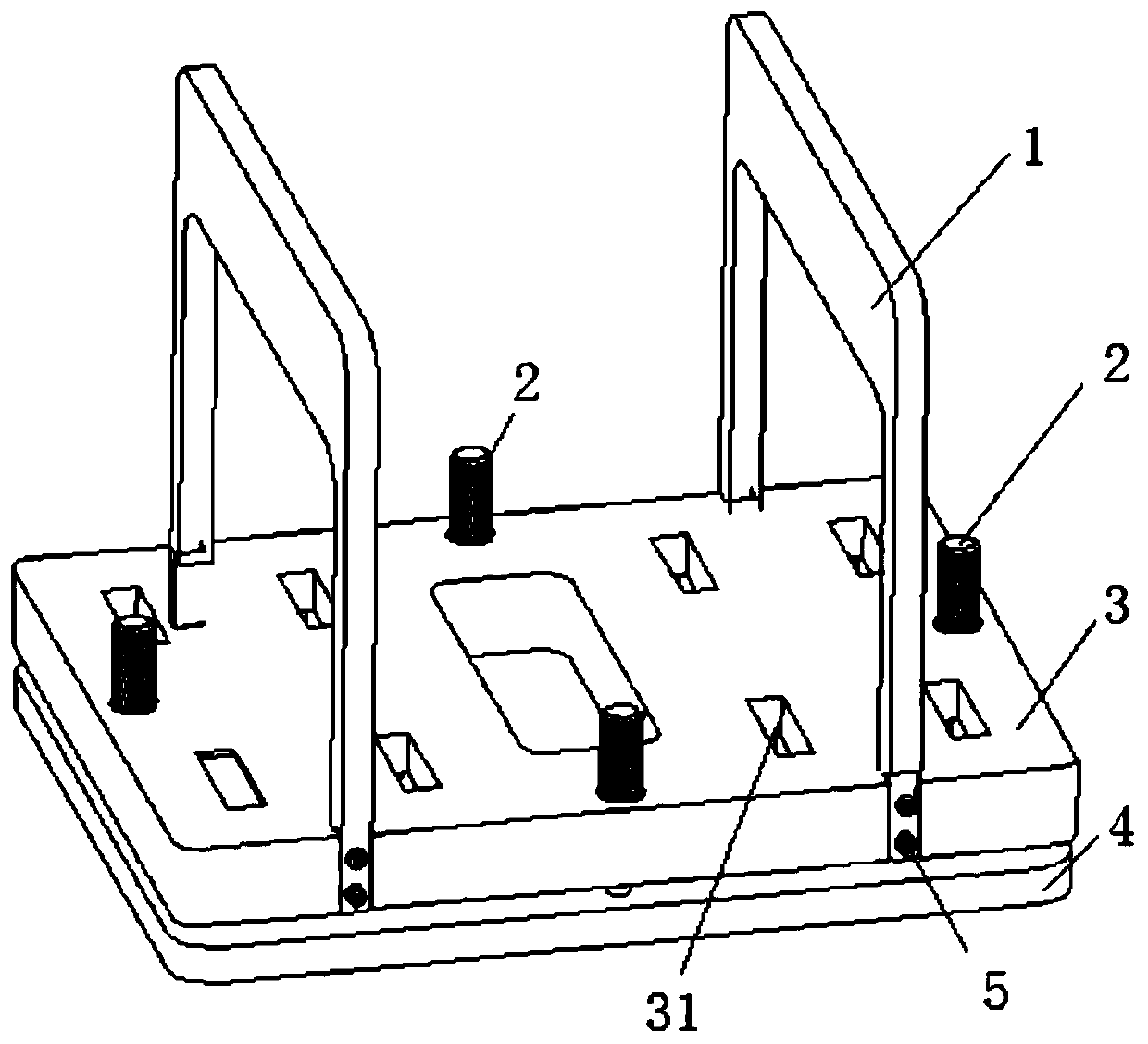

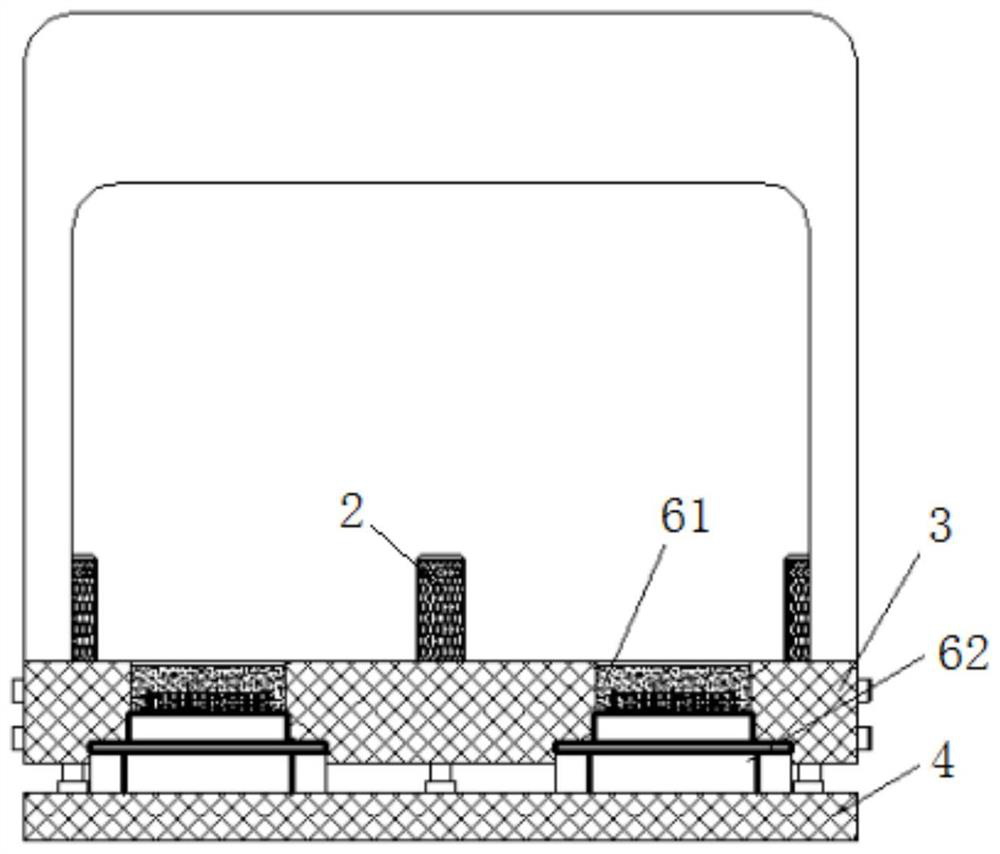

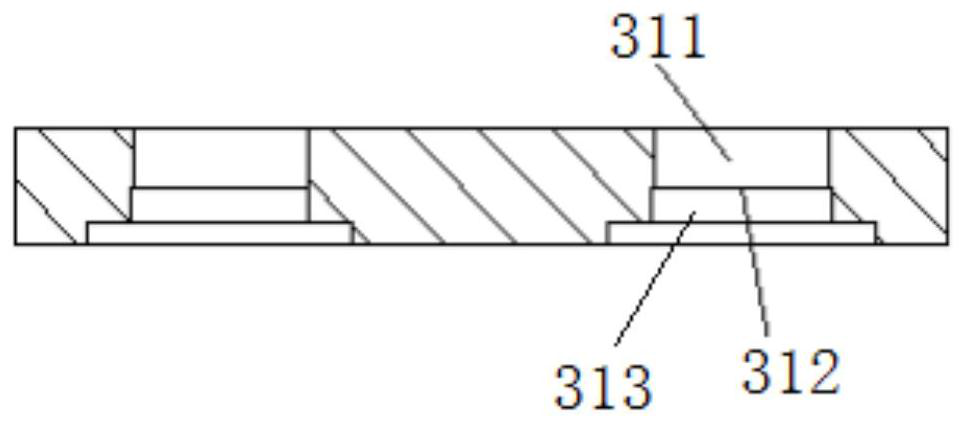

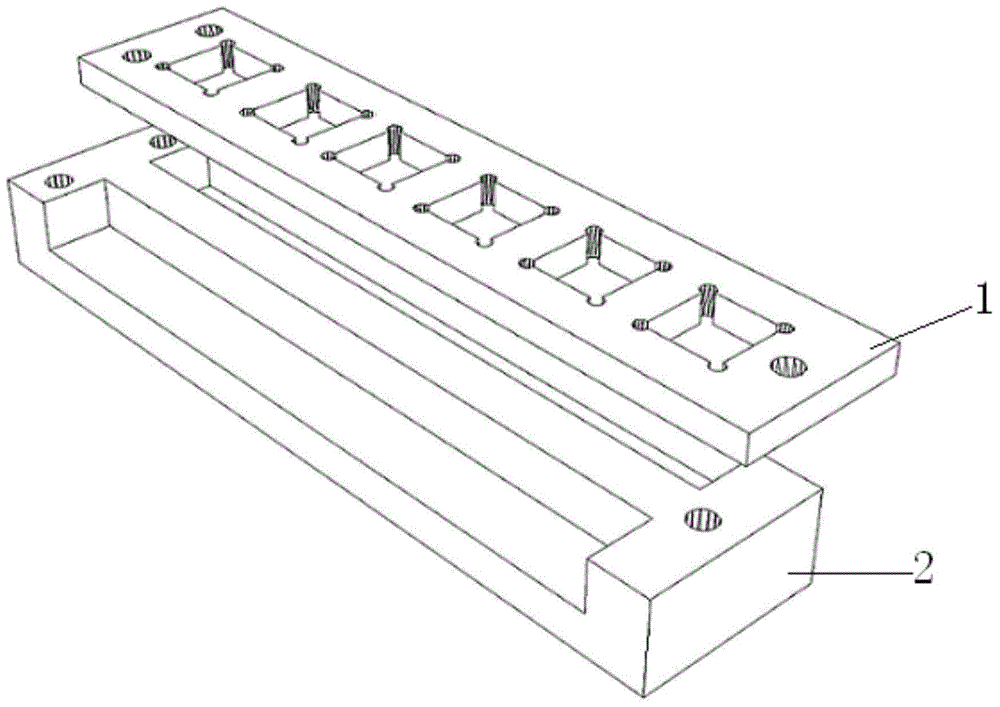

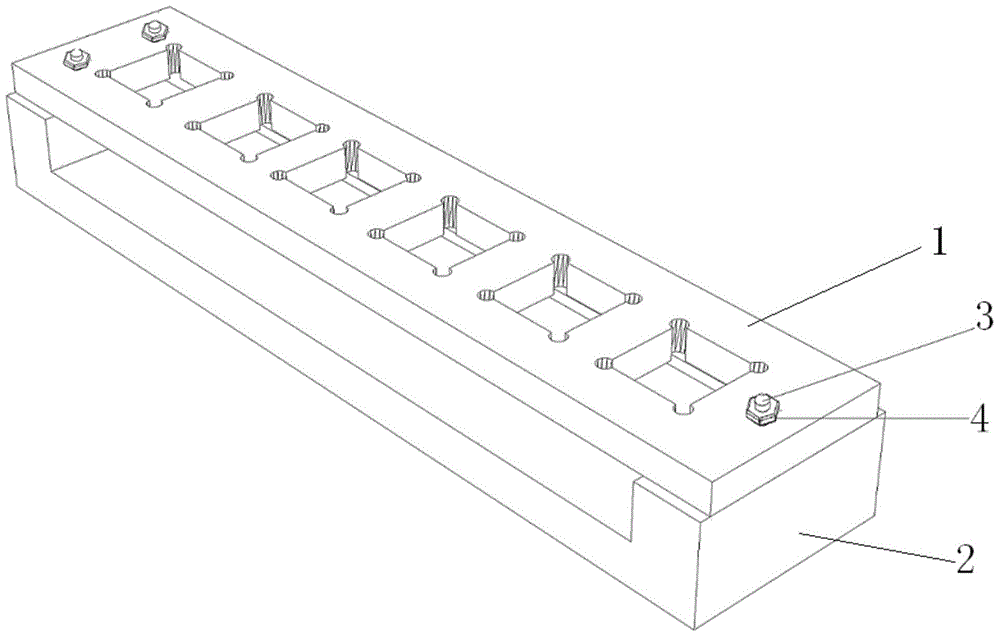

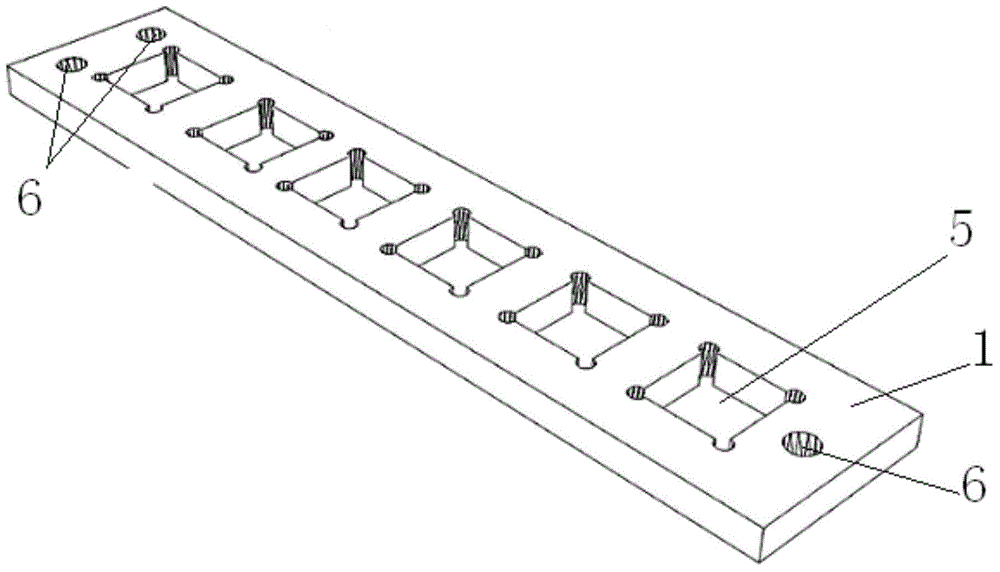

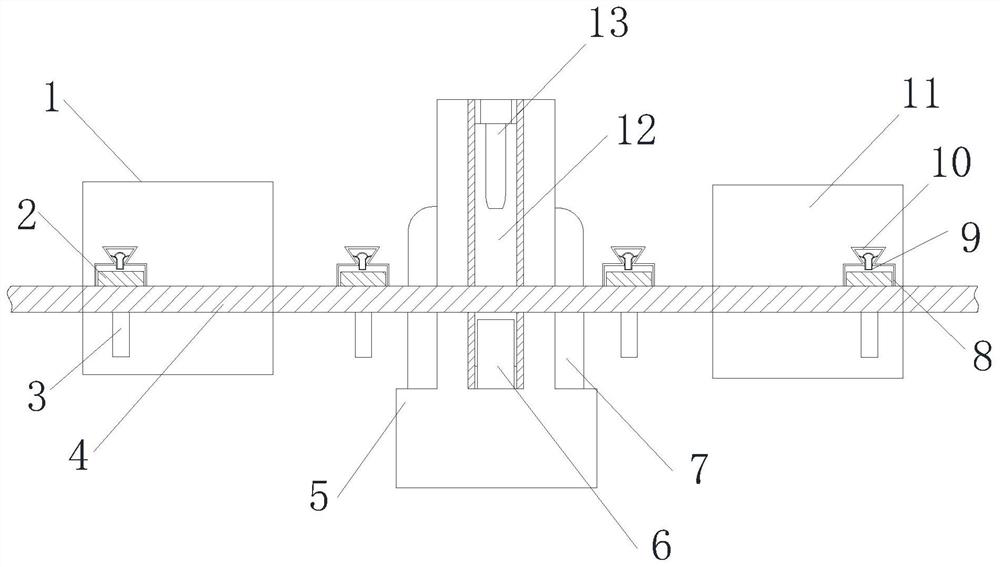

Rectangular electric connector encapsulation equipment and encapsulation method

ActiveCN111431005ASimplify the potting processImprove potting efficiencyDustproof/splashproof/drip-proof/waterproof/flameproof connectionStructural engineeringMechanical engineering

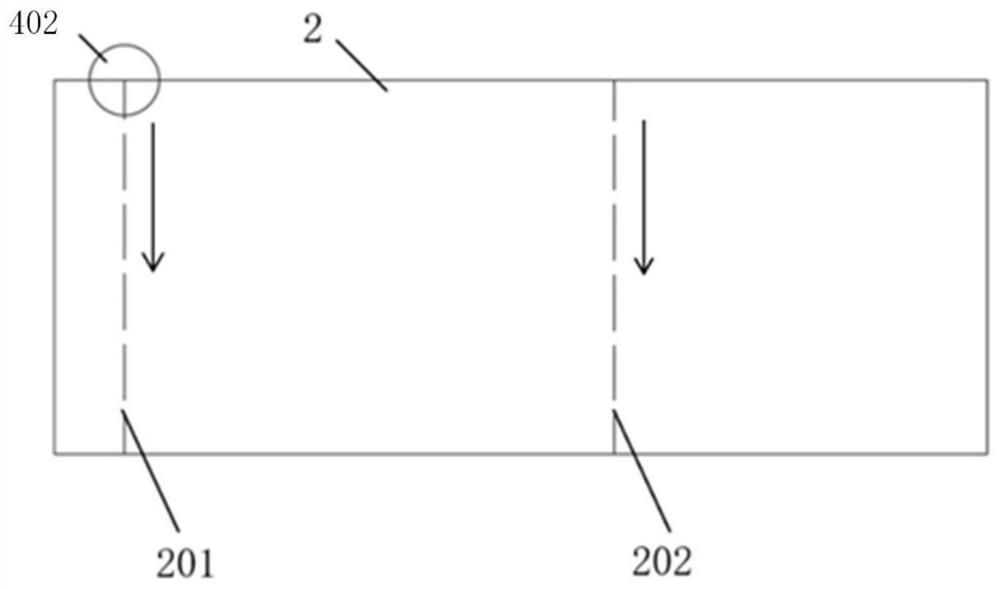

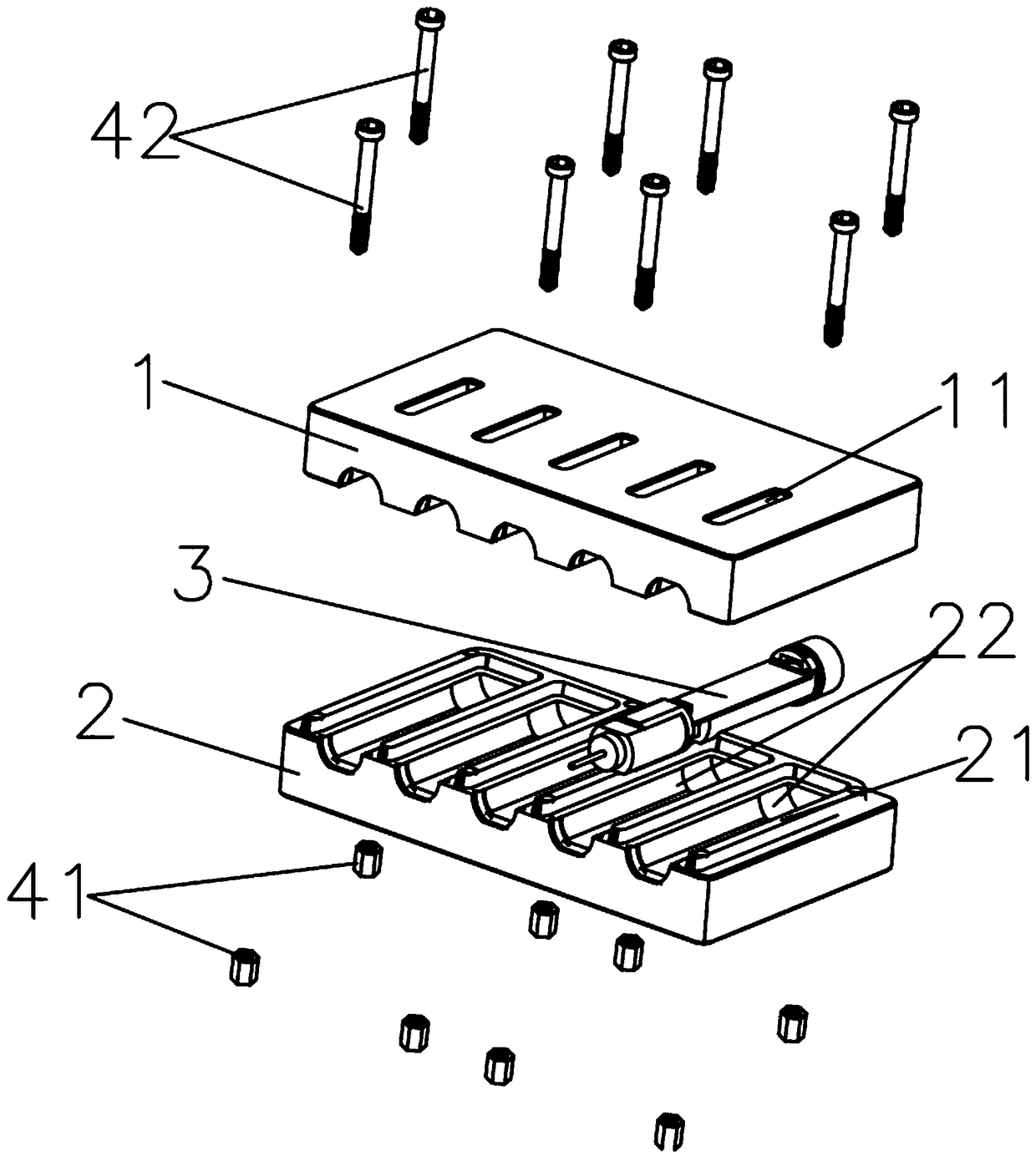

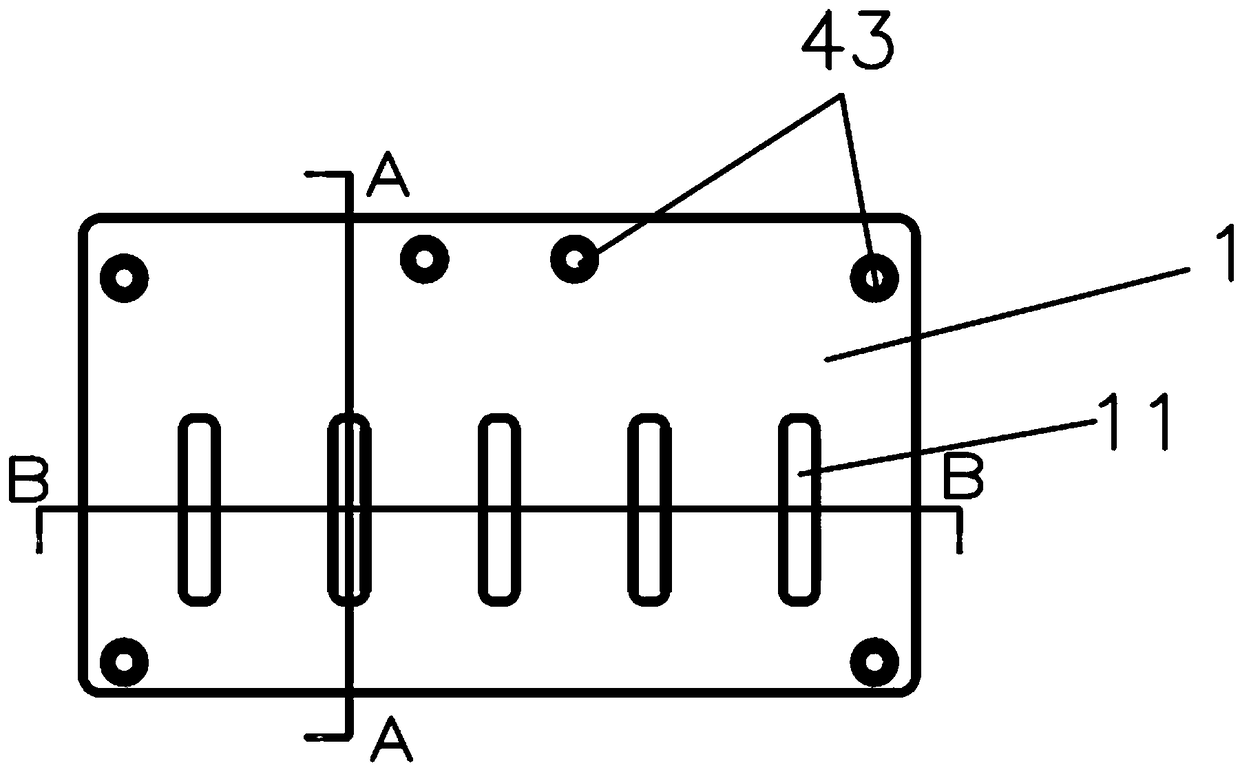

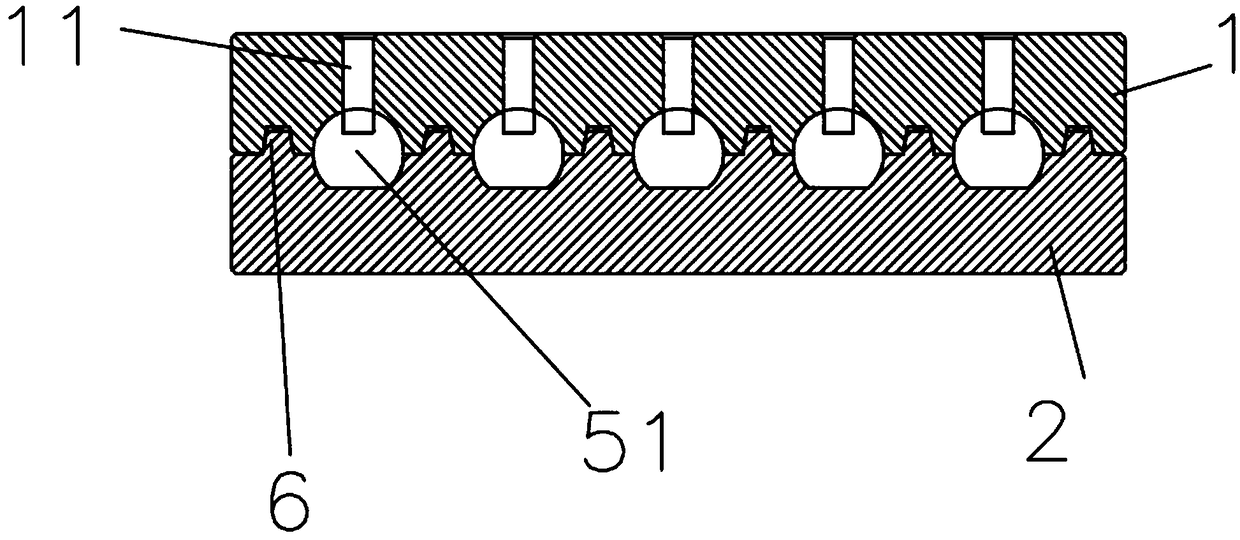

The invention relates to rectangular electric connector encapsulationpotting equipment and encapsulationa potting method, and the encapsulationpotting equipment comprises a encapsulationpotting mainboard which is provided with a plurality of encapsulationpotting grooves for encapsulatingpotting a plurality of rectangular electric connectors, and wherein the encapsulationpotting grooves are through grooves; the a wire lapping rod which is fixed on the encapsulating main board and is used for carding connecting wires encapsulated by the rectangular electric connector; the and a pocket plate which is used for locking the rectangular electric connector before potting encapsulation and supporting the rectangular electric connector after encapsulationpotting, and wherein the pocket plate can befixedly connected with the encapsulationpotting main board through a plurality of threaded fasteners.; when When the rectangular electric connector is installed, one end of the rectangular electric connector is inserted into one encapsulationpotting groove, and the pocket plate is fastened at the other end of the rectangular electric connector. According to the invention, a plurality of rectangular electric connectors can be encapsulated at the same time, the encapsulation process is effectively simplified, and the encapsulation efficiency is improved.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

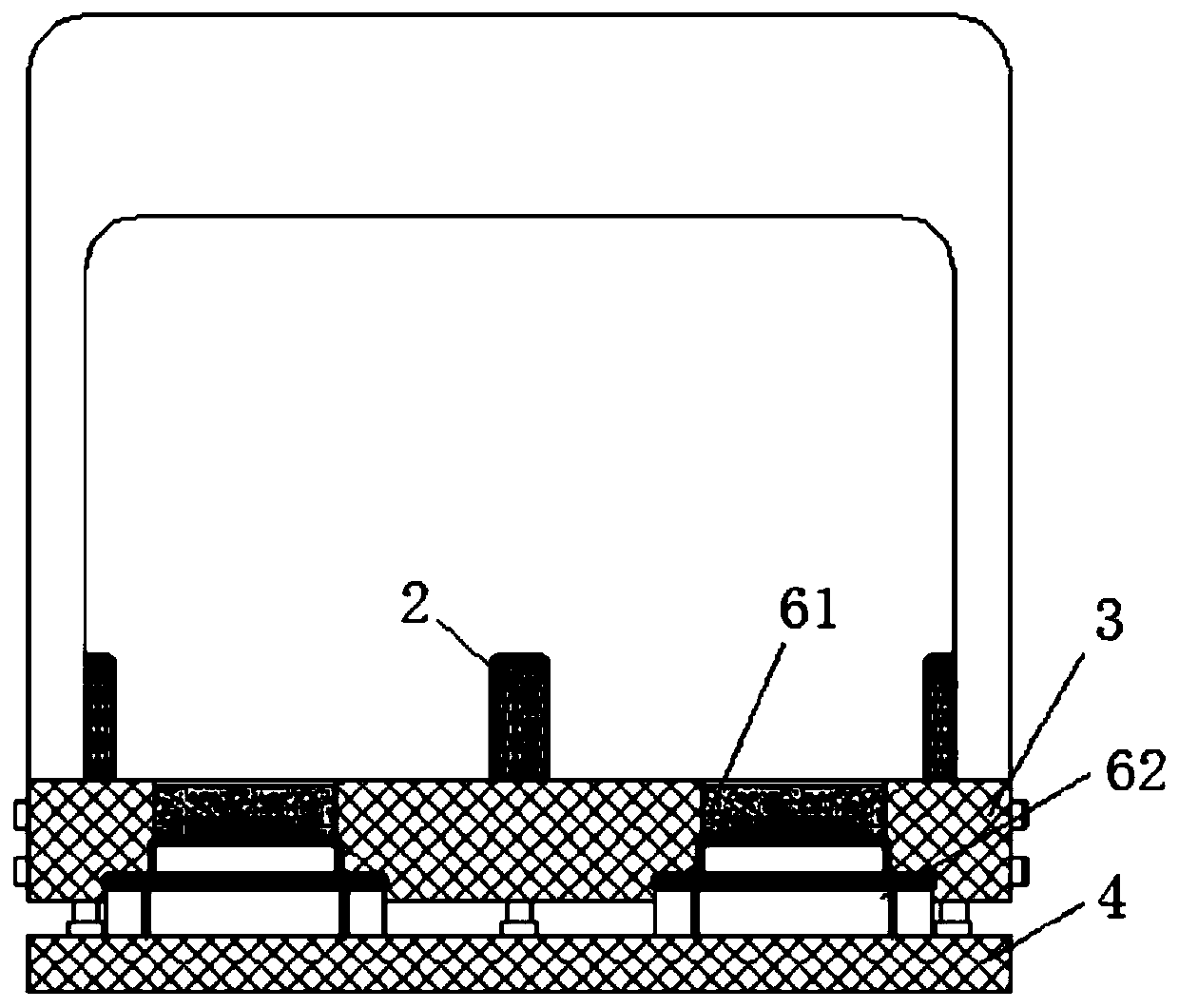

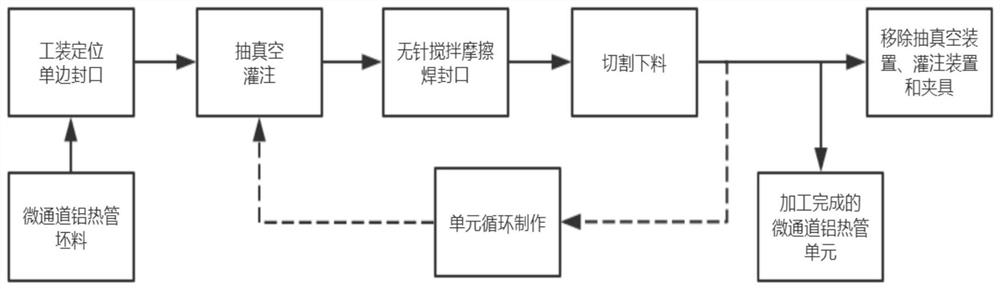

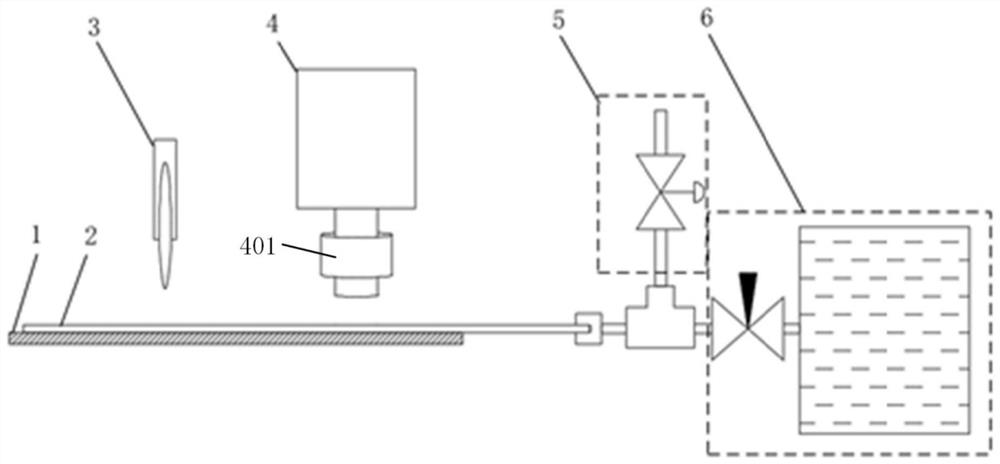

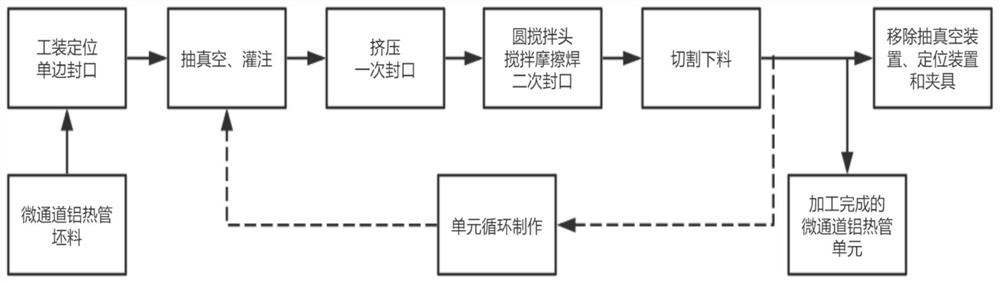

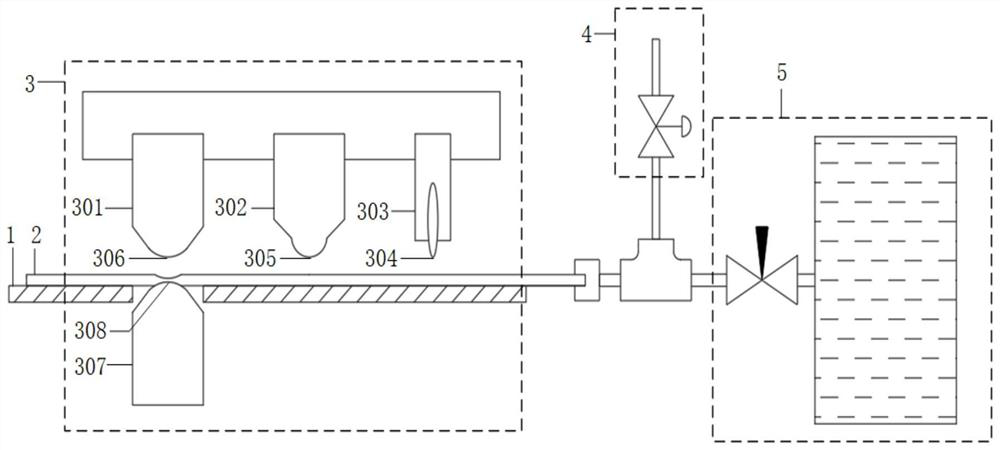

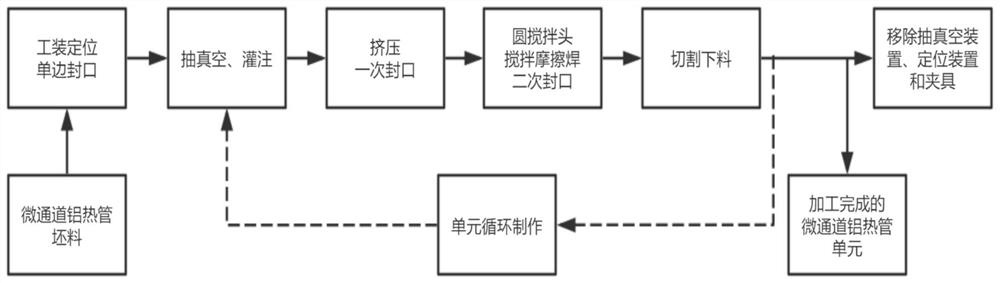

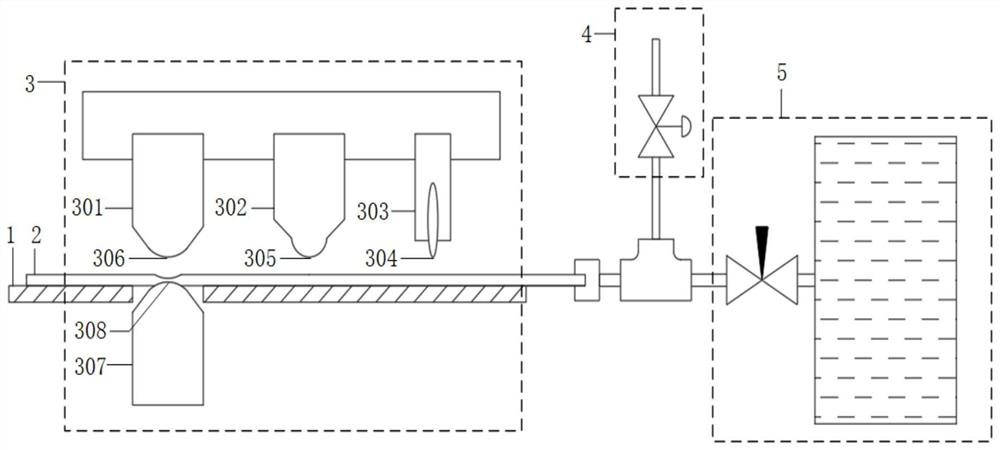

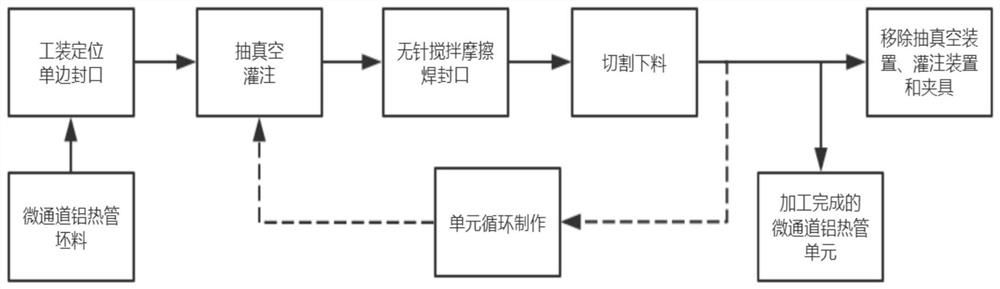

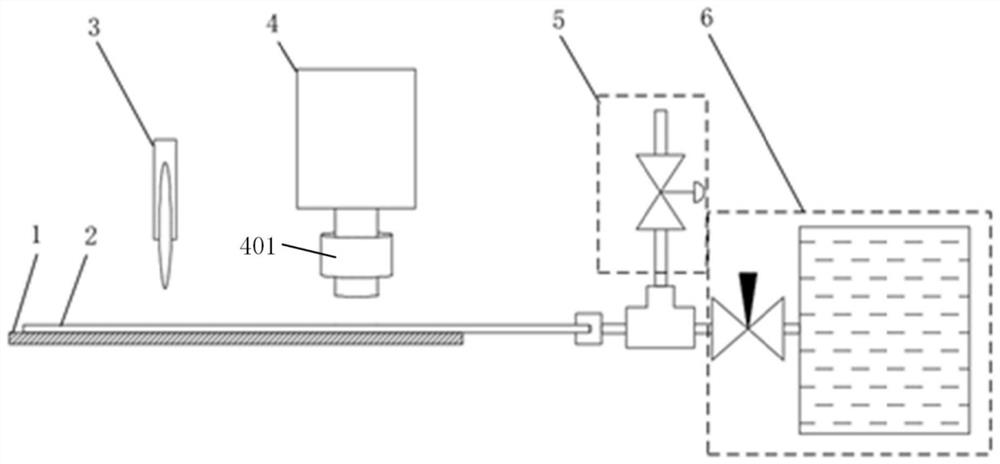

Material-saving efficient pouring and encapsulating process for needleless friction stir welding for porous microchannel aluminum heat tube

ActiveCN112207417AImprove potting efficiencyImprove reliabilityNon-electric welding apparatusFriction weldingEngineering

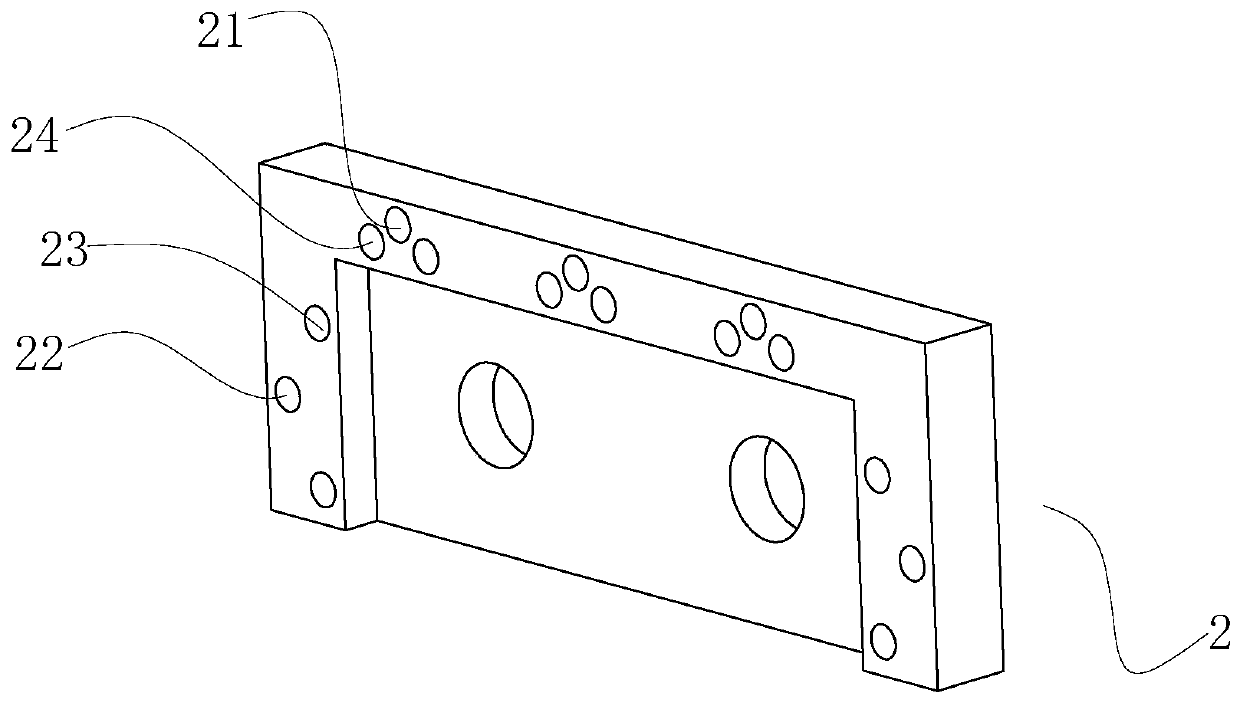

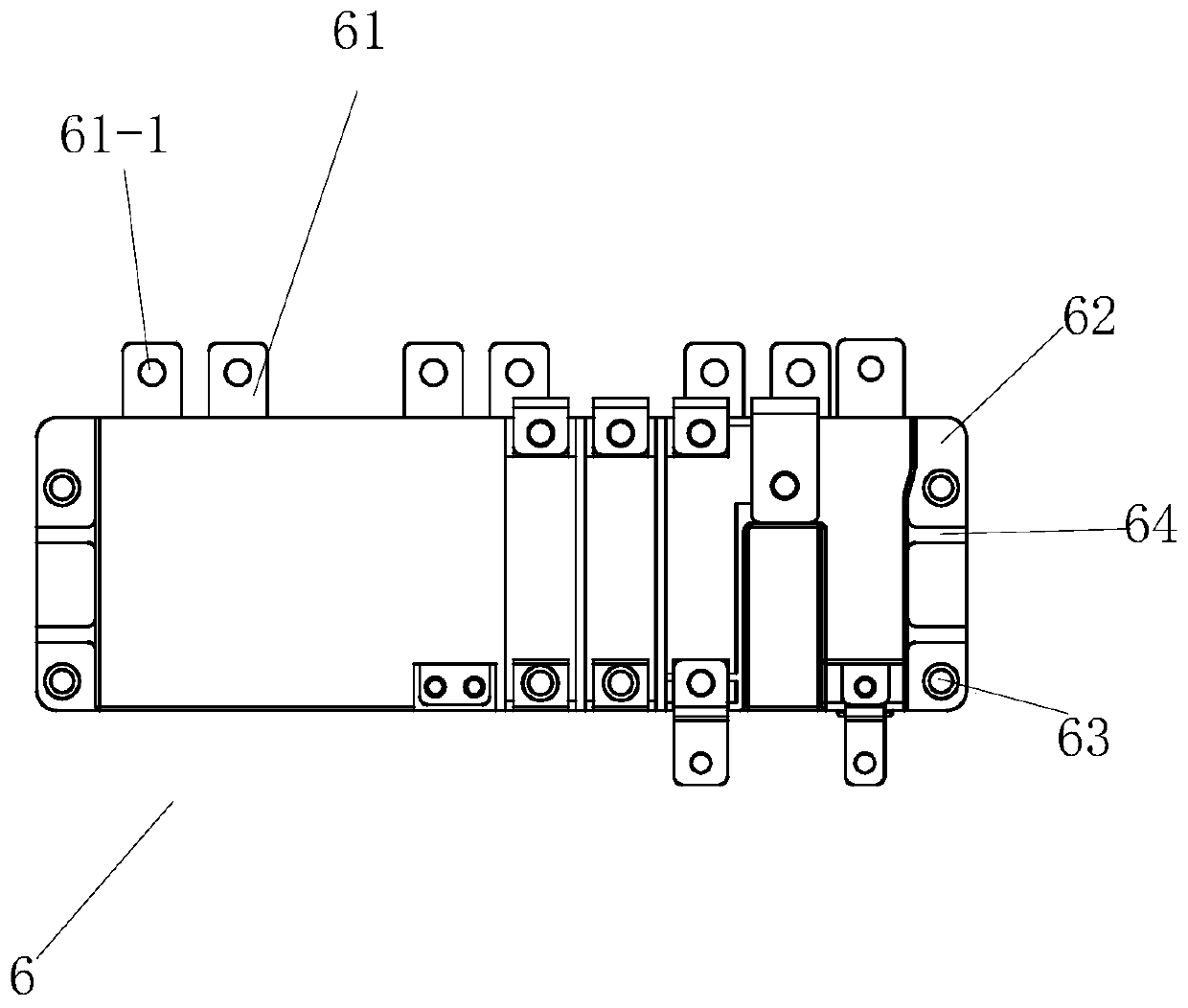

The invention belongs to the field of apparatus encapsulation and heat dissipation and relates to a material-saving efficient pouring and encapsulating process for needleless friction stir welding fora porous microchannel aluminum heat tube. The process comprises the following steps of internally vacuumizing the microchannel aluminum heat tube that is sealed at a single edge by using a vacuumizing device; pouring a working medium into the microchannel aluminum heat tube through a pouring device; welding and sealing the microchannel aluminum heat tube by means of a needleless friction stir welding process; and performing cutting along a weld joint direction at a 1 / 2 position of a weld joint by a cutting device and finishing the pouring and encapsulating process of the microchannel aluminumheat tube. Pouring and encapsulating manufacturing of the microchannel aluminum heat tube can be achieved by four steps of primary clamping, vacuumizing, pouring and primary needleless friction stirwelding, so that the processing and manufacturing flow is shortened greatly, and the process is high in reliability, low in rejection rate, high in production efficiency and high in utilization ratioof materials. Encapsulating equipment is low in demand on performance, a needleless stirring head is long in service life, and a production processes is green and environmental-friendly.

Owner:XI AN JIAOTONG UNIV

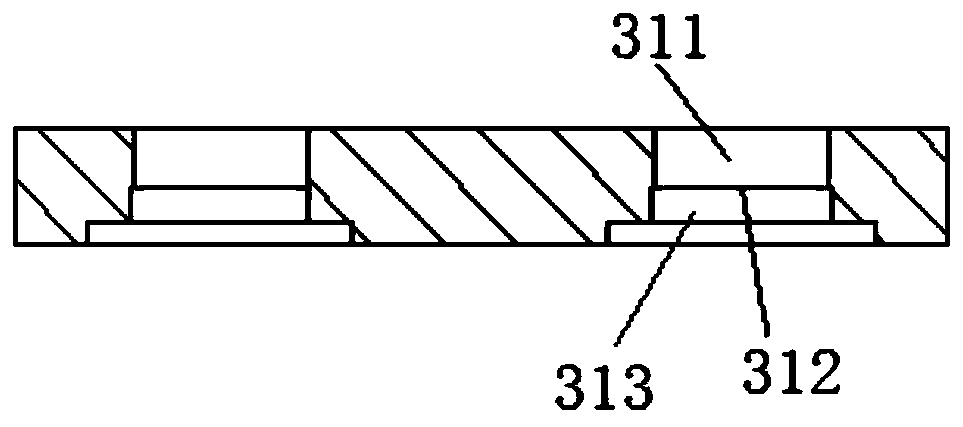

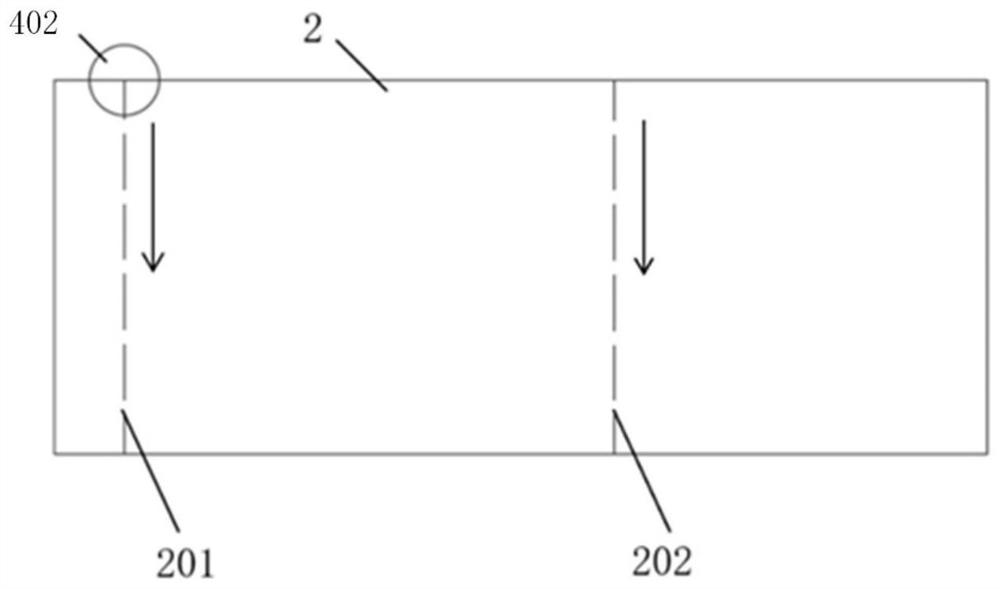

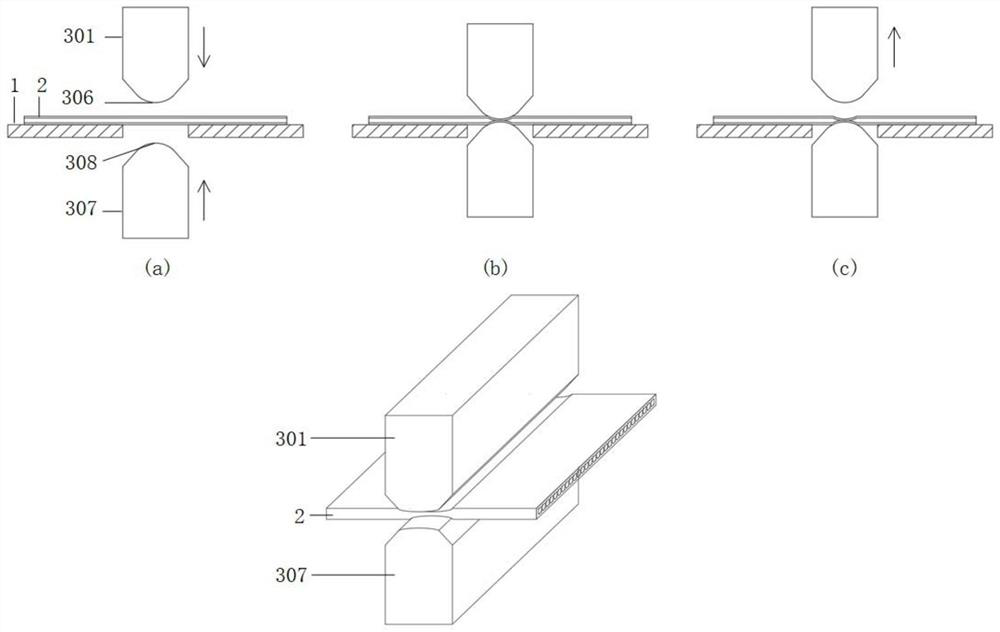

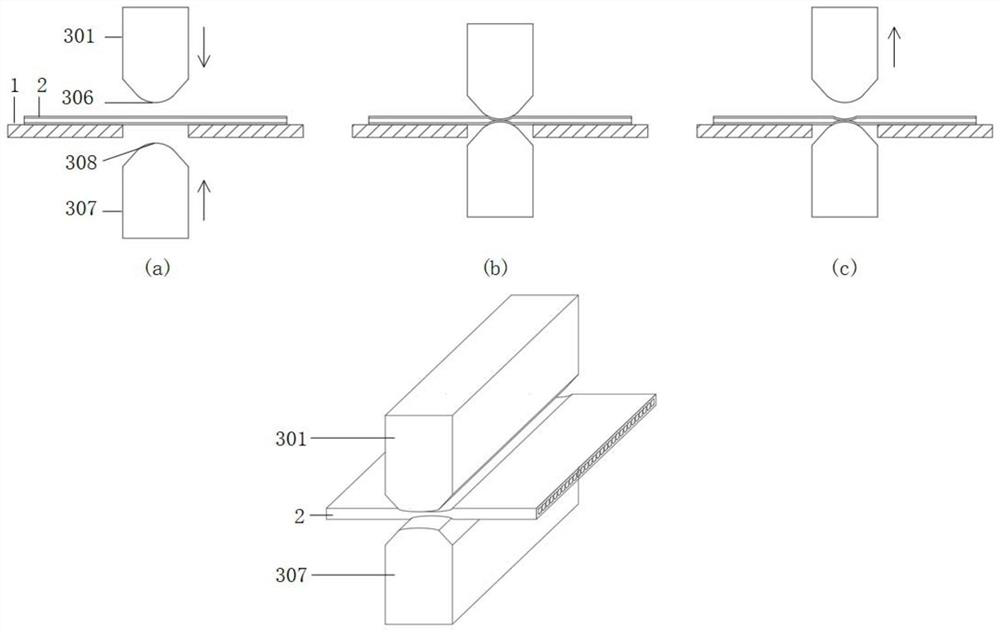

Pouring and encapsulating process for spherical friction stir welding of pre-extrusion of microchannel aluminum heat tube with narrow weld joint

ActiveCN112207418AImprove potting efficiencyEasy to operateNon-electric welding apparatusEngineeringPumping vacuum

The invention belongs to the field of apparatus encapsulation and heat dissipation and relates to a pouring and encapsulating process for spherical friction stir welding of pre-extrusion of a microchannel aluminum heat tube with a narrow weld joint. The process mainly comprises the following steps of (1) vacuumizing an environment in the micro heat tube sealed at a single edge to a high vacuum state; (2) pouring a working medium of a certain quantity into the micro heat tube; (3) performing extruding and sealing by using an extruding and sealing device; (4) welding and sealing the micro heat tube by means of a spherical friction stir welding process, wherein a welding direction is along a position of 1 / 2 of an extruding and sealing line; (5) performing cutting in the position of 1 / 2 of a weld joint by means of the cutting device along a weld joint direction, and finishing a pouring and encapsulating process of a micro heat tube unit; and (6) removing the vacuumizing device and the pouring device. The process can manufacture the microchannel aluminum heat tube unit with only five steps, so that a medium sealing and unloading section is shortened greatly, the processing and manufacturing flow is simplified, and the process is high in utilization ratio of materials, good in encapsulating effect, low in rejection rate and high in production efficiency. A spherical stirring head islong in service life and a production process is green and environmental-friendly.

Owner:XI AN JIAOTONG UNIV

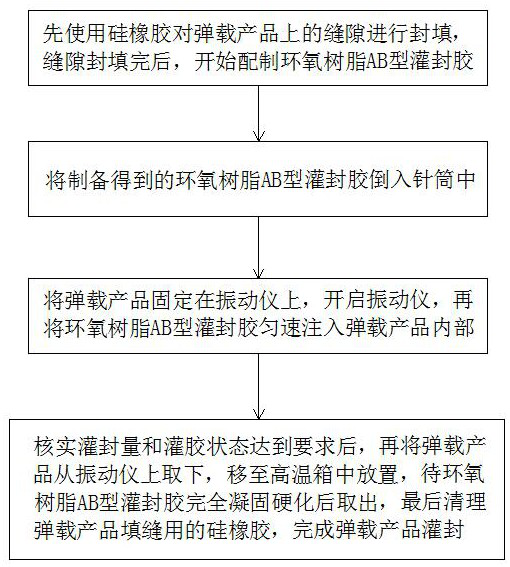

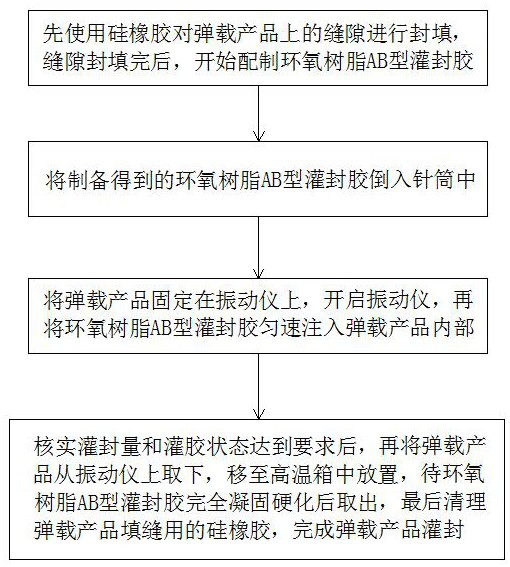

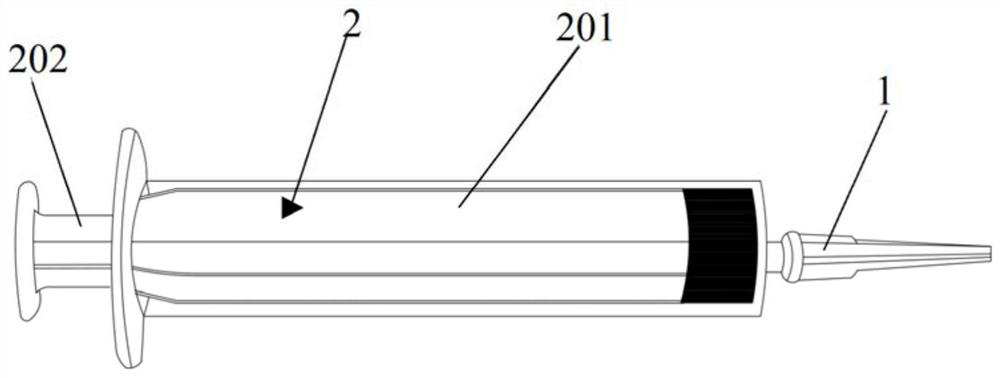

Anti-overload potting process for missile-borne product

ActiveCN113916068APotting operation is simple and easyImprove potting efficiencyAmmunitionAdhesiveMissile

The invention discloses an anti-overload potting process for a missile-borne product, and belongs to the technical field of missile-borne. The anti-overload potting process is characterized by comprising the following steps that a, caulking is carried out on a gap on the missile-borne product by using silicon rubber, and preparation of an epoxy resin AB type potting adhesive is started after the gap is caulked; b, the prepared epoxy resin AB type potting adhesive is poured into a needle cylinder; c, the missile-borne product is fixed on a vibration meter, the vibration meter is started, and the epoxy resin AB type potting adhesive is injected to the interior of the missile-borne product at a constant speed; and d, after the potting amount and the potting state are verified to meet the requirements, the missile-borne product is taken down from the vibration meter and transferred into a high-temperature box for placement, the missile-borne product is taken out after the epoxy resin AB type potting adhesive is completely solidified and hardened, finally, the silicone rubber for caulking the missile-borne product is cleaned, and the potting of the missile-borne product is completed. According to the anti-overload potting process, the whole potting operation is simple and easy to implement, the potting efficiency can be effectively improved, the potting uniformity can be kept in the potting process, and the potting quality and the potting effect are improved.

Owner:CHENGDU RDW TECH CO LTD

Micro-channel aluminum heat pipe pre-extruded narrow seam spherical friction stir welding perfusion packaging process

ActiveCN112207418BImprove potting efficiencySimple and fast operationNon-electric welding apparatusEngineeringWeld seam

The invention belongs to the field of device packaging and heat dissipation, and relates to a microchannel aluminum heat pipe pre-extruded narrow seam spherical friction stir welding filling packaging process, which mainly includes: 1) extracting the internal environment of the micro heat pipe that has been sealed on one side to a high temperature Vacuum state; 2) Pour a certain amount of working fluid into the micro heat pipe; 3) Extrude and seal the micro heat pipe by using the extrusion sealing device; 4) Use the spherical friction stir welding process to weld and seal the micro heat pipe, and the welding direction is along the extrusion sealing line 1 / 2 position; 5) Use the cutting device to cut along the weld seam direction at the 1 / 2 position of the weld seam, and the perfusion and packaging process of the micro heat pipe unit is completed; 6) Remove the vacuum device and the perfusion device. The invention only needs 5 processes to complete the production of the microchannel aluminum heat pipe unit, greatly shortens the intermediate sealing and blanking section, simplifies the processing and manufacturing process, has high material utilization rate, good packaging effect, high reliability, low scrap rate, and low production cost. The efficiency is high, and the service life of the spherical stirring head is long, and the production process is green and environmentally friendly.

Owner:XI AN JIAOTONG UNIV

A bomb-loaded product anti-overload potting process

ActiveCN113916068BPotting operation is simple and easyImprove potting efficiencyAmmunitionEpoxyPolymer science

The invention discloses an anti-overload potting process for missile-borne products, which belongs to the technical field of missile-borne products, and is characterized in that it comprises the following steps: a. First, use silicone rubber to seal and fill the gaps on the missile-borne products, and the gaps are sealed and filled Finally, start to prepare epoxy resin AB type potting glue; b, pour the prepared epoxy resin AB type potting glue into the syringe; c, fix the bomb-loaded product on the vibrator, turn on the vibrator, and then Epoxy resin AB-type potting glue is injected into the bomb-loaded product at a uniform speed; d. After verifying that the potting volume and potting state meet the requirements, the bomb-loaded product is removed from the vibrator and placed in a high-temperature box. After the epoxy resin AB type potting glue is completely solidified and hardened, take it out, and finally clean up the silicone rubber used for filling the gaps of the missile-borne products to complete the potting of the missile-borne products. The whole filling and sealing operation of the invention is simple and easy, can effectively improve the filling and sealing efficiency, and can maintain the filling and sealing uniformity in the filling and sealing process, and improve the quality and effect of the filling and sealing.

Owner:CHENGDU RDW TECH CO LTD

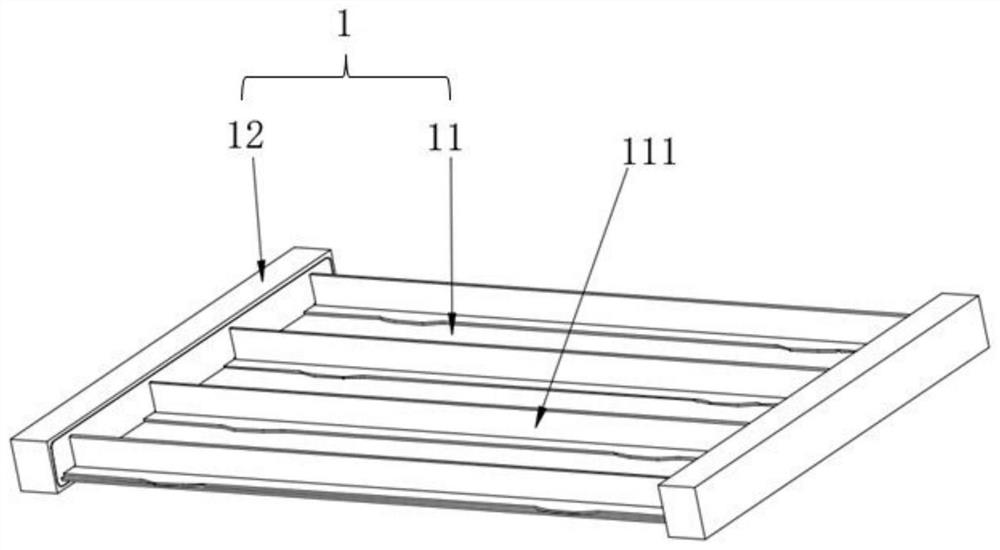

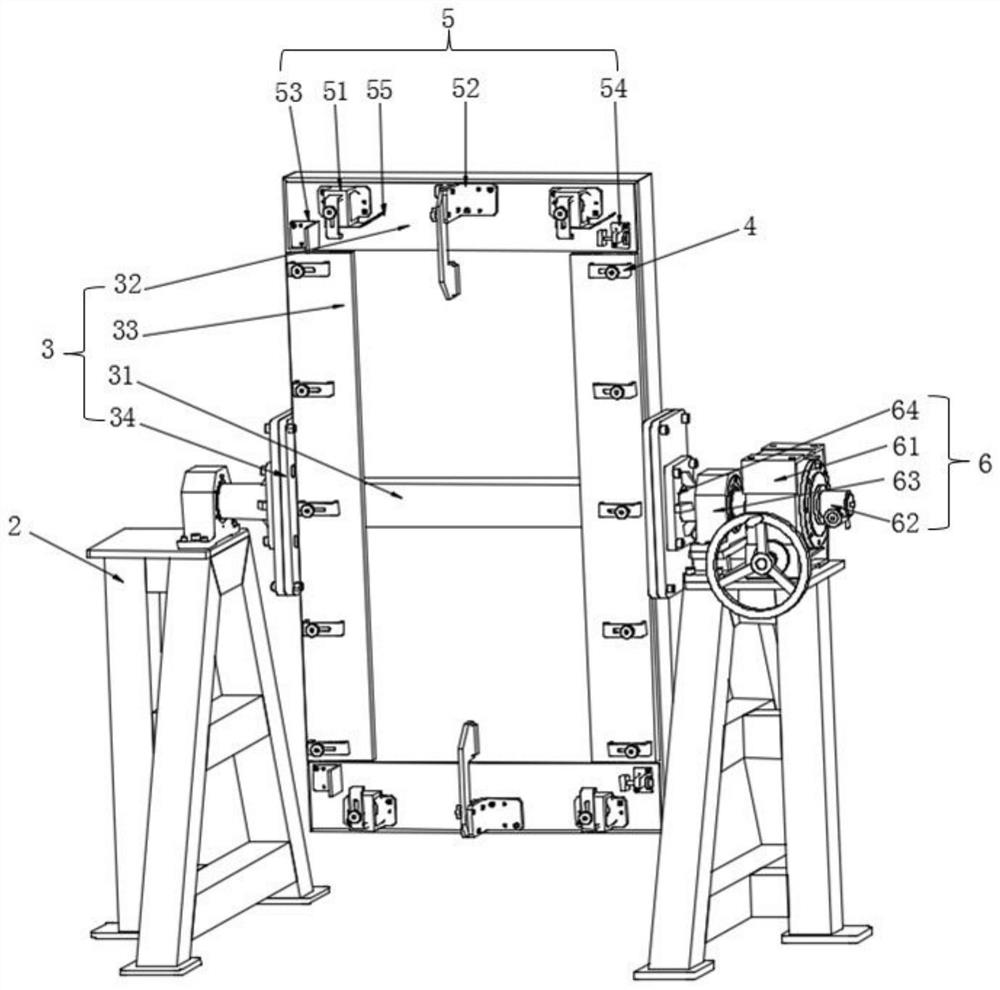

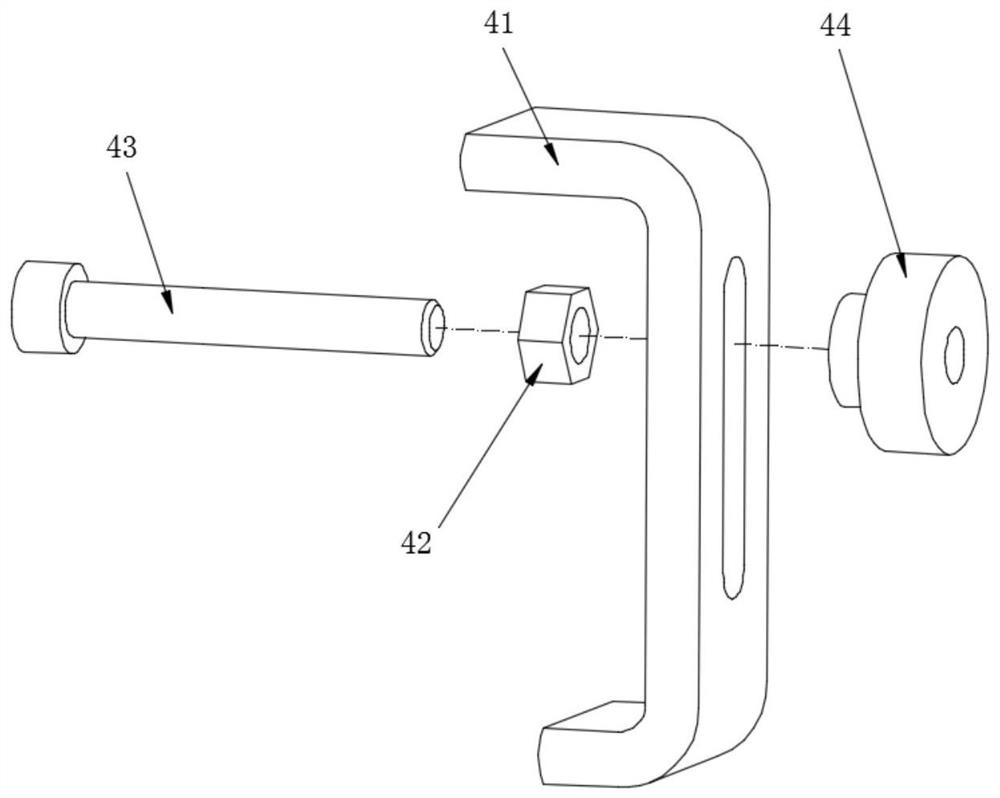

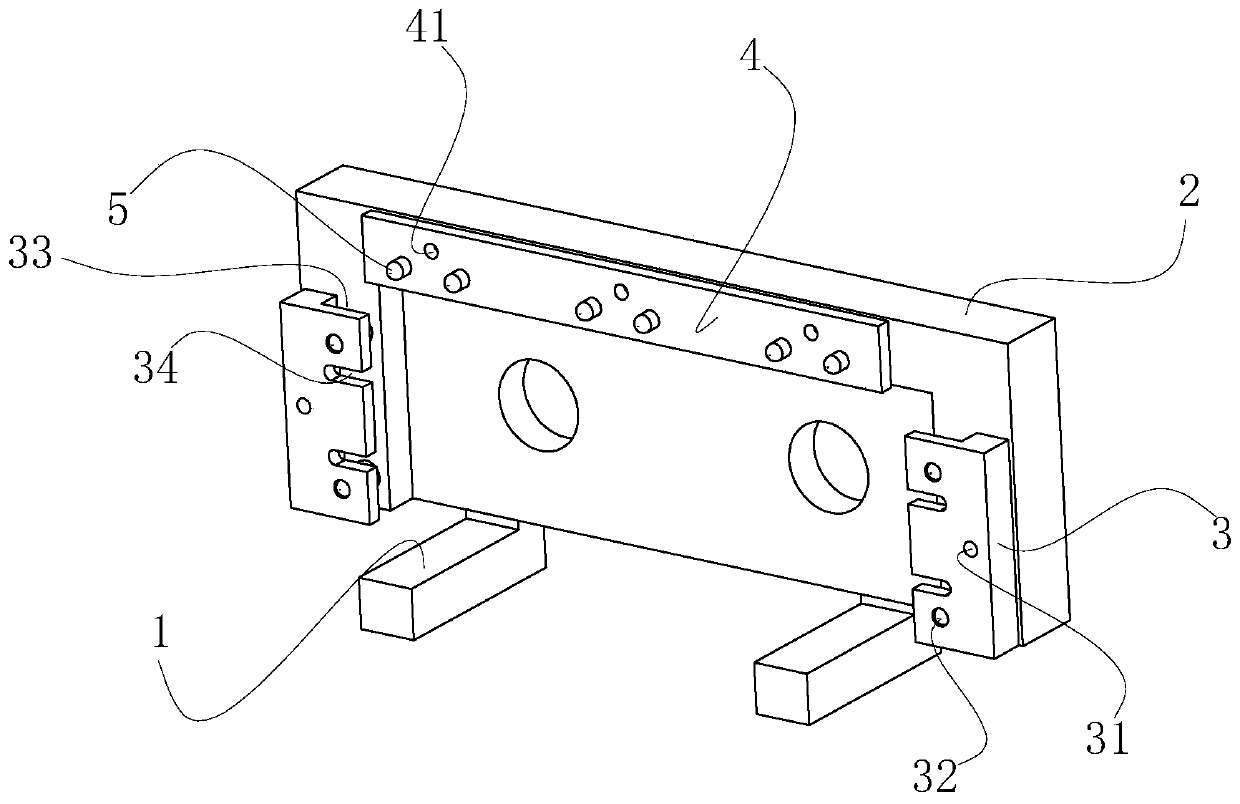

Glue filling clamp and glue filling method for stiffened wallboard compression test piece

PendingCN113670683AStable positionEnsure safetyMachine part testingPreparing sample for investigationStructural engineeringCompression test

The invention discloses a glue filling clamp and a glue filling method for a stiffened wallboard compression test piece. The clamp structure comprises a stand column, a frame, a pressing assembly, a positioning assembly and a turnover assembly, the stand column is fixedly installed on the ground through an expansion foundation bolt after being leveled, the turnover assembly is arranged at the upper end of the stand column, a shaft support of the turnover assembly is fixedly connected with the frame, the positioning assemblies are transversely arranged on the upper and lower sides of the frame, and the pressing assemblies are longitudinally arranged on the left and right sides of the frame. The stiffened wallboard compression test piece is fixed and accurately positioned on the inner side of the glue filling clamp through the pressing assembly and the positioning assembly, and the stiffened wallboard compression test piece is subjected to turnover glue filling through the turnover assembly.

Owner:XI'AN AIRCRAFT INTERNATIONAL

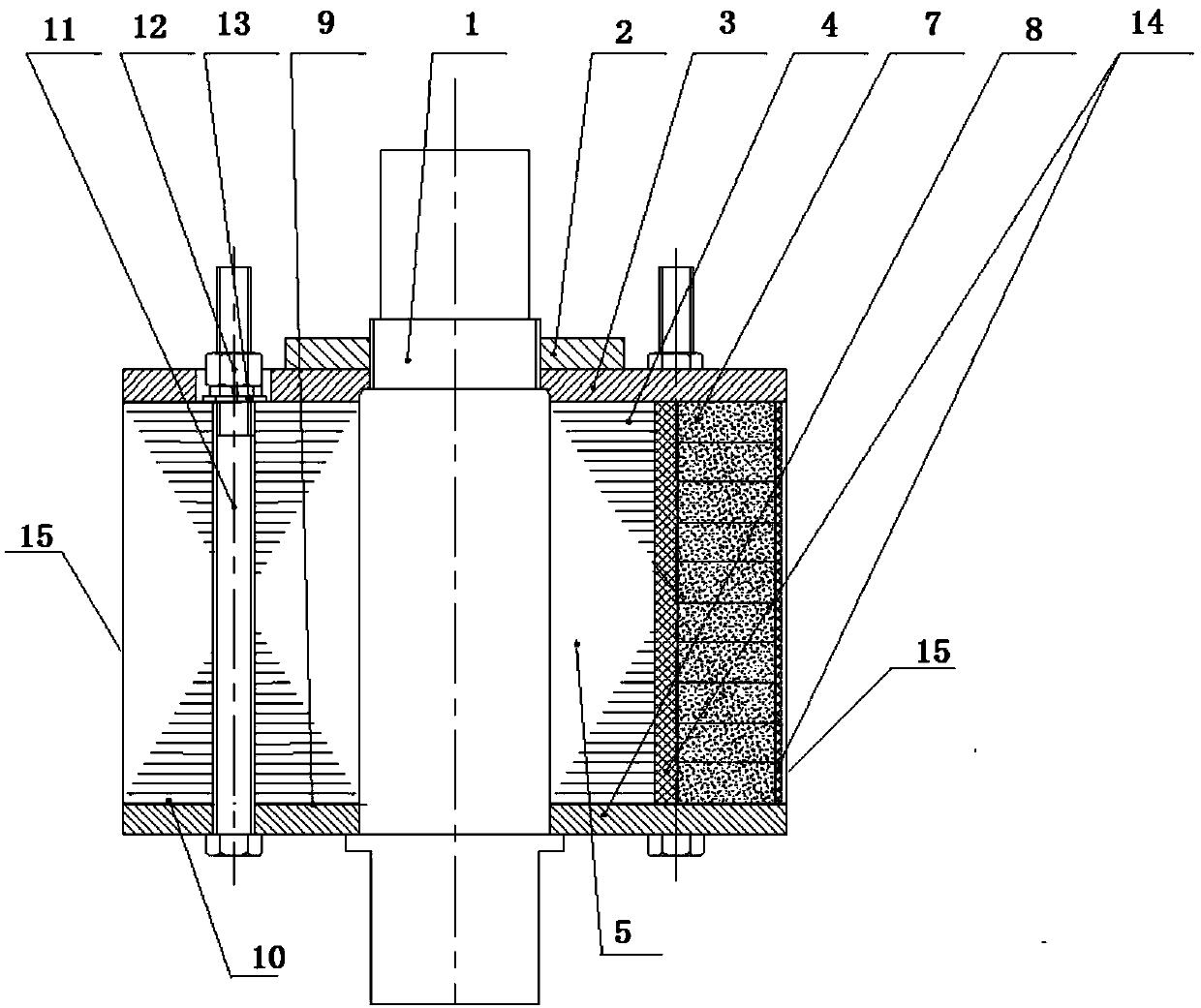

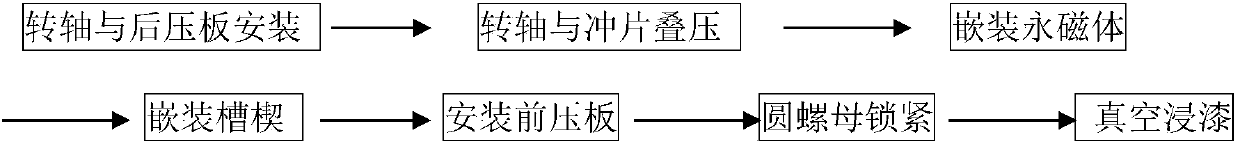

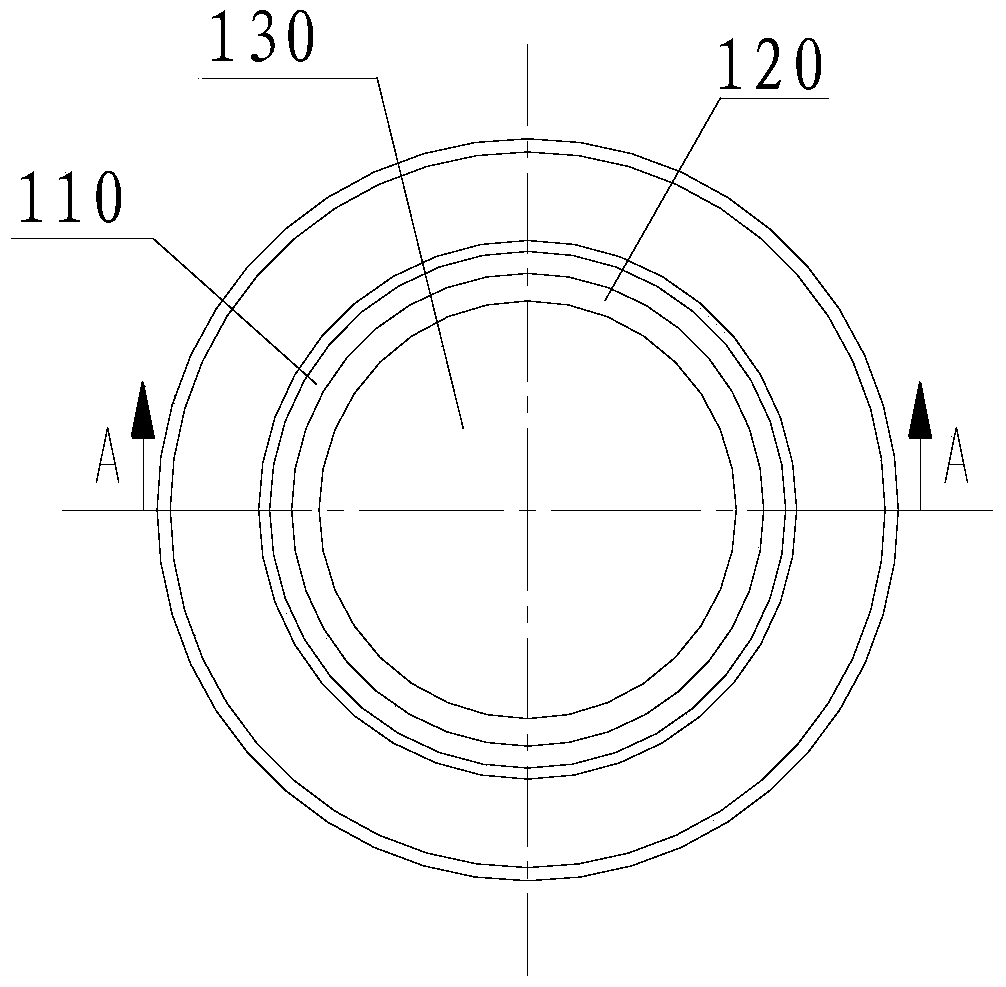

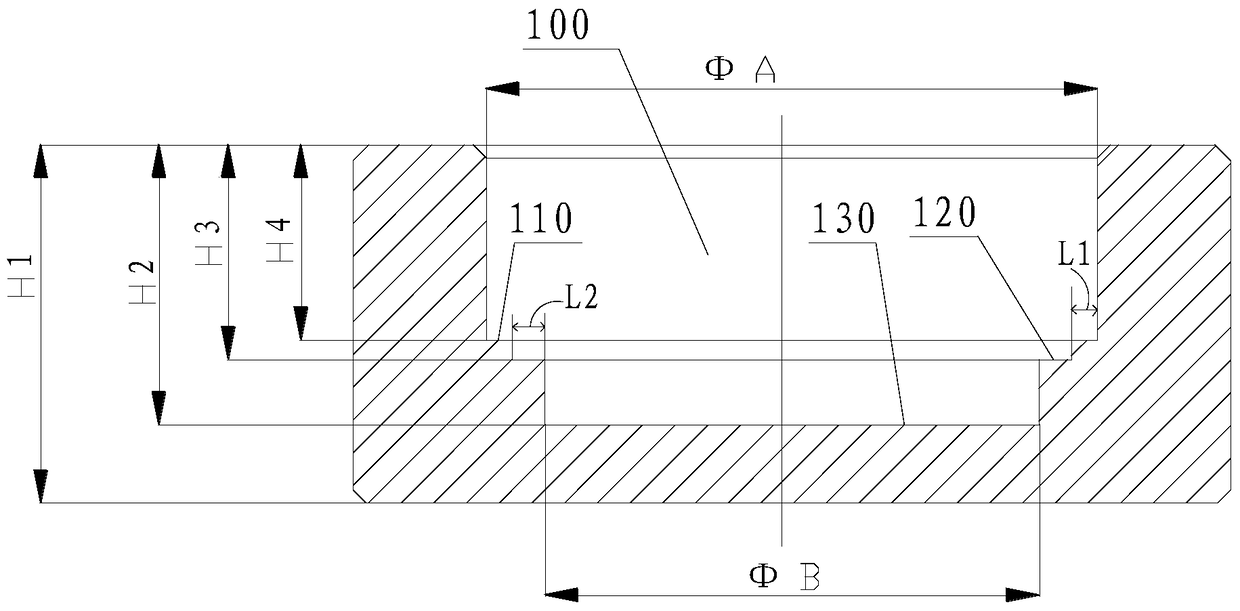

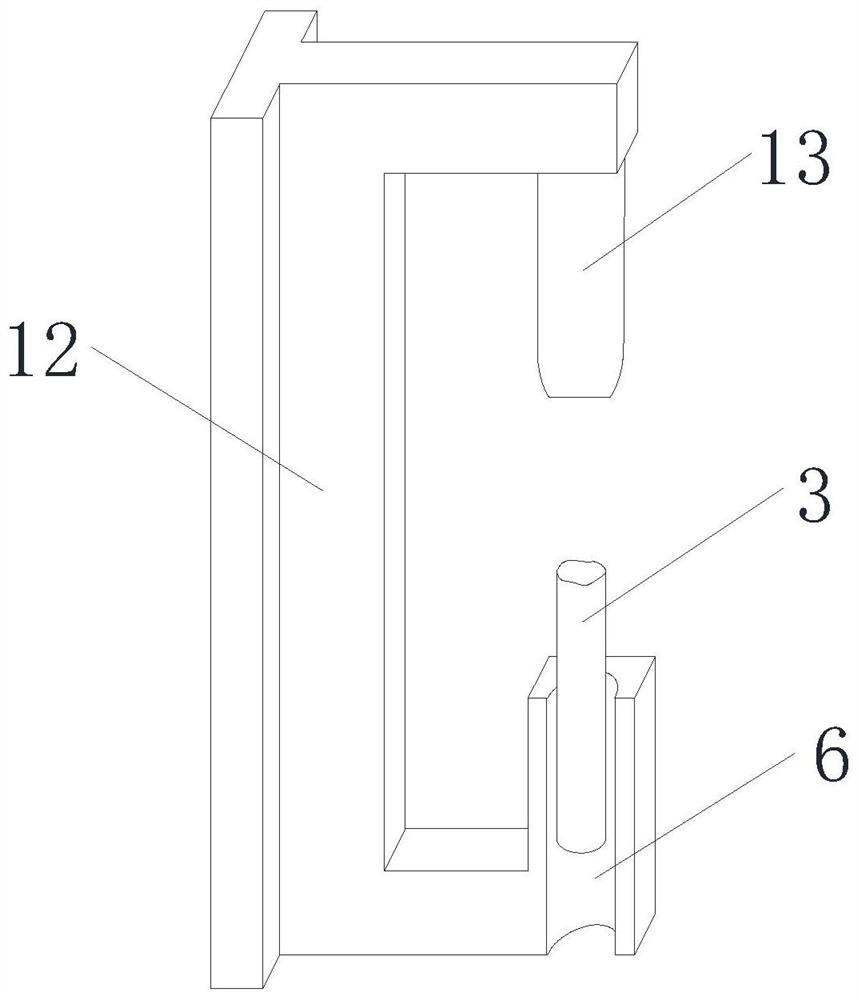

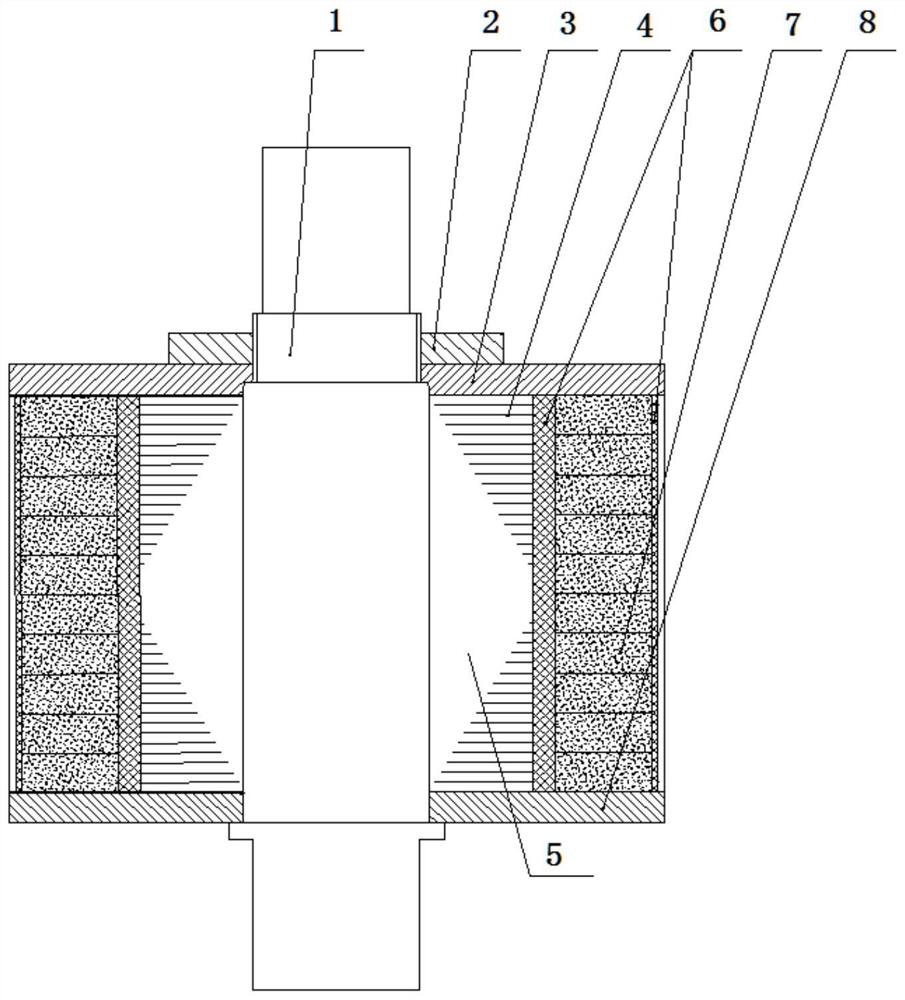

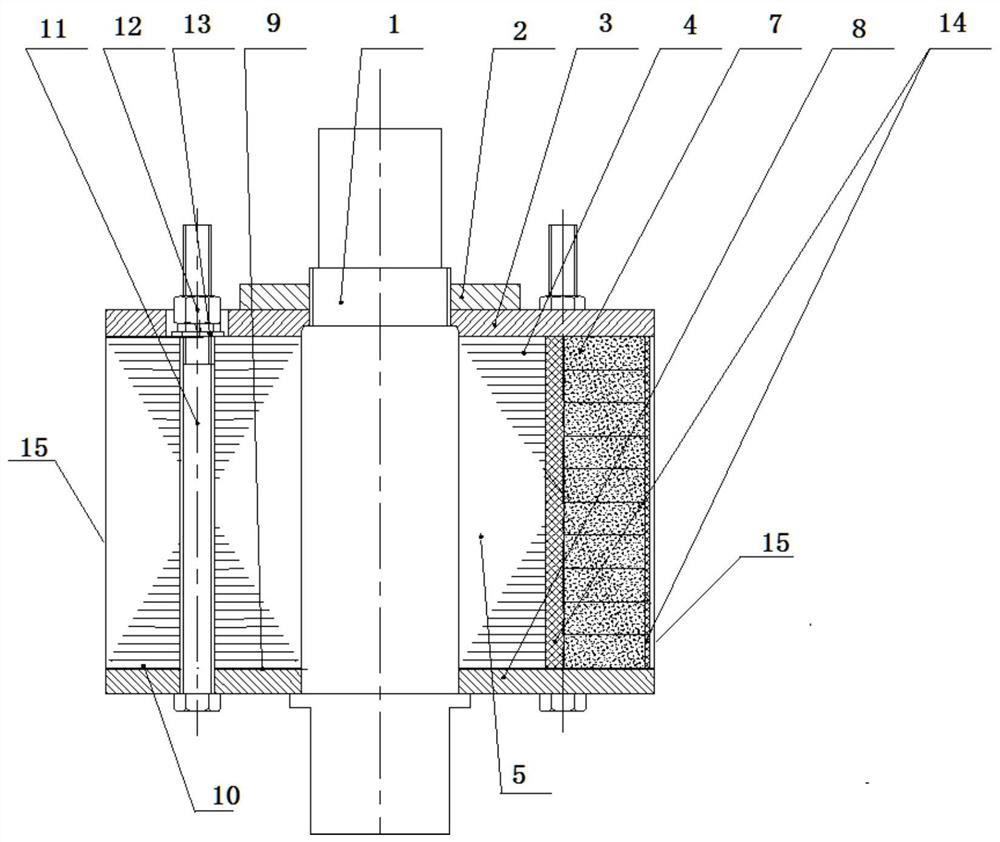

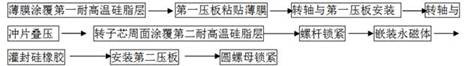

Manufacturing method of permanent magnet motor rotor

ActiveCN111371264AReduce gapAvoid churnManufacturing stator/rotor bodiesElectric machinePermanent magnet motor

The invention discloses a manufacturing method for a permanent magnet motor rotor. The method comprises the steps: coating a first surface of a polyimide film with a first high-temperature-resistant silicone grease layer, and adhering the second surface of the polyimide film on the surface of a first pressing plate to form a first assembly, or directly coating the surface of the first pressing plate with a Teflon coating to form the first assembly; sequentially sleeving the first assembly and a rotor punching sheet on a rotating shaft, then tightly pressing the first assembly and the rotor punching sheet to enable the rotor punching sheet to be laminated to form a rotor core, and then locking the rotor core and the first assembly; assembling a permanent magnet in the rotor core to obtain asemi-finished product, pouring a glue into the gap between the permanent magnet and the rotor punching sheet, and curing the pouring glue to obtain a workpiece; and installing a second pressing plateon the obtained workpiece, and locking the workpiece and the second pressing plate to obtain the permanent magnet motor rotor. The method is simple in technological process, easy to implement and lowin cost, and pouring sealant loss can be effectively prevented while high reliability of the rotor is guaranteed.

Owner:襄阳中车电机技术有限公司 +1

New energy automobile capacitor embedding tool

PendingCN110265234AReduce weightEasy to assembleEncapsulating capacitors apparatusNew energyEngineering

The invention discloses a new energy automobile capacitor embedding tool, which comprises supporting feet, a backboard, shell pressing plates, an electrode pressing plate and fasteners, wherein the backboard is supported by the supporting feet, and the backboard is obtained by engraving and milling a whole piece of cuboid-shaped aluminum plate; each shell pressing plate is L-shaped in upper cross section and composed of a fixing plate and a positioning plate, the positioning plate is arranged parallel to the backboard, the backboard and the shell pressing plates form a placement cavity therebetween, and the electrode pressing plate is a cuboid-shaped flat plate and fixed in front of the backboard by the fasteners. The backboard of the embedding tool is formed by engraving and milling an aluminum plate, and the weight is reduced by 60% or above compared with the commonly used iron tooling. When a capacitor is positioned by the new energy automobile capacitor embedding tool, a mounting seat of a capacitor shell is fixed in front of the backboard by the shell pressing plates, and an extraction electrode of the capacitor is fixed in front of the backboard by the electrode pressing plate; and the embedding tool is convenient to assemble and accurate in positioning, greatly improves the embedding efficiency and ensures the embedding quality.

Owner:CHANGZHOU CHANGJIE TECH

High-efficiency needle-free friction stir welding perfusion packaging process for porous microchannel aluminum heat pipes

ActiveCN112207417BImprove potting efficiencyImprove reliabilityNon-electric welding apparatusFriction weldingPumping vacuum

The invention belongs to the field of device packaging and heat dissipation, and relates to a high-efficiency needle-free friction stir welding pouring packaging process for porous microchannel aluminum heat pipes, including: using a vacuum device to vacuumize the inside of the microchannel aluminum heat pipes that have been sealed on one side; The working fluid is poured into the microchannel aluminum heat pipe through the perfusion device; the microchannel aluminum heat pipe is welded and sealed by the needle-free friction stir welding process; the cutting device is used to cut along the direction of the weld at the 1 / 2 position of the weld, and the microchannel aluminum The heat pipe unit perfusion encapsulation process ends. The present invention only needs 4 processes including one clamping-vacuumizing-perfusion and one needle-free friction stir welding sealing to realize the perfusion and packaging manufacturing of the micro-channel aluminum heat pipe unit, which greatly shortens the processing and manufacturing process, and has high reliability and low scrap rate Low cost, high production efficiency, high material utilization rate, low performance requirements for packaging equipment, long service life of needle-free stirring head, and green production process.

Owner:XI AN JIAOTONG UNIV

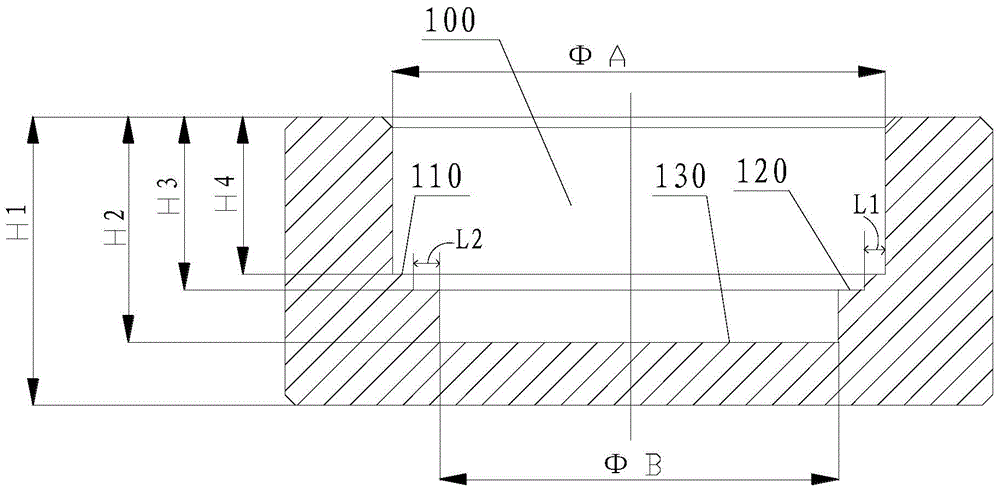

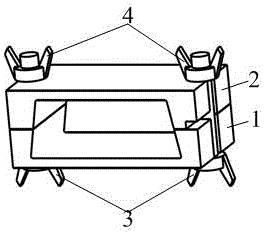

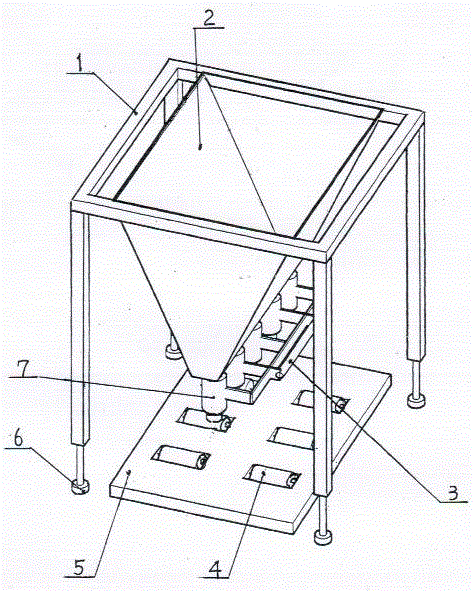

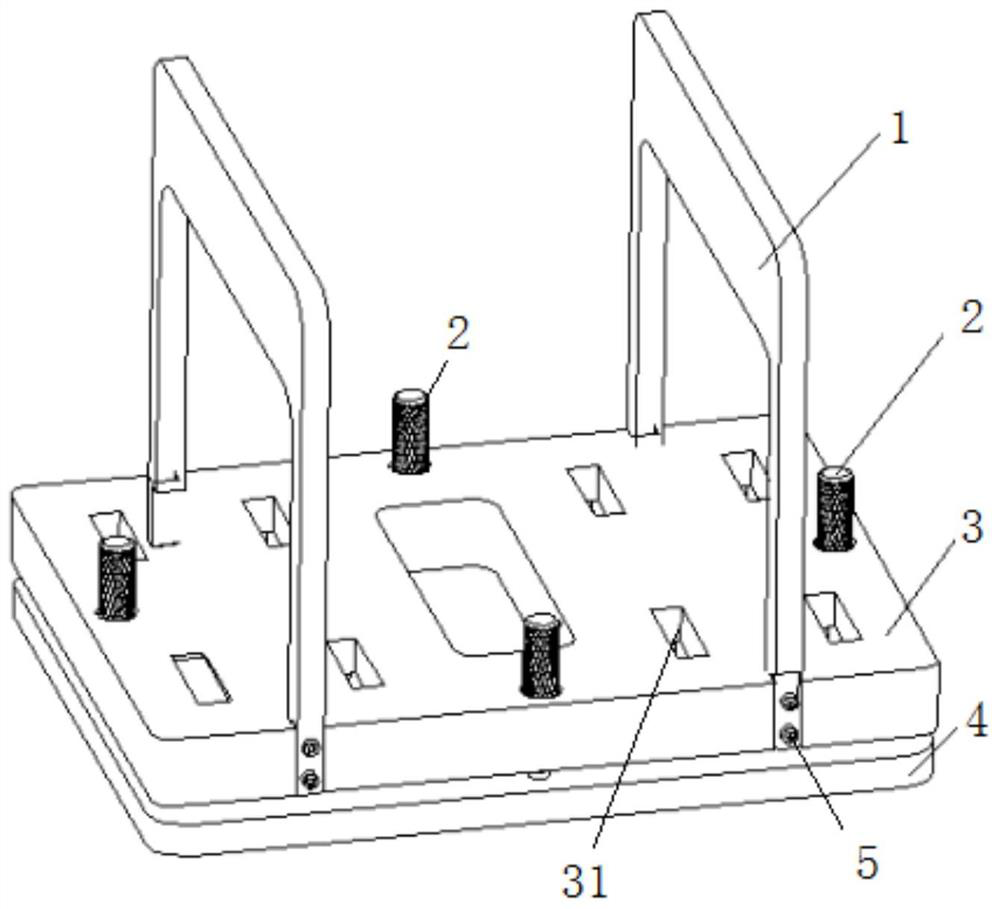

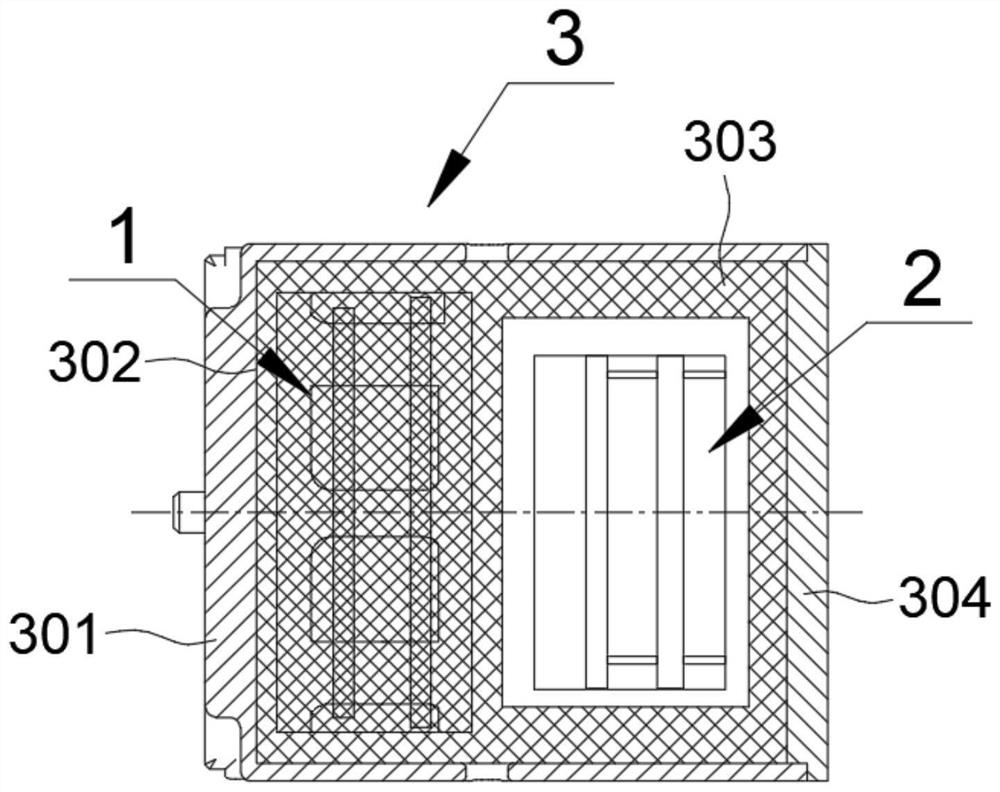

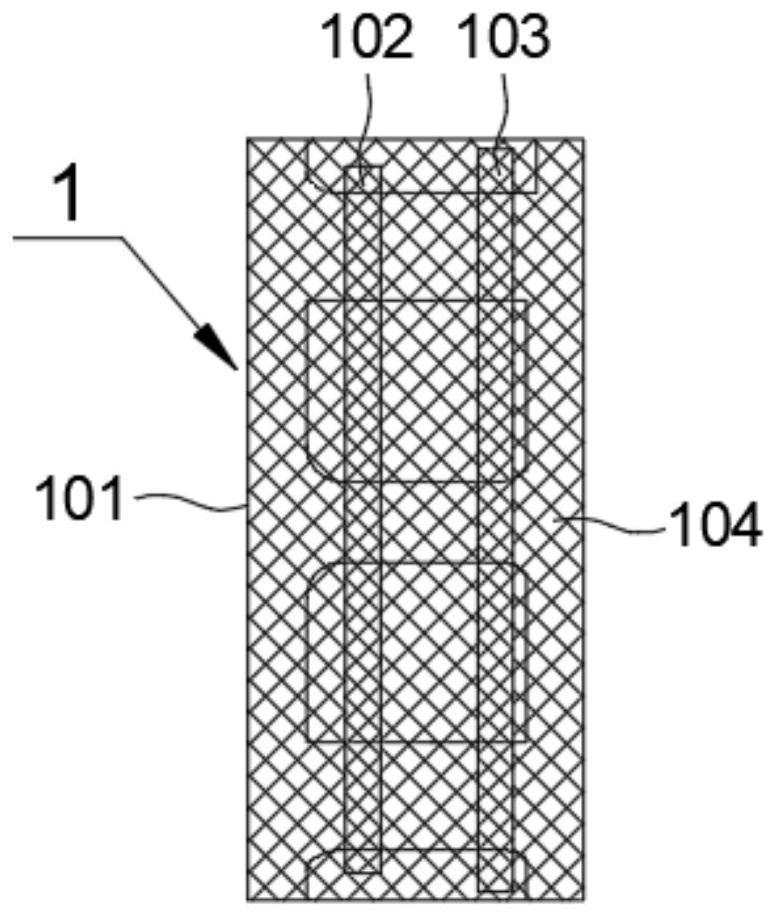

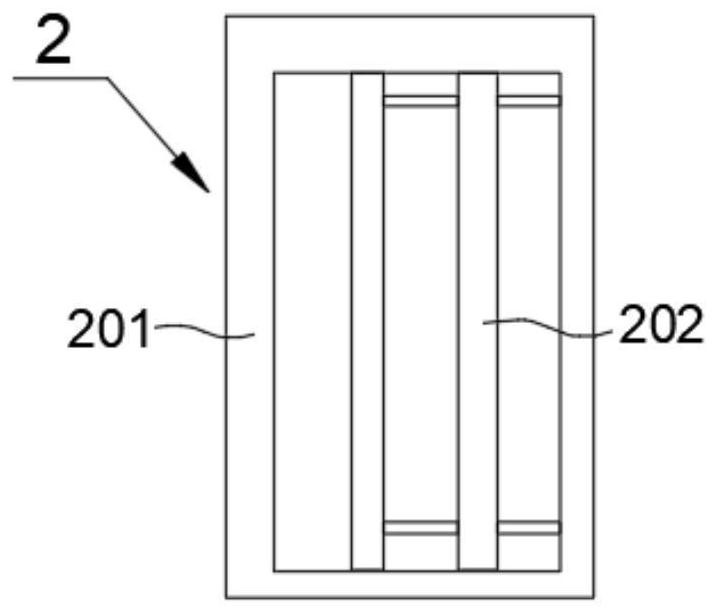

Capacitor embedding tool

InactiveCN106486299AFast pottingGuarantee the appearance qualityEncapsulating capacitors apparatusGround rollerElectronic component

The invention belongs to a production device of power and electronic components, especially to a capacitor embedding tool. The lower ends of four columns of a support (1) are provided with adjustable ground feet (6) respectively, an embedding charging basket (2) is fixedly mounted in the support (1), valves (7) are distributed uniformly in the lower end of the embedding charging basket (2), and are communicated with the embedding charging basket (2), a main valve (3) is arranged under the valves (7) in a communicated manner, a chassis (5) is mounted among the four adjustable ground feet (6) under the support (1), and ground rollers (4) are movably mounted on the chassis (5). The capacitor embedding tool is simple in structure and convenient to operate, can carry out embedding on the capacity rapidly, is free in the embedding process, saves materials, improves the embedding efficiency greatly, and ensures appearance and quality of the capacitor.

Owner:田丽芝

Hollow fiber membrane filter element potting mold and using method thereof

The present invention discloses a hollow fiber membrane filtration core potting mold and a use method thereof. The potting mold is made from a hydrophobic organic material and has advantages of simple structure, easy processing and easy use, wherein the hydrophobic organic material has a low surface energy so as to effectively reduce the adhesion between the potting glue and the potting mold, such that the potted and casted filtration core can be completely demolded, the demolding difficulty is reduced, the damage on the work-piece during the demolding process is avoided, and the potting efficiency is effectively improved. According to the use method of the potting mold, with the pre-treatment process on the potting mold, the demolding difficulty is further reduced, and the potting efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Filling and sealing glue for auxiliary gun probe and preparation method thereof

The invention provides filling and sealing glue for an auxiliary gun probe. The filling and sealing glue is prepared from the following components in percent by mass: 10-90wt% of high-aluminium fine powder, 5-40wt% of plate corundum, 10-50wt% of water glass and 0.5-10wt% of active-metal compound, wherein the active-metal compound is one or more of oxide, carbonate and chloride of active metal; theactive metal is one or more of zinc, aluminium, magnesium and calcium. The filling and sealing glue provided by the invention has the beneficial effects that water glass is used as a solvent, and theactive-metal compound is added, so that the use property of the filling and sealing glue is further improved; for the filling and sealing glue, the fluidity is lower, the initial setting time of curing is short, but the curing strength can reach 54MPa, the curing shrinkage is small and only 0.05%, the heat-shock stability is good and the highest resistable temperature is 1720 DEG C; no leakage iscaused, and the filling and sealing glue is cured without cracking after filling and sealing; the filling and sealing quality is high. The invention also provides a preparation method of the fillingand sealing glue for the auxiliary gun probe.

Owner:HUNAN RAMON SCI & TECH

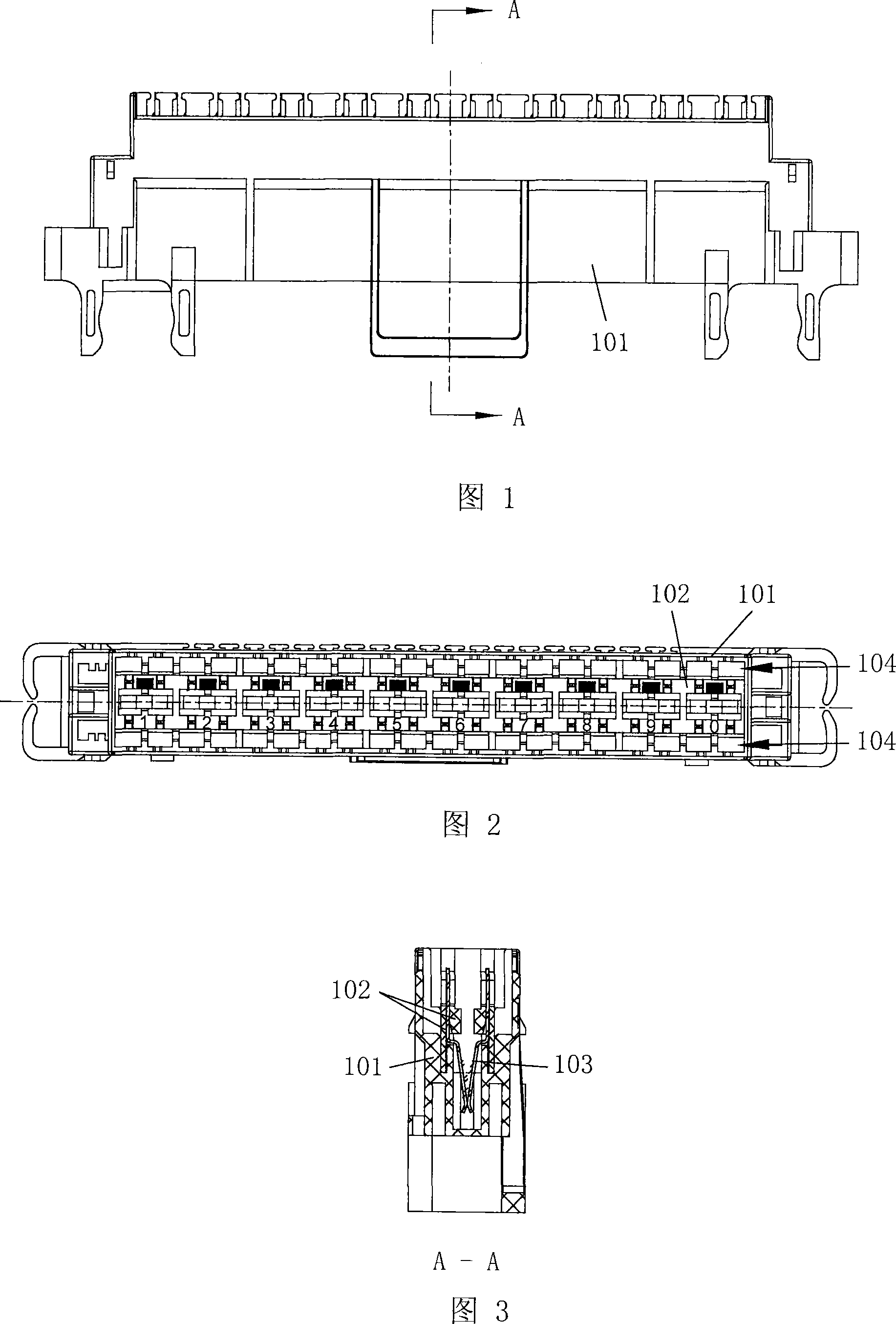

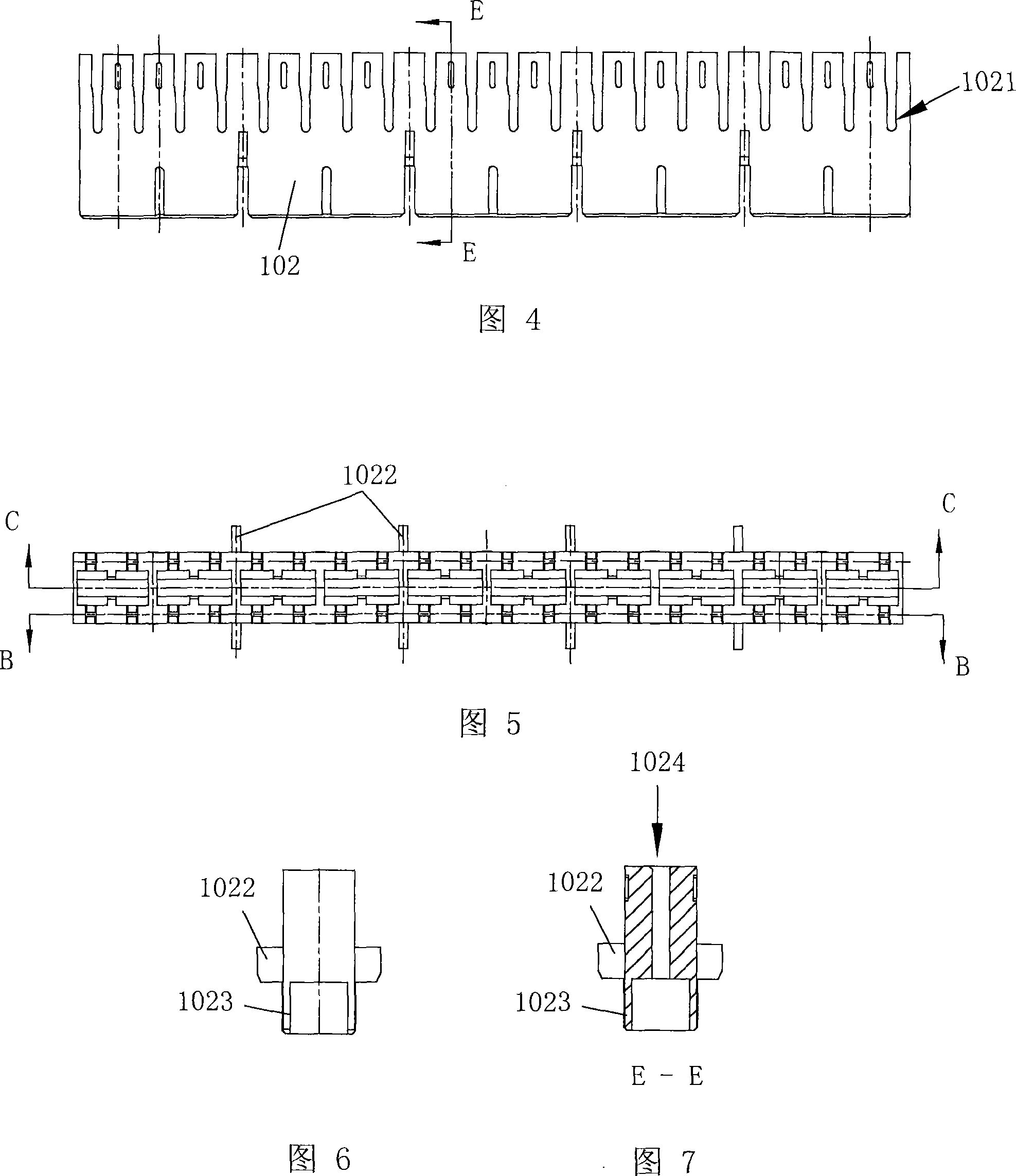

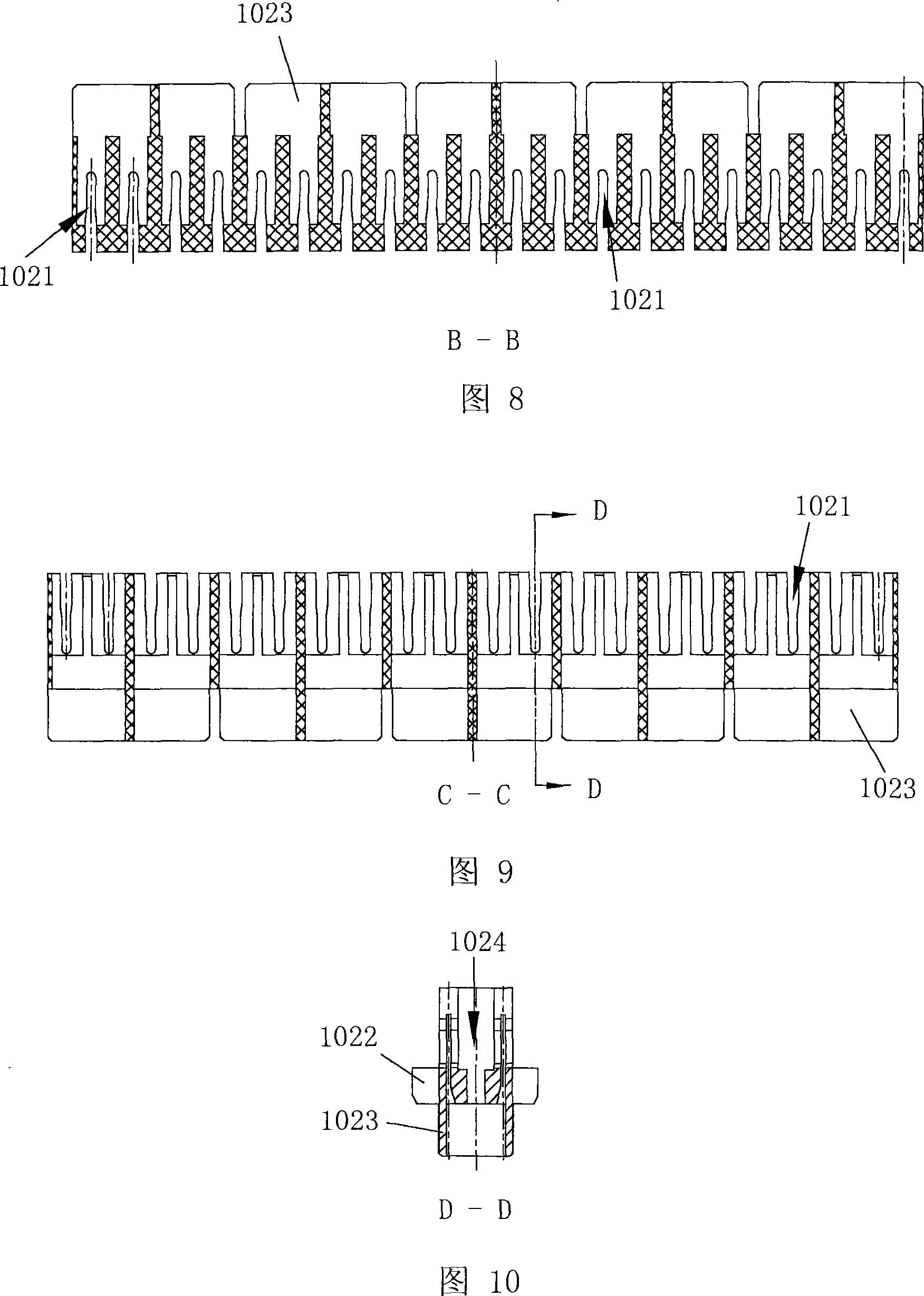

Distribution module

The invention relates to wire cable junction and wiring equipment in the telecommunication transmission field, in particular to a wiring module. The invention comprises a supporting rack, a terminal seat and a terminal piece, the terminal piece is arranged on the terminal seat; the supporting rack is provided with a groove, the groove is provided with an opening end, a bottom surface and a side wall, and a containing cavity is defined through the bottom surface and the side wall of the groove; the terminal seat is arranged in the groove of the supporting rack. The supporting rack is a plastic piece which is integrally molded, and the terminal piece is also the plastic piece which is integrally molded; a wire management opening is arranged at the top end of the side wall of the supporting rack, and a wire clamping opening is arranged at the top end of the terminal seat. The groove is strip-shaped, and only one terminal seat is arranged in the groove; a flute for containing anti-blushing agent is arranged at the bottom of the groove, the flute is positioned under the terminal seat in order that the fluid anti-blushing agent before solidifying flows in the groove. The invention provides the wiring module which has the advantages that the assembly is convenient, the wire bonding operation is convenient, and the pouring of the anti-blushing agent is highly effective.

Owner:SUS TELECOMM

A rectangular electrical connector potting equipment and potting method

ActiveCN111431005BSimplify the potting processImprove potting efficiencyDustproof/splashproof/drip-proof/waterproof/flameproof connectionElectrical connectionElectrical connector

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

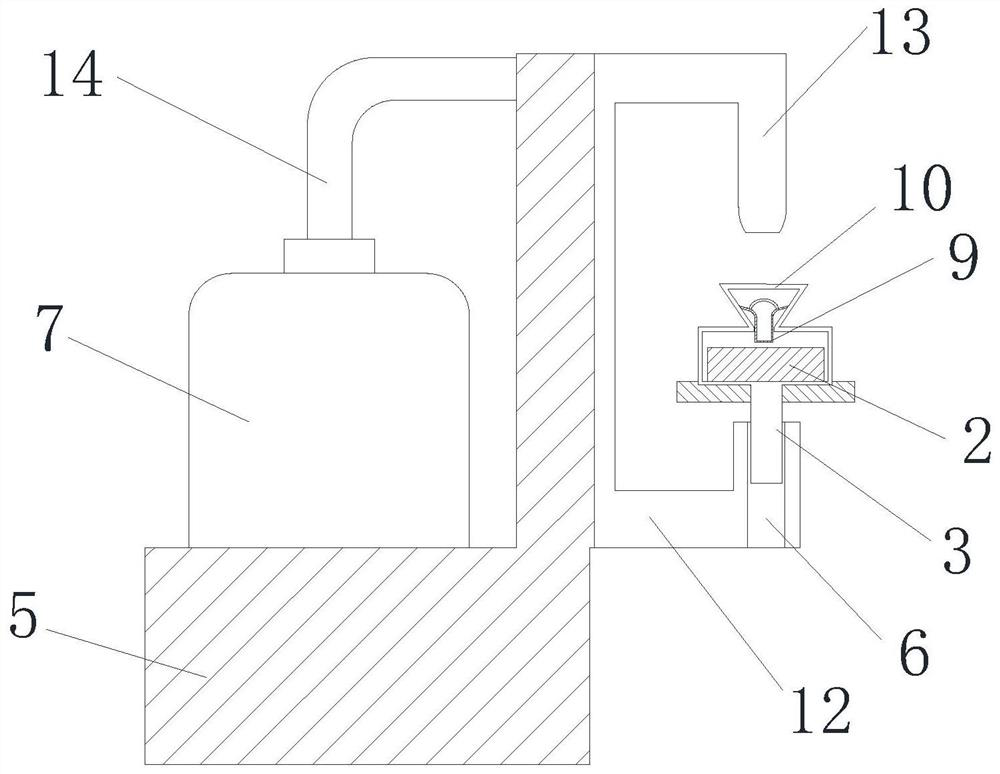

A transformer casing glue filling device and a glue filling method using the same

The invention discloses a transformer shell gluing device and a gluing method with the device. The device comprises a first embedment base and a second embedment base, wherein the first embedment base is detachably installed on the second embedment base and is provided with a plurality of channels in which transformer shells are embedded; the second embedment base is provided with a bump. When being embedded into the channels, the transformer shells are supported on the bump. The device is convenient to operate, and more transformer shells can be embedded within a short pouring sealant curing time, so that the gluing quality and efficiency of the transformer shells are improved, and members in the transformer shells are effectively protected. The invention further provides the gluing method with the device.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

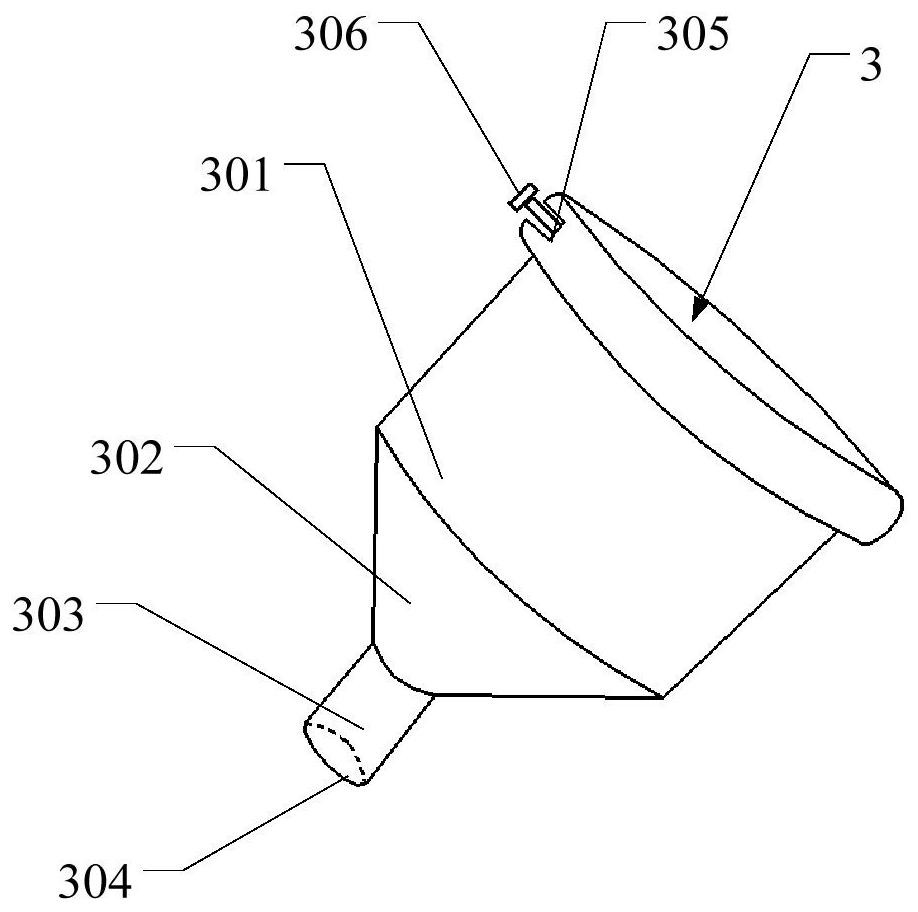

Potting device for electric connector

PendingCN112736616APotting realizationImprove potting efficiencyContact member cases/bases manufactureElectrical connectionEngineering

The invention discloses a potting device for an electric connector. The potting device comprises a glue solution injector and a hot air supply device; on the basis of the device, a glue solution can be heated through the hot air supply device to be converted into a flowing state, then the glue solution is injected into the glue solution injector, then the glue solution is injected into an electric connector base through the glue solution injector, and enough amount of glue solution is injected into the electric connector base. And then the hot air supply device is used for heating the glue solution in the electric connector base, so that the fluidity of the glue solution is enhanced, the electric connector base is quickly filled with the glue solution, and the potting of the electric connector is realized. on the basis of the device, the potting efficiency of the electric connector can be improved, the potting process is simple and easy to operate, the glue solution can be prevented from being bonded on an external wire of the electric connector in the potting process, and further the damage to the performance of the wire harness can be avoided.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

A new high-efficiency sealed wave energy generating device

ActiveCN108443051BImprove potting efficiencyIncrease speedHydro energy generationMachines/enginesWave power generationEngineering

The invention discloses a novel efficient sealing type wave power generation device. The device comprises three parts, namely, a generating body, an upper rotating body and a lower rotating body, wherein the upper rotating body and the generating body are coaxially arranged; and the upper rotating body and the lower rotating body form a rotating pair. The device has the advantages that a gum flowing groove is formed, and all magnet grooves in a shaft can be conveniently potted through a counterbore hole, and thus the potting efficiency is technically improved; the upper rotating body and the lower rotating body swing wing plates up and down and regularly circumferentially move in opposite directions, so that the rotating speed is increased, and the power generation efficiency is improved;magnets and coils are all sealed into potting gum when the device generates power, so that the sealing performance is high, and the service life is long; in addition, the mounting and maintaining costis low; the energy utilization efficiency is high; the structure is simple; and the integrated ideal is easily achieved.

Owner:TIANJIN POLYTECHNIC UNIV

A film capacitor potting device

ActiveCN110277245BImprove goodnessReduce leakageLiquid surface applicatorsFixed capacitor dielectricFilm capacitorIndustrial engineering

The invention discloses a film capacitor potting device, which includes a preheating furnace, a limit baffle, a curing furnace and a lower rubber hose. A conveying platform is arranged in the middle of the preheating furnace, and a capacitor fixing seat, a limiting rod is arranged under the capacitor fixing seat, and a capacitor body is arranged in the middle of the capacitor fixing seat. The invention adjusts the alignment of the capacitor by setting the sliding bracket and the limit baffle, improves the quality of the potting of the capacitor, reduces the situation that the potting glue leaks to the capacitor shell due to lack of alignment, and the potting effect is poor, and the device The structure is simple, no manual operation is required, and the degree of automation is high; by setting an open protective plate and a rotating thin tube above the fixing device, the lower rubber hose does not need to be set too thin, reducing the blockage of the lower rubber hose, and the rotating thin tube is easy to disassemble and can be cleaned in time and replacement, saving the time for maintenance of the potting device and improving potting efficiency.

Owner:宿迁华虹电子工业有限公司

A method of manufacturing a permanent magnet motor rotor

ActiveCN111371264BReduce gapAvoid churnManufacturing stator/rotor bodiesElectric machineryPermanent magnet motor

Owner:襄阳中车电机技术有限公司 +1

Filling and sealing process of motor stator core

InactiveCN102280975BImprove potting efficiencyEasy to remove the moldManufacturing stator/rotor bodiesEpoxyEngineering

The invention provides a filling and sealing process of a motor stator core. The filling and sealing process comprises the following steps of: (1) preparing a filling and sealing material; (2) arranging an upper die filling and sealing die and a lower die filling and sealing die on a motor stator and positioning; (3) injecting the prepared filling and sealing material from an upper die plate; and (4) curing at 75-85 DEG C for 20-40 percent. The filling and sealing material is prepared from the following raw materials, such as epoxy resin, a diluting agent, a curing agent, a flexibilizer, silicon micropowder, and the like according to certain proportions. Compared with the prior art, the invention has the advantages that the filling and sealing time is greatly shortened, the operation is convenient, the filing and sealing efficiency of a motor is effectively improved, and energy consumption is saved; the stator has high surface finish quality and good insulation and waterproofing property; meanwhile, the mechanical property of the motor is improved, and the running stability of the motor is better ensured.

Owner:NANJING GAOQI ELECTRIC

Silica gel preparation method

InactiveCN102641698BHigh quality consistencyGood defoaming effectColloidal chemistry detailsEngineeringSilica gel

The invention provides a silica gel preparation method which comprises the following steps of: respectively placing more than two aged raw material components for preparing silica gel in barrels of a stirring mechanism, maintaining in the vacuum state and respectively intermittently stirring the raw material components of the silica gel for foam discharging; arranging discharging holes in the barrels, communicating with transporting pipelines through transporting pumps, connecting the transporting pipelines with filling and sealing openings of the raw material components, arranging reflow pipelines capable of being closed between the filling and sealing openings and the transporting pumps, and sending the raw material components subjected to the foam discharging into respective transporting pipelines; and closing the filling and sealing openings of the transporting pipelines, and enabling the raw material components to return to the barrels through reflow pipelines to form reflow, and controlling the reflow states of the materials until the whole transporting pipelines of all components are in the vacuum state. The preparation method meets the requirements of an IGBT (Insulated Gate Bipolar Transistor) module for consistency and reliability of products produced massively and in batches.

Owner:XIAN YONGDIAN ELECTRIC

A potting jig for an electric toothbrush and a potting method for an electric toothbrush

ActiveCN106733426BImprove waterproof performanceImprove seismic performanceLiquid surface applicatorsCoatingsElectrical and Electronics engineeringPower toothbrush

The invention provides an encapsulating clamp for electric toothbrushes and an encapsulating method for the electric toothbrushes. The encapsulating clamp for the electric toothbrushes comprises an upper cover and a base; upper encapsulating grooves are formed in the upper cover; glue pouring ports are formed in the bottoms of the upper encapsulating grooves; lower encapsulating grooves are formed in the base; when the base and the upper cover are closed, the upper encapsulating grooves and the lower encapsulating grooves form encapsulating cavities used for encapsulating the electric toothbrushes; and a positioning hole is formed in one end of each encapsulating cavity. According to the encapsulating clamp for the electric toothbrushes and the encapsulating method for the electric toothbrushes, the upper encapsulating grooves and the lower encapsulating grooves of the encapsulating clamp for the electric toothbrushes are matched to form the encapsulating cavities, a worker puts electric toothbrush bodies to be encapsulated into the encapsulating cavities, glue is poured through the glue ports, and therefore the electric toothbrush bodies can be conveniently and quickly encapsulated, and independent encapsulating operation on a plurality of electric toothbrushes can be realized.

Owner:SHENZHEN JOINTRONIC TECH CO LTD

Data chain device suitable for high overload impact environment, and potting method thereof

PendingCN114007358AImprove performanceImprove the ability to resist high overloadCircuit arrangements on support structuresCasings/cabinets/drawers detailsAdhesiveProcess engineering

The invention discloses a data chain device suitable for a high overload impact environment, and a potting method thereof, and belongs to the technical field of high overload protection. By using the corresponding arrangement of a high-frequency module and a low-frequency module are correspondingly arranged, potting all parts in the low-frequency module in a first inner shell through a first potting adhesive and potting the low-frequency module and the high-frequency module in a middle shell through a second potting adhesive, the data link device which is good in integrity and resistant to high overload impact can be formed. According to the data chain device suitable for the high overload impact environment, energy generated when high overload impact occurs can be absorbed through deformation and damage of potting materials with different densities, and the purposes of reducing the impact pulse peak value and widening the impact pulse time are achieved, it is ensured that the data chain device can bear multiple times of high overload impact when applied in a severe environment, damage to internal components of the device due to the high overload impact effect is reduced, stability and reliability of device setting and application are fully ensured, and the data chain device has good application prospects and popularization value.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com