Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Form is therefore complex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

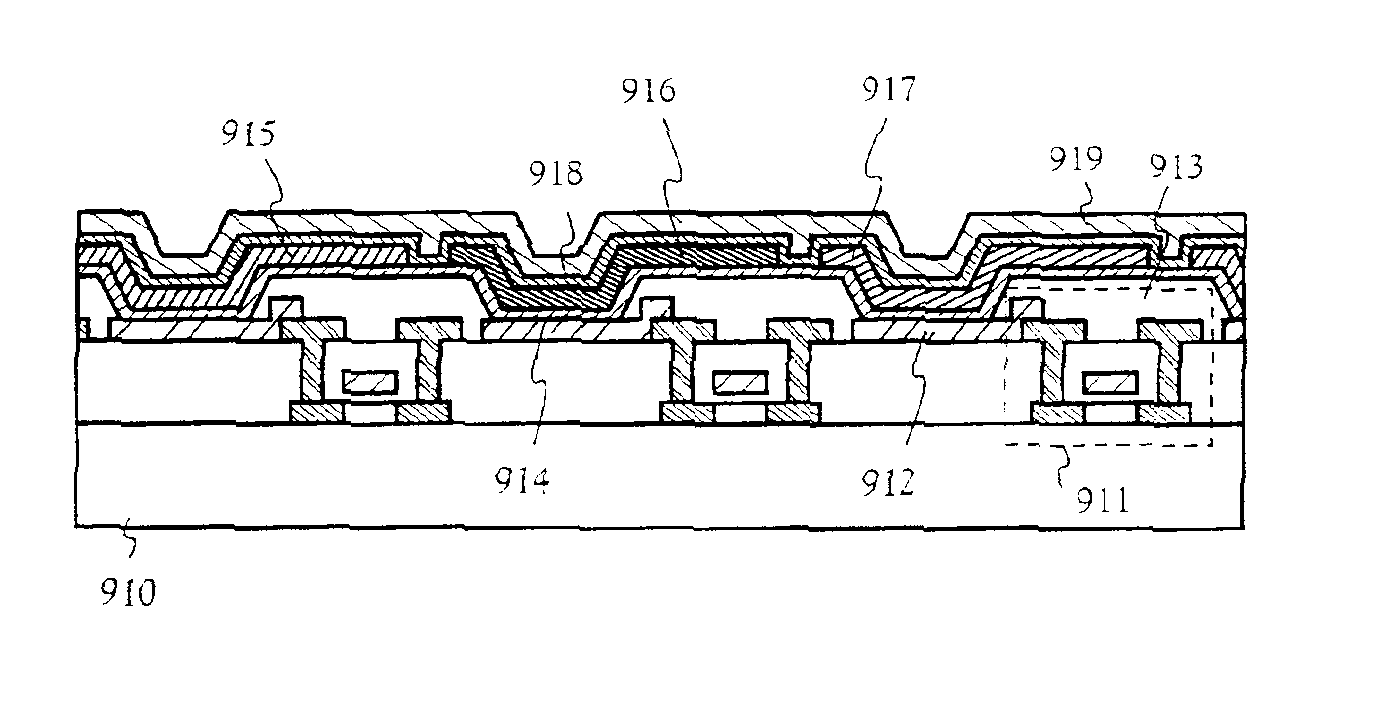

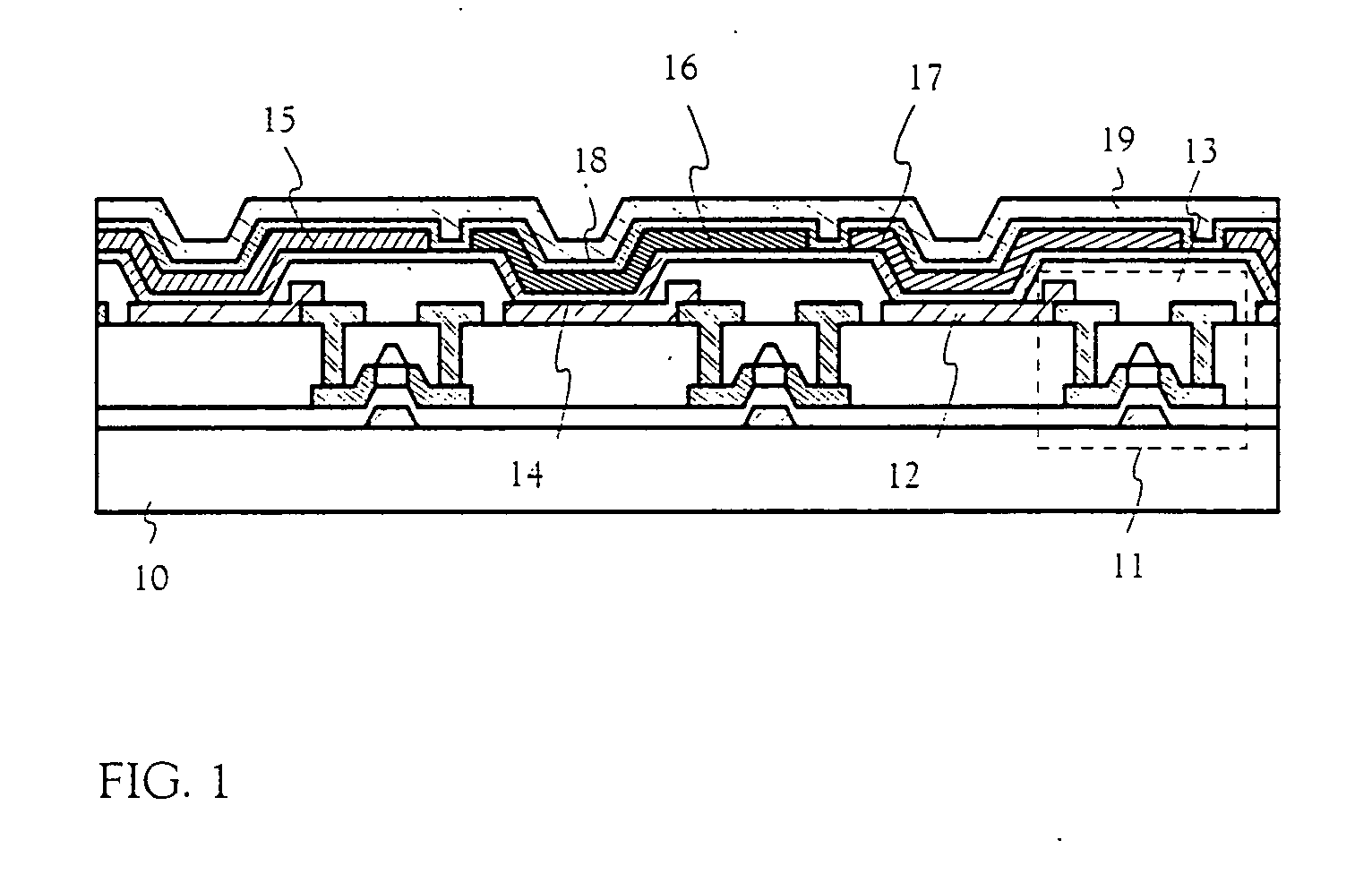

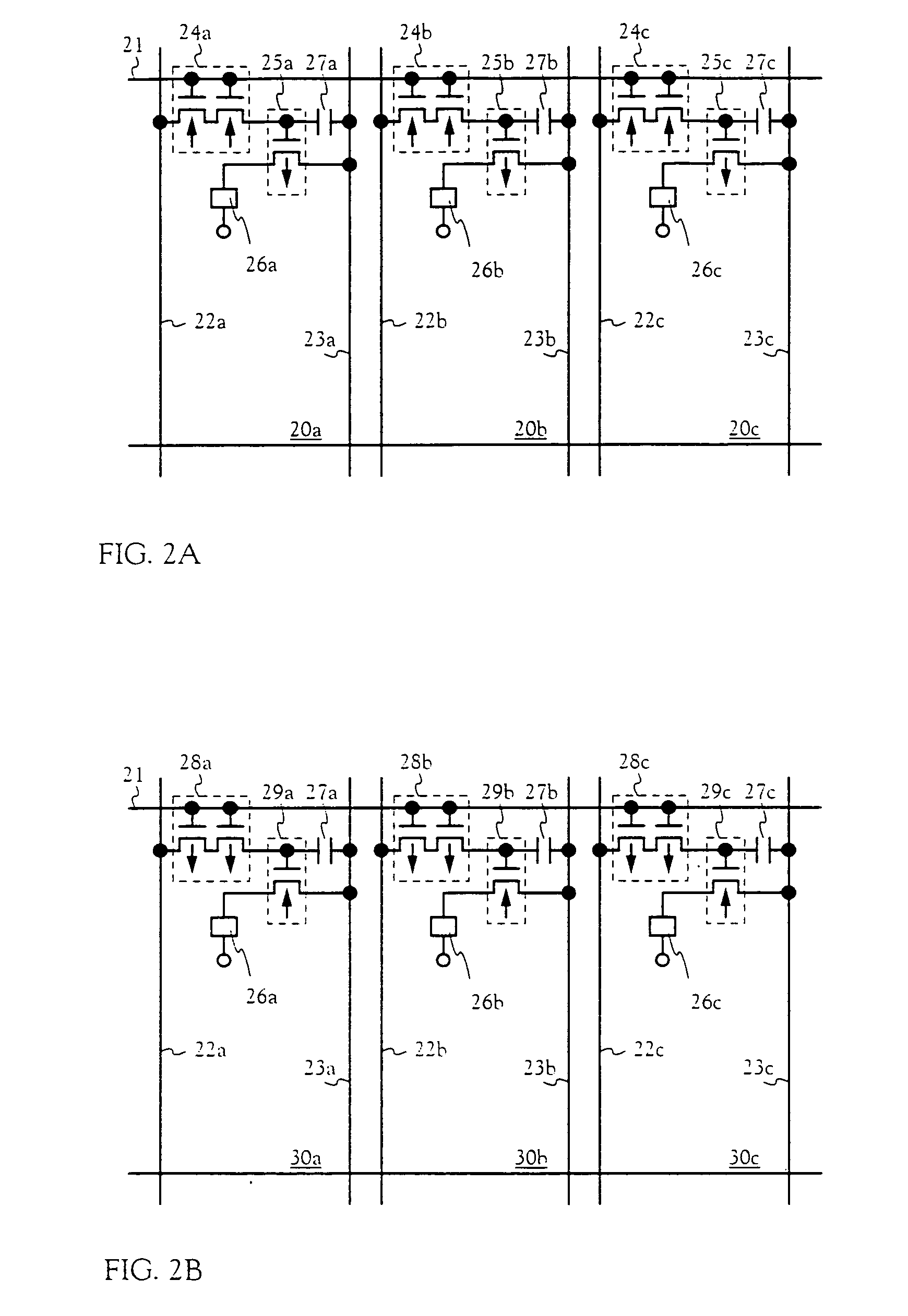

Light-emitting device having triplet and singlet compound in light-emitting layers

InactiveUS7339317B2Improve color balanceImprove image qualityDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceTriplet state

There is provided a light emitting device which enables a color display with good color balance. A triplet compound is used for a light emitting layer of an EL element that emits red color, and a singlet compound is used for a light emitting layer of an EL element that emits green color and a light emitting layer of an EL element that emits blue color. Thus, an operation voltage of the EL element emitting red color may be made the same as the EL element emitting green color and the EL element emitting blue color. Accordingly, the color display with good color balance can be realized.

Owner:SEMICON ENERGY LAB CO LTD

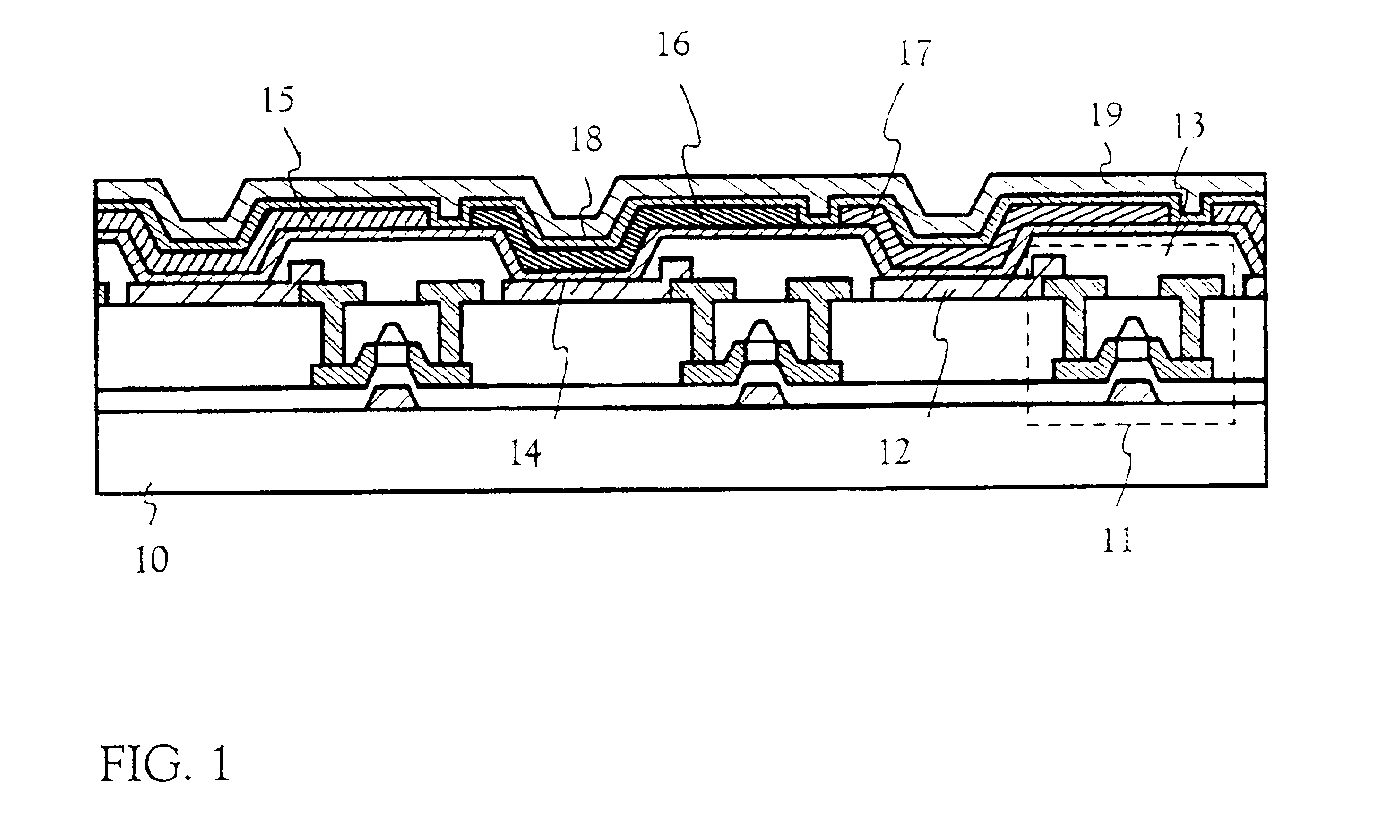

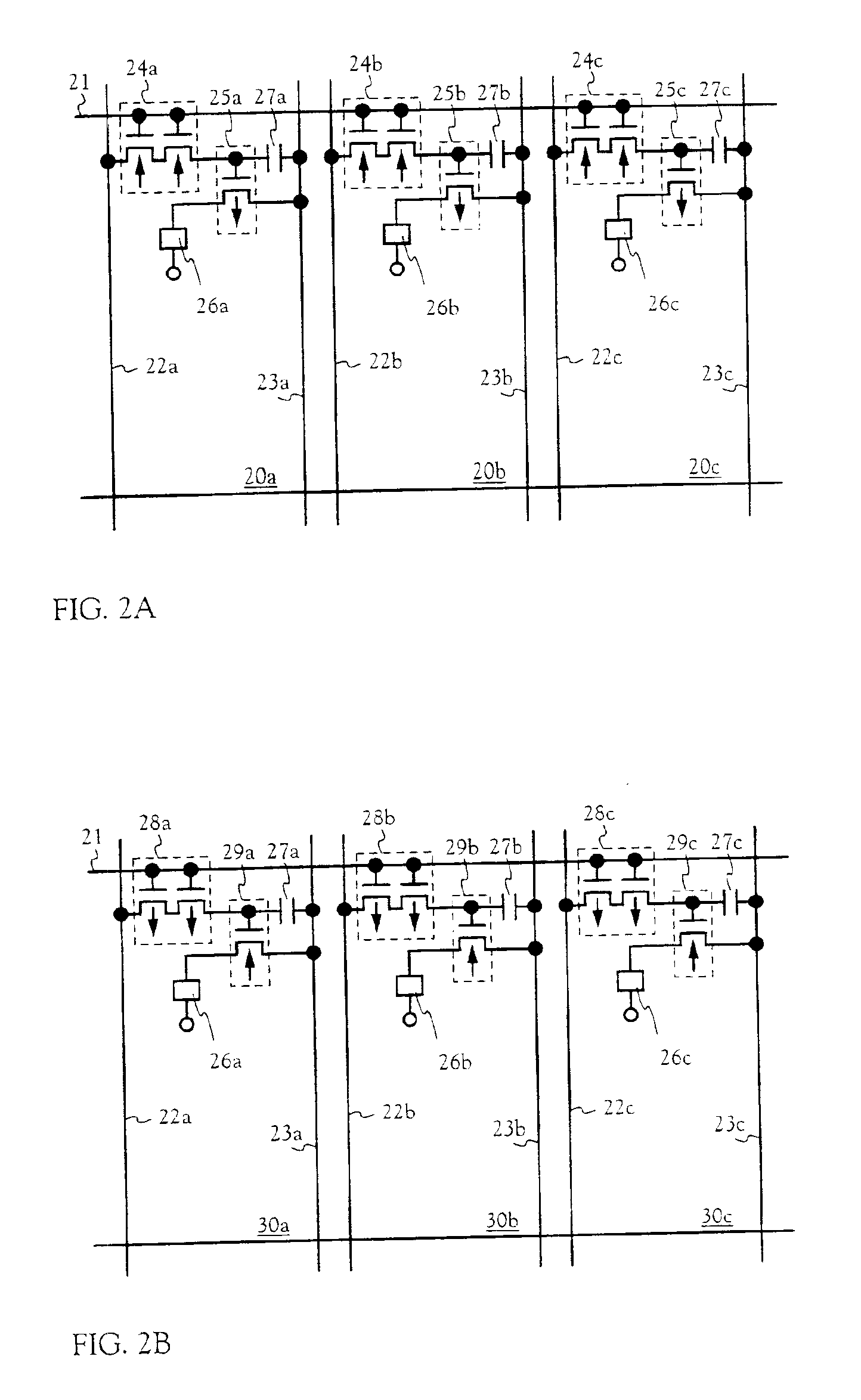

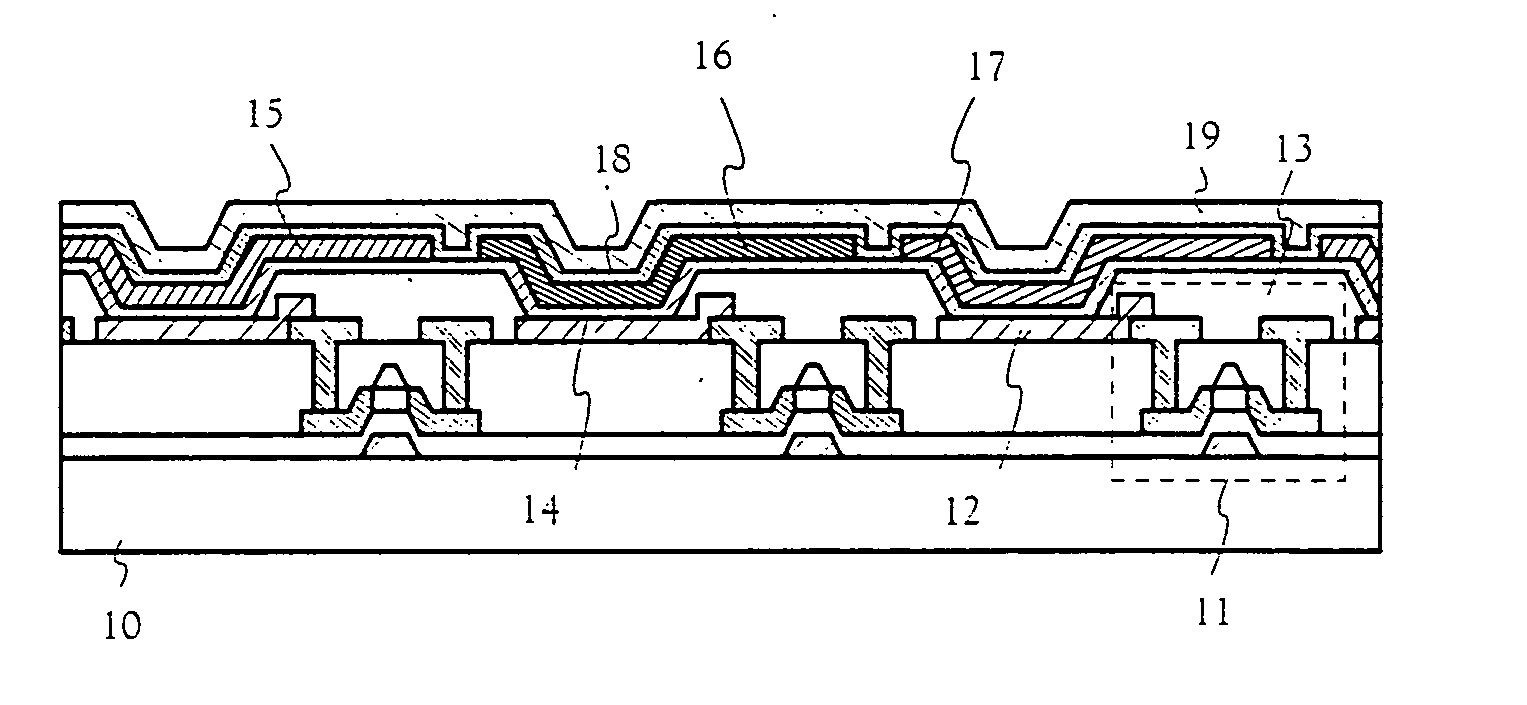

Light emitting device

InactiveUS20050233170A1Improve color balanceImprove image qualityDischarge tube luminescnet screensElectroluminescent light sourcesLight emitting deviceOperating voltage

There is provided a light emitting device which enables a color display with good color balance. A triplet compound is used for a light emitting layer of an EL element that emits red color, and a singlet compound is used for a light emitting layer of an EL element that emits green color and a light emitting layer of an EL element that emits blue color. Thus, an operation voltage of the EL element emitting red color may be made the same as the EL element emitting green color and the EL element emitting blue color. Accordingly, the color display with good color balance can be realized.

Owner:SEMICON ENERGY LAB CO LTD

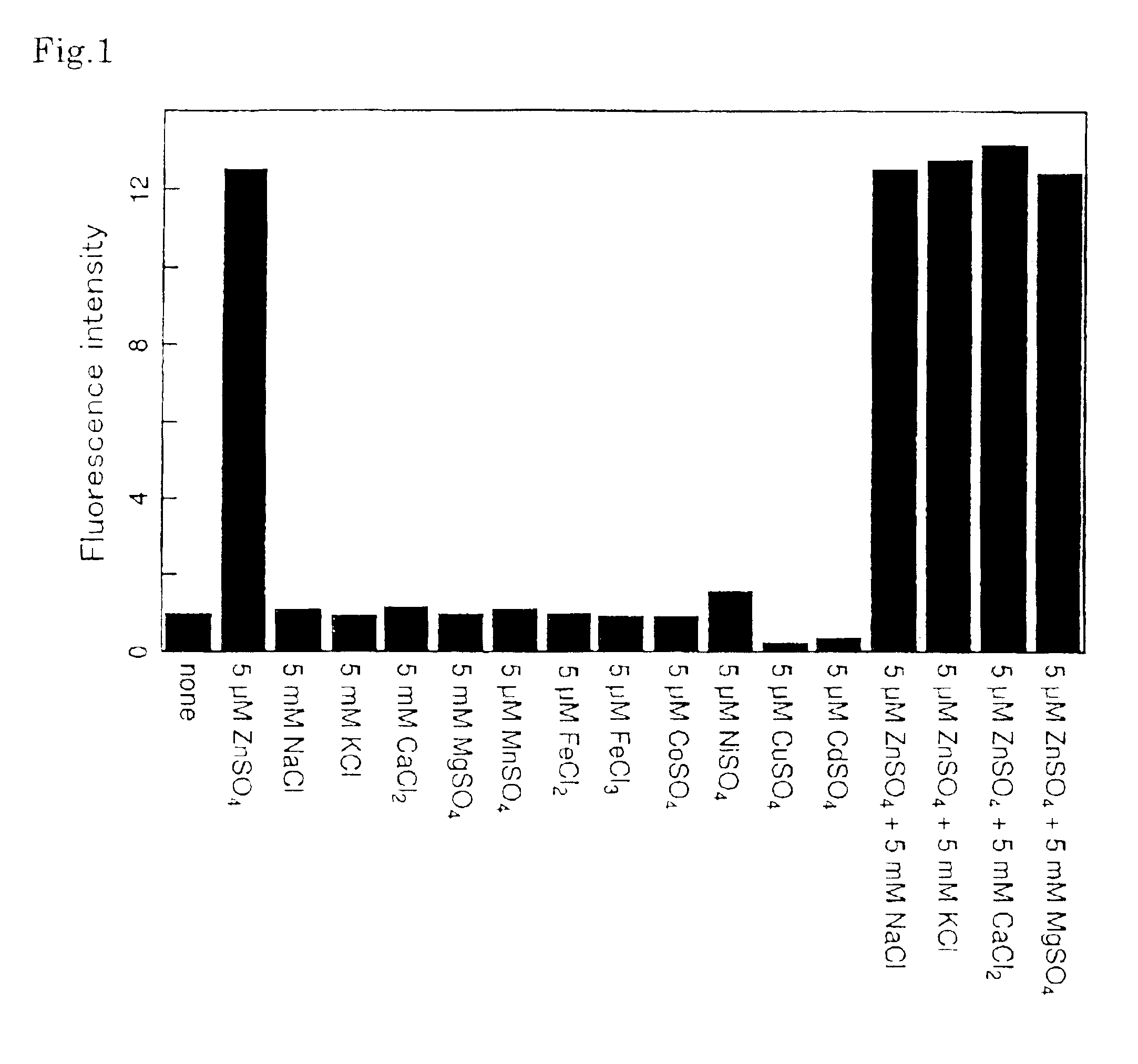

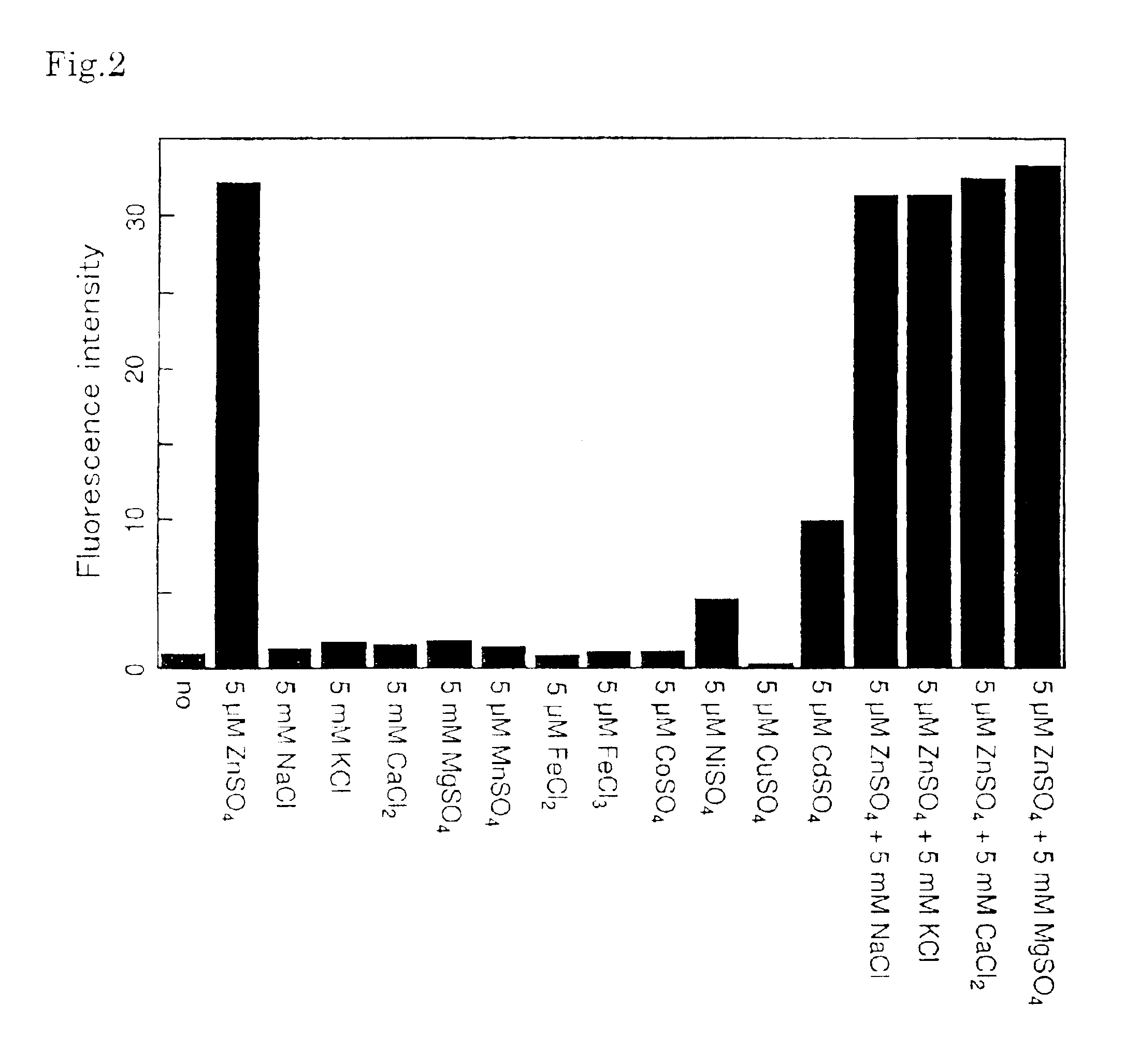

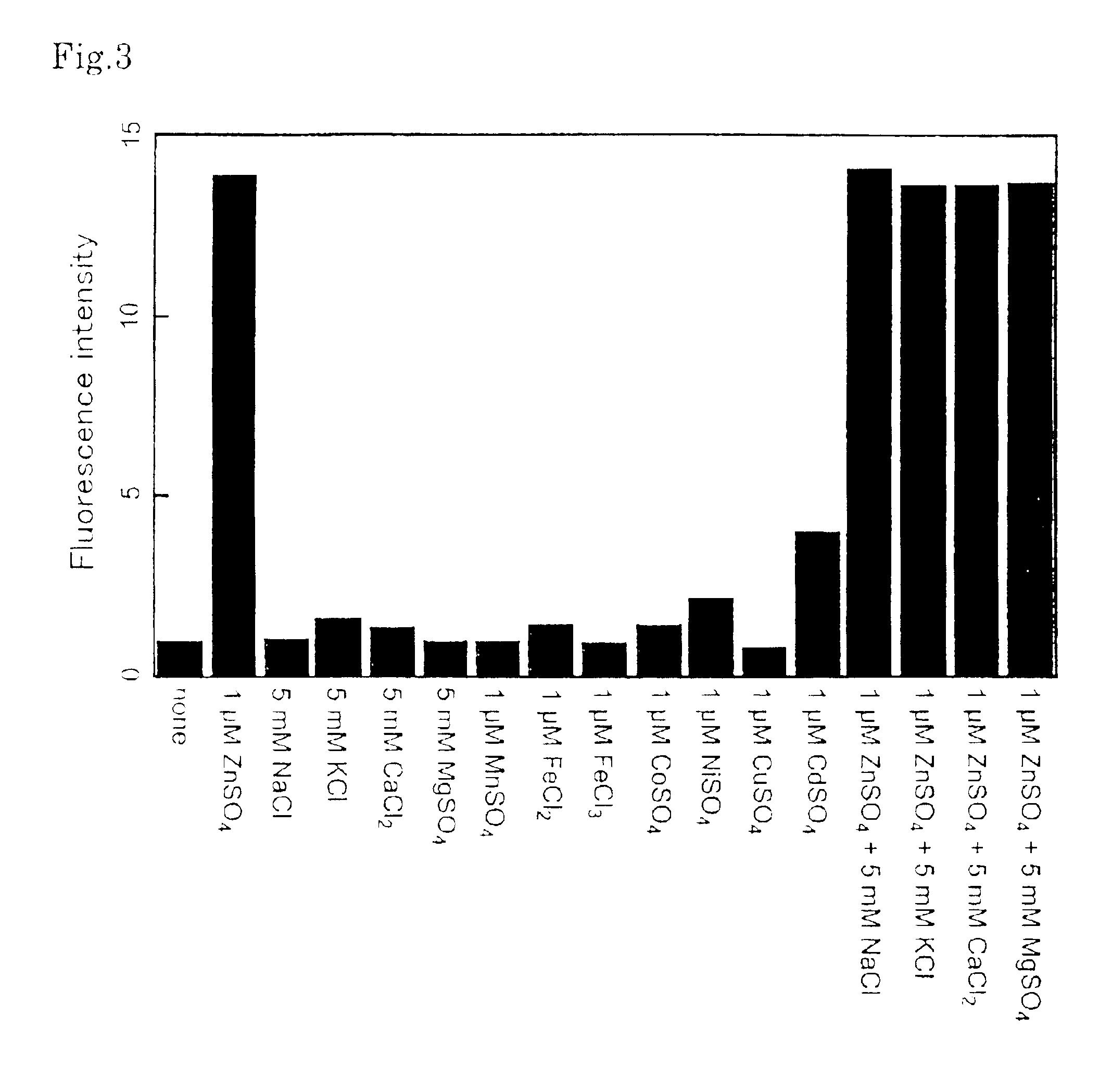

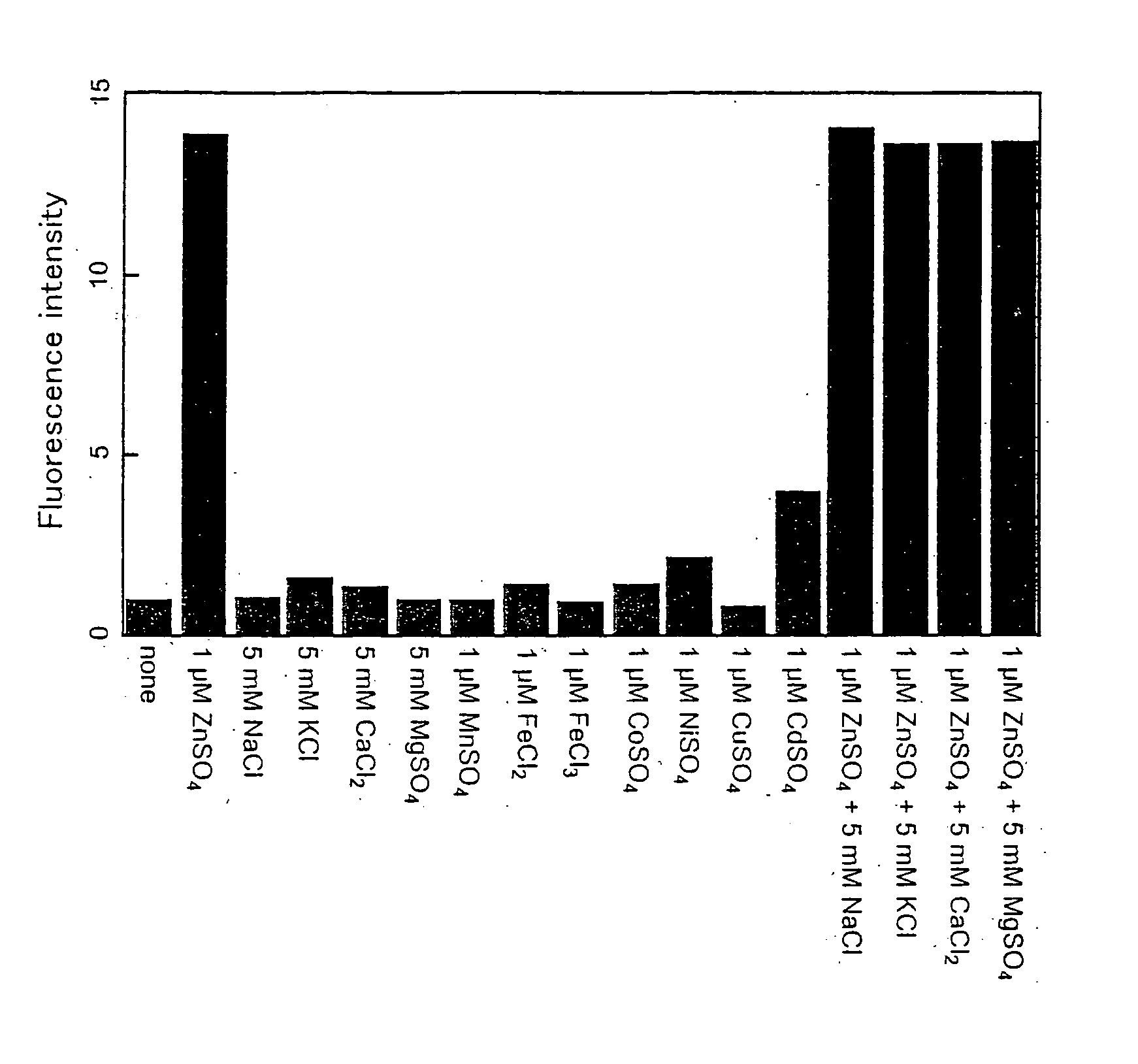

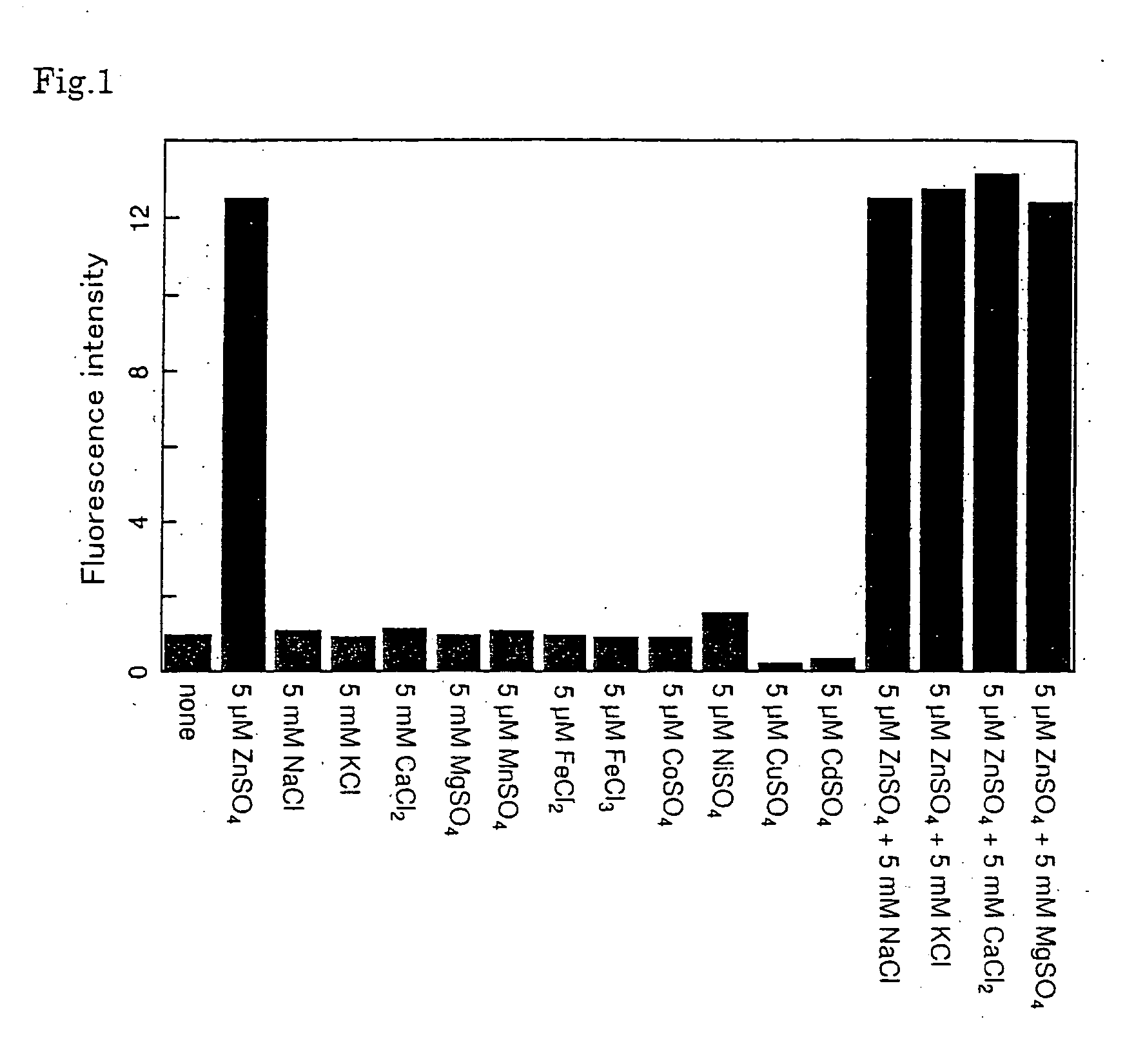

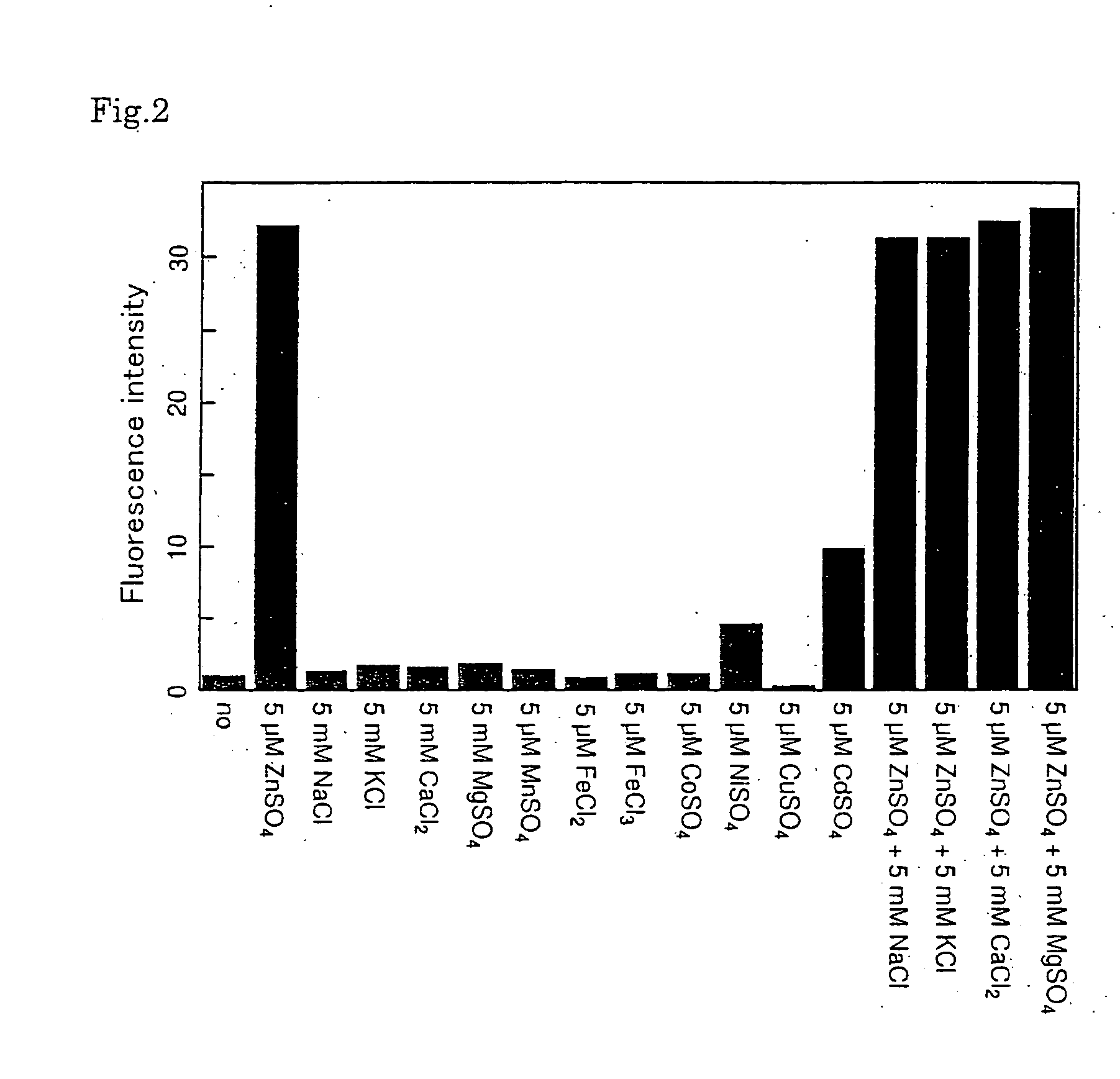

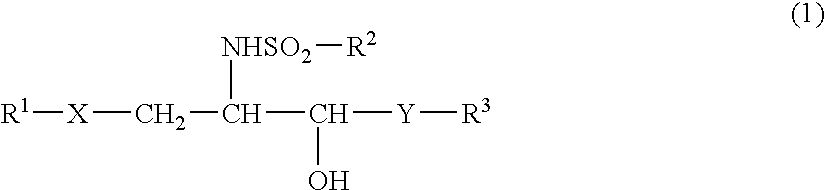

Fluorescent probe for the quantitation of zinc

InactiveUS6903226B2Strong specificityStrong fluorescencePyronine/xanthon/thioxanthon/selenoxanthan/telluroxanthan dyesDiaryl/thriaryl methane dyesFluoProbesChemical compound

A compound represented by general formula (IA) or a salt thereof useful as a fluorescent probe for zinc: wherein R1 and R2 represent a hydrogen atom or a group represented by formula (A), wherein X1, X2, X3, and X4 represent a hydrogen atom, an alkyl group, a 2-pyridylmethyl group, or a protective group for an amino group, and m and n represent 0 or 1 provided that R1 and R2 do not simultaneously represent hydrogen atoms; R3 and R4 represent a hydrogen atom or a halogen atom; and R5 and R6 represent a hydrogen atom, an alkylcarbonyl group, or an alkylcarbonyloxymethyl group, and R7 represents a hydrogen atom or an alkyl group.

Owner:NAGANO +1

Metal-ligand catalyst formation

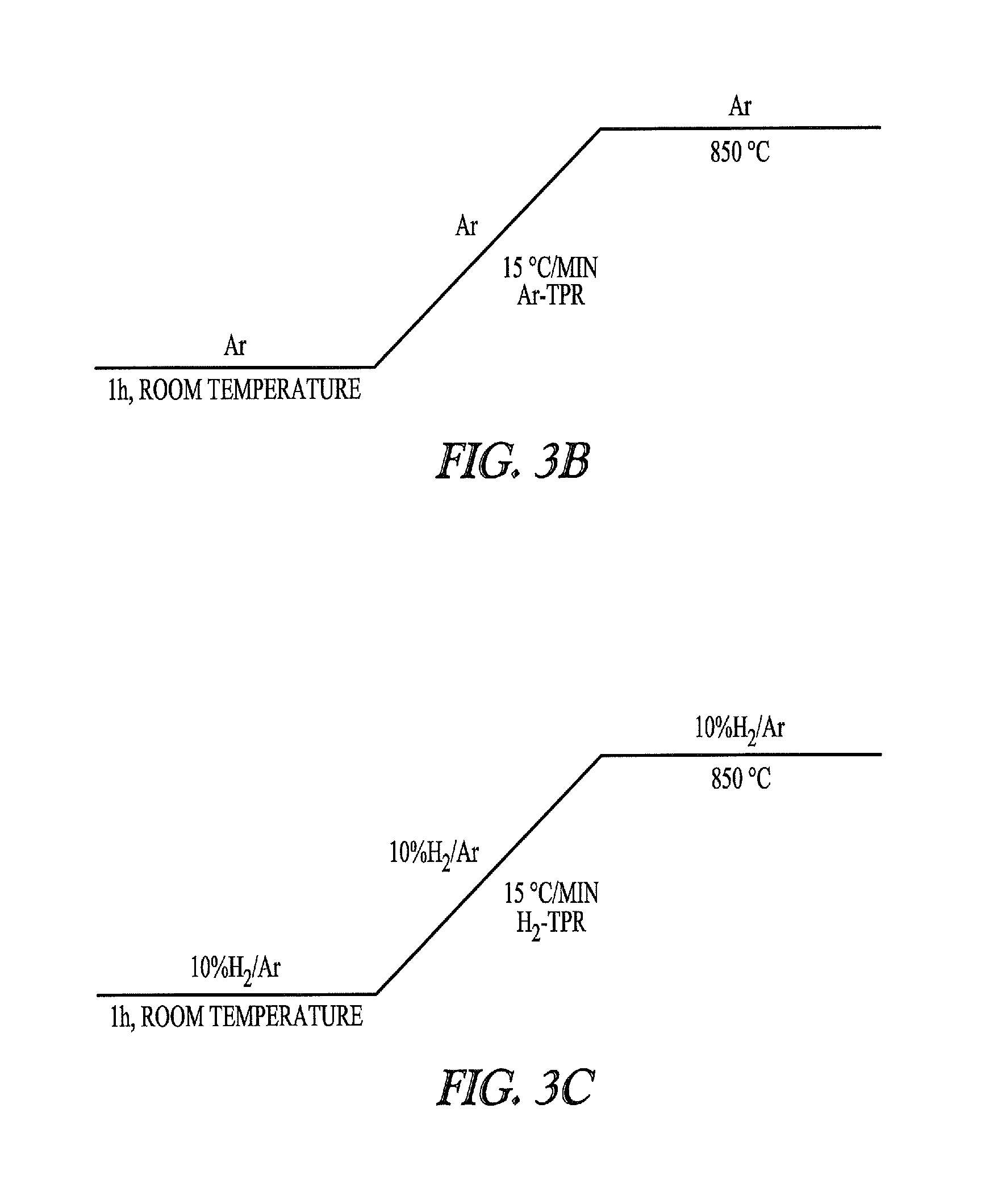

ActiveUS20130143730A1Excellent complex formation propertyForm is therefore complexOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsSulfurMetallic Nickel

As described herein, nickel treated with sulfur provides a surprisingly effective source of nickel atoms for generating nickel-phosphorus-containing ligand complexes useful as hydrocyanation catalysts.

Owner:INV NYLON CHEM AMERICAS LLC

Oral care products comprising a tetrabasic zinc-amino acid-halide complex

ActiveUS20150328111A1Limited amountForm is therefore complexCosmetic preparationsToilet preparationsDentistryZinc

Described herein are oral care compositions comprising a tetrabasic zinc halide and an amino acid; along with methods of making and using the same.

Owner:COLGATE PALMOLIVE CO

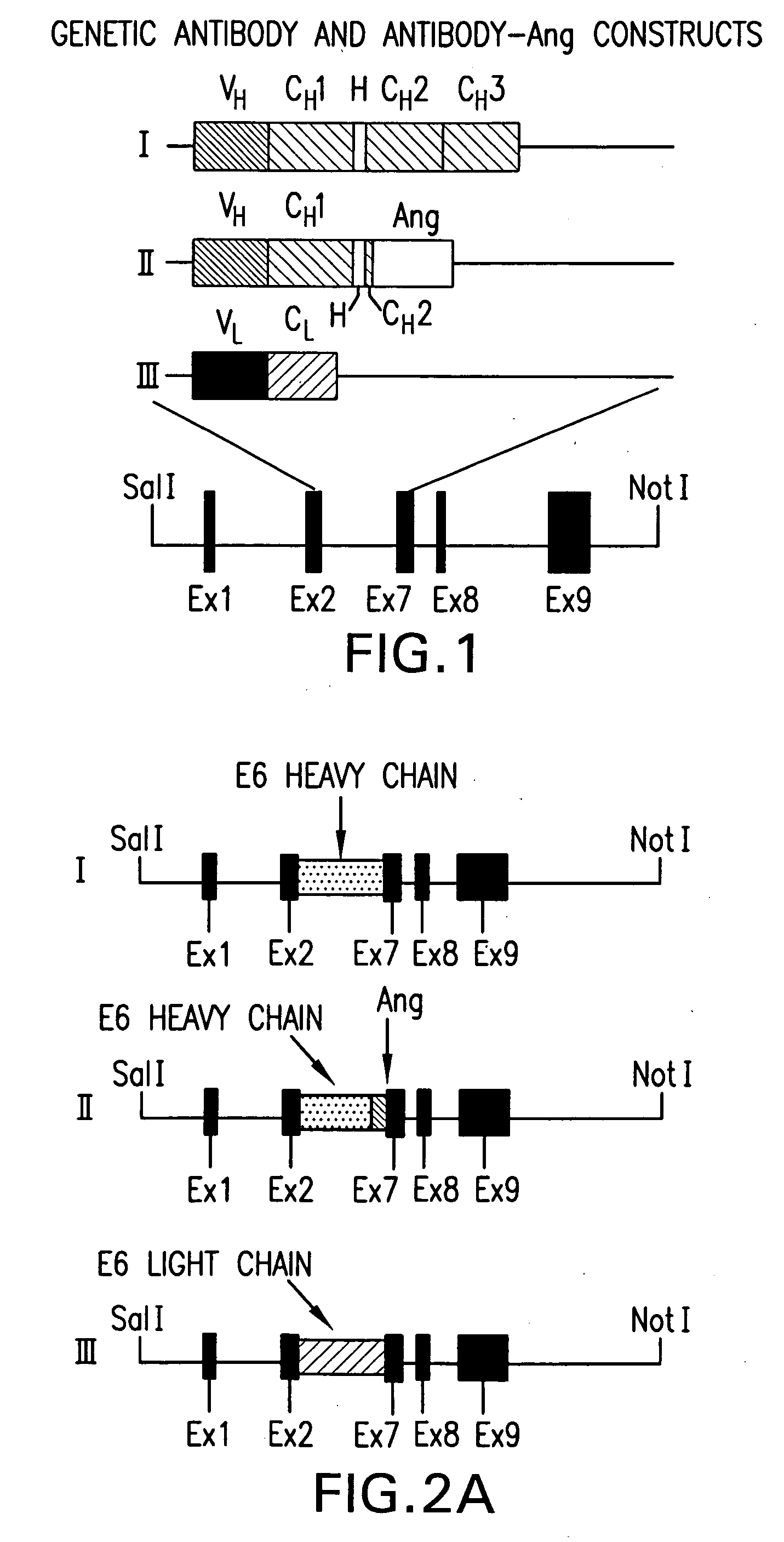

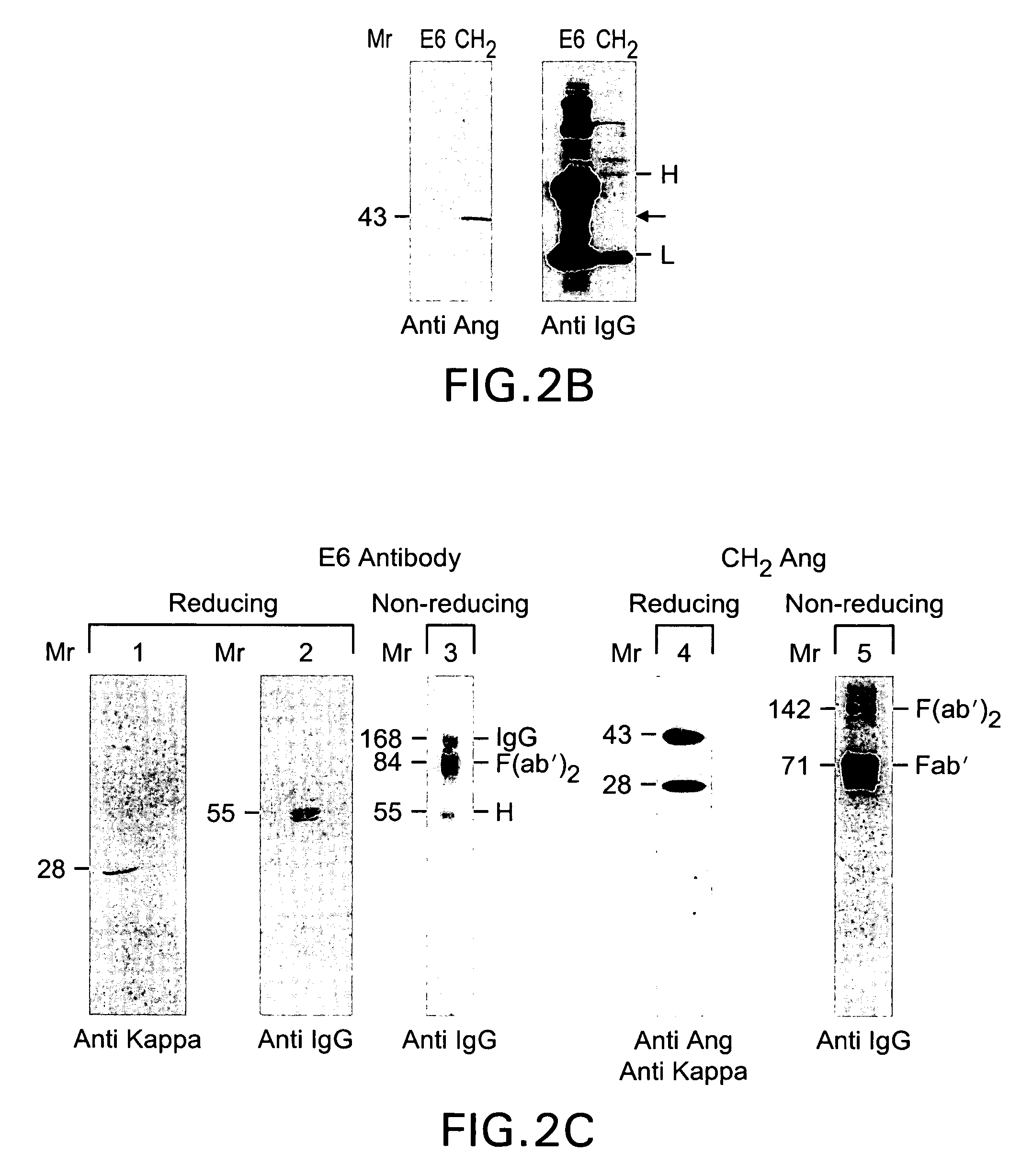

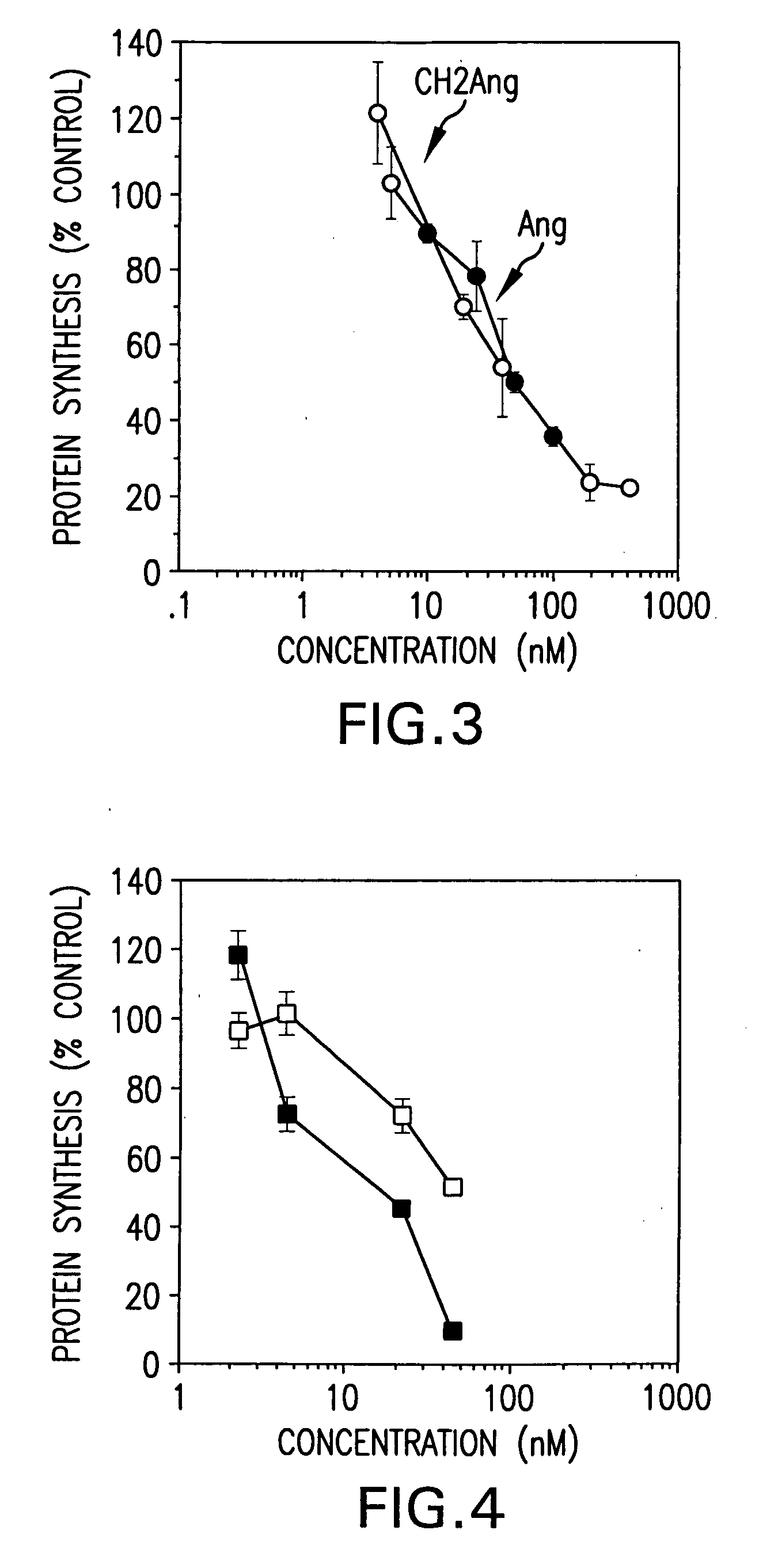

Transgenically produced fusion proteins

InactiveUS20060026695A1Resistant to digestionPromotes folding and assemblyPolypeptide with localisation/targeting motifVectorsTransgeneBiology

A method of making a transgenic fusion protein. The method inlcudes providing a transgenic animal which includes a transgene which provides for the expression of the fusion protein; allowing the transgene to be expressed; and, recovering the fusion protein, from the milk of the transgenic animal.

Owner:EDGE MICHAEL +4

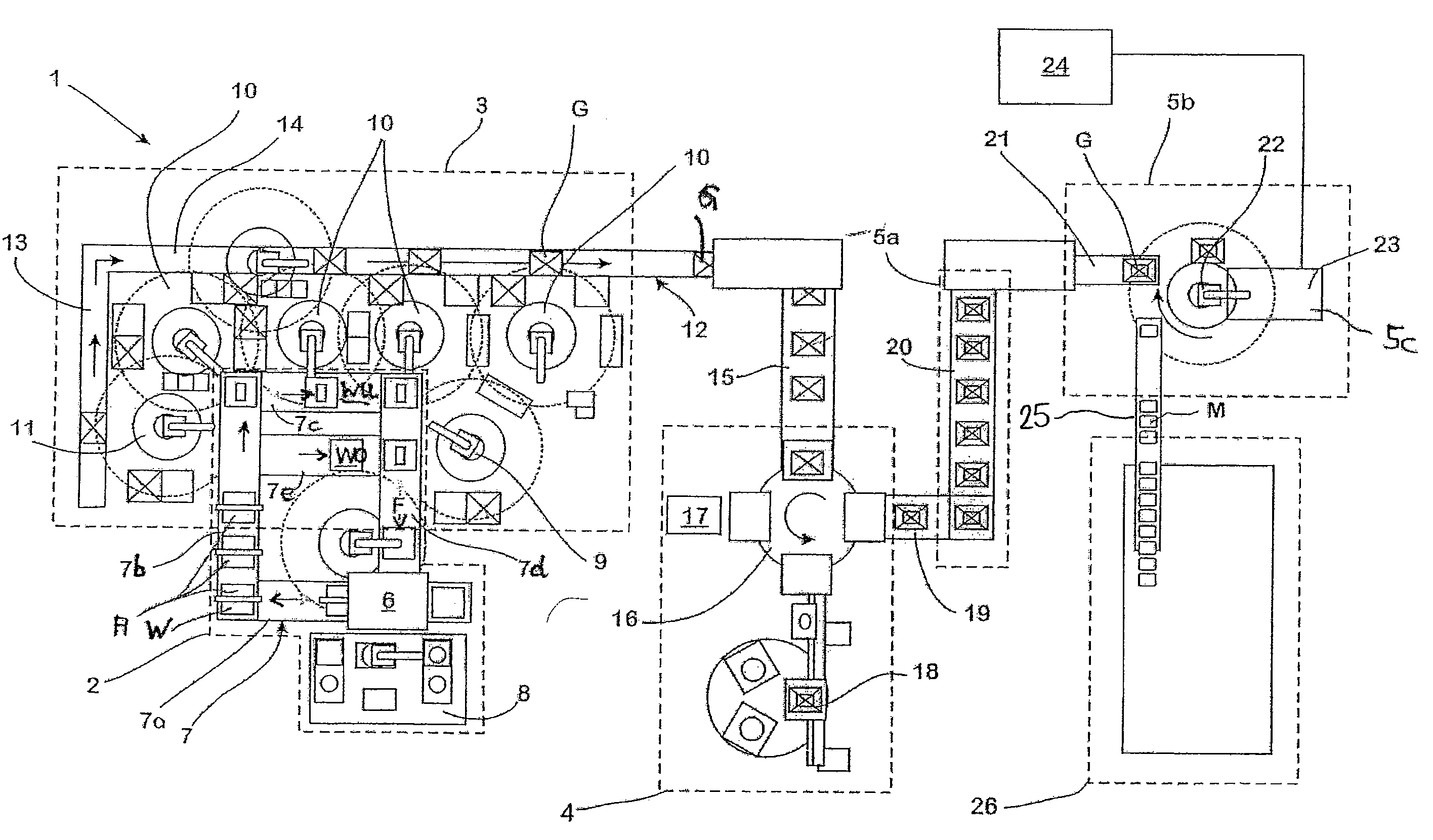

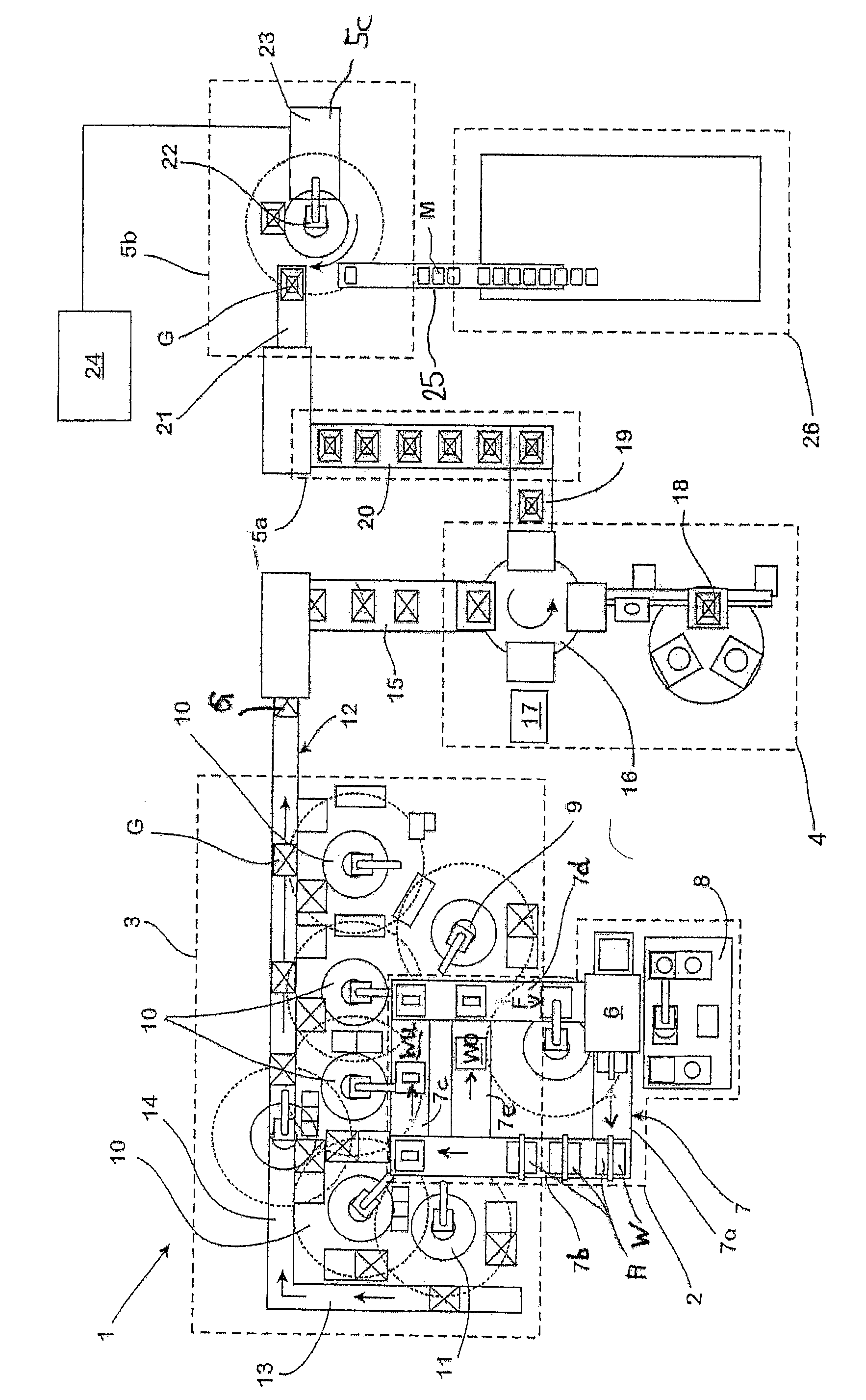

Production line and method for the production of cast parts, from a metallic melt, in particular a light molten metal, which takes place in a continuous cycle

InactiveUS7588070B2Increase load capacityForm is therefore complexPig casting plantsMoulding plantsProduction lineCycle time

The invention relates to a production line for the production of cast parts (M) from a metallic melt, in particular a light molten metal, which takes place in a continuous cycle, comprising a plurality of functional units, including a core production unit (2) for the production of casting cores, a mould assembly unit (3) for assembling casting moulds (G) formed as core packages, a casting unit for filling the molten metal into the casting moulds (G), a cooling unit (5a) for cooling the molten metal respectively contained in the casting moulds (G), and a demoulding unit (5b) for destructive removal of the casting mould (G) from the cast part (M). A production line of this type allows economical and flexible production of cast parts, in particular motor units, with a high loading capacity and complex form according to the invention in that the functional units (2 to 5b) successively passed through in each case are directly connected to each other by a respective conveying device (12, 19), and in that the cycle time with which the production line (1) ejects finished cast parts (M) is determined by the cycle time with which the core production unit (2) supplies the casting cores produced by the core production unit.

Owner:HYDRO ALUMINUM ALUCAST

Fluorescent probe for zinc

InactiveUS20050064308A1Strong specificityImprove accuracyBiocideOrganic chemistryHydrogen atomHalogen

A compound represented by general formula (IA) or a salt thereof useful as a fluorescent probe for zinc: wherein R1 and R2 represent a hydrogen atom or a group represented by formula (A), wherein X1, X2, X3, and X4 represent a hydrogen atom, an alkyl group, a 2-pyridylmethyl group, or a protective group for an-amino group, and m and n represent 0 or 1, provided that R1 and R2 do not simultaneously represent hydrogen atoms; R3 and R4 represent a hydrogen atom or a halogen atom; and R5 and R6 represent a hydrogen atom, an alkylcarbonyl group, or an alkylcarbonyloxymethyl group, and R7 represents a hydrogen atom or an alkyl group.

Owner:SEKISUI MEDICAL CO LTD

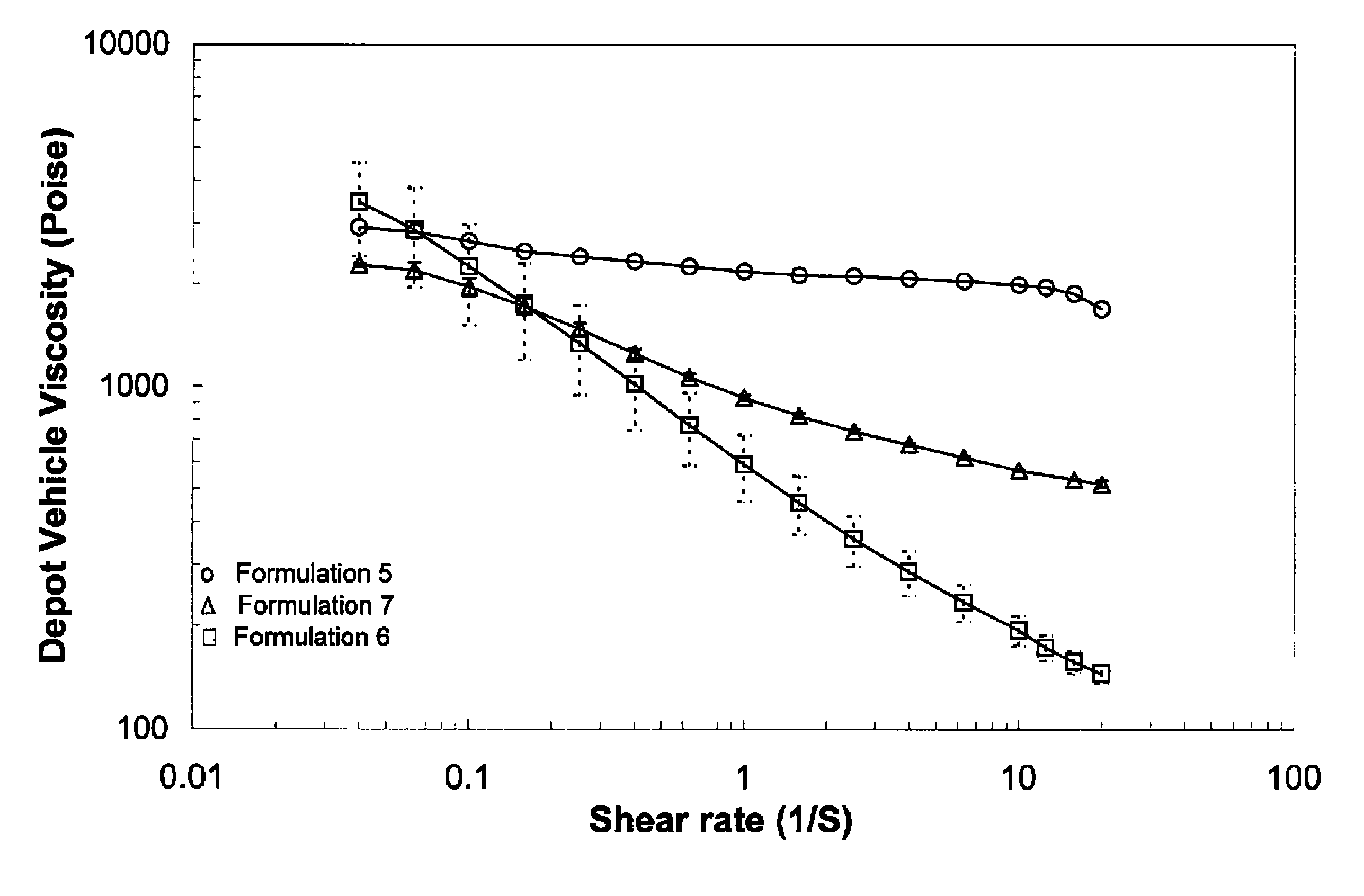

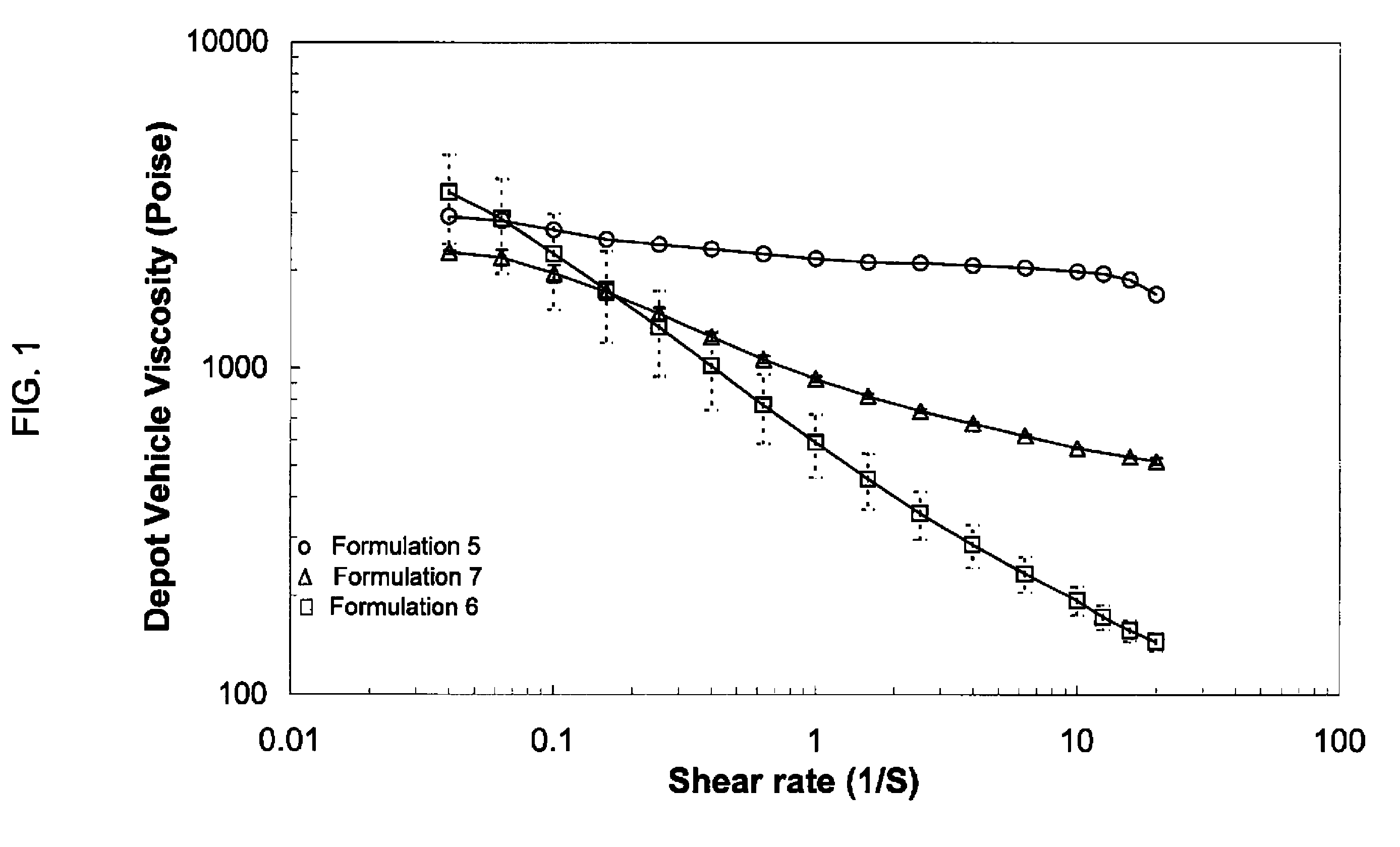

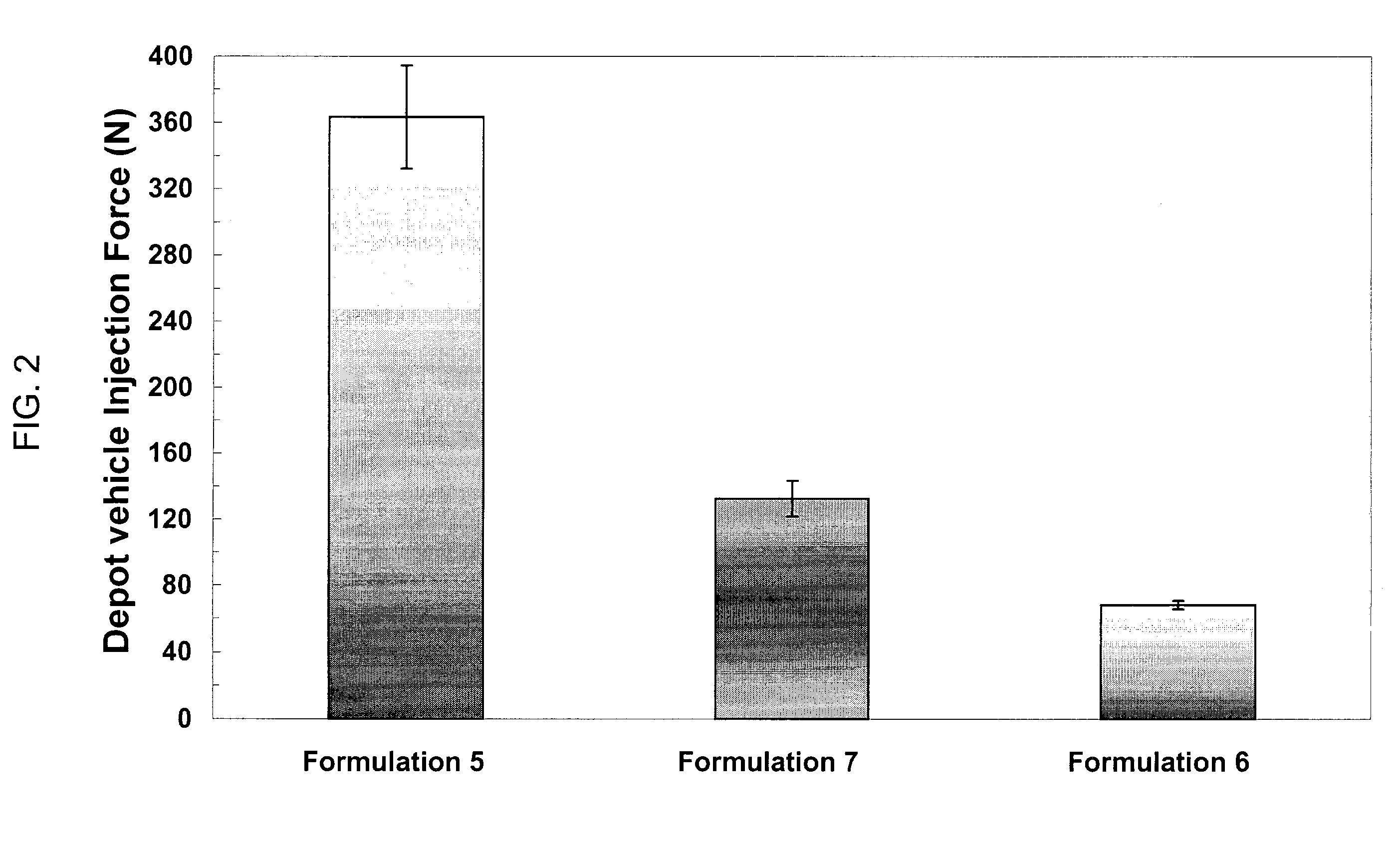

Injectable depot compositions and uses thereof

InactiveUS8252303B2Effective distributionBeneficial agent loading rateOrganic active ingredientsPowder deliveryAromatic alcoholAromatic ketones

Injectable depot compositions are provided that include a bioerodible, biocompatible polymer, a solvent having a miscibility in water of less than or equal to 7 wt. % at 25° C., in an amount effective to plasticize the polymer and form a gel therewith, a thixotropic agent, and a beneficial agent. The solvent comprises an aromatic alcohol, an ester of an aromatic acid, an aromatic ketone, or mixtures thereof. The compositions have substantially improved the shear thinning behavior and reduced injection force, rendering the compositions readily implanted beneath a patient's body surface by injection.

Owner:DURECT CORP

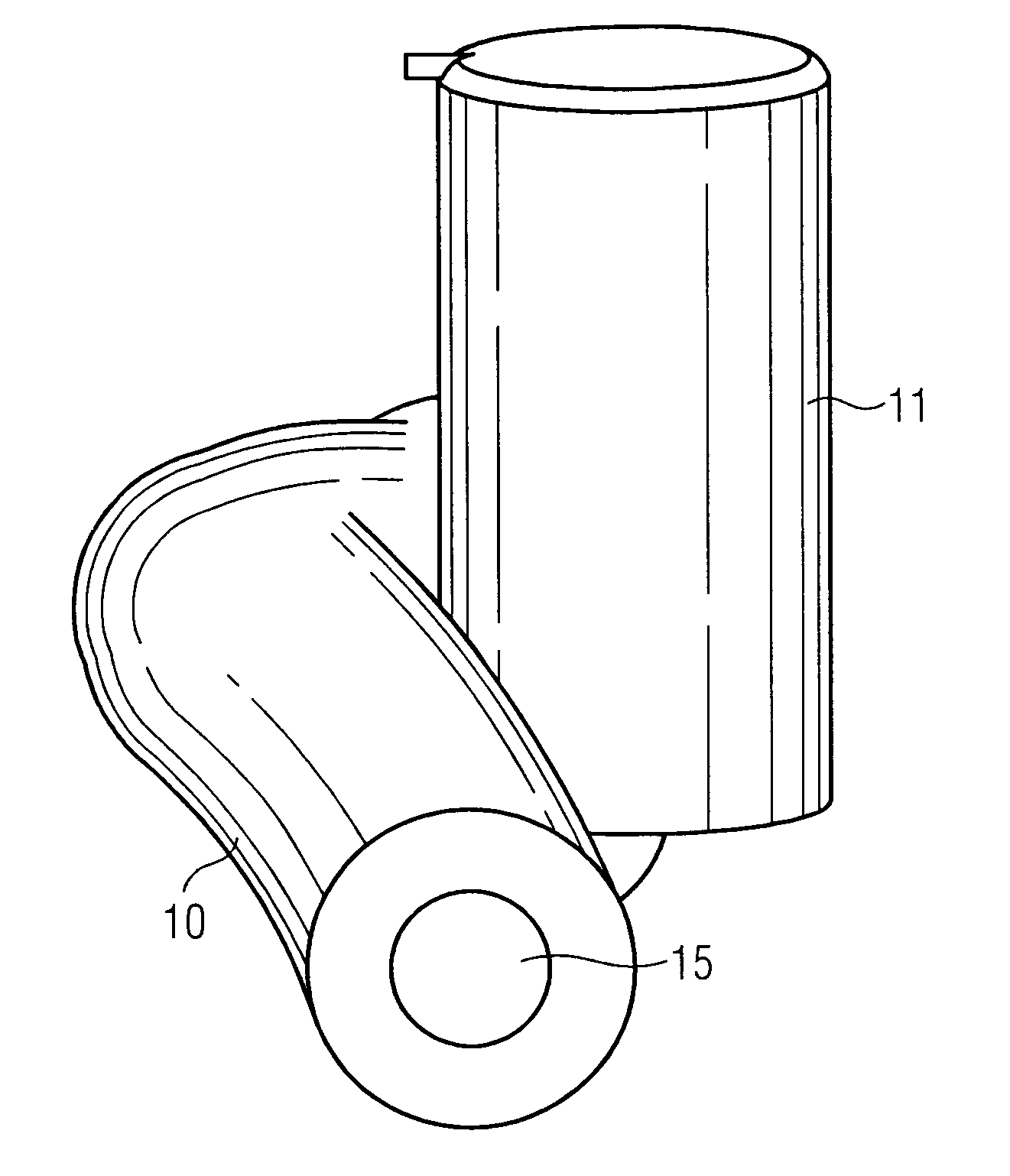

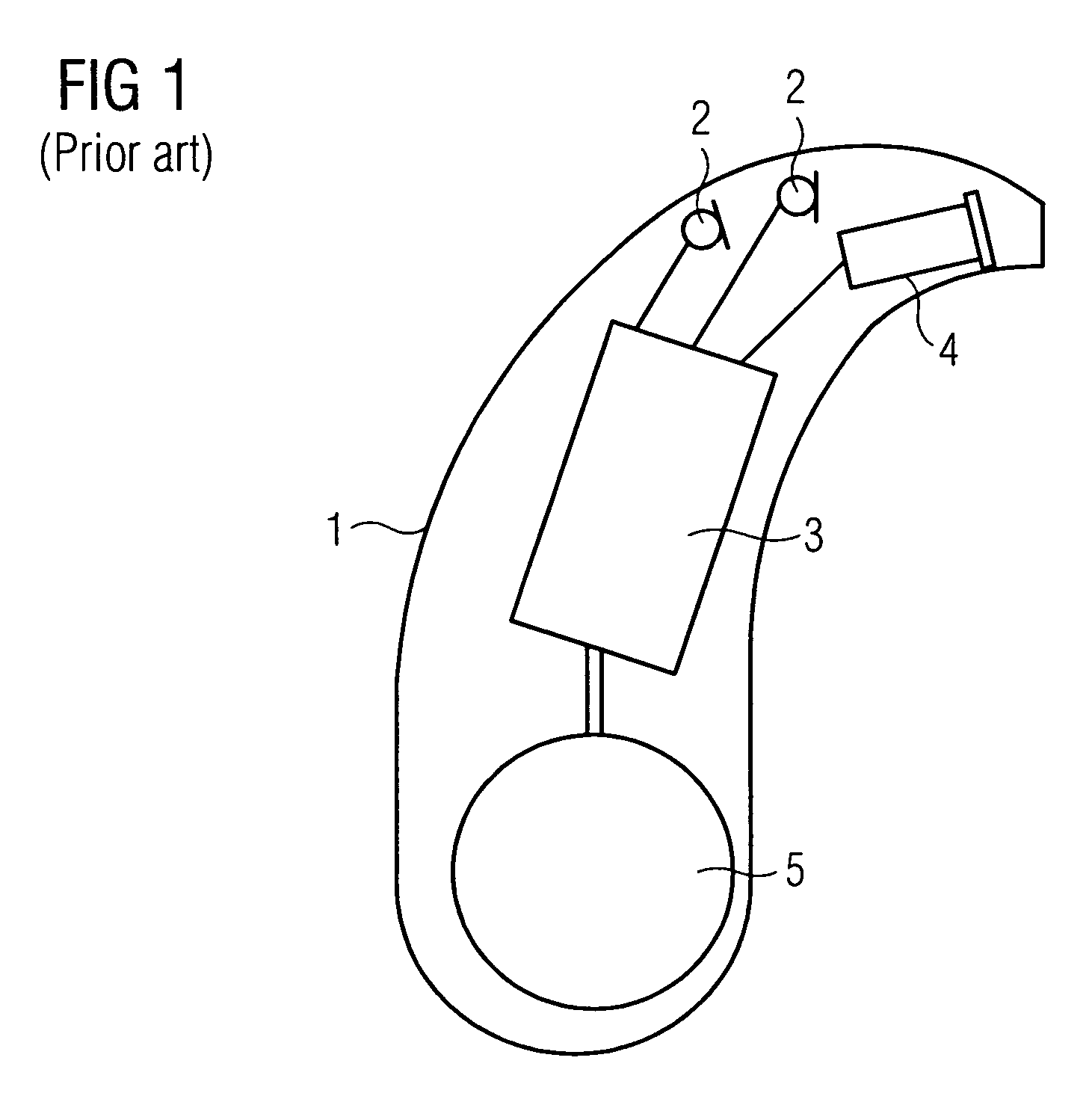

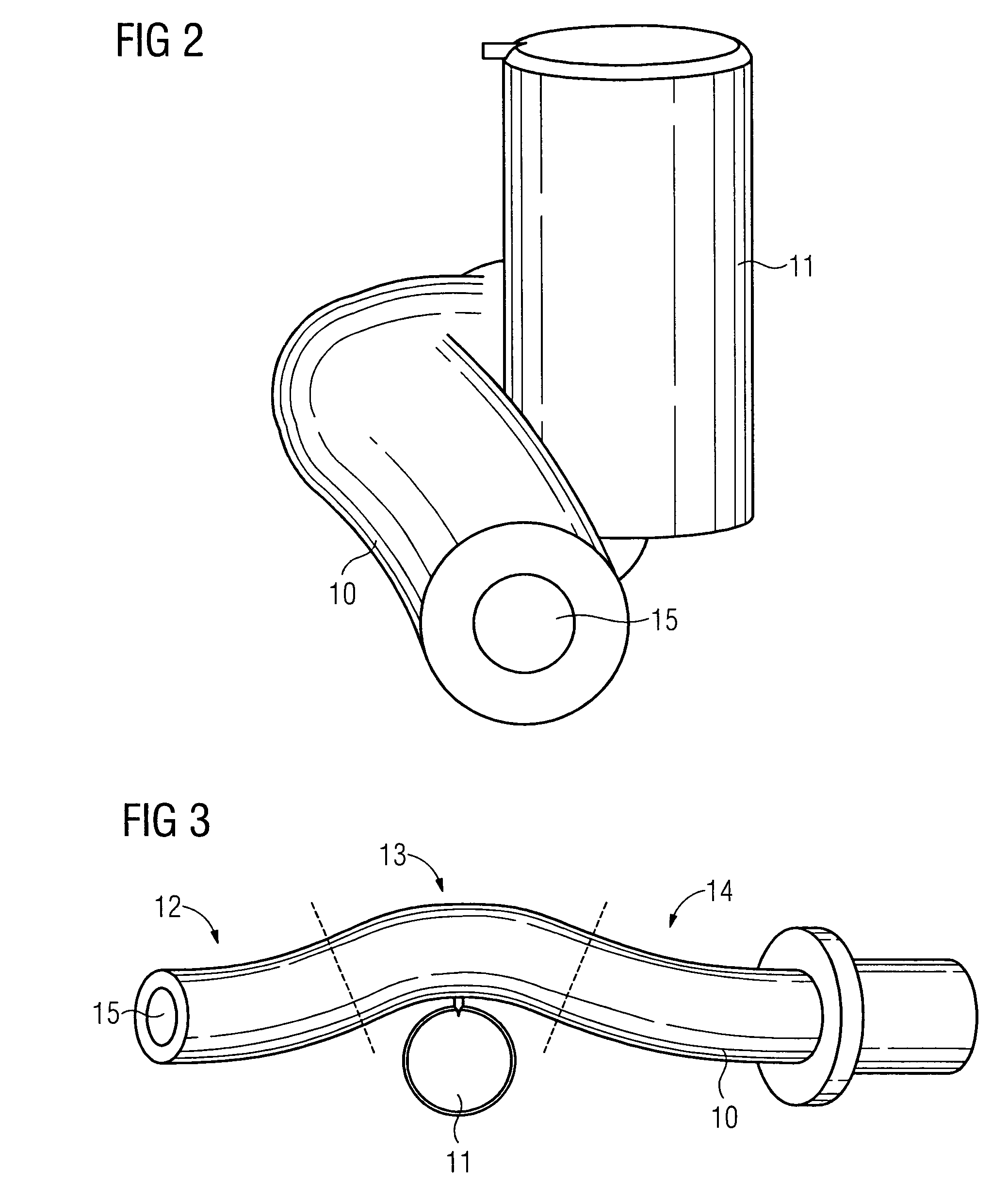

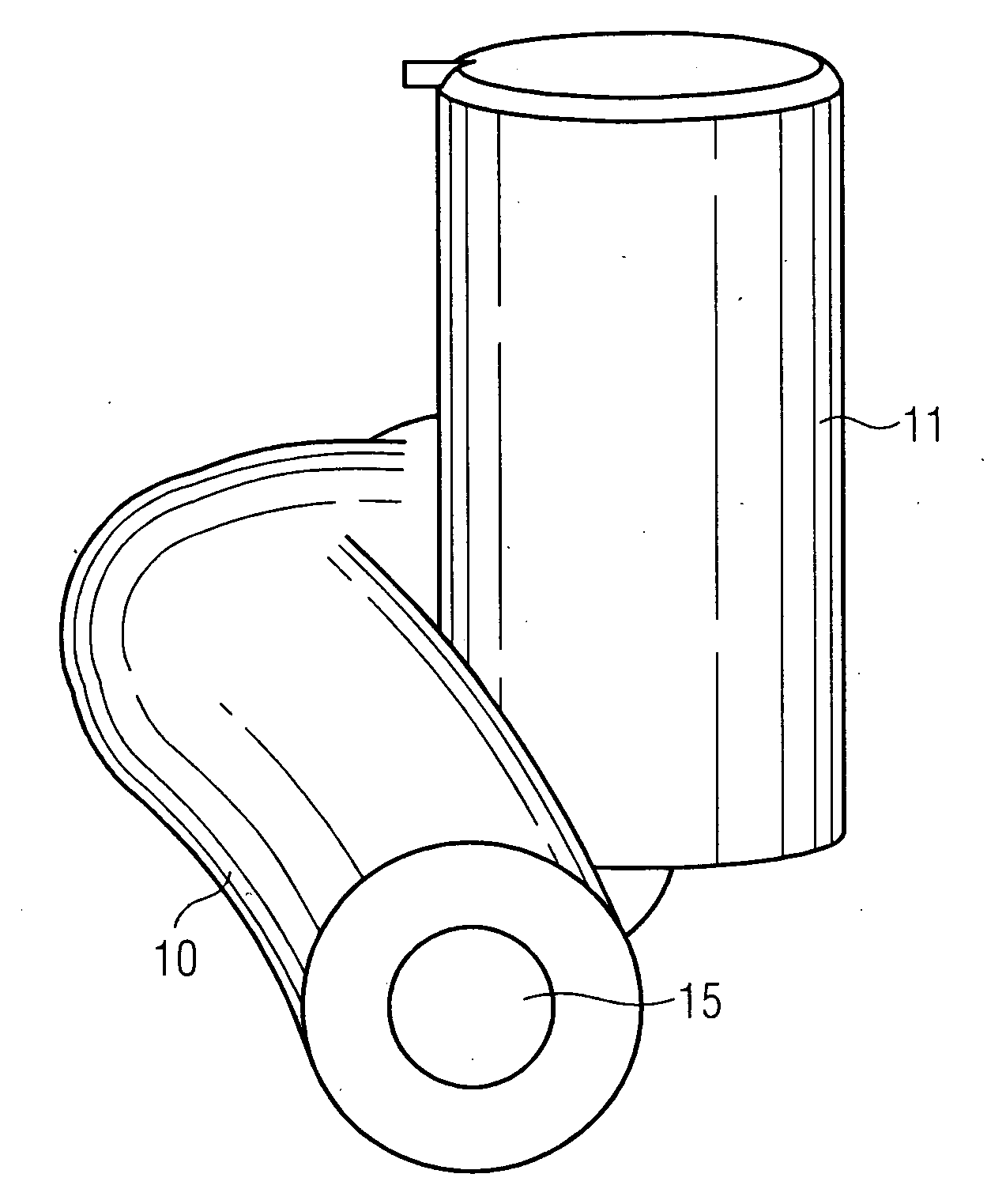

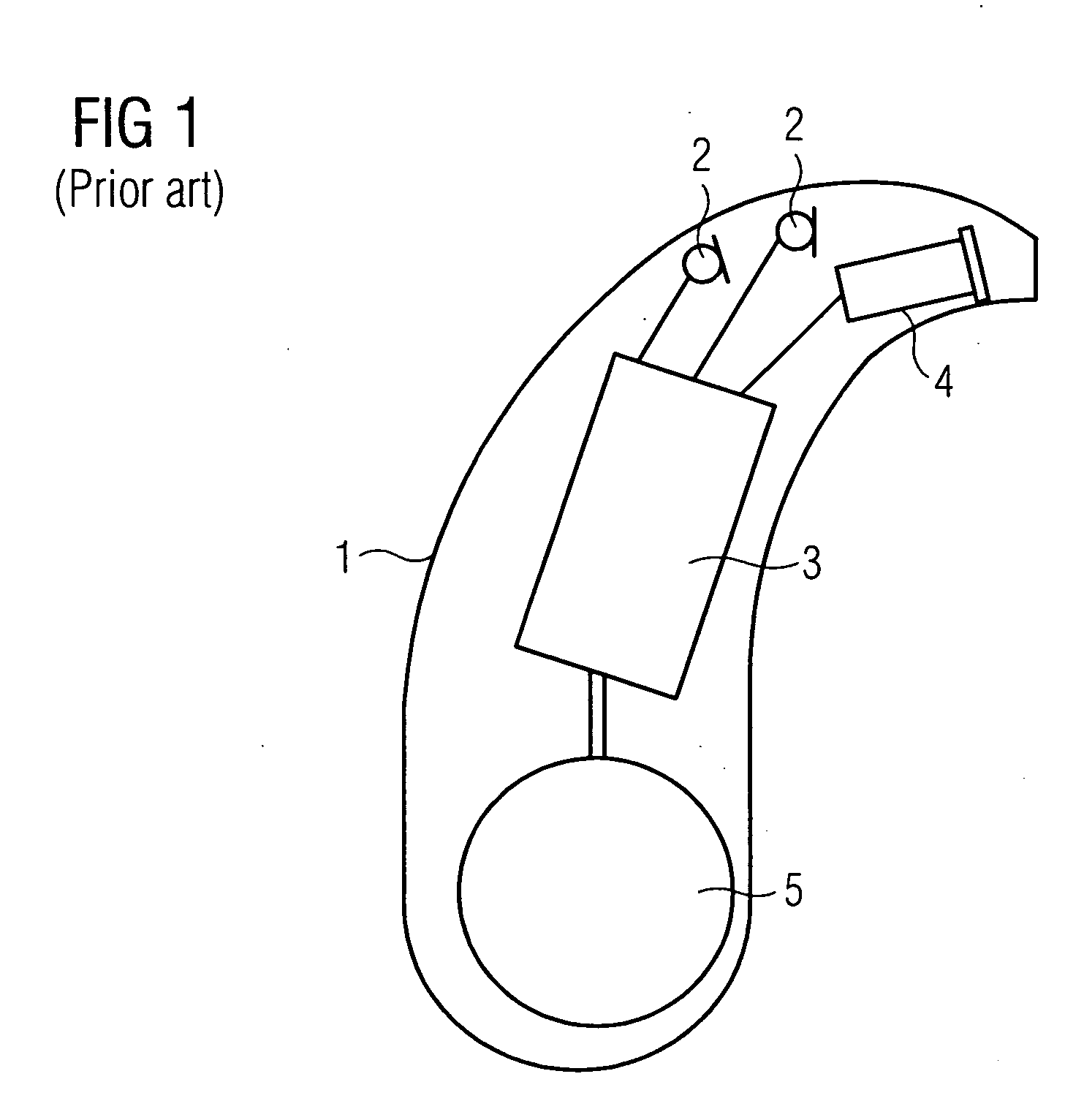

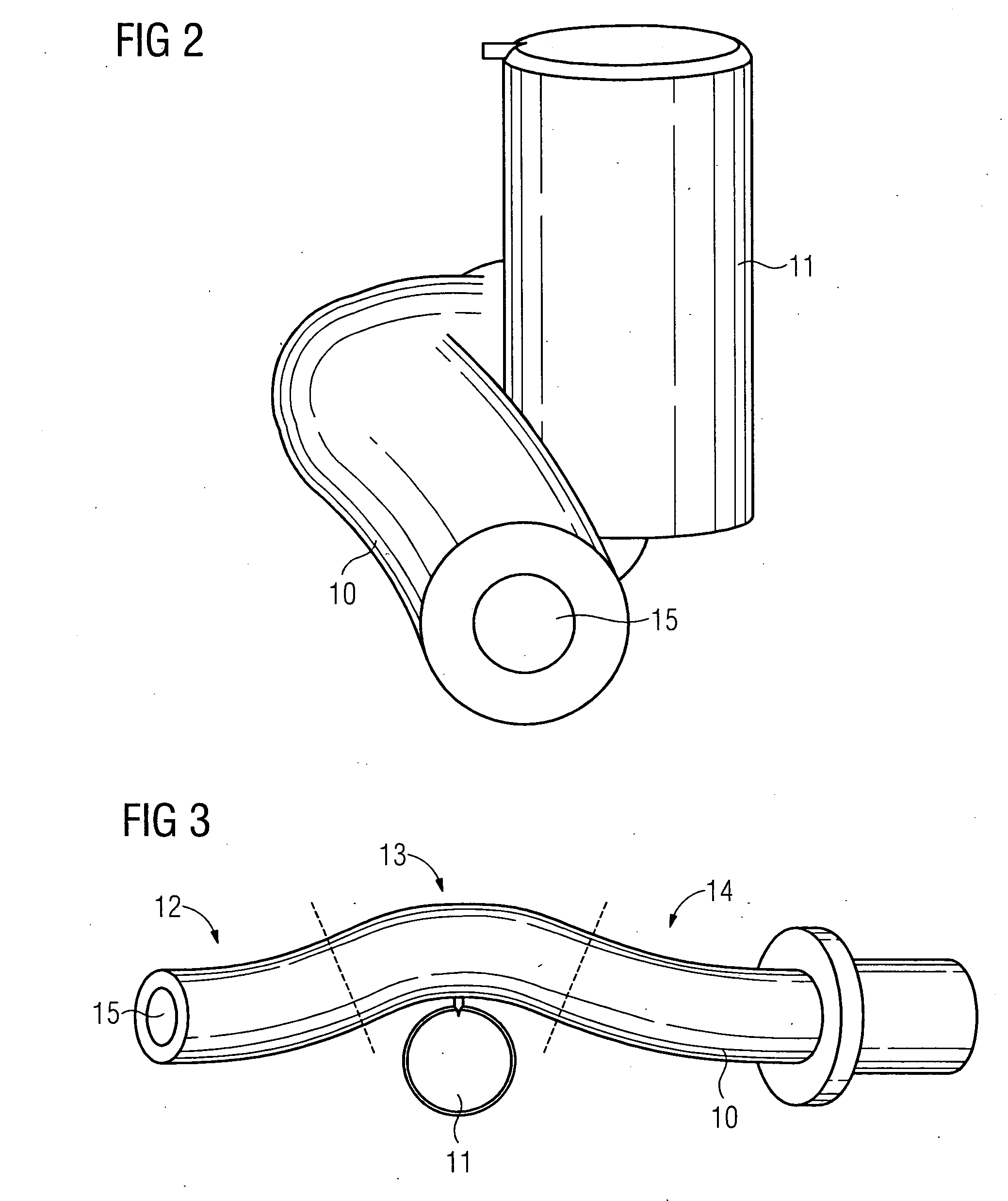

Sound channel for a hearing apparatus and corresponding production process

InactiveUS8094849B2Easy to produceForm is therefore complexFrequency/directions obtaining arrangementsDeaf-aid setsEngineeringHearing apparatus

A mechanically more stable and more complexly molded sound channel is to be provided for a hearing apparatus. Provision is made to this end for a sound channel, which has three sections in the longitudinal direction, the middle section of which has a different curvature or a larger internal circumference than the two outer sections, to be produced by injection molding. Here a negative of the sound channel is fixed within the injection molded form, with the negative consisting of a first material. The injection molded form with a second material, which has a higher melting point than the first material, is then extruded. The negative is then melted or burnt out of the cast sound channel. Very complex sound channel forms, for instance also with cavities and branching, can be realized in this way.

Owner:SIEMENS MEDICAL EQUIPMENT

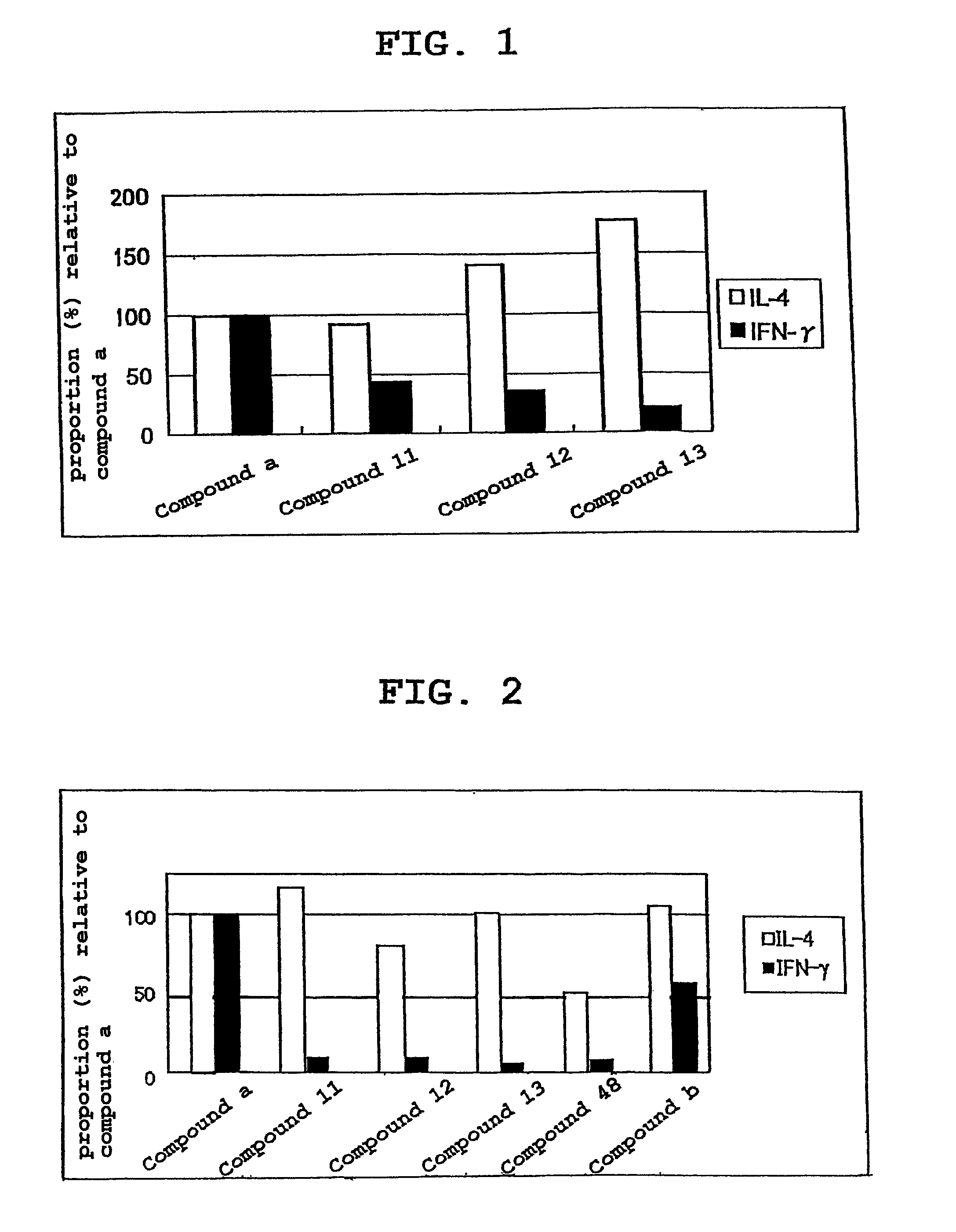

Glycolipid and use thereof

Owner:RIKEN

Sound channel for a hearing apparatus and corresponding production process

InactiveUS20090074217A1Promote meltingLow melting pointFrequency/directions obtaining arrangementsDeaf-aid setsEngineeringHearing apparatus

A mechanically more stable and more complexly molded sound channel is to be provided for a hearing apparatus. Provision is made to this end for a sound channel, which has three sections in the longitudinal direction, the middle section of which has a different curvature or a larger internal circumference than the two outer sections, to be produced by injection molding. Here a negative of the sound channel is fixed within the injection molded form, with the negative consisting of a first material. The injection molded form with a second material, which has a higher melting point than the first material, is then extruded. The negative is then melted or burnt out of the cast sound channel. Very complex sound channel forms, for instance also with cavities and branching, can be realized in this way.

Owner:SIEMENS MEDICAL EQUIPMENT

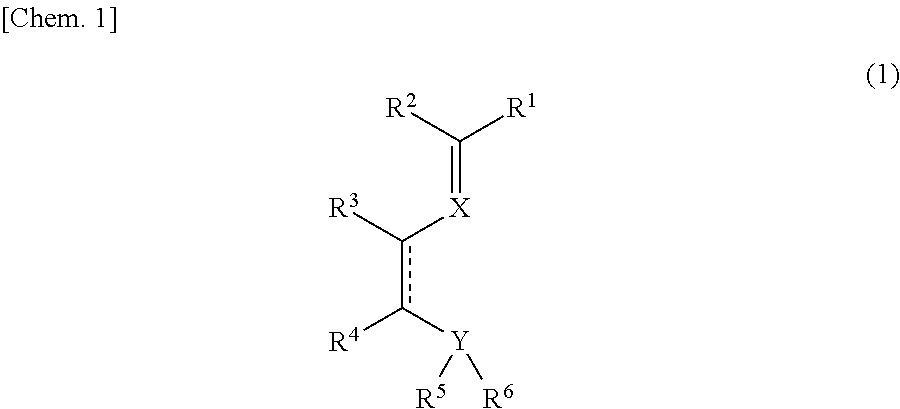

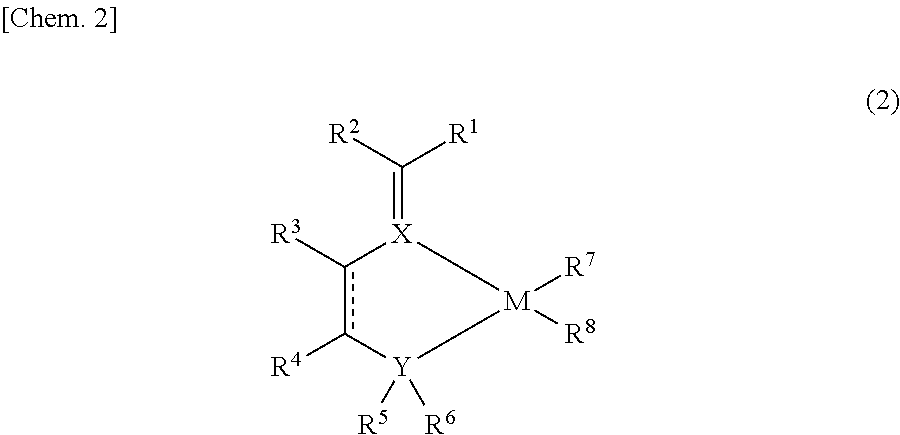

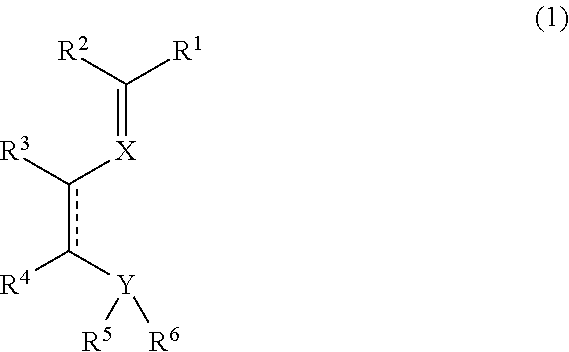

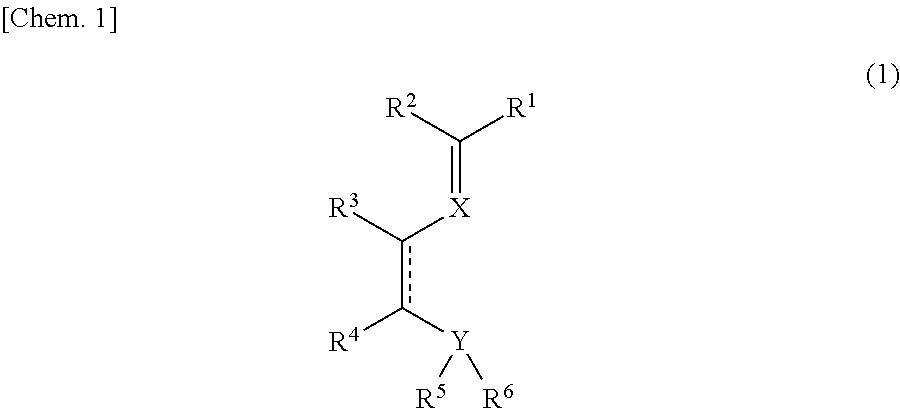

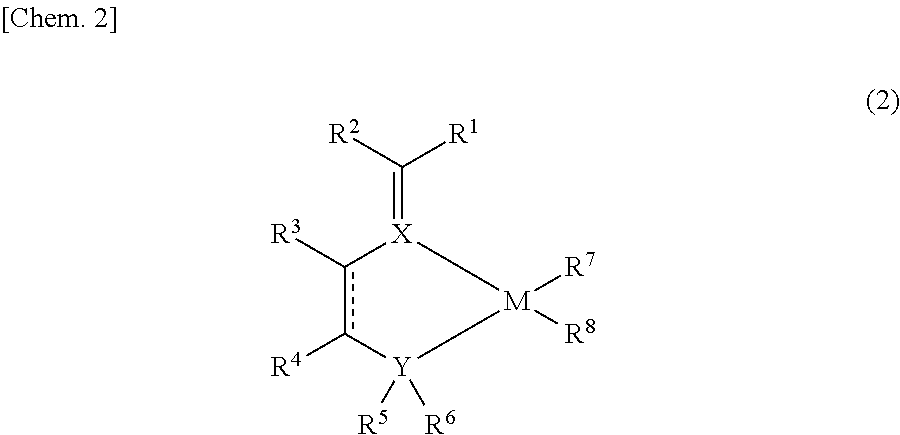

Imine compound, novel catalyst for olefin polymerization, and process for producing olefin polymer

ActiveUS9862783B2Form is therefore complexHigh molecular weightGroup 5/15 element organic compoundsNickel organic compoundsPolymer sciencePtru catalyst

Owner:JAPAN POLYPROPYLENE CORP +1

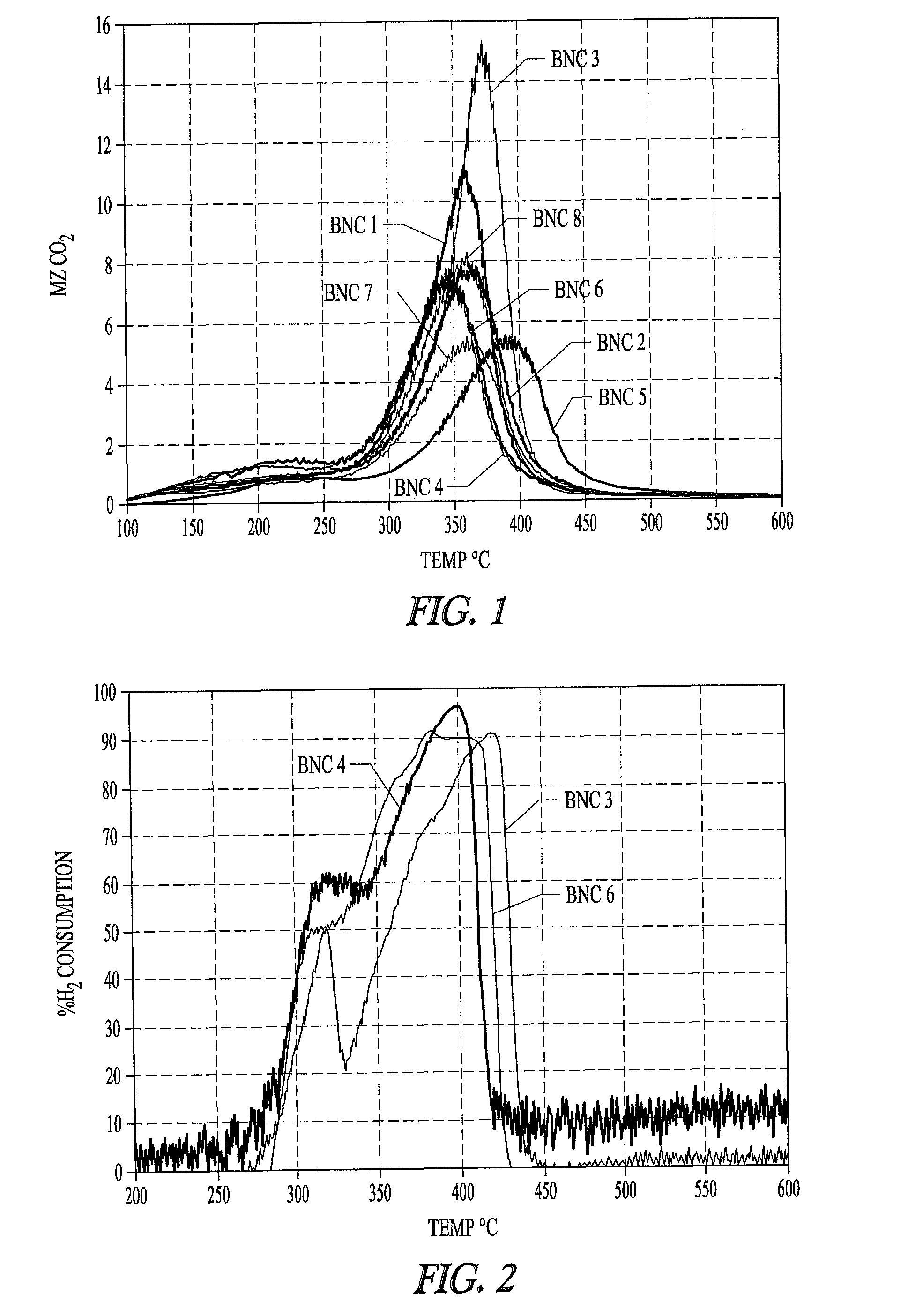

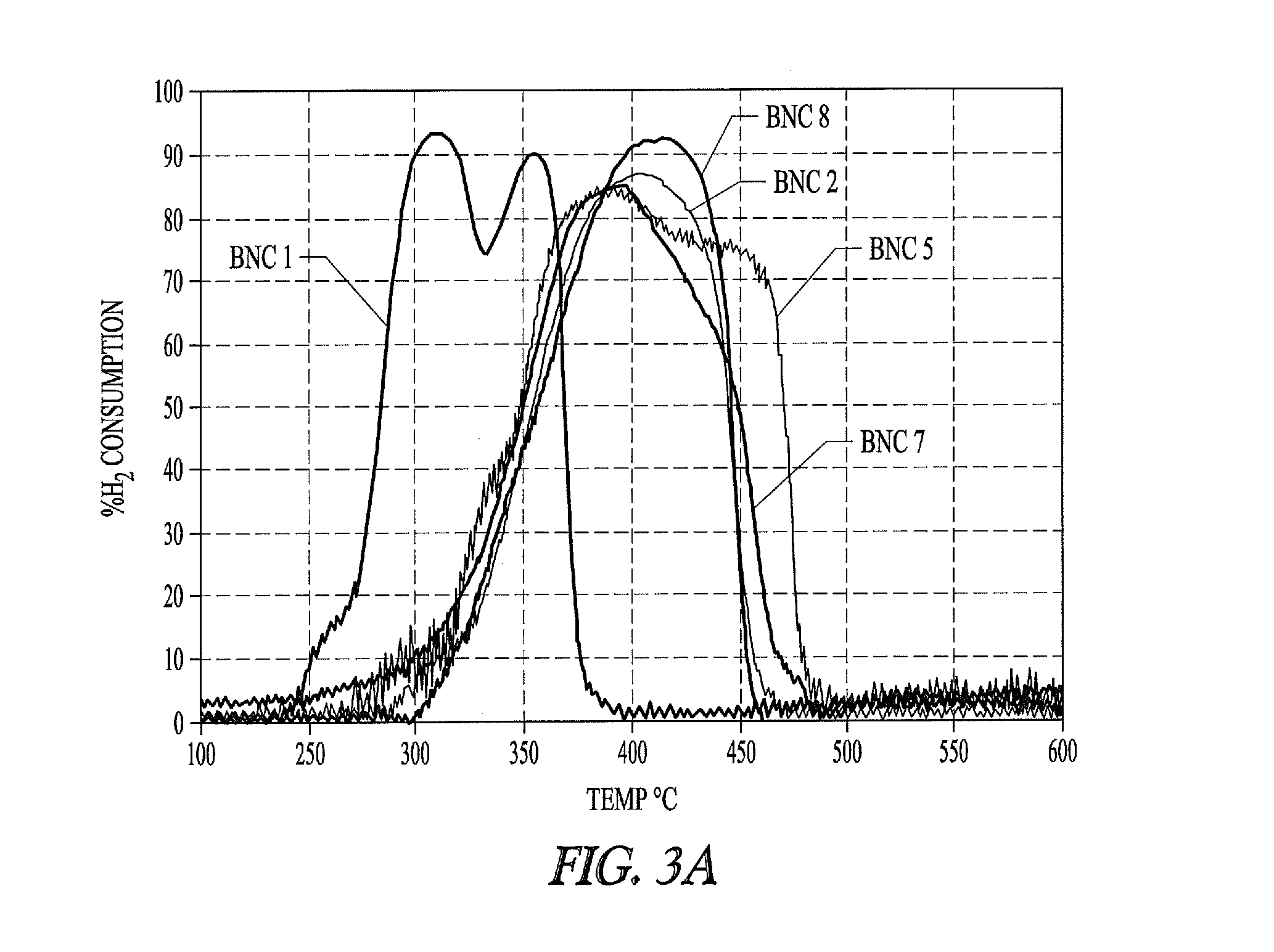

Nickel form for preparation of catalytic nickel-ligand complexes

ActiveUS9050591B2Form is therefore complexAvoid wastingNickel organic compoundsGlass/slag layered productsParticulatesGram

A novel nickel particulate form is provided that efficiently forms a zero-valent nickel complex with a phosphorus-containing ligands in an organic liquid to form a hydrocyanation catalyst. Particles in the nickel particulate form comprise nickel crystallites. For example, the nickel particulate form can have a BET Specific Surface Area of at least about 1 m2 / gm; an average crystallite size less than about 20-25 nm, the nickel particulate form can have at least 10% of the crystallites in the nickel form can have a diameter (C10) of less than about 10 nm, and / or there are on average at least about 1015 surface crystallites per gram nickel. A ratio of BET SSA to C50 for the nickel particulate form can be at least about 0.1×109 m / gm and preferably at least about 0.4×109 m / gm. Methods of preparation and use are also provided.

Owner:INV NYLON CHEM AMERICAS LLC

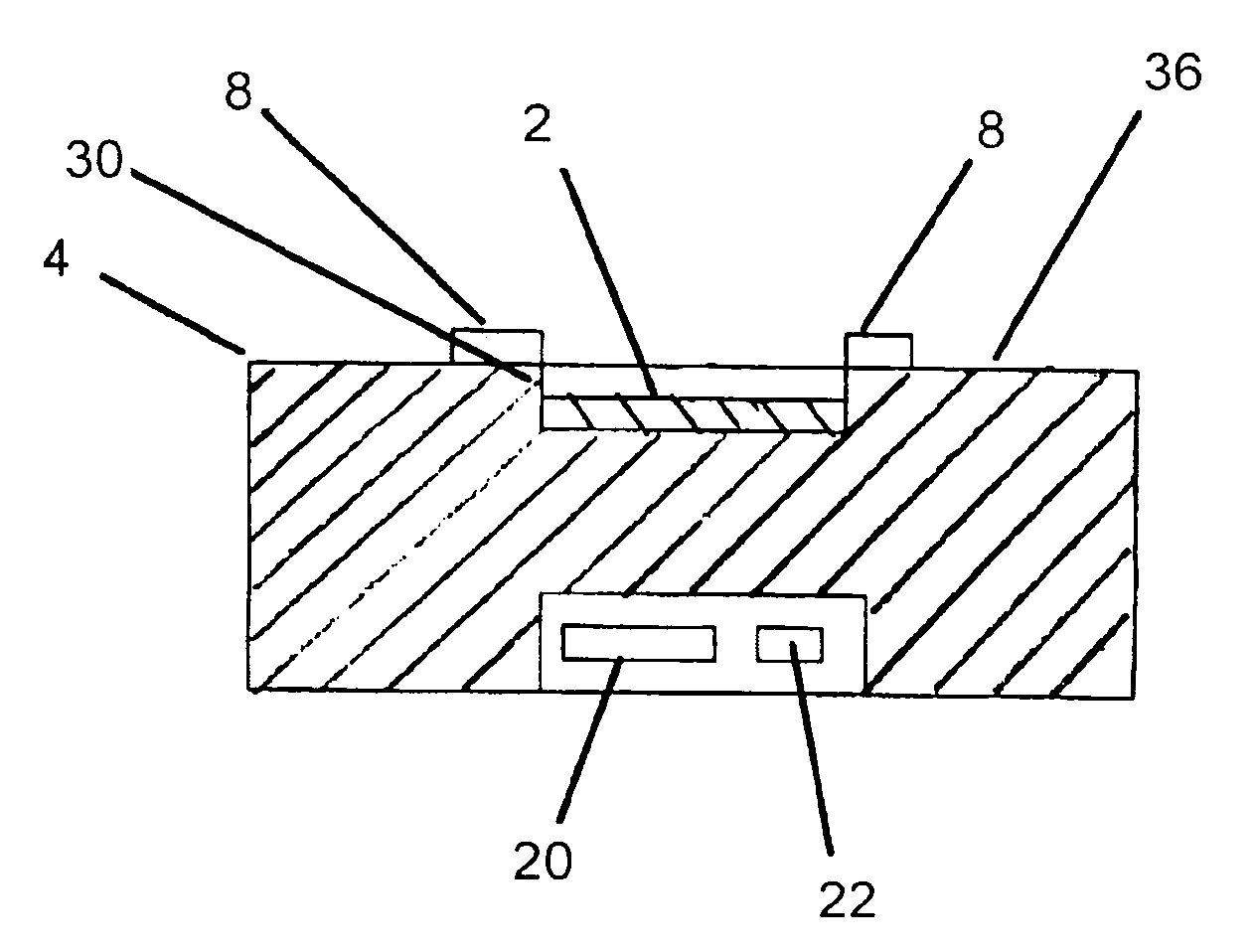

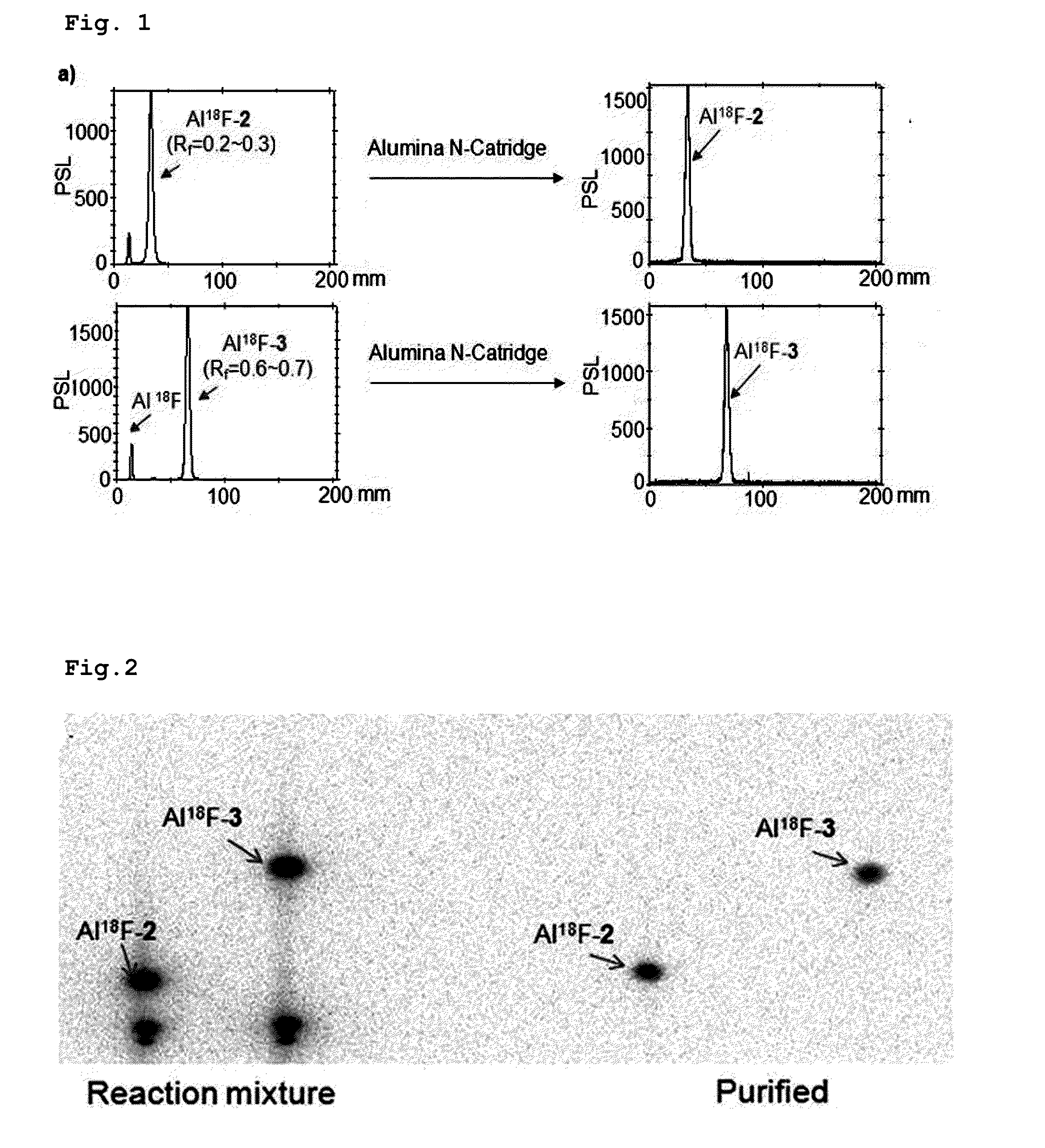

Optical analyzer and method for producing the same

ActiveUS20180166605A1High level of positional accuracyDiffusion of light be suppressSolid-state devicesTransmissivity measurementsPhotodetectorPhotovoltaic detectors

A passage (3) for a sample solution is formed in a sapphire base body (2) used as a substrate for semiconductor devices. An LED (4) and a photodiode (5) are formed on the base body (2) by a semiconductor manufacturing process so that they face each other across the passage (3). The LED (4) emits light into the base body (2). This light is transmitted through the sample solution in the passage (3), undergoing absorption according to the concentration and other properties of the solution. The transmitted light passes through the base body (2) and reaches the photodiode (5), producing a detection signal corresponding to the incident light amount. Since the light source and photodetector are integrated with the base body (2) serving as a flow cell, the present device is small and lightweight. Furthermore, no cumbersome task of aligning optical axes in the device-assembling process is needed.

Owner:SHIMADZU CORP

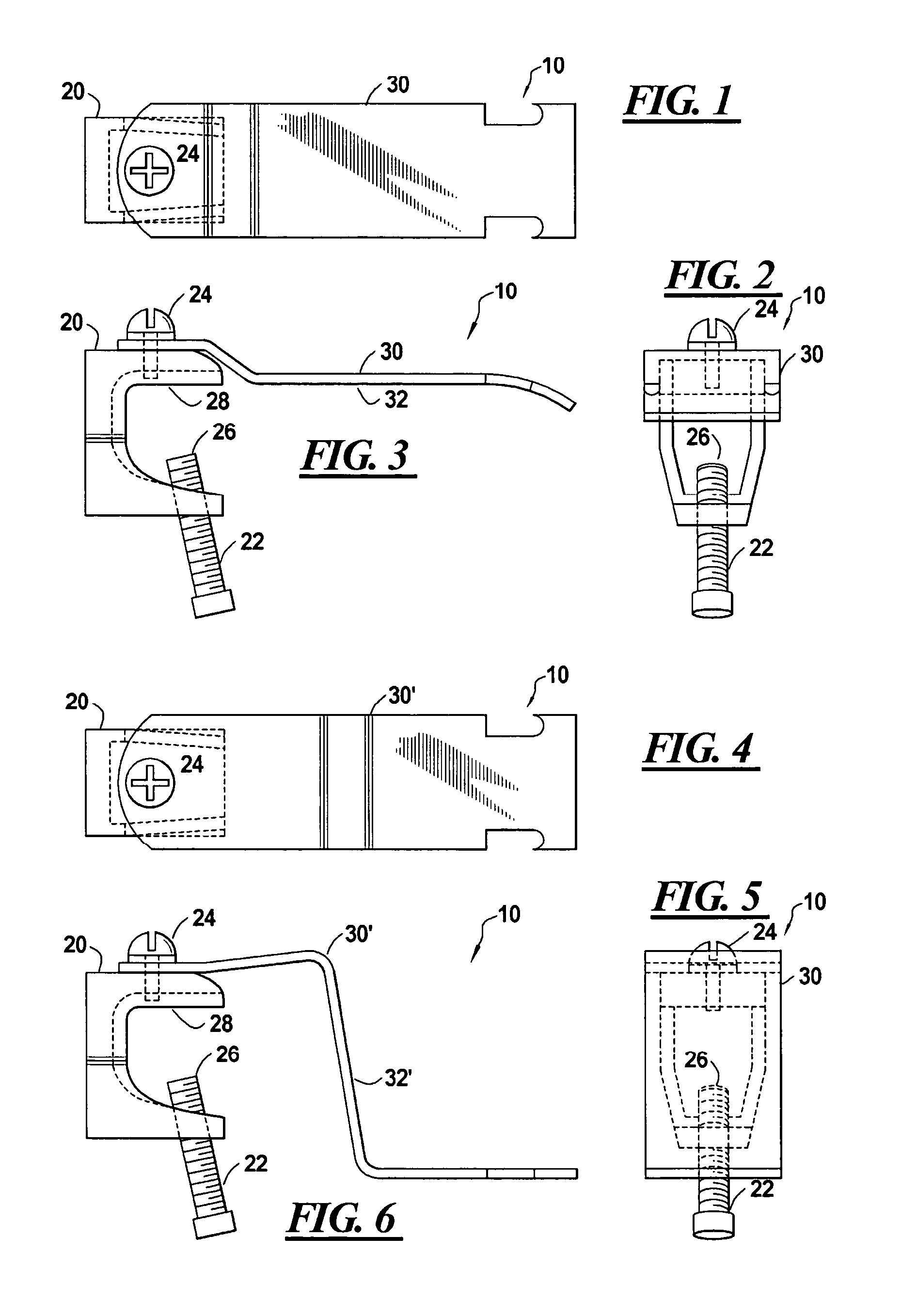

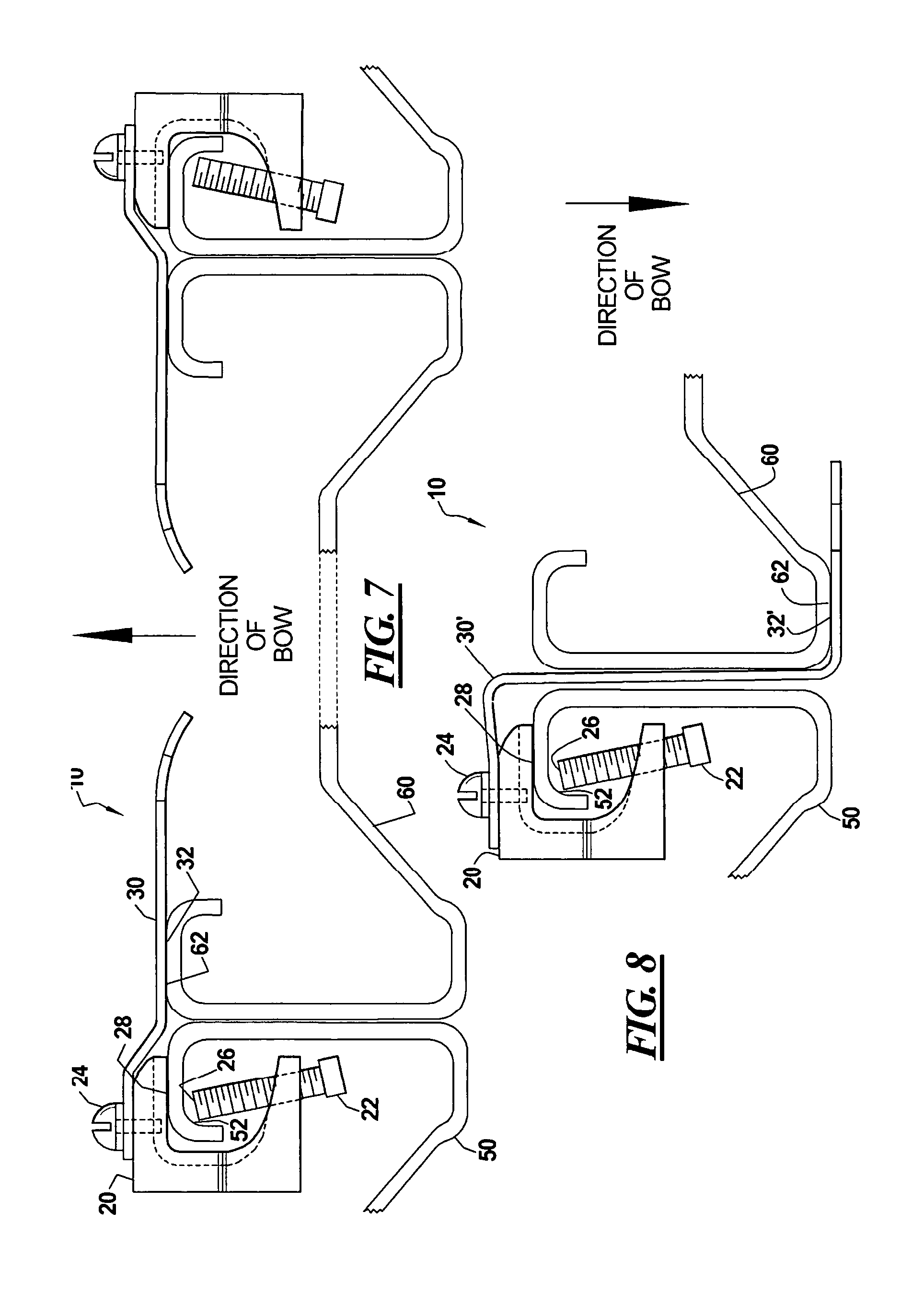

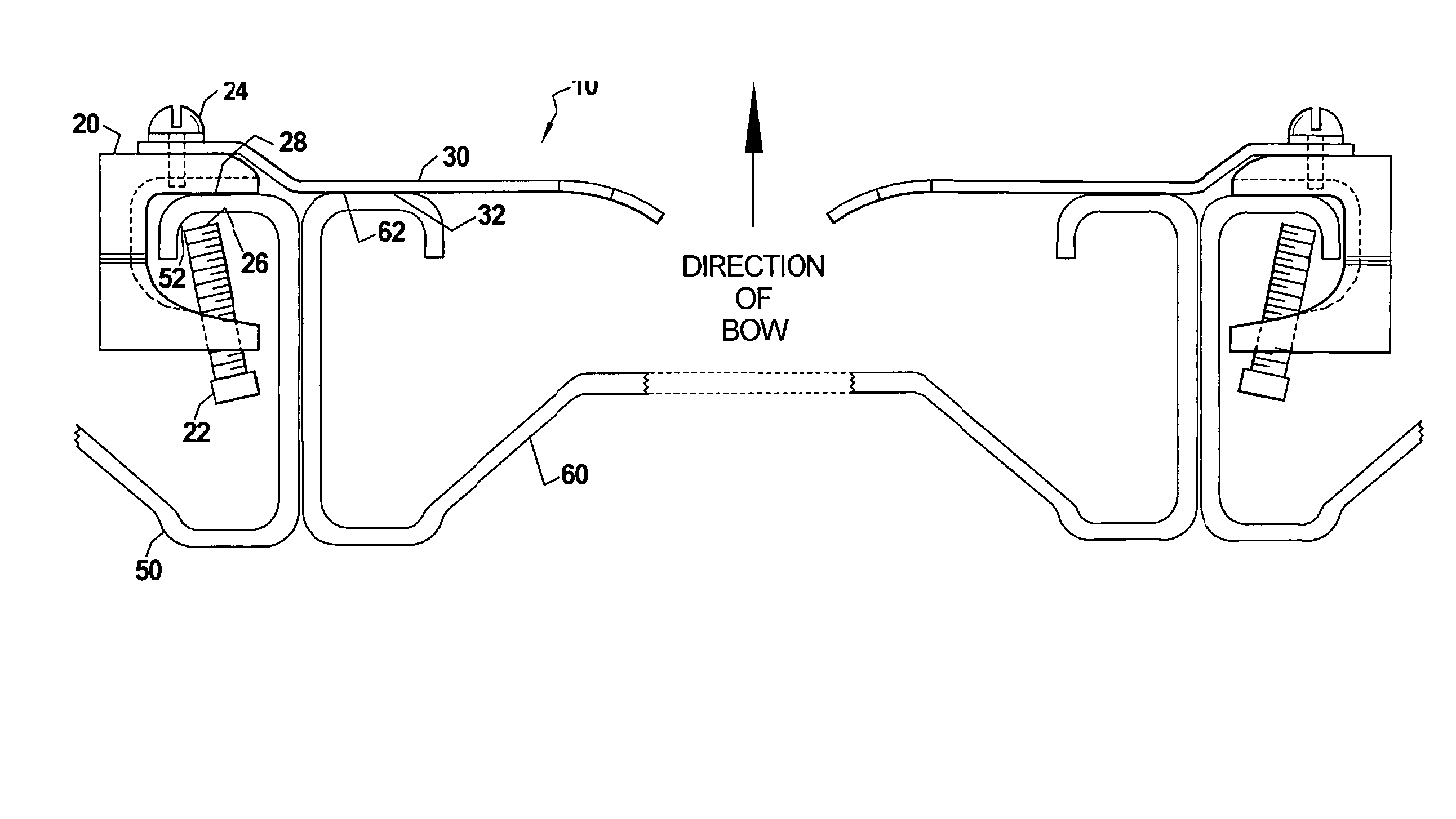

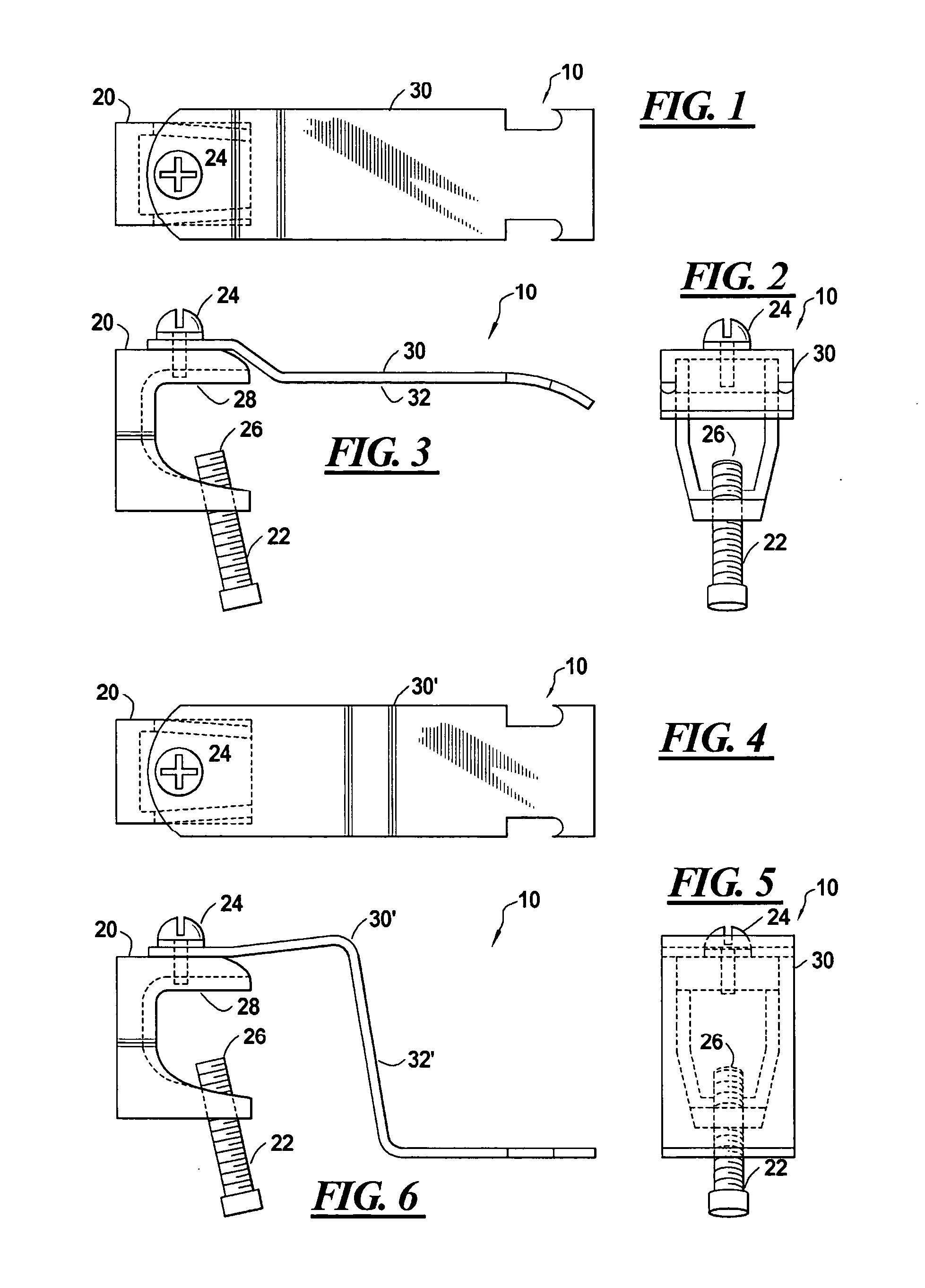

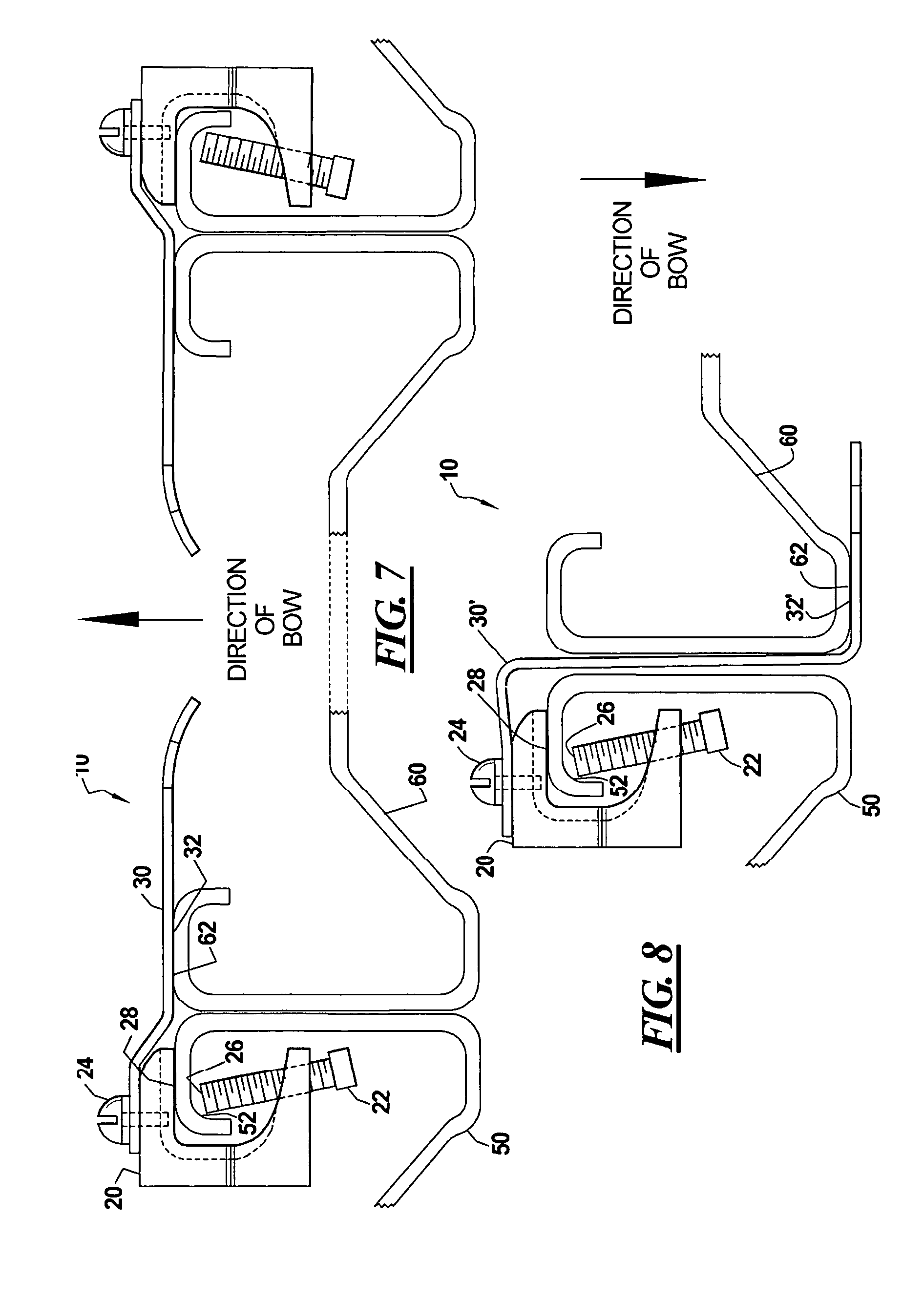

Method for minimizing bowing of collector plates in an electrostatic precipitator, and a collector plate-clip combination

InactiveUS6951580B1Avoid bowingInexpensive wayElectrode carrying meansBuilding reinforcementsEngineeringMechanical engineering

A bow-reduced precipitator collector plate assembly and an appertaining method include a precipitator collector plate that contacts a spring-like stiffening element configured to be attached to a fixed anchor or an adjacent anchoring collector plate. The stiffening element is configured to apply a force in a direction normal to a primary plane, which is generally co-linear but opposite in direction of a direction of bowing, of the precipitator collecting plate.

Owner:NISOURCE CORP SERVICES

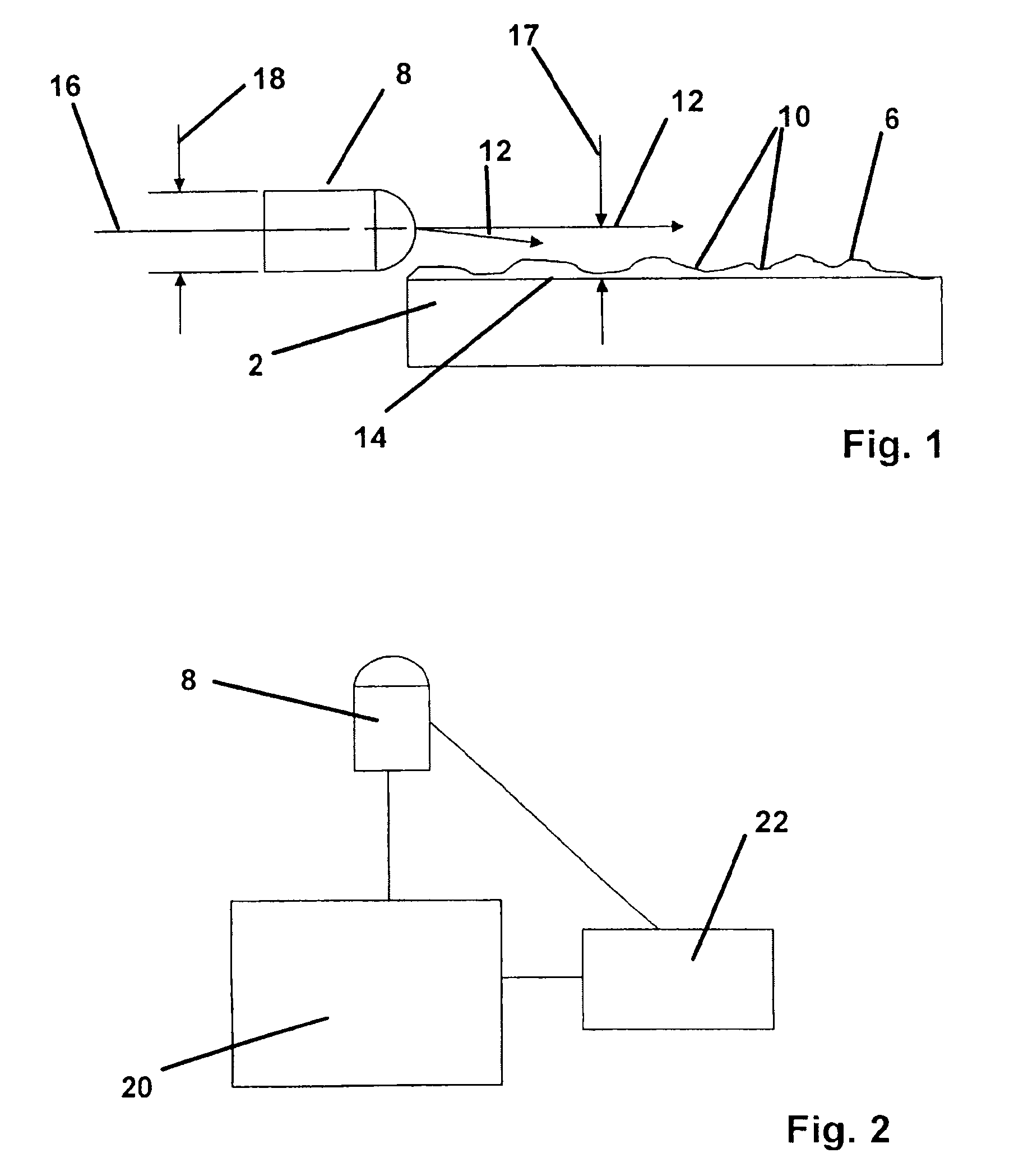

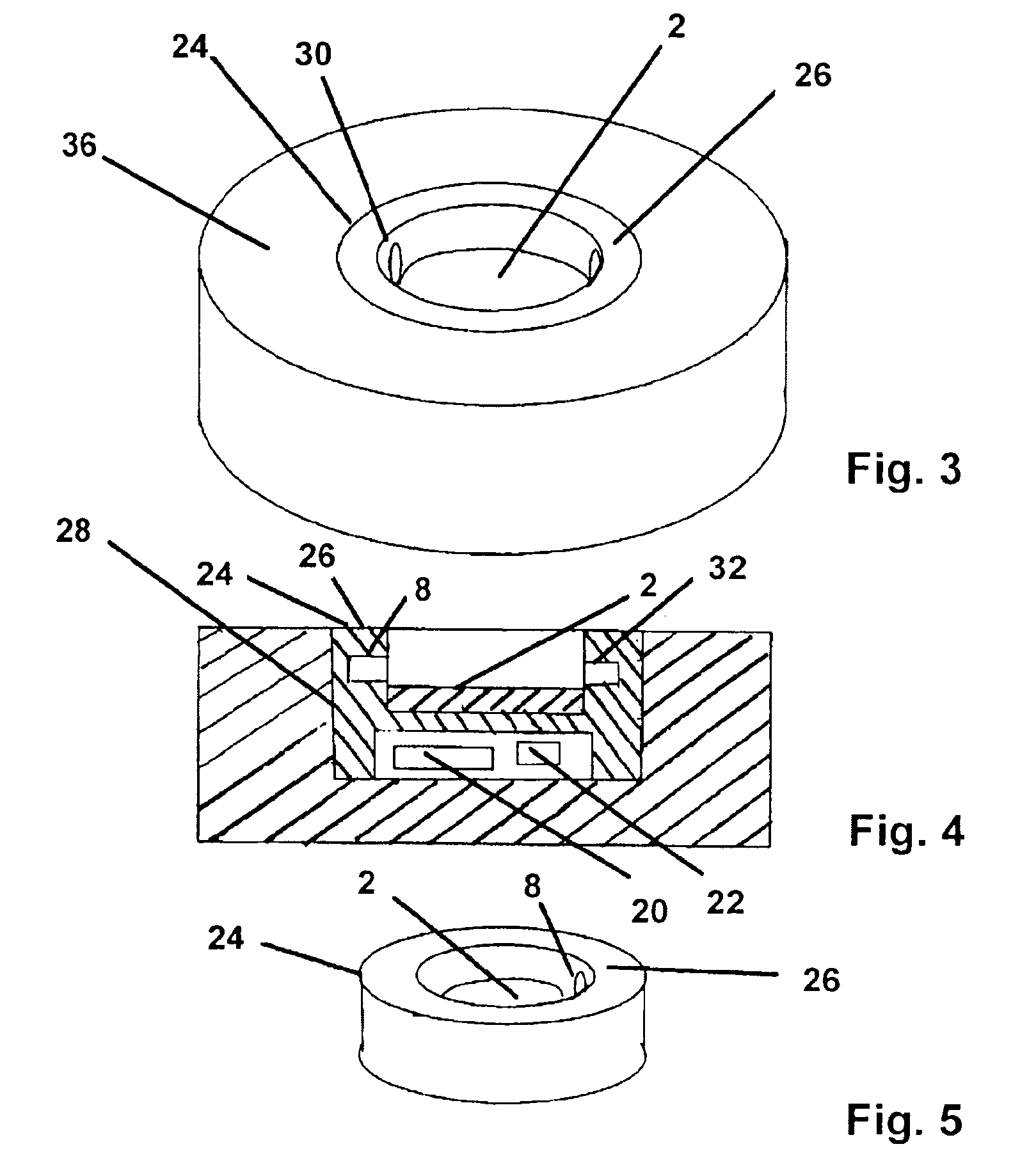

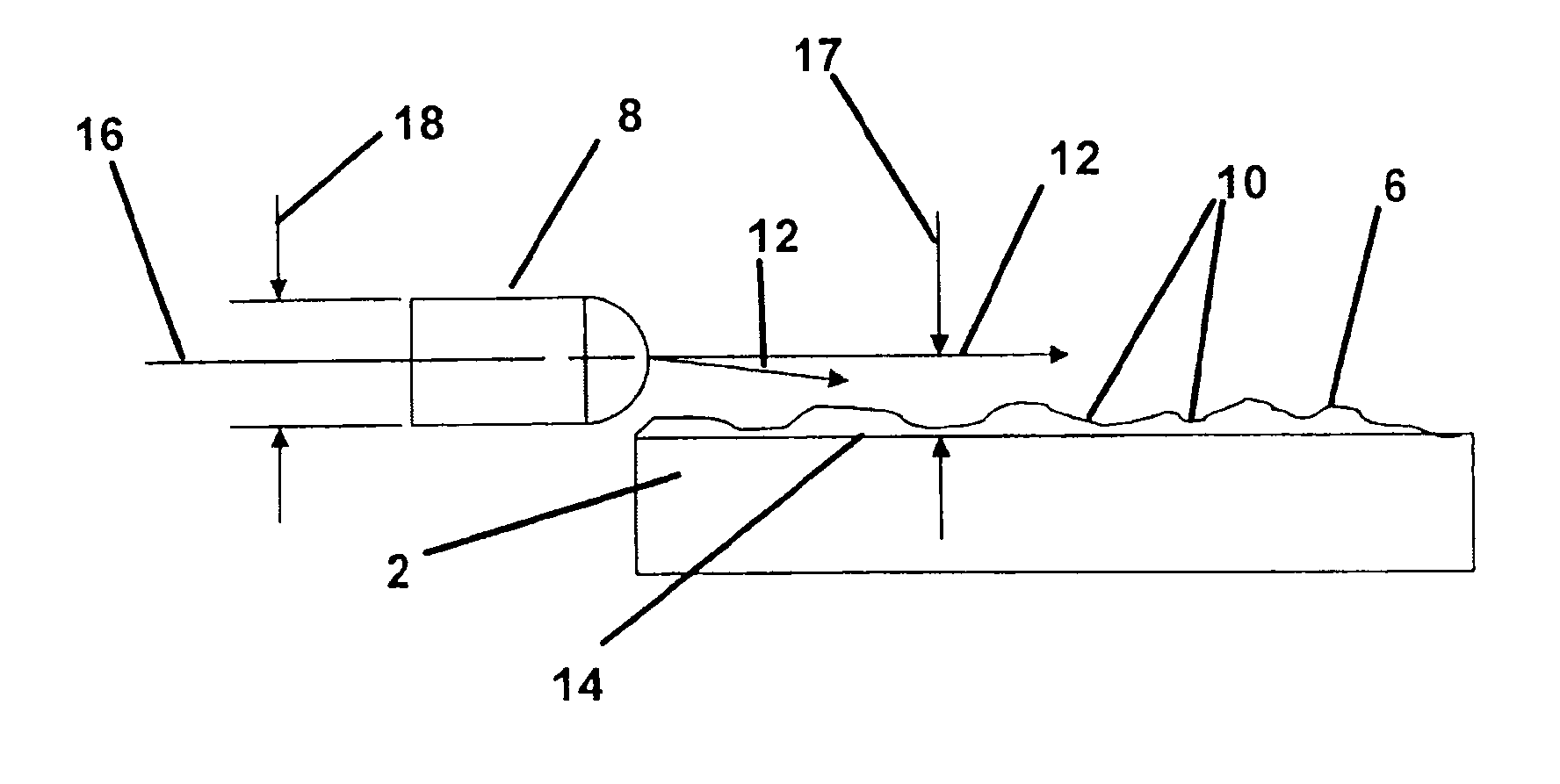

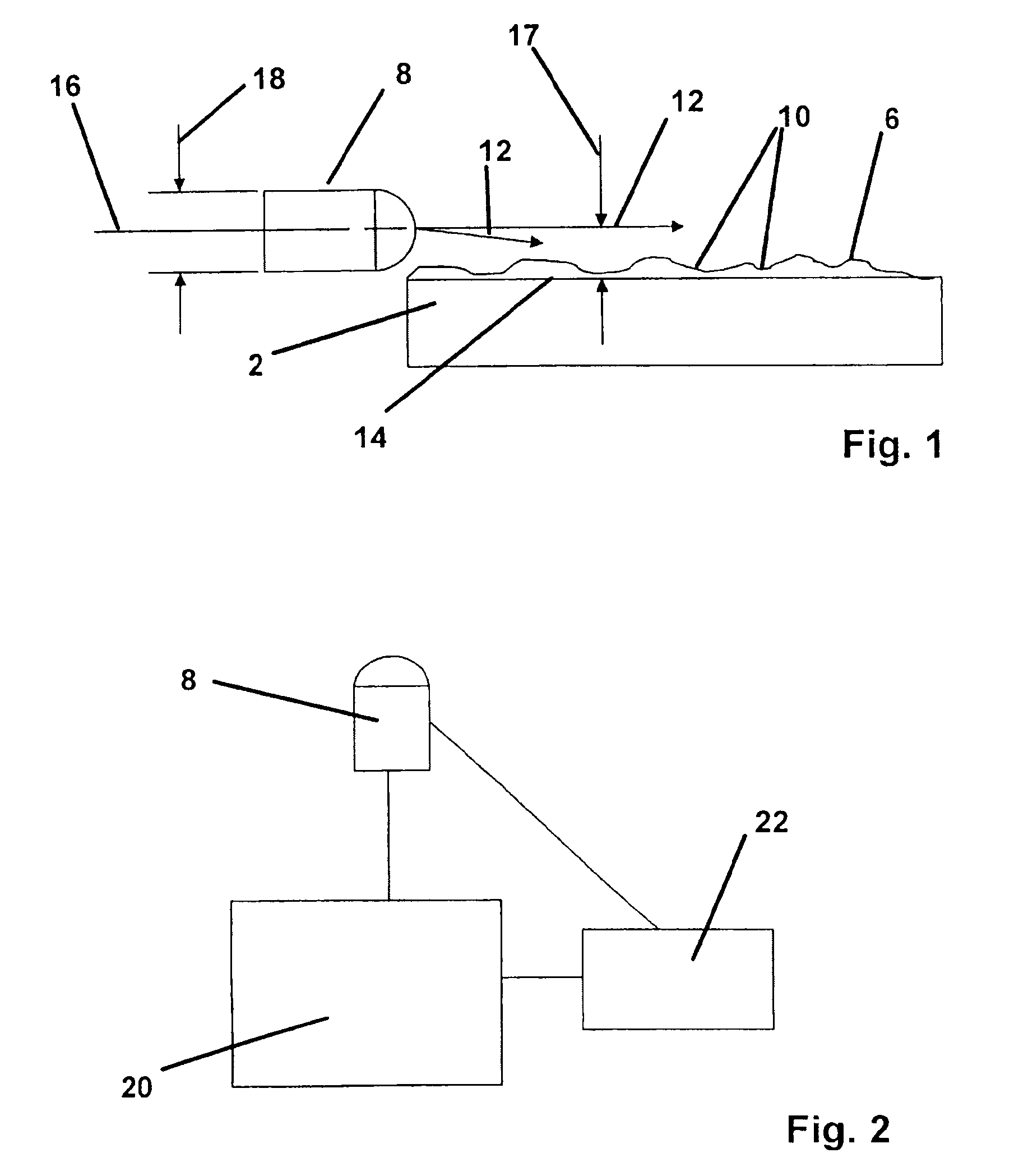

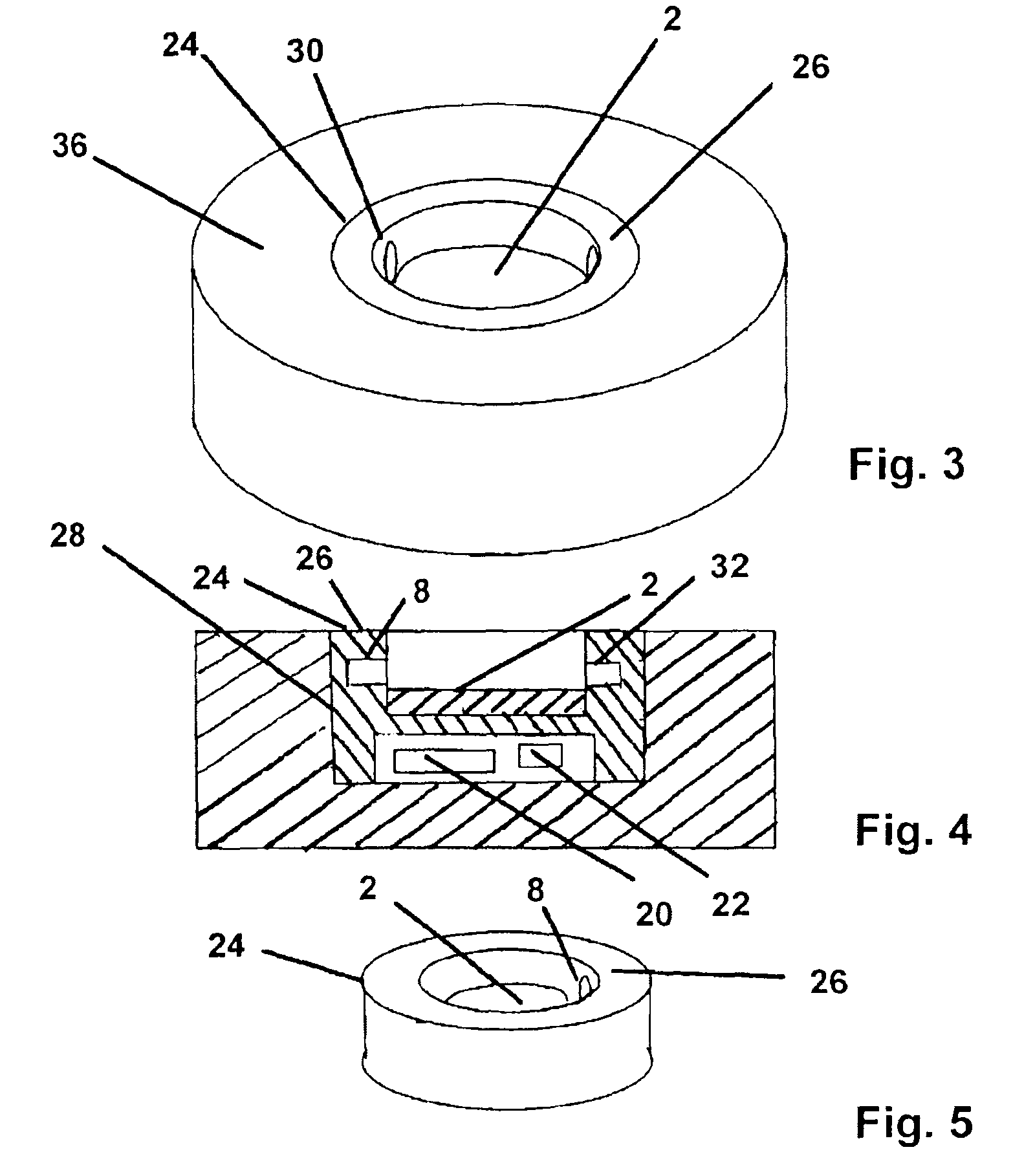

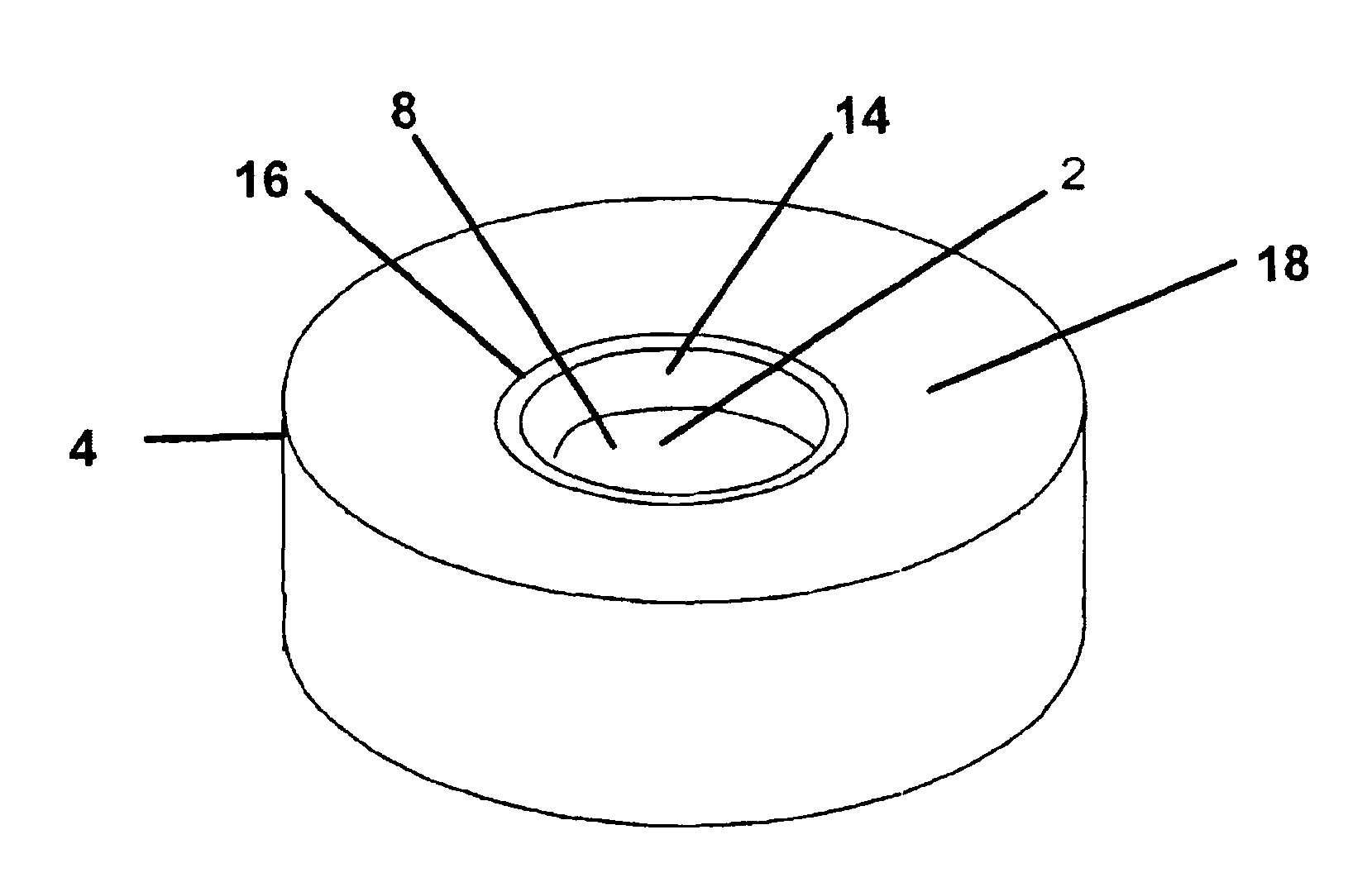

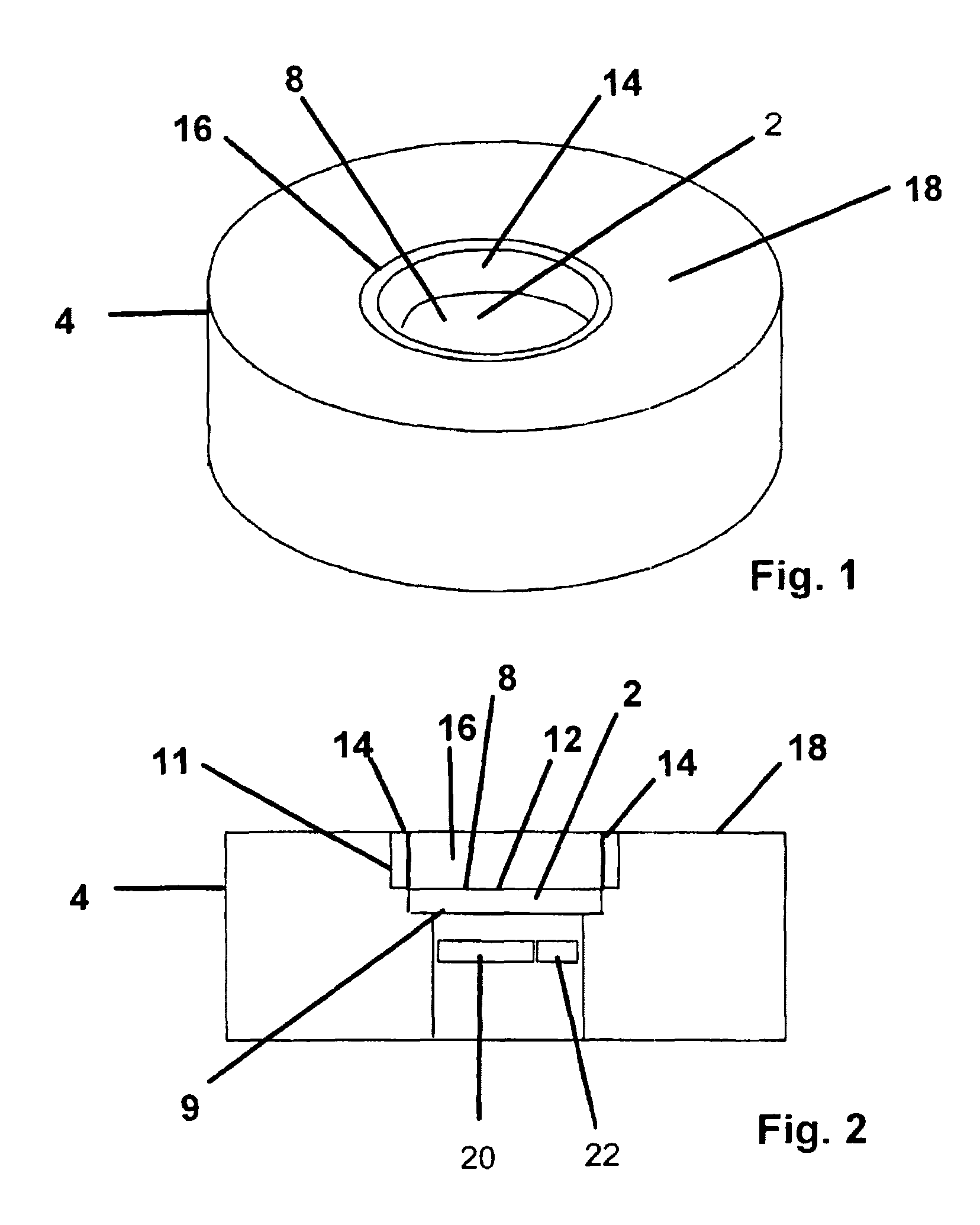

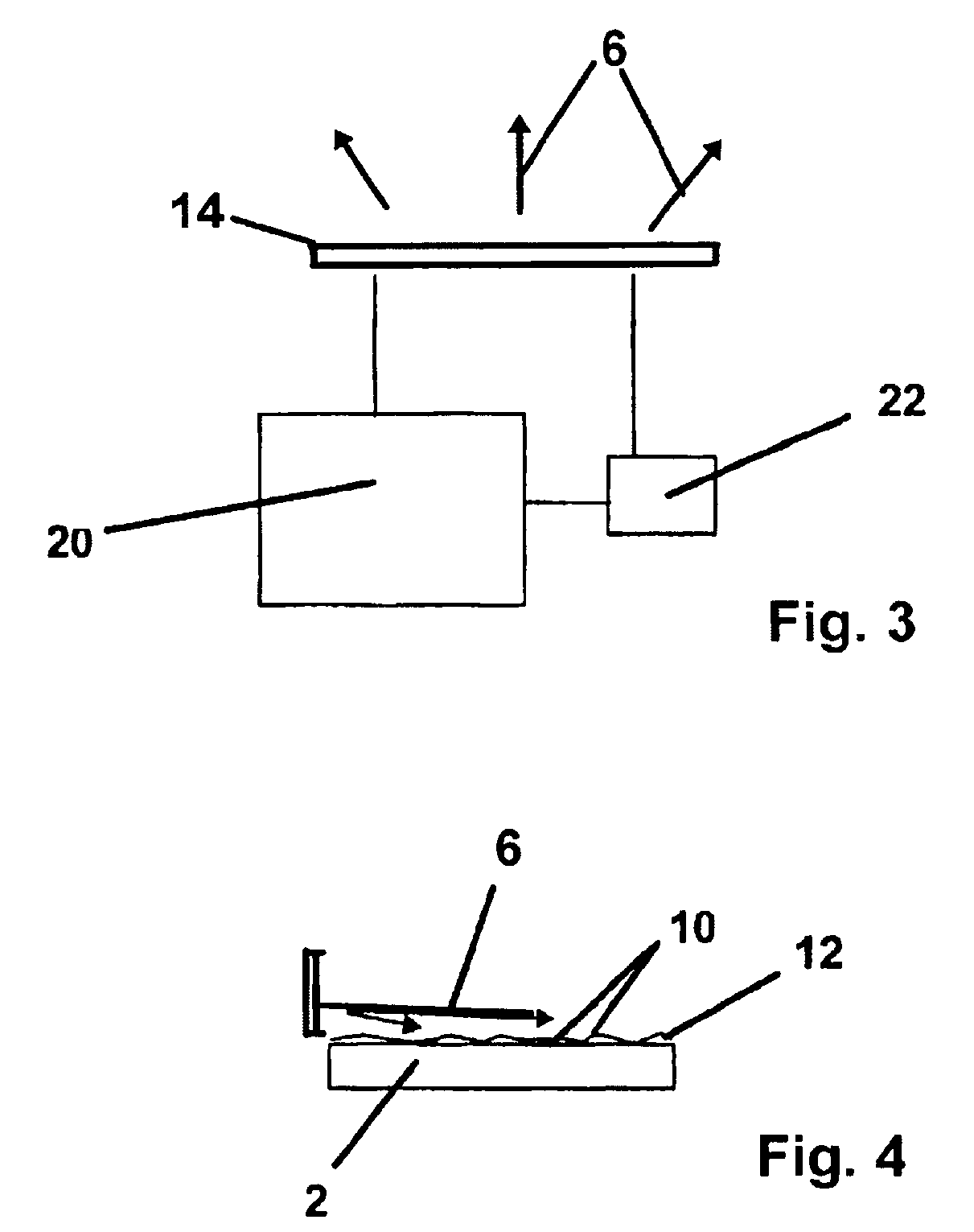

Apparatus and Method for Displaying an Object having Relief

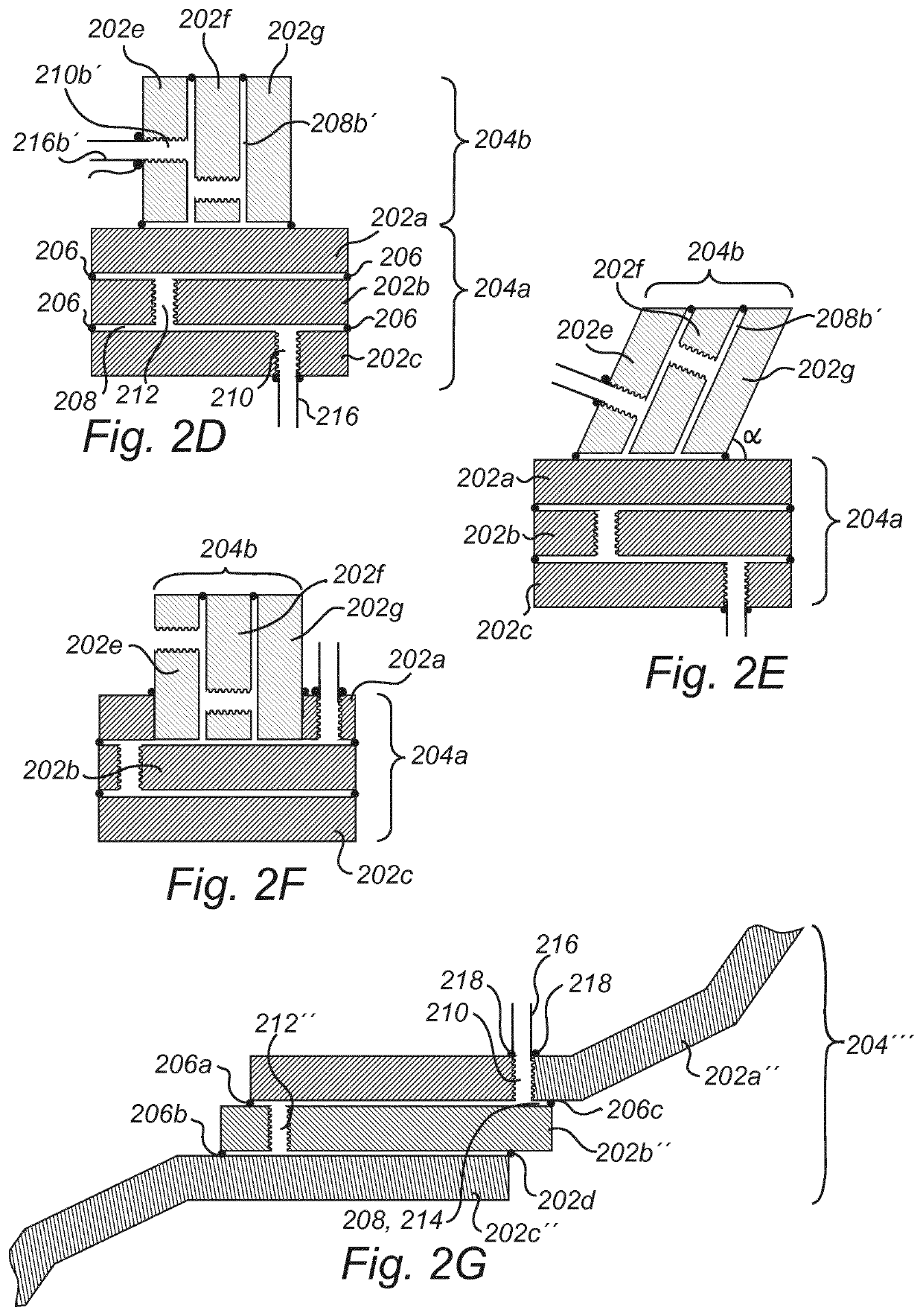

InactiveUS20080285261A1Increase valueEffective displayStampsLighting support devicesEngineeringLED lamp

The Invention is an apparatus for displaying a medallion in an item of memorabilia. The item of memorabilia defines a cavity. A holder is configured to be contained within the cavity and defines a medallion-receiving opening selectably receiving the medallion. The holder contains an LED lamp oriented generally parallel to the display surface of the medallion. The LED lamp causes the relief of the medallion to cast a shadow on the display surface of the medallion. The lustrous metal of the medallion reflects light from the relief to an observer.

Owner:RATMANSKY PAUL PHILLIP +1

Apparatus and method for displaying an object having relief

The Invention is an apparatus for displaying a medallion in an item of memorabilia. The item of memorabilia defines a cavity. A holder is configured to be contained within the cavity and defines a medallion-receiving opening selectably receiving the medallion. The holder contains an LED lamp oriented generally parallel to the display surface of the medallion. The LED lamp causes the relief of the medallion to cast a shadow on the display surface of the medallion. The lustrous metal of the medallion reflects light from the relief to an observer.

Owner:RATMANSKY PAUL PHILLIP +1

Method for minimizing bowing of collector plates in an electrostatic precipitator, and a collector plate-clip combination

InactiveUS20050223892A1Minimizes the bowing of a fresh plateAssist in the straightening of a collecting plateElectrode carrying meansBuilding reinforcementsEngineeringLinearity

Owner:NISOURCE CORP SERVICES

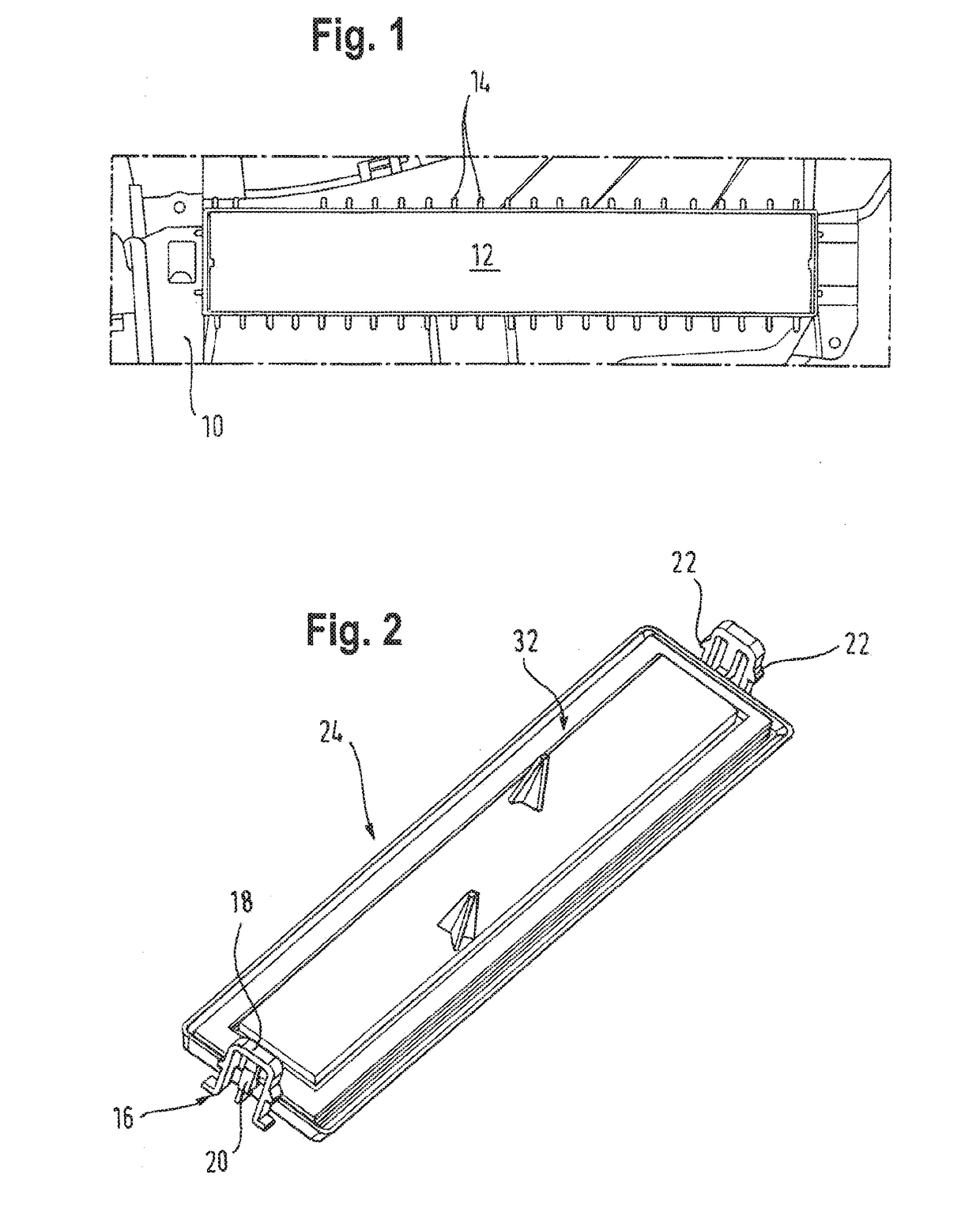

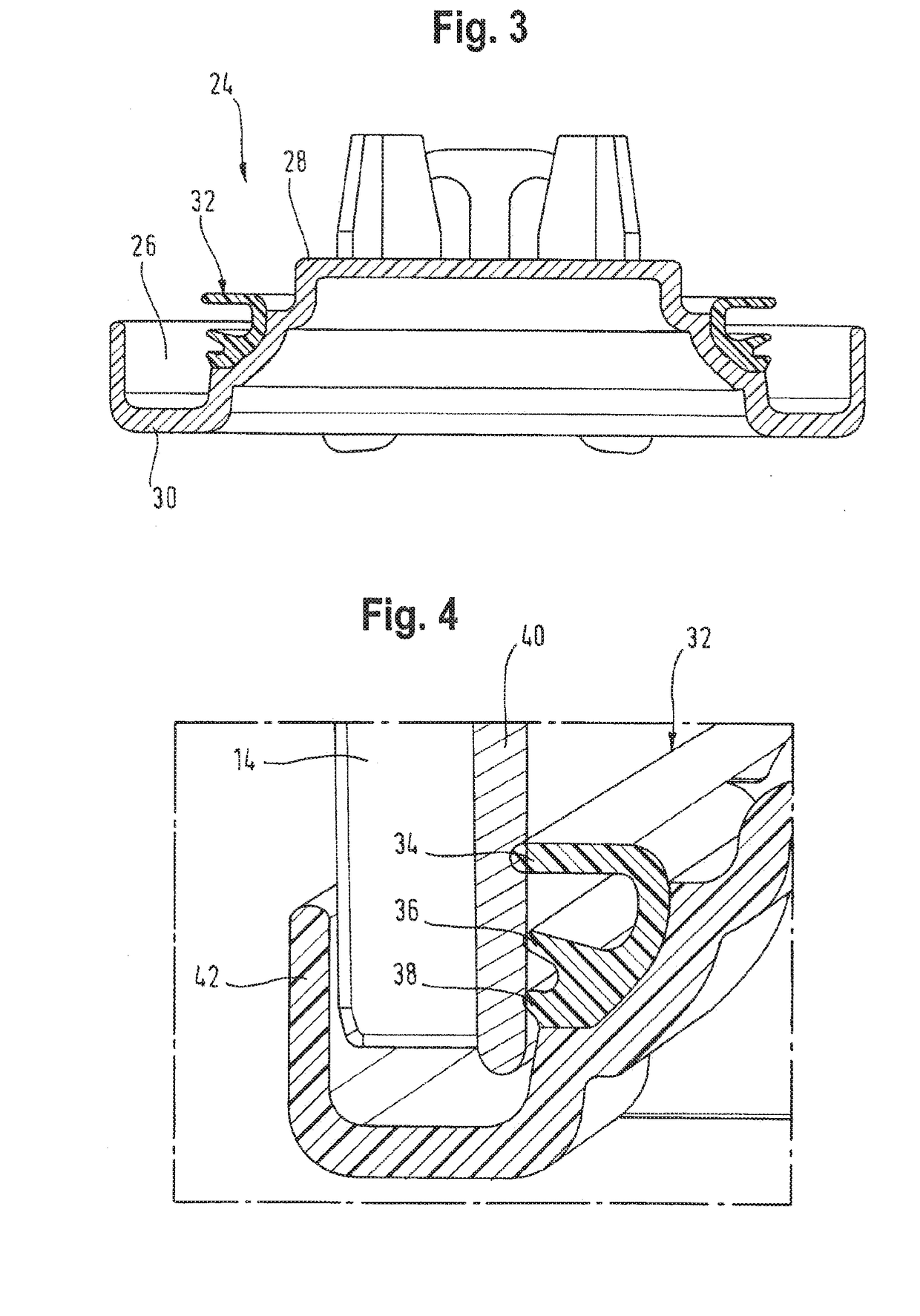

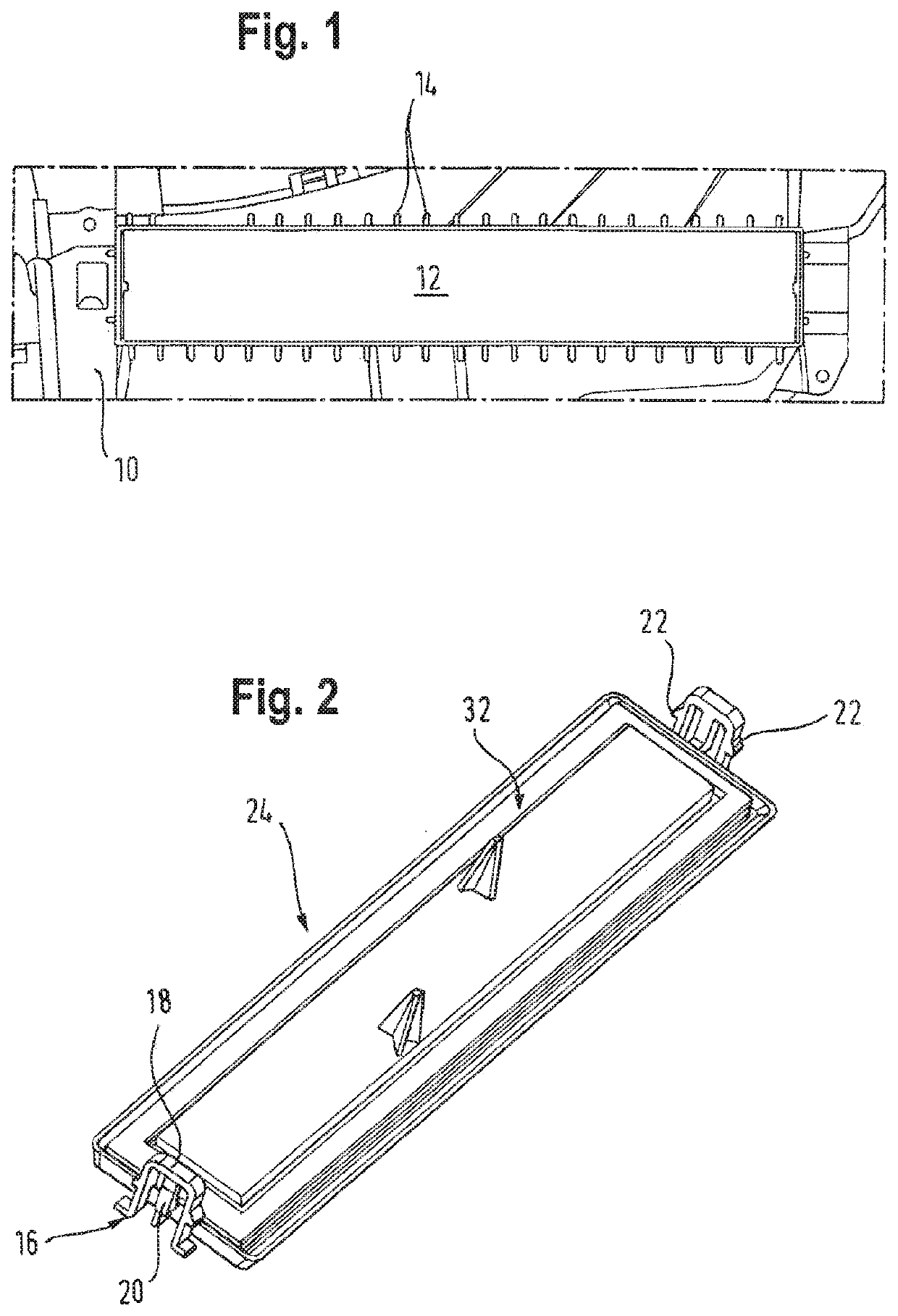

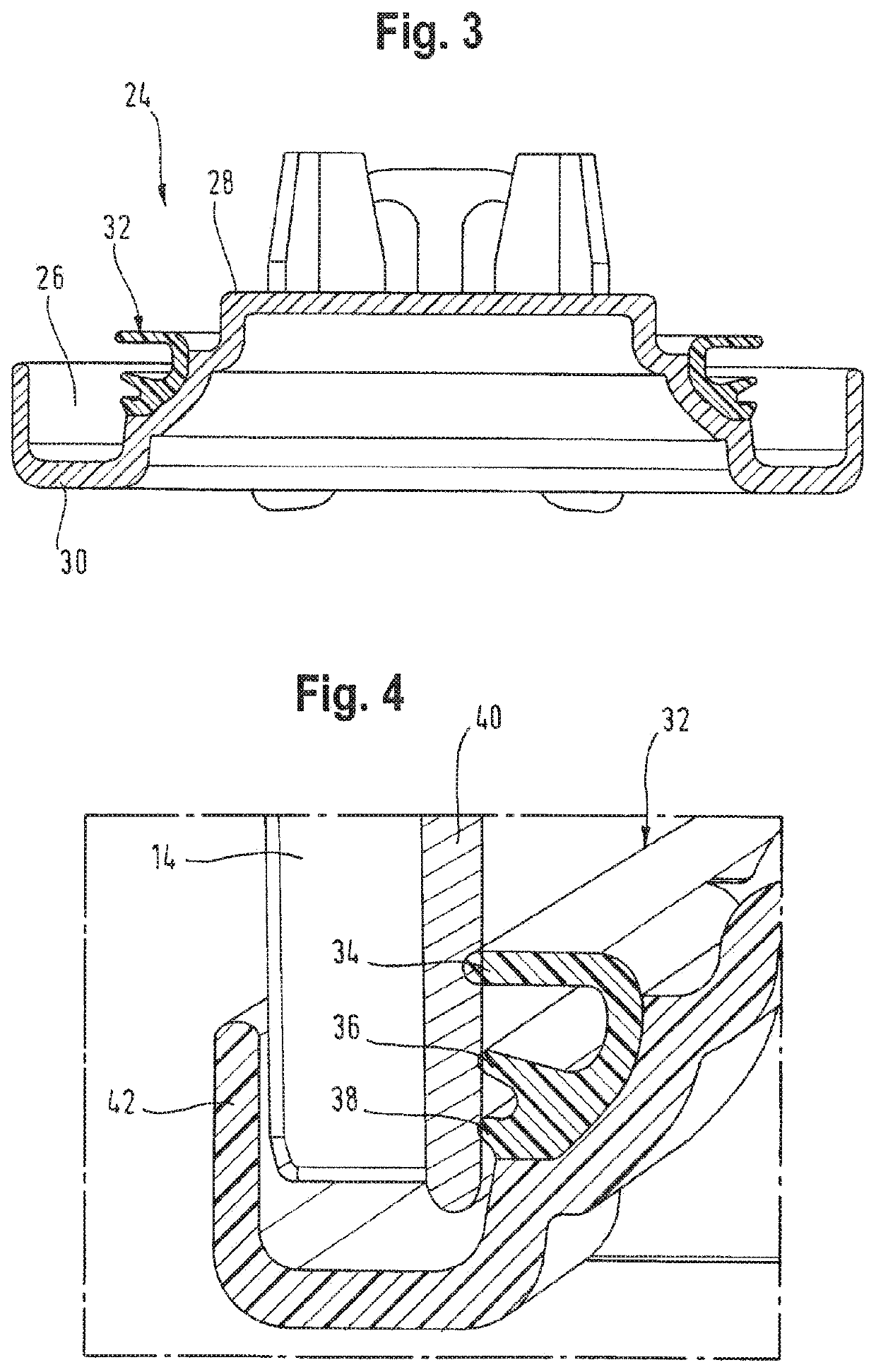

Housing, in paticular filter housing and air conditioning system for a vehicle

ActiveUS20180353890A1Minimal forceEasy to replaceAir-treating devicesDispersed particle filtrationEngineeringAir conditioning

Owner:HANON SYST

Imine compound, novel catalyst for olefin polymerization, and process for producing olefin polymer

ActiveUS20160237184A1Form is therefore complexHigh molecular weightGroup 5/15 element organic compoundsNickel organic compoundsOlefin polymerizationPolymer

Owner:JAPAN POLYPROPYLENE CORP +1

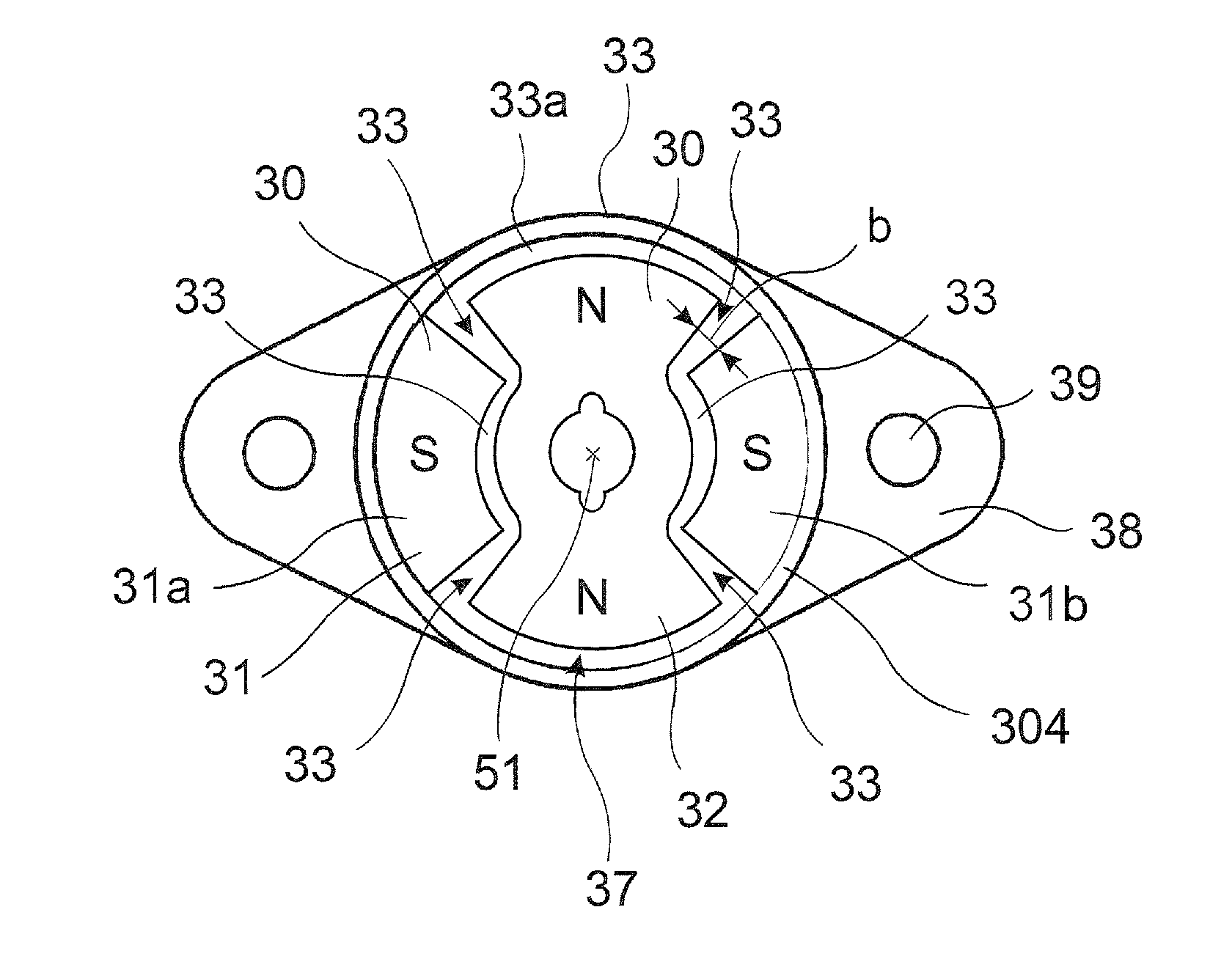

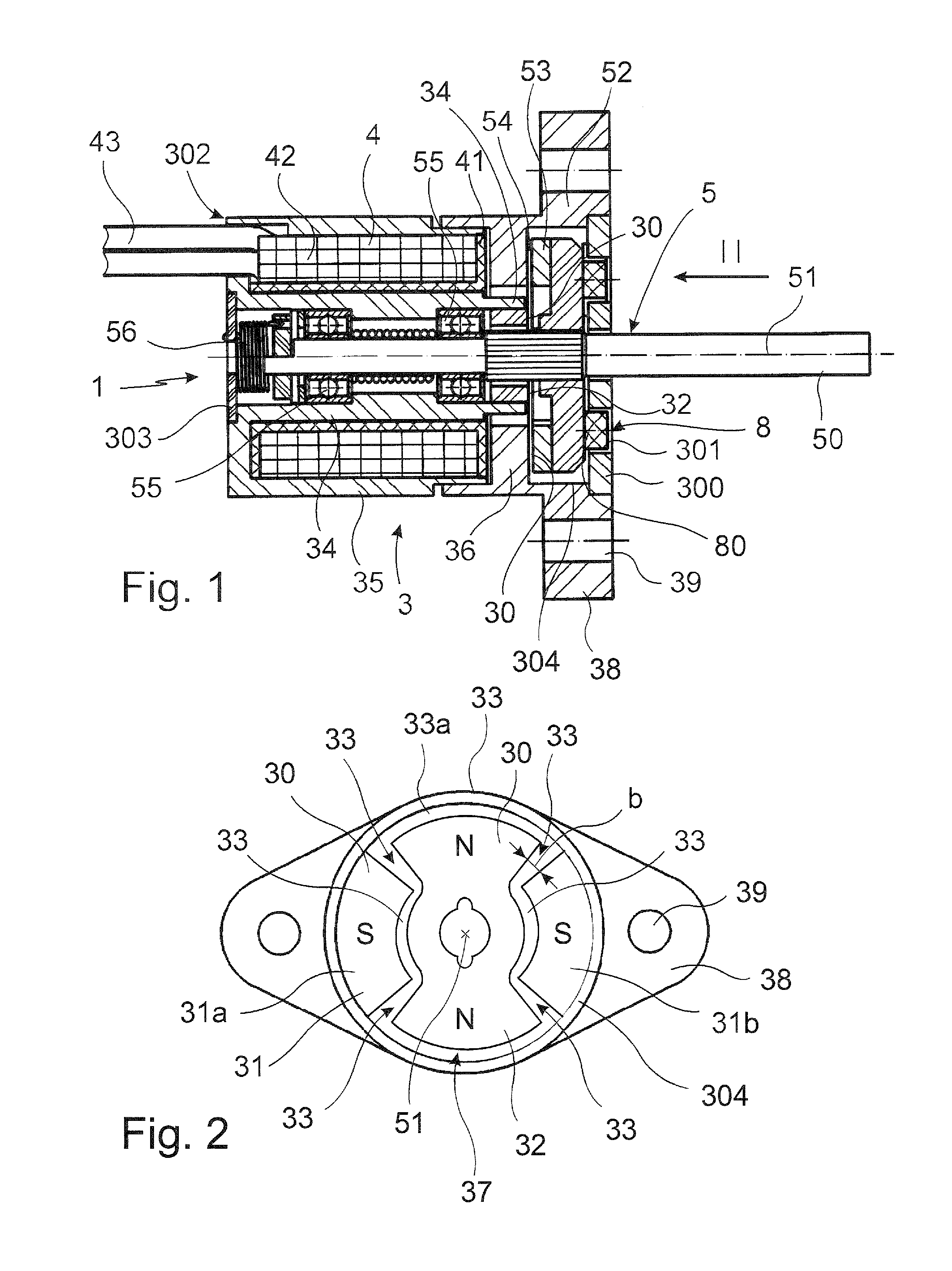

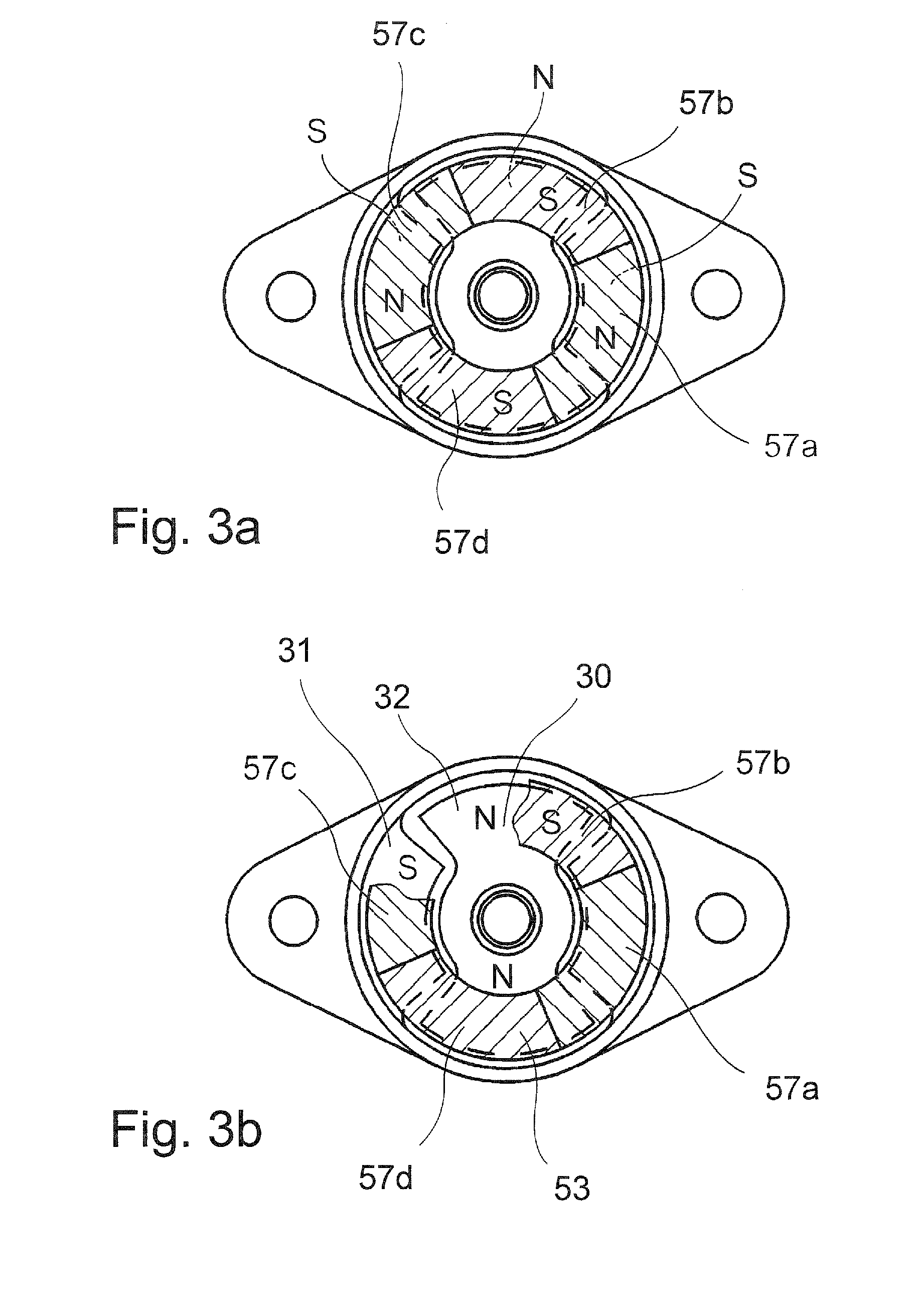

Rotary Solenoid

ActiveUS20110187483A1Heterogeneous distributionSave installation spaceDynamo-electric machinesElectromagnets with armaturesRotational axisMagnetic field

The invention refers to a Rotary Solenoid comprising a stator and rotor that can rotate around a rotational axis. The rotor has a rotor shaft on which a rotor disc is arranged. The rotor disc is, seen in the direction of the circumference, polarized alternating magnetically. The stator carries at least one coil. On the coil windings of electrically conducting wire are provided. For guiding the magnetic flow of the magnetic field generated by the coil a pole face consisting of several partial pole faces is provided.

Owner:SVM SCHULTZ VERW

Method For Manufacturing A Metal Based Component And A Single-Piece, Metal Based Component

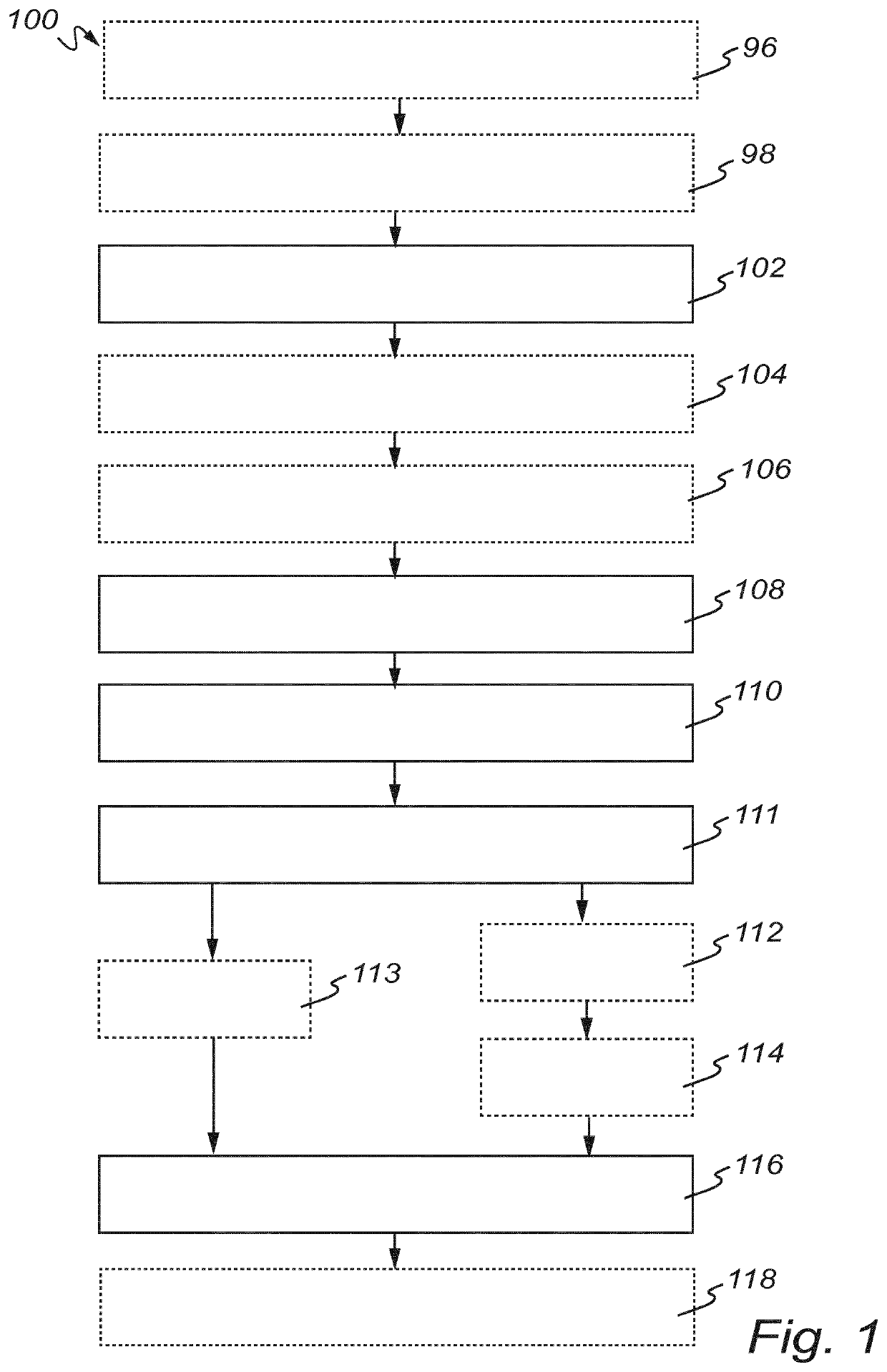

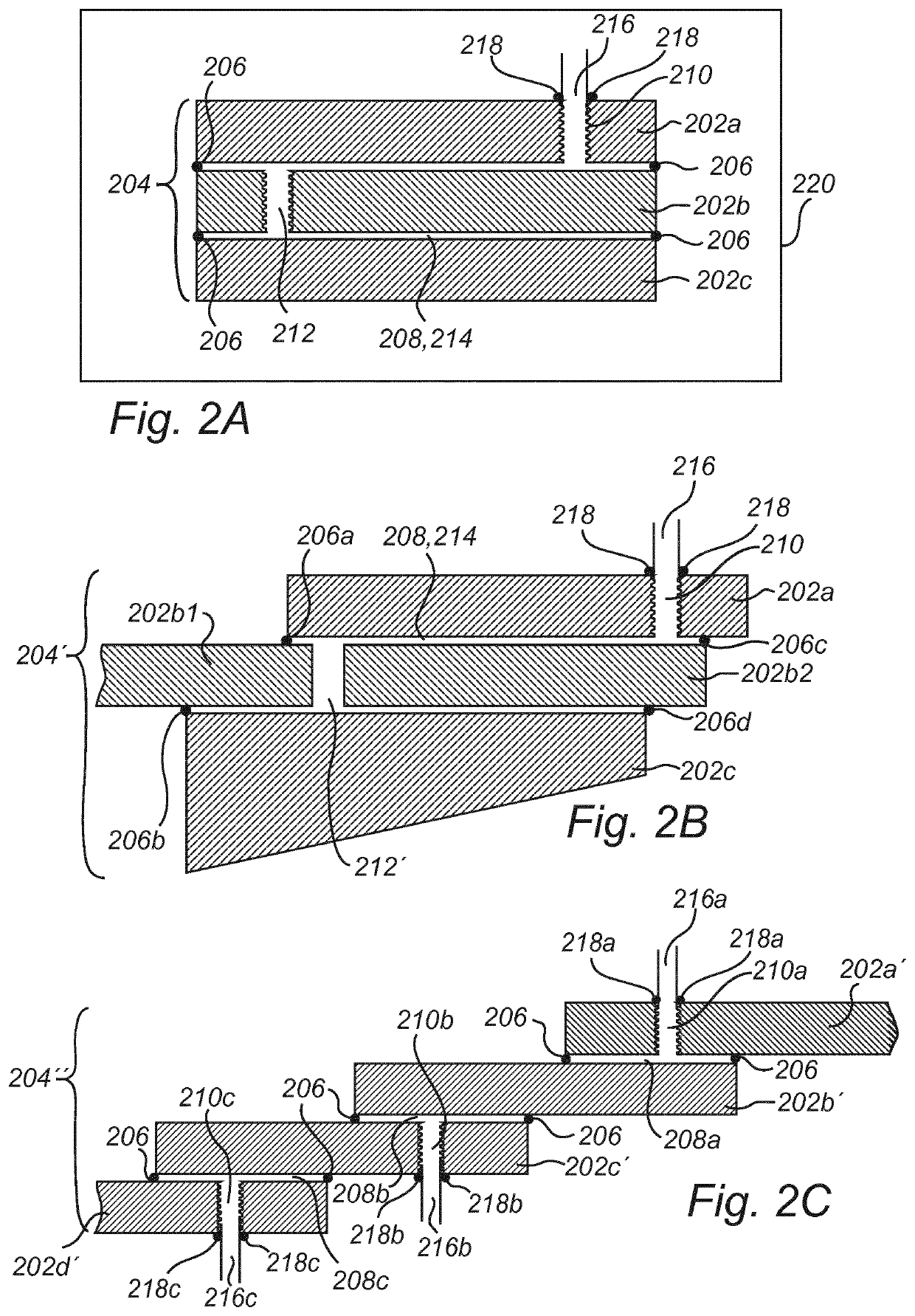

ActiveUS20200269346A1Cheap to prepareForm is therefore complexWelding/soldering/cutting articlesMetal working apparatusHot isostatic pressingSolid metal

The invention relates to a method for manufacturing a solid metal based component. The method comprising the steps of providing a plurality of metal based sheets; arranging the plurality of metal based sheets in a stack, 5 wherein the stack comprises a first metal based sheet, a last metal based sheet and at least one intermediate metal based sheet; perimetrically sealing at least a portion of the stack forming at least one cavity inside of the stack; removing gas from said at least one cavity, and subjecting the stack to a hot isostatic pressing process for a predetermined time at a predetermined 10 pressure and a predetermined temperature so that the plurality of metal based sheets of the stack bond metallurgically to each other to form a solid metal based component. The invention further relates to a single-piece metal based component.

Owner:HIPTEC AS

Apparatus for displaying an object having relief

InactiveUS20090056176A1Increase valueEffective displayStampsLighting support devicesEngineeringHockey puck

The present Invention is an apparatus for displaying a medallion in an item of memorabilia, such as a hockey puck or a model of a tire. A medallion is selectably retained by a cavity defined by the item of memorabilia. A light-emitting capacitor is disposed either in front of or behind the medallion, illuminating the surface of the medallion.

Owner:RATMANSKY PAUL PHILLIP +1

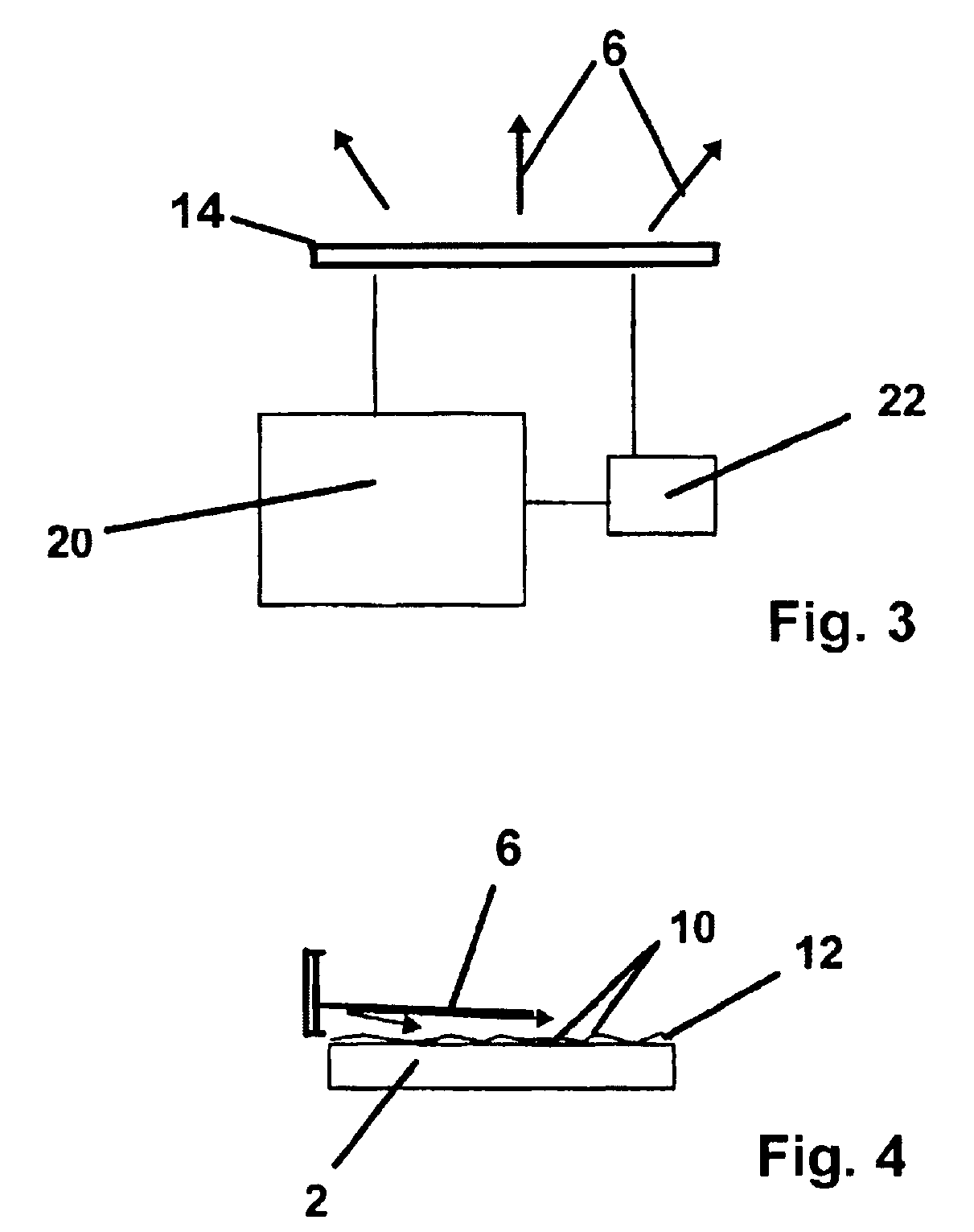

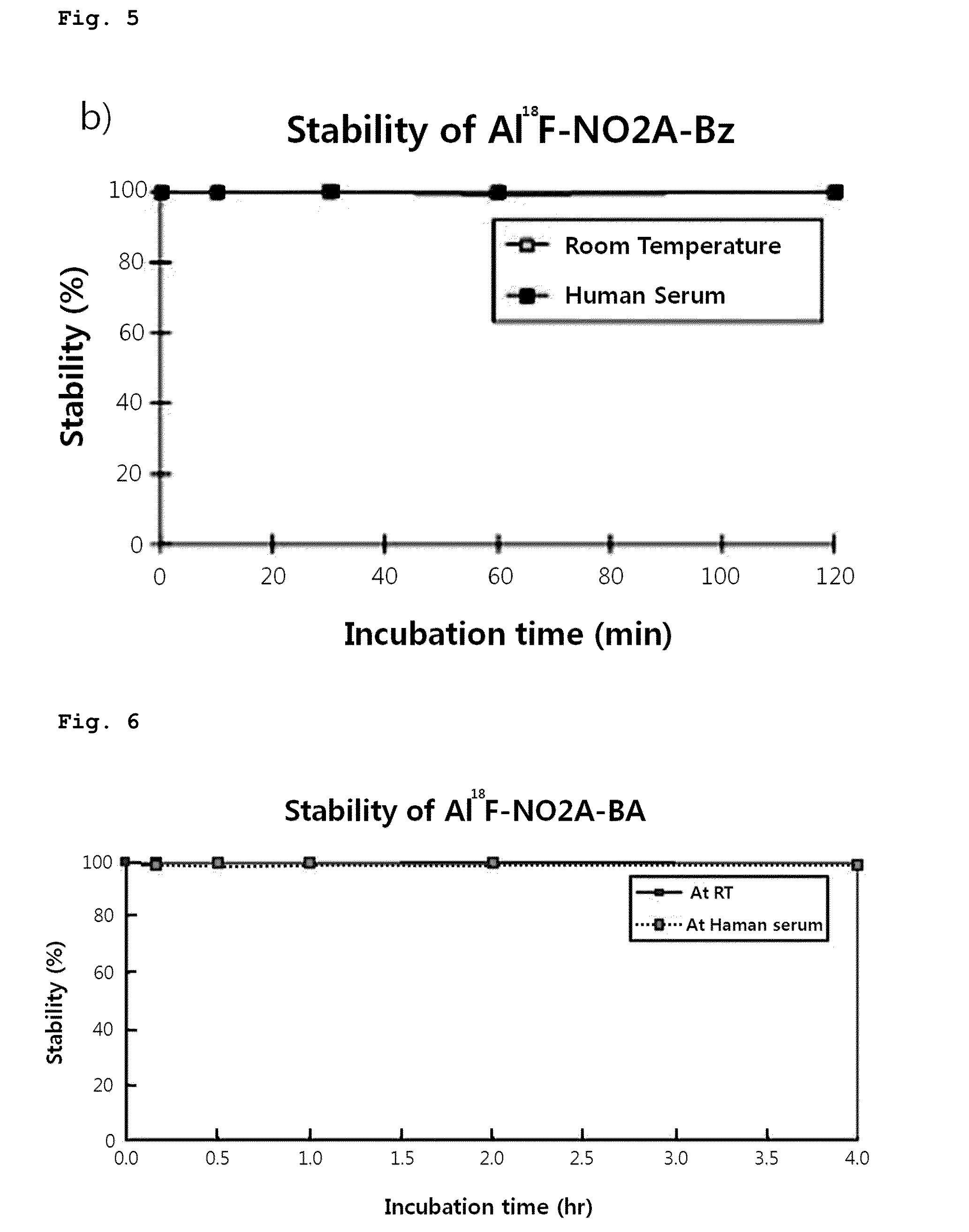

Triazanonane derivatives or pharmaceutically acceptable salt thereof for enhanced fluorine-18 labeling

ActiveUS9012604B2Easy to useForm is therefore complexRadioactive preparation carriersImmunoglobulinsMetalFluoride salt

The present invention relates to a triazanonane derivative indicated by the chemical formula 1 below, or a pharmaceutically acceptable salt thereof, and a method for preparing same, and the triazanonane derivative according to the present invention forms a complex with a metal-fluoride and displays an effect of increasing the labeling efficiency up to 78-90% when labeling F-18, thus enabling use in various radioactive medicine labeling(In the chemical formula 1, R1, R2, A. E. X, n and m are as defined in the present description.)

Owner:TELEFON AB LM ERICSSON (PUBL) +1

Apparatus for displaying an object having relief

InactiveUS8038323B2Increase valueEffective displayStampsLighting support devicesEngineeringHockey puck

Owner:RATMANSKY PAUL PHILLIP +1

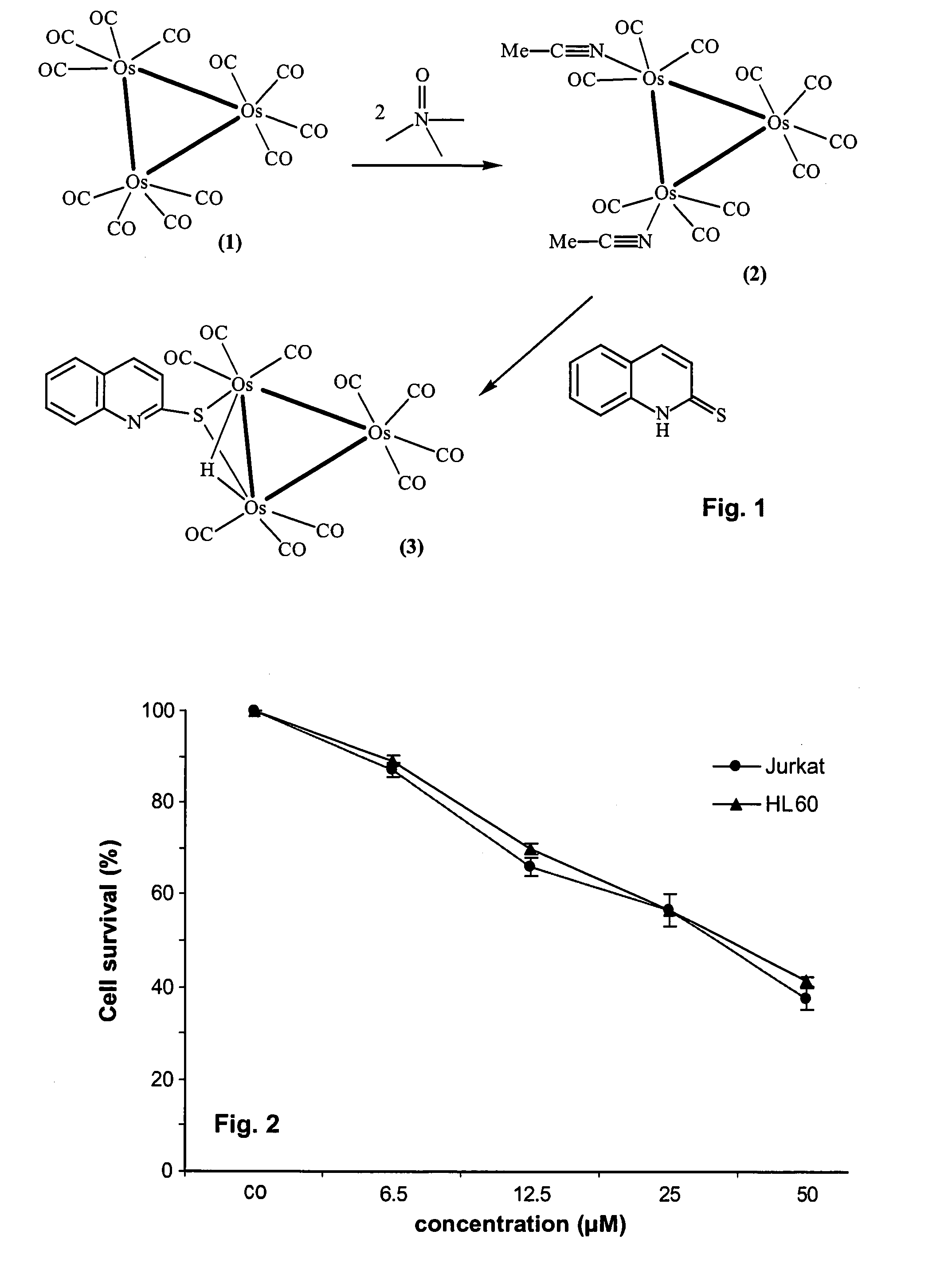

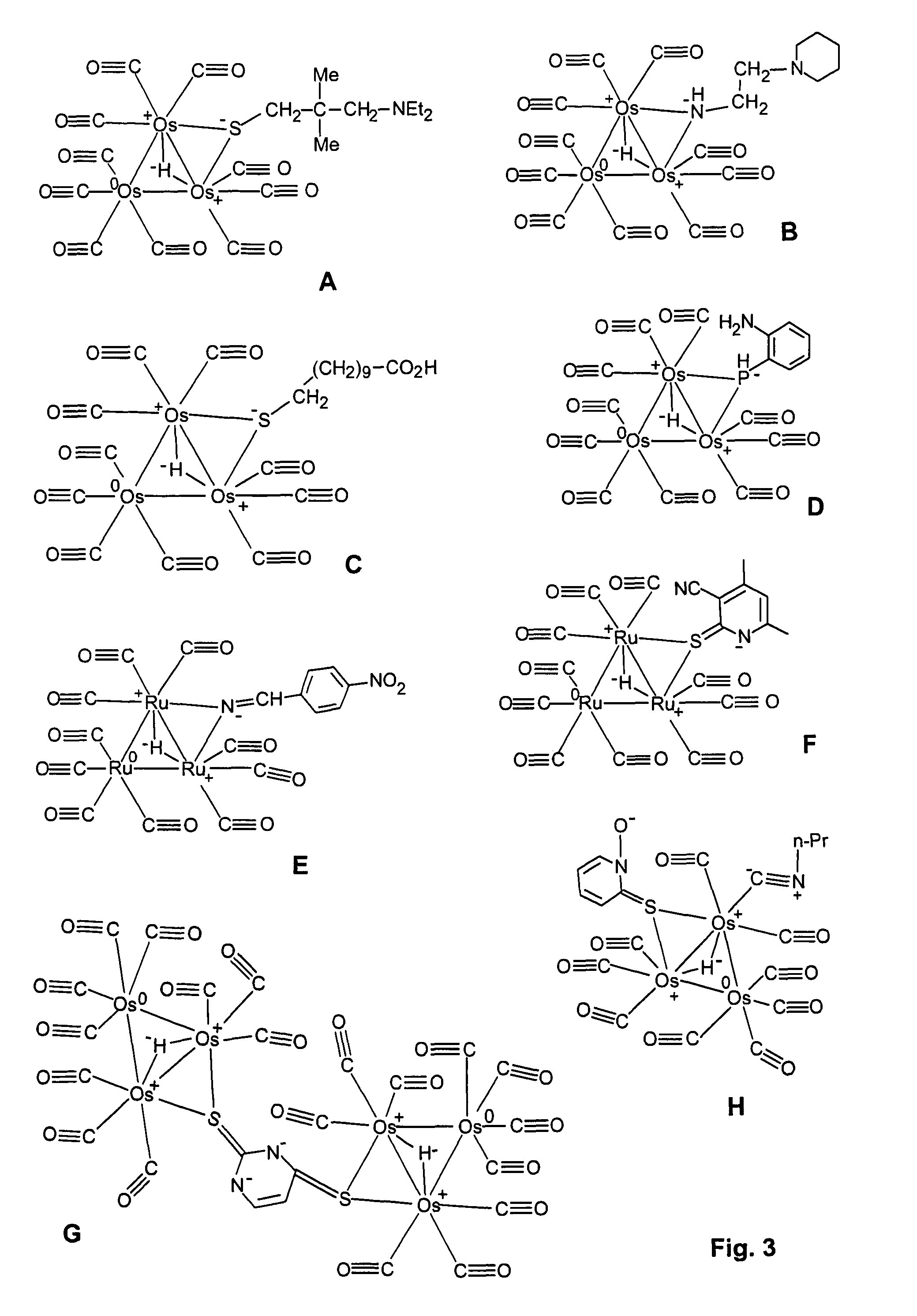

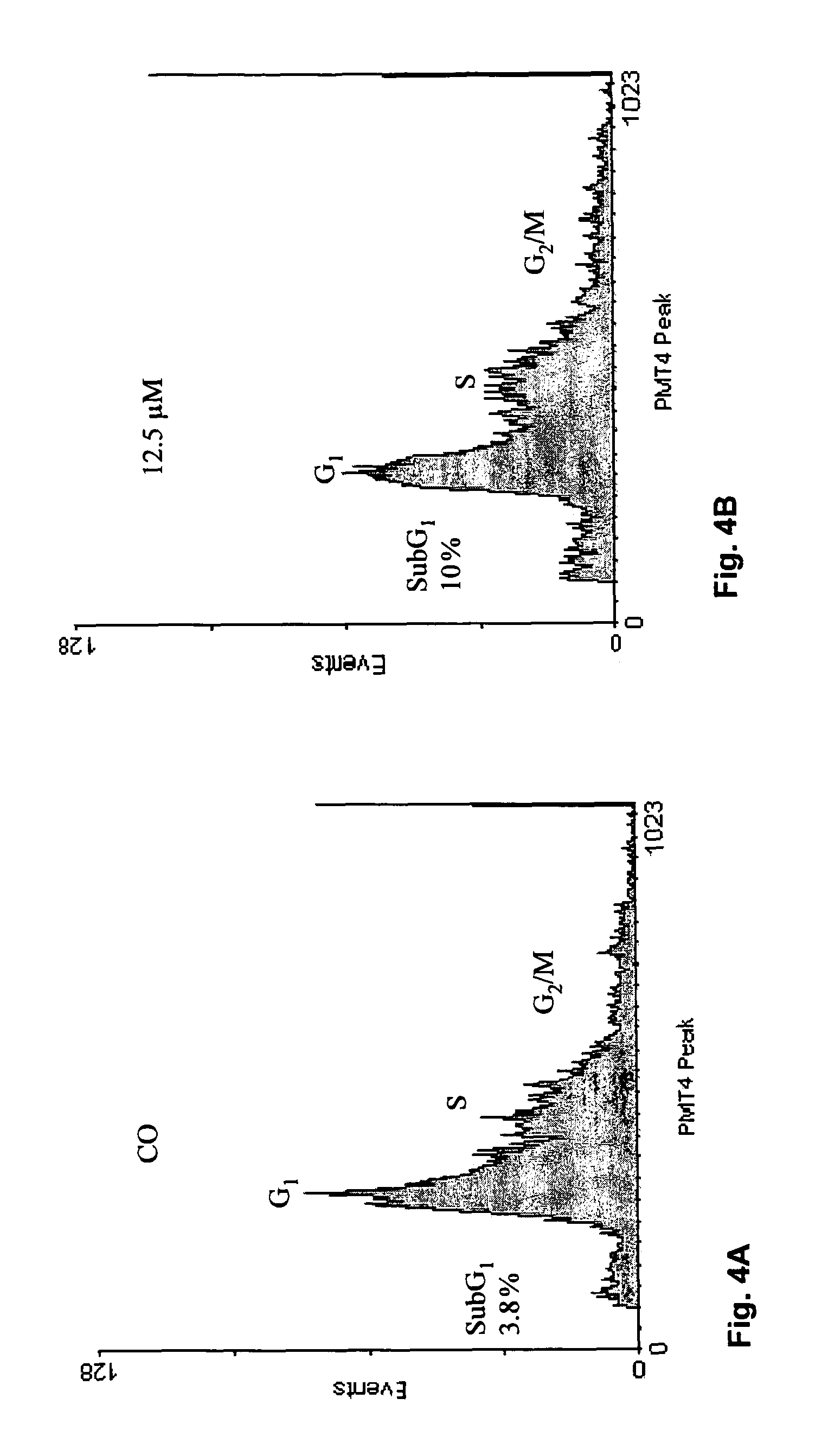

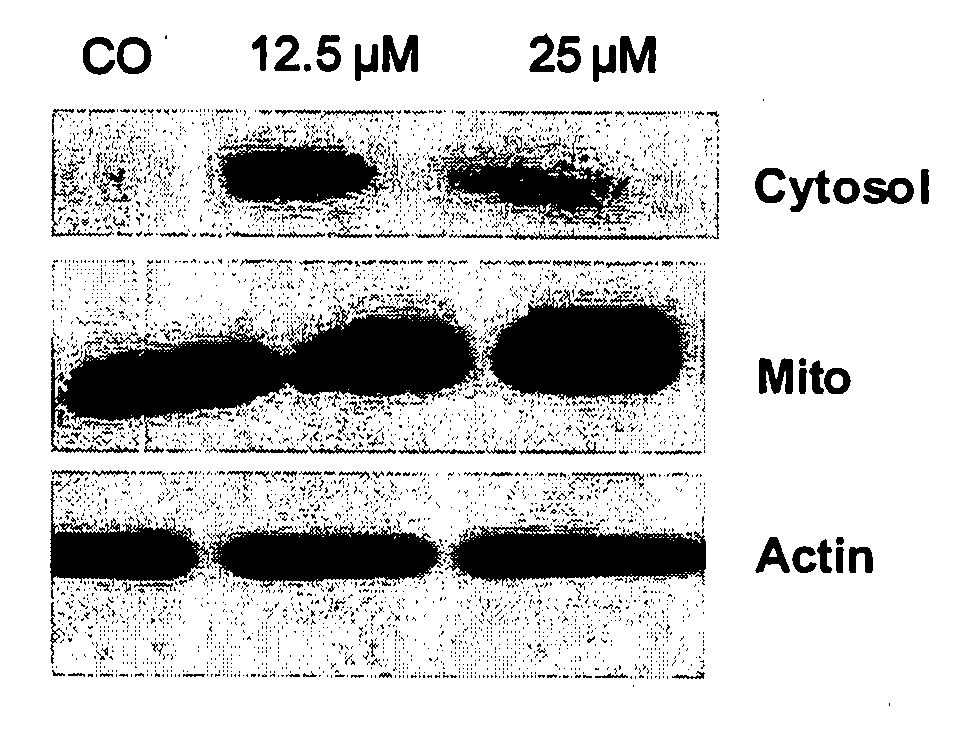

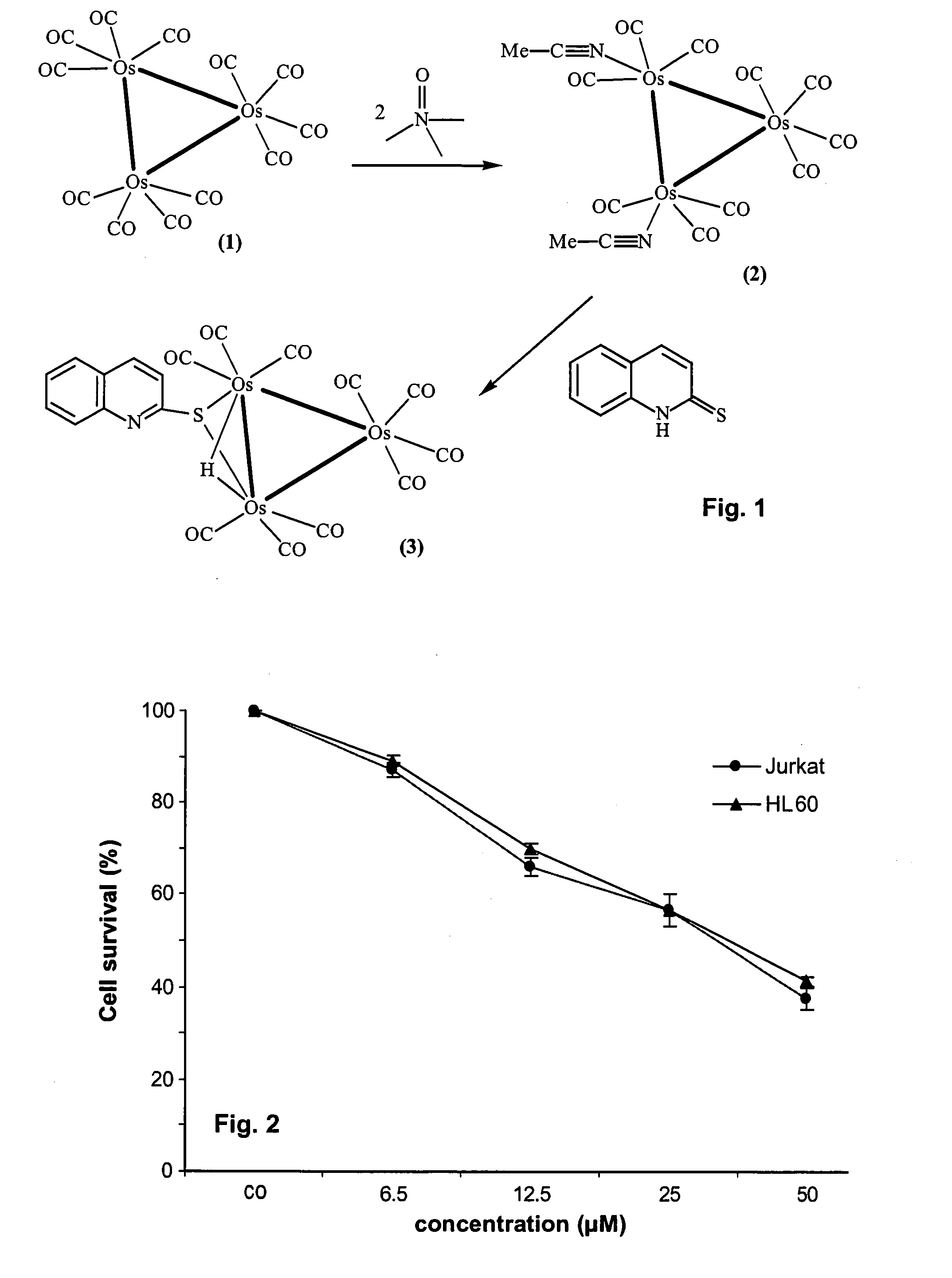

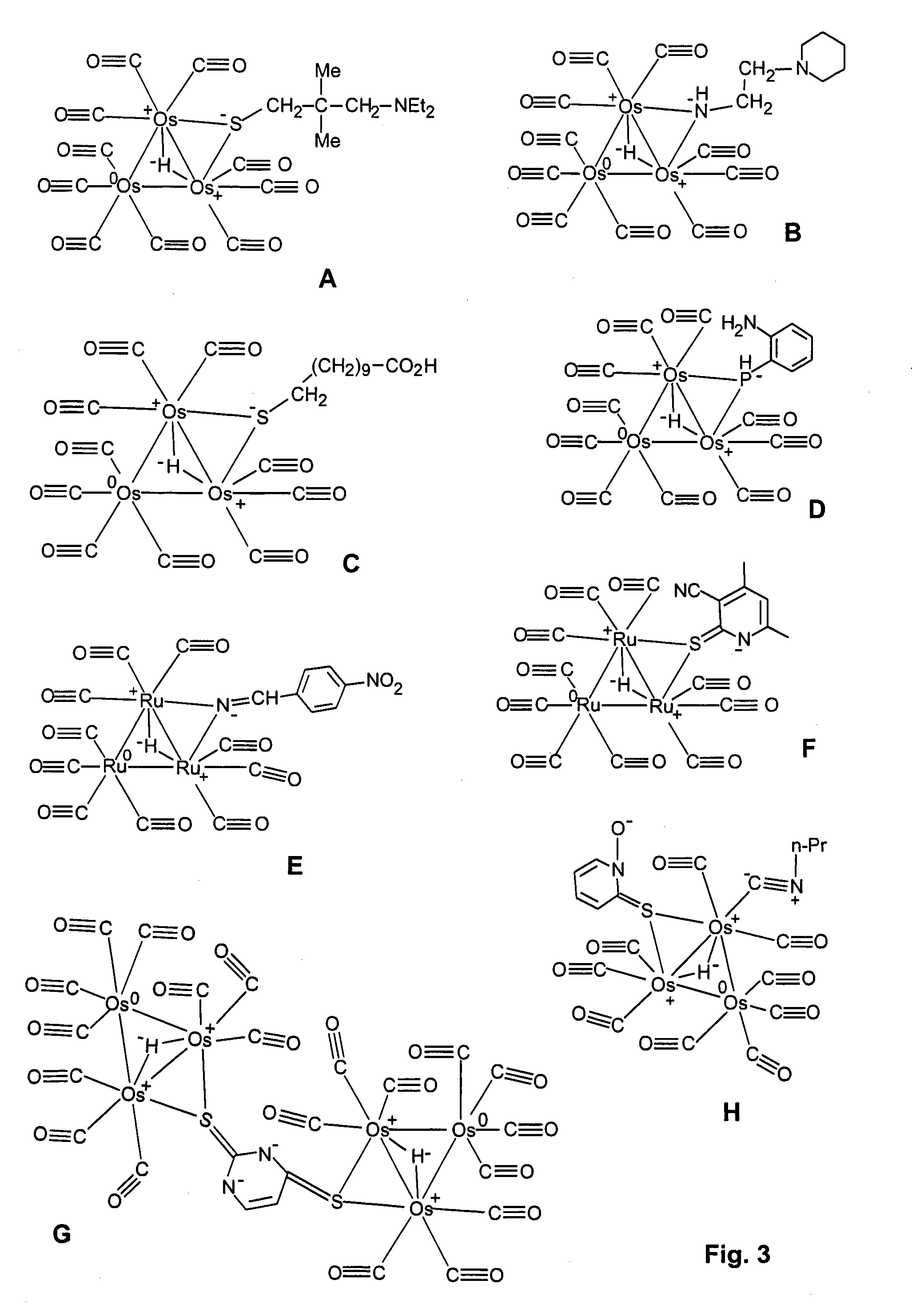

Metal triangulo compound and methods of using the same

The present invention relates to a metal triangulo compound. Provided is also a method of inducing apoptosis in a cell that comprises administering the metal triangulo compound. Provided is also a method of preventing carcinogenesis in a cell that comprises administering the metal triangulo compound.

Owner:NAT UNIV OF SINGAPORE

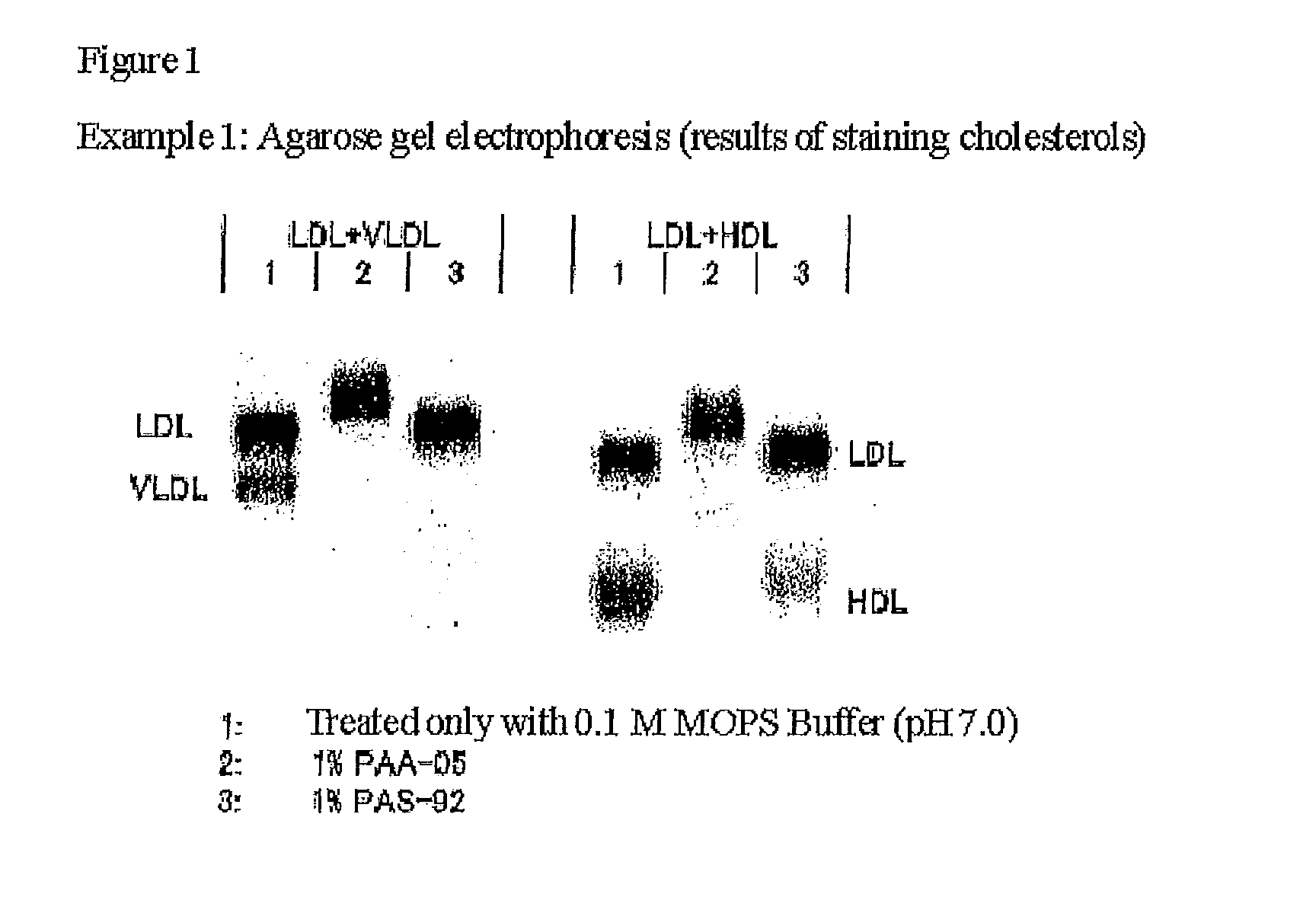

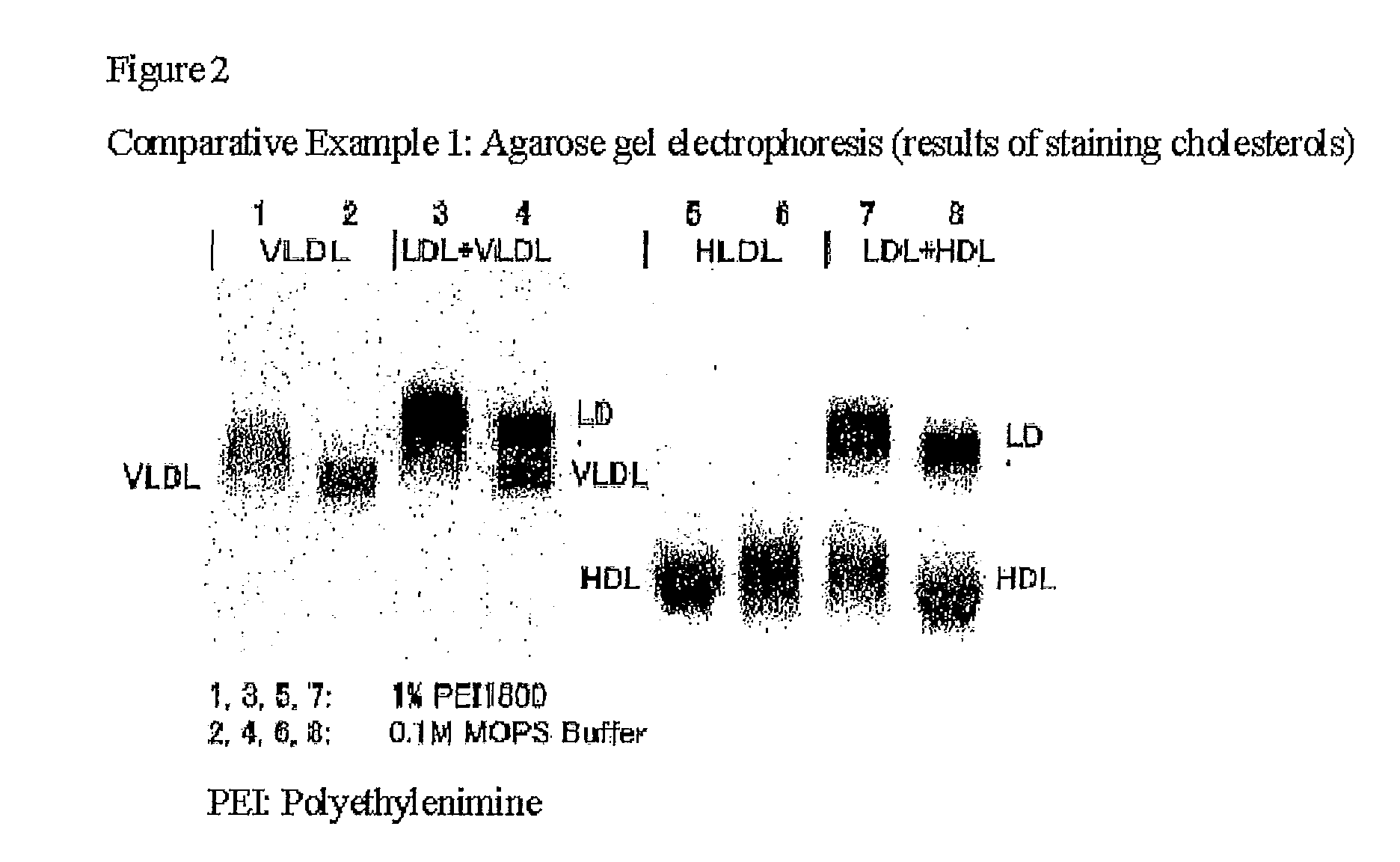

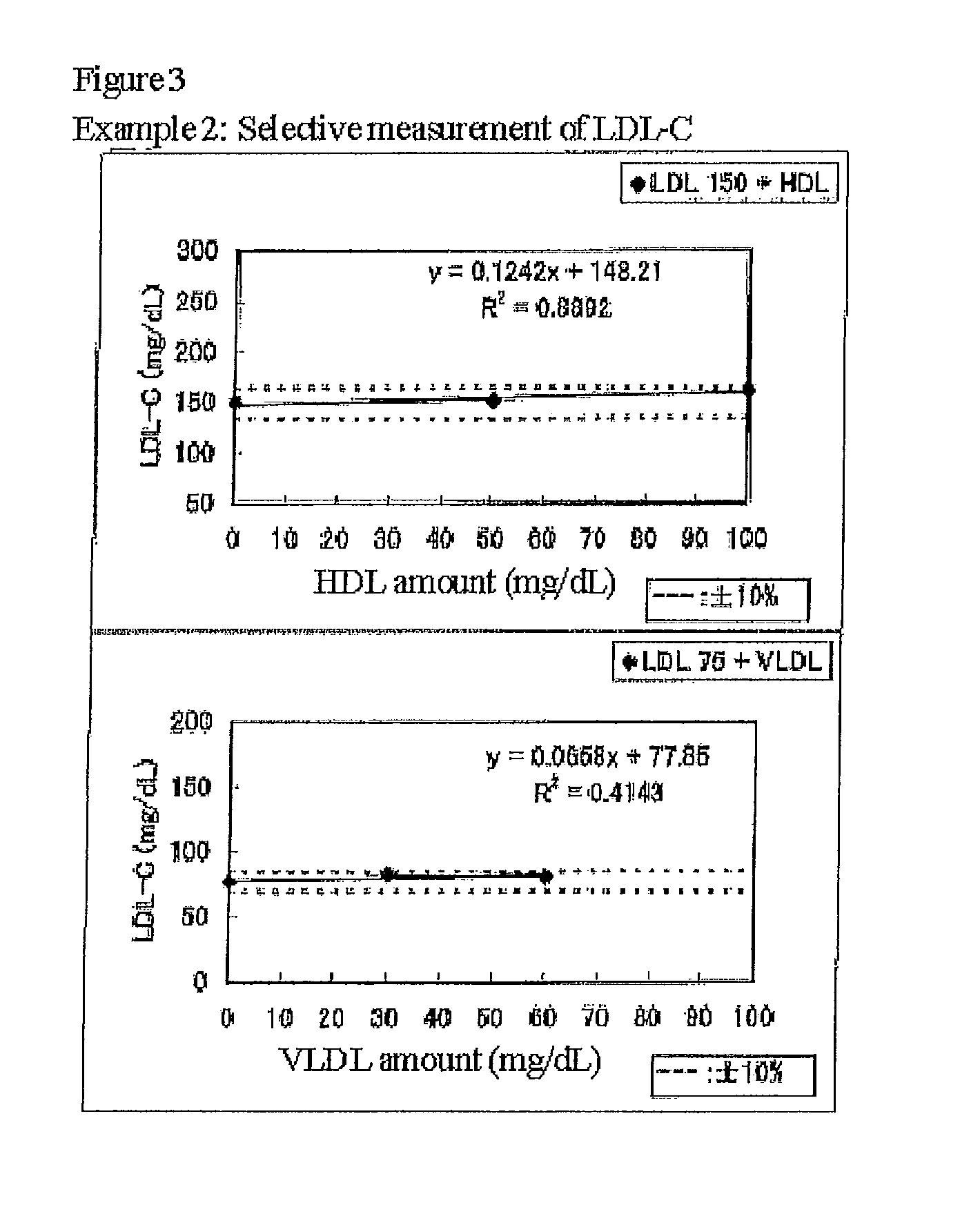

Method for measuring low density lipoprotein cholesterol

InactiveUS20110207160A1Low density lipoprotein cholesterolHigh selectivityMicrobiological testing/measurementWithdrawing sample devicesLow density lipoprotein cholesterolA lipoprotein

It is an object of the present invention to provide a method capable of measuring low density lipoprotein cholesterol (LDL) in a body fluid with high selectivity. The present invention provides a method for measuring low density lipoprotein cholesterol (LDL-C) in a body fluid, which comprises treating the body fluid with a polymer compound having an allylamine or diallylamine unit, and measuring the low density lipoprotein cholesterol (LDL-C) using (a) cholesterol esterase and (b) cholesterol oxidase or cholesterol dehydrogenase.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com