Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Flatten evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

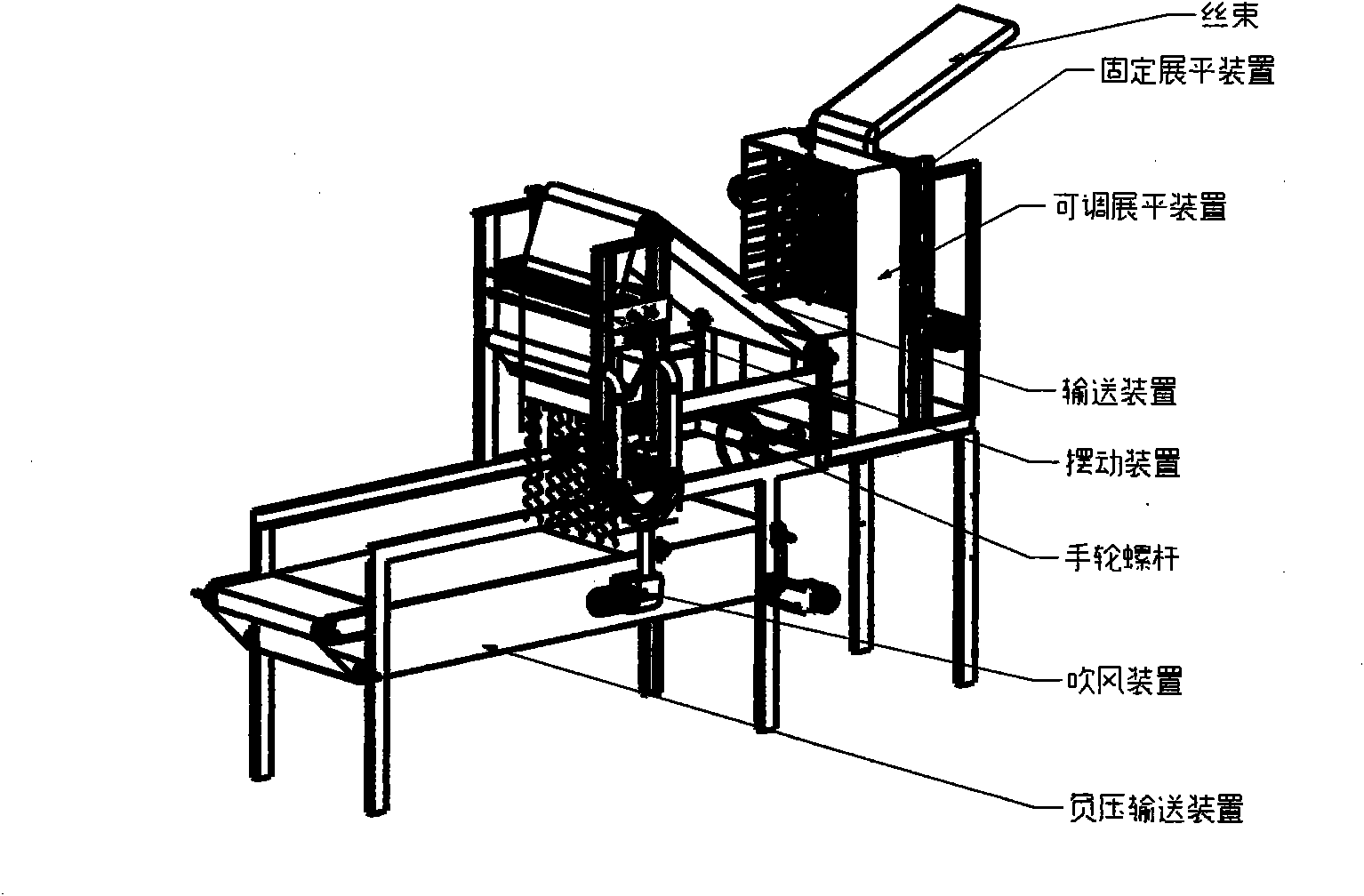

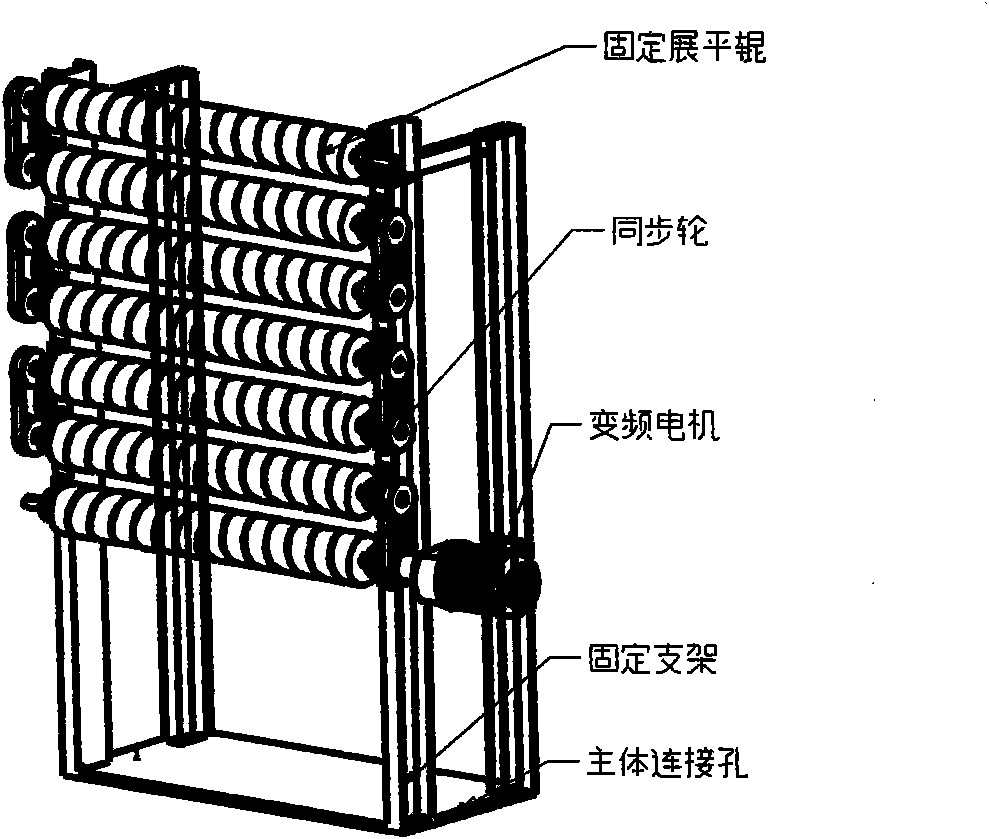

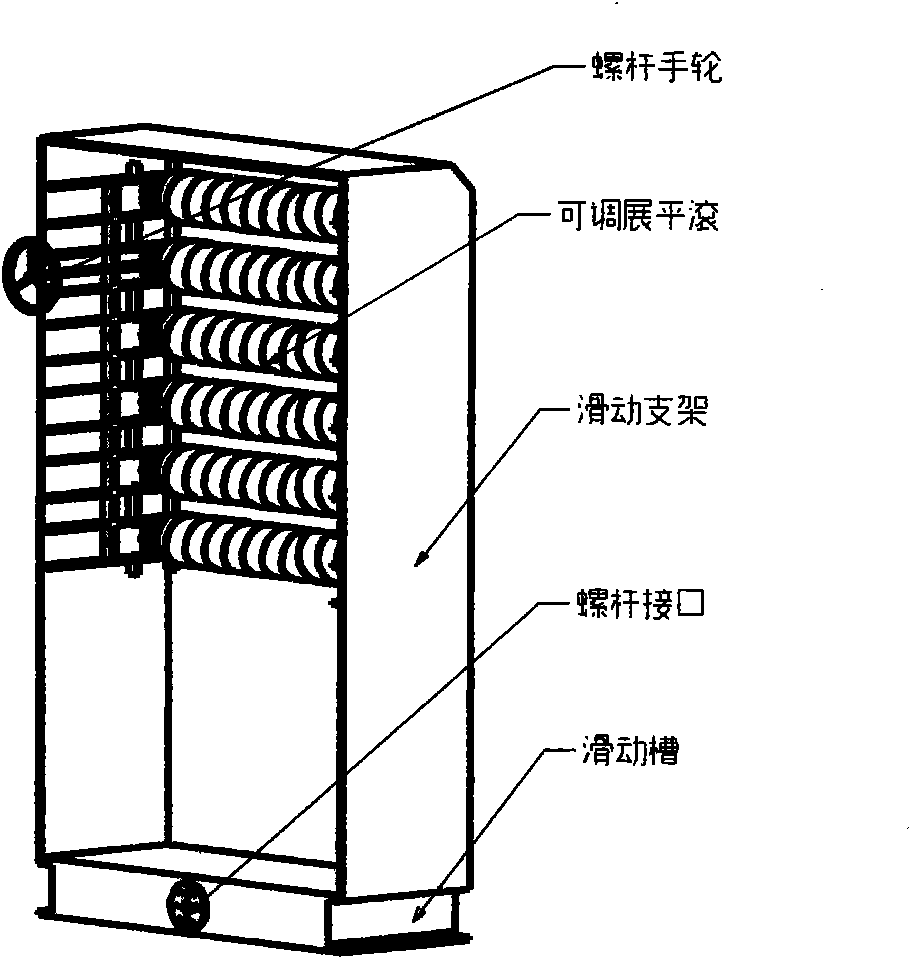

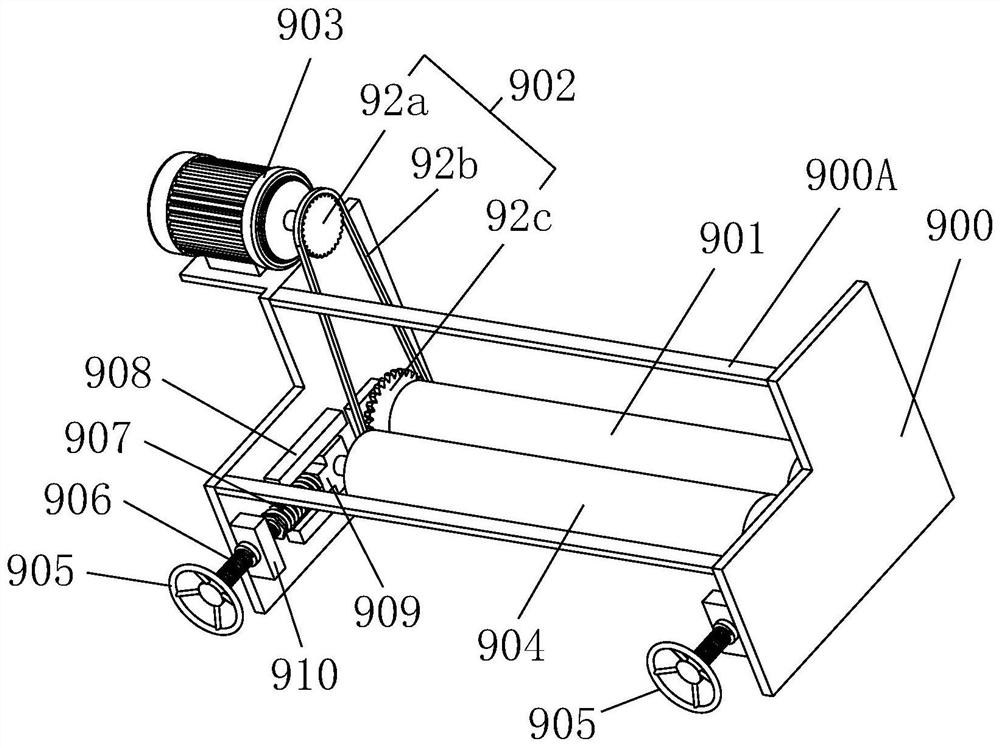

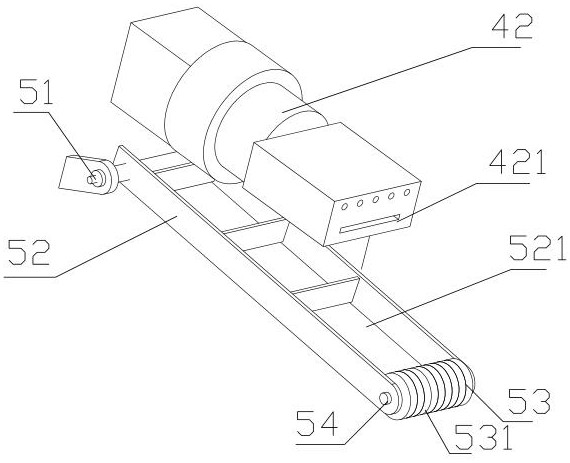

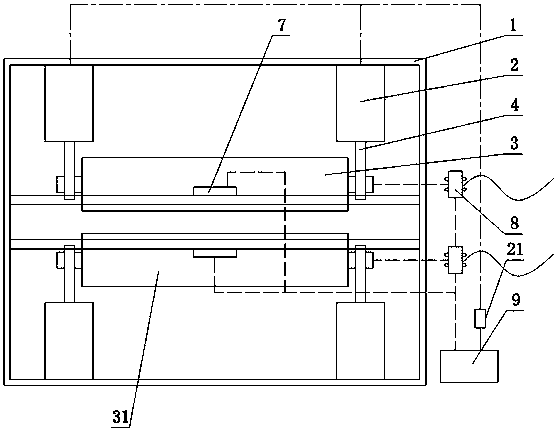

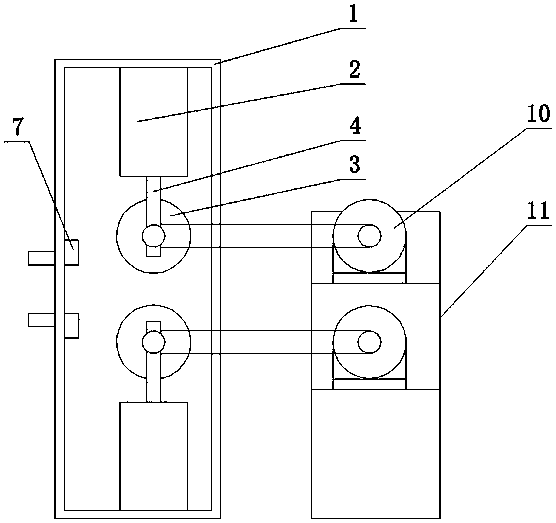

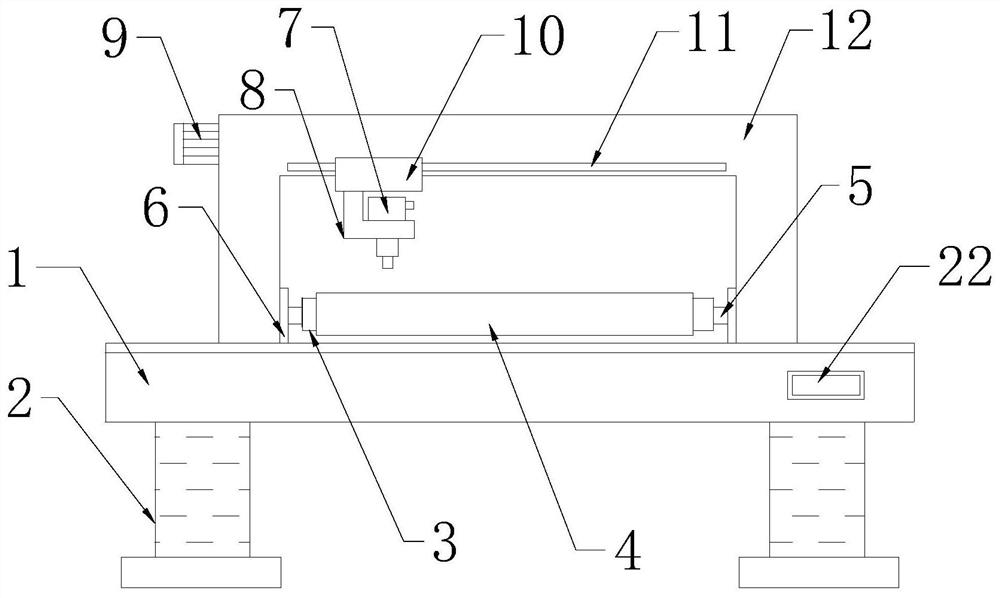

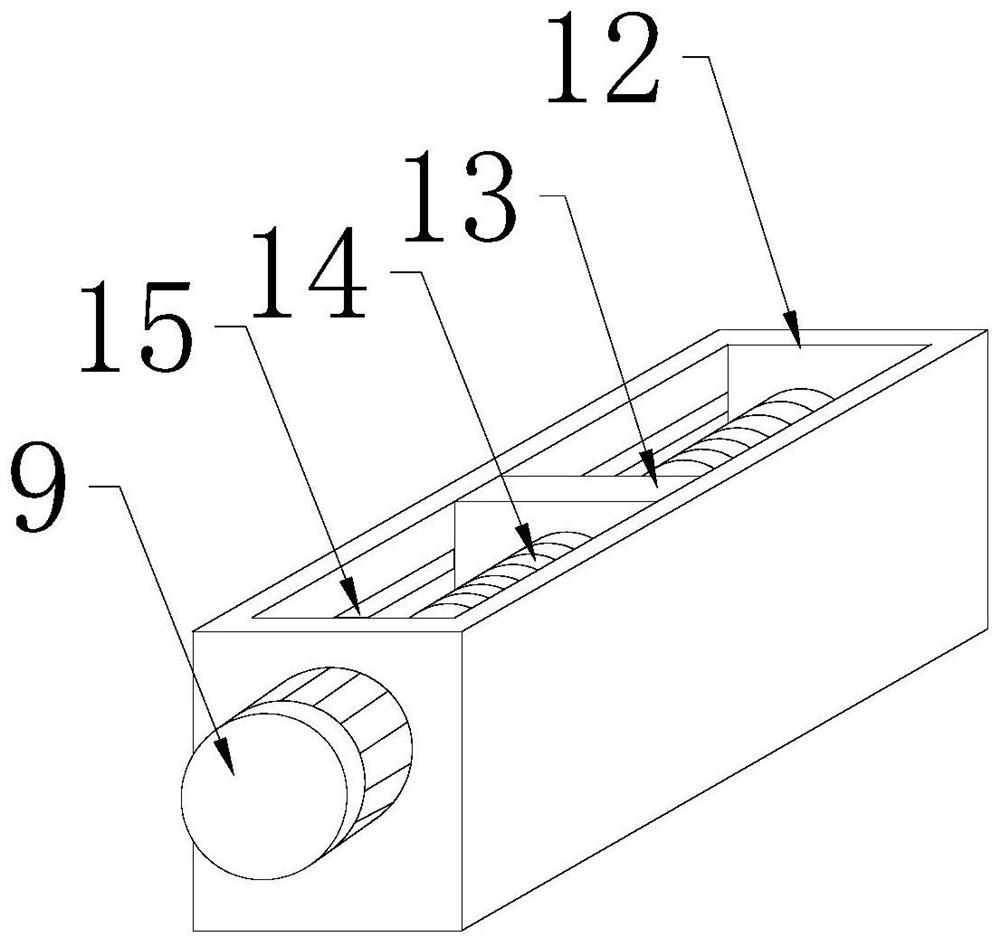

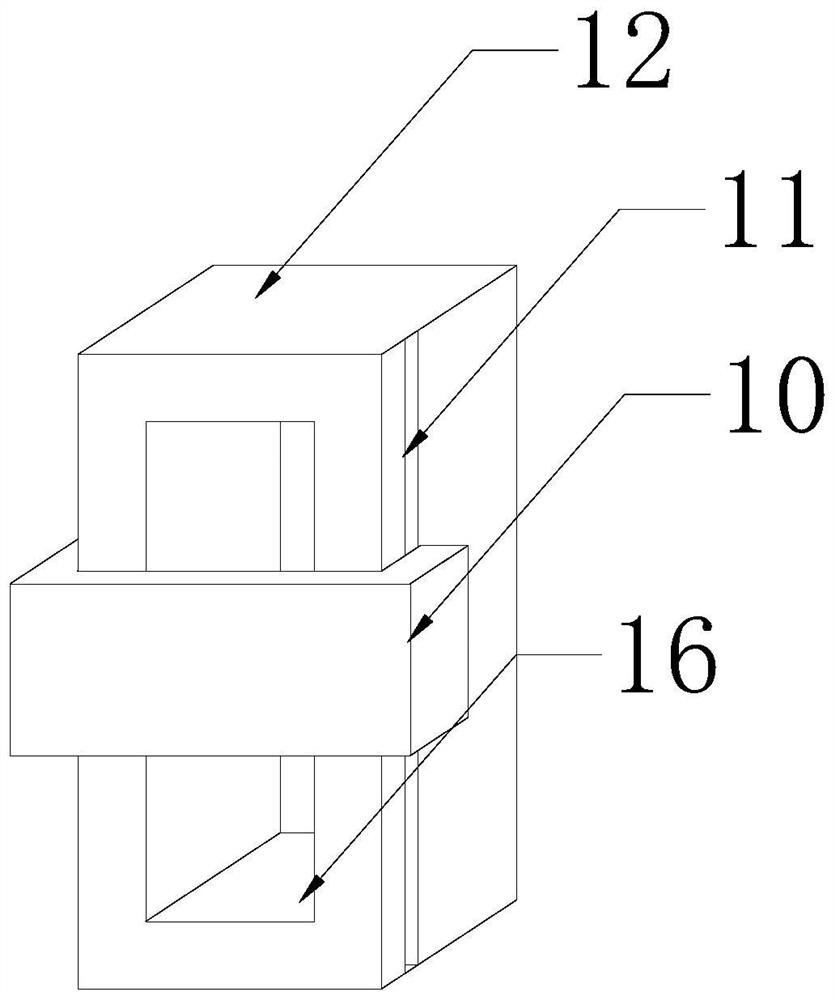

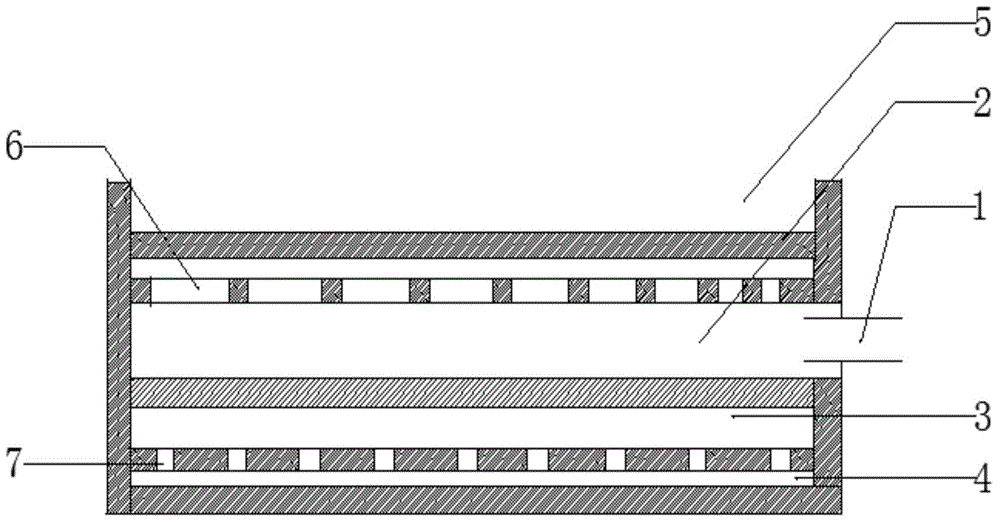

Chemical fiber filament flattening web former

InactiveCN102181982AHigh tensile strengthFlatten evenlyNon-woven fabricsEngineeringMechanical engineering

The invention discloses a chemical fiber filament flattening web former, which can solve the technical problems of non-uniform flattening, low snarling amplitude and poor tensile strength of non-woven fabrics. Filament bundles are rolled and flattened through multiple rollers of a fixed flattening device and an adjustable flattening device, the rolling clearance is adjusted by using a hand wheel screw, the filament bundles are conveyed to a swing device through a conveying device and enter a blowing device by simultaneous swing of clamping rollers, and the filaments blown to a snarling weaving state are conveyed to a next process by a negative pressure conveying device.

Owner:杨玉桥

MOX fuel rod, MOX fuel assembly and method for flattening axial power

InactiveCN108550405AAxial power reductionAxial power up toFuel elementsNuclear energy generationCombustionNuclear engineering

The invention relates to an MOX fuel rod, an MOX fuel assembly and a method of flattening the axial power. The MOX fuel rod includes a doped fuel, the doped fuel is distributed in the axially middle part of the MOX fuel rod, and the doped fuel is a fuel doped with a long-lived minor actinide. The fuel in the axially middle part of the MOX fuel rod is the doped fuel, and the long-lived minor actinide in the doped fuel is transmuted in a neutron field to form a short-lived or stable nuclide, so the cost and the difficulty of final treatment of a spent fuel are reduced, and the treatment problemof the long-lived minor actinide in the spent fuel solved; and the transmutation of the long-lived minor actinide in the doped fuel, absorbing neutrons in the neutron field, is used to reduce the fission reaction rate of the doped fuel in order to reduce the original axial power and fuel consumption in the MOX fuel rod and the power and fuel consumption at a high combustion position, so the purposes of flattening the axial power of the MOX fuel rod, enhancing the reactor core safety and improving the fuel utilization rate are achieved.

Owner:SUN YAT SEN UNIV

Gluing flattening equipment for wine box processing and processing method thereof

The invention discloses gluing flattening equipment for wine box processing. The equipment comprises an operation table, wherein a cover plate is clamped at the top end of the operation table, a through hole is formed in the top of the cover plate, a plurality of air pumps are arranged in the operation table, the top end of the cover plate is fixedly connected with a supporting frame, fixing mechanisms are fixedly connected to the two sides of the bottom of the supporting frame, a roller is arranged between the two fixing mechanisms, the two sides of the top of the supporting frame are respectively provided with a first sliding chute, the top of the supporting frame is connected with a clamping plate in a sliding mode through a first sliding chute, a telescopic fixing frame is fixedly connected to the bottom end of the clamping plate, and a gluing mechanism is arranged inside the telescopic fixing frame. The equipment discloses the gluing flattening equipment for the wine box processing and the processing method thereof, gluing can be carried out more stably through a servo motor, meanwhile, continuous gluing can be carried out, the stability and the gluing efficiency during gluingare improved, when the wine box is placed, the wine box can be fixed through a magnet, the wine box is simple and convenient, and damage to the wine box cannot be caused.

Owner:JIANGSU MEIJIA PACKAGE

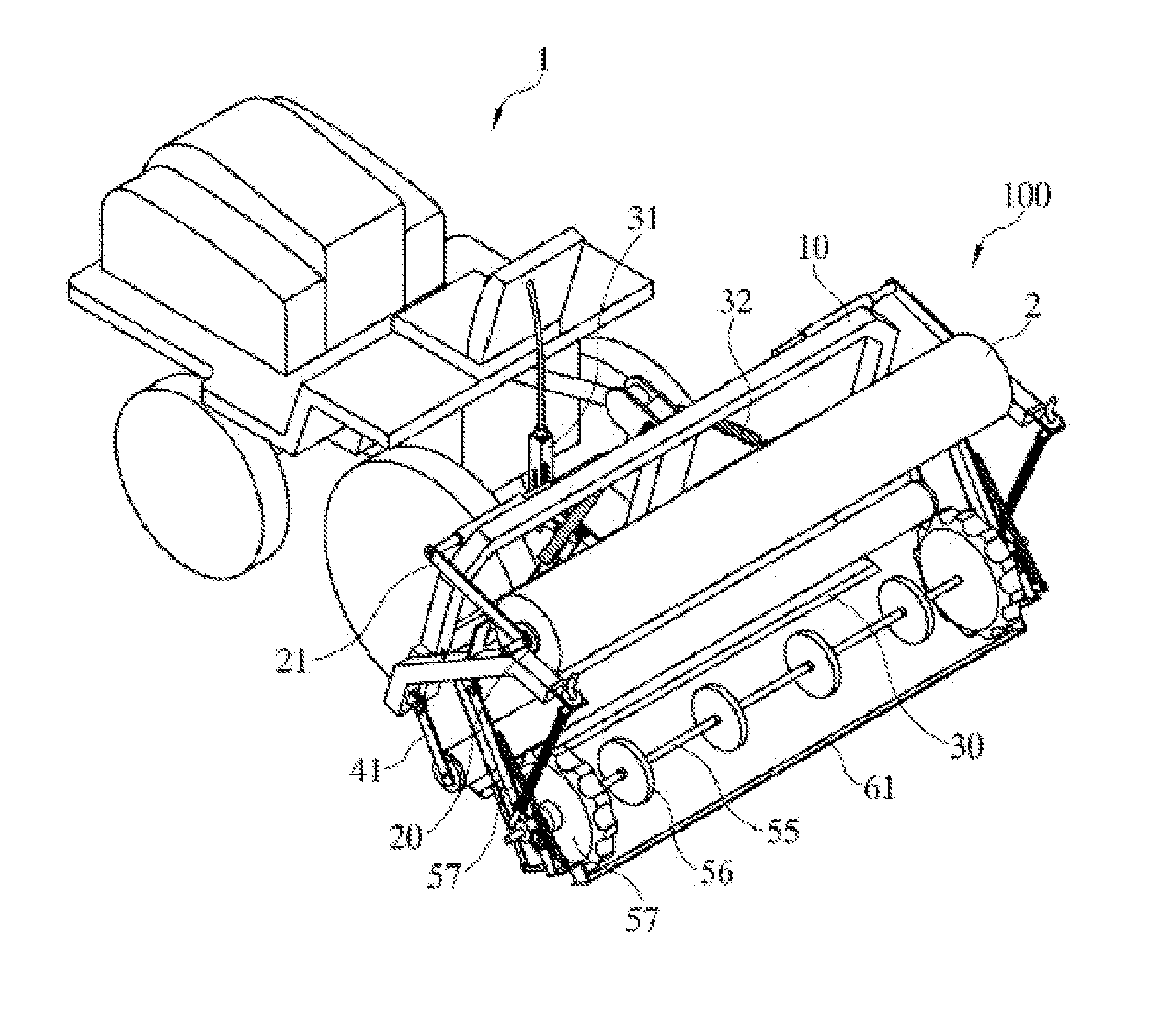

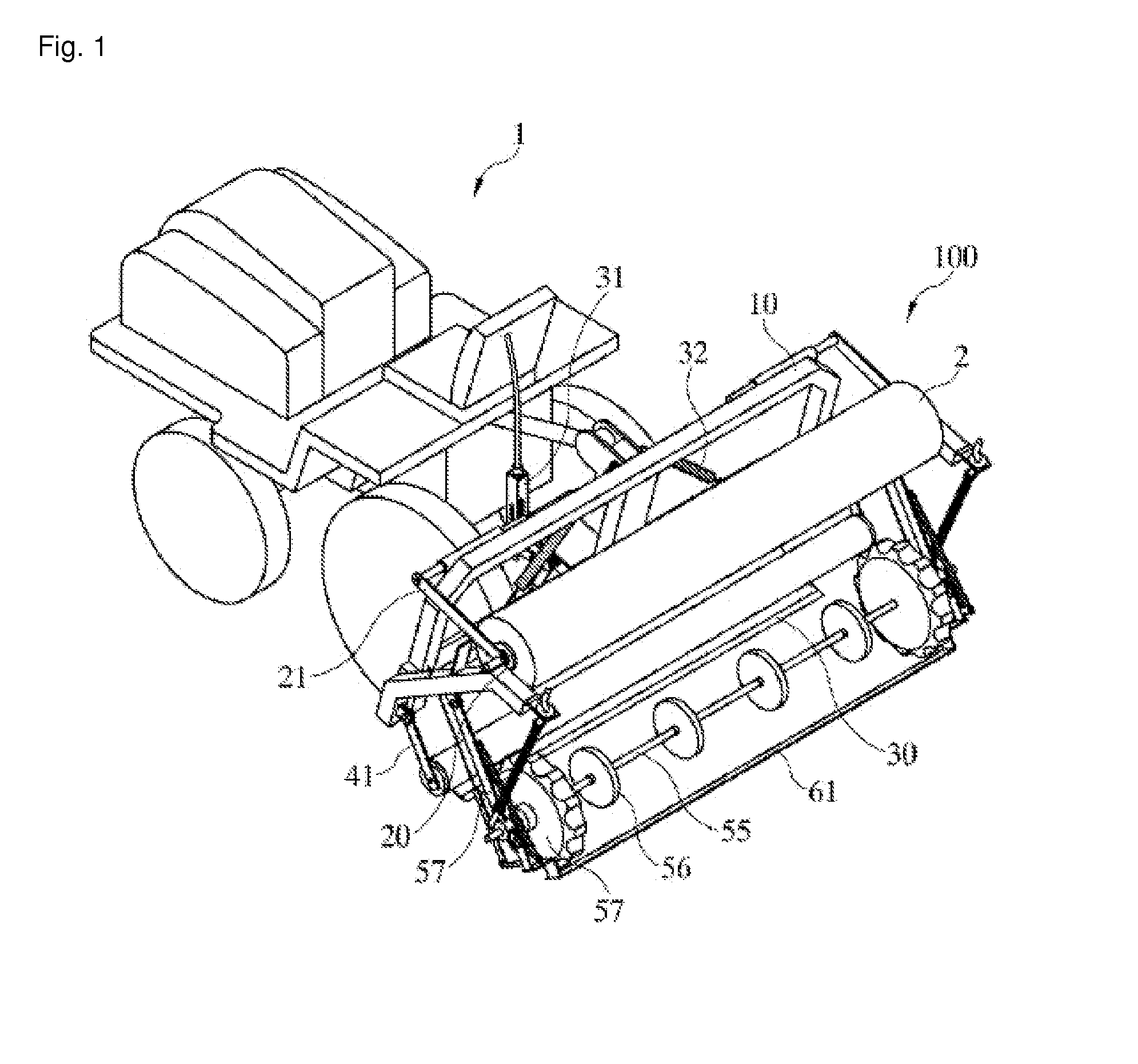

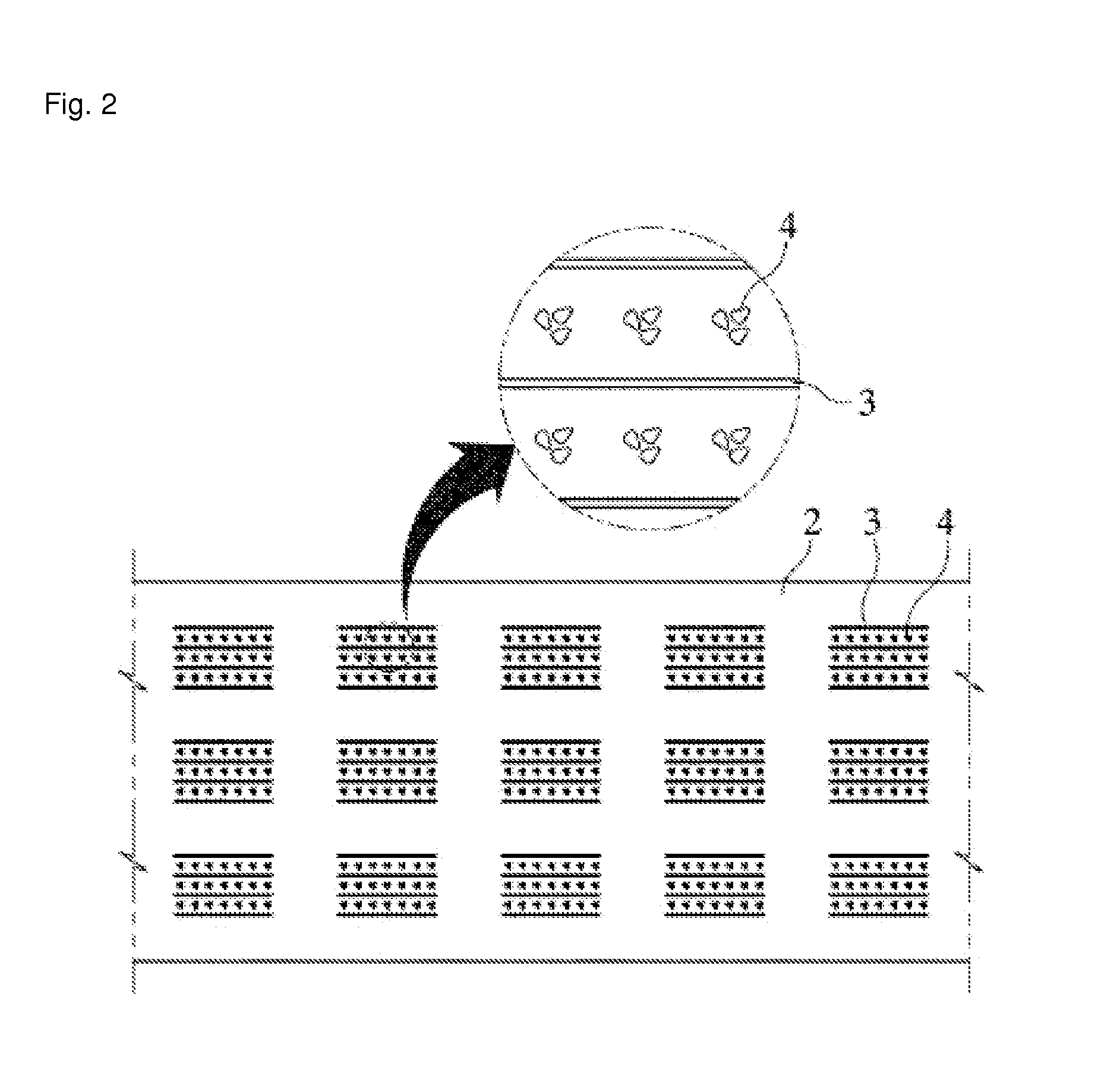

Apparatus for Laying Seed Film and Method for Laying Seed Film by Using the Apparatus for Laying the Seed Film

The present invention relates to an apparatus for laying a seed film (hereinafter, seed film refers to a mulching film to which seeds are adhered and coating same for use in sowing) and a method for laying the seed film by using same. More specifically, the present invention relates to the apparatus for laying the seed film and the method for laying the seed film by using the apparatus for laying the seed film, the apparatus comprising: a leveling board of which the angle can be adjusted; a seed film pressing portion for pressing the seed film which is unrolled; and a seed film fixing portion for fixing the seed film, thereby automatically laying the seed film on a rice paddy in a quick and convenient manner.

Owner:KWON OCK

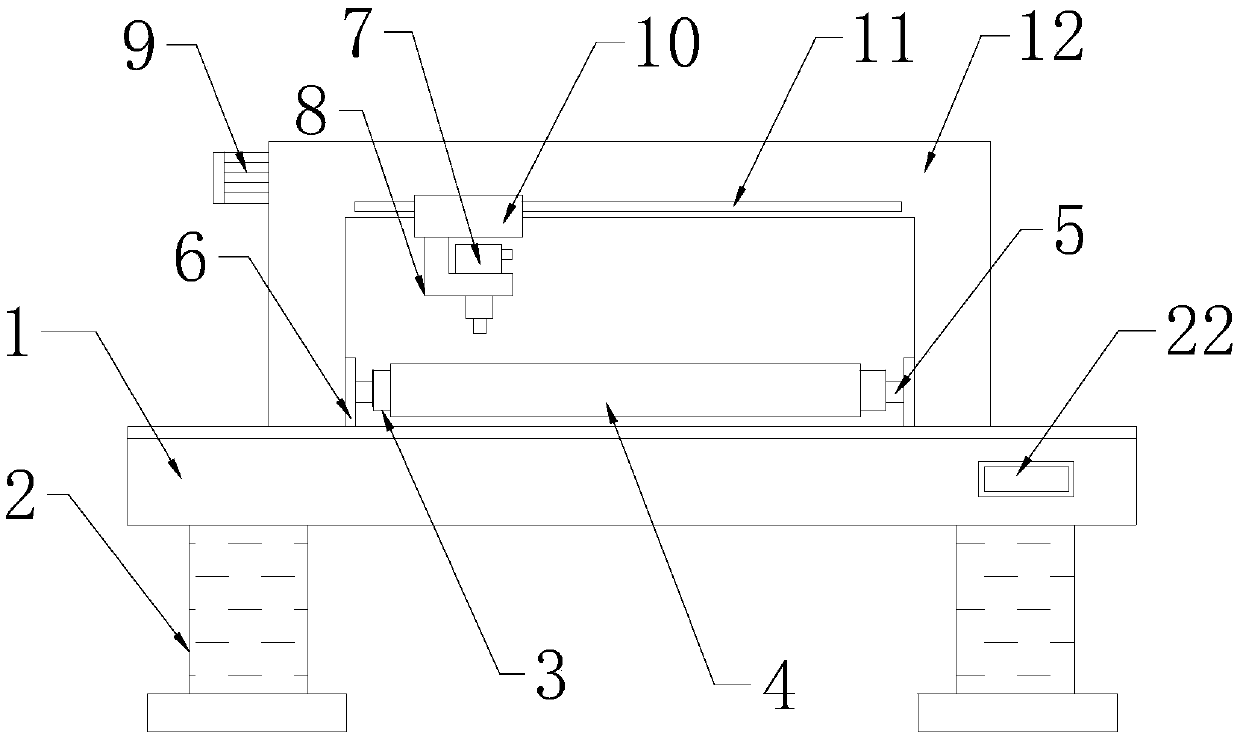

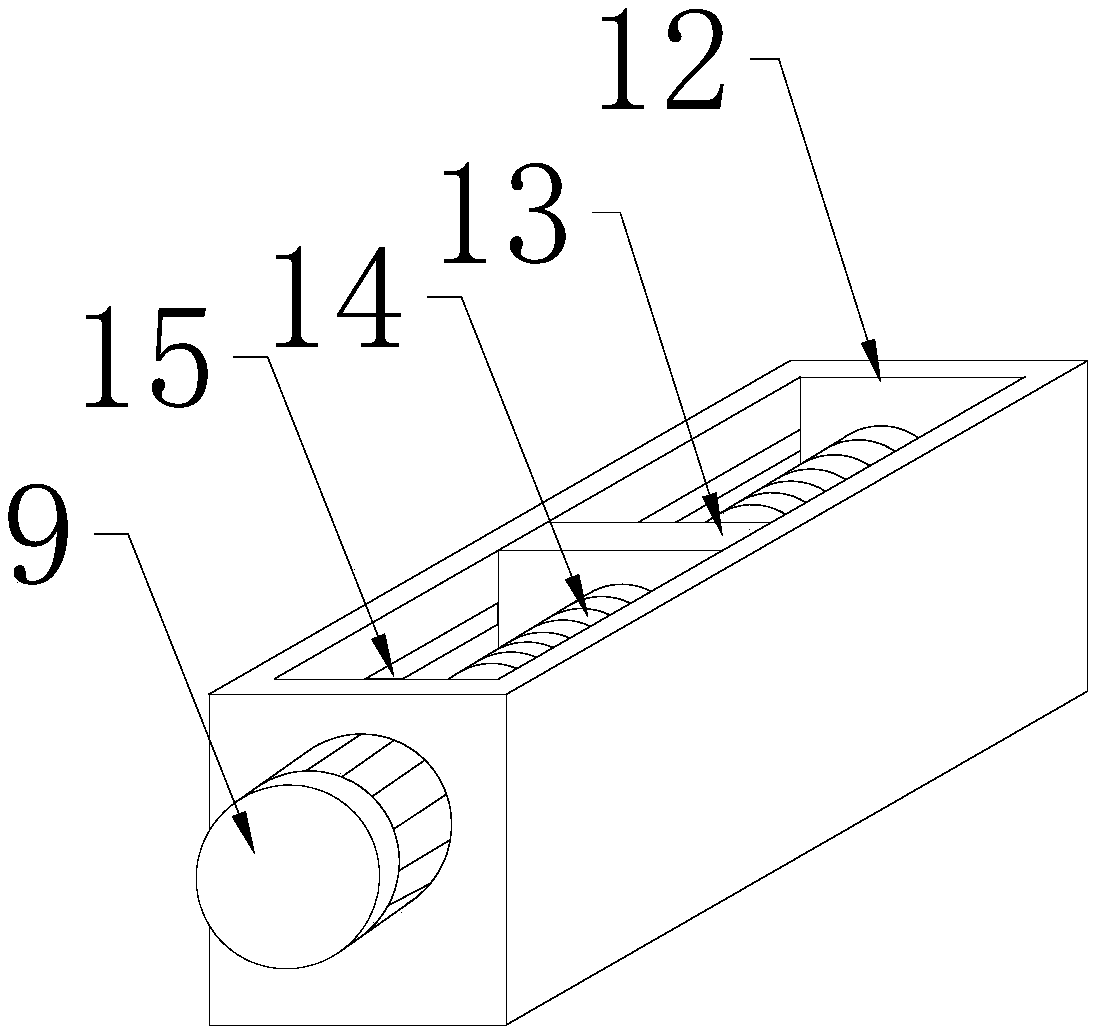

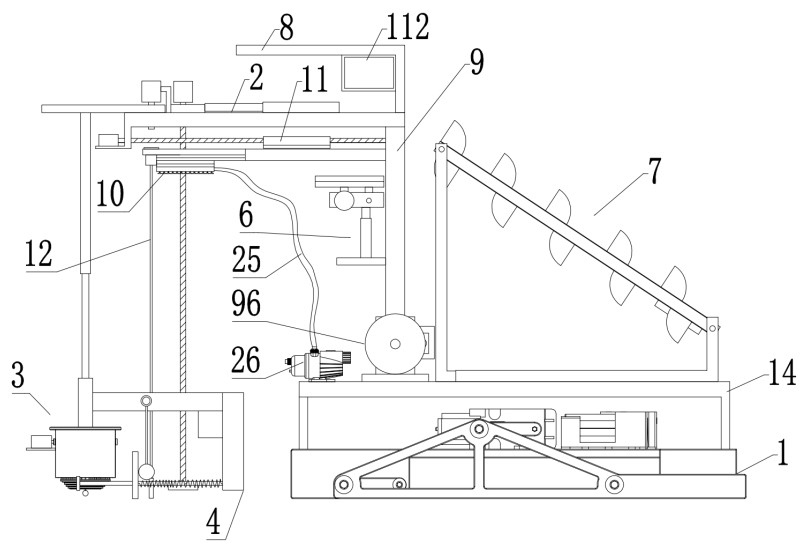

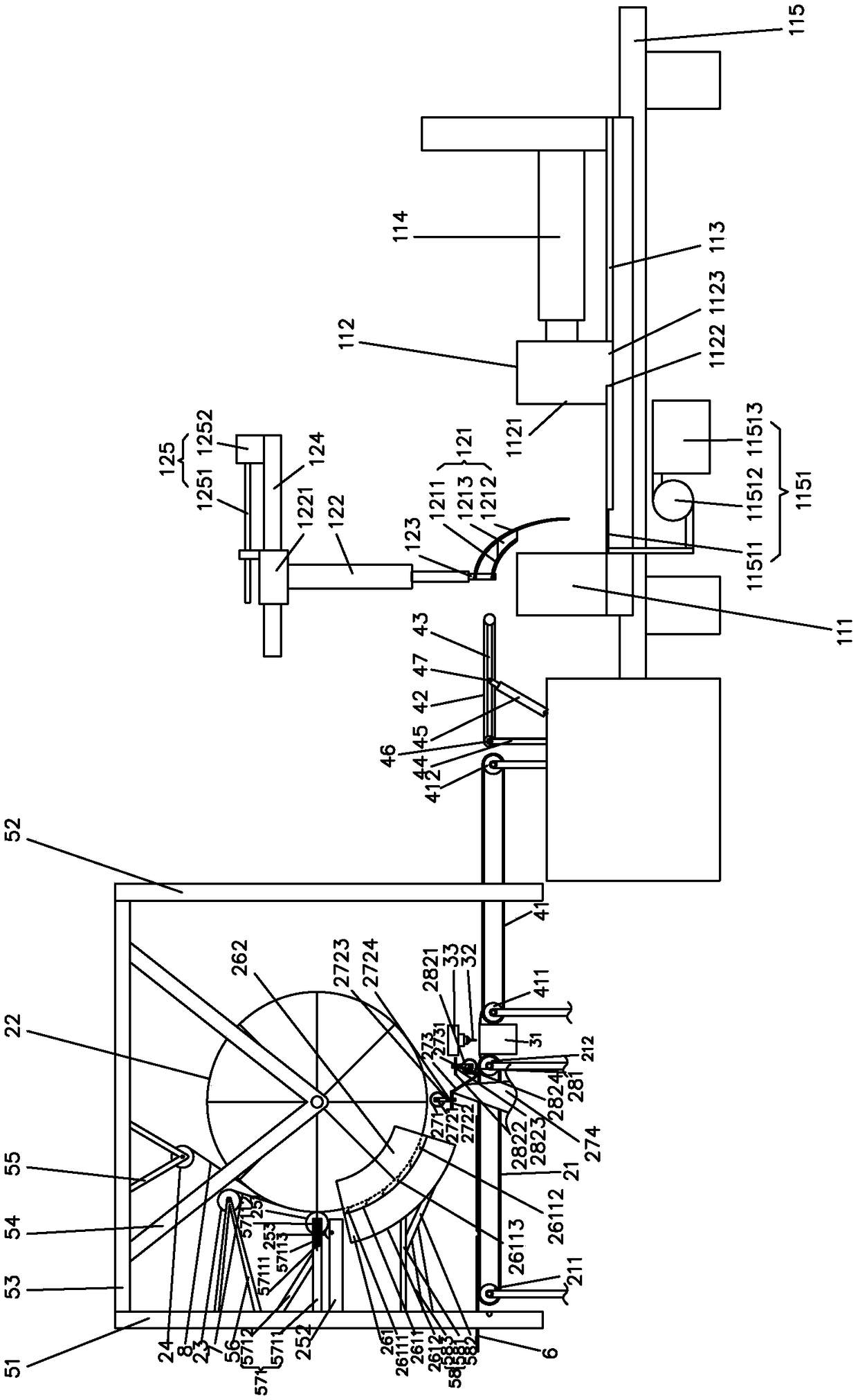

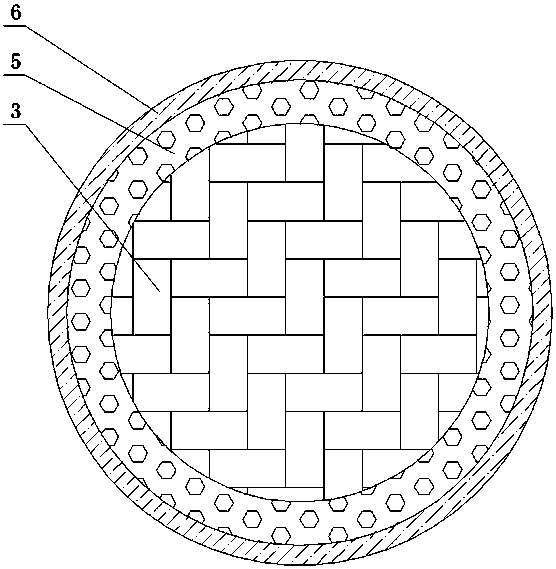

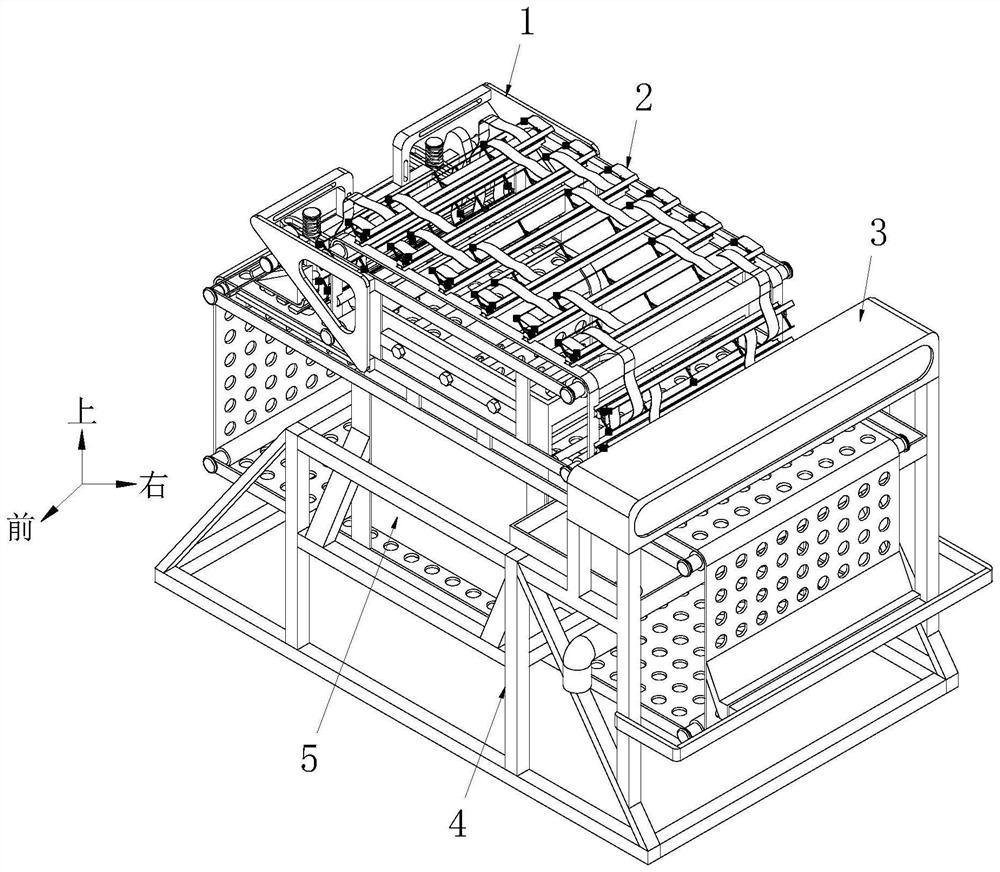

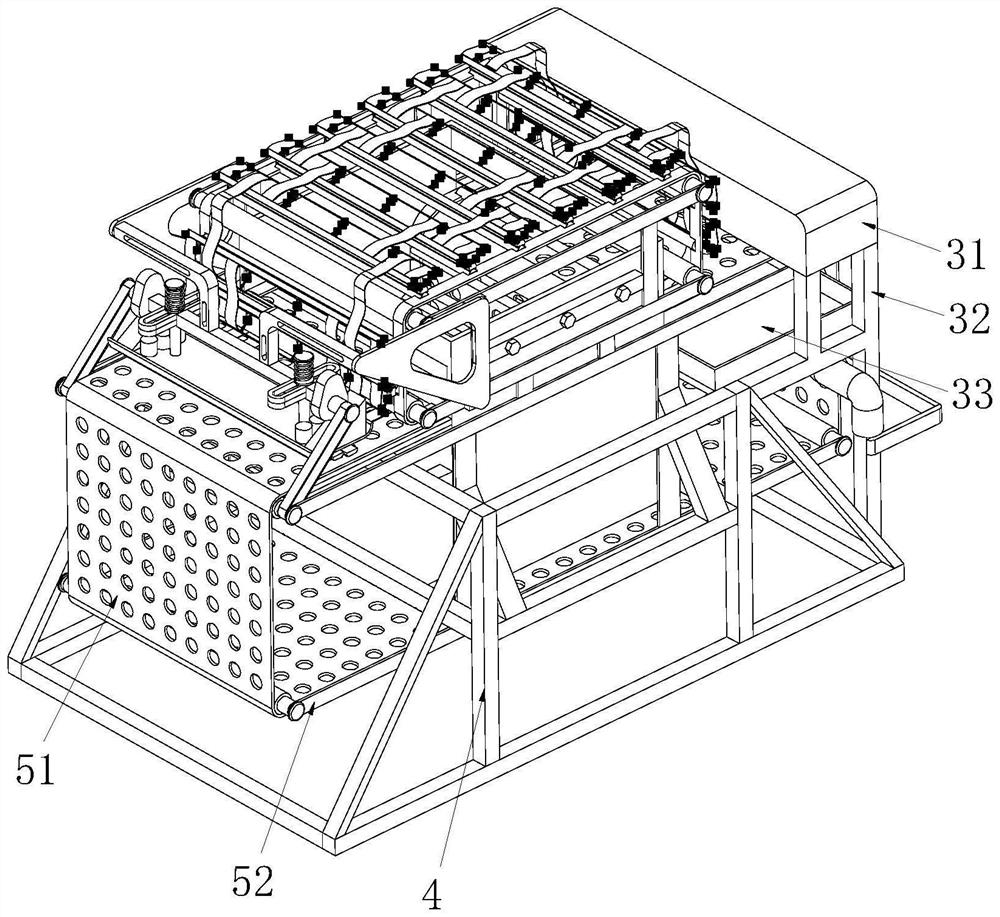

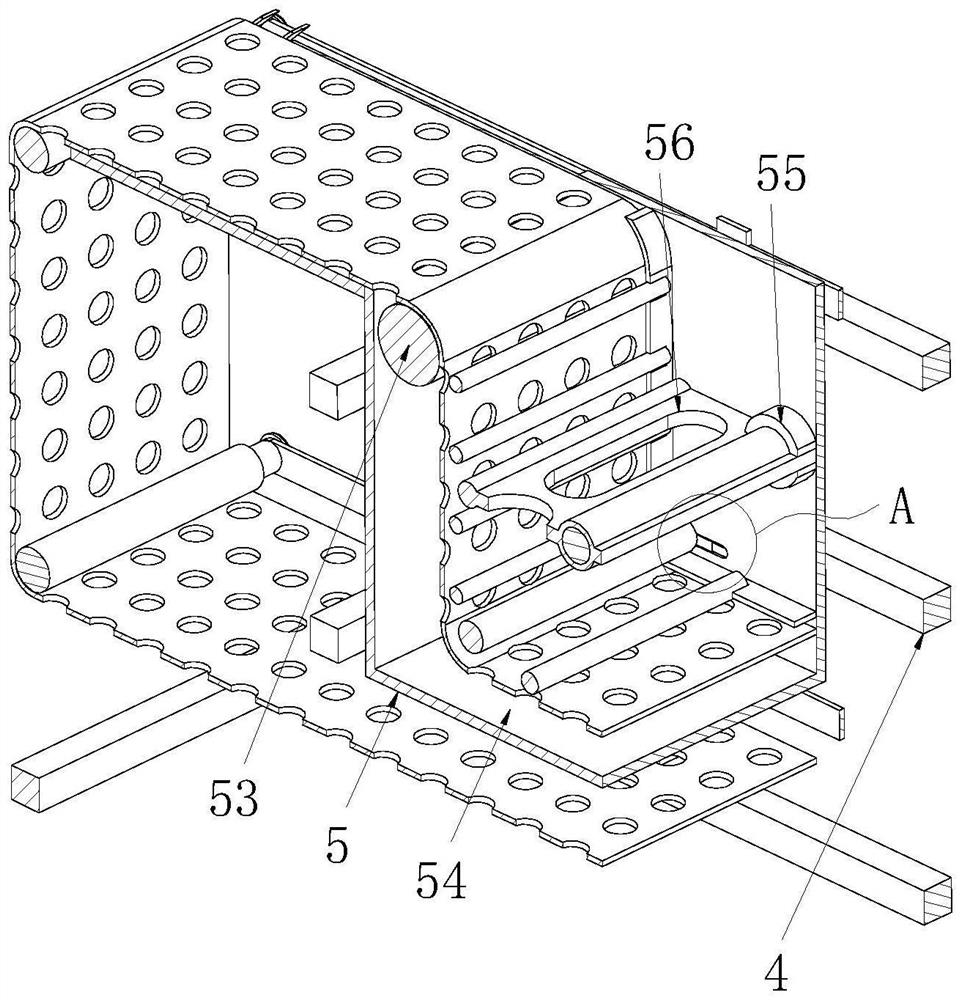

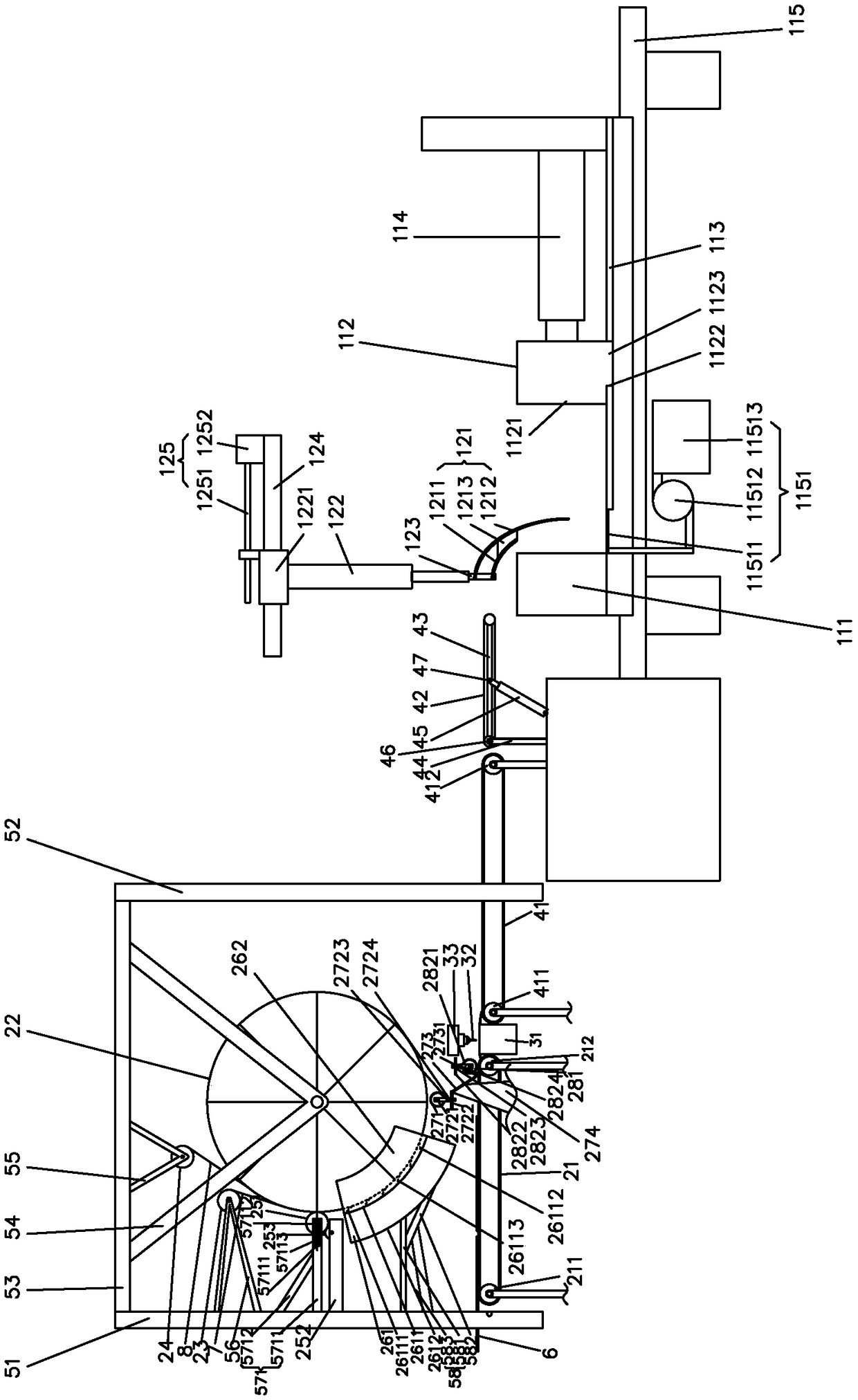

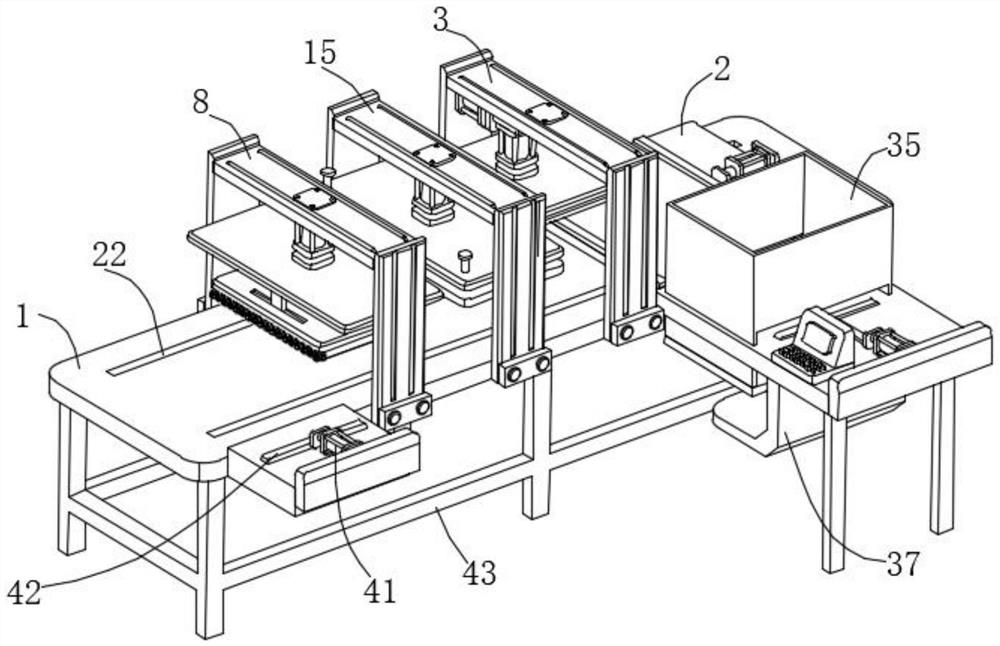

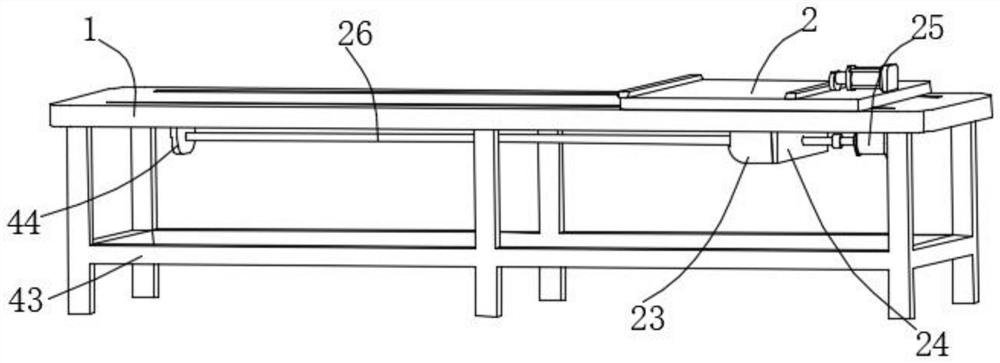

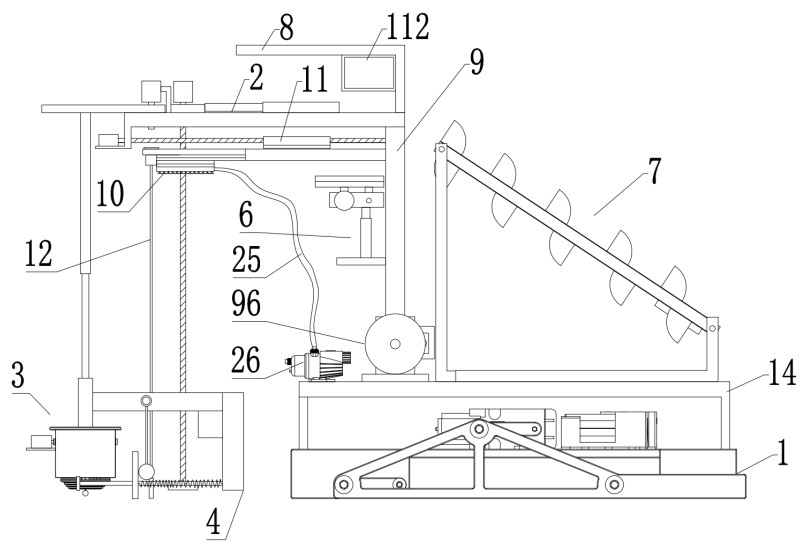

A high-efficiency plywood single-layer veneer production line

ActiveCN109049169BReduce liquidityAvoid large areas of sheddingPlywood pressesVeneer pressesCold airAdhesive glue

The invention provides a smooth plywood single-layer veneer production line. The structure form of a traditional single-layer veneer hot press is broken through, in the actual working process, under control of a master controller, a veneer production section conducts veneer operation on a mold plate blank, then, a continuous veneer mold plate is cut into veneer mold plate blocks through a cuttingproduction section, and the veneer mold plate blocks are conveyed by a conveying production section to a horizontal hot pressing forming device for hot pressing forming. An upper elastic sealing plate, a lower elastic sealing plate and two sealing baffles cooperate so that the zone between an inner circular-arc-shaped cooling plate and a solid glue net layer can be a sealed zone filled with cold air, the glue cooling effect can be remarkably improved, and energy resources are saved. Compared with the prior art, the smooth plywood single-layer veneer production line can conduct continuous and smooth single-layer veneer and hot pressing forming on the mold plate blank, the degree of mechanization is high, and the strength of a finished veneered plywood product is higher.

Owner:ZHANGZHOU XINHUACHENG MASCH MFG CO LTD

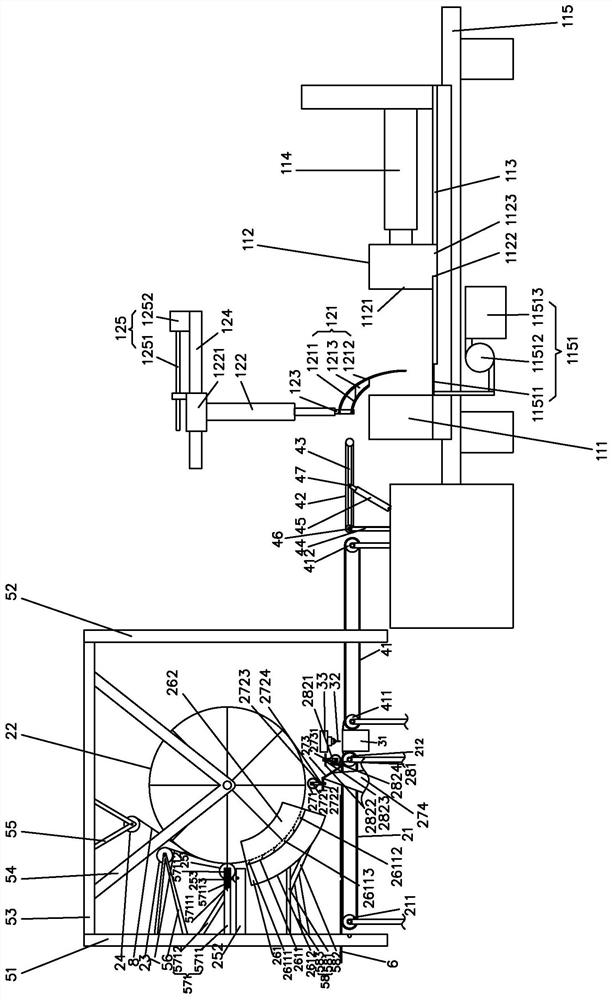

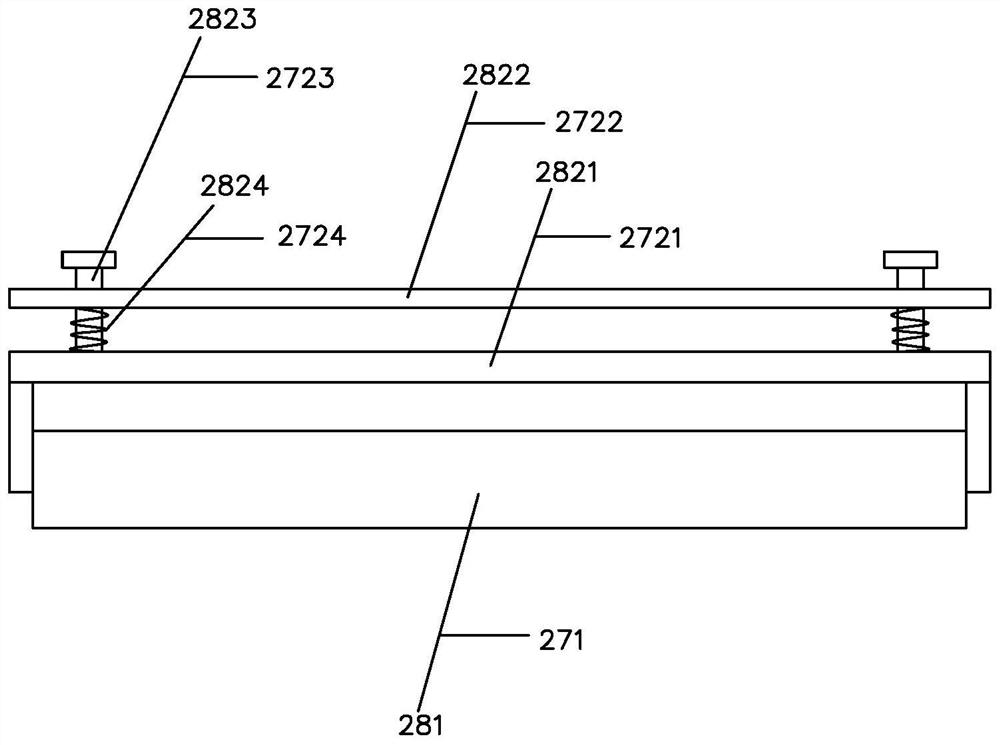

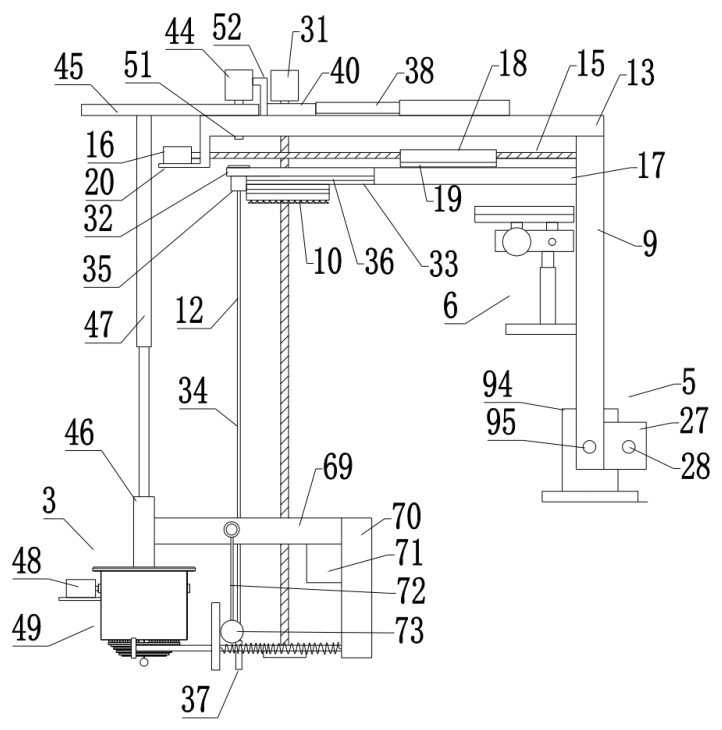

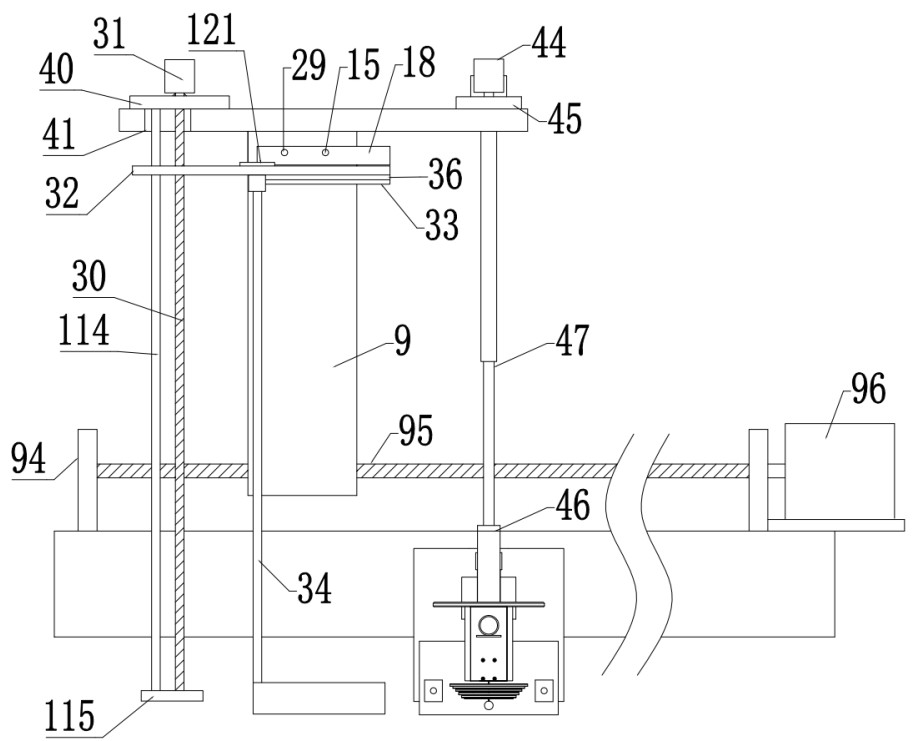

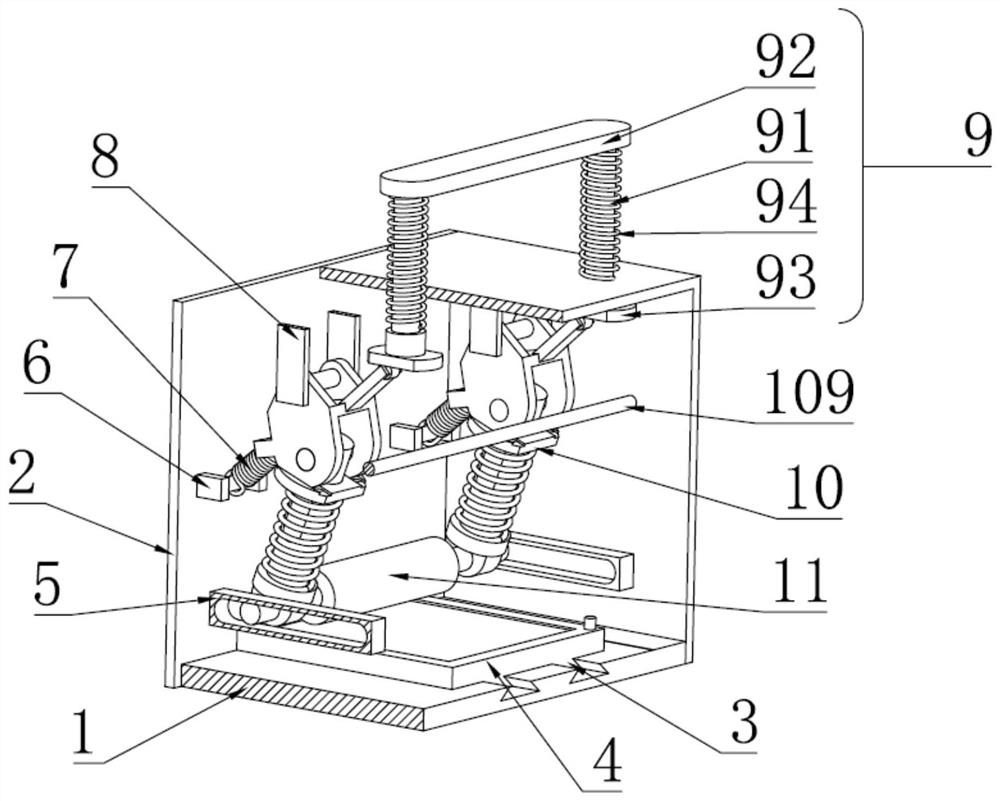

Self-positioning equidistant contradictory garden road greening auxiliary laying and building equipment

ActiveCN113529545AReasonable designSimple and fast operationRoads maintainenceBrickArchitectural engineering

The invention discloses self-positioning equidistant contradictory garden road greening auxiliary laying and building equipment. The equipment comprises an alternate rotation pre-self-flattening type walking mechanism, a magnetic attraction type non-contact feedback self-positioning masonry vacuum adsorption moving mechanism, a center divergence equidistant contradictory memory alloy buffering masonry compacting mechanism, a magnetic attraction back-swing type self-positioning side knocking mechanism, a transverse reciprocating moving mechanism and an adjustable masonry placing assembly. The invention belongs to the technical field of road construction of landscaping engineering, and particularly provides the self-positioning equidistant contradictory garden road greening auxiliary laying and building equipment which is provided with a feedback metal shifting piece which is arranged in advance and is not aligned with corners of bricks, achieves the technical effects of selective positioning shifting and accurate direction adjustment which are adaptive to various bricks under the condition that no positioning element or detection element exists, achieves non-contact driving movement of brick conveying, overcomes the contradictory technical problem that force needs to be applied to bricks but cannot be applied, and achieves lossless self-recognition positioning of brick side knocking.

Owner:徐州帝威伦新型建材有限公司

Film blowing equipment

The invention provides film blowing equipment. The film blowing equipment comprises a film blowing machine, a winding machine and an intermediate processing device arranged between the film blowing machine and the winding machine, wherein the intermediate processing device comprises a corona treatment module and a flattening module which are arranged in sequence in the plastic film winding direction; the corona module performs corona treatment on the outer surface of one side of a plastic film through a corona head, and the flattening module performs flattening traction on the penetrating plastic film through the abutting extrusion force between an active flattening traction roller and an auxiliary flattening traction roller, so that the plastic film can be kept flat at the front and backof the flattening module. Therefore, the film blowing equipment provided by the invention integrates the corona treatment and flattening processing functions, the plastic film is ensured to be in a flattened state during corona treatment and winding, and the problems of corona dead corners and uneven winding of the plastic film due to wrinkles are eliminated.

Owner:广州市金章塑料制品有限公司

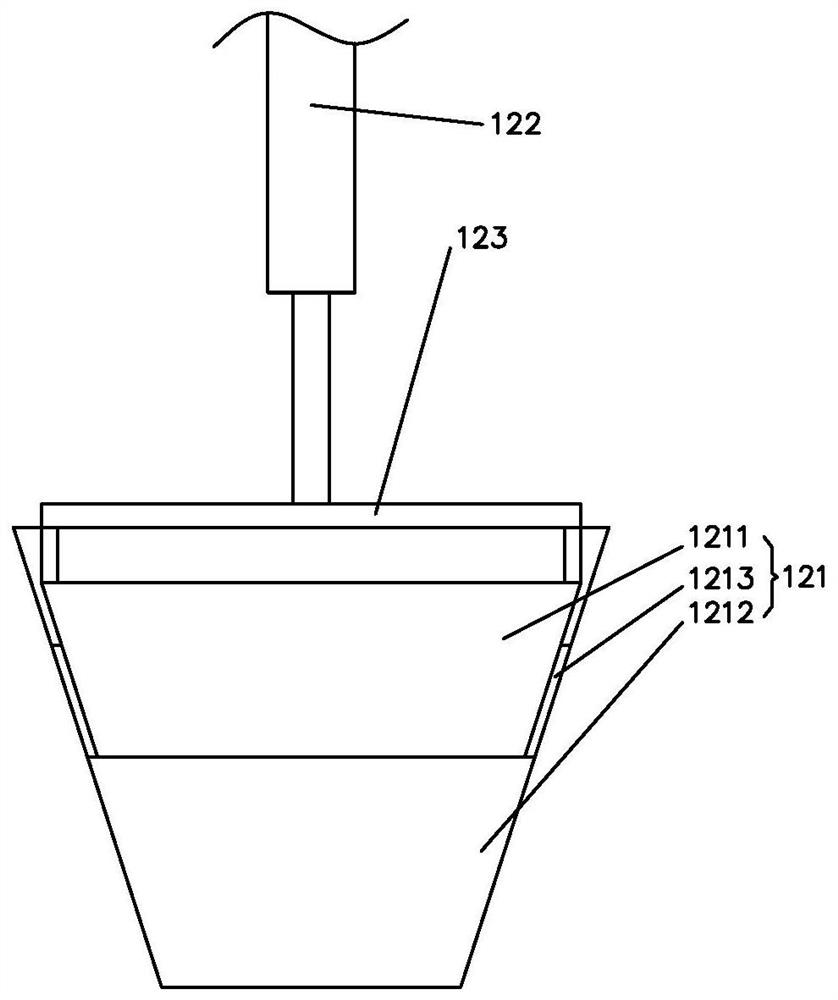

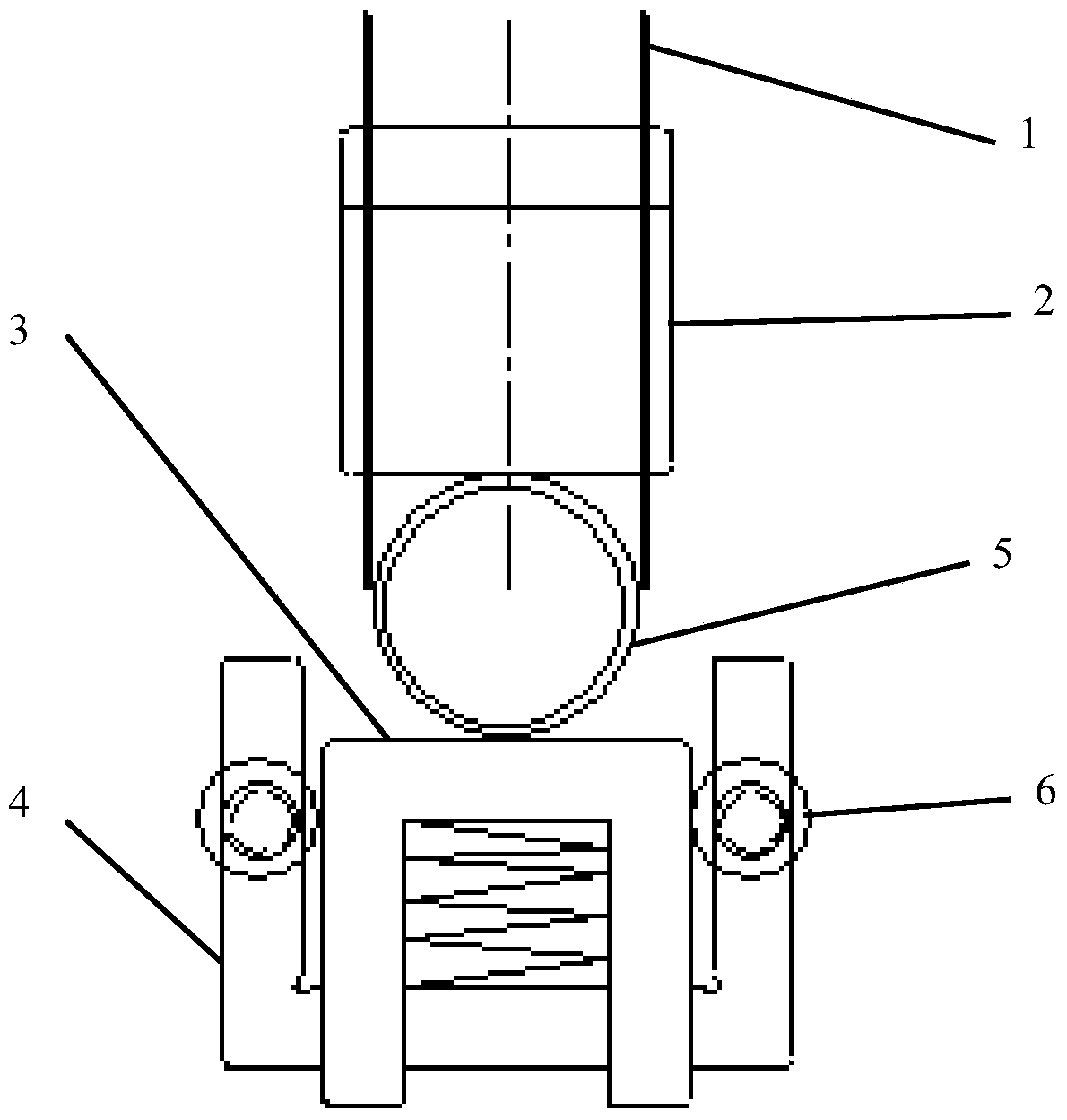

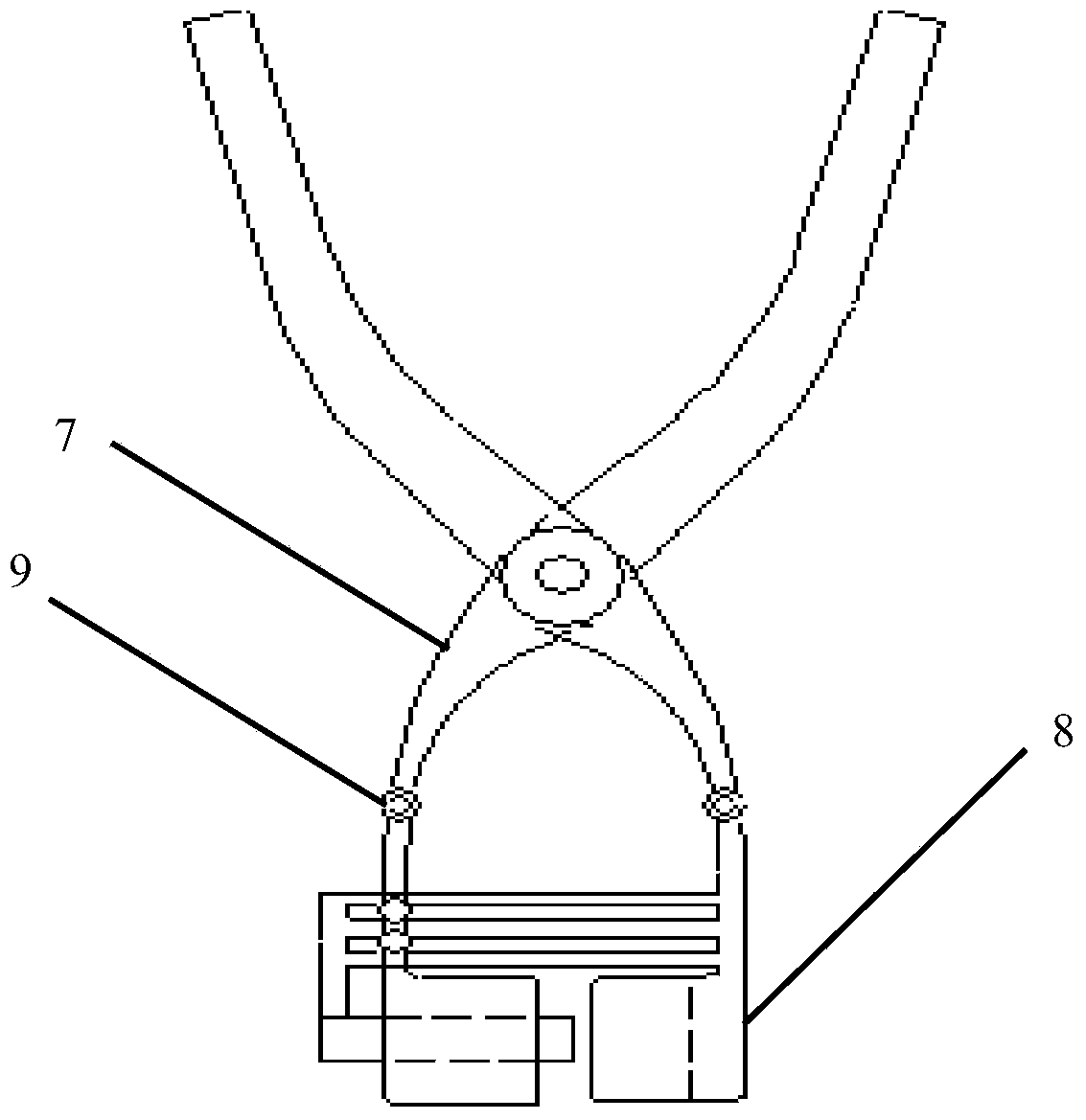

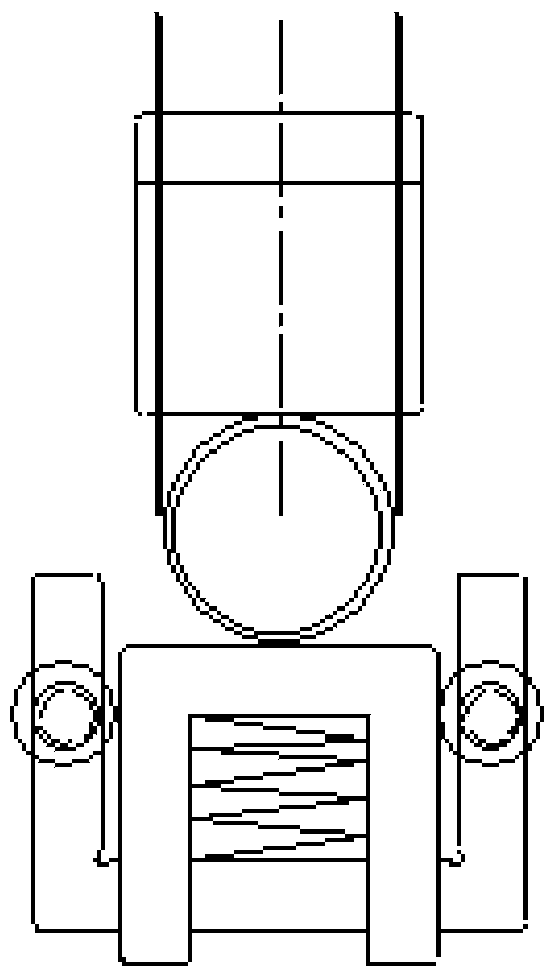

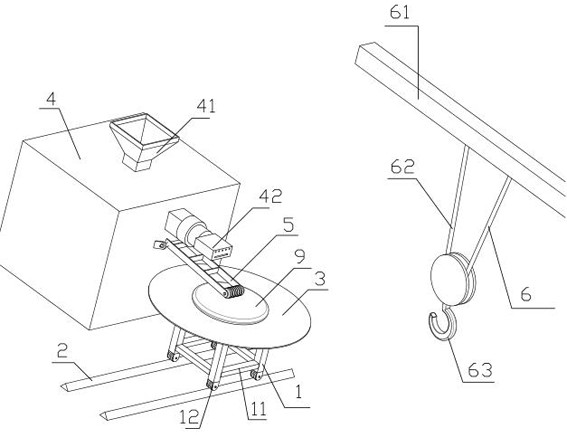

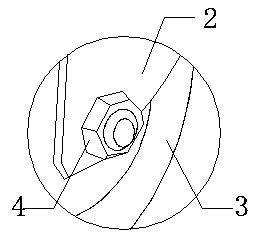

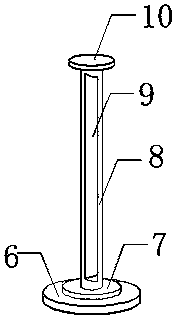

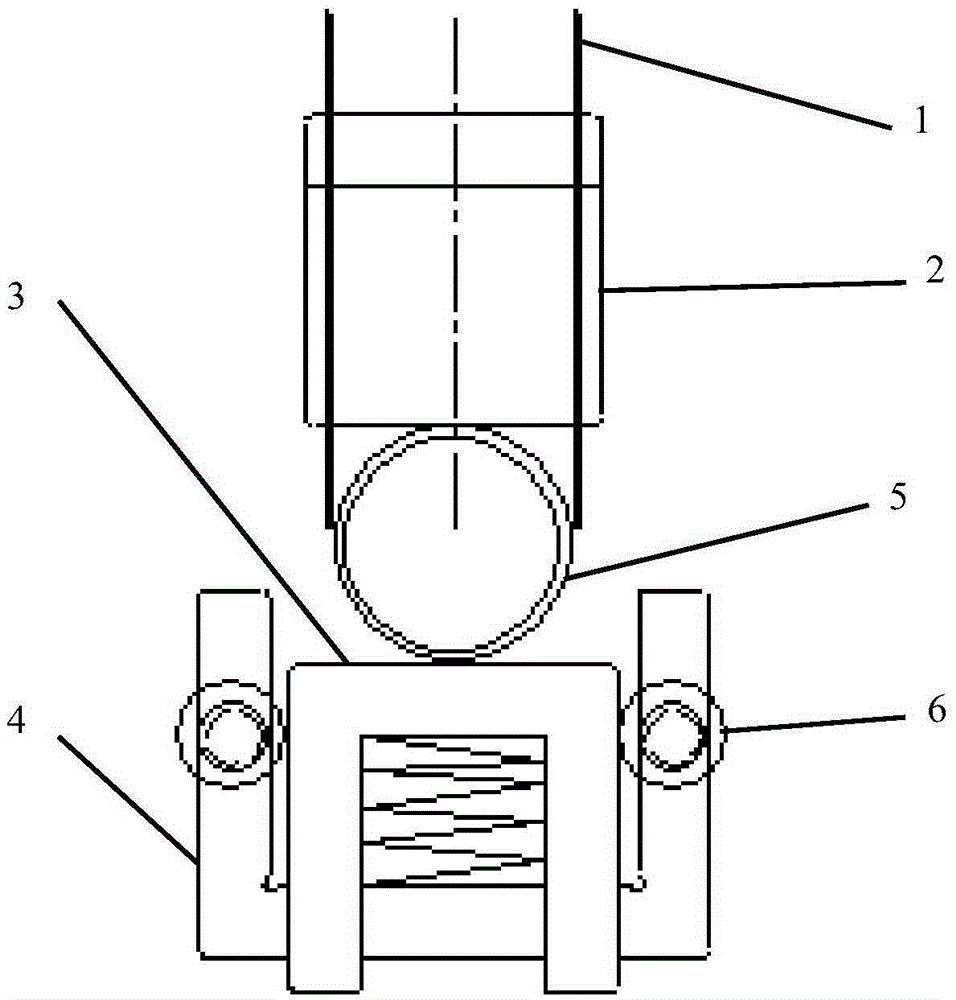

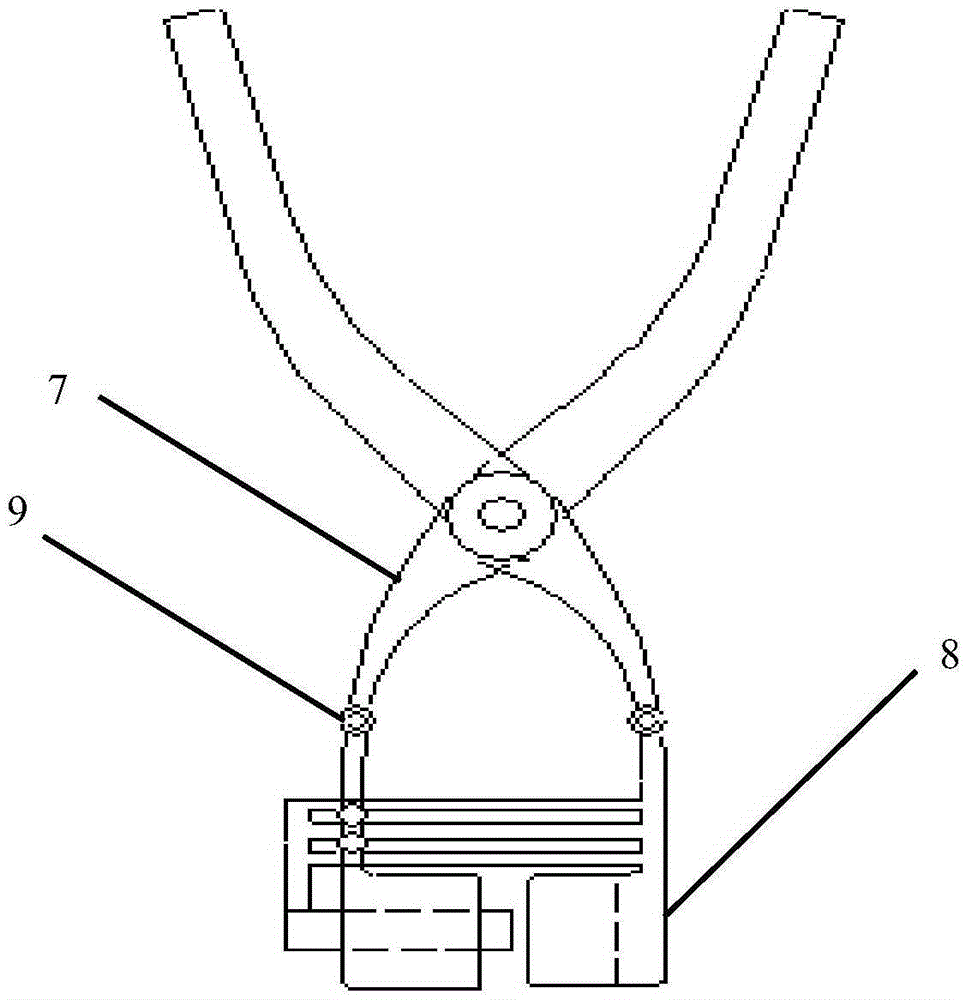

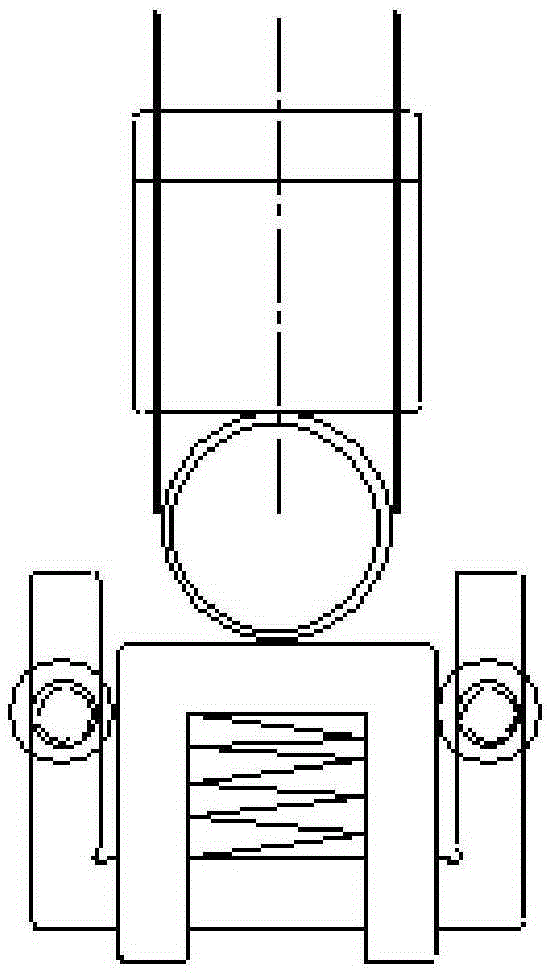

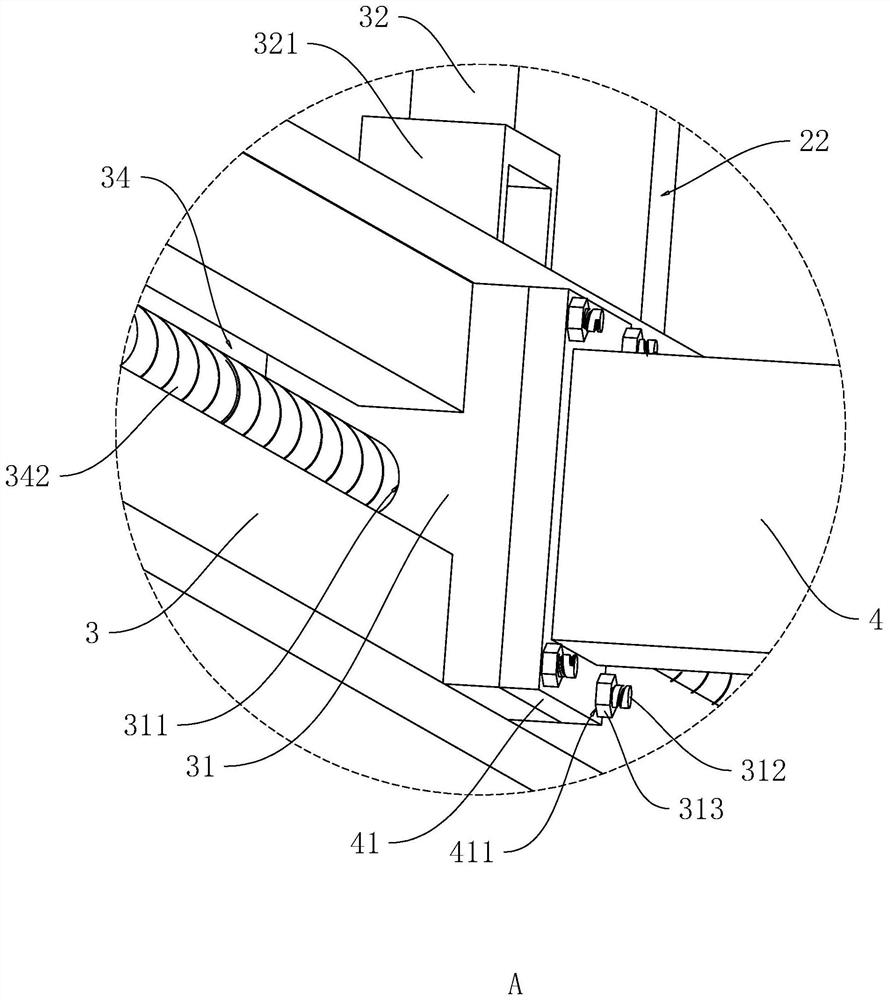

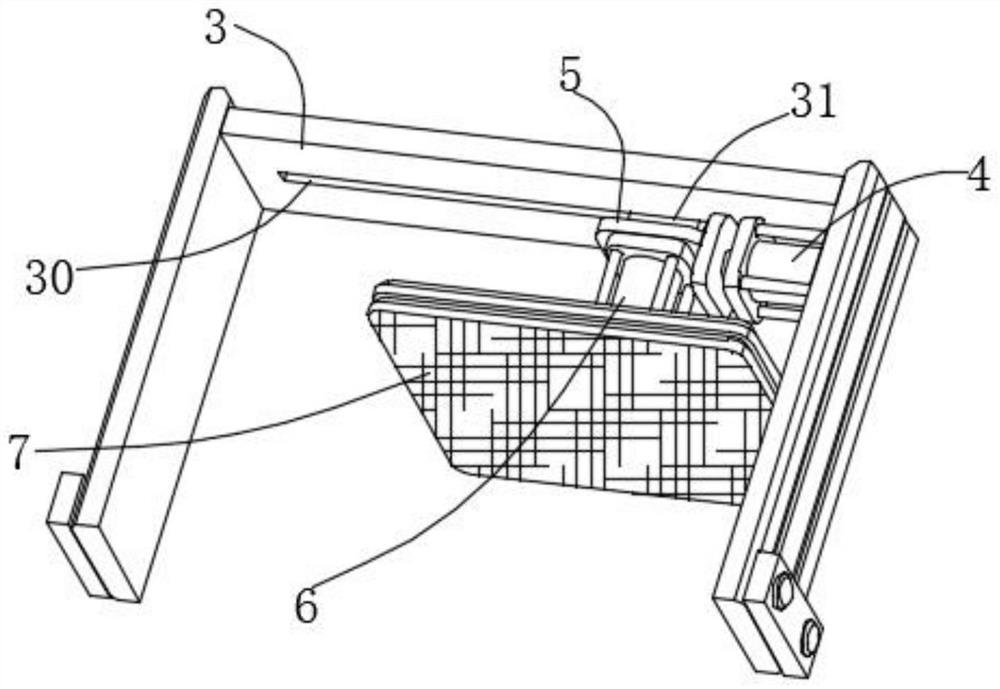

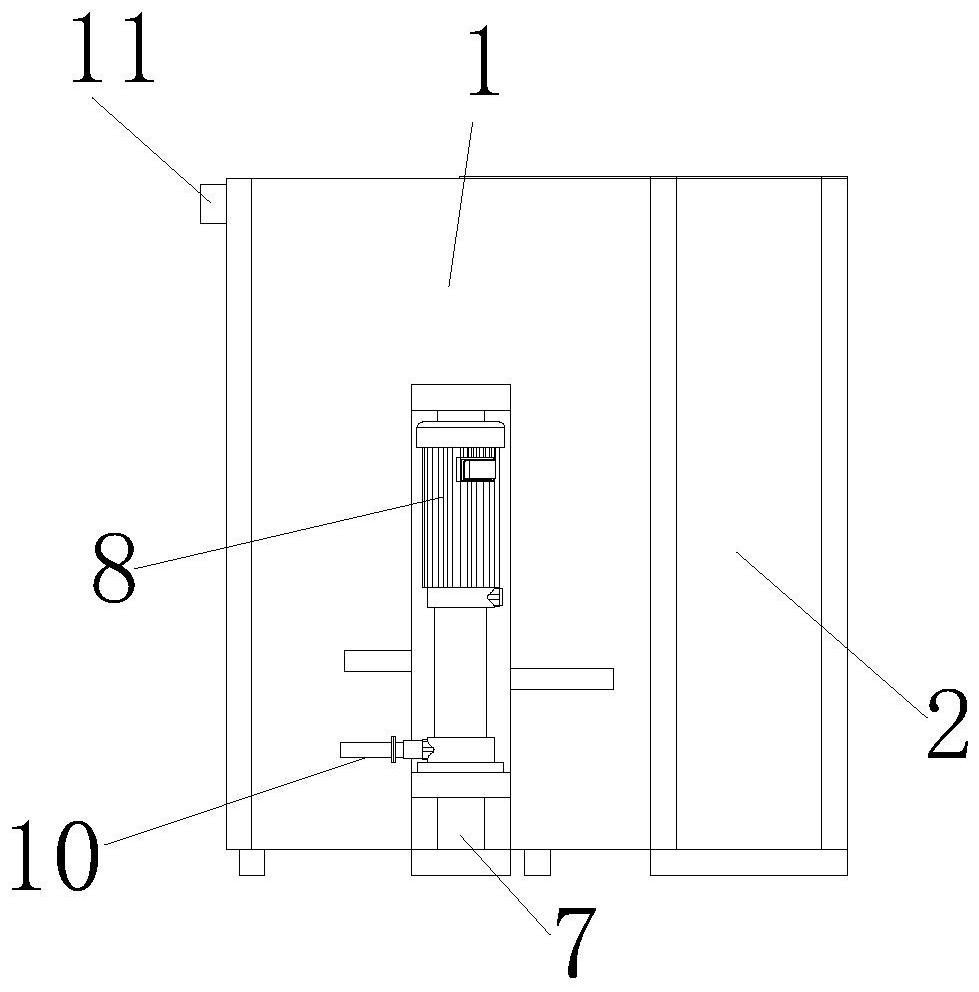

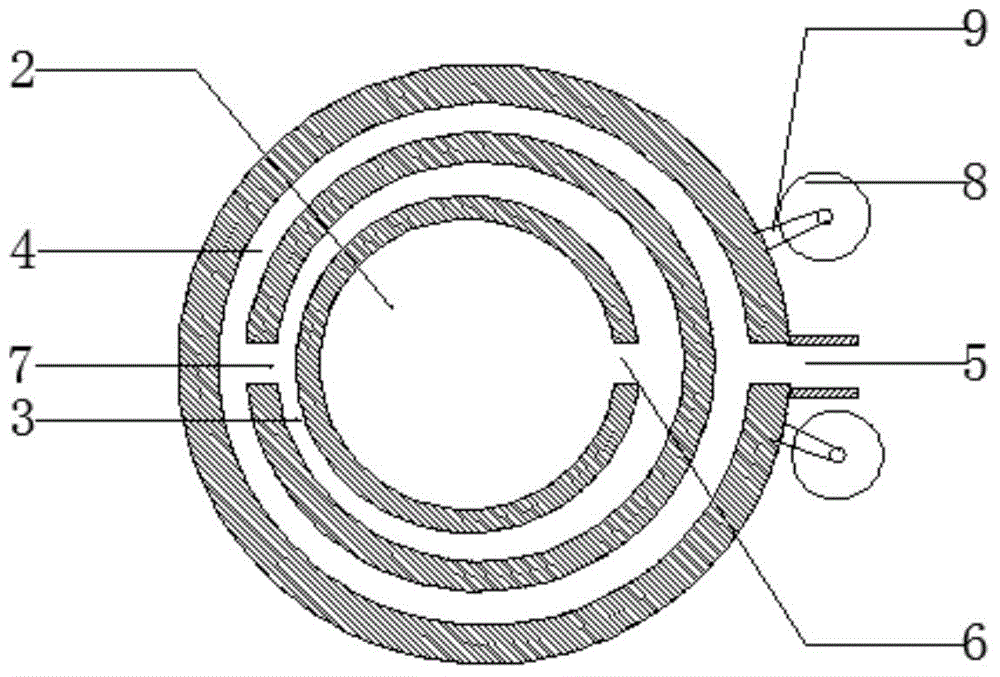

Device and method of pressing welding ring of electrode pin

The invention provides a device and a method of pressing a welding ring of an electrode pin. The device comprises a welding ring pickup device 1, an extrusion module 2, a spring table 3 and a groove 4, wherein the welding ring pickup device 1 is partially sleeved in the extrusion module 2, the extrusion module 2 is used for extruding the welding ring 5 positioned on the spring table 3, and the spring table 3 is arranged in the groove 4. Each of two sidewalls of the groove 4 comprises a roller 6 for shaping the edge of the extruded welding ring 5.

Owner:XIAN YONGDIAN ELECTRIC

Arranging device for arranging secretary data

The invention discloses an arranging device for arranging secretarial data, and belongs to the technical field of secretarial appliances. The arranging device comprises a stabilizing plate, wherein the top of the stabilizing plate is fixedly connected with a concave frame, the two sides of the inner wall of the concave frame are each provided with two first sliding grooves, the four first slidinggrooves are each internally connected with a first sliding block in a sliding mode, every two first sliding blocks form a group, and the opposite sides of the first sliding blocks of each sets of arefixedly connected with a same movable plate. Through the combined action of a motor, a bearing, a rotating shaft, a two-way threaded rod, a threaded cap, a second sliding groove, a second sliding block, a movable rod, the movable plates and a fixed plate, arranged data can be flattened, through the arrangement of a telescopic assembly and the fixed plate, the data placed on the stabilizing plate can be fixed, through the arrangement of a second groove and a third groove, when flattening is conducted, the telescopic assembly can be completely stored in the second groove and the third groove, and therefore the fixed plate can be evenly stressed to flatten the data.

Owner:新化县楚怡工业学校

High-yield environment-friendly food packaging material processing device and preparation method

InactiveCN107724178AEasy to openEasy inflowSpecial paperPaper/cardboardPulp and paper industryMaterials processing

The invention discloses a high-yield environment-friendly food packaging material processing device, and a preparation method. The high-yield environment-friendly food packaging material processing device comprises a paper pulp box; the upper surface of the paper pulp box is provided with a box cover; the lower surface of the paper pulp box is horizontally connected with a movable plate through aspringback hinge; an inclined plate is arranged on the lower end of the paper pulp box toward the right; the right side of the inclined plate is horizontally fixedly provided with a mould plate; the right side of the mould plate is fixedly connected with a solution box; a motor is fixedly connected with the bottom of the solution box; the upper end of the motor is connected with a first gear through a bearing. The box cover is used for covering the paper pulp box; a control rod is driven to move down so as to move the movable plate; paper pulp flows to the right side through the inclined plate; a blocking plate is adopted to prevent flow of materials to the outside; the solution box is used for storing PE film solution; the motor is used for driving the first gear to rotate; the first gearis used for driving a second gear to rotate; the surface of the second gear is uniformly provided with small holes for uniform falling of the PE film solution; a long shaft is adopted for driving connection plates to rotate; and an idler wheel is adopted for uniform pressing of paper pulp and the PE film solution.

Owner:FOSHAN HUIZHONG SENTAI TECH CO LTD

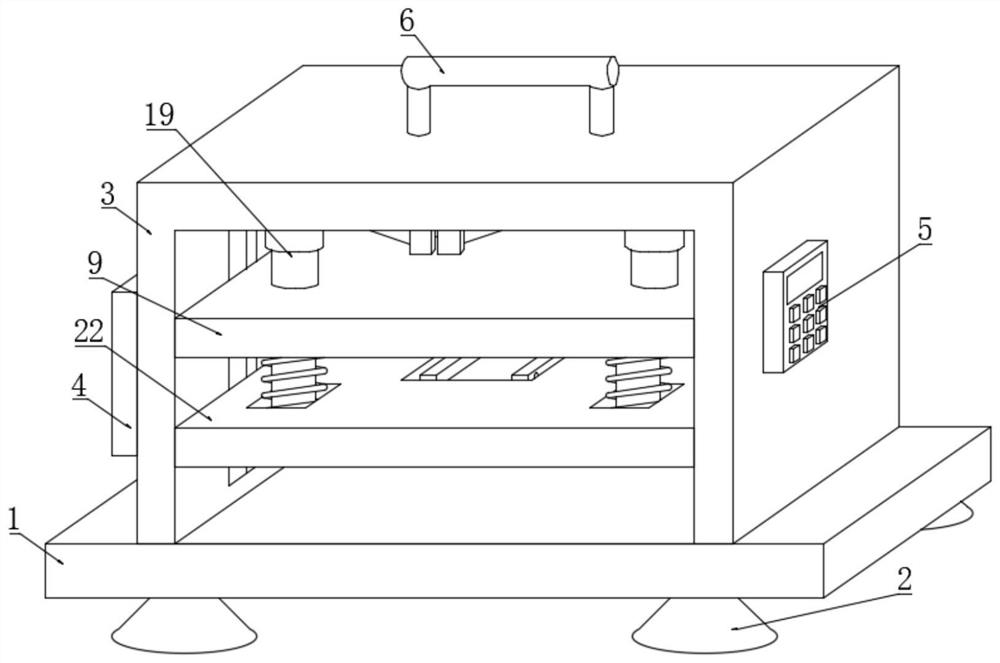

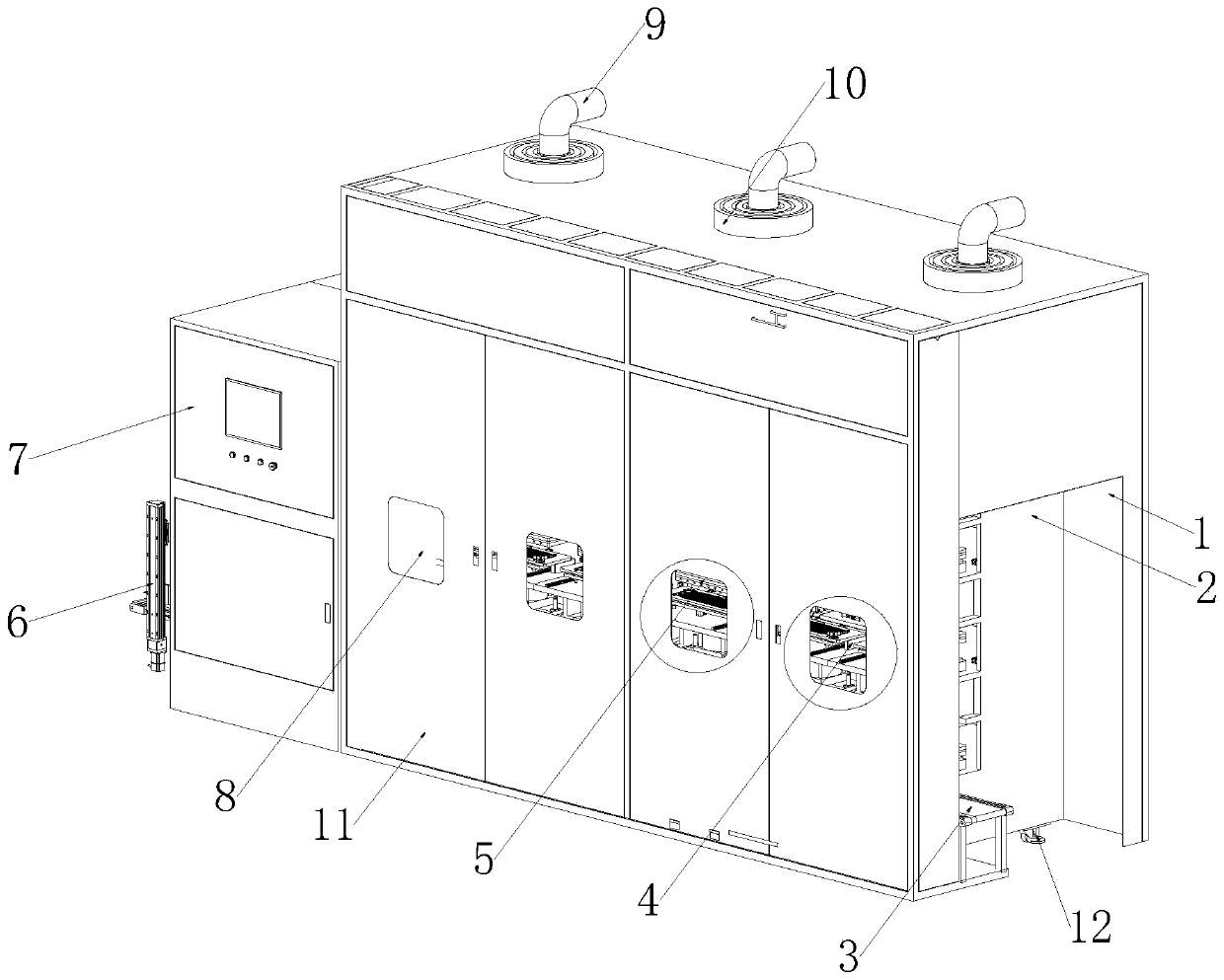

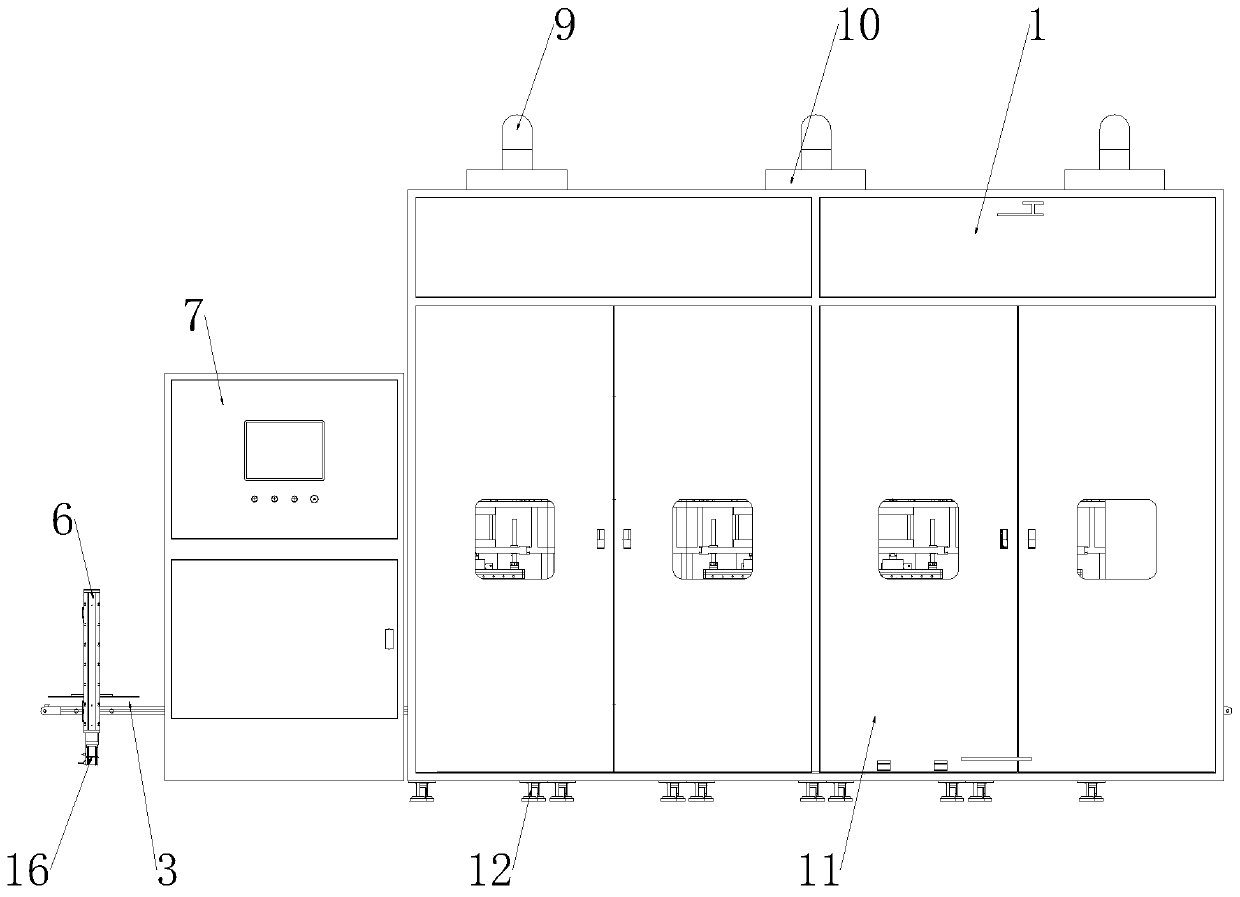

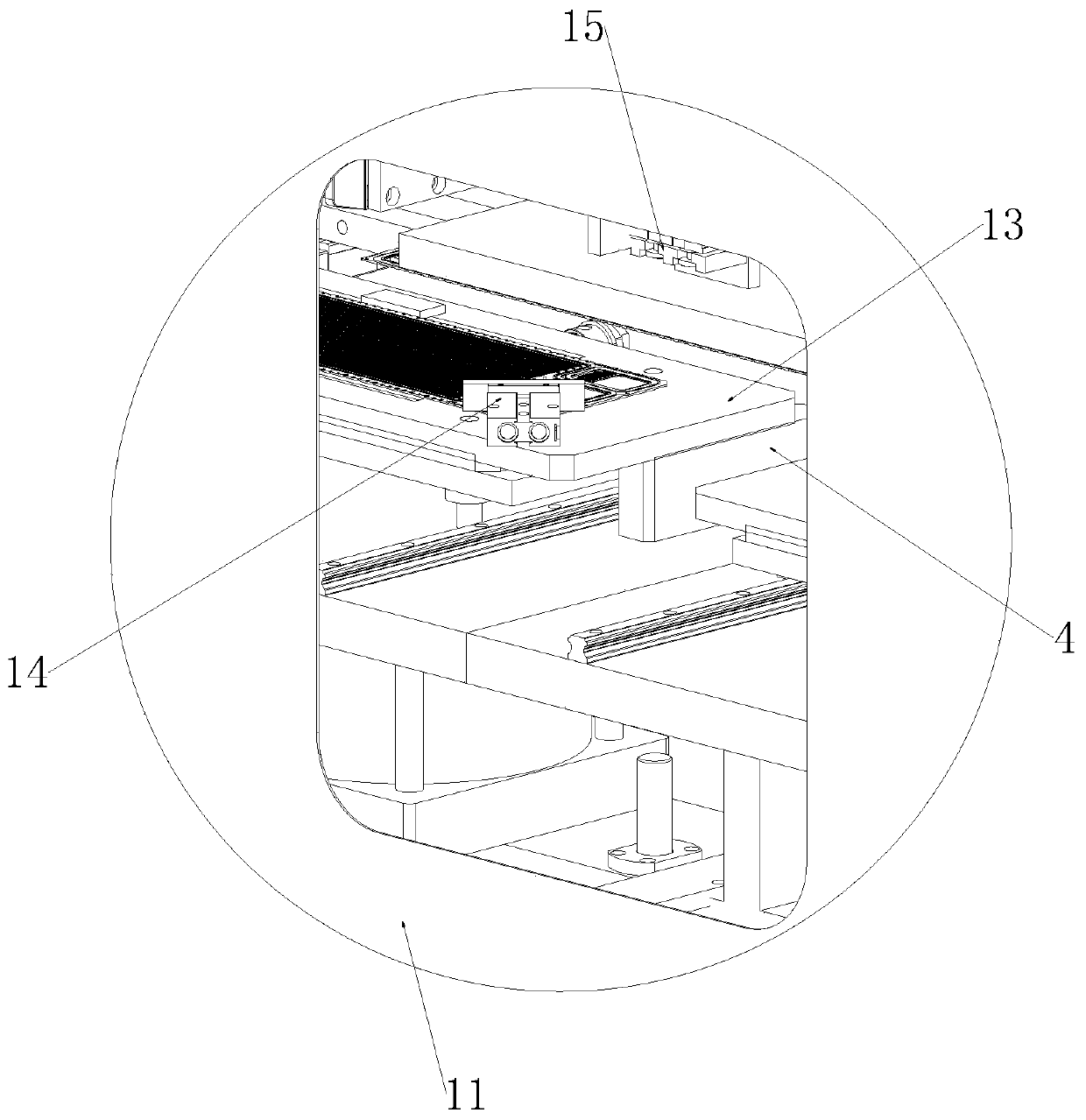

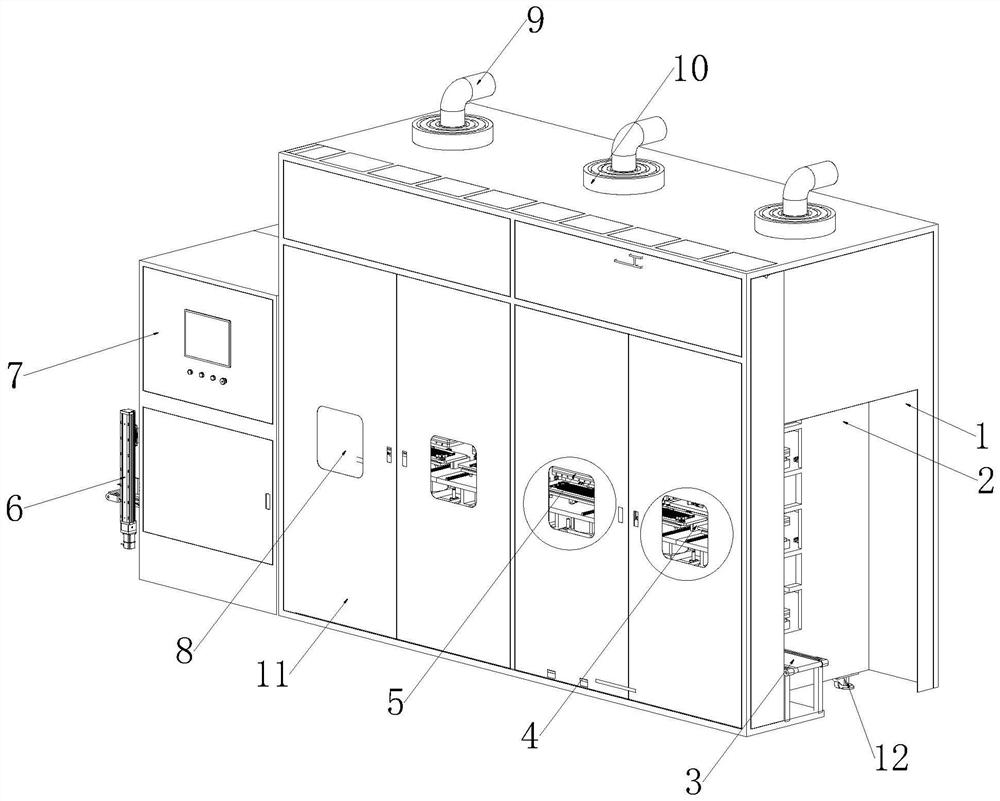

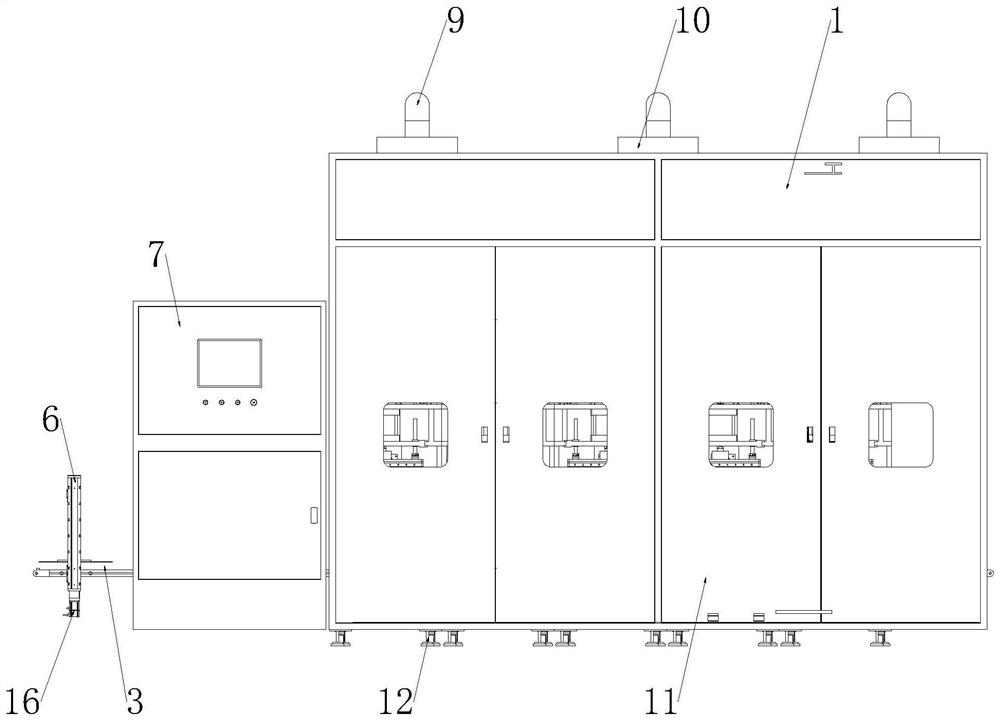

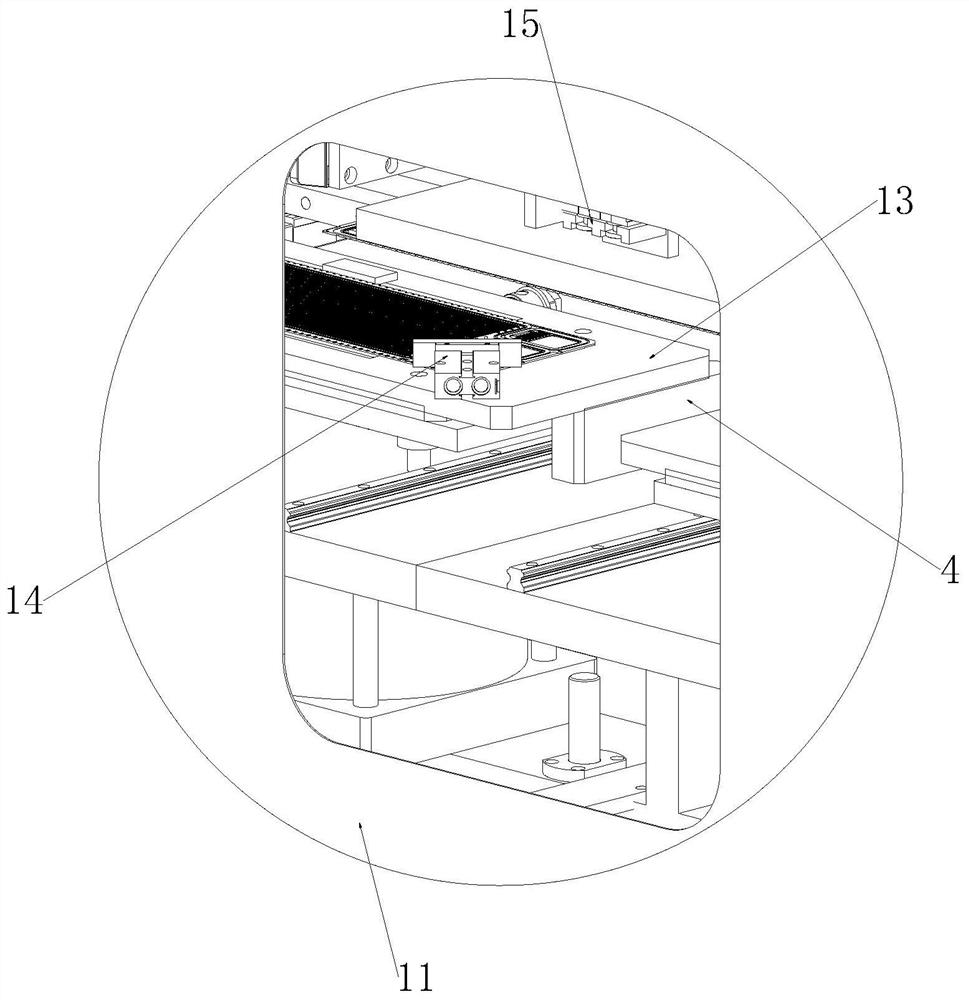

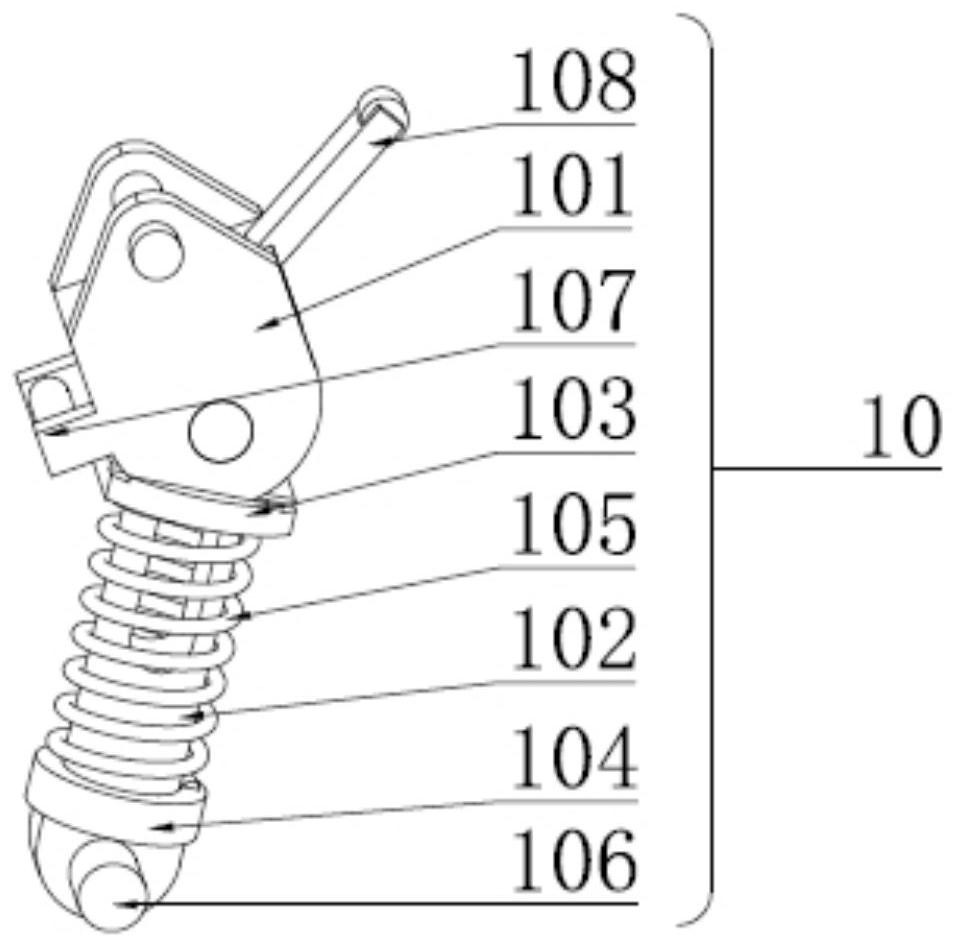

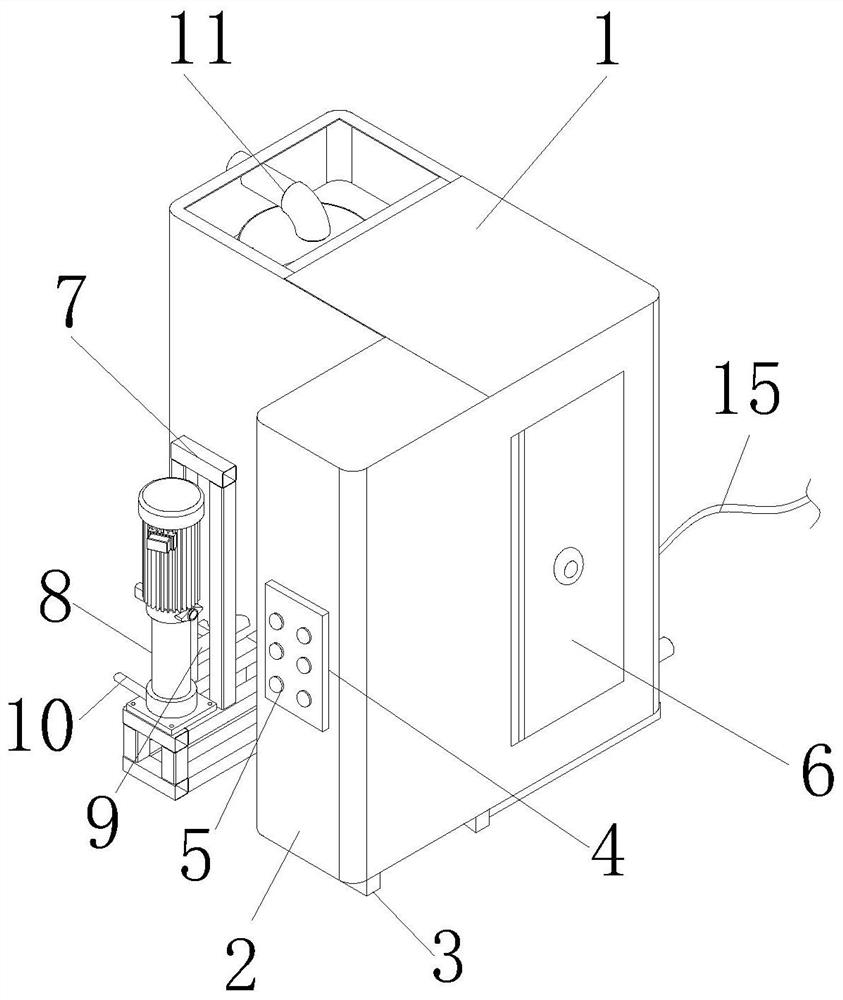

Hydrogen fuel cell bipolar plate thermocuring pressure maintaining equipment

ActiveCN110341225AShorten the lengthPrevent wet misalignmentFouling preventionFinal product manufactureLocking mechanismHydrogen fuel cell

The invention discloses hydrogen fuel cell bipolar plate thermocuring pressure maintaining equipment comprising an equipment body. A dustproof outer cover is installed at the top of the equipment body. A floor mat is installed at the bottom of the equipment body. A conveying line is installed on one side of the equipment body. A lifting mechanism is installed on one side of the conveying line. A base is installed at the bottom of the lifting mechanism. A lower heating jig is installed on the side face of the equipment body. An upper heating jig is installed at the top of the lower heating jig.A servo press is installed at the top of the upper heating jig. A locking mechanism is installed at the top of the lower heating jig. A door plank is installed on the side face of the dustproof outercover. A glass view window is embedded in the side face of the door plank. The hydrogen fuel cell bipolar plate thermocuring pressure maintaining equipment is provided with the upper heating jig, thelifting mechanism, the lower heating jig and the servo press, and thus the problems that common pressure maintaining equipment is only provided with a single pressure maintaining station, the space utilization rate is low, loss of electric power resources is large during work, production cost is high, and production efficiency is low are solved.

Owner:深圳市昆龙卓盈机电有限公司

Efficient plywood single-layer veneering production line

ActiveCN109049169AReduce liquidityAvoid large areas of sheddingPlywood pressesVeneer pressesProduction lineCold air

Owner:漳州鑫华成机械制造有限公司

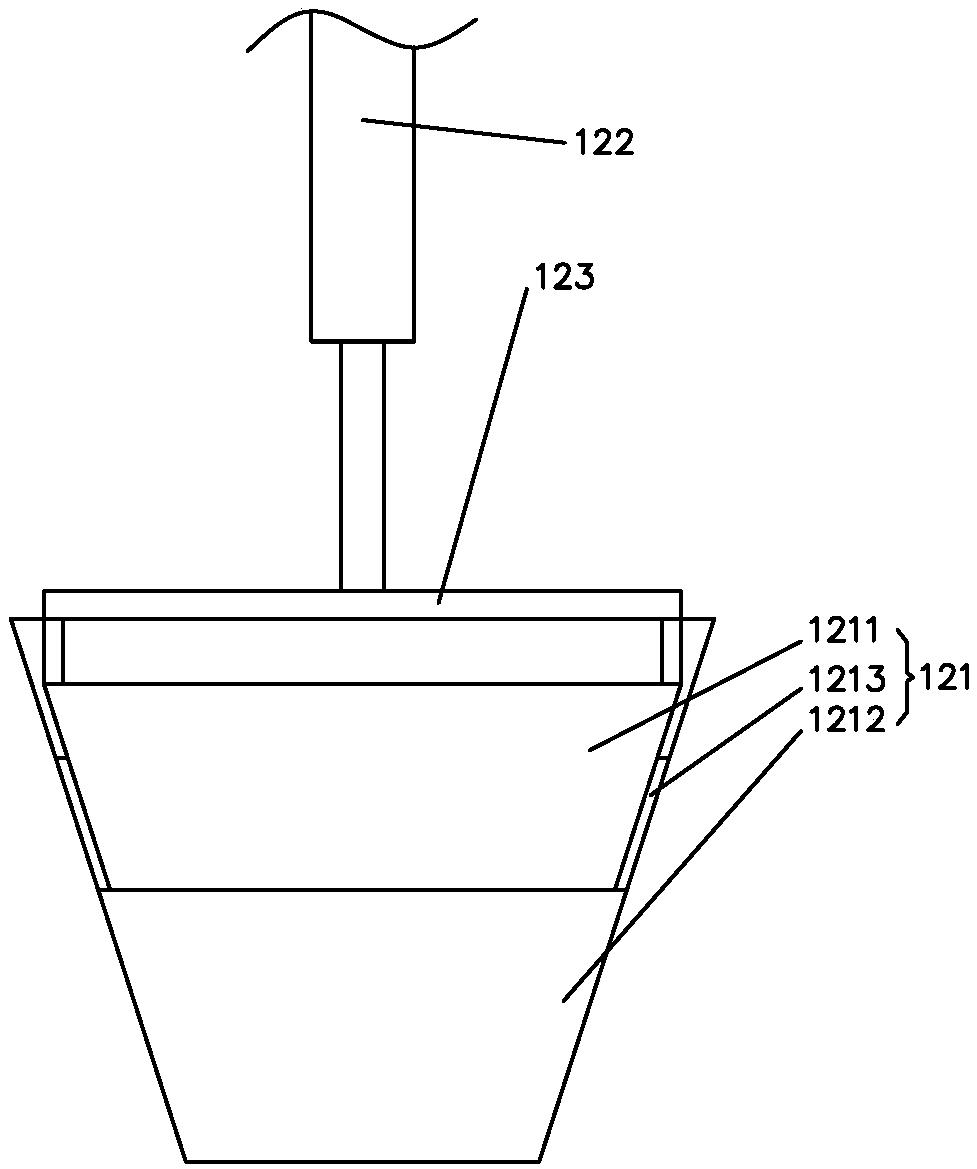

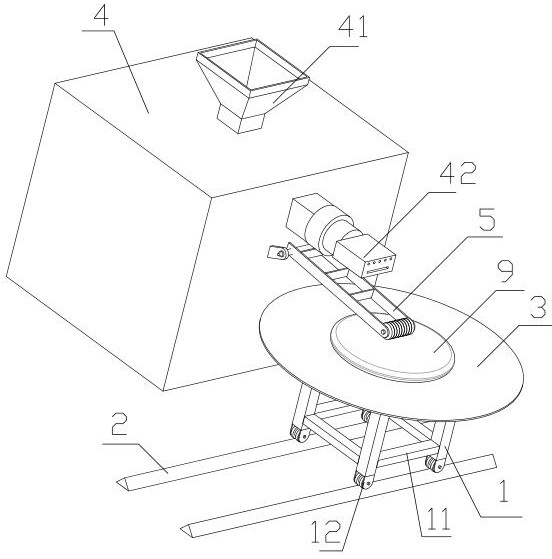

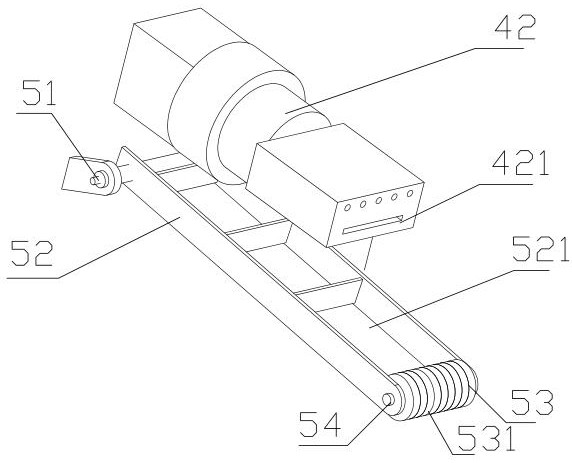

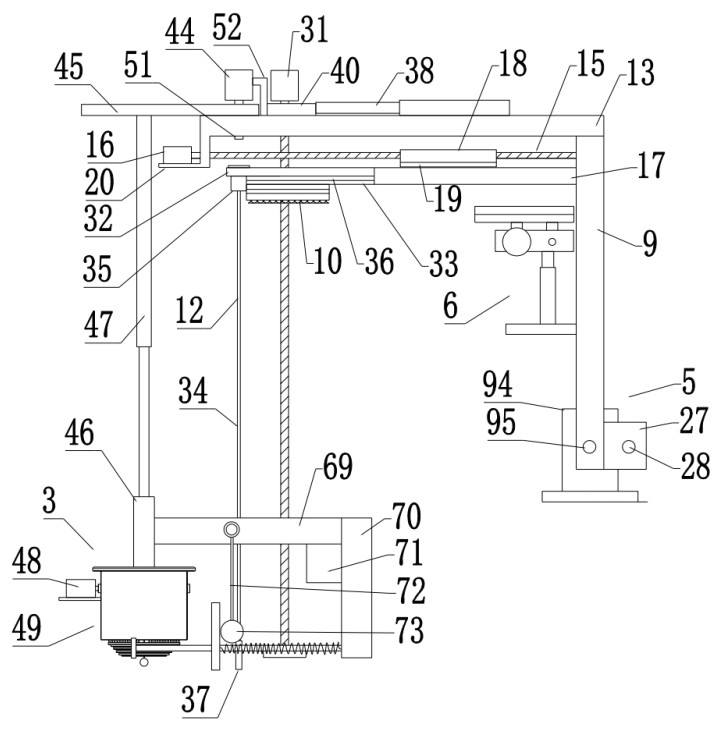

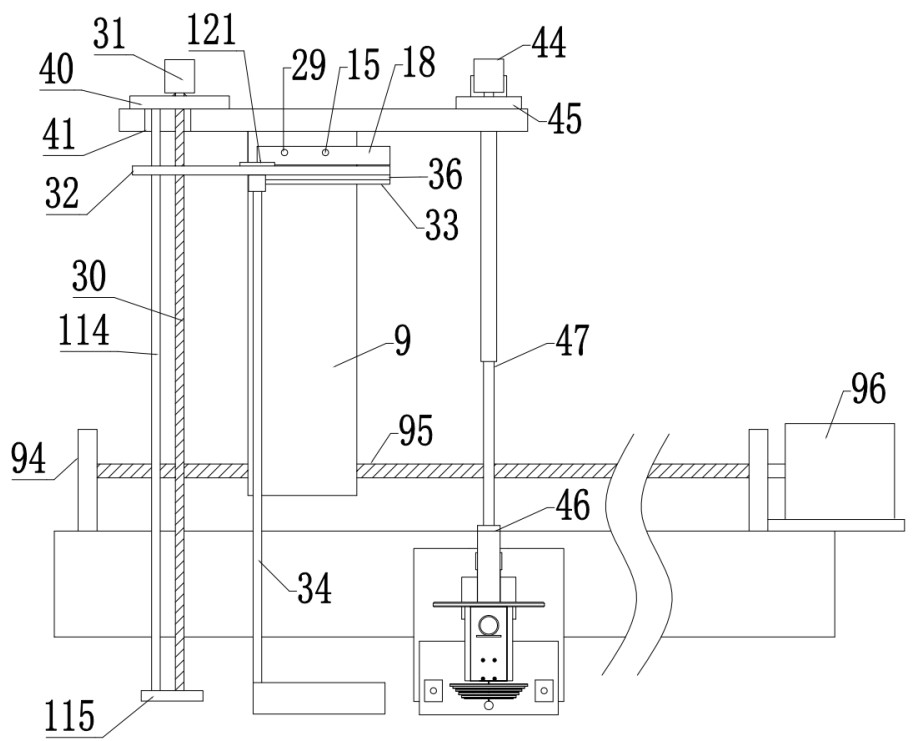

Manufacturing equipment and manufacturing method of inspection well

ActiveCN112388941APrecise and controllable positionGood molding effectMachiningIndustrial engineering

The invention relates to the technical field of municipal construction devices, in particular to design of machining and manufacturing equipment of an inspection well. According to the technical scheme, the manufacturing equipment of the inspection well comprises a bottom cover manufacturing device and a body conveying device, the bottom cover manufacturing device comprises a discharging device, the bottom cover manufacturing device further comprises a rotating disc located below an extrusion opening and used for bearing materials, a rotating disc driving device for driving the rotating disc to rotate, a sliding rail, a moving table connected with the rotating disc and a moving table driving device for driving the moving table to move on the sliding rail, and the body conveying device is used for conveying a body to the position above the rotating disc. According to the manufacturing equipment and a manufacturing method of the inspection well, the automation degree is high, the labor intensity of workers is low, material positioning is controllable in the bottom cover forming process, the forming effect is good, the combination of a bottom cover and a main body is convenient and rapid, the working procedure is simplified, and the efficiency is improved.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

A non-woven fabric coating production method and its flattening device

ActiveCN105127058BImprove the level ofFast and accurate coatingLiquid surface applicatorsPhysical treatmentEngineeringPlanishing

Owner:湖北慧狮塑业股份有限公司

A kind of hydrogen fuel cell bipolar plate thermal curing pressure maintaining equipment

ActiveCN110341225BShorten the lengthPrevent wet misalignmentFouling preventionFinal product manufactureHydrogen fuel cellEngineering

The invention discloses a hydrogen fuel cell bipolar plate thermal curing and pressure maintaining equipment, comprising an equipment body, a dust-proof cover is installed on the top of the equipment body, a foot pad is installed at the bottom of the equipment body, and a side of the equipment body is installed with a dust-proof cover. Conveying line, a lifting mechanism is installed on one side of the conveying line, a base is installed at the bottom of the lifting mechanism, a lower heating tool is installed on the side of the equipment body, and an upper heating tool is installed on the top of the lower heating tool, and the upper heating tool is installed A servo press is installed on the top of the lower heating tool, a locking mechanism is installed on the top of the lower heating tool, a door panel is installed on the side of the dustproof cover, and a glass window is embedded in the side of the door panel. The invention solves the general pressure maintaining equipment by setting the upper heating tool, the lifting mechanism, the lower heating tool and the servo press, only a single pressure maintaining station is set, the space utilization rate is low, the loss of power resources during operation is large, and the production cost is high. high and low productivity.

Owner:深圳市昆龙卓盈机电有限公司

Paper processing device

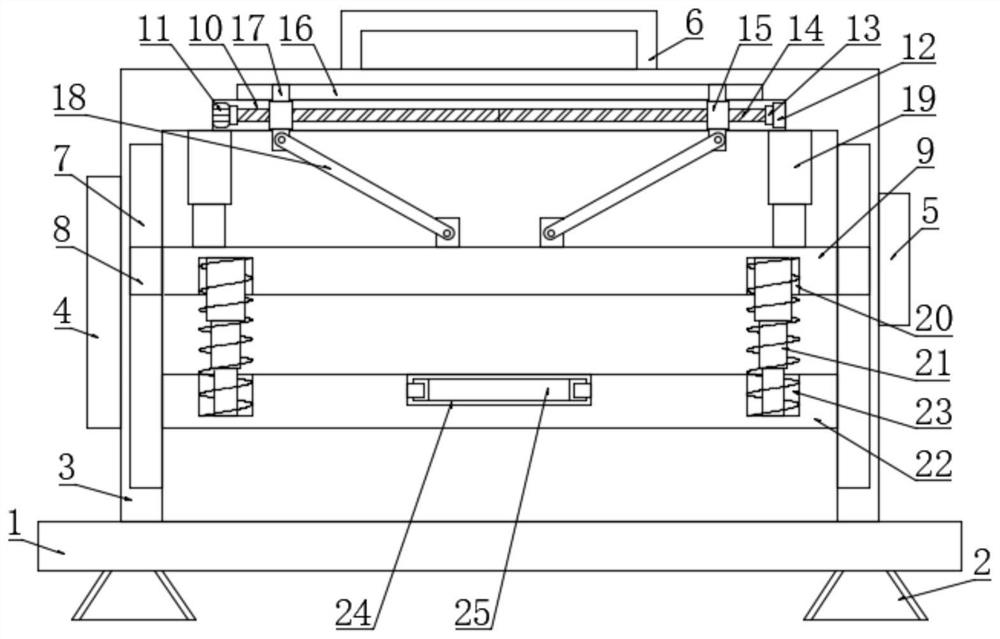

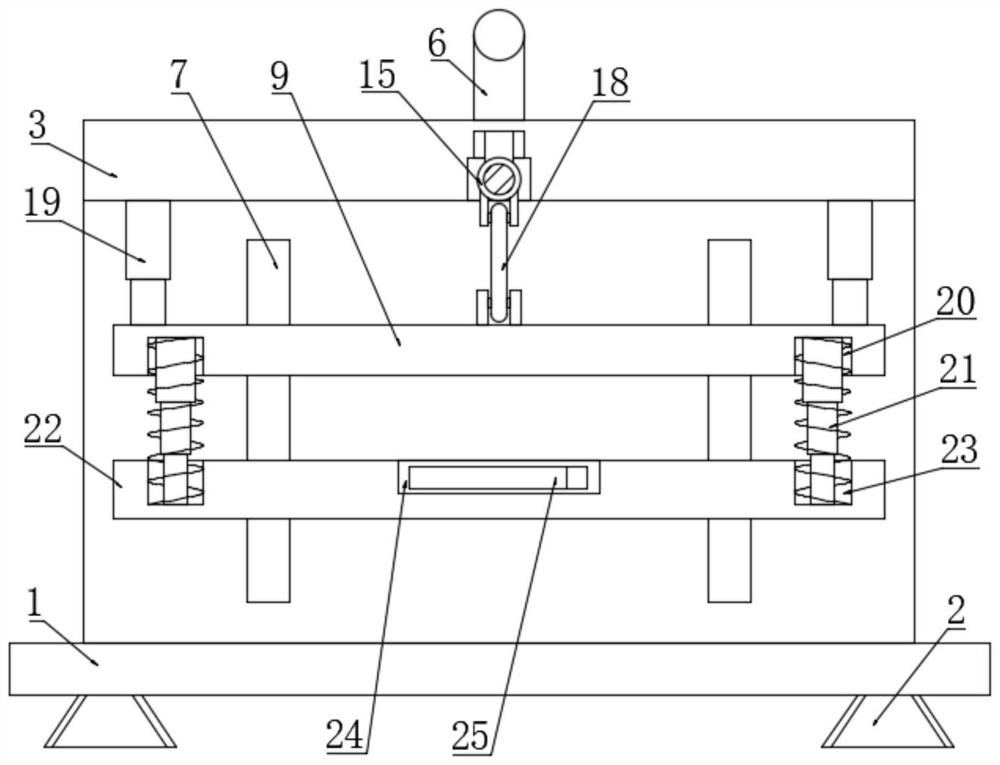

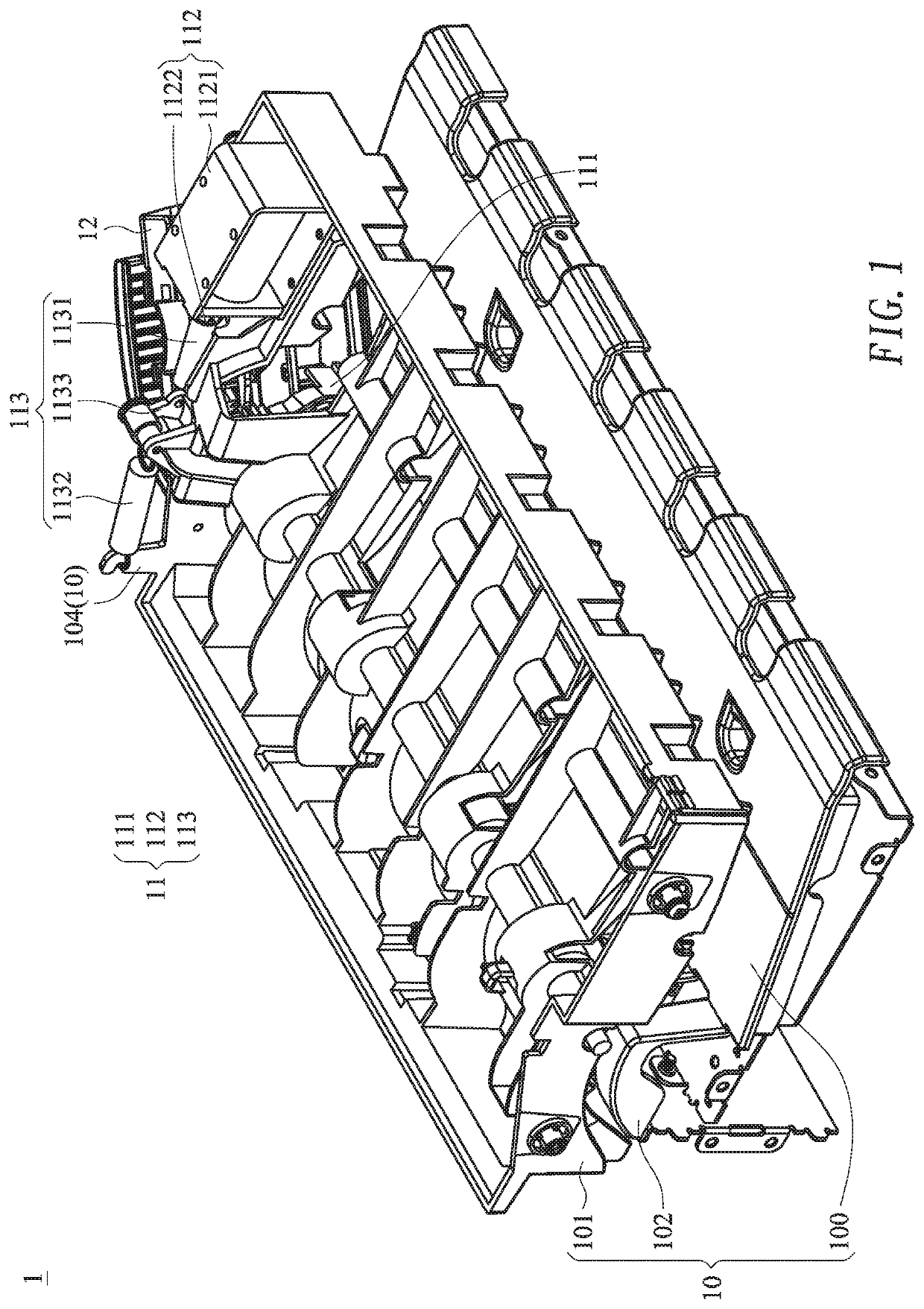

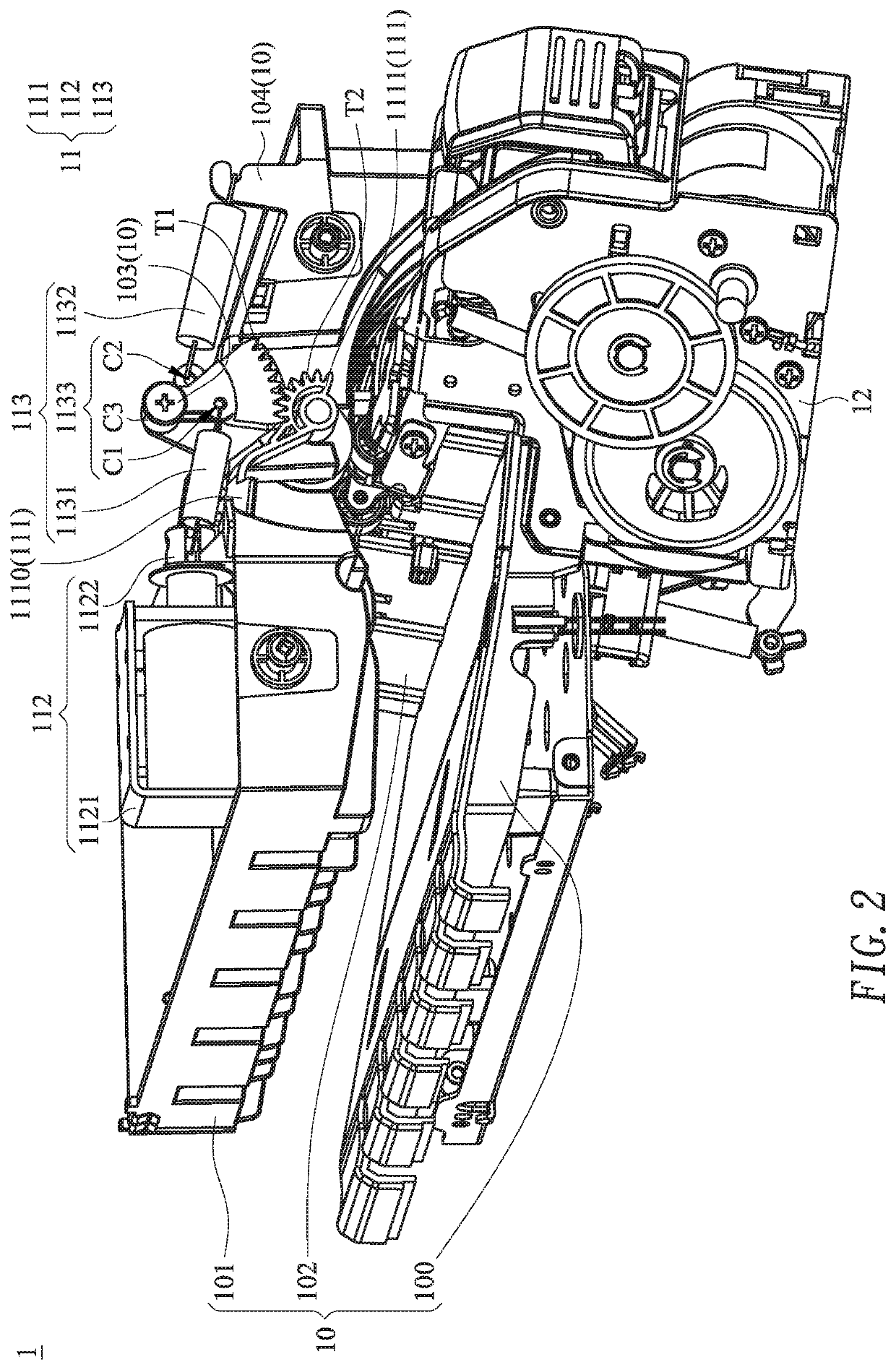

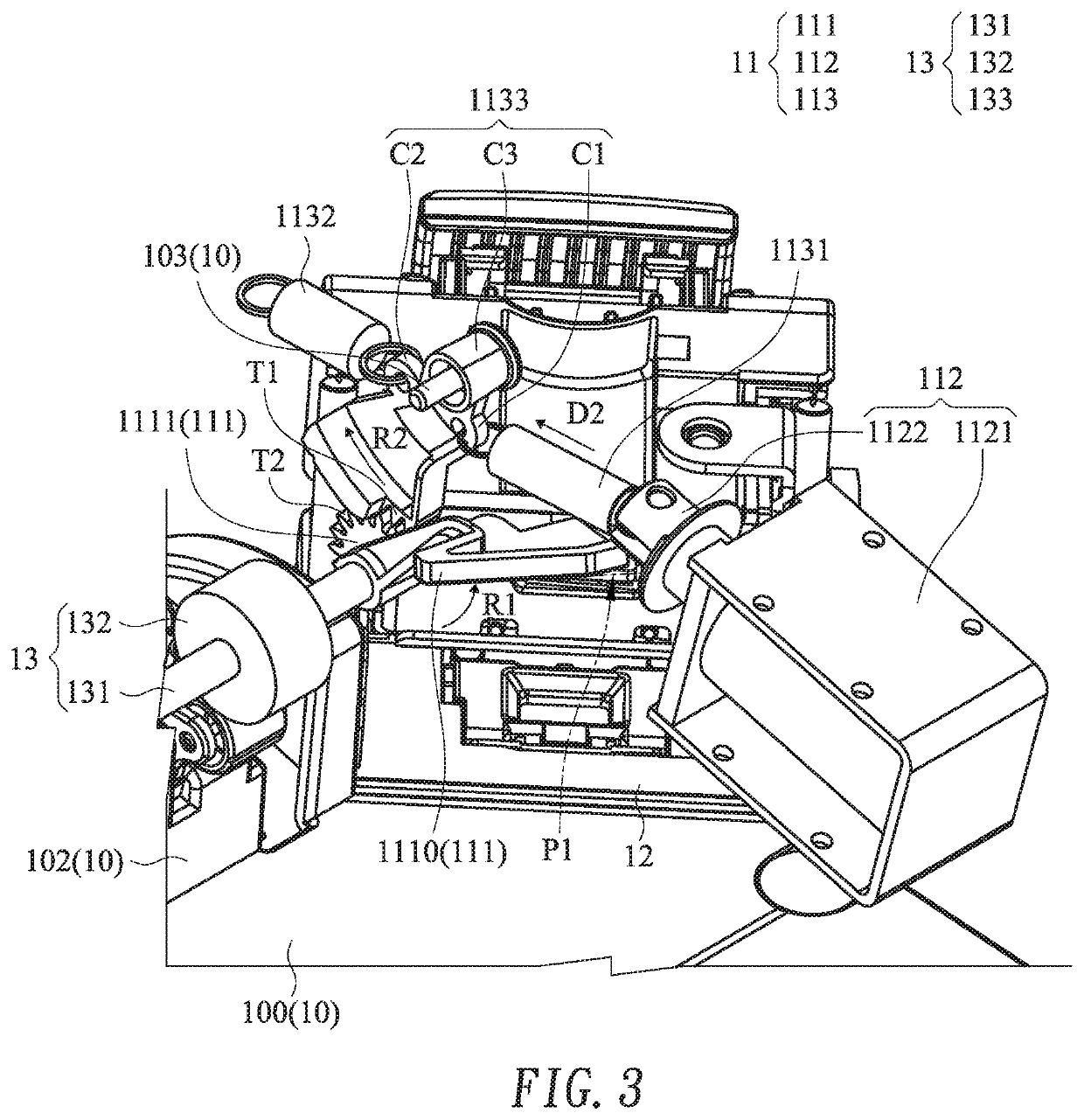

ActiveUS11117400B2Flatten evenlyImprove rigidityPile receiversOther printing apparatusStructural engineeringBar pressing

A paper processing device includes a casing and a paper pressing mechanism. The casing includes a paper placement platform. The paper placement platform is extended externally from the casing so as to support the plural papers. The paper pressing mechanism includes a pressing bar, a driving mechanism and a linking mechanism. The pressing bar includes a pressing structure. The linking mechanism is connected between the driving mechanism and the pressing bar. While the linking mechanism is driven by the driving mechanism, the pressing bar is moved with the linking mechanism and rotated relative to the paper placement platform, so that the pressing structure is moved from an initial position to a target position. When the pressing structure is moved to the target position and contacted with the plural papers, a guiding channel is defined between the pressing structure and the paper placement platform.

Owner:PRIMAX ELECTRONICS LTD

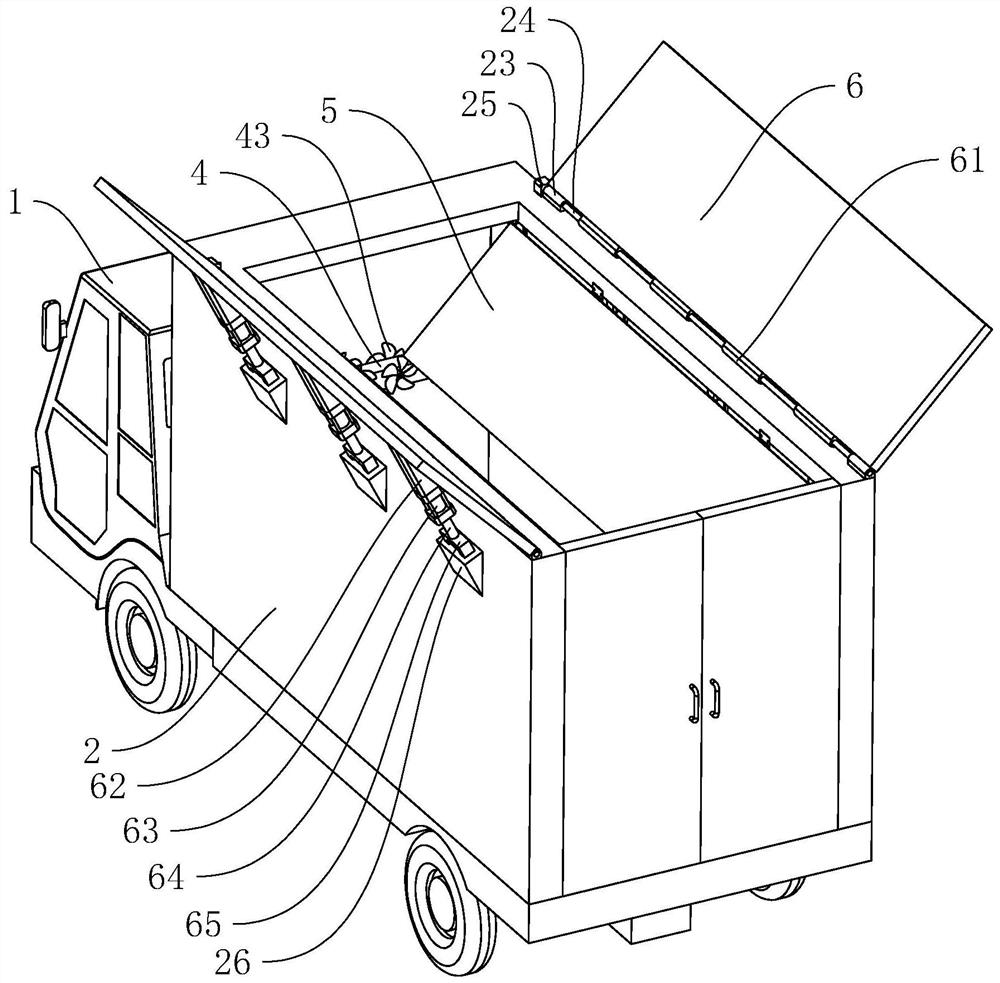

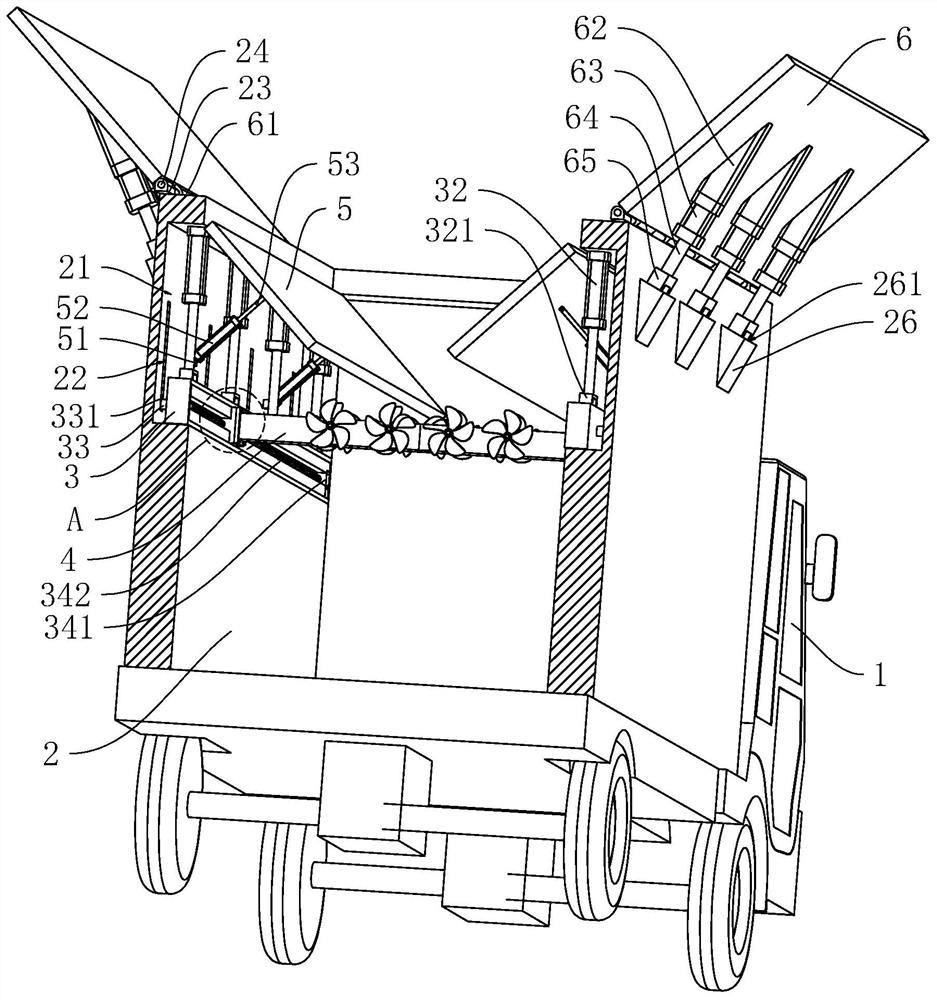

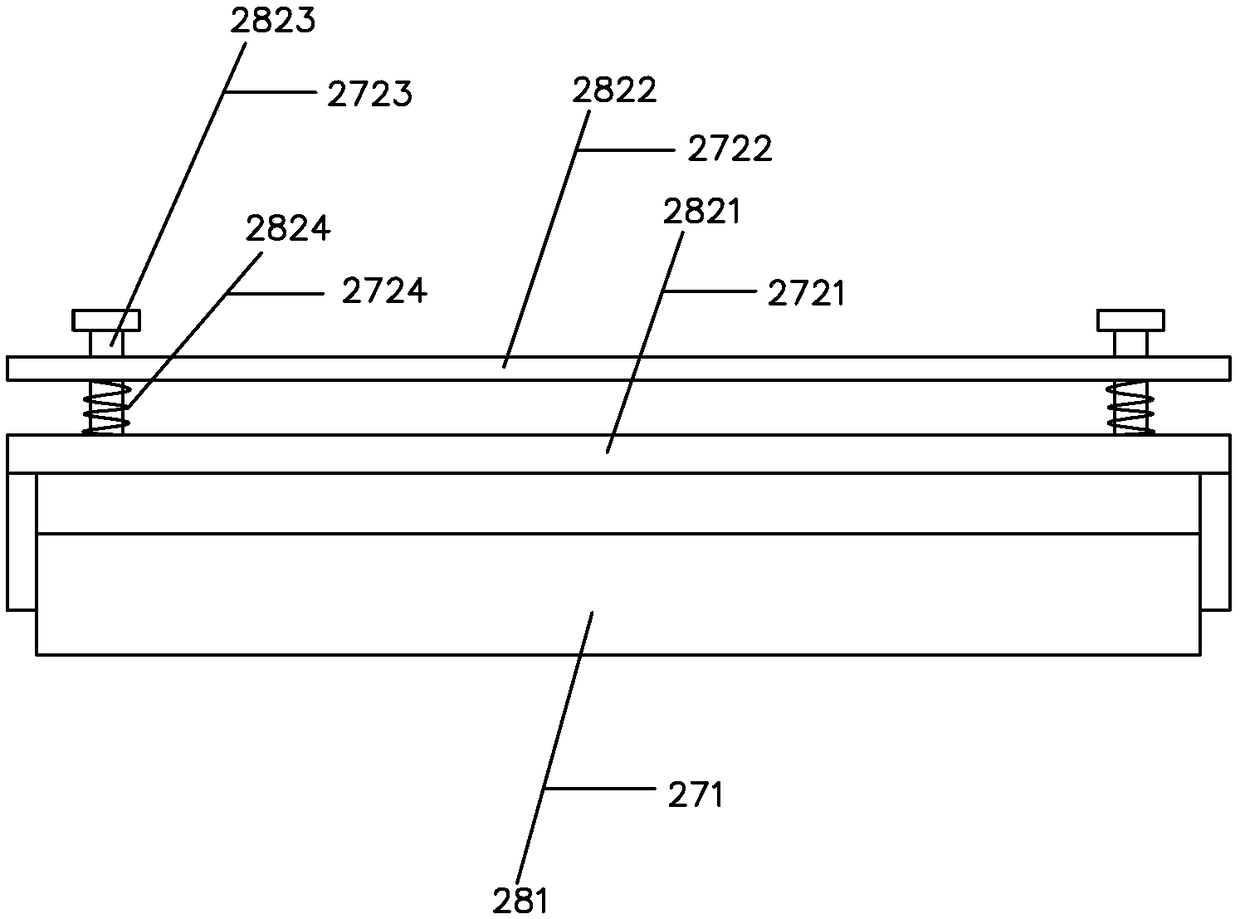

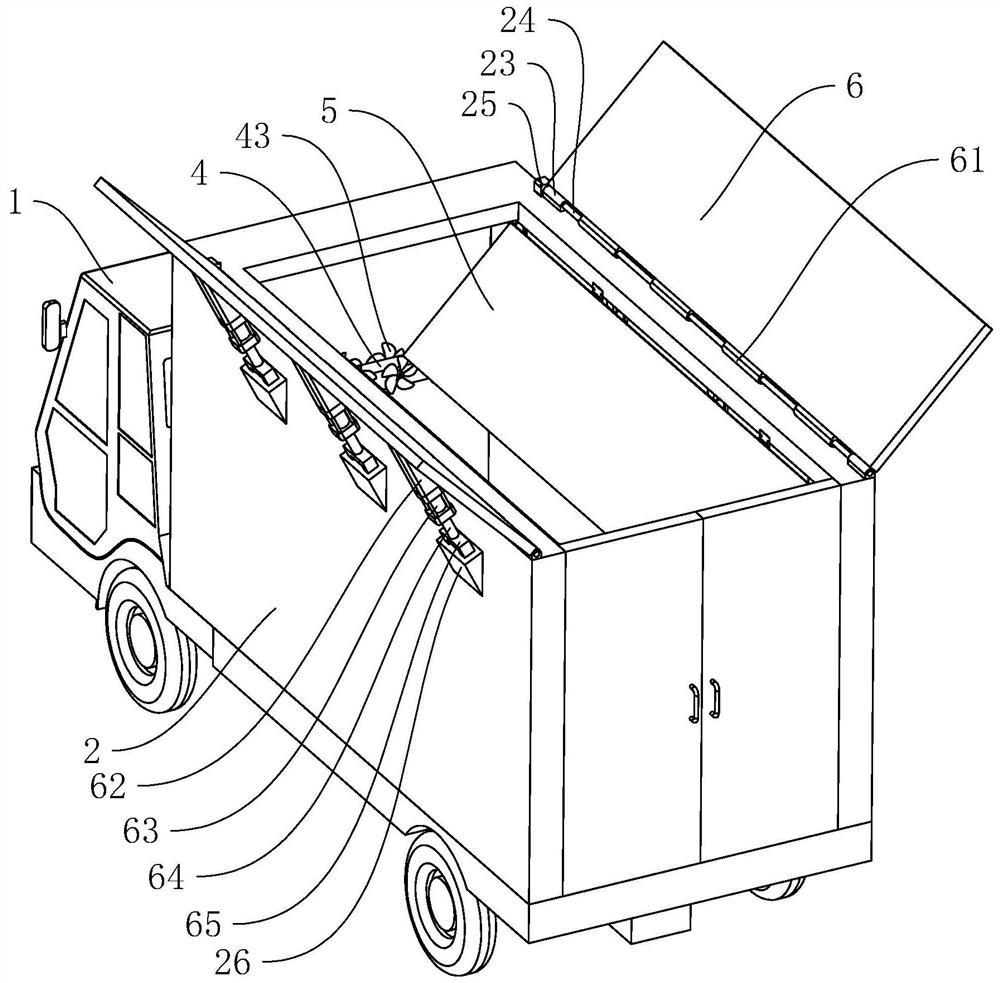

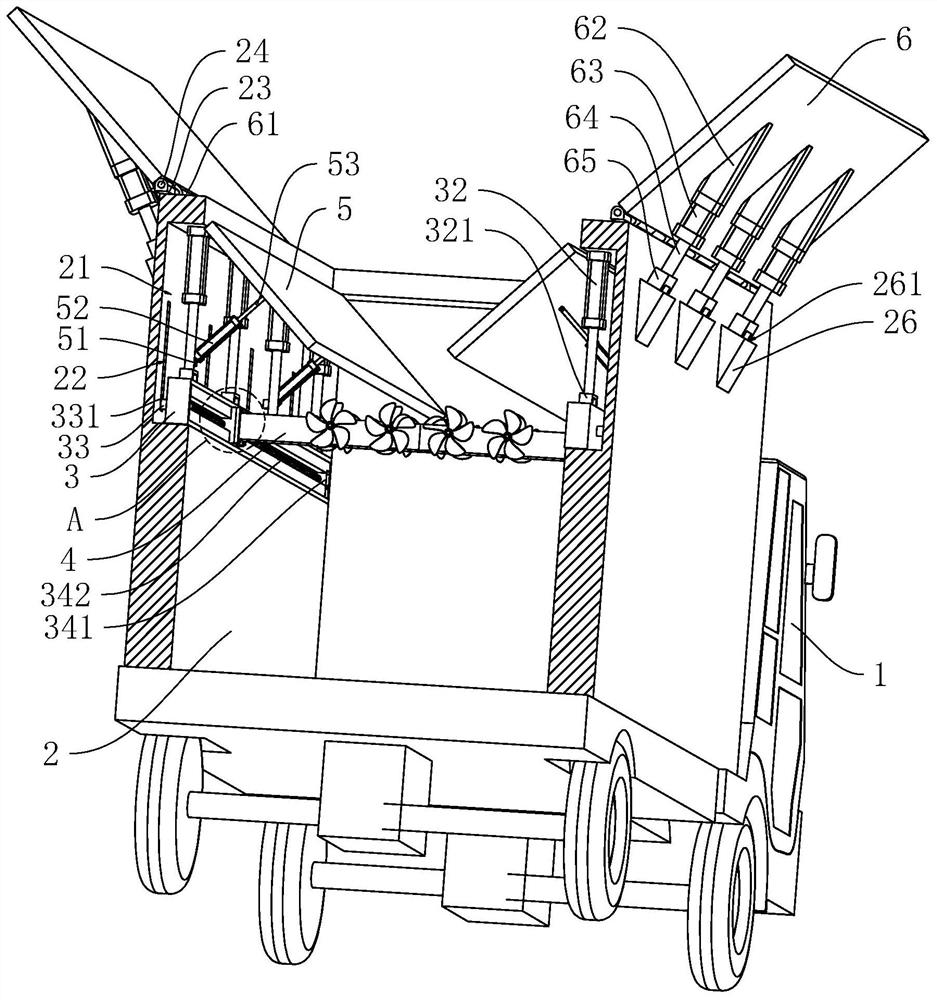

Equipment and method for transporting mud for earthwork excavation

ActiveCN113120097BEasy to stackFlatten evenlyGrain treatmentsLoading-carrying vehicle superstructuresSoil scienceSlide plate

The present application relates to a mud transporting equipment for earthwork excavation, which belongs to the technical field of construction earthwork conveying equipment, and includes a body of an earth moving vehicle and a bucket installed on the body of the dirt moving vehicle. A flattening mechanism for bulldozing the soil is symmetrically arranged, and the flattening mechanism includes a lifting plate arranged on the inner wall of the bucket through a lifting assembly, and a sliding plate is slidably connected to one side of the lifting plate, One side of the sliding plate is provided with a push plate through a locking assembly, and the lifting plate is provided with a driving assembly for driving the sliding plate to move. The application can facilitate the effective accumulation of soil inside the truck body, thereby facilitating the uniform flattening of the soil accumulated inside the truck body, thereby increasing the mud transporting capacity of the earth moving vehicle and speeding up the efficiency of mud transporting .

Owner:上海友海建设工程有限公司

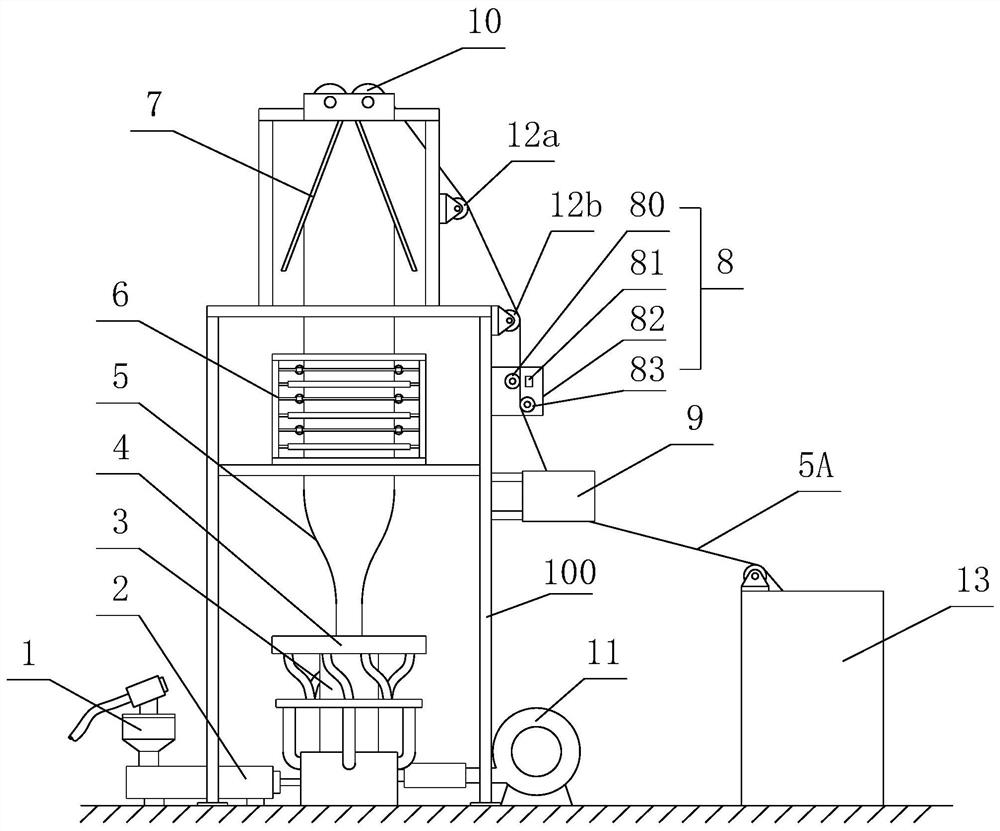

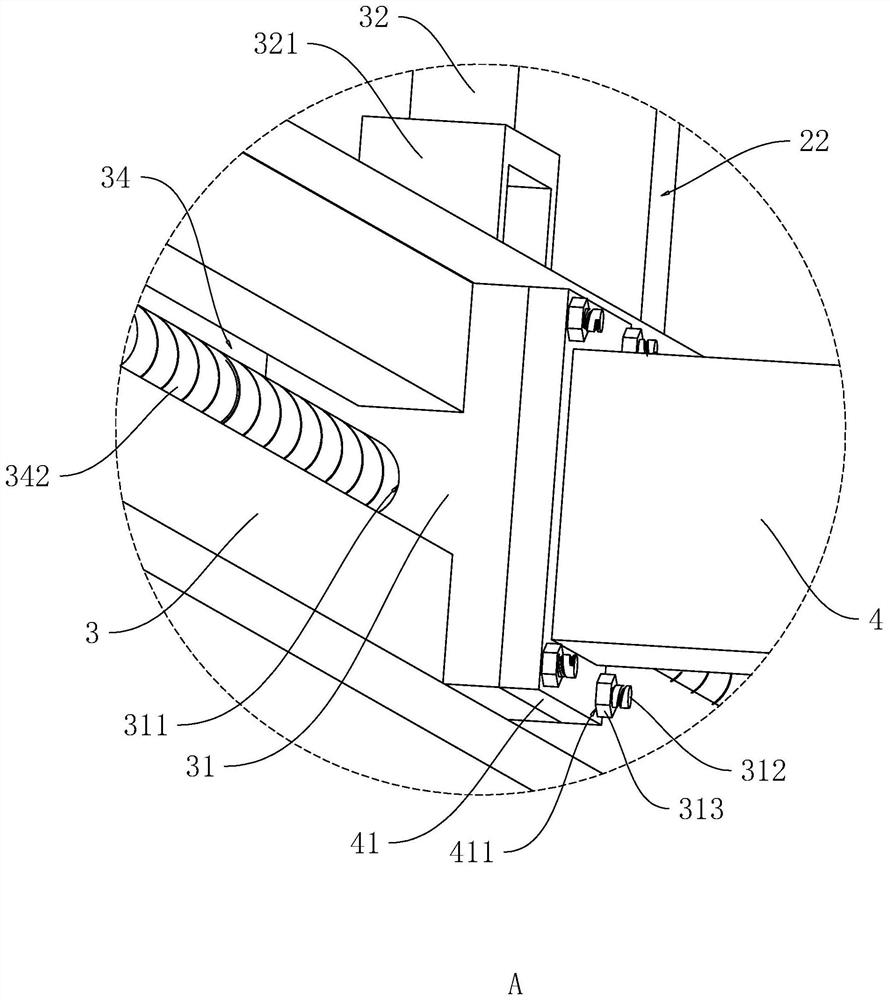

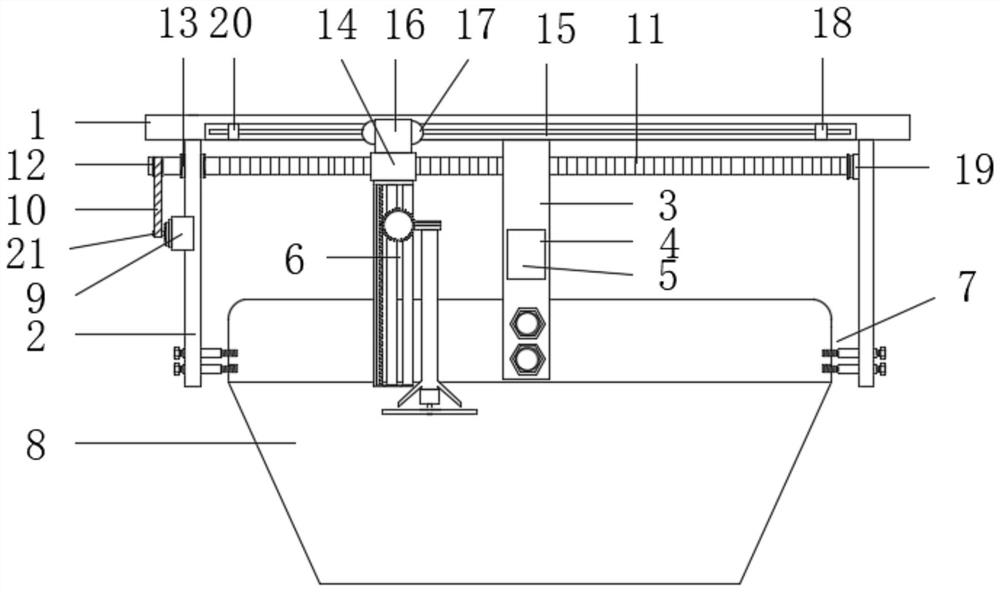

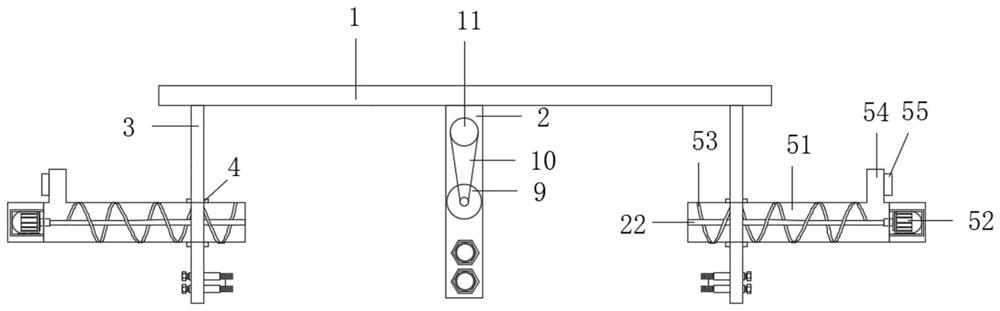

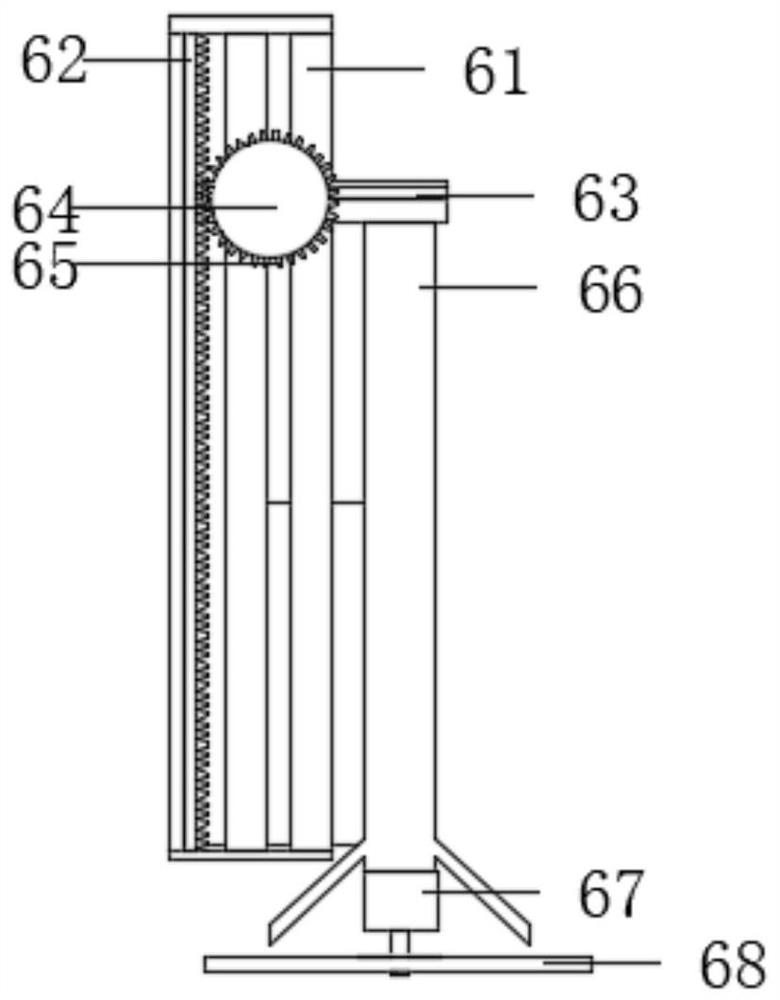

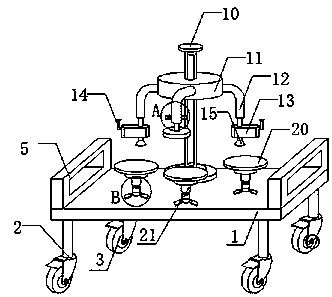

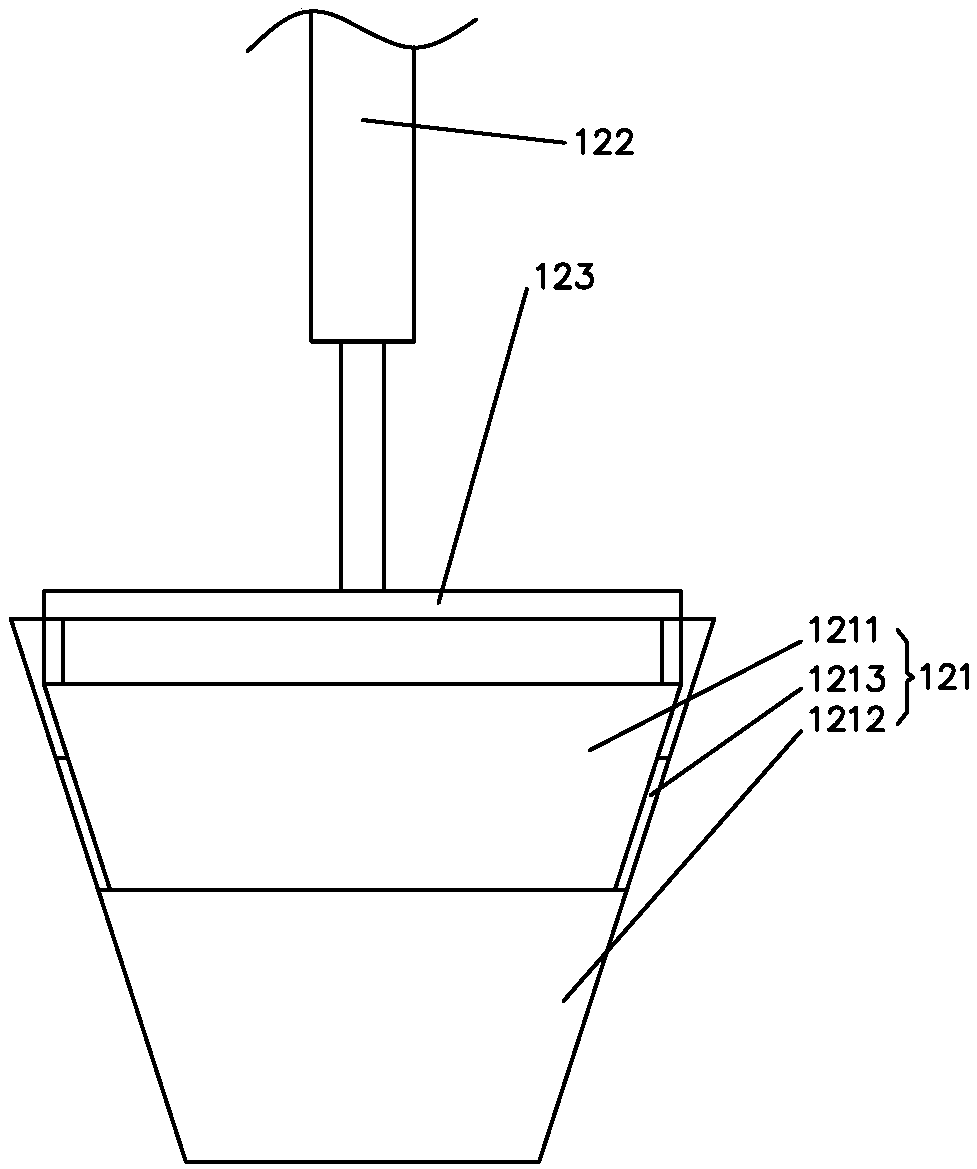

A kind of inverted separation bucket type material spreading device

ActiveCN109850594BImprove practicalityFlatten evenlyLarge containersLoading/unloadingEngineeringStructural engineering

The invention discloses an inverted separation bucket-type material spreading device, which comprises a cross top frame, the lower ends of which are respectively connected with a No. 1 fixing frame and a No. 2 fixing frame. The material barrel, both sides of the No. 1 fixed frame and the No. 2 fixed frame are equipped with a fixed frame limit mechanism, and the No. 1 fixed frame and the No. 2 fixed frame are connected with the spreading bucket through the fixed frame limit mechanism. A threaded rod is provided between the two side walls of the fixed frame. The present invention provides a limit mechanism for the fixed frame at the bottom of the No. 1 fixed frame and the No. 2 fixed frame, so that the material spreading device can be adapted to different diameters of material spreading buckets, increasing the The practicability of the device; by setting the tablet that can move horizontally and vertically, it is more convenient to flatten the blanks in the spreading bucket evenly; by setting two blank feeding bins, the feeding speed is increased, and the It is more uniform to fill the blank into the spreading bucket.

Owner:苏抒冉

Bottom cover manufacturing device suitable for inspection well

PendingCN112192234APrecise and controllable positionGood molding effectOther manufacturing equipments/toolsMachiningIndustrial engineering

The invention relates to the technical field of municipal construction devices, and particularly relates to design of a machining and manufacturing device for an inspection well. According to the technical scheme, the bottom cover manufacturing device suitable for the inspection well comprises a discharging device, wherein the discharging device comprises an extrusion device used for extruding materials, and the extrusion device comprises an extrusion opening; and the bottom cover manufacturing device further comprises a rotating disc located below the extrusion opening and used for bearing the materials, a rotating disc driving device for driving the rotating disc to rotate, a sliding rail, a moving table connected with the rotating disc and a moving table driving device for driving the moving table to move on the sliding rail. The bottom cover manufacturing device suitable for the inspection well is high in automation degree and low in labor intensity of workers, material positioningis controllable in the bottom cover forming process, and the forming effect is good.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

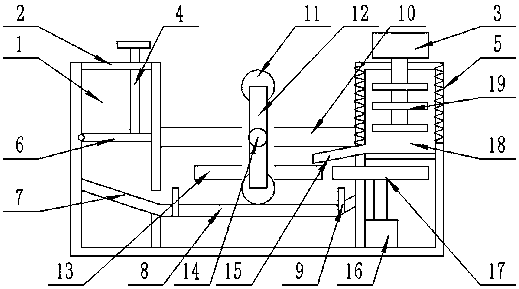

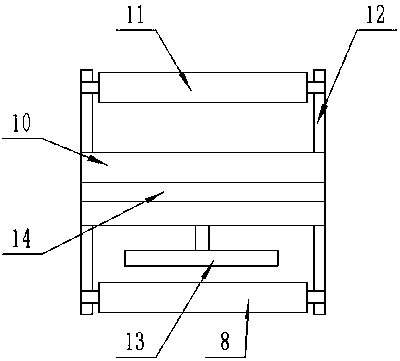

Pressing and flattening device for golden camellia compression packing

The invention discloses a pressing and flattening device for golden camellia compression packaging, comprising a working platform, support legs, universal wheels, fastening screws, pushers, a base plate, a rotating shaft, an upright column, a sliding groove, a top cover, an installation plate, shaft arms, water tanks, water inlet pipes, spray nozzles, a telescopic rod, a pressing plate, a screw rod, a screw cap, bottom discs, clamping columns, fixed parts, fasteners and movable parts. The pressing and flattening device has the advantages that through arranging the sliding groove at the uprightcolumn, the installation plate can slide up and down in the sliding groove, so as to drive the pressing plate to slide up and down, in this way, golden camellias on the bottom discs are and pressed and flattened, and pressing and flattening of the golden camellias is uniform and time-saving and labor-saving, so the pressing and flattening efficiency of the golden camellias is improved; and through the spray nozzles under the water tanks, operations of spraying water and wetting are performed on the golden camellias before pressing and flattening, so it is easy to press and flatten the goldencamellias into a desired shape according to the desired shape, and the efficiency of pressing and flattening the golden camellias is improved to a certain extent.

Owner:GUANGXI ZHONGGANG GAOKE GUOBAO CAMELLIA IND

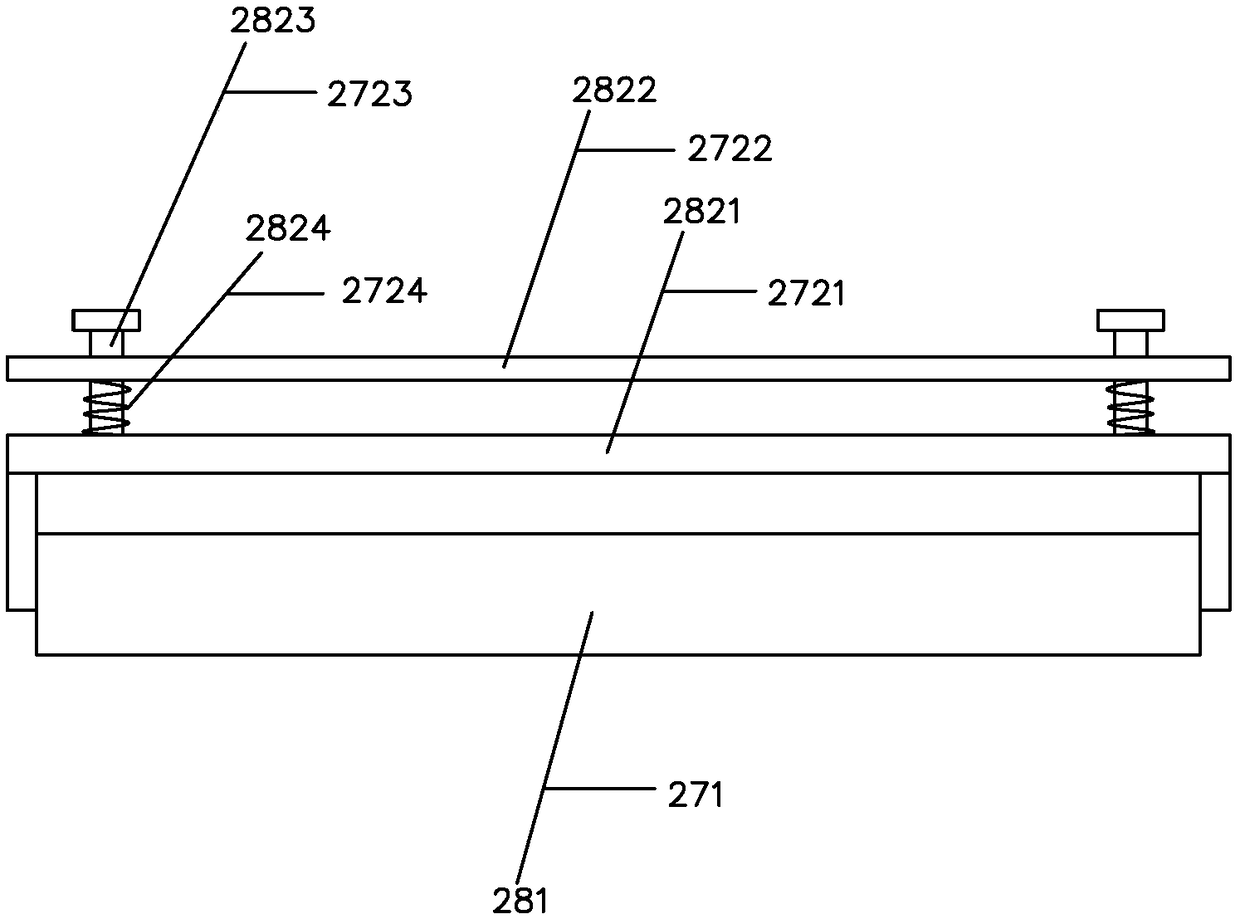

Viscose acetal fiber spinning forming post-processing system

PendingCN114525593AAvoid accumulationWash thoroughlyArtificial filament washing/dryingFilament manufacturePolymer scienceEngineering

The invention relates to the technical field of viscose acetal fiber material treatment, in particular to a viscose acetal fiber spinning forming post-treatment system which comprises a base, a cleaning assembly is connected to the upper portion of the base in an embedded mode, a limiting assembly is fixedly connected to the upper portion of the cleaning assembly, and a diffusion assembly is fixedly connected to the left side of the limiting assembly. The right side of the base is fixedly connected with a drying assembly, and a diffusion assembly flattens the wire harness-shaped viscose fibers, so that the viscose fibers can be in full contact with a cleaning solution during cleaning, impurities on the viscose fibers can be cleaned more thoroughly, and the cleaning efficiency is improved. After the flattened viscose fibers enter the space between the cleaning assembly and the limiting assembly under the interaction of the cleaning assembly and the limiting assembly, the limiting assembly limits the two ends of the viscose fibers, so that the situation that the cleaning process of the viscose fibers is not smooth due to accumulation of the viscose fibers in the cleaning process is avoided.

Owner:冯璐

Electrode pin welding ring pressing device and method

The invention provides a device and a method of pressing a welding ring of an electrode pin. The device comprises a welding ring pickup device 1, an extrusion module 2, a spring table 3 and a groove 4, wherein the welding ring pickup device 1 is partially sleeved in the extrusion module 2, the extrusion module 2 is used for extruding the welding ring 5 positioned on the spring table 3, and the spring table 3 is arranged in the groove 4. Each of two sidewalls of the groove 4 comprises a roller 6 for shaping the edge of the extruded welding ring 5.

Owner:XIAN YONGDIAN ELECTRIC

Smooth plywood single-layer veneer production line

ActiveCN109049170AReduce liquidityAvoid large areas of sheddingPlywood pressesVeneer pressesCold airProduction line

The invention provides a smooth plywood single-layer veneer production line. The structure form of a traditional single-layer veneer hot press is broken through, in the actual working process, under control of a master controller, a veneer production section conducts veneer operation on a mold plate blank, then, a continuous veneer mold plate is cut into veneer mold plate blocks through a cuttingproduction section, and the veneer mold plate blocks are conveyed by a conveying production section to a horizontal hot pressing forming device for hot pressing forming. An upper elastic sealing plate, a lower elastic sealing plate and two sealing baffles cooperate so that the zone between an inner circular-arc-shaped cooling plate and a solid glue net layer can be a sealed zone filled with cold air, the glue cooling effect can be remarkably improved, and energy resources are saved. Compared with the prior art, the smooth plywood single-layer veneer production line can conduct continuous and smooth single-layer veneer and hot pressing forming on the mold plate blank, the degree of mechanization is high, and the strength of a finished veneered plywood product is higher.

Owner:漳州鑫华成机械制造有限公司

Mud conveying equipment and method for earth excavation

ActiveCN113120097AEasy to stackFlatten evenlyGrain treatmentsLoading-carrying vehicle superstructuresSlide plateGeotechnical engineering

The invention relates to mud conveying equipment for earth excavation, and belongs to the technical field of building earth conveying equipment. The mud conveying equipment for earth excavation comprises an earth moving vehicle body and a vehicle hopper installed on the earth moving vehicle body, and bulldozing mechanisms used for bulldozing mud are symmetrically arranged in the two inner side walls of the vehicle hopper; the bulldozing mechanism comprises a lifting plate arranged on the inner side wall of the vehicle hopper through a lifting assembly, a sliding plate is slidably connected to one side of the lifting plate, a bulldozing plate is arranged at one side of the sliding plate through a locking assembly, and a driving assembly used for driving the sliding plate to move is arranged on the lifting plate. According to the invention, soil can be effectively accumulated in the vehicle hopper conveniently, so that the effect of uniformly bulldozing the soil accumulated in the vehicle hopper can be achieved conveniently, the soil conveying amount of the earth moving vehicle can be increased, and the soil conveying efficiency can be improved.

Owner:上海友海建设工程有限公司

Corrugated carton flattening assembly

InactiveCN114103254AHigh intelligenceImprove efficiencyEnvelopes/bags making machineryPaper dustCarton

The invention relates to a corrugated carton flattening assembly, and belongs to the technical field of corrugated cartons, the corrugated carton flattening assembly comprises a transversely arranged n-shaped table top, a moving plate is transversely mounted on the upper end face of the table top through a sliding mechanism, a fixing mechanism is mounted on the upper end face of the moving plate, and a first fixing frame is fixedly mounted at one end of the outer side wall of the table top; a connecting plate is transversely and fixedly installed on the inner side wall of the first fixing frame through a first electric push rod, the connecting plate is connected with the inner top face of the first fixing frame through a connecting mechanism, a soft brush plate is arranged, the first electric push rod indirectly drives the upper surface of the soft brush plate to conduct cleaning, and paper scrap particles on the upper surface of a paperboard are removed; paper scrap particles are prevented from leaving marks on the surface of the paperboard, so that the flattening quality of the device is improved.

Owner:南京塞拉多科技有限公司

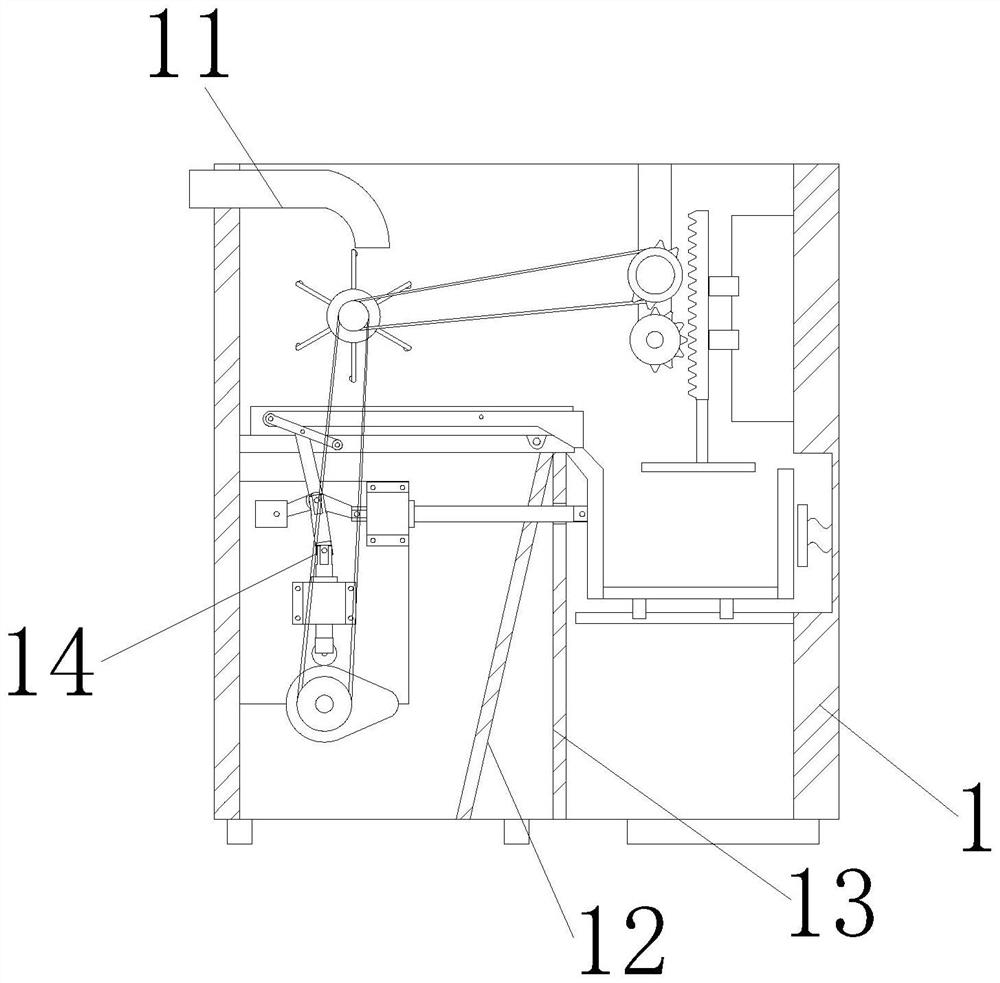

A manual flattening device for rheumatic analgesic ointment

ActiveCN111529391BFlatten evenlyEasy to operatePharmaceutical product form changeRheumatismEngineering

The invention discloses a manual flattening device for rheumatic analgesic ointment. Set in the chute opened in the inner cavity of the shell, the base is set on the upper wall of the slider, the slideway is set on the front wall of the inner cavity of the shell, and the fixing seat is set on a right wall of the back plate side, one end of the tension spring is rotatably set on the right wall of the fixing seat, the top of the fixing plate is set on one side of the upper wall of the inner cavity of the shell, and the bottom end of the pressing device is movably set on the shell The upper wall of the swing device extends to the inner cavity of the shell. The top of the swing device is rotatably arranged on the lower wall of the fixed plate, and the pressure roller is rotatably arranged at the bottom of the swing device. The operation steps of the device are simple. At the same time, the pressing pressure is uniform to avoid the problem of uneven distribution of plaster caused by uneven force.

Owner:李莉

A post-treatment device for cosmetics production wastewater

The invention discloses a post-processing device for cosmetics production wastewater, including a filter compression device. The invention provides a discharge mechanism inside the treatment box. When the first push rod is pushed to the upper end, the movable handle drives the protective frame to swing. The protective frame tilts and swings on the upper end of the fixed frame, so that the waste inside the filter frame is discharged, and the waste enters the inside of the pressure frame, so that the collected waste can be quickly and automatically discharged, and the waste discharge is convenient and fast. Advantages: By setting the pressing mechanism inside the processing box, the first incomplete gear drives the rack to move through the tooth angle at the upper end. When the first incomplete gear continues to rotate, the tooth angle at the upper end drives the second incomplete gear to reverse Turn clockwise, so that the second incomplete gear drives the rack to move to the upper end, so that the rack drives the pressing plate to reciprocate, and the waste is flattened, so that the waste can be quickly flattened and the waste can be collected smoothly. advantage.

Owner:HEFEI YOUYI MEDIA TECH CO LTD

Gluing flattening equipment for wine box processing and processing method thereof

ActiveCN109624397BGlue stableContinuous gluingBox making operationsPaper-makingWineElectrical and Electronics engineering

The invention discloses a gluing and flattening equipment for wine box processing, which comprises an operation table, a cover plate is clamped on the top of the operation table, and through holes are opened on the top of the cover plate, and several air boxes are arranged inside the operation table. For the pump, the top of the cover plate is fixedly connected with a support frame, and both sides of the bottom of the support frame are fixedly connected with a fixing mechanism, a roller is arranged between the two fixing mechanisms, and a first chute is provided on both sides of the top of the support frame to support The top of the frame is slidably connected with a clamping plate through the first chute, and the bottom end of the clamping plate is fixedly connected with a telescopic fixing frame, and the inside of the telescopic fixing frame is provided with a gluing mechanism. The present invention is a gluing and flattening equipment for wine box processing. And its processing method, through the servo motor, the glue can be applied more stably, and at the same time, the glue can be applied continuously, which improves the stability and efficiency of glue application. When placing the wine box, it can be passed The magnet is used for fixing, which is simple and convenient, and will not cause damage to the wine box.

Owner:JIANGSU MEIJIA PACKAGE

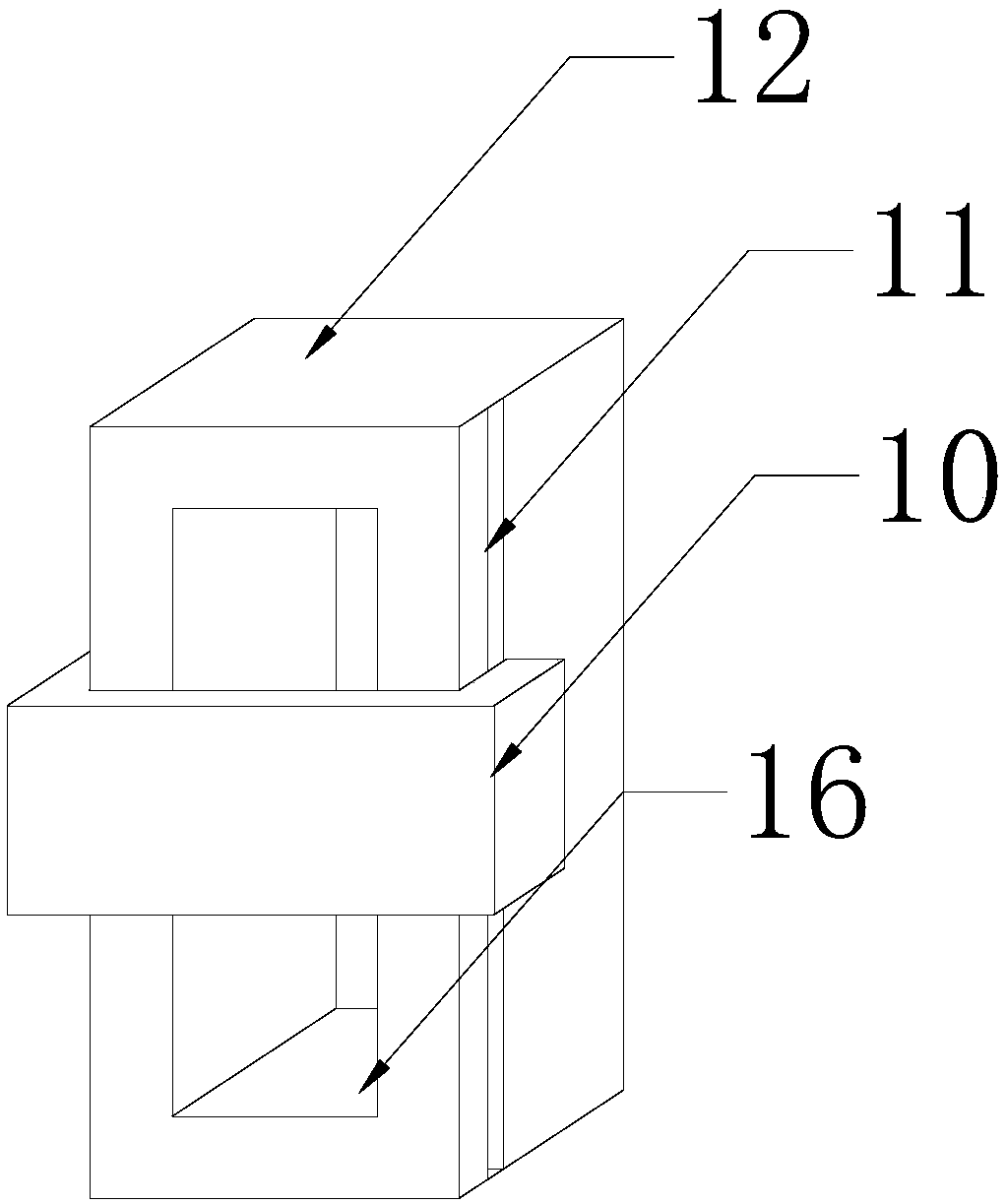

Mortar nozzle device

InactiveCN104612380AUniform Mortar ContentFlatten evenlyBuilding constructionsMaterials scienceNozzle

A mortar nozzle device comprises a spraying cavity. A mortar inlet is formed in one end of the spraying cavity. The spraying cavity comprises a first inner spraying cavity body, a second inner spraying cavity body and an outer spraying cavity body. The outer spraying cavity body wraps the second inner spraying cavity body which wraps the first inner spraying cavity body. The cross sections of the first inner spraying cavity body, the second inner spraying cavity body and the outer spraying cavity body are circular. A nozzle gap is formed in the outer spraying cavity body. First nozzle holes are formed in the first inner spraying cavity body and arrayed in the inner spraying cavity body at equal intervals. The areas of the first nozzle holes gradually increase from one side of the mortar inlet to the bottom of the spraying cavity. Second nozzle holes are formed in the second inner spraying cavity body and are equal in hole area. By means of the mortar nozzle device, mortar arrives at the second inner spraying cavity body and then the outer spraying cavity body after passing through the first inner spraying cavity body, the content of mortar at the mortar inlet is compensated for, the content of mortar in the whole spraying cavity is uniform, and mortar is evenly sprayed.

Owner:天津市亿腾顺泰建筑材料有限公司

A self-positioning equidistant contradictory garden road greening auxiliary paving and construction equipment

ActiveCN113529545BReasonable designSimple and fast operationRoads maintainenceArchitectural engineeringGreening

The invention discloses a self-positioning equidistant contradictory garden road greening auxiliary paving and construction equipment, which comprises an alternate rotation pre-self-flattening walking mechanism, a magnetic suction type non-contact feedback self-positioning masonry vacuum adsorption moving mechanism, and center divergence equidistant Contradictory memory alloy cushioning masonry compaction mechanism, magnetic suction swing back self-positioning side knocking mechanism, lateral reciprocating movement mechanism and adjustable masonry placement components. The invention belongs to the technical field of landscaping engineering and road construction, and specifically provides a pre-set feedback metal plectrum that is not aligned with the corners of masonry, so that it can be adapted to various masonry without any positioning components and detection components. The technical effect of selective positioning and precise direction adjustment realizes the non-contact driving movement of masonry transmission, overcomes the contradictory technical problem of both applying force to masonry and not being able to apply force, and realizes the masonry side. Non-destructive self-recognition and positioning self-positioning equidistant contradictory garden road greening auxiliary paving and construction equipment for knocking.

Owner:徐州帝威伦新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com