A non-woven fabric coating production method and its flattening device

A production method and technology of non-woven fabrics, which are applied in the field of non-woven fabric coating production methods and flattening devices, can solve problems such as unfavorable processing and large differences in single-point thickness, and achieve uniform flattening, low production costs, and high market share. The effect of large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

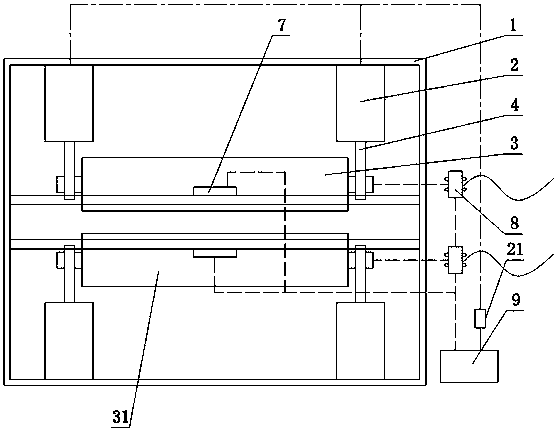

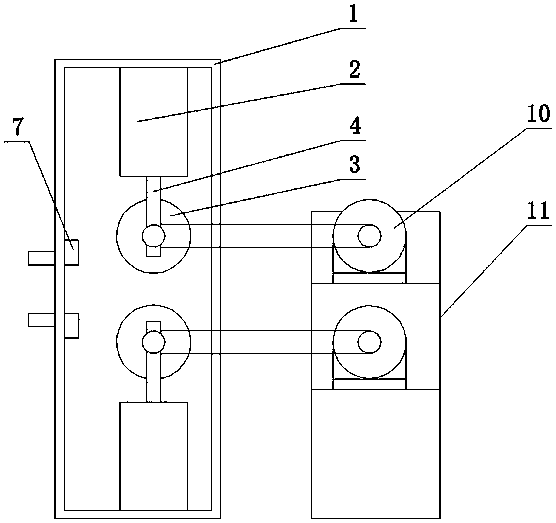

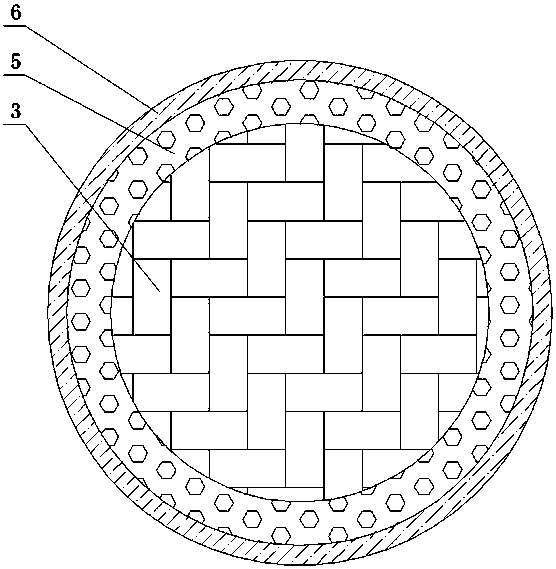

[0025] combine figure 1 , 2 As shown, the flattening device of the non-woven fabric coating is composed of a frame 1, a hydraulic cylinder 2, upper and lower flattening rollers 3, 31 and a piston rod 4, etc., and a pair of hydraulic cylinders are respectively provided on the upper and lower parts of the frame 1 2. The end of the piston rod 4 of the upper pair of hydraulic cylinders 2 is connected to the end of the upper flattening roller 3, the end of the piston rod 4 of the lower pair of hydraulic cylinders 2 is connected to the end of the lower flattening roller 31, and the hydraulic cylinder 2 passes through Adjust the height of the piston rod 4, and then adjust the gap between the flattening rollers 3 to affect the pressure of the flattening rollers 3 on the non-woven fabric. The upper and lower flatt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com