Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Expand the printing range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

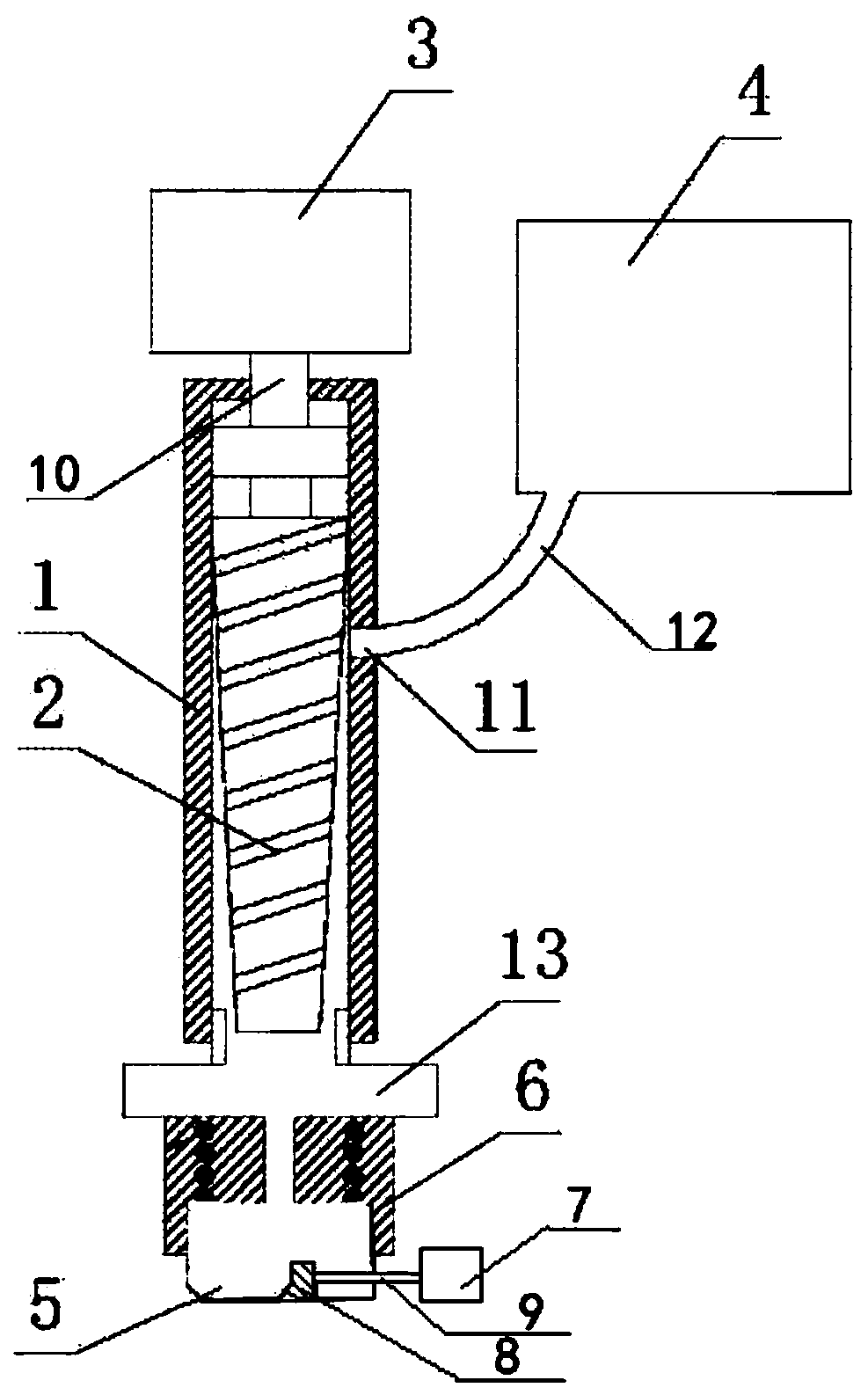

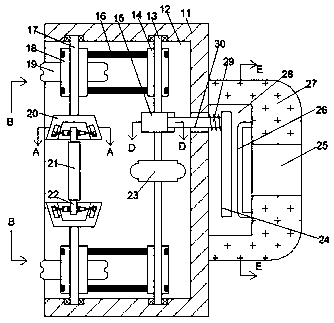

Fused deposition three dimensional printing nozzle and printer

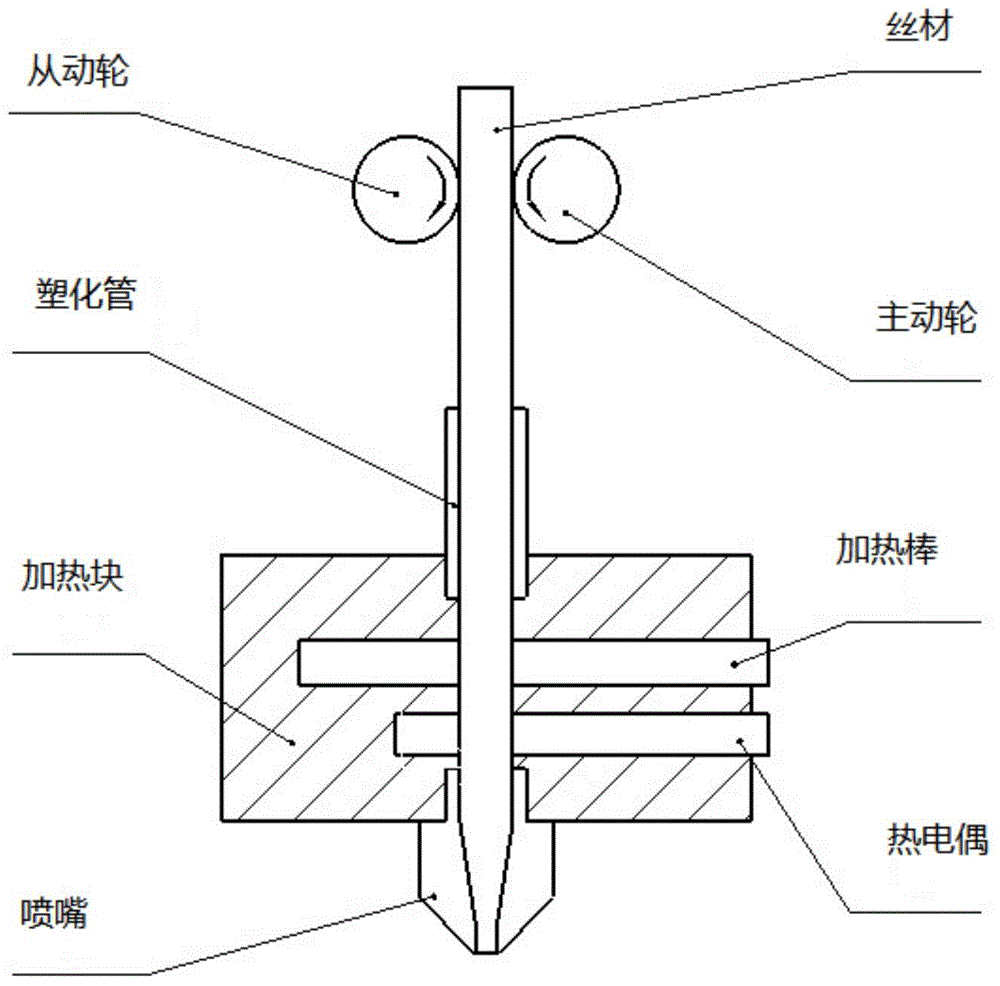

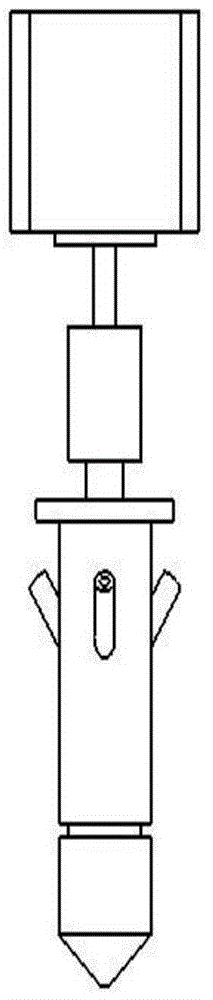

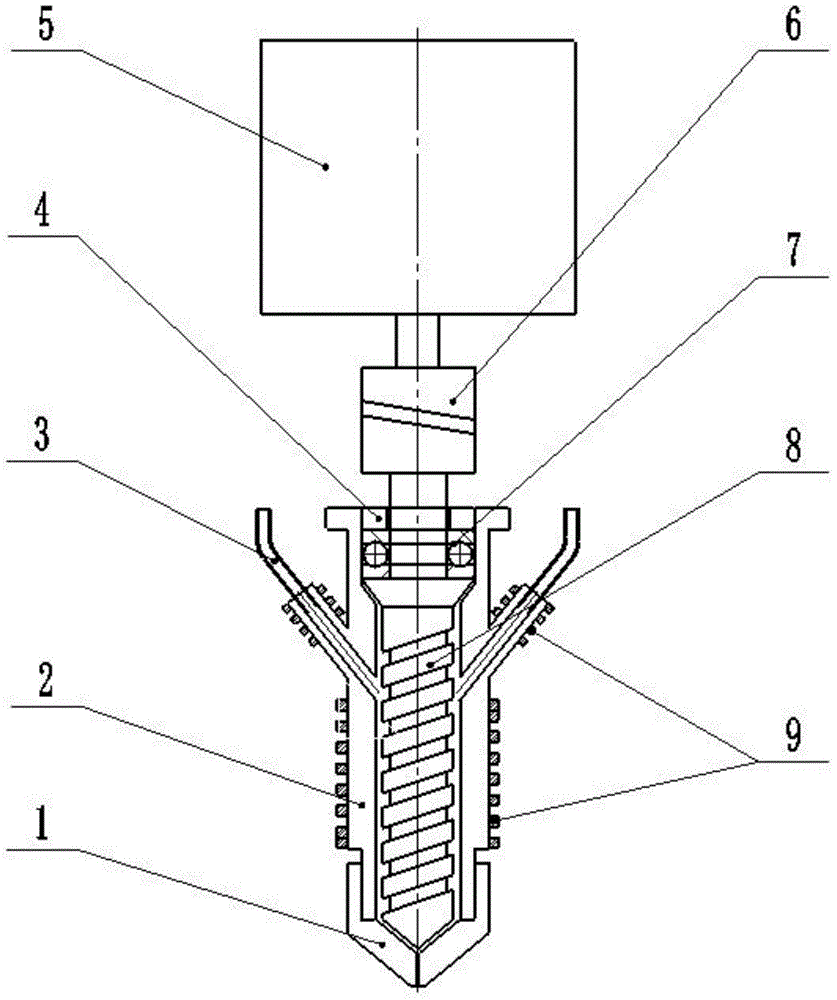

The invention discloses a fused deposition three dimensional printing nozzle and a printer. The fused deposition three dimensional printing nozzle comprises a screw machine barrel, a nozzle and screw shaft, wherein the nozzle is arranged at the lower portion of the screw machine barrel, the screw shaft is arranged in the screw machine barrel, the upper end of the screw shaft is connected with a motor shaft through a shaft coupling, the lower half segment of the screw shaft is provided with a thread slot, the upper portion of the barrel body of the screw machine body is provided with branch tubes used for mounting fed filament plasticizing tubes, and the periphery of the screw machine barrel and the branch tubes is provided with heaters. The screw machine barrel is used as a filament fusion and mixing container, the plasticizing tubes arranged in the branch tubes are used as filament inlets, the heaters are used to heat filaments in the plasticizing tubes and the screw machine barrel in order to fuse the filaments, and driving force is generated through screw rotation in order to stir and mix the fused filaments entering the screw machine barrel, push the mixed filaments into the nozzle and realize extrusion molding, so the filaments can be effectively fused and extruded.

Owner:HUAZHONG UNIV OF SCI & TECH

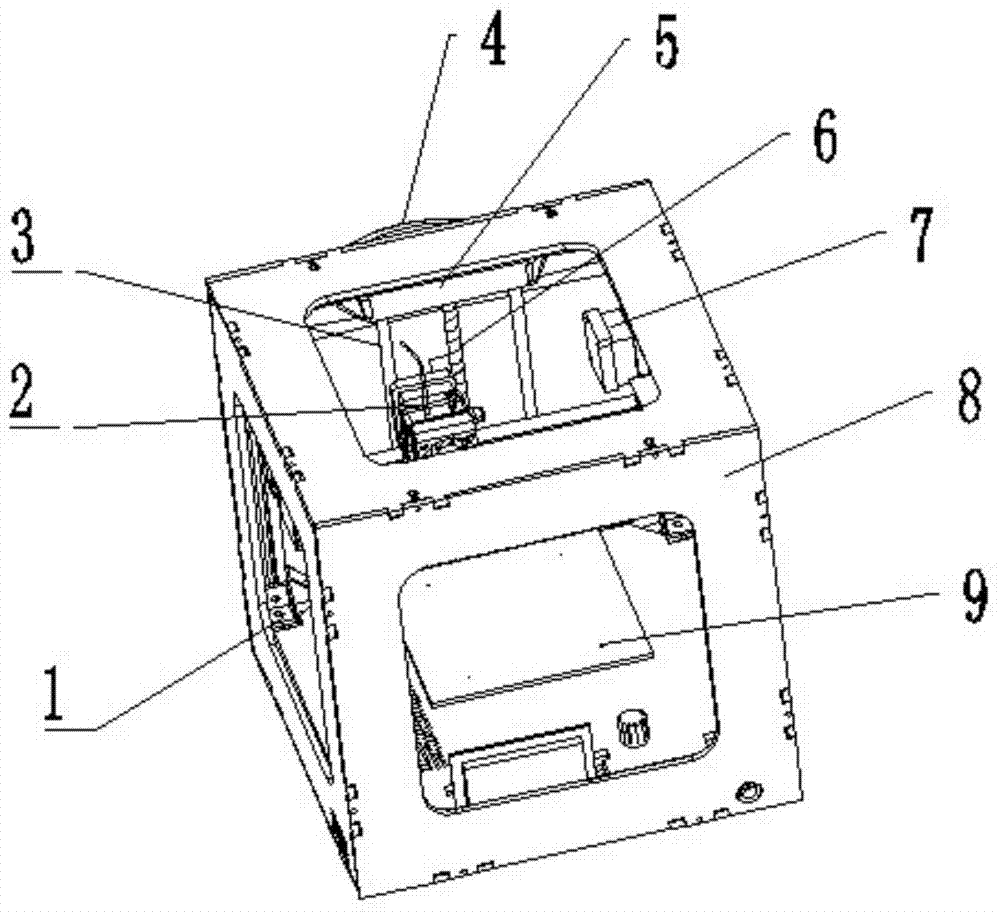

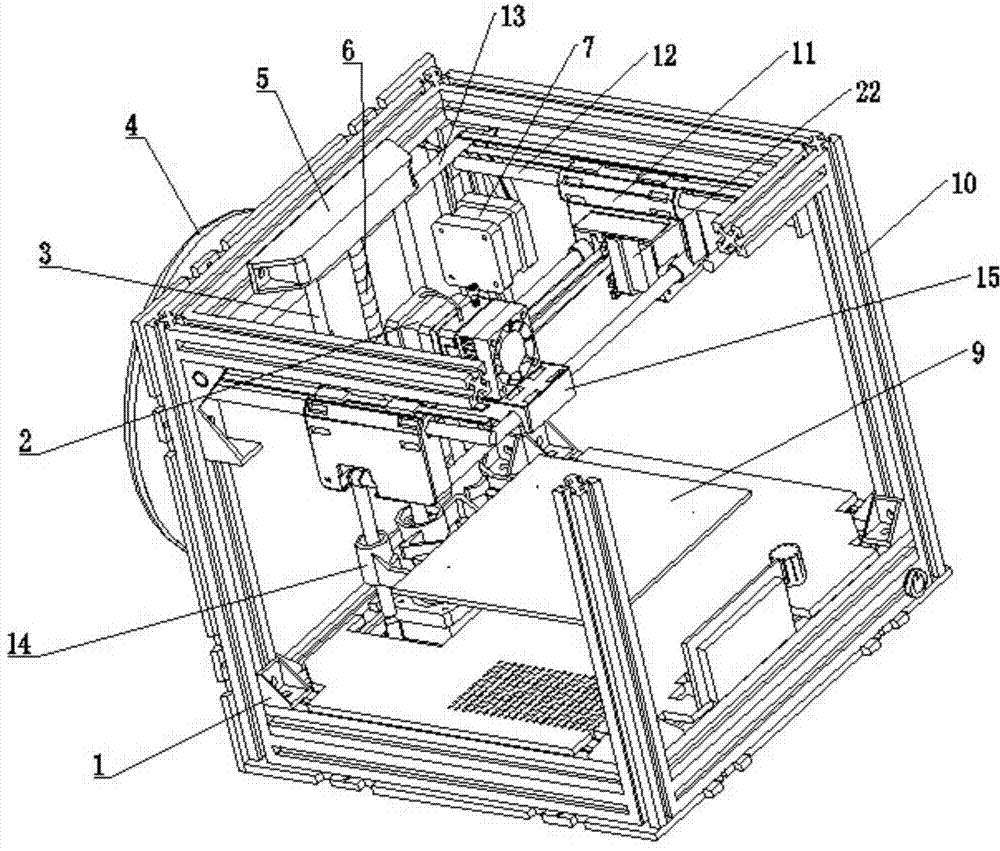

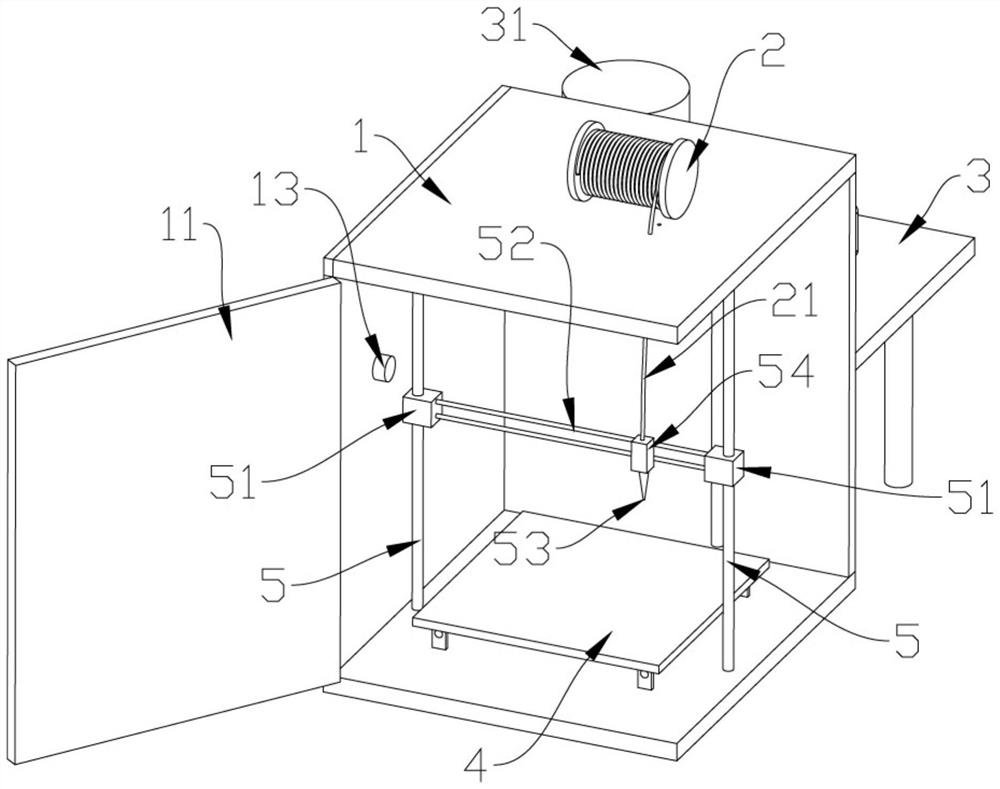

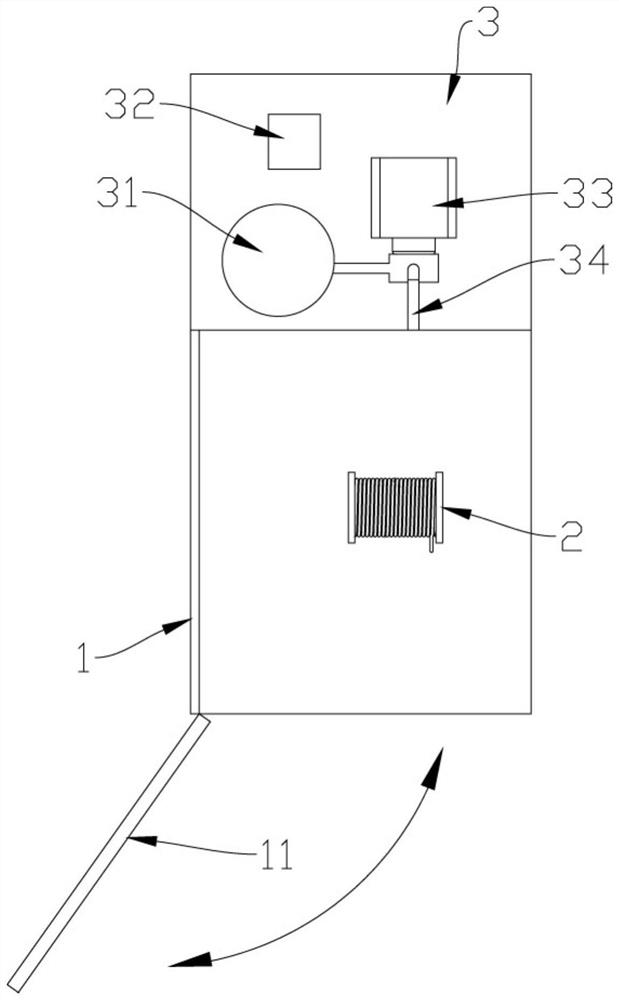

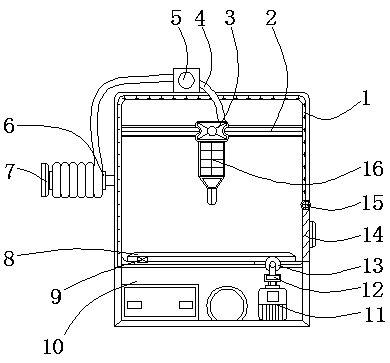

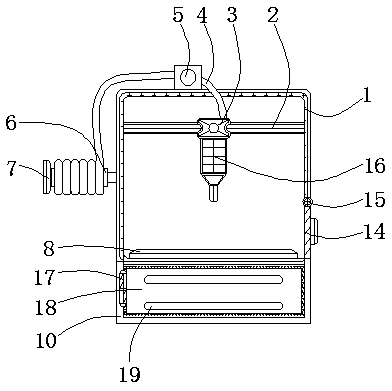

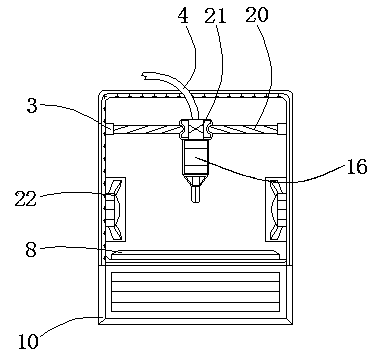

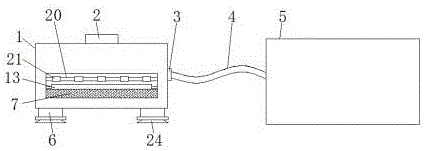

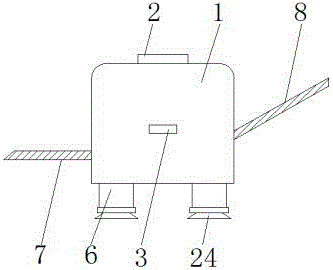

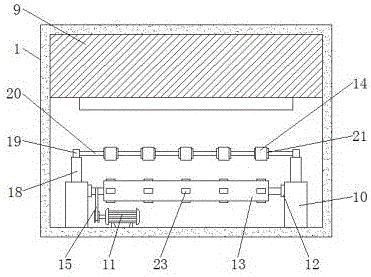

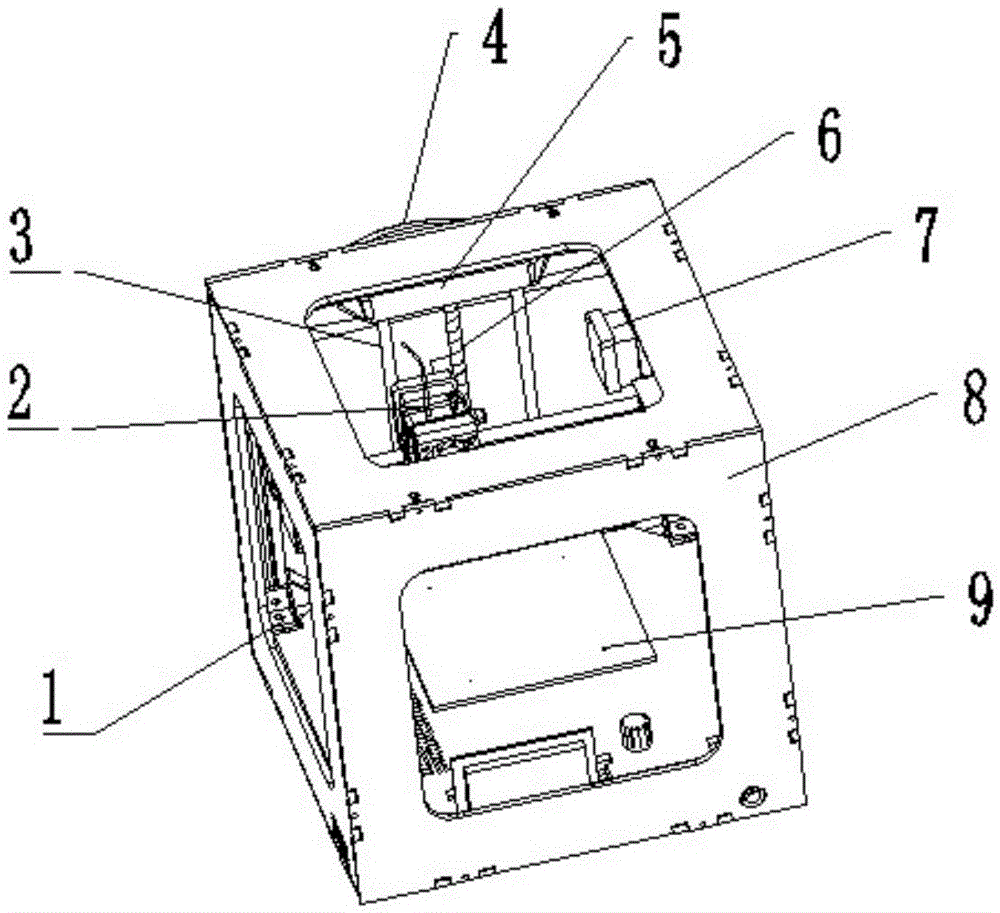

3D (three-dimensional) printer

The invention belongs to the technical field of 3D (three-dimensional) printers, and relates to a small desktop 3D printer which can reduce resonance. The 3D printer comprises a case, a machine frame, a printing unit, a drive device and a consumable mounting box, wherein the drive device comprises an X-axis drive motor, a Y-axis drive motor and a Z-axis drive motor; the drive device is fixed to the machine frame; the printing unit comprises a consumable extrusion device, a motor bracket, a printing platform and a platform bracket; the consumable extrusion device is fixedly mounted on the motor bracket; the printing platform is fixed to the platform bracket; the consumable mounting box is fixedly mounted on the case. The 3D printer has the beneficial effects that the overall structure is simple and attractive; consumables are convenient to replace; a phenomenon of wire blocking in a wire feed throat pipe is effectively avoided; the vibration generated when the 3D printer works is reduced; the printing quality of a product is improved; the internal space utilization rate of the 3D printer is improved; the printing range is large; the 3D printer is simple in structure and convenient to assemble.

Owner:青岛天智清华电子科技发展有限公司

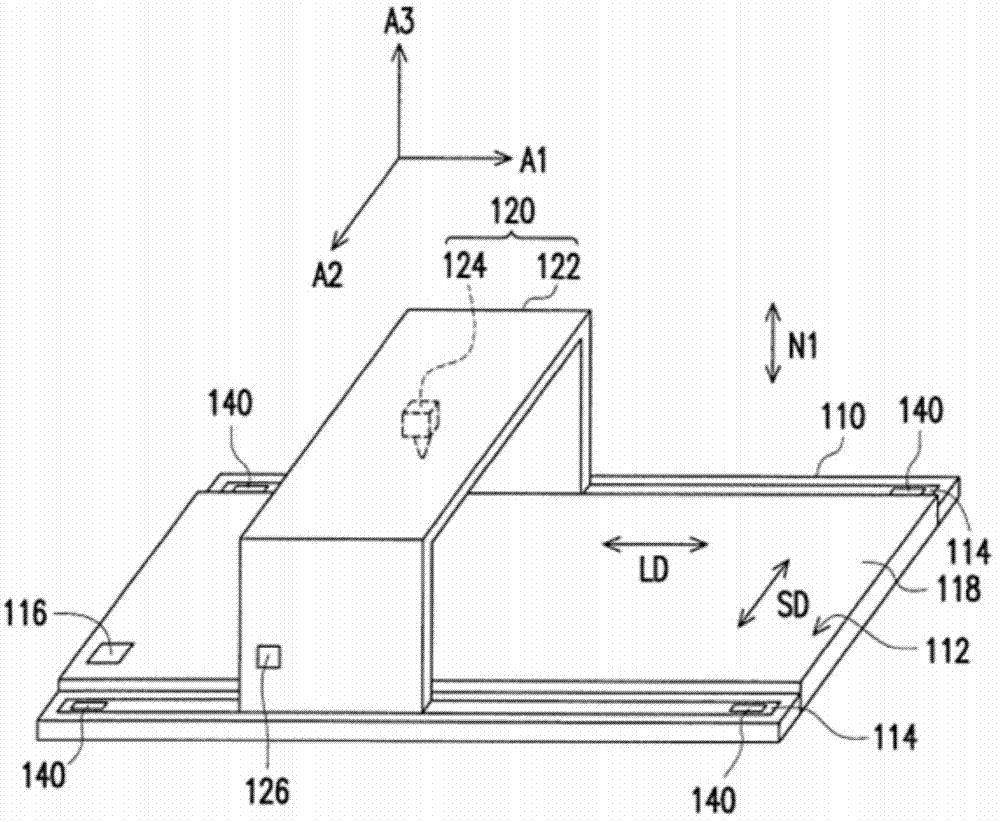

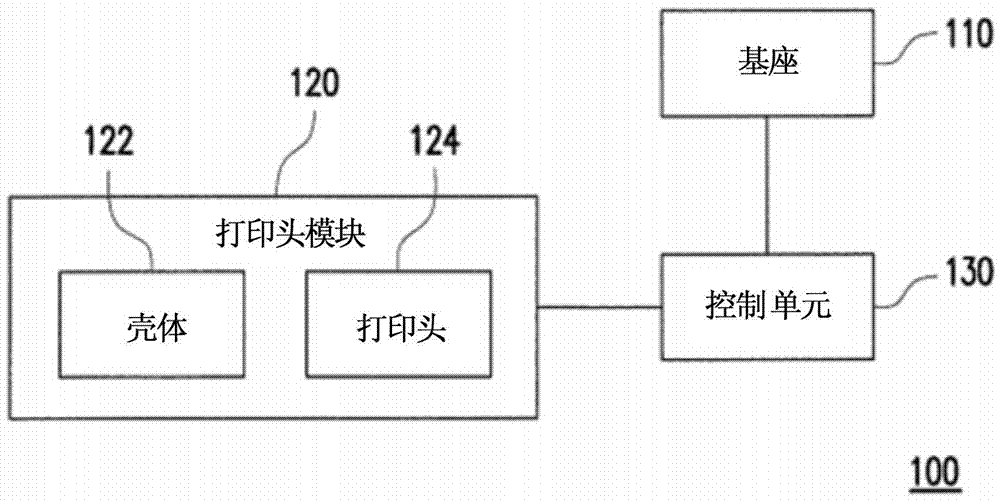

Three-dimensional printing apparatus

InactiveCN104708819AExpand the printing rangeIncrease change3D object support structuresManufacturing data aquisition/processingLong axisControl unit

A three-dimensional (3-D) printing apparatus includes a base, a printing head module and a control unit. The base includes a carrying surface and a guiding mechanism. The guiding mechanism extends along a long-axis direction of the base. The printing head module movably disposed on the guiding mechanism. The length of the base is greater than the length of the printing head module, such that the printing head module is suitable for moving relatively to the guiding mechanism. The control unit coupled to the base and the printing head module controls the printing head module to move relatively to the base according to extensional information of the digital 3-D model along the long-axis direction, such that the printing head module dispenses a material on the carrying surface to form a 3-D object when moving relatively to the base.

Owner:XYZPRINTING +2

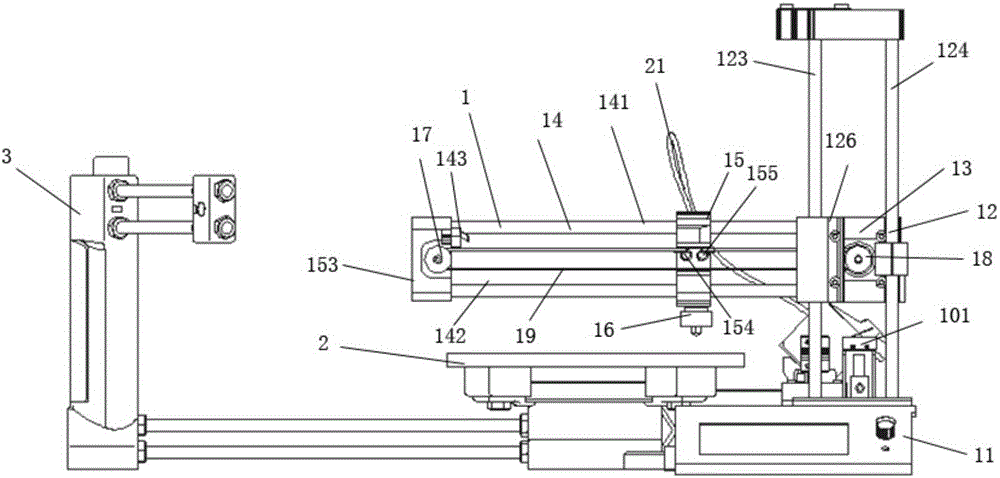

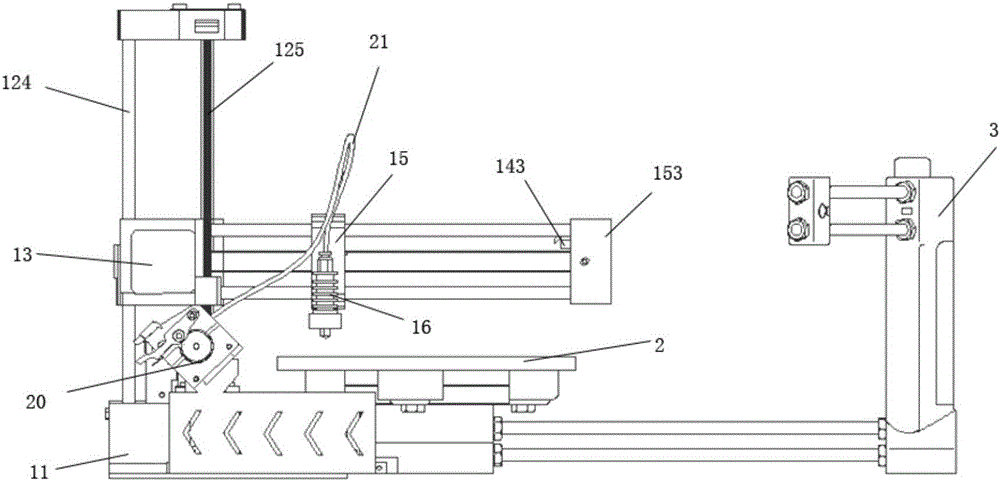

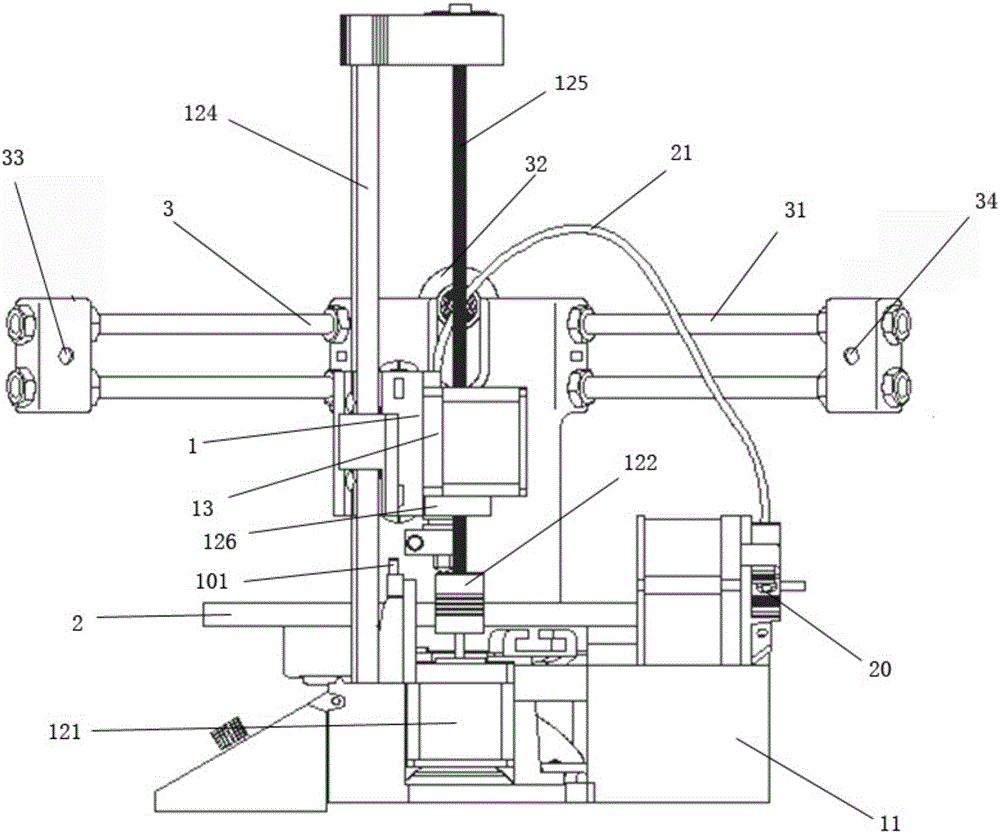

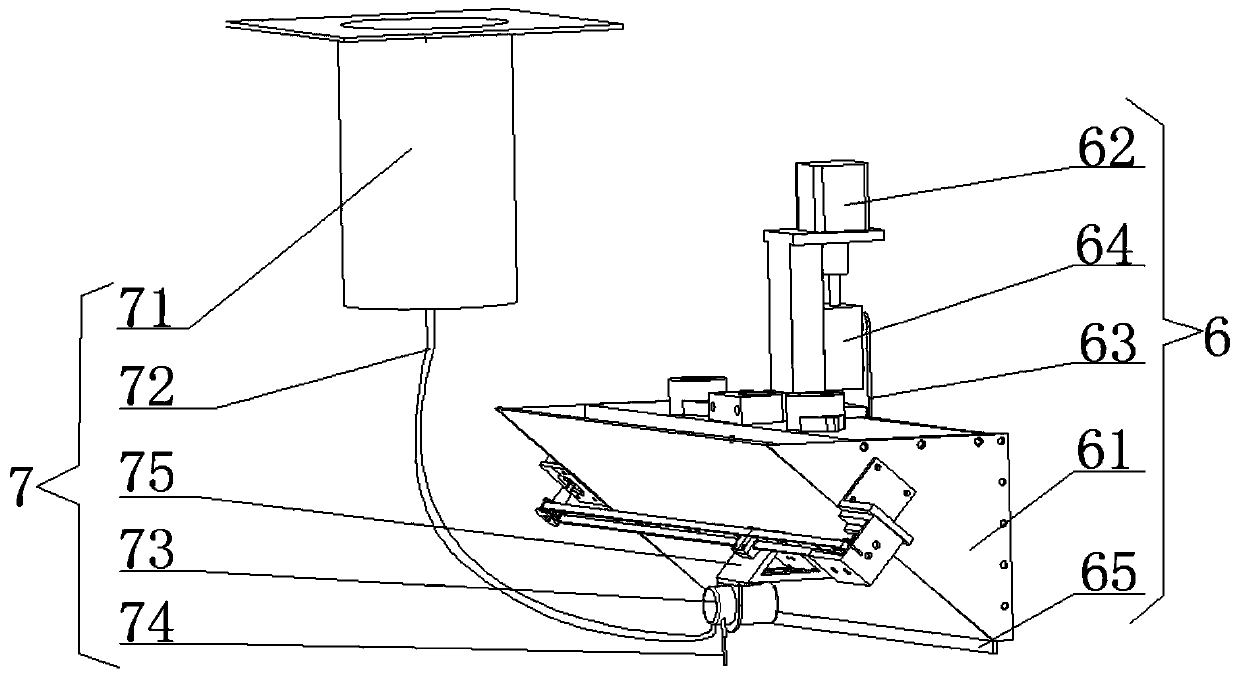

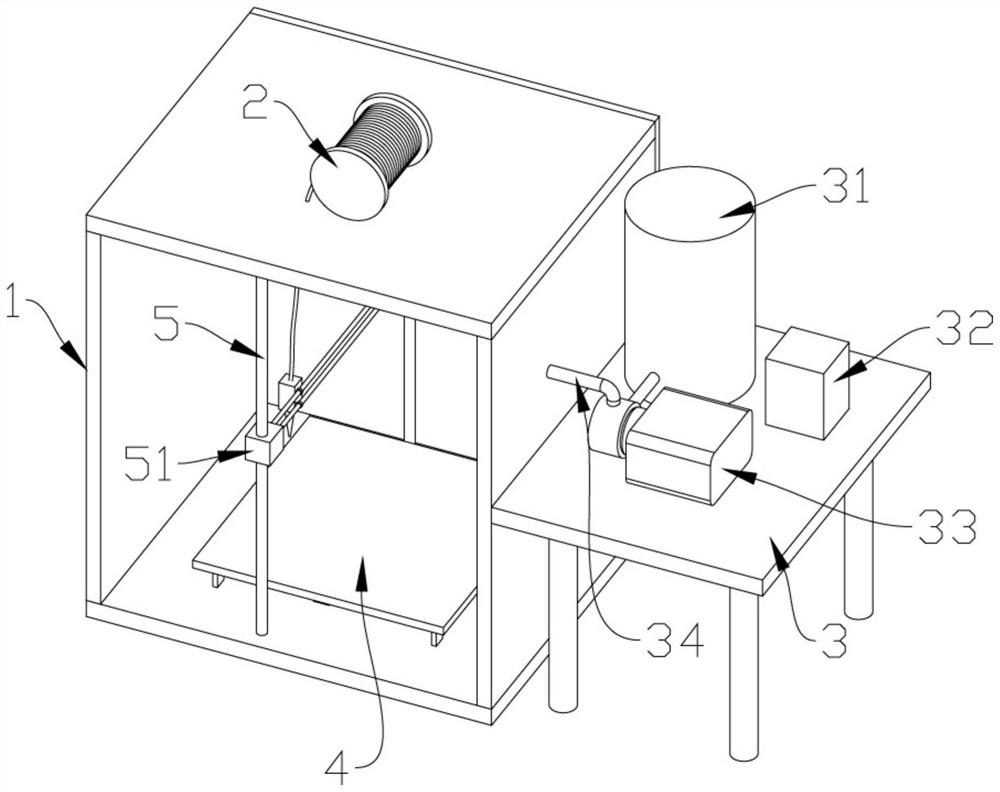

3D printing and scanning all-in-one machine

InactiveCN106313499ARealize the combinationIncrease profitAdditive manufacturing apparatus3D object support structuresEngineeringCantilever

The invention relates to a 3D printing and scanning all-in-one machine. The 3D printing and scanning all-in-one machine comprises printing equipment and further comprises a rotating platform and scanning equipment arranged at one side of the rotating platform. The printing equipment comprises a base arranged at the other side of the rotating platform, a vertical lifting device arranged on the base, a cantilever motor arranged on the vertical lifting device, a cantilever with one end connected with the vertical lifting device, a cantilever sliding block connected with the cantilever in a sliding mode, a printing head arranged on the cantilever sliding block, a first synchronous pulley, a second synchronous pulley and a synchronous belt. The first synchronous pulley is arranged at the other end of the cantilever. The second synchronous pulley is arranged at the position of the cantilever motor and is connected with a rotating shaft of the cantilever motor. The two ends of the synchronous belt wind across the first synchronous pulley and the second synchronous pulley separately and then are connected with the cantilever sliding block.

Owner:林子森

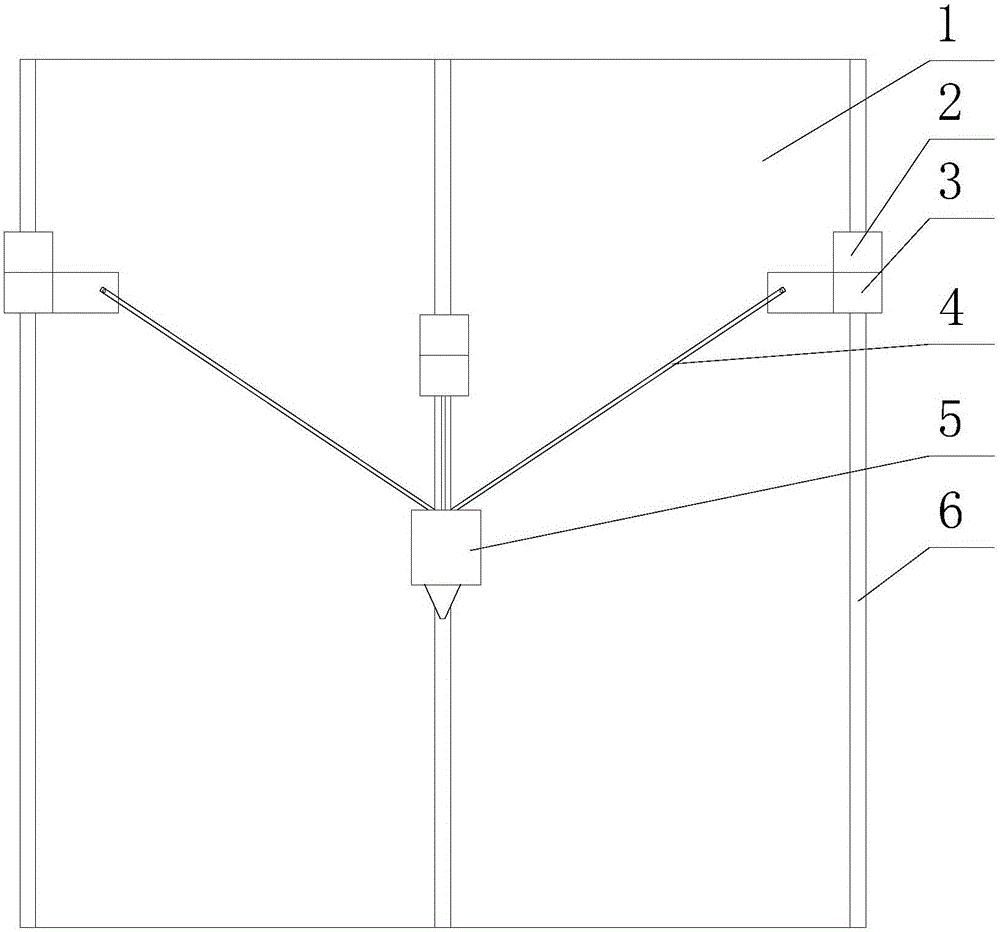

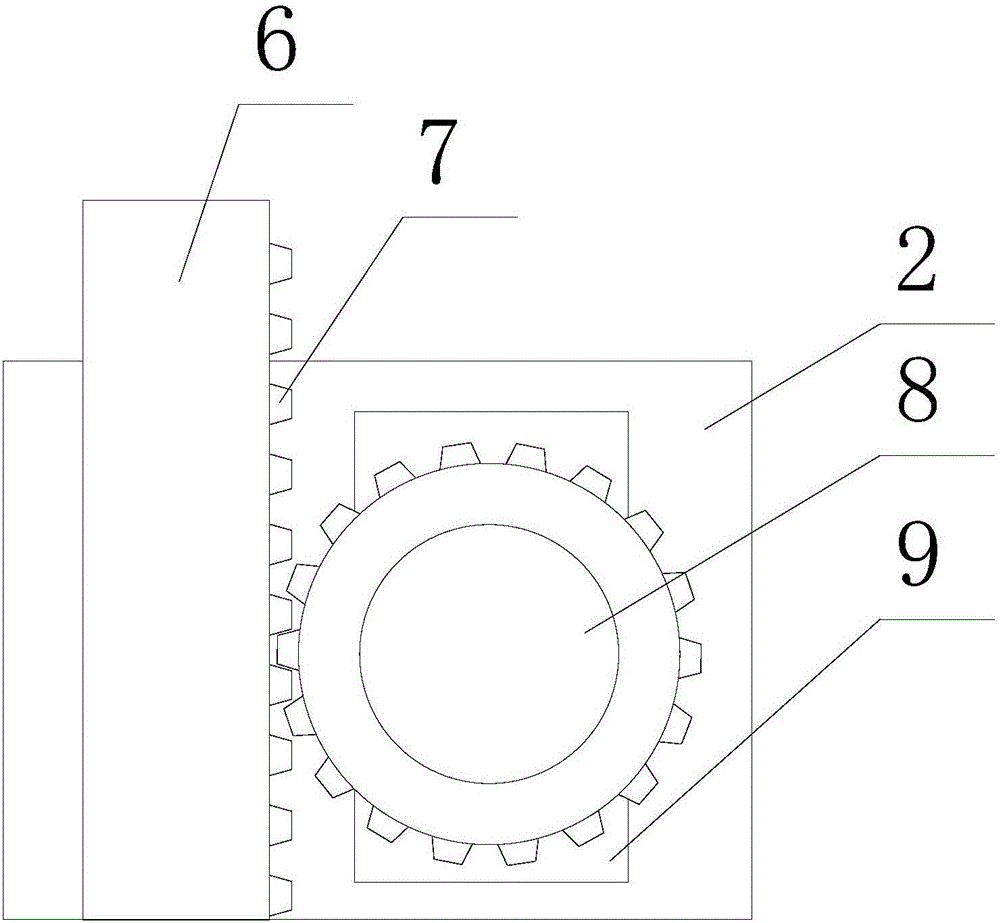

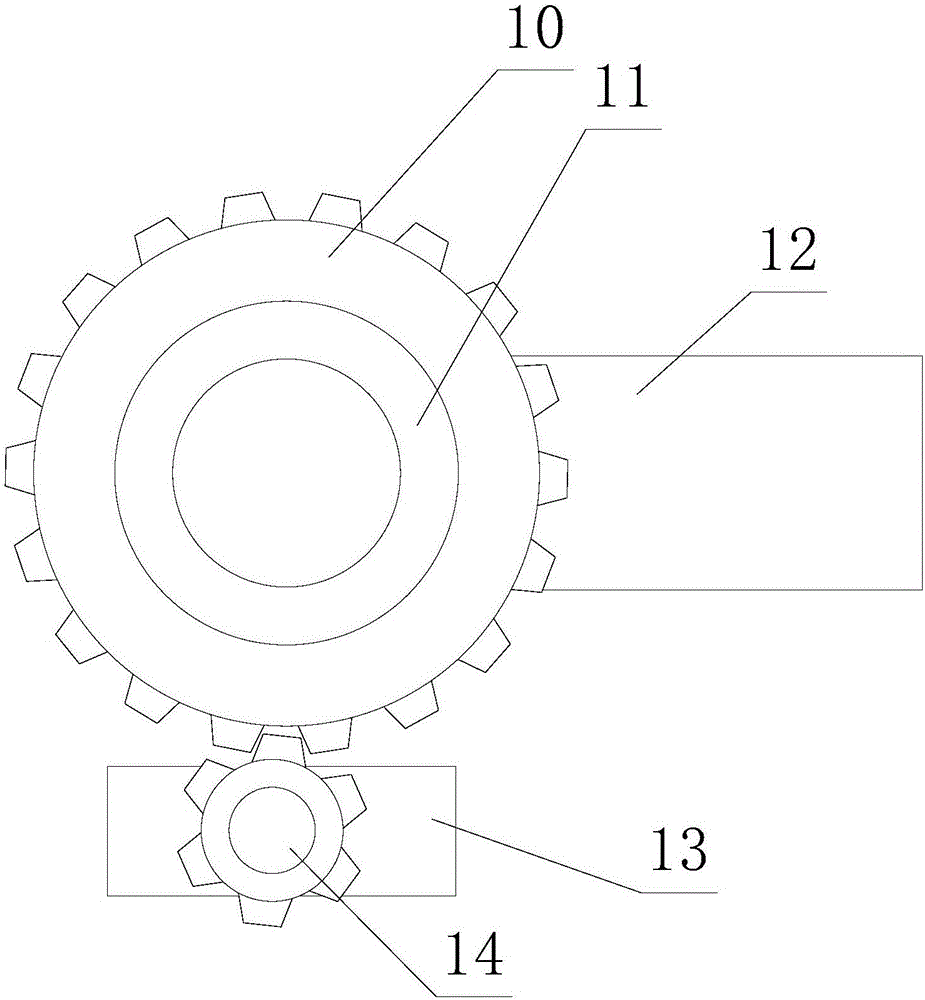

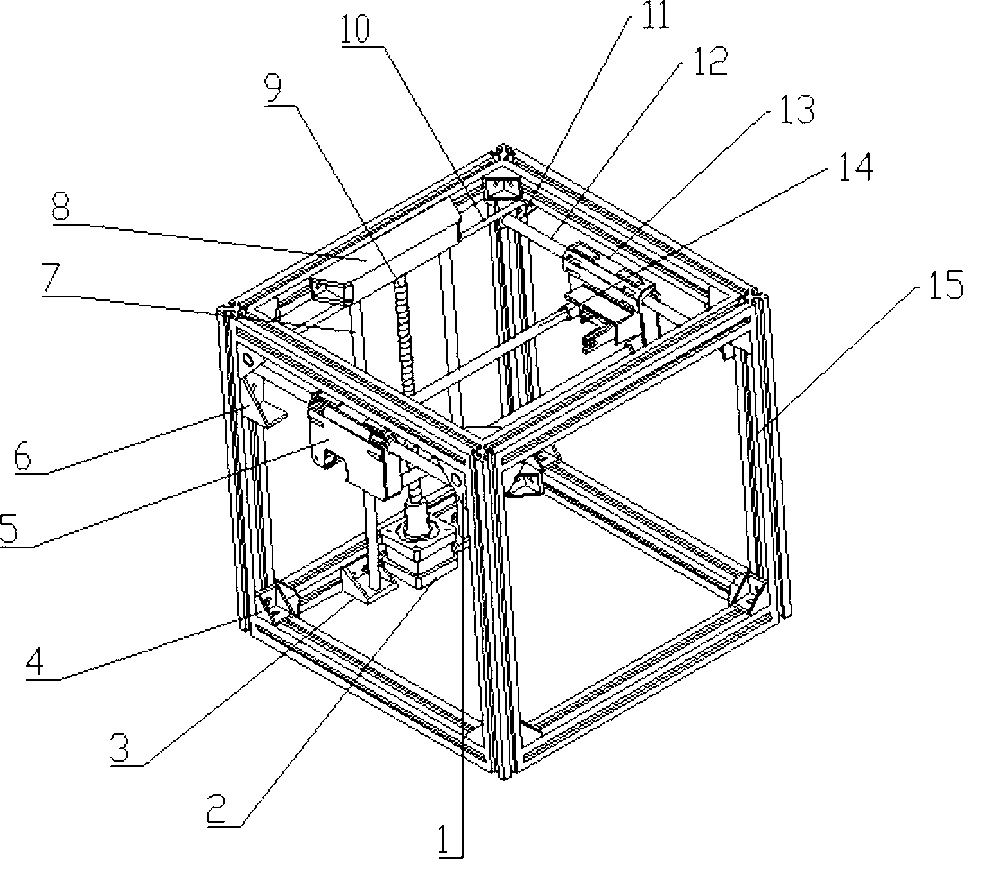

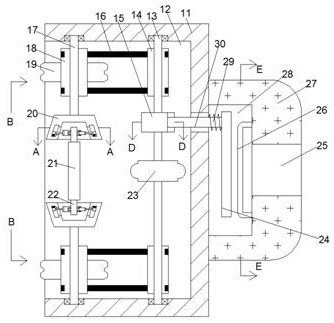

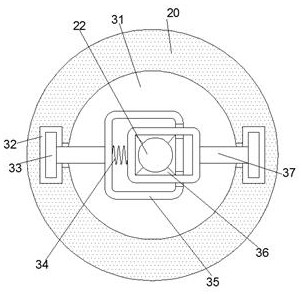

3D printer with high accuracy

InactiveCN106827538AHigh feasibilityIngenious designManufacturing driving meansEngineering3d printer

The invention relates to a 3D printer with high accuracy. The 3D printer comprises a shell body, supporting columns, sliding blocks, rotating assemblies, connecting rods, a PLC and a balancing assembly. Each sliding block is further provided with a first motor and a first round gear. Each rotating assembly comprises a second round gear, a bearing, a supporting rod, a second motor and a third round gear. The balance assembly comprises third motors, a fixed block, lead screws, an adjusting block, a spraying head and a balance unit. The balance unit comprises a pulling rope, a sphere, limiting blocks, springs, a touch block and touch pieces. The 3D printer with the high accuracy is ingenious in design and high in feasibility, the height of the spraying head can be adjusted through sliding of the sliding blocks, the printing range of the spraying head can be enlarged through the rotating assemblies and the accuracy is high, and the spraying head can keep the vertical state all the time through the balance assembly, so that the printing accuracy is guaranteed, and the printing quality is improved.

Owner:JIAXING MINHUI AUTOMOTIVE PARTS CO LTD

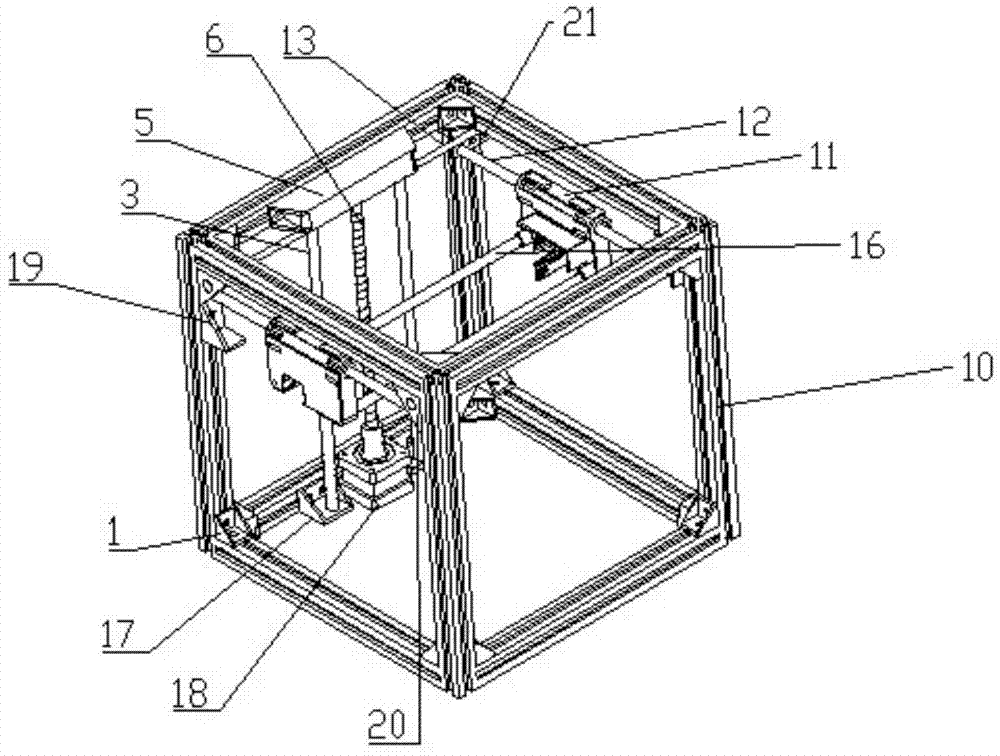

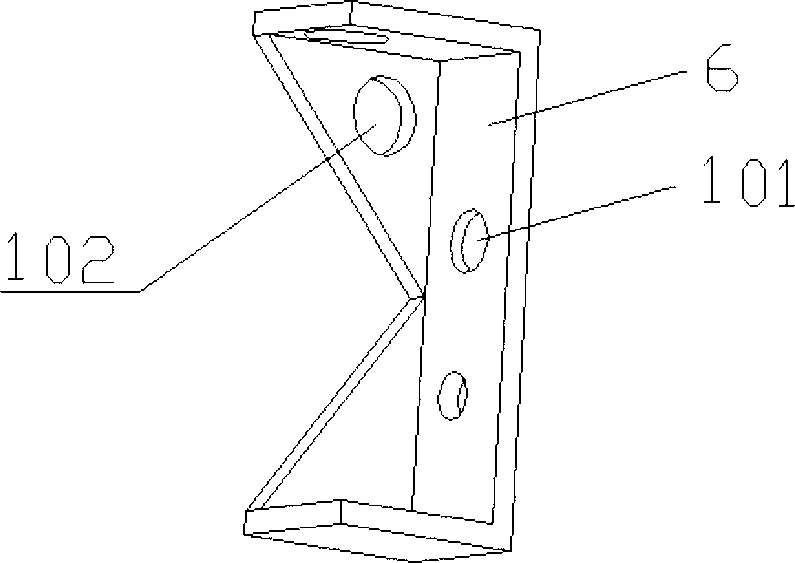

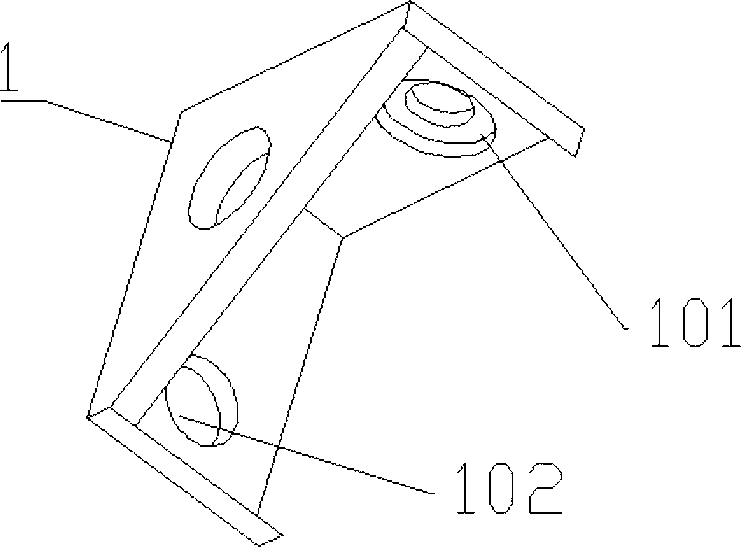

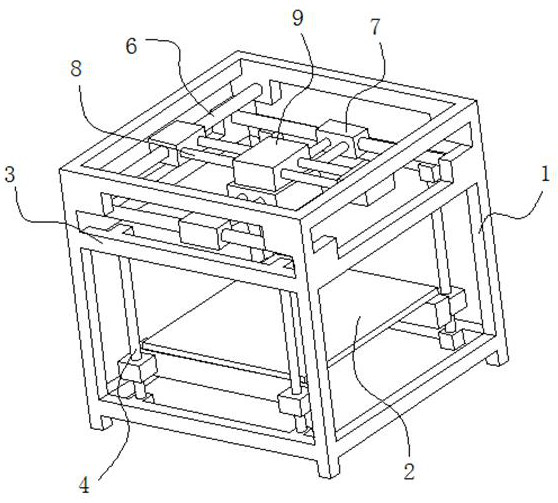

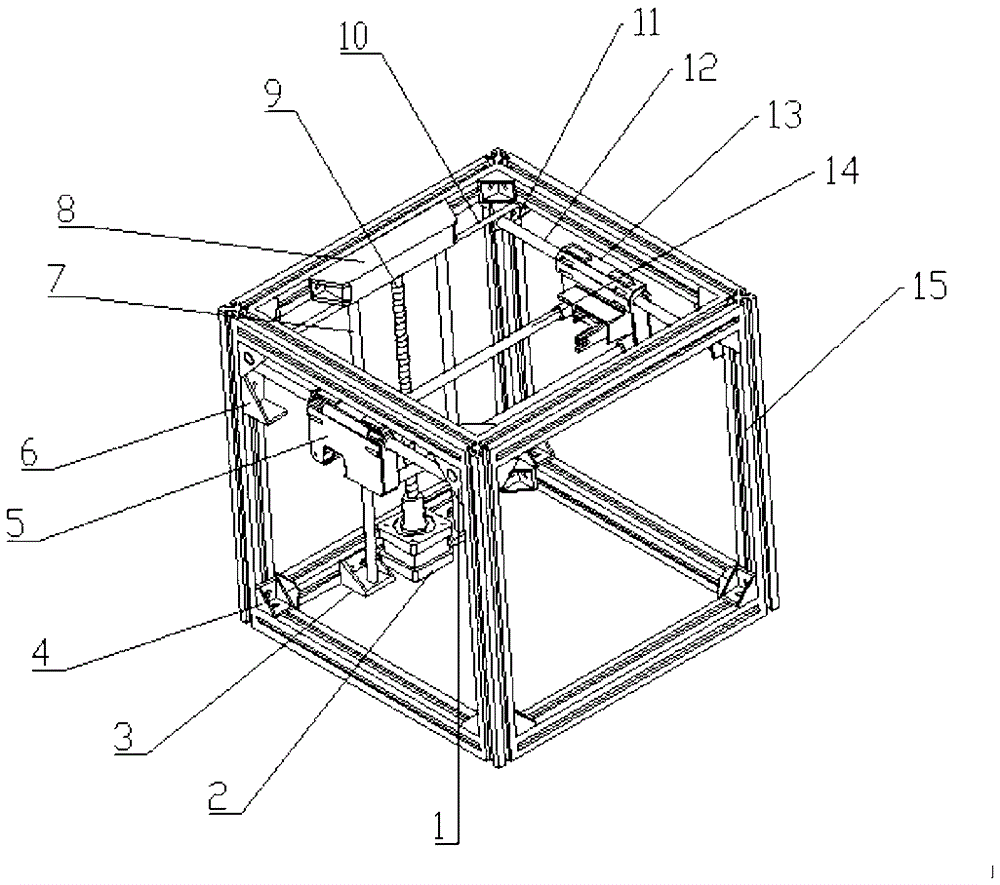

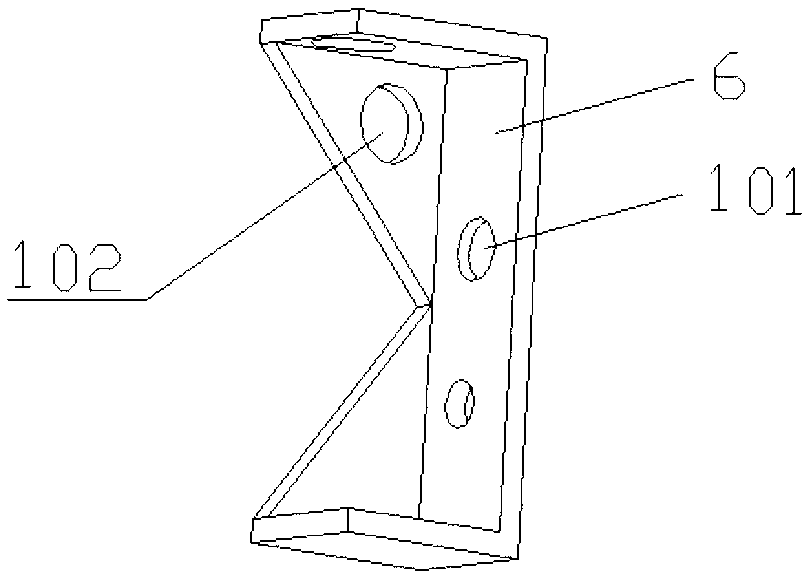

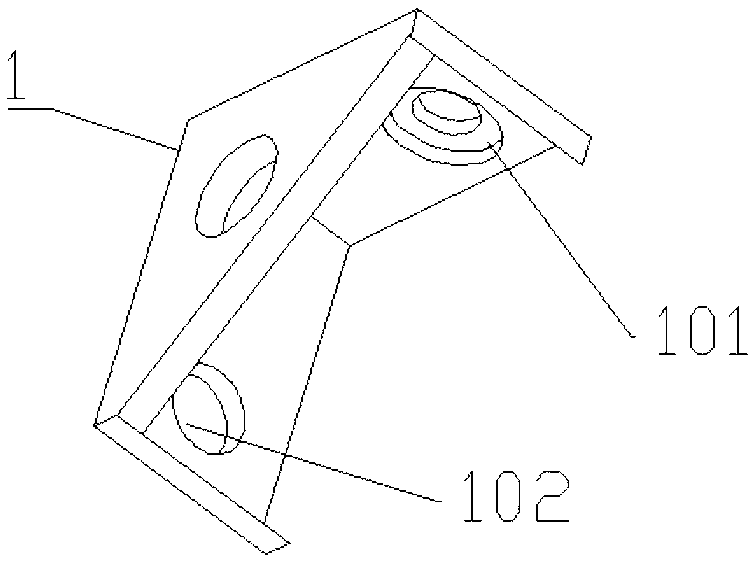

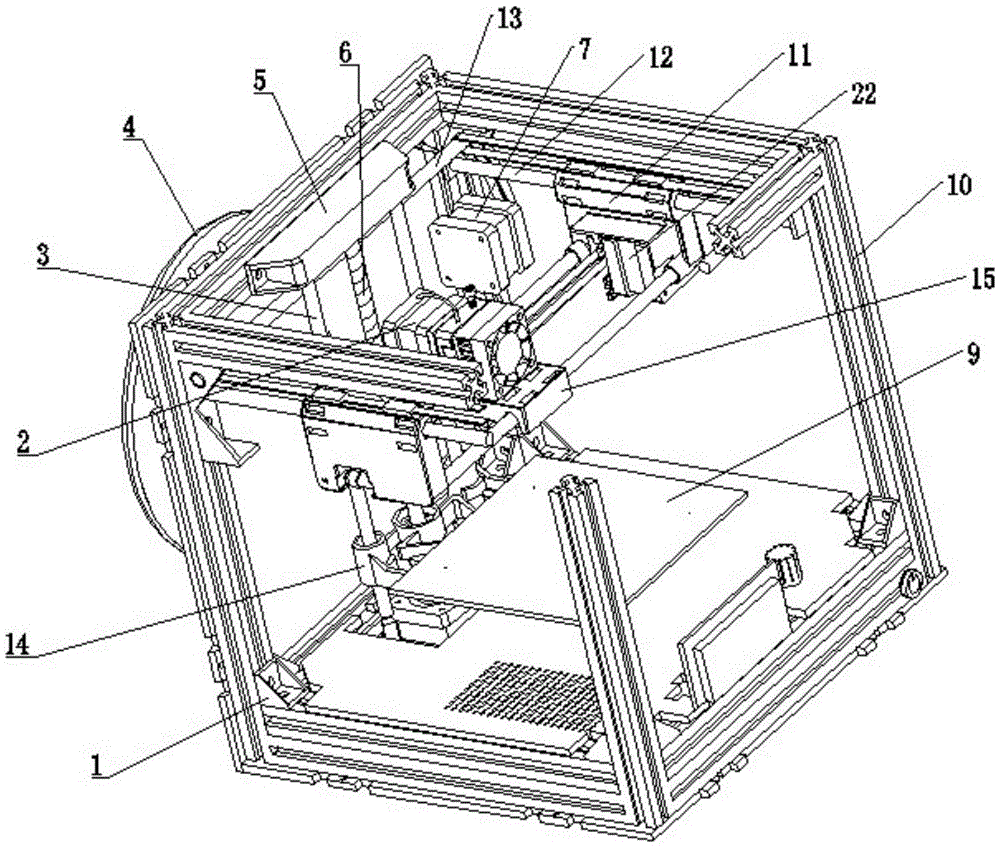

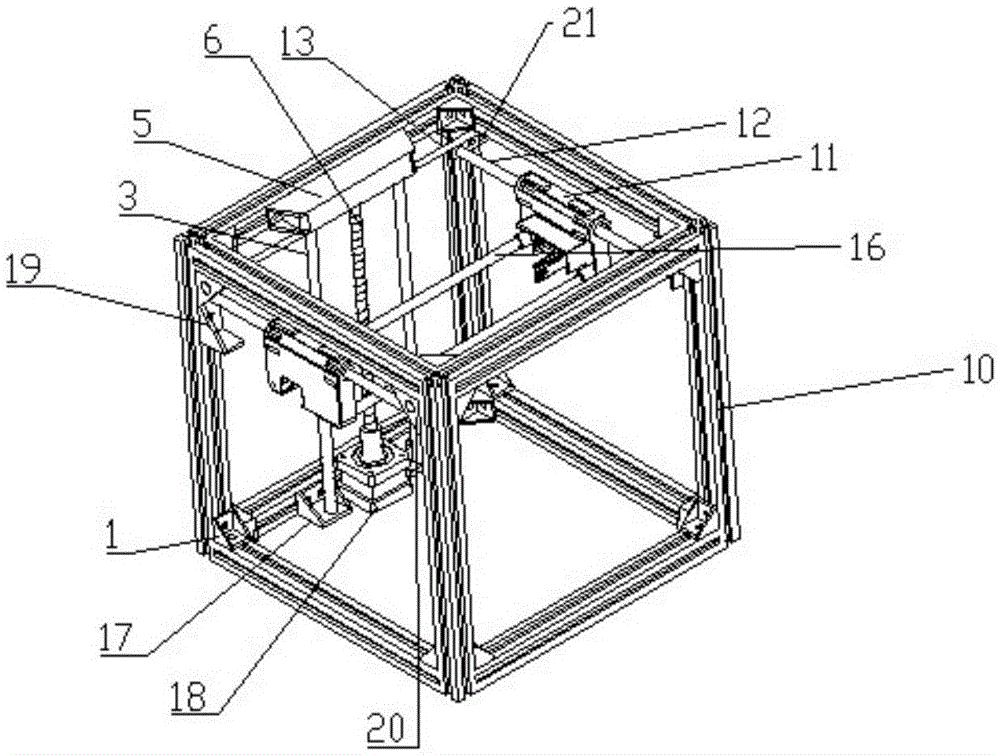

Three-dimensional printer frame

The invention belongs to the technical field of three-dimensional printers and relates to an anti-resonance three-dimensional printer frame which is used for a desktop three-dimensional printer. The anti-resonance three-dimensional printer frame comprises an X-axis sliding rod, a Y-axis sliding rod, a Z-axis sliding rod, a Z-axis threaded rod, locking pieces, connecting rods and a conveying belt supporting shaft, wherein the connecting rods are used as seamed edges to form a three-dimensional frame, and the connecting rods are connected in pairs by fixed pieces; the sliding rods, the threaded rod and the conveying belt supporting shaft are fixed on the three-dimensional frame by the locking pieces; a Z-axis driving motor is fixed on a rear-lower connecting rod on the three-dimensional frame, a Y-axis driving motor is fixed on a right-rear connecting rod on the three-dimensional frame, and an X-axis driving motor is fixed on a right fixer. Through the design, the vibration of the three-dimensional printer during operation is alleviated, the printing quality of a product is improved, and the utilization rate of inner space of the three-dimensional printer is increased. The three-dimensional printer frame has the advantages of wide printing range, simple structure and convenience in assembly.

Owner:青岛金石塞岛投资咨询服务有限公司

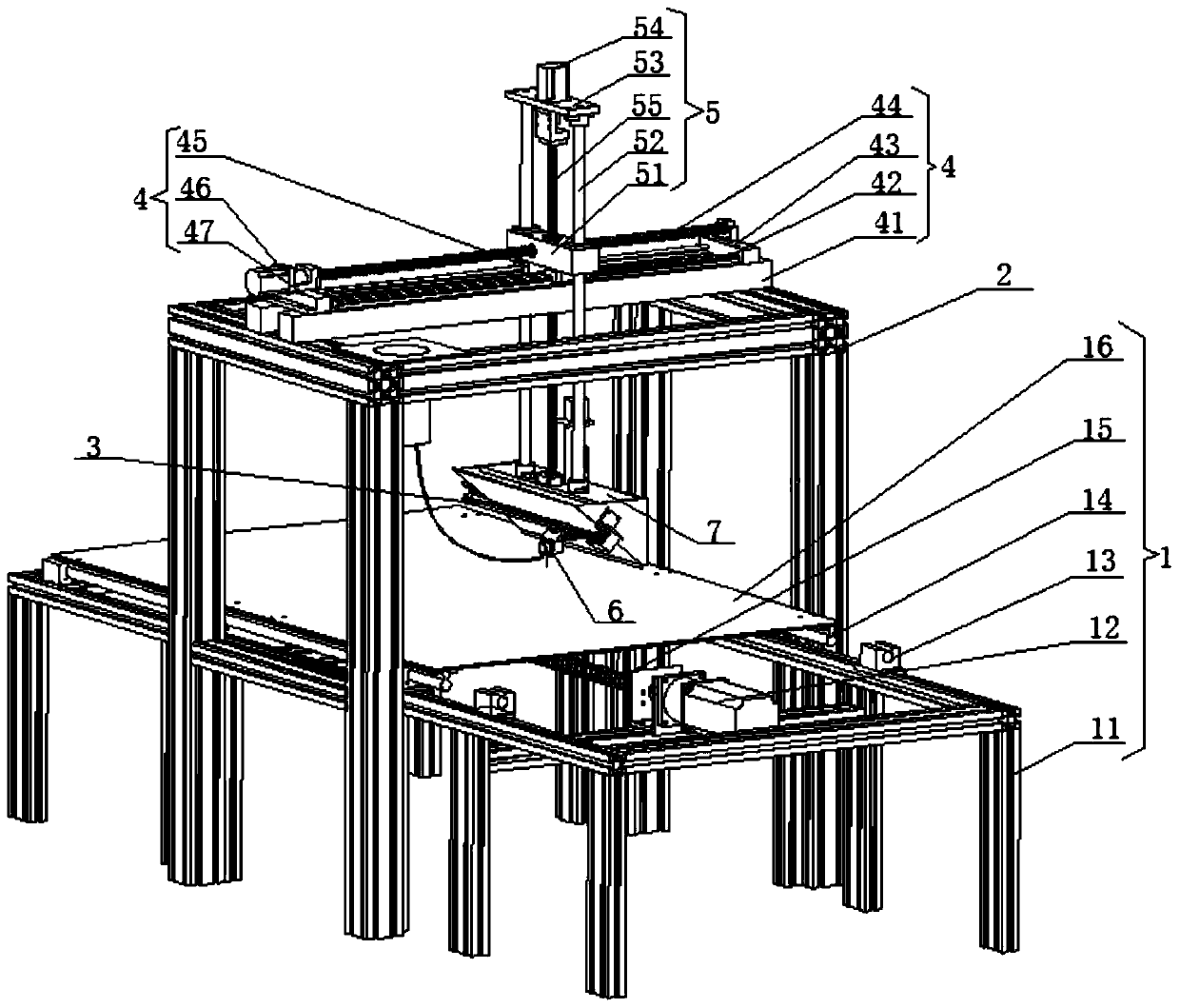

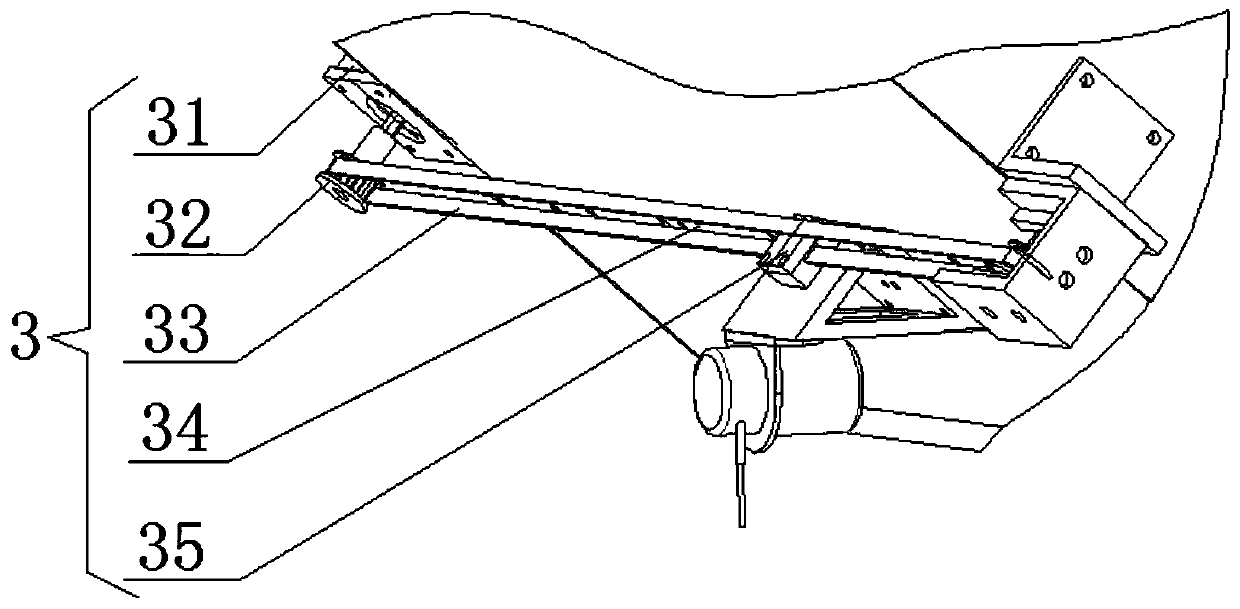

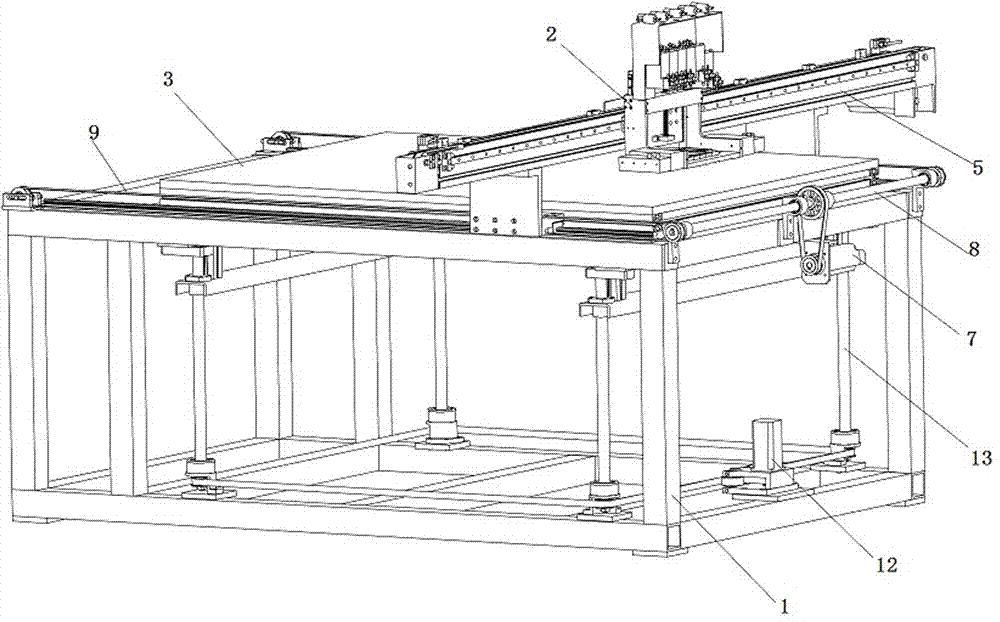

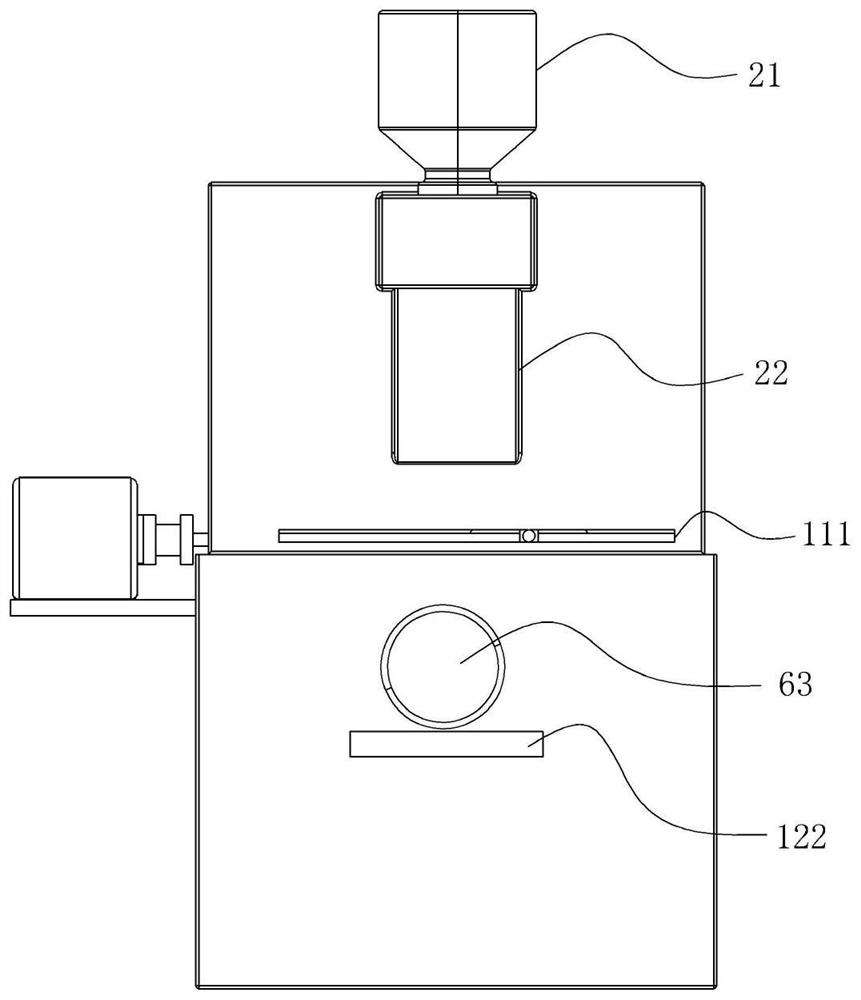

Large-scale powder bed spraying liquid bonded type three-dimensional (3D) printer

PendingCN110328850ARealize printingExpand the printing rangeManufacturing driving meansAdditive mnaufacturing with solid and fluid3d printerAdhesion promoters

The invention provides a large-scale powder bed spraying liquid bonded type three-dimensional (3D) printer which comprises a movable powder bed, a double-gantry rack, an X-axis movement mechanism, a Y-axis movement mechanism, a Z-axis movement mechanism, a powder laying device and an adhesion promoter spraying and dropping device. The X-axis movement mechanism, the Y-axis movement mechanism and the Z-axis movement mechanism are perpendicular to one another; the Y-axis movement mechanism is connected with the double-gantry rack and the Z-axis movement mechanism; the adhesion promoter spraying and dropping device and the X-axis movement mechanism are connected and arranged on the side surface of the powder laying device; the powder laying device and the Z-axis movement mechanism are connected; and a powder bed drive mechanism drives the powder bed to move in a reciprocating way so as to expand a printing area. The large-scale powder bed spraying liquid bonded type 3D printer provided bythe invention has the beneficial effects that a powder material and an adhesion agent are mixed so as to be laid on the powder bed, the adhesion promoter is then sprayed through the adhesion promoterspraying and dropping device and is reacted with the adhesion agent so as to be cured and formed, and a 3D entity is finally printed, so that the size range of a printable model is large, the printingefficiency is high, the cost is low, and the large-scale powder bed spraying liquid bonded type 3D printer is particularly suitable for quickly manufacturing a large-scale industrial model.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

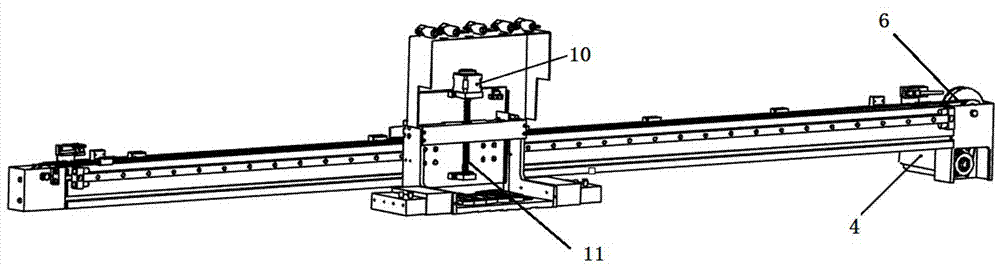

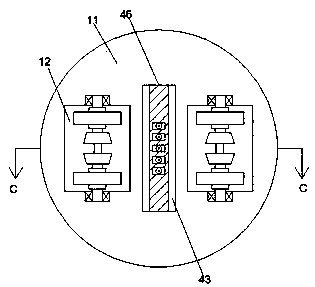

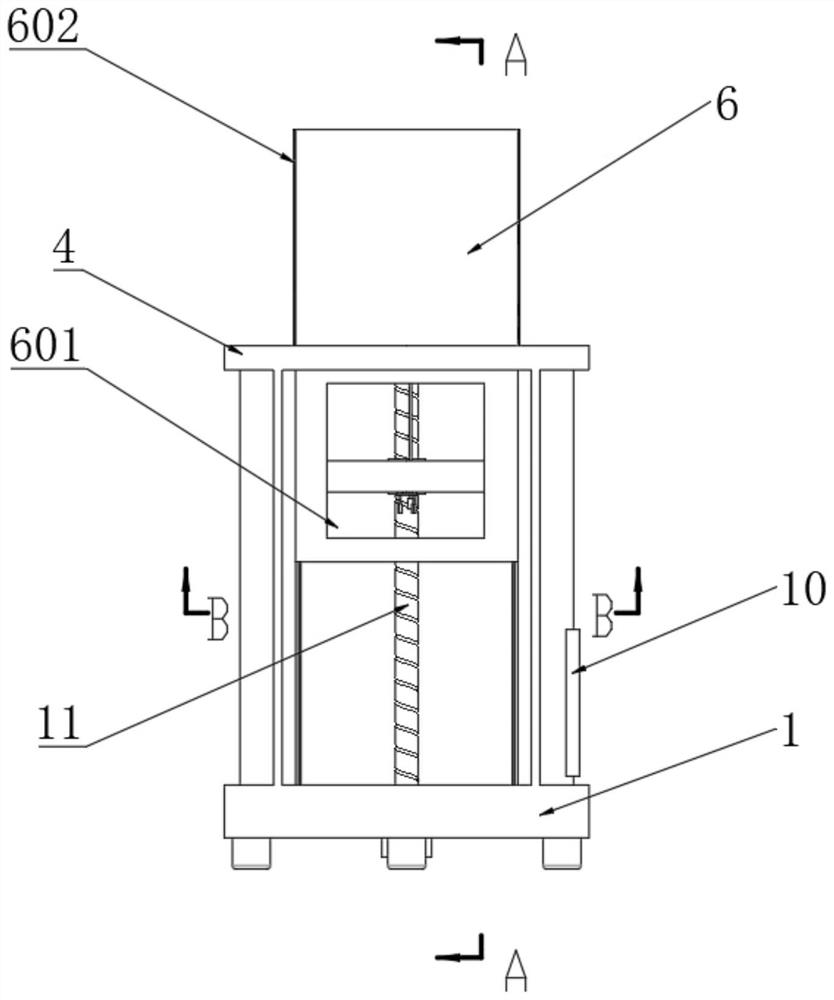

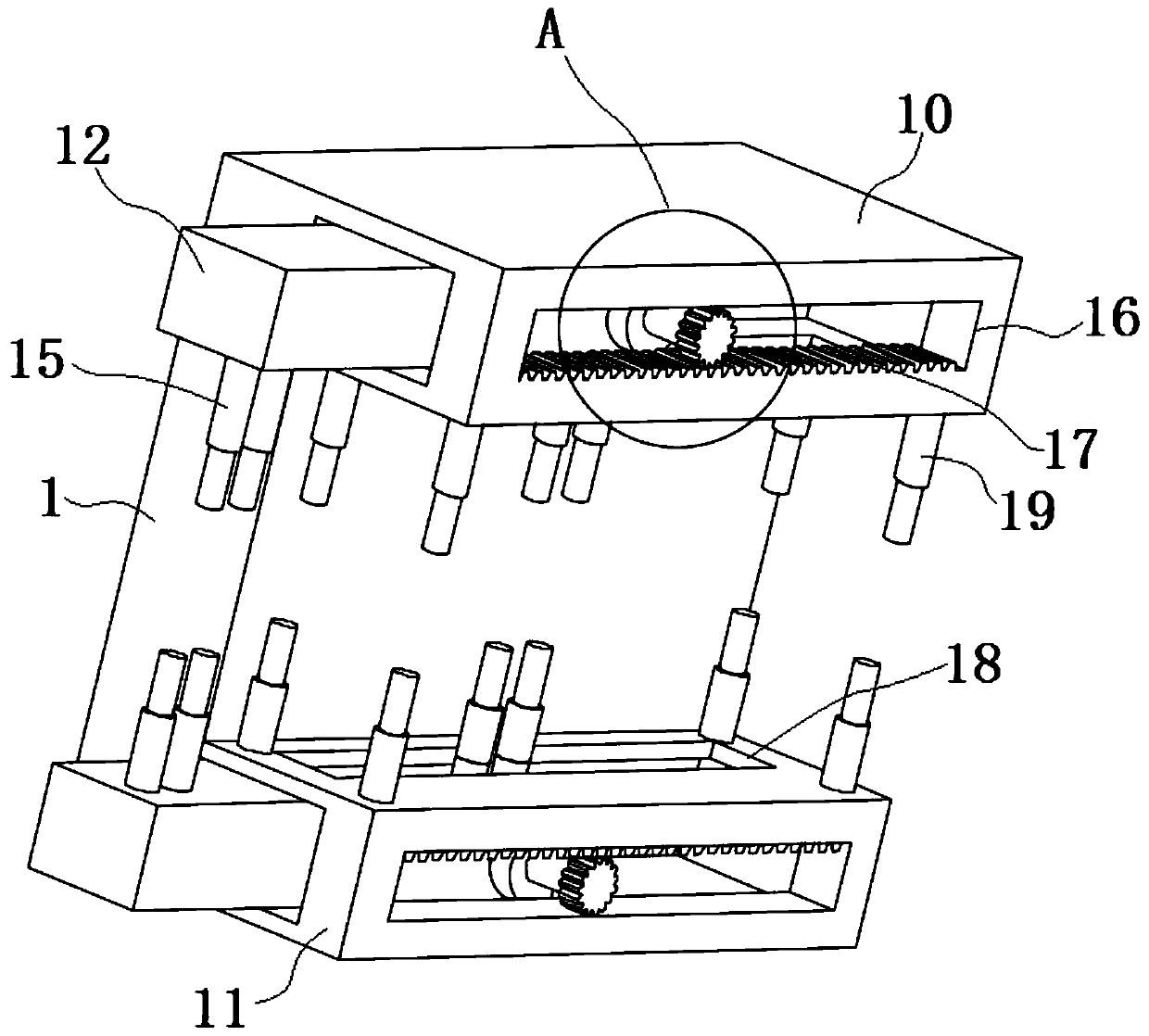

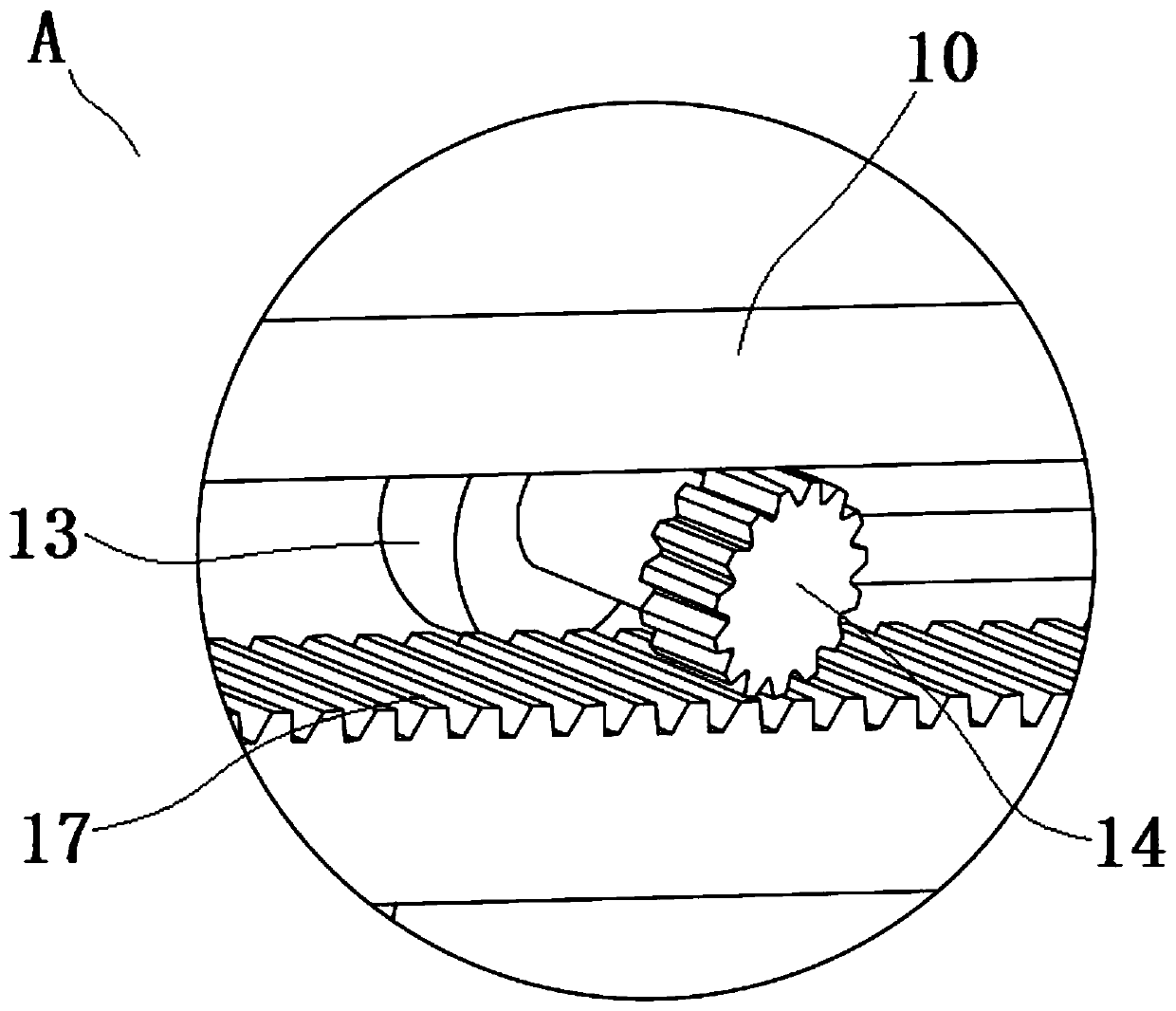

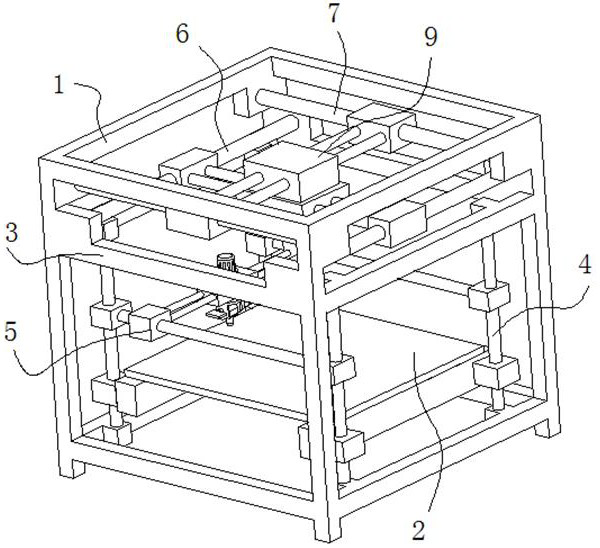

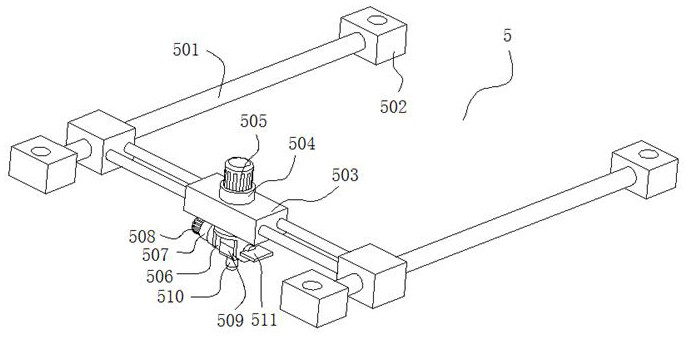

Printer with lifting worktable

PendingCN107379793ALarge printing areaExpand the printing rangeOther printing apparatusHeadstockComputer engineering

The invention relates to a printer with a lifting worktable. The printer comprises a printing frame, a printing headstock, the worktable, an X-axis transmission device, a Y-axis transmission device, a Z-axis positive axis rotation device and a Z-axis negative axis rotation device, wherein the printing headstock, the worktable, the X-axis transmission device, the Y-axis transmission device, the Z-axis positive axis rotation device and the Z-axis negative axis rotation device are fixed onto the printing frame. By the aid of the printer with the lifting worktable structure, the printing range of the printer is wider, a printing platform of the printer can be independently lifted up and down, the printing headstock of the printer can also be independently lifted up and down, the printing range of the printer is widened, working efficiency is greatly improved, and labor cost is reduced.

Owner:南京上优泽机械设备有限公司

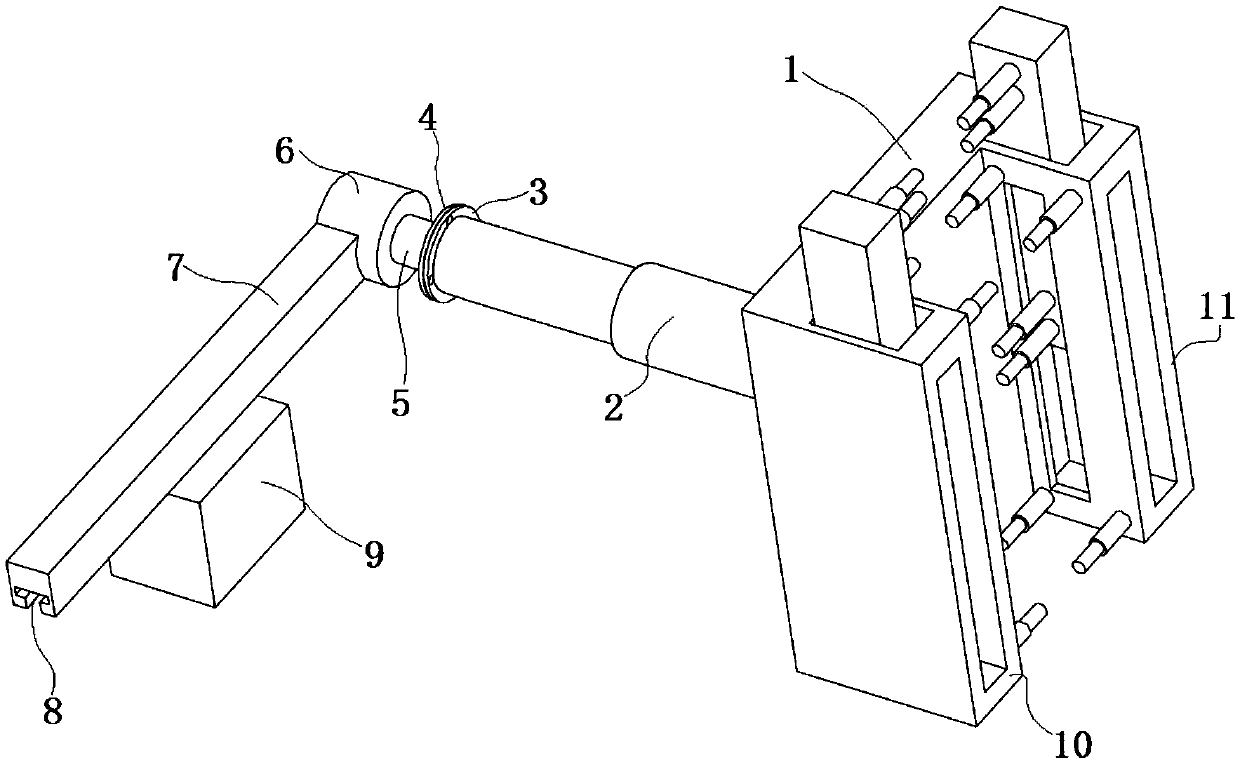

Novel quick printing spray head

InactiveCN110421851AChange lengthExpand the printing rangeApplying layer meansSpray nozzleEngineering

The invention discloses a novel quick printing spray head. The novel quick printing spray head comprises an extruding tube which is vertically arranged, a screw which is inserted into the extruding tube, a stock holder for storing printing materials, a ring-shaped spray nozzle, a movable valve, a motor for driving the screw to rotate, a motor for driving the valve to move, and a heating apparatuson the outer wall of the spray nozzle, wherein the movable valve is mounted inside the spray nozzle; the movable valve is connected to the motor for driving the valve to move through a rolling ball lead screw, and the motor can be controlled to drive the movable valve to move, so that the opening dimension of the spray nozzle can be changed. The novel quick printing spray head can change length ofthe spray nozzle in real time according to dimension changes of a model, increases the printing range of the spray nozzle, changes conventional dot printing into linear printing, and realizes once printing forming of each layer, so that printing speed is greatly increased; cooling time, in air, of each layer of the printing materials sprayed out by the spray nozzle is greatly reduced, and layerscan be guaranteed to be connected more tightly, so that strength of a printed part is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

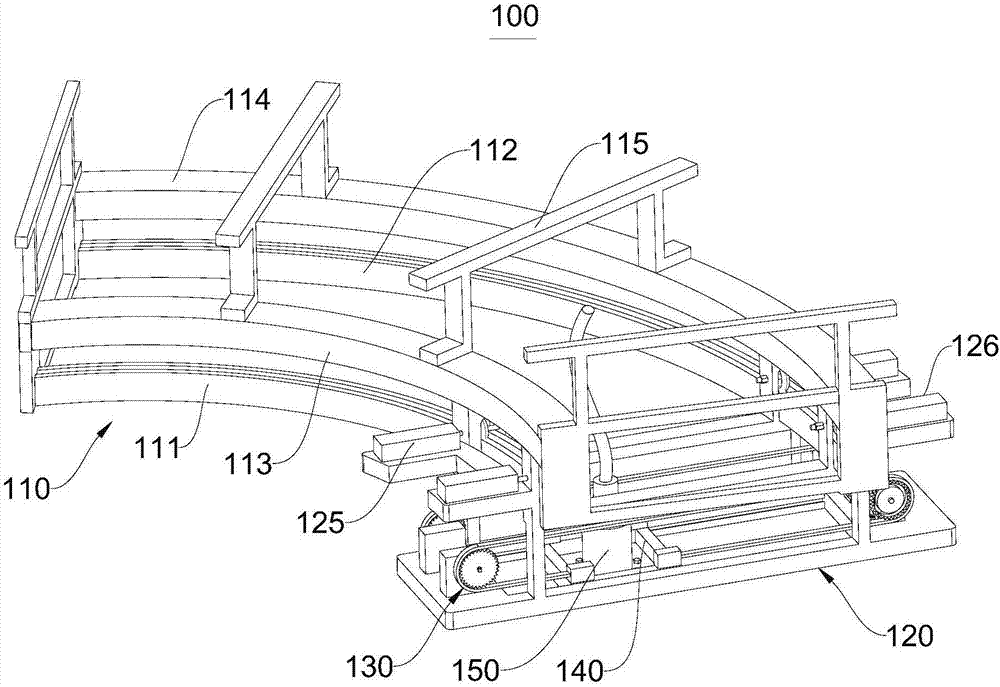

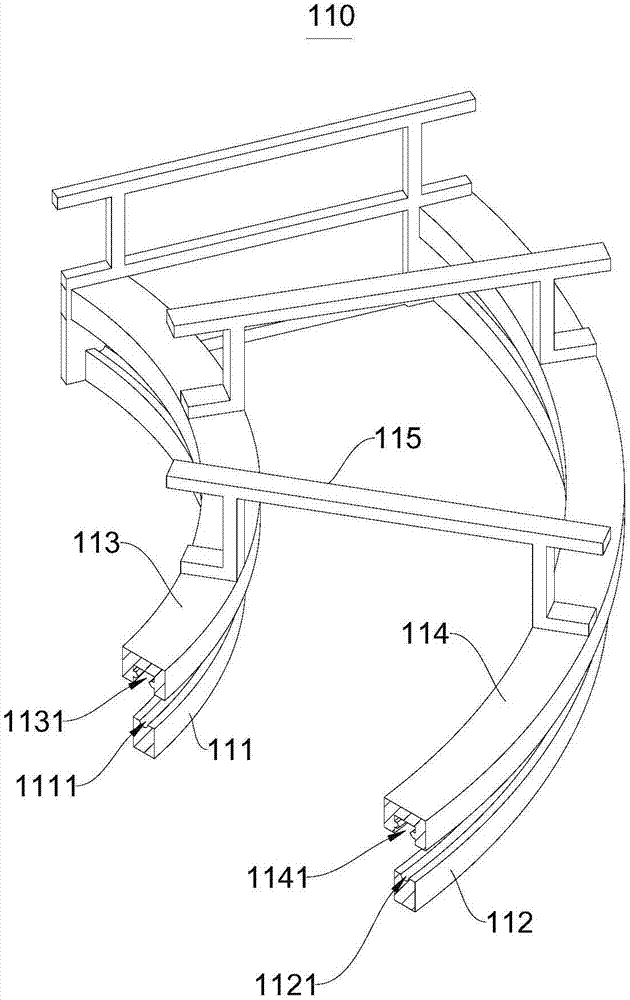

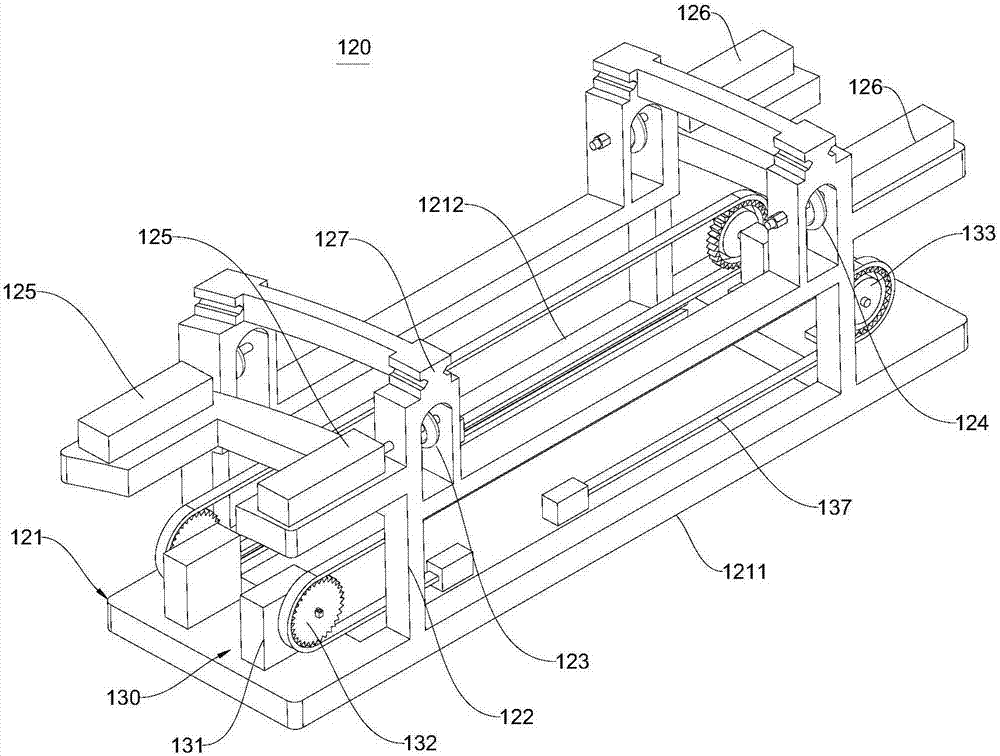

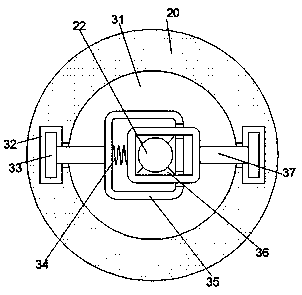

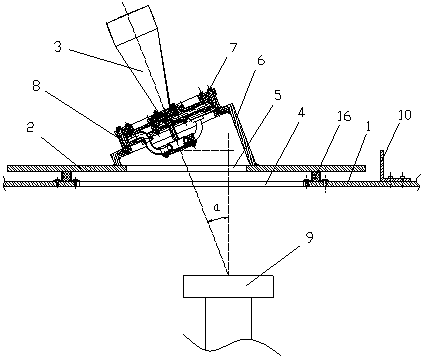

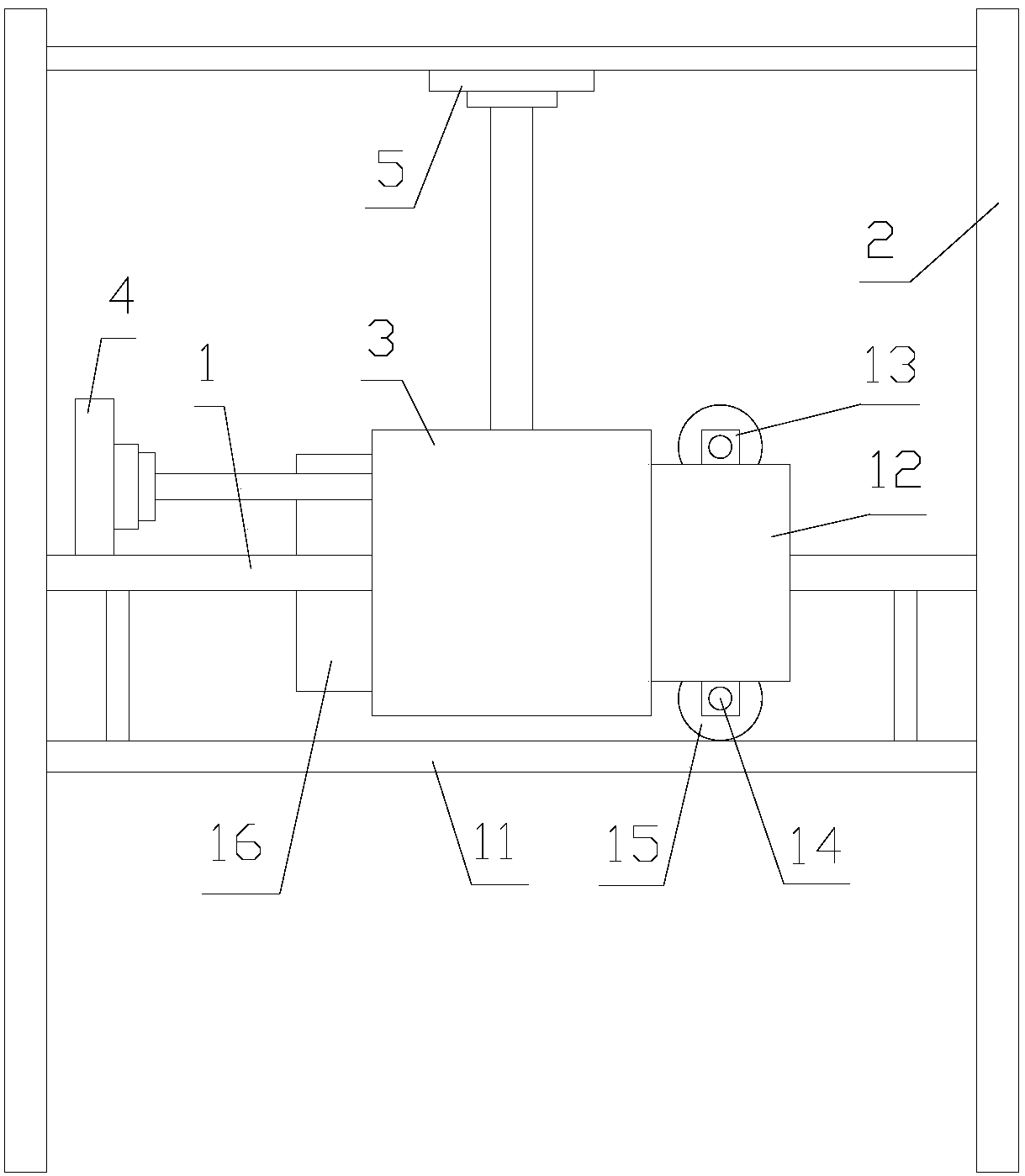

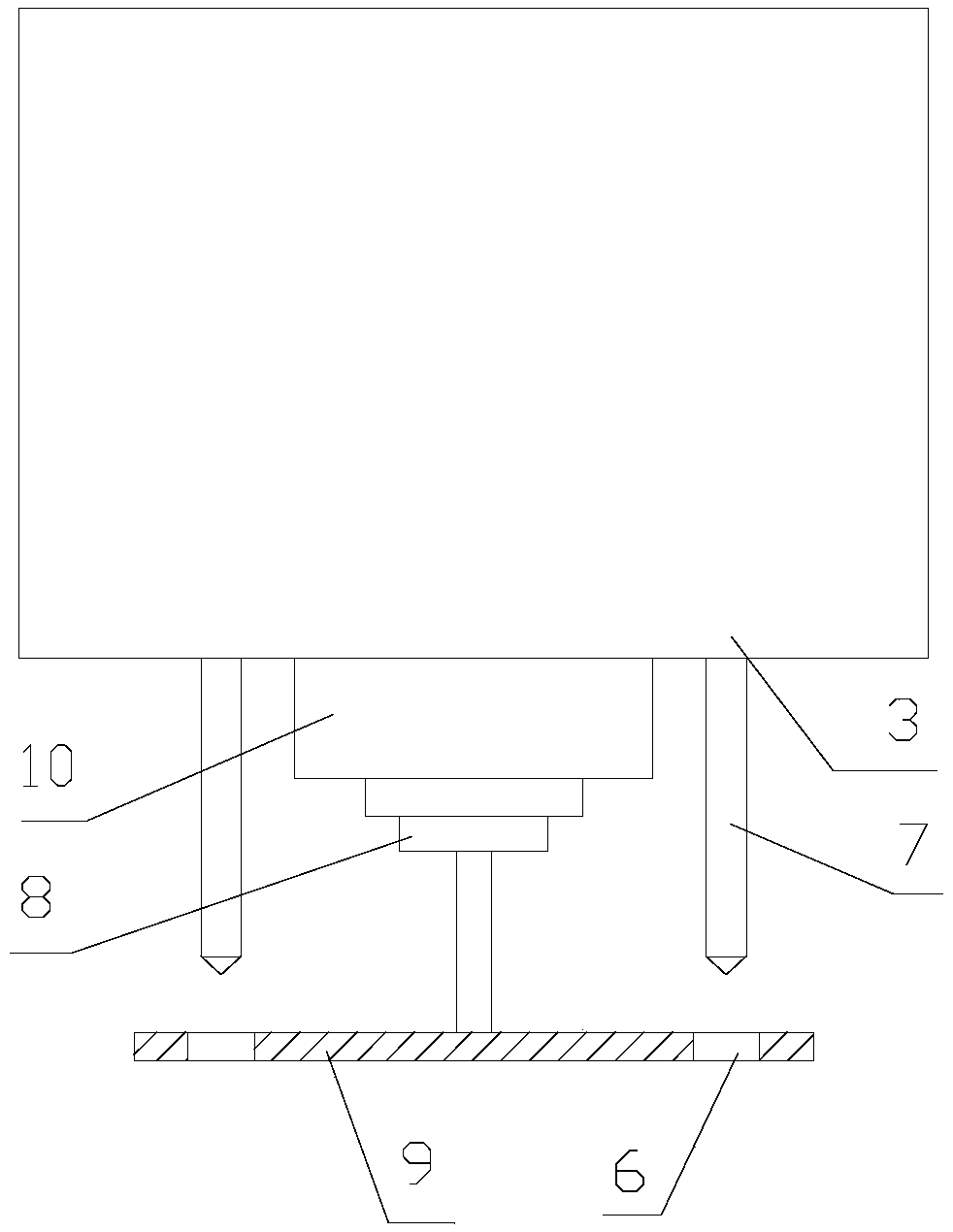

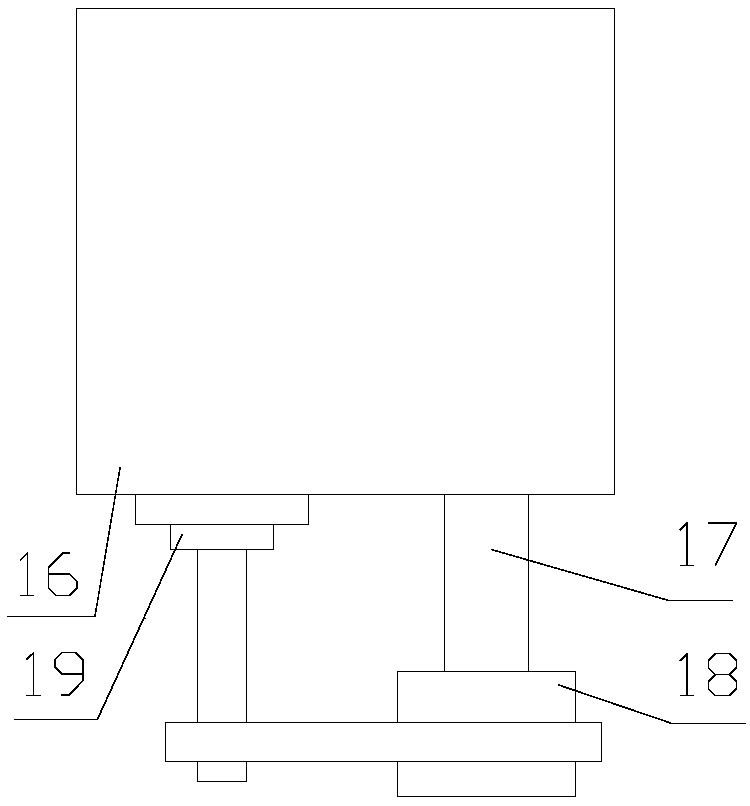

Laser drive mechanism and 3D printer

PendingCN107471640AExpand the printing rangeExpand the scope of activitiesManufacturing driving meansIncreasing energy efficiencyEngineering3d printer

The invention relates to the technical field of 3D print and discloses a laser drive mechanism and a 3D printer. The laser drive mechanism comprises a rail assembly, a main trolley, an auxiliary trolley and a laser emitting device. The main trolley is movably connected to the rail assembly. A guide rail of the rail assembly provides an arc movement path for the main trolley. The auxiliary trolley is movably connected to the main trolley and can move in the radial direction of the arc guide rail relative to the main trolley. The laser emitting device is arranged on the auxiliary trolley. The 3D printer comprises the laser drive mechanism and a work bench. The laser emitting device can select to conduct sintering or melting on powder printing materials on a workbench at different positions on a fan-shaped ring face (or a circular ring face) along with movement of the main trolley and the auxiliary trolley. In this way, the 3D printer with the laser drive mechanism has a wide printing range.

Owner:窦鹤鸿

Printing device based on ribbon

The invention discloses a printing device based on a ribbon; the printing device based on the ribbon comprises a printing shell, wherein the printing shell is provided with a transmission chamber withan opening at the left and symmetrical front and rear, the transmission chamber is rotationally connected with a driving shaft with symmetrical upper and lower sides; one end, close to the symmetrical center, of the driving shaft is provided with joining devices, wherein the joining devices abut againt each other and are connected with a sleeve structure; the driving shaft is provided with a mainbelt pulley, and the outer side of the main belt pulley is provided with a roller abutting against a wall; The printing device provided by the invention has the advantages of simple structure, hand-held structure and enlarged printing range, so that the printing result reduces the subsequent operation directly, and when the translation sliding is utilized, the friction force between a wheel and acontact surface can provide power for the whoe equipment without an external power supply; and a two-way clamping method is adopted, so that the ribbon is replaced conveniently.

Owner:南通亘赢科技有限公司

3D printing model device with cleaning mechanism

ActiveCN114311678AAchieve protectionRealize all-round printing operationAdditive manufacturing apparatus3D object support structures3d printStructural engineering

Owner:佳珩三维科技(太仓)有限公司

Oblique-atomization moving device for metal blanks

The invention relates to an oblique-atomization moving device for metal blanks. The oblique-atomization moving device comprises a base plate, a sliding platform, an atomizer, a driving device and a base disc. A first through hole is formed in the center of the base plate, slide rails are fixed on two sides of the base plate, the base disc is arranged below the first through hole correspondingly, the sliding platform is arranged on the base plate, the driving device controls the sliding platform to be in sliding connection along the slide rails of the base plate, a second through hole is formed in the sliding platform and corresponds to the first through hole, the atomizer is arranged on the sliding platform obliquely, and an injection orifice at the bottom of the atomizer is corresponding to the second through hole. The oblique-atomization moving device for the metal blanks adopts the movable atomizer and the base disc, so that printing range is enlarged greatly, dead corners during printing are avoided, and formability and material property are guaranteed.

Owner:佛山市元子新材料科技有限公司

Operation bracket platform for building 3D printing

InactiveCN109624323AExpand the printing rangeAny angle adjustmentManufacturing platforms/substratesArchitectural engineeringConstruction 3D printing

The invention discloses an operation bracket platform for building 3D printing, and a method, and relates to the technical field of 3D printing. The operation bracket platform comprises a base, and one surface of the base is fixedly connected with a hydraulic rod through a fixing block; the other end of the hydraulic rod is fixedly connected with a first circular ring; one surface of the first circular ring is fixedly connected with a second circular ring through a bolt; a straight rod is fixedly connected to one surface of the second circular ring; the other end of the straight rod is fixedlyconnected with a circular pipe; the circumferential side face of the circular pipe is fixedly connected with a transverse beam; a first sliding groove is formed in one surface of the transverse beam;and the inner surface of the first sliding groove is in transmission connection with a moving box. According to the operation bracket platform, by arranging a first fixing block and a second fixing block, the problem that existing building 3D printing equipment has height restriction; by arranging the circular pipe, the problem that the printing angle of the existing building 3D printing equipment cannot be adjusted at will is solved; and by arranging the transverse beam which can be assembled, the problem that the printing range of the existing building 3D printing equipment is small is solved.

Owner:FOSHAN UNIVERSITY

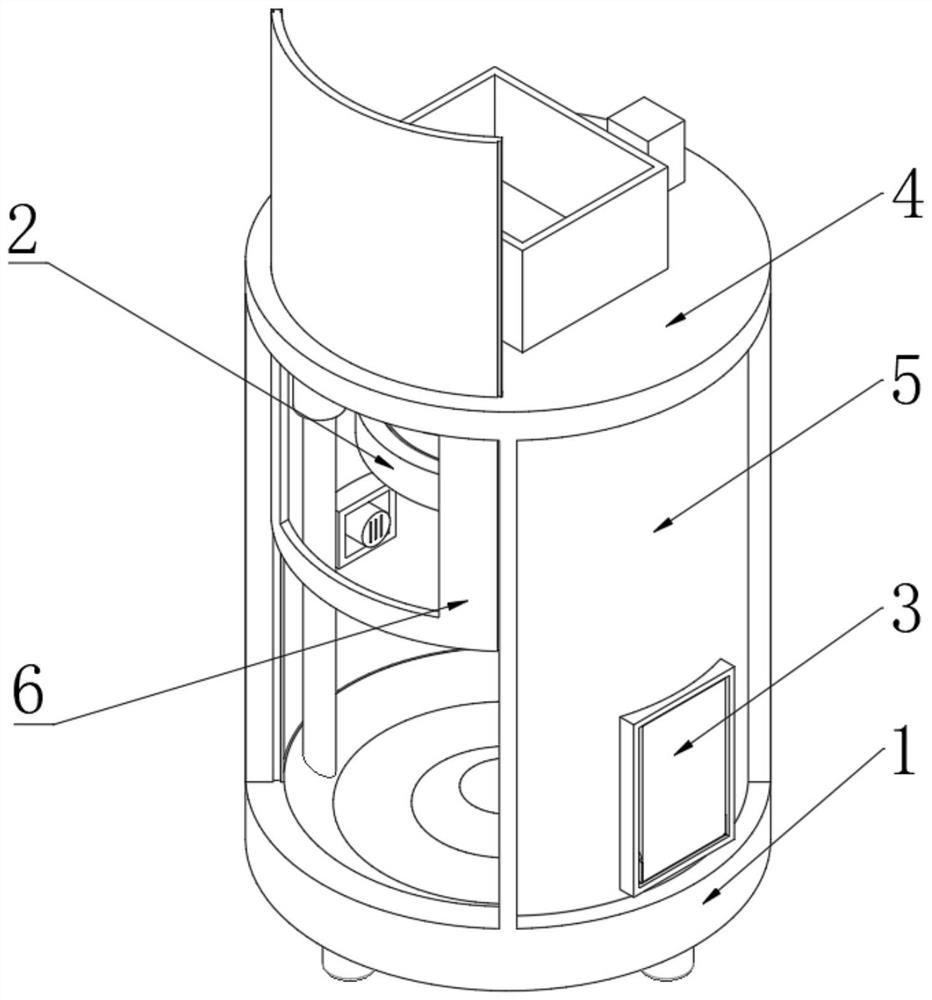

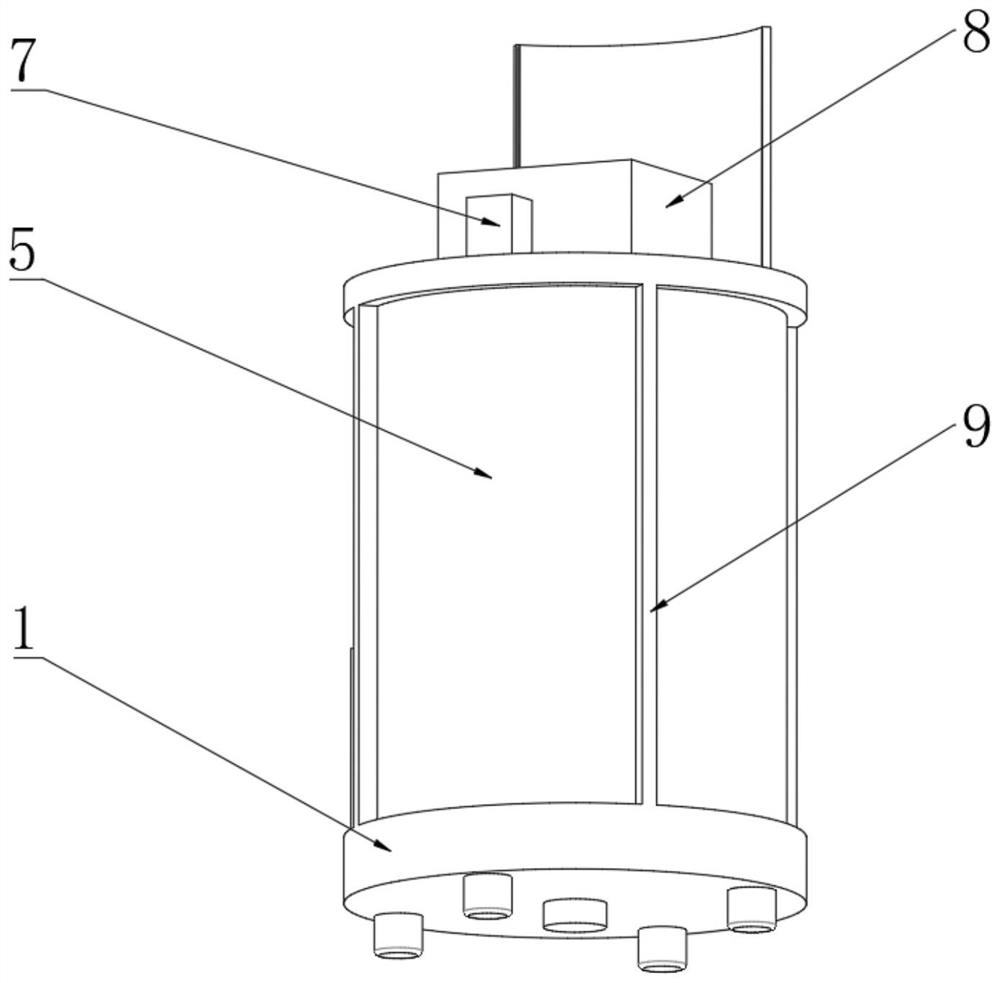

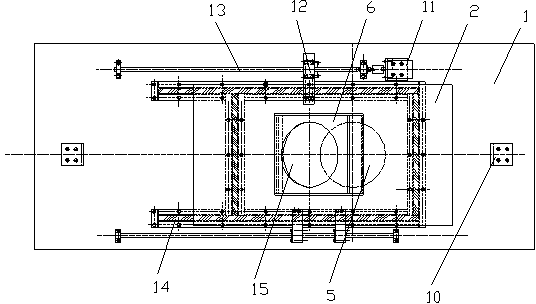

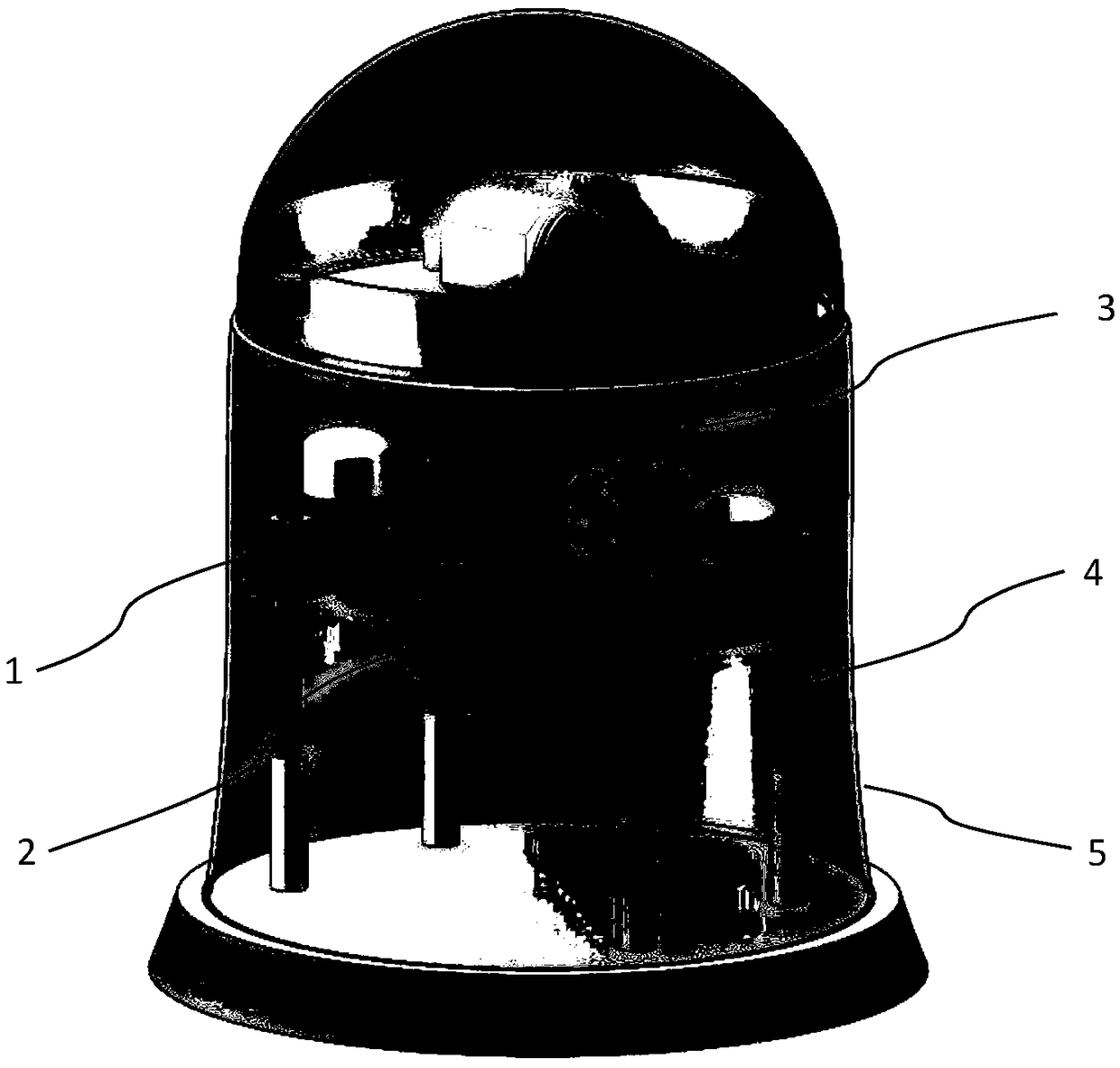

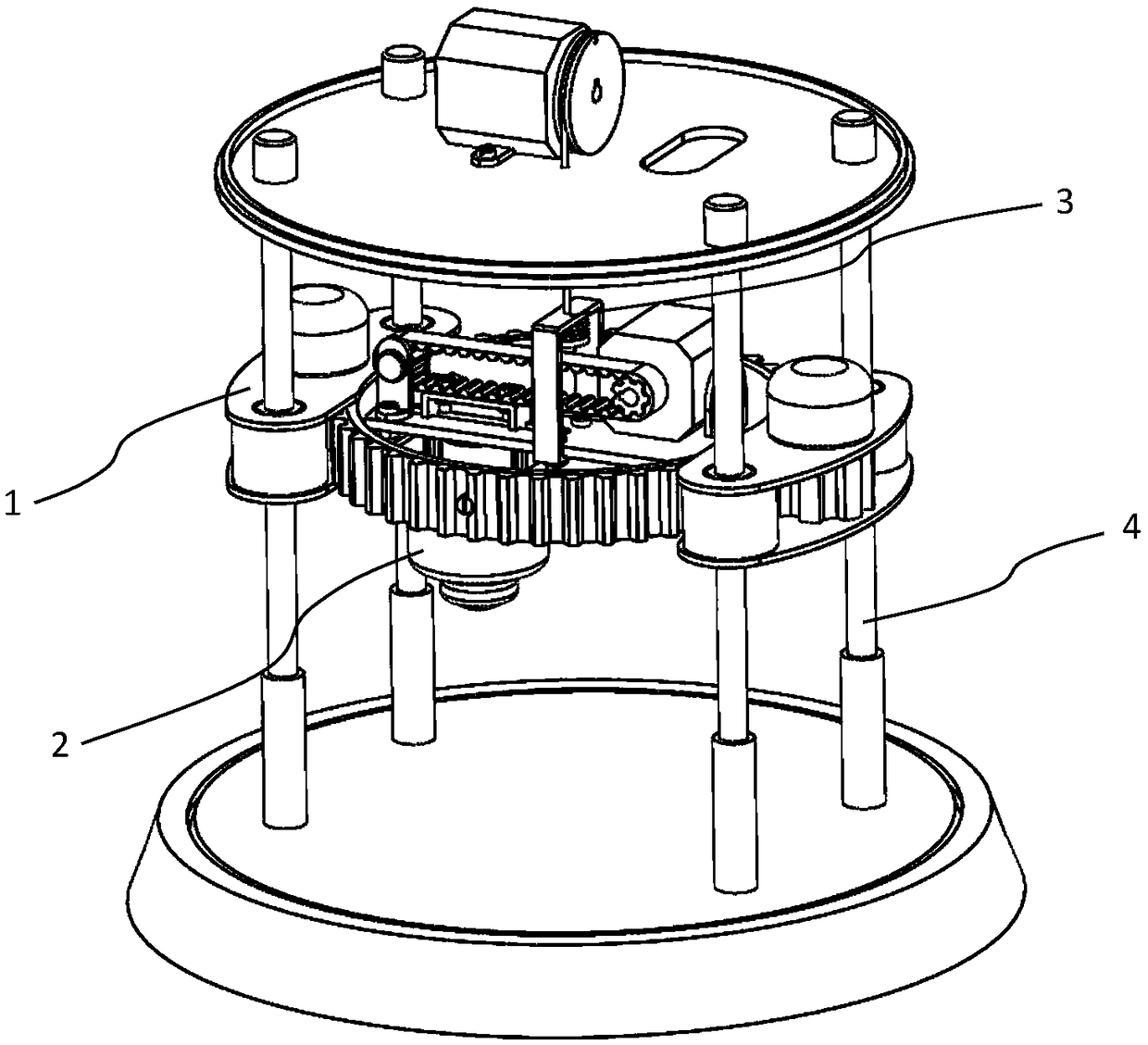

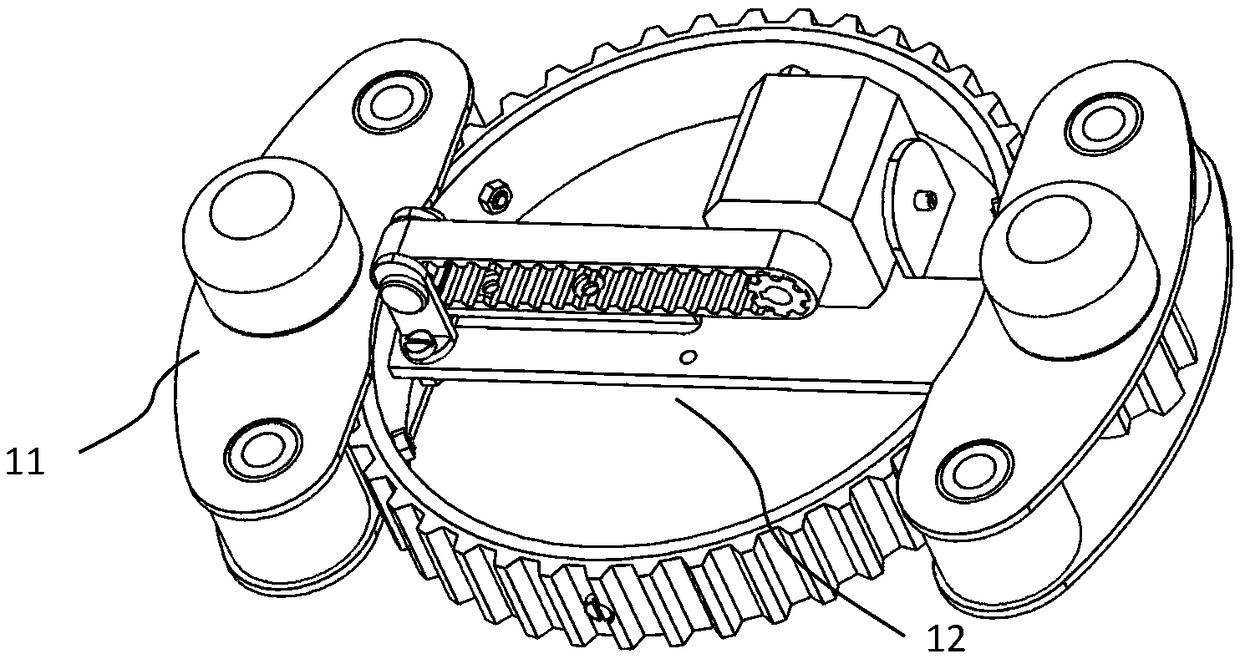

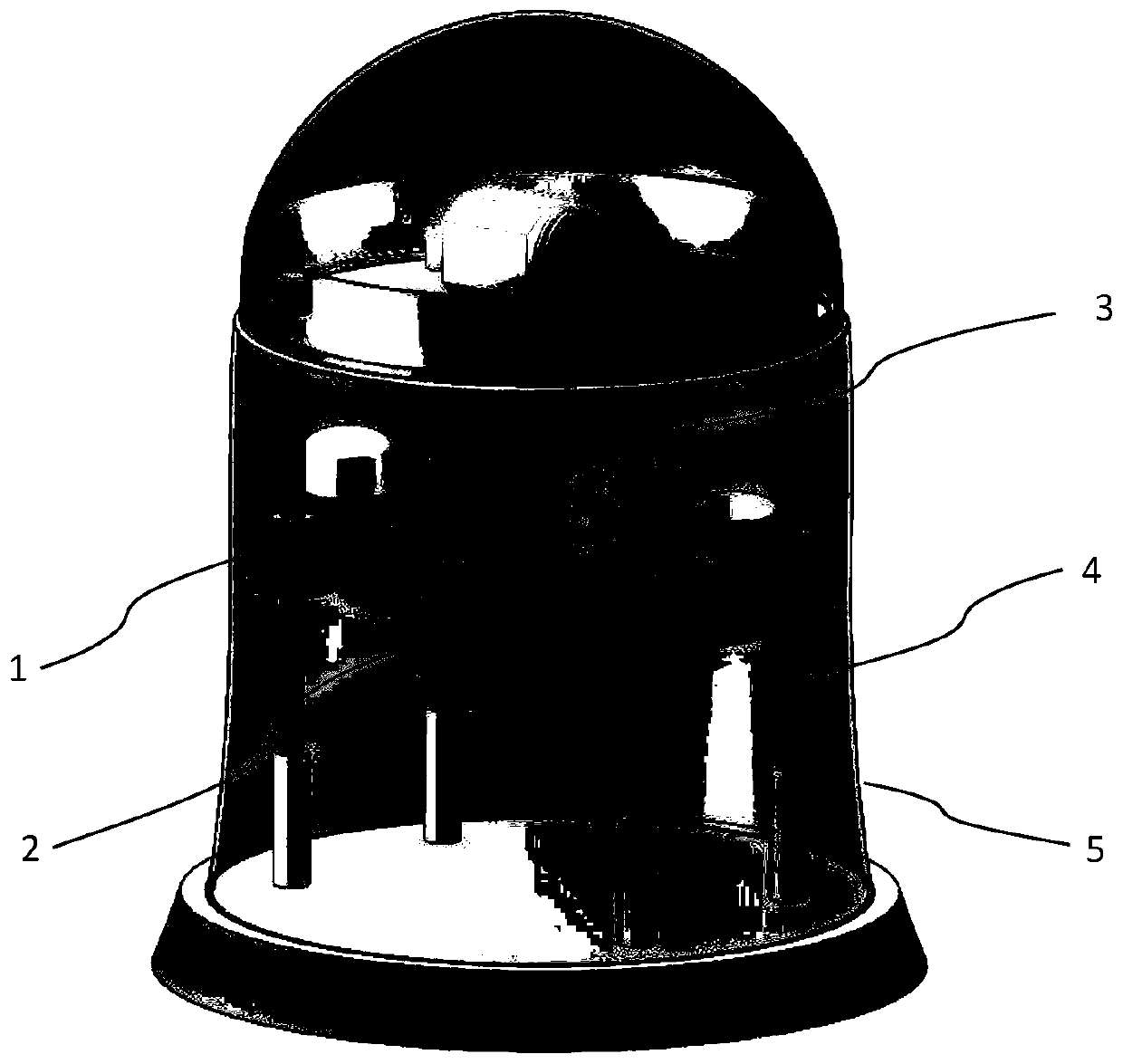

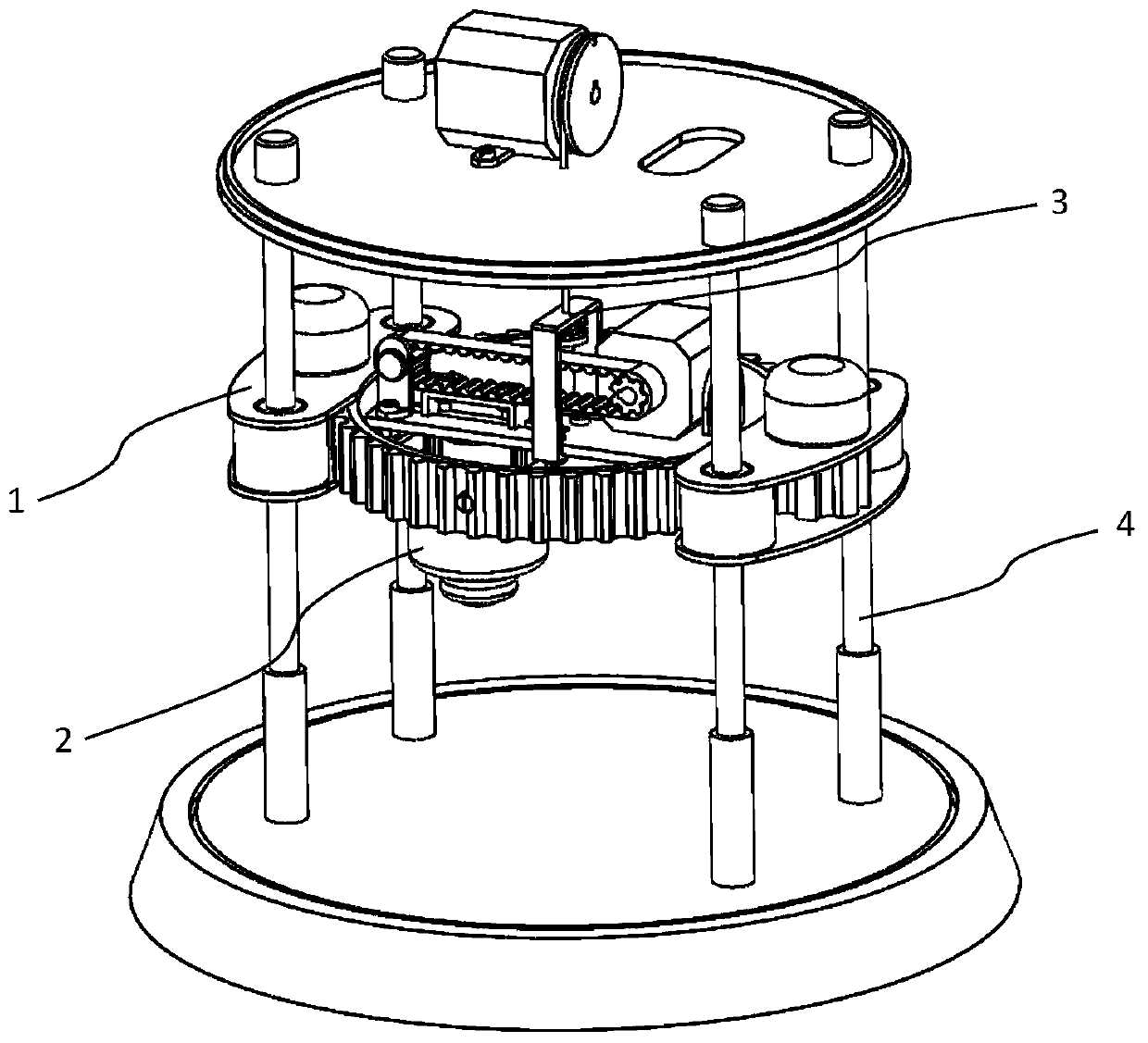

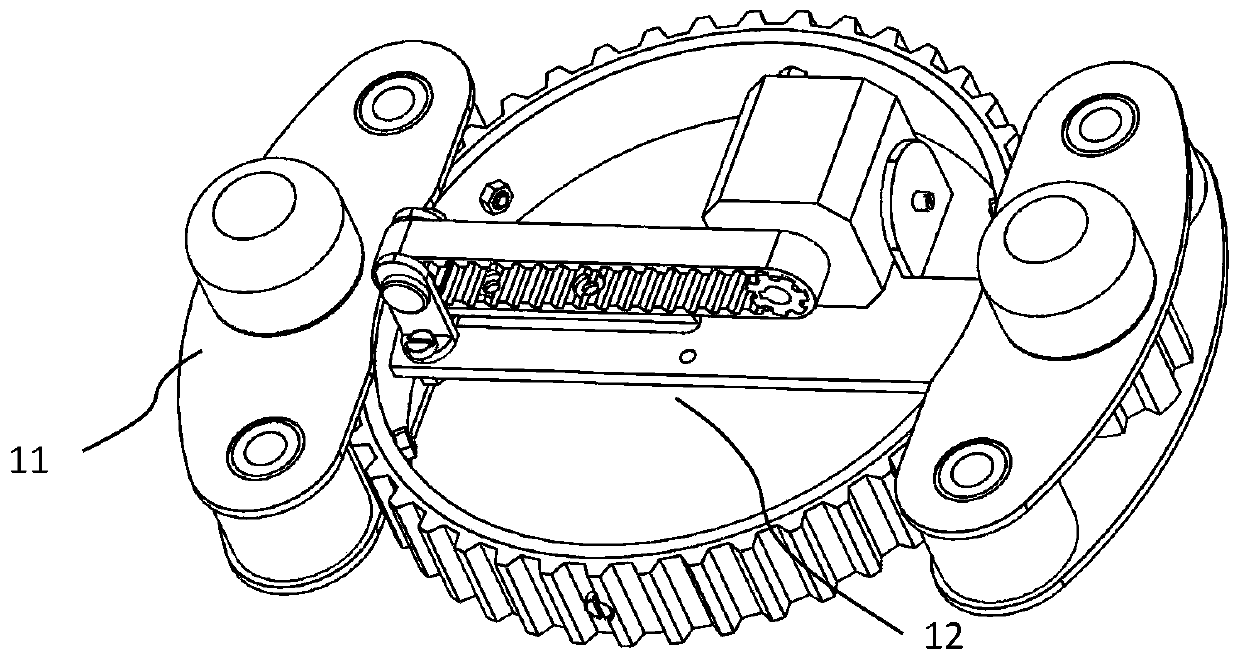

3D printer based on cylindrical coordinate system

ActiveCN109304860AReduce volumeExpand the printing rangeManufacturing driving meansAdditive manufacturing with liquidsLinear motionDrive motor

The invention discloses a 3D printer based on a cylindrical coordinate system. The 3D printer comprises an annular module, a spray head module, a lifting module, a main body frame and a printer outercover; the annular module is in sliding fit with a supporting column of the main body frame through a linear bearing, the annular module is fixedly connected with the lifting module through a liftingraising frame, and the lifting module is fixedly connected with the main body frame through a lifting driving motor fixed on a top cover; and under the cylindrical coordinate system, the spray head module needs to perform circumferential rotation motion, radial linear motion and axial lifting motion, wherein the circumferential rotation motion is completed through drive from a rotation driving sliding block of the annular module, the radial linear motion is completed through the cooperative drive from a radial driving module and a radial driven module of the annular module, and the axial lifting motion is completed through drive from the lifting module. The 3D printer has the characteristics of being compact in structure and reasonable in design, moreover, the size is small, the printing range is relatively large, and the stability and the printing precision are relatively high.

Owner:YANSHAN UNIV

Ceramic tile printing machine

The invention discloses a ceramic tile printing machine. The ceramic tile printing machine comprises a first guide rail, a second guide rail, an ink box assembly, a first power unit, a second power unit, a plurality of sprayers, an execution unit, a baffle and a controller. The first guide rail is movably arranged on the second guide rail. The length direction of the first guide rail is perpendicular to or obliquely intersects with the length direction of the second guide rail. The ink box assembly is movably connected with the first guide rail. The first power unit is used for driving the inkbox assembly to move along the first guide rail. The second power unit is used for driving the first guide rail to move along the second guide rail. The multiple sprayers are sequentially distributedand communicate with the ink box assembly. The baffle is provided with a plurality of through holes, and the multiple through holes correspond to the multiple sprayers in a one-to-one manner. The execution unit is used for driving the baffle to move so that the through holes can get in or disengage from the area below the sprayers. The ink box assembly and the execution unit are both in communication connection with the controller. The ceramic tile printing machine is good in ceramic tile printing effect.

Owner:HEFEI AIRWREN AUTOMATIC EQUIP CO LTD

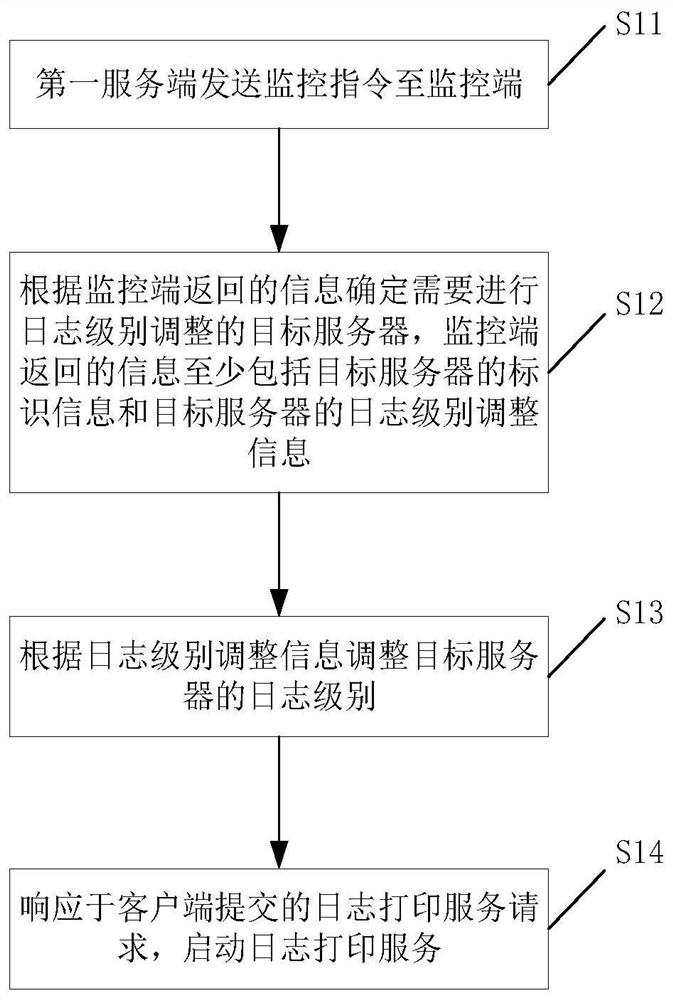

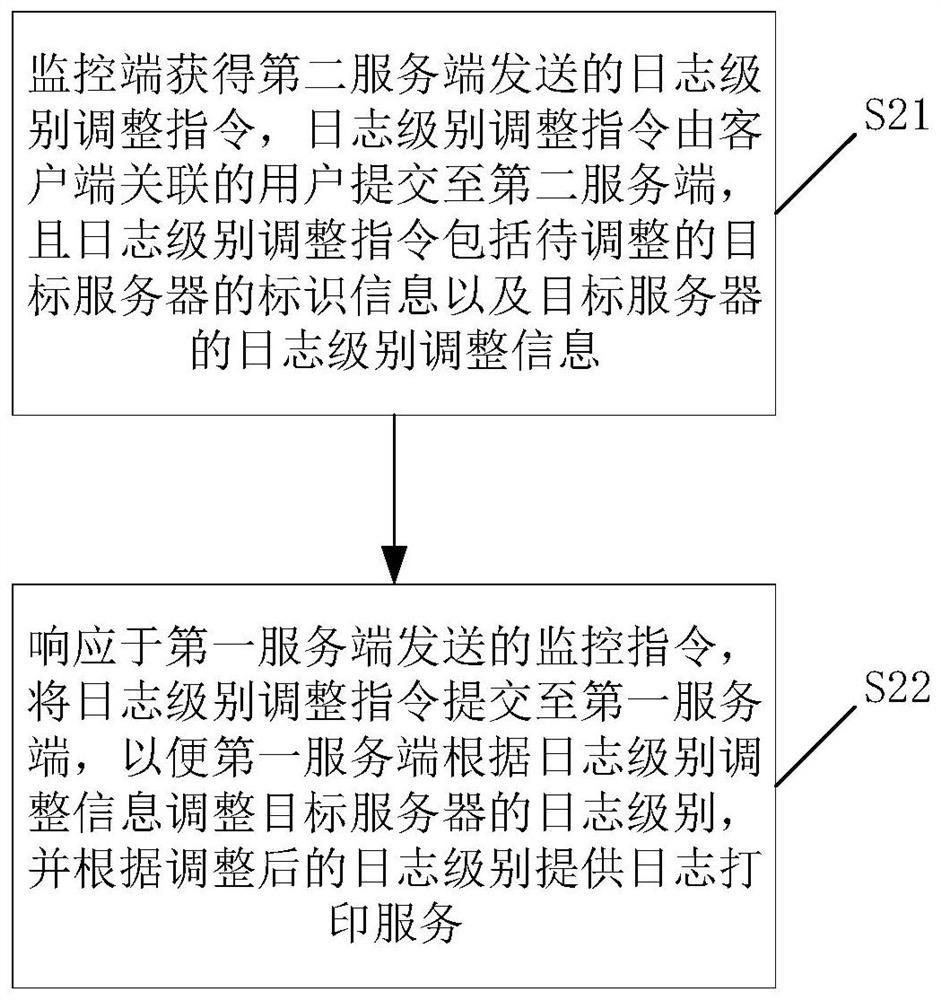

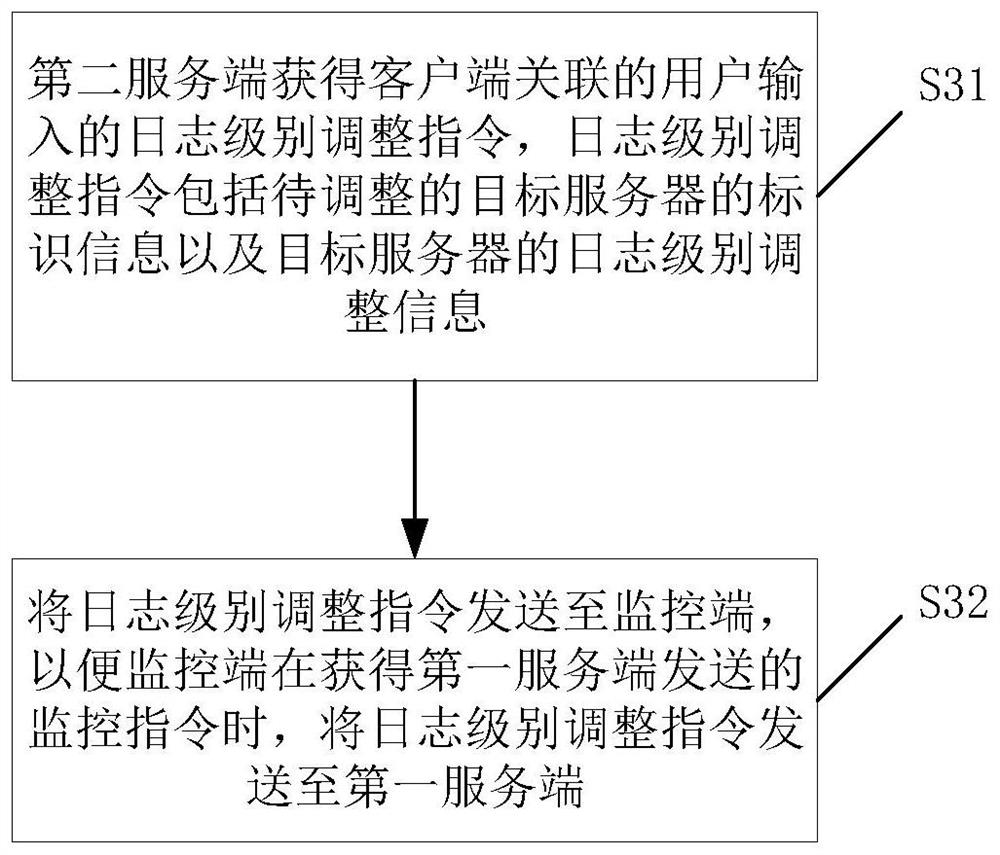

Method, system and device for log printing

ActiveCN112486435AReduce load pressureExpand the printing rangeDigital output to print unitsEngineeringReal-time computing

The invention relates to the technical field of computers, and discloses a method for log printing, which comprises the following steps: sending a monitoring instruction to a monitoring terminal by afirst service terminal; determining a target server needing log level adjustment according to information returned by the monitoring terminal, wherein the information returned by the monitoring terminal at least comprises identification information of the target server and log level adjustment information of the target server; adjusting the log level of the target server according to the log leveladjustment information; and in response to a log printing service request submitted by the client, starting a log printing service. In this way, the server load pressure can be reduced when the log level is adjusted, and the request time consumption is reduced; and meanwhile, the log printing range is expanded, and online problem tracing is facilitated. The invention further discloses a system and device for log printing.

Owner:QINGDAO HAIER TECH +1

Immersion type 3D printing device and 3D printing method

InactiveCN111941830AChanging the Cooling SituationEasy to control temperatureAdditive manufacturing apparatusManufacturing environment conditioning3d printProcess engineering

The invention relates to an immersion type 3D printing device which comprises a printing body and a liquid control device. The printing body is used for implementing 3D printing; and the liquid control device is used for injecting liquid into the printing body, so that a printed object is placed in the liquid, and the temperature of the liquid is controlled. Meanwhile, the invention further relates to a liquid 3D printing method. The liquid 3D printing method comprises the following steps that S200, the liquid control device inputs liquid into a box body; and S300, a printing assembly implements 3D printing in the box body, and an extruded material is placed in the liquid. Compared with the prior art, according to the 3D printing device and the 3D printing method, the printed object forming environment of the liquid is provided, the temperature is controllable, the number of optional printing materials is larger, and the application range of 3D printing is widened.

Owner:上海责代知识产权代理有限公司

A double-player 3D printer

ActiveCN110744816BDouble playWith multiple angle adjustment functionsManufacturing driving meansComputer printing3d printer

The invention discloses a double-type 3D printer and relates to the technical field of 3D printing. The invention includes a frame, a workbench and a printing assembly. A rectangular frame is fixed inside the frame, and a Z-axis transmission assembly is fixed between the rectangular frame and the bottom of the frame. The Z-axis transmission assembly is composed of four first electric slide rails. The platform is fixed between the slider parts on several first electric slide rails, the printing assembly includes a set of second electric slide rails, electric slider parts are fixed at both ends of the second electric slide rails, and a set of second electric slide rails The electric slider is connected with the slide rail portion on the first electric slide rail through transmission. The present invention can make the printer have the function of double-printing by setting the printing component on the existing 3D printer, has multiple angle adjustment functions, is adapted to 3D printing, realizes the functions of flexibility and a large printing range, and can work at the same time, solving the problem of Solved the problem of low working efficiency of existing 3D printers.

Owner:江西省致能智造产业技术研究有限公司

Heat radiation 3D printing machine with discharge hatch roll shaft provided with protection structure

InactiveCN109249615AStable discharge workAvoid frictionAdditive manufacturing apparatusRadiation3D printing

The invention relates to a heat radiation 3D printing machine with a discharge hatch roll shaft provided with a protection structure. The heat radiation 3D printing machine comprises a main body, a roll shaft, and a bar-shaped ventilating opening; a fixed rod is arranged at the internal wall of the main body; the external side of the fixed rod is movably provided with a first movable box; the internal side of the first movable box close to the central axis of the main body is connected with a movable rod; the external side of the movable rod is movably provided with a second movable box; the top of the second movable box is provided with a material bar; and the external side of the material bar is provided with a direction guide block. The beneficial effects are that: a projection, a groove, the main body, and a heat radiation fan are adopted, and the external side of the projection is designed to match the internal wall of the groove, so that in relative moving operation of the roll shaft and a printing tray, under the mutual engaging effect of the projection on the external wall of the roll shaft and the groove on the internal side of the bottom of the printing tray, more smoothdischarging operation can be completed by the printing tray, and under the effect of the externally sealed printing tray, the roll shaft is protected in discharging.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

Computer network based query printer

InactiveCN106488067ASpit out wellAvoid Paper JamsTypewritersOther printing apparatusDrive wheelPulp and paper industry

The invention discloses a computer network based query printer, and relates to the technical field of printing. The printer comprises a printer casing, a controller is fixedly mounted in the top of the printer casing, a USB interface is fixedly mounted in one side of the printer casing, a data wire is inserted into the USB interface, and one end, far from the USB interface, of the data wire is connected with a PC. Due to arrangement of a roller, a rotating rod and driven wheels, paper entering the printer can be pressed by the driven wheels, the roller rotates to output the paper, and the paper is prevented being blocked in the printer; and uneven paper can be printed and output rapidly, convenience is provided for use, and the working efficiency is improved.

Owner:天津思奇科技股份有限公司

3D printer rack

The invention belongs to the technical field of three-dimensional printers and relates to an anti-resonance three-dimensional printer frame which is used for a desktop three-dimensional printer. The anti-resonance three-dimensional printer frame comprises an X-axis sliding rod, a Y-axis sliding rod, a Z-axis sliding rod, a Z-axis threaded rod, locking pieces, connecting rods and a conveying belt supporting shaft, wherein the connecting rods are used as seamed edges to form a three-dimensional frame, and the connecting rods are connected in pairs by fixed pieces; the sliding rods, the threaded rod and the conveying belt supporting shaft are fixed on the three-dimensional frame by the locking pieces; a Z-axis driving motor is fixed on a rear-lower connecting rod on the three-dimensional frame, a Y-axis driving motor is fixed on a right-rear connecting rod on the three-dimensional frame, and an X-axis driving motor is fixed on a right fixer. Through the design, the vibration of the three-dimensional printer during operation is alleviated, the printing quality of a product is improved, and the utilization rate of inner space of the three-dimensional printer is increased. The three-dimensional printer frame has the advantages of wide printing range, simple structure and convenience in assembly.

Owner:青岛金石塞岛投资咨询服务有限公司

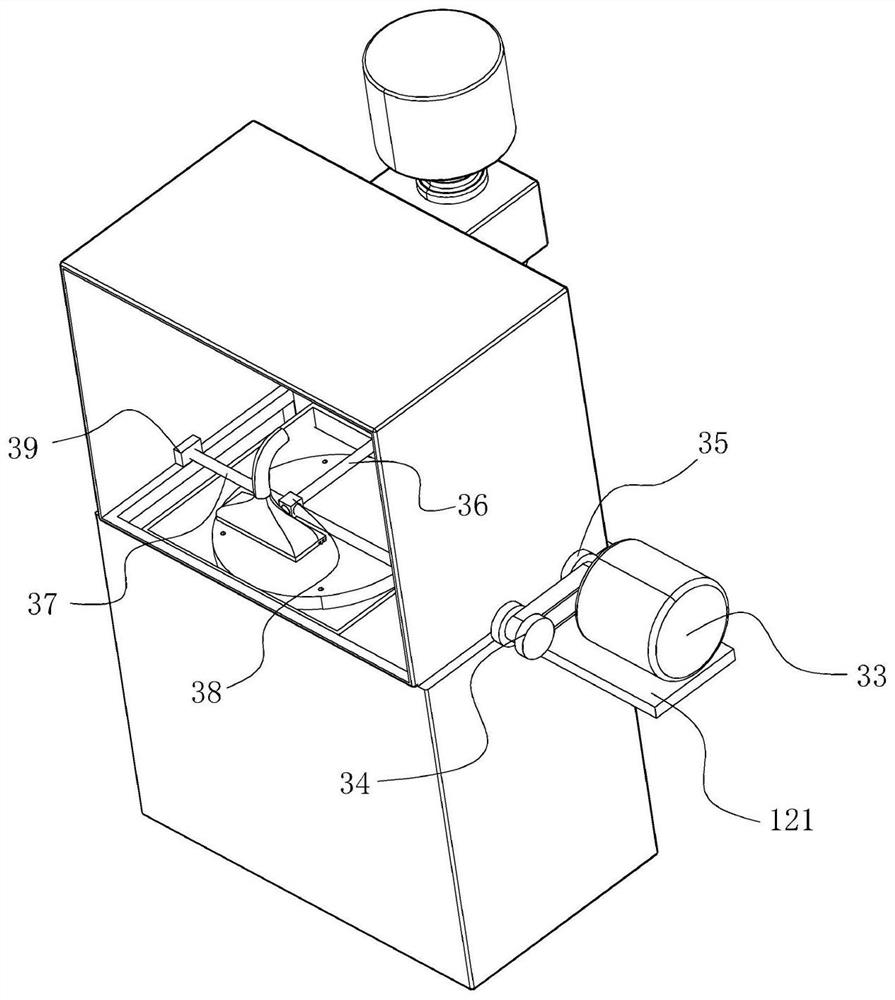

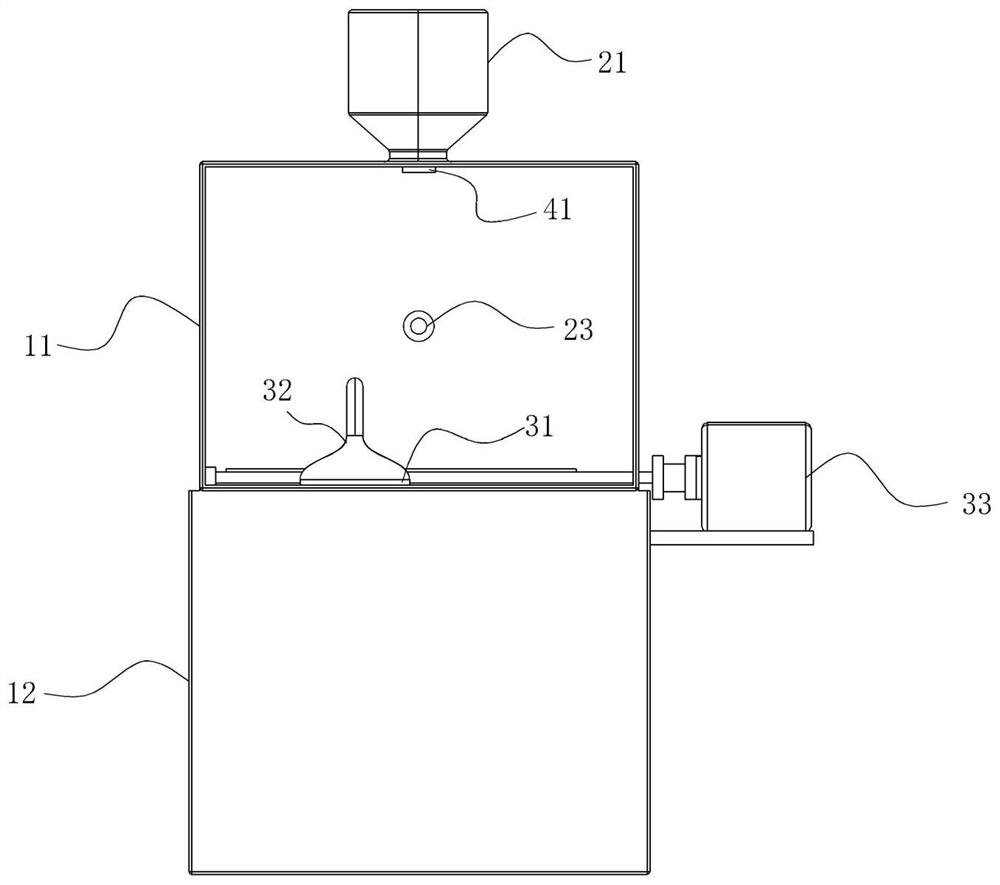

Continuous printing SLM equipment

ActiveCN114433876ASimple structureEasy to useAdditive manufacturing apparatusIncreasing energy efficiencyLaser transmitterEngineering

The invention discloses continuous printing SLM equipment. The continuous printing SLM equipment comprises a shell, a powder feeding device, a powder spreading device and a printing device; the shell comprises an upper box body and a lower box body, a powder feeding device is arranged on the rear side of the upper box body, an opening is formed in the front side of the upper box body, a printing device is arranged in the lower box body, and a powder spreading device is arranged above the printing device. The SLM equipment for continuous printing is simple in structure and convenient to use, through cooperative arrangement of the shell, the powder feeding device, the powder laying device and the printing device, on the premise that the laser transmitter is not moved, movement of the basic shaft and the powder laying trolley is achieved, and therefore the printing range in the printing process is widened, and large 3D parts can be conveniently printed.

Owner:ZHEJIANG SHENGLI TEXTILE CO LTD

An inkjet printing device

The invention discloses an inkjet printing device, comprising a printing part, a feeding part and a control system, the feeding part includes a feeding station and a printing station, and a jig is arranged at the feeding station of the feeding part , the jig is used to position the object to be printed on the loading station in the feeding part before inkjet printing, and separate the object to be printed before the positioned object to be printed enters the printing station. The inkjet printing device of the present invention reduces the cost of the entire device, saves working time, improves the positioning stability of the object to be printed, and operates in a semi-automatic mode in which feeding and printing are simultaneously performed Improve printing quality and printing efficiency; and design an eccentric adjustment mechanism to ensure the safety and reliability of the entire device.

Owner:BEIJING MEIKEYI

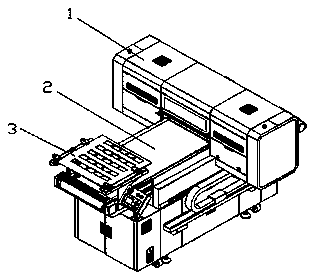

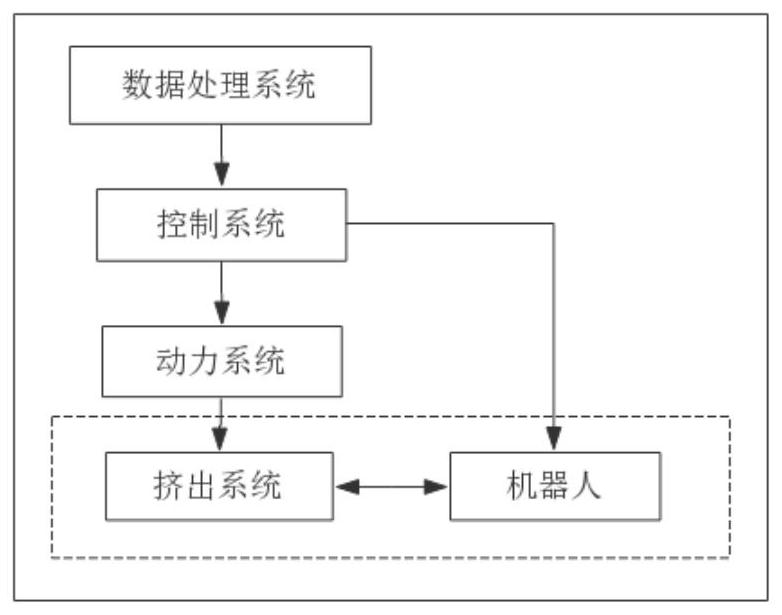

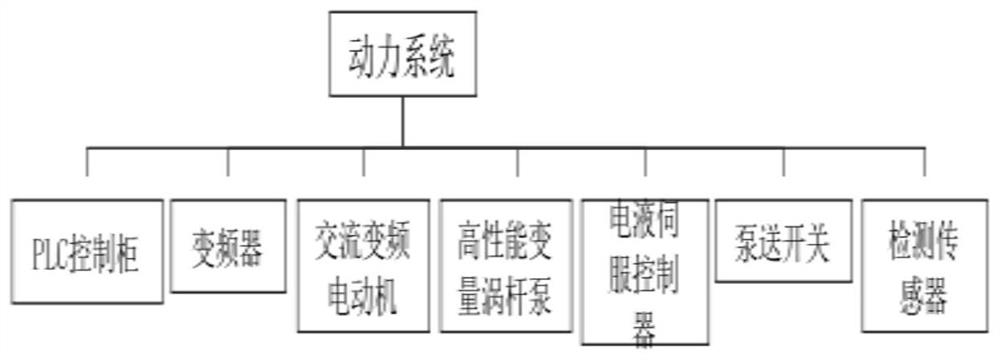

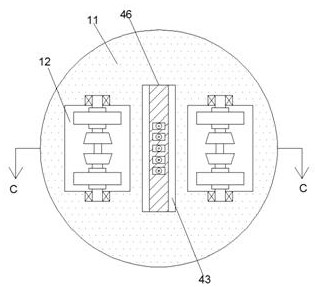

One-time multi-material 3D printing mechanism based on mechanical arm

InactiveCN111844723AGood effectImprove printing accuracyManufacturing driving meansManufacturing enclosuresData processing systemComputer printing

The invention belongs to the field of 3D printing, and specifically discloses a one-time multi-material 3D printing mechanism based on a mechanical arm. The one-time multi-material 3D printing mechanism comprises a data processing system, a control system, a dynamical system, a mechanical arm and an extrusion system, wherein the data processing system is used for presetting a printing path according to material characteristics; the control system is used for controlling the extrusion system to print according to the preset printing path by virtue of the dynamical system and the mechanical arm;the extrusion system comprises a multi-nozzle assembly, the multi-nozzle assembly is installed on the tail end of the mechanical arm and comprises a plurality of mutually independent single-nozzle units, each single-nozzle unit comprises a printing nozzle and a storage hopper which are connected with each other, and the diameters of the printing nozzles are varied. According to the one-time multi-material 3D printing mechanism, modeling software is combined with the mechanical arm, and additionally, the multi-nozzle assembly is designed, so that the extrusion speed of multiple nozzles with different diameters is adjusted on the basis of a one-time fixed moving speed, and the printing precision and the printing speed are increased.

Owner:HUAZHONG UNIV OF SCI & TECH

3D printer

Owner:青岛天智清华电子科技发展有限公司

A 3D printer based on cylindrical coordinate system

ActiveCN109304860BReduce volumeExpand the printing rangeManufacturing driving meansAdditive manufacturing with liquidsLinear motionComputer printing

The invention discloses a 3D printer based on a cylindrical coordinate system. The 3D printer comprises an annular module, a spray head module, a lifting module, a main body frame and a printer outercover; the annular module is in sliding fit with a supporting column of the main body frame through a linear bearing, the annular module is fixedly connected with the lifting module through a liftingraising frame, and the lifting module is fixedly connected with the main body frame through a lifting driving motor fixed on a top cover; and under the cylindrical coordinate system, the spray head module needs to perform circumferential rotation motion, radial linear motion and axial lifting motion, wherein the circumferential rotation motion is completed through drive from a rotation driving sliding block of the annular module, the radial linear motion is completed through the cooperative drive from a radial driving module and a radial driven module of the annular module, and the axial lifting motion is completed through drive from the lifting module. The 3D printer has the characteristics of being compact in structure and reasonable in design, moreover, the size is small, the printing range is relatively large, and the stability and the printing precision are relatively high.

Owner:YANSHAN UNIV

A printing device based on a ribbon

The invention discloses a printing device based on a color ribbon, which includes a printing case, and the printing case is provided with a drive chamber opening to the left and symmetrical front and back, and a drive shaft symmetrical up and down is rotatably connected in the drive chamber, and the drive shaft One end of the shaft close to the center of symmetry is provided with an engaging device, wherein a sleeve structure is connected between the engaging devices, and a main pulley is provided on the drive shaft, and the outer side of the main pulley is provided with a wall that can contact the wall. Connected roller; the invention has a simple structure, a handheld structure, and an expanded printing range, making the printing result more direct and reducing subsequent operations, and when using translational sliding, the friction between the wheel and the contact surface provides power for the entire device. No external power supply is required, and the two-way clamping method is used to facilitate the replacement of the ribbon.

Owner:南通亘赢科技有限公司

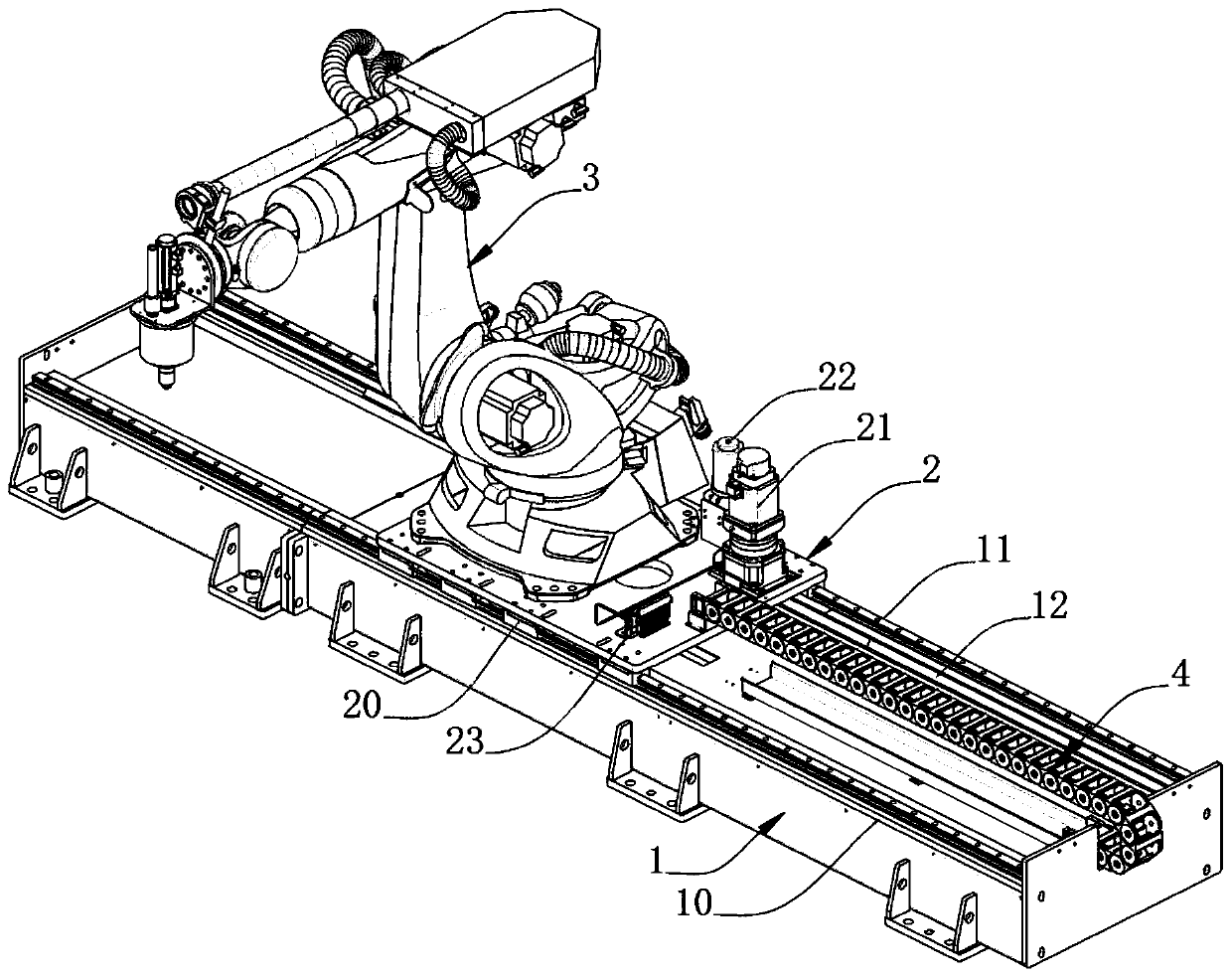

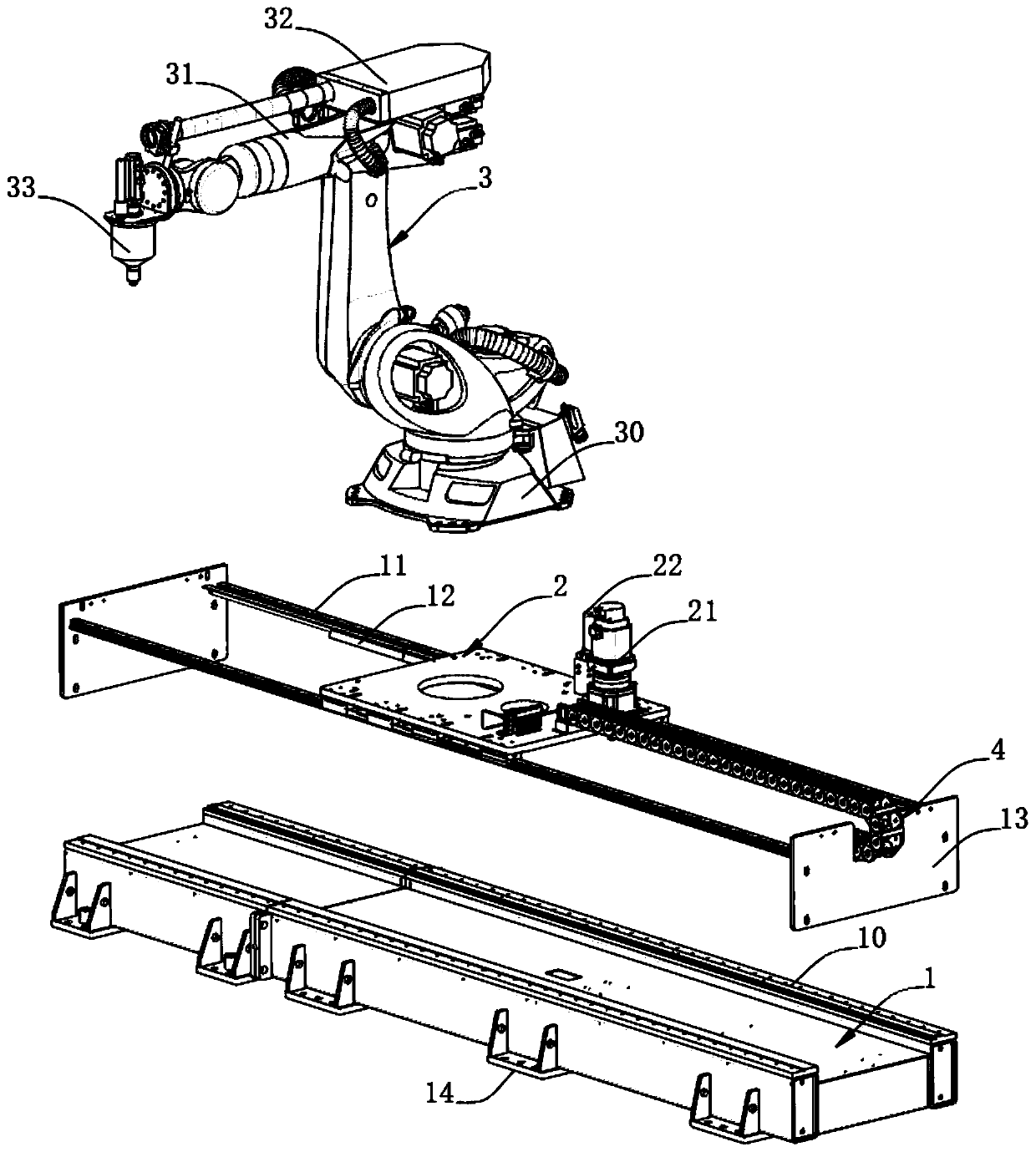

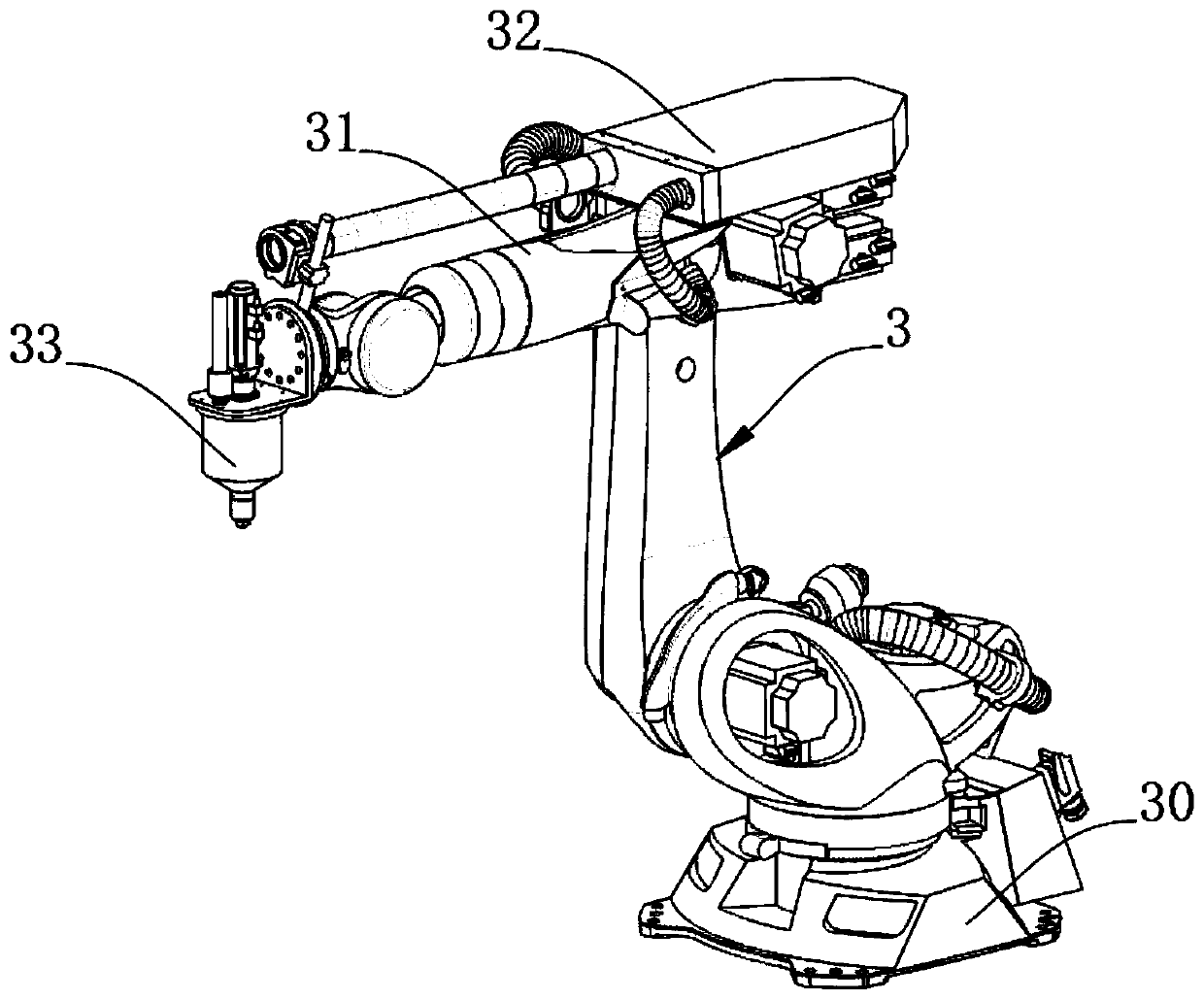

3D pottery clay printing robot and printing method thereof

PendingCN110171054AExpand the printing rangeFlexible slidingAdditive manufacturing apparatusCeramic shaping apparatusFixed frameCable carrier

The invention relates to the technical field of pottery clay printing equipment, in particular to a 3D (three-dimensional) pottery clay printing robot and a printing method thereof. The 3D pottery clay printing robot comprises a fixed frame and a machine arm arranged on the upper portion of the fixed frame, wherein a movable table and a drag chain are sequentially arranged above the fixed frame, abase is arranged at the bottom of the machine arm, the base is fixedly connected with the movable table through bolts, a front arm is installed at the top end of the machine arm, and a mud storage box is fixed above the front arm through bolts; and the front end of the front arm is provided with a printing head, the top surface of a fixing plate is fixedly provided with a sliding rail through bolts, a plurality of sliding blocks are fixed on two sides of the bottom of the movable table through bolts, a sliding groove is formed in one end of the sliding blocks, and the sliding groove is in sliding connection with the sliding rail. According to the 3D pottery clay printing robot, the machine arm is fixed on the movable table and slides back and forth on the fixed frame, so that the printingrange of the machine arm is increased; and a lubricating pump is arranged on the movable table, so that the friction coefficient of the sliding blocks and the sliding rail on the fixed frame is reduced, and the free movement of the machine arm is facilitated.

Owner:FOSHAN LONGSHEN ROBOT

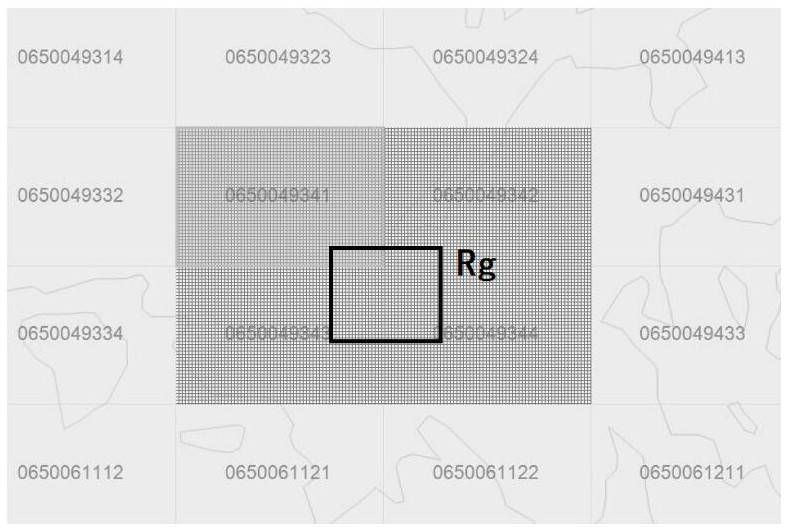

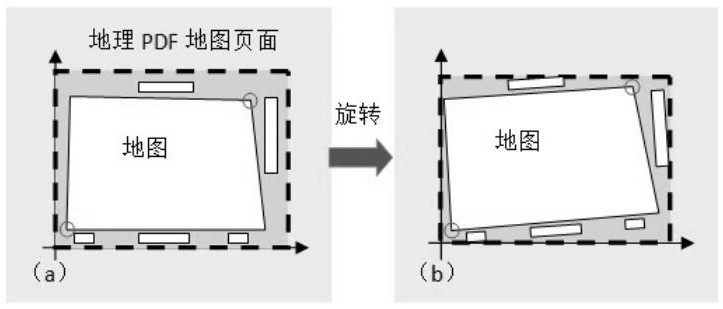

Printing method of cross-panel pagination based on geographic pdf map

ActiveCN108491173BExpand the printing rangeHigh precisionDigital output to print unitsComputer printingData mining

The invention relates to a cross-frame paging printing method based on a geographic PDF map. The geographic PDF map data is preprocessed, so that the content of the geographic PDF map of adjacent map frames maintains the spatial reference consistency, and is selected based on the connection chart to be printed. The geographic PDF map data range, retrieve the geographic PDF map file, according to the set geographic PDF map printing layout and pagination printing parameters, use the set grid to extract the content corresponding to the geographic PDF map of different map sheets, supplemented by necessary elements , and paginate the output directly on the printer. This method has a large printing range, supports selecting a large range of map content across the map within the effective range of geographic PDF map data in the same projection zone, and prints it out, and it improves the efficiency of making large wall charts or paper atlases for later stitching and gluing. Page margin accuracy.

Owner:中国人民解放军61540部队

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com