Immersion type 3D printing device and 3D printing method

A 3D printing and infusion device technology, applied in the field of 3D printing, can solve the problem of difficult to control the cooling environment, achieve the effect of temperature control and widen the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

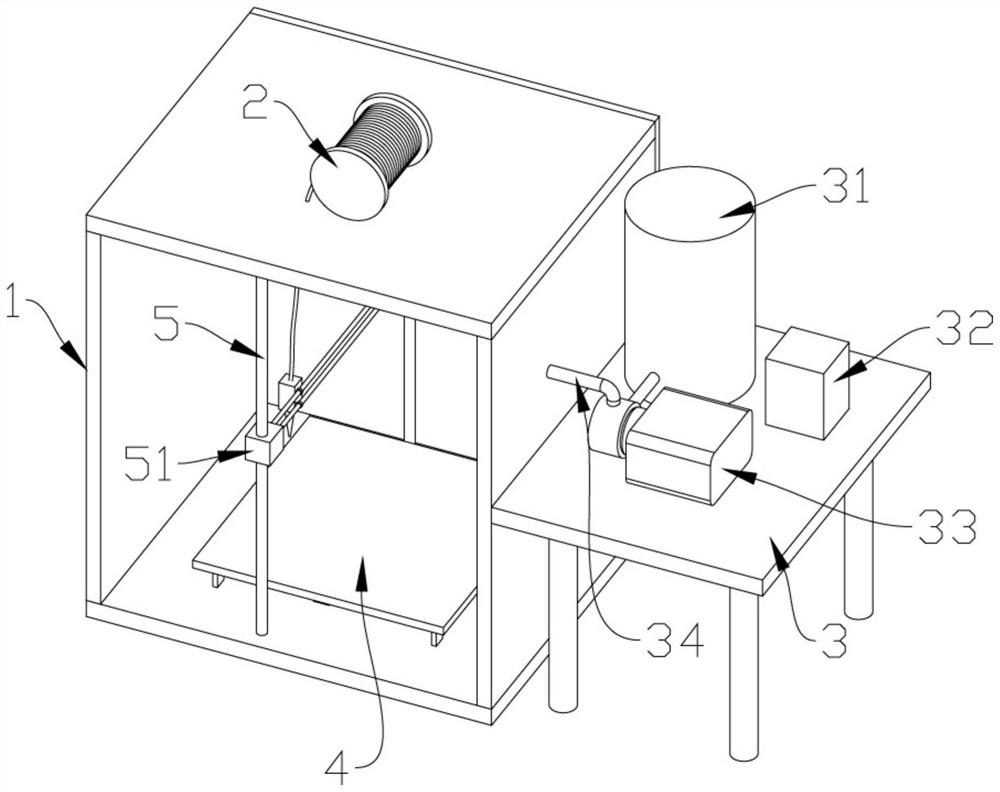

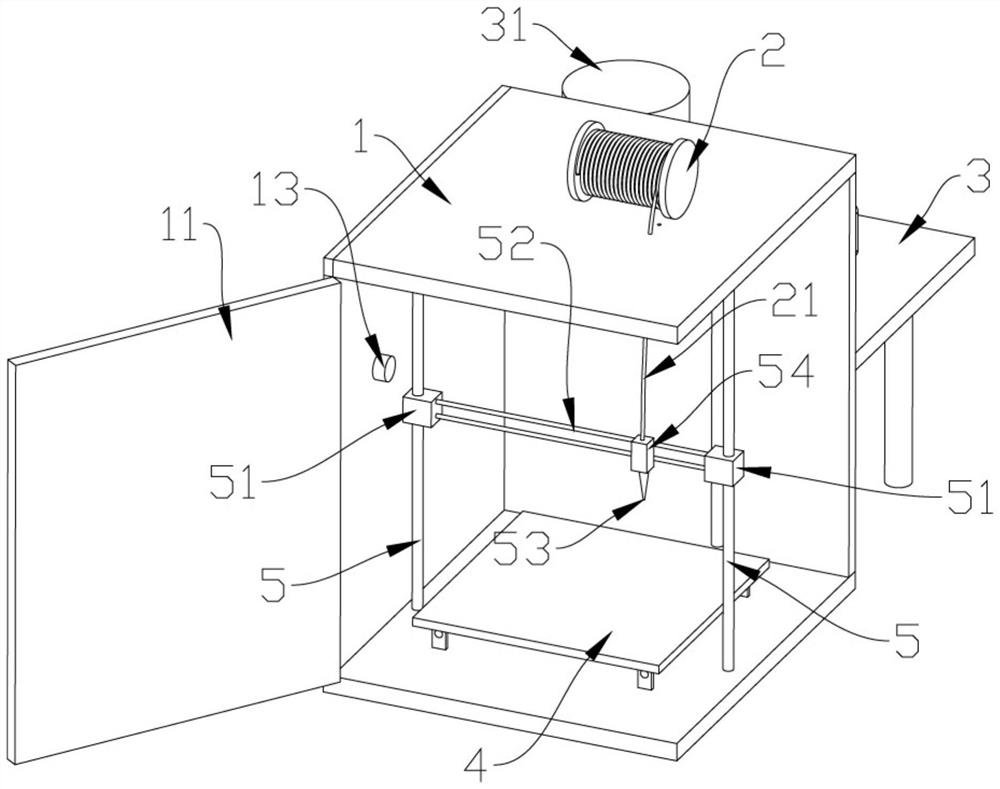

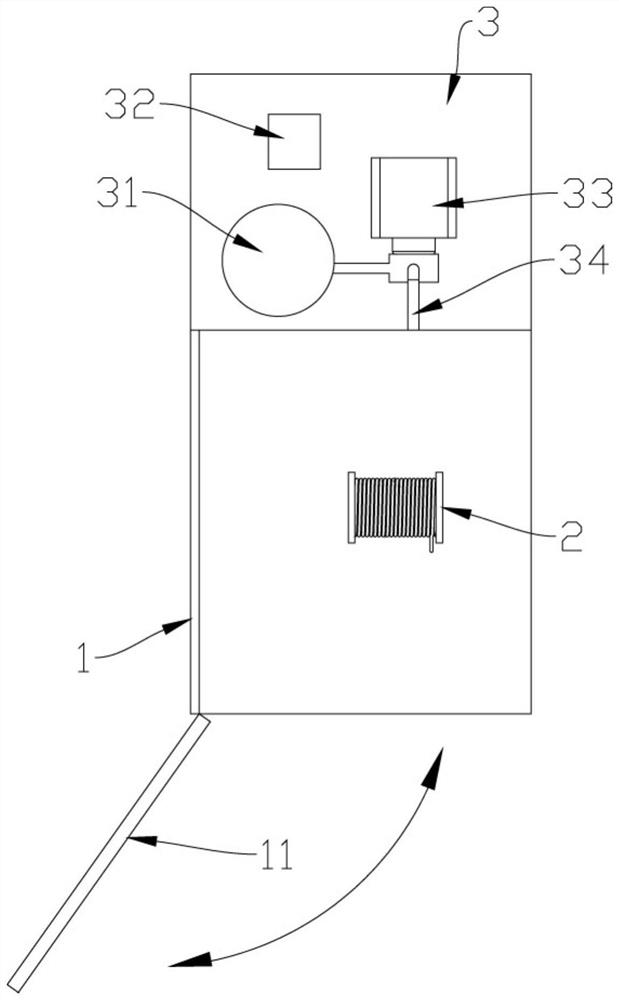

[0052] A liquid immersion type 3D printing device, including a printing body and a liquid control device, wherein: the printing body is used to implement 3D printing; the liquid control device is used to inject liquid into the printing body, so that the printed object is placed in liquid.

[0053] In this example, if Figure 1~5 As shown, the printing main body includes a box body 1, which is provided with an openable door panel 11, which can keep the sealing of the side and bottom of the box body 1 after the door panel 11 is closed; the door panel 11 and the box body 1 The rotating connection structure and sealing structure between them are conventional technologies, such as hinges, hinges, sealing rings, etc. Preferably, a transparent area, such as glass or plexiglass, can be provided on the box body 1 or the door panel 11 to facilitate observation of the printing operation therein.

[0054] The box body is provided with a printing assembly and a printing platform 4, and t...

Embodiment 2

[0060] A liquid immersion type 3D printing device, including a printing body and a liquid control device, wherein: the printing body is used to implement 3D printing; the liquid control device is used to inject liquid into the printing body, so that the printed object is placed in liquid.

[0061] In this example, if Figure 6-9 As shown, the printing main body includes a box body 1, which is provided with an openable door panel 11, which can keep the sealing of the side and bottom of the box body 1 after the door panel 11 is closed; the door panel 11 and the box body 1 The rotating connection structure and sealing structure between them are conventional technologies, such as hinges, hinges, sealing rings, etc. Preferably, a transparent area, such as glass or plexiglass, can be provided on the box body 1 or the door panel 11 to facilitate observation of the printing operation therein.

[0062] The box body is provided with a printing assembly and a printing platform 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com