3D printing model device with cleaning mechanism

A 3D printing and model device technology, applied in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve the problems of waste falling on the external ground, residual waste, and multiple waste, and achieve the effect of increasing the printing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

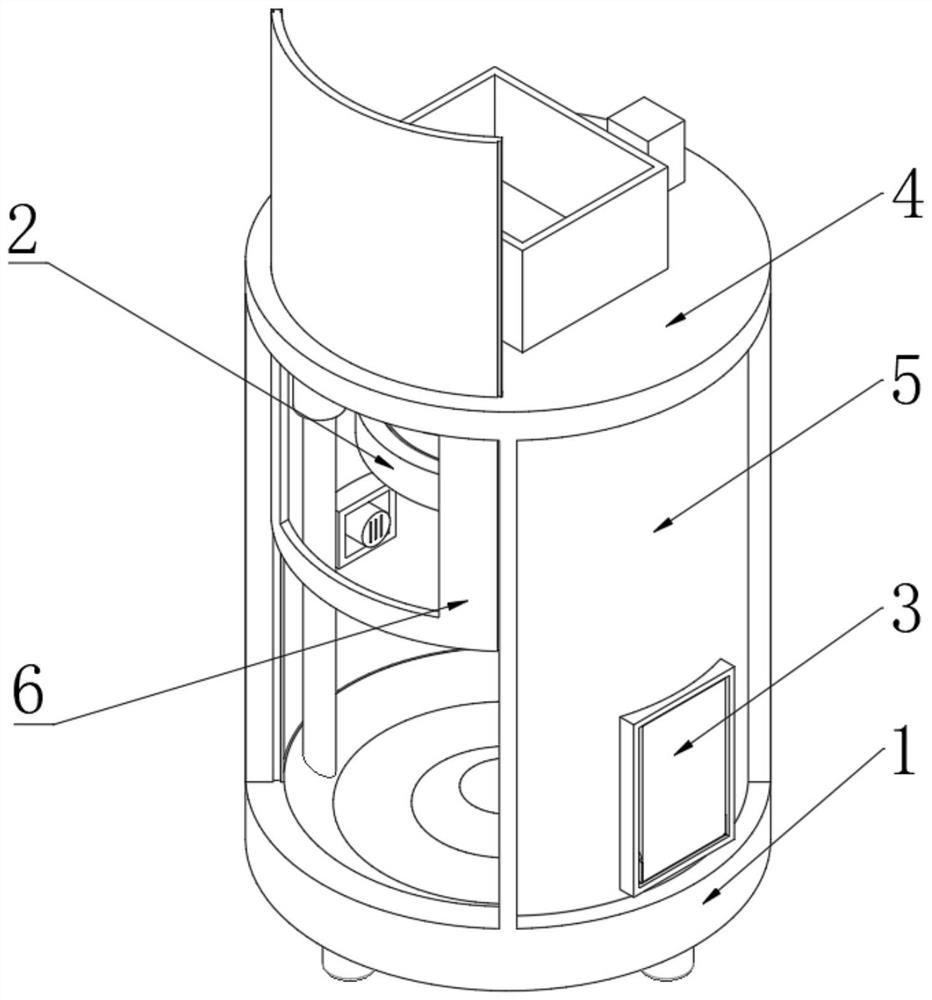

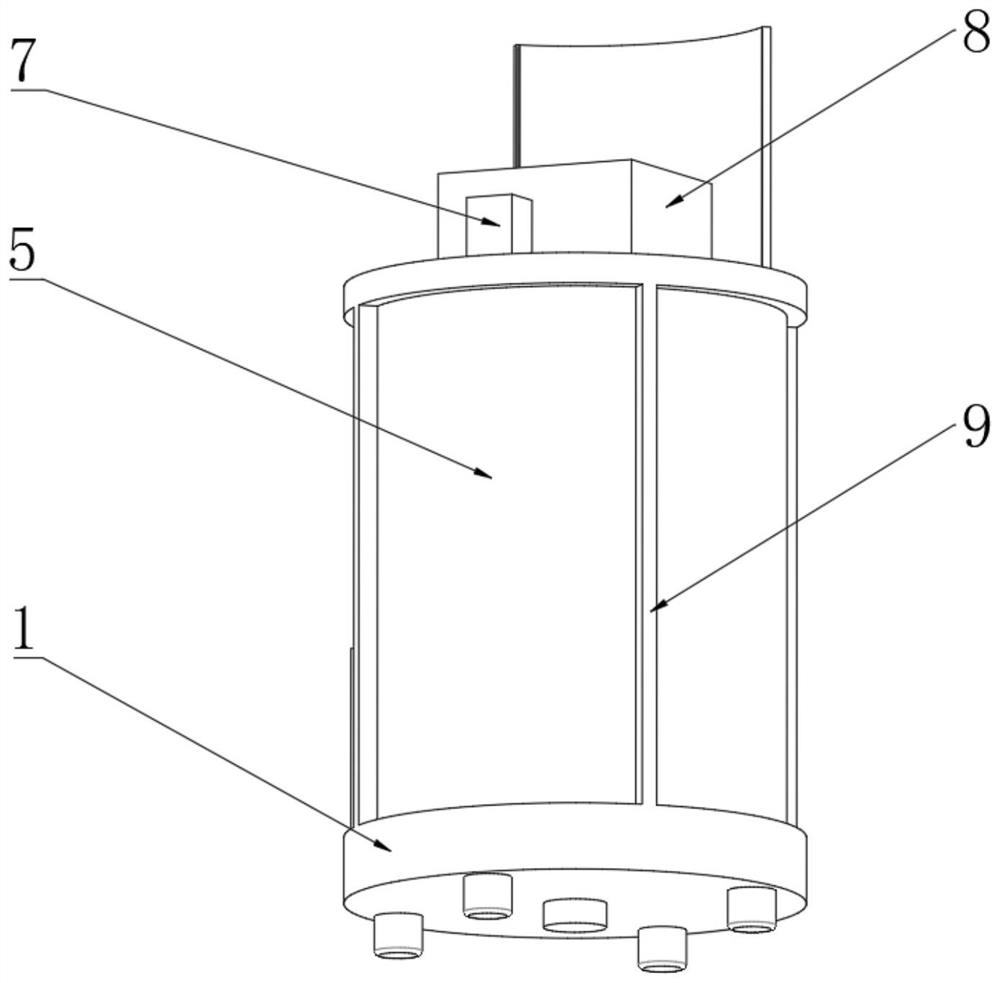

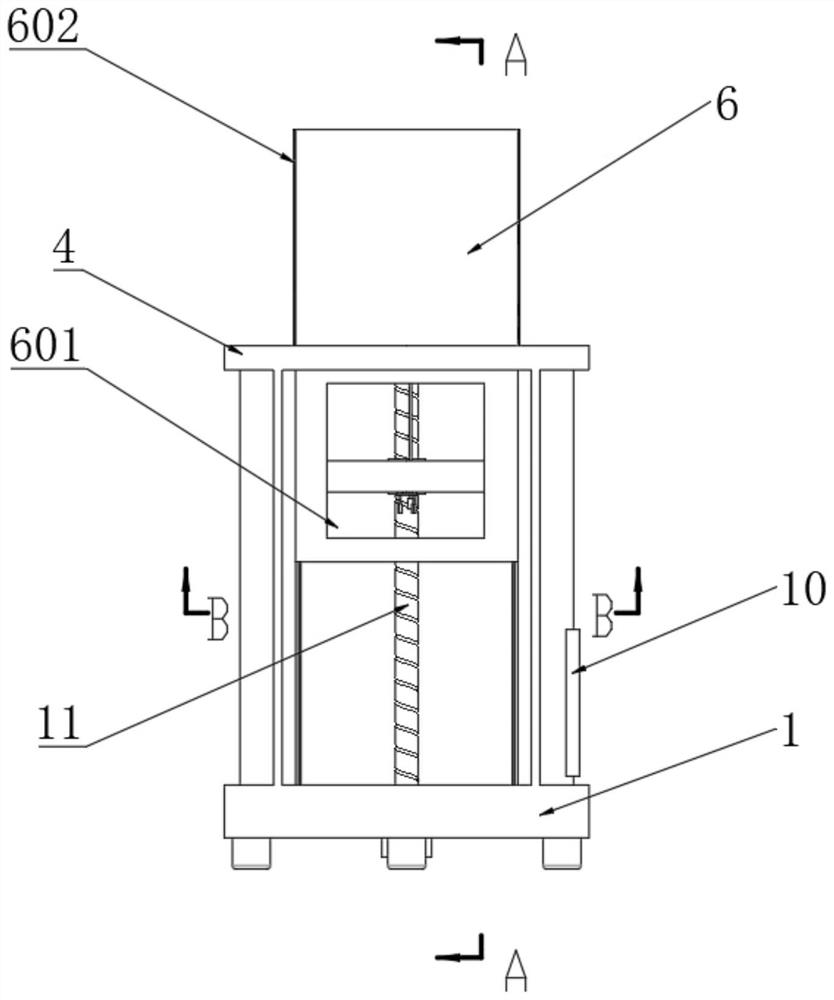

[0041] Such as Figures 1 to 15 As shown, a 3D printing model device with a cleaning mechanism includes a base 1 and a capping plate 4, and four connecting rods 9 are fixedly installed between the base 1 and the capping plate 4, wherein each adjacent connection on three sides A side baffle 5 is fixedly installed between the poles 9, and a side chute 901 is provided between the connecting poles 9 away from the side baffle 5, and the capping plate 4 on the side of the side chute 901 The body of the board is provided with a slot hole 401, and a sealing baffle 6 is interspersed between the slot hole 401 and the side chute 901, and a feeding frame 8 is fixedly installed in the middle of the upper surface of the top plate 4, away from the sealing baffle. The upper surface of the capping plate 4 on one side of 6 is fixedly installed with a first motor 7, the output end of the first motor 7 penetrates the capping plate 4 and is fixedly installed with a first screw 11, and the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com