Laser drive mechanism and 3D printer

A technology of laser drive and drive mechanism, which is applied in the field of 3D printing, can solve the problems of small printing range, small size of forming components, limiting the development and application of process technology, etc., and achieve the effect of large printing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

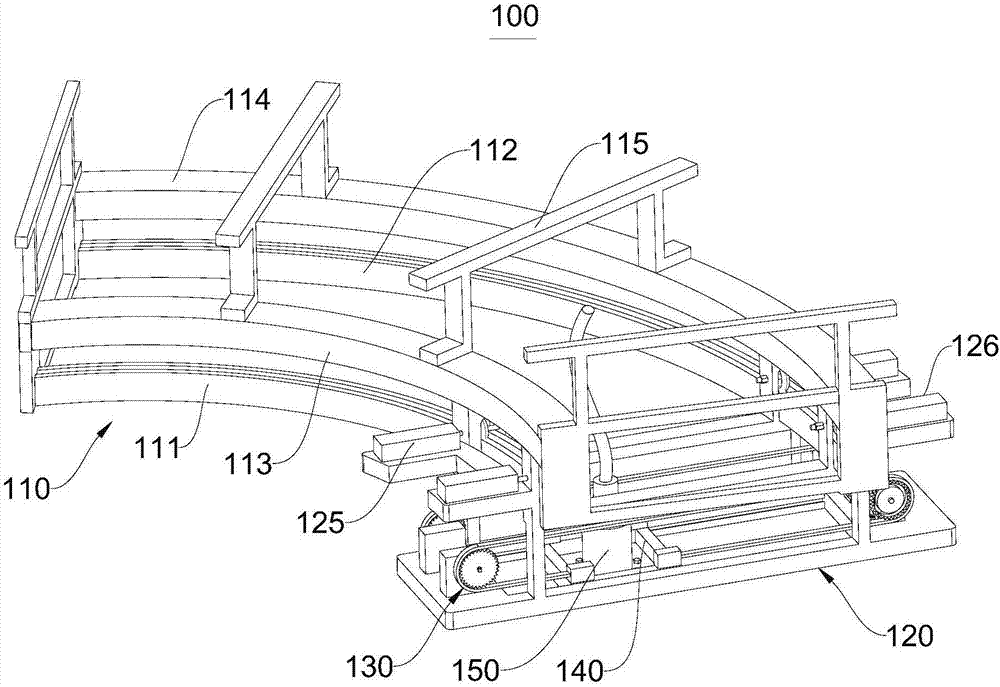

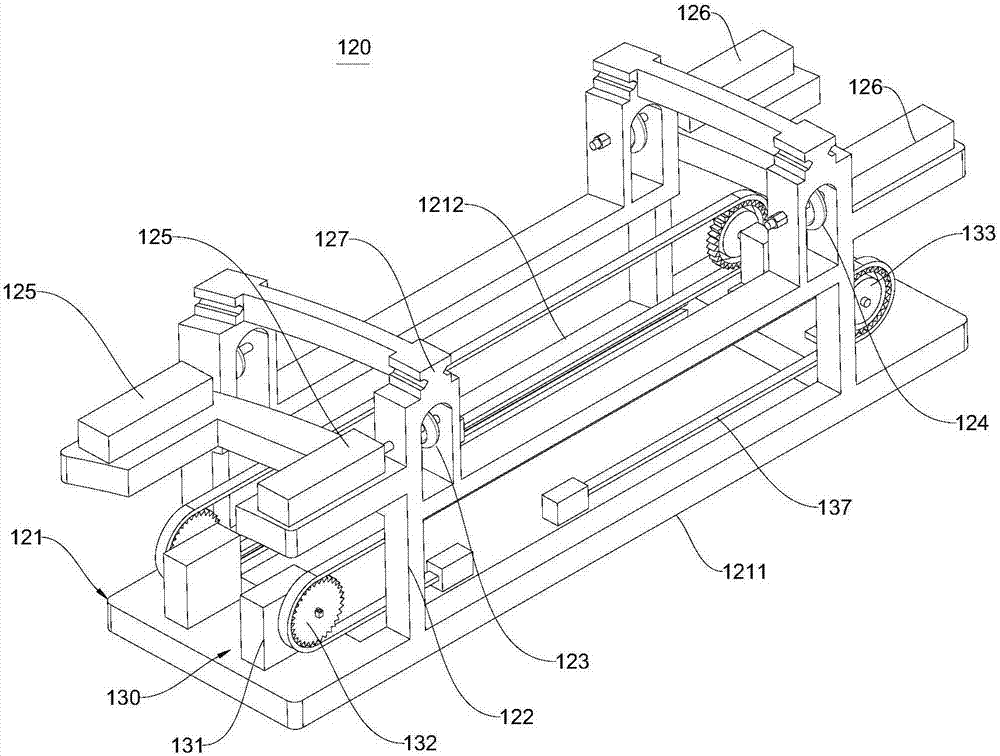

[0044] figure 1 It is a schematic diagram of the overall structure of the laser driving mechanism 100 in the embodiment of the present invention. Please refer to figure 1, the present embodiment provides a laser driving mechanism 100 , which includes a track assembly 110 , a parent car 120 , a sub-car 140 and a laser emitting device 150 disposed on the sub-car 140 . The mother car 120 is movably connected to the track assembly 110 and can move along the path defined by the track assembly 110 ; the child car 140 is movably connected to the mother car 120 and can move linearly relative to the mother car 120 . Therefore, the laser emitting device 150 mounted on the sub-car 140 can have a larger printing range under the movement of the mother car 120 and the sub-car 140 .

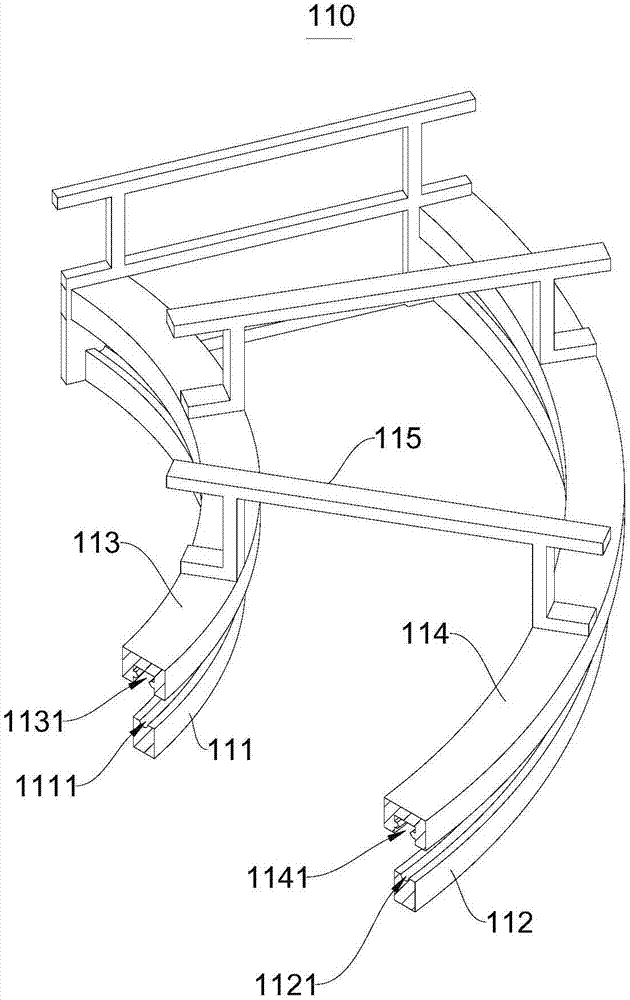

[0045] figure 2 It is a cross-sectional view of the track assembly 110 in the embodiment of the present invention. Please combine figure 1 and figure 2 , in this embodiment, the track assembly 110 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com